Barnstead Harvey MC8, MC10 User manual

HARVEY

®

Service Manual

Models MC8 &

MC10

Steam Sterilizer

LT1203X2 • 2/16/02

y

B

I

Barnstead

Harve

2

Table of Contents

Safety Information ..............................................................................................................................................4

Alert Signals........................................................................................................................................................4

General Specifications ........................................................................................................................................5

General Information ............................................................................................................................................6

Controls ON/OFF..............................................................................................................................................7

Cycle Select Switches ......................................................................................................................................7

Cycle Start/Stop................................................................................................................................................7

Programming Switches ....................................................................................................................................8

Display Window ................................................................................................................................................8

Cycle Phase Indicators ....................................................................................................................................8

Principles of Operation ........................................................................................................ ................................9

Cycle Description..............................................................................................................................................9

Controls Description........................................................................................................................................11

Trouble Analysis................................................................................................................................................15

Fuse Replacement..........................................................................................................................................15

Diagnostic Messages......................................................................................................................................15

Diagnostics Mode............................................................................................................................................19

Testing for Leaks .............................................................................................................. ..............................19

Power Supply Circuits ....................................................................................................................................20

Heater Control Unit ........................................................................................................................................22

Solenoid Control Circuits ................................................................................................................................24

Component Check Procedures ......................................................................................................................25

Service Data................................................................................................................... ...................................29

LED Indicators ................................................................................................................................................40

Test Points ......................................................................................................................................................40

Adjustments ....................................................................................................................................................42

LED Indicators ................................................................................................................................................43

Switch Panel Functions ..................................................................................................................................43

Setup and Adjustments ....................................................................................................................................47

Voltage Conversions ......................................................................................................................................47

Software Configuration....................................................................................................................................48

Unit Calibration................................................................................................................................................54

Unit Verification ..............................................................................................................................................57

Control PC Board Adjustments ......................................................................................................................60

Display Contrast Adjustment ..........................................................................................................................61

Repair and Replacement ..................................................................................................................................62

Cabinet Removal Control Panel......................................................................................................................62

Power I/O PC board............................................................................................................. ...........................63

Control PC Board ............................................................................................................... .............................63

Control Panel ..................................................................................................................................................64

Transformer PC Board (MC10) ......................................................................................................................65

Pressure Transducer ......................................................................................................................................65

Temperature Probe ........................................................................................................................................66

Thermal Cut-Off Switch ..................................................................................................................................66

Heater ............................................................................................................................................................67

Solenoid Valves ............................................................................................................................................67

3

TABLE OF CONTENTS

Chamber Door ................................................................................................................................................68

Door Handle and Latch Replacement ............................................................................................................68

Door Cover Replacement ..............................................................................................................................69

Appendix ..........................................................................................................................................................70

4

Safety Information

These symbols with related notes appear

throughout this manual.

Hot Surface

Hot surfaces alert you to a

possibility of personal injury if you

come in contact with a surface

during use or for a period of time

after use.

Caution

Cautions alert you to a possibility

of damage to the equipment.

Warning

Warnings alert you to a possibility

of personal injury.

Note

Notes alert you to pertinent facts

and conditions.

Alert Signals

NOTE:

This equipment has been tested and found to comply with the limits for a Class Adigital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can rediate radiofrequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

5

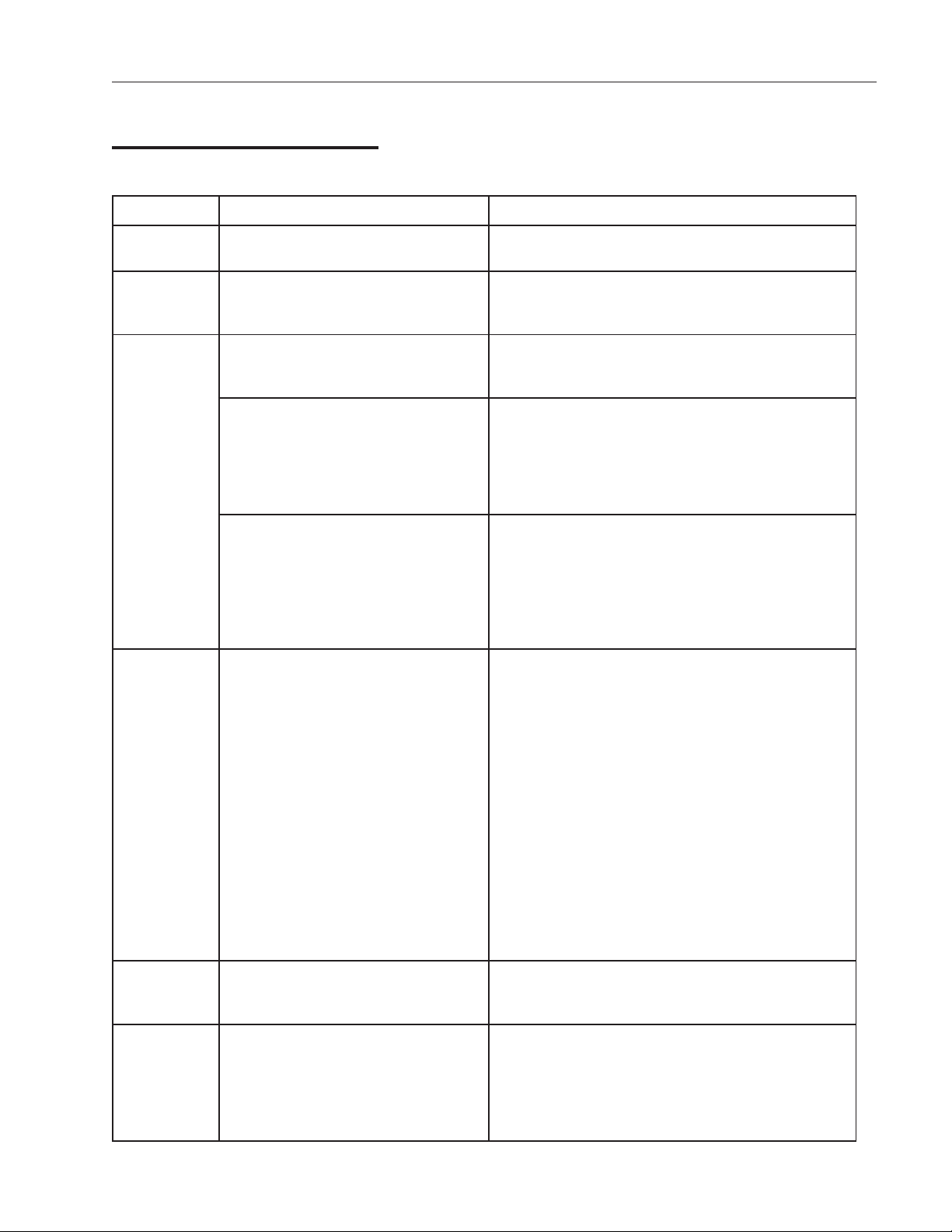

General Specifications

Cabinet Size 13-1/2” W x 16” H x 22” L 16” W x 18” H x 23” L

(330 mm W x 406mm H x 559mm L) (406mm W x 457mm H x 584mm L)

Chamber Size 8” diameter x 14-1/2” usable depth 10” diameter x 15-1/2” usable depth

(203mm diameter x 368mm) (254mm diameter x 393mm)

Tray Sizes Two 14” x 6-1/4” x 7/8” One 15-1/4” x 9” x 1-1/4”

(356mm x 135mm x 22mm) (387mm x 228mm x 32mm)

Shipping Weight 72 lbs (33 kg) 92 lbs (42 kg)

Heater Wattage 1350 Watts 1425 Watts

Electrical Rating 115 VAC, 50/60 Hz, 12 Amps or 115 Vac, 50-60 Hz, 12 Amps or

230 VAC, 50/60 Hz, 6 Amps 230 VAC, 50/60 Hz, 6 Amps

(See Note) (See Note)

Reservoir Capacity 3000 ml (approx. 3 quarts) 4000 ml (approx. 4 quarts)

Maximum Rated 45 psi (310 kPa) 45 psi (310 kPa)

Operating Pressure

Environmental Conditions

Operation 10° to 40°C (50° to 104°F) 10° to 40°C (50° to 104°F)

30% to 70% relative humidity, 30% to 70% relative humidity,

non-condensing non-condensing

Storage and Transport -20° to 60°C (-4° to 140°F) -20° to 60°C (-4° to 140°F)

10% to 100% relative humidity 10% to 100% relative humidity

Printer (Optional)

Electrical Rating 9 VAC; 1 WATT (idle), 9 VAC; 1 Watt (idle),

10 Watts (running) 10 Watts (running)

Non-Recirculating Water Accessory (Optional)

Size 6-3/4” W x 13-1/2” H 15-1/4” L 6-3/4” W x 13-1/2” H 15-1/4” L

(171mm W x 343mm H x 387mm L) (171mm W x 343mm H x 387mm L)

Capacity 11.36 L (approx. 3 gallons) 11.36 L (approx. 3 gallons)

MC8 MC10

6

General Information

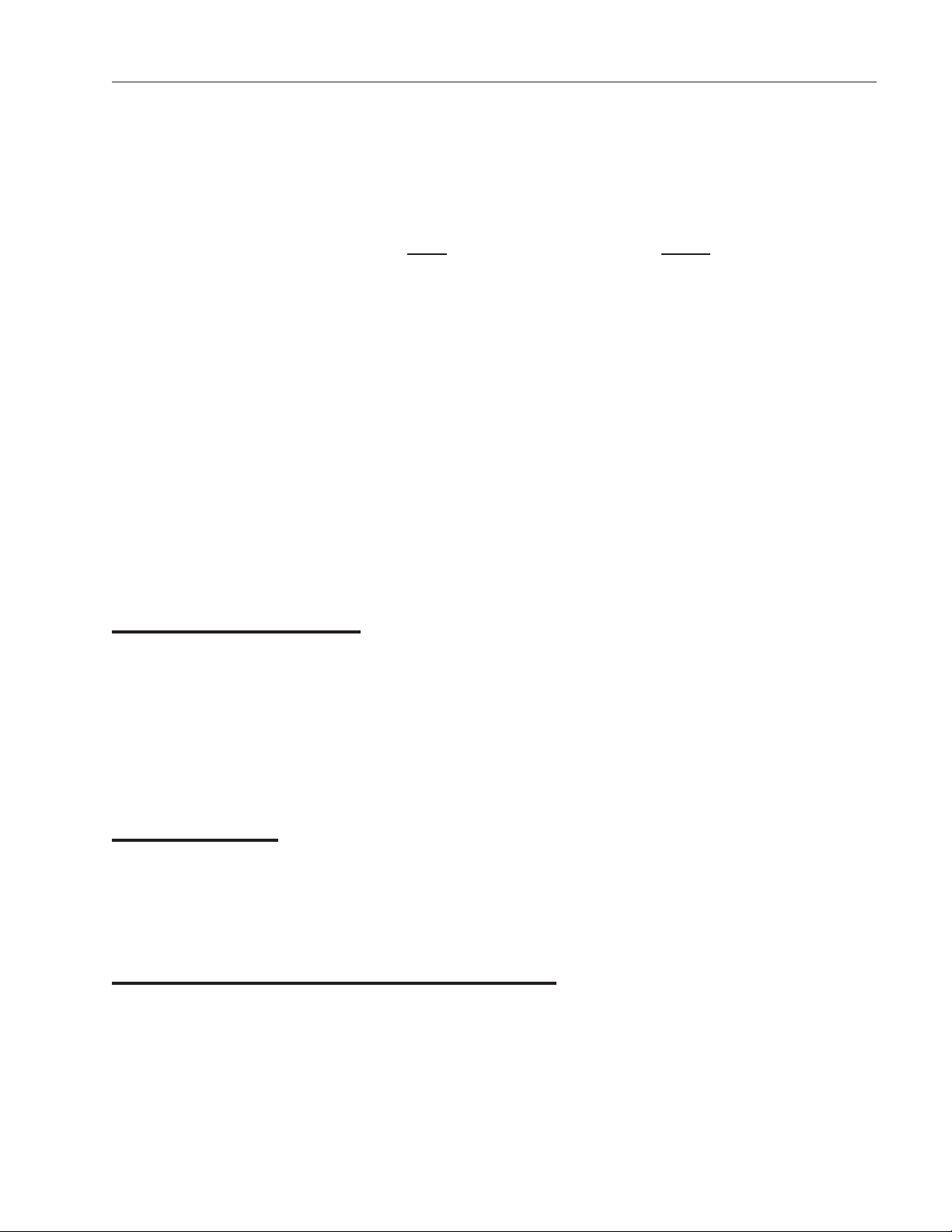

Figure 1

Control Panel

Cycle Phase Indicators

Cycle Select Switches

7

Controls ON/OFF

• CONTROLS ON: Turns ON the

Control Panel.

• CONTROLS OFF: Turns OFF the

Control Panel.

Cycle Select Switches

• UNWRAPPED INSTRUMENTS:

Selects cycle for unwrapped

instruments (3 minute exposure at

135°C).

• WRAPPED INSTRUMENTS: Selects

cycle for wrapped instruments ( 5

minute exposure at 135°C).

•PACKS: Selects cycle for linen packs

(30 minutes exposure at 121°C).

• LIQUIDS: Selects cycle for liquids and

glassware (30 minute exposure at

121°C, slow exhaust).

Cycle Start/Stop

• CYCLE START: Starts the selected

processing cycle.

• CYCLE STOP: Stops the cycle in

progress.

G

ENERAL

INFORMATION

Note

When the power cord is plugged

in and the controls are OFF, the

Control Panel will display the

time.

Note

Cycle times are adjustable from

minimum allowable exposure

time up to 99 minutes.

8

Programming Switches

• PROGRAM/SET: Used to set clock/calendar, select cycle parameters in memory.

•UPAND DOWN ARROWS: Used with

the PROGRAM/SET switch to select

operating procedures.

Display Window

A two-line LCD displays cycle parameters, counts

down exposure and drying times, and displays

messages.

Cycle Phase Indicators

• PROCESSING: Indicates load is being

processed at selected time and

temperature.

• COMPLETE: Indicates processing cycle

is complete.

•DRYING: Indicates load is drying for

selected time.

G

ENERAL I

NFORMATION

9

Cycle Description

Controls ON (Standby)

The vent valve is open when the unit is in

standby mode. The heater is turned on to warm

up the chamber.

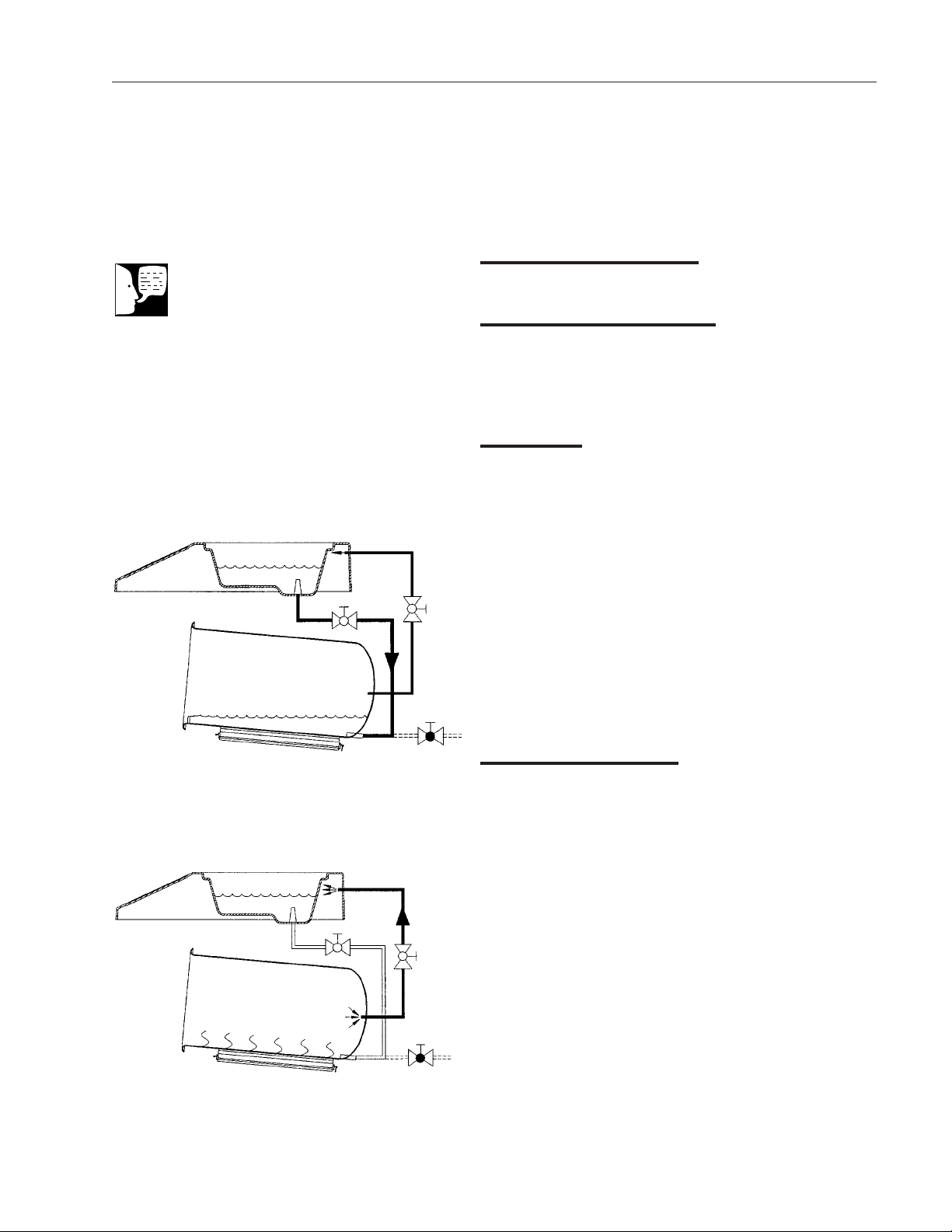

Fill Phase

When CYCLE START is pressed, a 30 second

delay begins, during which time the chamber

temperature is allowed to stabilize. For the

duration of this delay the display will read

“Cooling Chamber” and the current chamber

temperature. The sterilizer will wait up to 60

minutes for the chamber to drop below 70%

before the Fill Phase. When the chamber has

cooled, there is a 15 second delay and then

the fill valve is open for timed period. Water

from the reservoir enters the chamber.

Air Removal Phase

The fill valve is closed and the heater is turned

on. The water boils, producing pressure that

forces air out of the chamber through the vent

valve.

Principles of Operation

Figure 2

Fill Phase

Figure 3

Air Removal Phase

Note

For detailed cycle information,

refer to the cycle phase diagrams

in the Service Data section.

Reservoir

Fill

Vent

Reservoir

Heater

Air

Vent

Fill

10

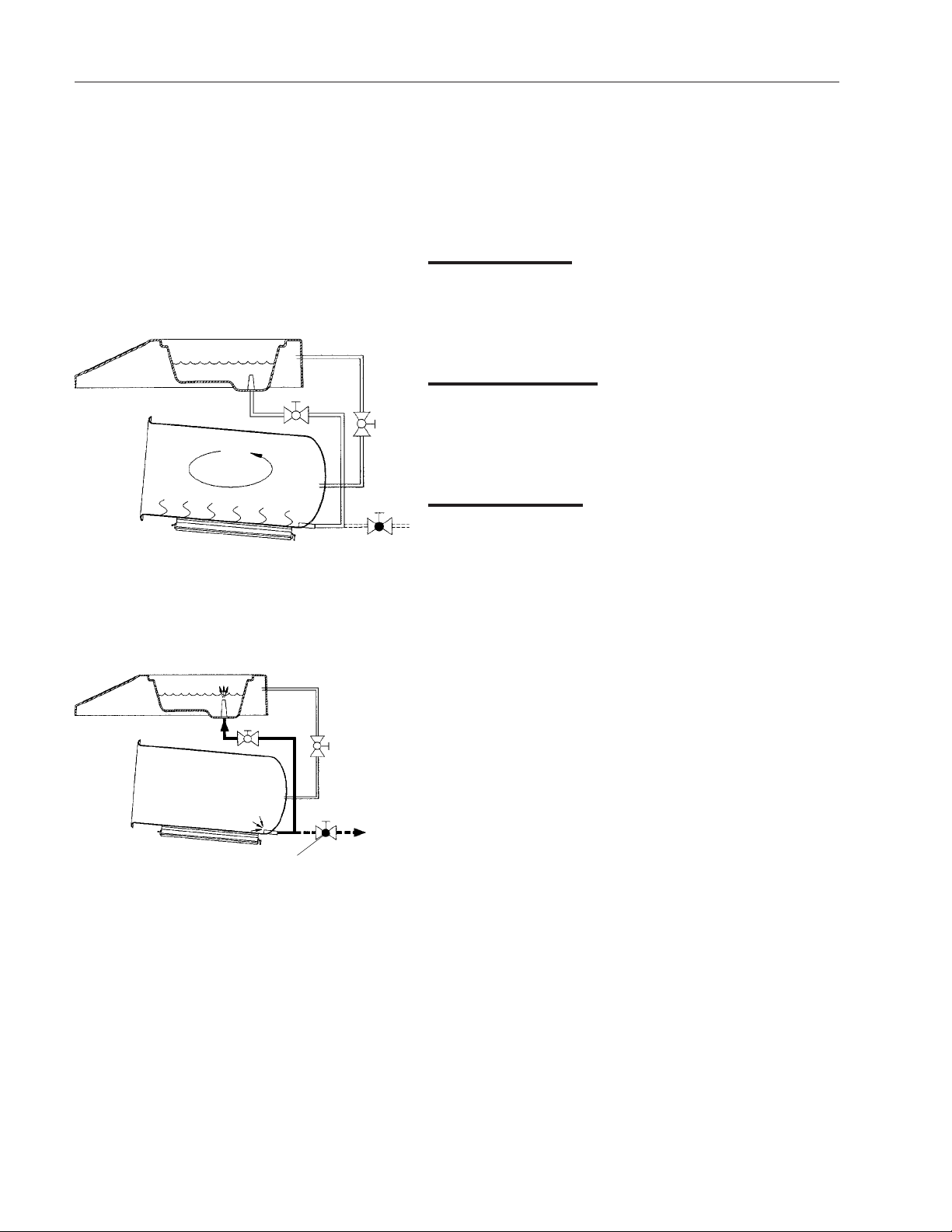

Heatup Phase

The vent valve is closed and the chamber

pressure increases until the exposure set point is

reached.

Exposure Phase

The exposure set point is maintained for a timed

period. The heater is controlled to maintain the

chamber temperature and pressure.

Exhaust Phase

Dry Goods (Recirculating Unit)

The heater is turned off and the fill (exhaust)

valve is opened. Steam exhausts back into the

reservoir. Near the end of the phase, the fill valve

is closed and the vent valve is opened to relieve

the remaining pressure.

Dry Goods (Non-Recirculating Unit)

The heater is turned off and the drain valve is

opened. Steam exhausts into the external

collection bottle. Near the end of the phase, the

drain valve is closed and the vent valve is

opened to relieve the remaining pressure.

Liquids (Recirculating Unit)

The heater is turned off and the fill (exhaust)

valve is opened and closed in small increments

to slowly bleed off the chamber pressure. Steam

exhausts back into the reservoir. Near the end of

the phase, the fill valve is closed and the vent is

opened to relieve the remaining pressure.

Liquids (Non-Recirculating Unit)

The heater is turned off and the drain valve is

opened and closed in small increments to slowly

bleed off the chamber pressure. Steam exhausts

into the external collection bottle. Near the end of

Figure 5

Exhaust Phase

PRINCIPLES OF

OPERA TION

Reservoir

Steam

Recirculating Drain

To

Collection

Bottle

Non-Recirculating

Drain

Figure 4

Exposure Phase

Fill

Heater

Reservoir

Steam

11

the phase, the drain valve is closed and the

vent valve is opened to relieve the remaining

pressure.

Drying Phase (Optional)

Open Door

The operator opens the door and leaves it ajar.

The heater is controlled to provide a heated

chamber for drying goods. The vent valve remains open.

Closed Door

The drying phase, if selected, starts

automatically at the end of the cycle. The heater is controlled to provide a heated chamber

for drying goods. The vent valve remains open.

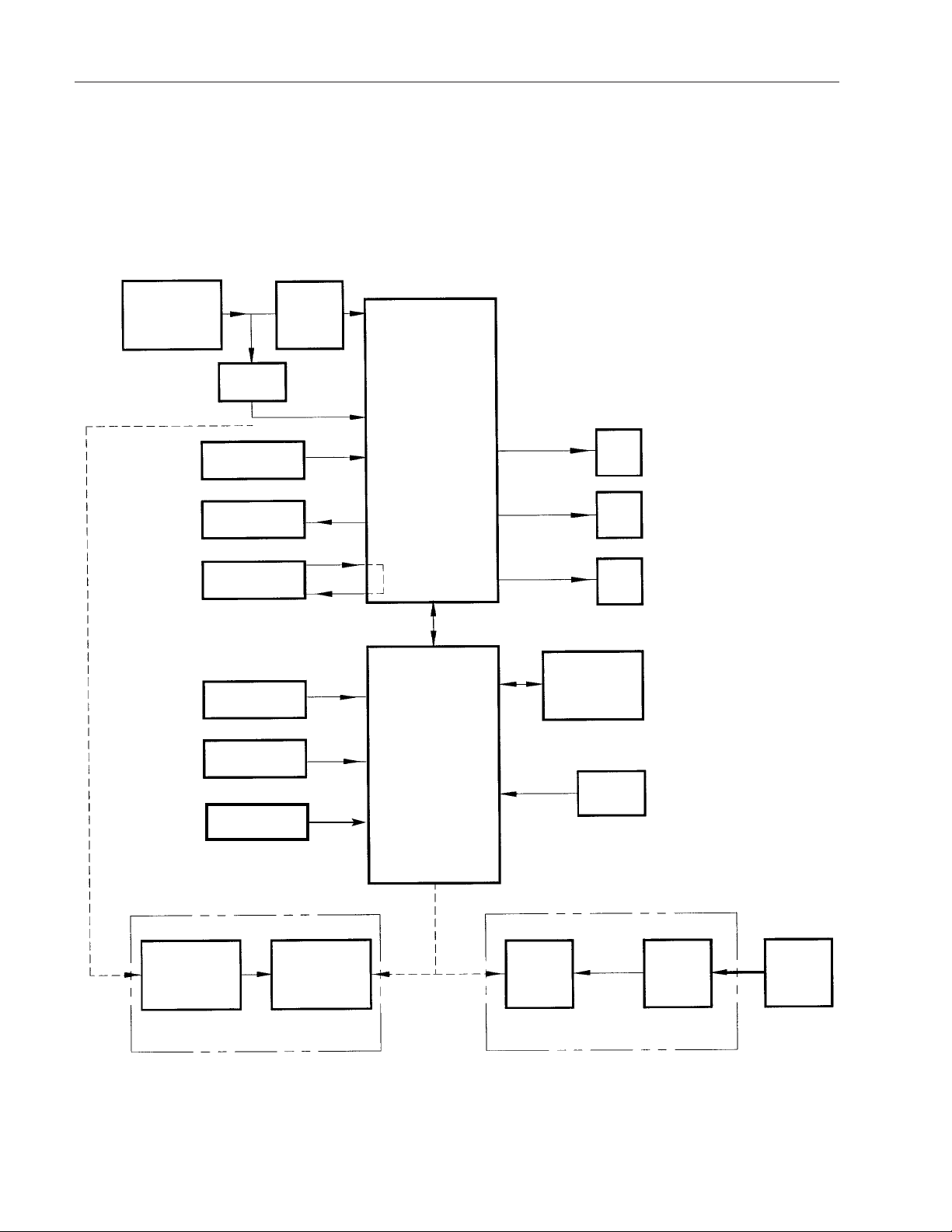

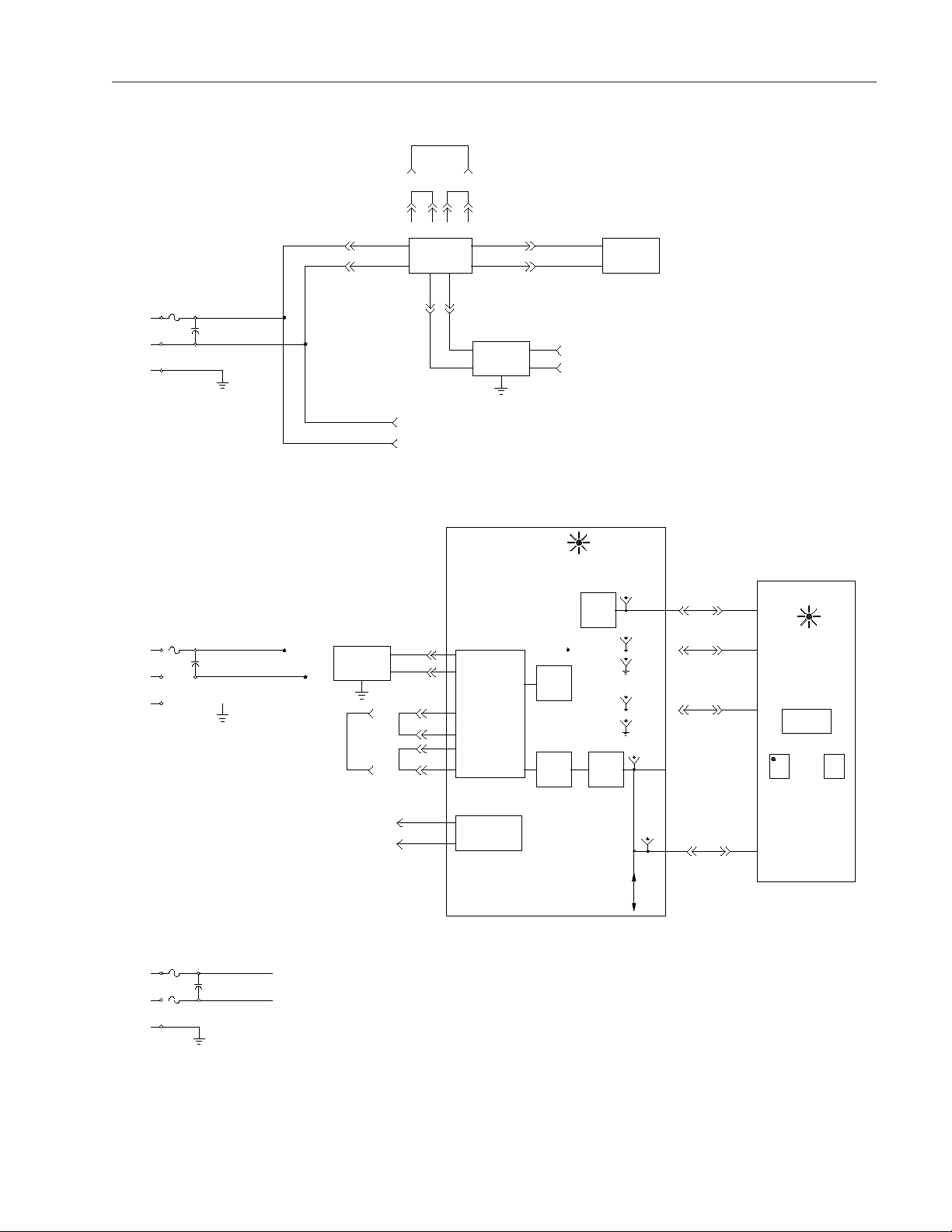

Controls Description

The electronic controls include the following

assemblies:

• Power I/O PC Board 2A

• Control PC Board 3A

• Control Panel 4A

• Printer 5A (optional)

•Transformer PC Board 6A (optional

MC10 printer)

Power Input

The customer supply input (115 or 230 VAC) is

routed to the EMI filter, Power I/O PC Board,

and Transformer PC Board. The filtered input is

applied to the Power I/O Board, which produces the required operating voltages for the

controls.

P

RINCIPLES OF

OPERA TION

12

Power I/O Board

The Power I/O PC Board produces +24 VDC for

the solenoid valves and +5 VDC for the control

circuits. The unfiltered supply voltage is routed to

the heater circuit.

The Power I/O PC Board communicates with the

Control PC Board via a serial data interface. In

response to commands from the Control PC

Board, the Power I/O PC Board controls solenoid

valves 1SOL through 3SOL and heater

1HTR/2HTR. The solenoid valves are activated

by the solenoid driver on the Power I/O PC

Board. The heater is activated by solid-state

relay 1SSR, mounted on the chassis.

If an over temperature condition should occur,

thermal switch 2SW will open to remove power

from the heaters.

Control PC Board

The Control PC Board contains a microprocessor

that controls the sterilization cycle. The

microprocessor monitors temperature, pressure

and switch inputs, and controls the solenoid

valves and heaters via the Power I/O PC Board.

The input from temperature sensor 1RT is an

analog voltage that is applied to a conditioning

circuit which produces coarse and fine control

voltages. These voltages are applied to the

microprocessor for precise control of the chamber temperature.

The pressure input from 1PT is an analog voltage that is applied directly to the microprocessor.

The amplitude of the voltage is proportional to

the pressure.

P

RINCIPLES OF

OPERA TION

13

The Control PC Board communicates with the

printer over a serial data interface.

Control Panel

The control panel is a membrane switch panel

connected to the Control PC Board by a ribbon

cable.

Printer

The MC8 printer connects to the printer receptacle on the back of the sterilizer. Power for the

printer is provided by a transformer-type wall

plug.

The MC10 printer is mounted next to the

Control Panel.

Transformer PC Board

The Transformer PC Board steps down the

input voltage to the level required by the MC10

printer.

P

RINCIPLES OF

OPERA TION

14

Figure 6

MC8/MC10 Block Diagram

PRINCIPLES OF

OPERA TION

Customer

Supply Input

(See Chart)

1FL

EMI

Filter

1HTR/2HTR

Heater

1SSR

Solid State Relay

1RT

Temperature

Probe

4SW

Door

Switch

Transformer Board

6A

Printer

5A

Control Board

3A

Serial

Data

Printer

5A

Transformer

1 T

Customer

Supply

Input

120V

1PT

Pressure

Transducer

Power I/O Board

2A

1Sol

Vent

2Sol

Fill

3SOL

Non-Rc

1C

Noise Filter

25W

Thermal Switch

(Optional printer for MC8 only)

(Optional Printer for MC10 only)

Control Panel

4A

Lever

Season

15

Fuse Replacement

Main Fuses

The main fuses are located on the back panel of

the sterilizer. 115 VAC units have one or two 15A

fuse. 230 VAC units have two 8A fuses.

Transformer Board

(MC10 Printer Option)

Fuses 1F and 2F (100 mA) are soldered on the

Transformer PC Board.

Diagnostic Messages

When a malfunction occurs, the Control Panel

will display a message describing the nature of

the problem. Some malfunctions will be due to

out of tolerance conditions during the

processing cycle.

The last five malfunctions will be listed in the

error log. The error log can be viewed by

entering factory setup mode:

1. Press CONTROLS ON.

2. Press and hold the CONTROLS OFF

switch.

3. Press and hold the PROGRAM/SET

switch.

4. Release the CONTROLS OFF switch

5. Release the PROGRAM/SET switch.

6. The error log will be displayed. Use the

up and down arrows to view the last five

entries.

Trouble Analysis

Caution

Factory setup mode should only

be used by authorized service

personnel.

16

Error log entries include the following information:

• ER number. Use this number to

determine the specific malfunction (see

diagnostic message tables, pp. 17-18).

• Cycle count during which malfunction

occurred.

• Date and time at which malfunction

occurred.

• Press CYCLE STOP when finished

viewing the error log.

T

ROUBLE A

NALYSIS

17

TROUBLE A

NALYSIS

Diagnostic Messages

egasseMnoitidnoCtluaFnoitcAevitcerroC

tseTfleS

deliaF

ooTerusserP

hgiH

.gisp

.neporodetrohsDTR:3RE

.egnarfo

rorrEslortnoC

.revird

sahgniwollofehtfoenO:6RE

:derrucco

.tsetflesgniruderuliafMORPEE:1RE.draoBCPlortnoCecalpeR

04dedeecxeerusserprebmahC:2RE

tuoegatlovrecudnarterusserP:4RE

dionelosmorfnoitacidnitluaF:5RE

.tiucricretaehkcehC

.sevlavdioneloskcehC

.draoBCPlortnoCno21JtanoitcennocDTRkcehC

.DTRecalpeR

no41JtanoitcennocrecudsnarterusserpkcehC

.draoBCPlortnoC

.2-41JtaegatlovkcehC

.recudsnarterusserpecalpeR

.draoBCPlortnoCno1JtanoitcennocelbackcehC

.stiucriclortnocdioneloskcehC

.draoBCPO/IrewoPecalpeR

.draoBCPlortnoCecalpeR

hcaertondiderutarepmetrebmahC

.tratselcycfosetunim51nihtiwC°09

detelpmoctonsawesahplavomerriA

ooTputaeH

gnoL

taehrevO

ooTtneV

gnoL

.C°541

.setunim03nihtiw

.tiucricretaehkcehC

hcaertondiderutarepmetrebmahC

04nihtiwerutarepmeterusopxe

.noitavitcaretaehlaitinifosetunim

sawremit,esahperusopxeehtgniruD

.setunim01nahteromrofdednepsus

dedeecxeerutarepmetrebmahC:7RE

llaftondiderusserprebmahC:8RE

setunim01nihtiwgisp0.1woleb

.esahptnevgnirud

.tiucricretaehkcehC

.evlavdionelosllifkcehC

.neercsretlifnaelC.rebmahcnisirbedrofkcehC

-noNehtgnisufievlavgnitalucricer-nonkcehC

.erutaefgnitalucriceR

.evlavdionelostnevkcehC

18

TROUBLE

ANALYSIS

Diagnostic Messages

egasseMnoitidnoCtluaFnoitcAevitcerroC

nepOrooD.elcycgnirudneporooD:9RE

ooTerusserP

woL

.erusopxegnirud

.hctiwsroodkcehC

.msinahcemkcolroodkcehC

.sevlavdioneloskcehC

gisp01lleferusserprebmahC:01RE

tniopteserusserperusopxewoleb

.teksagroodkcehC

.skaelrofgnipipkcehC

erutarepmeT

woLooT

rorrEtinU

erutarepmeT

hgiHooT

.erusopxegnirud

.pu-rewopgnirud

.detratselcycnehw

C°01lleferutarepmetrebmahC:11RE

tniopteserutarepmeterusopxewoleb

derruccoteserremitgodhctaW:21RE

sawerutarepmetrebmahC:31RE

setunim06nahteromrofC°07evoba

.tiucricretaehkcehC

.rorreraelcotFFOsserP

eraslortnocnehwtneserpllitssinoitidnoctluaffI

;nokcabdenrut

.tinuehtgulpnU

GNIMROFREP"retfanottubFFOehtdlohdnasserP

.deyalpsidsi"TSET-FLES

ecalper,tratserretfatneserpllitssinoitidnoctluaffI

.draoBCPlortnoCeht

.tiucricretaehkcehC

.selcycneewtebregnolloocotrebmahcwollA

19

Diagnostics Mode

When diagnostics mode has been enabled in

the factory setup mode, the following features

will be available:

• Automatic Cycle Start. If the door is

not opened within 30 seconds after a

cycle is completed, the software will

automatically start another cycle.

• Cycle Phase Advance. If the down

arrow is pressed during a timed phase

(fill, air removal, exposure, or drying),

the timer will be zeroed and the cycle

will advance to the next phase.

• Enhanced Data Display. During a

cycle, additional information is

displayed on the LCD: the cycle phase

and timer in minutes and seconds.

• Enhanced Data Printout. The message DIAGNOSTICS MODE will be

added to the standard printout. If any

malfunctions occur, a detailed

message will be printed.

Testing for Leaks

If the sterilizer cannot reach or maintain chamber pressure, inspect door gasket and replace

it if worn or damaged. Check piping connections for leaks by applying soapy water and

looking for steam bubbles.

Caution

Factory setup mode should only

be used by authorized service personnel.

Note

To enable the automatic cycle

start feature, RECYCLE must be

selected at the DIAGNOSTICS

prompt in factory setup mode.

To stop a cycle from repeating,

open the door or press CYCLE

STOP during the 30 second delay

between cycles.

Caution

If the user advances through an

un-timed phase and the temperature/pressure conditions are not

met for the Enhanced Data

Display phase, an error may occur.

T

ROUBLE A

NALYSIS

20

TROUBLE ANALYSIS

Power Supply Circuits

petSerudecorPnoitcAevitcerroC

:notonsikcolcfI

.nwolbfiecalper—sesufkcehC

1.drocrewopnigulP

2

3

4

ees,tiltonsi01SDfI.draoBCPO/IrewoPno01SDkcehC

.2pets

ees,tiltonsi01SDfI.draoBCPlortnoCno01SDkcehC

.3pets

:tneserptonerasegatlovylppusrewopfI

.6Jdna3JtanoitcennoctupnicakcehC

segatlovylppusrewopkcehC

.draoBCPO/IrewoPno

.swercs

.draoBCPO/IrewopecalpeR

:tneserptonerasegatlovylppusrewopfI

segatlovylppusrewopkcehC

.draoBCPlortnoCno

NOSLORTNOCsserP

.hctiws

.draoBCPO/IrewoP

.draoBCPlortnoCecalpeR

gnitnuomknistaehrotsisnartrewopfossenthgitkcehC

dnadraoBCPlortnocneewtebnoitcennocelbackcehC

.draoBCPlortnocecalper,noitcnuftonodslortnocfI

21

Figure 7

Power Supply Circuits

TROUBLE A

NALYSIS

230V

1

4

115V

N

GND

GND

L

L

N

4

5

TB1 TB1

4 2

5

2

3

3

IC

IC

115 VAC

(BK)

(W)

(W)

(BK)

J1

J2

LINE

FILTER

J7

J8

230 VAC 115 VAC

1 2 3 4

TRANSFORMER

J5

(BR)

J17

TO POWER

I/O BOARD

J18

J7

J5

J3

J8

BOARD

J4

J6

J6

(BL)

LINE

FILTER

TO POWER

I/O BOARD

(SEE NOTE)

TRANSFORMER

(BL)

(BR)

RECT

BRIDGE

RECT

BRIDGE

J4

J6

PRINTER

TO POWER

I/O BOARD

POWER

DS10

+5V

REG

RECT

BRIDGE

TP1

+5V

TP2

+14V

TP3

GND

TP5

+14V

TP6

GND

+24V

TP8

J2-5 J1-5

J2-2 J1-2

J2-3 J1-3

CONTROL

PC BOARD

POWER

DS10

(ON BACK

OF PCB)

DISPLAY

ON OFF

2

4

L1

IC

5

L2

GND

3

2F

230 VAC AND

DUAL VOLTAGE

MODELS

(W)

(BK)

J17

J18

HEATER

CONTROL

CIRCUIT

TP7

12V

J2-16 J1-16

TEST POINTS

TP1 -14 VDC

TP2 +14 VDC

TP3 GROUND

TP7 +5 VDC

22

TROUBLE

ANALYSIS

Heater Control Unit

petSerudecorPnoitcAevitcerroC

1

.draoBCP

otloocotrebmahcehtwollA

ehtretnE.erutarepmetmoor

sserP.sunemputesyrotcaf

ehtlitnunottubmargorpeht

TAEH"",TSETRETAEH"

sserP.deyalpsidsi"0FFO

ehtrewopotnottubtratseht

dnoces01dexifarofretaeh

yalpsidehtnehW.noitarud

kcehc"NOTAEH"swohs

O/IrewoPno)retaeH(1SD

:FFOsi1SDfI

CPO/IrewoPneewtebnoitcennocelbacnobbirkcehC

.draoBCPlortnoCdnadraoB

.draoBCPlortnoCecalpeR

.draoBCPO/IrewoPecalpeR

2

3

4.retaehfoytiunitnockcehC.tiucricnepofiretaehecalpeR

5.RSSretaehkcehC

.hctiwsffo-tuc

dna71JtatupnicarofkcehC

.draoBCPO/IrewoPno81J

lamrehtfoytiunitnockcehC

.snoitcennockcehC

.erutarepmetmoortatiucricnepofiecalpeR

Loading...

Loading...