Hammer Knife Mower

Serial No.10101-

Owner's operating manual

Read this manual and the owner's manual for the engine before using the machine.Required reading

Original lnstructions Ver.1.2

DANGER

WARNING

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

DANGER

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Warning for Safety

Purpose

Safe Operating Practices

Location of labels

1. Precautions as to use

2. Safety operation

3. Part names

4. Features

5. Specifications

6. Inspection before use

6-1. Lubrication to each part

6-2. Inspection of hydraulic oil

6-3. Hydraulic oil change

6-4. Battery

WARNING

6-5. Lubrication of friction surface of each part

7. Tightening each part

8. Engine starting sequence

8-1. Engine start

WARNING

8-2. Engine start . operation method

8-3. Engine stop method

CAUTION

8-4. Precautions to take when leaving the machine

9. Machine operation

CAUTION

9-1. Machine operation

CAUTION

9-2. Knife clutch

WARNING

9-3. Traveling lever

9-4. Mowing height adjustment

9-5. Working speed

9-6. Step (simple riding unit)

CAUTION

9-7. Traveling on the public roads and the limit of crew

9-8. Alarm buzzer

9-9. Side brake

10. Mower unit

10-1. Use of both sides of knife

10-2. Replacement of knife

10-3. Grinding the knife

10-4. Standard time for knife replacement

10-5. Hammer Knife inspection items

10-6. As for the protection cover

11. Operation on slope

11-1. Operation on slope

10

10

11

11

11

11

12

13

14

14

14

14

14

14

15

15

15

15

15

16

16

17

17

17

17

17

17

17

18

18

18

19

19

1

WARNING

2

2

5

7

8

9

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

11-2. Precautions as to Operation on a steep slope

CAUTION

CAUTION

12. Precautions as to maintenance

12-1. Precautions as to maintenance

WARNING

12-2. Prevention of damage due to high-pressure oil

DANGER

12-3. Precautions as to fuel handling

DANGER

12-4. Precautions as to battery handling

13. Maintenance schedule

14. Belt adjustment

14-1. Knife

14-2. Hydraulic pump

14-3. List of the place using belts

15. Crawler

15-1. Crawler tension

.

15-2. Installation

removal of crawler

15-3. Prevention of crawler tearing loose

15-4. Greasing the crawler

CAUTION

16. Adjustment of traveling section

CAUTION

16-1. Adjustment of neutral position of piston pump

16-2. Adjustment of neutral position of traveling lever

16-3. Confirmation after adjustment

17. Engine

Precautions as to handling of engine

18. Hoisting and jacking up the machine

CAUTION

18-1. Hoisting

18-2. Jacking up

CAUTION

19. Attaching/detaching the mower unit

19-1. Removal of mower unit

19-2. Installation of the mower unit

19-3. Hydraulic cylinder single-/double-acting changeover

20. Gear oil change for traveling motor

21. Wiring diagram

22. Hydraulic circuit

22-1. Valve module detail

23. Troubleshooting

23-1. Engine trouble

23-2. Traveling system trouble

23-3. Mower unit trouble

23-4. Overheating

23-5. Step trouble

24. Checklist

19

20

20

20

20

20

21

21

21

21

22

23

23

23

23

23

23

24

24

25

25

25

25

25

26

26

26

27

27

27

28

29

30

31

31

33

34

36

36

37

Warning for Safety

50h

Warning labels with the mark have been attached to this machine. The labels indicate

the items which are particularly important from the safety point of view, so please work

safety and always obey warnings.

Warning Marks

DANGER

Negligence of the warning will cause death or

serious injury.

Greeting

Thank you very much for purchasing the BARONESS HAMMER KNIFE MOWER

HMC156E/HMC172E.

This handling manual explains the method of correct use, adjustment and inspection

of the HAMMER KNIFE MOWER. Carefully read this manual before operation so as to

thoroughly understand the machine. The machine is shipped after sufficient trial operation

and inspection when it is completed at the factory. However, whether or not the machine

can exhibit its expected performance depends greatly on the handling method, as well

as the skill of inspection, adjustment, and lubrication before and after operation. Carefully

maintain your machine to bring out the best in the machine and for safe operation. Keep

this manual near the machine for future reference to confirm unclear points as necessary.

WARNING

CAUTION

CAUTION

Symbols

Negligence of the warning may cause death or

serious injury.

Negligence of the warning may cause injury and /

or physical damage.

In case of negligence of the instruction, machine

damage may be anticipated.

See the Handling Manual

Caution mark

(Rotating parts)

Caution mark

(Hot surface)

Fuel mark

(Light oil No.2)

Caution mark

(Exhaust gas)

Danger mark

(Flying objects)

Danger mark

(Blade rotation)

Grease

Every 50hours

Warning mark

(High-pressure oil)

Danger mark

(Strict prohibition of fire)

= CAUTION =

The type of the machine may change sequentially. Please inform us of the machine No.

when making an inquiry.

For improvement the contents of this manual are subject to change without notice.

CAUTION

Warning marks have been used in this Manual and machine to ensure that you can

operate it safely. Please read carefully to understand well.

Thoroughly understand the operation procedure and safety cautions before you operate

this machine.

The marks and accompanying explanations should be preserved in their entirety. If they

become lost or damaged please replace them immediately with new ones.

Caution mark

(Crushing)

Warning mark

(Clothes for safety)

-1-

-2-

Purpose

This machine is intended for cutting grass. Do not use this machine in any way other

than its intended purpose, and do not modify the machine. Operating this machine for

other purposes and modifying it may be very dangerous and may cause damage to the

machine.

This machine is not authorized for operation as a special motor vehicle. Do not operate

it on public roads.

Safe Operating Practices

The following instructions include the ones from the CEN standard EN 836:1997, ISO

standard 5395:1990, and ANSI B71.4-2004.

1. Training

Read the Owner's operating Manual and other training material carefully. Be familiar

with the controls, safety signs, and the proper use of the equipment.

If the operator or mechanic can not read English it is the owner’s responsibility to

explain this material to them.

All operators and mechanics should seek and obtain professional and practical

instruction. The owner is responsible for training the users. Such instruction should

emphasize:

the need for care and concentration when working with ride-on machines;

control of a ride-on machine sliding on a slope will not be regained by the

application of the brake. The main reasons for loss of control are:

Insufcient crawler(s) grip;

Being driven too fast;

Inadequate braking;

The type of machine is unsuitable for its task;

Lack of awareness of the effect of ground conditions, especially slopes;

Incorrect hitching and load distribution.

Never allow children or people unfamiliar with these instructions to use or service the

machine. Local regulations may restrict the age of the operator.

The owner/user can prevent and is responsible for accidents or injuries occurring to

themselves ,other people, or property.

Keep in mind that the owner, operator, and mechanic are responsible for accidents or

hazards occurring to other people or their property.

2. Preparation

Evaluate the terrain to determine what accessories and attachments are needed to

properly and safely perform the job. Only use accessories and attachments approved

by the manufacturer.

While operating, always wear substantial footwear, long trousers, hard hat, safety

glasses,mask, and ear protection. Long hair, loose clothing, or jewelry may get

tangled in moving parts. Do not operate the equipment when barefoot or wearing

open sandals.

Inspect the area where the equipment is to be used and remove all objects such as

rocks, toys and wire which can be thrown by the machine.

• Warning - Fuel is highly ammable. Take the following precautions:

Store fuel in containers specically designed for this purpose.

Add fuel before starting the engine. Never remove the cap of the fuel tank or add fuel

while the engine is running or when the engine is hot.

Refuel outdoors only and do not smoke while refueling.

If fuel is spilled, do not attempt to start the engine but move the machine away from

the area of spillage and avoid creating any source of ignition until petrol vapours have

dissipated;

Replace all fuel tanks and container caps securely.

Check that operator’s presence controls, safety switches and shields are attached

and functioning properly. Do not operate unless they are functioning properly.

If the brake operation is faulty or the parking brake lever has noticeable play, be sure

to adjust or repair them before operating the machine.

Replace faulty mufers.

Before using, always visually inspect to see that the blades, blade bolts, and cutting

assembly are not worn or damaged. Replace worn or damaged blades and bolts in

sets to preserve balance.

3. Operation

Do note operate the engine in a conned space where dangerous carbon monoxide

fumes can collect.

Only operate in good light, keeping away from holes and hidden hazards.

Before attempting to start the engine, disengage all blade attachment clutches, shift

into neutral, and engage the parking brake.

Only start engine from the operator’s position.

Avoid operating the equipment in wet grass, where feasible.

Remember there is no such thing as a safe slope. Travel on grass slopes requires

particular care.

To guard against overturning.

Do not stop or start suddenly when going up or downhill.

Machine speeds should be kept low on slopes and during turns.

Stay alert for humps and hollows and other hidden hazards.

Never operate across the face of the slope, unless the machine is designed for this

purpose.

Never drive the machine on a slope with an angle of gradient that is greater than that

specied or in a place where there is a danger of the machine slipping.

Never operate the machine with damaged guards, shields, or without safety protective

devices in place.

Be sure all interlocks are attached, adjusted properly, and functioning properly.

Never operate with the discharge deector raised, removed or altered.

Do not change the engine governor settings or overspeed the engine. Operating the

engine at excessive speed may increase the hazard of personal injury.

Do the following before leaving the operator’s position:

stop on level ground;

disengage the power take-off and lower the attachments;

change into neutral and set the parking brake;

stop the engine and remove the key.

Disengage the drive to attachments, stop the engine, and remove the ignition key in

the following conditions:

before refuelling;

befo re making h eight adjustme nt unless adj ustment can be mad e f rom the

operator's position:

before clearing blockages;

before checking, cleaning or working on the machine.

whenever you leave the machine;

after striking a foreign object or if an abnormal vibration occurs.

Inspect the machine for damage and make repairs before restarting and operating the

equipment;

Keep hands and feet away from the cutting units and the rotating parts.

Look behind and down before backing up to be sure of a clear path.

Do not carry passengers.

Never operate while people, especially children, or pets are nearby.

Slow down and use caution when making turns and crossing roads and sidewalks.

Stop the blades rotating before crossing surfaces other than grass.

Disengage drive to attachments when transporting or not in use.

When using any attachments, never direct discharge of material toward bystanders

nor allow anyone near the machine while in operation.

Do not operate the machine under the inuence of alcohol or drugs.

Take care when loading or unloading the machine into a trailer or a truck. Load or

unload the machine in a flat and safe place. Before loading or unloading, set the

parking brake on the truck or trailer, stop the engine, and chock the wheels.

When transporting the machine on a truck or a trailer, set the parking brake, stop the

engine, and fasten the machine to the truck with a rope or other suitable restraining

device that has sufcient strength.

When using a running board, select one with sufcient strength, length, and width and

that will not cause the machine to slip.

Close the fuel valve before transporting the machine.

Use care when approaching blind corners, shrubs,trees, or other objects that may

obscure vision.

Do not take your eyes off the road ahead. Do not operate the machine with no hands.

Reduce the throttle setting during engine run-out and, if the engine is provided with a

shut-off valve, turn the fuel off at the conclusion of operation.

-3-

-4-

4. Maintenance and Storage

Disengage drives on level ground, lower the atattachments, set parking brake, stop

engine and remove key from ignition. Wait for all movement to stop before adjusting,

cleaning or repairing.

When machine is to be parked, stored, or left unattended, lower the cutting units

unless a positive mechanical lock is provided.

To reduce the fire hazard, keep the engine, silencer/muffler, battery compartment

fuel storage area, cutting units and drives free of grass, leaves, or excessive grease.

Clean up oil or fuel spillage.

Allow the engine to cool before storing in any enclosure.

Only cover the machine with a sheet after hot parts have sufciently cooled down.

Never store the equipment with fuel in the tank inside a building where fumes may

reach an open ame or spark.

If the engine is provided with a shut-off valve,shut off valve while storing or

transporting.

Do not store fuel near ames.

Never allow untrained personnel to service machine.

Appropriately manage and correctly use the tools necessary for servicing or adjusting

the machine.

Use jack stands to support components when required.

Carefully release pressure from components with stored energy.

Be sure to depressurize the hydraulic system before performing maintenance

operations on it such as removing hydraulic equipment.

Check whether line connectors in the hydraulic system are properly tightened. Before

applying hydraulic pressure, check the connections of the hydraulic pressure lines

and the condition of the hoses.

When checking the hydraulic circuit for pinhole leaks or oil leakage from nozzles, do

not use your hands. Use items such as paper or corrugated cardboard to nd leakage

points. Be extremely careful with high-pressure oil as it may pierce your skin, resul.

If uid is injected into the skin it must be surgically removed within a few hours by a

doctor familiar with this form of injury or gangrene may result.

Disconnect battery before making any repairs. Disconnect the negative terminal rst

and the positive last. Reconnect positive rst and negative last.

Make sure that parts such as wires are not touching each other and that their covers

have not come off.

Use care when checking the blades. Wrap the blades or wear gloves, and use caution

when servicing them. Only replace blades. Never straighten or weld them.

Keep hands and feet away from moving parts. If possible, do not make adjustments

with the engine running.

Charge batteries in an open well ventilated area, away from spark and ames. Unplug

charger before connecting or disconnecting from battery. Wear protective clothing and

use insulated tools.

Keep all parts in good working condition and all hardware tightened. Replace all worn

or damaged decals.

Keep all nuts, bolts and screws tight to be sure the equipment is in safe working

condition.

If the fuel tank has to be drained, do this outdoors.

15

11

12

13

18

16

17

14

19

20

2

1

3

4

5

6

7

8

9

10

8

2

1

3

4

6

7

5

Location of labels

*Decals are indicated with ○ for warning and □ for instruction.

-5-

WARNING

WARNING

DANGER

DANGER

DANGER

DANGER

CAUTION

CAUTION

2

3

4

5

6

7

1

8

9

10

11

12

1

2

3

4

5

6

7

8

K4205001600

K4205001970

K4205001520

K4205001950

K4205001570

Decal, danger hammer knife

Pay attention to the flying object Do not allow people to approach

the front of the machine.

Hands injury - Keep a safe distance

from the machine.

Engine

oil

Hydraulic

oil

Gear oil

K4205001530

Decal, caution for rotating object

Watch for rotating parts - Keep your

hands away from the belts while the

engine is running.

K4205001600

Decal, caution for severe injury

May cut your hand or leg - Stop the

rotation and engine.

Otherwise you may get injured.

K4205001970

Decal, caution spouting coolant

Pay attention to the radiator - Do not

open the cap of radiator when it is in

the hightemperature.

High temperature - Do not touch, or

you will get burnt.

K4205001520

Decal, prohibition rope installation

Do not use the step to tow or rope.

K4205001950

Decal, caution exhaust gas

Pay attention to the exhaust gas Keep a safe distance from the

machine.

K4205001560

Decal, read Owner's manual

Instruction - Read the Owner's

Operating Manual before operating

or servicing the machine.

K4205001550

Decal, caution fire

Pay attention to fire - Read the

Owner's Operating Manual.

K4205001540

Decal, caution for high temperature

High temperature - Do not touch.

Otherwise, you will be burned.

K4209001090

Decal, oil handling instruction

Read the Owner's Operating

Manual about the designated oils.

K4209001110

Decal, slope work instruction

Operation on the slope - Read the

Owner's Operating Manual.

K4209001040

Decal, instruction of hoisting

Hoisting the machine - Read the

Owner's Operating Manual.

K4209001000

Fuel icon

Use No. 2 diesel fuel. (Low sulfur

or ultra-low sulfur diesel fuel only)

K4209001050

Decal, emergency engine stop

Loop the cord of emergency switch

around the arm or body tightly.

K4209000990

Decal, pilot lamp

K4209001030

Decal, overheat alarm buzzer

When overheated - Read the

Owner's Operating Manual.

K4203001200

Decal, traveling lever

K4203001210

Decal, P-brake

K4203001230

Decal, knife clutch lever

K4204000080

Decal, mowing height scale

When the cutting height set less

than 3cm or over 30cm, disengage

the knife clutch.

Unlock

Forward

High speed

Lock

Off

Backward

High speed

Low speed

Neutral

Low speed

On

5

10

15

20

25

30

cm

3

Glow

lamp

Oil pressure

lamp

Charge

lamp

Blade rotation

prohibition range

Blade rotation

prohibition range

Left-hand

Turning

Right-hand

Turning

Warning and Instruction Decal List

*Decals are indicated with ○ for warning and □ for instruction.

-6-

1

1

2

3

2

3

1

2

50h

K4209000380

Maintenance

Ordinary operation

Auto

Manual

High speed

Engine stop

(Auto glow)

On

High Low Low High

Start

K4209001060

Decal, step control changeover

switch

When cutting grass, switch to the

AUTO mode.

K4209001070

Decal, manual step control

Use it when the step control is in

the MANUAL mode.

K4209001080

Decal, cylinder single/double

changeover

K4203001220

Decal, engine rotation

K4209000380

Decal, greasing 50 Hr

K4209001020

Decal, read owners manual

Read the Owner's Operating

Manual.

K4204000070

Decal, mowing height switch

K4209001430

KEY SWITCH MARK

K4209000980

Hydraulic oil icon

Read the Owner's Operating

Manual.

Low speed

Inclination

to the left

Inclination

to the right

13

14

15

16

17

18

19

20

Desired

Locations

*Decals are indicated with ○ for warning and □ for instruction.

1. Precautions as to use

1-1.

WARNING

Preparation before use of machine

Be sure to check and maintain the machine before and after use.

The protective cover and other protective parts are provided to prevent users

from danger. Be sure to install them at the specified locations, and replace them

with new ones when they are broken.

Carefully read the warning labels and operation manual before operating the

machine to thoroughly understand the machine operation.

WARNING

Emergency switch1-2.

Unless the emergency switch is used, the engine may not stop in an emergency,

leading to death or serious injury.

Be sure to install the emergency switch correctly. Wind the string of the

emergency switch around your arm or body completely before using the

machine.

1-3.

DANGER

Be careful of rotating parts

The knife and other rotating parts are dangerous. Do not put your hands, feet, or

any other object in them or do not touch them during work or maintenance.

Check that there is no person or other objects that may break the machine

around the machine or in the area within 30 degrees and 100 m at the front of

the machine during operation.

Stones, wires, sticks, and other obstacles may cause damage to the knife or an

accident due to flying objects. Remove them before operating the machine.

-7-

CAUTION

Wires, vinyl and other objects may be wound around the knife shaft. When you

hear an abnormal sound, stop the engine, and remove such objects after the

knife shaft has stopped rotation.

Should the knife be broken, the knife shaft will be unbalanced, causing vibration,

which is very dangerous. Be sure to change the knives, otherwise the machine

will be broken.

CAUTION

Be careful of hot part1-4.

Do not touch the cover or muffler during operation or right after the machine

stops, otherwise a skin burn may result.

-8-

1

2

3

1

2

3

4

5

8

6

9

7

10

2. Safety operation

Blades rotate at high speed in the mowing machine under severe conditions such

as vibration, slope, and dust. Operation conditions are subject to the place of use,

existence of obstacles, condition of grass, etc. We sincerely desire that users should

inspect and maintain the machine completely, make efforts to master the machine

operation skill, take measures for safety, use the machine correctly so as not to do

harm to others, and give top priority to safety operation.

2-1.

Wear proper clothes that will not be caught in the

machine, and wear protective gear, goggles, shoes,

helmet, and gloves.

An apron and a towel wound around the waist, as

well as long strings especially, will cause the operator

to be caught in or pulled into the machine, which is

dangerous. Provide a fire extinguisher, first aid kit and

secure a means of communication to deal with an

emergency.

2-2.

2-3.

Before operating the machine, check the field by necessity. Pay attention to the

holes or obstacles.

Remove the objects that can fly apart as possible as you can. Give attention to the

flying debris not to injure people, animals, crops, buildings, automobiles and so on.

WARNING

WARNING

Do not use the machine when you are tired. When you feel tired while using the

machine, stop the work and take a rest.

Sick people, drunken people, and people under the influence of drugs are

not allowed to use the machine. The visual sense, nimbleness in action, and

judgment will be adversely affected.

When you are unfamiliar with machine operation, read the handling method and

safety precautions to understand them well before operating the machine. Do

not allow children to use the machine.

CAUTION

Clothes for safety

Avoid such operation

Check the operating place.

CAUTION

Do not operate the machine with mown grass, dust, etc. accumulated in the

cover, V-belt or around the engine or the transmission, otherwise fire or other

trouble may result. Remove them carefully. Improper maintenance and incorrect

operation and dry grass mowing might cause fire. Clean and check the machine

as shown below before and during work.

Remove dry grass, dust, and other obstacles from around the muffler and

engine.

Check the fuel hose for cracks due to deterioration.

Check for fuel leakage during fuel supply.

Fuel supply during engine operation is prohibited.

Check the wiring to prevent fire due to a short circuit.

Inspect the fuel tank and carburetor for fuel leakage due to operation on a slope.

Be sure to carry a fire extinguisher and water etc. when mowing dry grass.

When cutting dried grasses, clean the machine every 1 hour.

In case of fire, use extinguisher to extinguish it in the early stage. When the fire

expanded, evacuate to the safety place and report to the fire department.

Make sure of the expiry date of extinguisher at any time.

2-5.

The machine is not provided with any lighting equipment. Do not operate the

machine at nighttime or when the visibility is poor due to bad weather, etc.

Do not remodel the machine. Use genuine parts for maintenance to ensure safety.

Never use the machine for tree felling and wood chipping, tilling the farmland, or

some works other than mowing, otherwise the machine may lose its knife shaft

balance and cause failure.

WARNING

CAUTION

CAUTION

Prohibition of nighttime traveling and work

Remodeling of the machine prohibited2-6.

Prohibition of work other than mowing2-7.

Fire prevention2-4.

2-8.

35

20

67

18

24

8

16

15

14

13

21

12

11

22 23

17

9

10

4

19

21

When lending the machine to others, an unexpected accident may occur because

they have no knowledge about the safety precautions and handling method shown

in the operation manual. Hand over the operation manual and tell them to read it

carefully before using the machine, explaining the handling method well.

CAUTION

When lending the machine to others

Protection cover and Antiscattering chain

The protection cover is used to prevent stones, etc. from scattering foward. Be sure

to lower the protection cover during mowing operation.

The antiscattering chain is also used to prevent stones, etc. from scattering forward.

Be sure to install the chain to prevent damage to human beings, buildings, vehicles,

etc.

However, due to the structure of the machine, the protection cover and the

antiscattering chain can not prevent all the objects from scattering. Even when

installing these equipments, always exercise due care for surrounding area

(especially for forward) during operation.

3. Part names

CAUTION

Observe the precautions in "Precautions as to use" and "Safety operation" and pay

sufficient attention to the area around the machine during operation.

No. Name No. Name

1 Handle 13 Bottom roller

2 Side brake lever 14 Front roller

3 Throttle lever 15 Knife guard

4 Traveling lever 16 Muffler

5 Knife clutch lever 17 Fire extinguisher

-9-

6 Mower portion (Mower unit) 18 Precleaner

7 Protection plate 19 Main switch

8 Protection cover 20 Battery

9 Emergency switch 21 Fuel ller port (diesel fuel)

10 Step 22 Step control changeover switch

11 Sprocket 23

12 Crawler 24 Air cleaner

Cylinder single-/double- acting changeover switch

-10-

4. Features

This energy-saving type large mowing machine with a diesel engine is

manufactured for professional use especially for slope land operation. The mowing

width is 154 or 170 cm, and the maximum output is 26.5 kW. The machine is ideal

for mowing on river banks, skiing ground and major roads, as well as in other large

areas.

The rubber crawler ensure great hill climbing ability, and the low center of gravity

permits safe work even on a slope. The crawler section is provided with a seesaw

roller mechanism to cope with pitching, and the projections inside the crawler

are made long to prevent crawlers from coming off. The grease cylinder used for

crawler tension adjustment is easy to operate.

The machine travels hydraulically at variable speed. The single traveling lever

permits simple operation to move the machine forward and backward, change the

speed, and turn the machine. The position of the traveling lever can be selected

from five angles, ensuring satisfactory operation and improvement of work

efficiency.

The hydraulic system permits easy adjustment of mowing height. The special

structure of the mower unit permits long grass cutting length and easy collection of

cut grass. The grass stop shaft (option) makes the cutting length shorter.

The step (simple riding unit) keeps the machine horizontal by using an angle

sensor so as to enhance safety of the operator.

The hammer knives are attached to move freely and the structer lessens impact

of stones and other obstacles when they hit against the hammer knives, hardly

causing damage to the hammer knives.

The hammer knife is made of heat-treated special touch steel, ensuring sharp

cutting and durability and permitting use of both sides by reversing. The hammer

knives are attached by bolts and nuts, permitting easy change.

The four-cylinder diesel engine with a starter is easy to start, and the forced

lubrication system can withstand the instantaneous maximum inclination of 35

degrees.

The hitch method is adopted to install the mower unit, permitting easy installation/

removal of the portion.

5. Specifications

HMC156E HMC172E

Total length

Dimensions

Total width

Total height

1,717mm 1,910mm

Mitsubishi Diesel S4L2-E331KM 1.758L (1,758 cm3)

Engine

Rubber crawler

Speed change

(Hydraulic variable speed)

Hammer knife

Knife clutch

Mowing height

Mowing width

Max. output: 27.0 kW/3,000 rpm (36.7 PS/3,000 rpm)

30 7.2cm(51P)

Backward: 0-4.5 km/h

120 blades 140 blades

154cm 170cm

70 are/h (6.5 km/h) 77 are/h (6.5 km/h)

Efficiency

(Mowing width Operation speed 0.7)

Max. operating inclination

Ground pressure

Dry weight

Curb weight

The factory default maximum engine rpm is 2,400 rpm.

*

CAUTION

The idling speed of the engine is approx. 1,500 rpm. Set the idling speed to avoid

sympathetic vibration with the machine. The engine revolution may reach 3,200 rpm

under no-load condition.

16.7kPa

1,480kg

1,545kg

3,000mm

1,350mm

Fuel tank: 33 L (dm3)

35 7.2cm(51P)

Forward: 0-6.5 km/h

Belt tension type

3-30 cm

35

14.7kPa

1,520kg

1,585kg

CAUTION

1

2

3

1

2

3

4

For transportation of the machine, give attention to the width of the loading space.

HMC156E

Vibration Level

Hand-arm vibration

This machine was confirmed to transmit a maximum vibration level of 4.50 m/

s2 to hands and arms by measuring identical machines in accordance with the

procedure specied in ISO5349-1: 2001, 5349-2: 2001.

Sound Pressure Level

This machine was confirmed to have a continuous A-weighted sound pressure

level of 90 dB by measuring identical machines in accordance with the procedure

specified in directive EN836:1997.

Sound Power Level

This machine was conrmed to have a sound power level of 105 dB by measuring

identical machines in accordance with the procedure specied in directive 2000/14/

EC.

Vibration Level

Hand-arm vibration

This machine was confirmed to transmit a maximum vibration level of 4.50 m/

s2 to hands and arms by measuring identical machines in accordance with the

procedure specied in ISO5349-1: 2001, 5349-2: 2001.

Whole body vibration

This machine was conrmed to transmit a maximum vibration level of 1.30 m/s2 to

the whole body by measuring identical machines in accordance with the procedure

specied in ISO2631-1: 1997, 2631-2: 2003.

HMC172E

Sound Pressure Level

This machine was confirmed to have a continuous A-weighted sound pressure

level of 90 dB by measuring identical machines in accordance with the procedure

specied in directive EN836:1997.

Sound Power Level

This machine was conrmed to have a sound power level of 105 dB by measuring

identical machines in accordance with the procedure specied in directive 2000/14/

EC.

Whole body vibration

This machine was conrmed to transmit a maximum vibration level of 1.30 m/s2 to

the whole body by measuring identical machines in accordance with the procedure

specied in ISO2631-1: 1997, 2631-2: 2003.

6. Inspection before use

Inspect the machine according to "13. Maintenance schedule."

6-1. Lubrication to each part

Supply the specified quantity.

Don't use old oil.

Lubrication the friction surfaces of each part.

Refer to the diesel engine operation manual for the method of handling the

engine.

6-2. Inspection of hydraulic oil

Approx. 28 litters of hydraulic oil is in the hydraulic tank. Place the machine

horizontally and check that the level of the hydraulic oil is at the center of the oil

gauge.

6-3. Hydraulic oil change

CAUTION

Change the hydraulic oil one year or 500 hours later, whichever comes earlier.

Change the filter when the hydraulic oil is changed.

When the hydraulic oil is emulsified or its transparency is lost even slightly,

change it instantly.

For lling up the hydraulic oil, use the designated oil.

Use Shell Tellus S3MT46 or equivalent of ISO VG46 as hydraulic oil.

CAUTION

Change the hydraulic oil, after the machine cooled down sufciently.

When servicing the hydraulic system, lower the mowing units to the ground and

release the pressure.

-11-

-12-

U PPER LEVEL

UPPER LEVEL

L OWER LEVEL

LOWER LEVEL

U PPER LEVEL

UPPER LEVEL

L OWER LEVEL

LOWER LEVEL

1

1

2

6-4. Battery

Inspection of Battery

For details on handling the battery, please refer to the separate Battery Instruction

Manual.

DANGER

Keep re away while inspecting or charging the battery.

The battery may explode.

WARNING

Do not allow the battery fluid level to become lower than the LOWER LEVEL

(minimum uid level line).

The battery may explode if it is used or charged while the battery uid level is at

the LOWER LEVEL (minimum uid level line).

Clean the areas around the battery uid level lines using a cloth dampened with

water.

Make sure that the battery uid level is between the UPPER LEVEL (maximum

uid level line) and the LOWER LEVEL (minimum uid level line).

Supply of Battery Fluid

For details on handling the battery, please refer to the separate Battery Instruction

Manual.

DANGER

Be careful not to let your skin, eyes or clothes, etc., come into contact with battery

uid (electrolyte) or accidentally swallow the uid.

Should your skin or clothes come into contact with electrolyte, immediately wash

them away with water.

WARNING

When you supply battery uid, wear protective garments and safety glasses, etc.

If the battery fluid level is lower than halfway between the UPPER LEVEL

(maximum line) and LOWER LEVEL (minimum line), add puried water up to the

UPPER LEVEL (maximum line).

6-5. Lubrication of friction surface of each part

50h

Supply oil constantly to the inlet/outlet of the wire and the joint of each part to

prevent rusting. Supply grease to the grease nipple every 50 hours.

Crawler [26 places]

Both sides of knife shaft assy. (2 places)

Fulcrum of mower unit [2 places]

The drawing shows the right side.

*

Operation lever and neutral positioning [8 places]

Tension [3 places]

-13-

-14-

3

4

2

2

1

1

Start

Stop

Position

Energization and preheating

Charge

lamp

Glow

lamp

Oil

pressure

lamp

7. Tightening each part

Bolts are used for each part. After initial use of the machine, the bolts and nuts may

get loose. Tighten loose bolts and nuts.

Optimum tightening torque: N.m (kgf.cm)

M 6

M 8

M10

M12

M14

Ordinary bolt

8 (80)

18 (180)

36 (360)

60 (600)

90 (900)

Heat-treated bolt

16 (160)

36 (360)

72 (720)

120 (1200)

8. Engine starting sequence

8-1. Engine start

WARNING

Before starting the engine, read the diesel engine operation manual to

thoroughly understand the contents.

Put on the side brake and set all driving units at the neutral position.

Check that the covers are at correct positions and that there is no one

around the machine, and confirm safety before starting the engine.

Do not start the engine in a room without an appropriate ventilator.

Check that the knife clutch lever is disengaged before starting the engine.

8-2. Engine start.operation method

Shift the throttle lever to High rotation.

Check the indicators and preheating.

Key to “ON” position (energization

and pr eh e a t i ng ) le ts pr e h ea t i n g st a r t

automatically.

Start

After the glow lamp went out (completion of

preheating), Key to “START” position makes

the engine start.

If starting the engine before the glow

*

lamp goes out, it may cause blowout of

the fuse.

Operation

Key to “ON” position.

CAUTION

Within 5 seconds after starting the engine, the safety equipments do not function

due to the control circuit. Accordingly do not operate the machine for a period of

5 seconds after starting.

8-3. Engine stop method

Return the throttle lever to the slow-speed position.

Turn OFF the switch and remove the key.

8-4.

* When storing the machine outdoors or for a long time, be sure to put the

rubber cap on.

CAUTION

Park the machine in a horizontal state, turn off the engine, and check that all

movable sections have stopped. Then put on the side brake and remove the key

before leaving the machine. Never park the machine on a slope.

Precautions to take when leaving the machine

Traveling lever

Mowing height

adjustment

switch

Forward

Backward

Mowing height

Low

High

9. Machine operation

OFF

ON

Knife clutch lever

9-1. Machine operation

9-2. Knife clutch

Pull the knife clutch to your side to engage it, and push it forward to disengage it.

The engine cannot be started when the knife clutch is engaged.

CAUTION

Check that the operating condition of each part especially the safety of the side

brake, traveling lever and mower unit before operating the machine.

Operate the machine at slow speed so that the machine can be stopped

immediately in any case.

Remove obstacles from the operation area so that you and other people around

the machine will not be injured.

Do not start or turn suddenly, or the operator may be bucked off, or the machine

may slip or turn over on the slope. It is dangerous.

CAUTION

Engage the knife clutch right before starting mowing operation. Be sure to leave

it disengaged during any operation other than mowing.

Since the knife shaft rotates by the centrifugal force, engage the clutch halfway

until the rotation is normal. Do not engage the clutch completely at a stroke.

Even if the knife clutch disengaged, the knife shaft freewheels for a while. Do not

any operations until the knife shaft stops rotating completely.

9-3.Traveling lever

The traveling lever is at the center

of the rear section of the machine.

Push it forward to move the machine

forward, and pull it back to your side

to move the machine backward.

Adjust the speed by changing the

inclination of the lever.

Turn the traveling lever to the

direction of the desired direction

of turning. Return the lever to the

original position, and the machine will move straight.

The position of the traveling lever can be selected from five angles. Change the

position of the lever according to the operating conditions.

WARNING

When driving the machine on a steep slope, the machine will not stop even if the

traveling lever is released. When driving the machine on a slope, hold the traveling

lever with one hand and the handle with the other hand so that the machine can

stop any time. Never release them during traveling.

In case of losing control of travelling, stop the engine promptly.

9-4. Mowing height adjustment

The hydraulic method, in which a solenoid valve and cylinder are used, is adopted

for mowing height adjustment. Tilt the mowing height adjusting switch on the

traveling lever to your side to raise the mowing height, and tilt it forward to lower

the mowing height. The mowing height adjusting range is 3-30 cm. The knife

rotation above the range is prohibited for safety's sake though the mower portion

itself can be raised higher for the sake of transportation or storage. Adjust the

mowing height appropriately. Adjust the mower unit lowering speed with the valve

unit, which will be seen at the back of the fuel filler port when the right side cover is

opened.

CAUTION

Even though the engine does not run, key to “ON” position and control of the

cutting height adjusting switch make the mowing unit lower. When stopping the

machine, make sure to lower the mowing unit to the ground and after stopping the

engine, make sure to remove the key.

-15-

-16-

1

2

3

Stored positionDriving position

Step

Magnet catch

Hook

Hook for

fixing step

33221

1

9-5. Working speed

The working speed is hydraulic variable within the range of 0 - 6.5 km/h for forward

operation and 0 - 4.5 km/h for backward operation. Adjust the speed appropriately

with the traveling lever according to the condition of the geography and grass.

9-6. Step (simple riding unit)

The step is kept horizontal at all times by the angle sensor, automatic level control

box and electric cylinder. The "step control changeover switch" atop the electrical

equipment box permits switching from AUTO to MANUAL, and vice versa. When

the step control changeover switch is in the "MANUAL" position, the "step control

manual switch" on the control panel permits control.

CAUTION

However, be sure to set the step control changeover switch in the "AUTO" position

during mowing. Use the manual position only when maintaining the machine,

the automatic control circuit fails, or some other emergency arises. When the

automatic circuit fails, replace the part with a new one immediately. Do not operate

the machine for mowing on the manual control step.

CAUTION

Impact to the step will impose a burden on the supporting point, causing failure.

Exercise care so as not to strike the step against any object when moving the

machine backward or turning the machine.

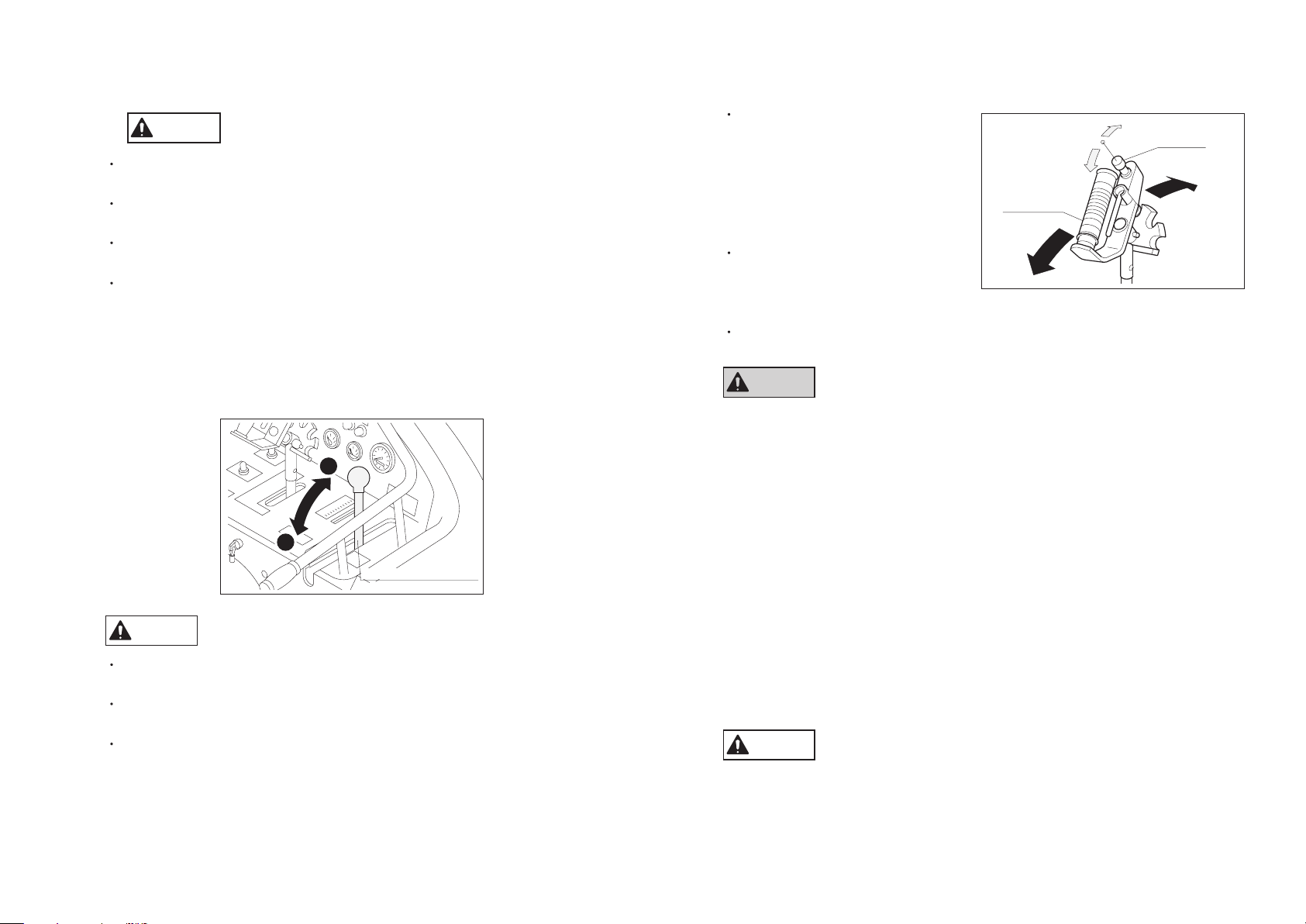

How to fold back the step (driving position → stored position)

*

Lift up the step ( ). Hold the pipe at the bottom of the step, when lifting. Keep

lifting the step and raise the hook for xing step ( ) and lean it to the rear direction

of the machine ( ).

Make sure the hook for fixing step and the hook of the step clutch each other

securely.

How to fold back the step (stored position → driving position)

*

Apply the reverse procedure to the above mentioned ( → → ). Avoid the step

falling down due to its own weight and make sure to hold it. Fix the hook for xing

step with the magnet catch.

Folding back the step

The step (simple riding unit) can be folded back to conserve space in the case of

storage or transport by truck etc.

CAUTION

The steel mesh is used on the standing surface of the step for antiskid purpose. Do

not touch the mesh directly for avoiding injury.

CAUTION

In the case of traveling or operating the machine without riding on the step, the

operator cannot keep the proper distance to the control devices and the operations

become unstable. Be sure to stand on the step for starting the machine.

Prohibition of traveling and/or operating the machine with the step

in the stored position.

9-7. Traveling on the public roads and the limit of crew

This machine is not allowed to travel on the public roads. Carry this machine on the

truck to move on the public roads.

CAUTION

Single operator are able to ride on this machine. No subsidiary worker is allowed to

stand on the step or the other part of the machine. Especially when the engine is

working, never let person ride on the mowing unit or crawler.

9-8. Alarm buzzer

When the alarm buzzer sounds, the engine is overheated. Stop operation, and

remove dust that is jamming in the radiator or air cleaner etc.

CAUTION

9-9. Side brake

When the machine is not to be moved, pull the side brake lever fully to your side,

and the brake will be applied to the hydraulic motor and the traveling lever will be

locked at the neutral position.

10. Mower unit

10-1. Use of both sides of knife

Both sides of the knife are sharpened. When one side is worn, remove the pair of

knives, and attach them reversely. The knife is attached to the knife shaft mounting

hitch section by 11 mounting pin 32 and the nut with disc washer, and the knife can

be removed easily.

Attach the mounting pin in the same direction as before.

* The tightening torque of the knife mounting pin is 32 - 36 N

as ordinary M10 bolts).

10-2. Replacement of knife

10-3. Grinding the knife

CAUTION

The knife shaft assy is balanced when shipped from our factory; therefore, unless

all the knifes of the same weight each are replaced at one time, or unless replaced

symmetrically on the right and left portions of the knife shaft, the weight balance

may be lost and vibration may be generated.

Since the hammer knife shaft assy are rotated at high speed, pay attention to the

weight balance when replacing the hammer knife.

CAUTION

When both sides of the knife are worn, grind each blade in a manner that the

weight of each knife will be the same as much as possible.

When the weight balance of the knife shaft assy including the knife blades is poor,

the knife shaft assy will generate vibration, breaking the machine.

.

m (almost the same

CAUTION

When checking the knife shaft assy or replacing the knives, make sure to stop the

engine and remove the key.

CAUTION

When the balance is lost, the knife shaft assy will vibrate because it is rotating at high

speed, which is very dangerous. Exercise care sufficiently.

CAUTION

Wear protective goggles and gloves when grinding the knife.

-17-

-18-

1

234

5

6

7

Protection cover

Link

Hook

10-4. Standard time for knife replacement

Operation with a worn knife not only prevents efficient operation but also leads to

loss of balance. Reverse or replace the hammer knife according to the illustration

shown below.

Replace the hammer knife immediately with a new one when it is broken or

abraded unevenly.

New knife Time to reverse Time to replace

10-5. Hammer knife inspection items

10-6. As for the protection cover

When checking the knife shaft assy, it is easy to work with raising the protection

cover.

How to raise and lower the protection cover.

For raising the protection cover, lift up the protection cover and hook up the hooks

on both sides of the protection cover with the rings on both sides of the knife frame.

After conrming the cover will not lower, get your hands off of the cover.

For lowering the protection cover, release the hooks from the rings on both sides

and lower the cover slowly.

No. Part Inspection item Correction

Knife blade

Mounting pin

Mounting hitch

Balance weight

Support shaft Uneven abrasion Repair by specialist(*2) or replacement

Bearing

knife shaft assy

*1 The tightening torque of the knife mounting pin is 32 - 36 N.m

Excessive tightening will damage the thread of the mounting pin.

*2 Special correction by balancing machine may be required.

Missing baldes Attach

Abrasion Reverse or replacement

Breakage, curvature or uneven

abrasion

Looseness Tightening(*1)

Wrong direction Attach correctly

Curved or open Correction or repair by specialist(*2)

Breakage or uneven abrasion Repair by specialist(*2) or replacement

Missing

Abrasion

No lubrication Lubricate

Unsmooth rotation Replacement

Twining of vines or cords etc. Remove

Distortion as a whole Replacement

Replacement

Repair by specialist(*2)

CAUTION

Implement operation of the protection cover after the knife shaft assy stops

completely.

When lowering the protection cover, pay attention not to pinch hands and feet.

When raising or lowering the protection cover, pay attention not to touch the

knives.

Protection cover should be kept lowering except for checking the mowing unit or

replacing the knives.

1

2

3

4

5

6

In regard to the anti-scattering chains

Protection cover

Link

Link

Hook

Chain

Shackle

Adjust the height of protection cover with the attached rings and shackles. If you

operate the machine without adjusting the height of cover, the chains are dragged

with the lowered cover and it may cause the damage of chains and cover.

Knife guard is omitted in the drawing.

*

11-2.

Be sure to observe the following matters when using the machine on a steep slope

of 20 degrees and above.

WARNING

Do not operate the machine when there is a risk of falling or slipping.

Before starting operation on a steep slope, check for holes, rocks, tree roots,

illegal throwaways, etc. Remove them, if any, and then carefully operate the

machine.

On a steep slope, operate the machine along the contour line, and turn the

machine in a place with a small angle of inclination as much as possible.

Do not operate the machine on a slope of 35 degrees and above, because the

machine is very likely to fall down sideways.

Exercise care sufficiently also when working on a slope of less than 35 degrees,

because the machine may slip down depending on the condition of the work site.

When ropes are used on a steep slope while working together with an assistant

worker, the machine may move to a very steep slope with an angle of inclination

that exceeds the allowable angle and the risk of falling down sideways will

increase, preventing safe operation. As a maker of the machine, we will prohibit

such operation.

Precautions as to operation on a steep slope

11. Operation on slope

CAUTION

The angle meter on the operation panel shows rough indication. If you feel it is

11-1. Operation on slope

When operating the machine on a slope, move the machine upward gradually from the

bottom of the slope along the contour line.

Release the traveling lever, and the lever will be set in the neutral position, stopping the

machine. For safety, stop the machine so that it will be positioned along the contour line.

When stopping the machine vertically on a slope, the machine may not be able to stop

immediately because of the inertia of the traveling machine. The machine is provided with a

hydraulic traveling system, and the step is provided with an automatic level control sensor.

When the machine is therefore turned toward the bottom of the slope, the machine will turn

smoothly because the center of gravity of the machine changes favorably, also ensuring the

operator since this way can avoid his position just below the machine during turn.

-19-

dangerous, stop the operation immediately.

CAUTION

On the border between slope and at eld, machine is rolling roughly. And so grip

the handle tightly and maintain your position.

-20-

12. Precautions as to maintenance

Be sure to provide an appropriate support so that the

CAUTION

12-1. Precautions as to maintenance

Thoroughly understand the method of required maintenance.

Do maintenance in a dry, clean place.

Before maintain the machine, stop the engine.

When starting the engine to check the movement, do not approach the movable

part.

Stop all driving parts, and operate respective control units to release the

pressure. (Lower the mowing unit to the ground)

Install all parts in a satisfactory state.

Repair or replace damaged parts immediately.

Replace worn or damaged parts.

Do not remodel the machine. Use genuine parts for maintenance to ensure

safety.

Remove dust, grease, and oil adhering to the machine.

Remove the minus (-) wiring from the battery before maintaining the electric

system.

When starting the engine, pay attention to the exhaust gas.

machine will be secured completely when the machine is to

be lifted during operation.

12-3.

DANGER

(JIS No.2 diesel oil)

Precautions as to fuel handling

Use of fire is prohibited strictly during fuel supply.

Put out all open fire and cigarettes.

Stop the engine to cool it outdoors before supplying fuel.

To prevent fire, keep the machine clean without dust, grease, or oil at all times.

Wipe off spilt fuel cleanly.

12-4. Precautions as to battery handling

Refer to the battery instruction manual for the method of handling the battery.

DANGER

Use of fire is prohibited strictly when checking or charging the battery. The

electrolyte is dilute sulfuric acid. Do not allow it to contact your body or the

machine. If the electrolyte adheres to your body or the machine, wash it off with

water immediately. Especially when it enters your eyes or you swallow it by

mistake, see a doctor immediately.

When removing the cable from the battery, remove the negative side first, and

when attaching the cable to the battery, attach the positive side first. When the

sequence is reversed, tools may touch the machine and cause a short circuit,

generating sparks. Connect the battery cables correctly to the positive and

negative sides. If the direction of connection is wrong, the battery and its electric

equipment will be damaged.

12-2.

WARNING

The high-pressure oil, when sprayed over the skin, will cause serious injury.

Release the pressure before removing the high-pressure line, hose, and joints.

Check the tightness of all joints before starting operation.

Use a small piece of cardboard to check for leakage. When your skin is sprayed

with high-pressure oil, you must see a doctor within two to three hours.

Prevention of damage due to high-pressure oil

13. Maintenance schedule

Knife adjusting rod

Lever adjuster

Tension pulley adjusting bolt

Knife shaft V-pulley

B3 V-pulley

B6 V-pulleyEngine pulley

CAUTION

Use the appropriate tools for the purpose of maintenance etc.

Refer to the diesel engine operation manual for the method of handling the engine.

Inspection, adjustment, replenishment and cleaning

Replacement

Maintenance

Engine oil

Oil filter

Engine

Fuel filter

Electromagnetic pump filter

Air cleaner element

Precleaner

Cooling water (qty, leakage, etc.)

Fuel (qty, leakage, etc.)

Hydraulic oil (qty, leakage, etc.)

Hydraulic oil filter

Tightening of hydraulic hose/joint

Hydraulic

motor oil

Electrolyte

Radiator core

Main unit

Side brake

Traveling lever

Neutral position

Emergency switch operation

Step operation

Operation of respective switches and meters

Lighting of pilot lamp

Knife tension operation

Strength of knife tension

V-belt tension

Crawler tension

Knife section

Breakage of hammer knife

Looseness of knife mounting bolt

Knife shaft bearing

Dust-proof cover and protection plate

Greasing each section

Others

Looseness of screw in each section

Accumulation of dust

Visible damage

* Replace the hydraulic hoses every 4 years.

Initial

After 10 hr

Initial

After 50 hr

Before

use

every

50hrs

every

100hrs

10hrs

every

200hrs

every

500hrs

14. Belt adjustment

14-1. Knife

Remove the knife shaft cover and adjust the tension of the belt put on the B3

V-pulley 30150 and knife shaft V-pulley by using the tension pulley adjusting

bolt.

Adjust the tension of the belt put on the B3 V-pulley 30175 and B6 V-pulley by

using the lever adjuster.

Adjust the tension of the belt put on the B6 V-pulley and engine pulley by using

the knife adjusting rod.

14-2. Hydraulic pump

Adjust the tension of the belt put on the engine pulley and hydraulic pump pulley by

using the lever adjuster.

-21-

14-3. List of the place using belts

Hydraulic pump

PSV2-16A

Engine

S4L2

Te nsion pulley Ass’y 4155

Bearing 62042RD

V-belt W4SB73

B5 engine pulley 175

Bearing 62062RS

Low edge cogged belt

H-PXSB54

V-belt W4SB64

B6V-pulley 54175

Te nsion pulley Ass’y 5752

B3V-pulley 301755F

Bearing 62062RD

B3V-pulley 30130-20

Bearing 62032RD

Knife shaft pulley 40170

V-belt W4SB58

P bearing 6308LLU

B2V-pulley 25175F

K8030000020

K0612062040

K2371400640

K242300008D

HMC15601001ZD

K2371400730

K2424000012

K2440000042

K8030000050

K0612062060

K2374200540

K0608062060

HMC15600601ZD

K0612062030

K2371400580

K242300007D

K0679063080

Knife shaft housing

Knife shaft

Intermediate shaft

-22-

As for the fan-belt, please refer the Owners operating Manual of Engine.

15. Crawler

2mm

1

2

50h

M14 bolt

Lower roller Ass’y

Rubber crawler

Grease nipple

Traveling hydraulic motor

Grease cylinder

Support pipe

Upper roller

Cylinder pipe

Small spring

Front roller receiver

Oil seal UE407210

Bearing 6306RS

O-ring P24B

Front roller

Spring stopper

Large spring

Sprocket

Crawler adjuster

15-1. Crawler tension

Adjust the crawler tension by supplying grease to the grease cylinder. Make

adjustment so that the crawler tension will be the same on both sides.

CAUTION

15-2. Installation.removal of crawler

When removing the crawler, loosen the M14 bolt (width across flats: 22) on the

grease cylinder, remove the grease, return the front roller to the original position,

lift the crawler that is to be removed above the ground, and then remove the

crawler. Reverse the order of removal when installing the crawler. Refer to the

preceding paragraph for the crawler tension.

15-3. Prevention of crawler tearing loose

Be sure to check that the crawler is not slackened and the crawler tension is

adjusted appropriately before operation.

15-4. Greasing the crawler

The seesaw roller fulcrum shaft in the crawler section is provided with a grease

nipple. Supply grease to the nipple every 50 hours. Use Excelite EP2 grease or

equivalent to ISO VG2. (Refer to "Lubrication of friction surface of each part")

16. Adjustment of traveling section

Conduct the following work before adjusting the traveling section:

Remove the crawlers on both sides, or place the machine on a stable base to lift

the crawlers on both sides.

Remove the rear cover.

Excessive crawler tension will cause the front roller to lose the clearance, causing

the crawler to come off easily and the machine to break easily. Exercise care.

CAUTION

When lifting the machine, be sure to use an appropriate support to

completely secure the machine.

-23-

Lock nut

(left-hand thread)

Lock nut

(right-hand thread)

Lock shaft

Groove

Groove

Traveling lever

Neutral stopper

M10 right-/left-hand thread rods

16-1. Adjustment of neutral position of piston pump

Pump

Mounting bolt

Left neutral lever

mounting base for pump

Right neutral lever

mounting base for pump

2

1

3

4

1

2

3

Loosen the mounting bolts of the neutral lever mounting bases for the pump on

both sides to keep the bolts loose.

Return the side brake lever to unlock the traveling lever.

Start the engine, and move the neutral lever mounting bases for the pump by

using a stick, etc. to determine the neutral position.

CAUTION

The engine is rotating. Be careful of the pulley, belt, sprocket (crawler), etc. during

operation.

When the neutral positions of both bases are determined, stop the engine and

tighten the mounting bolts.

Start the engine again to check that the sprocket (crawler) will not rotate.

-24-

16-2. Adjustment of neutral position of traveling lever

Loosen all the lock nuts of the M10 right-/left-hand thread rods.

Turn the two rods at right and left to adjust the length so that the lock shaft of the

traveling lever will be set in the neutral stopper groove when the side brake is

pulled.

Tighten all the lock nuts of the rods and check that the traveling lever is locked

completely when the side brake lever is pulled and that the traveling lever is

unlocked quickly when the side brake lever is returned.

16-3. Confirmation after adjustment

1

2

3

1

2

3

4

After the above-mentioned adjustment, confirm the following:

Stop the engine and move the respective levers to check for interference.

Check that the machine is in the neutral position and will not move even if the

engine is in the full-throttle state.

(When the side brake lever is pulled and returned)

After moving the traveling lever to move the machine, release the traveling lever,

and check that the machine will not move.

Refer to the diesel engine operation manual for the method of handling

the engine.

CAUTION

There is a risk of a skin burn. Do not open the radiator cap during or right after

operation.

18. Hoisting and jacking up the machine

17. Engine

CAUTION

a) Use the low sulfur or ultra low sulfur diesel fuel (JIS No.2 diesel).

b) The machine is to be operated under severe condition such as vibration, slopes,

and dust. Change the entire engine oil 10 hours after the initial operation. Then

while continuing inspection and replenishment before use, change the entire

quantity every 100 hours thereafter.

Change all the oil filters simultaneously as well.

When using the machine in a dusty place, change oil and the oil filters more

frequency.

The quantity of the engine oil is 5.5 liters. Use the diesel engine oil in the service

class CD or above specified by the API standard.

c) When air is sucked in the fuel system of a diesel engine, the engine will not be

started. Inspect and maintain the diesel engine at all times to prevent entry

of air into the fuel system. Operation will be difficult when the fuel filter and

electromagnetic pump filter are clogged with dust or when water remains in them.

Drain water or clean filters every 50 hours. Replace filters with new ones every

200 hours.

d) Keep a pre-cleaner attached to the suction port of the air cleaner at all times

during operation. Be sure to clean the dust cup before operation.

e) Mix antiseptics (long-life coolant) into water, and put the mixture in the reserve

tank up to the MAX position as a radiator cooling water. Change the cooling water

every 50 hours. Check and supply the cooling water before operation. When the

temperature is likely to drop below the freezing point, use an antifreeze mixture.

When the radiator fins are clogged with dust, blow air to clean them.

(JIS No.2 diesel oil)

Precautions as to handling of engine

18-1. Hoisting

CAUTION

a) Qualification necessary to use a crane to hoist the machine

For hoisting the machine, follow the appropriate laws of the country where it is

hoisted.

b) Hoisting procedure

Lower the mower portion until it touches the ground.

Pull out the four hoisting hooks and secure them with pins. Hook the wire ropes

completely with shackles. Use wire ropes with sufficient strength. Be sure to

use four ropes of 2.5 m or more in length.

Pay attention to the position of the center of gravity during hoisting to balance

the machine sufficiently. Do not approach the machine inadvertently during

hoisting.

When lowering the machine, keep the machine horizontally and lower it in a

manner that the crawlers at right and left will touch the ground at the same time.

Impact applied to the traveling motor (sprocket) at that time will cause failure.

Precautions as to hoisting

-25-

-26-

Attachment

mounting base

Hitch sections

Lock pin mounting hole

Mower unit

1

2

3

4

(Front side)

(Rear side)

Jacking-up points

Jacking-up points

Bottom view of Main frame

18-2. Jacking up

When jacking up the machine with hydraulic jacks, apply jacks to the jacking-up

points on the following drawing.

19. Attaching/detaching the mower unit

CAUTION

Be sure to install and remove the mower unit in a flat horizontal place. Stop the

engine unless it is necessary to move the attachment mounting base up and down or

to move the machine forward and backward.

19-1. Removal of mower unit

Remove the intermediate shaft belt cover and right crawler cover, and then

remove the belt that connects the machine and the mower unit.

Pull out 6 clip pin and remove the lock pin.

Set the cylinder single-/double-acting changeover switch in the "double-acting"

position, and lower the attachment mounting base.

After confirming that the hitch sections are separated, slowly move the machine

backward, and the operation is complete.

19-2. Installation of the mower unit

1

2

3

4

While engaging the hitch sections, slowly move the machine forward, and raise

the attachment mounting base to engage the hitch sections.

After confirming that the hitch sections are engaged completely, attach the lock

pin and secure it with 6 clip pin.

Set the cylinder single-/double-acting changeover switch in the "single-acting"

position.

After attaching the belt and adjusting the tension, attach the right crawler cover

and intermediate shaft belt cover, and the operation is complete.

19-3. Hydraulic cylinder single-/double-acting changeover

CAUTION

Before starting ordinary operation, be sure to set the cylinder single-/double-acting

changeover switch in the "single-acting" position, and change it to the "doubleacting" position before installing or removing the mower unit.

Operation with the changeover switch in the "double-acting" position will cause

the hitch sections to be subjected to a load when the machine climbs over a large

stone or some other obstacle, causing machine failure.

20. Gear oil change for traveling motor

CAUTION

The speed reducer of the hydraulic motor for traveling is filled with 0.35 litter of gear

oil. Flush the speed reducer 50 hours after initial operation and every 200 hours after

that, and after each flushing, fill the speed reducer with a new gear oil #140 (ISO

VG140).

Unless the oil is changed according to the specified time, the motor failure will result.

Be sure to change oil as specified.

-27-

21. Wiring diagram

Glow timer

Glow

timer

Glow relay

Control timer

Control timer

Safety relay

Safety

relay

Relay N.C.Relay

N.C.

Relay

3

3

PE

S

L

R

1

6

6

7

5

5

4

4

2

3

1

4

2

3

1

4

2

Solenoid valve

for raising/lowering

mower portion

Solenoid valve

for holding

mower portion

Solenoid valve

for fan rotation

changeover

Solenoid valve

for fan

actuation

-CAUTION-

Relay

1243

5

6

43

1243

(M6)

5211 8912 6310 741 163452

Red

(AV5)

Yellow

(AV5)

Yellow

(AV5)

Yellow (AV0.85)

Green and red

(AV1.25)

Yellow

and red

(AV1.25)

Red and yellow

(AV2)

Red and yellow (AV2)

Red and yellow (AV0.85)

Blue and yellow

(AV0.85)

Yellow and black

(AV0.85)

Yellow

and blue

(AV0.85)

White and blue (AV0.85)

White

and black

(AV0.85)

Yellow and red (AV0.85)

Red and white (AV0.85)

Red and black (AV0.85)

Red (AV2)

Red (AV1.25)

Red (AV1.25)

Gray (AV1.25)

Red (AV2)

Red

Red (AV5)

Red

(AV0.5)

Sky blue (AV0.5)

Red

Red (AV2)

Red (AV3)

Black (AV2)

Black

(AV1.25)

Black

(AV1.25)

Black (AV3)

Black (AV0.85)

Black

(AV0.85)

Black (AV0.85)

Black

(AV0.85)

Black

(AV1.25)

Black (AV30)

Black (AV30)

Black (AV5)

Black

(AV0.85)

Black

(AV0.85)

Pink (AV3)

Black (AV1.25)

Blue

(AV1.25)

Blue (AV5)

Blue

(AV1.25)

Green

(AV1.25)

Green

(AV1.25)

Green (AV5)

Blue (AV0.85)

Green (AV1.25)

Green (AV0.85)

Green (AV0.85)

Green (AV1.25)

Brown (AV1.25)

Blue (AV1.25)

Blue

(AV1.25)

Black (AV0.5)

Black (AV3)

Black

Green (AV0.5)

Brown (AV0.5)

Brown (AV0.85)

Brown (AV5)

Black (AV1.25)

Black (AV1.25)

Red (AV1.25)

Black (AV1.25)

Black and

white (AV0.5)

Black

Black

(AV2)

Black

White and red (AV2)

Red and white (AV0.85)

Blue and white

(AV0.85)

Red and white

(AV0.85)

White and red (AV1.25)

White (AV5)

White

Black and yellow (AV0.85)

White and yellow (AV0.85)

White and blue

(AV1.25)

Blue and white (AV1.25)

Yellow and red

(AV0.85)

Yellow and red

(AV0.85)

White and red

(AV2)

White and

red (AV2)

White (AV2)

White (AV0.85)

White (AV0.85)

White (AV2)

White

White (AV0.5)

White

(AV2)

White

(AV2)

White

Yellow

and red

(AV1.25)

Yellow

and black

(AV0.85)

Yellow and black (AV0.85)

Yellow and blue

(AV0.85)

Red

and blue

(AV2)

Orange (AV0.85)

Red (AV0.85)

Black (AV2)

Starter switch connection

OFF

1

2

BMSG2

50A

50A

5A 5A 5A 5A 5A 5A 5A 20A 20A 5A

(M5)

(M5)

(M6)

(M4)

(M4)

B

S

M

G1

G2

4-pole ON-ON switch2-pole ON-OFF-ON switch

*

(M6)

(M6)

(M6)

(M6)

2

*

*

1

*

(M6)

1

*

(M6)

1

*

(M6)

(M6)

1

*

1

*

(M6)

(M8)

(M6)

1

*

1

ER

L

SP

*

1

*

*

(M6)

(M6)

(M12)

(M4)

(M5)

T (M6)

B1 (M5)

M (M8)

(M6)

(M4)

(M5)

(M5)

(M8)

(M5)

1

*

1

P

P

B

R

L

R

L

*

1

*

*

(M6)

(M6)

(M6)

2

*

1

1

2

3

3

4

7

5

6

2

1

4

*

*

Inclination

sensor

Electric

cylinder

Horizontal

controller

box

Fan control

unit

Safety

switch

Tank

unit

Fuel

gauge

E

-

+

E

B

S

Water

temperat ure

gauge

(Flat connector)

(Flat connector)

(Flat connector)

Alarm