Tech 500 User Guide rev1.0 JUNE 2013

1

TABLE OF CONTENTS

IMPORTANT NOTICES 2

BEFORE YOU GET STARTED 3

TOOL LAYOUT 4

TOOL CONNECTIONS 5

POWER ON/OFF 6

CHARGING TOOL 7

TOOL DISPLAY AND ICONS 8

MENU SYSTEM

TEST BEFORE YOU TOUCH

RELEARN

REVIEW DATA

TOOLKIT

MY TOOL 11

TOOL POSITIONING/READING A SENSOR 20

UPDATING YOUR TOOL (PC) 29

UPDATING YOUR TOOL (SD Card) 32

UPDATING YOUR TOOL (Wireless)

APPENDIX A: INDUCTIVE CHARGING

APPENDIX B: VIN 37

APPENDIX C: FAQ’S & TROUBLESHOOTING GUIDE 38

APPENDIX D: DEFINITIONS 39

APPENDIX E: TPMS SYSTEM REVIEW 40

APPENDIX F: COMS ERROR TROUBLESHOOTING 42

APPENDIX G: Technical Support 43

LIMITED WARRANTY 44

TOOL REGISTRATION 47

Tech 500 User Guide rev1.0 JUNE 2013

2

INCLUDED IN Tech500 KIT:

Tech500 TPMS Tool [with protective Boot]

SD Card [in the tool]

Power Supply

Re-Learn Magnet

USB Cable

DB15 to OBDII Cable

Tech500 Quick Start Guide

Tech500 User Guide

Kit CD

IMPORTANT NOTICES

All specifications, illustrations and information contained within this manual are based on the

most current information available at the time of publication. BartecUSA reserves the right to

make changes at any time without obligation to notify any person or organization. BartecUSA

will do its best to keep you the customer informed of any changes that might affect the tools

performance.

FCC Compliance Model: DSW

FCC ID: SX8T500 IC: 5736A-T500

Contains FCC ID: QOQWT12 IC: 5123A-BGTWT12A

Contains FCCID: YOPGS1011MIP IC: 9154A-GS1011MIP

This device complies with Part 15 of the FCC Rules and with Industry Canada

license-exempt RSS standard(s). Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2)

This device must accept any interference received, including

interference that may cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux

conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2)

Tech 500 User Guide rev1.0 JUNE 2013

3

l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d'en compromettre le fonctionnement.

Note: Changes or modifications not expressively approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

Note: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at their expense.

BEFORE YOU GET STARTED

Before you get started using your Tech500 TPMS tool, there are a few items to review.

Charge your tool

The Tech500 is shipped with a fully charged battery, but due to shelf drain it may require

charging. It is recommended to charge your tool 2+ hours before use. (See page 6 for charging

instructions)

Register your tool

You can register your Bartec

Tech500 @ www.bartecusa.com.

Follow the on-screen prompts filling

in your information and tool serial

Tech 500 User Guide rev1.0 JUNE 2013

4

number. A valid serial number and supplier is required to process your registration, which can

take up to 24hrs once submitted.

Update your Tool

Once your tool is registered, verify the software level loaded to the level available online and

update your tool if necessary. Refer to section on tool updating for further instruction.

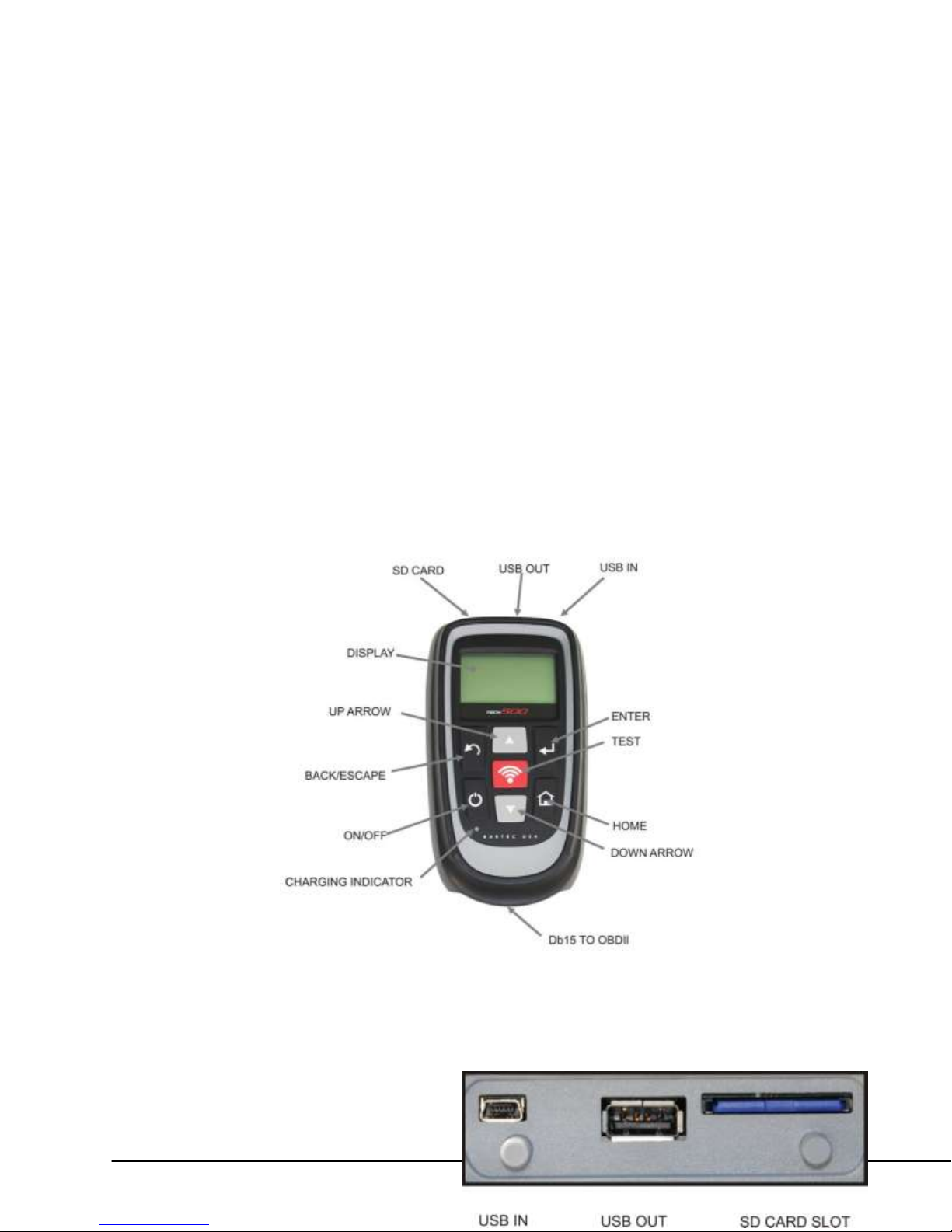

TOOL LAYOUT

TOOL CONNECTIONS

Tech 500 User Guide rev1.0 JUNE 2013

5

POWER ON/OFF SEQUENCE

The Tech500 is powered up using the ON/OFF key.

On/Off Key

To power the unit on press the On/Off Key for approx 2 seconds – the display will light showing

a logo and software version.

The unit will then display the Main Menu. All data (results and settings) from previous tests is

reloaded.

Tech 500 User Guide rev1.0 JUNE 2013

6

Power down the Tech500 by using the same ON/ OFF key.

On/Off Key

(Hold, then release when ‘Goodbye’ is displayed.) Auto power off is after 5 minutes of

inactivity.

The unit automatically powers up when the charger or USB port is in use- auto power off is not

operational.

CHARGING TOOL

NOTICE: Only use the power supply or USB cable that is included in the Tech500 tool kit to

charge this tool. The use of un-approved power supplies may damage your tool and will void

the tool warranty.

Tech 500 User Guide rev1.0 JUNE 2013

7

# of selections

USB indicator

Data stored on tool

Battery indicator

The Tech500 comes with the rechargeable battery already installed. Battery replacement must

be done at the factory.

For optimum performance, always keep your Tech500 sufficiently charged. It is recommended

that you charge the tool 2 + hours before first use.

The charge port is located on the right side of the tool and is the USB port opening.

TOOL DISPLAY AND ICONS

# of selections

Tech 500 User Guide rev1.0 JUNE 2013

8

FULL Charge

Partial Charge - charging shortly is

suggested.

The menu page number (e.g. x/y) on the status line indicates the menu page or item currently

displayed. The first number- x- indicates the item number selected. The second- y- indicates the

total number of items available.

USB Indicator

This status line indicator confirms the Tech500 is connected to the USB port of a computer.

Once communication has been established, results data can be viewed on the pc via the Mass

Storage Device feature. (Use the PC explorer program) “HTM File”

When the USB lead is removed the USB icon will disappear.

Battery Indicator/ Charging

This status line Indicator will illustrate the remaining charge status of the battery.

As different TPM types will ‘use up’ differing amounts of energy, the indicator can only provide

estimates of remaining life left before a recharge is required.

Tech 500 User Guide rev1.0 JUNE 2013

9

Little power in the battery- charging

required.

The battery is FLAT, requires

charging

When the battery is being charged the indicator segments ‘walk;’ from left to right.

When there is an insufficient amount of power remaining in the battery, the Tech500 will flash

its battery icon for two seconds, save all of the TPM Data and then power itself off.

Results Data Available Indicator

Indicates TPM data is available for viewing on the screen (using the View TPM Data command

from the main menu) or via a PC when the Tech500 is in its Mass Storage Device mode. (See

Section on Audit Mode)

Tech 500 User Guide rev1.0 JUNE 2013

10

Current report

Archived reports

When there is no data present, the TPM Data Indicator will not be visible.

To Access the Audit Data, connect your tool to the PC using the supplied USB Cable.

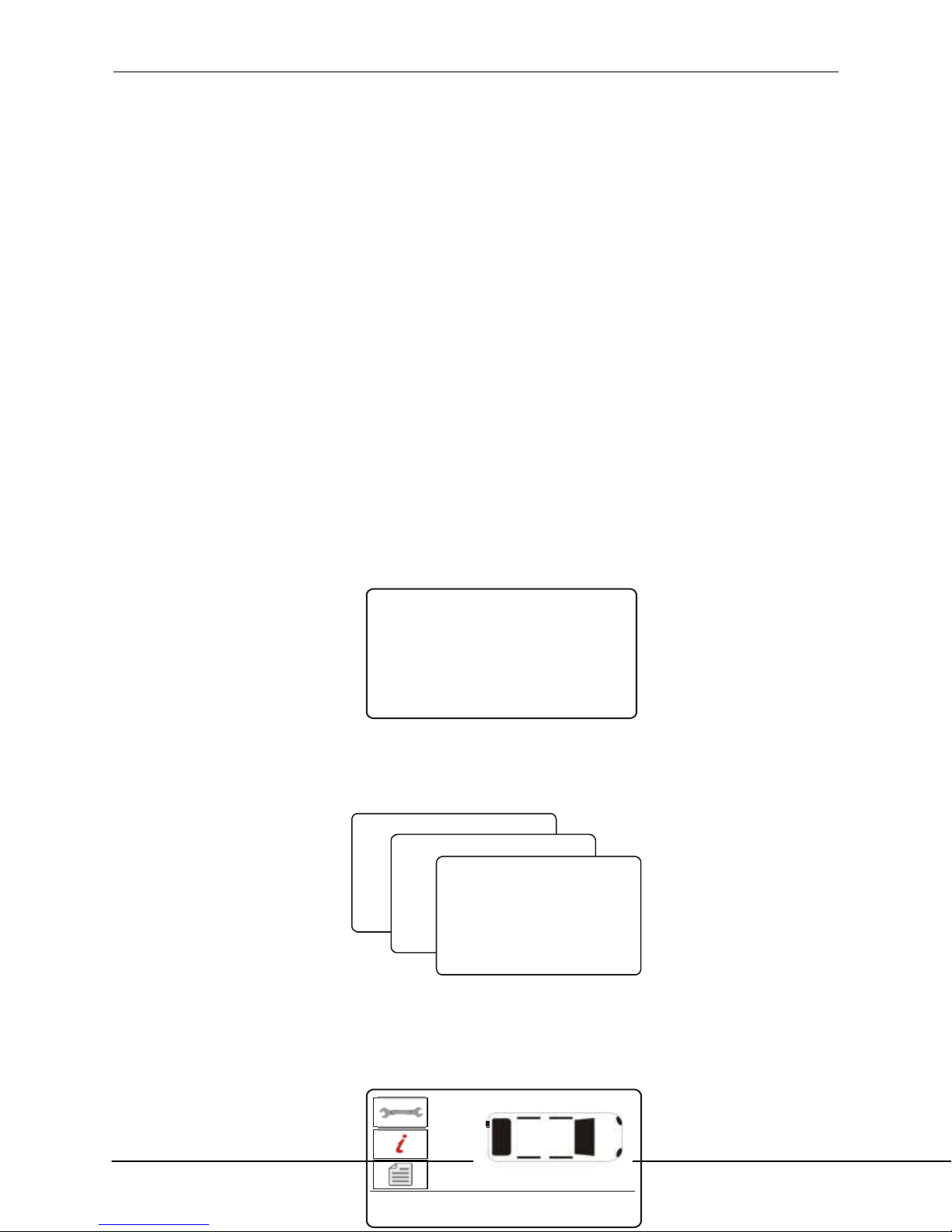

MENU SYSTEM

The Tech500’s menu system provides a hierarchy of instructions and commands. The top line of

the display will always indicate the current menu selected. The home key will always return to

the Main Menu screen- with ‘Select by Vehicle’ highlighted.

Tech 500 User Guide rev1.0 JUNE 2013

11

Up Arrow Key

Navigates up within the current menu

Down Arrow

Key

Navigates down within the current

menu

ENTER Key

Navigates to the next menu or actions

the currently selected item

Back/ESC Key

Navigates to the previous menu item

TEST Key

Commence a TPM test. Only works on

Audit Screen

Home Key

Always returns to the Home Menu

Menu Navigation

The menu system is navigated by the directional keys:

All menus wrap around. The enter key will primarily move to a sub menu.

Home Menu

This is the main screen- providing access to the main functional items of the Tech500.

Tech 500 User Guide rev1.0 JUNE 2013

12

TBYT/Relearn Toolkit

View Vehicle Info

Review Vehicle Data

1. Test Before You Touch

This Item is a sub menu, pressing the Enter Key will take the user to the “Test Before

You Touch” menu. The user should select the vehicle make, model and year. Used when

doing a pre-service scan.

2. Relearn

This Item is a sub menu, pressing the Enter Key will take the user to the “Test Before

You Touch” menu. The user should select the vehicle make, model and year. Used when

relearning the sensor ID’s to the vehicle.

3. Review Data

This item is a sub menu, pressing the Enter Key will take the user to the results screens.

Press directional arrows to examine the required results.

4. Toolkit

A sub-menu in which you will find your options for EZ sensor, RKE monitor, and UHF

monitor.

5. My Tool

Sub-menu containing important info about the tool itself.

Operations Screen

This screen is where you will complete all sensor testing and relearn steps.

Tech 500 User Guide rev1.0 JUNE 2013

13

Possible Scenarios

Successful Sensor Read

TPMS sensor was successfully activated and decoded. Displays pressure at wheel location.

Wrong Sensor Type

A TPMS sensor was activated and decoded, but does not match the protocol for the Make

Model Year that the tool was set-up for.

Failed Sensor Read

No Sensor Activation or Decode. May be wrong sensor fitment or non-functioning sensor. Tool

will prompt you to attempt reading the sensor 3 times.

Duplicate ID

A sensor with a duplicate ID has been read. The tool will direct you to re-read those sensors.

No Pressure

Sensor IDS read from ECU.

Low Battery

Tech 500 User Guide rev1.0 JUNE 2013

14

Select by Make

Buick

Cadillac

Chevrolet

Chrysler

Dodge

7/45

Chevrolet

Corvette

Corvette C5

Corvette C6

Corvette Z06

Cruze

9/29

Chevrolet Cruze

2011

2012

1/2

ID:8920758D TEMP: 85

Mode: Learn BAT: Norm

32

32

32

32

Diagnosis:

Sensor Failure Detected

View data or print audit

report for details

Press any key to continue

Home

Test Before You Touch

Relearn

Review Data

Toolkit

My Tool

1/5

Sensor’s internal battery has dropped below a certain voltage threshold.

TEST BEFORE YOU TOUCH

TPMS is a process. With that Bartec has integrated that process to the tool. The 1st step with

TPMS is to conduct a Test Before You Touch. (Note: operator can skip TBYT and go directly to

RELEARN although not recommended). Test Before You Touch will prompt you through getting

a status of the vehicle prior to service by verifying the sensors are working and when

supported, verify the Diagnostic Trouble Codes (DTC).

To verify year, use 10th digit of the VIN.

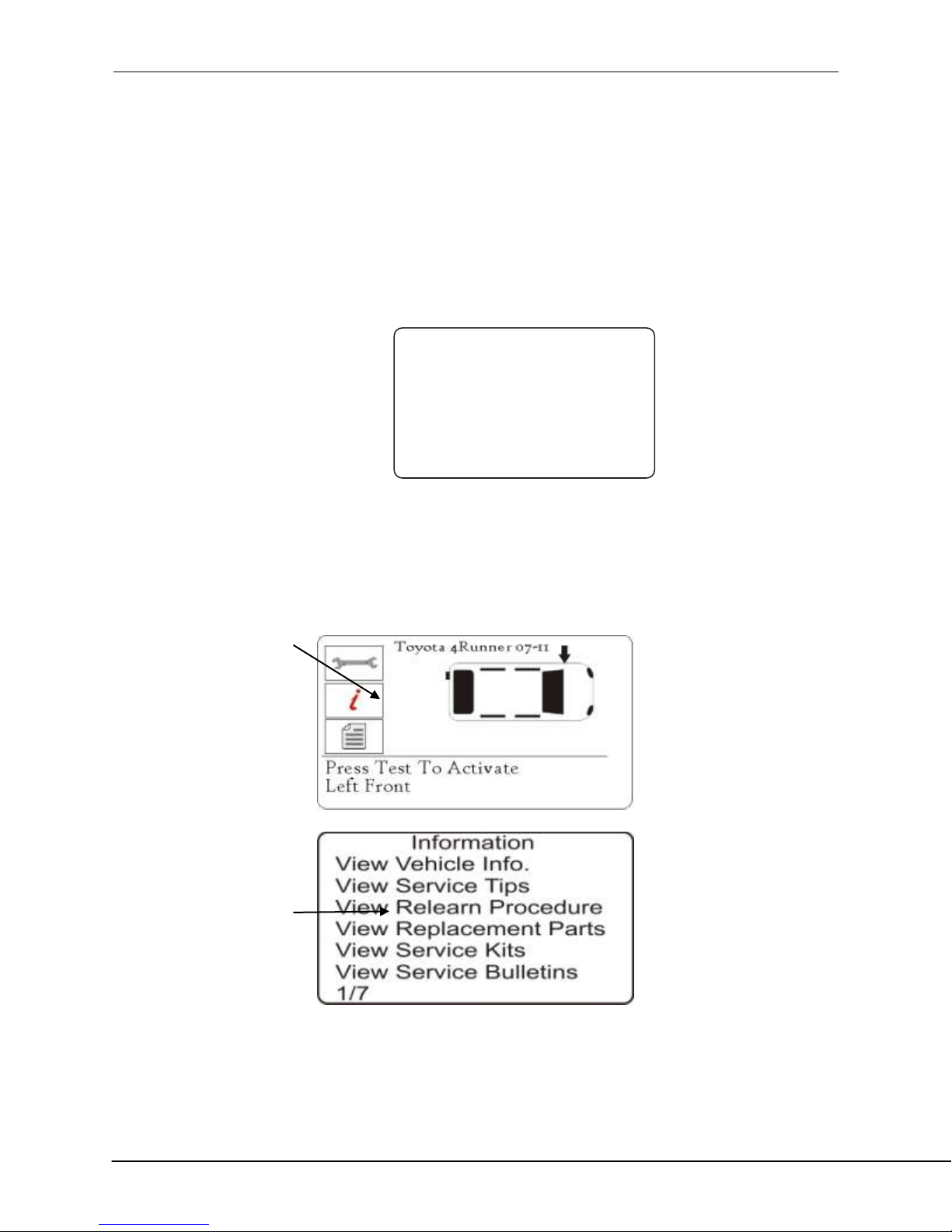

Vehicle Operations Screen

Tech 500 User Guide rev1.0 JUNE 2013

15

If equipped, tool will prompt user to connect to OBD and retrieve Diagnostic Trouble Codes

The Tech500 has the ability to Read out vehicle DTCs (Diagnostic Trouble Codes). Once read,

you will need to reference these codes with an external reference to determine the codes

definition.

Tech 500 User Guide rev1.0 JUNE 2013

16

Home

Test Before You Touch

Relearn

Review Data

Toolkit

My Tool

1/5

Select by Make

Buick

Cadillac

Chevrolet

Chrysler

Dodge

7/45

Chevrolet

Corvette

Corvette C5

Corvette C6

Corvette Z06

Cruze

9/29

Chevrolet Cruze

2011

2012

1/2

RELEARN

Stationary Relearns

Active (Drive) Relearns

OBD Relearns

Stationary Relearns:

Stationary Relearns use the vehicles on-board TPMS system to listen for transmissions from

TPM sensors while the vehicle is in a “Learn Mode”. This is usually achieved through a series of

functions on the vehicle to place the vehicle into this mode.

Once the vehicle is in Learn Mode, using your Tech500 to activate the sensors, the vehicle will

listen for the sensor IDS and learn them to the vehicle.

Using your Tech500 to perform Stationary Relearns:

Tech 500 User Guide rev1.0 JUNE 2013

17

>Inflate tires to Placard

>Capture all 4 I D’s

>Turn ignition to ON

>Plug OBDII Cable and select

>Write ID’s to Vehicle

>Leave vehicle in the ON position

>Start vehicle and ensure light is off

ID:8920758D TEMP: 85

Mode: Learn BAT: Norm

32

32

32

32

Active (Drive) Relearns:

Active or Drive Relearns

Some vehicles can be reset by driving. Refer to the on-screen re-learn procedures for details on

how far/long to drive.

To verify year, use 10th digit of the VIN.

Follow on-screen instructions

Vehicle Operations Screen

Tech 500 User Guide rev1.0 JUNE 2013

18

Home

Test Before You Touch

Relearn

Review Data

Toolkit

My Tool

1/5

Select by Make

Buick

Cadillac

Chevrolet

Chrysler

Dodge

7/45

Chevrolet

Corvette

Corvette C5

Corvette C6

Corvette Z06

Cruze

9/29

Chevrolet Cruze

2011

2012

1/2

ID:8920758D TEMP: 85

Mode: Learn BAT: Norm

32

32

32

32

OBD Relearns:

Connection to a vehicle allows the Tech500 to directly program the vehicle electronics module

with TPM ID’s.

Note that not all vehicles support vehicle communications modes.

Once 4 TPM ID’s are stored within the Tech500, it can be connected to the OBD interface using

the provided cable.

Vehicle Operations Screen

Tech 500 User Guide rev1.0 JUNE 2013

19

Home

Test Before You Touch

Relearn

Review Data

Toolkit

My Tool

1/5

Select by Make

Buick

Cadillac

Chevrolet

Chrysler

Dodge

7/45

Chevrolet

Corvette

Corvette C5

Corvette C6

Corvette Z06

Cruze

9/29

Chevrolet Cruze

2011

2012

1/2

Connect tool to OBD II Port

and Turn Ignition ON

Press Enter to Read

Vehicle TPMS related info.

Press ESC to Cancel

During vehicle communication, the BACK key is inhibited. Should the process be commenced

inadvertently, the tool can be left to timeout on its own accord - approximately 20 seconds.

Once the communication is complete, the tool will flash IDS Written Successfully.

IF an Error Message comes up during the COMS process, Refer to Appendix F for COMS error

trouble shooting.

Indirect system – Vehicle may require calibration at point of service or replacement. No wheel

sensors on this type of TPMS.

Follow on-screen instructions

Tech 500 User Guide rev1.0 JUNE 2013

20

>Inflate tires to Placard

>Capture all 4 ID’s

>Turn ignition to ON

>Plug OBDII Cable and select

>Write ID’s to Vehicle

>Leave vehicle in the ON position

>Start vehicle and ensure light is off

To verify year, use 10th digit of the VIN.

Follow on-screen instructions

Viewing Full Relearn Procedures

Tech 500 User Guide rev1.0 JUNE 2013

21

REVIEW DATA:

This menu- when selected- gives direct access to specific screens that display the TPM data. No

menu page name is provided- instead, the screen provides all of the TPM Data available from

the TPM Type read; this may include: TPM ID (Hexadecimal & Decimal) Battery State,

Temperature and Pressure.

Not all TPM’s provide the same data.

Tech 500 User Guide rev1.0 JUNE 2013

22

TOOLKIT

Program Sensor

Access to program Aftermarket sensors. For more information, please log into the

tools.bartecusa.com account.

RKE Test

Once the Screen appears as below, hold the Key Fob as shown, and press the function buttons

on the FOB. The Tech500 will check only for a signal present. Verifying the Key Fob is

transmitting is important when performing relearn processes that use the Key Fob.

Tech 500 User Guide rev1.0 JUNE 2013

23

UHF Monitor

Allows operator to search for sensor signals. This feature is used for advanced diagnostics to

determine if our signals may be causing issues during sensor activation and vehicle relearns.

MY TOOL

Settings

TPM ID:

Select whether the tool displays the TPM ID in DECIMAL or HEXIDECIMAL

Pressure:

Change how pressure is displayed on the tool screen. Choose between PSI or Bar.

Tech 500 User Guide rev1.0 JUNE 2013

24

Temperature:

Select units between Celsius or Fahrenheit.

Display Contrast:

Adjust tool display contrast.

Lang.:

Select Language for tool. Select English, Spanish or French.

Profile:

Allows user to select the profile. For more information, visit the tools.bartecusa.com

site.

.

Tool Info

Gives the operator the ability to reference:

- Software Version currently loaded

- Build Date of that Software

- Serial Number

New Features

Selecting New Features will allow you to reference the features and additions for the software

release currently loaded to your tool.

Update Tool

Tech 500 User Guide rev1.0 JUNE 2013

25

Puts tool into “Update Mode”. For more details and the update process refer to UPDATE TOOL

section of User Guide.

Usage

Gives the operator the ability to track the number of:

- Power Cycles

- Sensor Activations

- OBD Relearns

Support

On screen reference for Bartec USA Technical Support:

Toll Free Phone: (866) 407-8767

Email: mrose@bartecusa.com

TOOL POSITIONING/READING A SENSOR

Tech 500 User Guide rev1.0 JUNE 2013

26

Proper tool positioning is important to insure sensor activation and decode. Place the Tech500

on the tire, at the TPMS sensor, pointed toward the sensor location as shown above.

Sensor Activation/ Test

LF Activated Sensors

To test a sensor the tool should be placed alongside the valve stem

and the ‘Test’ key pressed.

(Note with Ford Banded sensor’s, the tool should be held

180°away from the stem.)

Magnet Activated Sensors

If the TPM requires a magnet, place the magnet over the

stem and then place the tool alongside the stem- while

pressing the test key.

Delta P activated sensors

If the sensor requires tire deflation (of the order of 10PSI), then deflate the tire and place the

tool alongside the stem while pressing the test key.

Tech 500 User Guide rev1.0 JUNE 2013

27

During testing, the screen confirms the sensor type being tested and displays a progress bar.

The progress bar shows the maximum possible time for a successful read- different makes of

TPM respond at different speeds/ time intervals.

Sensor activation can be aborted at any time by pressing the BACK key. When the activation is

aborted, the user will be returned to the previous menu.

Sensor Found Response

If there is a successful TPM Read, then the Tech500 will show the air pressure stored in that

wheel.

Incorrect Sensor Found

Tech 500 User Guide rev1.0 JUNE 2013

28

A TPM sensor that uses the same LF activation as the correct sensor for the Make, Model, and

Year selected has been found. Since there are many TPM sensors that look alike, it can be easy

to fit the wrong sensor, or have been supplied the wrong sensor.

If you get a ? during testing, verify the MMY you have selected as well as the sensor part

number that was fitted.

Sensor Not Found Response

If the search period expires without reading a TPM then the Tech500 will emit a single Audible

Beep and indicate on the display that no TPM was found.

The TPM Data will still be stored but will indicate that the

TPM Failed to Read if the sensor fails 3 times.

Tech 500 User Guide rev1.0 JUNE 2013

29

UPDATING YOUR TOOL (PC)

The tool is compatible with PCs running Windows operating systems (version XP or 2000).

USB ports can be either version 1 or 2.

Step 1:

Plug your USB cable to the computer ONLY. Make sure computer is on and you have no

programs running. Power the Tech500 on, and from the Main Menu, Select “My Tool”, then

select “Update Tool”.

Tool will prompt user to “Insert USB Lead to Transfer Update Files”. Insert the USB cable to the

Tech500.

Step 2:

Your tool should open a window on your computer screen. The tool now is seen by your

computer as a Removable Disk.

Tech 500 User Guide rev1.0 JUNE 2013

30

Step 3:

Copy and paste – Drag and Drop the Update file (*.MFU) provided to you into the Removable

Disk Window. Once Transfer is complete, disconnect tool.

Step 4:

The tool will now load the file update to the operating system.

Once the update is complete, the tool will shut itself off.

Tech 500 User Guide rev1.0 JUNE 2013

31

UPDATING YOUR TOOL (SD Card)

*In order to receive updates by SD card, you must request to be part of the SD card program*

Step 1:

Remove OLD SD card. Making sure not to mix, Insert the NEW SD card.

Power the Tech500 On, and From the Main Menu, Select “Update Tool”.

Step 2:

The tool will now load the file update to the operating system.

Once the update is complete, the tool will shut itself off.

Tech 500 User Guide rev1.0 JUNE 2013

32

UPDATING YOUR TOOL (Wireless)

Tech 500 User Guide rev1.0 JUNE 2013

33

Results Audit System

The Tech500 is capable of presenting all of its stored data within one or more computer files

when connected to a PC via an USB lead. This is the same ‘Mass Storage Mode’ such as used in

USB memory devices. No extra drivers or software have to be loaded onto the pc.

The files and the stored TPM Data enable the Tech500 to be used as part of an Auditing System.

The tool automatically goes into Mass Storage Device (MSD) mode when connected to an active

USB port on the pc.

It is not necessary to power up the tool prior to connecting to the pc - it will power up

automatically.

It is important not to accidentally press the enter key on the tool at the same time as

connecting to the pc.

The Tech500 will produce a single file for each type of TPM Part that has been read, and a

separate record within that file for each unique TPM of that type.

Viewing the Audit Files

To begin using the Auditing System ensure that the tool has some data available, indicated by

the Data Indicator icon, and then connect the Tech500 to a PC via its USB lead.

The PC will begin communicating with the Tech500. Once communication is established the

Tech500 will act as a MSD (Mass Storage Device). If the MSD does not automatically open its

explorer window on the PC, then the user may browse for the newly connected device

manually.

Once the explorer window is open, you may view a file by right clicking on the file and selecting

Open from the pop-up menu.

Tech 500 User Guide rev1.0 JUNE 2013

34

Audit File Presentation

The Data presented is in a HTML form format that displays not only information regarding the

TPM’s, but also automatically updates with the date. It provides data entry (typing) areas for

other tester and vehicle data.

Leaving Audit Mode

To leave the Audit mode

and re-enable the Tech500

simply remove the USB

lead.

APPENDIX A: INDUCTIVE

CHARGING

Tech 500 User Guide rev1.0 JUNE 2013

35

10 Digit in VIN

YEAR

W

1998

X

1999

Y

2000

1

2001

2

2002

3

2003

4

2004

5

2005

6

2006

7

2007

8

2008

9

2009

APPENDIX B: VIN

Vehicle Identification Number (VIN)

When using the Tech500, it is important to verify the Model Year you are working on to help

insure that you are looking for that proper sensor and are using the proper vehicle COMs when

necessary.

Tech 500 User Guide rev1.0 JUNE 2013

36

A

2010

B

2011

C

2012

D

2013

E

2014

F

2015

G

2016

H

2017

J

2018

K

2019

3 = 2003

By using the vehicles VIN, not the manufactured date, you

can accurately determine that vehicle’s Model Year. Refer

to that vehicle’s VIN, and locate the 10th digit from the left.

Take that digit and reference the chart on this sheet. This

will be the Model Year that you will want to select on your

tool.

APPENDIX C: FAQ’S & TROUBLESHOOTING GUIDE

Tech 500 User Guide rev1.0 JUNE 2013

37

1. The tool is set up correctly for make model and year but the tool does not work on the

sensor?

Answer: hold the tool in the proper position, TPM is actually faulty or vehicle has

incorrect TPM installed.

2. I have a faulty sensor and the dealership gave me a new one but it will not program to

the car. Answer: The dealership probably gave the wrong sensor. Many vehicles of the

same model might have 2 or 3 possible sensor variations to accommodate high and low

pressure ranges, frequency, etc.

3. I just rotated the vehicle’s wheels. Do I need to re-learn the sensors to the vehicle?

Answer: Yes if the car is position dependent.

4. The tool won’t turn on. Answer: Make sure battery is fully charged. Charge tool for 2+

Hours and retry power on.

5. Everything has been selected on the tool correctly but a P with the down arrow shows

up and when I press test the TPM does not initiate. Answer: The P with down arrow

means this is a DELTA P sensor. This means the tire pressure has to be let out before the

sensor will transmit.

Tech 500 User Guide rev1.0 JUNE 2013

38

APPENDIX D: GLOSSARY

TPMS – Tire Pressure Monitoring Systems, sometimes referred to as RTPMS.

Indirect System – TPM system that uses the ABS wheel sensors.

Direct System – TPM system that has sensors in the wheels that use RF.

LF – Low frequency, usually 125 kHz with respect to TPMS technology.

Continuous Wave – Type of LF signal that wakes Schrader Style Sensors.

Modulated Wave – A “patterned” LF signal that is designed for specific sensors.

UHF – Ultra High Frequency, 315 and 433.92 MHz, what the sensor transmits.

Re-Learn – The process of registering the sensor ID’s to the car.

Hi-Line – Type of car that has wheel arch initiators and usually a graphic display.

Lo-Line – Type of car that requires a tool to repair and only has warning light.

Wi-Fi – Wireless Network

Bluetooth – Wireless communication

Induction Charger – Wireless Charger by using the option fixture

Tech 500 User Guide rev1.0 JUNE 2013

39

APPENDIX E: TPMS SYSTEM REVIEW

When diagnosing TPMS systems, understanding what the tell-tale

light means is important.

When cycling the ignition for off to run, the TPMS tell-tale should

come on, and go off. This would indicate a system with no fault

present.

If the light comes on, and stays on for an extended period of time, this would be a pressure

problem. Check the tire pressures, and adjust to placard. NOTE: Some vehicles are equipped

with sensors in the spare. Also, with some vehicles, over pressure may turn on the light.

If the light comes on, and continues to flash, there is a system problem. System problems can

range from faulty sensor(s) to sensors on the vehicle that haven’t been learned to that vehicle.

Solid Light: Pressure Problem

Flashing Light: System Problem

Tech 500 User Guide rev1.0 JUNE 2013

40

APPENDIX F: COMS ERROR TROUBLESHOOTING

If you are having a problem or error during the COMS process, follow these steps before calling

customer support.

Check vehicle ignition

Vehicle ignition must be in the RUN position in order for vehicle COMS process to complete.

Check cable to tool connection

Insure the cable is connected at the DB15 and thumb screws are finger tight.

Check cable connection at vehicle

Make sure OBDII connection is good.

Verify Make, Model, and Year

COMS can change from Model to Model, and Year to Year. Verify the tool is set-up to the

proper MMY.

Verify tool power level

If your tool has a low battery charge, this may affect the COMS process. Charge tool and try

again.

Tech 500 User Guide rev1.0 JUNE 2013

41

APPENDIX G: TECHNICAL SUPPORT

(866) 407-TPMS

Technical Support

For technical support, please call us at 866-407-TPMS (8767). You can also contact us by email:

info@bartecusa.com or visit our website www.bartecusa.com for a complete directory.

For efficient and accurate service, please have the following information ready when contacting

us.

- Tool Serial Number: This allows the call info to be added to our database for

future reference.

- Make, Model, and Year: Support Team will need this information to

reference any information on this end.

- Have your tool registered: Gives you access to Technical Information on the

website that may assist you with your current issue.

- Sensor Part Number: if you have installed 1 or more sensors to this vehicle,

please have the part number ready in case the support team needs to

reference this information.

- Make sure tool is updated to latest software: Having the latest software will

ensure your tool has all the latest info and features.

- What is the TPMS light doing: Is the light on Solid or Flashing?

- Having vehicle in house: Having the vehicle in house will allow the tech

support team to walk you through the situation.

When you call in you will be asked to give your name, company name, serial number, and a

phone number before we can address your questions and issues. This data is used to better

serve the customer by tracking all data and issues.

Tech 500 User Guide rev1.0 JUNE 2013

42

LIMITED WARRANTY

Bartec products are guaranteed for a period of 1 year from the original date of purchase (either

from the factory or authorized dealer). In order for your warranty to become active, you must

register your tool with Bartec USA by mailing in the warranty card or registering on our website.

We warranty that the tool will be free from defects in material and workmanship, when

properly used. THIS WARRANTY APPLIES ONLY TO THE ORIGINAL CONSUMER PURCHASER OF

THIS PRODUCT. In the event of a defect, Bartec USA LLC will, at its discretion, repair or replace

the tool with a product of like kind or quality, which may be new or reconditioned. The repaired

or replaced product will be warranted for 90 days from the date of return shipment, or for the

balance of the original warranty, whichever is longer. Claims of all defects must be submitted

within 30 days of occurrence, and verified by an authorized Bartec representative.

To obtain service for your Bartec tool the purchaser must obtain a Return Materials

Authorization (RMA) number from Bartec USA customer service prior to shipping. Bartec shall

not be liable for any expense incurred by purchaser in order to remedy a defect without prior

authorization. To obtain your RMA number, you will need to provide at a minimum the follow:

1) Model and Serial Number, 2) Supplier from which the tool was purchased 3) Date of

purchase, 4) Description of problem, how and when it occurred. Please note that Bartec USA

may attempt to have you try some things in the field prior to issuing a RMA number to

determine if the tool does need to come back. The purchaser must return the product postpaid

with a copy of the original sales receipt, purchaser’s return address and the RMA number

clearly printed on the outside of the package to:

44231 Phoenix Drive

Sterling Heights, MI 48314

ATTN: Returns RMA#______

Tech 500 User Guide rev1.0 JUNE 2013

43

Bartec USA may refuse your delivery if the RMA number is not clearly marked on the outside of

the box.

Bartec USA reserves the right to refuse to provide service free-of-charge if the sales receipt is

not provided or if the information contained in it is incomplete or illegible or if the serial

number is altered or removed. Bartec USA is not reasonable for any losses or damage to the

product incurred while the product is in transit or is being shipped for repair. Bartec USA

recommends shipping UPS and insuring your shipment. Please note that your RMA will be

shipped back with the same or equivalent service that you sent it in by.

Limitations and Exclusions

This warranty does not apply to damage or loss by and or all the conditions:

- Freight Damage

- Decals, Overlays or Decorative Items

- Misuse or misapplication or failure to follow the directions, or failure to follow

cautions or warnings on product, operation, service guides, etc.

- Minor stress cracks in surfaces that are considered cosmetic and have no effect on

tool function or performance or safe use.

- Any damage related to fire, accident, misuse, acts of war, disaster, terrorism, or

God.

It is expressly agreed that the liability of Bartec limited WARRANTY IS EXCLUSIVE. BARTEC

DISCLAIMS ANY AND ALL OTHER WARRANTIES.

Bartec USA, LLC does its very best to insure the accuracy of the information contained in work

instructions, but cannot be responsible for errors or omissions by third party sources.

This warranty is exclusive to the original purchaser of the tool and is not transferable.

Exclusions:

The following items are excluded from the warranty coverage:

- periodic maintenance and repair or replacement of parts due to normal wear and

tear

- batteries (except internal)

- finishes

Tech 500 User Guide rev1.0 JUNE 2013

44

- service performed or attempted by anyone other than an authorized Bartec service

technician

Opening, dismantling or repairing of this product by anyone other than an authorized Bartec

technician will void this warranty.

Limitation of Liability

Under no circumstances shall Bartec be liable for any special, consequential or incidental

damage arising from any defect in products manufactured or sold by Bartec outside of the

responsibilities expressed by this warranty. No person, distributor or representative of Bartec is

authorized to make any representations on behalf of Bartec beyond those expressly stated in

the applicable literature. Bartec reserves the right to make design and other changes,

modifications, or improvements without any obligation to install the same on previously sold or

delivered products.

It is expressly agreed that the liability of Bartec is limited, and we do not function as an insurer.

The remedies set forth in this warranty shall continue the exclusive remedies available to the

purchaser or user and are in lieu of all other remedies expressed or implied. The liability of

Bartec, whether in contract, or in tort, under any warranty or otherwise, shall not exceed the

selling price by Bartec or the manufacture of the particular product made, sold, or supplied by

Bartec.

TOOL REGISTRATION FORM (By Fax or Mail)

First Name: ___________________________________

Last Name: ___________________________________

Company: ____________________________________

Address: _______________________________________

City: __________________________________________

State: _________________ ZIP: ____________________

Phone#: (_______)_______-___________

Tech 500 User Guide rev1.0 JUNE 2013

45

Fax #: (_______) __________-___________

Date of Purchase: ______/______/________________

Purchased From: _______________________________

Serial Number: ________________________________

Model: _______________________________________

Email Address: ________________________________

User name: __________________________________

Password: ___________________________________

Detach and mail to:

Bartec USA

44231 Phoenix Drive

Sterling Heights, MI 48314

Or fax to:

586-323-3801

Loading...

Loading...