Barrus Shire 15 15 CB, Shire 15 15 WB, Shire 15 15 RB, SHIRE 15 20 CB, SHIRE 15 20 RB User Manual

...

SHIR CANAL, WORK AND RIVER BOAT

ENGINE MANUAL

For the following engine models:

Shire 15 15 CB / WB / RB

SHIRE 15 20 CB / WB / RB

Please read in conjunction with the PRM Gearbox Manual

Enter your engine identification details in the spaces provided above.

E. P. BARRUS LIMITED, Launton Road, Bicester, Oxfordshire. OX26 4UR

Tel: 01869-363636 Fax: 01869-363610 www.barrus.co.uk

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 2 of 55

Declaration of Conformity for Recreational Craft Propulsion Engines to the

Directive No 2013/53/EU

Name of Engine Manufacturer: E.P.Barrus LTD

Name of Authorised Representative: E.P.Barrus LTD

Address: E.P.Barrus LTD, Launton Road, Bicester, Oxon, OX26 4UR, England

Name of Notified Body for exhaust emission assessment: HPi Verification Services Ltd

Address: The Manor House, Howbery Park

Town: Wallingford Post Code:OX10 8BA

Country: United Kingdom ID Number: 1521

Conformity assessment module used for exhaust emissions: B+C B+D B+E B+F G H

Or engine type-approved according to: Directive 2013/53/EU

Other Community Directives applied:

Description of Engine(s) and Essential Requirements

Engine Type: Inboard Engine Fuel Type: Diesel

Combustion Cycle: 4 Stroke

Identification of Engine(s) covered by this Declaration of Conformity

Engine Model

Engine Type

Engine Family code

Type Approval Certificate Number

Shire 15 15 CB/RB/WB

2M78

M78

HPiVS/R1105-002-I-02

Shire 15 20 CB/RB/WB

3M78

M78

HPiVS/R1105-002-I-02

Essential Requirements

Standards

Other normative

document/method.

Technical

file

Specify in more detail

*= Mandatory standard.

Annex 1.B- Exhaust Emissions

B.1 Engine Identification

R RCD (II)

R

2013/53/EU

B.2 Exhaust emission

requirements

R*

* EN ISO 8178- 1:1996

B.3 Durability

R

2013/53/EU

B.4 Owners Manual

R R

ISO10240

Annex 1. C- Noise Emissions

See Declaration of Conformity of the craft in which the engine(s) has(have) been installed

This declaration of conformity is issued under the sole responsibility of the manufacturer. I declare on behalf

of the engine manufacturer that the engine(s) [is (are) in conformity with the type(s) for which above

mentioned EC type-examination or type approval certificate(s) has (have) been issued and]1 will meet the

exhaust emission requirements of Directive 2013/53/EU when installed in a recreational craft, in accordance

with the engine manufacturer’s supplied instructions and that this (these) engine(s) must not be put into

service until the recreational craft which it is (they are) to be installed has been declared in conformity with the

relevant provisions of the above mentioned Directives.

Tim Hart

Sales Director

Signed: Bicester, UK

Date: 18/01/2016

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 3 of 55

PLEASE NOTE:

This manual has been compiled to help you to operate your engine and its associated parts

with safety and pleasure. Please read it carefully and familiarise yourself with the engine

and its parts before operation.

E.P.Barrus reserve the right to change the specification of its products and manuals without

prior notice.

Depending upon the equipment specification of the engine and accessories fitted, there

may be discrepancies with the information presented in this handbook. No claims may be

pursued in this respect.

WARNING:

THIS MANUAL FORMS AN INTEGRAL PART OF THE ENGINE IT ACCOMPANIES, IF

A TRANSFER OF TITLE OCCURS, IT MUST ALWAYS BE HANDED OVER TO THE

NEW OWNER.

WARRANTY

This Limited Warranty provides coverage for:

• Leisure Applications: Two (2) years from the date of warranty registration.

• Commercial Applications: One (1) year or a maximum of 1000 hour from the date of

warranty registration (whichever occurs first).

The repair or replacement of parts, or the performance of service under this warranty, does

not extend the life of this warranty beyond its original expiry date.

To ensure that you have been registered for your warranty, please ask your Boat-Builder or

Engine supplier to provide your portion of the registration form.

The Warranty will only apply if the following have been carried out:

1/ The Installation Check List in the Installation Section has been fully completed.

2/ The boat builder or engine installer has completed the Boat Builder Section on the

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 4 of 55

Service Record Card (located at the back of this manual) regarding hand over and

commissioning of boat.

3/ The registration form has been completed and returned to E.P Barrus.

PRM gearboxes are covered by a two (2) year warranty.

Engine alternator, starter motor and electrical components are only covered by a one (1)

year warranty.

CONDITIONS THAT MUST BE MET IN ORDER TO OBTAIN WARRANTY COVERAGE

Warranty coverage is only available from an authorised dealer in the country in which the

sale occurred. Routing maintenance outlined in the Owner’s Manual must be performed

using genuine parts in order to maintain warranty coverage. If the customer performs

maintenance, Barrus reserves the right to make future warranty coverage possible only with

proof of proper maintenance.

WARRANTY CLAIMS

Warranty claims shall be made by an authorised dealer or boat builder.

The dealer or boat builder will then arrange for the inspection and any necessary repairs. If

the repairs carried out are not covered by the warranty, the purchaser shall pay for all

related labour and material, and any other expenses associated with that service.

WHAT IS NOT COVERED

This limited warranty does not cover routine maintenance items, adjustments, normal wear

and tear, damage caused by abnormal use, operation of the product in a manner

inconsistent with the recommended operation/duty cycle section of the Owner’s Manual,

accident, submersion, improper installation (proper installation specification and techniques

are set forth in the Operations and First time running sections in this manual), use of an

accessory or part not manufactured or sold by us, or alteration or removal of parts.

Expenses related to crane-out, launch, towing, storage, telephone, rental, inconvenience,

slip fees, insurance coverage, loan payments, loss of time, loss of income, or any other

types of accidental or consequential damages are not covered by this warranty.

Engine electrical systems fitted with alternator boost charge systems or any other electrical

management systems are not covered by warranty.

Engine and fuel equipment is not covered by warranty if bio-diesel is used in the fuel

system. Also if no type of water trap is incorporated into fuel system.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 5 of 55

Index

Page

SECTION 1 – Safety Precautions ................................................................... 8!

1.! General ......................................................................................................................... 8!

2.! Lifting ............................................................................................................................ 8!

3.! Rotating Shafts and Belts ............................................................................................. 8!

4.! Exhaust System ........................................................................................................... 8!

5.! Launching and Lifting Boats ......................................................................................... 8!

6.! Batteries ....................................................................................................................... 8!

SECTION 2 – Engine Identification .............................................................. 10!

SECTION 3 – Installation ............................................................................... 11!

1.! Ventilation ................................................................................................................... 11!

2.! Engine Beds ............................................................................................................... 11!

3.! Cooling System (Canal Boats with Skin Tanks) ......................................................... 11!

4.! Skin Tanks (Canal Boats) ........................................................................................... 11!

5.! Engine Cooling Water Connections ........................................................................... 12!

6.! Pressurised Water Header Tank ................................................................................ 12!

7.! Shaft Connection and Propeller Selection .................................................................. 14!

8.! Engine Anti-Vibration Mounts ..................................................................................... 14!

9.! Engine Alignment ....................................................................................................... 15!

10.! Electrics ...................................................................................................................... 16!

11.! Electrical Options ....................................................................................................... 16!

12.! Engine Oil ................................................................................................................... 16!

13.! Fuel ............................................................................................................................ 17!

14.! Coolant ....................................................................................................................... 17!

15.! Calorifier ..................................................................................................................... 18!

16.! Control Cables ............................................................................................................ 19!

17.! Domestic Battery Bank ............................................................................................... 19!

18.! Control Panel .............................................................................................................. 20!

19.! Exhaust System (Canal Boat) .................................................................................... 21!

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 6 of 55

20.! Exhaust System (Work Boat / River Boat) ................................................................. 22!

21.! Hydraulic Drive Transmissions ................................................................................... 24!

22.! Installation Check List ................................................................................................ 25!

SECTION 4 – Operation ................................................................................. 26!

1.! Starting the engine for the first time ........................................................................... 26!

2.! Starting Procedure ..................................................................................................... 27!

3.! Stopping Procedure .................................................................................................... 27!

4.! Refuelling ................................................................................................................... 28!

5.! Diesel Fuel Additive .................................................................................................... 28!

6.! Exhaust Back Pressure .............................................................................................. 28!

7.! Single Lever Side Mount Operation - Optional (RDG9210055) ................................. 28!

SECTION 5 – Service Procedure .................................................................. 29!

1.! Daily Maintenance ...................................................................................................... 29!

2.! Engine Oil and Filter Change ..................................................................................... 29!

3.! Air Filter Check and Change ...................................................................................... 29!

4.! Gearbox Oil Change ................................................................................................... 30!

5.! Disposal of Oil and Related Items .............................................................................. 31!

6.! Fuel Filter Drain – Shire 15 15/20 .............................................................................. 31!

7.! Fuel Filter Change ...................................................................................................... 32!

8.! Fuel System Bleeding ................................................................................................ 32!

9.! Cooling System .......................................................................................................... 32!

10.! Belt Adjustment .......................................................................................................... 33!

11.! Belt Maintenance ........................................................................................................ 34!

12.! Belt Replacement ....................................................................................................... 34!

13.! Control Panel Maintenance ........................................................................................ 34!

14.! Sacrificial Anode Change ........................................................................................... 35!

15.! Raw Water Pump Impellor Change (Work Boat & River Boat) .................................. 35!

16.! Engine Heat Exchanger Tube Stack Flushing ............................................................ 36!

17.! Winterization of Seawater Cooling System (Work Boat & River Boat) ....................... 37!

SECTION 6 – Service Schedule .................................................................... 38!

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 7 of 55

1.! Specifications and Capacities .................................................................................... 38!

2.! Service Intervals ......................................................................................................... 38!

SECTION 7 – Wiring Diagrams ..................................................................... 40!

1.! Engine Wiring Diagram Shire 15 15/20 ...................................................................... 40!

2.! Standard Control Panel Wiring Diagram .................................................................... 41!

3.! Deluxe Control Panel Wiring Diagram (Additional Option – SS1551) ........................ 42!

4.! RDG20710110 – Standard Control Panel .................................................................. 43!

5.! RDG20710111 – Deluxe Control Panel (Additional Option – SS1551) ...................... 43!

6.! Overall Dimensions of the Control Panels .................................................................. 44!

SECTION 8 – Technical Data ........................................................................ 45!

SECTION 9 – General Arrangement Drawings ............................................ 47!

1.! General Arrangement Shire 15 15 Canal Boat ........................................................... 47!

2.! General Arrangement Shire 15 15 River Boat ............................................................ 48!

3.! General Arrangement Shire 15 20 Canal Boat ........................................................... 49!

4.! General Arrangement Shire 15 20 River Boat ............................................................ 50!

SECTION 10 – Dealer List ............................................................................. 51!

SECTION 11 – Shire Service Parts ............................................................... 53!

SECTION 12 – Shire Service Record Card .................................................. 54!

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 8 of 55

SECTION 1 – Safety Precautions

1. General

It is the responsibility of the installer/operator to ensure that the finished installation

complies with the relevant Health & Safety requirements and the recreational craft directive

before commissioning.

Ensure that the engine battery isolator switch is in the off position and the key removed

from the control panel before carrying out any maintenance or repairs.

2. Lifting

The Lifting points supplied with the engine are for lifting the engine/gearbox only. A suitable

spreader bar must be employed to prevent over-stressing either bracket during any lift.

3. Rotating Shafts and Belts

The engine and its accessories are not intended to be put into operation until they are

integrated into the boat as a whole. No person should be in the engine compartment and

the engine cover or deck hatches should be closed whilst the engine is running.

4. Exhaust System

Exhaust gases may have temperatures as high as 650°C and contain elements which are

harmful if ingested.

It is therefore essential that exhaust systems are gas tight and lagged to prevent accidental

burning.

5. Launching and Lifting Boats

Care must be taken when launching or craning new boats into or out of the waterway, so

that water does not enter the engine via the exhaust system or air vents. It is recommended

that these are blocked temporarily whilst undertaking this procedure.

6. Batteries

WARNING:

EXPLOSIVE GASES / SULPHURIC ACID

• Batteries can produce explosive gases; keep sparks and flames away from the

battery.

NO SMOKING

• Batteries contain sulphuric acid; if splashed on skin or eyes, flush well with water and

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 9 of 55

seek medical advice.

• Keep battery tops and battery compartment ventilated at all times

• If disconnecting the battery; remove the earth lead FIRST; and re-connect it last.

• If charging the battery; ensure that the charger is switched off before connecting and

disconnecting.

• Do not tip the battery on its side.

• Please see label on battery or manufacturer’s instructions for specific information.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 10 of 55

SECTION 2 – Engine Identification

Please quote the engine identification number during any enquiry or when ordering spare

parts. Use the space below to record these details.

This can be found engraved into the brass plate on the top of the engine rocker cover and

stamped to the crankcase next to the starter motor.

Note: Canal Boat Engines (CB) do not have identification initials on the engraved plate.

An example of the engine identification plate is shown below (Figure 1):

Description of Models:

CB: Canal Boat Engine: Keel cooled dry exhaust manifold.

WB: Work Boat Engine: Seawater / Heat Exchanger cooled, dry exhaust manifold

with either dry exhaust system (same as a Canal Boat) or

water injected exhaust system.

RB: River Boat Engine: Can also be used for sea going applications. Seawater / Integral

exhaust manifold, heat exchanger cooled. Water injected exhaust system.

Note: There are a number of optional extras that may be fitted to an engine that are not

listed here.

SHIRE

1550$D$XXXXX

Indicates Model Type or Optional Extras:

RB = River Boat

WB = Work Boat

D = Deluxe Panel

3 = 3:1 Ratio Gearbox

Engine Model

Build Number

Serial Number

Figure 1: Engine Identification Badge

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 11 of 55

A list of common item service part numbers can be found in Section 11, Shire service parts.

SECTION 3 – Installation

1. Ventilation

• All internal combustion engines radiate heat and require cool, clean air to aid

complete combustion.

• Please Ensure that adequate engine room ventilation is provided, by fitting at least

two vents of an aperture of not less than 10,000mm2 each (16in2).

An allowance must be made for any rills, louvres or bends placed in the airflows and

generally an increase of 25% in area is sufficient to overcome any restriction

problems.

2. Engine Beds

• These should be a minimum of 10mm thick, extended rearward and be welded to the

hull and forward to the bulkhead. Webs or gussets must be welded in place midway

to prevent flexing.

3. Cooling System (Canal Boats with Skin Tanks)

• Ensure pipe work to and from the skin tanks is of sufficient bore. A minimum of

28mm (11/6“) is recommended Ensure tight bends and elbows are avoided or kept to

a minimum.

4. Skin Tanks (Canal Boats)

The ideal skin tank internal thickness is between 50 and 75mm, the table below will indicate

a suitable tank size. However, volume will not compensate for lack of surface area. It

should be recognised that fitting a large calorifier will increase the theoretical cooling

capacity only until it is up to temperature. It is unlikely that a boat on the inland waterways

will operate at full power for long periods of time.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 12 of 55

Height

Length

Air Bleed Points

Coolant to

Engine

Coolant from

Engine

Figure 2: Skin Tank Flow Diagram

Recommended Skin Tank Size

Engine

HP

KW

Skin tank surface

area m2

Suggested

Height mm

Suggested Length mm

15

15

11

0.75m

600

1000

20

20

15

0.75

600

1250

Note: Skin tank size must be increased by approx. 10% if a hydraulic drive transmission is

fitted.

5. Engine Cooling Water Connections

For Canal Boats:

These are on the Left hand (Port) side of the engine:

• Shire 15 and 20 28mm (1 1/6”) OD

• The hose must be capable of taking water at temperatures in excess of 90°c. The

hose should also be non-collapsible.

For River Boats & Workboats:

• Seawater inlet hose size: 19mm (¾”)

• Water cooled exhaust hose size: 50mm (2”)

6. Pressurised Water Header Tank

• The pressurised header tank should be mounted higher than the level of the engine,

no less than 300mm, and no more than 1m from the engine, to prevent cooling

system air locks.

• The two hosetails on the plastic header tank have different hole diameters. Please

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 13 of 55

make sure they are connected the correct way around as per Figure 3 and Figure 4.

Note: Not fitted to RB engines

Figure 3: Shire 15 20 Canal Boat Header Tank Connections

Figure 4: Shire 15/20 Work Boat Header Tank Connections

Large ID Hole

Small ID Hole

Large ID Hole

Small ID Hole

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 14 of 55

7. Shaft Connection and Propeller Selection

• Some type of flexible coupling must be used to connect the gearbox output flange to

the propeller shaft flange.

• Please note, underperforming engines will not be covered under warranty if the

cause of the poor performance is found to be the use of an inappropriate propeller.

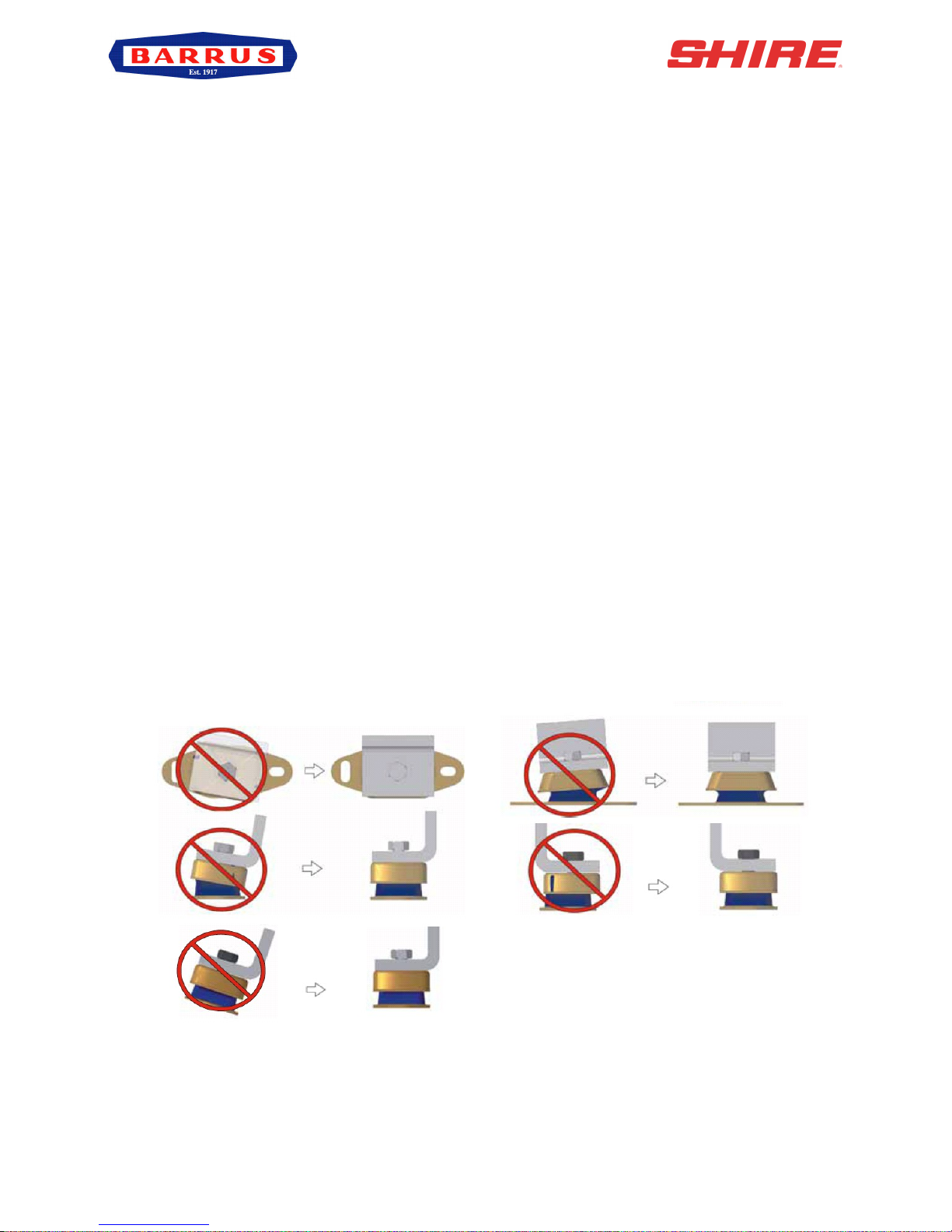

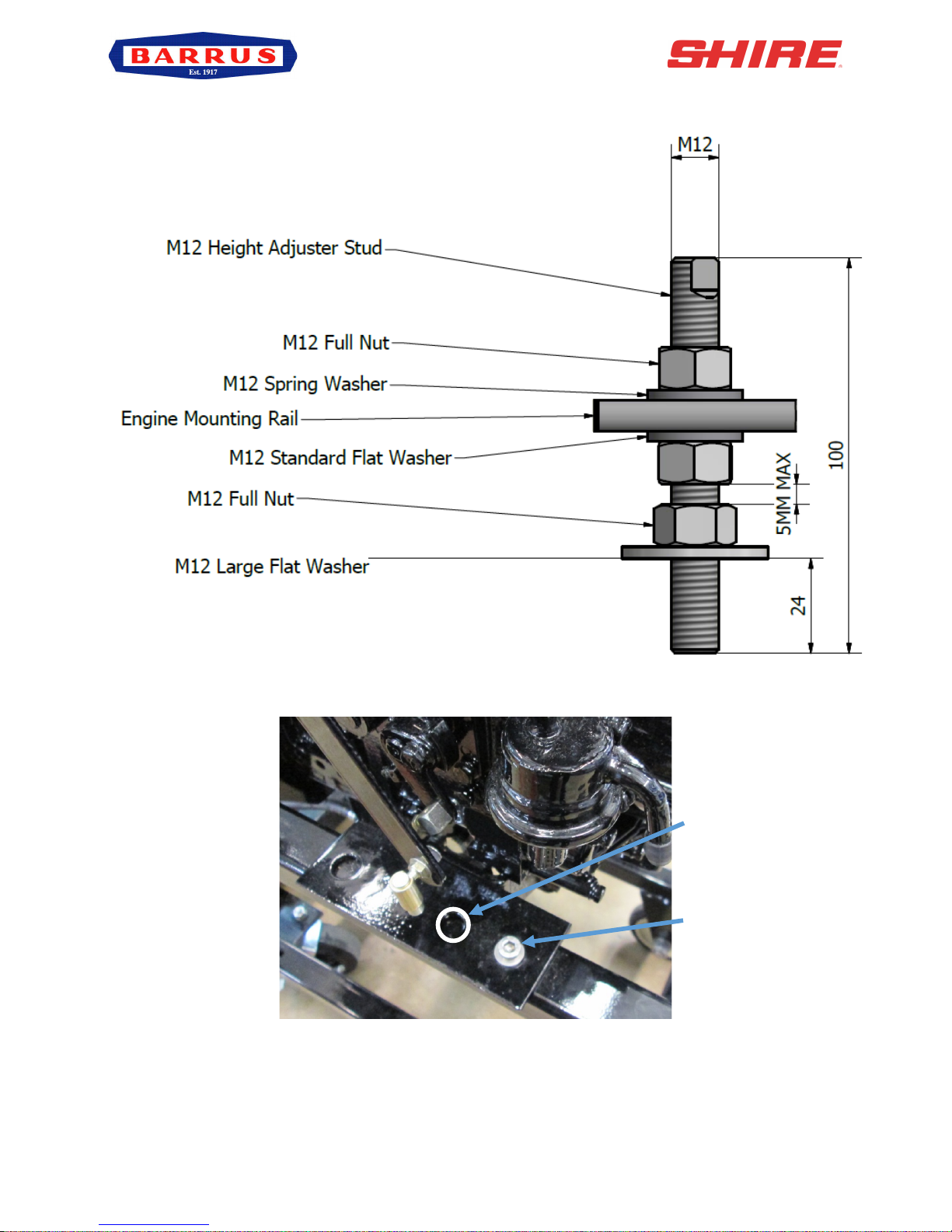

8. Engine Anti-Vibration Mounts

• Ensure that the engine feet do not end up at the top of the thread on the engine

mounts, this puts undue pressure on them and can result in excessive engine

movement and premature mount failure. If this is a problem put steel packing plates

under the mounts.

• Ensure that the engine has been installed for at least 24 hours before shaft

alignment is checked, to allow the mounts time to settle under the engine weight.

• Ensure that the anti-vibration mount centre screw is sufficiently raised so as not to

touch the engine bed. If this occurs, excessive engine vibration will be experienced

through the hull.

• Alternative mounting holes for the anti-vibration mounts are available. Your new

engine maybe replacing an old engine so suitable holes may align with your existing

mounting holes

• For the best results, the mounting screw for the front mount should go into the most

forward hole in the bracket. The mounting screw for the rear mount should go into

the most rearward hole in the bracket.

Figure 5: Correct Anti-Vibration Mount Installation

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 15 of 55

Figure 6: Correct Anti-Vibration Mount Installation

Figure 7: Anti-Vibration Mount Installation Points

9. Engine Alignment

• The gearbox output shaft flange and propeller shaft input flange must be almost

Alternative mounting

position if engine

compartment space is

Normal mounting position

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 16 of 55

perfectly aligned. A maximum of 0.05mm (0.002”) misalignment in any plane is

acceptable. Ensure alignment is rechecked after the first 4 hours of running, after the

first month and thereafter annually.

• If the engine is out of alignment it will result in excessive vibration and possible

damage to the stern tube and propeller shaft.

• Boats that are fitted with fully flexible drive couplings should still have the engine and

shaft alignment as close as possible. A dummy shaft may be required for this

purpose. Note: Some types of flexible shaft couplings require the input and output to

be misaligned, check with the coupling manufacturer’s installation instructions.

• Minimum clearance of 25mm between rails and engine beds.

10. Electrics

• Do not attach any part, hose or cable to the engine wiring harness. There is a

warning label attached to the harness to remind you of this.

• Connect the wiring extension harness multi plug to the panel plug and the other end

to the engine.

• Connect the start battery positive cable to the engine starter motor solenoid terminal.

• The starter motor battery cable must have a cross sectional area of at least 50mm2.

• For twin alternator engines, connect the domestic battery positive cable to the 70A

alternator B+ terminal (see wiring diagram). This ensures that the 50A alternator

charges the start battery and the 70A alternator charges the domestic battery,

removing the requirement for a split charging system or relay.

• Negative battery terminal must be connected to a common earth point.

11. Electrical Options

• Standard engine is a single 50A Alternator.

• Option 1, is a single 70A Alternator. (SS1491)

• Option 2, is Twin Alternators 50A and 70A (CB engine only)

• Electrically operated stop solenoid (energise to run). (SS1553 or SS1554)

• Deluxe Control Panel. (SS1551)

12. Engine Oil

• All Shire engines are supplied fully run in.

• Check oil levels in engine and gearbox before starting

• Use good quality engine oil SAE 10W / 40 API class CD.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 17 of 55

WARNING:

ENGINE OIL WITH A HIGHER API CLASS THAN CD IS UNSUITABLE FOR CANAL

BOAT OPERATION AND WILL CAUSE ENGINE DAMAGE IF USED.

13. Fuel

• Ensure the main fuel tank is clear of dirt and water.

• A separate water trap must be fitted to all engine installations.

• Connect fuel feed return hoses from engine to main supply and return lines to main

fuel tank, ensuring they are connected the correct way around. The hose to the fuel

pump is the inlet.

• The engine hoses are supplied with 5/16” (8mm) OD metal hose tails and should be

securely fitted to the main supply and return pipes with compression fittings.

• The engine hoses should have sufficient slack to absorb engine movement without

placing strain on the hoses and be securely clipped to prevent accidental damage

and chafing.

• Loosen the bleed screw on the top of the primary fuel filter/water trap. Depress and

pump the spring loaded plunger on top of the fuel filter assembly. Close when fuel

begins to flow clearly (no bubbles). It is rarely necessary to bleed the injection pump

or injectors upon installation as the engine will already have fuel in it from the engine

run in and test procedure.

14. Coolant

• Prepare coolant mix of 50% clean tap water and 50% antifreeze. Please make sure

that the antifreeze used is suitable for the silicone hoses fitted to the engine.

• Open the calorifier taps (if fitted) to fill the calorifier system and displace air.

Canal Boats: To fill the cooling system for the first time, fill the skin tank via the inlet hose

connection or filler plug if fitted.

• Fill the engine through white plastic expansion tank.

Note: After running the engine for the first time, monitor the water level frequently as

trapped air bubbles may be expelled. Top up the system as necessary.

Workboats: Dry Manifold, fill the engine through the white expansion tank.

Note: After running the engine for the first time, monitor the water level frequently as

trapped air bubbles may be expelled. Top up the system as necessary.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 18 of 55

Riverboats with Water Cooled Manifold: Remove filler cap on top of water cooled

exhaust manifold and fill cooling system through here. Run engine at idle for a few minutes

with cap removed to ensure air is removed and allow a 13mm (1/2”) air gap in top of

manifold to allow for expansion.

Note: Water Tap (CB & WB engines only) on side of engine must be opened to fill engine

and must be closed to the off position to run the engine. (Figure 8)

Figure 8: Water Tap on CB & WB Engines

15. Calorifier

For Canal Boats:

• The calorifiers are positioned as per (Figure 9)

Figure 9: Position of Calorifiers on a Canal Boat

For Work Boats:

• The calorifiers are positioned as per (Figure 10)

Figure 10: Position of Calorifiers on a Work Boat

Water Tap

Inlet

Outlet

Inlet

Outlet

Seawater

Pump

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 19 of 55

For River Boats:

• The calorifiers are positioned as per (Figure 11)

Figure 11: Position of Calorifiers on a River Boat

WARNING:

• The temperature of coolant flowing to the calorifier from the engine can be between

85 and 90°C. A blender valve must be incorporated in the calorifier/hot water system

outlet to lower the hot water temperature for domestic use.

16. Control Cables

• Connect engine speed control cable. With the engine off, ensure that the engine

speed control lever achieves full travel from idle to full speed. Adjust if necessary.

• Check the gearbox shift lever selects positively and that the drive direction

corresponds with the gearshift control lever. Ensure that the gearbox control lever

and the gearshift lever are both in neutral before connection. Adjust if necessary.

17. Domestic Battery Bank

Domestic battery banks that are too large create excessive loads on the domestic

alternator. Alternators running at maximum output for prolonged periods of time will

eventually fail prematurely; alternators that fail due to the battery bank being over the

maximum recommended size will not be covered by warranty.

Higher output additional alternators, or travel power kits are available: if larger battery

banks are required discuss your individual power requirements with the boat builder or

dealer.

• The maximum domestic battery bank is calculated using the following:

- Live aboard, three times domestic alternator, maximum output current.

- Weekend cruising or hire fleet use, three and a half times domestic

alternator, maximum output current.

Outlet

Inlet

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 20 of 55

Example 1:

Live aboard application fitted with a 70amp domestic alternator

3 x 70 = 210 ampere/hour maximum battery bank size

Example 2:

Weekend cruising or hire fleet application fitted with 50amp domestic alternator

3.5 x 50 = 175 ampere/hour maximum battery bank size.

Note: For boats with single alternators and using domestic batteries, it is strongly advised to

use a split charge relay system and separate batteries. This will ensure that the start battery

does not become discharged.

18. Control Panel

All Shire engines are supplied with high quality engine control panel that all show RPM and

hours run and include warning lights and a warning buzzer. The deluxe panels also have

additional gauges for the water temp, oil pressure and battery charging. The panels are

designed to be splash proof and are correctly installed with the gauges vertical. Do not

install so that they remain out in the open, or cover up when not on use.

The control panel engine tachometer is supplied already calibrated to measure correct

engine speed. If a new control panel, tachometer or alternative alternator is fitted, the tacho

will require re-calibrating.

Control Panel Calibration Procedure:

• Connect Control panel plug to engine wiring loom plug.

• Turn ignition on (do not start engine).

• Press and hold black button on rear of tacho until “H-“appears on the digital display

at the bottom of the tacho (on the front).

• When pressing and holding the black button on rear of tacho, the value displayed will

increase / decrease until the button is released. Then when pressing again it will

increase / decrease in the other direction. Keep doing this until the digitally

displayed value on the bottom of tacho reaches the correct value, according to the

type of alternator (see below table). This must be set to the alternator with blue and

black wire connected to it.

• Confirm settings to tacho meter reader.

• An optical tachometer is required to check the reading.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 21 of 55

Barrus Alternator (Amps)

Barrus Tacho reading

50

10.50 – 11.00

70

15.00

50 & 70 (Twin Alts)

Only the 50 Amp alternator requires calibration

Alternative or non-standard alternators will require calibrating and checking by trial and

error, with a hand held tacho until the engine speed and indicated tachometer speed are

the same.

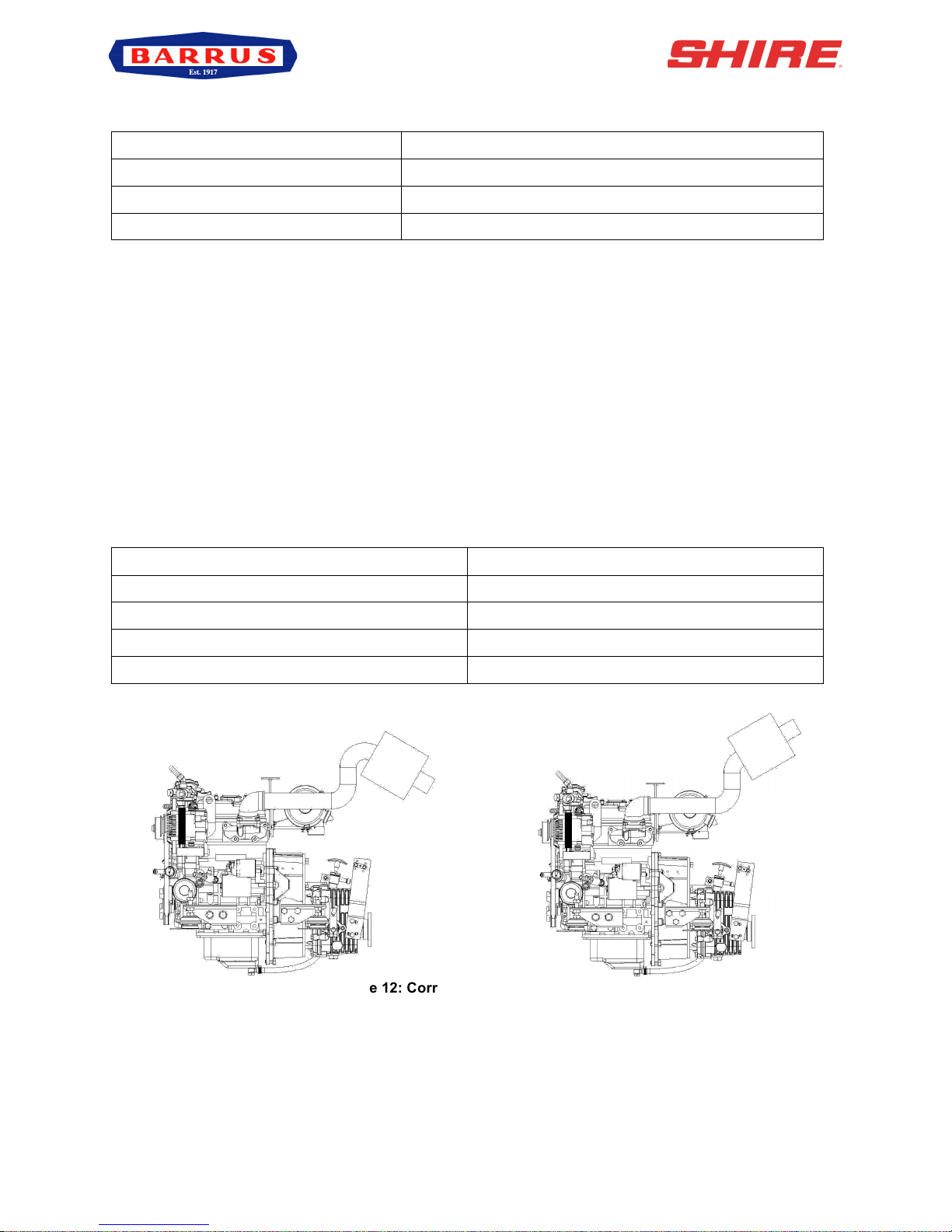

19. Exhaust System (Canal Boat)

The exhaust outlet size on the engine is 1½” BSP female. There must be a flexible exhaust

hose of suitable exhaust grade between the engine and the silencer or hull outlet. The

outlet must be above the waterline at all times. The exhaust fittings and silencer (if fitted),

must not be smaller than 1½” BSP. Exhaust silencers, flexible exhaust hose connections

and lagging blanket are all available as optional extras:

Part Description

Part Number

Exhaust Coupling 1½” x 1½” BSP

RDG1916

Exhaust Silencer DSA-38

RDG1911

Flexible Exhaust Hose (18”)

RDG1879

Blanket 18” Flexy Exhaust

RDG2477

Figure 12: Correct Installation of Exhaust

• Make sure the exhaust increases then decreases in height as shown in (Figure 12).

ü

X

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 22 of 55

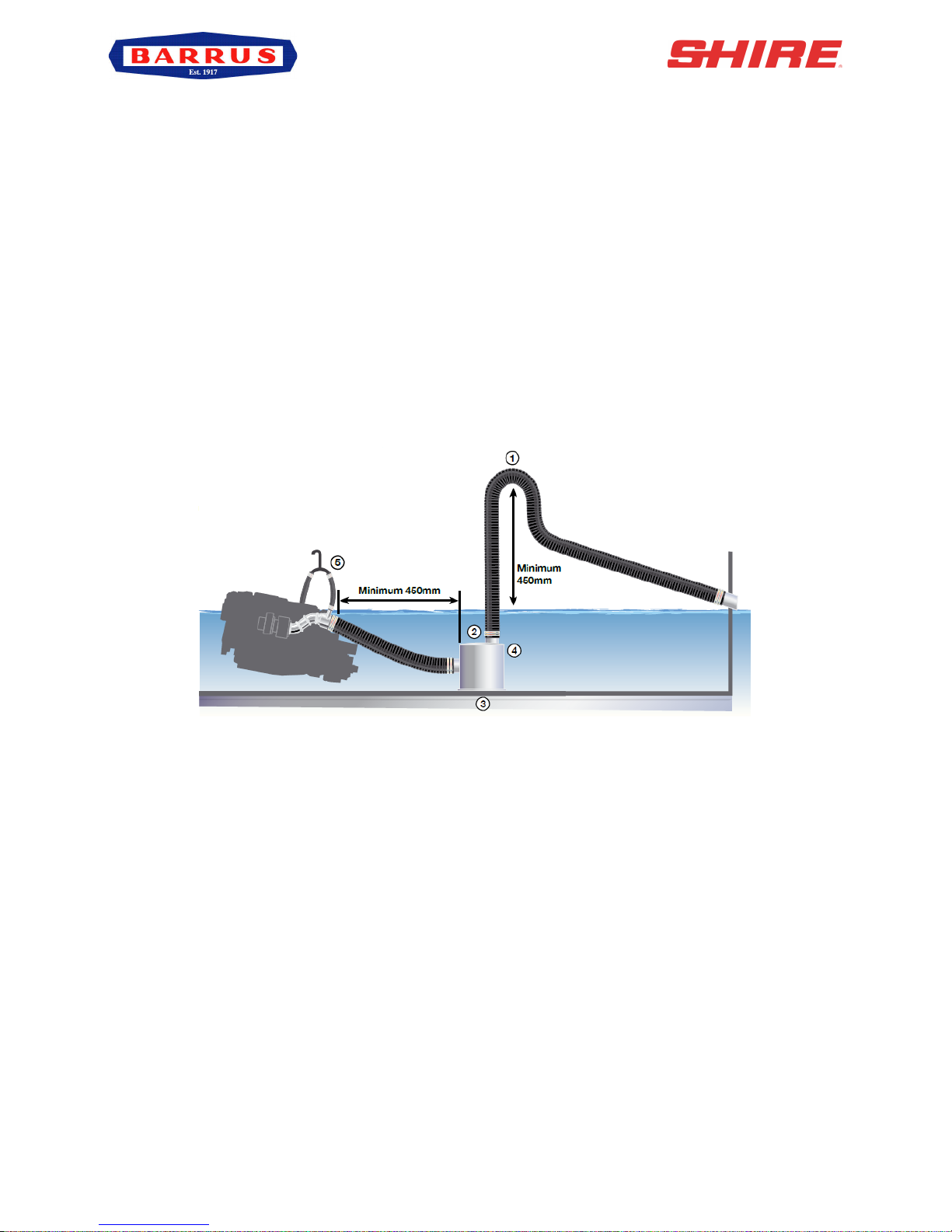

20. Exhaust System (Work Boat / River Boat)

Use 50mm ID suitable marine flexible exhaust hose on the 20 Work Boat model engine.

The exhaust system must not be restricted in any way.

Note: If the engine is installed low down in the boat, below the outside water level, a system

such as a Lift Silencer with a siphon break system, must be used to prevent sea water from

flowing back down the exhaust and into the engine.

• Lift Silencer

The correct installation of the lift silencer is vital to safety, and to avoid back flooding of

the engine. Figure 13 shows how to install the lift silencer correctly (Note: Halyard (M&I)

Limited have given Barrus permission to use the diagram).

Figure 13: Correct Installation of the Lift Silencer

1. The swan neck must reach at least 450mm (18”) above the waterline, when

installed on hull centreline.

2. The top of the silencer should be at least 300mm (12”) below the water injection

point.

3. The silencer must be installed as near as possible to the centreline of the hull,

particularly where severe angles of heel are expected. The swan neck must be

450mm above heeled water line.

4. Remember that 15% of the volume of the exhaust hose may be water. The size

of the silencer selected must be such that water draining into it will fit it by no

more than one third.

5. A siphon break must be used.

The silencer may only be used in a Water Injected marine exhaust system. The overall

design of the system, and choice of components, will have a result on the back pressure in

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 23 of 55

the exhaust which is vital to the performance and life of the engine. Barrus recommend

that Halyard (M&I) Limited are used for the Lift Silencer, Siphon Break and other

components. Contact Halyard (M&I) Limited for further information.

The silencer must be drained before the boat is craned or transported and during the

winter.

There must be at least 450mm distance between the water injection point and the position

of the silencer to allow adequate cooling of the exhaust gases. Maximum temperature

during continuous operation of the silencer is limited to 85 degrees centigrade. Normally in

a well-designed system, the temperature of the silencer should be between 50-70 degrees

centigrade. Such operation will result in longer exhaust life.

Connections to the silencer should be made using suitable exhaust hose, which is type

approved by Lloyds and DNV. Do not use oil or grease to lubricate hoses when installing,

wetting the inside of the hoses with water will help them slip more easily over the silencer

spigots. A minimum of 2 hose clips must be used. Securely tighten all hose clamps, but be

careful not to overtighten.

The silencer should be positioned within 300mm of the centre line of the vessel, or to the

engine on which it is installed. This is particularly important on sailing vessels where a

substantial angle of heel can be encountered. On systems where the exhaust manifold is

near or below the water line. A siphon break should be used to prevent the water flow

continuing after the engine shut down.

In all installations the silencer should be at the lowest point if the entire exhaust system.

The top of the silencer should be at least below the exhaust manifold outlet for the best

performance. If a distance less than is allowed, the margin of safety for preventing reverse

flow of water toward the manifold will decrease.

• Siphon Breaker Fitting Instructions

1. The unit must be positioned upright, well above waterline. The height above

waterline will vary from vessel to vessel but will be between 150mm and 2

metres. Please seek guidance on this if you are unsure, or if you are not familiar

with the correct way to incorporate a siphon breaker into your particular exhaust

system.

2. The inverted “U” bend at the top must be connected to a hose draining into the

bilge, or over the side of the vessel. In no circumstances must this drain into a

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 24 of 55

sealed container, such as a bottle due to the risk of back siphoning. After fitting,

run the engine and check the unions for leaks. Check again after 5 running hours.

3. The siphon break is equally suitable for use with a marine toilet water inlet.

4. The ½” unit may also be used with 5/8” systems. The 3/4” and 1” units may only

be used with the correct hose.

• Siphon Breaker Maintenance

1. On commercial vessels achieving in excess of 150 engine hours per year, the

unit should have the small valve removed from the top and this should be

thoroughly washed in warm soapy water to remove salt encrustation.

2. On a pleasure vessel this should be done twice a year.

3. On reassembly the engine should be run and the unit checked for leaks. The

hose junctions should also be checked for leaks as part of the daily inspection

procedure for sea cocks, water pipes, oil levels, etc.

21. Hydraulic Drive Transmissions

If an engine is to have a hydraulic drive transmission attached to it, a number of points must

be observed.

Bobtail engines (i.e. Engines supplied without a marine gearbox), normally do not have a

gearbox oil cooler fitted. However if a cooler is supplied, this will only be suitable to cools a

conventional marine gearbox.

Hydraulic drive transmissions generate far more heat than a conventional marine gearbox.

Therefore the size of the oil cooler installed must be calculated by the hydraulic drive

transmission supplier: to ensure it has sufficient cooling capacity and is sized appropriately

taking into account:

• Maximum engine power.

• High ambient summer air temperature.

• Summer River/Canal/Sea temperature.

• No additional restriction to engine coolant flow is present.

Skin tanks will also need to be increased by approx. 10% to dissipate the additional heat

generated.

Oil coolers should be installed in the seawater cooling system after the engine, not before.

Coolers that are installed before the engine will invalidate the engine warranty.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 25 of 55

22. Installation Check List

Please tick box !

Engine alignment correct, clearance all round, check propeller turns by

hand (Ensure ignition is off battery and battery master switch is off)

Anti-Vibration mounts correct height, spacers if necessary. Make sure all

nuts are tight

Exhaust system as specified

Battery leads are of correct size, tightened and start battery is charged

Check tension of alternator belts & wiring connected

Belt alignment checked and corrected if necessary

Check fuel system is connected correctly and primed

Fuel line water trap installed and water drained off

Check header tank and skin tank connections are correct way round,

constant pipework rise to header tank

Check level of coolant in header tank and correct ratio of antifreeze to

water

All air has been bled from skin tank, calorifier and pipework

Engine and gearbox oil levels are as specified

Throttle and gear cables correctly adjusted and operating smoothly

All pipework and cabling supported and not chaffing, slack to allow

movement of engine

Confirm engine control panel, gauges and warning lights are all

operational

Suitable specification of hose between seacock and seawater pump with

no restrictions is fitted

Run the engine for 20 minutes with the boat tied up and in gear (at ½

speed). Check for leaks and that all systems operate correctly

Check & Set the Engine Idle Speed to 850-875 rpm

Check for leaks

Explain/Demonstrate daily/weekly/periodic maintenance checks

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 26 of 55

SECTION 4 – Operation

1. Starting the engine for the first time

• Remove ignition key.

Explain/Demonstrate off season storage and maintenance

Installer’s signature

Installer name/company

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 27 of 55

• Ensure all oil and coolant levels are checked.

• Ensure both the engine and domestic batteries are connected. Both battery master

switches must be turned on. Failure to do so may damage the domestic alternator.

2. Starting Procedure

• Ensure the gearshift control level is set to neutral and that persons are clear of any

moving parts.

• Insert ignition key.

• For standard engines ensure the fuel stop knob is pushed into the run position.

• Turn key to on position.

• Observe warning lights (and gauges on deluxe panel).

• Listen for warning buzzer.

• The cold starter glow plug light will illuminate.

• When the glow plug light extinguishes, turn key to second position, start, and hold to

crank.

• Crank the engine for no more than 15 seconds.

• On engine start, immediately release key.

• Key will return to first position, on.

• The warning buzzer will stop and on the deluxe panel the oil pressure gauge will

show an oil pressure of 3.1-4.1 bar (45-60 psi).

• Should any warning light not go out, or if there is no reading on the oil pressure

gauge, the buzzer will continue sounding. In this case, stop the engine immediately

and check the relevant system. Note: If the charge light does not go out, briefly

increase the engine speed.

• Stop engine immediately if any abnormal noises are detected.

• Visually check the engine for oil, fuel and coolant leaks (after initial start-up and at

regular intervals). Note: The engine must be stopped and ignition key removed to

carry out this check.

3. Stopping Procedure

For Standard Engine:

• Move speed control lever to the idle position.

• Pull manual stop control knob on control panel.

• Turn ignition key to off position.

For Engine with Optional Electric Stop:

• Move speed control lever to idle position.

• Turn key to off position.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 28 of 55

4. Refuelling

• All Shire engines run on diesel fuel. DO NOT USE BIODIESEL

• Please note that when the vessel is to be left for any period of time, the fuel tank

should be left full to eliminate the build-up of condensation and formation of water in

the fuel tank.

5. Diesel Fuel Additive

• The use of diesel fuel additive is strongly recommended on Shire engines. The

quality of the fuel available when cruising is often unknown; also the fuel may have

been in storage for long periods of time. The use of additives will ensure that your

engine fuel injection system is in top condition. This should result in many years of

smooth reliable operation without the cost and inconvenience of expensive

breakdowns due to poor quality fuel. It has also been found that improvements in

fuel consumption and start ability are an added benefit of using this product.

• Diesel fuel additive is available from your Shire dealer in a handy 375ml container

(Part Number: RDG80210219)

6. Exhaust Back Pressure

• The back pressure falls within the manufacturers recommended range when using

the exhaust system recommended for the engine.

• The maximum allowable back pressure is 0.35 Bar (4 PSI)

7. Single Lever Side Mount Operation - Optional (RDG9210055)

To engage forward or reverse gear:

• Lift the safety latch under the handle before shifting.

To rev the engine in neutral:

• Pull the lever out sideways from the main body.

• Lift the safety latch under the handle then shift.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 29 of 55

SECTION 5 – Service Procedure

CAUTION:

REMOVE THE IGNITION KEY BEFORE WORKING IN ENGINE COMPARTMENT.

1. Daily Maintenance

• Check the oil level in the sump. Make sure it lies between the upper and lower mark

lines on the dipstick.

• For Shire 15 15/20 Canal Boat/Work Boat, check the coolant level in the water bottle.

It must be between the level indicators.

• For Shire 15 15/20 River Boat, check the level in the exhaust heat exchanger.

• Check the oil level inside the governor of the fuel injection pump. Refill it if

insufficient.

• Check for leakage of oil, water and air.

• Check the installation of the engine. Make sure all mounting bolts are tightened, as

well as other components.

2. Engine Oil and Filter Change

• Change the engine oil while the engine is still hot.

• Remove the blanking plug in the sump pump spout (6mm Allen key).

• Place a plastic tube over the spout and into a container. Operate the pump handle

to empty the sump. Note: Remember to refit the blanking plug afterwards.

• Place a drip tray under the engine to catch the small amount of oil that will escape

from the oil filter. Using the strap type oil filter removal tool supplied, slacken the

filter from the engine block in an anti-clockwise direction. Remove the tool and spin

off the filter.

• Lightly oil the new filter O ring seal and install the filter onto the engine. Spin it on in

a clockwise direction and finally tighten by hand only as firmly as you can.

• Refill the sump using the oil filler cap in the rocker cover on top of the engine.

• Oil level should be to the top mark on the dipstick.

• Run the engine for 5 minutes before checking the oil level with the dipstick and top

up if required.

• Do not exceed the maximum oil level marker as this may cause damage to the

internal components of the engine.

3. Air Filter Check and Change

• Release the three spring clips. Pull off the end cover to reveal the filter element.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 30 of 55

The element simply pulls out.

• To fit the new element, slide the open end of the filter element into the main body.

Gently push the element until fully seated. Refit the end cover.

• The air filter is constructed from pleated paper. Inspect it closely for dust or dirt. The

air filter cannot be cleaned and must be replaced when dirty. The engine requires

clean unrestricted air to run efficiently. Failure to maintain the air filter could result in

smoke, increased fuel consumption and ultimately engine damage. Note: Only the

single outer element is used for Marine engines.

4. Gearbox Oil Change

Note: Some engines will have an optional gearbox sump pump fitted. To change the oil in

this circumstance, follow the same procedures as were outlined for changing the engine oil.

For engines without a gearbox sump pump follow the procedure below.

• Change the gearbox oil while it is still hot (Please refer to the gearbox manual for

more information).

• Place a tray beneath the gearbox that will hold at least 5 litres.

• Replace the drain plug. Ensure that the sealing washer (if used) is still in place and

in good condition before tightening. Fit a new washer if required.

• Refill the gearbox with oil to the upper mark on the dipstick (the PRM 80 only has

one mark which is the max level mark. The PRM 60 and PRM 150 have two marks,

the top one is the max level and the bottom one is the minimum level). Refer to the

PRM owner’s manual for more details. Section 6 contains details of oil specifications.

• Do not overfill the gearbox as this can damage the internal components.

Figure 14: PRM 60

Filler Plug

Dipstick

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 31 of 55

Figure 15: PRM 80

Figure 16: PRM150 Gearbox (Optional)

5. Disposal of Oil and Related Items

• Please dispose of used oil and oil filters safely with due regard for the environment

and take to your local waste oil disposal point.

• Do not allow oil or contaminated parts to enter the inland water way system.

6. Fuel Filter Drain – Shire 15 15/20

• Place a small drain bowl under the primary fuel filter / water trap.

• Loosen the drain screw located in the bottom of the fuel filter / water trap (Figure 17)

• Drain off any water.

• Once the water has been drained, retighten the drain screw.

• It is unlikely the complete fuel system will require bleeding.

• Ensure the fuel tank is full prior to bleeding the fuel system.

• Run for 5 minutes.

• Check that the drain union is tight and that there are no leaks.

• Do not over tighten the drain screw.

Note: The boat builder must have fitted an additional water trap in the fuel system. Ensure

that this is drained regularly.

Level dipstick / Filler Plug

Level dipstick / Filler Plug

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 32 of 55

Figure 17: Fuel Filter Drain Screw

7. Fuel Filter Change

• Ensure the fuel tank is at least ¾ full prior to undertaking this procedure.

• Turn off the main boat fuel supply tap. This is located on or near the fuel tank.

• Place a small drip tray under the filter body.

• Remove the fuel filter in the same way as the oil filter in Part 1 of Section 5.

• Smear a small amount of clean fuel on all of the O ring seals that are supplied with

the new filter element.

• Screw the new element back into the filter head. Tighten by hand only.

• Turn the main boat fuel supply tap back on.

• Ensure the system is correctly bled before attempting to start up.

8. Fuel System Bleeding

• Ensure the fuel tank is at least ¾ full prior to undertaking this procedure.

• Open the bleed screw on top of the engine fuel filter.

• Operate the fuel lift pump by hand or if there is an electric fuel pump, turn the ignition

keys on.

• After the fuel filter has been purged of air, close the bleed screw.

• Undo ALL the injector pipe connections.

• Crank the engine over with the starter motor. When fuel can be seen, stop cranking.

• Tighten the injector pipe connections.

• Wipe off any excess fuel.

• Crank the engine.

• The engine should now start. If it does not start, repeat the above procedure.

• Check for any leaks and clean up any spilt fuel.

9. Cooling System

Drain Screw

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 33 of 55

CAUTION:

DO NOT CHECK THE COOLANT LEVEL WHEN THE ENGINE IS HOT. REMOVE THE

IGNITION KEY BEFORE WORKING IN ENGINE COMPARTMENT.

For All Models

• To check the coolant level, ensure that the engine has been shut down for at least

half an hour.

For Canal Boats & Work Boats

• The coolant level can be checked visually and should be between the two level

marks formed on the front of the white plastic expansion tank.

For River Boats

• Remove the lid from the water cooled exhaust manifold/heat exchanger. The level

should be ½” (13mm) below the filler neck.

For All Models

• If required, top up the level with coolant (50% clean tap water and 50% ethylene

glycol based anti-freeze) through the expansion tank filler cap.

• Do not use water only to top up as this weakens the coolant mix, reducing the level

of frost protection and anti-corrosion protection of the coolant.

10. Belt Adjustment

CAUTION:

REMOVE THE IGNITION KEY BEFORE WORKING IN ENGINE COMPARTMENT.

• Depress the longest run of the drive belt to be checked. If the travel exceeds 15-

20mm using hard finger pressure, the belt needs re-tensioning.

• Loosen the upper adjuster on the alternator. Loosen the lower mounting pivot nut

and bolt. Pull out either using hand pressure, or a small plastic/wooden lever.

• Pull the alternator away from the engine to tighten the belt.

• Hold the alternator in position and retighten all the bolts

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 34 of 55

Note: If the belts are over tightened, alternator bearing failure will occur.

11. Belt Maintenance

• Do not allow oil to contact the belt. Oil attacks the construction of the belt. This

reduces the drive efficiency and ultimately cause it to fail prematurely.

• Replace the belt if it cracks or splits and as the adjustment nears the limit of travel.

Note: Some boat builders may remove one or more of the alternators during the installation

of the engine. It is essential that when the alternators are refitted that the alignment is

perfect or premature belt wear will occur.

12. Belt Replacement

CAUTION:

REMOVE THE IGNITION KEY BEFORE WORKING IN ENGINE COMPARTMENT.

• Ensure that you have the correct replacement belts before starting this procedure.

Some engines may have been fitted with non-standard optional alternators which

may not use the belt sizes listed. Make a note of these belt sizes upon delivery.

• Loosen the top adjuster bolts and the lower mounting pivot nut and bolt.

• Push the alternator towards the engine to loosen the belt.

• Remove the belt.

• Hold the belt in position over the top alternator pulley. Rotate the engine if required

by hand, to guide the new belt into the “vee”.

• Re-tension the belt as above.

13. Control Panel Maintenance

CAUTION:

REMOVE THE IGNITION KEY BEFORE WORKING IN ENGINE COMPARTMENT.

TURN BATTERY ISOLATION SWITCHES OFF.

• To replace an illumination bulb: Release the panel from its mounting. The bulbs

are accessible from the rear of the panel. Remove the wires, unscrew the nut and

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 35 of 55

pull out the bulb housing from the panel. Remove the bulb and replace. Refit bulb

housing, screw the nut back up and refit the wires.

• To replace any gauge: Release the panel from its mounting. The gauges are

accessible from the rear of the panel. Unplug the wire connectors, unscrew and pull

the gauge out of the panel. Replace the gauge and refit. Reattach the wiring

connectors.

Note: Periodically squirt a lubricant into the key switch slot when the key has been

removed. A lubricant such as WD40 – with silicon, would be suitable. Other lubricants are

available. Then with the battery master switch turned off, operate the key switch a couple

of times. This will ensure the lubricant works into the mechanism.

14. Sacrificial Anode Change

For Work Boats

• The anode is located in the “T” fitting on top of the engine at the front facing forward

(Figure 18).

Figure 18: Work Boat Anode Location

For River Boats

• The anode is located on the water cooled manifold (Figure 19).

Figure 19: River Boat Anode Location

15. Raw Water Pump Impellor Change (Work Boat & River Boat)

• The pump is located on the front of the engine.

• Remove the pump cover plate.

• Remove the pump impeller (special tools are available from chandleries to assist

with this task).

Anode

Anode

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 36 of 55

• Note: Do not lever against the front of the pulley housing as it is easily damaged.

• Inspect the pump housing and front housing for damage or wear.

• Replace the impellor.

• Replace the cover plate gasket if damaged.

• Replace any other worn components as necessary.

16. Engine Heat Exchanger Tube Stack Flushing

For Work Boats

• When the engine is cold, drain the water from the engine block. Remove the hose

from the tap and drain.

• Drain water from the heat exchanger. The drain plug is in the bottom of the heat

exchanger end cap.

• Disconnect the pipes and hoses from the engine heat exchanger.

• Remove the heat exchanger from the engine.

• Mark the position and remove the end caps from the heat exchanger. When refitting

the end caps please ensure that they are in the same orientation as they were

previously.

• Carefully remove the tube stack from the centre of the heat exchanger.

• Fully flush between the tubes to remove any dirt of scum build up.

• Inspect the tube stack and replace if damaged.

• Reassemble and refit, checking the end cap “O” rings are in good condition.

• Refill the engine with coolant as described earlier.

For River Boats

• When the engine is cold, drain the water from the engine block. Remove the plug

from the engine block by the starter motor.

• Drain water from the heat exchanger. The drain plug is in the bottom of the heat

exchanger / water cooled manifold.

• Mark the position and remove the end caps from the heat exchanger along with the

“O” rings. When refitting the end caps please ensure that they are in the same

orientation as they were previously.

• Carefully remove the tube stack from the centre of the heat exchanger.

• Fully flush between the tubes to remove any dirt of scum build up.

• Inspect the tube stack and replace if damaged.

• Clean out the manifold if required.

• Reassemble and refit, checking the end cap “O” rings are in good condition.

• Refill the engine with coolant as described earlier.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 37 of 55

17. Winterization of Seawater Cooling System (Work Boat & River Boat)

• To prevent frost damage to the seawater cooling circuit components due to water

freezing, ensure all seawater or raw water is drained from the system.

• Alternatively, run neat antifreeze through the seawater pump inlet to protect the

system.

• Ensure that the antifreeze is drained before starting the engine during the next

season. This is to ensure that it does not get into the marine environment. Dispose

of the antifreeze correctly.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 38 of 55

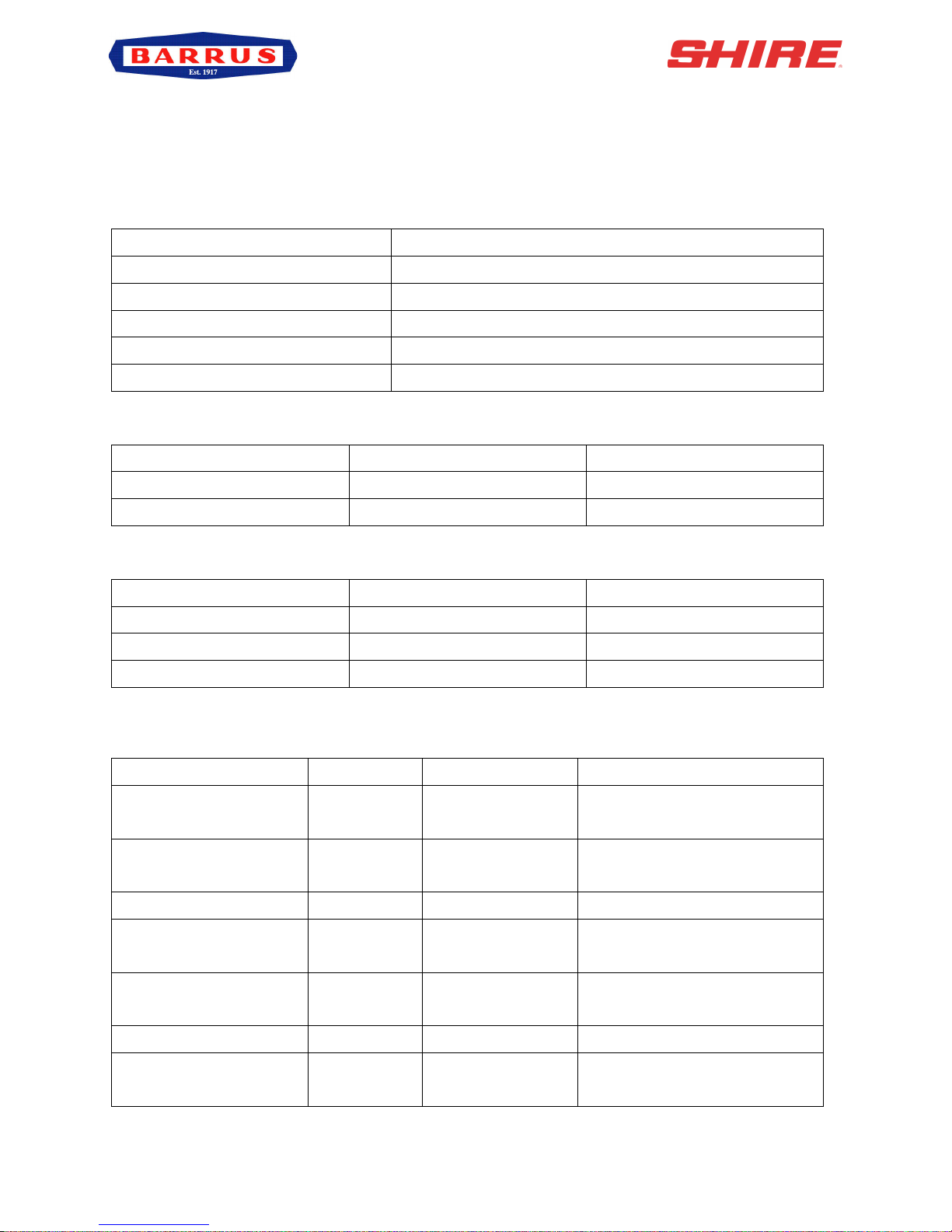

SECTION 6 – Service Schedule

1. Specifications and Capacities

Specification of Coolants and Lubricants to use:

Component

Lubricant

Engine

SAE 10W 40 API Class CD Oil

Coolant

50% Clean Water + 50% Ethylene Glycol Antifreeze

PRM 60 Gearbox

ATF (Automatic Transmission Fluid) Oil

PRM 80 Gearbox

ATF (Automatic Transmission Fluid) Oil

PRM 150 Gearbox

Engine Oil

Engine Oil Capacity (with Filter):

Engine

Capacity (Litres)

Capacity (Pints)

15

1.73 3 20

2.6

4.5

Gearbox Oil Capacity (Excluding Cooler where fitted):

Gearbox

Capacity (Litres)

Capacity (Pints)

PRM 60

0.3

0.52

PRM 80

0.57

1.0

PRM150

1.4

2.5

2. Service Intervals

Check

Change

Notes

Engine Oil & Filter

Daily (Level)

Every 150 Hours

OR 12 Months*

First change after 25 hours

Gearbox Oil

Weekly

(Level)

Every 300 Hours

OR 12 Months*

First change after 25 hours

Coolant Level

Daily (Level)

Every 24 Months

-

Diesel Fuel Filter

50 hours

Every 300 hours

OR 12 Months*

Drain water every 50 hours

OR Monthly**

Air Filter Element

150 Hours

Every 300 hours

OR 24 Months*

Sooner if required

Drive Belts

Daily

As required

Adjust as necessary

Key Switch

Lubricate

Every 150 hours

OR 12 Months*

As per instructions in Section

12 - Control Maintenance

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 39 of 55

Sea Water Pump

Impellor (WB/RB Only)

150 Hours

Every 300 hours

OR 24 Months*

Sooner if required

Sacrificial Anodes

150 Hours

Every 450 hours

OR 12 Months*

Check and change more

frequently if local conditions

require it

Main Heat Exchanger

450 Hours

Or check more frequently if

local conditions require it.

Remove & clean as per

instructions in Section 5

* Whichever occurs first.

** If large quantities of water are found in the fuel when the filter is drained, increase the

frequency of draining.

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 40 of 55

SECTION 7 – Wiring Diagrams

1. Engine Wiring Diagram Shire 15 15/20

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 41 of 55

2. Standard Control Panel Wiring Diagram

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 42 of 55

3. Deluxe Control Panel Wiring Diagram (Additional Option – SS1551)

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 43 of 55

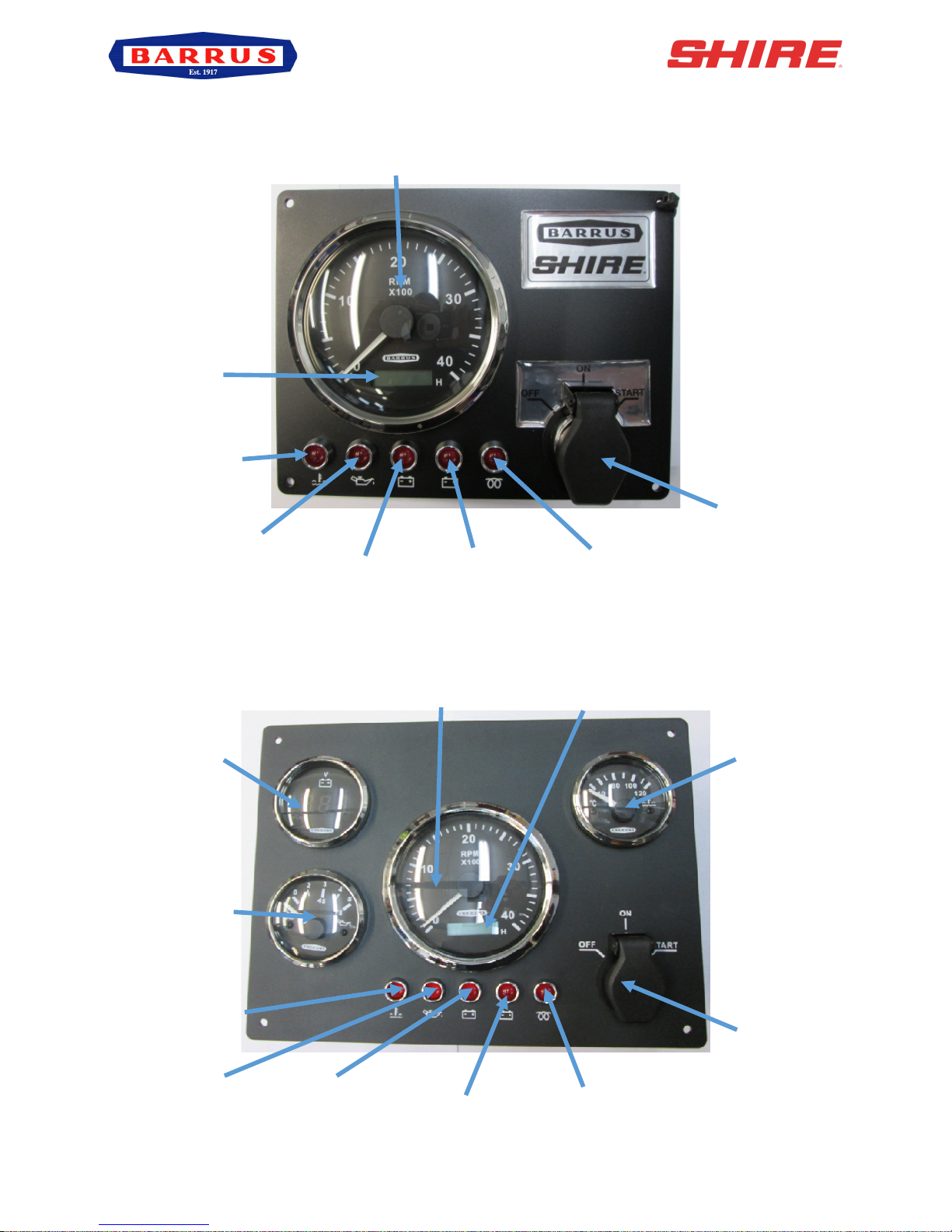

4. RDG20710110 – Standard Control Panel

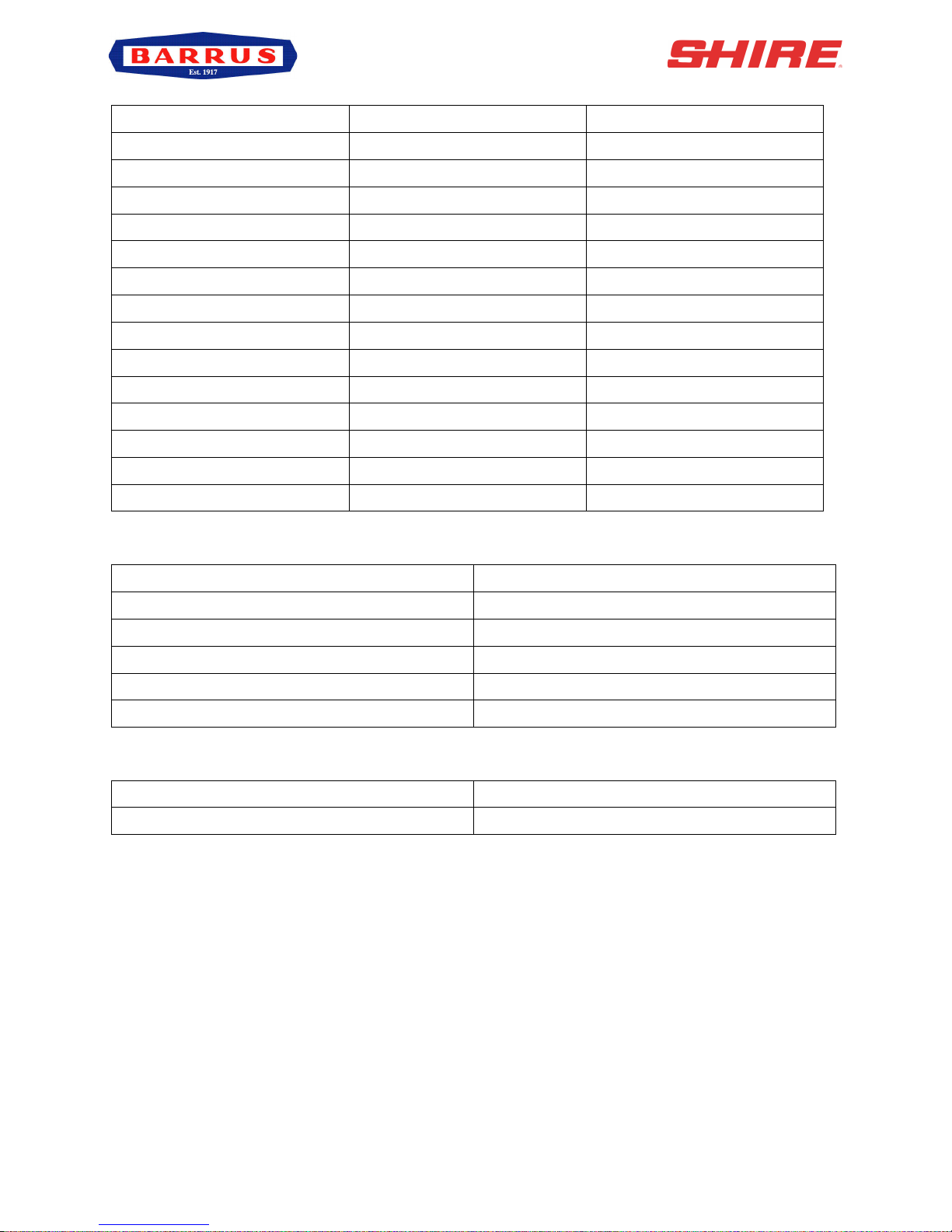

5. RDG20710111 – Deluxe Control Panel (Additional Option – SS1551)

Tachometer

Hour Meter

Water

Temperature

Warning Light

Oil Pressure

Warning Light

50A Alternator

Charge Light

Glow Plug Light

Key Flap &

Ignition Switch

50A Alternator

Voltage Output

Tachometer

Key Flap &

Ignition Switch

Glow Plug Light

50A Alternator

Charge Light

Oil Pressure

Warning Light

Water

Temperature

Warning Light

Oil Pressure

Gauge

Water

Temperature

Gauge

Hour Meter

Optional Additional

70 amp Alternator

Optional Additional

70 amp Alternator

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 44 of 55

6. Overall Dimensions of the Control Panels

RDG20710110 - Standard Control Panel (All Dimensions are in mm)

RDG20710111 – Deluxe Control Panel (All Dimensions are in mm)

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 45 of 55

SECTION 8 – Technical Data

Model

Shire 15 15

Shire 15 20

Type

In Line, Water Cooled, 4 Stroke

In Line, Water Cooled, 4 Stroke

Combustion Chamber

Swirl Chamber

Swirl Chamber

Type of Cylinder Liner

Dry

Dry

Number of Cylinders 2 3

Bore (mm)

78

78

Stroke (mm)

78.4

78.4

Displacement (L)

0.749

1.123

Compression Ratio

22.1

22:1

Firing Order

1-2

1-2-3

Rated Output/Speed (kw/r/min)

11/3000

15/3000

Max Torque/Speed (Nm/r/min)

37.4/1820

59.2/1960

Min Fuel Consumption (g/kw.h)

≤ 272

≤ 280

Lube Oil Consumption (g/kw.h)

0.272

0.272

Direction of Rotation of

Crankshaft

Counter Clockwise (View from

Flywheel End)

Counter Clockwise (View from

Flywheel End)

Lubrication System

Combination of Pressure and

Splash

Combination of Pressure and

Splash

Cooling System

Forced Water Cooled

Forced Water Cooled

Valve Timing

Intake Valve opens

8° Before T.D.C

Intake Valve closes

42° After B.D.C

Exhaust Valve opens

42° Before B.D.C

Exhaust Valve closes

14° After T.D.C

Valve Clearance (cold)

Intake Valve (mm)

0.15~0.20

Exhaust Valve (mm)

0.15~0.20

Max Speed (r/min)

≤ 3200

Idle Speed (r/min)

850~875

Fuel Injection Timing (°)

14~17°

Injection Pressure (MPa / PSI)

16~17 / 2320~2465

Max Exhaust Temperature (°C)

≤ 550

Max Oil Temperature (°C)

≤ 105

Normal Outlet Water Temperature (°C)

80~90

Oil Pressure

At Rated Speed (kPa) / (PSI)

310~413 / 45~60

At Idle Speed (kPa) / (PSI)

≥ 50 / ≥ 7.25

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 46 of 55

Fuel Injector

Model

Axis Needle Type

Fuel Injection Pump

Type

Plunger Type

Plunger Diameter (mm)

6.0

Lube Oil Pump

Type

Inner and Outer Rotors

Cooling Water Pump

Type

Centrifugal Type

Speed (r/min)

4000

Flow (L/min)

100 Lift (mW.G)

6

Starting Motor

Type

QDY1257A

Power (kW)

1.2 Voltage (V)

12

Alternator

Output (A)

50 Voltage (V)

14

Recommended Start Battery Size

Capacity (A.h)

≥ 65

Voltage (V)

12

Torques for Main Bolts

Cylinder Head bolts (Nm)

80~90

Main Bearing Cap (Nm)

50~60

Connecting Rod Bolts (Nm)

50~55

Flywheel Bolts (Nm)

80~90

Main Crank Pulley Bolt (Nm)

110~130

Main Bearing Seat Bolts (Nm)

60~70

Servicing Period

Fuel Injector Test/Replace

500 Hours

Engine Valve Clearances

500 Hours

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 47 of 55

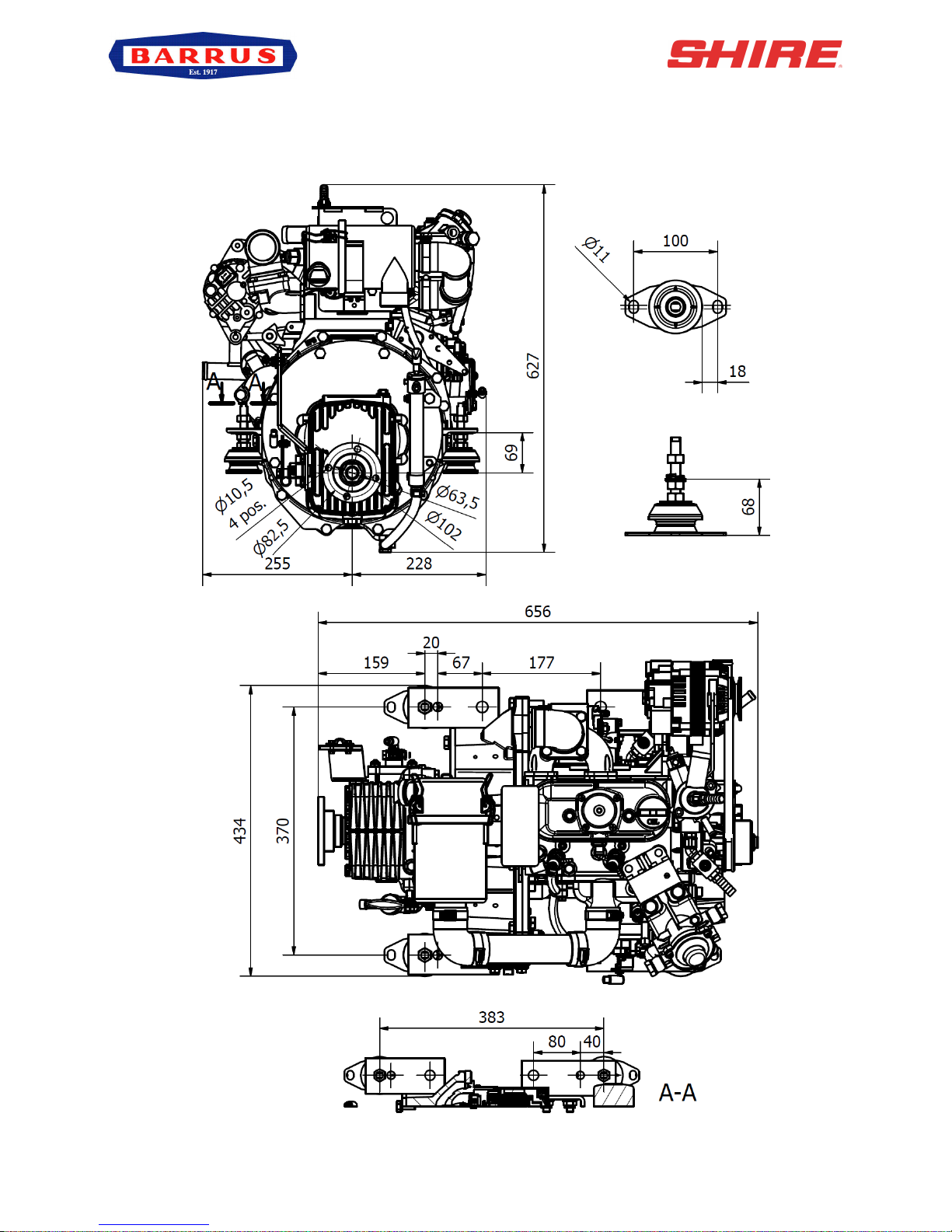

SECTION 9 – General Arrangement Drawings

1. General Arrangement Shire 15 15 Canal Boat

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 48 of 55

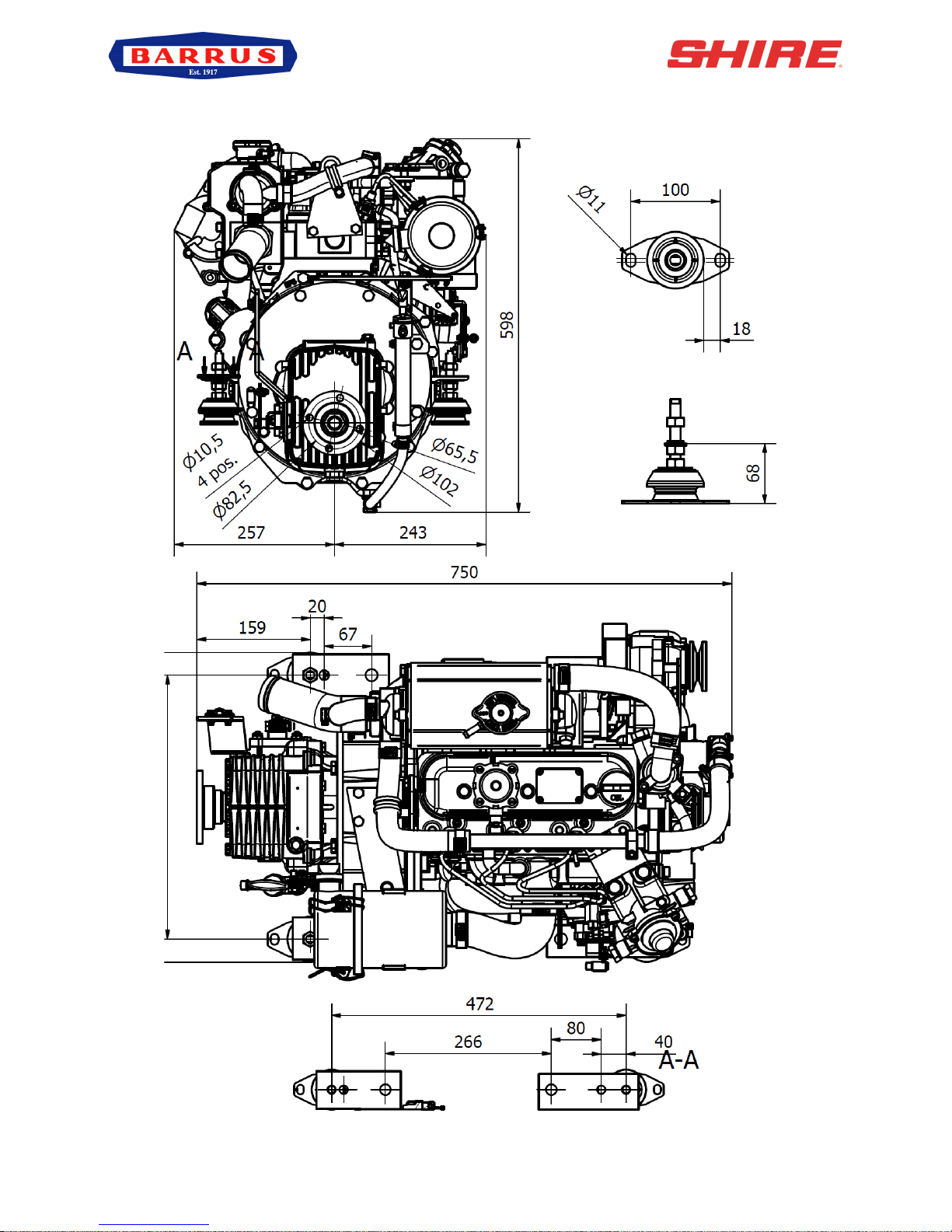

2. General Arrangement Shire 15 15 River Boat

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 49 of 55

3. General Arrangement Shire 15 20 Canal Boat

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 50 of 55

4. General Arrangement Shire 15 20 River Boat

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 51 of 55

SECTION 10 – Dealer List

Area

Company

Telephone

Email

BERKSHIRE

Bluenine Marine

01189 406482

bluenine@marine7957.fsnet.co.uk

Aquatec Marine

07880793686

sales@aquatecmarine.com

Driveline Marine

0118 942 3877

tam@drivelinemarine.com

CHESHIRE

Nantwich Canal Centre

01270 625122

info@nantwichcc.com

CORNWALL

Black Dog Marine

01503 265898

blackdogmarine@googlemail.com

Cellar Marine

01326 280214

john@cellarmarine.com

G B Smith & Son

01208 862815

info@gbsmithandson.co.uk

CUMBRIA

Windermere Aquatic Ltd

01539 442121

service@aquaticboatcentres.com

DERBYSHIRE

Midland Canal Centre

01283 701933

info@mccboats.co.uk

DEVON

Sleeman & Hawkin Ltd

01626 778266

keith@sleeman-hawkin.co.uk

Tonto Marine

01803 844399

enquiries@tontomarine.co.uk

Mobile Marine

01297 631821

mobilemarine@btconnect.com

Darthaven Marina

01803 752242

admin@darthaven.co.uk

ESSEX

French Marine Motors Ltd

01206 305233

01255 850303

info@frenchmarine.com

HAMPSHIRE

Marine Power Ltd

0238 0403918

info@marine-power.co.uk

HEREFORDSHIRE

Starline Marine

01684 593443

narrowboats@starline.demon.co.uk

HERTFORDSHIRE

P & S Marine

01923 248372

pandsmarinellp@gmail.com

LANCASHIRE

British Waterways

01257 481054

@emmalene.foster@bwml.co.uk

LEICESTERSHIRE

Foxton Boat Services Ltd

01162 792285

tony@foxton-boats.freeserve.co.uk

LONDON

De La Hunty Marine

02089 792121

delahuntymarine@btinternet.com

NORFOLK

French Marine Motors Ltd

01603 722079

info@frenchmarine.com

NORTHAMPTON

Grand Junction Boat Co.

01604 858043

grandjunco@talk21.com

NOTTINGHAM

Farndon Marina

01636 705483

info@farndonmarina.co.uk

OXFORDSHIRE

Service Engine UK

01993 835157

info@serviceenginesuk.co.uk

SHROPSHIRE

Maestermyn (Marine) Ltd

01691 662424

enquiries@maestermyn.co.uk

STAFFORDSHIRE

JD Boat Services Ltd

01902 791811

jdboats@btinternet.com

Stone Boatbuilding Company

01785 812688

sales@stonebuilding.co.uk

Streethay Warf

01543 414770

pat@streethaywarf.freeserve.co.uk

WARWICKSHIRE

Barry Hawkins Narrowboats

01827 711762

boats@hawkinsyard.freeserve.co.uk

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 52 of 55

Onboard Energy

02476 393333

sales@onboardenergy.com

Springwood Haven Leisure Ltd

0845 4566572

enquiries@springwoodhaven.co.uk

Valley Boat Services Ltd

07990528123

enquiries@valleycruises.co.uk

WEST MIDLANDS

Stephen Goldsbrough Boats

01564 778210

andy@sgboats.com

WILTSHIRE

Foxhangers Marine

01380 828795

info@foxhangers.co.uk

WORCESTERSHIRE

J L Pinder & Son

01527 876438

sales@jlpinderandsons.co.uk

Starline Narrowboats

01684 874774

narrowboats@starline.demon.co.uk

YORKSHIRE

Rodley Boat Centre

01132 576132

John.snowdenz@ntlworld.com

MONMOUTHSHIRE

Castle Narrowboats

01873 830001

castlenarrowboats@btinternet.com

EIRE

Dun Laoghaire Marine Services

00353 12104776

info@dlms.ie

O’Sullivans Marine

003536 67124524

brian@sulliansmarine.com

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 53 of 55

SECTION 11 – Shire Service Parts

Model

15/20 CB

15/20 WB

15/20 RB

Fuel Filter

RDG906A3

RDG906A3

RDG906A3

50A Alt Belt

GB/T12732-2008

GB/T12732-2008

GB/T12732-2008

70A Alt Belt (Single

Alt Engine)

GB/T12732-2008

GB/T12732-2008

GB/T12732-2008

70A Alt Belt (Twin

Alt Engine)

- - -

Air Filter Element

3011-T3-0004

3011-T3-0004

3011-T3-0004

Oil Filter

119305-35151

119305-35151

119305-35151

Sea Water Pump

Impeller

N/A

RDG010A3

RDG010A3

Sea Water Pump

N/A

RDG907A4

RDG907A4

Zinc Anti Corrosive

Anode

N/A

119574-44150

80162

Zinc Sticker

N/A

124220-09340

124220-09340

Fuses:

The electrical system is fitted with three or four blade type fuses:

a) Control Panel supply: 15amp (RDG3245)

b) Engine start control system: 15amp (RDG3245)

c) Engine stop control system: 40amp (RDG3246)

d) Glow Plug Fuse: 40amp (RDG3246)

Relays:

e) Cold Start Relay: (RDG1396)

f) Starter Relay: (RDG5279)

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 54 of 55

Engine Oil:

Engine Oil is available from your Shire Dealer in convenient 5 litre containers (Part Number

RDG6110).

Diesel Fuel Additive:

Diesel fuel additive is available from your Shire Dealer in a handy 375ml container (Part No

RDG80210219).

SECTION 12 – Shire Service Record Card

c) 40A

b) 15A

d) 40A

f) Starter Relay

e) Cold Start Relay

a) 15A

RDG603A13 – Issue 7 – Shire 15 Manual 15_20 – CB_WB_RB

Page 55 of 55

SERVICE RECORD CARD

Model: ………………………………………………………………………

Engine No: ………………………………………………………………..

Carried out by E.P.Barrus

Print Name:

Actual Hours:

Signed:

Boat Builder Stamp:

Commission of Boat and Hand Over to Customer.

(Refer to the Installation Check List Page in this

Manual).

Date:

Signed:

Dealer Stamp:

Actual Hours:

Signed:

Dealer Stamp:

Actual Hours:

Signed:

Dealer Stamp:

Actual Hours:

Signed:

Dealer Stamp:

Actual Hours:

Signed:

Dealer Stamp:

Actual Hours:

Signed:

Dealer Stamp:

Actual Hours:

Signed:

Please refer to Owner’s Manual for service intervals

PDI

1st

2nd

3rd

4th

5th

6th

Loading...

Loading...