3000EN

Ç

3030300EN

0

0

/

2

U

03

10/2022

202

USER

ER

cod. 3000EN

ed. 03 - 10/2022

EN

USER

IT

- Istruzioni per l'uso e la manutenzione

110540

110541

110542

LEGGERE ATTENTAMENTE LE ISTRUZIONI PRIMA DI INSTALLARE LA MACCHINA

READ THE INSTRUCTIONS CAREFULLY BEFORE INSTALLING THE MACHINE

LIRE ATTENTIVEMENT LES INSTRUCTIONS AVANT D'INSTALLER LA MACHINE

LESEN SIE VOR DER INSTALLATION DES GERÄTES AUFMERKSAM DIE VORLIEGENDEN

GEBRAUCHSANLEITUNGEN

LEER ATENTAMENTE LAS INSTRUCCIONES ANTES DE INSTALAR LA MÁQUINA

ВНИМАТЕЛЬНО ПРОЧИТАЙТЕ ЭТИ ИНСТРУКЦИИ, ПРЕЖДЕ ЧЕМ ПРИСТУПАТЬ К УСТАНОВКЕ МАШИНЫ

LER ATENTAMENTE AS INSTRUÇÕES ANTES DE INSTALAR A MÁQUINA

Vi ringraziamo per aver acquistato un nostro apparecchio.

Le istruzioni per l’installazione e la manutenzione nonché il suo impiego, che troverete sulle pagine

che seguono, sono state preparate per assicurare una lunga vita e un perfetto funzionamento del

vostro apparecchio.

Seguite attentamente queste istruzioni.

Noi abbiamo ideato e costruito questo apparecchio secondo le ultime innovazioni tecnologiche. Voi

ora dovrete averne cura.

La vostra soddisfazione sarà la nostra migliore ricompensa.

Thank you for choosing our machine.

The instructions for installation, maintenance and use found on the following pages have been prepared to ensure a long life

and a perfect operation of your unit.

Please, do follow the instructions carefully.

We have designed and built this machine using the latest innovative technologies. Now you shall take good care of it.

Your full satisfaction is our greatest reward.

Nous vous remercions d’avoir choisi notre machine.

Les instructions pour l’installation, l’entretien et l’utilisation qui figure dans les pages suivantes ont été préparées pour assurer

une longue durée de vie et un fonctionnement parfait de votre appareil.

S’il vous plaît, veuillez suivre attentivement les instructions.

Nous avons conçu cette machine, en utilisant les dernières technologies innovantes. Vous devrez maintenant en prendre soin.

Votre satisfaction est notre plus grande récompense.

Wir danken Ihnen für den Kauf dieses Gerätes.

Die Anleitungen zu Installation, Wartung und Betrieb des Gerätes, die Sie auf den folgenden Seiten finden, wurden erstellt, um

Ihrem Gerät eine lange Lebensdauer und einen ordnungsgemäßen Betrieb zu gewähren.

Befolgen Sie diese Anweisungen aufmerksam.

Dieses Gerät wurde nach dem letzten Stand der Technik entwickelt und konstruiert. Diese Anleitung soll Ihnen dabei helfen, es

gebührend zu pflegen.

Ihre Zufriedenheit ist für uns die beste Entlohnung.

Gracias por haber adquirido uno de nuestros productos.

Las instrucciones para la instalación y mantenimiento, así como su uso, que se encuentran en las páginas que siguen, se han

preparado para asegurar una larga vida y un funcionamiento fiable de su unidad.

Sígalas atentamente.

La máquina ha sido proyectada y fabricada con las últimas innovaciones tecnológicas. Por favor, utilícela con cuidado.

Su satisfacción es nuestra mejor recompensa.

Благодарим Вас за выбор нашей продукции.

Инструкции по установке, использованию и обслуживанию, представленные в настоящем руководстве, были

подготовлены для того, чтобы обеспечить долгую и исправную службу Вашего оборудования.

Пожалуйста, точно следуйте приведённым в руководстве указаниям и рекомендациям.

Мы разработали и изготовили это оборудование в соответствии

Теперь его судьба зависит от Вас.

Лучшая награда для нас - Ваше удовольствие от работы с нашим оборудованием.

Obrigado por adquirir um dos nossos aparelhos.

As instruções de instalação, manutenção e utilização que encontrará nas páginas seguintes foram preparadas para garantir

uma longa duração e um perfeito funcionamento do seu aparelho.

Siga estas instruções escrupulosamente.

Idealizámos e construímos este aparelho segundo as últimas inovações tecnológicas. Agora, cabe-lhe a si cuidar dele.

A sua satisfação será a nossa melhor recompensa.

с самыми последними техническими достижениями.

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

Contents Page

WARNINGS 4

1. MACHINE INSTALLATION 7

1.1 Dataplate 7

1.2 Reception of the appliance 8

1.3 Hydraulic connection 8

1.3.1 Water supply characteristics 8

1.4 Electrical connection 9

1.5 Ventilation/Steam evacuation 9

2. MACHINE DESCRIPTION 10

2.1 Machine description 10

2.2 Machine features 12

3. CONTROL PANEL AND RELATIVE SYMBOLS 13

4. OPERATION 14

4.1 Cutlery and crockery loading 15

4.2 Use of detergent (optional) 16

4.3 Use of rinse aid 16

4.4 Drain pump system (optional) 16

4.5 Regeneration device (optional) 17

4.6 Compliance with hygiene regulations and H.A.C.C.P. 18

5. MAINTENANCE 19

5.1 Regular Maintenance 19

5.2 Special Maintenance 20

6. ALARMS 20

7. ENVIRONMENTAL ASPECTS 22

7.1 Packing 22

7.2 Disposal 22

8. ECOLOGICAL ASPECTS 22

8.1 Recommendations for optimum use of energy, water and additives 22

9. TROUBLESHOOTING 23

EN

page 3

WARNINGS

This instruction booklet must be kept with the dishwasher for future

consultation. If the dishwasher is sold or transferred to another user,

make sure the booklet always goes with the appliance so that the new

owner can have the necessary information on operation and the relative

instructions.

The instruction booklet must be carefully read before installation and

first use of the dishwasher.

The user must comply with the following rules:

• Adaptation of the electrical and water systems for dishwasher installation must only be

carried out by qualified operarators.

• This dishwasher must only be used by adults. This is a professional machine to be used

by qualified personnel, and installed and repaired exclusively by a qualified technical

assistance service. The Manufacturer declines any responsibility for improper use,

maintenance or repair.

• This appliance can be used by trained youth aged from 15 years and above. It cannot be

used by persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge.

• Children shall not play with the appliance.

• Cleaning and user maintenance shall not be made by children without supervision.

• The user must not carry out any repair and/or maintenance operations. In any case

contact qualified personnel.

• Accompany the hood in opening and closing.

• Servicing of this dishwasher must be performed by authorized personnel.

Note: Use original replacement parts only. Otherwise the product warranty is

invalidated and the manufacturer is no longer responsible.

• The dishwasher is designed only and solely for washing plates, glasses and various pots

and pans with human food type of residue. DO NOT wash articles polluted with petrol,

paint, bits of steel or iron, fragile objects or material not resistant to the washing process.

Do not use acidic corrosive chemical products or alkaline and solvents or chlorine based

detergents.

• Make sure the dishwasher is not resting on the power cord or the filling and drain hoses.

Level the machine by adjusting the support feet.

• Do not use the appliance or any part of it as a stepladder or means of support as it has

EN

page 4

been designed exclusively to bear the weight of the dishrack containing dishes to be

washed.

•

The dishwasher is designed only and solely for washing plates, glasses and

various pots and pans with human food type of residue. DO NOT wash articles

polluted with petrol, paint, bits of steel or iron, fragile objects or material not

resistant to the washing process. Do not use acidic corrosive chemical products

or alkaline and solvents or chlorine based detergents.

• Do not open the machine door when operating. In any case, the machine has a special

safety device which immediately stops the unit if the door is open, thus preventing water

spillage. Always switch the machine completely off and drain the water tank, before

accessing inside.

This machine must be disconnected from the main electrical supply after use at

•

the end of the day and for any service/maintenance operation following this

procedure:

Switch the machine off from the control panel.

Drain the tank by removing the overflow pipe.

Disconnect the electrical supply by the omni-polar switch (main switch located

on the wall).

Shut the water supply valve(s).

Disregarding the aforesaid prescriptions is a serious misuse and can cause

damages and injures to property and people, and will relieve the manufacturer

from whatever liability.

• Do not use old load pipe, but only new ones.

• The user must not carry out any repair and/or maintenance operations. In any case

contact qualified personnel.

• Do not use old load pipe, but only new ones.

• Do not put material or objects on the machine.

• Some important rules must be followed for using this appliance:

Never touch the appliance with wet hands or feet

Never use the appliance when barefoot

Do not install the appliance in places exposed to water sprays.

• Do not dip bare hands into water containing detergent. If this should occur, wash them

immediately with plenty of water.

• The washing and the rinsing water is not potable because of the presence of chemical

additives. In case of contact with skin or eyes wash them immediately with plenty of water

and check the safety instructions of the detergent manufacturer. If necessary, contact a

doctor.

• Only follow the instructions given in the manufacturer’s booklet for cleaning operations

(see chap. 5. MAINTENANCE).

• The machine has an IP (see serial number label on the machine) protection rating against

accidental water splashes and is not protected against pressurized water jets. Pressurecleaning systems shall, therefore, not be used on this machine.

• This appliance is designed to work at room temperatures from 5 °C up to a max. 35 °C, in

a suitable room.

• Do not use water to extinguish fires on electrical parts.

• Do not cover the intake or dissipation grids.

• Water infeed to the machine 400 kPa maximum.

EN

page 5

Note: The manufacturer declines any responsibility for accidents to people or

any damage deriving from failure to observe the above listed instructions.

ATTENTION: DO NOT INSERT HANDS AND/OR TOUCH THE PARTS

LOCATED AT THE BOTTOM OF THE WASH TANK AND/OR AT THE END

OF THE WASH CYCLE.

ATTENTION: INTERNAL CLEANING OF THE MACHINE SHALL BE

CARRIED OUT AT LEAST 10 MINUTES AFTER THE POWER SWITCH HAS

BEEN TURNED OFF.

EN

page 6

1. MACHINE INSTALLATION

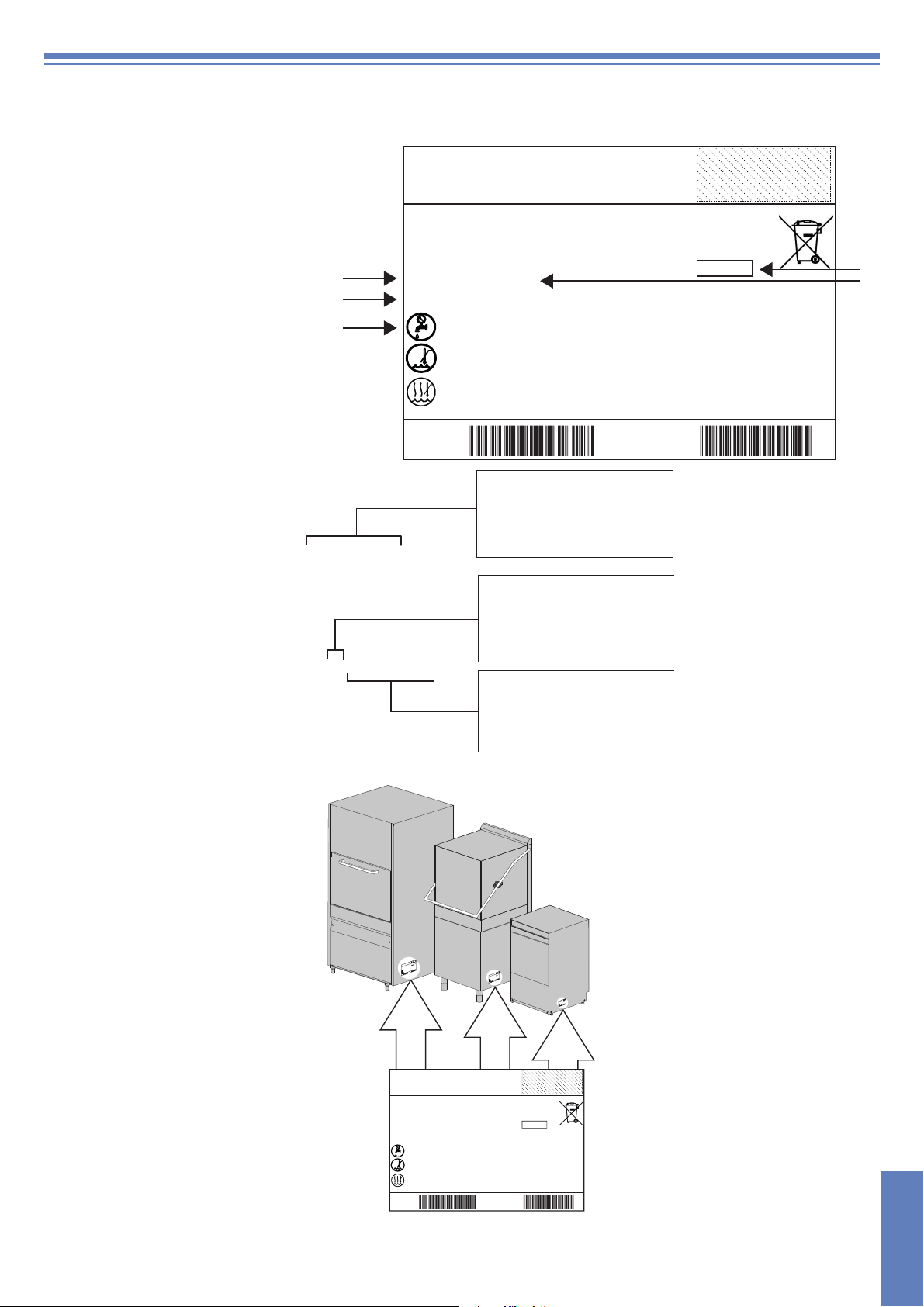

1.1 Dataplate

A Power source

B Total power installed

C Dynamic Pressure

D Envelope protection degree

E Total electricity absorption

Model DW XXXX

A

B

C

/QFGN(COKN[ &9::::

/QFGN%QFG

&'5%4+26+10

50 6[RG&9::::::

80*< ZZ#

ZZZZ9

ZZZÄZZZM2C

/#:

*1

/#:

/#:

/#:

ZZ°%

ZZ°%

ZZM2C

Model S/N

)$0,*/,$352'2772

)$0,/<352'8&7

)$0,//('8352'8,7

)$0,/,$352'8&72

)$0,/,('(6352'8.7(6

ɋȿɊɂəɉɊɈȾɄɌȺ

IPXX

/#&'+0+6#.; ;;;;

D

E

S/N DW X xxxxxxx

S

RoH

X

X

IP

:

:

:

&9:

0

1

+

6

2

+

G

[

R

4

[

%

6

5

COKN

'

(

&

N

G

F

Q

/

G

F

:

Q

:

%

:

:

#

FGN

:

Q

ZZ

/

9:

&

;

0

;

5

*<

;;

0

;

.

8

#

6

+

C

0

+

2

M

9

&'

Z

Ä

Z

#

Z

Z

/

#:

/

%

°

ZZ

/N

#:

S

/

l

1

ca

*

k

Z

ZZ

l

e

Mod

ANNO

YEAR

ANNÉE

AÑO

JAHR

ȽɈȾȼɕɉɍɋɄȺ

1

2

3

4 [[[[[[[[

180(52',6(5,(

6(5,$/180%(5

180e52',6e5,(

180(52',6(5,(

6(5,(11800(5

ɋȿɊɂɃɇɕɃɇɈɆȿɊ

HS

o

R

HS

Ro

PXX

I

:

:

:

:

9

&

0

1

+

6

2

+

G

[

R

4

N

K

[

%

6

O

5

C

'

(

&

N

G

F

Q

/

G

F

:

Q

:

%

:

N

G

:

IPXX

#

F

:

Z

Q

Z

/

:

9

:

&

:

:

:

9

&

0

0

1

;;

5

6+

;

<

2

[

+

N

*

K

;

G

4

R

O

%

[

C

5

6

(

'

0

N

;

&

G

.

F

8

Q

#

/

6

G

F

C

0+

Q

2

:

%

M

:

N

:

'+

:

9

QFG

:

&

#

Ä

/

Z

ZZ

#

Z

Z

:

Z

/

9

&

:

0

#

5

/

<

*

;;

0

%

8

;;

°

Z

Z

;

.

N

C

6#

2

+

:

M

#

9

Z

+0

/

Z

Ä

Z

'

Z

l

1

a

&

c

*

#

k

Z

/

Z

Z

:

#

/

%

°

Z

Z

:

#

/

1

S/N

l

*

a

c

k

Z

Z

Z

lS/

e

d

Mo

el

d

o

M

S

RoH

X

X

P

I

:

::

9:

&

0

1

+

6

2

+

G

[

4

N

K

[R

%

6

O

5

C

'

(

&

N

G

F

Q

/

G

:

QF

:

%

:

N

G

:

:

Z#

QF

Z

/

9:

&

;

0

;

5

;

<

*

;

0

;

.

8

#

6

+

0

C

+

2

M

'

9

&

Z

Ä

Z

#

Z

Z

/

:

#

/

%

°

Z

Z

N

/

:

#

S

/

l

1

a

c

*

k

Z

Z

Z

l

ode

M

/QFGN(COKN[ &9::::

&'5%4+26+10

/QFGN%QFG

50 6[RG&9::::::

80*< ZZ#

ZZZZ9

ZZZÄZZZM2C

/#:

*1

ZZ°%

/#:

/#:

ZZ°%

/#:

ZZM2C

Model S/N

IPXX

/#&'+0+6#.; ;;;;

EN

page 7

1.2 Reception of the appliance

Before accepting the machine, verify that all the data on the data-plate corresponds to the

required ones and to the ones of the available electrical supply (see paragr. 1.1 Dataplate).

After removing the packing, ensure that the appliance has not been damaged in transport. If so,

do notify the seller immediately about the problem. If the damage might question the machine

safety, do not install it.

The installation and the starting of the machine must be carried out by trained operators only,

even if the machine is coming from another site and it has been used, already.

For disposal of the packing see paragr.

7.2 Disposal.

1.3 Hydraulic connection

Connect the machine's water supply with an interrupt valve capable of quickly and completely shutting off water intake. Make

sure that the water supply pressure comes within the values given in the table Tab. 1. If it is less than 2 bar dynamic pressure

(200 kPa) a pressure pump must be installed to guarantee optimal machine operation (by request, the dishwasher can be

supplied with a pump). If, however, the water supply pressure is greater than 4 bar (400 kPa), a pressure reducing device must

be installed.

For water with average hardness greater than 8 °f, a water softener must be used. This will result in cleaner dishes and longer

life of the appliance. By request, the machine can be equipped with a water softener

If the machine is equipped with a water-softener, a regeneration of the resins shall be done on regular basis. In machines

equipped with optional regeneration device it is advisable to use water at a temperature not above 40 °C, so as not to alter the

characteristics of the resins.

Note: Any damage caused by limestone (calcareous water higher-up than 8 °f and without water-softener) will not be covered

by warranty.

In order to ensure the optimum performance, the water supply temperature must come within the range given in table Tab. 1.

Machines shall be made with extra power in case of cold water infeed.

Each machine is provided with a rubber tube with a 3/4” threaded attachment for water filling.

Connect the emptying tube, supplied with the appliance, to the union elbow located under the tub so that water flows freely. If it

is not possible to empty the water at a level lower than the drain of the appliance, it is advisable to install an emptying pump,

which can be provided by request.

The emptying tube should always be connected to a siphon to prevent odor back-up from the screen.

Water characteristics table Min Max

Static Pressure 200 kPa 400 kPa

Dynamic Pressure 150 kPa 350 kPa

Water hardness 2 °f 8 °f

Cold water-supply temperature 5 °C 50 °C

Hot water-supply temperature 50 °C 60 °C

Tab. 1

Capacity 10 l/min

1.3.1 Water supply characteristics

The machine water supply must be potable, in compliance with the legislation in force.

The inlet water must also meet the parameters given in the table Tab. 1.

Water parameters table Min Max

Chlorine

pH 6,5

Water hardness 8 °f

Iron

Manganese

Tab. 2

1

Out of range values might lead to corrosion and jeopardize the life of the machine.

2

Should the water hardness is higher it is compulsory to install a water softener and check periodically its operation.

3

Out of range values might lead scaling and sediments with a consequent lower performance, functionality, and expected life

of the machine.

4

4 Desired value: Out of range values might lead stainless steel blackening/tarnishing.

It is recommended a water test once a year.

1

3

4

2 mg/l

1

8,5

3

2-3

0,2 mg/l

0,05 mg/l

EN

page 8

1.4 Electrical connection

Electrical connection must be carried out in compliance with the legislation in force and the relevant technical standards.

Make sure that the voltage is the same as reported on the data-plate.

It is necessary to install a suitable omni-polar automatic fuse switch sized according to the absorption that assures

the complete disconnection from the network in an overvoltage category III condition.

This switch must be incorporated in the supply network, dedicated only and exclusively to this circuit and installed in

the immediate vicinity.

The machine has to be absolutely turned off by this switch: only this switch gives the full warranty of complete

detachment from the electric network.

Make sure the appliance is linked to an efficient ground connection.

The machine is also provided with a terminal (marked with the symbol ) placed on the back end. It shall be used to

bond different appliances via the external bonding conductor, in order to avoid the risk of electric shock.

ATTENTION: Check very carefully if the “ground connection” of the machine is properly sized and fully

efficient, and that not too many units are connected to it. An undersized or poor “ground connection”

might lead to corrosion and/or pitting effect on the stainless steel plates, even to perforation.

FOR APPLIANCES USING A THREE-PHASE POWER SUPPLY, FOLLOW THE INSTRUCTIONS AND

WIRING DIAGRAM ATTACHED TO THE APPLIANCE. ATTENTION TO CORRECT SENSE OF TRIPHASES PUMPS ROTATION (if present).

1.5 Ventilation/Steam evacuation

Ensure adequate ventilation of the room according to the legislation in force in the country of installation and the relevant

technical standards. For example, for European countries, please refer to the EN 16282-1 standard.

EN

page 9

2. MACHINE DESCRIPTION

2.1 Machine description

Wall-hung main power

switch:

at installation

serviceman supply and

care, according to local

laws

Standard equipment for machine with a 500 mm rack:

Control panel

Door

nr. 1 500x500 mm plates rack

Capacity per plate rack:

12 soup plates or

18 flat plates

Max Ø = 340 mm

Standard equipment for machine with a 400 mm rack:

Option A)

nr. 2 400x400 mm square

glasses racks

nr. 1 cutlery basket

nr. 1 saucers holder

nr. 1 500x500 mm glasses rack nr. 1 cutlery basket

EN

page 10

Option B)

nr. 2 round racks Ø 400 mm

nr. 1 support for round rack

Standard equipment for machine with a 370x370 mm rack:

Option A)

nr. 2 370x370 mm square

glasses racks

Option B)

nr. 1 cutlery basket

nr. 1 saucers holder

nr. 1 cutlery basket

nr. 1 saucers holder

nr. 2 Round racks Ø 370 mm

nr. 1 support for round rack

Standard equipment for machine with a 350x350 mm rack:

Option A)

nr. 2 350x350 mm square

glasses racks

nr. 1 cutlery basket

nr. 1 saucers holder

nr. 1 cutlery basket

nr. 1 saucers holder

EN

page 11

Option B)

nr. 2 Round racks Ø 350 mm

nr. 1 support for round rack

OPTIONAL:

Detergent dispenser Drain pump Water softener

nr. 1 cutlery basket

nr. 1 saucers holder

2.2 Machine features

The machine has a noise level below 70 dB(A).

EN

page 12

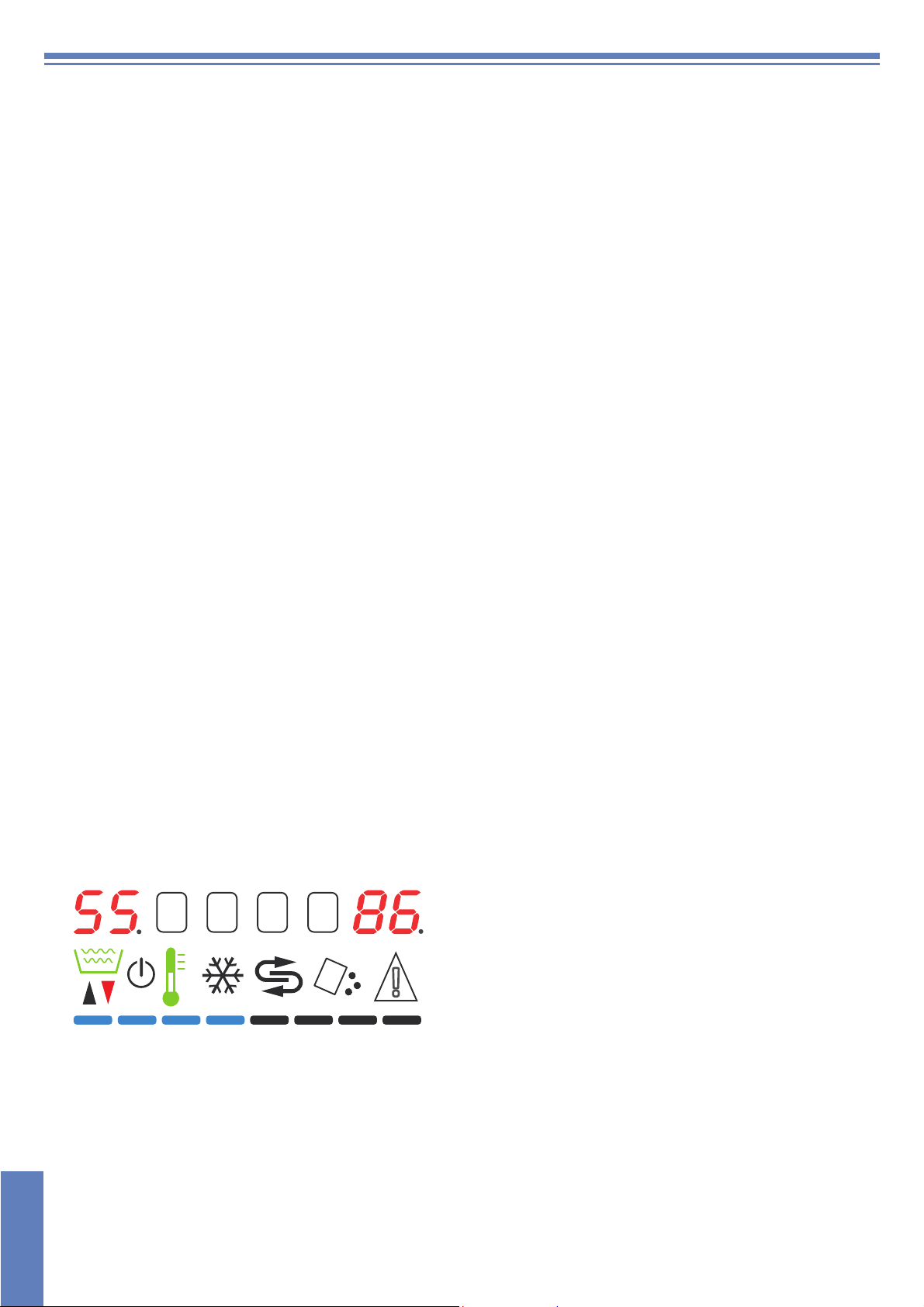

3. CONTROL PANEL AND RELATIVE SYMBOLS

F

CONTROLS

A) Switching – On / STAND BY key

B) Regeneration key (option)

C) Extra cold rinse key (optional)

D) Drain Push-button (optional)

E) START push-button to start up cycle / select cycle

F) Display

F12F15 F14 F13

F11 F10

1 32 4

F16

S

!

F1

F3

F5

F6F7F8

F9

INDICATORS

F1) Cycle scrolling bar

F2) Tank filling indicator

F3) Tank draining indicator

F4) STAND BY indicator

F5) Set temperature reached, signal

F6) Regeneration cycle indicator (option)

F7) Supplementary cold rinse indicator (option)

F8) Salt shortage indicator (option)

F9) Machine alarm indicator

F10) Boiler temperature indicator

F11) Washing type 4 (180 seconds)

F12) Washing type 3 (120 seconds)

F13) Washing type 2 (90 seconds)

F14) Washing type 1 (60 seconds)

F15) Tank temperature indicator

F16) Tank filling/draining indicator

F2

F4

EN

page 13

4. OPERATION

• Check that the filter is correctly fitted in its seat (Pict. 1 - Pict. 2).

• The filter must be cleaned after every 20 wash cycles and whenever necessary.

DO NOT use the appliance without the filter..

•

• Insert the overflow tube in the special seat inside the tub (Pict. 1 -Pict. 2 ).

• Close the dishwasher door.

• Insert the special rinse aid dispenser tube in the liquid container and check that the quantity of additive is sufficient for daily

use (see paragr.

• Open the water valve.

Pict. 1 Pict. 2

• Turn the main power switch ON. The machine is on STAND-BY mode (indicator F4 ON).

• Turn the button A. The power-on of the machine will be displayed by the indicator F4 switching OFF and by the indicators

F15 and F10 and by the one of the washing cycles switching ON.

• Make sure that the overflow pipe is correctly inserted and that the door is shut. The machine will automatically start filling the

sump. The indicators F16, F2 and the scrolling bar F1 switch on.

• Then, when the sump is full, the push button START E swtich on and the heating step will start.

• Indicator F5 switches on when the washing and rinsing water temperature is reached.

• The indicators F15 and F10 show the tank and boiler temperatures, respectively.

4.3 Use of rinse aid).

1 32 4

S

!

• Insert the rack filled with dishes to wash. The objects must be correctly placed in the rack.

• Select the wanted washing cycle (1 - 2 - 3 - 4) by pushing the button START E; after a few seconds (about 5 seconds) the

indicators F14, F13, F12, F11 will start scrolling. Release the button when the cycle light indicator desired is ON. (see chap.

4. OPERATION)

• Before starting the wash-cycle, in absence of an automatic dosing system, put the detergent in the sump. When the

temperature indicator F5 will turn ON, press the START E button for at least a second. The beginning of the cycle is indicated

by the flashing of the selected cycle indicator, by the increasing of the brightness of the button START E and by the progress

of the scroll bar F1.

• At the end of the washing cycle, a hot rinse cycle will take place.

1 32 4

S

!

1 32 4

S

!

1 32 4

S

!

EN

page 14

• The button START E will flash when the cycle is completed.

Note: At cycle end with the door closed, dishes do not get dried Take out the baset or keep the door open to allow the evaporation

and the drying of the dishes.

For machines equipped with

• For the supplementary cold rinse, push the button C until the relative light indicator F7 is on and start the cycle by pushing

the button START E.

• After this cycle, the glasses will remain wet. At any switching on and off of the machine, the function final cold rinse will be

automatically disabled.

• Repeat this operation when this function is needed.

supplementary cold rinse:

1 32 4

S

!

• Drain cycle: remove the overflow pipe. For machines equipped with drain pump see paragr. 4.4 Drain pump system

(optional).

• At the end of the day, clean the machine (see chap. 5. MAINTENANCE).

• Switch the machine off by pushing button A and shut the water valve. When the indicator F4 turns ON, the machine is on

STAND-BY mode. (see chap. 4. OPERATION)

• Turn off the main wall switch.

4.1 Cutlery and crockery loading

Before cutlery and crockery loading in the machine, coarsely clean them from the leftover food.

It isn't necessary to rinse the cutlery an crockery under water.

WARNING: Do not wash articles polluted with petrol, paint, chips of steel or iron, ash, sand, wax,

lubricant grease. These substances damage the machine. Do not wash fragile objects or material not

resistant to the washing process.

Note the following recommendations:

• Crockery and cutlery should not be inserted inside one another, covering each other.

• Place the crockery in order to all surfaces can be reached by water; otherwise the dishes are not

washed.

• Make sure all the crockery are in a stable position and that the hollow containers don't overturn

(cups, glasses, bowls, etc.).

• Place in the rack all the hollow containers such as cups, glass, etc. upside-down.

• Place the crockery with deep hollow with upper face downwards, so that water can flow out.

• Make sure the smaller crockery do not fall from the rack.

• Check all the wash arms runs freely and they are not blocked by too tall or too prominent crockery.

Eventually, run a manual rotation of the arms to check it.

Pict. 3

Some foods, such as carrots, tomatoes, and others, may contain some natural dyes substances, that in large amounts, can

alter the crockery and plastic parts colors.

Any discoloration does not mean that the plastic is not heat resistant.

EN

page 15

Crockery and cutlery not suitable for dishwasher

Not suitable for dishwasher:

• Wooden crockery and cutlery or with wooden parts; water at high temperature causes deformation to wood. Also the

adhesives used are not suitable for treatment in the dishwasher; a consequence could be the handles detachment.

• Crafts, precious vases or decorated glasses.

• Not heat-resistant plastic crockery.

• Copper, brass, pewter or aluminum objects: they may become discolored or opaque.

• The decorations on glass, after a certain number of washes, can lose gloss.

• Fragile glasses or crystal items, if often washed, can become opaque.

We recommend to buy exclusively crockery and cutlery suitable for dishwashing.

After several washes, the glass can become opaque.

It is mandatory to repeat the washing cycle if at the end of the cycle the crockery are not well clean or if there are

washing residues (glasses, cups, bowls, etc. with liquid inside).

4.2 Use of detergent (optional)

The detergent must be of good quality, of NON-FOAMING type, specific for the mechanical washing of dishes.

The use of liquid detergents is recommended.

The dosing has to be done following the recommendations of the detergent manufacturer and in accordance with the water and

dishes characteristics.

The detergent has to be inserted only in the wash tank. 1cm of the detergent drawn into the tube is equal to about 0,15 g. A

correct amount of detergent is very important for a successful wash.

Note: It is forbidden to use detergents with chlorine-based reagents.

4.3 Use of rinse aid

The machine is equipped with a rinse aid dispenser. The machine automatically draws the rinse aid chemical.

The dosing has to be done following the recommendations of the rinse aid manufacturer and in accordance with the water

characteristics.

Note: Too much chemicals produces foam that reduces the effectiveness and lifetime of the washing pumps.

Too much chemicals might leave residuals on the dishes.

4.4 Drain pump system (optional)

To drain completely the wash-tank keep the machine ON, extract the overflow pipe and shut the door. Press the button D for at

least one second (see chap. 3. CONTROL PANEL AND RELATIVE SYMBOLS). The drain pump will automatically drain the

wash-tank.

The indicators F16, F3 and the scrolling bar F1 switch ON.

Once the machine is completely drained, the machine will turn off and the indicator F4 switch ON (stand-by mode).

If you want to refill the machine for a new cycle, wait for 5 seconds before to switch it on by pressing the button A. (see chap. 3.

CONTROL PANEL AND RELATIVE SYMBOLS).

Opening the door will stop the machine that will re-start when the door is shut.

During the wash-rinse cycle the water in excess is automatically drained.

1 32 4

S

!

EN

page 16

4.5 Regeneration device (optional)

Should the machine be equipped with a water-softener circuit, this will be fully automatic. When needed, a 120” regeneration

cycle will automatically activate. During this phase, the regeneration indicator F6 lights up.

If needed the cycle can be activated even during the wash-tank loading.

If the activation is made during the wash-cycle, this will be longer.

The circuit board is designed to call periodically for a 20 min. manual regeneration cycle (according with the water hardness

adjusted). The indicator F6 flashes. This regeneration cycle can also be activated by the user, should the rinse quality be

dissatisfactory.

1 32 4

S

1 32 4

S

!

IMPORTANT: Before starting a regeneration cycle check if there is salt in the special container.

When the F8 indicator flashes on the display it means that the salt level in the bowl is low (only on

machines equipped with the optional Water Softener).

• To start the regeneration cycle, switch the machine OFF with the key A.

• Take off the overflow pipe. Drain the wash-tank.

• For machines equipped with drain pump see par. 4.4 Drain pump system (optional).

• Press the button B. The regeneration indicator F6 lights up and the machine carries out with the various phases.

• The cycle is finished when the indicator F6 goes off after around 20 minutes.

1 32 4

S

!

!

Note: Regeneration times will be blocked only if the door is opened.

The optional regeneration is not allowed in the following conditions:

• During programming.

• During the wash cycle.

• During manual draining.

• if the door is open; in this case the message door will be displayed for about 4 seconds.

• If the machine is ON.

In case of water hardness above 35 °f an external water softener is recommended.

EN

page 17

4.6 Compliance with hygiene regulations and H.A.C.C.P.

• When starting the machine ON, no wash-cycle will be starting until the set boiler and wash-tank temperatures are reached.

During operation, the machine will not start the rinse cycle till the set boiler temperature is reached.

• The machines are equipped with a temperature indicator F5 which lights up when the boiler and the tub have reached the

preset temperature (see chap. 3. CONTROL PANEL AND RELATIVE SYMBOLS - values set by the manufacturer). It is

recommended to wait for this light to go on before starting the next cycle.

• Scrape food from the dishes carefully in order not to clog the filters, nozzles and pipes.

• Unload the wash tub and clean the filters at least twice a day.

• Check that the amount of detergent and rinse aid dispensed is correct (as suggested by the supplier of the product). In the

morning, before starting the machine, check that the quantity of chemicals in the canisters is enough for daily supply.

• Always clean the support floor of the dishes.

• Extract the rack with clean hands or gloves to avoid finger marks.

• Do not dry or polish the dishes with non-sterilized cloths, brushes, or dusters.

EN

page 18

5. MAINTENANCE

WARNING: The machine is not protected against water jets, therefore do not use pressure cleaning

systems. Contact your cleaning products retailer for detailed instructions on the methods and products

to use for periodic sanitizing of your appliance. DO NOT use bleach or chlorine-based detergents for

cleaning the appliance.

5.1 Regular Maintenance

In order to ensure perfect performance, the appliance must be completely cleaned at least once a day in the following way:

• Turn the switch to 0 (see chap. 3. CONTROL PANEL AND RELATIVE SYMBOLS).

• Turn off the main wall switch.

• Turn off the water tap.

• Remove the overflow tube to empty the water. For appliances provided with emptying pump follow the indications as

described on paragraph 4.4 Drain pump system (optional).

• Remove the filter and clean it with a brush under running water.

• Remove the rotors by loosening the fixing screws, and thoroughly clean the nozzles and cleaning and rinsing arms under

running water

• If presents, remove the surface filters and clean it with a brush under running water (see Pict. 4).

• Refit all the parts and arrange the impellers in their seats, securing them with the relative fixing screw. Take extreme care to

re-assemble the nozzles in the right position (open and / or closed nozzles) and that the arms are installed with the right axial

angle.

• Clean the tub thoroughly using specific products.

• At the end of the day, it is advisable to leave the dishwasher door open.

Pict. 4

Automatic cycle of machine self-cleaning/rinsing:

• The machine should be in stand-by mode (red-lighted indicator F4), remove the overflow pipe and close the door.

• Push the button START E for 5 seconds. An automatic cycle of 15 seconds will start, after this the machine will be in stand-by

mode.

• When flashing the indicators F16 - F3 - F9 means that the tank is not empty.

• When displaying door means that the door is open.

1 32 4

S

• Turn off the water tap.

• Turned off the machine by switching the main power switch OFF.

Note: It is advisable to replace the tub water by refilling the tub at least every 20 wash cycles, or twice

a day. Do not use metal brushes or corrosive products which can damage the machine.

!

1 32 4

S

!

1 32 4

S

!

EN

page 19

5.2 Special Maintenance

Once or twice a year have a qualified technician inspect the machine:

1 Clean the electrovalve filter.

2 To remove residual deposits.

3 To check the watertight of the seals for water loading and unloading connections.

4 Check the perfect state and/or wear of the components. If a component is damaged or oxidized replace it

immediately with genuine spare parts only

5 Check the efficiency of the dispensers

6 Check the efficiency of the door safety switch.

7 Tighten firmly all electrical connections.

Pay attention to do not wet the motor or any electric part.

Perform maintenance with the wall-mounted main switch turned OFF.

Every 3-4 years of machine use, double-check the tightening and the efficiency of all electrical contacts, with special

attention to the contacts of starters and relays.

Increase controls frequency if the machine is operating in heavy or intensive conditions.

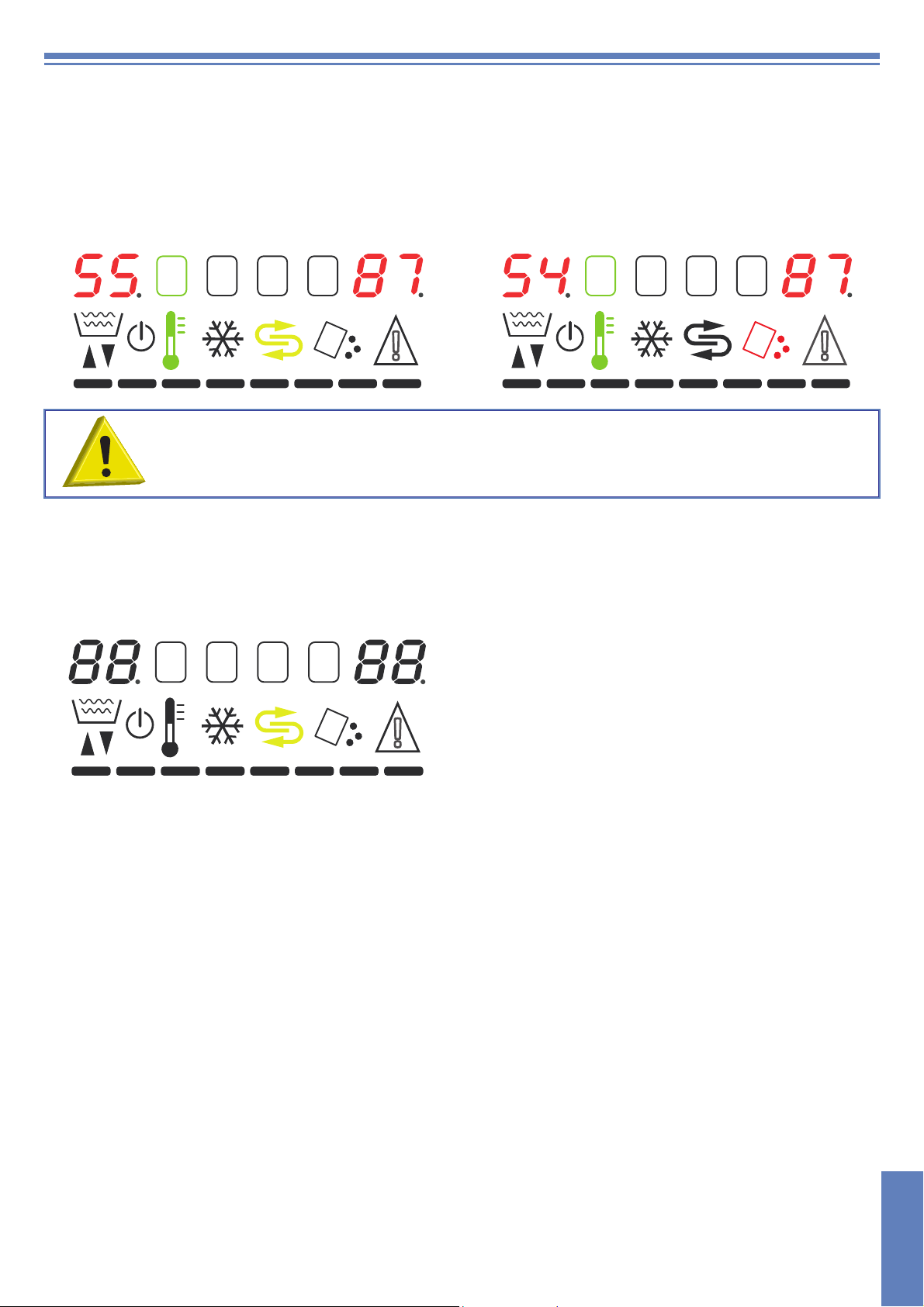

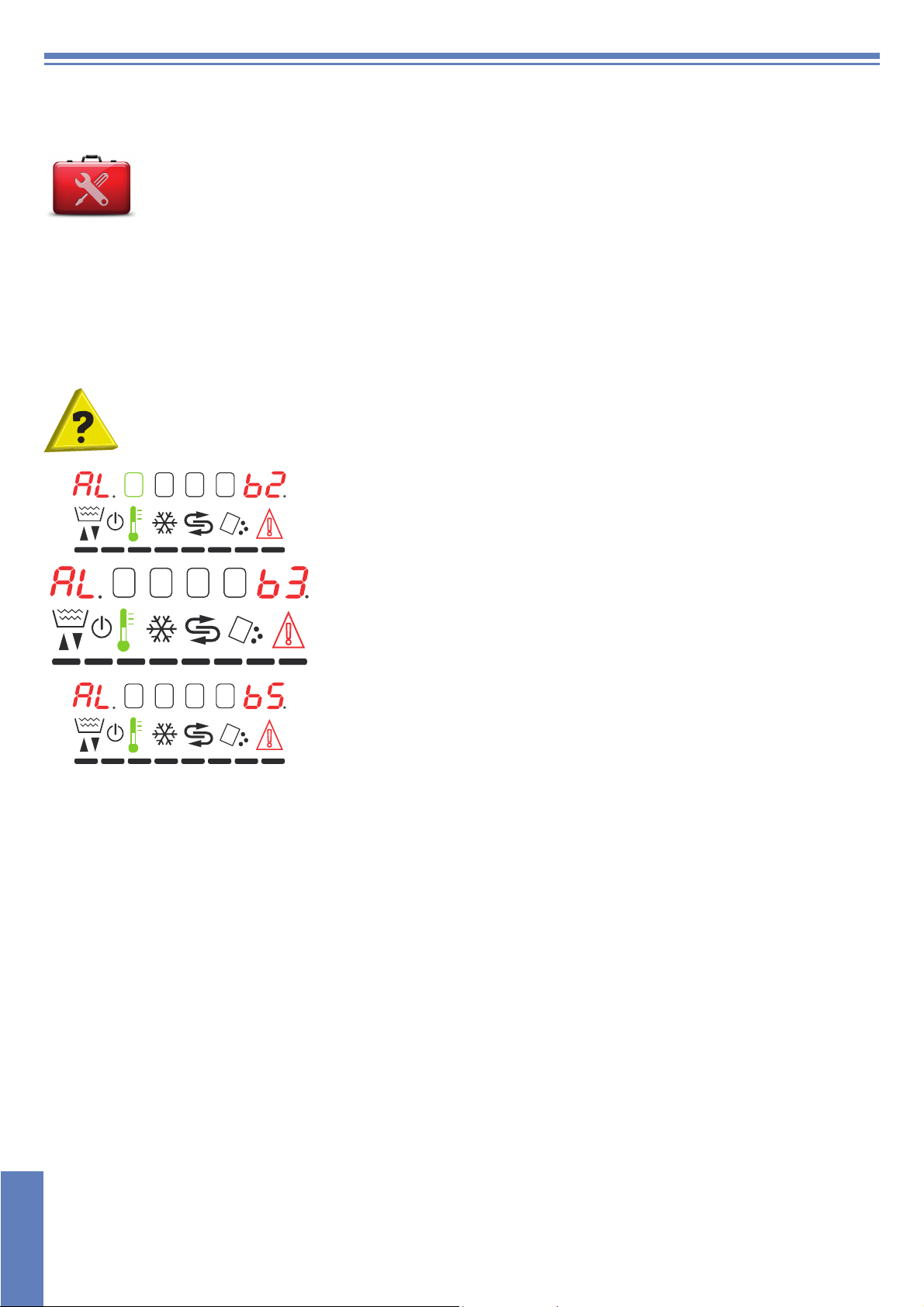

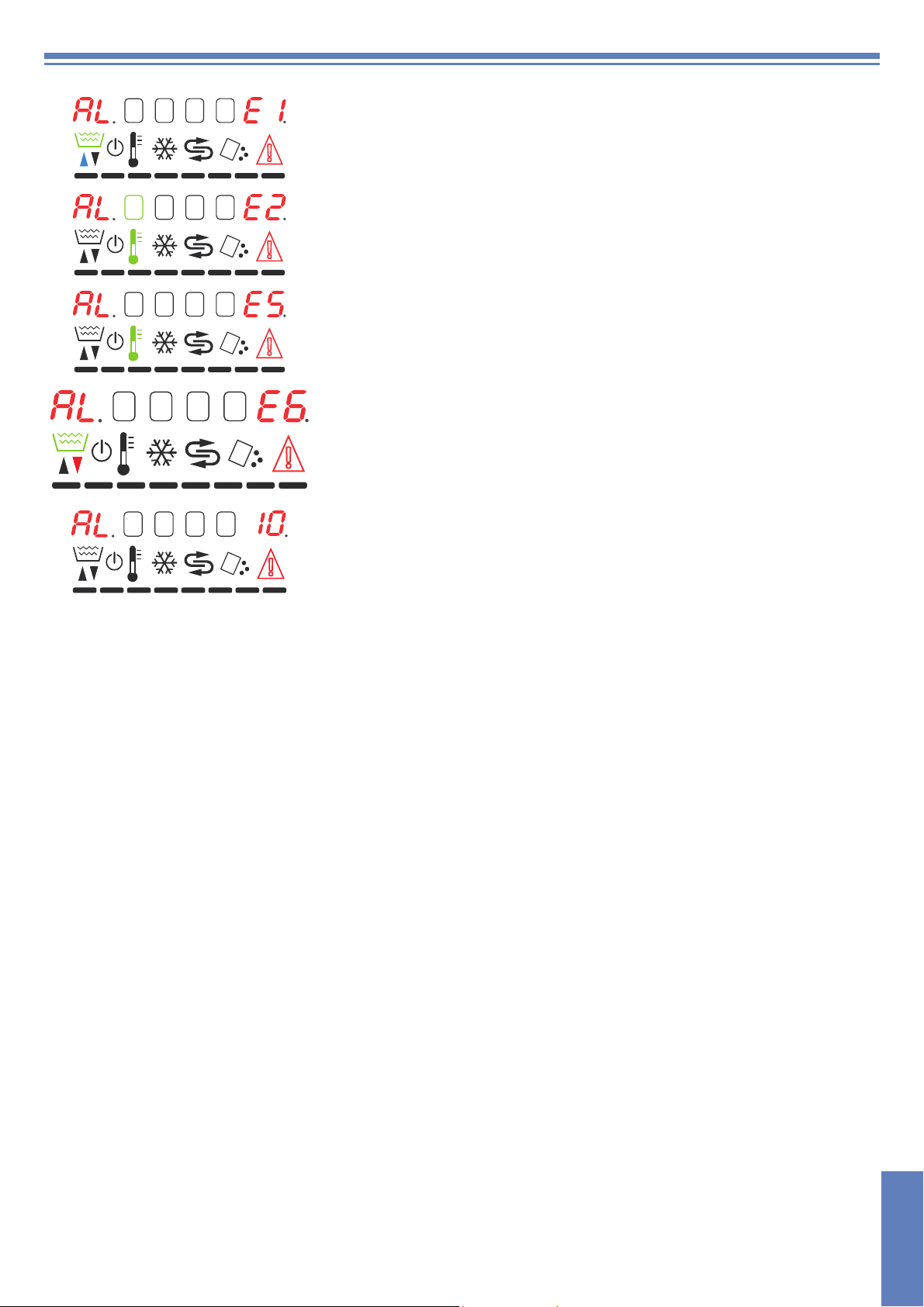

6. ALARMS

Alarms will be displayed by the lighting of LEDs. according to their typology.

1 32 4

S

1 32 4

S

1 32 4

S

B2

BOILER PROBE FAILED

The circuit board does not detect the boiler sensor.

!

!

!

Contact Technical Service.

B3

BOILER HEATING ALARM

The factory-set boiler temperature was not achieved in the maximum foreseen

time limit.

Contact Technical Service.

B5

BOILER OVERHEATING

The water temperature in the boiler exceeded 105 °C.

Contact Technical Service.

EN

page 20

1 32 4

S

E1

WATER LOAD FAILED

The machine wash-tank was not filled in the maximum foreseen time limit.

!

Contact Technical Service.

1 32 4

S

1 32 4

S

1 32 4

S

1 32 4

S

E2

TANK PROBE FAIL

The circuit board does not detect the wash-tank sensor.

!

!

!

!

Contact Technical Service.

E5

TANK OVERHEATING

The wash-tank temperature exceeded 90 °C.

Contact Technical Service.

E6

TANK DRAINING FAILED

The draining of the wash-tank was not completed within the maximum foreseen

time limit.

Contact Technical Service.

10

BREAK TANK FILLING FAILURE

The Break Tank safety pressure switch was not activated within the time set.

Contact Technical Service.

EN

page 21

7. ENVIRONMENTAL ASPECTS

7.1 Packing

The packing consists of the following:

• a wood pallet;

• a nylon bag (LDPE);

• multi-layered cardboard;

• polystyrene foam (PS);

• polypropylene support (PP).

All above materials, shall be disposed and treated in accordance with the Local Laws in force.

7.2 Disposal

The equipment is marked with the symbol (see Pict. 5).

An efficient waste disposal procedure contributes to avoiding any potential environmental or health hazards as

well as promoting the recycling and re-utilization of materials from which our appliances are constructed.

Pict. 5

An efficient waste disposal procedure contributes to avoiding any potential environmental or health hazards as well as

promoting the recycling and re-utilization of materials from which our appliances are constructed.

If the user does not comply with the regulations he/she shall be subject to the penalties foreseen by each member state.

Disconnect electricity and water before disposal.

Cut the electrical cable to ensure that further use is impossible.

All metal parts are recyclable as they are made of stainless steel.

Recyclable plastic parts are marked with the plastic material symbol.

8. ECOLOGICAL ASPECTS

8.1 Recommendations for optimum use of energy, water and additives

Dispensing of salt: A pre-set quantity (by the manufacturer) of salt is injected in the resins every regeneration

cycle. t is important to observe the number of regeneration cycles recommended in paragraph 4.5

Regeneration device (optional) in order to avoid salt spills or lime deposits..

If possible, use the machine at full load: This will avoid wasting detergent, rinse aid, water and energy.

Detergents and rinse aids: Use detergents and rinse aids having the highest biodegradability so that the environment is better

respected. Have the correct dosage according to the water hardness checked at least once a year. An excess of product

pollutes rivers and seas, whereas an insufficient amount compromises dish washing and/or hygiene.

Tank and boiler temperatures: The temperatures of the tank and boiler are set by the manufacturer so as to get the best

washing results with the majority of detergents on the market. These can be reset by the installer according to the detergent

used. (see paragr. Temperature adjustment).

Cleaning off: Carefully clean off the kitchenware using water at ambient temperature with moderation so as to make removal

of animal fats easier. To remove encrusted matter, soaking in hot water is recommended.

Notes: Wash the objects as soon as possible in order to prevent the deposits from drying and jeopardizing the effectiveness of

the washing.

To get an efficient wash, it is advisable to regularly clean and maintain the dishwasher (see chap.5. MAINTENANCE).

Non-compliance with the above recommendations or with any and all information within the manual could result in

a waste of energy, water, and detergent, further causing an increase in user costs and/or a reduction in

performance.

EN

page 22

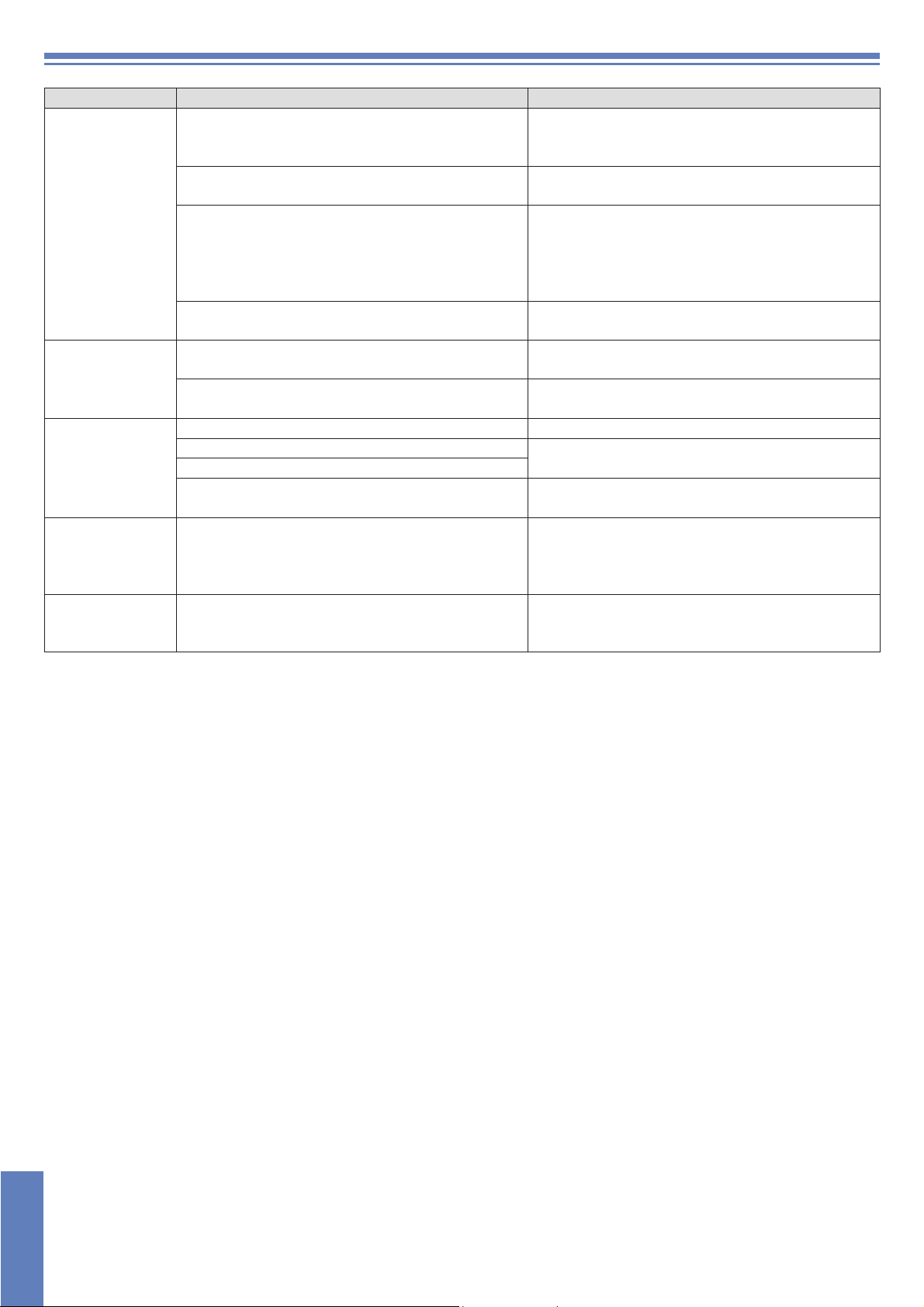

9. TROUBLESHOOTING

Type of Problem Possible Causes Cure

The appliance

does not start

The appliance

does not draw

water

Unsatisfactory

washing results

Presence of foam

Glasses or dishes

are not

completely dry

The main switch is turned off Turn on the switch

The water tap is closed Open the water tap

Clean the rinsing arm nozzles, the pipes and the

The rinsing arm nozzles or the electrovalve filter

are clogged and/or caked with lime deposits

Faulty pressure switch

The washing nozzles are clogged or the washing

arms do not rotate

Unremoved grease or starch Detergent concentration too low

Check tank temperature (which must be between

50 °C and 60 °C).

Length of washing cycle inadequate for type of

grime build-up

Wash water too dirty

Use of unsuitable products Use no-foam detergents or reduce the dose in use.

Tub temperature too low

Insufficient rinse aid

The rack is unsuitable for the glasses and dishes

The dishes have been too long in the tub

Rinse water temperature is less than 75 °C - 80 °C Check the temperature of the boiler thermostat

Surface of dishes and glasses too rough or porous

for material wear

Surface of objects too rough or porous for material

wear

electrovalve filter. If the machine has a water

softener check the salt content or regenerate the

resins more often

Replace the pressure switch (call the Technical

Assistance service)

Unscrew and clean the nozzles and the rotating

column, refit them correctly in their seats

Adjust the thermostat or check correct heating

element operation

Choose a longer cycle if possible, otherwise repeat

wash cycle

Empty water from the tub, clean filters; refill the tub

and correctly reposition the filters

Adjust the thermostat or check correct heating

element operation

Increase the amount of rinse aid by turning the

screw on the dispenser (see paragraph

dispenser)

Use a suitable rack enabling the dishes to be tilted

so water can run off

As soon as the cycle stops, remove the rack with

pots and tools so that they can dry more quickly in

the air.

Replace type of dishes and glasses used

Replace type of the objects used.

Rinse aid

EN

page 23

Type of Problem Possible Causes Cure

Decrease the amount of rinse aid by turning the

Streaks and spots

on glasses and

dishes

The appliance

suddenly stops

during the cycle

During wash cycle

the machine stops

and draws water

minutes-> Min,

day-> day,

month-> Mon,

year-> year).

The washing

pump doesn't

work

Too much rinse aid

The water is too hard

For appliances with conditioners: too little salt in

the salt container or the resins have not been

properly regenerated

Salt present in dishwasher tub

The appliance is connected to an overloaded

circuit

A safety device has been activated

Water from the previous day has not been replaced Empty the tub and refill it

The tub water temperature is too high

Faulty pressure switch

The overflow tube is incorrectly positioned

Little pressure on feeding Take out the boiler pipe and drain the pump

The pump is blocked Call the Technical Assistance service

fine-adjustment screw on the dispenser (see

paragraph

Check the water quality. Water must not exceed 8

°f (5 °d) in hardness

Fill the salt container (coarse salt: 1-2 mm grains)

and regenerate the resins more often. If lime

deposits are also observed on the body of the

machine, have a qualified technician check the

operation of the water softener

Thoroughly clean and rinse the appliance, and

avoid spilling salt when filling the container

Connect the appliance separately (call the

Technical Assistance service)

Check safety devices (call the Technical

Assistance service)

Have the Technical Assistance service check the

thermostat and the pressure switch

Remove the overflow tube and correctly reposition

it

Rinse aid dispenser)

EN

page 24

Note: For any other problems, contact the Technical Assistance service.

The manufacturer reserves the right to alter the technical characteristics without prior notice.

Loading...

Loading...