Page 1

CAB COMBO WORKSHOP

OWNER’S MANUAL AND

OPERATING INSTRUCTIONS

04.2013Revision 104

Manual Part# 164271

Caution: Read all safety and operating

instructions before using this equipment.

This manual MUST accompany the

equipment at all times.

Barranca Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

Toll-Free: (800) 630-7682

Phone: (310) 523-5867

Fax: (310) 257-3063

www.barrancadiamond.com

Page 2

TABLE OF CONTENTS

Thank you for selecting the Barranca Diamond Cab Combo Workshop. We are certain that you will be

pleased with your purchase. Barranca Diamond takes pride in producing top quality products for hobbyists and commercial lapidary users throughout the world. This product is manufactured in the United

States.

This owner’s manual contains information necessary to operate and maintain your Cab Combo Workshop safely and correctly. Operated correctly, the Cab Combo Workshop should provide you with

years of service. Please take the time to familiarize yourself with the Cab Combo Workshop by reading

and reviewing this manual.

If you should have questions concerning your Cab Combo Workshop, please call Barranca Diamond

at: (310) 523-5867 or Toll Free: (800) 630-7682.

TABLE OF CONTENTS

SAFETY

Safety Precautions 3

California Proposition 65 Warning 6

Electrical Requirements 7

PRODUCT SPECIFICATIONS 9

SETUP

Contents 10

Unpacking 10

Transport 10

Installation of Blade 11-12

Rock Vise 13

OPERATION AND ADJUSTMENT

Pre-Start 14

Start-Up 15

Pump Set-Up 16-17

Needle Valves 17

Drain Valves 17

Trim Sawing 18

Diamond Wheels 18-19

Expandable Drum & Resin Belts 20

Polishing with Diamond Paste 20

Polishing with Leather Buff Pad 21

MAINTENANCE

Diamond Wheel Replacement 22

Coolant Replacement 27

Belt 27

Blade Arbor & Pulleys 28

Electric Motor 28

Diamond Blade 29

Submersible Pump 30

EXPLODED VIEW & PARTS LIST 32-36

WARRANTY 37-39

2

Page 3

CAB COMBO WORKSHOP SAFETY

SAFETY PRECAUTIONS

Read and follow all safety, operating and maintenance instructions. Failure to read and follow

these instructions could result in injury or death to you or others. Failure to read and follow these

instructions could also result in damage and/or reduced equipment life. In order to prevent injury, the

following safety precautions should be followed at all times!

READ OWNER'S MANUAL BEFORE USE

Before using this equipment, ensure that the person operating this machine has read and

understands all of the instructions in the manual. Precaution is the best insurance against accidents.

Read and understand all safety precautions, messages, warnings and hazard symbols. You are

responsible for your own safety.

ALWAYS USE SAFETY GLASSES

Safety glasses should always be worn when working around power tools. In addition, a face, dust

mask or respirator should be worn if a cutting operation is dusty. Everyday eyeglasses only have

impact resistant lenses and may not prevent eye injury - they are NOT safety glasses.

USE PROPER APPAREL

Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry that may be caught in

moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair.

Hand protection (plastic gloves) and a shop bib are recommended during sawing to prevent stains to

clothing. Avoid prolonged exposure of skin to the sawing lubricant and wash skin immediately after

contact. Do not touch the work material until the motor is off and the machine has come to a complete

stop.

ALWAYS USE HEARING PROTECTION

To reduce the possibility of hearing loss, always use hearing protection when operating power

equipment.

KEEP GUARDS IN PLACE

In order to prevent injury, never operate the saw without the guards in place!

REMOVE ADJUSTING KEYS AND WRENCHES

Form a habit of checking to see that keys and adjusting wrenches are removed from the power tool

before

it is turned on.

ELECTRICAL SHOCK

Never touch electrical wires or motor components while the motor is running. Exposed, frayed or worn

electrical wiring and plugs can be sources of electrical shock that could cause severe injury or burns.

Use the GFCI (Ground Fault Circuit Interrupter Switch) included with the unit attached to the main

motor power cord plug and keep plugged into the power receptacle outlet source.

3

Page 4

CAB COMBO WORKSHOP SAFETY

DISCONNECT TOOLS

Power tools should always be disconnected before servicing or when changing accessories, such as

blades, bits, cutters and the like.

REDUCE THE RISK OF UNINTENTIONAL STARTS

Make sure the ON/OFF switch is in the OFF position before plugging in a power tool.

ROTATING OR MOVING PARTS

Keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never operate the

engine with covers, shrouds or guards removed.

MAINTAIN TOOLS WITH CARE

Keep tools clean for the best and safest performance. Always follow maintenance instructions for

lubricating and when changing accessories.

KEEP WORK AREA CLEAN

Cluttered work areas and benches invite accidents.

DO NOT USE IN DANGEROUS OR HAZARDOUS ENVIRONMENTS

Do not operate equipment in dangerous or hazardous environments. Do not use power tools in damp

or wet locations nor expose them to rain. Always keep the work area well lighted. Always work in a

well ventilated area.

KEEP CHILDREN AWAY

All visitors and children should be kept a safe distance from the work area. Keep power cords

disconnected when tool is not in use.

MAKE THE WORKSHOP KID-PROOF

Make the workshops kid-proof by using padlocks, master switches and by disconnecting all power

cords.

USE THE RIGHT TOOL

Do not force a tool or an attachment to do a job that it was not designed to do.

SECURE WORK

Clamps or a vise should be used to hold work whenever practical. Keeping your hands free to operate

a power tool is safer.

DO NOT FORCE THE TOOL

A power tool will do a better job and operate more safely at the feed rate for which it was designed.

USE THE RIGHT TOOL TO SERVICE THE SAW

Do not force a tool or an attachment when servicing or operating the Cab Combo Workshop. Use the

correct tools for service or adjustments.

4

Page 5

CAB COMBO WORKSHOP SAFETY

DO NOT OVERREACH

Keep proper footing and balance at all times by not overreaching.

DO NOT OPERATE A TOOL WHEN TIRED

When tired, take a break and relax.

DIRECTION OF FEED

Always feed work into a blade or cutter in the direction shown in this manual. All blades, grinding

wheels or polishing belts should always be installed such that rotation is in the direction of the arrow

imprinted on the blade, wheel or belt.

ONLY OPERATE AT THE PROPER SPEED

Severe personal injury and damage to the motor or equipment can result if operated at speeds above

maximum.

NEVER LEAVE A TOOL RUNNING UNATTENDED – TURN POWER OFF

Do not leave a tool until it comes to a complete stop. Always turn the tool off, and disconnect the

power cord to its source, when leaving the work area or when work is finished. Do not leave extension

cords attached to the power cord or power receptacle (wall outlet) when leaving the work area.

CHECK FOR DAMAGED OR WORN PARTS

Before using a power tool, check for damaged parts. A guard or any other part that is damaged

should be carefully checked to determine if it would operate properly and perform its intended

function. Always check moving parts for proper alignment or binding. Check for broken parts and

mountings and all other conditions that may affect the operation of the power tool. A guard, or any

damaged part, should be properly repaired or replaced.

USE RECOMMENDED ACCESSORIES AND PARTS

Consult the owner’s manual for recommended accessories and parts. Using improper parts and

accessories may increase the risk of personal and/or bystander injury.

USE THE PROPER EXTENSION CORD

If using an extension cord, make sure it is in good condition first. When using an extension cord,

be sure to use one heavy enough to carry the current your product will draw. An undersized cord

will cause a drop in line voltage that will result in a loss of power and overheating. Table on page 8

shows the correct AWG (American Wire Gauge) size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

USE A GROUND FAULT CIRCUIT INTERRUPTER

Use of a Ground Fault Circuit Interrupter (GFCI) between the end of power cord and wall outlet is

required at all times.

USE THE PROPER POWER SOURCE

This tool is only to be used with a 120 volt 60 HZ power source. Ensure power source is at least 15

amps and 110 to 120 volts. Low voltage current can adversely effect electric motor performance and

overall life.

5

Page 6

CAB COMBO WORKSHOP SAFETY

USE THE RECOMMENDED COOLING AND LUBRICATING FLUIDS

Never operate a tool dry that requires coolant or lubricant. This can lead to shortened tool life, tool

damage and personal injury.

MAINTAIN TOOLS WITH CARE

Keep the diamond blade sharp, the sawing lubricant clean and reservoir filled to the correct level

for the best and safest performance. Always follow the maintenance instructions for sharpening the

blade, lubricating and servicing the Cab Combo Workshop.

SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in their composition

may give off dust or mists containing crystalline silica. Silica is a basic component of sand, quartz,

brick clay, granite and numerous other minerals and rocks. Repeated and/or substantial inhalation of

airborne crystalline silica can cause serious or fatal respiratory diseases, including silicosis. In addition, California and some other authorities have listed respirable crystalline silica as a substance

known to cause cancer. When cutting such materials, always follow respiratory precautions.

Use appropriate NIOSH-approved respiratory protection where dust hazard may occur. Paper masks

or surgical masks without a NIOSH approval number are not recommended because they do little to

protect the worker. For more information about respirator programs, including what respirators have

received NIOSH approval as safe and effective, please visit the NIOSH website at:

http://www.cdc.gov/niosh/topics/respirators

Observe OSHA regulations for respirator use (29 C.F.R.§1910.134 and §1503.1).

Visit http://www.osha.gov for more information.

CALIFORNIA PROPOSITION 65 MESSAGE

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contain chemicals known (to the State of California) to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead, from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium, from chemically treated lumber

For further information, consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/docs/96-112/

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

Your risk from these exposures varies depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well-ventilated area, and work with approved safety

equipment, such as the dust masks that are specially designed to lter out microscopic particles.

Where use of a dust extraction device is possible, it should be used. To achieve a high level of dust

collection, use an industrial vacuum cleaner.

6

Page 7

CAB COMBO WORKSHOP SAFETY

ELECTRICAL REQUIREMENTS AND GROUNDING INSTRUCTIONS

In order to prevent potential electrical shock and injury, the following electrical safety precautions and

symbols should be followed at all times!

In case of a malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance with all local codes and ordinances.

• Do not modify the plug provided – if it will not fit the outlet; have the proper outlet installed by a

qualified electrician.

• Improper connections of the equipment-grounding conductor can result in a risk of electric shock.

The equipment-grounding conductor is the wire that has a green outter surface, with or without

yellow stripes. If repair or replacement of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

• Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

• Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that

accept the tool’s plug.

• Repair or replace a damaged or worn cord immediately.

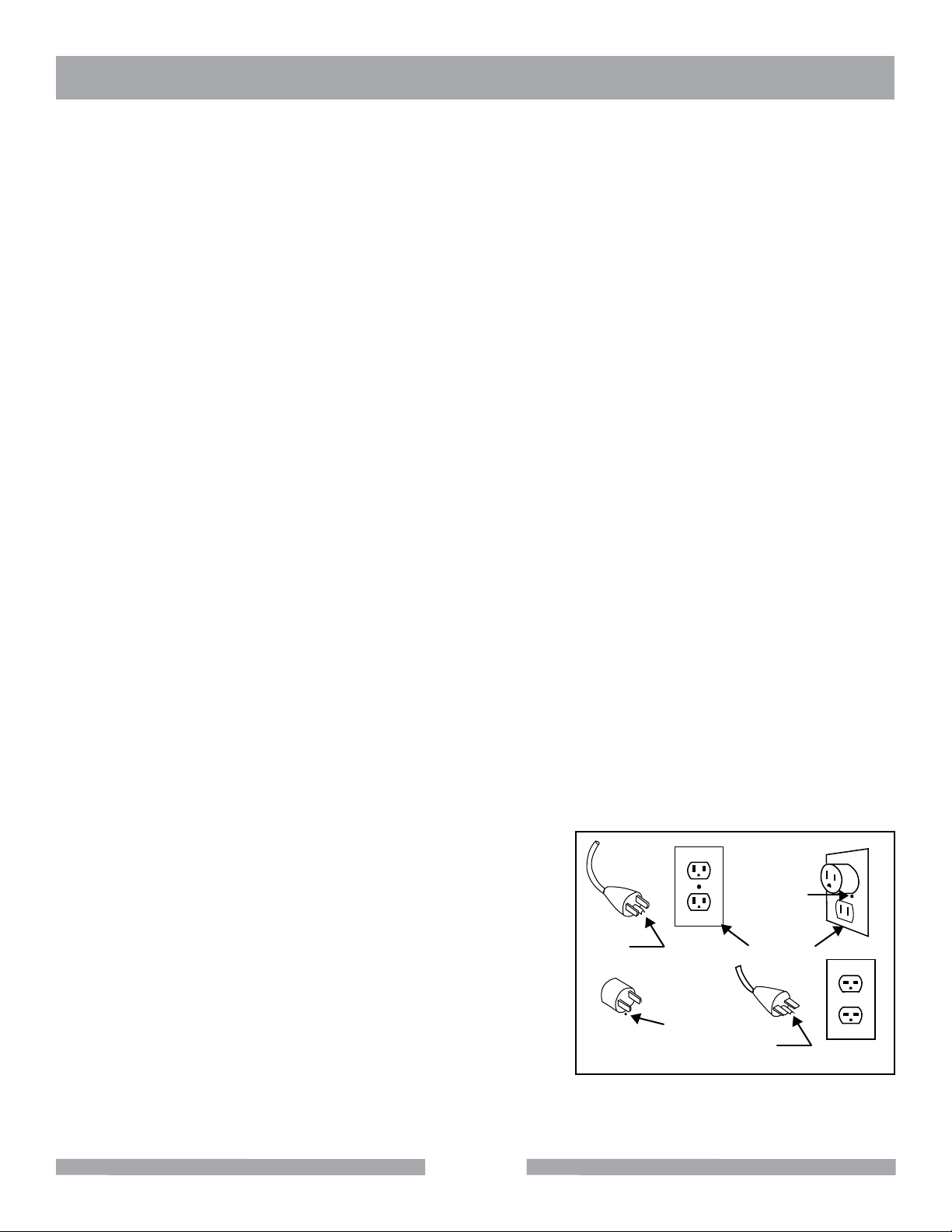

This tool is intended for use on a circuit that has an outlet that looks like the one shown in Sketch A.

The tool has a grounding plug that looks like the plug illustrated in Sketch A. A temporary adapter,

which looks like the adapter illustrated in sketches B and C, may be used to connect this plug to a

2-pole receptacle as shown in Sketch B, if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet can be installed by a qualied electrician. The green-colored rigid ear, plug, and the like, extending from the adapter, must be connected

to a permanent ground, such as a properly grounded outlet box.

NOTE: Use of a temporary adapter is not permitted in Canada.

To reduce the risk of electrocution, keep all connections dry

and off the ground.

(A)

Metal Screw

Cover of

Grounded

Outlet Box

Grounding

Pin

(B)

(D)

A Ground Fault Circuit Interrupter (GFCI) should be provided

on the circuit(s) or outlet(s) to be used for this power tool.

Receptacles are available, having built-in GFCI protection, and

may be used for this measure of safety.

When using an extension cord, the GFCI should be installed

closest to the power source, followed by the extension cord,

and lastly, the saw.

Grounding

Pin

ADAPTER

Grounding

Means

(C)

Circuit and Adapter Information

7

Page 8

CAB COMBO WORKSHOP SAFETY

ELECTRICAL REQUIREMENTS AND GROUNDING INSTRUCTIONS

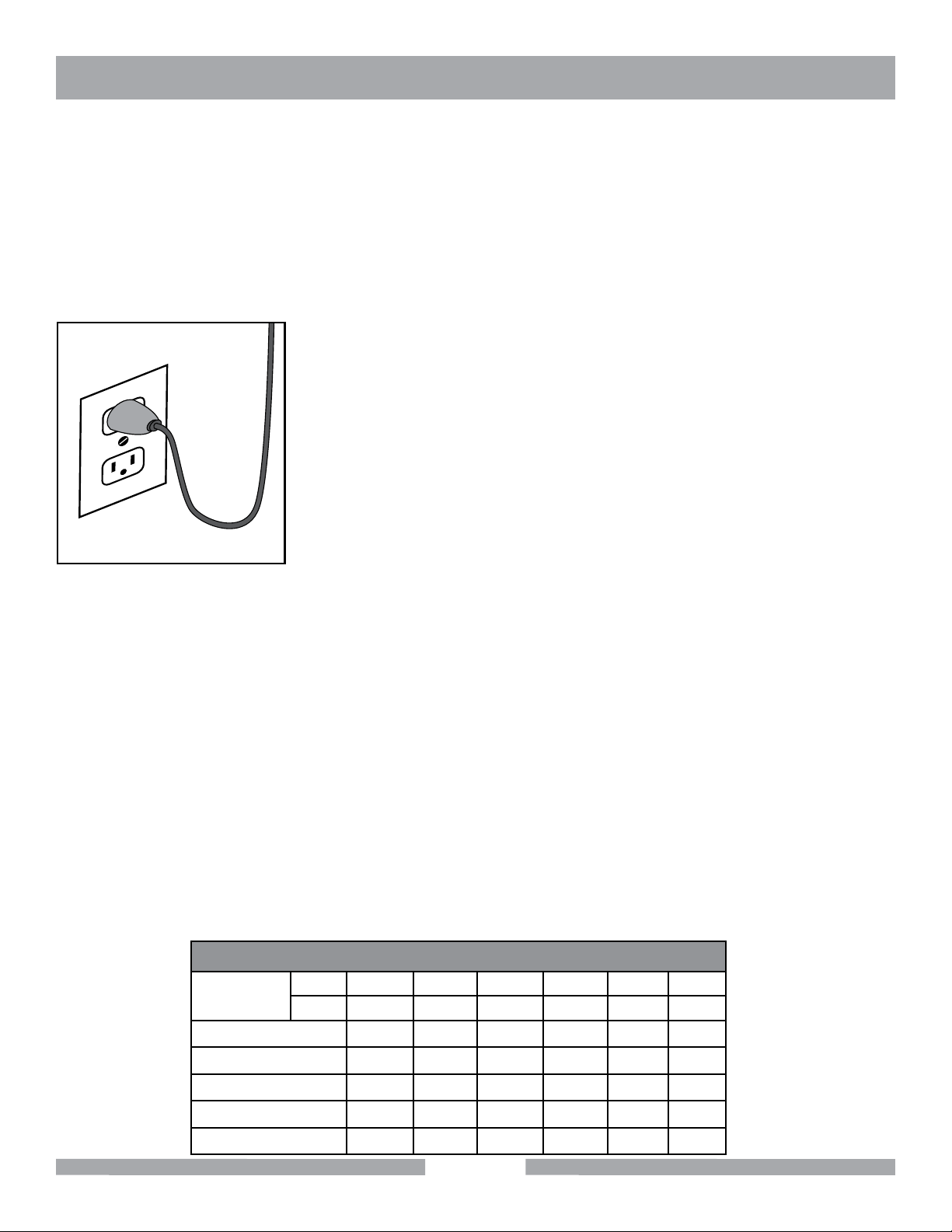

To avoid the possibility of the appliance plug or receptacle getting wet, position the tool to one side of

a wall mounted receptacle. This will prevent water from dripping onto the receptacle or plug. A “drip

loop," shown in Fig 2, should be arranged by the user to properly position the power cord relative to

the power source.

The “drip loop" is the part of the cord below the level of the receptacle, or the connector, if an

extension cord is used. This method of positioning the cord prevents the travel of water along the

power cord and coming in contact with the receptacle.

If the plug or receptacle gets wet, DO NOT unplug the cord. Disconnect

the fuse or circuit breaker that supplies power to the tool. Then unplug

and examine for presence of water in the receptacle.

Use only extension cords that are intended for outdoor use. These

extension cords are identified by a marking “Acceptable for use with

outdoor appliances; store indoors while not in use." Use only extension

cords having an electrical rating not less than the rating of the product.

Drip Loop

edges. Always disconnect the extension cord from the receptacle before disconnecting the product

from the extension cord.

Do not use damaged extension cords. Examine extension cords before

using and replace if damaged. Do not abuse extension cords and do not

yank on any cord to disconnect. Keep cords away from heat and sharp

To reduce the risk of electrocution, keep all connections dry and off the ground. Don't touch the plug

with wet hands.

Use of undersized extension cords will result in low voltage to the motor that can result in motor

burnout and premature failure. Barranca Diamond warns that equipment returned to us showing signs

of being run in a low voltage condition, through the use of undersized extension cords, will be repaired

or replaced totally at the customer's expense. There will be no warranty claim.

To choose the proper extension cord:

• Locate the length of extension cord needed in Table below.

• Once the proper length is found, move down the column to obtain the correct AWG size required for

that length of extension cord.

EXTENSION CORD LENGTH

Nameplate

Amperes

0 - 5 16 16 16 14 12 12

5.1 - 8 16 16 14 12 10 •

8.1 - 12 14 14 12 10 • •

12.1 - 15 12 12 10 10 • •

115V 25' 50' 75' 100' 150' 200'

250V 50' 100' 150' 200' 300' 400'

15.1 - 20 10 10 10 • • •

8

Page 9

CAB COMBO WORKSHOP SPECIFICATIONS

CAB COMBINATION WORKSHOP SPECIFICATIONS

Part #8300011 Carbide wheels and diamond belts

Part #8300012 Diamond wheels and diamond belts

Part #8300010 Carbide configuration without motor, GFCI, switch & base board

Part #8300013 Diamond configuration without motor, GFCI, switch & base board

Part #8300014 No wheels, belts, blade, GFCI, switch, motor, base board or polishing

supplies

Horsepower 1/3 HP

Motor Voltage/Frequency 110 volt/60 Hz

Amperage 5.8 Amps

Motor RPM 1725

Motor Arbor Diameter 1/2"

Duty Continuous, automatic thermal protection shut-off

Motor Arbor Bearings Ball bearings, permanently sealed

Blade Capacity 6" diameter

Saw Lubricant Oil or water with rust inhibitor (Tool Cool)

Motor and Shaft Pulley 2" OD x 5/8" bore (shaft) and 2" OD x 1/2" bore (motor)

Shaft Bearings Permanently sealed 5/8" OD shaft ball bearings

Blade Arbor Flanges 2" OD x 5/8" bore aluminum

Maximum Depth of Cut Not to exceed 1" for most cuts

Brazed Diamond Wheel 80 and 200 grit

Diamond Resin Belts 400, 600, 1200 and 3000 grit 6" x 1-1/2" wide belt size

Expandable Rubber Drum 6" x 1-1/2" wide x 5/8" arbor

Shaft Type 5/8" precision-machined stainless steel

Wheel and Blade Flanges Aluminum 2" OD x 5/8" bore

Wheel Spacers 7/8" OD x 5/8" ID aluminum (length varies for wheels and drum)

Convex Polishing End Hub 6" aluminum hub disc with 5/8"-11 right hand thread

Lubricant capacity of reservoir tank: 1/4 gallon will cover 1/4" of 6" blade.

Pump: MK Submersible pump (part #155987-VP), variable flow control with 1/4" ID tubing.

Water Control Valves: 3 stainless steel control valves, brass lever cock valve with barb for 1/4" ID tubing mounted on rear of the hood.

ON/OFF Switch Box: Lever operated switch box and pigtail female plug receptacle for submersible

pump.

Standard Polishing Supplies: Three 6" Polytex pads, three diamond paste syringes (5 grams ea.),

diamond paste (8,000, 14,000 and 50,000 grit), 6" leather buffing pad, 100 grit green silicon carbide

blade sharpening stick (1" x 1" x 6"), 3M On-Off cement, submersible pump, 1/4" ID clear tubing, 3/8"

ID clear tubing and GFCI.

9

Page 10

CAB COMBO WORKSHOP SETuP

CONTENTS

In the shipping crate, you will find one Barranca Diamond Cab Combo Workshop, one 6" x 0.020 x 5/8"

303 Pro diamond blade, one Ground Fault Circuit Interrupter (GFCI) and one 1" x 1" x 6" sharpening

stick.

If included as part of your specific order you will also find a variety of accessories.

UNPACKING

Your Cab Combo Workshop has been shipped from the factory thoroughly inspected and tested. Remove the crating material (wood and plastic) from the baseboard and around the machine carefully using Phillips and standard screwdrivers, and a box cutter knife. Any accessories should be removed from

the unit and put aside.

TRANSPORT

For safe transport, lubricant should be removed from the saw tank coolant and wheel reservoirs of the

Cab Combo Workshop. Removal of the 6" diamond blade is recommended to prevent damage during

transport.

10

Page 11

CAB COMBO WORKSHOP SETuP

INSTALLATION OF BLADE

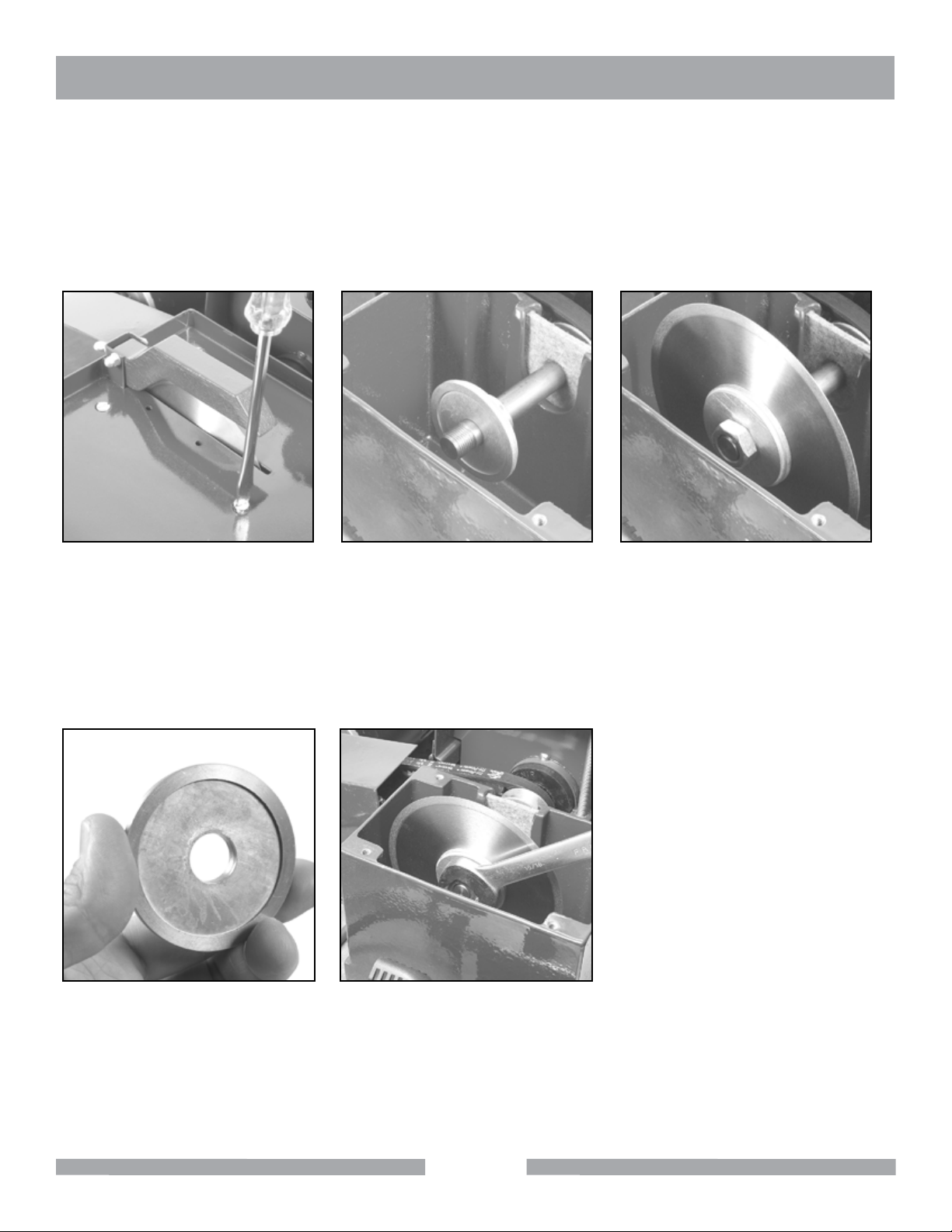

Remove the saw table by unscrewing the four flat-head machine screws (fig 1) that secure the table

to the reservoir tank. Remove the saw table and the cork gasket installed between the saw table and

reservoir tank.

Remove the diamond blade from its carton and mount on the 5/8" blade arbor between the two aluminum flanges (fig 2 & 3) with the concave sides of the flanges facing the blade (fig 4).

Fig 1 - Four flat-head machine screws

secure the saw table to the reservoir

tank

Fig 2 - Inner flange on shaft Fig 3 - Outer flange and nut installed

on shaft

A 5/8"-18" left-hand fine-thread jam nut secures the flanges and blades to the arbor shaft. When installing the blade, use an adjustable wrench to turn the nut counterclockwise to tighten the nut against

the arbor flange (fig 5). Do not over-tighten the jam nut.

Fig 4 - Concave side of flange Fig 5 - Tightening the blade on the

arbor shaft

The included 303 Pro diamond blade is manufactured to cut in a petroleum, mineral, or synthetic

water-soluble lubricant. Although water can be used with the Cab Combo Workshop, it is not recommended as the steel arbor shaft and blade core can rust. In addition, poor sawing performance and

short blade life can result. If water must be used, it is recommended that a rust inhibitor be added,

such as Tool Cool (8 oz. to 1 gallon water or one tablespoon per tank).

11

Page 12

CAB COMBO WORKSHOP SETuP

INSTALLATION OF BLADE (continued)

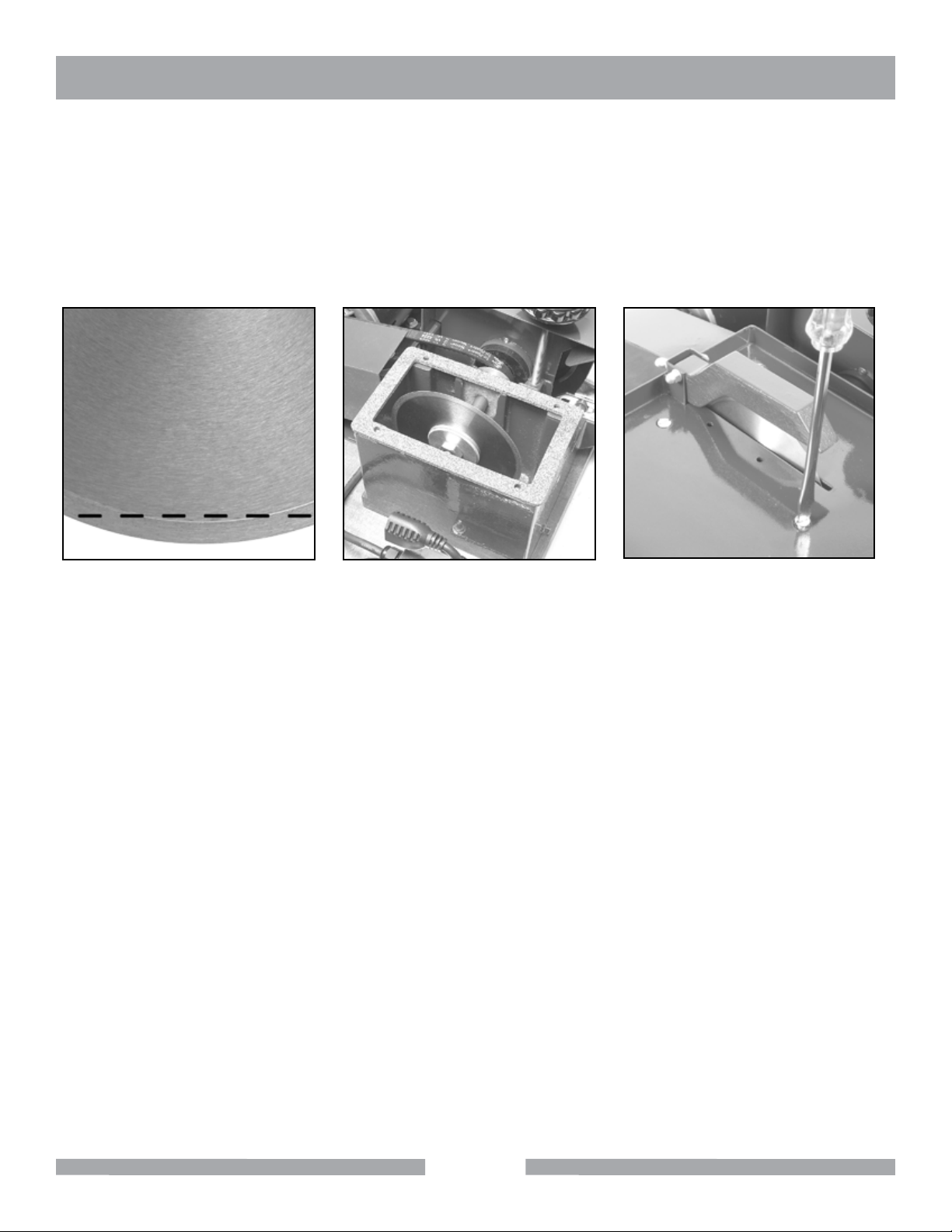

Fill the coolant reservoir so that the lubricant fluid covers the bottom 1/4" of the blade (fig 6). Do not

overfill the oil reservoir, as excess fluid will result in unnecessary spraying of fluid while sawing, possibly causing damage to the arbor bearings and motor. Once the lubricant has been added, position the

cork gasket on top of the reservoir (fig 7) and reattach the saw table with the four mounting screws (fig

8).

Fig 6 - Fill the coolant reservoir so that

the lubricant fluid covers the bottom

1/4" of the blade

Fig 7 - Cork tank gasket in place prior

to mounting saw table

Fig 8 - Attach the saw table by

installing and tightening the 4 flat

head machine screws

12

Page 13

CAB COMBO WORKSHOP SETuP

Rock Vise

A trim saw rock vise assembly (part number 8300015 - fig 9) is optional with the Cab Combination

Workshop. This assembly is purchased separate from the unit as it does not come as standard

equipment with the Cab Combo Workshop (diamond or carbide). The vise can be ordered as an assembly, ready to be installed on the trim saw table to enable the user to securely hold gemstone material while trimming to the desired thickness.

Fig 9 - Trim saw rock vise Fig 10 - Rear acorn nut being fastened

to the 5/16" sliding rod

The rock vise assembly comes with a 5/16" diameter stainless steel slider rod which fastens into the

trim saw table top through two mounting holes. Once the vise is secured to the table with the two

acorn nuts fastened to the 5/16" sliding rod (fig 10 & 11), the vise is ready for use. The jaws (metal and

wood plates) are opened by loosening the wing nut studs (fig 12) and moving the jaws to the desired

position to secure the material to be cut. The user can index the cross feed or adjust for parallel slab

cuts to a desired gemstone thickness by loosening the cross feed lock on the back of the vise (fig 13)

and turning the cross feed thumb screw on the left side of the vise (fig 13) to the desired position. User

should periodically lubricate the slider rod by smearing a small amount of wheel-bearing grease on the

surface of the rod.

Fig 11 - Rock vise secured to saw

table

Fig 12 - Wing nut studs Fig 13 - Cross feed lock (right) and

cross feed thumb screw (left)

13

Page 14

CAB COMBO WORKSHOP OPERATION AND ADJuSTMENT

PRE-S TART

Remove the belt guard and check to see that the belt is properly tensioned. Finger tip pressure on the

belt (halfway between the motor and drive shaft pulleys) should show approximately 1/2" of belt deflection (fig 14). If the belt requires adjustment, loosen the motor mounting bolts and move the motor

slightly toward the saw to decrease belt tension or away from the saw to increase belt tension. Tighten

the motor mount bolt and recheck the belt tension. When the belt is properly tensioned, check that all

motor mount bolts are securely tightened and replace the belt guard.

Check all 4 motor mount bolts (fig 15), motor arbor pully setscrew (fig 16), blade/wheel shaft pully

setscrew (fig 17), belt guard mounting nuts and saw table mounting machine screws to make sure they

are tight.

Fig 14 - Checking belt deflection Fig 15 - Motor mount bolts (one on either side of the

motor and two under the rear of the motor)

Fig 16 - Motor arbor pulley Fig 17 - Blade/wheel shaft pulley

14

Page 15

CAB COMBO WORKSHOP OPERATION AND ADJuSTMENT

START-UP

Place the Cab Combo Workshop on a strong flat table or bench. A power

test can now be conducted to make sure the motor is operating and all

moving wheels and blades are correctly aligned and secured to the main

shaft. Plug the enclosed Ground Fault Circuit Interrupter (GFCI) Switch

into a 110 to 120 volt 60 Hz minimum 15-amp circuit wall outlet (fig 18).

If needed, plug an extension cord into the GFCI. If an extension cord is

used, use one that is at least 14-gauge wire and no longer than 25 feet.

The Cab Combo Workshop power cord is attached to the ON/OFF switch

box on the left side of the unit. Make sure the switch box lever is in the

OFF (fig 19) position before plugging into the GFCI or extension cord.

To energize and test the GFCI, push the RESET button (fig 20) on the

switch and a red window will appear to indicate the switch is energized. If

the TEST button is pushed, the switch will click off indicating the GFCI is

functioning correctly.

Fig 18 - GFCI

Fig 19 - Power switch in the OFF

position

Fig 20 - GFCI reset button Fig 21 - Power switch in the ON

position

The Cab Combo Workshop is now ready for a power up test to be performed. Turn the lever to the ON

position (fig 21) on the switch box. Make sure no unusual sounds or vibrations occur when the motor

engages. If the shaft or motor pulley should loosen, they may hit the sides of the saw tank, hood, motor or belt guard causing a rubbing noise. If this happens, shut off the unit, unplug the power cord from

the switch box and adjust, align, and securely retighten the pulleys with an Allen wrench. Liquid thread

locker (removable type) can be used on the setscrew threads to prevent loosening.

15

Page 16

CAB COMBO WORKSHOP OPERATION AND ADJuSTMENT

PUMP SET-UP

A submersible electric water pump is used to supply water to the polishing wheels as coolant and

lubricant. The pump has a flow control adjustment on one side and should be adjusted for maximum

water intake (fig 23). It is recommended that a 5 gallon bucket be used as a water reservoir into which

the submersible pump should be placed. The level of the reservoir water should be monitored so that

water pump always remains fully submerged.

Fig 22 - Pump inlet adjustment set to

minimum flow

Fig 23 - Pump inlet adjustment set to

maximum flow

Fig 24 - Water pump hose attached to

pump outlet

Connect the pump to the brass ON/OFF barbed lever valve at the rear of the hood with the included

1/4" ID water hose. Insert one end of the 1/4" ID water hose over the water pump outlet (fig 24) and the

other end over the barbed end of the water control lever valve inlet (fig 25).

Fig 25 - Water control inlet valve with

valve in the open position

Fig 26 - Electrical outlet for water

pump

The pump can be plugged into the female receptacle plug accessory attached to the main switch box

(fig 26) when using the Cab Combo Workshop. Power to run the pump will occur once the switch box

lever is placed in the ON position. The pump should be operated in maximum flow setting. This will

allow sufficient water to reach the brass valve inlet on the rear of the hood to provide water to each of

the three needle valve knob controlled water tubes to each of the three work stations.

16

Page 17

CAB COMBO WORKSHOP OPERATION AND ADJuSTMENT

PUMP SET-UP (continued)

Keep the water hose away from the electric motor and belt guard to prevent damage from moving

parts and electric shock hazard. The pump should always be used with clear, clean water so as to

avoid grit/abrasive material or rock fragments from scratching the gemstones during polishing. For optimal water flow, adjust both the pump and the brass intake valve to their fully open positions. Should

less water be desired, turn the brass lever on the inlet valve to restrict flow to the hood (fig 25).

NEED LE VALVE S

The three stainless needle valves (fig 27) are for fine control of water to each of the three grinding

and polishing stations. For best results, close the valves to the stations not in use. To shut off flow to

a needle valve, simply turn the grey ribbed knob clockwise until it closes to a firm stop (do not overtighten). To open maximum flow to a needle valve, simply turn the grey ribbed knob counterclockwise

until the valve stops.

Fig 27 - The three stainless needle

valves

Fig 28 - Drain valves in the open

position

DRAIN VALVES

A length of 3/8" ID tubing is provided with the Cab Combo Workshop for drainage of excess water

from the front base of the reservoir where the two drain valves are located within the reservoir base

(fig 28).

To drain off the excess build-up of cooling water on the diamond wheels and expandable drum belts,

connect length of 3/8" ID clear tubing to each drain valve (fig 28) and route them into a 5 gallon collection bucket for dirty water.

Do not recycle dirty water from the drain valves into a collection bucket for pumping back up to the

intake valve on the rear of the hood as the contaminants (rock grit, slurry and abrasive particles) will

likely scratch the gemstone material being worked and possibly clog the stainless steel water control

valve.

17

Page 18

CAB COMBO WORKSHOP OPERATION AND ADJuSTMENT

TRIM SAWING

Trim saw cutting of rock material is best performed on material that is under 1/2" in thickness and less

than 4" in length. The rock slab to be cut should rest firmly and flatly on the saw table in front of the

blade prior to beginning a cut (fig 29). Cut the slab using light but firm pressure, letting the blade do

the work without forcing the slab. Forcing the material into the blade may result in a damaged blade

and possible injury to the user as well. Forcing may also stall the blade, overheat the motor, damage

the belt and yield poorly sawed surfaces of the rock material.

Fig 29 - Cutting material Fig 30 - Blade guard in operating

position

Fig 31 - Blade guard adjustment

thumb screw

It is absolutely necessary that the user wear safety glasses while using the Cab Combo Workshop to

prevent eye injury. It is highly recommended to use a combination of personal protective gear at all

times such as face shield/safety glasses and a vinyl apron. Make sure the blade guard is in place and

adjusted as low as possible (to minimize the spray of cutting solution during sawing) but still clears the

top of the blade (fig 30). The height of the blade guard is adjusted with the guard thumbscrew (fig 31)

at the rear of the blade guard.

Should the blade be damaged for any reason, do not use the Cab Combo Workshop until the blade

is replaced. Continuous rim blades cannot be repaired if dished, kinked or damaged and should be

replaced with a new blade immediately.

DIAMOND WHEELS

The Diamond Cab Combo Workshop comes equipped with two 6" OD x 1-1/2" wide brazed diamond

wheels in two diamond abrasive grit sizes (80 and 200 grit). Both wheels are manufactured to a low

tolerance OD circumference run-out for maximum wheel life and to prevent pounding and poor performance during grinding. The high temperature brazed diamond bond provides excellent abrasive

performance when grinding the rough shape of the gemstone material. Diamond wheels must have an

uninterrupted flow of water during use for proper cooling and flushing.

A tool rest is attached to the reservoir base of the Cab Combo Workshop in front of both the 80 and

200 grit diamond wheels (fig 32). If a dop-stick is being used to hold the gemstone material, the user

can use the tool rest to securely hold the dop-stick while grinding, shaping and sanding. The tool rest

18

Page 19

CAB COMBO WORKSHOP OPERATION AND ADJuSTMENT

mount can be adjusted by loosening the positioning bolt (fig 33), moving the tool rest to the desired

height and distance from the wheel, and then retightening the positioning bolt. The tool rest can also

be completely removed (fig 34) from the Cab Combo Workshop if the operator desires.

Fig 32 - Tool rests Fig 33 - Tool rest positioning bolt Fig 34 - Grinding with tool rest

removed

Rough shaping of the gemstone material should be performed first with the 80-grit wheel with maximum water flow from the hood mounted water control valve. It is recommended that you only pump

clean water to the Cab Combo Workshop water system and never recycle your drain water back to

your grinding wheels or expandable drum.

Due to the steel alloy construction and brazed nickel diamond bounding of both wheels, a “ringing"

noise will be heard during grinding and sanding. This is normal and should be of no concern. Should

coolant/flushing water flow be interrupted while grinding with the brazed diamond wheels, the diamond

may “glaze over" or dull the diamond bond. The diamond bond can be “dressed open" or sharpened

by taking the green carbide stick and lightly touching it to the diamond grinding face of the wheel while

rotating (fig 35). Only apply a slight pressure - for no more than 2 seconds - with full flow of cooling

water when “dressing open" the wheels. Do not oversharpen as the wheel life will be shortened.

Always ensure there is a clear, constant drip of water flowing off the rotating wheels into the reservoir

tank. Additionally, don’t force the gemstone material while grinding with the diamond wheel. Allow the

diamond bond on the wheel to work smoothly with a constant and steady application of hand pressure.

Rotate your gemstone while grinding to uniformly remove material, nicks and flat spots.

Remember, satisfactory results are dependent on the user's skill and experience, as well as the gemstone and equipment being used.

19

Page 20

CAB COMBO WORKSHOP OPERATION AND ADJuSTMENT

Fig 35 - Carbide stick applied to diamond wheel

Fig 36 - Resin belt installed and centered on expandable drum

Fig 37 - Polytex pad being applied to

the convex polishing disc

EXPANDABLE DRUM AND DIAMOND RESIN BELTS

The Cab Combo Workshop comes with four diamond resin belts (6“ OD x 1-1/2" wide) in abrasive grit

sizes: 400, 600, 1,200, and 3,000 (6 micron). These are to be placed over the edge and outer rim of

the 6" x 1-1/2" rubber expandable drum (fig 36).

Be sure to center the diamond resin belt so that the width of the belt fits completely over the width

of the rubber drum. Once the Cab Combo Workshop is turned on, the rotation of the shaft and rubber drum will cause the drum to expand outward, which will expand the rubber drum and tension the

belt on the drum. It is to be expected that the diamond resin belts will slide somewhat sideways while

sanding or polishing material. To safely and correctly use the belt, shut the unit off and reposition or

realign the belt over the drum and restart the unit.

Under no circumstances should the belts be used dry, as the build-up of heat from the grinding friction

with the gemstone material will cause the belts to wear out prematurely and possibly tear. Therefore,

keep a constant stream of water from the needle water control valve on the top of the hood (far right

valve) on at all times. Do not circulate dirty water from the reservoir tank or from a collection container

back into the water valves or else contaminant abrasive particles may scratch the gemstone. Always

pump from a clear and clean water reservoir to the diamond wheels and belts. For best results always

dry the gemstone material and check for scratches before proceeding to the next wheel or belt diamond grit size. Do not skip belts in the four belt sequence (400, 600, 1,200, and 3,000 grit).

POLISHING WITH DIAMOND PASTE

The Cab Combo Workshop comes with three syringes (5 grams each) of diamond paste in abrasive

grit sizes: 8,000, 14,000 and 50,000. These diamond pastes are to be used with the three 6" OD

Polytex polishing pads with adhesive backing on the foam covered convex 6" end polishing disc.

Once the gemstone material has been sanded and polished with the 3,000 grit (6 micron) diamond

resin belt, remove the paper backing on the Polytex pad to expose the adhesive surface, placing it

firmly without creases on the foam convex surface of the 6" end polishing disc on the right end side of

the Cab Combo Workshop (fig 37).

20

Page 21

CAB COMBO WORKSHOP OPERATION AND ADJuSTMENT

POLISHING WITH DIAMOND PASTE (continued)

Lightly smear with your fingertip a small amount diamond paste on the center of the mounted Polytex

pad with the unit operating and the polishing disc rotating. The diamond paste will evenly spread over

the surface of the Polytex pad once polishing of the gemstone starts. Move the gemstone in a rocking

and rotating motion from the center of the disc toward the outside edge.

Use only one dedicated Polytex polishing pad with each respective diamond paste syringe (i.e. keep

a labeled Polytex pad for the 8,000 grit paste in a zip-lock bag labeled 8,000 grit). Do not use a single

Polytex pad with two or more diamond pastes or else cross-contamination and poor polishing of the

gemstone material may result.

The Polytex pad can be removed from the foam rubber covering of the convex polishing disc by

slowly pulling the Polytex pad off the foam and placing it in a zip-lock plastic bag properly labeled with

the syringe paste diamond grit size for future use. No water or extender fluid is needed to effectively

disperse the diamond paste from the syringe on the Polytex pads. If the adhesive backing becomes

weak with repeated use, you can apply a few drops of 3M On/Off cement to improve the adhesive

connection to the foam disc.

POLISHING WITH THE LEATHER BUFF PAD

For final polished gemstone results, place the 6" cowhide leather pad (rough side out) on the foam

polishing end disc using the 3M On/Off adhesive cement (red box) to hold the leather pad securely

while buffing the gemstone in a rocking motion (fig 38 & 39). Only use a small amount (8 to 10 dabs)

of 3M On/Off adhesive cement on the smooth cowhide surface, smearing it uniformly before placing

it over the foam rubber on the polishing disc. When the final polish finish of your gemstone has been

achieved, remove the leather disc and place it in a zip-lock bag for future use. It is not necessary to

use any polishing media or liquid (water) when buffing the gemstone with the leather disc. Be sure

to firmly grip the gemstone by hand or with a dop-stick (wood dowel or aluminum rod) cemented or

epoxied to the back of the gemstone while using the leather buff pad.

Fig 38 Fig 39

21

Page 22

CAB COMBO WORKSHOP MAINTENANCE

DIAMOND WHEEL REPLACEMENT

When worn-out, the diamond wheels and expandable drum can be removed and replaced.

1. Remove the belt guard from motor mount (fig 40).

2. Loosen the motor mount nuts, sliding the motor toward the saw so that the belt can be removed

from the motor pulley (fig 41).

3. Remove the 4 flat-head screws that secure the saw table (fig 42) and remove the saw table from

the coolant tank (fig 43).

4. Remove the blade from the arbor shaft.

5. Unscrew and remove the locking knobs from the hood (fig 44).

6. Slide the motor away from the Cab Combo Workshop and rotate the hood back (fig 45) to expose

the shaft assembly.

7. Hold the expandable drum in one hand to keep the shaft assembly stationary and with the other

hand remove the polishing hub by rotating it counter-clockwise (fig 46).

8. Hold the expandable drum in one hand to keep the shaft assembly stationary and with an adjust-

able or box wrench, remove the jam nut on the right end of the unit by turning it counter-clockwise

(fig 47).

9. Lift the shaft assembly out of the bearing seats (fig 48).

10. Loosen the set screw that secures the right-side bearing collar (fig 49) and slide the bearing off the

shaft. If the set screw has scarred the shaft, it may be necessary to file the burr off the shaft with a

small, fine flat file or piece of emery paper.

11. Remove the diamond wheels and spacers from the shaft.

12. There is no need when replacing the diamond wheels to loosen or remove the left-side bearing

collar and bearing.

Fig 40 - Remove belt guard from motor

mount.

Fig 41 - Remove belt from motor pulley

22

Page 23

CAB COMBO WORKSHOP MAINTENANCE

DIAMOND WHEEL REPLACEMENT (continued)

Fig 42 - Remove machine screws from table Fig 43 - Remove saw table from coolant

Tank

Fig 44 - Remove the locking knobs Fig 45 - Cab Combo Workshop with hood

rotated back

Fig 46 - Remove polishing hub from shaft Fig 47 - Remove the jam nut

23

Page 24

CAB COMBO WORKSHOP MAINTENANCE

DIAMOND WHEEL REPLACEMENT (continued)

Fig 48 - Shaft assembly removed from Cab

Combo Workshop

Fig 49 - Loosen the set screw that secures

the right-side bearing collar

SHAFT REASSEMBLY

Bearing

Collar

Splash

Guard

Fig 50 - Diamond wheel shaft assembly (shown without diamond wheels and polishing drum)

Bearing

1-1/4"

Spacer

Bushing

Wheel

3-5/16"

Spacer

Wheel

Bushing

1-5/16"

Spacer

1"

Spacer

Bearing

Collar

Bushing

Flange

Drum

Reassembly of the shaft with the new diamond wheels is the reverse of the disassembly instructions.

Please keep the following points in mind when reassembling:

1. Install diamond wheels with the inside faces facing each other (fig 51 & 52). Be sure the diamond

wheel bushings are installed (fig 50).

2. The bearings have a permanently mounted bushing that extend from one side of the center

bearing. This extension must face away from the diamond wheels (fig 53 & 54) on both ends of the

arbor shaft.

3. The arbor shaft collars have one recessed side and one flat side (fig 55 & 56). The recessed side

should face the bearing and mate against the extended portion of the bearing bushing.

4. There should be a flange installed on both sides of each diamond wheel and the expandable drum.

Make sure the concave side of the flange (fig 4) faces the wheels and drum.

5. When tightening the set screw in the right side bearing collar, stand the arbor shaft up on end

(blade end of the shaft on the floor) and push down with a light to medium pressure on the bearing

collar. This will provide enough compression between the shaft components so that the diamond

wheels and expandable drum do not become disengaged from the shaft during grinding and polishing operations.

24

Page 25

CAB COMBO WORKSHOP MAINTENANCE

6. When installing the shaft assembly back in the Cab Combo Workshop, make sure the rubber

mounted bearings are centered in the bearing seat (fig 57 & 58). If the left bearing is centered in the

bearing seat and the right bearing is not properly centered, make sure the aluminum spacers are in

the correct order and that the bearings and arbor collars are properly installed.

7. Install the sanding drum with arrow of rotation facing direction of rotation (fig 59).

8. Make sure diamond wheel and drum bushings are installed.

9. Make sure the coolant splash guard is installed properly (fig 60).

Fig 51 - Outside face of diamond

wheel

Fig 53 - Bearing correctly installed Fig 54 - Bearing incorrectly installed

Fig 52 - Inside face of diamond

wheel

25

Page 26

CAB COMBO WORKSHOP MAINTENANCE

SHAFT REASSEMBLY (continued)

Fig 55 - Bearing collar correctly

installed

Fig 57 - Bearing correctly seated Fig 58 - Bearing incorrectly seated

Fig 56 - Bearing collar incorrectly

installed

Fig 59 - Arrow on drum indicates

direction of rotation

Fig 60 - Coolant splash guard

installed

26

Page 27

CAB COMBO WORKSHOP MAINTENANCE

COOLANT REPLACEMENT

The trim saw tank on the Cab Combo Workshop requires periodic routine maintenance to remove and

properly discard the build-up of rock mud, sludge and dirty lubricating fluid (oil) from the oil tank reservoir. It will be apparent to the user after prolonged sawing that the lubricating fluid is dirty and needs

to be changed if the oil residue on the saw table (after cutting) is thick and dark with rock sludge

build-up.

The oil liquid can be removed rapidly by removing the square-head drain plug attached to the bottom

drain hole at the base of the coolant reservoir (fig 61). The oil should be collected in a container and

either reused or properly disposed of.

Fig 61 - Drain plug Fig 62 - Refill the cutting lubricant res-

ervoir to cover 1/4" of the bottom edge

of the blade

Fig 63 - Check belt deflection

To prevent the overflow of oil and rock sludge onto the baseboard or floor, use a bucket or collection container placed under the baseboard to allow the free flow of oil and sludge into the bucket for

proper disposal. The thicker solid sludge residue in the tank will likely not flow through the 1/4" diameter drain hole. Therefore the sludge should be removed after the slab saw oil lubricant is drained, by

removing the saw tabletop and extracting the sludge with a spatula or spoon.

Once the sludge is removed, wipe the inside of the tank with disposable towels and refill the cutting lubricant to cover 1/4" of the bottom edge of the blade (fig 62). The diamond blade should be

removed from the arbor shaft while removing the sludge. Be sure to check the coolant level inside of

the reservoir after every 3 to 5 hours of use as the fluid will absorb onto the rock material and will be

reduced over time due to heat and evaporation.

BELT

The Cab Combo Workshop arbor is driven from the electric motor by a AX-24 rubber belt. The Belt

tension is adjusted at the factory. However, if it is necessary to service this belt, unplug the Cab

Combo Workshop from its power source and remove the fasteners that secure the belt guard housing

to the motor. The belt tension should be checked periodically by removing the guard and depressing

the belt in the middle between both the motor and blade arbor 2" OD pulleys. There should be 1/2" of

27

Page 28

CAB COMBO WORKSHOP MAINTENANCE

deflection when the belt is pushed down (fig 63). If the belt tension should become loose, poor sawing

performance or slipping will result. If the belt is too tight (i.e. no deflection) the belt, electric motor, pulleys and blade arbor bearings may wear out prematurely or the motor may overheat and shut off. Belt

tension can be adjusted by loosening the two mounting bolts attached to the base of the motor mount

and sliding the motor cradle base forward or backward to increase or decrease belt tension. Be sure

to adequately retighten the motor mount nuts and replace and attach the belt guard to the table as

well.

BLADE ARBOR ASSEMBLY AND PULLEYS

The Cab Combo Workshop is equipped with a 5/8" OD arbor shaft with 2" OD x 5/8" bore aluminum

flanges and spacers, two rubber sealed ball bearings, felt gasket and 2" OD x 5/8" bore die cast zinc

coated pulley. Should the bearings wear out on the arbor shaft, poor sawing, grinding and polishing

performance and overheating may result causing permanent damage to the shaft, bearings, belt and

motor. This main stainless steel shaft arbor assembly can be purchased from Barranca Diamond as

a complete unit. Periodically check the tightness of the hood attachment knobs (fig 64) to make sure

they are securely tightened to the aluminum body of the Cab Combo Workshop. Should the 2" OD die

cast pulleys on either the motor (fig 65) or blade arbor shaft need to be removed or replaced, loosen

the setscrew on the hub of each pulley with a US standard Allen type wrench. The setscrews can be

secured with liquid thread locker (removable type) to prevent loosening due to vibration.

Fig 64 - Hood attachment knobs. Fig 65 - Motor arbor shaft pulley. Fig 66 - Motor reset button.

28

Page 29

CAB COMBO WORKSHOP MAINTENANCE

ELECTRIC MOTOR

The Cab Combo Workshop is equipped with a 1/3 HP 1725 RPM single-phase 120 volt 60 Hz 8 amp

motor. The motor shaft has sealed ball bearings and requires no lubrication. The motor is protected

from thermal damage (overheating) with an automatic shut-off switch. If the motor overheats it will

automatically shut off and restart once its internal components cool down and the motor is restarted

manually (red button). Be sure to shut off the main motor by placing the switch lever to the OFF position and disconnecting the power source. After allowing the motor to cool (2 to 3 hours), push the red

reset button on the side of the motor (fig. 66) and restart the unit by turning the switch to ON. If the

motor does not restart after a cool down period, remove the motor and have an authorized repair service center inspect the motor. Barranca Diamond can refer you to an authorized motor repair service

center in your area.

Please note: On Cab Combo Workshops prior to serial number 850, the motors do not have a reset

switch. Therefore it is imperative that if the saw motor should stop during operation that the power to

the main motor be shut off by placing the toggle switch in the MIDDLE/OFF position as the motor will

restart automatically once cooled down.

DIAMOND BLADE

Periodically, the diamond blade on the Cab Combo Workshop will need to be sharpened or replaced.

A dull or “glazed over" diamond blade can stall and cause the motor to shut off and possibly damage

the blade or “dish" the core. Once the saw begins to labor or struggle to cut, try using a sharpening

stick (green or white silicon carbide material, 60 to 100 grit size) on the blade.

If no sharpening stick is available, use an abrasive material such as cinder block or brick to remove

the glazing over the diamonds on the edge of the blade. Do not oversharpen the blade.

Eventually all diamond blades wear out and must be replaced. New continuous rim diamond blades

(303 Pro) should be mounted on the blade arbor so that the arrow marked on the steel core is pointing in the direction of blade rotation. If the arrow cannot be found, use a hand lens or magnifying

glass on the blade edge, find the head and tail of any diamond and orient with the tail trailing behind.

For notched rim diamond blades (297 or 301 models), it does not matter which way the blade is orientated on the arbor shaft.

29

Page 30

CAB COMBO WORKSHOP MAINTENANCE

SUBMERSIBLE PUMP

Periodically remove the plastic inlet cover on the submersible water pump (fig 67 & 68). Remove the

filter element (fig 69) and clean any obstructions such as sludge or rock mud that may be found. Clean

the filter with warm, soapy water. Replace the filter (fig 70 & 71) and test the pump to ensure it's functioning properly.

Fig 67 - Water Pump Fig 68 - Slide pump inlet cover off the

pump body

Fig 70 - Replace clean filter Fig 71

Fig 69 - Slide the filter element out the

back of the inlet cover

30

Page 31

NOTES

31

Page 32

CAB COMBO WORKSHOP EXPLODED VIEW

32

Page 33

CAB COMBO WORKSHOP PARTS LIST

Item Description Part # Qty

1 Pad, Polishing 6" Polytex 14615 3

2 Pad, Polishing 6" Leather 14617 1

3 Nut, Hex, 5/16"-18 10 119 6 2

4 Fitting, Plastic, 1/4" FNPT X 1/4" BARB 128 3 97 1

5 Hose, Vinyl, 1/4" x 3/8" TSAW 132 951 1

6 Washer, 3/8" SAE Flat 150923 6

7 Washer, 1/2" SAE Flat 150924 2

8 Screw, Soc HD Cap, 1/4"-20 x 1" 151049 1

9 Screw, Hex Head Machine, 5/16"-18 x 3/4" 151369 2

10 Washer, 5/16" SAE Flat 151754 10

11 Nut, Hex, 1/4"-20 151893 7

12 Washer, 1/4" SAE Flat 151915 11

13 Screw, Hex Head Machine, 5/16"-18 x 1/2" 152473 6

14 Screw, Socket Head Cap, 1/4"-18 x 3/4" 152587 7

15 GFCI, 120V, 15A 152610 1

16 Screw, Hex, 3/8"-16 x 3/4" 153527 4

17 Washer, SAE Flat, #10 154369 2

18 Clamp, Hose 1/2" - 3/4" 154394 1

19 Label, Safety 1558 0 6 1

20 Pump, Water 115V, 60Hz 155987-VP 1

21 Nut, Hex 10-32 156269 6

22 Screw, Shoulder Thumb, 1/4"-20 x 1" 160461 1

23 Nut, 10-32 161040 1

24 Pulley, 2" x 1/2" Bore 161070 1

25 Belt, Micro-V AX-24 161085_CC 1

26 Barb Fitting, 1/8" NPTF 161343 10

27 Bracket, Tool Rest LH 1614 42 1

28 Cross, #10-32 161532 2

29 Flap, Wheel 161557 3

30 Gasket, Tank 161566 1

31 Hood Weldment 161629 1

32 Knob, 3/8"-16 161651 2

33 Knob, Ridged, Gray 161652 3

34 Top, Motor Mount 161668 1

35 Bottom, Motor Mount 161669 1

36 Motor 1/3 HP 161672 1

37 Oil, Tool Cool, 8 oz. 16172 9 1

38 Plug, Pipe 1/8" 16176 3 1

39 Polishing Compind, 01 Micron 16176 6 1

33

Page 34

CAB COMBO WORKSHOP PARTS LIST

Item Description Part # Qty

40 Polishing Compund, 02 Micron 161767 1

41 Polishing Compund, 2-4 Micron 16176 8 1

42 Rod, Threaded 3/8" -16 x 6" LG 161829 2

43 Screw, Flat Head Phillips Machine, 1/4"-20 x 3/4" 161856 4

44 Screw, Pan Head Slot Machine, 10-32 x 1 1/2" 161874 1

45 Screw, Pan Head Phillips 10-32 x 3/8" 161875 6

46 Screw, Pan Head Phillips Machine, 1/4"-20 x 3/8" 161877 4

47 Table, Weldment 16196 4 1

48 Guard, Splash 161965 1

49 Tool Rest 161974 2

50 Valve, 10/32 161989 3

51 Adaptor, Male Pipe 1/8" NPTF 161991 2

52 Valve, 1/8" NPTFM x 1/4" Tube 161992 1

53 Guard, Blade, Comp 162152 1

54 Bracket, Hose Mount 162154 3

55 Adaptor, Male Pipe 1/8" NPTF 162315 1

56 Tubing, Clear PVC 1/8" x 1/4" 162505 1

57 Tie, Nylon .10 x 4.0 162506 1

58 Washer, Flat Large I.D. 1/2" 162510 2

59 Clip, Hose Retainer 16 2511 1

60 Guard, Belt 164578 1

61 Tank, Casting Machined 166064 1

62 Box, Shipping, Cab Combo 166216 1

63 Bracket, Tool Rest RH 1664 39 - 02 1

64 Assembly, Shaft 166608 1

65 Guard, Inner Belt 167860 1

66 Switch Assembly 168116 1

67 Board, Base 168706 1

34

Page 35

CAB COMBO WORKSHOP EXPLODED VIEW

35

Page 36

CAB COMBO WORKSHOP PARTS LIST

Item Description Part # Qty

1 Flange, Outer 2"-3/8" 135830 8

2 Blade, MK-303c, 6" x .020 x 5/8" Bore 153692 1

3 Collar, Shaft w/ Set Screw 161017 1

4 Pulley, 2" x 5/8" Bore 161020 1

5 Pin Roll, 3/16" x 1" 161089 1

6 Bearing, Rubber, 5/8" Shaft 161348 2

7 Nut, Hex Jam, 5/8"-18 LH 16170 4 1

8 Spacer, I 162507 1

9 Spacer, II 162508 1

10 Spacer, III 162509 1

11 Nut, Hex Jam, 5/8"-18 162897 1

12 Polishing Wheel, RH 166065 1

13 Shaft, Arbor 166414 1

14 Spacer, IV 166606 1

15 Drum, 6" x 1-1/2" Expandable Rubber 390006 1

16 Wheel, Brazed 80 496080 1

17 Wheel, Brazed 170 496200 1

36

Page 37

CAB COMBO WORKSHOP WARRANTY

BARRANCA DIAMOND LIMITED WARRANTY

Please complete the warranty registration card and return. Any problems encountered should be directed to

Barranca Diamond Customer Service department at (800) 630-7682 M-F 8am - 5pm PST.

NOTE THIS INFORMATION FOR FUTURE USE:

MODEL NUMBER:

SERIAL NUMBER:

PURCHASE PLACE:

PURCHASE DATE:

Barranca Diamond warrants to the original retail purchaser for a period of 1 year except as noted, from the

date of purchase all products covered by this Warranty to be free of defects in materials and workmanship.

This Warranty shall not apply to any parts that have been subjected to misuse or improper service, that had

been damaged in transit or handling, or that have been altered or repaired by unauthorized representatives.

This Warranty does not cover defects caused by or resulting from misuse, abuse, neglect or damage caused

by accident or the failure to provide reasonable maintenance. This Warranty is void if the product or any of its

individual components is altered or modied by the purchaser or if the product is used in a manner or with a

blade not recommended by the manufacturer.

Any claim arising under this Warranty must be submitted by the original purchaser within the warranty period

specied above, and shall include proof of purchase. During said warranty period Barranca Diamond shall,

at its option, either replace or repair, at no charge to the original purchaser, any parts or components that are

found to be defective by Barranca Diamond. Barranca Diamond shall not be responsible for or obligated to

pay for freight or other transportation related costs or expenses in connection with any defective products or

components that are either returned to Barranca Diamond’s facility or any authorized repair station and/or any

replacement products or components that are shipped from Barranca Diamond pursuant to this Warranty.

Parts and labor needed to maintain products and the replacement of components due to normal wear and tear

are the purchaser’s responsibility and are not covered by this Warranty. All products or components replaced

under warranty become the property of the manufacturer. All replacement parts will be considered to be part

of the original product and any warranty on such parts will expire coincidentally with the original Warranty.

Barranca Diamond will pay for parts and labor in connection with warranty repairs conducted by Barranca Diamond or its authorized repair centers. Replacement part(s) installed by anyone else will be provided without a

charge for such replacement part(s), but this Warranty will not apply to labor charges in connection therewith.

IN NO EVENT SHALL ANY LIABILITY UNDER THIS WARRANTY EXCEED THE REPLACEMENT COST OF

ANY DEFECTIVE PRODUCT OR COMPONENT THEREOF, AND BARRANCA DIAMOND SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OR FOR ANY OTHER DAMAGE OR LOSS

NOT EXPRESSLY ASSUMED AS SET FORTH HEREIN.

The foregoing constitutes an expressed warranty on the terms set forth above and is the only warranty or

warranties applicable to the products it covers. All other warranties, including, without limitation, the implied

warranty of merchantability and/or tness for a particular purpose or use being denied. This limited warranty is

expressly in lieu of all other warranties, whether expressed or implied.

37

Page 38

CAB COMBO WORKSHOP WARRANTY

Specics Applicable to Limited Warranty of Diamond Blades and Core Bits:

Laser Welded Blade and Bit Warranty:

If the laser weld between the segment and the steel core or barrel fails during normal use, the blade

or bit will be replaced free of charge. Blades and bits damaged due to careless or improper use are

not covered under this warranty.

Brazed Blade, Bit, and Cup Wheel Warranty:

If the brazed bond between the segment and the core, barrel, or cup fails within the rst .050 of segment wear, the blade, bit, or cup will be replaced free of charge. Blades, bits, and cup wheels damaged due to careless or improper use are not covered under this warranty.

Continuous Rim Blade Warranty:

If the bond between the rim and the core fails during normal use, the blade will be replaced free of

charge. Blades and bits damaged due to careless or improper use are not covered under this warranty.

Exclusions:

Barranca Diamond does not warrant the following components, which carry their own manufacturer’s

warranty for the indicated periods:

Electric Motors Manufacturer’s Warranty

Baldor: 1 year

Ryobi: 1 Year

Soga: 1 Year

Gas Engines Manufacturer’s Warranty

Honda: 2 years

Engine Power Information

Engine power ratings are calculated by the individual engine manufacturer and the rating method

may vary among engine manufacturers. Barranca Diamond Products makes no claim, representation

or Warranty as to the power rating of the engine on this equipment and disclaims any responsibility

or liability of any kind whatsoever with respect to the accuracy or the engine power rating. Users are

advised to consult the engine manufacturer’s owners manual and website for specic information

regarding the engine power rating.

38

Page 39

CAB COMBO WORKSHOP WARRANTY

REPLACEMENT PARTS

Replacement parts for this tool may be ordered from your Barranca Diamond distributor or directly from

Barranca Diamond. Please have the following information ready before calling:

• Model and serial number of the machine

• Date of purchase

• Description of parts being ordered (see parts list)

RETuRN MATERIALS PROCEDuRE

To expedite the service relative to the return of a product purchased through Barranca Diamond, please have

the following information available:

• Model and serial number of the machine

• Date of purchase

• Distributor’s name

Then please call Barranca Diamond at (310) 523-5867 or toll free at 800-630-7682 to obtain a Return Goods

Authorization number (RGA) authorizing the return.

Please Note:

• Ensure your item(s) are prepaid to the destination

• Return items must have been purchased within the previous twelve (12) months

• Follow the packaging instructions in the following section

• Be sure to include the RGA number, return address and your phone number on or within the

return shipping box.

PACKAGING INSTRuCTIONS

Ship the equipment using its original shipping crate if possible. Secure inside the shipping crate. Ensure all

parts are secured in the packaging to prevent movement. Do not ship the equipment partially exposed.

39

Page 40

CAB COMBO WORKSHOP

OPERATION & PARTS MANUAL

Barranca Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

Toll-Free: (800) 421-5830

Phone: (310) 539-5221

Fax: (310) 539-5158

www.barrancadiamond.com

Loading...

Loading...