Page 1

FIREBALL 2 AXLE SPHERE MACHINE

OWNER’S MANUAL & OPERATING INSTRUCTIONS

Manual Part # 164270

Caution: Read all safety

and operating instructions

before using this equipment

Barranca Diamond Products, Inc.

22815 Frampton Avenue

Torrance, CA 90501

Phone: 310-523-5867

Toll Free: 800-630-7682

FAX: 310-523-5869

www.barrancadiamond.com

Page 2

INTRODUCTION:

We at Barranca Diamond want to thank you for selecting the Barranca Diamond Fireball Sphere Machine.

We are certain that you will be pleased with your purchase. Barranca Diamond takes pride in producing the

nest products in the industry.

Operated correctly, your Fireball Sphere Machine should provide you with years of quality service. In order to

help you, we have included this manual. This owner’s manual contains information necessary to operate and

maintain your Fireball Sphere Machine safely and correctly. Please take a few minutes to familiarize yourself

with the Fireball Sphere Machine by reading and reviewing this manual.

If you should have questions concerning your Fireball Sphere Machine, please feel free to call Barranca

Diamond at: (310) 523-5867 or Toll Free: (800) 630-7682.

TABLE OF CONTENTS

SAFETY

Safety Precautions 3

Safety Procedures 5

California Proposition 65 Message 5

Product Specifications 6

Setup

Contents 7

Unpacking & Assembly 7

Transport 7

Operation & Adjustment

Pre-start Inspection

Startup

Sphere Grinding 10

Sphere Polishing 11

8

9

Maintenance 12

Trouble Shooting 13

Parts List 14

Customer Service 16

Ordering Information 16

Return Material Policy 16

Packaging Instructions 16

Warranty 16

Barranca Diamond Fireball Sphere Machine Manual Effective Date 9/28/062

Page 3

SAFETY PRECAUTIONS

Read and follow all safety, operating and maintenance instructions. Failure to read and follow these

instructions could result in injury or death to you or others. Failure to read and follow these instructions

could also result in damage and/or reduced equipment life. In order to prevent injury, the following safety

precautions should be followed at all times!

KEEP GUARDS IN PLACE

In order to prevent injury, keep guards in place and in working order at all times.

ELECTRICAL SHOCK!

Never touch electrical wires or components while the motor is running. Exposed, frayed or worn electrical

motor wiring can be sources of electrical shock that could cause severe injury or burns.

ACCIDENTAL STARTS!

Before starting the motor, be sure the ON/OFF switch is in the “OFF" position to prevent accidental starting.

Place the ON/OFF switch in the OFF position and unplug cord prior to servicing, repairs or maintenance.

ROTATING OR MOVING PARTS

Keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never operate a power tool

with shrouds or guards removed.

ALWAYS USE SAFETY GLASSES

Safety glasses should always be worn when working around power tools. Everyday eyeglasses only have

impact resistant lenses and may not prevent eye injury; they are NOT safety glasses.

ALWAYS USE HEARING PROTECTION!

To reduce the possibility of hearing loss, always use hearing protection when operating equipment.

REMOVE ADJUSTING KEYS AND WRENCHES

Form a habit of checking to see that keys and adjusting wrenches are removed from the power tool before it

is turned on.

KEEP WORK AREA CLEAN

Cluttered work areas and benches invite accidents.

DO NOT USE IN DANGEROUS ENVIRONMENTS

Do not operate equipment in dangerous environments. Always keep the work area well lighted.

KEEP CHILDREN AWAY

All visitors and children should be kept a safe distance from work area.

MAKE WORKSHOP KID PROOF

Make the workshops kid proof by using padlocks, master switches or by removing starter keys.

DO NOT FORCE THE TOOL

A power tool will do a job better and safer operating at the rate for which it was designed.

USE THE RIGHT TOOL

Do not force a tool or an attachment, to do a job that it was not designed to do.

WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry that may be caught in moving

parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

3

Page 4

DO NOT OVERREACH

Keep proper footing and balance at all times by not overreaching.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for the best and safest performance. Always follow maintenance instructions for

lubricating and when changing accessories.

SHUTDOWN TOOL

The machine should always be shutdown before servicing or when changing accessories.

USE RECOMMENDED ACCESSORIES

Consult the owner’s manual for recommended accessories. Using improper accessories may increase the

risk of personal or by-stander injury.

NEVER LEAVE TOOL RUNNING UNATTENDED – TURN POWER OFF

Do not leave a tool until it comes to a complete stop. Always turn a power tool OFF when leaving the work

area, or, when a cut is finished.

CHECK FOR DAMAGED PARTS

Before using a power tool, check for damaged parts. A guard or any other part that is damaged should be

carefully checked to determine it would operate properly and perform its intended function. Always check

moving parts for proper alignment or binding. Check for broken parts, mountings and all other conditions

that may affect the operation of the power tool. A guard or any damaged part should be properly repaired or

replaced.

Barranca Diamond Fireball Sphere Machine Manual Effective Date 9/28/064

Page 5

Safety Procedures

The following tips and procedures should be closely followed during grinding and polishing of rock specimens

in your Fireball Sphere Machine:

1) Always read the instructions manual included with the machine prior to use and call the factory or dealer

if any questions or problems should arise.

2) Do not use excessively long drop cords. A good 14 gauge extension drop cord can be used, but should

the motor shut off automatically it may indicate the cord is too thin and long for the circuit and motor

amperage. When in doubt, use short cords at least 14 gauge in thickness and no longer than 25 feet in

length.

3) Never attempt to touch or grab sphere material or grinding/polishing cups while the machine is in

operation. The sudden and strong cup torque and rotation can cause serious injury to the operator.

4) Hand protection (plastic gloves) and a shop bib are recommended during sphere machine use to prevent

stains to clothing. Avoid prolonged exposure of skin to the grinding water and wash skin immediately after

contact. Do not touch the work material (sphere) until the motor is off and the sphere material has come

to a complete stop.

5) Always use the belt guards in their mounted positions. Belts should only be changed with all power

sources disconnected. Any and all maintenance and servicing should be done without any power source

connection as well.

6) Keep caster wheels locked whenever machine is not being moved.

7) Use of a Ground Fault Interrupter Switch between the end of power cord and wall outlet is required at all

times.

8) The Fireball Sphere Machine is only to be used with a 120 volt 60 HZ power source. Insure power source

is at least 15 amps.

WARNING

Sawing, grinding, and drilling generates dust. Excessive airborne particles may cause irritation to eyes, skin

and respiratory tract. To avoid breathing impairment, always employ dust controls and protection suitable

to the material being sawed, ground, or drilled; See OSHA (29 CFR Part 1910.1200). Diamond Blades

improperly used are dangerous. Comply with American National Standards Institute Safety Code, B7.1 and,

Occupational Safety and Health Act covering Speed, Safety Guards, Flanges, Mounting Procedures, General

Operating Rules, Handling, Storage and General Machine Conditions.

CALIFORNIA PROPOSITION 65 MESSAGE WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other activities contain chemicals known

[to the State of California] to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead, from lead-based paints

• Crystalline silica, from bricks and cement and other masonry products

• Arsenic and chromium, from chemically treated lumber

• Asbestos forming minerals

Your risk from these exposures varies depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

5

Page 6

Fireball Sphere Machine Specications

Motor Baldor VM3545

Horsepower 1 HP

Motor Voltage 220V / 50-60 Hz

Input Voltage 120V / 60 Hz

Amperage 7 Amps

Motor RPM Range 115 to 1725

Shaft RPM Range 50 to 120

Arbor Size 1/2"-13 thread

Adjustable Speed Drive Controller Baldor 1D150201-ER

Max Sphere Size 8" Diameter

Machine Dimensions L x W x H 70" x 24" x 48"

Dry Weight 650 lbs.

Part Number 8303000

Motor

Single phase, continuous duty. Baldor VM3545 motor does not contain automatic thermal protection or reset

button.

Grinding Head Drive Mechanism

Stainless steel rod with belt and pulley system. Moveable grinding head is adjusted by hand crank screw rod.

Cooling/Flushing System

Submersible electric water pump feeds a nozzle directed water ushing system using a plastic collection pan.

Nozzle is on a magnetic mount and is manually adjusted. Submersible pump should only be used with clean

and not with water recycled from collection pan.

Shaft Bearings

Sealed ange mount ball bearings with zerk ttings for grease lubrication. Double sealed, watertight shaft

bearing below grinding area.

Engagement/Disengagement Control

Lever operated clutch system using silicon bronze shoe with block (adjustable set screws).

Indexing of Moveable Grinding Head

Crank handle operated stainless steel screw system to adjust horizontal position of moveable grinding cup.

Vertical angle of cups position adjusted by knob screws (2).

Frame Legs

14 gauge steel construction with locking casters.

ON/OFF Power Control

Variable speed power controller and toggle switch box.

Barranca Diamond Fireball Sphere Machine Manual Effective Date 9/28/066

Page 7

CONTENTS

In the wood crate, you will nd one Barranca Diamond Fireball Sphere Machine, one set of 3-1/2" sphere

grinding cups, one set of 4-1/2" sphere grinding cups, one set of 3-1/2" Velcro resin pad mounting cups, one

set of 4-1/2" Velcro resin pad mounting cups, one set of 4" resin diamond pads, one set of 5’" resin diamond

pads, owner’s manual, warranty card, and 4 leg casters.

UNPACKING & ASSEMBLY

Your Fireball Sphere Machine has been shipped from the factory thoroughly inspected and tested. Remove

the machine from the pallet by unbolting legs from crate pallet and place it on a at surface. Install casters

on legs – one at a time. Grease threads prior to installing cups. Do not over-tighten the grinding cups prior to

use.

TRANSPORT

Fireball Sphere Machines weights 650 pounds dry. Do not attempt to move a machine that is not mounted

on casters without assistance. Ensure caster wheels are locked when in transport or when in use to prevent

machine from rolling away.

Be sure power cord is disconnected.

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

7

Page 8

PRE-START INSPECTION

Once the Fireball sphere machine has been uncrated and the caster wheels installed on the frame legs,

position the machine in a level work area. Prior to attaching the desired set of sphere diamond grinding cups

to the fixed and moveable heads determine which size cups to use based on the rock material diameter to

be ground into a sphere shape. The preparation of the rock material can be performed by slab sawing a

cube into a 26 faced pre-formed block shape or diamond drilling (core drilling) a cube 3 to 4 cuts to remove

material prior to grinding the 8 high points on a bench grinder or angle grinder to as close a sphere shape as

possible.

A pre-start power test should be performed before attaching the sphere grinding cups by attaching a power

cord (extension 14 gauge) to the male plug attached to the aluminum ON/OFF lever switch box. Turn ON/OFF

lever to the ON position and open the power Baldor Adjustable Speed Drive controller cover to access the

front panel of the drive controller. The button marked FWD (forward) should be pushed first to engage power

to the grinding cups through the motor to gear box to grinding heads.

Drive Controller & Switch Box Drive Controller Front Panel

Press the button marked (UP arrow) to increase the grinding head rotational speed from a low of

50 RPM incrementally in steps to 115 RPM. The use of the button (DOWN arrow) will incrementally

decrease the grinding head rotational speed as well. Because of the 10 to 1 gear reduction and 33% pulley

reduction the actual shaft RPM is as follows: Display RPM x 0.1 (gear reduction) x 0.33 (pulley reduction). For

example, 1249 RPM on the display will result in a shaft RPM of 41.2. To shut off power and rotational speed

to the grinding heads push the button marked STOP and this will reduce the grinding head rotational speed

to zero at which time the power toggle switch ON/OFF lever should be turned to the OFF position. Once the

lever on the aluminum power box is put in the OFF position all power to both the Baldor Adjustable Speed

Drive-Motor-Grinding Heads and submersible pump (if hooked up to the auxiliary plug receptacle) will be shut

off.

Barranca Diamond Fireball Sphere Machine Manual Effective Date 9/28/068

Page 9

START UP

Prior to placing the sphere cups on the grinding head shafts, open the moveable head to a position along

the horizontal plane of the sphere machine. This is done by first loosening the brass nut on the thread bar

adjacent to the crank handle and rotating it along the shaft a few inches (fig. 1).

Fig. 1 Brass nut loosened Fig. 2 Brass nut tightened

This will allow free adjustment of the moveable head to the desired position. Liberally grease the head shaft

threads prior to installing sphere cups. Place a sphere cup on each of the 1/2"-13 threaded shafts of both the

fixed and moveable heads and hand tighten snuggly against the sphere cup holder face. The cups can be

tightened with use of a pipe wrench on the sphere cup shank to ensure cups are snuggly secured to the 1/2"13 thread (do not over tighten). Once cups are attached, place rock sphere material between cups and slowly

rotate crank wheel by hand (clockwise) stopping at a point that still allows some rotation of sphere material

between cups. Once adjusted to desired position, lock the threaded horizontal adjustment brass nut against

the plate adjacent to the crank handle (fig. 2). Do not over-tighten.

Once the sphere material is in place between the grinding cups and the moveable head is adjusted and

locked, connect the water pump to the base of the Loc-Line hose manifold and submerge the pump in a 5

gallon bucket of water. Adjust the tip of the Loc-Line nozzle to direct water flow as close to the top of the

sphere material as possible. A constant flow of water onto the sphere material must be maintained to flush

the grindings and keep the diamond cups and pads (when Velcro pad mounting cups are used) in good

condition. Any loss of water to the grinding surface of the diamond cups or polishing resin pads during use of

the machine will likely result in short diamond tool life. You can reduce or increase the waterflow to the LocLine nozzle by adjusting the flow restrictor that crimps the clear tubing between the Loc-Line assembly and

the water pump.

Loc-Line hose in position Waterflow restrictor

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

9

Page 10

SPHERE GRINDING

Initial sphere grinding with the diamond grinding cups is critical to obtaining a near equal dimension sphere

shaped solid prior to moving to the diamond resin pad polishing phase. Due to the high points of the

pre-formed block of material due to slab sawing a cube into a 26 faced solid or diamond core bit drilling,

significant impact and rough grinding of this non-spherical shaped solid occurs in the preliminary grinding

(sphere shaping) phase. Once the sphere material is ground to the closest sphere shape per the user’s

discretion, the grinding cups (2) can be removed and the Velcro lined pad holder cups can be installed on the

stationary and moveable heads. If during the rough sphere grinding phase the material appears to be forming

a shape other than a sphere with near equal X, Y, and Z radii dimensions, it would be prudent to check the

following possible causes:

1) Sphere material is rotating in a preferred procession or orbital path hence the block is not being

randomly ground in all directions. This often results in an ellipsoidal shaped solid (i.e. egg shaped). Use

the 3/4" hard plastic rod to keep the sphere material rotating in a random grinding rotation. Adjust rod

position to keep rod in constant contact with the sphere.

3/4" hard plastic rod in place Motor control display

2) Experiment with slower and faster turning speeds (rotation RPM) of the stationary and moveable

grinding heads by adjusting the RPM of the machine at the motor variable velocity controller using

the UP and DOWN arrows. These adjustments are step by step or incremental depending

on how much pressure is kept on these UP or DOWN arrows. Range of output shaft velocity is 0 to

115 RPM. Because of the 10 to 1 gear reduction and 33% pulley reduction the actual shaft RPM is as

follows: Display RPM x 0.1 (gear reduction) x 0.33 (pulley reduction). For example, 1249 RPM on the

display will result in a shaft RPM of 41.2. The user will have to determine by trial and error based on the

type of material being used how fast or slow the turning velocity of the moveable and stationary head will

need to set to.

3) Grinding pressure can be increase or decreased using the horizontal threaded rod crank. Loosen lock nut

and turn handle clockwise to decrease pressure or counter clockwise to increase pressure. Be sure

to retighten lock nut after each adjustment. This adjustment can be performed while grinding cups are

turning.

Grinding head lock nut handle Grinding head height adjustment knob

Barranca Diamond Fireball Sphere Machine Manual Effective Date 9/28/0610

Page 11

SPHERE POLISHING

The sphere grinding phase will require the most attention as it is the users inspection of the material and

shape that determines if the sphere is ground to his or her satisfaction. On soft materials (i.e. travertine,

serpentine, fluorite, etc.) the time to “rough out" or grind the preformed block into a sphere shape is

significantly less than the time to grind out a sphere of hard and dense lapidary materials such as jasper,

jade, agate, quartz, etc. Therefore, experience from trial and error will dictate how much time the user must

devote to rough sphere grinding. High grinding velocities do not necessarily yield shorter rough sphere

grinding time. The user will have to closely monitor the sphere block during course grinding to determine if a

sphere has been obtained.

Once the sphere material is ground to the user’s satisfaction and the cups are changed to the Velcro lined

resin pad holder cups, the first diamond resin pad that should be placed in the holder cup is dependent on

the severity of scratches and marks that need to be removed from the material and its relative hardness. For

example, a soft material like travertine can be rapidly polished to remove scratches from the grinding cups

using a 120 and or 220 grit pad wedges. Harder materials like agate and jasper require more aggressive pads

(i.e. 30 or 50 grit) to remove stubborn grinding phase scratches and high spots.

Once the stubborn scratches are removed with the resin diamond wedges in the Velcro lined holder cups

in the 30 to 220 grit range, the final sequence of polishing to a high mirror like finish will be performed in

the diamond grit range of 400, 800, 1800, 3500, 8500, and 13,000 mesh resin diamond wedges. An even

higher final finish can be obtained with cerium, aluminum, or tin oxide polishing compounds if felt wedges (not

included with machine) are used. For most lapidary material the use of the 13,000 grit diamond pads will yield

a satisfactory polish.

FINAL TIPS ON USE OF DIAMOND RESIN WEDGES FOR POLISHING

The following tips should be adhered to by the user to obtain the highest mirror polish on the sphere material:

1) Rinse and clean each diamond resin wedge with a tooth brush and clean water after each use. Be sure to

dry pads after cleaning and store in a sealable plastic bag.

2.) Do not reuse water from collection pan. Only pump clean water to nozzle from a 5 gallon bucket.

3) Rinse clean completely the slurry catch plastic pan after each grit size change. The pad holder cups

should be cleaned as well between pads with a toothbrush and clean water.

4) Ensure resin diamond wedges are placed securely inside the holder cups and that the Velcro is in good

condition and affixed securely to the cast iron inside of the cups to prevent the pads from shifting or falling

out during polishing. Periodically, the user will have to remove the Velcro strips and replace with new

Velcro strips (super glue epoxy is recommended to hold the Velcro strips securely).

Velcro pad holder cup

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

11

Page 12

MAINTENANCE

The Fireball Sphere Machine is assembled with factory applied grease to the adjusting threads for the

horizontal and vertical threaded bars. The user should regrease all grease fittings on the stationary and

moveable head thread zerk fittings and the base mount bearings on the drive shaft every 15 to 20 days of use

with premium wheel bearing grease. There are 3 main zerk fittings for greasing the base mount sealed ball

bearings.

The center (white) base mount bearing has waterproof seals to cope with the abrasive nature of the rock

material and water/slurry that falls on this bearing. Do not over grease the bearings (base mount) as the seals

may be damaged (one or two pumps of a lever pump action gun is all that is needed for each bearing every

15 to 30 days of use).

There are two grease zerk fittings on the vertical adjustments on both grinding head mount (one on the

outside and one on the inside). These fittings should be greased every 15 days of use. Periodically apply

grease by hand to the threads of the horizontal threaded rod.

Center base mount bearing End base mount bearing

Grinding head external zerk fitting Horizontal threaded rod and grinding

head internal zerk fitting

Barranca Diamond Fireball Sphere Machine Manual Effective Date 9/28/0612

Page 13

The 10:1 gearbox attached to the 1 HP Baldor motor (1725 RPM) does not need to be lubricated with gearbox

oil as this is a sealed unit. Should any gear box oil be observed leaking from the shaft seals be sure to call

Barranca Diamond before resuming use of the Fireball Sphere Machine.

The Fenner “flexible" segmented belts can withstand significant strain due to the movement of the grinding

heads during vertical adjustments. Should a belt link break, these links can be readily purchased from most

auto supply stores, Motion Industries, Inc. or McMaster Carr Supply Co. Individual links can be replaced with

use of a wrench or pliers.

Fenner segmented belt

TROUBLESHOOTING

Machine Will Not Start

Check power cord and receptacle. Check GFCI switch, push reset button and attempt to restart grinding

heads at variable speed panel. Push ON button and increase RPM by depressing UP arrows. RPM of

grinding heads will increase or decrease each time either the UP or DOWN arrow buttons are depressed

Sphere Materials Locking or Hanging up and Belts Slipping

Stop machine, loosen locking nut on horizontal threaded rod and rotate crank handle clockwise to increase

gap between grinding heads. Sphere material must turn freely between grinding heads for proper operation.

Retighten locking nut once moveable head is correctly adjusted. Horizontal crank handle adjustment can be

performed while grinding heads are turning.

No Water Delivered to Loc-Line Nozzle

Check submersible pump to see if functioning properly. Pump flow should be uninterrupted so a constant

stream of water leaves the tube prior to entering the Loc-Line magnetic base. Flow restrictor (in line crimp)

should be loosened and readjusted to desired flow. Excessive flow is not required, only enough water to flush

grindings/slurry, and cool diamond cups/pads.

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

13

Page 14

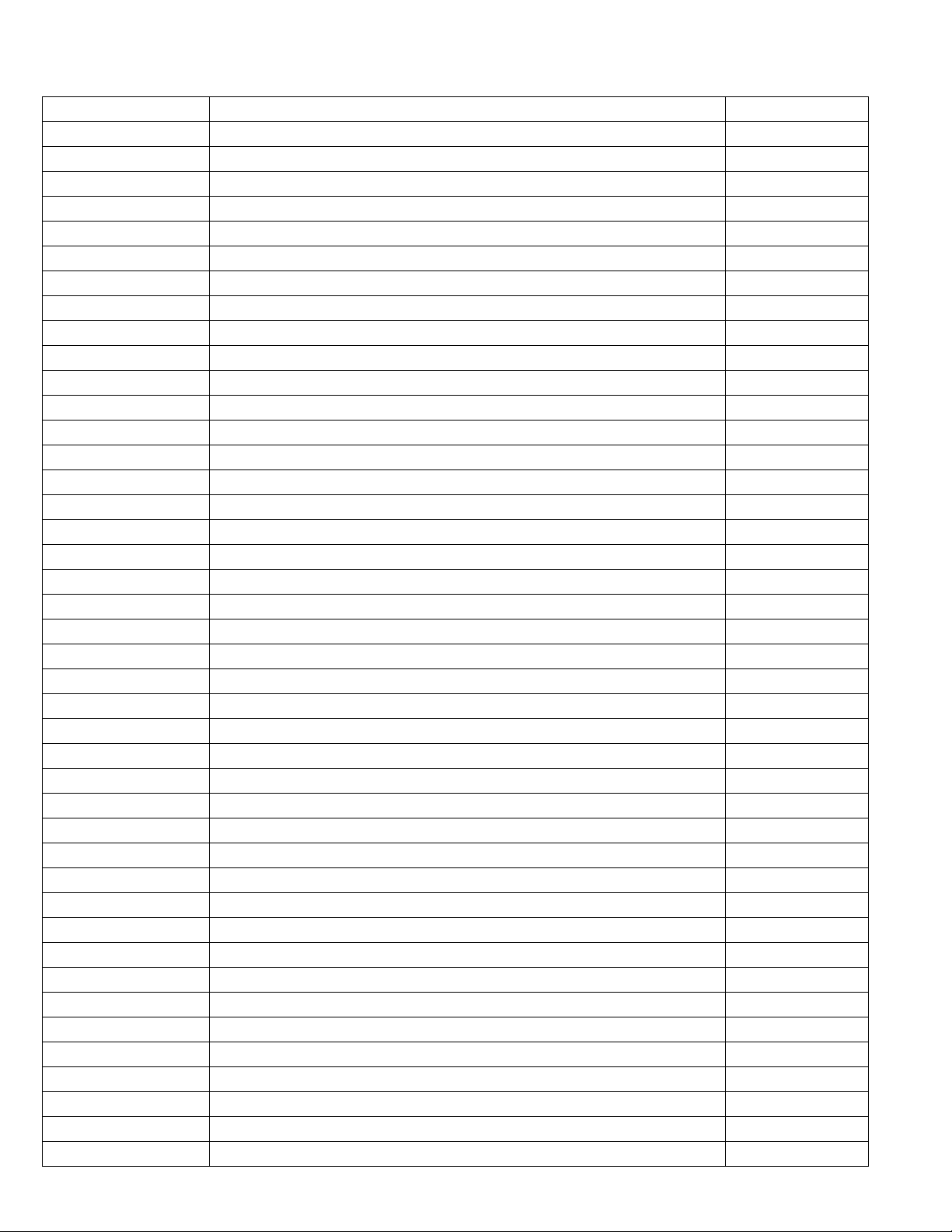

Parts List Fireball Sphere Grinding/Polishing Machine

Part # Part Description/Specification Quantity

VM3546 Motor, Baldor, 1HP, 220v, 60Hz 3 Phase 1725 RPM 56C 1

ID15J101-ER AC Inverter (variable speed control) 120 volts, 50/60Hz 1

GF1818AG Gear reducer box 10:1 Baldor 918 series 1

135855 Linear bearing assembly, MK-1O1 frame 2

134759 Bar, chrome plated, 3/4" MK-1O1 guide bar 2

5968K43 Bearing, flange mount, 3/4" bore 2

6670K21 Bearing, flange mount 3/4" bore stainless inserts waterproof 1

1517771 Cover, guide bar MK-101 2

152393 Spacer, guide bar nylon MK-1O1 4

154636 Arbor shaft assembly 3/4 shaft MK-2000/5000 2

98805A036 Rod, threaded 3/4-16 stainless 20"

88915K71 Rod, solid 3/4 stainless 48"

6867K67-7/8 Gear, spur 4" OD 48 teeth 14.5 degree angle 7/8" bore no hub 1

6867K67-3/4 Gear, spur 4" OD 48 teeth 14.5 degree angle 3/4" bore 1

6432K21 Collar, 3/4" bore zinc plated 2

6204K21 Pulley, cast iron 3/4" bore x 4" OD 2

6204K32 Pulley, cast iron 3/4" bore x 6" OD 2

100375V38105 Fenner belt, 1/2" wide x 36" 1

JFI-2024-24 Igus bushing synthetic 1-1/4" OD 2

NA Garlock bushing, synthetic 3/4" ID x 7/8" OD x 3/4" Long 3

523009 Cup to shaft 3/4" adaptor, custom 1/2"-13 thread steel 2

10095K49 Loc-Line manifold for nozzle 1/4" hose 1

10095K11 Loc-Line hose assembly 1/4" hose 13 inch long 1

155987 Pump, Lil’ Giant submersible MK-370 saw 1

6022K38 Handle, crank revolving, aluminum dished 6" OD 1

60205K49 Knob, stainless threaded blind hole 1/2"-20 2

157736 Pan, plastic MK-370 saw 1

9949T96 Wheel, caster 3" x 1-1/4" with swivel brake 4

92620A745 Cap screw, 1/2"-20 x 1-1/4" zinc plated 4

97345A700 Shoulder bolt 1/2"-20 x 1-1/4" zinc plated 4

159865 Box, aluminum switch MK-212 30 Amp 1

159539 Cover, switch box MK-212 1

159489 Plate, switch box MK-212 1

159490 Lever, switch box MK-212 On/Off 1

158799 Bushing, switch box MK-212 1

159492 Seal, lever switch, MK-212 1

159491 Gasket, cover MK-212 1

159909 Cord, 18/3 SJTW x 5-1512 MK-212 1

7082K23 Cord, 14/3 SJEOW 300 VAC 60"

152610 Ground fault circuit interrupter switch 110 volts 15 amps 1 1

91105 Diamond sphere grinding cup 4-3/4" OD x 1/2"-13 thread 2

91106 Diamond sphere grinding cup 5-3/4" OD x 1/2"-13 thread 2

Barranca Diamond Fireball Sphere Machine Manual Effective Date 9/28/0614

Page 15

91105blnk Velcro lined resin pad holder cup 4-3/4" OD x 1/2"-13 thread 2

91106blnk Velcro lined resin pad holder cup 5-3/4" OD x 1/2"-13 thread 2

374009 Diamond resin pad set 4" OD (30, 50, 120, 220, 400, 800,1800,

3500, 8500, 10,000, 13,000) wedge cut for holder

375009 Diamond resin pad set 5" OD (30, 50, 120, 200, 400, 800, 1800,

3500, 8,500, 10,000, 13,000) wedge cut for holder

2 set 11pc. per

set

2 set 11pc. per

set

8695K175 3/4" diameter black polyurethane 80a durometer 4" long 2 pc.

92174A470 Nut, hex jam brass 3/4"-16 1 pc.

Barranca Diamond Products Phone: 310-523-5867 www.barrancadiamnd.com

15

Page 16

ORDERING INFORMATION

You may order Barranca Diamond products through your authorized Barranca Diamond distributor

Parts may be ordered directly from your Barranca Diamond distributor or Barranca Diamond Products.

Please have the following information ready before calling:

• The model and serial number of the machine

• Date of purchase

• Distributor’s name

• The part description for the parts or accessories being ordered

RETURN MATERIALS POLICY

For return items, call Barranca Diamond at (310) 523-5867.

To expedite the service relative to the return of a product purchased through Barranca Diamond, please

observe the following:

NOTE: Return items must have been purchased within the previous twelve (12) months.

• Have the model number and serial number of the machine.

• Have the date when the machine was purchased.

• Have the dealer’s name.

• Contact Barranca Diamond customer service for approval to return the item(s).

• Obtain a returned Goods Authorization number (RGA) authorizing the return from Barranca Diamond

Products.

• Ensure your item(s) are prepaid to the destination

• A warranty card must be on le with Barranca Diamond Products with correct serial number.

• Follow the packaging instructions in the following section

PACKAGING INSTRUCTIONS

If transporting on wooden skid, remove caster wheels and bolt down legs to skid. If transporting without the

use of a skid, make sure caster wheels are locked and unit is securely strapped to vehicle.

Warranty Period

1 year from date of purchase against material or manufacturing defects in workmanship or material failure.

Warranty does not cover against misuse of machine or neglect of maintenance. Electric motors damage by

misuse, low voltage, long drop cord, etc. are not covered by the warranty. Baldor and Leeson motors can be

repaired at a local service center. Barranca can provide a list of authorized Baldor or Leeson repair centers in

your area.

Warranty Against Defects

Barranca Diamond Products guarantees the Fireball Sphere Grinding Machine against defective materials

and factory defects which may have occurred during assembly or damage during shipping. Defective parts

or assembly problems should be brought immediately to the attention of the dealer and Barranca Diamond.

Repair parts and components are available and can be shipped. Please call Barranca Diamond should any

problems or defects be found. Customer service can be obtained by calling us at (310) 523-5867 or (800)

630-7682. Damaged electric motors should be repaired at an authorized Baldor or Leeson motor repair

center.

Disclaimer

Barranca Diamond Products, Inc. does not guarantee that a user’s methods and materials will always yield a

sphere to his/her satisfaction. Sphere making is a challenging task requiring quality material, user patience,

persistence and awareness at all times.

Barranca Diamond Fireball Sphere Machine Manual Effective Date 9/28/0616

Loading...

Loading...