Page 1

p

p

Barnett International

Limited Warranty

The crank cocking device is guaranteed to the original purchaser to

be free of manufacturing defects for a period of one year from the

date of purchase. Our liability extends to parts, labor and return

transportation to the consumer.

Not covered are: Ropes, transportation of defective product to our

Service Dept., damaged caused by abuse , modification or failure to

erform normal maintenance, any other expense, consequential

damages, incidental damages or incidental expenses including

damage to property or person.

How to obtain service: DO NOT returns the unit to the dealer.

Dealers are not authorized to make exchanges, replacements or

refunds on our behalf. Attach to the product our name, address,

telephone number and letter describing the problem. Carefully

ackage and return the product, transportation charges prepaid to:

Barnett International, Inc.

Attn: Service Department

13447 Byrd Drive

Odessa, FL 33556

There are no warranties expressed or implied. This warranty gives

you specific legal rights and you may also have other, which vary

from state to state.

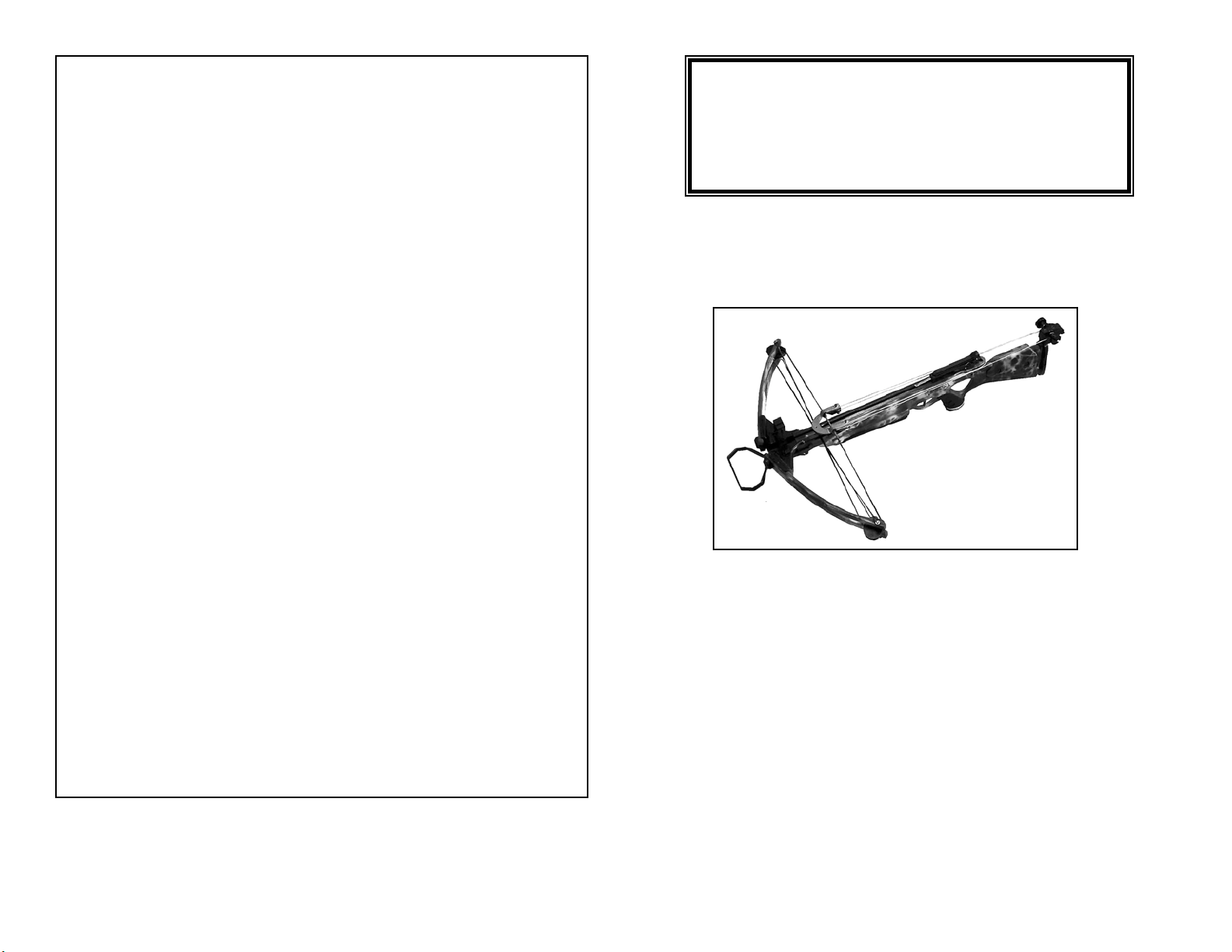

Revolution

Crank Cocking Device

Installation & Operation

Page 2

DO NOT TURN THE HANDLE BACKWARDS

N

WHILE DRAWING THE BOW! THIS WILL

DAMAGE THE ROPE!

The latch mechanism should always be engaged when

cocking the crossbow. An audible clicking sound should

be present while turning the handle in a forward

rotation. If this clicking sound is not present, place

safety in engaged position.

Un-cocking the Crossbow- do not un-cock the

crossbow with the Crank Cocking Device. This could

cause injury to your crossbow. The best way to un-cock

your crossbow with a crank-cocking device attached is

to shoot an arrow into the ground. You may want to

Warranty registration card (attached) must be mailed

within 10 days of purchase to validate the warranty.

WARRANTY CARD

ame______________________________ Age______

Address______________________________________

City____________________ State______ Zip_______

Date of Purchase__________ Phone # _____________

Place of Purchase__________________ Price Paid____

Purchase Address______________________________

City____________________ State _____ Zip _______

Registration completed by: Dealer ( ) Consumer ( )

Sales Representatives Name:

Registration _________________________________

Page 3

1. Loosen stock extender set screws. Fig 1

p

2. Turn adjustment wheel clock-wise to remove stock

extender.

With stock extender removed make sure there are (5) five

holes on the butt of crossbow. Fig 2 If not see Step B.

3.Line up the (5) five holes of the CCD butt plate bracket

with the 5 holes on the butt of the crossbow. Install the 2

#6 Philips head screws through the butt plate and into the

gunstock. Fig 3 Do not yet tighten all of the way.

4.Put the stock extender back into the crossbow making

sure the stock extender moves in and out freely. Fig 4

Pull stock extender out without moving butt plate.

Tighten the two #6 Philips head screws.

5.Slide stock extender back into crossbow making sure

stock extender moves freely, if not repeat step 4.

Fig 1

Fig 2

6. Re-install stock extender and adjustment wheel . Adjust to

desired length. Re-tighten stock extender screws.

7. Installing spool assembly – Slide spool assembly onto the

CCD butt plate dovetail. Fig 5 Install “holding” screw if you

desire to keep the crank on as a permanent mount. See note

in box on following page.

8. Release safety/anti-reverse latch by pushing it down until

held by the spring plunger.

9. Turn off safety/anti-reverse latch, unwind spool by pulling

CCD rope.

10. Place u-bracket on the flight track with both hooks

tightly on either side on the track; pull center excess of rope

behind the pistol grip in the grove. Figure 5 A

11. Engage safety latch. Fig 6

12. Install crank handle on desired side of CCD and crank

clock-wise (NOTE: For left hand handle installation turn

counter clock-wise.) until the crossbow safety engages and

you hear an audible click. Remove hooks and wind rope onto

spool.

Fig 3 Fig 4

STEP B If you only have 3-predrilled holes in the stock;

line up the butt plate with the existing holes in stock. Using

encil trace the two extension holes, drill holes using .125

drills to a depth of 1/8” to 1/4 “, continue installation with

step 3.

Fig 5

Fig 5A

Loading...

Loading...