117261 / D6110 Digital

117201 / D10110 Digital

V1/0414

GB/UK

ENGLISH

Translation

of the original instruction manual

Read these instructions before using and keep

them available at all times!

1. General information .............................................................................................. 41

1.1 Information about the instruction manual ........................................................... 41

1.2 Key to symbols ................................................................................................... 41

1.3 Liability and Warrantees .................................................................................... 42

1.4 Copyright protection ........................................................................................... 42

1.5 Declaration of conformity ................................................................................... 42

2. Safety ...................................................................................................................... 43

2.1 General information ........................................................................................... 43

2.2 Safety instructions for use of the device ............................................................ 43

2.3 Intended use ...................................................................................................... 44

3. Transport, packaging and storage ....................................................................... 45

3.1 Delivery check .................................................................................................... 45

3.2 Packaging .......................................................................................................... 45

3.3 Storage .............................................................................................................. 45

4. Technical data ........................................................................................................ 46

4.1 Overview of parts ............................................................................................... 46

4.2 Technical specification ....................................................................................... 47

5. Installation .............................................................................................................. 50

5.1 General safety instructions................................................................................. 50

5.2 Setup ................................................................................................................. 51

5.3 Water connection ............................................................................................... 53

5.4 Drain connection ................................................................................................ 54

5.5 Electric connection ............................................................................................. 54

5.6 Start-up and commissioning............................................................................... 55

6. Operation manual .................................................................................................. 57

6.1 Safety tips for the user ....................................................................................... 57

6.2 Operation elements ............................................................................................ 58

6.3 Introduction to the device operation ................................................................... 60

6.4 Manual programming ......................................................................................... 62

6.4.1 Setting of cooking temperature .................................................................. 62

6.4.2 Setting of cooking time .............................................................................. 62

6.4.3 Temperature setting and automatic pre-heating ........................................ 63

6.4.4 Selection of operation mode ...................................................................... 63

6.4.5 Cooking with use of core (option) .............................................................. 65

6.4.6 Food preparation with use of delta T function ............................................ 66

- 39 -

Programming of the multiple-phase cooking ............................................. 67

6.4.7

6.4.8 Setting of the automatic pre-heating of the device chamber ...................... 68

6.4.9 Opening and closing of steam outlet ......................................................... 69

6.5 Navigation in the recipes menu .......................................................................... 70

6.5.1 Saving the cooking program in the device memory ................................... 70

6.5.2 Loading the cooking program from the memory ........................................ 70

6.5.3 Modification of the cooking program save in the memory .......................... 71

6.5.4 Removing the program or its part from the memory .................................. 71

6.5.5 Importing and exporting the recipes from the USB memory ...................... 72

7. Cleaning and maintenance ................................................................................... 73

7.1 Safety advice ..................................................................................................... 73

7.2 Cleaning ............................................................................................................. 73

7.3 Fan cleaning ...................................................................................................... 74

8. Possible Malfunctions ........................................................................................... 75

9. Waste disposal ...................................................................................................... 76

Bartscher GmbH

Franz-Kleine-Str. 28

D-33154 Salzkotten phone: +49 (0) 5258 971-0

Germany fax: +49 (0) 5258 971-120

- 40 -

1. General information

1.1 Information about the instruction manual

This instruction manual contains information about the installation, operation and

maintenance of the device and should be consulted as an important source of

information and reference guide.

Awareness of the safety instructions and instructions for use in this manual will ensure

the safe and correct use of the device.

In addition to the information given here, you should comply with any local Health and

safety Controls and generally applicable safety regulations.

The instruction manual forms part of the product and should be kept near the device

and easily accessible for anyone carrying out the installation, servicing, maintenance or

cleaning.

1.2 Key to symbols

In this manual, symbols are used to highlight important safety instructions and any

advice relating to the device. The instructions should be followed very carefully to avoid

any risk of accident, personal injury or material damage.

WARNING!

This symbol highlights hazards, which could lead to injury.

Please follow the instructions very carefully and proceed with particular attention

in these cases.

WARNING! Electrical hazard!

This symbol draws attention to potential electrical hazards. If you do not follow

the safety instructions, you may risk injury or death.

CAUTION!

This symbol highlights instructions, which should be followed to avoid any risk of

damage, malfunctioning and/or breakdown of the device.

NOTE!

This symbol highlights tips and information, which have to be followed for

an efficient and trouble-free operation of the device.

WARNING! Hot surface!

This symbol is a warning that the device surface is hot when in use. Ignoring this

warning may result in burns!

- 41 -

1.3 Liability and Warrantees

All the information and instructions in this manual take into account standard safety

regulations, current levels of technical engineering as well as the expertise and

experience we have developed over the years.

The instruction manual was translated with all due care and attention. However, we do

not accept liability for any translation errors. The German version of this instruction

manual is definitive.

If the delivery consists of a special model, the actual scope of delivery may differ from

the descriptions and illustrations in this manual. This is also the case for special orders

or when the device has been modified in line with new technology.

NOTE!

Read this manual carefully and thoroughly before any operation of the device,

and especially before turning it on!

Manufacturer is not liable for any damages or faults caused by:

- violation of advice concerning operation and cleaning;

- use other than designed;

- alterations made by user;

- use of inadequate spare parts.

We reserve the right to make technical changes for purposes of developing and improving

the useful properties.

1.4 Copyright protection

The instruction manual including any texts, drawings, images or other illustrations is

copyright. No part of this publication may be reproduced, transmitted or used in any

form or by any means without permission in writing from the manufacturer. Any person

who commits any unauthorized act in relation to this publication shall be liable to claims

for damages. All rights reserved.

NOTE!

The contents, texts, drawings, pictures and any other illustrations are copyright

and subject to other protection rights. Any person unlawfully using this

publication is liable to criminal prosecution.

1.5 Declaration of conformity

- 42 -

The device complies with the current standards and directives of the EU.

We certify this in the EC declaration of conformity. If required we will be

glad to send you the according declaration of conformity.

2. Safety

This section provides an overview of all important safety aspects.

In addition every chapter provides precise safety advice for the prevention of dangers

which are highlighted by the use of the above mentioned symbols.

Furthermore, attention should be paid to all pictograms, markers and labels on the

device, which must be kept in a permanent state of legibility.

By following all the important safety advice you gain an optimal protection against all

hazards as well as the assurance of a safe and trouble-free operation.

2.1 General information

This device is designed in accordance with the presently applicable technological

standards. However, the device can pose a danger if handled improperly and

inappropriately.

Knowing the contents of the instruction manual as well as avoiding mistakes and thus

operating this device safely and in a fault-free manner is very essential to protect

yourselves from the hazards.

To prevent hazards and to ensure optimum efficiency, no modifications or alterations to

the device that are not explicitly approved by the manufacturer may be undertaken.

This device may only be operated in technically proper and safe condition.

2.2 Safety instructions for use of the device

The specifications regarding the industrial safety are based on the Regulations of the

European Union applicable at the time of manufacturing the device.

If the device is used commercially, the user is obliged to ensure that the said industrial

safety measures concur with the state of the rules and regulations applicable at the time

in question for the entire period of use of the device and to comply with the new

specifications.

Outside the European Union, the industrial safety laws applicable at the place of

installation of the device and the regional territorial provisions must be complied with.

Besides the industrial safety instructions in the instruction manual, the general safety and

accident prevention regulations as well as environment protection regulations applicable

for area of application of the device must be followed and complied with.

- 43 -

2.3 Intended use

CAUTION!

The device has been designed and built for commercial use and should be

operated only by qualified personnel in kitchen facilities.

Safe operation is only guaranteed when using the device for its intended purpose.

Any technical interventions, as well as assembly and maintenance are to be made by a

qualified customer service only.

The combi steamer compact is designed only for preparation of appropriate food:

CAUTION!

Any use going beyond the intended purpose and/or any different use of the

device is forbidden and is not considered as conventional.

Any claims against the manufacturer or his authorized representative as a

consequence of experiencing damages resulting from unconventional use are

impossible.

The operator is liable for all damages resulting from inappropriate use.

- 44 -

3. Transport, packaging and storage

3.1 Delivery check

Please check the delivery upon completeness and transport damage immediately

after receipt. In case of visible damage do not accept or accept the delivery with

reservation only.

Note the extent of damage on the carrier’s bill of delivery. Trigger off the complaint.

Hidden damages should be reclaimed immediately after notice, as claims for damages

can only be asserted within the effective period for complaints.

3.2 Packaging

Please do not throw away the covering carton of your device as it might be useful for

storage purposes, when moving or, in case of damages, when the device must be sent

back to a repair center. The outer and inner packing material should be removed

completely from the device before installation.

NOTE!

If you liked to dispose the packing, consider the regulations applicable in your

country. Supply re-usable packing materials to the recycling.

Please inspect the device upon completeness. In case any part is missing please

contact our customer service center immediately.

3.3 Storage

Keep the package closed until installation and under consideration of the outside

indicated positioning- and storage markings.

Packages should be stored under consideration of the following:

- Do not store outdoors.

- Keep it dry and dust-free.

- Do not expose it to aggressive media.

- Do not expose it to direct sunlight.

- Avoid mechanical shocks and vibration.

- In case of longer storage (> 3 months) make sure you check

the state of the packaging and the parts regularly.

If required refresh or renew.

- 45 -

⑧

⑨

⑩

⑪

⑫

⑬

⑭

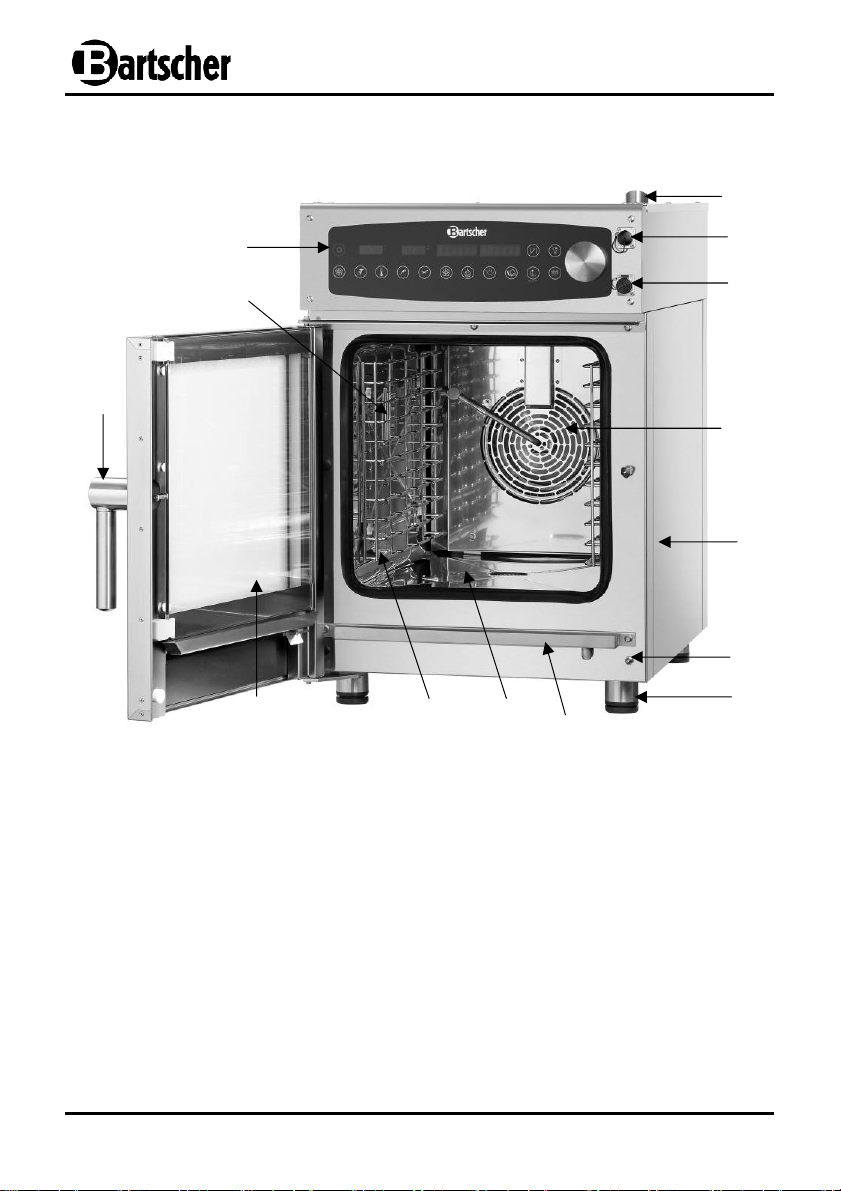

4. Technical data

4.1 Overview of parts

⑭

⑬

⑫

①

③

④

②

⑥

⑤

⑪

Steam outlet

①

USB connection

②

Temperature probe connection

③

Fan

④

Housing

⑤

Microswitch

⑥

Adjustable feet

⑦

- 46 -

⑦

⑨

⑩

⑧

Drain tray

Steamer chamber

Rails for shelves

Glass door

Glass door handle

Steamer chamber illumination

Control panel

4.2 Technical specification

Name

Combi steamer compact

Model:

Code-No.:

Capacity: up to 6 x 1/1 GN up to 10 x 1/1 GN

Temperature range: 50 °C – 280 °C

Power supply:

Rigid water

connection:

Water pressure: max. 3 bar

Dimensions:

Weight: 85.0 kg 95.0 kg

Equipment:

We reserve the right to make technical changes!

D6110 Digital D10110 Digital

117261 117201

6.9 kW / 400 V

50/60 Hz 3 NAC

3/4“

W 519 x D 803 x H 770 mm W 519 x D 803 x H 1,010 mm

1 spare fat filter for the electronic cooling fan,

1 grate 1/1 GN, 1 tray 1/1 GN, 1 water supply hose

13.8 kW / 400 V

50/60 Hz 3 NAC

Protective devices

The device is equipped with the following protective systems:

Door microswitch

The microswitch interrupts the device operation after opening the door: either the

heating system and the fan are turned off. After closing the door the interrupted

cycle is continued. It is forbidden to manually activate the microswitch when the door

is opened.

Motor overheating protection

The fan motor is equipped with the overheating protection which interrupts the

operation in case of overheating. The fan motor operation is restored automatically

when the temperature drops to the value in the safe range.

- 47 -

Steamer chamber protective thermostat

When the temperature in the steamer chamber reaches 350°C the thermostat opens

the supply circuit of the device heaters.

That protection must be reactivated by the technical service personnel as its

operation indicates that other elements must be inspected.

CAUTION!

That protection must be reactivated by the technical service personnel as its

operation indicates that other elements must be inspected.

Properties of the combi steamer compact Digital

• Model CNS

• Maximum capacity up to 6 x 1/1 or 10 GN 1/1

• Digital control can be configured with up to 99 programmes, up to 9 cooking phases

per program

• Compact longitudinal sliding GN

• Functions:

Air circulation/steaming/combined steaming/ delta T cooking / cooking in low

temperature / quick cooling / steamer compact devices with the automatic

cleaning system on demand

• Reversible motor operation (clockwise/counterclockwise) to optimize the cooking

climate

• Steam generation with use of direct injection

• 3 levels of fan speed control

• Adjustable steam outlet

• Steamer chamber illumination

• Double door glazing, easy opening of internal door for cleaning

• Removable rails for shelves

• Front connection for the optional core

• Front USB connection

- 48 -

Pressure limiter for the combi steamer compact

Core tem

perature sensor

Auxiliary equipment (not included in the delivery)

devices

• Made from chrome-plated brass, connection 3/4”

• Initial setpoint 3 bar, adjustment from 1 to 6 bar

• Maximum inlet pressure 16 bar

• Maximum operational temperature 65°C

• Weight: 0.4 kg

Code-No. 533051

Manual shower

• Hose length 2 m

• 1/2” cut-off valve for rigid water connection

• Handle for fixing on the combi steamer compact

Code-No. 116005

• Cable length: approx. 1.8 m

Code-No. 116000

The ideal supplement:

The matching holder, Code-No. 116008

Core temperature sensor set

Consisting of core temperature sensor and matching

holder to attach to the combi steamers

• Magnetic holder: W 130 x D35 x H 30 mm

• Weight: 0.57 kg

Code-No. 116009

- 49 -

5. Installation

5.1 General safety instructions

CAUTION!

All installation, connection and maintenance works for the device must be

performed by the qualified and authorized technician according to the valid

international, national and local regulations.

• Read through these instructions carefully before the installation and operation.

• Keep this operation manual. When the device is transferred to the third party, this

operation manual should be transferred as well.

• All operations connected with the installation, assembly, operation and maintenance

must be performed by the specialized personnel having required authorization

(from the producer or vendor). The required operations must be performed

according to the installation regulations for a given country and the safety

regulations.

• Do not use the accessories and spare parts not recommended by the producer.

They may be dangerous for the user and other people or may damage the device

and cause loss of warranty rights.

• Periodically inspect the electric supply cable for damages. Do not operate the device

with the damaged supply cable. When the cable is damaged it should be replaced

by the service company or qualified electrician in order to avoid the hazards.

• The defective installation, operation errors and maintenance and cleaning mistakes as

well as any modifications may cause the incorrect operation, damages and injuries.

• The producer is not responsible for the injuries or damages resulting from not

following the above regulations or tampering and using non-original spare parts.

• In case of failures or incorrect operation the device must be turned off. The required

repairs should be performed by the service company authorized by the producer

with use of original spare parts.

• Do not place other heat sources in the device vicinity, like deep fryers or cooking

plates.

• Do not store any flammable products in the device vicinity.

• In case of longer standstill disconnect the water and electric power supply.

- 50 -

• Any modification of the device must be authorized and performed by the authorized

professional technical personnel.

• It is forbidden to make any modifications in wiring of the device.

• In case not following the safety instructions above the device safety may become

limited.

The device fulfils the requirements of the low-voltage directive 2006/95/EC.

Moreover the device conforms to the following regulations regarding the electric

installations:

• EN 60335 general part;

• EN 60335-2-42;

The device fulfils the requirements of the electromagnetic compatibility directive

2004/108/EC.

5.2 Setup

• In the beginning make sure that there are no elements blocking the way to the

installation place through the doors, corridors or other communication routes.

• CAUTION: The device may overturn during transport, which may damage the device

itself, other objects or cause the injuries. Use the means appropriate for the device

weight. The device should not be dragged or tilted, but lifted perpendicularly to the

ground and handled in the horizontal direction.

• Before positioning the device check the dimensions and exact positions of the

electric, water, and extraction connections.

• The device must be positioned in a room with sufficient ventilation (not outdoors) in

order to avoid excessive concentration of harmful substances in the air.

• We recommend to position the device under the hood or to remove hot vapours and

odours from the device chamber outside.

• Remove the external package (wooden crate and/or carton box) and utilize it

according to the regulations valid in the country of installation.

• Check the device for damages and position it in the operation place.

• Never position the device in the vicinity of the flammable materials or containers with

such materials (walls, furniture, partition walls, gas cylinders) as it may cause the fire

hazard. When it is not possible, insulate such materials with use of non-flammable heat

insulation, following all fire protection regulations.

- 51 -

• The device must be positioned on the even surface to avoid its slipping or turning

over.

• The floor in the installation place must have load carrying capacity sufficient for

weight of the device, its base and weight with full load.

Fig. 1

The device is not designed for installation

in the furniture and it is required to keep the

minimum distance of 50 mm from the walls

and other devices (fig. 1).

Assure the possibility of full opening of the glass

door (180°).

Position the device in such way that its back side

is easily accessible for connecting the electric and

water supply and for maintenance.

Level the device. Use the level and appropriately

position the adjustable feet (fig. 2).

The height differences or tilting may negatively

influence the device operation.

Carefully remove the protective foil from the

external walls, avoiding leaving the glue

residuals.

Check if the ventilation holes and the vapours

outlet are not covered or blocked.

Fig. 2

- 52 -

5.3 Water connection

Fig. 3

The potable water connection must be positioned

in the vicinity of the device.

The water pressure must not be higher than 3 bar

(300 kPa). If the water pressure is higher, install

the pressure reducer before the device.

The water pressure should be in range

of 1.8 – 3 bar.

We recommend to install the water

softener/descaler in order to obtain the hardness

vale of 3 – 7° (German) (0.6 – 1.2 mmol/l).

For water hardness of 7° (German) and above

we recommend to connect the device with use

of appropriate water softener and the pressure

up to 3 bar.

The device is equipped with connection for the

delivered water supply hose. For the devices with

6 trays the connection is located in the bottom left

side (fig. 3), and for the devices with 10 trays – in

the bottom right side (fig. 4).

Before connection flush the system with sufficient

amount of water in order to remove any iron

particles.

Connect „Aqua“ connection to appropriate

installation of cold water supply with installed

cut-off valve and filter.

Make sure that the valve is installed in easily

accessible place.

Caution: In case of water supply hose damage

replace it with new one, do not reuse old hose.

Fig. 4

- 53 -

5.4 Drain connection

Fig. 5

Water flowing from the device drain may be hot

(90°C), therefore the drain hoses should be

resistant to such temperature.

The water drain is located in the bottom back

section of the device and is equipped with

connection pipe (Ø 40 mm).

Connect the pipe with the drain element (fig. 5,

pos. A).

The drain element is the water seal. However we

recommend to connect the drain pipe with open

funnel.

Check if the internal water seal is filled with water,

and if not, fill it through the drain in the device

chamber.

5.5 Electric connection

WARNING! Electric shock hazard!

The device can cause injuries due to improper installation!

Before installation and connecting the local power grid specification should be

compared with that of the device (see type label).

Connect the device only in case of compliance!

The electric installation must have appropriate earthing, conforming to the valid regulations.

The safety of the electric installation may be assured only when that installation fulfils the

requirements of the standards.

Before connecting the device make sure that the voltage and frequency values on the

rating plate are consistent with the existing electric installation. The allowable voltage

deviation is ±10%.

In order to connect the device directly to the power supply it is required to install the

interrupting switch between the device and the installation, suitable for the power. The

contacts of that switch must have the gap appropriate for the installation instructions,

assuring full disconnection in the overvoltage category III. The interrupting switch

should be installed in a place always accessible for the personnel.

- 54 -

Position the main switch, connected to the supply

cable, in „0“ (zero) position. Check if the cable

section is suitable for the power consumed by the

device.

The power supply values are specified in the table

below:

Fig. 6

117261/

D6110

117201/

D10110

400 V 3N 50/60 Hz

5 x 2.5 mm2

5 x 4 mm2

230 V 3 50/60 Hz

208 V 3 50/60 Hz

4 x 2,5 mm

2

4 x 12 AWG

4 x 6 mm

2

4 x 8 AWG

230 V 50/60 Hz

3 x 6 mm

//

230 V 2 50/60 Hz

208 V 2 50/60 Hz

2

//

//

//

//

The device must be connected to the potential levelling circuit of

efficiency conforming to the valid regulations.

The connection is the terminal fixed to the frame and marked with

Fig. 7

the symbol in fig. 7.

5.6 Start-up and commissioning

• Before the first start-up the device must be thoroughly inspected in order to confirm

the consistency of the device and its installation with the valid regulations, technical

data and recommendations for safety, included in this document.

Moreover take into consideration the following:

Temperature in the installation place must be higher than +4°C.

The device chamber must be empty.

- 55 -

All package elements must be completely removed, including the protective foil

on the external walls.

The venting holes must be permeable.

The parts disassembled during the installation must be reinstalled.

The main switch of the electric installation must be turned on and the gas and

water cut-off valves before the device must be opened.

Inspection during commissioning

• The commissioning of the device is realized upon the basis of the test cycle allowing

for checking the correctness of operation and may reveal any damages or problems.

• Start the device with use of main switch

T1

(fig. 8, page 62).

• Set baking cycle for 10 min. at temperature of 150°C and humidity 25%.

• Press key

T14

(fig. 8) „Start/Stop“.

• Perform thorough inspection according to the following:

The device chamber illumination is turned on after pressing key

It is turned off automatically after 45 seconds or after pressing key

T13

T13

(fig. 8).

again.

The device is turned off after opening the glass door and is turned on again after

closing it.

The thermostat for the temperature adjustment in the device chamber is

activated when the preset temperature is reached. The heater(s) is (are)

turned on periodically.

The fan motor(s) direction is changed automatically every 3 minutes

(that time depends on the cooking time).

In case of devices with two fans in the chamber the motors rotate in the same

direction.

• Check the water outlet direction from the moistening hose in the chamber in relation

to the fan.

• At the end of the cooking cycle the acoustic signal is emitted.

- 56 -

6. Operation manual

6.1 Safety tips for the user

CAUTION!

Carefully read the manual below as it includes the safety and operation

instructions.

Store the manual to use it at any moment.

The defective installation, operation errors and maintenance and cleaning

mistakes as well as any modifications may cause the incorrect operation,

damages and injuries.

CAUTION!

The device is designed for professional use and must be operated by the

professional personnel.

• All persons using the device must follow the recommendations and instructions in

this manual.

• The device must be operated by the trained personnel only. In order to limit the risk of

accidents or damages it is important that the personnel is periodically and precisely

instructed in range of safety.

• The device is not to be used by persons (also children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction.

• Children should be supervised to ensure that they do not play with the device.

• Never leave the flammable materials in the vicinity of the device. Fire hazard!

• During cooking or after it the containers for food and other objects may be very hot;

maintain caution during handling to avoid burns. They must be touched only in the

protective gloves. Burn hazard!

• Maintain special caution during opening the door of the device, during work and after

it. Burn hazard during emission of hot vapours from the device.

• Pay attention to the hot areas of the device surface which temperature may exceed

60°C.

- 57 -

T1 D1 D2 D3 D4

T13

M T11

T2 T4 T5

T6 T7

T8 T9 T3 T10 T12 T14

• Do not place any flammable objects or food articles with alcohol in the device: the

self-ignition and fire may occur, which may lead to explosions.

• Avoid salting of food in the device chamber. Whet it is necessary, clean the device

as quickly as possible: the device chamber may become damaged.

• Open the device door carefully when the chamber is hot. Burn hazard!

• In case of damages of the glass door elements immediately turn the device off and

contact the service company. Do not use the device before the door replacement.

• In case of standstill (e.g. 12 hours) leave the glass door slightly opened.

• In case of longer standstill (e.g. a few days) disconnect the water and electric power

supply.

6.2 Operation elements

Key Name

T1

ON/OFF

T2

Selection of operation mode

T3

∆T (cooking delta T)

T4

Temperature

T5

Core

- 58 -

Fig. 8

Function

Device turning on and off

Setting of air circulation / steam moistening /

combined steam moistening

Cooking in ∆T mode

Cooking in constant temperature

Temperature setting for the core (option)

T6

Time

T7

Fan Setting of fan speed 1 – 3

T8

Moistening

T9

Cooking phases / pre-heating

T10

Programs Selection of saved cooking programs

T11

Steam outlet Opening / closing of steam outlet

T12

ESC key Return key

T13

Steamer chamber illumination Turning on/off the device chamber illumination

T14

Start / Stop Activation / deactivation of cooking

D1

Temperature indicator

D2

Time / core indicator Indicator of cooking time or core temperature

D3

Fan speed / humidity indicator Indicator of fan speed and preset humidity

Cooking phase / program

D4

indicator

Setting of cooking time or selection of no

limitation mode

Setting of moistening in COMBI and STEAM

MOISTENING modes

Programming / activation and deactivation of

cooking phases and setting of pre-heating

Indicator of temperature in the cooking

chamber or ∆T

Indicator of program number or cooking phase

Knob rotation allows for setting of required

M

Knob / CODER

value. Knob pressing confirms the entered

value.

- 59 -

T1 D1 D2 D3 D4

T13

M

T11

T2 T4 T5

T6 T7

T8 T9 T3 T10 T12 T14

6.3 Introduction to the device operation

The device has been designed for preparation of the food products in closed rooms and

must be used for that purpose only. Any other use is considered incorrect and

dangerous and is forbidden.

The device must be supervised during the operation.

We recommend to pre-heat the device before cooking with use of automatic pre-heating

function (section 6.4.8, page 68).

The display is equipped with the touch sensors. In order to select a given function it is

required to press the corresponding key. In order to set the selected cooking parameter it

is required to press the flashing key.

Caution: using of thick gloves may make precise pressing of keys difficult.

Rotation of knob M (fig. 9) allows for setting the value of selected function (e.g. increase

or decrease temperature/time/humidity).

The entered value is confirmed by pressing knob M (fig. 9) or appropriate key.

Hint: pressing knob M (fig. 9) allows for deactivation of an alarm.

Device turning on and off

Pressing and holding key T1 (fig. 9) for 3 seconds turns the device on or off. After

turning on the device is in the standby mode and waits for setting of the cooking

parameters.

After turning the device off by longer pressing the main switch T1 (fig. 9) the cut-off valve

before the device is closed.

After turning the device off the electronic assembly ventilation above the chamber may

still operate in order to assure its cooling.

Fig. 9

- 60 -

Activation / deactivation of cooking

Pressing of key

T14

(fig. 9) allows for starting or stopping of the cooking process. Door

opening interrupts the cooking process. After closing the door the already started

cooking process is continued from the interruption point. The ongoing cooking cycle

may be interrupted with use of key

Cooling of device chamber

Press and hold key Esc

key

T14

“Start/Stop” (fig. 9) to start cooling. Only then it is allowed to close the door.

T12

(fig. 9) until the initial settings are restored. Then press

Cooling of the device chamber operates only when the temperature measured in the

chamber exceeds 50°C.

Steamer chamber illumination

In order to turn the illumination on press key

automatically after the defined time or after pressing key

T14

(fig. 9).

T13

(fig. 9). The illumination turns off

T13

(fig. 9) again.

- 61 -

D1 D2

inF 230 50 HU

MANUELL

T6 T4

T1

6.4 Manual programming

6.4.1 Setting of cooking temperature

Turn the device on by pressing key T1 (fig. 10), after turning on the device is in the

standby mode and waits for setting of the cooking parameters.

Press key

to increase the value or counterclockwise to decrease it. Press knob M or key T4

(fig. 10) to confirm the value. The set temperature is displayed on the indicator D1

(fig. 10). The cooking temperature depends on selected operation mode (section

6.4.4, page 63) and is:

Steam: min. 50°C - max. 120°C

6.4.2 Setting of cooking time

Use key T6 (fig. 10) to set the required cooking time, or select “no limitation“ mode.

After turning the device on the indicator D2 (fig. 10) normally shows setting “inF” (“no

limitation“).

The value may be changed by pressing key T6 (fig. 10). Then turn knob M clockwise to

increase the value or counter clockwise to decrease it.

The setting “no limitation“ is set by rotating knob M counter clockwise until the

indicator D2 (fig. 10) displays “inF”.

Press knob M (fig. 10) or key T6 (fig. 10) to confirm the value.

T14

(fig. 10) to set the cooking temperature. Then turn knob M clockwise

Air circulation: min. 50°C - max. 280°C

Combi: min. 50°C - max. 250°C

Fig. 10

- 62 -

T1 D

3

00:50

50

FAN 3

T7

MANUELL

6.4.3 Temperature setting and automatic pre-heating

The fan speed may be set to one of three available speeds:

SPEED 1 (low)

SPEED 2 (medium)

SPEED 3 (high)

Press key T7 (fig. 11) to set the fan speed.

Then turn knob M clockwise to increase the value or counterclockwise to decrease it.

Press knob M (fig. 11) or key T7 (fig. 11) to confirm the value. The set fan speed is

displayed on the indicator D3 (fig. 11).

6.4.4 Selection of operation mode

The device allows for selection of one of three available operation modes:

HOT AIR

COMBI

STEAM

In HOT AIR mode the food is prepared only with use of hot air and no moisture in form of

steam is introduced into the chamber (reduction of product humidity).

In STEAM mode air is enriched with steam (humidity 100%).

In COMBI mode either hot air and steam are used in adjustable ratio (set by the user).

Fig. 11

- 63 -

D

3

00:50

50

70 HU

MANUELL

T8

After turning on the device is normally in HOT AIR mode.

T8

Press key

(fig. 12) to switch into that mode.

Indicator D3 (fig. 12) shows humidity 0= 0 HU. Rotate knob M (fig. 12) to set the

required value. Press knob M (fig. 12) or key T8 (fig. 12) to confirm the operation

mode.

STEAM mode may be selected with use of key T8 (fig. 12). Indicator D3 (fig. 12) shows

value 100= 100 HU. Rotate knob M (fig. 12) to set the required value and confirm it

by pressing knob M (fig. 12) or key T8 (rys. 12).

COMBI mode may be selected with use of key T8 (fig. 12). Indicator D3 (fig. 12) shows

humidity between 10 and 90= 10 HU / 90 HU. Press key T8 (fig. 12) and rotate knob M

(fig. 12) to set the required value. Press knob M (fig. 12) or key T8 (fig. 12) to confirm the

value.

According to the description above the operation mode may change depending on preset

humidity:

Humidity = 0 HOT AIR Food preparation with use of hot air.

Humidity = 10-90 COMBI

Food preparation with use of hot air

and in presence of steam.

Humidity = 100 STEAM Food preparation in presence of steam

Fig. 12

- 64 -

D

1 D

2

20 C 200 0 HU

MANUELL

T5

6.4.5 Cooking with use of core (option)

An alternative for the cooking time / program phase is monitoring of the preparation

process with use of temperature measurement inside the product. That operation mode

is especially suitable for meat, poultry, and fish.

Press key T5 (fig. 13), indicator D2 (fig. 13) displays the preset temperature. Rotate knob

M

(fig. 13) clockwise to increase the temperature or counterclockwise to decrease it.

Press knob M (fig. 13) or key T5 (fig. 13) to confirm the value.

Hint: food preparation temperature must be always 5°C higher than the preset

temperature inside the product.

Core position (option):

The core should be placed in the prepared product in such way that its tip is positioned

in the central part of the highest volume.

Approximate temperature values inside the product:

FOOD TYPE

PREPARATION

METHOD

TEMPERATURE

Beef rare 50 °C

medium 60 °C

well 70 °C

Drumsticks well 80 °C

Chicken breast well 73 °C

White meat well 70-75 °C

General cooking well 85-90 °C

Fish boiled 67-72 °C

Fig. 13

- 65 -

TIME

TEMPERATURE

D

1 D

2

00:50

50

0 HU

T5

T3

MANUELL

6.4.6 Food preparation with use of delta T function

In opposition to the constant temperature, food preparation with use of delta T function is

realized according to the temperature rise in the device chamber in parallel to the

temperature rise inside the product, measured with use of core, always accordingly to the

preset value of delta T. Delta T corresponds to the temperature difference between the

product interior and the device chamber, which is maintained by the device until the end of

cooking (fig. 14). Food preparation with use of delta T function requires the core.

After pressing key T3 (fig. 15) the indicator D1 (fig. 15) shows ∆

T (

delta T)

.

Rotate knob M clockwise to increase the

Chamber temperature

value or counter clockwise to decrease it.

Press knob M or key T5 (fig. 15) to

confirm the value. Then set the

temperature in the product according to

Product temperature

the previous section.

Use of ∆T cooking mode:

Fig. 14

∆T mode is especially suitable for preparation of roast meat or ham of medium and

large size. That preparation method uses temperature in the device chamber lower than

in traditional preparation. The longer preparation time makes the product more crispy

and allows to avoid big weight losses.

The following ∆T are recommended:

• 30°C for red meat of temperature in the product b etween 45°C and 55°C;

• 25°C for red meat of temperature in the product b etween 75°C and 85°C.

Fig. 15

- 66 -

D

1 D

2

50 C 268 30 HU

STEP 3

T9 T2

6.4.7 Programming of the multiple-phase

cooking

Each cooking program may consists of multiple phases, for which various settings are

defined (preparation method, temperature, time, etc.). Each cooking program may

include up to 9 phases.

After entering the parameters for the first cooking phase as described above press key

T9

(fig. 16) and rotate knob M clockwise. Indicator D4 (fig. 16) displays the second

phase S T E P 2. Press key T2 (fig. 16) to confirm the intention of programming of the

next cooking phase.

Enter the parameters for the second cooking phase and repeat the steps described

above to add the successive cooking phases to the program.

Hint: adding of the successive cooking phase is possible only when the finish time or

the temperature inside the product are entered. If neither of those two parameters is set,

switching to the next phase during the food preparation is not possible.

Hint: during switching to the next cooking phase key T2 (fig. 16) flashes until pressing.

Flashing of that key indicates that the phase is not programmed and the device is

unable to realize it.

Programming examples:

Phase 1: STEAM 110°C 15 min. FAN 3 100 HU

Phase 2: STEAM 205°C 6 min. FAN 1 0 HU

Phase 3: COMBI 168°C 50°C FAN 1 30 HU

Fig. 16

- 67 -

D

4

00:50

50

0 HU

PRE? Y

T9 T14

6.4.8 Setting of the automatic pre-heating of the device chamber

In order to achieve good preparation effect we recommend pre-heating of the device

chamber with use of pre-heating function.

It may be realized automatically during the start of the cooking program.

After entering the parameters for the first cooking phase as described above press key

T9

(fig. 17) and rotate knob M (fig. 17) counterclockwise until the indicator D4 (fig. 17)

shows PRE? N. Press knob M (fig. 17) to activate the automatic pre-heating. The

indicator D4 (fig. 17) shows PRE? Y. Then rotate knob M (fig. 17) clockwise to return

to the selected cooking phase or start the new phase.

After starting with key

The automatic pre-heating heats the device to the temperature higher by 25°C than the

temperature set for phase 1 in order to assure better temperature after opening of the

glass door and placing the cold product in the chamber.

When the entered temperature is reached the acoustic signal is emitted. Then it is

allowed to place the food in the device chamber.

Caution: pre-heating must be realized with empty chamber. Before placing the

food inside wait for the acoustic signal.

T14

(fig. 17) the device starts pre-heating.

PRE? Y STEP 1 STEP 2 STEP 3 STEP 4 →

Fig. 17

- 68 -

00:50

50

0 HU

MANUELL

T9 T14

T11

6.4.9 Opening and closing of steam outlet

In HOT AIR mode there is a possibility of adjusting of the steam outlet opening and

closing. The steam outlet is designed for removing the moisture from the device

chamber.

Press key

T11

(fig. 18) to open the steam outlet.

Opening and closing of steam outlet is indicated by the state of key

ON = STEAM OUTLET OPENED

OFF = STEAM OUTLET CLOSED

Hint: the adjustment of steam outlet is possible only in HOT AIR mode. In COMBI

and STEAM modes the outlet is controlled automatically by the device.

T11

(fig. 18):

Fig. 18

- 69 -

D

4

00:50

50

0 HU

PRG 15

T9 T14

T10

6.5 Navigation in the recipes menu

6.5.1 Saving the cooking program in the device memory

Each cooking program defined in the manual mode and consisting of one or more

phases may be saved in the internal memory of the device for easy opening with use of

start menu and using in the future.

After entering all required cooking parameters press key

The indicator D4 (fig. 19) displays the number of the first free program in the memory

(for example, if there are 3 saved programs with numbers 1, 2 and 3, number 4 will be

displayed as the next free place in the memory).

Rotate knob M (fig. 19) to select the program number.

Then save the selected position by pressing key

The indicator D4 (fig. 19) shows MEM.

6.5.2 Loading the cooking program from the memory

In the standby mode press key T10 (fig. 19) and rotate knob M (fig. 19) to select the

number program, which is to be loaded, on indicator D4 (fig. 19).

Then start the cooking process by pressing key “Start/Stop”

Hint: the cooking phases for a given program may be previewed by pressing key T9

(fig. 19) and rotating knob M (fig. 19).

The indicator D4 (fig. 19) shows the current cooking phase (STEP).

T10

T10

(fig. 19) for 3 seconds.

(fig. 19) for 3 seconds.

T14

(fig. 19).

Fig. 19

- 70 -

D

4

00:50

50

0 HU DEL? Y

T9 T14 T10

6.5.3 Modification of the cooking program save in the memory

After selecting the cooking program its parameters may be changed according to

section “Manual programming”.

To save the changes press key

T10

(fig. 20) for 3 seconds. The modified program

overwrites the previous version.

6.5.4 Removing the program or its part from the memory

The program saved in the memory may be removed as a whole or partially.

Removing the whole cooking program:

1. Select the program to be removed

2. Select its first cooking phase (STEP 1)

3. Press and hold key

4. The indicator

5. Rotate knob

Confirm the operation by pressing knob M.

In order to remove a part of the cooking program select the cooking phase

to be removed and press key T9 (fig. 20). Then follow the instructions in

sections 4 and 5 above.

Hint 1: removing of one cooking phase removes also all successive

Example: if a program consists of 5 phases, removing of phase 3 removes also

Hint 2: after removing only a part of the program its remains are saved

T9

(fig. 20)

D4

(fig. 20) shows DEL? N

M

(fig. 20), the indicator D4 (fig. 20) displays the question DEL? Y.

phases.

phases 4 and 5.

in the memory as the last record (i.e. without the removed

phases).

Fig. 20

- 71 -

D

4

D

3

D

1 D

2

T9 T10

6.5.5 Importing and exporting the recipes from the USB memory

The device allows for importing and exporting the

cooking programs from the USB memory to the device.

Importing of cooking programs:

1. Turn the device on.

2. Connect the compatible USB memory to the USB

port (fig. 21).

Fig. 21

3. Press knob

M

(fig. 22) and key

T10

(fig. 22)

simultaneously.

4. The importing operation is finished when the display indicators show the following

information:

D1 D2 D3

uSb TFINISH E UPLOAD

5. Now it is allowed to remove the USB memory.

D4

Exporting of cooking programs:

1. Turn the device on.

2. Connect the compatible USB memory to the USB port.

3. Press knob M (fig. 22) and key T9 (fig. 22) simultaneously.

4. The exporting operation is finished when the display indicators show the following

information:

D1 D2 D3

D4

uSb TFINISH EDOWNLOAD

5. Now it is allowed to remove the USB memory.

Fig. 22

- 72 -

7. Cleaning and maintenance

7.1 Safety advice

CAUTION!

Before any activities connected with cleaning it is required to disconnect the

power supply, close the water supply and wait for complete cooling of the device.

o In order to assure reliable operation, hygiene and efficiency the device should be

cleaned everyday after work.

o Do not use any acid products, abrasive agents, caustic cleaning agents containing

sand or soda lye.

o Do not use steel wool, wire brushes or steel spatulas.

o In order to protect yourself from the eletric shock never immerse the device, supply

cable or plug in water or other fluids.

CAUTION!

The device is not designed for flushing with direct water jet. Therefore do not use

the pressurized jet for cleaning the device (inside and outside).

7.2 Cleaning

Regular cleaning of the device chamber

o The shelves rails may be removed from the device for easier cleaning. To do this,

unscrew the fixing bolts and remove the rails.

o Clean the device chamber only with lukewarm water and gentle cleaning agent.

All washed surfaced should be rinsed with clean water and thoroughly dried.

Pay attention to not to leave any washing agent residuals.

External cleaning

o Clean the external surfaces of the device only with cloth soaked in water.

o Use only agents designed for cleaning of high-grade stainless steel, as improper

cleaning agents may cause corrosion of the device.

o Do not use the agents containing chlorine (bleachers, hydrochloric acid, etc.).

o After cleaning dry and polish the surface with dry cloth.

- 73 -

To maintain correct temperature of the electronic

ld be cleaned

Cleaning of the device door

o Before cleaning of the door the device must

be completely cooled down.

o Double glazing facilitates cleaning. The internal

glass may be opened.

o To do this, loosen the upper and lower steel plate

locking the internal glass. Rotate the plates

clockwise.

o Tilt the internal glass (fig. 23).

o Clean the internal glass on both sides and the

device door with use of appropriate agents.

o Do not use any aggresive and abrasive cleaning

agents.

o Close the internal glass and put the steel plates in

Fig. 23

the initial position.

CAUTION!

Before closing of the device make sure that the internal glass is fixed with the

steel plates, otherwise it will not be possible to close the door.

7.3 Fan cleaning

Fig. 24

CAUTION!

In case of „Hi Temp“alarm the most probable reason is excessive contamination

of the fan. Clean the fan immediately!

- 74 -

elements of the device the fan shou

periodically, at least once a month.

The fan is located in the back part of the device

(fig. 24). Cleaning procedure:

1. Grab the fan tongue and pull it up from

the slot.

2. Remove the fan from the housing, clean

with lukewarm water and neutral cleaning

agent and dry with clean cloth.

3. Put the fan back into the housing and

slide into the slot.

8. Possible Malfunctions

Failure

The device cannot be

turned on

When it is still not possible to start the device after above activities, contact the

service company.

The fan stops during

the operation

When the failure persists contact the service company.

The chamber

illumination does not

work

When the failure persists contact the service company.

• Check if there is electric voltage and the main switch is

turned on.

• Check the fuses in the device.

• Make sure that the glass door is properly closed.

• Check if the parameters of selected cooking cycle are

correct.

• Make sure that there are no error messages.

Possible solutions

• Turn the device off and wait until the overheating protection

starts the motor automatically.

• Make sure that the ventilation holes are permeable.

Use only temperature-resistant light bulbs!

The internal illumination bulb replacement procedure:

- make sure that the switch before the device is

turned off,

- loosen the bolts and remove the shelves rails

from the left internal wall of the device,

- unscrew the illumination cover bolts,

- remove the cover, glass and seal,

- replace the damaged bulb with new halogen bulb 25 W,

- replace the cover, glass and seal,

-

reinstall the shelves rails.

The water is not

supplied through the

moistening pipes

When the failure persists contact the service company.

• Check if the water valve is opened.

- 75 -

CAUTION!

The above problems only serve for orientation and as examples. Should these or

similar problems occur, turn the device off immediately and discontinue using it. If

the failure cannot be removed, immediately contact the service company or vendor

in order to inspect and repair the device. Prepare the article number and the device

serial number specified on the rating plate on the back. Never attempt to repair the

device by yourself.

9. Waste disposal

Discarding old devices

At the end of its service life the discarded device has to be disposed in accordance with

the national regulations. It is advisable to contact a company which is specialized in

waste disposal, or just contact the local disposal service in your community.

WARNING!

To exclude any abuse and the dangers involved make the waste device unfit for

use before disposal. For that purpose disconnect device from mains supply and

remove mains connection cable from the device.

NOTE!

For the disposal of the device please consider and act

according to the national and local rules and

regulations.

Bartscher GmbH

Franz-Kleine-Str. 28

D-33154 Salzkotten phone: +49 (0) 5258 971-0

Germany fax: +49 (0) 5258 971-120

- 76 -

Loading...

Loading...