Floating Head Greens Mower

Owner's Operating Manual

Serial No. LM101:10001-

"Required reading"

Read this manual and the Owner's Manual for the engine before using the machine.

Ver.1.0

This product can expose you to

chemicals including Carbon

Monoxide, which is known to the

State of California to cause birth

defects or other reproductive harm.

For more information go to

www.P65Warnings.ca.gov.

WARNING:

318yi8-006E

Warning

LM101

Regulations

California Proposition65

(For California, USA)

California Proposition65_001

CALIFORNIA SPARK ARRESTER

(For California, USA)

Operation of this equipment may create

sparks that can start fires around dry

vegetation.

A spark arrester may be required.

The operator should contact local fire

agencies for laws or regulations relating to fire

prevention requirements.

The engine of this machine is equipped with a

spark arrester.

In some areas there are local, state, or federal

regulations requiring that a spark arrester be

used on the engine of this machine.

Thank you for purchasing the Baroness machine.

This manual explains proper handling,

adjustment, and inspection of your machine.

Prior to use, carefully read this manual to

thoroughly understand the contents for safe and

correct operation.

We hope you will use the machine safely, and

take advantage of its best performance.

LM101

Greeting

Caution

696cq5-001

Danger

Danger

Warning

Caution

Important

LM101

Introduction

Read this manual carefully to ensure that you thoroughly understand how to properly operate and maintain this

machine, and to avoid causing injury to yourself or others.

The operator is responsible for operating the machine properly and safely.

Do not perform maintenance on the machine other than that described in this manual.

Be sure to also read the Owner's Manual for the engine, battery, etc.

Maintenance should only be performed by a certified specialist.

If you have any questions concerning maintenance or genuine parts, please contact your local Baroness dealer or

Kyoeisha.

When making inquiries about this machine, please specify the machine's model designation and serial number.

When loaning or transferring this machine, please also provide this manual together with the machine.

Kyoeisha Co., Ltd.

The information described in this manual is subject to change for improvement without prior notice.

When replacing parts, be sure to use genuine Baroness parts or parts designated by Kyoeisha.

Note that the Baroness product warranty may not apply to defects caused by the use of parts from other

companies.

Warning Symbols

This manual uses the following warning symbols for handling precautions that are important for your

safety.

Warning symbol

This symbol indicates the articles regarding “Danger,” “Warning,” or “Caution.”

Those articles describe important safety precautions and so read them carefully to understand completely before

operating the machine.

Failure to adequately follow these safety precautions may cause an accident.

This symbol indicates that serious injury or death will occur if the warning is ignored.

This symbol indicates that serious injury or death may occur if the warning is ignored.

This symbol indicates that injury or damage to property may occur if the warning is ignored.

This symbol indicates precautions on the mechanism of the machine.

Purpose

This machine is intended for cutting turf grass at

golf courses.

Do not use this machine in any way other than

its intended purpose, and do not modify the

machine.

Operating this machine for other purposes and

modifying it may be very dangerous and may

cause damage to the machine.

LM101

Introduction

LM101

Introduction

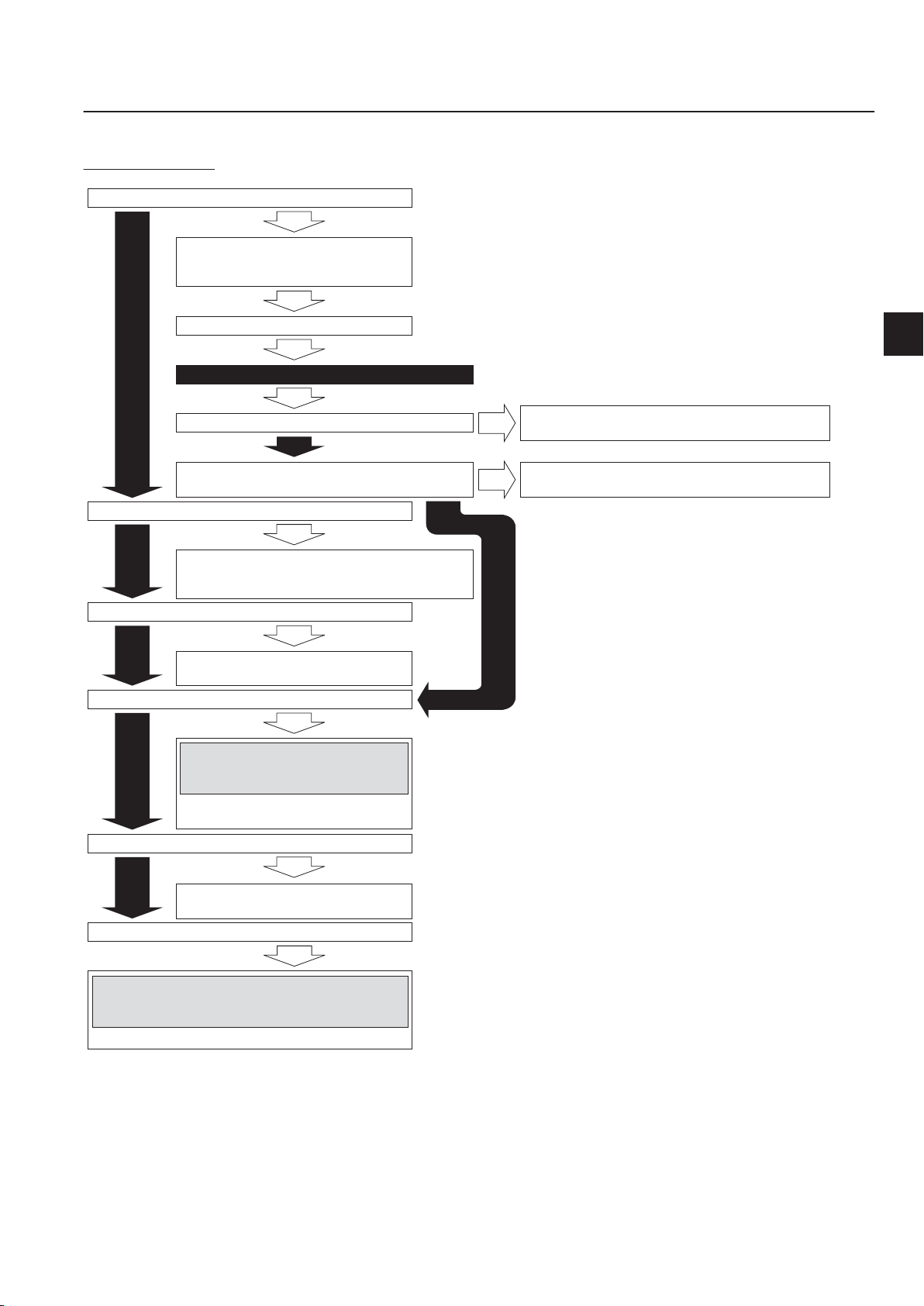

Safety .............................................................. Page 1-1

Safe Operating Practices ...............................Page 1-2

Disposal .......................................................... Page 2-1

Recycle and Waste Disposal ......................... Page 2-2

Product Overview .......................................... Page 3-1

Specifications .................................................Page 3-2

Names of Each Section ................................. Page 3-3

Safety Signs and Instruction Signs ................ Page 3-4

Handling Instructions .................................... Page 4-1

Preparation for Use ........................................Page 4-2

Inspection Before Use ................................... Page 4-3

Tightening torques ......................................... Page 4-8

Adjustment Before Operating ...................... Page 4-12

Procedure to Start / Stop Engine ................. Page 4-18

Operation of Each Section ...........................Page 4-20

Instruments .................................................. Page 4-26

Travel of Machine ........................................ Page 4-26

Cutting Work ................................................ Page 4-27

Transporting .................................................Page 4-29

LM101

Contents

Maintenance ................................................... Page 5-1

Maintenance Precautions .............................. Page 5-2

Maintenance Schedule .................................. Page 5-4

Greasing ........................................................ Page 5-7

Maintenance (Mower) .................................. Page 5-10

Maintenance (Main Body) ............................Page 5-23

Long-Term Storage ......................................Page 5-25

Troubleshooting Procedures of Aftercut

Appearance ................................................. Page 5-26

LM101

Contents

Safe Operating Practices ...................... Page 1-2

Training ..................................................Page 1-2

Preparation ............................................ Page 1-2

Operation ...............................................Page 1-3

Maintenance and storage ...................... Page 1-4

LM101

Safety

Safety

Page 1-1

Danger

Danger

Warning

LM101

Safety

Failure to adequately follow these safety

precautions may cause an accident resulting in

injury or death.

This machine is designed to ensure safe

operation and has been tested and inspected

thoroughly before shipment from the factory.

The machine is equipped with safety devices

to prevent accidents.

However, whether the machine demonstrates

its original performance level depends on the

manner in which it is operated and handled,

as well as the manner in which it is managed

on a daily basis.

Inappropriate use or management of the

machine may result in injury or death.

Observe the following safety instructions to

ensure safe operation.

Safe Operating Practices

The following instructions include the ones from

CEN standard EN 836: 1997, ISO standard

5395: 1990, and ANSI B71.4-2004.

Training

Read this manual and other training material

1.

carefully.

Be familiar with the controls, safety signs,

and the proper use of the equipment.

If the operator or mechanic can not read

2.

English it is the owner's responsibility to

explain this manual to them.

All operators and mechanics should seek

3.

and obtain professional and practical

instruction.

The owner is responsible for training the

users.

4.

Never allow people unfamiliar with these

instructions to use or service the machine.

Local regulations may restrict the age of the

operator.

The owner/user can prevent and is

5.

responsible for accidents or injuries

occurring to themselves, other people, or

property.

Keep in mind that the owner, operator, and

6.

mechanic are responsible for accidents or

hazards occurring to other people or their

property.

Preparation

Evaluate the terrain to determine what

1.

accessories and attachments are needed to

properly and safety perform the job.

Only use accessories and attachments

approved by the manufacturer.

While operating, always wear substantial

2.

footwear, long trousers, hard hat, safety

glasses, and ear protection. Long hair, loose

clothing, or jewelry may get tangled in

moving parts.

Do not operate the equipment when barefoot

or wearing open sandals.

3.

Inspect the area where the equipment is to

be used and remove all objects such as

rocks, toys and wire which can be thrown by

the machine.

4.

Exercise care in the handling of fuel.

Warning-Fuel is highly flammable.

Take the following precautions.

Store fuel in containers specifically

[1]

designed for this purpose.

Add fuel before starting the engine.

[2]

Never remove the cap of the fuel tank or

add fuel while the engine is running or

when the engine is hot.

Refuel outdoors only and do not smoke

[3]

while refueling.

If fuel is spilled, do not attempt to start the

[4]

engine but move the machine away from

the area of spillage and avoid creating any

source of ignition until petrol vapours have

dissipated.

Replace all fuel tanks and container caps

[5]

securely.

Check that operator's presence controls,

5.

safety switches and shields are attached and

functioning properly.

Do not operate unless they are functioning

properly.

If the brake operation is faulty or the parking

6.

brake lever has noticeable play, be sure to

adjust or repair them before operating the

machine.

Replace faulty mufflers.

7.

Page 1-2

Safe Operating Practices

Operation

Do not operate the engine in a confined

1.

space where dangerous carbon monoxide

fumes can collect.

Only operate in good light, keeping away

2.

from holes and hidden hazards.

3.

Before attempting to start the engine,

disengage all attachments, shift into neutral,

and engage the parking brake.

4.

Start the engine or switch on the motor

carefully according to instructions and with

feet well away from the blades.

5.

Avoid operating the equipment in wet grass,

where feasible.

6.

Always be sure of your footing on slopes.

7.

Walk, never run.

8.

Remember there is no such thing as a safe

slope.

Travel on grass slopes requires particular

care.

To guard against overturning:

[1]

Do not mow excessively steep slopes.

[2]

Do not stop or start suddenly when going

up or downhill.

[3]

Engage clutch slowly, always keep

machine in gear, especially when traveling

downhill.

[4]

Machine speeds should be kept low on

slopes and during tight turns.

9.

Never operate the machine with damaged

guards, shields, or without safety protective

devices in place.

Be sure all interlocks are attached, adjusted

and functioning properly.

10.

Do not change the engine governor settings

or overspeed the engine.

Operating the engine at excessive speed

may increase the hazard of personal injury.

11.

Pay attention not to touch hot parts.

12.

Do the following before leaving the

operator's position.

[1]

Stop on level ground.

[2]

Disengage the cutting unit and traction

drive;

[3]

Set the parking brake;

[4]

Stop the engine.

13.

Stop the engine in the following conditions.

[1]

Before refueling.

Safety

Before removing the grass catcher/

[2]

catchers.

Before making height adjustment unless

[3]

adjustment can be made from the

operator's position.

[4]

Before cleaning blockages.

[5]

Before checking, cleaning, or working the

machine.

[6]

Whenever you leave the machine.

[7]

After striking a foreign object or if an

abnormal vibration occurs.

Inspect the machine for damage and

make repairs before restarting and

operating the equipment.

14.

Keep hands and feet away from the cutting

units and the rotating parts.

15.

Never pick up or carry a lawnmower while

the engine is running.

16.

Look behind and down before backing up to

be sure of a clear path.

17.

Never operate while people, especially

children, or pets are nearby.

18.

Slow down and use caution when making

turns and crossing roads and sidewalks.

19.

Stop the blades rotating before crossing

surfaces other than grass.

20.

Disengage drive to attachments when

transporting or not in use.

21.

When using any attachments, never direct

discharge of material toward bystanders nor

allow anyone near the machine while in

operation.

22.

Do not operate the machine under the

influence of alcohol or drugs.

23.

Take care when loading or unloading the

machine into a trailer or a truck.

Load or unload the machine in a flat and

safe place.

Before loading or unloading, set the parking

brake on the truck or trailer, stop the engine,

and chock the wheels.

When transporting the machine on a truck or

a trailer, set the parking brake, stop the

engine, and fasten the machine to the truck

with a rope or other suitable restraining

device that has sufficient strength.

When using a running board, select one with

sufficient strength, length, and width and that

will not cause the machine to slip.

24.

Close the fuel valve before transporting the

machine.

LM101

Safety

Safe Operating Practices

Page 1-3

LM101

Safety

Use care when approaching blind corners,

25.

shrubs, trees, or other objects that may

obscure vision.

Do not take your eyes off the road ahead. Do

26.

not operate the machine with no hands.

27.

Reduce the throttle setting during engine

run-out and, if the engine is provided with a

shut-off valve, turn the fuel off at the

conclusion of operation.

Maintenance and storage

Disengage drives on level ground,

1.

disengage the cutting unit, set parking brake,

stop engine and disconnect spark plug wire.

Wait for all movement to stop before

adjusting, cleaning or repairing.

2.

To reduce the fire hazard, keep the engine,

silencer/muffler, compartment fuel storage

area, cutting unit and drives free of grass,

leaves, or excessive grease. Clean up oil or

fuel spillage.

3.

Allow the engine to cool before storing in any

enclosure.

4.

Only cover the machine with a sheet after

hot parts have sufficiently cooled down.

5.

Never store the equipment with fuel in the

tank inside a building where fumes may

reach an open flame or spark.

6.

If the engine is provided with a shut-off

valve, shut off valve while storing or

transporting.

7.

Do not store fuel near flames.

8.

Never allow untrained personnel to service

machine.

9.

Allow the engine/muffler to cool before

checking/maintenance.

Appropriately manage and correctly use the

10.

tools necessary for servicing or adjusting the

machine.

Use jack stands to support components

11.

when required.

Carefully release pressure from components

12.

with stored energy.

Make sure that parts such as wires are not

13.

touching each other and that their covers

have not come off.

Use care when checking the cylinders/reels

14.

and bed knives.

Wear gloves and use caution when

[1]

servicing them.

Be careful during adjustment of the

[2]

machine to prevent entrapment of the

fingers between moving blades and fixed

parts of the machine.

Keep hands and feet away from moving

15.

parts.

If possible, do not make adjustments with the

engine running.

16.

Keep all parts in good working condition and

all hardware tightened.

Replace all worn or damaged decals.

17.

Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working

condition.

18.

Check the grass catcher frequently for wear

or deterioration.

19.

If the fuel tank has to be drained, do this

outdoors.

Page 1-4

Safe Operating Practices

Recycle and Waste Disposal ................ Page 2-2

About Recycle ........................................Page 2-2

About the Waste disposal ......................Page 2-2

LM101

Disposal

Disposal

Page 2-1

LM101

Disposal

Recycle and Waste Disposal

About Recycle

Recycling battery etc. is recommended for

environmental conservation and economical

use of resources.

It may be required by local laws.

About the Waste disposal

Make sure that waste generated when

servicing or repairing the machine is disposed

of in accordance with local regulations.

(e.g. waste oil, antifreeze, rubber products, and

wires etc.)

Page 2-2

Recycle and Waste Disposal

Specifications ........................................ Page 3-2

Specifications .........................................Page 3-2

Sound pressure level .............................Page 3-3

Sound power level ................................. Page 3-3

Vibration level ........................................ Page 3-3

Names of Each Section ......................... Page 3-3

Serial Number Plate ...............................Page 3-3

LM101

Product Overview

Safety Signs and Instruction Signs ..... Page 3-4

About Safety Signs and Instruction

Signs ......................................................Page 3-4

Positions of Safety Decals and

Instruction Decals .................................. Page 3-4

Explanation about Safety Decals

and Instruction Decals ........................... Page 3-5

Product Overview

Page 3-1

LM101

Product Overview

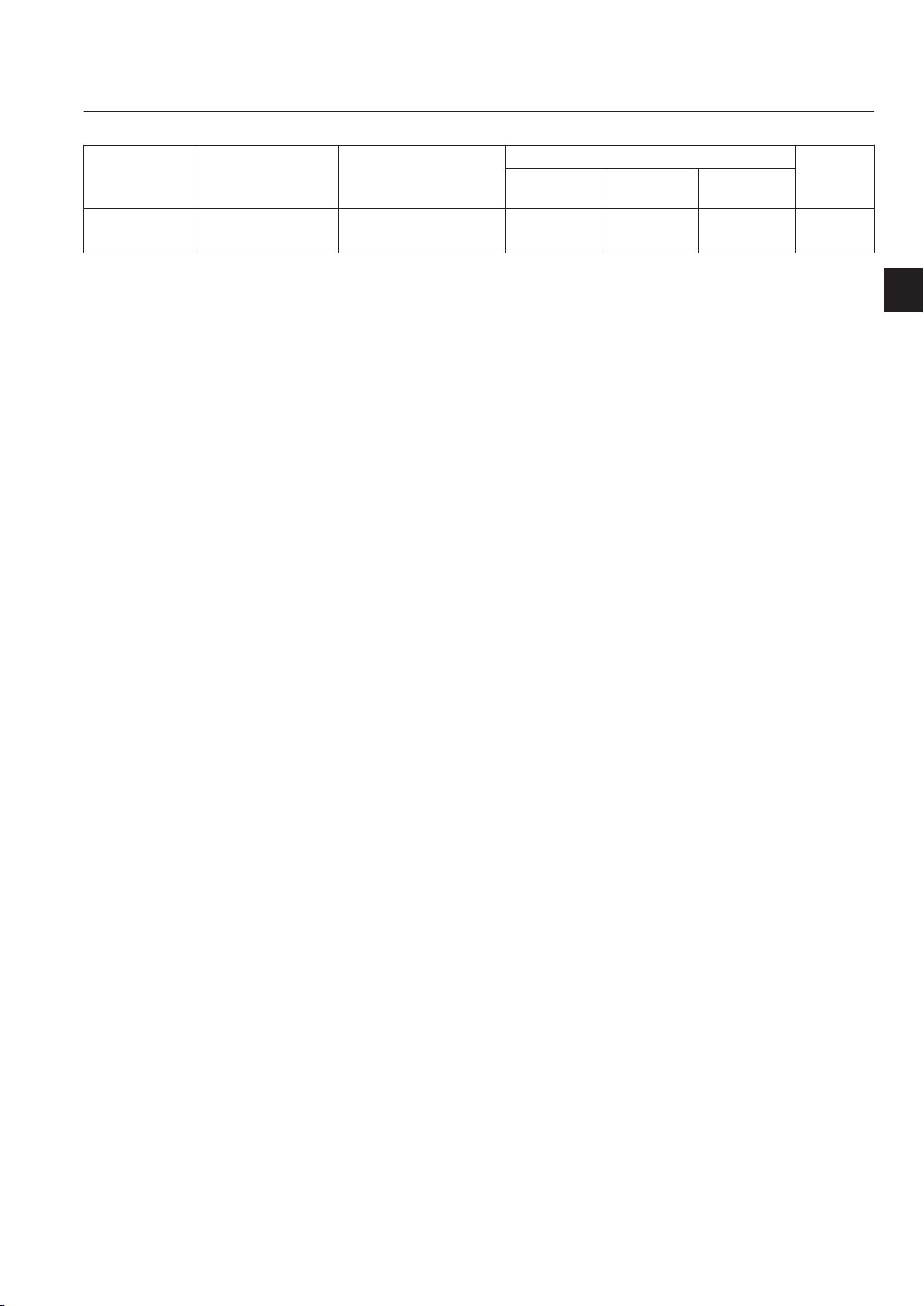

Specifications

Specifications

Model LM101

Total

length

Dimensions

Weight

Minimum turning radius -

Engine

Fuel tank capacity Gasoline 0.53 U.S.gals

Fuel consumption 237.57 g/PS・h (rated output) 323 g/kW・h (rated output)

Engine oil capacity 0.15 U.S.gals

Operating width (Mowing width) 22.92 in 55.7 cm

Operating height (Mowing height)

Blades 9 ・ 11 9 ・ 11

Drive

Speed (HST) -

Speed (Mechanical) 2.92 mph (@3,000 rpm) 4.7 km/h (@3,000 rpm)

Efficiency

Maximum inclination for operation -

Tire size 4.10/3.50-6

Tire pneumatic pressure 17.40 psi

Battery -

Total

width

Total

height

Total weight (empty fuel tank) 251.32 lb 114 kg

Grass catcher

Groomer

Traveling wheel (for one

machine)

Model HONDA GX120

Type Gasoline air-cooled engine (OHV) four-stroke single-cylinder

Total displacement 7.20 cu.in.

Maximum output 2.6 kW (3.5 PS)/3,600 rpm

Traveling Mechanical

Mowing Mechanical

with grass catcher 61.02 in 155 cm

without traveling wheel 37.01 in 94 cm

Steering handle 43.70 in 111 cm

*1

*1

*1

7.28 lb 3.3 kg

7.94 lb 3.6 kg

15.21 lb 6.9 kg

118 cm3 (0.118 L)

Gasoline 2.0 dm3 (2.0 L)

0.56 dm3 (0.56 L)

0.118 - 1.142 in [0.118 - 1.063

*2

in]

0.52 acres/hour

(2.92 mph x mowing width x 0.8)

3.0 - 29.0 mm [3.0 - 27.0 mm]

2,094 m2/h

(4.7 km/h x mowing width x 0.8)

120 kPa (1.2 kgf/㎝2)

*2

The factory default maximum engine rpm is 3,100 rpm.

*1

: Total weight includes *1 parts.

*2

: The indicated lowest mowing height is for general application. It may be adjusted according to

the state of green and the bed knife to be installed.

The value in the brackets [ ] is the mowing height of the machine equipped with a groomer.

Page 3-2

Specifications

Sound pressure level

1

2

3

6

7

9

10

11

18

21

22

22

A

23

20

17

19

12

14

16

15

13

8

4

5

quwxcl-081

4ogipb-001

Sound pressure level

This machine was confirmed to have a

continuous A-weighted sound pressure level

of 87 dB by measuring identical machines in

accordance with the procedure specified in

ISO 5395-1:2013.

Sound power level

Sound power level

This machine was confirmed to have a sound

power level of 98 dB by measuring identical

machines in accordance with the procedure

specified in directive 2000/14/EC.

Vibration level

Hand-arm vibration

This machine was confirmed to transmit a

vibration level of 2.70 m/s2 to hands and arms

by measuring identical machines in

accordance with the procedure specified in

ISO 5349-1:2001,ISO 5349-2:2001.

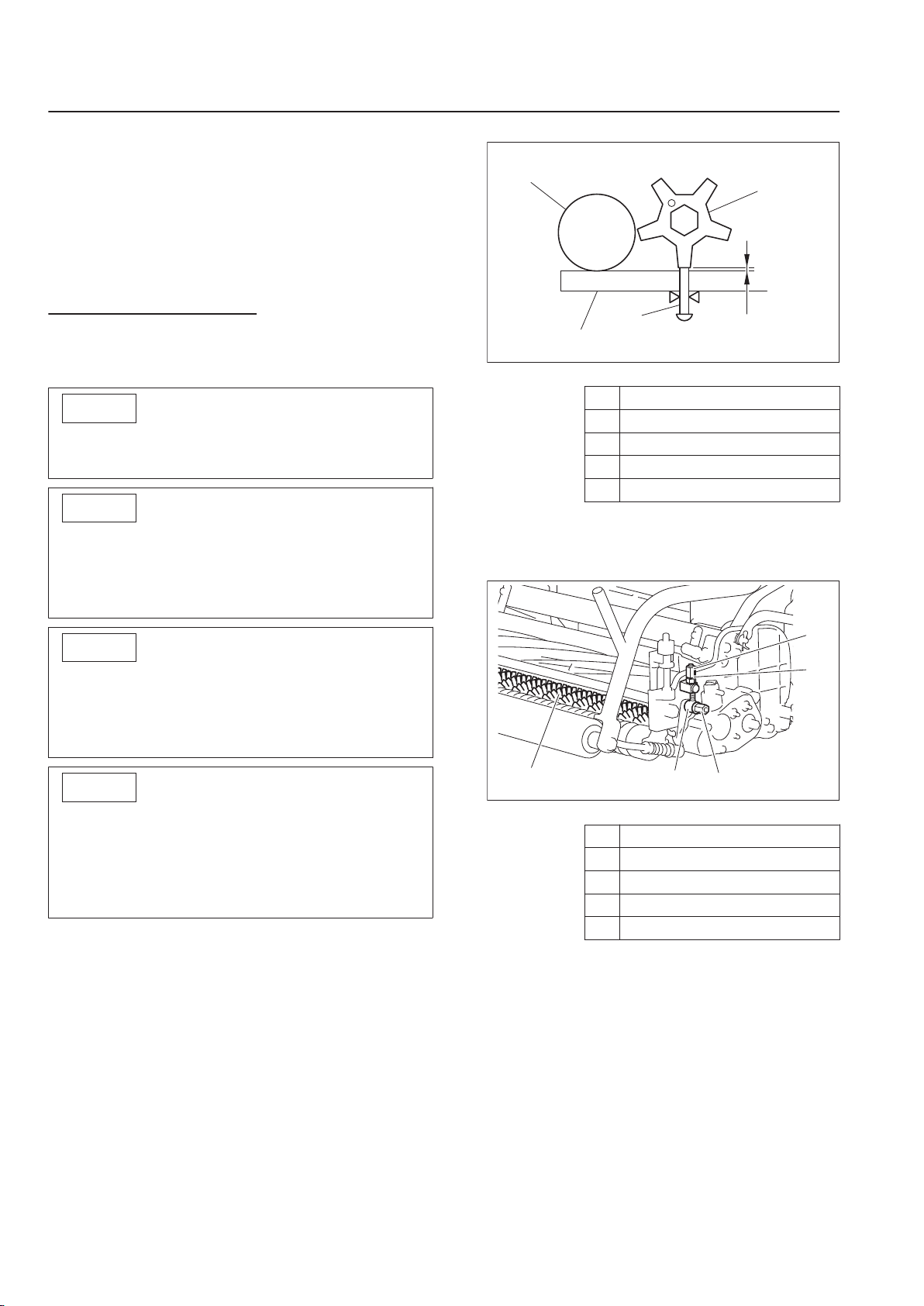

Names of Each Section

LM101

Product Overview

Handle

1

2 Throttle lever

3 Engine switch

4 Main clutch lever

5 Safety lock switch

6 Brake lever

7 Engine

8 Engine clutch cover

9 Light

10 Reel cutter

11 Bed knife

12 Front roller

13 Rear roller

14 Grass catcher roller

15 Grass catcher

16 Groomer

17 Groomer clutch lever

18 FOC (High/Low Clip) selector lever

19 Unit clutch cover

20 Drum clutch cover

21 Drum

22 Traveling tires

23 Stand

A Serial number plate

Product Overview

Names of Each Section_001

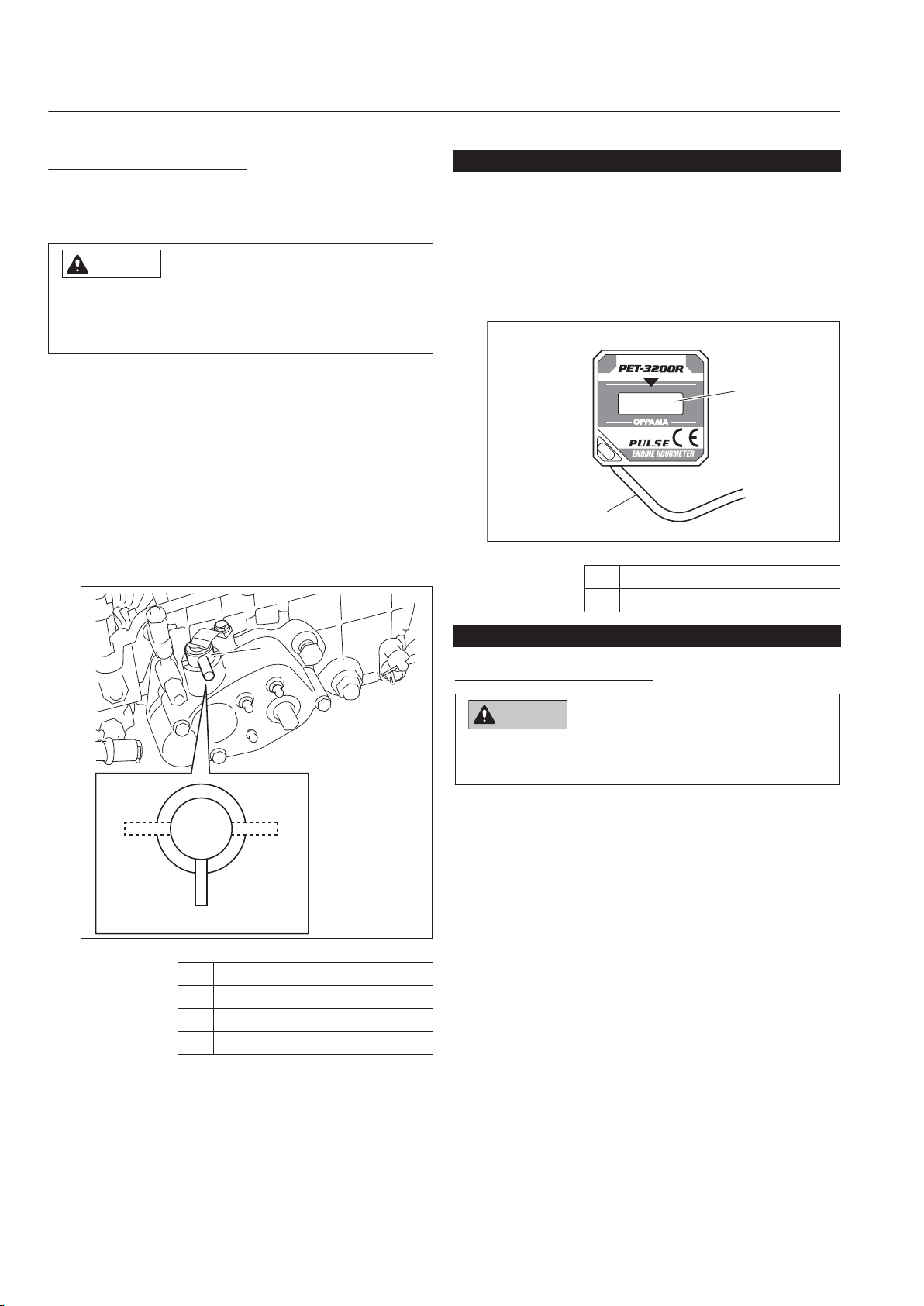

Serial Number Plate

The serial number plate indicates the model

and serial number of the machine.

Serial Number Plate_001

Names of Each Section

Page 3-3

Warning

LM101

Product Overview

Safety Signs and Instruction Signs

About Safety Signs and Instruction Signs

Safety decals and instruction decals are

attached to this machine.

Make sure that they are preserved in their

entirety. If they are damaged, become dirty, or

peel off, replace them with new ones.

Part numbers for decals that need to be

replaced are listed in the parts catalog.

Order them from a Baroness dealer or

Kyoeisha.

Positions of Safety Decals and Instruction Decals

6

3

6

2

1

4

Positions of Safety Decals and Instruction Decals_001

5

6

6iul4h-111

Page 3-4

Safety Signs and Instruction Signs

Explanation about Safety Decals and Instruction Decals

Warning

Danger

Danger

Danger

Danger

㹉㸲㸰㸮㸳㸮㸮㸯㸳㸷㸮

1

2

3

4

qigqnx-118

Danger

Danger

qigqnx-126

Danger

Danger

qigqnx-010

K4205002150

DECAL, CAUTION HANDLING

Use lead-free gasoline.

1.

2.

LM101

Product Overview

Read the Owner's Operating Manual.

3.

1

Flying objects - All persons other than the operator

must keep a safe distance from the machine.

4.

May cut your hand or leg - When the blades are

rotating, keep away from the machine.

K4205001760

DECAL, CAUTION PTO

2

May catch your arm - Keep away from PTO moving

parts during the engine running.

Product Overview

K4205001600

DECAL, CAUTION TO MUTILATION

3

May cut your hand or leg - Stop the cutter rotation

and engine. Otherwise you may get injured.

Safety Signs and Instruction Signs

Page 3-5

qigqnx-015

Warning

qigqnx-120

qigqnx-119

LM101

Product Overview

K4205001330

4

DECAL, CAUTION TO NOISE

K4205001300

DECAL, WARNING ENGINE OIL

5

Check engine oil and gearbox levels before starting.

WARNING

CHECK ENGINE OIL AND

GEARBOX LEVELS

BEFORE STARTING

K4205001300

K4209000370

6

DECAL, GREASING EACH 10-HOURS

Add grease every 10 hours.

Page 3-6

Safety Signs and Instruction Signs

LM101

Handling Instructions

Preparation for Use ............................... Page 4-2

Install the Handle ...................................Page 4-2

Connection of Engine Switch Cord ........Page 4-2

Installing the Stand ................................ Page 4-2

Confirmation of the Operation ............... Page 4-3

Inspection Before Use ...........................Page 4-3

Reel Cutter (Cutting Cylinder) and

Bed Knife (Bottom Blade) ...................... Page 4-3

Air Cleaner .............................................Page 4-3

Drum ......................................................Page 4-4

Tire .........................................................Page 4-5

Brake ..................................................... Page 4-5

Wire ....................................................... Page 4-5

Engine ....................................................Page 4-5

Engine Oil .............................................. Page 4-5

Fuel ........................................................Page 4-6

Oil Leakage ............................................Page 4-7

Main Clutch Lever ................................Page 4-24

Drum Clutch Lever ...............................Page 4-24

Unit Clutch Lever ................................. Page 4-25

FOC (High/Low Clip) Selector Lever ... Page 4-25

Engine Clutch Cover ............................Page 4-25

Groomer Clutch Lever ......................... Page 4-26

Instruments .......................................... Page 4-26

Hour Meter ...........................................Page 4-26

Travel of Machine ................................ Page 4-26

Traveling the Machine ......................... Page 4-26

Cutting Work ........................................ Page 4-27

Cutting Work ........................................Page 4-27

Removing/Installing Traveling Tires .... Page 4-27

Removing/Installing Grass Catcher ..... Page 4-28

Transporting .........................................Page 4-29

Handling Instructions

Tightening torques ................................ Page 4-8

Standard tightening torques .................. Page 4-8

Principal tightening torques ................. Page 4-10

Adjustment Before Operating .............Page 4-12

Adjustment of Handle .......................... Page 4-12

Adjustment of Blade Engagement ....... Page 4-12

Adjustment of Cutting Height ...............Page 4-13

Adjustment of Groomer ........................Page 4-16

Procedure to Start / Stop Engine ....... Page 4-18

Start / Stop of Engine .......................... Page 4-18

Operation of Each Section ..................Page 4-20

Precautions for Operating the

Machine ............................................... Page 4-20

Cautions before Leaving the

Machine ............................................... Page 4-20

Description about Operation Decals ....Page 4-20

Light Switch ......................................... Page 4-23

Engine Switch ......................................Page 4-23

Throttle Lever .......................................Page 4-23

Brake Lever ......................................... Page 4-23

Safety Lock Switch .............................. Page 4-24

Transporting Procedure .......................Page 4-29

Page 4-1

1

2

3

45

6

gifnuq-002

Warning

2

1

eo4kem-002

1

5

6

3

2

4

y7fthb-001

LM101

Handling Instructions

Preparation for Use

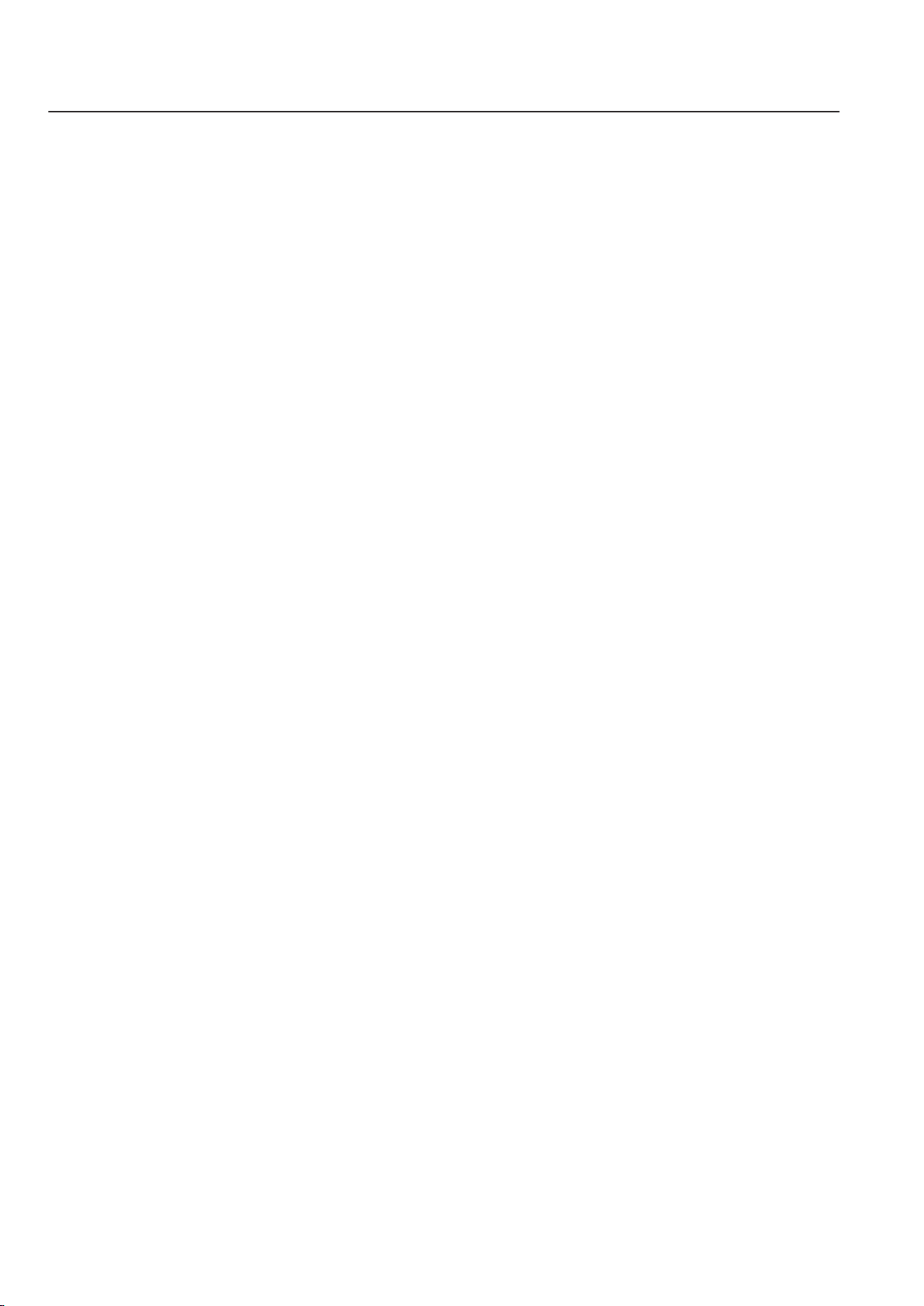

Install the Handle

Put the handle pin on the left frame into the

1.

hole at the left-side lower edge of the handle.

While pressing the right-side lower edge of

2.

the handle inward, put the handle pin of the

right frame into the hole.

3.

Secure the lower edges (slotted section of

the handle adjusters) of the right and left

sides of the handle to the rear frame stay

from the back with the bolts, conical spring

washers, and washers.

2.

The crimp terminal is secured to the engine

crankcase with a hexagon bolt.

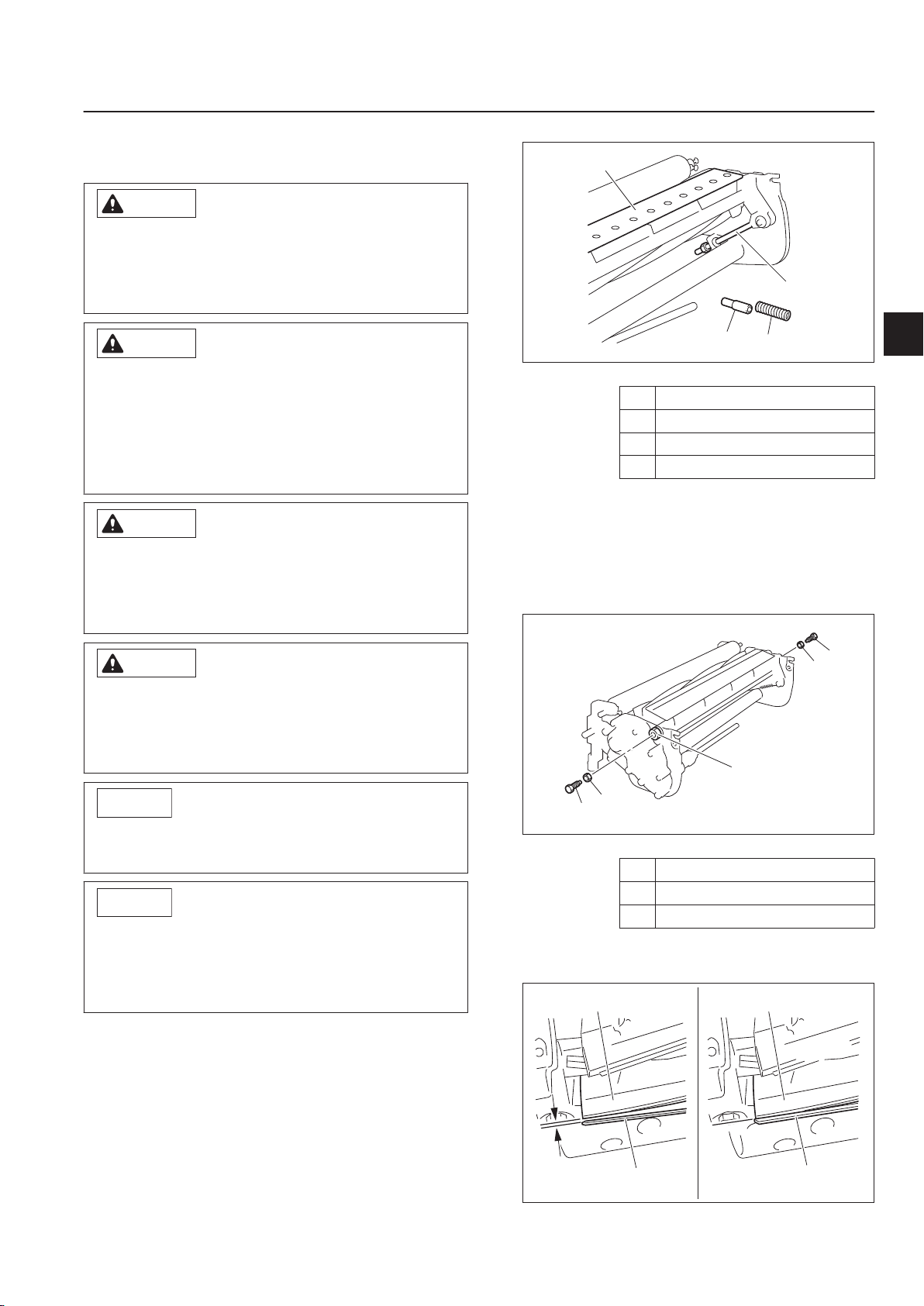

Connection of Engine Switch Cord_001

Plug

1

2 Crimp terminal

Installing the Stand

Install the Handle_001

Lower edge of handle

1

2 Handle pin

3 Handle adjuster

4 Bolt

5 Conical spring washer

6 Washer

Connection of Engine Switch Cord

When the connection of the engine switch

cord is incomplete, the engine will not stop

even if the engine switch is operated.

Check that the cord is correctly connected.

When assembling the handle, check the

connection of the engine switch cord.

There are two connections - plug and crimp

terminal.

The plug is connected to the plug connected

1.

to the engine.

With the inside projection side set to the

1.

right, temporarily secure the left side of the

stand to the frame with the bolt, washer

(inside), and nut (outside).

Put the spring on the projection of the frame

2.

and the projection at the right edge of the

stand.

Installing the Stand_001

Stand

1

2 Bolt

3 Washer

4 Nut

5 Projection

6 Spring

While pulling the right side of the stand

3.

backward, make alignment with the hole in

the frame, and secure the stand with the

bolt, washer (inside), and nut (outside).

Page 4-2

Preparation for Use

Tighten the bolt, washer, and nut at the left

Step:4

Step:3

1

4

2

3

y7fthb-002

1

pd9d4r-015

4.

side of the stand that were temporarily

secured.

Installing the Stand_002

Stand

1

2 Bolt

3 Washer

4 Nut

Handling Instructions

Make sure that the reel cutter (cutting

2.

cylinder) and the bed knife (bottom blade)

are not cracked.

Check to see how much the reel cutter

3.

(cutting cylinder) and the bed knife (bottom

blade) are worn.

4.

Make sure that the reel cutter (cutting

cylinder) and the bed knife (bottom blade)

have not changed color due to heat from

grinding.

5.

Check to see whether or not the second

edge face (relief) remains at the point of

reel cutter (cutting cylinder).

6.

Make sure that the welding between the

reel cutter (cutting cylinder) and the disc

has not come off.

Air Cleaner

Inspection of Air Cleaner

LM101

Handling Instructions

Confirmation of the Operation

Check that the brake operates completely.

1.

Check that the engine clutch operates

2.

completely.

If necessary, make adjustment.

3.

Inspection Before Use

Be sure to perform an inspection before you

start using the machine so that you will be able

to take advantage of its optimum performance

for a long period of time.

Reel Cutter (Cutting Cylinder) and Bed Knife (Bottom Blade)

Inspection of Reel Cutter (Cutting Cylinder) and Bed Knife (Bottom Blade)

The reel cutter (cutting cylinder) and bed knife

(bottom blade) may become dull due to

frequent use, objects crushed during mowing,

or damage caused during transportation.

Inspect the reel cutter (cutting cylinder) and

bed knife (bottom blade), and if necessary,

adjust the blade engagement, perform back

lapping, or resharpen or replace the reel

cutter (cutting cylinder) and the bed knife

(bottom blade).

Check to see whether or not the edge of

1.

the reel cutter (cutting cylinder) and the bed

knife (bottom blade) are too blunt to cut.

For details on handling the engine, please

refer to the Engine's Owner's Manual.

The air cleaner is a component that removes

dirt from the intake air to prevent wear of the

cylinder liners and piston rings so that the

engine will always operate smoothly.

A contaminated air cleaner element may

cause malfunction of the engine.

Make sure that there is no damage to the

1.

air cleaner.

Make sure that the air cleaner element is

2.

not contaminated.

Inspection of Air Cleaner_001

Air cleaner

1

Inspection Before Use

Page 4-3

Caution

Important

1

2

3

6

4

5

7

yt4sup-014

LM101

Handling Instructions

Cleaning of Air Cleaner

For details on handling the engine, please

refer to the Engine's Owner's Manual.

A contaminated air cleaner elements may

cause malfunction of the engine.

To maximize the life of the engine, clean the

air cleaner properly.

Remove the wing screw, and then remove

1.

the cover.

2.

Remove the screw, and then remove the air

cleaner elements.

3.

Remove the urethane element from the

paper element.

When cleaning the paper element, do not use

petroleum solvents.

Replace the air cleaner elements when it gets

damaged or dirty.

Clean the urethane element with white

4.

kerosene and then soak it in the engine oil

and wring out.

Remove dirt and dust from the paper

5.

element with blowing air or patting.

Assemble the paper and urethane

6.

elements.

Attach the air cleaner elements with the

7.

screw.

Set the cover, and then secure it firmly with

8.

the wing screw.

Drum

Inspection of Drum

Make sure that the drum is not cracked or

1.

damaged.

Make sure that there is no abrasion or

2.

adhesion of the drum.

Make sure that there is no play in the fit of

3.

the drum and the bearing.

Cleaning of Air Cleaner_001

Wing screw

1

2 Cover

3 Screw

4 Air cleaner element

5 Urethane element

6 Paper element

7 Gasket

Page 4-4

Inspection Before Use

Danger

Danger

Caution

Important

1

2

bgmiun-019

1

2

3

bgmiun-015

LM101

Handling Instructions

Tire

Inspection of Tires

Check the pneumatic pressure of the tires.

1.

2.

Make sure that there are no cracks,

damage or abnormal wear.

Tire size Pneumatic pressure

Tire for

traveling

4.10/3.50-6

120 kPa (1.2 kgf/

cm2)

Brake

Inspection of Brake

Make sure that the brake wire is not cracked

or damaged.

If the wire is cracked or damaged, replace it

with a new one immediately.

Engine Oil

Inspection of Engine Oil

For details on handling the engine, please

refer to the Engine's Owner's Manual.

Screw the oil level gauge firmly.

Stop the engine, wait for 10 to 20 minutes

1.

for the engine to cool down, and then check

the oil level.

Position the machine so that the engine will

2.

be level, then check the engine oil level

without screwing the oil level gauge into the

oil filling port.

Handling Instructions

Park the machine on a flat place.

Do not park the machine on a slope.

Pull up the brake lever and make sure that

1.

the brake can operate completely.

Pull the brake lever up to the top and make

2.

sure that it can lock the brake lever.

Make sure that the brake is not applied

3.

even slightly after releasing the brake lever.

Wire

Inspection of Wire

Make sure that the wire is not cracked or

1.

damaged.

If the wire is cracked or damaged, replace it

2.

with a new one immediately.

Engine

Inspection of Engine-Associated Parts

For details on handling the engine, please

refer to the Engine's Owner's Manual.

Check the fuel system parts for loosened or

1.

cracked joints and leakage. Replace the

parts if necessary.

Blow compressed air to clean any grass or

2.

flammable materials that may be attached

on or around the muffler.

Inspection Before Use

Inspection of Engine Oil_001

Oil level gauge (Oil filling port)

1

2 Drain plug

The appropriate engine oil level should be

3.

between the upper and lower limit lines on

the gauge.

Inspection of Engine Oil_002

Oil level gauge

1

2 Upper limit

3 Lower limit

Screw the oil level gauge firmly.

4.

Page 4-5

Important

Important

Important

Important

1

2

bgmiun-019

1

2

guc5f6-012

Danger

Danger

Warning

Warning

Caution

LM101

Handling Instructions

Supply of Engine Oil

For details on handling the engine, please

refer to the Engine's Owner's Manual.

Do not supply too much engine oil. Otherwise,

the engine may be damaged.

Do not mix different types of engine oil.

Be sure to use engine oil that is classified as

API Service Grade SE or higher, with an SAE

Viscosity that is appropriate for the operating

environment (ambient temperature).

Screw the oil level gauge firmly.

Fuel

Inspection of Fuel Quantity

Level the machine and then remove the tank

cap to inspect fuel quantity from the fill port.

Inspection of Fuel Quantity_001

Tank cap

1

2 Fuel tank

Fuel Supply

Remove the oil level gauge.

1.

Through the oil filling port, supply new

2.

engine oil until the engine oil reaches a

level in the upper limit lines on the oil level

gauge.

Position the machine so that the engine will

3.

be level, then check the engine oil level

without screwing the oil level gauge into the

oil filling port.

Screw the oil level gauge firmly.

4.

Supply of Engine Oil_001

Oil level gauge (Oil filling port)

1

2 Drain plug

Do not supply fuel above FULL level of the

fuel gauge.

If you supply too much fuel, it might overflow

from the fuel cap when you travel or work on a

slope.

Keep fire away while refueling.

Do not smoke while refueling.

Supply fuel after the engine is stopped and

has well cooled down.

Pay attention not to touch hot parts.

Inspect the fuel quantity and put fuel

(gasoline) if insufficient.

The fuel tank capacity is approximately 2.0

dm3 (2.0 L).

Page 4-6

Inspection Before Use

1

2

A

2e4emp-008

Fuel Supply_001

Fuel strainer

1

2 Filling opening

A Maximum limit of fueling

Oil Leakage

Inspection of Oil Leakage

LM101

Handling Instructions

Handling Instructions

After approximately 50 hours of operation,

some joints may be loosened and oil and

grease may leak.

Be sure to retighten the parts.

Check the bottom of the machine for oil and

grease leakage.

Inspection Before Use

Page 4-7

Important

M

4 T

4.8

tib3yb-001

LM101

Handling Instructions

Tightening torques

Standard tightening torques

Bolts and Nuts

A number of bolts are used in each part of this machine.

Be sure to re-tighten the bolts and nuts, because they may be loosened at the earlier stage of the

use.

As to the bolts and nuts without any special instruction, tighten them in appropriate tightening torque

with proper tool.

Too much tightening may cause the looseness or damage of the screw.

The strength of tightening is determined by types of screws, strength, the friction of thread face or

base face and others.

The table below is for the galvanized or parkerized bolts.

In case that the strength of internal thread is weak, it is not applied.

Do not use rusty or sand attached "screw."

Otherwise, it may cause insufficient tightening even if you apply the specified tightening torque.

The friction of the screw face becomes higher and the tightening torque is canceled out by the

friction, therefore sufficient tightening cannot be applied.

If "screw" is wet by water or oil, do not tighten it with normal tightening torque.

If the screw is wet, the torque coefficient will get smaller and it may result in too much tightening.

Too much tightening may cause looseness by the screw stretched or result in damage.

Do not use a bolt experienced too much burden.

Using the impact wrench requires the skill.

Do exercise as much as possible for steady tightening.

General bolt

Strength classification 4.8

Nominal

diameter

N-m kgf-cm lb-in

M5 3 - 5 30.59 - 50.99 26.55 - 44.26

M6 7 - 9 71.38 - 91.77 61.96 - 79.66

M8 14 - 19 142.76 - 193.74 123.91 - 168.17

M10 29 - 38 295.71 - 387.49 256.68 - 336.34

M12 52 - 67 530.24 - 683.20 460.25 - 593.02

M14 70 - 94 713.79 - 958.52 619.57 - 831.99

M16 88 - 112 897.34 - 1142.06 778.89 - 991.31

M18 116 - 144 1,182.85 - 1,468.37 1,026.72 - 1,274.54

M20 147 - 183 1,498.96 - 1,866.05 1,301.10 - 1,619.73

M22 295 3,008.12 2,611.05

M24 370 3,772.89 3,274.87

M27 550 5,608.35 4,868.05

M30 740 7,545.78 6,549.74

Page 4-8

Tightening torques

8 T

8.8

8

tib3yb-002

11T

10.9

11

tib3yb-003

LM101

Handling Instructions

Heat-treated bolt

Strength classification 8.8 Strength classification 10.9

Nominal

diameter

N-m kgf-cm lb-in N-m kgf-cm lb-in

M5 5 - 7 50.99 - 71.38 44.26 - 61.96 7 - 10 71.38 - 101.97 61.96 - 88.51

M6 8 - 11 81.58 - 112.17 70.81 - 97.36 14 - 18 142.76 - 183.55 123.91 - 159.32

M8 23 - 29 234.53 - 295.71 203.57 - 256.68 28 - 38 285.52 - 387.49 247.83 - 336.34

M10 45 - 57 458.87 - 581.23 398.30 - 504.51 58 - 76 591.43 - 774.97 513.36 - 672.68

M12 67 - 85 683.20 - 866.75 593.02 - 752.34 104 - 134 1,060.49 - 1,366.40 920.50 - 1186.03

M14 106 - 134 1,080.88 - 1,366.40 938.21 - 1,186.03 140 - 188 1,427.58 - 1,917.04 1,239.14 - 1,663.99

M16 152 - 188 1,549.94 - 1,917.04 1,345.35 - 1,663.99 210 - 260 2,141.37 - 2,651.22 1,858.71 - 2,301.26

M18 200 - 240 2,039.40 - 2,447.28 1,770.20 - 2,124.24 280 - 340 2,855.16 - 3,466.98 2,478.28 - 3,009.34

M20 245 - 295 2,498.27 - 3,008.12 2,168.50 - 2,611.05 370 - 450 3,772.89 - 4,588.65 3,274.87 - 3,982.95

M22 - - - 530 5,404.41 4,691.03

M24 - - - 670 6,831.99 5,930.17

M27 - - - 1,000 10,197.00 8,851.00

M30 - - - 1,340 14,628.78 11,860.34

Handling Instructions

Note:

The same values are applied to "fine screw thread."

Tightening torques

Page 4-9

LM101

Handling Instructions

Principal tightening torques

Tightening Torque by Model

LM101

Tighten the following bolts and nuts at the torque specified in the table.

For thread locking adhesive, apply a middle strength thread locker (ThreeBond 1322 or equivalent

anaerobic sealant).

Tightening torque Thread

Location Code Part name

K0160000132

K0160000082

Mower

Clutch K0013060251 BOLT, HT M6-25

Frame K001A080201

Handle K0010100252 BOLT, HT M10-25 29 - 38

Vertical brush

Vertical K6083000143

LM54G--0132Z0

LM54G--0133Z0

K0071000222

LM54GS-1231A0 SCREW

K0185160003

K0160000302

K0160000302

NUT, SMALL P1.5

M20-10

NUT, SMALL P1.5

M20-8

BOLT, SUS

MOUNTING MOWER

(LH)

BOLT, SUS

MOUNTING MOWER

(RH)

SCREW, HT + FLAT

HEAD M6-12

BOLT, W/HEXAGON

HOLE, M8-20

NUT, LEFT-HANDED

P1.5 M16-3

NUT, SPECIAL P1

M17 (Blade fixation

side)

NUT, SPECIAL P1

M17 (Lock side)

PIN, STEPPED FOR

FIXING (RH) CASE

N-m kgf-cm lb-in

7

(Reference

values)

45

(Reference

values)

29 - 38

(Reference

values)

29 - 38

(Reference

values)

7 - 9

14

(Reference

values)

14 - 19

18

(Reference

values)

45

(Reference

values)

5 - 10

45

(Reference

values)

6 61.18 53.11 -

71.38

(Reference

values)

458.87

(Reference

values)

295.71 -

387.49

(Reference

values)

295.71 -

387.49

(Reference

values)

71.38 -

91.77

142.76

(Reference

values)

142.76 -

193.74

295.71 -

387.49

183.55

(Reference

values)

458.87

(Reference

values)

50.99 -

101.97

458.87

(Reference

values)

61.96

(Reference

values)

398.30

(Reference

values)

256.68 -

336.34

(Reference

values)

256.68 -

336.34

(Reference

values)

61.96 -

79.66

123.91

(Reference

values)

123.91 -

168.17

256.68 -

336.34

159.32

(Reference

values)

398.30

(Reference

values)

44.26 -

88.51

398.30

(Reference

values)

locking

adhesive

-

-

-

-

-

-

-

-

-

-

-

-

Page 4-10

Tightening torques

Location Code Part name

Vertical LM54GAS1230Z3

BOLT, CLAMPING

CASE (LH)

Handling Instructions

Tightening torque Thread

N-m kgf-cm lb-in

6 61.18 53.11 -

LM101

locking

adhesive

Handling Instructions

Tightening torques

Page 4-11

A

B

1

2

3

75uxaw-011

Caution

A

B

C

1

zhz6po-009

1

2

fofmiy-002

LM101

Handling Instructions

Adjustment Before Operating

Adjustment of Handle

The height of the handle can be adjusted

according to the Operator's working position.

Move the handle adjusters supporting the

handle up or down and fix them with the bolts.

Adjustment of Handle_001

Bolt

1

2 Conical spring washer

3 Washer

A High

B Low

Adjustment of Blade Engagement

When checking the sharpness of the blades

with newspaper, be sure to stop the engine

and protect your hands with gloves etc.

Pay attention not to let the reel cutter (cutting

cylinder) catch your gloves. Otherwise, you

may injure your hand or fingers.

Stop the engine.

1.

Set the FOC (High/Low Clip) selector lever

2.

to the "Stop" position.

1 FOC (High/Low Clip) selector lever

A High clip

B Low clip

C Stop

Adjust the engagement between the reel

3.

cutter (cutting cylinder) and the bed knife

(bottom blade) so that newspaper (one

piece) will be cut cleanly by the edge of both

blades when the blades in their entirety

come slightly into contact with each other via

the cutter adjustment nuts.

Insert a strip of newspaper into the space

4.

between the reel cutter (cutting cylinder) and

the bed knife (bottom blade) at an angle of

90 degrees.

Then, rotate the reel cutter (cutting cylinder)

counter-clockwise (when you face the mower

unit from the left) to check the sharpness of

the blades.

Check the sharpness of the entire range

(three or four points from left edge to right) of

the reel cutter (cutting cylinder).

If a gap is created between edges:

・

Loosen (rotate counter-clockwise) the

cutter adjustment nut to apply more

contact pressure between the reel cutter

(cutting cylinder) and the bed knife

(bottom blade).

If the reel cutter (cutting cylinder) is too

・

tight to turn:

Tighten (rotate clockwise) the cutter

adjustment nut to reduce the contact

pressure between the reel cutter (cutting

cylinder) and the bed knife (bottom blade).

If the sharpness is not improved by the

・

adjustment:

Perform back lapping to the reel cutter

(cutting cylinder).

Page 4-12

Adjustment of Blade Engagement_001

Adjustment of Blade Engagement_002

Adjustment Before Operating

1 Cutter adjustment nut

Important

Important

1

2

A

A

33i8xn-002

2 Spring

Adjustment of Cutting Height

Adjust the cutting height to fit your cutting work.

This applies the set cutting height that differs

from the actual cutting height.

Cutting Height and Thickness of Bed Knife (Bottom Blade)

LM101

Handling Instructions

The recommended minimum cutting heights

are based on those of common greens.

They may vary according to the green

conditions and machine specifications.

If the green undulation is hard, set it a little bit

higher in order not to damage the green

surface.

Minimum cutting height is recommended for

each thickness of blade as follows.

Type of blade

Standard blade

Tipped blade

Thickness of

blade

(mm/inch)

1.5 3.0 K2511000270 1.5 Bed knife (bottom blade) 55G Standard

2.0 3.5 K2511000280 2 Bed knife (bottom blade) 55G

2.5 4.0 K2511000050 2.5 Bed knife (bottom blade) 55G

3.0 4.5 K2510000060 3 Bed knife (bottom blade) 62.5-559

5.0 7.0 K2510000160 5 Bed knife (bottom blade) 62.5-559

Recommended

minimum cutting

height (mm/inch)

Handling Instructions

Code Part name Remarks

Cutting Height and Thickness of Bed Knife (Bottom Blade)_001

Standard blade

1

2 Tipped blade

A Thickness of blade

Adjustment Before Operating

Page 4-13

1

2

3

4

3kws2a-018

1

2

3

4

3kws2a-019

4

1

32

C

B

A

3kws2a-020

B

4

1

32

C

A

3kws2a-021

LM101

Handling Instructions

Adjustment of Rear Roller

You can adjust the rear roller by 3 stages.

Adjust the rear roller in a position that suits

your work requirements.

Remove nuts A, washers A, S washers A

1.

and bolts A on the right and left sides.

To obtain desired cutting position,

3.

determine the direction of bolt B and install

the rear roller assy.

Cutting position

Aggressive cutting position

・

Long distance of offset and large angle of

bed knife

Adjustment of Rear Roller_001

Bolt A

1

2 Washer A

3 S washer A

4 Nut A

Remove washers B and nuts B on the right

2.

and left sides, and then remove the rear

roller assy from the frame.

Standard cutting position

・

Adjustment of Rear Roller_002

Rear roller assy

1

2 Bolt B

3 Washer B

4 Nut B

Adjustment of Rear Roller_003

Reel cutter

1

2 Bed knife

3 Rear roller assy

4 Bolt B

A Cutting height

B Offset distance

C Bed knife angle

Adjustment of Rear Roller_004

Reel cutter

1

2 Bed knife

3 Rear roller assy

4 Bolt B

A Cutting height

B Offset distance

C Bed knife angle

Page 4-14

Adjustment Before Operating

42

C

B

A

3

1

3kws2a-022

4

3

2

1

3kws2a-016

2

1

9

3

8

4

5

7

6

A

3kws2a-017

3

A

2

1

3kws2a-007

LM101

Handling Instructions

Less aggressive cutting position

・

Short distance of offset and small angle

of bed knife

Adjustment of Rear Roller_005

Reel cutter

1

2 Bed knife

3 Rear roller assy

4 Bolt B

A Cutting height

B Offset distance

C Bed knife angle

Adjustment of Front Roller

Set the slide caliper to the required cutting

1.

height, adjust the neck position of the

cutting height screw of the cutting height

gauge and securely lock with a wingnut.

Loosen the nut fixing the roller bracket of

2.

right and left.

3.

Set the cutting height gauge to the front

roller and rear roller at the right and left end

of the mower unit.

Adjustment of Front Roller_002

Front roller

1

2 Roller bracket

3 Front groomer

4 Reel cutter (Cutting cylinder)

5 Rear roller

6 Bed knife (Bottom blade)

7 Cutting height gauge

8 Small screw for cutting height

9 Small screw for groomer

A Cutting height

Adjust the front roller up and down by the

4.

roller adjuster to determine the position of

the front roller, in order not to have a gap

with the neck position of the cutting height

screw of the cutting height gauge, at the

edge of the bed knife.

Handling Instructions

Adjustment of Front Roller_001

Front roller

1

2 Roller bracket

3 Roller adjuster

Adjustment Before Operating

4 Nut

Repeat the same process at the opposite

5.

side for the adjustment of cutting height.

Adjustment of Front Roller_003

Bed knife (Bottom blade)

1

2 Small screw for cutting height

3 Cutting height gauge

A Cutting height

Page 4-15

Important

Important

Important

Important

1

4

3

2

A

2qrq2r-002

1

54

2

3

2qrq2r-007

LM101

Handling Instructions

6.

Tighten the nuts that secure the right and

left roller brackets to secure them firmly.

Again, make sure that the cutting height is

7.

at the required position by applying the

cutting height gauge to the front roller and

the rear roller at each edge of right and left

of the mower unit.

Adjustment of Groomer

Note:

Depending on the specifications, this function

may not be available.

Adjust the front groomer according to the

condition of the green before use.

Adjustment of Groomer_001

Dethatching blade

1

2 Small screw for groomer

3 Cutting height gauge

4 Front roller

A Operating height

Set the grooming height more than 0.0 mm

from the ground.

If the groomer blades are set deeper than the

ground surface, the groomer shaft may break.

The front groomer, when it is put too low, may

apply an excessive load to the engine and

transmission section and cause malfunction or

failure.

When using the grooming brush, adjust the

height so that it will be equal to the cutting

height.

The brush will be worn easily when the height

is too low.

1.

Set the slide caliper to the required operating

height, adjust the end of the small screw for

groomer of the cutting height gauge and

securely lock with a wing nut.

Loosen the nuts B fixing the right and left

2.

groomer adjustment screws.

Loosen the right and left special high nuts.

3.

Adjustment of Groomer_002

Front groomer

1

2 High nut

3 Nut A

4 Nut B

5 Groomer adjustment screw

Page 4-16

Adjustment Before Operating

Apply the cutting height gauge to the front

2

1

9

3

8

4

5

7

6

A

3kws2a-017

Important

1

54

2

3

2qrq2r-007

4.

roller and the rear roller at the right and left

edges of the mower unit.

Adjustment of Groomer_003

Front roller

1

2 Roller bracket

3 Front groomer

4 Reel Cutter (Cutting Cylinder)

5 Bed knife (Bottom blade)

6 Rear roller

7 Cutting height gauge

8 Small screw for cutting height

9 Small screw for groomer

A Operation height

Adjust the position so that the small screw for

groomer can contact the dethatching blades.

LM101

Handling Instructions

Adjustment of Groomer_004

Front groomer

1

2 High nut

3 Nut A

4 Nut B

5 Groomer adjustment screw

Note:

In the case that the front groomer is not

used, you do not have to change the set

grooming height.

Loosen the nuts fixing the right and left

groomer adjustment screws, lift the groomer

and tighten the right and left nuts to raise the

front groomer so that it cannot contact the

lawn.

Next time the groomer is used, loosen the

right and left nuts, lower the groomer and

tighten the nuts so that it can return to the

grooming height set previously.

Handling Instructions

Adjust the nuts A up and down so that the

5.

right and left sides can be parallel.

Repeat the same process at the opposite

6.

side for the adjustment of grooming height.

Tighten the nuts B that secure the right and

7.

left groomer adjustment screws.

8.

Tighten the right and left high nuts.

Reconfirm that the grooming height is at the

9.

required position by applying the cutting

height gauge to the front roller and the rear

roller at the right and left edges of the mower

unit.

Adjustment Before Operating

Page 4-17

Warning

Caution

BA

1

v2e27i-035

A

B

1

v2e27i-037

B

2

1

A

v2e27i-040

A

1

B

B

v2e27i-055

BA

1

v2e27i-043

LM101

Handling Instructions

Procedure to Start / Stop Engine

Start / Stop of Engine

Procedure to Start Engine

Before starting the engine, make sure that

there are no other people or obstacles around

the machine.

Make sure that the engine clutch cover is

installed in the prescribed position.

Make sure that the engine switch is in the

1.

"OFF" position.

Don't grip the main clutch lever.

3.

Procedure to Start Engine_003

Main clutch lever

1

2 Safety lock switch

A ON

B OFF

Set the fuel cock to the "Open" position.

4.

Procedure to Start Engine_001

Engine switch

1

A ON

B OFF

Make sure that the brake is locked.

2.

Procedure to Start Engine_002

Brake lever

1

A Lock

B Unlock

Procedure to Start Engine_004

Fuel cock

1

A Close

B Open

Set the engine switch to the "ON" position.

5.

Procedure to Start Engine_005

Engine switch

1

A ON

B OFF

Page 4-18

Procedure to Start / Stop Engine

Shift the throttle lever halfway from low

B

1

A

v2e27i-050

A

A

B

1

v2e27i-056

1

v2e27i-048

A

B

1

B

v2e27i-057

B

2

1

A

v2e27i-040

B

1

A

dgvd7o-002

6.

speed to high speed position.

Procedure to Start Engine_006

Throttle lever

1

A High speed

B Low speed

Set the choke lever to the "Close" position.

7.

Handling Instructions

Set the choke lever to the "Open" position.

9.

Procedure to Start Engine_009

Choke lever

1

A Close

B Open

Procedure to Stop Engine

Don't grip the main clutch lever.

1.

LM101

Handling Instructions

Procedure to Start Engine_007

Choke lever

1

A Close

B Open

Pull the recoil starter, and the engine will

8.

Procedure to Stop Engine_001

Main clutch lever

1

2 Safety lock switch

A ON

B OFF

start.

Set the throttle lever to low speed position.

2.

Procedure to Start Engine_008

1

Recoil starter

Procedure to Stop Engine_002

Procedure to Start / Stop Engine

Page 4-19

BA

1

v2e27i-035

A

1

A

B

dgvd7o-006

Caution

Caution

Caution

Caution

6

7

9

2

3

4

5

8

1

8zq6pd-023

LM101

Handling Instructions

1 Throttle lever

A High speed

B Low speed

Set the engine switch to the "OFF" position.

3.

Procedure to Stop Engine_003

Engine switch

1

A ON

B OFF

Set the fuel cock to the "Close" position.

4.

Cautions before Leaving the Machine

Park the machine on a flat place.

Do not park the machine on a slope.

Check that the engine has stopped.

Make sure that the brake lever is locked.

Description about Operation Decals

Procedure to Stop Engine_004

1

A Close

B Open

Operation of Each Section

Fuel cock

Precautions for Operating the Machine

Under any circumstances drive the machine at

such a speed that you can stop it immediately

Page 4-20

for emergencies.

Description about Operation Decals_001

Engine switch mark

1

2 Decal, accelerator

3 Decal, brake

4 Decal, light switch

5 Sticker, ON/OFF A (Unit clutch)

6 Sticker, ON/OFF A (Drum clutch)

7 Sticker, reel rotation

8 Decal, groomer indication

9 Decal, alignment 10300 (Set of 2pcs)

Operation of Each Section

-

OFF ON

8zq6pd-006

HIGH

LOW

6n6oux-014

6n6oux-092

1

2

6n6oux-086

ON

OFF

8zq6pd-011

1

ENGINE SWITCH MARK

It illustrates the positions of the engine switch.

-

DECAL, ACCELERATOR

2

It illustrates Low/High of the engine rotation speed.

HIGH:High Speed

LOW:Low Speed

LM101

Handling Instructions

Handling Instructions

K4209001200

3

DECAL, BRAKE

It illustrates the locking position for the parking brake.

K4203001610

DECAL, LIGHT SWITCH

Note:

4

Depending on the specifications, this function may

not be available.

It illustrates ON/OFF of the light.

K4203001140

5

STICKER, ON/OFF A

It shows ON/OFF of the unit clutch.

Operation of Each Section

Page 4-21

ON

OFF

8zq6pd-011

8zq6pd-022

Normal

Stop

Reverse

8zq6pd-014

8zq6pd-012

LM101

Handling Instructions

K4203001140

6

STICKER, ON/OFF A

It shows ON/OFF of the drum clutch.

K4203001690

STICKER, REEL ROTATION

It illustrates High / Low clip of the reel cutter rotation

7

speed.

Low: Low Clip

High: High Clip

K4203001120

DECAL, GROOMER INDICATION

Note:

Depending on the specifications, this function may

8

not be available.

It illustrates the changeover of rotational direction of

the groomer.

Normal: Normal rotation

Reverse: Reverse rotation

K4209001230

DECAL, ALIGNMENT 10300 (SET OF 2PCS)

Note:

9

Depending on the specifications, this function may

not be available.

Affix the decal in indicative positions for operational

support.

Page 4-22

Operation of Each Section

A

B

1

bnec97-022

BA

1

v2e27i-035

B

1

A

v2e27i-045

Important

A

B

1

v2e27i-037

LM101

Handling Instructions

Light Switch

Note:

Depending on the specifications, this function

may not be available.

The light switch is located in the handle panel.

Flip up the switch to turn on the light, and down

to turn off.

Light Switch_001

Light switch

1

A ON

B OFF

Engine Switch

The factory default engine rpm (maximum) is

set to 3,100 rpm.

Operate at about 3,000 rpm.

Throttle Lever_001

Throttle lever

1

A High speed

B Low speed

Brake Lever

Avoid quick operation.

Carefully and slowly operate the machine.

Handling Instructions

The engine switch is located in the handle.

To start the engine, set the engine switch to

the “ON” position, and to stop it, set to the

“OFF” position.

Engine Switch_001

Engine switch

1

A ON

B OFF

Throttle Lever

The throttle lever is located in the handle and

enables you to adjust the engine rpm.

Move the throttle lever toward HIGH (high

speed) to increase the engine rpm, and toward

LOW (low speed) to reduce the rpm.

Note:

Operation of Each Section

The brake lever is located in the handle.

Pull up the brake lever to activate braking and

the travel of the machine is stopped.

Pull the brake lever up to the top and the brake

lever is locked with brake applied.

Push down the brake lever to release the

brake.

Note:

Lock the brake lever to apply Parking Brake.

Brake Lever_001

Brake lever

1

A Lock

B Unlock

Page 4-23

Important

A

B

2

1

6zsd1y-001

Important

Important

B

2

1

A

k7k67l-002

Caution

1

dckng4-001

LM101

Handling Instructions

Safety Lock Switch

The safety lock switch is located in the handle.

While the main clutch is in the "OFF" position,

the safety lock is activated.

Grip the main clutch lever while pushing the

safety lock switch to unlock the safety lock.

Main Clutch Lever_001

1

2 Safety lock switch

A ON

B OFF

Drum Clutch Lever

Main clutch lever

Safety Lock Switch_001

Main clutch lever

1

2 Safety lock switch

A Lock

B Unlock

Main Clutch Lever

Avoid quick operation.

Carefully and slowly operate the machine.

The main clutch is not activated unless the

safety lock released.

The main clutch lever is located in the handle.

Unlock the safety lock and then grip the main

clutch lever to traveling forward with rotating

the reel cutter.

Release the main clutch lever from the hands

to stop the machine traveling and the reel

cutter rotating.

Operate and set the lever to the proper

position in accordance with the purpose when

the main clutch lever set to the OFF position.

The drum clutch lever is located at the rear of

the right frame side.

Set the lever to ON to activate the drum and

the traveling wheels.

Set the lever to OFF for neutral.

Drum Clutch Lever_001

Drum clutch lever

1

Note:

The machine can be moved easily with the

lever OFF when the engine stopped.

Page 4-24

Operation of Each Section

Caution

ON

1

OFF

xzqhpm-001

Caution

1

B

A

C

el1q3z-002

1

2

paspfk-003

LM101

Handling Instructions

Unit Clutch Lever

Operate and set the lever to the proper

position in accordance with the purpose when

the main clutch lever set to the OFF position.

The unit clutch lever is located above the left

frame.

Set the lever to the ON position and the power

is transmitted from the transmission case to the

unit.

Set the lever to the OFF position and the

power from the transmission case to the unit is

cut off.

This is suitable for the work when the turf

condition is not so good.

When the lever is shifted to "Stop", the drive

transmission for the reel rotation gear is

disengaged.

FOC (High/Low Clip) Selector Lever_001

FOC (High/Low clip) Selector Lever

1

A High clip

B Low clip

C Stop

Handling Instructions

Engine Clutch Cover

The engine clutch cover is on the left side of

the engine, covering the engine clutch.

The engine clutch cover can be opened and

Unit Clutch Lever_001

Unit clutch lever

1

closed with the fastening bolt taken off and put

on.

Note:

Set the lever to the OFF position when

traveling.

FOC (High/Low Clip) Selector Lever

Operate and set the lever to the proper

position in accordance with the purpose when

the main clutch lever set to the OFF position.

Engine Clutch Cover_001

The FOC (High/Low Clip) selector lever is in

the right side of the unit.

There are three changeover positions.

When the lever is shifted to "High clip", the reel

cutter (cutting cylinder) rotates faster, and the

clip pitch (cutting interval) becomes shorter.

This is suitable for the work in good turf

condition.

When the lever is shifted to "Low clip", the reel

cutter (cutting cylinder) rotates slower

compared to "High clip" and the clip pitch

becomes longer.

Operation of Each Section

Engine Clutch Cover

1

2 Fastening bolt

Page 4-25

Caution

1

BA

C

aqilnf-003

1

2

uknn6v-002

Warning

LM101

Handling Instructions

Groomer Clutch Lever

Note:

Depending on the specifications, this function

may not be available.

Operate and set the lever to the proper

position in accordance with the purpose when

the main clutch lever set to the OFF position.

The groomer clutch lever is in the left side of

the unit.

There are three changeover positions.

When the lever is in the "Normal rotation"

position, the groomer rotates in the same

direction as the blade reel cylinder.

When the lever is in the "Reverse rotation"

position, the groomer rotates in the opposite

direction of the blade reel cylinder.

When the lever is in the "Rotation stop"

position, the groomer does not rotate.

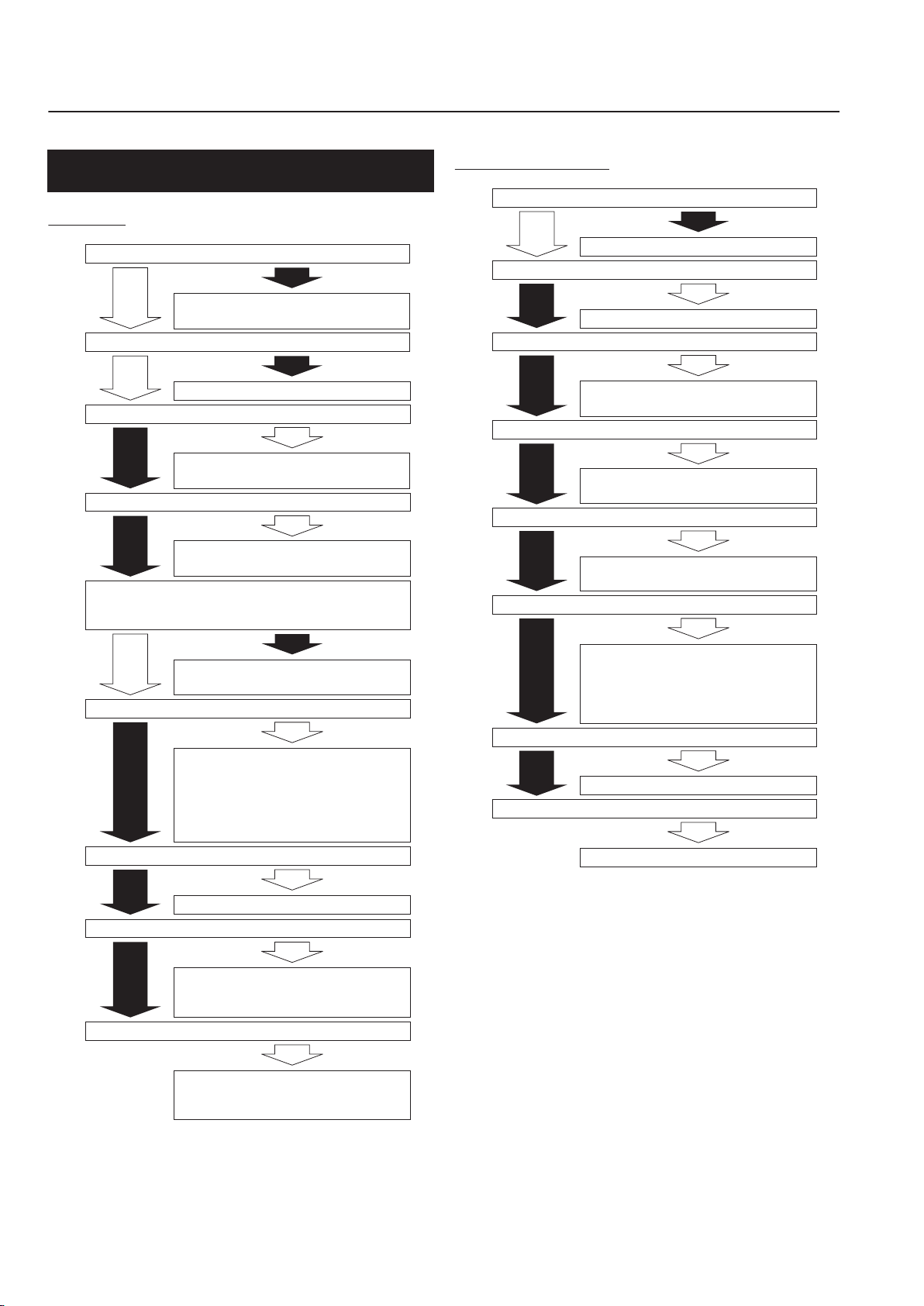

Instruments

Hour Meter

The hour meter is located in the operation

panel, and indicates the accumulated operation

time of the engine.

It accumulates time up to 9999:59 and then the

count automatically returns to 0000:00.

Hour Meter_001

Hour meter

1

2 Antenna lead wire

Groomer Clutch Lever_001

Groomer clutch lever

1

A Normal rotation

B Reverse rotation

C Rotation stop

Travel of Machine

Traveling the Machine

Do not start to move or stop the machine

abruptly.

Install traveling tires.

1.

Flip up the stand.

2.

Set the drum clutch lever to "ON" position.

3.

Start the engine.

4.

Release the brake.

5.

Release the safety lock and grip the main

6.

clutch lever slowly.

The machine can start traveling.

7.

Page 4-26

Instruments

Warning

Caution

Caution

Caution

Important

1

2

x9pzjh-006

1

2

x9pzjh-002

1

x9pzjh-007

LM101

Handling Instructions

Cutting Work

Cutting Work

Do not start to move or stop the machine

abruptly.

Do not operate on a steep slope.

Be sure to operate at an appropriate speed for

the mowing site.

For mowing on an undulated surface, mow

with lowered cutting speed.

Be sure to attach the grass catcher.

Discharge the clippings at the right time during

operation.

Traveling tires are used to travel.

Removing Traveling Tires:

1.

Stop the engine.

2.

Flip down the stand.

Removing/Installing Traveling Tires_001

Stand

1

2 Traveling tire

While holding the lever of the wheel mount

3.

plate to the release position, pull the

traveling tire toward to remove it.

Handling Instructions

Remove the traveling tires.

1.

Flip up the stand.

2.

Install the grass catcher.

3.

Move the FOC (High/Low Clip) selector lever

4.

to the desired position.

Move the drum clutch lever to the "ON"

5.

position.

Move the groomer clutch lever to the desired

6.

position.

Move the Unit clutch lever to the "ON"

7.

position.

Start the engine.

8.

9.

Release the brake.

Release the safety lock and grip the main

10.

clutch lever slowly to start mowing.

Note:

The factory default maximum engine rotation

speed is set to 3,100 rpm.

Operate at about 3,000 rpm.

Removing/Installing Traveling Tires

Removing/Installing Traveling Tires_002

Traveling tire

1

2 Wheel mount plate

Remove the traveling tires before cutting

work.

Cutting Work

Removing/Installing Traveling Tires_003

Traveling tire

1

Repeat the same process for removing the

4.

opposite traveling tire.

Page 4-27

Important

1

A

A

2

x9pzjh-008

Important

1

2

A

x9pzjh-005

Caution

2

1

bos35l-005

LM101

Handling Instructions

Installing Traveling Tires:

The drum shaft and the traveling tires have

mating parts each other.

Make sure of their shapes to install the

traveling tires.

Removing/Installing Traveling Tires_004

Traveling tire

1

2 Drum shaft

A Mating parts

Removing/Installing Grass Catcher

Stop the engine before removing/installing the

grass catcher.

Removing Grass Catcher:

Lift up the grass catcher and remove it from

the grass catcher fitting bars.

Installing Grass Catcher:

Insert the grass catcher fitting bars into the

slots of the grass catcher.

Make sure that the wheel mount plate is

grooved on the drum shaft.

Otherwise the tires may come off.

Removing/Installing Traveling Tires_005

Traveling tire

1

2 Wheel mount plate

A Groove

When installing traveling tires, follow the

reverse procedure to removing.

Removing/Installing Grass Catcher_001

Grass catcher

1

2 Grass catcher fitting bar

Page 4-28

Cutting Work

Transporting

Caution

Important

Important

Transporting Procedure

When loading and unloading the machine,

wear non-slip shoes and travel slowly.

When securing the machine with a rope, do

not tie the rope to the engine.

When securing the machine with a rope, be