INSTRUCTION MANUAL FOR DISHWASHERS

BEDIENUNGSANLEITUNG FÜR GESCHIRRSPÜLMASCHINE

MANUEL D’INSTRUCTIONS POUR LAVE-VAISSELLE

MANUALE DÌ ISTRUZIONE PER LAVASTOVIGLIE

MANUAL DE INSTRUCCIONES PARA LAVAVAJILLAS

MANUAL DE INSTRUÇÕES PARA MÁQUINA DE LAVAR LOUÇA

HANDLEIDING VOOR AFWASMACHINES

BRUGSVEJLEDNING TIL OPVASKEMASKINE

INSTRUKTIONSMANUAL FÖR DISKMASKINER

ASTIANPESUKONEIDEN KÄYTTÖOPAS

ΕΧΕΙΡΙ∆ΙΟ ΧΡΗΣΗΣ ΓΙΑ ΠΛΥΝΤΗΡΙΟ ΠΙΑΤΩΝ

109.750

109.751

109.760

109.761

GB

F

I

E

P

NL

DK

SV

FI

GR

D

INSTRUCTION MANUAL FOR DISHWASHERS

Page 1 of 12

GB

CONTENTS

CHAP 1 PREFACE ..................................................................................................................... 2

CHAP 2 INSTALLATION ............................................................................................................ 2

2.1 U

NPACKING ........................................................................................................................ 2

2.2 P

OSITIONING....................................................................................................................... 2

2.3 E

LECTRICAL CONNECTION ................................................................................................... 3

2.4 P

LUMBING CONNECTION ...................................................................................................... 3

2.5 C

ONNECTION TO THE DRAIN LINE ......................................................................................... 4

CHAP 3 RISKS AND IMPORTANT WARNINGS ....................................................................... 4

CHAP 4 USING YOUR APPLIANCE .......................................................................................... 5

4.1 SYMBOLS USED ................................................................................................................... 5

4.2 S

TARTING UP...................................................................................................................... 5

4.3 L

OADING AND WARMING UP ................................................................................................ 5

4.4 W

ASHING CYCLE................................................................................................................. 5

4.5 T

URNING OFF THE APPLIANCE ............................................................................................. 6

4.6 D

ISCHARGING THE APPLIANCE............................................................................................. 7

4.6.1 Models without discharging pump ............................................................................. 7

4.6.2 Models with discharging pump .................................................................................. 7

4.7 R

EGENERATING THE ION EXCHANGE RESINS ....................................................................... 7

4.8 E

ND OF SERVICE................................................................................................................. 8

CHAP 5 MAINTANANCE ............................................................................................................ 8

5.1 HYGIENE AND CLEANING ...................................................................................................... 8

5.2 R

OUTINE MAINTENANCE (DAILY) ........................................................................................... 8

5.3 W

EEKLY MAINTENANCE ....................................................................................................... 9

5.4 A

NNUAL MAINTENANCE ..................................................................................................... 10

CHAP 6 ADJUSTMENTS AND SETTINGS .............................................................................. 10

6.1 DISPENSER ....................................................................................................................... 10

6.1.1 Rinse agent dispenser ............................................................................................. 10

6.1.2 Models with no detergent metering unit .................................................................. 11

6.1.3 Models with detergent dispenser (available on request) ......................................... 11

CHAP 7 DEINSTALLATION ..................................................................................................... 12

CHAP 8 DISPOSAL .................................................................................................................. 12

8.1 C

ORRECT DISPOSAL OF THIS PRODUCT ............................................................................. 12

In legal terms, the manufacturer reserves the property of this document. It is forbidden to reproduce it or divulge it with any means

without prior written authorisation.

The manufacturer reserves the right to introduce changes in order to achieve the improvements it deems necessary without prior notice.

-

-

INSTRUCTION MANUAL FOR DISHWASHERS

Page 2 of 12

GB

Chap 1 PREFACE

Failure to follow the instructions provided in the attached documentation may jeopardize

safety of the appliance and immediately cancel the warranty.

The warnings contained in this manual provide important information regarding

safety during the various installation, operation and maintenance stages.

Carefully store all documentation near the appliance; give it to the technicians and operators who

will be using it. It is the operator’s duty to read, understand and learn this manual before

starting any operation on the machine. The appliance is intended for the professional washing of

dishes for communities, so installation, use and maintenance must in all cases to be performed by

trained personnel who follow the manufacturer’s instructions. Do not leave within the reach of

children. The choice of materials, construction in conformity with CE safety directives and complete

testing ensure the quality of this machine. In addition to this manual, you will find in the machine:

x wiring diagram

x topographic table

The manufacturer declines all responsibility for damage to things or injuries to persons

deriving from failure to comply with the instructions given or from improper use of the

machine.

Chap 2 INSTALLATION

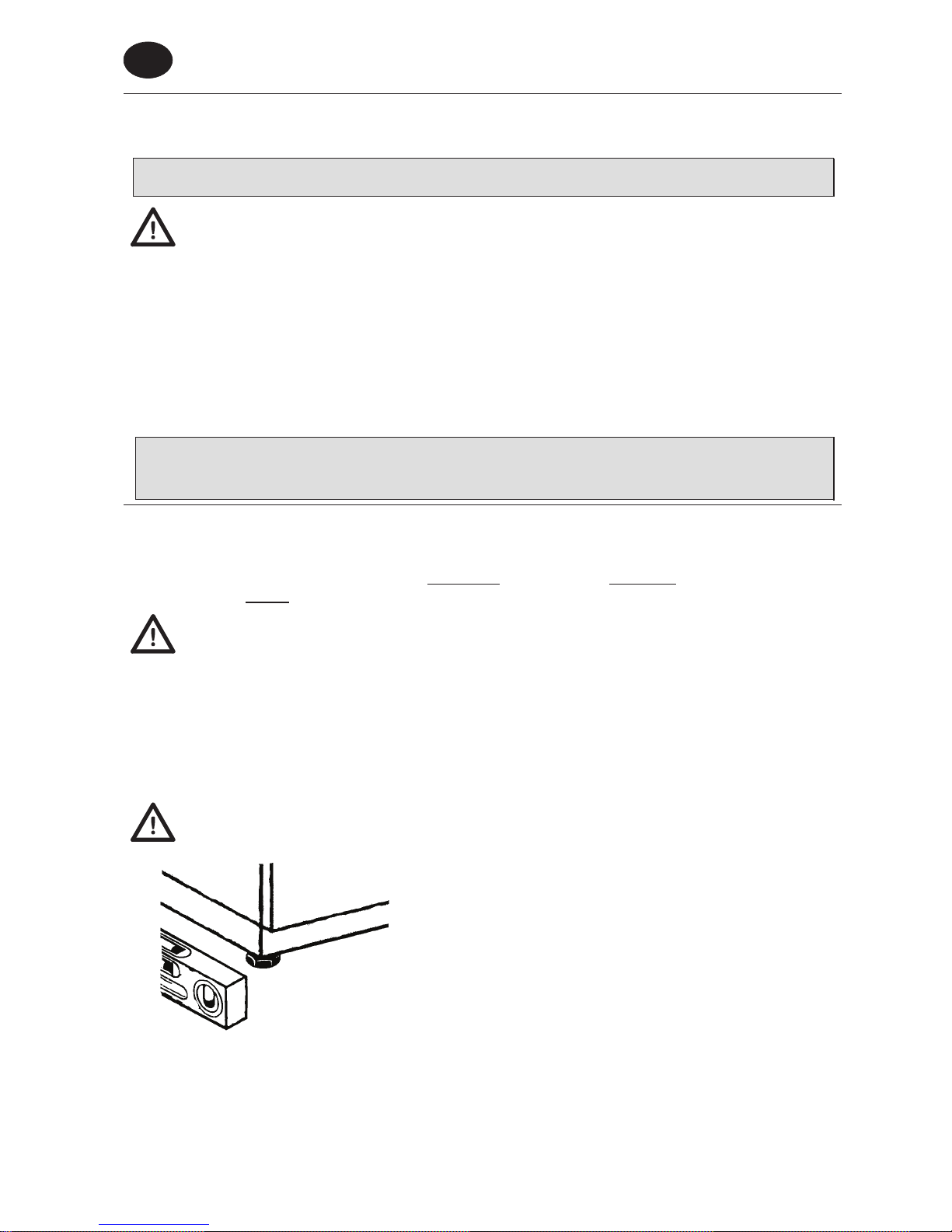

Proper installation is essential in order for the machine to operate well. Some of the data needed for

machine installation can be found on the data plate

placed on the right side of the machine and in

duplicate on the cover

of this manual.

Only qualified, authorised technicians must install the machine.

2.1 Unpacking

Check that the packing is in perfect condition and write down any damage found on the delivery

note. After you have removed the packing, make sure the appliance is intact. If the machine is

damaged, immediately notify the dealer by fax or by registered letter with advice of receipt and the

haulage contractor that transported it. If the damage is such as to jeopardize machine safety, do not

install and/or use until a qualified technician services it.

The packing components (plastic bags, foam polystyrene, nails, etc. ...) must not be

left within the reach of children and pets as they may be dangerous.

2.2 Positioning

x Check that there are no objects and materials in the

installation area that can be damaged by steam that

may exit the machine during operation, or at least

that they are sufficiently protected.

x In order to ensure stability, install and balance the

machine on its four feet.

x Different installation solutions must be agreed upon

and approved by the manufacturer.

INSTRUCTION MANUAL FOR DISHWASHERS

Page 3 of 12

GB

Mod.

V~ Hz kW A

S/N

H2O

kPa °

C

2.3 Electrical connection

x There must be an omnipolar type of main switch

that disconnects all contacts, including the

neutral, with a distance of at least 3 mm between

the open contacts and with safety circuit breaker

tripping or connected with fuses, to be sized or

calibrated in conformity with the power indicated on

the machine’s data plate.

x The main switch must be located on the electric line

close to the installation, and it must serve only one

appliance at a time.

x Electric network voltage and frequency must coincide

with those given on the data plate.

x There must be an effective earthing system in

conformity with the prevention standards in force for

operator and equipment safety.

x The power supply cable (type H07RN-F only) must

not be pulled or crushed during normal operation or

routine maintenance.

x The unipotential terminal fastened to the body must

be connected to a unipotential cable having a section

suited to the application.

x Respect the polarities indicated in the wiring

diagram.

x Consult that attached wiring diagram for additional

information.

Do not use adaptors, multiple socket-outlets or cables of inadequate type and section

or with extension connections not compliant with plant engineering standards in

force.

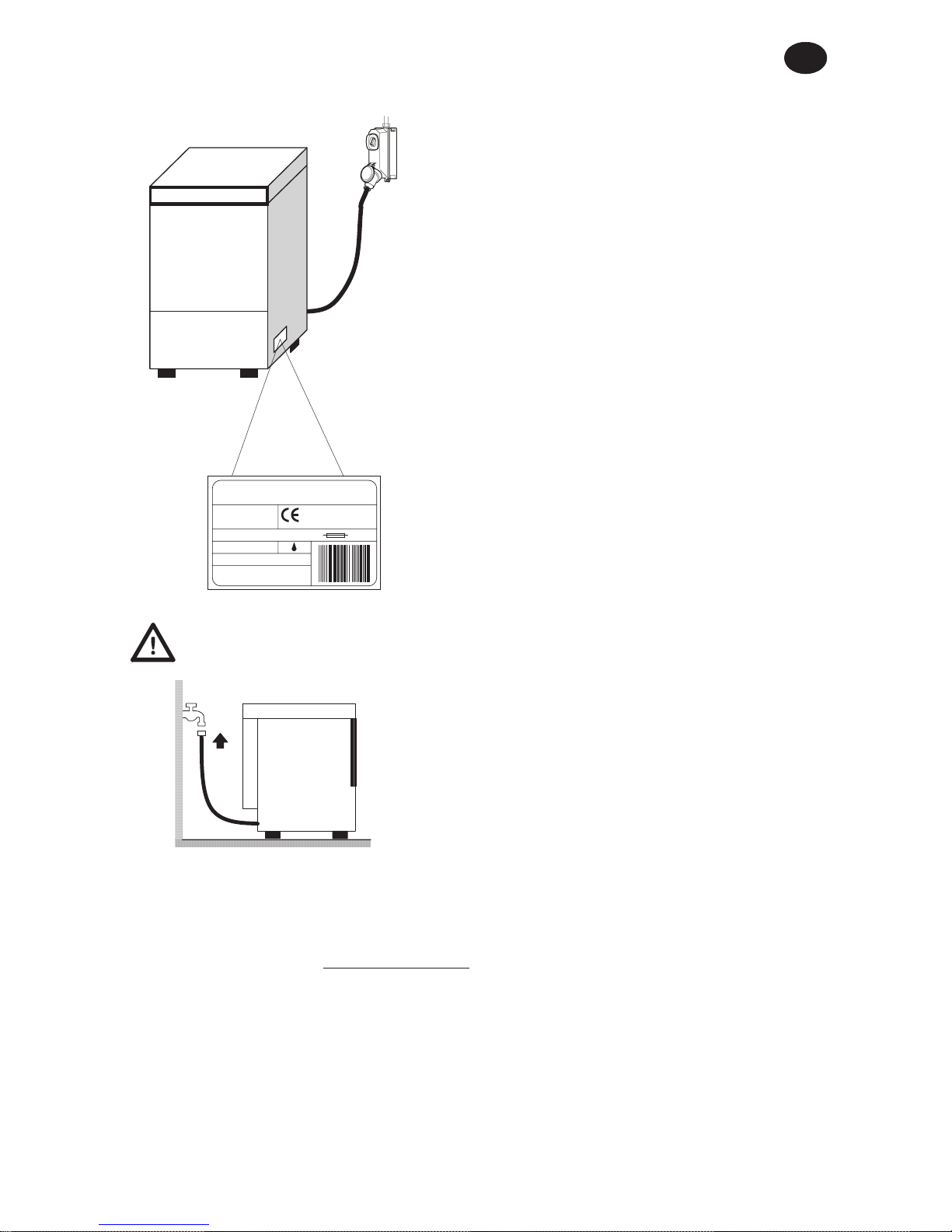

2.4 Plumbing connection

The appliance is to be connected to the water network

with a hose. There must be a slide on-off, ball or gate

valve able to quickly and completely turn off the water

if necessary between the water network and the

appliance’s solenoid valve. The on-off valve must be on

the line near and right before the appliance.

x If the system is new or barely used, have the water run a long time before making the

connection.

x The water supply, temperature and pressure must be compatible with what is indicated on the

machine’s technical data plate.

x

If the water’s hardness is greater than 14 F (8 dH), we recommend you use the machine with

internal water softener (available on request

). If the water’s hardness is greater than 35 F (19.5

dH), we recommend you install an external water softener upline of the solenoid valve.

Loading...

Loading...