Barnes 2ADE11, 2ADE13, 2CDE11, 2CDE13, 3ADE151 Installation And Operation Manual

...

BARNES

®

BARNES

INSTALLATION and OPERATION MANUAL

Diaphragm Pumps

Models:

2ADE11, 2CDE11

2ADE13, 2CDE13

3ADE151, 3CDE151

3ADE153, 3CDE153

DISCONTINUED

Parts NOT available

IMPORTANT! Read all instructions in this manual before operating pump.

As a result of Crane Pumps & Systems, Inc., constant product improvement program,

product changes may occur. As such Crane Pumps & Systems reserves the right to

change product without prior written notifi cation.

A Crane Co. Company

420 Third Street 83 West Drive, Bramton

Piqua, Ohio 45356 Ontario, Canada L6T 2J6

Phone: (937) 778-8947 Phone: (905) 457-6223

Fax: (937) 773-7157 Fax: (905) 457-2650

www.cranepumps.com

Form No. 082924-Rev. F

TABLE OF CONTENTS

SAFETY FIRST ............................................................................................... 3

A. PUMP SPECIFICATIONS ............................................................................... 4 - 5

B. GENERAL INFORMATION ............................................................................. 6

C. PREPARE PUMP FOR OPERATION ............................................................. 6

D. MAINTENANCE INSTRUCTIONS .................................................................. 7

E. TROUBLE SHOOTING ................................................................................... 7

F. REPLACEMENT PARTS ................................................................................. 7

EXPLODED VIEW .......................................................................................... 8

PARTS LIST - SERIES 2CDE & 3CDE ........................................................... 9 - 10

PARTS LIST - SERIES 2ADE & 3ADE ........................................................... 11 - 12

RETURNED GOODS POLICY ........................................................................ 13

WARRANTY .................................................................................................. 14

START-UP REPORT ....................................................................................... 17 - 18

WARRANTY REGISTRATION

Other brand and product names are trademarks or registered trademarks of their respective holders.

® Barnes is a registered trademark of Crane Pumps & Systems, Inc

1987, 1997, 1998, 2002, 3/06, 9/06 Alteration Rights Reserved

2

SAFETY FIRST!

Please Read This Before Installing Or Operating Pump.

This information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this information,

observe the following symbols:

IMPORTANT! Warns about hazards that can result

in personal injury or Indicates factors concerned with

assembly, installation, operation, or maintenance which

could result in damage to the machine or equipment if

ignored.

Always wear eye protection when working on pumps.

Make sure lifting handles are securely fastened each

time before lifting. DO NOT operate pump without

safety devices in place. Always replace safety devices

that have been removed during service or repair.

Secure the pump in its operating position so it can not

tip over, fall or slide.

CAUTION ! Warns about hazards that can or will cause minor

personal injury or property damage if ignored. Used with symbols

below.

WARNING ! Warns about hazards that can or will cause serious

personal injury, death, or major property damage if ignored. Used

with symbols below.

Hazardous fl uids can

cause fi re or explosions, burnes or death

could result.

Biohazard can cause

serious personal injury.

Rotating machinery

Amputation or severe

laceration can result.

Toxic Fumes Breathing can cause

nausea, fainting or death

Extremely hot - Severe

burnes can occur on contact.

Hazardous fl uids can Hazardous pressure, eruptions or explosions could cause personal

injury or property damage.

Hazardous voltage can

shock, burn or cause death.

Eye protectiong required

Only qualifi ed personnel should install, operate and repair pump.

WARNING! Operation against a closed

discharge valve will cause premature bearing

and seal failure on any pump, and on end

suction and self priming pump the heat build

may cause the generation of steam with resulting dangerous

pressures. It is recommended that a high case temperature

switch or pressure relief valve be installed on the pump body.

CAUTION! Pumps build up heat and pressure

during operation-allow time for pumps to cool

before handling or servicing.

WARNING! - DO NOT pump hazardous materials

(fl ammable, caustic, etc.) unless the pump is specifi cally

designed and designated to handle them.

CAUTION! - Do not block or restrict discharge hose, as

discharge hose may whip under pressure.

WARNING! - DO NOT wear loose clothing that may

become entangled in the impeller or other moving parts.

Always wear appropriate safety gear, such as safety

glasses, when working on the pump or piping.

WARNING! - Keep clear of suction and discharge

openings. DO NOT insert fi ngers in pump with power

connected.

DO NOT exceed manufacturers recommendation for

maximum performance, as this could cause the motor

to overheat.

When towing pump behind a vehicle, make sure hitch is

properly attached, always attach safety chains.

WARNING! If Engine driven, never operate in an

enclosed building or area where exhaust gases can

accumulate. Never operate near a building where

exhaust gases can seep inside. Never operate in a

pit or sump without making provisions for adequate

ventilation.

WARNING! Do not breathe exhaust fumes when

working in the area of the engine. (Exhaust gases are

odorless and deadly poison.)

WARNING! Allow exhaust system to cool before

touching.

Never add fuel to the tank while the engine is running.

Stop engine and allow to cool.

Do not smoke while refueling the engine

Do not refuel near open fl ame

Carefully read instruction manuals supplied by engine

manufacture before attempting to assemble, operate

or service the engine or any part. The “WARNING”

statements indicate potentially hazardous conditions for

operator or equipment.

WARNING! Products Returned Must Be Cleaned,

Sanitized, Or Decontaminated As Necessary Prior

To Shipment, To Insure That Employees Will Not Be

Exposed To Health Hazards In Handling Said Material.

All Applicable Laws And Regulations Shall Apply.

Bronze/brass and bronze/brass fi tted pumps may

contain lead levels higher than considered safe for

potable water systems. Lead is known to cause cancer

and birth defects or other reproductive harm. Various

government agencies have determined that leaded

copper alloys should not be used in potable water

applications. For non-leaded copper alloy materials of

construction, please contact factory.

IMPORTANT! - Crane Pumps & Systems, Inc. is not

responsible for losses, injury, or death resulting from a

failure to observe these safety precautions, misuse or

abuse of pumps or equipment.

3

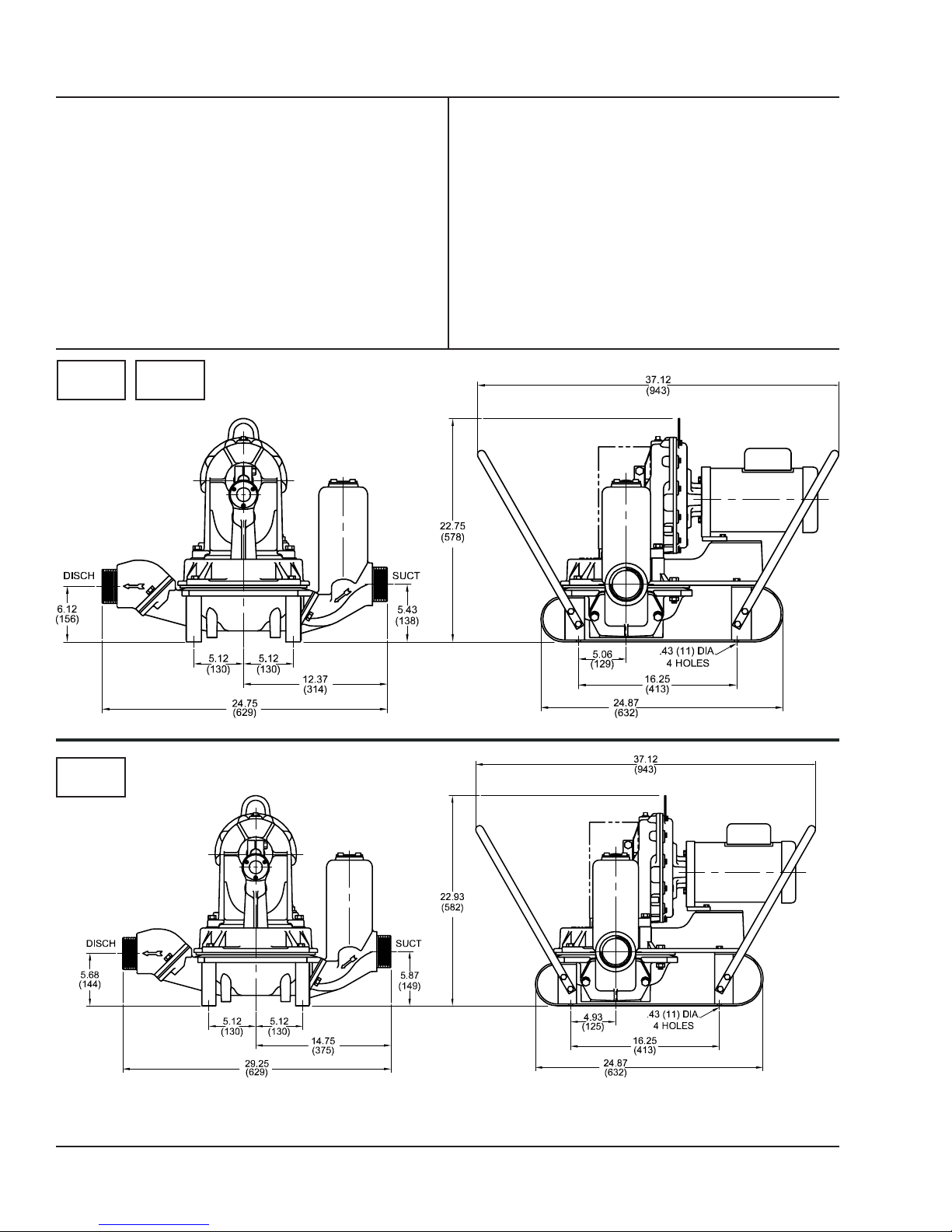

SECTION: A - PUMP SPECIFICATIONS: Skid Mounted

SUCTION/DISCHARGE:

2ADE-2CDE ....... 2” x 2" NPT

3ADE-3CDE ........ 3” x 3” NPT

LIQUID TEMPERATURE ... 160°F (71°C) Continuous

SUCT/DISCH CHAMBER

ADE ..................... Aluminum, Class 319

CDE ..................... Cast Iron ASTM A-48, Class 30

WATER BOX

ADE .................... Aluminum, Class 319

CDE ..................... Cast Iron ASTM A-48, Class 30

DIAPHRAGM BOTTOM

ADE ..................... Aluminum, Class 319

CDE ..................... Cast Iron ASTM A-48, Class 30

DIAPHRAGM ..................... Thermal Plastic Elastomer (TPE)

inches

(mm)

2”

BEARING ........................... Ball

FLAP VALVE ...................... Natural Rubber

PAINT ................................. Air Dry Enamel

TRANSMISSION ................ Enclosed, Oil Bath, Double

Reduction

GEAR RATIO ................. 43:1

OUTPUT STROKES .......... 41 Per Minute

MOTOR: Design ................. TEFC NEMA B Torque curve,

C-Face, Squirrel cage induction

Insulation ............. Class B

SINGLE PHASE ................. Dual Voltage 115/230

THREE PHASE ................. Dual Voltage 230/460

OPTIONAL EQUIPMENT ... Across the Line Manual Starter

3”

IMPORTANT !

1.) DO NOT USE FOR PUMPING FLUIDS WITH A FLASH POINT OF LESS THAN 100°F.

2.) MAKE CERTAIN THAT PUMP AND/OR MOTOR ASSEMBLY AND CONTROLS HAVE THE APPROPRIATE RATINGS FOR THE GIVEN APPLICATION

AREA CLASSIFICATION. (ie DIVISION I, AGENCY LISTING ETC.)

4

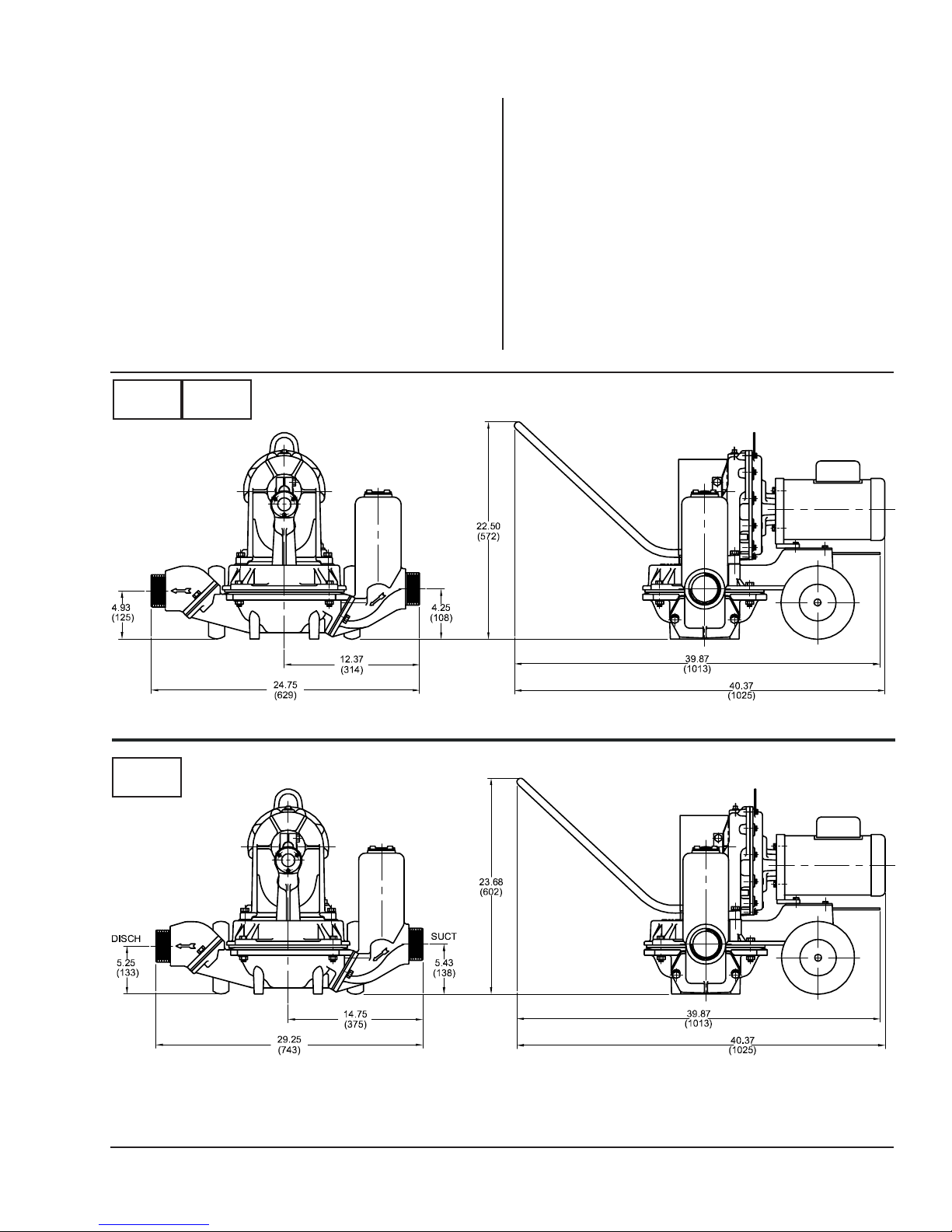

SECTION: A - PUMP SPECIFICATIONS: Wheel Mounted

SUCTION/DISCHARGE:

2ADE-2CDE ....... 2” x 2" NPT

3ADE-3CDE ........ 3” x 3” NPT

LIQUID TEMPERATURE ... 160°F (71°C) Continuous

SUCT/DISCH CHAMBER

ADE ..................... Aluminum, Class 319

CDE ..................... Cast Iron ASTM A-48, Class 30

WATER BOX

ADE .................... Aluminum, Class 319

CDE ..................... Cast Iron ASTM A-48, Class 30

DIAPHRAGM BOTTOM

ADE ..................... Aluminum, Class 319

CDE ..................... Cast Iron ASTM A-48, Class 30

DIAPHRAGM ..................... Thermal Plastic Elastomer (TPE)

BEARING ........................... Ball

inches

(mm)

2”

FLAP VALVE ...................... Natural Rubber

PAINT ................................. Air Dry Enamel

TRANSMISSION ................ Enclosed, Oil Bath, Double

Reduction

GEAR RATIO ..................... 43:1

OUTPUT STROKES .......... 41 Per Minute

TIRES ................................. 8” x 1.75 (used on ADE & CDE11-1

............................................ ADE & CDE13-1

MOTOR: Design ................. TEFC NEMA B Torque curve,

C-Face, Squirrel cage induction

Insulation ............. Class B

SINGLE PHASE ................. Dual Voltage 115/230

THREE PHASE ................. Dual Voltage 230/460

OPTIONAL EQUIPMENT ... Across the Line Manual Starter

3”

IMPORTANT !

1.) DO NOT USE FOR PUMPING FLUIDS WITH A FLASH POINT OF LESS THAN 100°F.

2.) MAKE CERTAIN THAT PUMP AND/OR MOTOR ASSEMBLY AND CONTROLS HAVE THE APPROPRIATE RATINGS FOR THE GIVEN APPLICATION

AREA CLASSIFICATION. (ie DIVISION I, AGENCY LISTING ETC.)

5

SECTION B: GENERAL INFORMATION

B-1) To the Purchaser:

Congratulations! You are the owner of one of the fi nest pumps

on the market today. Barnes® Pumps are products engineered

and manufactured of high quality components. Over one

hundred years of pump building experience along with a

continuing quality assurance program combine to produce a

pump which will stand up to the toughest applications.

This Barnes Pumps manual will provide helpful information

concerning installation, maintenance, and proper service

guidelines.

B-2) Receiving:

Upon receiving the pump, it should be inspected for damage

or shortages. If damage has occurred, fi le a claim immediately

with the company that delivered the pump. If the manual is

removed from the packaging, do not lose or misplace.

B-3) Storage:

Short Term - Barnes Pumps are manufactured for effi cient

performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as factory

assembled, in a dry atmosphere with constant temperatures

for up to six (6) months.

Long Term - Any length of time exceeding six (6) months, but

not more than twenty four (24) months. The units should be

stored in a temperature controlled area, a roofed over walled

enclosure that provides protection from the elements (rain,

snow, wind blown dust, etc..), and whose temperature can be

maintained between +40 deg. F and +120 deg. F.

If extended high humidity is expected to be a problem, all

exposed parts should be inspected before storage and all

surfaces that have the paint scratched, damaged, or worn

should be recoated with a water base, air dry enamel paint. All

surfaces should then be sprayed with a rust-inhibiting oil.

Pump should be stored in its original shipping container.

B-4) SERVICE CENTERS:

For the location of the nearest Barnes Service Center, your

Barnes representative or Crane Pumps & Systems, Inc.,

Service Department in Piqua, Ohio, telephone (937) 778-8947

or Crane Pumps & Systems Canada Inc., Bramton, Ontario

(905) 457-6223.

SECTION C: PREPARE PUMP FOR OPERATION :

1. Before making electrical power connections, check for

proper grounding of motor and application. All electrical

contacts and connections must be properly insulated and

enclosed.

2. Prior to connecting to the power line, check nameplate

for proper voltage. The motor should be installed in

compliance with the National Electrical Code or the

Canadian Electrical Code and any other applicable codes.

Voltage at motor NOT to exceed + or - 10% of nameplate

voltage.

3. For best performance locate pump as close to water as

possible. Vertical suction lift should not exceed

25 ft. (7.6M) At high lifts, 15 ft. (4.5M) and up, a foot valve

is recommended, and a size smaller suction hose, will

give better operation and same capacity.

4. Extra heavy faced nipples in suction and discharge

connections protect the threads in these castings.

To connect a hose fi tted with a male nipple, use a

coupling or union. Seal threads with grease or thread

sealer to prevent air leaks. To connect a hose fi tted with

a female coupling, gasket must be in place and in good

condition. Suction hose must be in good condition with

no leaks and lining tight. A loose lining will collapse under

suction and keep liquid from being drawn into pump. A

coarse strainer at end of suction hose is advisable if there

is a possibility of pumping large, hard, unbreakable solids,

such as, rocks, wood, tin cans, etc., that could be caught

between connecting rod and water box, causing pump

damage.

5. To lead water away, connect non-collapsible suction hose

to nipple in discharge connection. Discharge hose should

not be smaller than suction hose and not kinked. It is

helpful to use a short piece of hose at any time, with

open end raised a foot or so above discharge connection.

This retains water to seal the discharge valve and

improves capacity and operation. Discharge head should

never exceed 25 ft. (7.6M).

6. On high lifts, or if pump has been idle and valves are dry,

remove cap on suction chamber and pour water into pump.

This will seal valves and speed up priming. Replace cover

securely to keep air from leaking into suction line.

7. Drain pump in freezing weather by tipping unit toward

discharge side with hoses disconnected.

8. Check oil level in the pump transmission. If it is not up to

the oil level plug in the cover, top off with an

SAE 80 - 90 EP gear lube. Transmission oil capacity is

20 oz. (550 ml).

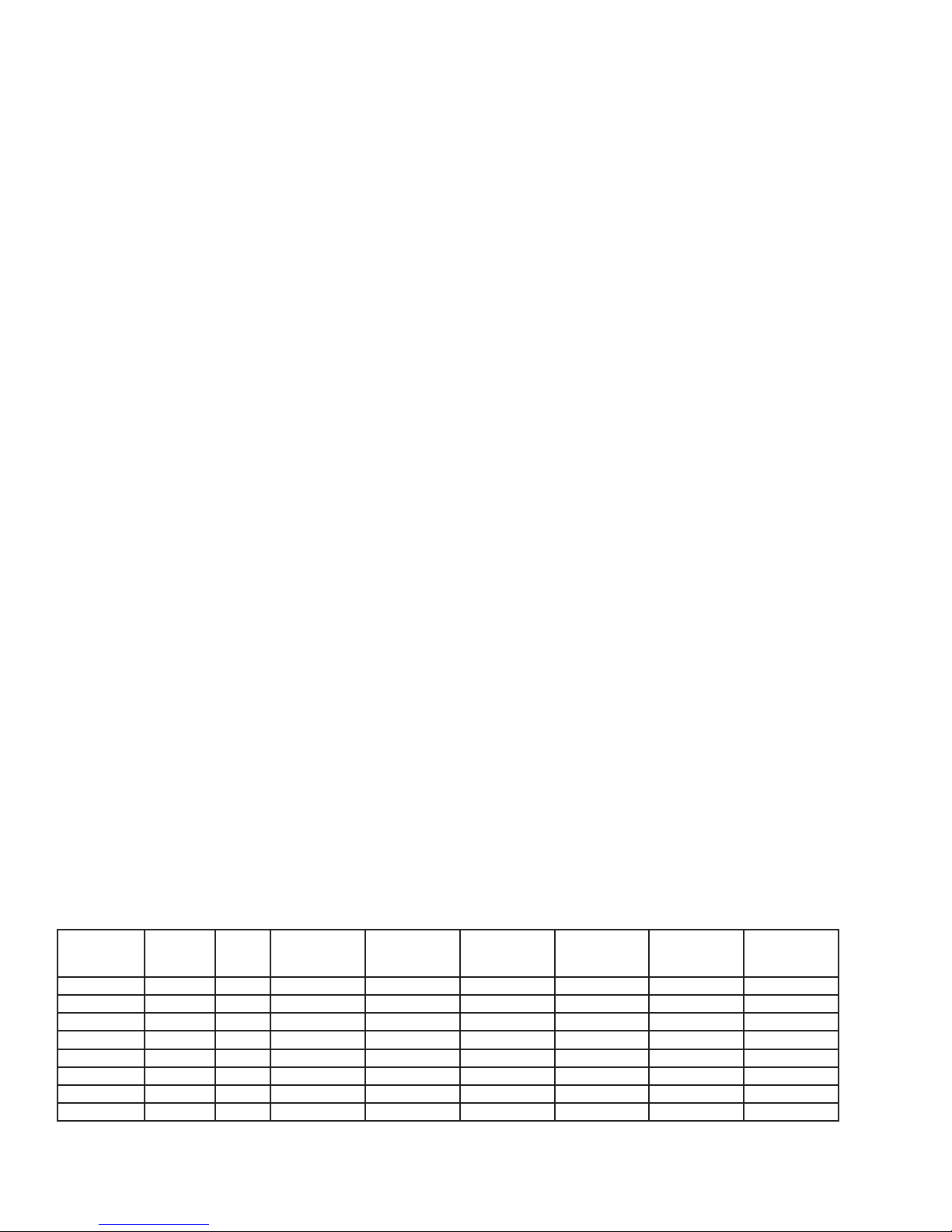

MODEL NO SIZE

NPT

INCHES

2ADE11 2 1.0 115/230/1 60 1750 K 12.8/6.4 37

2ADE13 2 1.0 230/460/3 60 1750 J 3.8/1.9 22

2CDE11 2 1.0 115/230/1 60 1750 K 12.8/6.4 37

2CDE13 2 1.0 230/460/3 60 1750 J 3.8/1.9 22

3ADE151 3 1.5 115/230/1 60 1750 J 17.2/8.6 52

3ADE153 3 1.5 230/460/3 60 1750 J 4.6/2.3 29

3CDE151 3 1.5 115/230/1 60 1750 J 17.2/8.6 52

3CDE153 3 1.5 230/460/3 60 1750 J 4.6/2.3 29

(*) Electrical data subject to Motor manufacture.

HP VOLT/PH Hz RPM

(Nom)

NEMA

START

CODE *

FULL

LOAD

AMPS *

LOCKED

ROTOR

AMPS *

6

Loading...

Loading...