BAR

Elektronik GmbH

®

Mini-PLC

STG-680

H

Art. No. 0850-0680

MANUAL

TABLE OF CONTENT

Page:

Document:

Date:

Revision:

1/8

9021-0016 -A

04.08.2016

A

Mini-PLC STG-680

Art. No. 0850-0680

MANUAL

1 SAFETY INSTRUCTIONS ...................................... 2

2 DESTINATED USE .................................................. 2

3 DISCLAIMER .......................................................... 2

4 PRODUCT DESCRIPTION ..................................... 2

4.1 Features .................................................................. 2

4.2 Applications ...........................................................2

4.3 General description ..............................................2

4.4 MODBUS Programming with miCon-L ...............3

4.5 Delivery content ....................................................3

5 INSTALLATION ....................................................... 3

5.1 Mounting ................................................................3

5.2 Wiring ......................................................................3

5.2.2 Connecting the power supply ................................. 4

5.2.3 Connecting the inputs .............................................4

5.2.4 Connecting the outputs ...........................................4

5.2.5 Connecting the MODBUS interface ........................ 4

6 OPERATION AND PROGRAMMING ..................... 5

6.1 Software download ............................................... 5

6.2 Virtual COM port driver installation ....................5

6.3 miCon-L Software Installation ............................5

6.4 Connecting the Mini-PLC ..................................... 5

6.5 First steps in miCon-L ..........................................5

7 APPENDIX ..............................................................7

7.1 Specications ........................................................ 7

7.1.1 General ....................................................................7

7.1.2 Power supply ........................................................... 7

7.1.3 Inputs ....................................................................... 7

7.1.4 Outputs ....................................................................7

7.1.5 MODBUS interface .................................................. 7

7.1.6 Security features ...................................................... 7

7.1.7 Program and data memory .....................................7

7.1.8 Timebase (oscillator) ................................................ 8

7.1.9 Electrical connection ...............................................8

7.1.10 Electromagnetic compatibility (EMC) ......................8

7.1.11 Environmental conditions ........................................8

7.1.12 Weight and dimensions ........................................... 8

7.1.13 Ordering information ...............................................8

7.2 Documents, videos and software .......................8

7.3 Disposal ..................................................................8

7.4 Conformity declaration ........................................8

© 2014-2016 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved.

9021-0016-A

BAR

Elektronik GmbH

®

Mini-PLC

STG-680

H

Art. No. 0850-0680

MANUAL

Page:

Document:

Date:

Revision:

2/8

9021-0016 -A

04.08.2016

A

1 SAFETY INSTRUCTIONS

This manual contains notices which you should observe

to ensure your own personal safety, as well as to protect

the product and the connected equipment. These notices

are highlighted in the manual by a warning symbol and are

marked as follows according to the level of danger:

Only qualied personnel should be

allowed to install and work on this

equipment. Qualied persons are

dened as persons who are authorized

to commission, to ground and to tag

circuits, equipment and systems in

accordance with established safety

practices and standards.

Turn off the power supply before

performing any wiring operations!

Short circuits can be harmful, critical and

can cause explosions and serious burns!

Please read this manual carefully and

observe all safety instructions!

2 DESTINATED USE

The Mini-PLC is designed for universal measuring, controlling and regulating applications.

It must not be used for life critical, medical or fail safe

applications.

3 DISCLAIMER

BARTH Elektronik GmbH assumes no liability for usage

and functionality of the Mini-PLC in case of disregarding this manual. The strict accordance of this manual

is important since the installation methods, peripheral

connections, usage and maintenance can not be controlled by BARTH Elektronik GmbH. Therefore BARTH

Elektronik GmbH assumes no liability for any claim.

4 PRODUCT DESCRIPTION

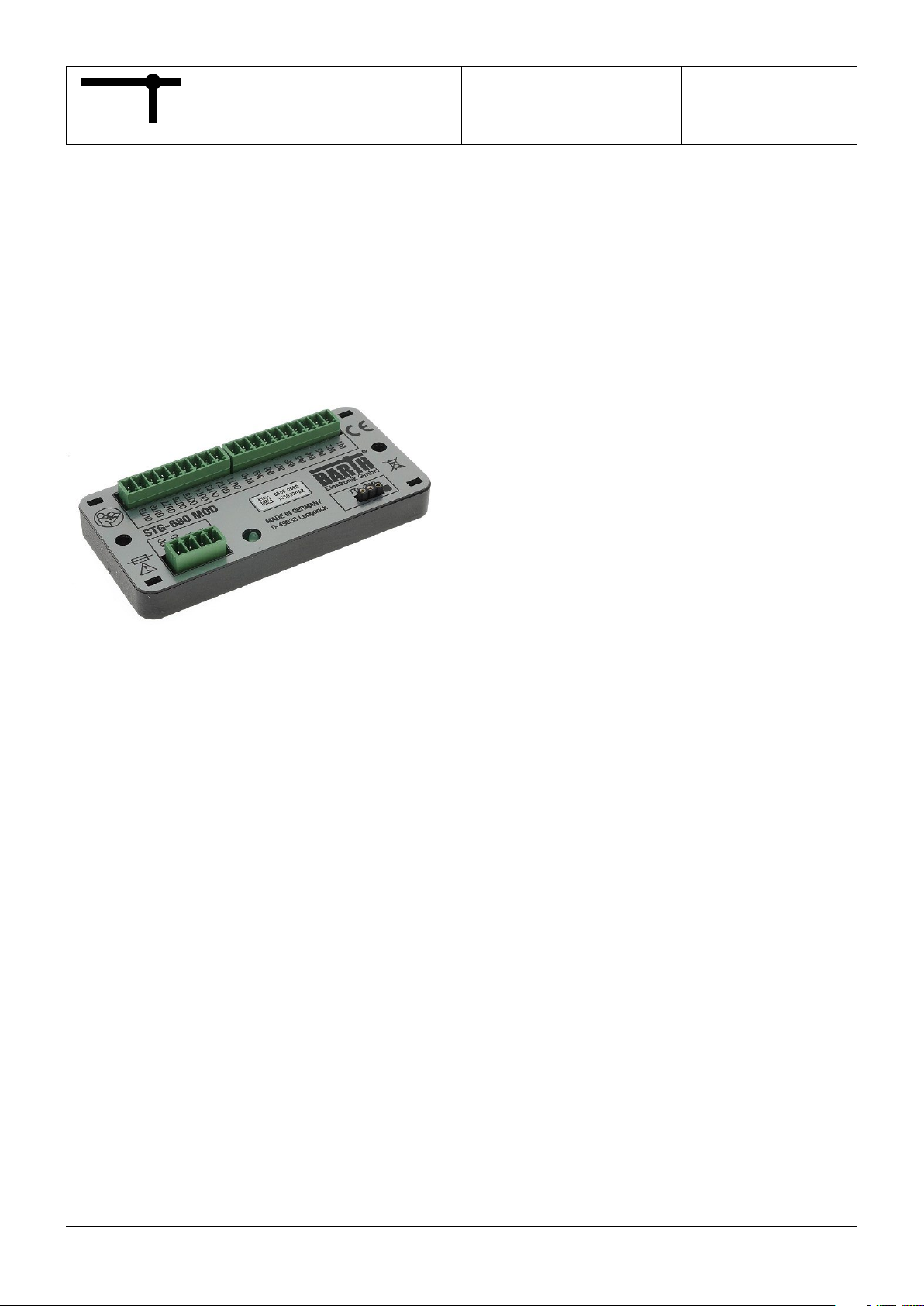

The picture below shows the BARTH® Mini-PLC STG-680

with the connection cable VK-16 (Art. No. 0019-0016).

The Mini-PLC is shipped without the USB connection cable

VK-16.

4.1 Features

• 6 analog Inputs 0..10 VDC, 12 bit ADC

• 4 digital Inputs up to 1 kHz

• 8 Power Outputs up to 1.5 A

• 1 Power PWM Output 2 A/1 to 10 kHz

• 1 MODBUS RTU Interface

• Graphically programmable MODBUS Data

• Reliable Solid-State Outputs

• Fail Safe Oscillator

• Programmable Status LED

• TTL-232/USB Connection to PC

• Intuitive graphical Programming Capability

• Wide Operating Voltage Range 7..32 VDC

• Wide Operating Temp. Range -40..+60°C

• Ultraat Housing, Height 11 mm

• Vibration resistant and rugged Sealing

• Engineered and manufactured in Germany

4.2 Applications

• Industrial Automation

• Building Automation

• Process Control

4.3 General description

The innovative STG-680 extends the established BARTH®

Mini-PLC series with an additional model featuring a rugged

MODBUS interface with graphical programming and congurating capability.

With similar dimensions in comparison to the STG-650, the

STG-680 provides outstanding graphical programming at

lowest current consumption and the well-known small form

fa ctor.

The MODBUS interface allows the user to connect a variety

of industrial network components to the Mini-PLC.

The STG-680 does not need any peripheral components to

operate. Both inputs and outputs features highly integrated

and rugged protection circuits to operate the Mini-PLC in

really harsh environment. These outstanding features open

up a variety of application elds in industrial and also in battery-powered applications.

The STG-680 is also available as customer-tailored OEM

version.

© 2014-2016 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved.

9021-0016-A

BAR

Elektronik GmbH

®

Mini-PLC

STG-680

H

Art. No. 0850-0680

MANUAL

Page:

Document:

Date:

Revision:

3/8

9021-0016 -A

04.08.2016

A

4.4 MODBUS Programming with miCon-L

Without learning a difcult programming language the

BARTH® Mini-PLC can be easily programmed using simple and vivid graphical function blocks. This block design

meets graphical standards of the latest graphical programming languages.

The miCon-L software suite features MODBUS programming, simulation and test in one unique software design

tool. The exible programming option offers a variety of

possibilities in industrial applications.

Programming the STG-680 follows using the USB port

of your PC with installed miCon-L software suite and the

VK-16 USB Connection Cable. The miCon-L Software supports full simulation and visualisation operation modes.

miCon-L provides a variety of visualisation blocks and

interactive elements to control and debug the Mini-PLC.

5 INSTALLATION

5.1 Mounting

The Mini-PLC must be installed and wired

by a trained technician who knows and

complies with both the universally applicable engineering rules and the regulations and standards that apply in specic

cases.

Fastening the STG-680 follows using either the integrated

mounting holes for screws or the holes for cable ties. The

cable tie installation method is recommended for fastening

the STG-680 on wiring harness, tubes or other mechanical

parts.

Take care to meet the environmental conditions of the

STG-680.

5.2 Wiring

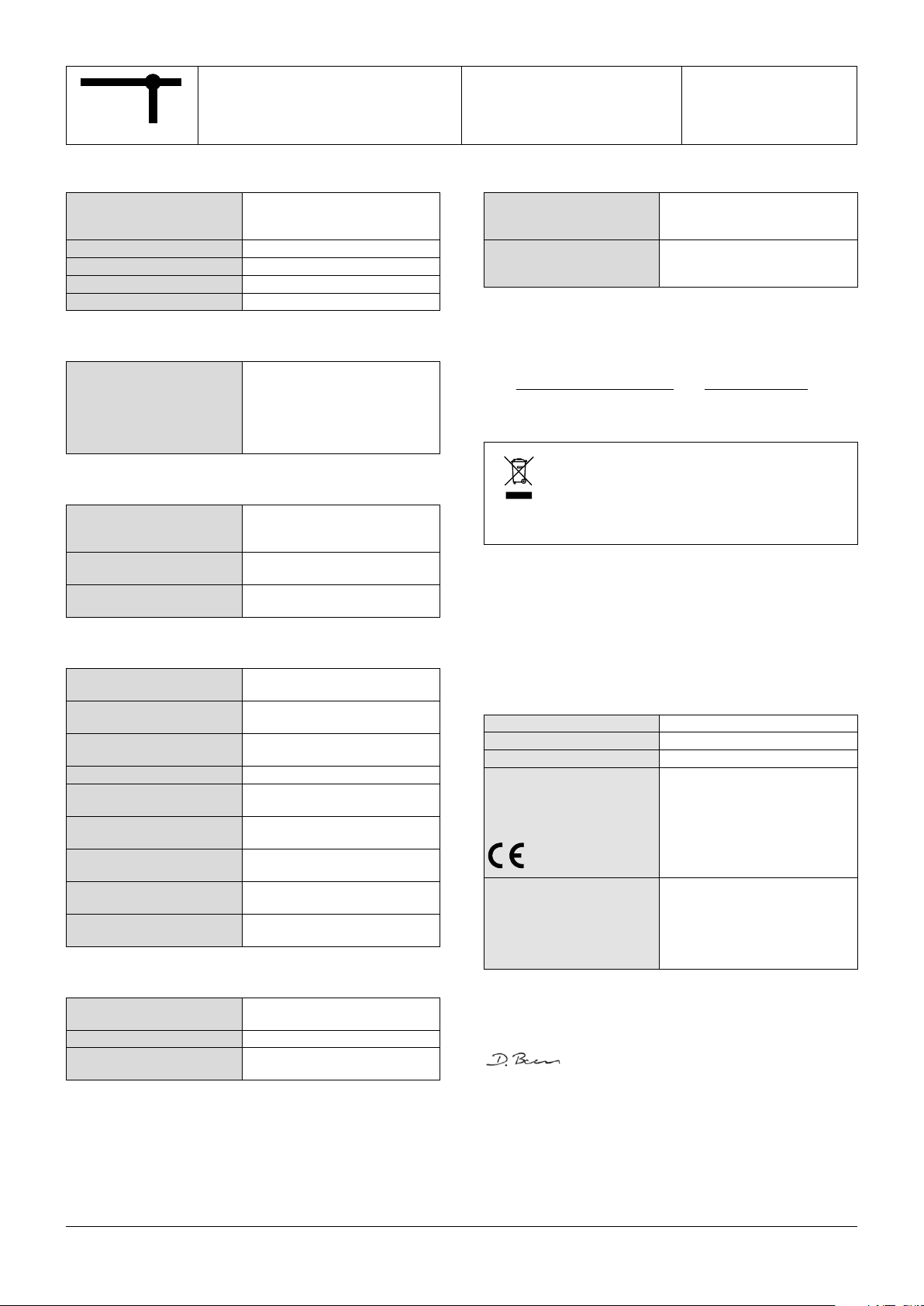

5.2.1 Overview

The graphic below shows the connection layout of the

BARTH® Mini-PLC STG-680.

X1 connector: supply and MODBUS pins

X2 connector: inputs

X3 connector: outputs

X4 connector: TTL-232/USB interface (via VK-16)

For detailed information please read the BARTH® miCon-L

manual and the BARTH® Application Notes on:

www.micon-l.de

www.barth-elektronik.de

4.5 Delivery content

• BARTH® Mini-PLC STG-680

• Spring terminal connectors (for supply, MODBUS, I/O)

© 2014-2016 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved.

9021-0016-A

BAR

Elektronik GmbH

®

Mini-PLC

STG-680

H

Art. No. 0850-0680

MANUAL

Page:

Document:

Date:

Revision:

4/8

9021-0016 -A

04.08.2016

A

5.2.2 Connecting the power supply

The STG-680 features an outstanding wide supply voltage

range from 7 to 32 VDC at lowest current consumption.

So the Mini-PLC can be integrated within battery supplied

12V or 24V DC systems (cars, trucks, battery powered cars,

forklifts and digger, for example).

Turn off the power supply before performing any wiring operations!

False electrical connection, voltage

reversal or disregarding the electrical

specications may cause irreversible

damage of the Mini-PLC!

Connect the supply voltage of 7 to 32 VDC to the 4-pole

terminal X1 of the STG-680. Wire the positive supply to the

‚+VDD‘ marked connection. The negative (ground) will be

wired to the ‚GND‘ connection. All terminals are carried out

as plugable spring terminal connectors for a wire gauge of

0.25 to 1.5mm².

Ensure correct power supply voltage

range and polarisation! External fusing of

5A max. is mandatory! Disregarding may

cause irreversible damage of the PLC!

5.2.3 Connecting the inputs

You can connect sensors, switches or buttons to the inputs.

The sensors may be temperature, ow, pressure, photoelectric sensors or proximity switches, for example.

The STG-680 is well suitable for any sensor featuring a voltage output, 0 to 10 VDC, for example.

Common features of the inputs

• IN1 to IN6 are selectable analog/digital inputs

• IN7 to IN10 are pure digital inputs (up to 1kHz)

• Wide input voltage range 0 to 32VDC

• IN1 to IN6 are 0 to 10 V compatible

• Comprehensive integrated protection circuits

• Outstanding electromagnetic compatibility (EMC)

• Electrostatic discharge protection (ESD)

Due to the pull-down resistors integrated in the STG-680

any switch (NO/NC) can simply be connected between the

positive supply (VDD) of the STG-680 and the desired input.

The voltage at any input must not exceed

32VDC referred to ground (GND).

Higher voltages or reverse voltage lower

than -32VDC may cause irreversible

damage of the Mini-PLC!

5.2.4 Connecting the outputs

Depending on load type and current the STG-680 is able

to drive electric loads directly without any additional driver

or protection circuit. The Mini-PLC provides 4 digital solidstate highside outputs and 1 solid-state lowside switch.

Common features of outputs OUT1 to OUT8

• Rugged solid-state higside switch up to 1.5A

• Paralleling permissible up to 6A

• Short circuit protection and current limitation

• Fast demagnetization of inductive loads

• Stable behaviour at undervoltage

• Comprehensive integrated protection circuits

• Outstanding electromagnetic compatibility (EMC)

• Electrostatic discharge protection (ESD)

Features of output OUT9

• Solid state lowside switch with PWM capability

• Sinks up to 2A

• Rugged solid-state design

• Fast demagnetization of inductive loads

• Outstanding electromagnetic compatibility (EMC)

• Electrostatic discharge protection (ESD)

The 9-pole connector X3 contains the digital outputs of

the Mini-PLC. While OUT1 to OUT8 are overload-protected

highside switches, OUT9 is carried out as lowside switch

with PWM capability without short circuit protection. A logical HIGH within miCon-L will switch the Mini-PLS´s supply

voltage at OUT1 to OUT8, while OUT9 switches lowside

(GND). Aviod a sink current exceeding 2A at OUT9 because

this outputs is not protected against short-circuiting or

overload current !

The total current sourced by OUT1 to

OUT8 must not exceed 6A!

Avoid reverse voltage at any output higher

than the Mini-PLC´s supply voltage!

OUT5 provides NO short circuit protection.

Take care the sink current not exceeds 2A!

Negligence may cause irreversible

damage of the Mini-PLC!

Please refer to the appendix for detailed electrical specication of the outputs.

5.2.5 Connecting the MODBUS interface

The X1 connector of the STG-680 contains the MODBUSspecic RS-485 pins ‚A‘ and ‚B‘.

The voltage at A or B must not exceed -10

or +15 VDC referred to ground (GND). Higher voltages may cause irreversible damage of the Mini-PLC!

The 10-pole connector named X2 contains the inputs of

the Mini-PLC. While IN7 to IN10 are pure digital inputs, IN1

to IN6 provide both digital or analog (0-10V) functionality.

The voltage range for all inputs may not exceed 32 VDC.

All inputs refer to GND. Please refer to the appendix for

detailed electrical specication of the inputs.

© 2014-2016 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved.

There is no termination resistor integrated in the STG-680.

Please refer to the appendix for detailed electrical specication of the MODBUS interface.

9021-0016-A

BAR

Elektronik GmbH

®

Mini-PLC

STG-680

H

Art. No. 0850-0680

MANUAL

Page:

Document:

Date:

Revision:

5/8

9021-0016 -A

04.08.2016

A

6 OPERATION AND PROGRAMMING

6.1 Software download

BARTH® supplies a free software license download package

for Microsoft® WINDOWS® which includes:

• Virtual COM port driver for USB connection

• miCon-L Software Suite

• Sample Programs for BARTH® Mini-PLC

Please download this package from:

www.micon-l.de

6.2 Virtual COM port driver installation

Before you connect the Mini-PLC to the PC you have to install the USB-/COM-port driver (folder ‚USBdriver‘) from the

software download package. Please follow the instructions

of the SETUP routine.

6.3 miCon-L Software Installation

Now install the miConL software suite from the ‚miCon-L‘

folder. Select your language le and follow the setup instructions of miConL.

6.4 Connecting the Mini-PLC

To operate the STG-680, rst establish proper power supply

connection to the X1 connector.

6.5 First steps in miCon-L

Establish the PC connection using the VK-16 connection

cable and run miConL. For choosing the correct virtual

COM-Port please click the right button (congure serial

interface) located on the main menu page and conrm the

added virtual COM-Port used by the STG-680.

Now start miConL with creating a new project (Project->

New) or open a miCon-L sample application (Project>Open).

For programming and PC connection the USB connection

cable VK-16 (Art. No. 0091-0010) and a PC with installed

Windows operating system are mandatory.

For Mini-PLC connection please use the 3-way X4 terminal.

© 2014-2016 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved.

9021-0016-A

BAR

Elektronik GmbH

®

Mini-PLC

STG-680

H

Art. No. 0850-0680

MANUAL

Page:

Document:

Date:

Revision:

6/8

9021-0016 -A

04.08.2016

A

Creating a new project the desired Mini-PLC model and the

project name have to be dened. After opening or creating

a project the workspace of miConL with it´s libraries (right)

is shown.

Additional help and a detailed user manual is provided

within the miCon-L help and the miConL context menu

(right mouse button).

You can nd sample programs in the ‚SAMPLE_PROGS‘

folder which is part of the miCon-L download package.

For detailed information and help please have a closer look

at the documents related to the miCon-L Software Suite:

http://www.micon-l.de

© 2014-2016 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved.

9021-0016-A

BAR

Elektronik GmbH

®

Mini-PLC

STG-680

H

Art. No. 0850-0680

MANUAL

Page:

Document:

Date:

Revision:

7/8

9021-0016 -A

04.08.2016

A

7 APPENDIX

7.1 Specications

7.1.1 General

Hardware design BARTH® Mini-PLC

Programming miCon-L Software,

Interfaces TTL-232 (5V TTL level)

fully enclosed in proprietary PU

resin, tiny and rugged housing

with plugable spring terminal

connectors, ultra-lightweight

graphical (function block style),

simulation, MODBUS

programming and visualisation,

free license

USB (VK-16 required)

reserved for miCon-L software

communication

MODBUS RTU

7.1.2 Power supply

Operating voltage 7 to 32 VDC

Current consumption nominal 15 mA at 32 VDC

Fusing 8 A max. (external)

Voltage reversal protection yes

ESD/TVS protection yes

Heat dissipation air

(at full load)

(depending on conguration)

mandatory for voltage reversal

protection

(combined with external fuse)

normally < 2 W

7.1.4 Outputs

Number digital 8+1

Number PWM 1

Output OUT1 - OUT8 Output type: solid state (highside)

I

<= 1.5 A (resistive load)

OUT

@ f

= 0 to 100 Hz

OUT

U

>= UIN-0,45 V

OUT

I

<= 4 A (paralleling permissible)

TOT

Maximal allowable load

inductance for a single switch off

(one output):

VDD=12VDC, IL=1.5A, ZL<=70mH

VDD=12VDC, IL=1A, ZL<=200mH

On-state resistance VDD to OUT:

RON<=180 mOhm

Turn-on time: tON<=250 µs

Turn-off time: t

PWM output OUT9 Output type: solid state (lowside)

I

<= 2 A (resistive load)

OUT

@ f

= 1 kHz to 10 kHz

OUT

I

<= 1 A (resistive load)

Potential isolation no

OUT

<=270 µs

OFF

7.1.5 MODBUS interface

MODBUS Protokol: RTU

Baud: 1.200, 2.400, 4.800, 9.600,

19.200, 38.400, 56.000 Kbit

Parity: no, Stopbit: 1

exibly graphically congurable

data format

7.1.3 Inputs

Number digital 4+6

Number analog 6

Digital input IN7 - IN10 UIN = 0..30 VDC

Analog input IN1 - IN6 UIN = 0..10 VDC

Accuracy ADC

IN1 - IN6

ADC resolution

(internal)

Potential isolation no (common GND)

ESD/TVS protection yes

Permissible cable lenght

(per input)

RIN > 30 kOhm

U

<= 2 VDC

LOW

U

> =4VDC

HIGH

fIN <= 1 kHz

tIN >= 1 ms

RIN > 16 kOhm

fIN <= 100Hz

tIN >= 10 ms

± 1% (<0.15 VDC)

12 Bit

normally 40 m

Meets or exceeds the requirements of ANSI Standards TIA/

EIA-422-B and TIA/EIA-485-A

and ITU Recommendations V.11

and X.27

No termination resistor integrated

7.1.6 Security features

Security Features Watchdog (WD)

Fail safe oscillator 16 MHz (FSO)

Brown out detection (BOD)

Power up timer (PUT)

7.1.7 Program and data memory

Flash program memory 64 k

cell endurance: 10.000 min

characteristic retention: 40 yrs

EEPROM data memory 1024 byte

byte endurance 100.000 min.

characteristic retention: 40 yrs

© 2014-2016 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved.

9021-0016-A

BAR

Elektronik GmbH

®

Mini-PLC

STG-680

H

Art. No. 0850-0680

MANUAL

Page:

Document:

Date:

Revision:

8/8

9021-0016 -A

04.08.2016

A

7.1.8 Timebase (oscillator)

Primary Oscillator Crystal quartz MEMS unit

Nominal Frequency 16.000 MHz

Frequency tolerance ±50 × 10

Frequency aging ±5 × 10-6 / year max.

Second Fail Safe Oscillator 16 MHz

(precise ‚micro-electro-mechanical system‘)

-6

7.1.9 Electrical connection

Electrical Connection plugable spring terminal

connectors 0.25 to 1.5 mm²

Manufacturer: Phoenix Contact

Series: COMBICON

Type: FMC1,5/x-ST-3,5

7.1.10 Electromagnetic compatibility (EMC)

Electrostatic discharge

(ESD) on IN1 to IN10

Electrostatic discharge

(ESD) on OUT1 to OUT8

Electromagnetic elds Field strength 10 V/m

20 kV air discharge

30 kV contact discharge

(IEC/EN 61 000-4-2, level 3)

8 kV (human body model)

(MIL-STD883D)

(IEC/EN 61000-4-3)

7.1.11 Environmental conditions

Operation temperature -40..+60 °C

Storage temperature -40..+70 °C

Relative humidity 5 to 95% non-condensing

Air pressure (in operation) 500 to 1500 hPa

Shock resistance min. 100 m/s²

Vibration resistance min. 50 m/s² @ 10..150 Hz

Degree of protection IP 20, limited by connectors

Drop Drop height: 500mm

Free fall (packaged) 1500 mm

(IEC 60068-2-1/2)

(IEC 60068-2-1/2)

(IEC 60068-2-30)

(IEC 60068-2-27)

(IEC 60068-2-6)

(EN 50178, IEC 60529)

(IEC 60068-2-31)

(IEC 60068-2-32)

7.1.12 Weight and dimensions

Weight 80 g

Dimensions 93 x 45 x 15 mm (LxWxH)

Mounting via two M4 screws or 3.6mm

(without connectors)

cable ties

7.1.13 Ordering information

Ordering information

Mini-PLC

Ordering information

accessory

Mini-PLC STG-680

Art. No. 0850-0680

GTIN 4251329400149

USB connection cable VK-16

Art. No. 0091-0016

GTIN 4251329400187

7.2 Documents, videos and software

Detailed information, additional documents, application

notes and videos relating to this product are downloadable

from www.barth-elektronik.de and www.micon-l.de

7.3 Disposal

If you wish to nally dispose of the

product, ask your local recycling centre

or dealer for details about how to do

this in accordance with the applicable

disposal regulations.

7.4 Conformity declaration

For the following designated product it is hereby conrmed,

that the construction in that technical design brought by us

in trafc corresponds to the standards specied below. In

the event of any alternation which has not been approved

by us being made to any device as designated below, this

statement shall thereby be made invalid.

Description Mini-PLC

Type STG-680

Art. No. 0850-0680

Directive

2004/108/EG relating toelectromagnetic

compatibility (EMC)

RoHS Directive

2011/65EU

BARTH® Elektronik GmbH

Lengerich, 03.08.2016

Dipl.-Ing. (FH) D. Barth

Managing Director

Applied norms:

2004/108/EG

2004/108/EC

2014/30/EU

We herby declare that our

product is compilant to the RoHS

Directive on restriction of the use

of certain hazardous substances

in electrical and electronic appliances.

© 2014-2016 BARTH Elektronik GmbH | Im Depot 1-3 | D-49838 Lengerich | www.barth-elektronik.de

® BARTH is a registered trademark. All rights reserved.

9021-0016-A

Loading...

Loading...