Service & Installation Instructions

Keep this booklet for future reference

BMD-48 SERIES

BMD-51 SERIES

BMD-54 SERIES

BMD-G SERIES

BSD SERIES

BSD-T SERIES

For Additional Copies Please Contact:

Barker Sales & Service

703 Franklin Street

P.O. Box 478

Keosauqua, Iowa 52565

Tel: 319/ 293-3777

Fax: 319/ 293-3776

Or Visit:

www.barkersales.com

Updated 5/21/07

Table of Contents

General Information

Case Descriptions - - - - - - - - - - - - - - - - - - - - -3

Shipping Information - - - - - - - - - - - - - - - - - - -3

Case Sections

BMD Series - - - - - - - - - - - - - - - - - - - - - - - -4

BSD Series - - - - - - - - - - - - - - - - - - - - - - - -5

Mechanical View - - - - - - - - - - - - - - - - - - - - -5

Installation Instructions

Location - - - - - - - - - - - - - - - - - - - - - - - - - - - -6

Crate Removal - - - - - - - - - - - - - - - - - - - - - - -6

Compressor - - - - - - - - - - - - - - - - - - - - - - - - -6

Case Exterior Loading - - - - - - - - - - - - - - - - - -6

Leveling - - - - - - - - - - - - - - - - - - - - - - - - - - - -6

Joining Lineups - - - - - - - - - - - - - - - - - - - - - - -6

Drain, Electrical and Refrigeration

Connections - - - - - - - - - - - - - - - - - - - - - - - - -6

Humidifier System - - - - - - - - - - - - - - - - - - - - -7

Glass Adjustment - - - - - - - - - - - - - - - - - - - - -7

Shelving - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Installation Checklist - - - - - - - - - - - - - - - - - - -8

Refrigeration Information

Case Operation - - - - - - - - - - - - - - - - - - - - - -9

Typical Component Settings - - - - - - - - - - - - -9

Electronic Thermostat - - - - - - - - - - - - - - - - - -9

Refrigeration Loads - - - - - - - - - - - - - - - - - - -10

Electrical Information

Amperage Information - - - - - - - - - - - - - - - - -11

Wiring Color Code - - - - - - - - - - - - - - - - - - - -11

Ballast Information - - - - - - - - - - - - - - - - - - -12

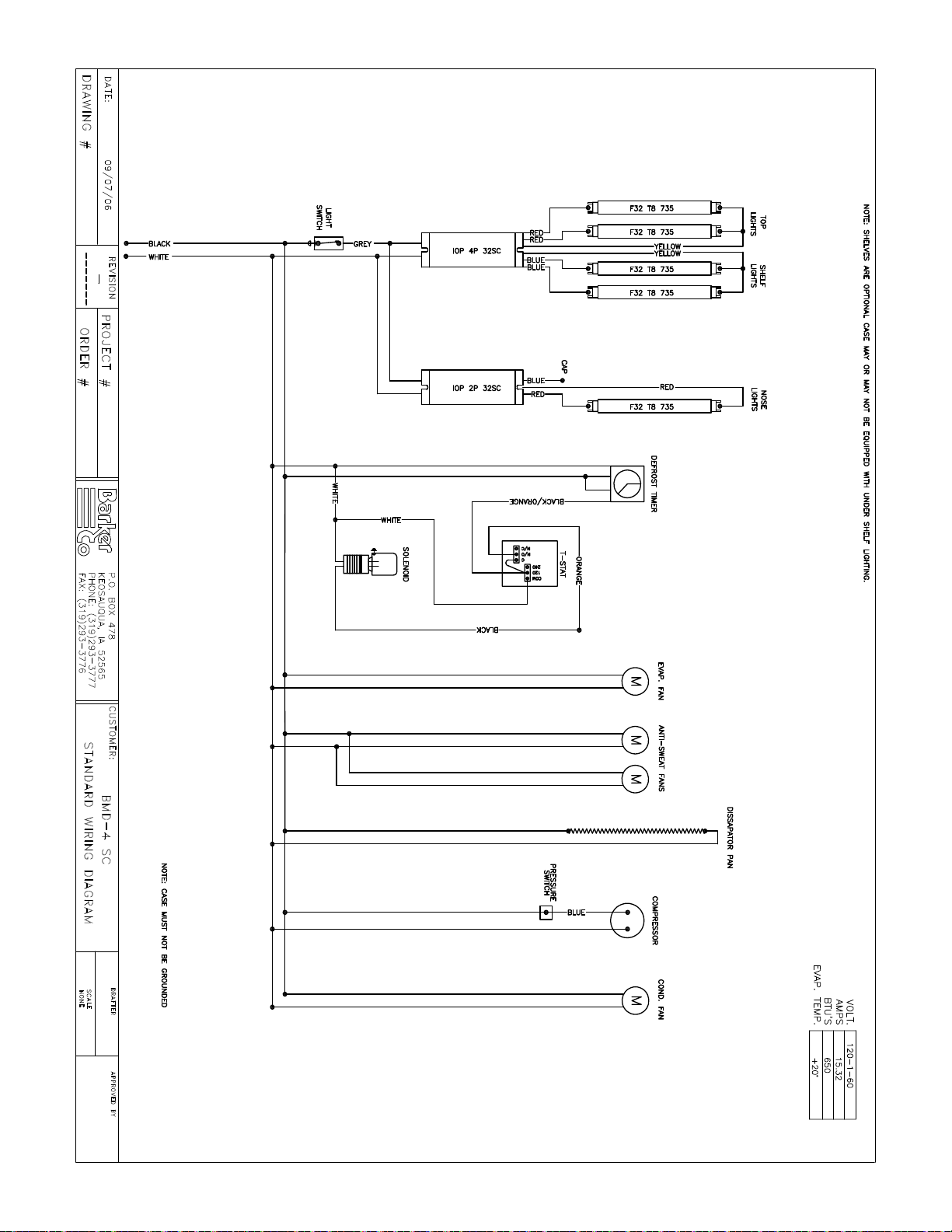

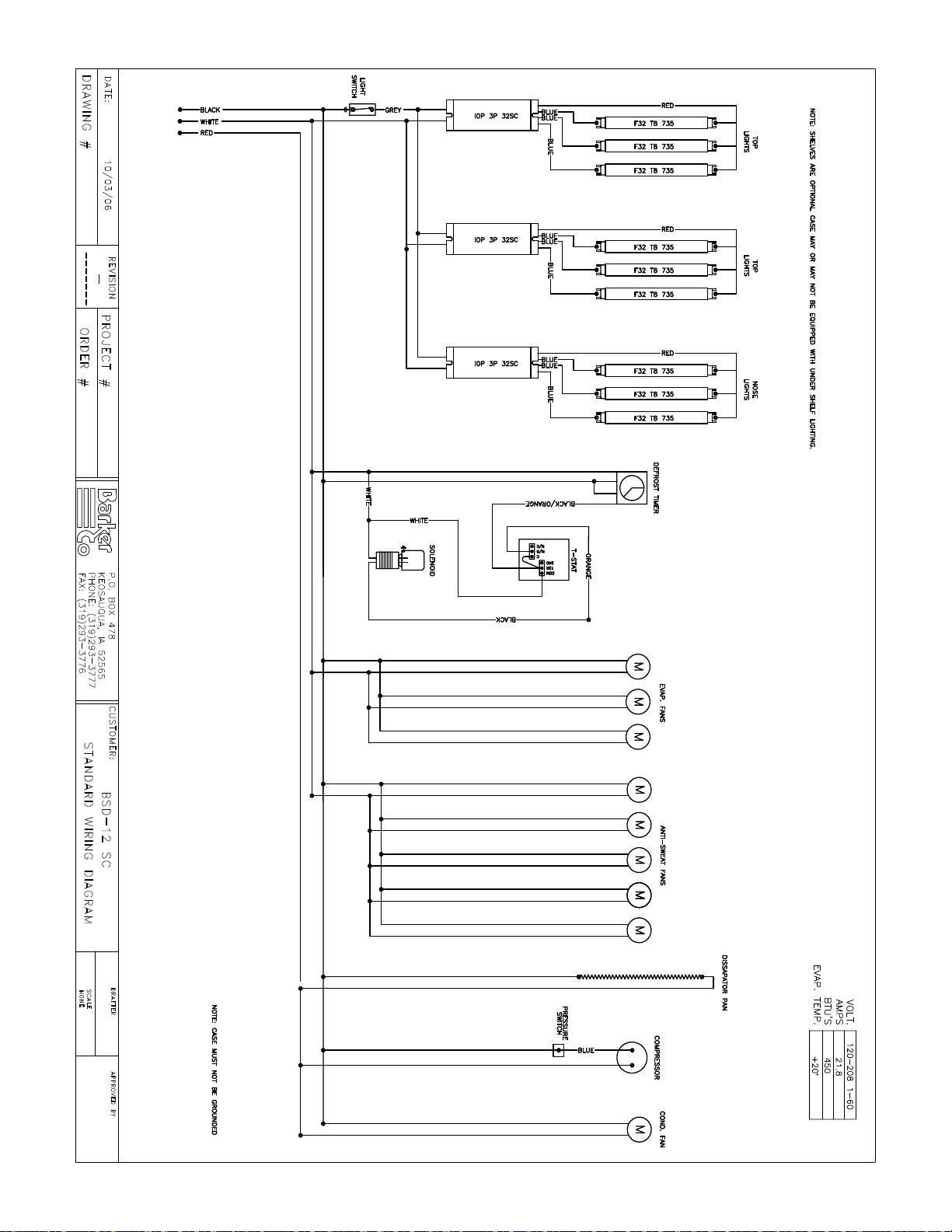

Wiring Diagrams

BMD-R - - - - - - - - - - - - - - - - - - - - - - - - - - - -13

BMDG-R - - - - - - - - - - - - - - - - - - - - - - - - - -18

BSD-R - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

BSDT-R - - - - - - - - - - - - - - - - - - - - - - - - - - -28

BMD-SC - - - - - - - - - - - - - - - - - - - - - - - - - - -33

BMDG-SC - - - - - - - - - - - - - - - - - - - - - - - - -38

BSD-SC - - - - - - - - - - - - - - - - - - - - - - - - - - -43

BSDT-SC - - - - - - - - - - - - - - - - - - - - - - - - - -48

Maintenance Information

Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - -53

Light Bulb Replacement - - - - - - - - - - - - - - - -53

Load Limits - - - - - - - - - - - - - - - - - - - - - - - - -53

Service

Evaporator Coil Layout - - - - - - - - - - - - - - - -54

Troubleshooting Guide - - - - - - - - - - - - - - - -56

Service Department - - - - - - - - - - - - - - - - - - -57

Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - -57

Warranty - - - - - - - - - - - - - - - - - - - -58

IMPORTANT!!

KEEP FOR FUTURE REFERENCE

General Information

This booklet contains information on: This booklet contains information on:

BMD Series

Service, Multi-Deck Deli Case, with Front Lift Glass

BMDG Series

Service, Muti-Deck Deli Case, with Front Lift Glass and Gravity Coil Refrigeration

BSD Series

Service, Single Deck Deli Case, with Front Lift Glass

BSDT Series

Service, Single Deck Deli Case, with Front Tilt Glass

The BMD and BSD Series conform to the following standards

Shipping Information

IMPORTANT!

FOR YOUR PROTECTION PLEASE READ AND OBSERVE THE FOLLOWING INSTRUCTIONS:

Transportation companies assume all liability from the time a shipment is received by them until the time it is

delivered to the consumer. Our liability ceases at the time of shipment.

All shipments leaving our plant have been carefully inspected. If a shipment arrives with the crating or packaging damaged, have the carrier note the condition on the receipt. Check as soon as possible for concealed damage.

If it is found that the shipment has been damaged in transit, please DO NOT return it to us, but notify and

file a claim with the carrier at once. FAILURE TO FOLLOW THIS PROCEDURE WILL RESULT IN

REFUSAL BY THE CARRIER TO HONOR ANY CLAIMS WITH A CONSEQUENT LOSS TO THE CONSUMER.

If a UPS shipment has been damaged, retain the damaged material and the carton and notify us at once.

WE will file a claim.

GOODS SHOULD NOT BE RETURNED FOR CREDIT UNLESS AUTHORIZED BY OUR SALES DEPARTMENT.

Case Drawings

BMD-48 Series

BMD-51 Series

BMD-72 Series

BMD-G Series

BSD Series

BSD-T Series

MECHANICAL VIEW (for all models shown)

Installation Instructions

Location

This refrigerated display case has been designed

for displaying and storing perishable food product.

It is engineered for air-conditioned stores with a

maximum ambient of 75° F and 50% relative humidity.

When selecting the location for placement of this

case, avoid the following conditions:

Excessive air movement

• Doors

• Air-conditioned vents

• Other air sources

Excessive heat

• Windows

• Sun

• Flood lamps 8 feet or less from the product

• Other heat sources

Crate Removal

Move case as close as possible to its location.

Remove all crating and shipping braces above the

shipping pallet. Loosen the plastic dust cover from

the pallet, but leave cover over the case to protect it

while removing the case from the pallet. Carefully,

lift case up and off the pallet. Remove dust cover.

Installation hardware ships in an installation packet

located inside the case.

Compressor

The 6', 8', 10 and 12' Self-Contained cases are

equipped with a shipping block under the compressor. This block must be removed upon installation.

Loosen all four nuts on the compressor hold down

screws. Lift or pry the compressor up and remove

the shipping block. DO NOT retighten screws, as

the compressor should be left free to float on the

spring mounts.

FAILURE TO REMOVE THE SHIPPING BLOCK

WILL RESULT IN EXCESSIVE NOISE, REFRIGERANT LEAKS AND WILL VOID WARRANTY

PROTECTION.

Case Exterior Loading

These cases are not designed for excessive external weight. DO NOT WALK ON THE TOP OF THE

CASES. Walking on top of cases could cause personal injury and damage to the case.

Leveling

To ensure proper operation of the refrigeration system and drainage of the condensate, the case

MUST BE LEVEL. Use a carpenter level to level

front to back and side to side. Shim as necessary.

Drain, Electrical and Refrigeration

Connections on Remote Cases

1. Drains are located in the center of the case.

Connect PVC drains to existing floor drains.

Provide as much downhill slope as possible and

avoid long runs of drain lines. Do not install

condensate drains in contact with non-insulated

suction lines in order to prevent condensate

from freezing. Install the 1" PVC trap, which is

provided with the case. All drains must be

trapped.

Joining Lineups

1. Begin all lineups leveling from the highest point

of the store floor.

2. Remove front and rear toe kicks by removing

screws on all sides. Set and level first case.

3. Apply foam tape to facing ends of lineup. Level

second case to first case and seal with a good

grade silicone on all edges of each case.

4. Line up bottom boltholes in lower toe kicks (bolts

for these are located in the installation packet

inside the case) and line up bolt stud located in

top rear strut with bolthole in adjoining case.

Slide cases together. Insert lower bolts and

place nuts on bolts. Tighten securely.

THE FRONT OF THE CASES MUST BE FLUSH!

5. Atop joining plate is also located in the canopy

of the case. Ensure that case is properly leveled

so that the screw holes in this plate align over

the screw holes in the adjoining case. Shim as

necessary.

6. Screw in top plate and ensure all bolts are

fastened tightly.

7. Seal all seams. Use metal U-channel located

inside case to seal and cover where interior

case beds join.

2. Electrical connections are made through the

power supply box of each case, which can be

accessed by removing the back panel above the

toe kick. The power supply is located in the

raceway as shown to the right. Voltage requirements and component amperes can be found in

the electrical section of this manual, but always

check the data tag located on the exterior of the

case. Case must be grounded.

3. Refrigeration connections will be made through

the refrigeration stub up located on the

customer left side of the case (see mechanical

view). See refrigeration information section for

caseloads and recommended settings.

Refrigeration lines may be headed together for

all cases in a lineup, if desired, by lines through

the access area under the case. Seal all

access holes with a good grade silicon or foam

tape to prevent recirculation. All lines must be

correctly sized.

For proper refrigeration performance, PRODUCT

MUST NOT BE PLACED IN A POSITION WHERE

IT MAYAFFECT THE AIR CURTAIN. Air discharge

and return air vents must remain unobstructed.

Humidifier System -

This optional feature is installed at the factory.

Initial hook-up is as follows:

1. Read installation/service guide, which accompanies unit.

2. If connecting a lineup, which shares a common

control system, connect companion case dis

charge lines.

3. For all cases, connect water supply.

NOTE: It is recommended that a pre-filter be

added to the water supply.

4. Check for leaks.

Adjust water pressure as needed. See manufacturers installation guide for further information.

Glass Adjustment

Lift Glass is installed at the factory with the case

perfectly level, if adjustments need to be made to

align the glass first check to insure the case was

properly leveled during installation.

NOTE: This is a 2-person operation. One person

must hold the glass at all times.

1. Lift the glass to its highest position as shown in

drawing to the right.

2. Loosen allen screws. (See profile next page.)

3. Starting at the right side, tap the wedge with a

#2 standard screwdriver. Repeat procedure on

the left side. Continue working right to left until

the wedge recesses into the aluminum

extrusion.

EXTREME CARE MUST BE TAKEN NOT TO

TAP THE WEDGE TOO HARD.

4. Slide the glass right or left as needed.

5. Tighten the right allen screw while holding the

left side of the glass firmly. Be careful to keep

the glass level.

6. Tighten the remaining allen screws.

7. Lower glass into position. Repeat as necessary

until glass is completely level.

NOTE: the entire glass clamp and glass can be

moved sideways by loosening the allen screws that

are located in the glass clamp hinges.

Doors

Rear load doors are shipped inside the case. Push

top of doors all the way into top door tracks. Push

bottom of door over bottom door tracks and lower

over tracks. Doors are labeled inside and outside

for easy installation.

Optional Shelving

Shelves are shipped separately. To place shelving,

hold shelf straight and fit brackets straight into

channel. Place shelf directly above light outlet.

Plug in light making certain the plug is fully

engaged. All cases with shelf lights are equipped

with an interlocking plug system. Shelf lights will not

operate if plugs are not fully seated.

NOTE: If the shelf light is not in use, the plug

attached to the receptacle must be fully seated.

Installation Checklist

Before supplying electrical power and starting

case check the following:

1. Compressor Area (For Self-contained cases).

Remove shipping block on units with semihermetic compressors. Check location of

controls.

2. Evaporator Area.

Check to ensure evaporator fan pressure plates

are secure and in proper position NOTE: Hinged

portion of pressure plates are secured for

shipping with mounting screws. Screws do not

have to be removed for case operation but must

be removed to use hinge.

3. Lighting System

Check to ensure male plugs are completely

inserted in female sockets and that all lamps are

securely seated in light fixture.

4. Case Leveling

Visually check case. If lift glass is out of

adjustment or case looks out of square, use a

carpenter's level and shim as needed.

After supplying power to the case and starting unit:

1. Check to ensure all fans are operational.

2. Check all lights.

3. Check case temperature and adjust thermostat

as needed. See refrigeration section of this manual

for case settings.

Electronic Thermostat

The electronic thermostat is

located at the rear

of the case in the electronic

raceway. The thermostat is

equipped with a liquid crystal

display providing a constant

readout of the sensed temperature.

NOTE: The LCD display will be

blank during defrost. Atouch

keypad that allows the users to

select the set point temperature, differential and the heating

/cooling modes.

Programming Steps for the ETC, Electronic

Temperature Control

All thermostats are pre-set and cycle checked at the

factory.

STEP 1: Press the set key once to access the

Fahrenheit/Celsius mode. The display will dis

play either F degrees Fahrenheit or C for

degrees Celsius. Press the

up arrow or the

down arrow so the display indicates F.

STEP 2: Press the set key again to gain access to the

setpoint. The LCD will display the current

Setpoint and the S1 will be blinking. Press

the up arrow to increase or the down arrow

to decrease the temperature setting.

STEP 3: Press the set key again to gain access to the

differential. The LCD will display the current

differential and the DIF 1 will be blinking.

This should be set at 2°F

.

STEP 4: Press the set key again to gain access to the

cooling or heating mode. The LCD will dis

play the current mode. Press either the up

arrow or the down arrow to set the display in

the C1, cooling mode.

STEP 5: Press the set key once more and the pro

gramming is complete. Set the lock to keep

the set point.

STEP

1.

2.

3.

4

.

DISPLAY INDICATION

F or C

S1 (blinking)

DIF (blinking)

C1/H1

DESCRIPTION

Fahrenheit or Celsius Scale

Setpoint Temperature

Differential Temperature

Cooling or Heating Mode

Refrigeration Information

Case Operation

Refrigeration

The refrigeration in this case is thermostatically

controlled. The case refrigerates until the cut out

point on the thermostat is reached. The thermostat

opens, cutting power to the liquid line solenoid.

The compressor continues to run, the system

pumps down causing the pressure switch to open,

cutting power to the compressor. Note: Some

cases may be ordered with EPR valves to control

case temperature. For proper refrigeration performance, PRODUCT MUST NOT BE PLACE WHERE

IT WILL AFFECT THE AIR CURTAIN.

Defrost

This case is equipped with an OFF CYCLE defrost

system. The timer cuts the power to the liquid solenoid. The unit stays in off cycle defrost until the

defrost timer re-energizes the liquid solenoid.

NOTE: The evaporator fan runs continuously.

For Self Contained Cases

Thermostat cut out

Deli, Bakery 28°-30°

Fresh Meat, Seafood 26°

CRO valve

R-22 55-58

404A 75

134A N/A

TXV: 10° Superheat

Pressure switch

R-22 Low - 20 lb/55 lb High - 350 lb

404A Low - 20 lb/55 lb High - 350 lb

134A Low - 7 lb/25 lb High - 225 lb

Typical Component Settings

NOTE: The above settings are approximate and

will vary slightly with product load, lighting, store

ambient conditions etc. Evaporator fans run constantly.

Wiring

Schematic

Thermostat

For Remote Cases

Thermostat cut out

Deli, Bakery 28°-30°

Fresh Meat, Seafood 26°

EPR Valve (saturated suction temp.)

Deli 18°-20°

Fresh Meat & Seafood 14°

TXV 10° superheat

Refrigeration Loads

p

p

y

p

Model BTU Lin/F t Evap Tem

BMD Series-enclosed base

BMD-4 650

BMD-6 650

BMD-8 650

BMD-10 650

BMD-12 650

BMD Series-

edestal base or bullet legs

BMD-4 650

BMD-6 650

BMD-8 650

BMD-10 650

BMD-12 650

BMD Gravit

Coil Series

BMD-G-4 425

BMD-G-6 425

BMD-G-8 425

BMD-G-10 425

BMD-G-12 425

BSD Series-enclosed base

BSD-4 450

BSD-6 450

BSD-8 450

BSD-10 450

BSD-12 450

BSD Series-

edestal base or bullet legs

BSD-4 450

BSD-6 450

BSD-8 450

BSD-10 450

BSD-12 450

+20

+20

+20

+20

+20

+20

+20

+20

+20

+20

+15

+15

+15

+15

+15

+20

+20

+20

+20

+20

+20

+20

+20

+20

+20

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

Defros t

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

90"/24 hr.

90"/24 hr.

90"/24 hr.

90"/24 hr.

90"/24 hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

BSD Tilt Glass Series

BSD-T-4 450

BSD-T-6 450

BSD-T-8 450

BSD-T-10 450

BSD-T-12 450

+20

+20

+20

+20

+20

o

o

o

o

o

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

20"/4hr.

Wiring Color Code

Electrical Information

A

A

A

A

A

A

ANA

A

ANA

A

ANA

A

ANA

A

ANA

ANA

ANA

ANA

ANA

ANA

A

A

A

A

A

ANANA

ANANA

ANANA

ANANA

ANANA

Green------------------------Ground

Black-------------------------Hot

White ------------------------Neutral

Red --------------------------208/220 Only

Brown -----------------------Interlock System

Orange----------------------Thermostat

Orange----------------------Liquid Solenoid

Purple -----------------------Hot Gas Defrost

Purple -----------------------Defrost Terminator

Gray -------------------------Light Switch

Black/White----------------Pressure Switch

Red ----------Lights

Yellow -------Lights

Blue----------Lights

Secondary Wiring Color Code

SEE BALLAST DIAGRAM FOR EACH CASE

NOTE: Case must be grounded

Remote Case Data - Electrical 120 Volt Additional Loads for Self-Contained Units

Model Evap Fans

BMD Series-enclosed base

BMD-4 0.6 0.76 0.49 N

BMD-6 0.6 0.95 0.75 N

BMD-8 1.2 1.5 0.95 N

BMD-10 1.2 2.25 1.54 N

BMD-12 1.8 2.25 1.54 N

Add 5 amps if a humidification system is added. A separate power source is not needed.

BMD Series-pedestal base or bullet legs

BMD-4 0.55 0.76 0.49 2.08 1/3 120-1-60 5.6/29 0.58 5.0 0.26

BMD-6 1.1 0.95 1.75 4.16 1/2 120-1-60 9.4/51 1.4 6.6 0.52

BMD-8 1.1 1.5 0.95 4.16 3/4 120-1-60 9.8/65 1.7 8.3 0.52

BMD-10 1.1 1.54 1.54 4.16 1 120-208 1-60 5.7/40 0.94 4.8 0.52

BMD-12 1.65 1.54 1.54 6.24 1 120-208 1-60 5.7/40 0.94 4.8 0.78

Add 5 amps if a humidification system is added. A separate power source is not needed.

Cornice &

Nose Lts

Shelf Lts

Anti-Sweat

Heaters

HP Voltage RLA/LRA

1/3 120-1-60 5.6/29 0.58 5.0 0.52

1/2 120-1-60 9.4/51 1.4 6.6 0.78

3/4 120-1-60 9.8/65 1.7 8.3 1.04

1 120-208 1-60 5.7/40 0.94 4.8 1.3

1 120-208 1-60 5.7/40 0.94 4.8 1.56

Cond

Pan Heater Air Sweep Fan

Fan

BMD Gravity Coil Series

BMD-G-4 N

BMD-G-6 N

BMD-G-8 N

BMD-G-10 N

BMD-G-12 N

BSD Series-enclosed base

BSD-4 0.6 0.76 N

BSD-6 0.6 0.95 N

BSD-8 1.2 1.5 N

BSD-10 1.2 2.25 N

BSD-12 1.8 2.25 N

Add 5 amps if a humidification system is added. A separate power source is not needed.

BSD Series-pedestal base or bullet legs

BSD-4 0.6 0.76 N

BSD-6 0.6 0.95 N

BSD-8 1.2 1.5 N

BSD-10 1.2 1.54 N

BSD-12 1.8 1.54 N

Add 5 amps if a humidification system is added. A separate power source is not needed.

BSD Tilt Glass Series

BSD-T-4 0.6 N

BSD-T-6 1.2 N

BSD-T-8 1.2 N

BSD-T-10 1.2 N

BSD-T-12 1.8 N

DRY CASES - USE LIGHTING SPECIFICATIONS REMOTE CASES - 20 MINUTES DEFROST EVERY 4 HOURS

0.76 N

0.95 N

0.95 N

1.54 N

1.54 N

1/2 120-1-60 7/36 0.7 5.0 0.52

1/2 120-1-60 9.4/51 1.3 6.6 0.78

3/4 120-1-60 11.8/66.3 1.64 8.3 1.04

1 120-1-60 8.2/65 1.7 8.3 1.3

1 120-1-60 11.4/93 1.7 8.3 1.56

1/3 120-1-60 5.6/29 0.58 5.0 0.52

1/2 120-1-60 9.4/51 1.4 6.6 0.78

3/4 120-1-60 9.8/65 1.7 6.6 1.04

1 120-208 1-60 5.7/40 0.94 4.8 1.3

1 120-208 1-60 5.7/40 0.94 4.8 1.56

2.08 1/3 120-1-60 5.6/29 0.58 5.0 0.26

4.16 1/2 120-1-60 9.4/51 1.4 6.6 0.52

4.16 3/4 120-1-60 9.8/65 1.7 6.6 0.52

4.16 1 120-208 1-60 5.7/40 0.94 4.8 0.52

6.24 1 120-208 1-60 5.7/40 0.94 4.8 0.78

1/3 120-1-60 5.6/29 0.58 5.0 0.52

1/2 120-1-60 9.4/51 1.4 6.6 0.78

3/4 120-1-60 9.8/65 1.7 6.6 1.04

1 120-208 1-60 5.7/40 0.85 4.8 1.3

1 120-208 1-60 5.7/40 0.85 4.8 1.56

Fans

Ballast Information

Ballasts are located in the electronic raceway at the rear of the case.

Model Model

BMD-4 (1) 3P, (1) 2P BSD-4 (1) 3P

BMD-6 (2) 4P, (1) 2P BSD-6 (1) 4P, (1) 2P

BMD-8 (2) 4P, (1) 2P BSD-8 (1) 4P, (1) 2P

BMD-10 (5) 2P BSD-10 (3) 2P

BMD-12 (5) 3P BSD-12 (3) 3P

BMD-4G (1) 3P BSD-4T (1) 2P

BMD-6G (1) 4P, (1) 2P BSD-6T (1) 2P

BMD-8G (1) 4P, (1) 2P BSD-8T (1) 2P

BMD-10G (2) 4P BSD-10T (1) 3P

BMD-12G (3) 3P BSD-12T (1) 3P

Main Power Supply

Nose light and Canopy

Ballast Boxes

Digital Thermostat

LH and RH Shelf

Ballast Boxes

Ballast and Light Terminal and

Light Power Supply Terminal

Maintenance Information

Cleaning

Case Exterior

Clean surfaces frequently with warm water and mild

detergent. Do not use strong alkali solutions, steel

wool, or abrasive cleansers.

Non-Glare Glass

Non-glare glass surfaces are coated to reduce the

glare from lighting. Care must be taken not to

scratch the coating. Use the following products only.

Cleaning Cloths

Scotch-Brite High Performance Cloth - manufac-

tured by 3M and available in most grocery stores

under the name Scothch-Brite Microfiber Cleaning

Cloth in a 12" x14" size. This cloth is washable and

may be reused as long as it remains clean.

Spontex Microfibre Cleaning Cloth - distributed

by Spontex and available in most grocery stores

under the same name in a 15.75" x 12" size. This

cloth is washable and may be reused as long as it

remains clean.

The cleaning cloths named above will normally

remove dust, grease, oil and fingerprints without the

need for cleaning fluids. Alight spray of the cleaning fluids listed below will reduce the time required

for cleaning.

Cleaning Fluid - for more difficult cleaning jobs,

these products are recommended:

Windex - standard product only (extra-strength

or specialty products may not be suitable)

Glass-Plus - standard product only (extrastrength or specialty products may not be suiable)

Warm Water

DO NOT USE

the following types of materials can

be used for cleaning glass with anti-reflective

coatings.

Coarse Paper Towels

Scouring Pads or Powders

Steel wool or Steel Fiber Materials

Blades

Acidic or highly Alkaline detergents

Fluorine based detergents

Case Interior

All shelving and lower deck can be removed for

cleaning (See installation instructions for removing

and setting shelving). Check to make sure the

case drain(s) are not clogged. Clean interior with

warm water and a mild detergent. Asanitizer

should be used after washing to eliminate bacteria.

Rinse thoroughly being careful not to flood drain

system. Avoid spraying water directly into electrical

connections. DO NOT USE A HIGH PRESSURE

WATER HOSE. MAKE SURE FANS ARE SHUT

OFF WHEN CLEANING THE INTERIOR OF THE

CASE. Drains should be cleaned once a month.

Light Replacement

The fluorescent lights in this case are furnished with

plastic safety shields and end caps. When replacing fluorescent lamps, be certain to reinstall safety

shield and caps. (See illustration). If the bulb is not

fully seated the lights will not operate. BE SURE

BULBS ARE FULLY SEA TED.

The light switch is mounted to the right side of the

ceiling. See mechanical drawing for ballast box

location.

p

Load Limits

DO NOT place product in merchandisers until all

refrigeration controls have been adjusted and are at

the proper operating temperature. DO NOT place

product above load limits or in such a way that the

discharge or return air grill are blocked. This will

effect the performance of the case and effect the

defrost system.

Evaporator Coil

Clean as needed.

Condenser Coil

FAILURE TO CLEAN COILS WILL VOID WARRANTY. Clean condenser coil every three months or as

needed with a whisk broom or vacuum. Disconnect

power when servicing. FINS ON CONDENSER

COIL ARE SHARP!

Condensate Heater

(Evap-O-Way)

Add one teaspoon of scale remover or white vinegar to condensate heater pan once every three

months or as needed. Heater is designed for 75º

and 50% relative humidity. The condensate pan

may overflow if design limits are exceeded.

Seafood Application

Plexiglas should be removed for cleaning. Reinstall

Plexiglas by placing in front of case. Ice will hold it

in place. PLEXIGLAS MUST BE IN PLACE TO

KEEP ICE OUT OF AIR SCREEN.

A.

To remove bulb, grasp lamp

holder on either end of the bulb

and with equal pressure pull

down.

B.

Install new bulb into the

plastic safety tube protector.

Insert bulb into end cap.

lamp holder

C.

Position the bulb and cap

cap

bulb in safety tube

Caution: Failure to install bulb fully into light socket will cause

remature bulb life and may cause damage to light fixture

under the lamp holder

and with even pressure

press the bulb into the

light fixture.

Service

WA

RNING!

DISCONNECT THE ELECTRICAL POWER WHEN SERVICING OR REPLACING ANY ELECTRICAL COMPONENT.

Evaporator Coil Area

To access Evaporator Coil area, remove bottom

deck by lifting up and out to expose pressure plate

cover and evaporator fans. Remove screws as

shown to the left and lift pressure plate cover up.

Evaporator Fans

Pressure Plate

Evaporator Coil

Drain

Washout Drain Pan

Drain and refrigeration connections are located on

the customer left side at the back of the case.

1" PVC running trap with 11/2" to 1" reducer coupling

Liquid and suction line refrigeration

connection points

Thermo static expansion valve

Refrigerant is predetermined.

TXV Bulb

Schrader valve

(suction line)

Solenoid valve

(liquid line)

Drain Pan Access

Service Instructions

1. Read the Installation and Service manual.

2. See the trouble-shooting guide in the event

of problems.

3. If service is needed contact Barker Company for

an authorized service person in your area.

Before calling for service locate the case model

and serial number on the data tag located on

the customer left, outside back of the case, the

customer left, inside top of the case, or contact

the factory for location.

Problem Cause Action

Case temperature is too warm. Case is in defrost.

Product load may be over its limits

blocking airflow.

Ambient conditions may be affecting the case operation.

Condensing coil or evaporator coil

is clogged or dirty.

Review T-Stat settings.

Redistribute product.

Check case position in store. Is the case

located near an open door, window, or air

conditioning vent?. RH should not be over

50% and temperature above 75º.

Clean coil.

Case temperature is too cold. The T-Stat Temp is set too low.

Ambient conditions may be affecting the case operation.

Condensing coil or evaporator coil

is clogged or dirty.

Check setting. See factory guidelines.

Check case position in store. Is the case

located near an open door, window, or air

conditioning vent? RH should not be over

50% and temperature above 75º.

Clean coil.

Condensation on glass. Inadequate air circulation.

Product load may be over its limits

blocking airflow.

Ambient conditions may be affecting the case operation.

Check grill on die board for adequate airflow over glass.

Redistribute product.

Check case position in store. Is the case

located near an open door, window, or air

conditioning vent? RH should not be over

50% and temperature above 75º.

Water has pooled under case. Case drain is clogged.

Check PVC drains under case for

leaks.

Evaporator pan is overflowing.

Clear drain.

Repair as needed.

Check electrical supply to dissipater pan.

Check float assembly.

(Note: Cases equipped with electric dissipater pans should NEVER have food

products washed or poured into the drain

as it will result in damage to the heating

element.)

Frost or ice on evaporator coil. Check evaporator fans.

Defrost clock doesn't work.

Check electrical connections. Have unit

serviced by a qualified service technician.

Troubleshooting Guide

Barker Sales & Service Department

IMPORTANT INFORMATION!

FOR PROMPT SERVICE WHEN CONTACTING THE FACTORY FOR SUPPORT, BE SURE TO HAVE CASE MODEL AND SERIAL

NUMBER HANDY.

(THIS INFORMATION IS LOCATED ON THE DATATAG ATTACHED TO THE CASE. SEE BELOW FOR DATATAG LOCATIONS)

For any warranty or service issues not covered by this manual, for tech support, or for warranty service calls, please

contact the Barker Service Manager in your area.

Jody Jones - Eastern Service Manager: (319) 293-8308

• Connecticut • Delaware • Florida

• Georgia • Maine • Maryland

• Massachusetts • New Hampshire • New Jersey

• New York (Eastern) • North Carolina • Pennsylvania (Eastern)

• Rhode Island • South Carolina • Vermont

• Virginia

Bill Connor - Midwestern Service Manager: (319) 293-8307

• Alabama • Arkansas • Indiana

• Iowa • Kansas • Kentucky

• Louisiana • Michigan • Mississippi

• Missouri • Nebraska • New York (Western)

• Ohio • Oklahoma • Pennsylvania (Western)

• Tennessee • West Virginia

Gregg Rupe - 2nd Midwestern Service Manager: (319) 293-8324

• Alaska • CANADA • EUROPE

• Hawaii • Illinois • MEXICO

• Minnesota • North Dakota • South Dakota

• Texas • Wisconsin

Gary Winslow - Western Service Manager: (319) 293-8306

• Arizona • California • Colorado

• Idaho • Montana • Nevada

• New Mexico • Oregon • Utah

• Washington • Wyoming

Parts

Ordering Procedure

1. Contact the Service Parts Department

Melissa Marshall

703 Franklin Street

PO Box 478

Keosauqua, IA 52565

Tel: 319-293-8323

Fax: 319-293-8377

mmarshall@barkercomp

any.com

2. Provide the serial number of the case containing the part.

To locate the serial number look on the data tag located on the

customer left, outside back of the case, the customer left, inside

top of the case, or contact the factory for location.

3. If parts are to be returned for credit, contact the Parts

Department. Do not send parts without authorization.

BEFORE SERVICING

ALWAYS DISCONNECT ELECTRICAL

POWER AT THE MAIN DISCONNECT

WHEN SERVICNG OR REPLACING

ANY ELECTRICAL COMPONENT.

703 Franklin Street

P.O. Box 478

Keosauqua, Iowa 52565

Tel:319/293-3777

Fax:319/293-3776

www.barkersales.com

One Year Factory Warranty

For all shipments with original delivery points in the continental U.S. but with a final destinations outside the continental U.S., Barker Company warrants to the original purchaser that every new Barker merchandiser, the cabinet

and all parts thereof, to be free from defects in material or workmanship, under normal use and service, for a period of one (1) year from the date of original installation or 15 months after shipment date from Barker Company,

whichever occurs first.

Barker Company will replace, in its sole and absolute discretion, without cost to the original equipment purchaser,

any part or parts thereof, which inspection by Barker Company or proven to the satisfaction of the Company to

have been defective. Replacement parts will be shipped to the original point of shipment. Any installation and / or

service work will be at the expense of the original purchaser.

For all shipments within the continental U.S. , Barker Company warrants to the original purchaser that every new

Barker merchandiser, the cabinet and all parts thereof, to be free from defects in material or workmanship, under

normal use and service, for a period of (1) year from the date of original installation or 15 months after shipment

date from Barker Company, whichever occurs first.

Barker Company will replace, in its sole and absolute discretion, without cost to the original equipment purchaser,

any part or parts thereof, which inspection by Barker Company or proven to the satisfaction of the Company to

have been defective.

All warranty service work must be pre-authorized by Barker Company (800-814-0446). Barker Company reserves

the rights to designate the service provider, time in which labor is to be performed and specify amount of time per

warranty problem.

COMPRESSOR WARRANTY: The standard compressor warranty is for a period of one (1) year from the date of

original installation or 15 months after shipment date. A four-year compressor warranty extension is available at an

additional cost to the original purchaser/user. If compressor issues arise after the initial warranty period expires,

please provide the Company with the applicable serial number to determine whether a four-year compressor warranty extension was purchased prior to the ship date.

What is NOT Covered by Factory Warranty

This Limited Warranty also does not apply to any equipment, or parts thereof, that has been subject to misuse,

neglect, accident, misapplication or problems caused by improper installation and/or lack of periodic maintenance.

This Limited Warranty does not include glass breakage.

Barker Company shall under no circumstances be responsible for any loss, cost of damage beyond repair or

replacement, whether incidental or consequential, other than specifically identified in the foregoing Limited

Warranty including but not limited to any spoilage, shrinkage or damage to commodities or product during installation or operation of the Company's equipment caused by failure of refrigeration, or loss of business resulting therefrom.

WARRANTY CLAIMS. All claims should include: the serial number of the cabinet, proof of purchase, date of installation, and all pertinent information supporting the existence of the alleged defect. Any action for breach of these

warranty provisions must be commenced within one (1) year after that cause of action has accrued.

WARRANTY REGISTRATION CARD

Failure to forward this Warranty Registration Card within 21 days of installation

VOIDS ANY AND ALL WARRANTIES, whether by contract or at law.

(Name of company purchaseing merchandiser)

(Type of business) (City & State of Purchaser)

(Cabinet Serial #) (Date of installation)

(Signature of store owner)

This card must be mailed

immediately after installation

date to the address below for

warranty to be in effect.

P.O. Box 478

Keosauqua, IA 52565

Loading...

Loading...