BARNSTEAD|THERMOLYNE FB1310M, FB1315M, FB1310M-26, FB1318M, FB1310M-33 Operation And Repair Manual And Parts List

...Page 1

BARNSTEAD|THERMOLYNE CORPORATION

Type FB1300 & FB1400

Furnaces

OPERATION AND REPAIR MANUAL

AND PARTS LIST

SERIES 1256 & 1257

Model Numbers

FB1310M, FB1310M-26, FB1314M, FB1315M, FB1318M,FB1310M-33

FB1410M, FB1410M-26, FB1414M, FB1415M, FB1418M, FB1410M-33

LT1256X1 • 8/27/01 Serial Number

Page 2

Table of Contents

Safety Information ..............................................................................................................................................3

Important Information....................................................................................................................................3

Warnings ......................................................................................................................................................4

Introduction..........................................................................................................................................................5

Intended Use ................................................................................................................................................5

General Usage..............................................................................................................................................5

Principles of Operation ................................................................................................................................5

General Specifications ........................................................................................................................................6

Declaration of Conformity ............................................................................................................................7

Unpacking ..........................................................................................................................................................8

Installation ..........................................................................................................................................................9

Site Selection................................................................................................................................................9

Electrical Connections..................................................................................................................................9

Operation ..........................................................................................................................................................10

Power Switch..............................................................................................................................................10

Cycle Light..................................................................................................................................................10

Door Safety Switch ....................................................................................................................................10

Single Setpoint Controller ................................................................................................................................10

Basic Operation ..........................................................................................................................................11

Buttons and Indicators................................................................................................................................11

To View or Change the Setpoint ................................................................................................................12

To View the Display Units ..........................................................................................................................12

To View the % Output Power......................................................................................................................12

Controller Parameters ................................................................................................................................12

Alarms ........................................................................................................................................................13

Sensor Break Protection ............................................................................................................................14

Overt Temperature Protection (OTP)..........................................................................................................14

Tuning ........................................................................................................................................................15

Furnace Loading ..............................................................................................................................................16

Preventive Maintenance....................................................................................................................................17

Troubleshooting ................................................................................................................................................18

Maintenance and Servicing ..............................................................................................................................19

To Replace Heating Element......................................................................................................................19

To Replace Thermocouple..........................................................................................................................22

To Replace Insulation ................................................................................................................................24

To Replace Door Switches ........................................................................................................................25

To Replace Solid State Relay ....................................................................................................................26

To Replace PC Board (Controller)..............................................................................................................26

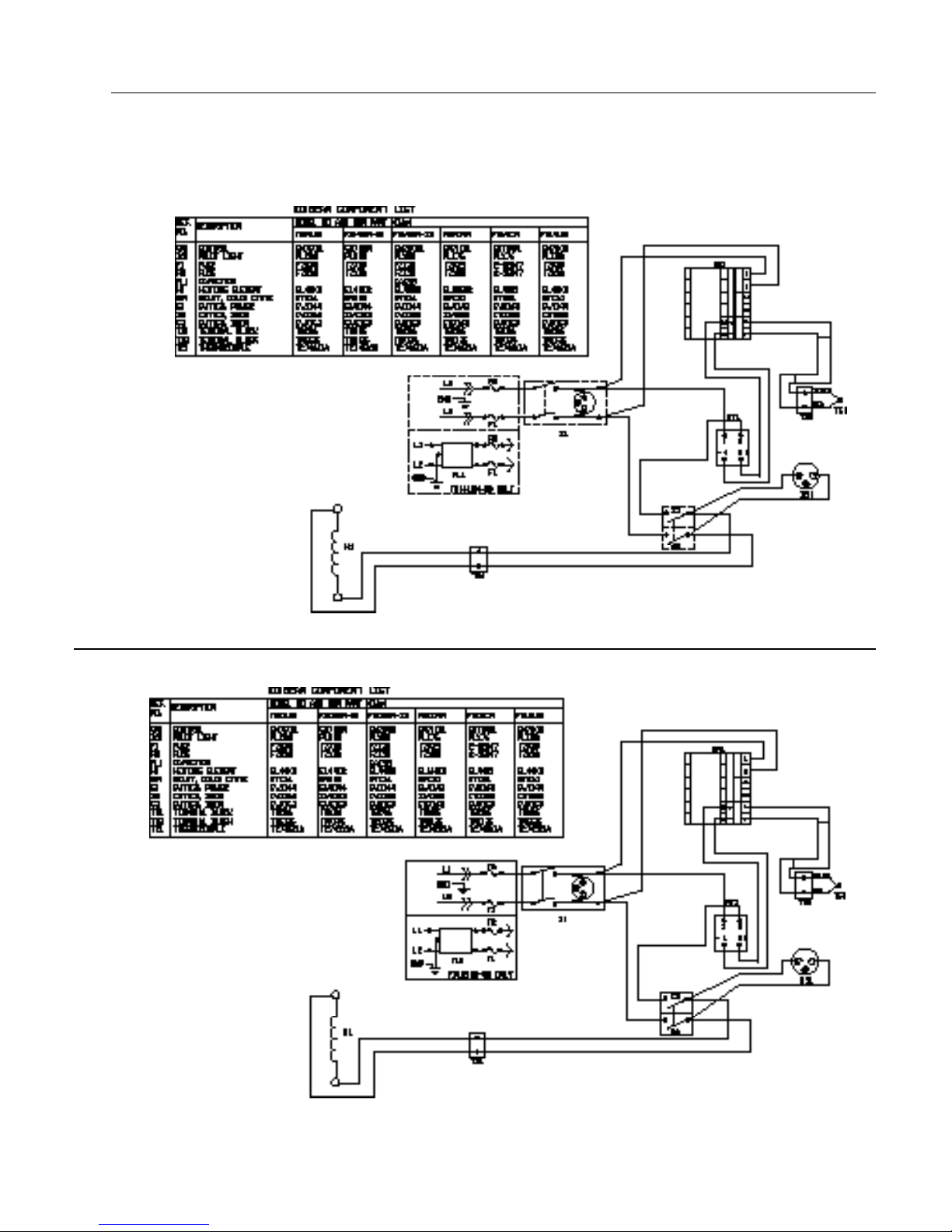

Wiring Diagram..................................................................................................................................................27

Exploded View ................................................................................................................................................28

Page 3

Important Information

This manual contains important operating and

safety information. You must carefully read and

understand the contents of this manual prior to

the use of this equipment.

Your Thermolyne FB1300 Model or FB1400

Model Furnace has been designed with function,

reliability, and safety in mind. It is your responsibility to install it in conformance with local electrical codes. For safe operation, please pay

attention to the alert signals throughout the manual.

Warnings

To avoid electrical shock, this furnace must:

1. Use a properly grounded electrical outlet

of correct voltage and current handling

capacity.

2. Be disconnected from the power supply

before servicing.

3. Have the door switch operating properly.

To avoid burns:

1. “Caution: Hot Surface. Avoid Contact.”

Do not touch the exterior or interior surfaces of the furnace during use or for a

period of time after use.

To avoid personal injury:

1. Do not use in the presence of flammable

or combustible materials — fire or explosion may result. This device contains

components which may ignite such

material.

2. Refer servicing to qualified personnel.

Safety Information

Alert Signals

Warning

Warnings alert you to a

possibility of personal injury.

Caution

Cautions alert you to a

possibility of damage to the

equipment.

Note

Notes alert you to pertinent facts

and conditions.

Hot Surface

Hot surfaces alert you to a

possibility of personal injury if

you come in contact with a

surface during use or for a

period of time after use.

Page 4

Please note the following WARNINGS:

WARNING

This warning is presented for compliance with California Proposition 65 and other regulatory agencies and only applies to the insulation in this product. This product contains refractory ceramic, refractory ceramic fiber or fiberglass insulation, which can produce respirable

dust or fibers during disassembly. Dust or fibers can cause irritation and can aggravate

preexisting respiratory diseases. Refractory ceramic and refractory ceramic fibers (after

reaching 1000°C) contain crystalline silica, which can cause lung damage (silicosis). The

International Agency for Research on Cancer (IARC) has classified refractory ceramic fiber

and fiberglass as possibly carcinogenic (Group 2B), and crystalline silica as carcinogenic to

humans (Group 1).

The insulating materials can be located in the door, the hearth collar, in the chamber of the

product or under the hot plate top. Tests performed by the manufacturer indicate that there

is no risk of exposure to dust or respirable fibers resulting from operation of this product

under normal conditions. However, there may be a risk of exposure to respirable dust or

fibers when repairing or maintaining the insulating materials, or when otherwise disturbing

them in a manner which causes release of dust or fibers. By using proper handling procedures and protective equipment you can work safely with these insulating materials and

minimize any exposure. Refer to the appropriate Material Safety Data Sheets (MSDS) for

information regarding proper handling and recommended protective equipment. For additional MSDS copies, or additional information concerning the handling of refractory ceramic

products, please contact the Customer Service Department at Barnstead|Thermolyne

Corporation at 1-800-553-0039.

SAFETY INFORMATION

Page 5

Intended Use

The FB1300 Model and FB1400 Model furnaces are general purpose laboratory and heat

treating furnaces. For optimum element life,

observe the following temperature ranges:

100°C (212°F) to 982°C (1800°F) for continuous

use, or from 982°C (1800°F) to 1100°C

(2012°F) for intermittent use. Continuous use is

operating the furnace for more than three

straight hours, and intermittent use is operating

the furnace for less than three hours.

The unit consists of a heating chamber and a

digital controller. See Figure 1 for the overall

shape and general features of the unit.

General Usage

Do not use this product for anything other than

its intended usage.

Principles of Operation

The furnace chamber is heated by a single

three section resistant heater which is embedded in a refractory material. The chamber is

insulated with a ceramic fiber insulation. The

temperature is controlled by an electronic control. The temperature is measured by a thermocouple and is registered on a digital display. For

safety, door switches are incorporated to

remove power from the heating elements when

the door is opened. The furnace is supported by

the control section which also houses the electrical connections.

Introduction

Page 6

General Specifications

FB1300 Models

Dimensions: (handle not included)

Chamber: 4” W x 3.75” H x 4.5” D (10.2 x 9.5 x 11.4 cm)

Overall : 7.9” W x 13.8” H x 8.5” D (20.0 x 34.9 x 21.6 cm)

Weight: 15.7 lb. (7.1 kg)

Electrical Ratings:

Model # Volts Amps Watts Phase Frequency

FB1310M 220-240 4.4 1060 1 50/60

FB1310M-26 220-240 4.4 1060 1 50/60

FB1310M-33 220-240 4.4 1060 1 50/60

FB1314M 100 10.6 1060 1 50/60

FB1315M 120 8.9 1060 1 50/60

FB1318M 208 5.1 1060 1 50/60

Temperature: Operating Range (continuous): 982°C; (intermittent): 1100°C.

Environmental Conditions:

Operating: 17°C - 27°C; 20% - 80% relative humidity, non-condensing. Installation

Category II (over-voltage) in accordance with IEC 664. Pollution Degree 2 in

accordance with IEC 664. Altitude limit: 2,000 meters.

Storage: -25°C - 65°C; 20% - 80% relative humidity.

FB1400 Models

Dimensions: (handle not included)

Chamber: 5.00” W x 4.25” H x 6.00” D (12.7 x 10.8 x 15.2 cm)

Overall: 9.7” W x 15.8” H x 11.1” D (24.6 x 39.0 x 28.3 cm)

Weight: 23 lb. (10.4 kg)

Electrical Ratings:

Model # Volts Amps Watts Phase Frequency

FB1410M 220-240 6.3 1520 1 50/60

FB1410M-26 220-240 6.3 1520 1 50/60

FB1410M-33 220-240 6.3 1520 1 50/60

FB1414M 100 14.5 1520 1 50/60

FB1415M 120 12 1450 1 50/60

FB1418M 208 7.3 1520 1 50/60

Temperature: Operating Range (continuous): 982°C; (intermittent): 1100°C.

Environmental Conditions:

Operating: 17°C - 27°C; 20% - 80% relative humidity, non-condensing. Installation

Category II (over-voltage) in accordance with IEC 664. Pollution Degree 2 in

accordance with IEC 664. Altitude limit: 2,000 meters.

Storage: -25°C - 65°C; 20% - 80% relative humidity.

Page 7

Declaration of Conformity

Barnstead|Thermolyne hereby declares under its sole

responsibility that this product conforms with the technical requirements of the following standards (-33 models

only):

EMC: EN 50081-1 Generic Emission Standard;

EN 50082-1 Generic Immunity Standard.

Safety: EN 1010-1-92 Safety requirements for

electrical equipment for

measurement,control and

laboratory use; Part I:

General Requirements

EN 1010-2-010 Part II: Particular requirements

for laboratory equipment for the

heating of materials

per the provisions of the Electromagnetic Compatibility

Directive 89/336/EEC, as amended by 92/31/EEC and

93/68/EEC, and per the provisions of the Low Voltage

Directive 73/23/EEC, as amended by 93/68/EEC.

The authorized representative located within the

European Community is:

Electrothermal Engineering, Ltd.

419 Sutton Road

Southend On Sea

Essex SS2 5PH

United Kingdom

Copies of the Declaration of Conformity are available

upon request.

GENERAL SPECIFICATIONS

Page 8

Unpacking

1. Visually check for any physical

damage to the shipping container.

2. Inspect the equipment surfaces that

are adjacent to any damaged area.

3. Open the furnace door and remove

the packing material from inside the

furnace chamber.

4. Vacuum the chamber prior to use to

remove the insulation dust due to

shipment.

5. Retain the original packaging material if reshipment is foreseen or

required.

Page 9

Installation

Caution

Be sure ambient temperature does

not exceed 40°C (104°F). The recommended ambient temperature is

17°C - 27°C. Ambients above this

level may result in damage to the

controller.

Caution

Allow at least six inches of space

between the furnace and any combustible surface. This permits the

heat from the furnace case to

escape so as not to create a pos-

sible fire hazard.

Site Selection

Install furnace on a sturdy surface and allow

adequate space for ventilation.

Electrical Connections

The electrical ratings are located on the specification plate on the back of the furnace.

Consult Barnstead/Thermolyne if your electrical service is different than those listed on the

specification plate. Be sure the front power

switch is in the OFF position before connecting the furnace to your electrical supply.

Warning

To avoid electrical shock, this furnace must always use a properly

grounded outlet of correct voltage

and current handling capacity.

Page 10

Operation, All Modes

Warning

To avoid personal injury do not use

in the presence of flammable or

combustible chemicals; fire or

explosion may result. This device

contains components which may

ignite such materials.

Power Switch

Both the ON/OFF power switch and the digital

display will illuminate when power is switched

Hot Surface

Caution: Avoid Contact. To avoid

burns, this furnace must not be

touched on the exterior or interior

surfaces during use or for a period

of time after use.

ON. The furnace will begin to heat to the controller's current setpoint. (See the instructions

for your type of controller for information on

checking and setting the setpoint.)

Cycle Light

The amber cycle light will illuminate whenever

the power is being applied to the heating elements. The cycle light will turn on and off as

the furnace reaches the setpoint.

Warning

Always wear safety glasses or a

safety shield and high temperature

gloves when loading or unloading

the furnace. Long sleeved, fire

retardant clothing and a fire retardant apron is also recommended.

Warning

To avoid electrical shock, the door

safety switch must be

operating properly.

Door Safety Switch

The door safety switch removes power from

the heating elements when the door is

opened. Open and close the door a few

times; note that the amber CYCLE light will

switch off when the door is opened. If this

condition is not true, consult the

Troubleshooting section before proceeding.

This check must be done when the furnace is

heating and the cycle light is illuminated.

Page 11

Single Setpoint Controller

Output 1

PAGE

Button

Single Setpoint Models

Output 2

SCROLL

Button

DOWN ARROW

Button

Temperature

Display

Display

Window

UP ARROW

Button

The single setpoint model furnace controller

is a single setpoint controller which provides a

single digital display to indicate the current

chamber temperature or setpoint temperature.

This temperature controller features sensor

break protection and self-tuning capability.

Basic Operation

When the controller is turned ON it will perform a short self-test and then display the

measured value (process value) in the HOME

DISPLAY.

Buttons and Indicators

OP1 (Output 1): Illuminates when the logic

output is ON.

OP2 (Output 2): Illuminates when the relay

output is ON (will go out during an alarm situation).

PAGE button: Allows you to select a new list

of parameters.

Note

If at any time you want to return to

the HOME DISPLAY, simultaneously press the PAGE and

SCROLL buttons.

SCROLL button: Allows you to select a parameter within a list of parameters.

DOWN button: Allows you to decrease a

value.

UP button: Allows you to increase a value.

To View or Change the

Setpoint

To view the setpoint, press and release the

UP or DOWN buttons. If you want to change

the setpoint, continue pressing until the

Page 12

SINGLE SETPOINT CONTROLLER

desired setpoint value is displayed and then

release the button. A few seconds after the button

is released, the controller will accept the new

value and revert to the HOME DISPLAY.

To View the Display Units

From the HOME DISPLAY press the SCROLL

button. The display will show the temperature

units in °C/F/K and then return to the HOME DISPLAY. (Call Customer Service if you require a different temperature unit.)

To View the % Output Power

From the HOME DISPLAY press the SCROLL

button twice. Press and release the UP or DOWN

button to view the % output power. This value is a

read-only value and cannot be changed.

Controller Parameters

Home display

°C: Temperature units in Celsius. Temperature

units can not be changed without entering the

configuration. Contact Customer Service if a different temperature unit is required.

OP: % output power demand.

IdHi: Deviation high alarm.

Al List

IdHi: Deviation high alarm.

Page 13

SINGLE SETPOINT CONTROLLER

Atun List

tunE: One-shot autotune enable.

Pid List

Pb: Proportional band (in display units).

ti: Integral time in seconds.

td: Derivative time in seconds.

ACCS List Code: Access code (Code need-

ed to enter or change the other configuration

parameters which are not normally accessible.) Not accessable.

Alarms

The controller will flash an alarm message in

the home display if an alarm condition is

detected.

2FSH: Measured value full scale high alarm.

IdHi: Measured value deviation high alarm.

S.br: Sensor break: check that sensor is con-

nected correctly.

L.br: Loop break: check that the heating cir-

cuits are working properly.

Ld.F: Heater Circuit fault: indication of either

an open or short solid sate relay, a blown

fuse, missing supply or open circuit heater.

Note

The following alarm messages

are factory default settings and

may vary if you have changed

the configuration of your

controller:

IDHi: = 50°C

2FSH = 1125°C

Page 14

SINGLE SETPOINT CONTROLLER

Sensor Break Protection

This controller provides sensor break protection in

the event the thermocouple opens. If an open thermocouple condition occurs, the digital display will

blink “S.br” and the power to the heating element

will be shut OFF (Cycle light will extinguish).

Over-Temperature Protection

(OTP)

The OTP will be in effect during any alarm condition when the temperature of the furnace has deviated beyond the limit. The “Deviation High” alarm is

the only alarm value which can be changed. To

change it, press the SCROLL button until “IdHi”

appears on the display. Press the UP or DOWN

button to select the OTP value you desire. We recommend a value of 20° above your working temperature to provide protection for your workload.

Tuning

This controller incorporates a self-tuning feature

which determines the optimum control parameters

for the best temperature accuracy with your load

and setpoint. Use this feature the first time you use

your furnace and each time you change either your

setpoint or the type of load you are heating.

Barnstead|Thermolyne recommends you use this

feature to provide the best temperature accuracy

the controller can attain. To use the tuning feature:

1. Adjust the setpoint to your desired value.

2. Press the PAGE button until display reads,

“Atun.”

Note

Furnace must be at ambient

temperature before starting a tune.

Page 15

SINGLE SETPOINT CONTROLLER

3. Press the SCROLL button. Display

will read, “tunE.”

4. Press the UP or DOWN button to

select, “on.”

5. Simultaneously press the PAGE and

SCROLL buttons to return to the

HOME DISPLAY. The display will

alternately flash between “tunE” and

the HOME DISPLAY while tuning is in

progress.

6. The controller will then turn the heating on and off to induce an oscillation.

When the measured value reaches

the required setpoint the first cycle will

end.

7. Tuning will be complete after two

oscillation cycles and then the tuner

will turn itself off.

Note

Tune has completed when “tunE”

stops flashing on display.

8. Normal control function will resume

after the controller calculates tuning

parameters.

Page 16

• For best results of furnace loading, use

less than two-thirds of any dimension of

the chamber. Maintain a 3/4" clearance

between the load and the sides of the

chamber.

• If you are heating a number of small

parts, spread them throughout the middle two thirds of the chamber.

• Keep objects away from thermocouple.

• Raise your load up off the furnace floor

with small pieces of ceramic or a hearth

plate to promote even heating.

• Use insulated tongs and mittens when

loading and unloading furnace.

• Always wear safety glasses.

Furnace Loading

Caution

Do not overload your furnace

chamber or allow the load to

touch the thermocouple. If the

load is to be heated uniformly, it

should not occupy more than

two-thirds of any dimension of

the chamber. Failure to observe

these cautions could result in

damage to furnace components

and/or load.

Page 17

Preventive Maintenance

Warning

Before using any cleaning or

decontamination method

except those recommended

by Barnstead|Thermolyne,

users should check with

Barnstead|Thermolyne that

the proposed method will not

damage the equipment.

Contamination is a major cause of element failure,

therefore, when possible, remove the fume forming

material before heating (e.g., cleaning cutting oil

from tool steel).

The resistance wire is high-grade nickel-chromium.

Some chemicals, notably sulphur, halogens, and

cyanides, attack this wire at high temperatures, so

avoid spilling these chemicals in the furnace or

heating them any hotter than necessary. The

refractory cement helps to protect the wire, but will

not completely immunize it from damage.

Warning

Disconnect the furnace from

power supply before cleaning.

Warning

Opening the door for an

extended period of time will

cause the painted surfaces

above the door to be discolored or burnt.

All heating elements must be considered expendable, and replacement is expected; however, reasonable care in their use will greatly extend the service they will give. As the manufacturer has no control over the use or care of the elements, no specific service guarantee can be made.

Housekeeping is vital to your electric furnace—

KEEP IT CLEAN! Run your furnace up to 871°C

(1600°F) empty occasionally to burn off the contamination that may exist on the insulation and elements. Run for approximately two hours with the

door slightly open. See warning.

Element life is reduced somewhat by repeated

heating and cooling. If the furnace is to be used

again within a few hours, it is best to keep it at the

operating temperature or at a reduced level such

as 260°C (500°F).

During normal use, the thermocouple in your furnace can become oxidized and cause inaccurate

readings; therefore, we suggest that if you regularly

use your furnace you should change your thermocouple once every six months to assure the accuracy of your controller readings.

Clean by wiping the outside case of the unit with a

damp cloth and mild soap solution.

Page 18

Troubleshooting

Problem Possible Causes Corrective Action

The furnace does not heat No power. Check power source and fuses or

(CYCLE light does not illuminate). breakers.

Power is not cut to heating elements Door switches are not functioning Re-align or replace door switches.

when the door is open.

Defective electrical hookup. Repair electrical hookup.

Thermocouple has oxidized and Replace thermocouple.

opened the circuit. (Open thermocouple

is indicated on the display as a

temperature of 0-5 degrees).

Fuse(s) blown Replace fuse(s).

Controller malfunction. Replace controller.

Door switches malfunction. Re-align or replace door safety switches.

Defective solid state relay. Replace output relay.

Slow heatup. Low line voltage. Install line of sufficient size and proper

Heavy load in chamber. Lighten load in chamber.

Wrong heating element. Install proper element.

Repeated element burnout. Overheating furnace. Keep furnace under maximum

Heating harmful materials. Enclose material in container. Clean up

Contamination present from Replace insulation material.

pervious burnout.

Inaccurate temperature Oxidized or contaminated Replace thermocouple.

readout. thermocouple.

Poor thermocouple connection. Tighten connections.

Improper loading procedures. Use proper loading procedures.

Poor ventilation of base. Clear area around furnace base.

Thermocouple connections Reconnect thermocouple correctly.

reversed. (Indicated by

downscaling of temperature on

display.)

voltage. (Isolate furnace from other

electrical loads.)

temperature.

spills in and on chamber. Ventilate

chamber by opening door slightly when

heating known harmful reagents.

Controller malfunction. Replace controller.

Page 19

Figure 3: Replacement of a Heating Element

Maintenance and Servicing

Warning

Disconnect the furnace from the

power supply before servicing.

Refer servicing to qualified

personnel.

To Replace Heating Element

1. Set the furnace on its top. (See Figure 3).

Remove thermocouple cover. (If

equipped.)

Note

Perform only maintenance

described in this manual.

Contact an authorized dealer or

our factory for parts and

assistance.

Note

It is seldom necessary to disconnect the thermocouple from

the controller if the thermocouple is in good condition.

Thermocouple cover

Porcelin

insulation

2. Remove screw and clamp holding thermocouple, then grasp the thermocouple

at the bend where it enters the furnace

chamber and pull straight back. Retain

porcelain insulator.

3. When the thermocouple tip is clear of the

furnace back, bend it out of the way.

4. Remove the screws holding the steel

back plate to the case.

5. Remove the steel back plate.

Step 1(if equipped)

Heating element

with rough side up

Straight edge

(or board)

Step 4

Step 2

Bend up

Step 5 Step 6

Step 3

Page 20

MAINTENANCE AND SERVICING

Note

The hearth plate contains no

heating coil, and may be saved

for re-installation if it is in good

condition. The hearth plate is

replaceable independent of the

heating element.

6. Remove the back insulation block by opening the door and gently pushing it out.

Support this insulation block while removing

it, as it is quite soft and easily crumbled at

the edges.

7. Remove bottom cover to obtain access to

terminals.

These steps will expose the heating element leads

and insulating bushings in the bottom plate of the

furnace.

8. Cut the element leads between the element

and the terminal block. (There are two

leads.) The element and hearth plate unit

may now be removed by pushing it straight

back out of the furnace. Use care not to

damage the chamber insulation when

removing the hearth plate and element as it

can be reused if it has not been contaminated.

9. Remove the old element lead wire and

power wires from the terminal block, and

save the sleeving for re-installation on the

new element leads. Sleeving must be

replaced if cracked or brittle!

10. New elements are shipped flat to protect

them from damage in shipment, and to save

space in storage. They must be formed

before installation.

11. Place the element on a flat surface with the

rough side up. Place a board or other

straight edge along one row of notches.

12. Gently bend the element along the straight

edge. The refractory cement will break

along the row of notches.

Page 21

MAINTENANCE AND SERVICING

Note

Nicking or damaging the element leads will cause premature element failure.

Make the bend 90°, avoiding excessive bending. (The element wires will be exposed at the

corner thus formed. This will not affect its life

or performance.)

13. Bend the other side of the element.

14. Place the hearth plate across the open end of

the ‘’U” shaped element.

15. Slide the element and hearth plate unit into

the chamber, pushing it firmly against the

hearth collar. Use care not to damage the soft

insulation. Remove any crumbs of insulation

that may get between the unit and the hearth

collar.

16. Thread the element leads through the ceramic bushings. Bend the leads so they lie close

to the refractory plate and the bottom insulation block. (The easiest and safest way to do

this is to press the wire flat with a stick or

blunt pusher. Do not use a sharp object or

nick the wire.)

17. Replace the sleeving and bend the lead 3/4

turn around the terminal screw. Cut off the

excess wire. Replace power wires on top of

element lead wires and tighten screw. Do not

cross the wire over itself around the terminal;

this makes it difficult to keep the connection

tight and prevents good electrical contact. If

you have excess wire, cut it off. Make sure

element lead wires are not touching any other

wires.

18. Replace the back insulation block and back

plate.

19. Examine the thermocouple, and, if it is good,

reinsert it into the chamber. It should extend

Page 22

MAINTENANCE AND SERVICING

about 1-1/2" into the chamber. Make sure

porcelain insulator is in place for the thermocouple to pass through on the steel

back plate. Replace clamp and screw.

(Excessive scaling, pitting, or cracks are

some indications that the thermocouple

may need to be replaced.)

20. Replace bottom cover of control unit.

21. Replace thermocouple cover.

22. If replacement of back insulation is necessary, carefully redrill hole for thermocouple, using back cover as guide.

23. Reconnect furnace to power supply.

24. Test operation of furnace.

Warning

Disconnect the furnace from the

power supply before servicing.

Note

If the thermocouple touches metal,

this could short out the signal,

causing the control to display room

temperature. This could cause the

furnace temperature to run away,

possibly damaging furnace components.

To Replace Thermocouple

1. Set furnace on its top.

2. Remove thermocouple cover. (If equipped.)

3. Remove screw and clamp holding the thermocouple, then grasp the thermocouple at

the bend where it enters the chamber and

pull it straight back from the furnace. Retain

porcelain insulator.

4. Remove bottom cover.

5. Disconnect the thermocouple from the terminal block by removing the screws on the

terminals. Pull the thermocouple through

the hole in the furnace base and discard.

6. Insert the new thermocouple into the back

of the furnace chamber. Make sure the

porcelain insulator extends through the

steel back plate to prevent the lead wires

from touching metal.

Page 23

MAINTENANCE AND SERVICING

Note

If the control temperature display

moves downward, the thermocouple leads are reversed.

7. Thread the thermocouple through the hole

in the base which has a nylon insulator,

replace clamp and screw.

8. Bend the thermocouple sharply toward terminal block.

9. Secure the two yellow wires marked “+”

together on the terminal block. Secure the

two red wires “-” together on the adjacent

terminal. Make sure connections are secure

to terminal block.

A polarity test of the thermocouple and lead wire is

easily made with the use of a magnet. On chromel

alumel thermocouples and lead wire, the non-magnetic wire is positive ( + ) and the magnetic wire is

negative ( - ).

Warning

Disconnect furnace from power

supply before servicing.

10. Replace bottom plate.

11. Replace thermocouple cover. (If equipped.)

12. Reconnect furnace to power supply.

13. Test operation of furnace.

To Replace Insulation

1. Remove thermocouple cover. (If equipped.)

2. Set furnace on its top and remove screw

and clamp securing thermocouple, then

grasp thermocouple and remove by pulling

it straight back. Retain porcelain insulator.

3. Remove back plate.

4. Remove bottom cover.

5. Disconnect the element leads from terminal

block.

Page 24

MAINTENANCE AND SERVICING

Note

Identify or mark wires disconnected to ensure proper placement and connection when reinstalling.

6. Disconnect thermocouple leads from terminal

block.

7. Remove four nuts holding control section to

furnace chamber.

8. Remove the ground nut.

9. Remove the control section from the furnace

chamber. Remove plates, screws, spacers

and nuts. Be sure to note how plates are

assembled together for reassembly.

10. Remove back piece of insulation by opening

door and pushing it out gently.

11. Remove bottom piece of insulation by lifting it

out.

12. Remove element and hearth plate by pulling

it straight back out of the furnace chamber.

(Be careful not to damage elements.)

13. Remove side insulating pieces.

14. To remove top insulating piece and hearth

collar, position the furnace on its side.

Remove both objects from furnace.

15. Reposition furnace on its top. Reinsert new

hearth collar and the new top piece of insulation. Insert the new side pieces of insulation last.

16. Reinsert element and hearth plate unit into

the chamber, pushing it firmly against the

hearth collar. (Be careful not to damage

insulation.)

17. Reinsert new bottom piece of insulation over

hearth plate. (Element leads and ceramic

bushings should be exposed above insula-

tion bottom piece.)

Page 25

MAINTENANCE AND SERVICING

18. Thread the element leads and ceramic

bushings through the bottom plate. Bend

the leads so they lie close to the refractory

plate and the bottom insulation block. (The

easiest and safest way to do this is to press

the wire flat with a stick or blunt pusher. Do

not use a sharp object or nick the wire.)

Secure plate to furnace chamber.

19. Reverse steps 1-9 to reassemble furnace.

To Replace Door Switches

1. Place furnace upside down and remove bot-

tom cover.

2. Disconnect wires from door switches. Identify

or mark wires disconnected from door switch-

es to ensure proper placement and connection when reinstalling.

3. Remove two screws and nuts from door

switches and slide door switches out.

4. Install new door switches to bracket. Place

furnace in an upright position. Adjust door

switches until a click is heard from the

switches, when furnace door is approximately 2" from being completely closed. Secure

door switches to bracket.

5. Place furnace upside down. Reconnect the

wires to new door switches.

6. Replace bottom cover and place furnace

upright.

7. Reconnect furnace to power supply.

8. Test operation of door switches as

described in step 4.

Warning

Disconnect furnace from power

supply before servicing.

Page 26

MAINTENANCE AND SERVICING

Warning

Disconnect furnace from power

supply before servicing.

Warning

Disconnect furnace from power

supply before servicing.

To Replace Solid State Relay

1. Place furnace upside down and remove the

bottom cover.

2. Disconnect the wires from the solid state

relay. Identify or mark the wires disconnected to ensure proper placement and connection when re-installing.

3. Remove solid state relay from bottom cover.

Note placement of solid state relay.

4. Install new solid state relay and reconnect

wires.

5. Replace bottom cover and place furnace

upright.

6. Reconnect furnace to power supply.

To Replace Controller

1. Place furnace upside down and remove

bottom cover.

2. Disconnect wires from the controller.

Identify or mark wires disconnected to

ensure proper placement and connection

when re-installing.

3. Remove the controller from bottom cover.

4. Install new controller and secure.

5. Reconnect wires identified in step 3 to new

controller.

6. Replace bottom cover and place furnace

upright.

7. Reconnect furnace to power supply.

Page 27

Wiring Diagrams

FB 1400 models

FB1300 models

Page 28

EXPLODED VIEW

Page 29

EXPLODED VIEW

29

Page 30

Quantity

Key# Description Required Part Number

1 Heating element (100V - FB1314M) 1 EL140X2

1 Heating element (120V - FB1315M) 1 EL44X1

1 Heating element (208V - FB1318M) 1 EL44X3

1 Heating element (240V - FB1310M, -33) 1 EL44X2

1 Heating element (100V - FB1414M) 1 EL186X2

1 Heating element (120V - FB1415M) 1 EL48X1

1 Heating element (208V - FB1418M) 1 EL48X3

1 Heating element (208V - FB1410M, -33) 1 EL48X2

2 Thermocouple (FB1300 models) 1 TC1256X1

2 Thermocouple (FB1400 models) 1 TC746X1A

3 Solid State Relay (all models) 1 RYX34

4 Door Switches (all models) 2 SWX163

5 Control (FB1300M & FB1400M models except FB1410M-33) 1 CN71X81

5 Control (FB1400M-33 model only) 1 CN71X101

6 Insulation Btm (all FB1300 models) 1 JC44X1

6 Insulation Btm (all FB1400 models) 1 JC48X2

7 Insulation Back (all FB1300 models) 1 JC44X4

7 Insulation Back (all FB1400 models) 1 JC48X1

8 Insulation Top (all FB1300) 1 JC44X3

8 Insulation Top (all FB1400) 1 JC48X3

9 Insulation Hearth Collar (FB1300) 1 HC44X1

9 Insulation Hearth Collar (FB1400) 1 HC48X1

10 Insulation Sides (FB1300) 2 JC460X2

10 Insulation Sides (FB1400) 2 JC48X4

11 Cycle Light (amber) (all 100V & 120V) 1 PLX76

11 Cycle Light (amber) (all 208V & 240V) 1 PLX82

12 Terminal Block 1 TRX136

13 Terminal Block 1 TRX96

14 Power Switch (100 & 120V models) 1 SWX143

14 Power Switch (208 & 240V models) 1 SWX144

15 Door Assembly (FB1300 all models) 1 DR347X1A

15 Door Assembly (FB1400 all models) 1 DR348X1A

16 Element Sleeving (all models) 1 SL745X1

17 Element Sleeving (all FB1300 models) 1 SL59X2

18 Hearth Plate (all FB1300 models) 1 PH44X1

18 Hearth Plate (all FB1400 models) 1 PH48X1

19 Filter (all -33 models) 1 CAX98

20 Fuse Holder (all models) 1 FZX26

21 Fuse 10 amp .25 x 1.25 - (Buss™ Type ABC, 2 FZX30

240V & 208V models)

21 Fuse 15 amp .25 x 1.25 (Buss™ Type ABC, 2 2-58147

120V models)

21 Fuse 20 amp .25 x 1.25 (Buss™ Type ABC, 2 FZX29

100V models)

22 Dial Plate Label (FB1300) 1 DLX248

22 Dial Plate Label (FB1400) 1 DLX249

Replacement Parts List

Page 31

Page 32

One Year Limited Warranty

BARNSTEAD|THERMOLYNE CORPORATION (“BARNSTEAD”) warrants that if a product manufactured by

Barnstead shall be free of defects in materials and workmanship for one (1) year from the first to occur of (i)

the date the product is sold by BARNSTEAD or (ii) the date the product is purchased by the original retail customer (the “Commencement Date”). Except as expressly stated above, BARNSTEAD MAKES NO OTHER

WARRANTY, EXPRESSED OR IMPLIED, WITH RESPECT TO THE PRODUCTS AND EXPRESSLY DISCLAIMS ANYAND ALL WARRANTIES, INCLUDING BUT NOT LIMITED TO, WARRANTIES OF DESIGN,

MERCHANT ABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

An authorized representative of BARNSTEAD must perform all warranty inspections. In the event of a defect

covered by BARNSTEAD’s warranty, BARNSTEAD shall, as its sole obligation and exclusive remedy, provide

free replacement parts to remedy the defective product. In addition, for products sold by BARNSTEAD within

the continental United States or Canada, BARNSTEAD shall provide provide free labor to repair the products

with the replacement parts, but only for a period of ninety (90) days from the Commencement Date.

BARNSTEAD’s warranty provided hereunder shall be null and void and without further force or effect if there

is any (i) repair made to the product by a party other than BARNSTEAD or its duly authorized service representative, (ii) misuse (including use inconsistent with written operating instructions for the product), mishandling, contamination, overheating, modification or alteration of the product by any customer or third party or

(iii) use of replacement parts that are obtained from a party who is not an authorized dealer of BARNSTEAD.

Heating elements, because of their susceptibility to overheating and contamination, must be returned to the

BARNSTEAD factory and if, upon inspection, it is concluded that failure is due to factors other than excessive

high temperature or contamination, BARNSTEAD will provide warranty replacement. As a condition to the

return of any product, or any constituent part thereof, to BARNSTEAD’s factory, it shall be sent prepaid and a

prior written authorization from BARNSTEAD assigning a Return Goods Number to the product or part shall

be obtained.

IN NO EVENT SHALL BARNSTEAD BE LIABLE TO ANY PARTY FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, OR FOR ANY DAMAGES RESULTING FROM LOSS OF

USE OR PROFITS, ANTICIPATED OR OTHERWISE, ARISING OUT OF OR IN CONNECTION WITH THE

SALE, USE OR PERFORMANCE OF ANY PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, TORT (INCLUDING NEGLIGENCE), ANY THEORY OF STRICT LIABILITY OR REGULATORY

ACTION.

Loading...

Loading...