FR Fours mixtes à vapeur série V

GB Combi steamer serie V

DE Kombidämpfer Serie V

116050 / V 5230

116060 / V 6640

116070 / V 10640

V1/0215

- 39 -

ENGLISH

Translation

of the original instruction manual

Table of contents

1.Safety ........................................................................................................................ 40

1.1 Safety instructions ............................................................................................... 40

1.2 Key to symbols .................................................................................................... 41

1.3 Hazard sources ................................................................................................... 42

1.4 Proper use ........................................................................................................... 44

2. General information ................................................................................................ 45

2.1 Liability and Warrantees ...................................................................................... 45

2.2 Copyright protection ............................................................................................ 45

2.3 Declaration of conformity ..................................................................................... 45

3. Transport, packaging and storage......................................................................... 46

3.1 Delivery check ..................................................................................................... 46

3.2 Packaging ........................................................................................................... 46

3.3 Storage ................................................................................................................ 46

4. Technical data ......................................................................................................... 47

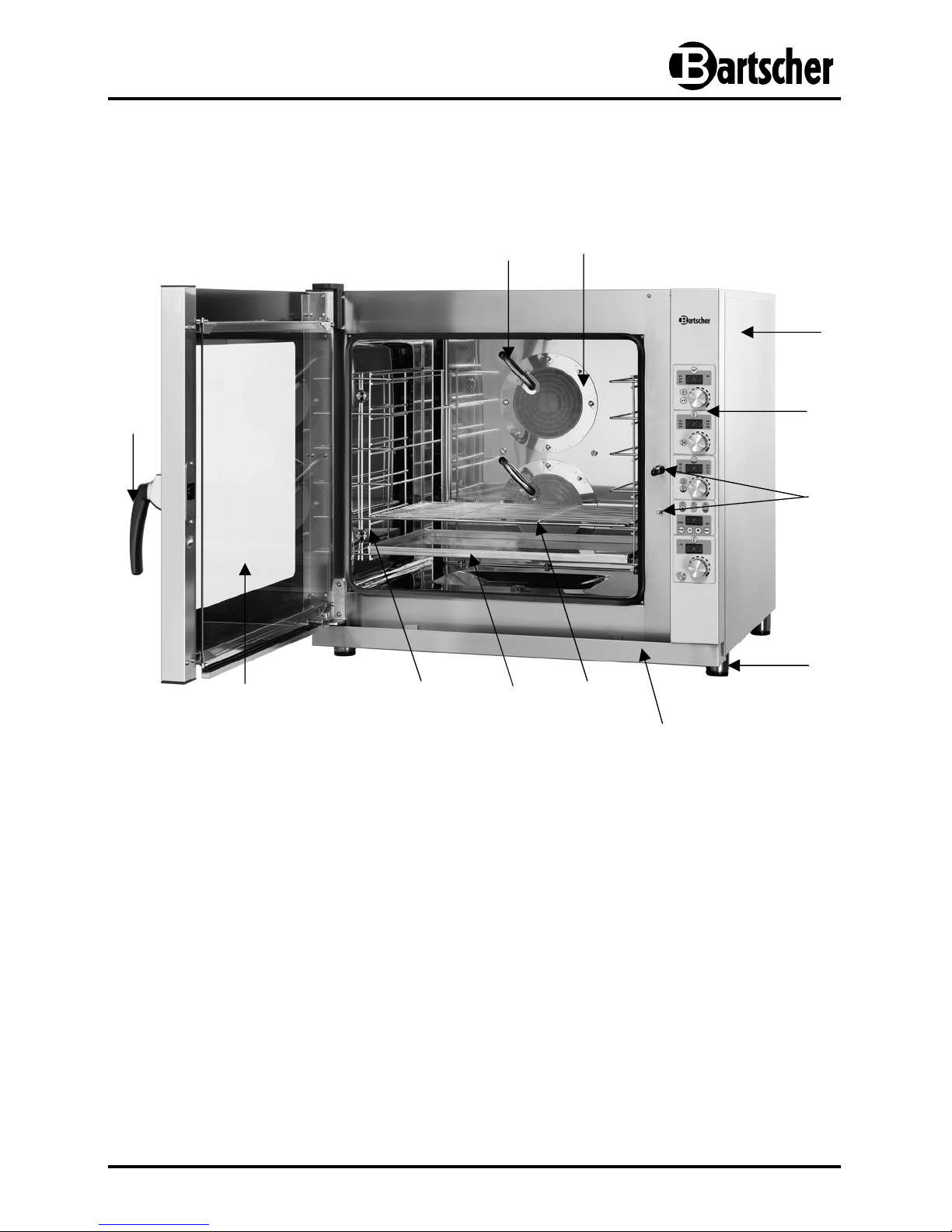

4.1 Overview of parts ................................................................................................ 47

4.2 Technical specification ........................................................................................ 48

5. Installation and operation ....................................................................................... 53

5.1 Instructions for the installer ................................................................................ 53

5.1.1 Instructions ................................................................................................ 53

5.1.2 Preparation ................................................................................................ 53

5.1.3 Place of installation .................................................................................... 54

5.1.4 Preparing to Install ..................................................................................... 55

5.1.5 Power supply connection ........................................................................... 56

5.1.6 Water connection....................................................................................... 58

5.1.7 Water outlet ............................................................................................... 59

5.1.8 Steam outlet vent....................................................................................... 59

5.2 Operation ........................................................................................................... 60

5.2.1 Safety tips for the user ............................................................................... 60

5.2.2 First use ..................................................................................................... 61

5.2.3 Operation elements / Functions the buttons and keys ............................... 62

5.3 Cooking instructions ........................................................................................... 68

6. Cleaning and maintenance ..................................................................................... 71

6.1 Standard cleaning and maintenance ................................................................... 71

6.2 Special maintenance ........................................................................................... 74

7. Waste disposal ........................................................................................................ 76

GB/UK

- 40 -

Read this instruction manual before using and

keep them available at all times!

This instruction manual contains information about the installation, operation and

maintenance of the device and should be consulted as an important source of

information and reference guide.

Awareness of the safety instructions and instructions for use in this manual will ensure

the safe and correct use of the device.

In addition to the information given here, you should comply with any local Health and

safety Controls and generally applicable safety regulations.

The instruction manual forms part of the product and should be kept near the device

and easily accessible for anyone carrying out the installation, servicing, maintenance or

cleaning.

1.Safety

This device is designed in accordance with the presently applicable technological

standards. However, the device can pose a danger if handled improperly and

inappropriately.

All persons using the device must follow the recommendations and instructions

in this instruction manual.

1.1 Safety instructions

• Please keep these instructions and give them to future owners of the device.

• Preserve this manual safely. When passing on/selling the device to a third party, the

manuals must be handed over along with the device.

• This device may only be operated in technically proper and safe condition.

• The device is not intended for use by individuals (including children) with physical or

mental disabilities, insufficient experience, and/or insufficient knowledge unless such

persons are under the care of a person responsible for their safety or have received

instructions regarding appropriate use of the device.

• Children should be observed to ensure that they are not playing with the device.

• Only a qualified technician and using original spare parts and accessories should

carry out repairs and maintenance of the device. Do not attempt to repair the

device yourself.

• Do not use any accessory or spare parts that have not been recommended by the

manufacturer. These can be dangerous for the user or lead to damages of the

device or personal injury, and further, the warranty expires.

- 41 -

• To prevent hazards and to ensure optimum efficiency, no modifications or alterations

to the device that are not explicitly approved by the manufacturer may be undertaken.

• Never allow the power cable to come into contact with heat sources or sharp edges.

The power cable should not hang over the side of the working surface. Ensure that no

one can step on or trip over the cable.

• The power cable must not be folded, bent or tangled, and must always remain fully

unrolled.

• Never place the device or other objects on the power cable.

• Do not lay the cable over carpets or heat insulations. Do not cover the cable.

Keep away the cable from operating range and do not dunk it into water.

• Inspect the power cable regularly for damage. Never use the device if the cable is

damaged. If the power cable is damaged, have an authorised service center or

qualified electrician replace it.

• The device is not adapted for use with an external timer or remote control.

• Never leave the device unattended when in use.

• Do not move or tilt the device when in operation.

• Only use the device indoors.

1.2 Key to symbols

In this manual, symbols are used to highlight important safety instructions and any

advice relating to the device. The instructions should be followed very carefully to avoid

any risk of accident, personal injury or material damage.

WARNING!

This symbol highlights hazards which could lead to injury.

To avoid them please follow the instructions very carefully and proceed with

particular attention in these cases.

WARNING!

This symbol highlights dangerous situations which could lead to injury or death.

To avoid them please follow the instructions very carefully and proceed with

particular attention in these cases.

- 42 -

CAUTION!

This symbol highlights dangerous situations which could lead to light

injuries, or damage, malfunction, and/or destruction of the device.

To avoid them please follow the instructions very carefully and proceed

with particular attention in these cases.

NOTE!

This symbol highlights recommendations and information aimed for

effective and trouble-free device operation.

1.3 Hazard sources

DANGER!

Electric shock hazard!

To avoid the hazard results please follow the safety instructions below.

Do not use the device in case of incorrect operation, damages or dropping on the

floor. When the cable is damaged it should be replaced by the service company or

qualified electrician in order to avoid the hazards.

The supply cable must be disconnected from the socket only by pulling the plug.

Never carry or lift the device by the supply cable.

In any case do not open the device housing. In case of electrical or mechanical

modifications the electric shock hazard will occur.

Never immerse the plug in water or other liquids.

Do not use any acid agents and make sure no water ingresses the device.

Never operate the device with moist hands or standing on wet floor.

Remove the plug from its socket:

- when the device is not used,

- in case of anomalies during operation,

- before cleaning.

- 43 -

DANGER!

Suffocation hazard!

Prevent access of children to the package materials like plastic bags and

foamed polystyrene elements.

The temperatures of food containers or other objects during and after cooking can

be very high; be particularly careful when handling them to avoid burns. You may

only grasp them wearing protective gloves.

Open the device door with particular caution: There is a risk of burns by escaping

high temperature steam.

When using a core temperature sensor, before removing baking trays from the

device make sure that the sensor has been removed from the food and forms no

obstacle.

The outside surfaces of the device may reach a temperature

exceeding 60 °C. To avoid burns, do not touch the a reas or parts

marked with this symbol.

WARNING!

Risk of fire or explosion!

In case of improper use of the device, inflammation of the content may cause a risk of

fire or explosion.

To avoid the risk, follow these safety instructions:

• Do not put any flammable objects and spirit-based food into the device: they may

cause spontaneous combustion and fire which in turn can lead to explosions.

• Never leave easily inflammable materials near the device.

• Do not deposit or use any flammable substances near the device.

- 44 -

CAUTION!

• Avoid salting dishes in the combi steamer cooking chamber. If you cannot avoid this,

make sure to clean it as soon as possible since salt may damage the cooking

chamber.

• Use your fingers to operate the control panel; using any other object may damage

the device and result in voiding the guarantee.

1.4 Proper use

CAUTION!

This device has been designed and built for commercial use only

and should be operated by qualified personnel only.

The operational safety of the device is assured only in case of proper use, according

to the operation manual.

All technical activities like installation and maintenance must be performed by the

qualified service personnel only.

The combi steamer is intended only for the preparation of certain food:

- baking fresh and frozen confectionery products and bread;

- heating all kinds of fresh and frozen food products;

- steaming vegetables, meat and fish;

- the option of cooking in the vacuum may be used only with the appropriate bag;

- maintaining the temperature of chilled and frozen meals.

CAUTION!

Any use going beyond the intended purpose and/or any different use of the

device is forbidden and is not considered as conventional.

Any claims against the manufacturer or his authorized representative as a

consequence of experiencing damages resulting from unconventional use

are impossible.

The operator is liable for all damages resulting from inappropriate use.

- 45 -

2. General information

2.1 Liability and Warrantees

All the information and instructions in this manual take into account standard safety

regulations, current levels of technical engineering as well as the expertise and

experience we have developed over the years.

The instruction manual was translated with all due care and attention. However, we do

not accept liability for any translation errors. The German version of this instruction

manual is definitive.

If the delivery consists of a special model, the actual scope of delivery may differ from

the descriptions and illustrations in this manual. This is also the case for special orders

or when the device has been modified in line with new technology.

CAUTION!

Read this manual carefully and thoroughly before any operation

of the device, and especially before turning it on!

Manufacturer is not liable for any damages or faults caused by:

- violation of advice concerning operation and cleaning;

- use other than designed;

- alterations made by user;

- use of inadequate spare parts.

We reserve the right to make technical changes for purposes of developing and improving

the useful properties.

2.2 Copyright protection

The instruction manual including any texts, drawings, images or other illustrations is

copyright. No part of this publication may be reproduced, transmitted or used in any

form or by any means without permission in writing from the manufacturer. Any person

who commits any unauthorized act in relation to this publication shall be liable to claims

for damages. All rights reserved.

NOTE!

The contents, texts, drawings, pictures and any other illustrations are

copyright and subject to other protection rights. Any person unlawfully

using this publication is liable to criminal prosecution.

2.3 Declaration of conformity

The device complies with the current standards and directives of the EU.

We certify this in the EC declaration of conformity. If required we will be

glad to send you the according declaration of conformity.

- 46 -

3. Transport, packaging and storage

3.1 Delivery check

Please check the delivery upon completeness and transport damage immediately

after receipt. In case of visible damage do not accept or accept the delivery with

reservation only.

Note the extent of damage on the carrier’s bill of delivery. Trigger off the complaint.

Hidden damages should be reclaimed immediately after notice, as claims for damages

can only be asserted within the effective period for complaints.

3.2 Packaging

Please do not throw away the covering carton of your device as it might be useful for

storage purposes, when moving or, in case of damages, when the device must be sent

back to a repair center. The outer and inner packing material should be removed

completely from the device before installation.

NOTE!

If you liked to dispose the packing, consider the regulations applicable in

your country. Supply re-usable packing materials to the recycling.

Please inspect the device upon completeness. In case any part is missing please

contact our customer service center immediately.

3.3 Storage

Keep the package closed until installation and under consideration of the outside

indicated positioning- and storage markings.

Packages should be stored under consideration of the following:

- Do not store outdoors.

- Keep it dry and dust-free.

- Do not expose it to aggressive media.

- Do not expose it to direct sunlight.

- Avoid mechanical shocks and vibration.

- In case of longer storage (> 3 months) make sure you check

the state of the packaging and the parts regularly.

If required refresh or renew.

- 47 -

4. Technical data

4.1 Overview of parts

①

Housing

⑦

Tray

②

Control panel

⑧

Guiding rails

③

Safety lock device

⑨

Device door

④

Height adjustable feet

⑩

Door handle

⑤

Drain

⑪

Fan

⑥

Grid

⑫

Grease filter

⑧

⑦

①

⑨

⑩

⑤

⑪

⑥

④

③

⑫

②

- 48 -

4.2 Technical specification

Properties of combi steamers series V

Model CNS

Electronic control with 99 programmes and up to 9 phases in each programme

Functions: convection, steaming, combi steaming

Reversing engine direction (clockwise and counter-clockwise rotation)

for an optimal cooking chamber temperature

6 speed adjustable fan

Steam generation through direct injection

Illuminated cooking chamber

Convenient side-loading tray

Front-side connection for core temperature sensor

LED indicators for temperature, time, humidity, programme, core temperature

Prepared for attaching a core temperature sensor

Double door glazing, inner door can be opened easily for cleaning

Removable support rails

Combi steamer V 5230

up to 5 x 2/3 GN

Capacity of up to 5 x 2/3 GN

Distance between insertions 75 mm

Temperature range: 0 °C to 260 °C

Connection to water supply 3/4“

Power: 3.3 kW / 230 V 50-60 Hz 1 NAC - plug-in

Size: W 700 x D 780 x H 613 mm

Weight: 52.2 kg

Code-No. 116050

Delivery includes 1 grid 2/3 GN, 1 baking tray 2/3 GN, 1 grease filter,

water supply hose, drain hose

- 49 -

Combi steamer V 6640

up to 6 x 600x400

Capacity of up to 6 x 600 x 400 mm

Distance between insertions 75 mm

Temperature range: 0 °C to 260 °C

Steam control system: guarantees a constant cooking space atmosphere

Adjustable steam extractor

Connection to water supply 3/4“

Power: 9.6 kW / 400 V 50-60 Hz 3 NAC

Size: W 925 x D 955 x H 837 mm

Weight: 97.6 kg

Code-No. 116060

Delivery includes 1 grid 600x400, 1 baking tray 600x400, 1 grease filter,

water supply hose, drain hose

Combi steamer V 10640

up to 10 x 600x400

Capacity of up to 10 x 600 x 400 mm

Distance between insertions 75 mm

Temperature range: 0 °C to 260 °C

Steam control system: guarantees a constant cooking space atmosphere

Adjustable steam extractor

Connection to water supply 3/4“

Power: 14.4 kW / 400 V 50-60 Hz 3 NAC

Size: W 925 x D 955 x H 1120 mm

Weight: 133 kg

Code-No. 116080

Delivery includes 1 grid 600x400, 1 baking tray 600x400, 1 grease filter,

water supply hose, drain hose

We reserve the right to make technical changes!

- 50 -

Protective devices

The device is equipped with the following protective and safety systems:

Door microswitch

The microswitch interrupts the device operation after opening the door: both the

heating system and the fan(s) are turned off. After closing the door the interrupted

cycle is continued.

It is forbidden to manually activate the microswitch when the door is opened.

Motor overheating protection

The fan motor is equipped with overheating protection which interrupts the operation

in case of overheating. The fan motor operation is restored automatically when the

temperature drops to a value in the safe range.

Safety thermostat of the cooking chamber

When the temperature in the cooking chamber reaches 350°C, the safety thermostat

opens the supply circuit of the device heaters.

CAUTION!

The safety thermostat must be reactivated by the technical service personnel

as its operation indicates that other elements must be inspected.

- 51 -

Auxiliary equipment (not included in the delivery)

Manual shower

• Hose length 2 m

• 1/2” cut-off valve for rigid water connection

• Handle for fixing on the combi steamer compact

Code-No. 116005

Core temperature sensor

for combi steamers series V

• Cable length: ca. 1.8 m

• Weight: 0.14 kg

Code-No. 116071

Pressure limiter for the combi steamer compact

devices

• Made from chrome-plated brass, connection 3/4”

• Initial setpoint 3 bar, adjustment from 1 to 6 bar

• Maximum inlet pressure 16 bar

• Maximum operational temperature 65°C

• Weight: 0.4 kg

Code-No. 533051

1 pair of GN guiding rails

for use of 7 baking trays 1/1GN

Suitable for combi steamers 116060

Stainless steel

Distance between insertions 50 mm

Weight: 3.2 kg

Code-No. 116073

- 52 -

1 pair of GN guiding rails

for use of 12 baking trays 1/1GN

Suitable for combi steamers 116080

Stainless steel

Distance between insertions 50 mm

Weight: 5.2 kg

Code-No. 116074

Extraction hood

for combi steamers series V

Suitable for installation for combi

steamers: 116060, 116080

Stainless steel

Stainless steel filter

On/off switch

Power:

0.145 kW / 230 V 50 Hz

Size: W 925 x D 1000 x H 235 mm

Weight: 34.4 kg

Code-No. 116099

Base unit

for combi steamers series V

116060, 116080

CNS 18/10

Capacity: 10 x GN 1/1

Size: W 920 x D 665 x H 800 mm

Weight: 18.6 kg

Code-No. 115072

- 53 -

5. Installation and operation

5.1 Instructions for the installer

CAUTION!

Any works related to the installation, connection and maintenance of the

device may only be carried out by a qualified and licensed technician in

accordance with the applicable international, national and local regulations.

5.1.1

Instructions

• Read this instruction manual carefully before installing and starting the device.

• At all stages of the installation, assembly, operation and maintenance, the works

should be performed by qualified personnel who meet the requirements for

professional training (approved by the manufacturer or vendor), and taking

into account the applicable legislation of the country of installation and

regulations on product safety and safety at work.

• Improper installation, operation, maintenance or cleaning, and any changes or

modifications may lead to malfunction, damage or injuries.

• The manufacturer disclaims any liability for damage to persons or property caused

by the failure to comply with these rules or due to the user’s tampering of any

components of your appliance and failure to use the original spare parts.

• Any modification of the device must be authorized and performed by authorized

professional technical personnel.

• It is forbidden to make any modifications in the wiring of the device.

• In case of not following the safety instructions above, the device’s safety may

become limited.

5.1.2

Preparation

• Immediately after receiving the appliance, make sure that it has not been damaged

in transit, and that the packaging is not damaged. In the case of damage or missing

components, immediately notify the shipper or vendor/manufacturer providing the

article and serial numbers (nameplate is on the back of the unit) and attaching

photo evidence.

• Make sure that you will have access to the installation site and will not have

problems to pass through doors, corridors, or other passages.

- 54 -

• NOTE: During its shipment the unit may get overturned which may cause damage to

property or people as well as pose some difficulties. Please use a means of

transport appropriate to the weight of the device. Never pull or tilt the device; it

should be raised vertically from the ground and moved horizontally.

5.1.3

Place of installation

• The device should be placed indoors (never outdoors!) In a well ventilated room.

• Prior to positioning the combi steamer, check its dimensions and exact location of

the power and water connections, and of the exhaust duct.

• It is recommended to place the combi steamer under a kitchen hood outlet or

provide the outflow of hot vapours and fuses from the cooking chamber outside of

the building

• The combi steamer must be placed on an even surface to prevent its slipping or

tipping.

• The place of installation of the combi steamer must support the weight of the unit at

full load. Its gross weight can be found on the nameplate at the back of the combi

steamer.

• If the combi steamer are placed above

proofers, stainless steel tables or other

combi steamers it is not advisable to use the

upper surface to insert the GN containers so

that the user could look into the containers.

• For safety reasons, once you have

positioned the device, attach this

sticker "Risk of burning"

(provided in the package) on the combi

steamer at a height of 1600 mm from

the floor (see Figure on the right).

• Make sure that the combi steamer position allows for complete opening of its door

(180°).

• Position the combi steamer so that its back is easily accessible to enable the

connection of water and power supplies and its maintenance.

• The device is not suitable for external housing; it is necessary to keep a minimum

distance of 5 cm from all sides.

- 55 -

• The device shall never be placed near heat sources, fryers or other sources of hot

liquids; in case it is not possible to meet this requirement, the safe distance is 50 cm

from the sides and top of the device and 70 cm at its rear.

• Never place the device near combustible materials or containers made of flammable

materials (such as walls, furniture, partitions, gas cylinders) since it could lead to a

fire hazard. In case it is not possible to meet this requirement, cover the flammable

components with non-flammable thermo-insulating material, and follow the fire

regulations strictly.

5.1.4

Preparing to Install

• Remove the outer packaging (wooden box and/or cardboard) and dispose of them in

accordance with the regulations in force in the country of installation.

Remove the protective film

• Remove the protective film completely from the

external and internal walls.

• Remove any accessories, informational materials and

plastic bags from the combi steamer.

Adjusting the feet

CAUTION!

Do not use the combi steamer without the feet.

• When the combi steamer is used without the

feet, the air flow needed to cool digital

components and external walls is not provided,

and this can cause overheating and damage to

the combi steamer.

• The adjustable feet are attached with the

packed unit and must be screwed to the

combi steamer.

• The correct flat position of the combi steamer ensures its trouble-free operation.

Such position is achieved by adjusting the feet and checking it with a spirit level.

To adjust the feet, simply tighten or loosen them.

- 56 -

Attaching the drip tray

• The drip tray is used to collect liquids which

may flow out through the front door of the

combi steamer. Place the tray in front of the

combi steamer and fasten it with screws found

in a bag provided in the package. The screws

are screwed into the threaded inserts in the

lower front part of the combi steamer (Figure

on the right).

Attaching the drip tray drain

• Fit a plastic closure and a white water drain

hose which is found in the package. Make

sure that the hose is installed and fixed in

such a way as to allow the water to properly

drain from the drip tray to the sewage

network (Figure on the right).

5.1.5

Power supply connection

DANGER! Electric shock hazard!

In the case of improper installation the device may cause injuries!

Before the installation compare the local power grid parameters with the

parameters of the combi steamer power supply (see the nameplate). The

device can be powered only when these data are consistent!

• Before connecting to the power grid, make sure that the voltage and frequency

indicated on the nameplate correspond with those of the local power grid.

The allowable deviation in voltage is ± 10%.

• When the device does not have wheels to facilitate its movement we recommend to

connect the device to the power supply first, and then position it in its workplace.

• Make sure the power cord does not get damaged when moving the combi steamer.

This way the combi steamer will be connected to the power supply without difficulty

and in a more safety manner. The power cord shall be placed so that it does not

reach the ambient temperature higher than 50 °C at no point.

- 57 -

Combi steamer with power cord and power plug (116050)

• The combi steamer 116050 is equipped with a 3x 2.5 mm² H05RR F power cord and

a power plug. To establish the power supply connection, simply insert the plug into the

appropriate socket (the socket must match the provided plug and withstand the load

required for the device and specified on the nameplate).

• The device is supplied with an approved and certified power cord and power plug:

do not tamper with them or change anything in them.

• The device must be positioned so that the plug is easily accessible at all times.

Combi steamer (116060, 116080) with 380 – 415V 3NAC power cable (without plug)

• This steam convection oven must be connected to a power source compliant with

international national and local regulations. Installation must be performed by a

qualified electrician. Follow the instructions located at the back of the device.

Connection to the equipotential bonding system

• This connection should be made between different devices with the use of a plug-in

terminal marked with this symbol. The connection terminals are found at the

back of the device.

• The terminals allow connecting a yellow/green connection cord with a cross section

between 2.5 and 10 mm²

• The unit must be connected to the equipotential bonding system whose efficiency

should be checked in accordance with the guidelines of the applicable provisions.

- 58 -

5.1.6

Water connection

• Make sure the device is placed near a drinking water connection.

• Before connecting the device, allow enough water through to remove any remnants

in the piping so that they did not get into the magnetic valves.

• It is necessary to install a shut-off valve and

mechanical filter between the plumbing and the

device (Figure on the right).

• On the back of the device, in the area marked

with a label, the combi steamer has an input

G3/4'' with a filter

• The device is provided with a water hose with

2 meters in length fitted with connectors G3/4''

and return valve for liquids as required by

applicable regulations.

CAUTION!

The combi steamer can be connected to

the water piping using the supplied water

hose only! Do not use other hoses or recycled hose.

• The water must be supplied at a pressure

between 150 kPa (1.5 bars) to 200 kPa (2 bars)

and a maximum temperature of 30°C.

If the value of the inlet pressure is higher than

200 kPa (2 bars), you must install a pressure

adapter set at 200 kPa (2 bar).

• In order to ensure trouble-free operation of the device, the water should have a

hardness of maximum 5°dH to prevent lime deposits. For higher values a water

softening station should be installed first.

- 59 -

5.1.7

Water outlet

• The water at the outlet of the combi steamer may reach high temperatures (90°C).

The hoses used to drain this water out should be resistant to such temperatures.

• The water outlet is placed in the lower part at the

back of the combi steamer and it should be

connected to the provided drain hose into an open

drain; the diameter of the hose cannot be smaller

than the diameter of the device’s water outlet.

• Install a suitable trap between the combi steamer

and the sewage system to prevent the escape of

any vapours from the combi steamer and

penetration of odours from the sewage system.

• Avoid strictures in flexible hoses and bents in rigid pipes. Along the entire course

of the hose, there should be a slope of at least 5% to ensure adequate drainage.

Nearly horizontal sections should be no longer than one meter.

• The combi steamer should have its own connection to the sanitary sewer system.

If more than one device or systems are connected to the same pipe, make sure

that pipe dimensions allow for regular and unobstructed drainage.

• Observe local regulations and standards.

5.1.8

Steam outlet vent

• During cooking hot vapours and other fuses are formed;

they are let out through an outlet pipe from the cooking

chamber which in the upper area of the back of the

combi steamer. Do not put or place any things above

the outlet so as not to hinder the smoke collection and

not to damage these things.

• We recommended to place the combi steamer under a

kitchen hood or to provide a pipe to collect hot steam

and odours whose dimensions shall not be smaller than

those of the steam outlet vent in the combi steamer.

- 60 -

5.2 Operation

5.2.1 Safety tips for the user

CAUTION!

Carefully read the manual below as it includes the safety and operation

instructions.

Store the manual to use it at any moment.

The defective installation, operation errors and maintenance and cleaning

mistakes as well as any modifications may cause the incorrect operation,

damages and injuries.

• All persons using the device must follow the information provided in the instruction

manual and the safety instructions.

• The device may be used only by qualified personnel. To avoid the risk of accidents

or damages to the device, it is also fundamental that the personnel regularly

receive precise instructions regarding safety.

• Never place the device near heat sources.

• Do not place any other heat sources, e.g. fryers or cooking plates, near the device.

• The temperatures of food containers or other objects during and after cooking can

be very high; be particularly careful when handling them to avoid burns. You may

only grasp them wearing protective gloves or pot holders. Risk of burning!

• When cooking in containers filled with liquids, be particularly careful to avoid

spilling the liquids both during cooking and removing the containers from the

device. Risk of burning!

• Open the device door with particular caution: There is a risk of burns by escaping

high temperature steam.

The outside surfaces of the device may reach a temperature

exceeding 60°C. To avoid burns, do not touch the ar eas or parts

marked with this symbol.

• When the glass components of the door become damaged or broken, immediately

turn the device off and contact customer service. Do not use the device until the

device door has been replaced.

• When the device is not used for a short time (e.g. 12 h), leave the door slightly open.

• When it is not used for a longer time (e.g. many days), turn off the water and power

supply to the unit.

- 61 -

5.2.2 First use

• Make sure there are no items (accessories, packaging film, manuals, etc.) in the

cooking chamber.

• Prior to the first use, make sure the installation was properly completed in terms of

the stability and levelling of the device, and power and cold water supply connection.

• The air vents must left be open and shall not be covered with anything.

• The device components that might have been dismantled for the time of installation

should be fitted again.

• Make sure that the shelf rails supporting the trays or GN containers are properly fixed

to the inner side walls; otherwise the containers with warm or hot food may fall or slip

down and cause burns.

• Heat the empty combi steamer at 200°C (392°F) for about 30 minutes to remove any

smell of thermo-insulation.

• Prior to the first use, clean the device from the inside and the outside with warm

water and a neutral detergent, and then wipe off with clean water. Follow the

instructions provided in Chapter 6. "Cleaning and maintenance".

WARNING!

Never clean the device with water jets or steam under pressure!

• For acceptance purposes, run a test cycle which will allow checking the operation

of the device and identify any potential defects/problems.

• Turn the combi steamer on and set the heating cycle with a temperature of up

to 150°C for 10 minutes with medium humidity .

• Carefully check the following points:

The light turns on in the cooking chamber.

The combi steamer turns off (heating, steam injection, fan motor) when the

door opens and resumes operation when the door closes again.

The thermostat controlling the heating temperature responds upon reaching

the set heating temperature and the heating unit turns off.

The fan motors automatically reverses the direction of rotation. The rotation

must be reversed every two minutes.

The fan motors rotate in the same direction.

Check if the water coming out from the hoses in the moisture exhaust system

placed in the cooking chamber flows towards the fans.

- 62 -

5.2.3 Operation elements / Functions the buttons and keys

Control panel

Control lamps: phases

Cooking phases

Time +1

Set-up key: fan speed

Control lamps: fan

speed

Control lamp: device door

Control lamps: steam extractor

Set-up key: steam extractor

Humidification key

ON/OFF key

Programme activation key

Selection keys + / -

Control lamp: programme

Control lamp: core

temperature sensor

Connection point

Core temperature sensor

Display: cooking time

Rotary button: core temperature

Display: operation

Display: humidity

Display: cooking temperature

Display: core temperature

Illumination key

START/STOP key

Control lamp: memory

Save key

Rotary button: cooking time

Rotary button: humidity

Rotary button: cooking

temperature

Control lamp: heating elements

Control lamp: humidity

TIMER AREA

TEMPERATURE AREA

CORE TEMPERATURE

SENSOR AREA

HUMIDITY AREA

ACTIVATION AREA

- 63 -

ACTIVATION AREA

ON/OFF key

Once the combi steamer has been connected to the power supply, the control panel

lights up and "OFF", appears on the display.

START/STOP key

This key is used to start/stop the previously set programme or cooking cycle.

ILLUMINATION key

This key is used to turn on or off the illumination inside the combi steamer.

P/M key

This key is used to change the operation mode: manually or according to the

programme. In case of the programme mode it is possible to select the desired

programme by pressing the selection keys ( + / - ).

MEMORY key

This key is used to save the programmes generated or changed by the operator.

TIMER AREA

In this area of the control panel commands to set the cooking times are presented.

To set the desired cooking time, turn the rotary button:

clockwise to increase the value,

counter-clockwise to decrease the value.

The set cooking time appears on the display and, depending on the selected setting,

the countdown or progression of the cooking time is displayed.

When the INF indication (completed) appears on the display, it means that the combi

steamer remains operational until the operator stops it manually.

Note: After opening the device door, the countdown stops and is continued after

closing the device door.

- 64 -

Cooking phases key

This key is used to select different phases forming a cooking programme.

By pressing the key F the operator can move to the next phase (the present phase

is indicated by the activated control lamp F1, F2, F3 or F4).

It is possible to change the parameters for each phase: time, temperature, steam

percentage, opening/closing of the steam extractor, fan speed and core

temperature.

Time + 1 key

This key is used to increase the value of the cooking time which appears on the

display; each press increases the value by 1 minute.

TEMPERATURE AREA

In this area of the control panel is located a rotary button used to set the cooking time

of the food. To increase or decrease the temperature which appears on the display,

turn the rotary button clockwise.

Fan speed key

This key is used to increase or decrease the fan speed. There are 6 options to set

the available fan speed.

The selected fan speed is indicated by the activated control lamp. To change the fan

speed from 1 to 2 etc. (max. to 6) and then get back to 1, press the key several times.

CORE TEMPERATURE SENSOR AREA

How to use the core temperature sensor correctly: Choose the thickest place in the food

to insert the core temperature sensor. Insert it from the top down until it hits the middle.

The inserted sensor measures the temperature of the food and stops the operation of

the device once the internal temperature set by using the rotary button has been

reached (the selected value of the core temperature sensor appears on the display).

This cooking method is used to set the cooking temperature (by turning the rotary button

of the temperature setting); however, it is not used to set the cooking time, because the

cooking process is stopped once the internal temperature of food controlled by the core

temperature sensor has been reached.

Note: It is necessary to ensure that the temperature set in the core temperature sensor

is lower than the temperature set for cooking, because otherwise the operation

continues without achieving the desired result, until the operator stops the combi

steamer manually.

- 65 -

HUMIDITY AREA

In this area of the control panel (devices 116060 and 116080) commands to set the

steam percentage and the opening/closing of the steam extractor (and as a result the

discharge of steam out of the cooking chamber) are presented. To select the values

between 0 and +10 which correspond to the settings mentioned below, turn the

humidification rotary button clockwise or counter-clockwise:

VALUE SETTING

+10 Steam extractor opened – 100% steam

+9 Steam extractor opened – 90% steam

+8 Steam extractor opened – 80% steam

+7 Steam extractor opened – 70% steam

+6 Steam extractor opened – 60% steam

+5 Steam extractor opened – 50% steam

+4 Steam extractor opened – 40% steam

+3 Steam extractor opened – 30% steam

+2 Steam extractor opened – 20% steam

+1 Steam extractor opened – 10% steam

0 Steam extractor opened – 0% steam

In case of the devices

116060

and

116080

it is possible

to set the opening/closing of the steam extractor manually

by pressing the set-up key "Steam extractor". In this

way the selected settings are overridden, however, they

remain in the temporary memory. To reset them, simply

turn the humidification rotary button slightly.

On the left side of the display the control lamps for the

steam extractor are located, which turn on according to

the selected process (opening/closing).

Humidification key (devices 116060 and 116080)

This key is used to start the operation with humidification as long as the key is

pressed. The control lamp lights up once the humidification key has been pressed

or once the settings of the humidification (% steam) make the emission of steam

necessary to maintain the selected percentage of humidity in the inside.

- 66 -

In the humidity area, on the right side of the display control lamps for the heating

elements are also presented. The green light indicates that the heating elements

are turned off; the red light indicates that the heating elements are turned on.

The control lamp for the device door on the left is green when the device door is

closed; and red when the device door is opened.

In device 116050 the Humidity area of the control panel

is arranged differently. It is not possible to adjust the

opening/closing of the steam extractor.

To go to the settings, press the humidification key.

To set the amount of steam in the range between

0 - 10 (0 - 100%) in 10% steps, turn the humidification

rotary button. The set amount will appear on the

display.

On the right side of the display the control lamps for the heating element and humidity

are presented. The green control lamp for the heating element indicates that the heating

element is turned off; the red one indicates that the heating element is turned on.

The control lamp for humidity is activated during the whole humidification process.

The control lamp for the device door on the left is green when the device door is closed;

and red when the device door is opened.

ADDITIONAL FUNCTIONS

PREHEAT function

This function is used only when saved programmes have been called up. It heats the

cooking chamber to the temperature set by 30°C high er than the temperature set in the

programme phase (the preheating phase starts to reach the desired temperature of the

cooking chamber of whatever programme phase has been called up, when the cooking

chamber has not yet reached the temperature provided for by the programme. This

function is used to compensate for the effects of heat loss through the opening of the

device door and inserting food into the cooking chamber.

To activate/deactivate the preheating function:

press together the selection keys + and – in the Activation area, until the

list of the adjustable settings appears on the display (set time, set order,

language, etc.);

press the selection key + until Preheat appears;

press the P/M key – the current setting (ON/OFF) appears on the Timer Display;

- 67 -

turn the rotary button to change the setting: ON (preheating activated), OFF

(preheating deactivated);

press the ON/OFF key in the Activation area

to save the selected setting.

After the selection and activation (by pressing the START/STOP key) of the programme,

the PRE indication will appear on the display and the control lamp of the device door will

flash (green). It means that the preheating phase has started. Once the preheating

temperature has been reached, the acoustic signal is emitted. Opening the device door

(to put food into the combi steamer) discontinues the signal. The programmed phase

starts. To discontinue the signal without activating the phase or deactivating the

preheating function, simply press the START/STOP key.

By pressing the START/STOP key during the preheating phase, but before the acoustic

signal, the device is turned off; by pressing the same key once again, the preheating

phase restarts at the point where it has been interrupted.

During the preheating phase the humidifier does not work. Each modification of the

programme during the preheating phase changes the settings of the phase F1.

PAUSE function

It is possible to set a "pause" function (e.g. to facilitate the acidification of food). During

this phase the fans as well as the heating and humidification processes are turned off

and the steam extractor is closed. To set a programme with a pause, press the set-up

key "Fan speed" for at least 4 seconds until the Pause function reads in. The blinking

indication STOP will appear on the Temperature display, alternately with the present

temperature in the cooking chamber (it will appear also when the programme has

completed the pause phase). During the pause, set the pause duration using the Timer

rotary button. Continue by pressing the key F and setting the next phases of the

programme.

LANGUAGE, DATE, TIME function

In order to set the language:

press at the same time the selection keys + and – in the Activation area, until the

list of the adjustable settings appears on the Operation display (set time, order,

language, etc.);

press the selection key + until Language appears;

press the P/M key – the current setting (italiano, english, etc.) will appear on the

Timer Display;

to change the setting, turn the rotary button until you get to the desired setting;

press the ON/OFF key in the Activation area

to save the selected setting.

- 68 -

In order to set the date/time:

press at the same time the selection keys + and – in the Activation area, until the list

of the adjustable settings appears on the display (set time, order, language, etc.);

press the selection key + until set time appears;

press the P/M key – Day will appear on the Timer Display;

turn the Timer rotary button until the desired day is displayed;

press the P/M key – Hours will appear on the Timer Display;

turn the Timer rotary button until the hour is displayed;

press the P/M key – Minutes will appear on the Timer Display;

turn the Timer rotary button until the desired minutes are displayed;

press the P/M key – Date will appear on the Timer Display;

turn the Timer rotary button until the desired date is displayed;

press the P/M key – Month will appear on the Timer Display;

turn the Timer rotary button until the desired month is displayed;

press the P/M button – Year will appear on the Timer Display;

turn the Timer rotary button until the desired year is displayed;

press the ON/OFF key in the Activation area to save the selected setting;

press again the ON/OFF key in the Activation area to leave the menu.

5.3 Cooking instructions

Manual cooking

This mode does not allow for using several cooking phases. To select the manual

mode, simply press the P/M key in the Activation area and then set the required

parameters using the rotary buttons for temperature, timer, humidity, core

temperature sensor, set-up key "Fan speed".

Note: It is not possible to select the cooking time and the temperature of the key

temperature sensor at the same time. It is necessary to select only one of these

2 parameters. Press the START/STOP key to start cooking.

- 69 -

Programmed cooking

The combi steamer is equipped with a memory for 99 programmes, out of which 16 are

preprogrammed.

NO. DESCRIPTION

PHASE 1 PHASE 2 PHASE 3

MIN

°C

% steam

Extraction hood

Fan speed

Core temp. sensor °C

MIN

°C

% steam

Extraction hood

Fan speed

Core temp. sensor °C

MIN

°C

% steam

Extraction hood

Fan speed

1

CASSEROLE

& GRATIN

20 150 0 5 5 180 0 6

2

PAELLA

(BROWNING)

5 200 -10 6 18 180 0 4

3

SOUFFLЀ

15 140 0 3 5 180 0 3

4

CHICKEN

10 100 +5 6 40 180 -10 6 10 200 -10 6

5

PORK

10 120 +5 5 160 +1 6 67 5 180 -10 6

6

ROAST BEEF

10 120 +10 6 160 -10 6 50

7

LAMB

5 120 +5 6 170 -10 6 55

8

SALMON

160 0 6 60

9

SCAMPI

~100gr

9 100 +10 6

10

BACKED

POTATO

10 100 +10 6 30 190 -10 6

11

CARROTS

15 100 +10 6

12

FRESH

BREAD

10 180 -4 4 4 200 -10 4

13

CROISSANT

12 160 -1 4 6 180 -10 5

14

SPONGE

ROLL

25 160 0 3 12 175 0 3

15

BEIGNT

3 160 0 3 14 180 0 4

16

COOLING

30 0 6

- 70 -

To call up one of the preprogrammed programmes:

press the P/M key until P01 appears on the Operation Display;

by pressing the selection keys + or - select the number of the programme;

press the START/STOP key to start the programme.

It is possible to generate and save new individualized programmes from the

programme's memory field 17. Proceed as follows:

press the P/M key until P01 appears on the Operation Display;

by pressing the selection keys + and - select the number of the programme

to be saved;

Once you have found a free programme (or an already existing one that you

want to change), the control lamp F1 will light up on the Timer display. Set the

parameters (temperature, time/temperature of the core temperature sensor, fan

speed, steam, steam extractor) of the phase F1;

After pressing the key F, the control lamp F2 will light up and you can continue

with setting the second phase. In the same way set also the third and fourth

phase. To cancel a phase, simply set the Timer rotary button at END.

Once you have completed the setting process, press the Memory key in the

Activation area and keep it pressed until the memory control lamp starts to blink.

Now the programme is saved. It is recommended to maintain written records for

the generated programmes in order not to forget them.

To check whether a programme has been already set or is free, simply watch the

indications appearing on the display; when a programme is free, the values END,

30°C and 00 steam will appear.

You can change already saved programmes by following the same steps as in case

of setting a new programme.

You cannot delete a programme; it is only possible to change a programme.

The only programme that cannot be changed is programme No. 16 – Cooling.

P16 - Cooling programme

This programme allows for quick cooling of the device by making it possible to open

the device door during operation without stopping it.

The fan motors continue to work, however, the humidification system and heating

elements remain inactive. The programme is stopped manually by pressing the

START/STOP key once the selected temperature has been reached.

Note: when executing programme No. 16 "Cooling" it is forbidden, for any reason

whatsoever, to remove the fan housing and to touch the fans or the heating elements

as long as they are moving or are hot.

- 71 -

6. Cleaning and maintenance

6.1 Standard cleaning and maintenance

WARNING!

Before carrying out any cleaning activities disconnect the power supply

and wait until the device cools down completely.

The device should not be directly sprayed with water. Therefore, do not

use a pressurized jet to clean the device (either inside or outside)!

The user of the device is required to clean and maintain it regularly.

Regular cleaning of the cooking chamber

o To ensure trouble-free operation, hygiene and efficiency of the device, it should

be cleaned at the end of every working day.

o Do not use cleaning acids, scouring, caustic agents containing sand or soda lye.

o Make sure that water does not penetrate inside the device.

o To protect yourself against an electric shock, never immerse the device, cords

or plug in water or other liquids.

o While cleaning take the following steps:

turn the device on and set the temperature dial at 80 °C;

turn the combi steamer on and allow it to run for 10 minutes. Generate steam;

turn the device off and let it cool down;

clean the cooking chamber with warm water and a mild detergent, then rinse

it with clean water.

WARNING! Risk of burning!

Never clean the cooking chamber at a temperature exceeding 70°C.

o Daily cleaning of the device’s cooking chamber seal should be done using a mild

cleaner to ensure its unaffected status and efficient performance.

o To clean dirt deposits use a plastic spatula or sponge soaked in vinegar or warm

water only.

o Note: if there is grease or food residue in the cooking chamber, it should be

removed immediately since it may catch fire during combi steamer operation.

- 72 -

Cleaning external surfaces

o To clean the external surfaces of the device, use a cloth dampened in warm water

only.

o With the exception of special cleaning agents for stainless steel, using

inappropriate cleaning agents to clean external surfaces may cause corrosion of

the device.

o Do not use any products containing chlorine (bleach, hydrochloric acid, etc.).

o After cleaning, use a soft, dry cloth to wipe and polish the surface.

Cleaning the device door

A

B

o To clean the inside glass door, allow

the device to cool down completely.

o The double glass door allows easy

cleaning, because you can remove

the inner pane.

o Loosen the upper and lower holding

devices that holds the internal glass

(Figure A, on the left).

o Pull the inner pane out (Figure B,

on the left).

o Clean the inner glass on both sides

using the appropriate cleaner.

o Do not use any scouring agents or

cleaners that might scratch the

elements.

o Close the inner glass by fixing the

holding devices in the original position.

CAUTION!

Before closing the device door make sure that the internal glass is fixed

with the holding devices, otherwise the door will not close tightly.

- 73 -

Replacing the lamp

DANGER! Electric shock hazard!

Strictly follow the instructions below to avoid electric shock or injury:

o Cut off the power supply and allow the

combi steamer to cool down.

o Unscrew the bolts with which the side

container rails are secured to the walls.

Remove them from the cooking chamber.

o Remove glass cover A. Make sure not to

damage seal C. Replace lamp B by a lamp of

the same parameters.

o Screw glass cover A back. Make sure not to damage seal C.

o Re-attach the container rails to the side walls and make sure that they

are securely fastened.

o If the glass cover turns out to be faulty or damaged, do not use the combi

steamer until it is replaced (please contact your customer service).

Replacing and cleaning the cooling filter (the back)

DANGER! Electric shock hazard!

Strictly follow the instructions below to avoid electric shock or injury:

Cut off the power supply and allow the

device to cool down.

Unscrew the bolts fixing the filter and

replace or clean the filter.

After completion of the process,

reassemble all parts.

- 74 -

6.2 Special maintenance

o On a regular basis (at least one a year), have the device checked by a qualified

licensed technician. Please contact the customer service department for that matter.

o Before performing any operation, disconnect the power supply, closing off the water

taps and wait until the combi steamer cools down.

o Before moving the unit from its normal position, check if the wiring and piping are cut

off in the right way.

o If the device has wheels make sure that electrical wires, tubes or other attachments

are not damaged in the process.

o Avoid placing the unit near heat sources (such as fryers, etc.).

o After the operation and position the device in its place of normal installation, and make

sure that all the electrical and water connections are made in accordance with the

standards before starting the unit.

Troubleshooting

In the event of a fault, disconnect the device from the power supply and turn off the

water supply. Before contacting customer service, check the nature of malfunction

described in the table below.

Fault Reason Solution

The device does not

start by pressing

the START/STOP

switch

• The device door is not

closed

• The microswitch does not

signal the closed device

door

• Close the device door

• Contact customer service

The device is

completely turned

off

• No power supply

• The power supply

connection has not been

established properly

• The motor safety

thermostat has been

activated

• Restore power supply

• Check the power supply

connection

• Contact customer service

- 75 -

Fault Reason Solution

Uneven

cooking/baking

• The fans do not reverse

the rotation direction

• One of the fans does not

work

• One of the resistors is

broken

• Contact customer service

• Contact customer service

• Contact customer service

The light is

turned off

• The lamp is loose

• The lamp is burnt out

• Place the lamp in the

holder correctly

• Replace the lamp as

described in the section

"Replacing the lamp".

When pressing the

humidification key

or turning the rotary

button no water

flows out of the

hoses

• The water inlet is closed

• The water supply

connection has not been

established properly

• The water inlet filter is

clogged with dirt

• Open the water shut-off

valve

• Check the water supply

connection

• Clean the water filter

When the device

door is closed water

leaks through the

seal

• The seal is dirty

• The seal is damaged

• There is a problem with

closing the device door

• Clean the seal with a

damp cloth

• Contact customer service

• Contact customer service

The fan stops

during operation

• The safety thermostat of

the fan motor has been

activated

• Turn off the combi steamer

and wait until the thermal

protection restarts the

motor automatically.

Should the problem repeat,

contact customer service.

The above problem cases are just examples for your orientation. If such or similar

problems occur, you should immediately turn off the device and stop using it.

If the defects cannot be removed, you must immediately contact customer service

or your dealer. Please quote the article and serial number of the device; this data

can be found on the nameplate of the device. Never attempt to make any repairs

on your own.

- 76 -

7. Waste disposal

Discarding old devices

At the end of its service life the discarded device has to be disposed in accordance with

the national regulations. It is advisable to contact a company which is specialized in

waste disposal, or just contact the local disposal service in your community.

WARNING!

To exclude any abuse and the dangers involved make the waste device unfit

for use before disposal. For that purpose disconnect device from mains

supply and remove mains connection cable from the device.

CAUTION!

For the disposal of the device please consider and

act according to the national and local rules and

regulations.

Bartscher GmbH

Franz-Kleine-Str. 28

D-33154 Salzkotten phone: +49 (0) 5258 971-0

Germany fax: +49 (0) 5258 971-120

Loading...

Loading...