Barloword W4000 User Manual

Assembly and operating instructions

Instructions de montage et de fonctionnement

Istruzioni di montaggio e funzionamento

Instrucciones de montaje y funcionamiento

Montage- und Betriebsanleitung

Water Still

Merit

W4000 & W4000/EURO

2

Before use

If the equipment is not used in the manner described in this

manual the protection provided by the equipment may be

impaired.

Note: The Merit Water Still is classified as “Permanently

Connected Equipment” and should be connected to the

electricity supply by a qualified electrician in the manner

described in the electrical installation section of this manual.

The Merit Water Still is designed to operate under the following

conditions:

❖ For indoor use only

❖ Ambient temperature range +5°C to +40°C

❖ Altitude up to 2000m

❖ Relative humidity not exceeding 80%

❖ Mains supply voltage fluctuations not

greater than ±10% of nominal

❖ Overvoltage category II IEC60364-4-443

❖ Pollution degree 2 IEC664

Limitations of use

This product meets the applicable E.C. harmonised standards for

radio frequency interference and may be expected not to interfere

with, or be affected by other equipment with similar qualifications.

We cannot be sure that other equipment used in its vicinity will meet

these standards and we cannot guarantee that interference will not

occur in practice. Where there is a possibility that injury, damage or

loss might occur if equipment malfunctions due to radio frequency

interference, or for general advice before use, please contact the

Service Department of Bibby Scientific Ltd.

Merit Water Still English

W4000 & W4000/EURO

The Merit Water Still complies with the

following European Directives:

89/336/EEC - E.M.C. DIRECTIVE

Amended by 92/31/EEC and 93/68/EEC

73/23/EEC - L.V.D. Amended by 93/68/EEC

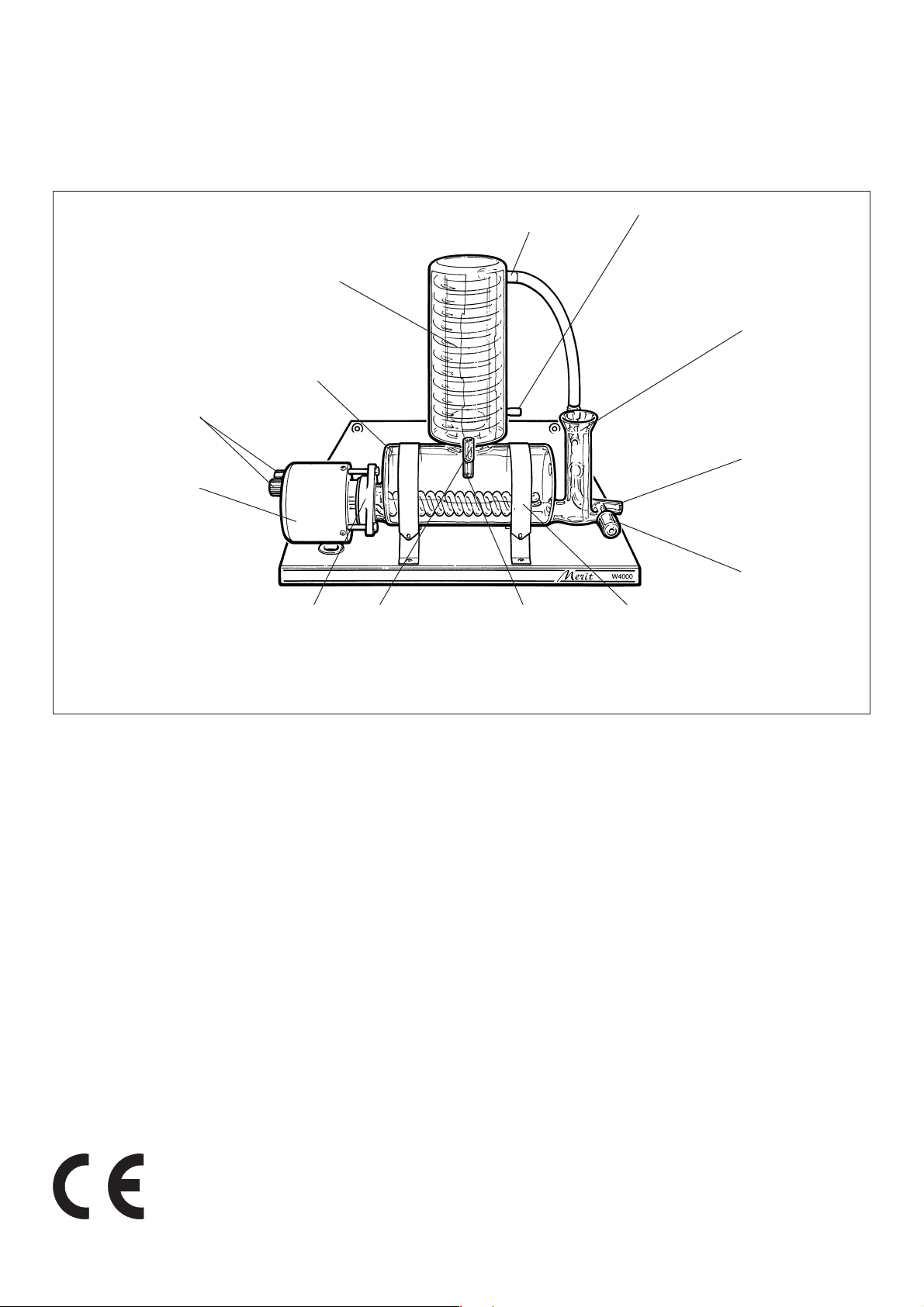

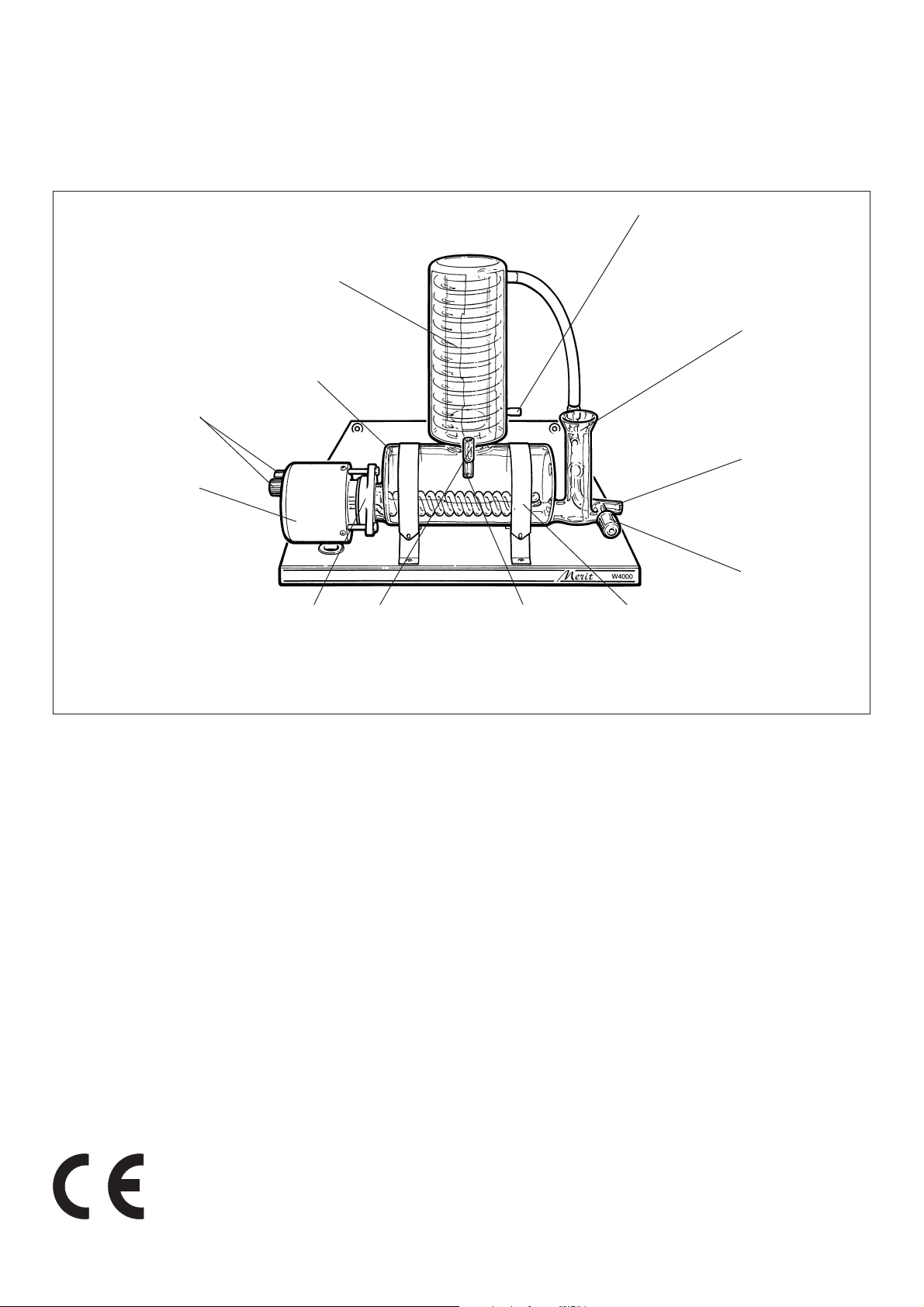

Figure 1 General assembly

Condenser

Boiler

Thermostat reset

buttons

Heater

Vent Distillate

outlet

Straps

Stopcock

To drain

Constant level

control

Cooling water inlet

Gaskets and

flange

Cooling water outlet

3

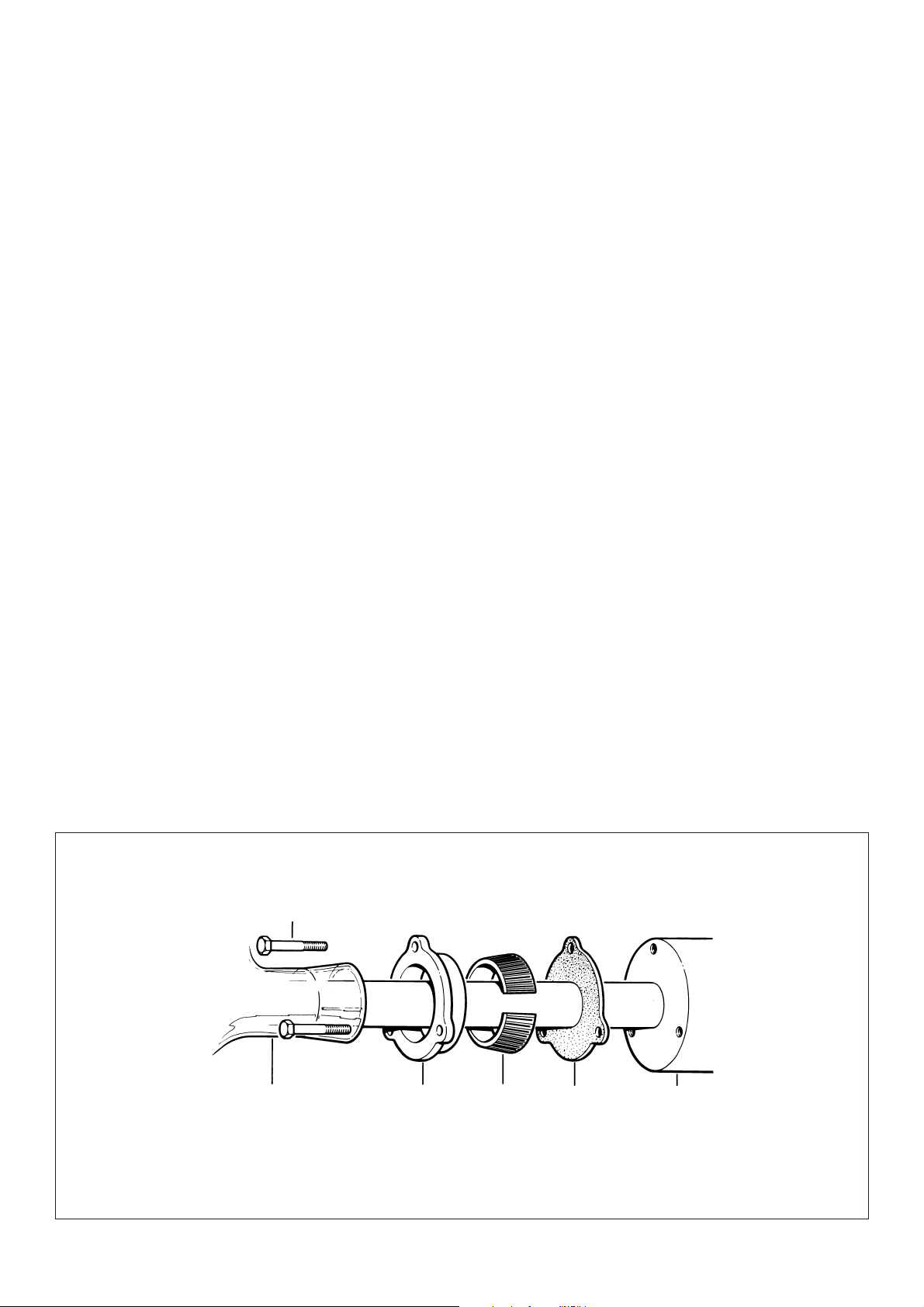

ii) Take the plastic insert and place this round the glass tube

and into the metal flange. Pull the flange and insert

towards the end of the glass tube so that they press onto

the glass.

iii) Place the rubber gasket over the heater coils and then

insert the heating element through the tapered glass tube

and into the boiler.

iv) Now secure the heater using the 3 bolts provided. Do not

over tighten.

4. Place the boiler and heater assembly in the ‘cradle’ of the

stand. Ensure the stopcock on the boiler is facing to the front.

Feed the electric cable of the heater through the hole in the

base of the support stand. Secure with the 2 straps provided.

5. Ensure that the sealing o-ring and stabilising o-ring are correctly

positioned, as shown in Figure 3. Fit the condenser WC48/M2

by mounting it onto the vapour tube of the boiler. Ensure the

distillate outlet tube of the condenser faces the front and the

cooling outlet faces parallel to the unit.

Location

The Merit Water Still can be wall or bench mounted. Select a

convenient location which has access to the following services:–

Electricity Supply

Before connection please ensure that the line supply is suitable.

The Merit Water Still W4000 is suitable for supplies rated at

3kW, 220-240V, 50/60Hz~ single phase.

W4000/Euro is suitable for supplies rated at 3kW, 200-240V,

50/60Hz~ single phase.

Water Supply

A cold water supply capable of providing a minimum flow rate of

60 l/hr.

Drain

A waste water drain located below the level of the still so that the

drain pipe can fall away straight without kinks or bends, to allow an

unimpeded flow.

Reservoir

A distillate collection reservoir should be located beneath the still.

Assembly

1. Unpack the water still and identify the following components:–

Qty. Component Catalogue No.

1 Support stand with 2 boiler straps W4000/S

1 Boiler W4000/B

1 Condenser WC48/M2

1 Heater A6/6 (240V)

or A6/6/EURO (220V)

1 Hose Kit W4000/HK

1 Gasket Kit W4000/GK

2. Take the metal stand and place in the desired location.

Note that 2 screw holes are provided for wall fitting.

3. Take the boiler W4000/B, the heater and gasket kit W4000/GK.

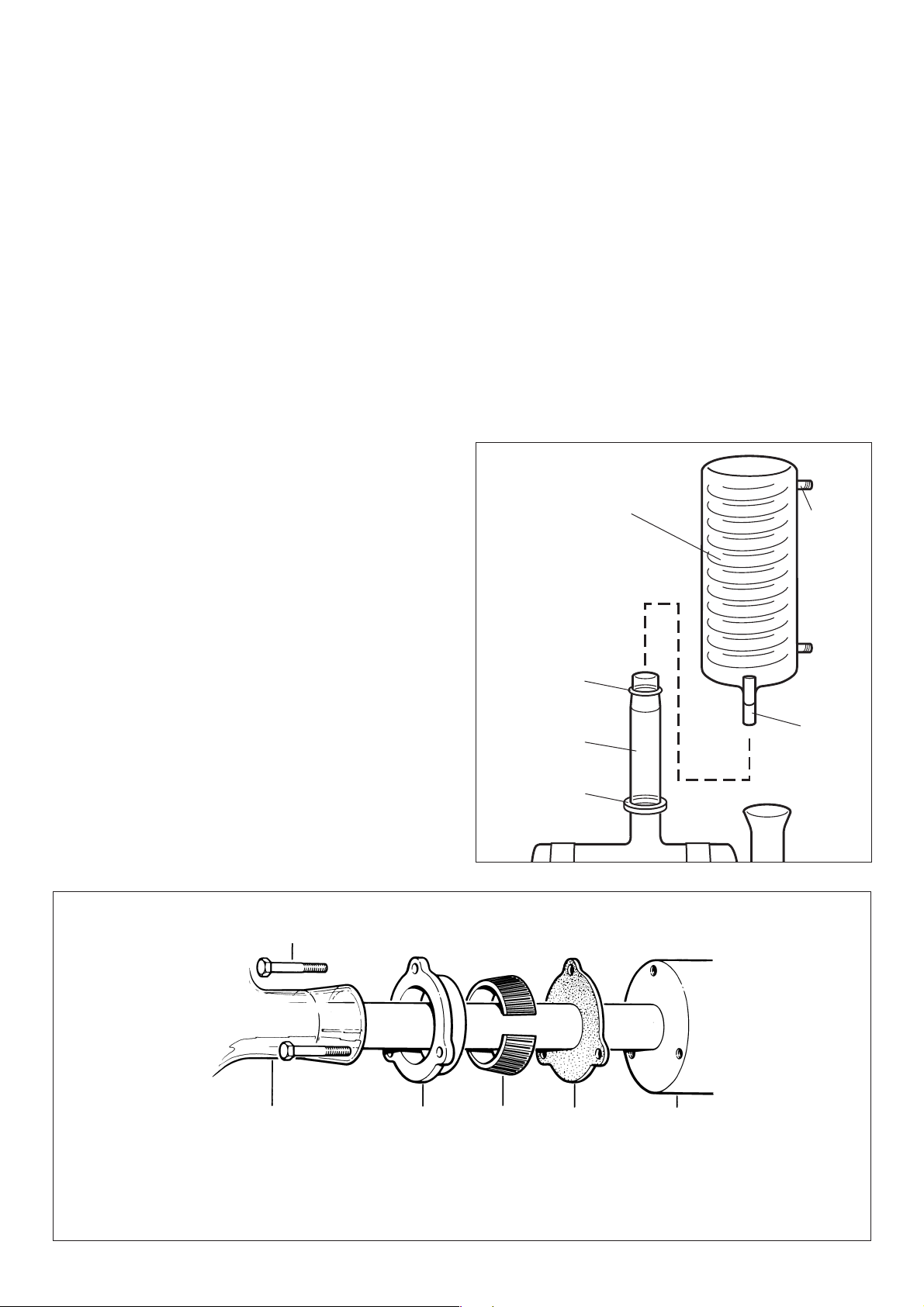

Assemble the heater into the boiler as shown in Figure 2.

i) Place the metal flange over the tapered glass tube of the

boiler – ensuring that the flat side of the flange faces the

boiler.

Figure 3

Figure 2 Flange assembly

Bolts

Tapered

glass

tube

Metal

flange

Plastic

insert

Rubber

gasket

Heater

Cooling

water

outlet

Outlet

tube

Condenser

Sealing o-ring

Vapour tube

Stabilising o-ring

4

Operation

1. Turn on the cold water supply and adjust the flowrate to

approx. 60 l/h.

Note: It is strongly recommended to measure the flow

rate, failure to do so can result in possible injury from hot

water exiting from the Still. If a flow meter isn't available

a simple measurement can be performed with a 1L beaker.

Over a timed period of five minutes the beaker should be

completely filled five times.

Observe that the water flows via the condenser and into the

boiler. Wait until the boiler has attained its correct operating

level and make sure that the excess water is flowing freely to

drain.

2. Switch on the electricity supply to the heating element at the

mains isolation switch.

For the W4000/EURO version, switch on the switch situated on

the heater.

3. After a few minutes the water will start to boil and distillate will

emerge from the condenser. With new glassware, or after

cleaning, it is advisable to allow this to run to drain for

approximately 30 minutes before beginning collection.

4. To turn off the still, first turn off the heating element but allow

the cooling water to continue for a further 10 minutes to allow

the still to cool.

WARNING!

Do not use this equipment to distil any liquid other than

water.

Safety cut-outs

The Merit Water Still is protected by two safety cut-outs:

Boiler heater thermostats

Should the boiler water level fall and expose the

element the thermostats will operate and turn off

the electricity supply to the element.

6. From the hose kit take the 225mm length of 8mm bore plastics

hose fitted with screwthread connectors at either end. Referring

to Figure 1, screw one end of the hose to the upper outlet of

the condenser and the other end to the glass thread on the

constant level control. If the Still has been correctly assembled

the hose should comfortably reach, without any strain.

7. Take the 1000mm length of 16mm bore plastic hose and

carefully connect to the outlet of the constant level control. For

easy connection first warm the hose with hot water.

Secure with a tie strap.

8. Lead the free end of the tubing to drain, ensuring it falls away

from the still with no kinks or bends to impede water flow.

9. Ensure the stopcock on the constant level control is closed.

10. Connect the lower inlet of the condenser to the cold water feed

supply. A plastic screwthread connector is provided for easy

attachment to the condenser.

Select good quality tubing and ensure all connections are

secured with hose clips.

11. Connect the distillate outlet on the condenser to a suitable

collection reservoir.

Electrical installation

THIS EQUIPMENT MUST BE EARTHED!

The electrical installation should only be carried out by a qualified

electrician.

The equipment is supplied with 1.7m of flexible triple core circular

cable to CMA 3183 TQ specification. The conductors are 1.5mm

2

to

BS 6360 Class 5 insulated with E.P.R. The outer sheath is 85°C heat

resisting type C.S.P. to HOFR, BS 6500 Table 9.

Connection to the mains electrical supply, should be via a double

pole isolation switch with a continuous current carrying capacity of

15A at 250v and overcurrent protection should be provided by either

an approved fuse rated at 15A, 250V in each pole or a double pole

approved circuit breaker of similar rating.

These devices should be sited near to the equipment and clearly

marked – “Disconnect device for Merit Water Still“

Connect to the line supply noting that the wires in the instrument

lead are coloured in accordance with the following code:–

Brown – Live

Blue – Neutral

Yellow/Green – Earth

Mains Cable Replacement

If the mains cable requires replacement, only specially prepared spare

mains lead obtained from Bibby Scientific should be used.

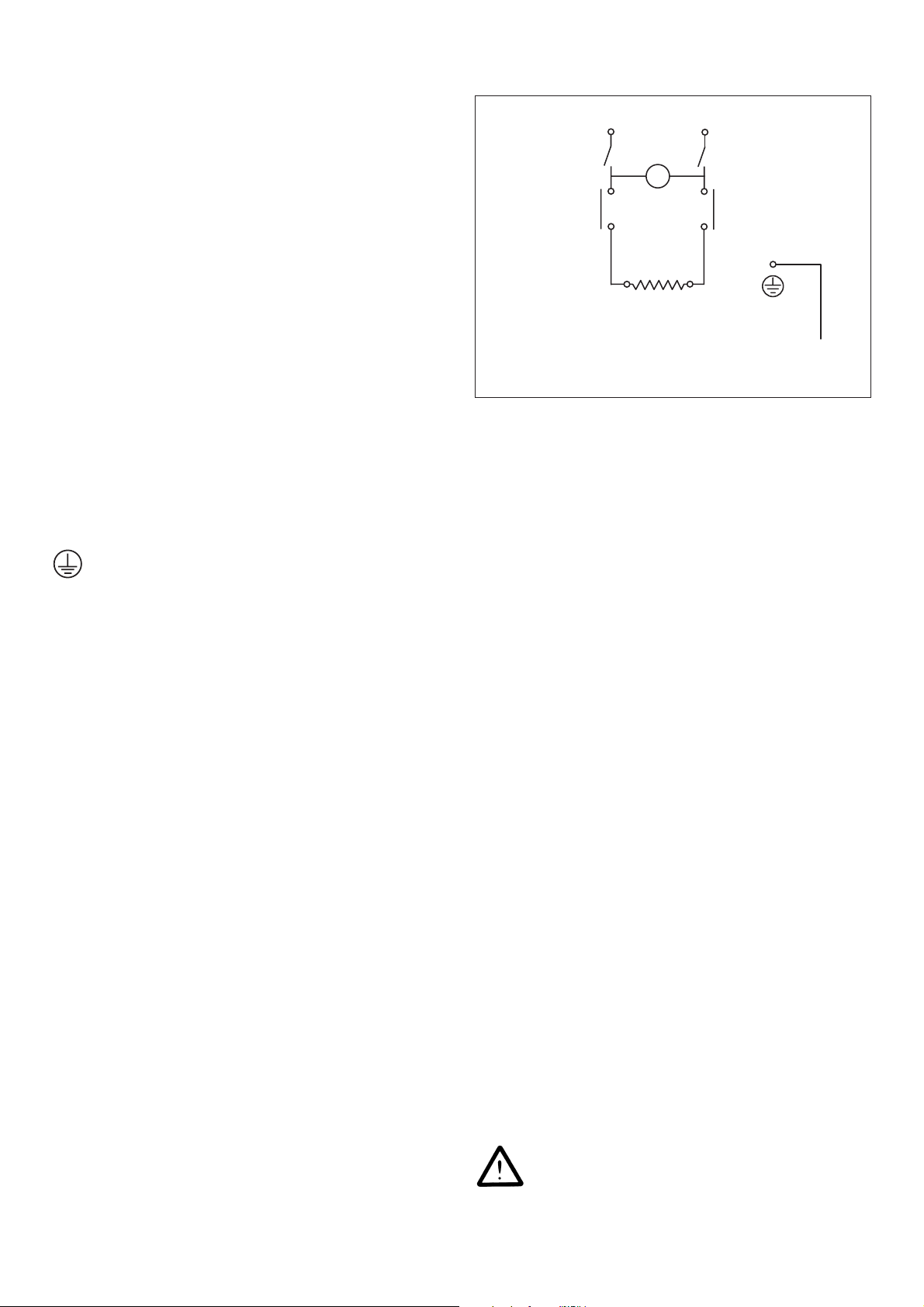

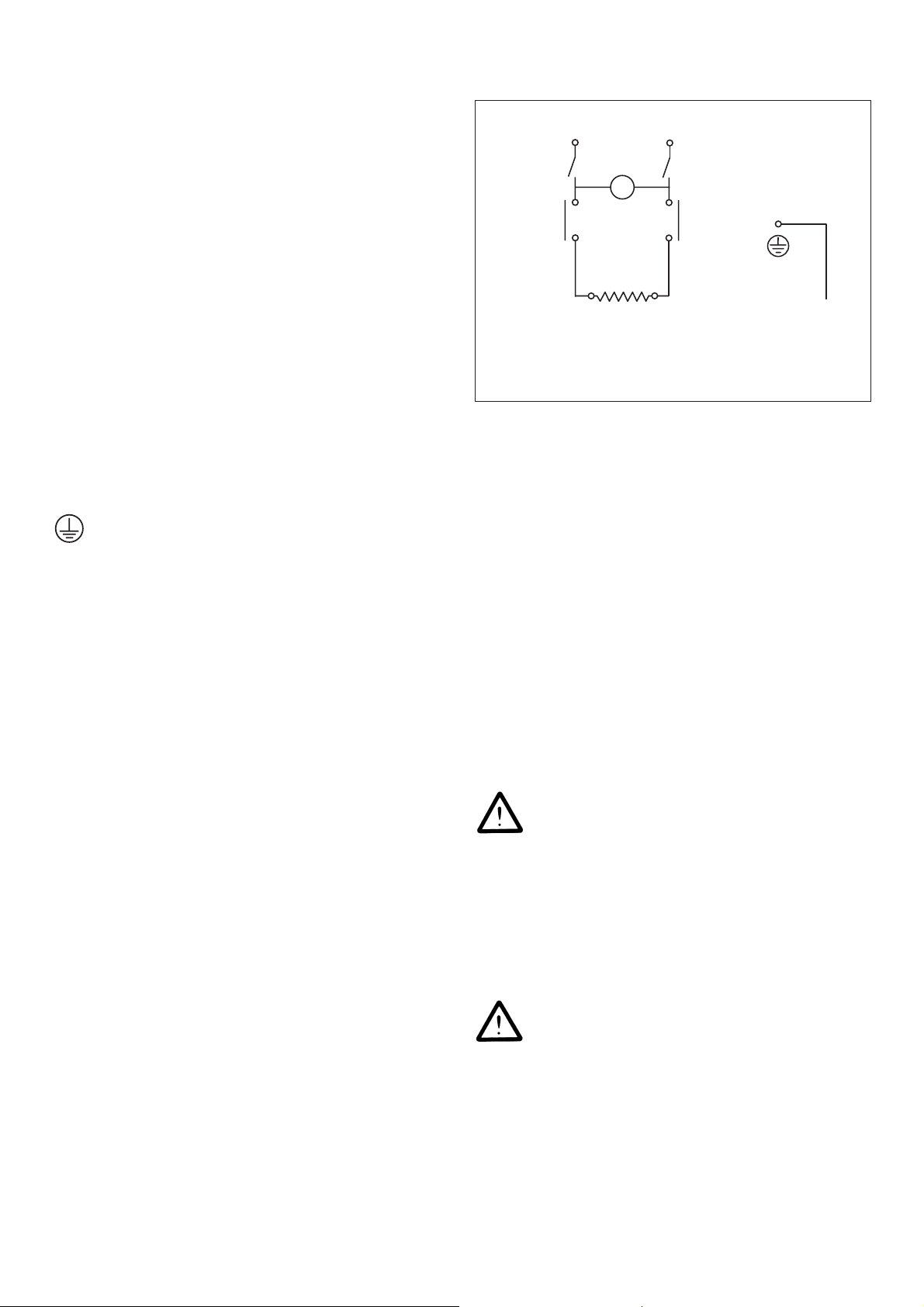

Circuit diagram

(S) Denotes safety critical component.

LN

~240V

(S)

Switch

(W4000/EURO only)

(S)

Thermostat

Lamp

(S)

Thermostat

E

Element

Heater flange

5

After operation of either of the thermostats, normal operation may

be resumed by resetting the thermostats by means of their respective

reset buttons mounted on the end of the heater end cover.

Remove the black plastic cover and then press the button – a slight

click will be heard if the thermostat had operated.

Before resetting either thermostat the still should be

allowed to cool completely and the cause of cut-out

operation identified and rectified.

If the thermostats continue to operate consult a qualified electrician

or the Service Department of Bibby Scientific Ltd.

Care and maintenance

Note: Before commencing any maintenance, cleaning or fault

finding the equipment should be isolated from the mains

electricity supply. These operations should be only carried out

by suitably qualified personnel.

Only spare parts supplied or approved by Bibby Scientific Ltd., or its

agent should be used. Fitting of non-approved parts may affect the

performance or safety of the equipment.

Maintenance

Due to the nature of these parts it is necessary to periodically check

the quality of the plastic connectors and hoses. There should be no

strain on the connectors or hoses. Both the hoses and connectors

should be intact without any cracking. If any damage is discovered

on these parts the Still should immediately be turned off, as detailed

under the "Operation" section of this manual, and not used again

before these parts are replaced. Please refer to the "List of spare

parts" section of this manual for order codes.

Cleaning

Over a period of operation scale deposits will build up inside the

boiler. To obtain optimum performance from the still, the scale

should be removed on a regular basis.

The time span between cleaning depends greatly on the hardness of

the water supply and the amount of use. Frequently used stills in

hard water areas may need descaling once a week whereas in a soft

water area several weeks may elapse before descaling is necessary.

Note: Heavy scaling will reduce distilled water quality and can

shorten the life of the heating element.

It is possible to descale the Merit Water Still without dismantling the

glassware by following these instructions in conjunction with Control

of Substances Hazardous to Health regulations (COSHH) 1988.

1. Switch off the electricity supply to the still and allow it to cool

completely.

2. Turn off the cooling water supply.

3. Open the stopcock on the constant level control and allow the

boiler to drain completely, Close stopcock.

4. Turn on the cooling water supply and allow the boiler to fill to

approximately half way to its normal operating level. Turn off

the water supply.

List of spare parts

The following components are available from most laboratory

suppliers. In case of difficulty, please contact Bibby Scientific Ltd.

Cat. No.

Boiler W4000/B

Condenser WC48/M2

Heater (complete with thermostats) 240V A6/6

(complete with thermostats) 220V A6/6/EURO

Set of heater fixings (flange, gasket, insert and bolts) W4000/GK

Hose kit W4000/HK

5. Into the open funnel of the constant level control carefully add

about 1 litre of 10% formic acid solution or kettle descaler.

Do not use strong acids such as hydrochloric, this can cause

severe corrosion of the metal heating element.

WARNING!

ALWAYS HANDLE ACIDS WITH GREAT CARE. PROTECTIVE

CLOTHING, GLOVES AND FACE-MASKS SHOULD BE WORN

DURING THE DESCALING OPERATION.

REMOVE ANY ACID SPILLS IMMEDIATELY.

Turn on the water supply and fill the boiler to the normal

operating level. The water will flush the acid into the boiler. The

water supply should be turned off when the level in the boiler is

slightly below the overflow.

6. Leave the acid in the boiler to desolve the scale. This may take

some time depending on the severity of the build-up.

7. Open the stopcock and allow the boiler to drain.

Note: If the acid in the boiler has not been completely

neutralised the liquid flowing to drain may be highly

acidic. All necessary safety precautions should be

observed around the drain and any effluent control

procedures followed.

8. Close the stopcock, turn on the water and allow the boiler to fill

with cold water. Turn off the water, re-open the stopcock and

allow the boiler to drain. Repeat this procedure three times.

9. The Merit Water Still may now be restarted by referring to the

instructions given under “Operation” in this manual.

Note: The stand and outer surfaces of the glassware should be

cleaned using a damp cloth and a mild detergent solution.

Warranty

Bibby Scientific Ltd warrants this instrument to be free from defects

in material and workmanship, when used under normal laboratory

conditions, for a period of three (3) years. In the event of a justified

claim Bibby Scientific will replace any defective component or replace

the unit free of charge.

This warranty does NOT apply if damage is caused by fire, accident,

misuse, neglect, incorrect adjustment or repair, damage caused by

incorrect installation, adaptation, modification, fitting of non

approved parts or repair by unauthorised personnel.

This Warranty does not include the heater element which is only

guaranteed for up to 1000 hours in use.

6

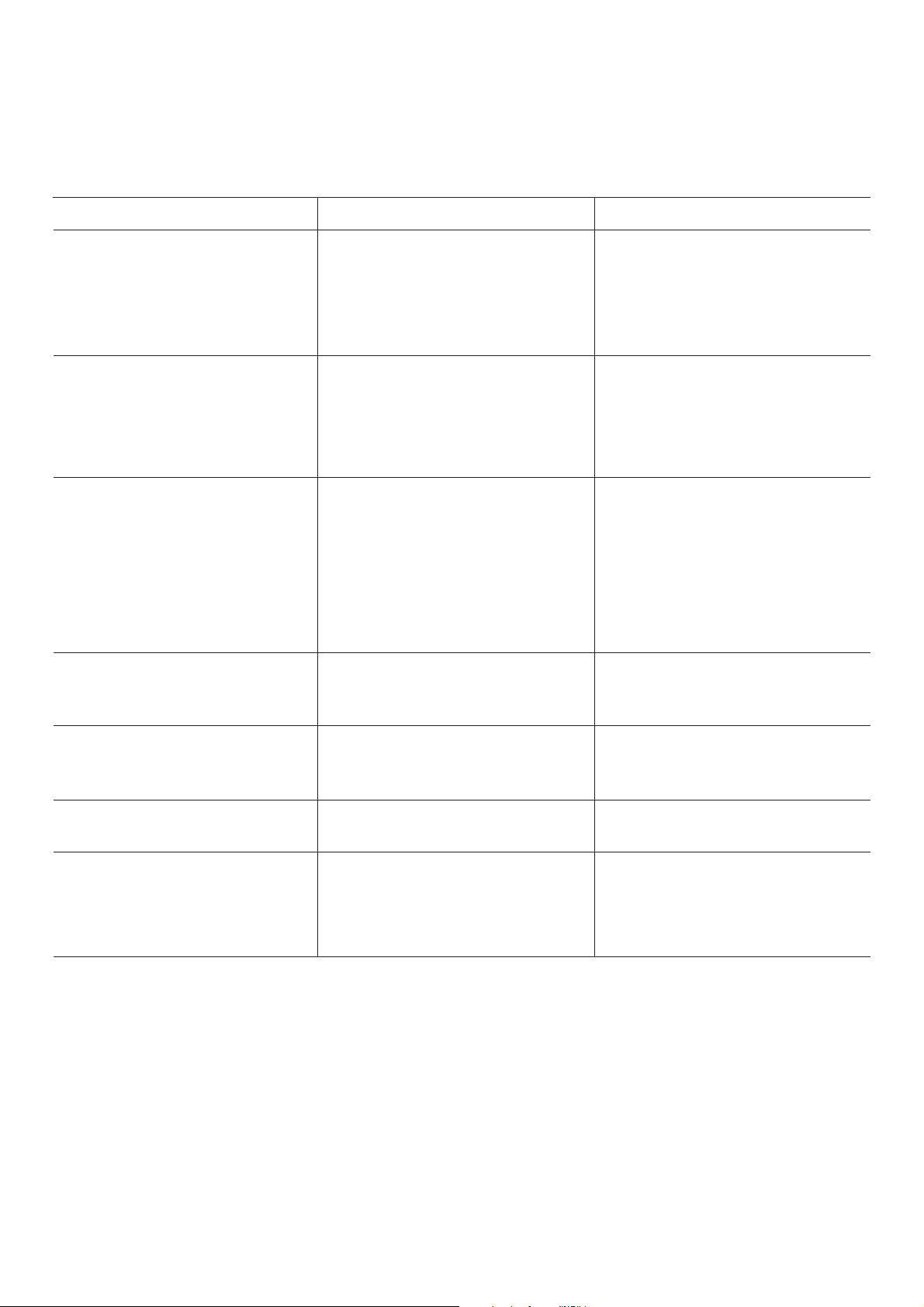

Fault finding

In the event of operating difficulties with your Merit Still, please consult the following notes.

If these fail to identify and remedy the fault, then you are advised to seek the help of your

supplier or the Service Department of Bibby Scientific Ltd.

Note – Fault finding should only be carried out by suitably qualified people.

Symptom Cause Remedy

1. Water level in boiler is too a) Supply of feed/cooling water a) Increase flowrate of water to

LOW. e.g. – heater exposed. is insufficient. approx. 60 litres/hour.

b) Stopcock on boiler inadvertently b) Close stopcock.

left open.

2. Water level in boiler is too a) Supply of feed/cooling water a) Reduce flowrate of water to

HIGH. e.g. – boiling water is excessive. approx. 60 litres/hour.

surging into condenser. b) Flow of drainage water b) Ensure drainage tubing falls

is constricted. freely.

3. Water in boiler is “pumped” a) Tubing from condenser distillate a) Ensure tubing falls freely to

out of boiler to drain. outlet to reservoir is constricted. reservoir without kinks or bends.

b) Vent on condenser distillate b) Remove obstruction.

outlet is blocked.

c) Supply of feed/cooling water c) Increase flowrate of water to

is insufficient. approx. 60 litres/hour.

4. Distillate temperature is Flow of cooling water is insufficient. Increase flowrate of water to

high, e.g. – above 50°C. approx. 60 litres/hour.

5. Distillate rate less than 4 litres/hour. Mains voltage low –

Excessive cooling water flow. Reduce to 60 litres/hour.

6. Distillate quality poor*. Boiler heavily scaled. Clean boiler.

7. Heater not working. a) Burnt-out heater. a) Replace heater.

b) Mains electricity fuse blown. b) Replace fuse.

c) Thermostat operated. c) Reset.

*Distillate quality when determined by pH or electrical conductivity is greatly affected by temperature and the

presence of absorbed carbon dioxide.

7

Avant l’utilisation

Si l’appareil n’est pas utilisé de la manière décrite

ci-après, les sécurités prévues peuvent être défaillantes.

N.B. L’appareil à cau distillée MERIT est classé parmis les

«appareils connectés en permanence» et doit être raccordé par

un électricien qualifié comme décrit dans la section

«installation électrique» de ce manuel.

Le distillateur MERIT est prévu pour fonctionner dans les conditions

suivantes :

❖ Utilisation en intérier uniquement.

❖ Température d’utilisation +5°C à 40°C.

❖ Altitude < 2000m.

❖ Humidité relative < 80%.

❖ Alimentation électrique ne variant pas de ±10%

autour de la valeur nominale.

❖ Survoltage catégorie II IEC60364-4-443.

❖ Degré de pollution 2 IEC664.

Limites d’applications

Cet appareil est conforme aux normes européennes standards

concernant les fréquences radios et ne doit pas ou ne peut être

perturbé par un autre appareil ayant les mêmes spécifications.

Toutefois, nous ne pouvons garantir qu’un autre appareil, utilisé à

proximité, ne répondant pas à ces normes, ne provoque pas

d’interférences. Dans le cas ou le distillateur aurait subi des

dommages à cause des interférences, ne pas hésiter à contacter le

service aprés-ventes Bibby Scientific France.

Distillateur Français

W4000 & W4000/EURO

Le distillateur MERIT est en conformité avec les

normes Européennes:

89/336/EEC - E.M.C. DIRECTIVE

Amendées par 92/31/EEC & 93/68/EEC

73/23/EEC - L.V.D. Amendée par 93/68/EEC

Figure 1 : Vue d’ensemble

Réfrigérant

Bouilleur

Boutons de

rearmement

thermostat

Elément

Chauffant

Event Sortie

distillat

Anneau de

fixation

Robinet

Sortie eau de

refroidissement

Contrôleur

de niveau

Entrée de l’eau

Joint

d’étanchéité

et collier de

fixation

8

Installation

Le distillateur MERIT peut être installé sur une paillasse ou fixé au

mur. Choisir un emplacement à proximité des dispositifs suivants:

Alimentation électrique:

Avant de connecter l’appareil, vérifier que l’alimentation électrique

est correcte. Modèle W4000 EURO pour alimentation électrique 3kW

220V, 50/60Hz monophasé.

Alimentation en eau:

Source d’eau froide capable de fournir un débit minimum de 60 l/hr.

Evacuation:

Dispositif d’évacuation ou évier situé en dessous de l’appareil de

façon à ce que le tuyau d’évacuation d’eau ne présente aucun

coude.

Réservoir de recette:

Un réservoir de recette du distillat pourra être installé sous l’appareil.

Montage

1. Déballer le distillateur et identifier les

composants suivants:–

Qte Designation Référence

1 Support muni de 2 anneaux

métalliques de fixation W4000/S

1 Bouilleur 775421

1 Réfrigérant 775361

1 Elément chauffant 220V /3kW 775422

1 Jeu de tuyaux 775426

1 Jeu de colliers de fixation 775424

2. Installer le support à l’emplacement choisi. 2 trous permettent

de le visser au mur si nécessaire.

3. Prendre le bouilleur, l’élément chauffant et le jeu de colliers.

Assembler selon la figure 2.

i) Placer le collier métallique autour du tube évasé à

l’extrémité du bouilleur. Le côté plat du collier métallique

doit faire face au bouilleur.

ii) Insérer le collier en graphite à l’intérieur du collier

métallique. Tirer le collier métaliique et son insert en

graphite vers l’extrémité du bouiller de façon à ce qui’ils

exercent une pression sur le tube évasé.

iii) Insérer le joint en caoutchouc par dessus les spires de

l’élément chauffant. Introduire l’élément chauffant dans le

bouilleur.

iv) Fixer l’élément chauffant en vissant les 3 boulons. Ne pas

serrer à bloc.

4. Placer le bouiller et l’élément chauffant sur le support. Le

robinet doit alors faire face à l’utilisateur. Faire passer le câble

d’alimentation à travers l’orifice situé à la base du support. Fixer

le bouilleur avec les 2 anneaux métalliques.

5. Enfiler le réfrigérant sur le tube vapeur du bouilleur. L’orifice de

sortie du distillat doit faire face à l’utilisateur.

Figure 2

Boulon

Tube évasé Collier

métallique

Collier en

graphite

Joint en

caoutchouc

Elément

chauffant

9

Mise en route

1. Ouvrir le robinet d’eau froide et régler le débit à 60 litres/heure

environ. L’eau doit circuler à travers le réfrigérant. Attendre que

le niveau d’eau dans le bouilleur soit stable. Vérifier que l’eau

s’écoule normalement vers l’évacuation.

2. Allumer l’interrupteur de l’élément chauffant.

Observer l’ébullition et vérifier que le distillat s’écoule

normalement vers le réservoir de recette.

ATTENTION !

NE PAS UTILISER CET APPAREIL POUR DISTILLER AUTRE CHOSE

QUE DE L’EAU.

Thermostats de sécurité

Le distillateur MERIT est protégé par deux thermostats de sécurité.

Thermostat de sur-chauffe du bouilleur.

Si le controleur de niveau est défectueux et expose

l’elément chauffant à une sur-chauffe, le thermostat

agit et coupe l’alimentation électrique de la

résistance.

Après l’opération d’un des deux thermostats, il suffit de les réarmer

en appuyant simplement sur le bouton adéquoit situé à gauche de

l’élément chauffant.

Retirer le capuchon plastique et appuyer sur le bouton (un léger «

clic » doit se produire).

AVANT LE REARMEMENT, IL FAUT ATTENDRE LE

REFROIDISSEMENT DE L’APPAREIL, ET LA CAUSE DU

DECLENCHEMENT DES THERMOSTATS, IDENTIFIEE ET

RECTIFIEE.

Si le thermostat continue de se déclencher, consulter un électricien

qualifié ou le service technique de Bibby Scientific France.

6. Dans le jeu de tuyaux, prendre le tube 225mm de long et 8mm

de diamètre équipé de connecteurs à vis à ses 2 extrémités.

Visser une extrémité du tuyau sur le raccord à vis supérieur du

réfrigérant et l’autre extrémité sur le raccord à vis du contrôleur

de niveau (voir figure 1).

7. Prendre le tuyau de 1000 mm de long et 16 mm de diamètre.

Fixer avec précaution son extrémité en sortie du contrôleur de

niveau. Pour faciliter cette opération, passer prélablement

l’extrémité du tuyau sous l’eau chaude. Fixer avec un collier.

8. Placer l’extrémité libre du tuyau vers l’évacuation, en s’assurant

qu’il ne présente aucun coude pouvant perturber l’écoulement

de l’eau.

9. Vérifier que le robinet du contrôleur de niveau est fermé.

10. Visser le connecteur plastique sur le raccord à vis inférieur du

réfrigérant. Fixer le tuyau d’alimentation en eau froide sur ce

connecteur. Choisir un tuyau de bonne qualite et vérifier que

toutes les connexions sont renforcées par un collier.

11. Relier par un tuyau l’orifice de sortie du distillat au réservoir de

recette.

Installation electrique

CET APPAREIL DOIT ETRE RELIE A LA TERRE !

L’installation électrique doit être effectuée par un électricien qualifié.

L’appareil est livré avec un câble de 1,7m (conforme aux

spécifications CMA 3183 TQ). Les fils conducteurs, de section

1,5mm

2

(conformes aux spécifications BS 6360 classe 5) protégés

avec de l’EPR. La résistance à la température est de 85°C et de type

CSP à HOFR, BS 6500, table 9.

Le raccordement à l’alimentation électrique doit être effectué par

l’intermédiaire d’un disjoncteur bi-polaire 15A/250V ou de deux

fusibles, de pouvoir de coupure identique.

Cet équipement doit se trouver à proximité de l’appareil et être

clairement identifier «protection pour distillateur MERIT».

Raccorder le câble selon les indications suivantes:

Marron - Phase

Bleu - Neutre

Jaune/vert - Terre

Si le câble d’alimentation nécessite un remplacement, un câble

spécial, fournis par Bibby Scientific France, doit être utilisé.

Schema de principe

PN

Lampe

(S)

Thermostat

120°C

Element

Chauffant

(S)

Interrupteur

(S)

Thermostat

120°C

(S) Composant de sécurité

T

Couvercle

~240V

Loading...

Loading...