DC400/A

USER INSTRUCTION SUPPLEMENT

M/N DC400/A, P/N 101-00802

Doc. P/N: 61-101-00802.EF2

Revision G

January 7, 2015

_________________________________________

Adapter Module

MOD C, used with

DC400 OR DC400A

Corporate Headquarters

4101 Northwest 29th Street

Miami, Florida 33142

www.barfieldinc.com

Email: gsesales@barfieldinc.com

P/N’s 101-00800 or 101-00850

Digital DC Fuel Quantity Test Sets

For

BEECHCRAFT MODELS

1900/1900C, UA and UB

and

1900C/1900D, UC and UE

Barfield Inc. Confidential and Proprietary Information.

This document and all the information contained herein is the sole property of Barfield Inc.

No intellectual property rights are granted by the delivery of this document or the disclosure of its content.

This entire document is proprietary information and shall not be reproduced or disclosed to a third party without

the express written consent of Barfield Inc.

This document and its content shall not be used for any purpose other than that for which it is supplied.

Copyright © 2015 Barfield Inc. All Rights Reserved.

THIS PAGE INTENTIONALLY LEFT BLANK

APPLICABILITY

This manual is one of a family of manuals, each developed to address an individual

Adapter Module especially designed for the DC-400 / DC-400A Digital Fuel Quantity Test

Sets. It contains complete instructions for the maintenance, inspection, testing,

troubleshooting, and calibration of the Gull Airborne and Ragen Data Fuel Quantity

Systems.

These aircraft include (at the time of this writing):

1900 ............................... S/N UA

1900C ............................. S/N UB

1900C ............................. S/N UC

1900D ............................. S/N UE

61-101-00802.EF2 (REV. G) APP

January 7, 2015 Page iii

THIS PAGE INTENTIONALLY LEFT BLANK

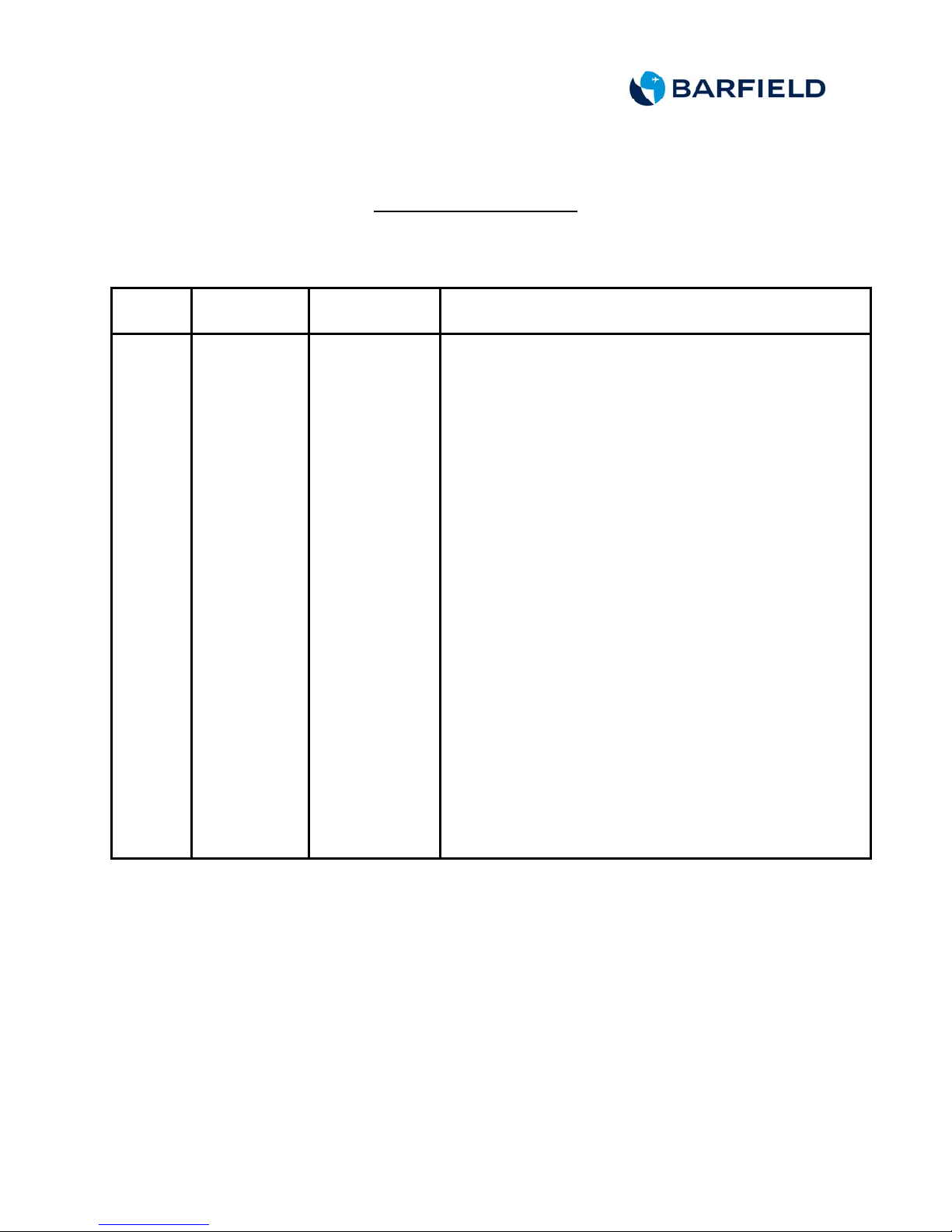

REVISION RECORD

REV.

A

B

C

D

E

F

G

260-00678

260-00729

260-00779

260-01003

260-01076

ECO #

N/A

260-00617

REV. DATE

Mar/17/03

May/20/03

Sep/15/06

Jan/23/09

Apr / 29 / 10

Apr/29/14

Jan/07/15

First Issue. This supplement replaces

56-101-00802 manual and covers MOD B (or

earlier) releases of 101-00802.

For Mod C or later releases of adapter module.

Modifications to the company logo, company

contact information and listed part 101-00814

were implemented. Beech probe adapter cable

101-00829 is a reflection of the said changes to

adapter cable 101-00814.

Updated Company Logo

List of Approved Repair Facilities and

Recertification Information were added (page iv)

Revised per feedback from Beech and added

section 7. System Wiring Integrity Test.

Updated Barfield logos.

DESCRIPTION OF CHANGE

61-101-00802.EF2 (REV. G) REV

January 7, 2015 Page v

THIS PAGE INTENTIONALLY LEFT BLANK

r

LIST OF APPROVED REPAIR FACILITIES

The manufacturer of this equipment does not recommend the user to attempt any maintenance

or repair. In case of malfunction, contact the manufacturer, to obtain the list of approved repai

facilities worldwide, ensuring that this equipment will be serviced using proper procedures and

certified instruments. A Return Maintenance Authorization (RMA) number will be assigned

during this call, to keep track of the shipment and the service.

BARFIELD PRODUCT SUPPORT DIVISION

Telephone: (305) 894-5400 Shipping Address:

(800) 321-1039

Barfield, Inc.

Fax:

Miami, Florida 33142

Email:

Barfield, Inc.

P.O. Box 025367

Miami, FL 33102-5367

USA

(305) 894-5401 4101 NW 29th Street

gsesales@barfieldinc.com USA

Mailing Address:

Barfield Adapter Module, P/N 101-00802, has a one-year recertification requirement.

Qualified technicians in a shop equipped with the necessary tooling, facilities, and

Barfield-approved procedures must perform the maintenance required by this unit.

61-101-00802.EF2 (REV. G) LOARF

January 7, 2015 Page vii

RECERTIFICATION

THIS PAGE INTENTIONALLY LEFT BLANK

CONTACT INFORMATION

USERS ARE REQUESTED TO

NOTIFY THE MANUFACTURER OF

ANY DISCREPANCY, OMISSION OR

ERROR FOUND IN THIS SUPPLEMENT.

PLEASE SEND YOUR COMMENTS TO:

BARFIELD, INC.

ATTN: GSTE

4101 NORTHWEST 29TH STREET

MIAMI, FL 33142

USA

TELEPHONE (305) 894-5400

(800) 321-1039

FAX (305) 894-5401

EMAIL ADDRESS: gsesales@barfieldinc.com

61-101-00802.EF2 (REV. G) CONTACT INFO

January 7, 2015 Page ix

THIS PAGE INTENTIONALLY LEFT BLANK

TABLE OF CONTENTS

Applicability

Revision Record

List of Approved Repair Facilities / Recertification

Contact Information

Table of Contents

List of Tables

PAGE

1. Description ........................................................................................................ 1

2. Operation

1. System Insulation Test ................................................................................. 3

2. Insulation Test (Individual Probes) ............................................................... 8

3. System Capacitance Test ........................................................................... 12

4. Capacitance Test (Individual Probes) ......................................................... 15

5. Indicator Test ............................................................................................... 21

6. Preferred Calibration Test (with Dry Tanks) ................................................ 26

7. System Wiring Integrity Test ....................................................................... 29

3. Alternate Tests

1. Probes Bench Test ...................................................................................... 34

2. Indicator Bench Test ................................................................................... 37

3. Alternate Calibration (Wet Tanks) ............................................................... 41

61-101-00802.EF2 (REV. G) TOC

January 7, 2015 Page xi

THIS PAGE INTENTIONALLY LEFT BLANK

LIST OF TABLES

PAGE

1. Conductance to Megaohm Conversion ...................................................................... 6

2. Tank Capacitance Empty ........................................................................................... 14

3. Tank Capacitance Full ............................................................................................... 14

4. Probe Capacitance Empty (1900/1900C, UA and UB) .............................................. 18

5. Probe Capacitance Empty (1900C/1900D, UC and UE) ........................................... 18

6. Probe Capacitance Full (1900/1900C, UA and UB) .................................................. 19

7. Probe Capacitance Full (1900C/1900D, UC and UE) ............................................... 19

8. Add for Full .................................................................................................... 27

61-101-00802.EF2 (REV. G) LOT

January 7, 2015 Page xiii

THIS PAGE INTENTIONALLY LEFT BLANK

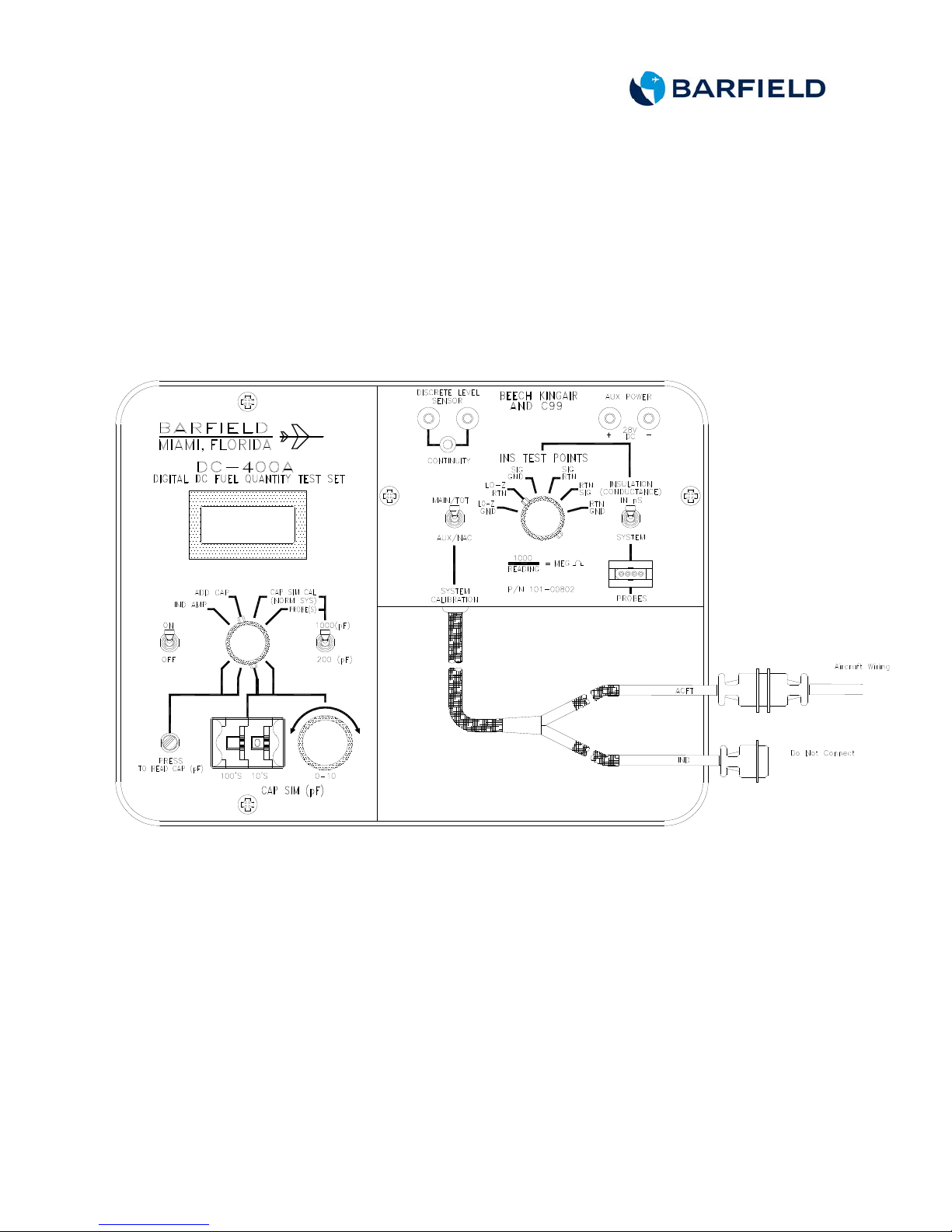

CHAPTER 1 DESCRIPTION

A. Capabilities

(1) Complete testing of fuel quantity system.

(2) Testing of individual fuel tanks.

(3) Testing of indicators.

(4) Dry and wet tank calibration.

B. Panel Controls

(1) See Instruction Manual 56-101-00850 for details on the DC400A Fuel

Quantity Test Set. See Technical Manual 57-101-00800 for information

on the DC400 Digital Fuel Quantity Test Set.

(2) Refer to Aircraft Maintenance Manual for description of the aircraft fuel

quantity system.

C. Aircraft System Description

(1) Refer to the Aircraft Maintenance Manual for specific procedures and

maintenance practices.

D. Equipment Required (or equivalent)

(1) DC400A Digital Fuel Quantity Test Set, P/N 101-00850 or the DC400

Digital Fuel Quantity Test Set, P/N 101-00800

(2) Barfield Instruction Manual 56-101-00850 (DC400A) or Barfield

Technical Manual 57-101-00800 (DC400)

(3) Fuel Quantity Adapter Module, P/N 101-00802

(4) Probe Adapter Cable, Barfield P/N 101-00829 or 101-00814

(5) Test leads, banana plug to alligator clip, P/N 101-01012

(6) 15-pin adapter cable, Barfield P/N 101-00831 or 101-00817

NOTE: Barfield adapter cables are available as a separate

purchase.

(7) A 1900/1900C/1900D Beech Probe adapter pin

(8) A 28 VDC Power Supply

(9) A Probe Selector Unit:

For 1900/1900C, UA and UB: P/N 114-389001/935

For 1900C/1900D (UC, UE): P/N 118-389004/935

61-101-00802.EF2 (REV. G) CH. 1

January 7, 2015 Page 1 of 44

E. Precautions

(1) Refer to Aircraft Maintenance manual for proper fueling and defueling

procedures. Observe all safety precautions.

(2) Refer to the Aircraft Maintenance manual for location of the system

components and instructions for removal and replacement.

(3) Insure fuel quantity circuit breakers are open and they remain open

while aircraft and test set connections are broken or made.

(4) Insure power remains OFF unless otherwise specified.

F. Preliminary

(1) To insure the integrity of all system components, perform the

Insulation, Capacitance tests first. Then, perform one of the Indicator

tests (System or Bench) and, if necessary, the Probe Bench test.

These tests will provide an effective means for troubleshooting the

system.

(2) After performing an indicator test and before returning the aircraft to

service, calibrate the aircraft fuel quantity system using the Preferred

(or Alternate) Calibration Test.

(3) Failure to calibrate the system could result in an inaccurate fuel

quantity indication.

G. Disclaimer

(1) BARFIELD, INC., neither a vendor nor supplier of fuel quantity systems

or an airframe manufacturer, has no control over calibration figures or

procedures. A variant between actual values and those recommended

may exist. However, the information presented is correct to the best of

our knowledge at time of publication and is presented for reference

only.

61-101-00802.EF2 (REV. G) CH. 1

January 7, 2015 Page 2 of 44

CHAPTER 2 OPERATION

1. SYSTEM INSULATION TEST

Note: Refer to PRECAUTIONS and PRELIMINARY sections (Chapter 1).

Note: This test may be performed with either wet or dry tanks.

A. Aircraft Preparation

(1) Disconnect the aircraft battery.

Caution: When lowering or raising pilot fuel panel, insure aircraft

battery is disconnected.

(2) Access the indicator.

(3) Open the circuit breakers.

Caution: When breaking or making indicator connections, insure that

the applicable circuit breaker(s) are open.

(4) Disconnect the aircraft wiring plug at the indicator.

B. Test Set Preparation

(1) Set the ON/OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to IND AMP.

(3) Set the INSULATION/SYSTEM switch to INSULATION.

(4) Rotate the INS TEST POINTS switch to LO-Z/GND.

(5) Set the AUX/MAIN switch to MAIN/TOT.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 3 of 44

C. Connecting Test Set

(1) Set up the test set (T/S) as shown in Figures 1 and 2.

(2) Connect the test set ACFT connector to the aircraft wiring plug

removed from the indicator.

(3) Connect the test set ACFT connector to the ACFT connector of the

adapter cable.

(4) Do not connect the test set IND connector of the adapter cable.

(5) Do not connect the test set IND connector.

Figure 1 Insulation Test Connector Setup

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 4 of 44

Figure 2 Insulation Test Connector Setup

D. Test

(1) Set the test set ON/OFF switch to ON.

(2) Allow time for the test set display to stabilize.

(3) Verify that the test set reading is less than 50nS.

Note: The display reading is in nS (nano Siemens). To get an

equivalent MΩ (megaohms) measurement, divide 1000 by the

test set display reading.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 5 of 44

Test Set Display Reading Equivalent MΩ

1. Less than 1

1000 1.

500 2.

200 5.

100 10.

050 20.

020 50.

010 100.

005 200.

002 500.

001 1,000.

000 Greater than 1,000

Example: 1000/50 = 20 MΩ

Table 1 Conductance to Megaohm Conversion

(4) Rotate the INS TEST POINTS switch through each remaining

position.

(5) Allow test set to stabilize. Sometimes the reading never completely

stabilizes. If the reading is in the acceptable range after 30 seconds it

should be considered OK.

(6) Verify T/S reading is less than 50 nS at each position except

SIG/RTN.

(7) With switch rotated to SIG/RTN, verify an “over range” test set

reading of “1”.

Note: If P/N 114-389001-17 probe (Gull Airborne) is installed in the

(8) Connect the aircraft battery.

(9) Close circuit breakers.

(10) If testing 1900C/1900D, UC and UE aircraft, set the aircraft fuel panel

select switch to AUX and maintain.

Note: The fuel quantity select relay shorts the signal lead to return

(11) Rotate INS TEST POINTS switch through remaining positions.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 6 of 44

collector tank, an “over range” reading also appears when the

switch is placed in the LO-Z/RTN position.

lead of “MAIN/TOTAL” or “AUX/NAC” that is not selected.

Also, due to continuity through diodes inside the probe, a short

on “RTN/GND” shows as a short on “SIG/GND”.

(12) Allow test set to stabilize. Sometimes the reading never completely

stabilizes. If the reading is in the acceptable range after 30 seconds it

should be considered OK.

(13) Verify the test set reading is less than 50nS at each position except

SIG/RTN.

(14) With switch rotated to SIG/RTN, verify a test set “over range” reading

of “1”.

(15) Release fuel panel select switch.

Note: If a test does not meet specification, repeat test to verify

readings. If wrong reading remains, isolate fault by referring to

the aircraft wiring drawings and disconnecting the interconnect

fuel line receptacle. Then, repeat test. Verify that the reading

with the fuel panel select switch in any position is less than

005 nS. If fault remains, the problem may be with the a/c

wiring between interconnect fuel line receptacle and the

indicator connector. Correct the fault and perform the

Insulation Test (Individual Probes). (See section 2.

INSULATION TEST (INDIVIDUAL PROBES). When all

problems are corrected, perform the System Insulation Test

again.

(16) Set T/S ON/OFF switch to OFF.

(17) Open circuit breakers

(18) Disconnect a/c battery.

Note: If testing the opposite side, repeat procedure.

E. Disconnecting/Reconfiguring

(1) Disconnect the test set from the aircraft harness.

(2) Reconnect the aircraft wiring plug to the indicator.

(3) Return the aircraft to its original configuration.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 7 of 44

2. INSULATION TEST (INDIVIDUAL PROBES)

Note: This test may be performed with wet or dry tanks.

A. Aircraft Preparation

(1) Access the interconnect fuel line receptacle (left or right) which is

located under the panel’s just outboard of the engine nacelles.

Caution: When breaking or making indicator connections, insure

applicable circuit breakers are open.

(2) Open the circuit breakers.

(3) Disconnect the a/c connector at the interconnect fuel line receptacle.

B. Test Set Preparation

(1) Set the ON/OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to IND AMP.

(3) Set the INSULATION/SYSTEM switch to INSULATION.

(4) Rotate the INS TEST POINTS switch to LO-Z/GND.

(5) Set the AUX/MAIN switch to MAIN/TOT.

C. Connecting the Test Set

(1) Set up the T/S as shown in Figure 3 or Figure 4.

(2) Connect the 1900, 1900C or 1900D Probe Selector Unit (see chapter

one, section D, Equipment Required, for the appropriate part

numbers) to the Interconnect Fuel Line Receptacle connector (if the

aircraft has UA or UB serial numbers) or to the Main Harness

disconnect and the Aux Harness disconnect (if the aircraft is UC or

UE serial numbers).

(3) Connect the adapter cable to the Probe Selector unit.

(4) Connect the T/S ACFT connector to the adapter cable.

(5) Do not connect the T/S IND connector.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 8 of 44

INSULATION TEST

Figure 3 1900 / 1900C (UA & UB) Individual Probes

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 9 of 44

INSULATION TEST

Figure 4 1900C / 1900D (UC & UD) Individual Probes

D. Test Procedure

(1) Rotate the 1900/1900C or 1900D Probe Selector Unit switch to the

ALL position.

(2) Set the T/S ON/OFF switch to ON.

(3) Allow time for the T/S display to stabilize. Sometimes the reading

never completely stabilizes. If the reading is in the acceptable range

after 30 seconds it should be considered OK.

(4) Verify that the T/S display reading is less than 50 nS. (Refer to Table

1).

(5) Rotate the INS TEST POINTS switch through remaining positions

and verify that each reading is less than 50 nS EXCEPT when the

switch is at the SIG/RTN position.

(6) With the switch in the SIG/RTN position, the T/S reading with be an

“overrange” of 1.

Note: If ALL insulation is out of tolerance, each individual Probe

must be tested.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 10 of 44

(7) At the Fuel Probe Selector Unit, select a probe.

(8) Rotate the INS TEST POINTS selector to each position for each

probe and test every probe.

Note: If testing aircraft serial numbers UC or UE and using Probe

Selector Unit P/N 118-389004/935, set the ALL/EACH switch

to EACH, the MAIN/AUX switch to MAIN. Then, rotate the

switch through the MAIN probe positions to take readings. To

read the AUX probes, set the ALL/EACH switch to the ALL

position, the MAIN/AUX switch to the AUX and the

BOTH/EACH switch to BOTH to take readings. If also testing

individual AUX probes, set the ALL/EACH switch to EACH, the

BOTH/EACH switch to EACH and rotate the switch through

the two AUX probe positions and take readings.

(9) Verify that the T/S reading for each probe is less than 50 nS (the total

conductance of ALL probes should not be greater than 50 nS)

EXCEPT when the selector is in the SIG/RTN position.

Note: When reading are taken on an individual probe or several

probes in parallel, readings when the switch is in the SIG/RTN

pos will range between 1500 and an “overrange” of 1.

If P/N 114-389001-17 probe (Gull Airborne) is installed in the

collector tank, an “overrange” reading will also appear when

the INS TEST POINTS switch is set in the LO-Z/RTN position.

(10) Set the T/S ON/OFF switch to OFF.

E. Disconnecting/Reconfiguring

(1) Disconnect the T/S ACFT connector from the adapter cable.

(2) Disconnect the adapter cable from the Fuel Probe Selector Unit.

(3) Disconnect the Fuel Probe Selector Unit from the Interconnect Fuel

Line Receptacle connector (for 1900/1900C, UA and UB aircraft serial

numbers) or from the Main and Aux Harness disconnects (for 1900D

and UC and UE aircraft serial numbers).

(4) Connect the Interconnect Fuel Line Receptacle connector to the

aircraft wiring plug (for UA and UB S/N’s) or connect the MAIN and

ZUX Harness disconnects to aircraft wiring plugs (UC and UE S/N’s

and 1900D)

(5) Return the aircraft to its original configuration.

Note: Repeat procedure to test the opposite side.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 11 of 44

3. SYSTEM CAPACITANCE TEST

A. Aircraft Preparation

B. Test Set Preparation

C. Connecting Test Set

Note: Refer to PRECAUTIONS and PRELIMINARY sections (Chapter 1).

(1) Disconnect aircraft battery.

Caution: When lowering or raising pilot fuel panel, insure aircraft

battery is disconnected.

(2) Access the indicator.

(3) Open the circuit breakers.

(4) Disconnect the aircraft wiring plug located at the indicator.

(1) Set the test set ON/OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to PROBE(S).

(3) Set the INSULATION/SYSTEM switch to SYSTEM.

(4) Set the MAIN/TOT-AUX/NAC switch to MAIN/TOT.

(5) Set the 200 (pF)/1000 (pF) switch to 200 (pF) if empty, or 1000 (pF) if

FULL.

(1) Connect the test set as shown in Figures 5 and 6.

Figure 5 System Capacitance Test Connector Setup

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 12 of 44

Figure 6 Figure System Capacitance Test Connector Setup

(2) Connect the test set ACFT connector to the aircraft wiring plug

removed that is from indicator.

(3) Do not connect the test set IND connector.

D. Test

(1) Set the test set ON/OFF switch to ON.

(2) If testing aircraft S/N’s UC or UE, set the aircraft fuel panel select

switch to MAIN or TOTAL.

(3) Push and hold the test set PRESS TO READ CAP (pF) pushbutton.

(4) Verify that the tanks’ value is within tolerances as specified in Table 2

(Tank Capacitance Empty) or Table 3 (Tank Capacitance Full).

Note: The following values are valid as of this publication’s release

date and provided as reference. Refer to the Aircraft

Maintenance Manual for actual test values.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 13 of 44

MAIN/TOTAL AUX/NAC

Aircraft Type Min Nom Max Min Nom Max

1900 (UA)

1900C (UB)

1900C (UC)

1900D (UE)

141.6 157.7 173.0 --- --- ---

156.3 159.3 162.2 63.1 64.1 65.1

Table 2 Tank Capacitance Empty

MAIN/TOTAL AUX/NAC

Aircraft Type Min Nom Max Min Nom Max

1900 (UA)

1900C (UB)

1900C (UC)

1900D (UE)

233.3 259.2 285.1 ---- ---- ----

292.6 295.6 298.6 114.2 115.2 116.2

Table 3 Tank Capacitance Full

(5) Release pushbutton.

(6) If testing serial numbers UC or UE, set the aircraft fuel panel select

switch to AUX.

(7) Push and hold the PRESS TO READ CAP (pF) pushbutton.

(8) Verify that the tanks’ value is within tolerances as specified in Table 2

(Empty) and Table 3 (Full).

Note: Ensure that capacitance is within specifications. If a test is

not within specification, perform the Capacitance Test for

Individual Probes (Section 4). When all faults are corrected,

restart this System Capacitance Test.

(9) Set the test set ON/OFF switch to OFF.

Note: If testing the opposite side, repeat procedure.

E. Disconnecting/Reconfiguring

(1) Disconnect the test set from the aircraft harness.

(2) Reconnect the aircraft wiring plug to the indicator.

(3) Reconnect the aircraft battery.

(4) Close the circuit breakers.

(5) Return the aircraft to its original configuration.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 14 of 44

4. CAPACITANCE TEST (INDIVIDUAL PROBES)

Note: Refer to PRECAUTIONS and PRELIMINARY sections (Chapter 1).

A. Aircraft Preparation

Caution: When breaking or making indicator connections, insure that the

applicable circuit breaker(s) are open.

(1) Access the Interconnect Fuel Line Receptacle, left or right, located

under the panel’s just outboard of the engine nacelles (if testing UA

or UB serial numbers) or, access the Main Harness disconnect and

Aux Harness disconnect (if testing the UC or UE serial numbers).

(2) Open the circuit breakers.

(3) Disconnect the aircraft connector at the Interconnect Fuel Line

Receptacle (if testing UA or UB serial numbers) or the Main Harness

disconnect and Aux Harness disconnect (if testing the UC or UE

serial number).

(4) If testing UC and UE serial numbers, connect P/N 118-389004/935

between the Aux harness disconnect and the Main harness

disconnect. If testing UA or UB serial numbers, connect probe

selector unit 114-389001/935 between the interconnect fuel line

receptacle and the connection in the fuel line.

B. Test Set Preparation

(1) Set the ON/OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to PROBE(S).

(3) Set the INSULATION/SYSTEM switch to SYSTEM.

(4) Set the MAIN/TOT-AUX/NAC switch to MAIN/TOT.

(5) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 15 of 44

C. Connecting Test Set

(1) Connect the T/S as shown in Figure 7 or Figure 8.

(2) Connect the appropriate Probe Selector Unit to the Interconnect Fuel

Line Receptacle connector (if testing 1900/1900C, UA and UB) or to

the Main Harness disconnect and Aux Harness disconnect (if testing

UC and UE).

(3) Connect the adapter cable to the Probe Selector Unit.

(4) Connect the T/S ACFT connector to the adapter cable. Do not

connect the T/S IND connector.

Figure 7 Capacitance Test 1900 / 1900C, UA and UB Individual Probes

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 16 of 44

Figure 8 Capacitance Test 1900C / 1900D, UC and UE Individual Probes

D. Test Procedure

(1) Rotate the Probe Selector Unit switch to ALL.

(2) Set the T/S switch to ON.

(3) Press and hold in the PRESS TO READ CAP (pF) pushbutton.

(4) Verify that the value shown is within tolerances specified in Table 4,

Table 5 (for empty tanks) or Table 6, or Table 7 (for full tanks).

(5) Release the pushbutton.

Note: The following values are valid as of this publication’s release

date and provided as reference. Refer to the Aircraft

Maintenance manual for actual test values.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 17 of 44

AIRCRAFT 1900/1900C, UA and UB

TANK UNIT BEECH PROBE P/N MIN NOM MAX

Integral Outboard 114-389001-29, -31 17.91 19.90 21.89

Integral Inboard 114-389001-25, -27 20.03 22.25 24.48

Integral Combined 114-389001-25, -27 or –29 and -31 37.94 42.15 46.37

Leading Edge

Outboard

Leading Edge Inboard 114-389001-9, -11 24.75 27.50 30.25

Box Section 114-389001-13, -15 15.89 17.66 19.43

Center Section

Outboard

Center Section

Inboard

Collector Tank 114-389001-17, -19 7.24 8.04 8.84

114-389001-1, -3 21.01 23.34 25.67

114-389001-5, -7 19.82 22.02 24.22

114-389001-21, -23 14.91 16.57 18.23

Table 4 Probe Capacitance Empty (in pF)

AIRCRAFT 1900C/1900D, UC and UE

TANK UNIT LOCATION

WING STATION

41.85 118-389004-41 (75-134-9) 36.6 37.1 37.6

79.65 118-389004-43 (75-134-10) 26.5 27.0 27.5

124.59 118-389004-45 (75-134-11) 6.7 7.2 7.7

135.86 118-389004-13 (75-134-4) 48.2 48.7 49.3

171.29 118-389004-47 (75-134-12) 23.6 24.1 24.6

194.85 118-389004-21 (75-134-6) 23.0 23.5 24.0

223.49 118-389004-25 (75-134-7) 28.6 29.1 29.6

276.01 118-389004-49 (75-134-13) 26.4 26.9 27.4

BEECH PROBE P/N (Ragen P/N) MIN NOM MAX

Table 5 Probe Capacitance Empty (in pF)

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 18 of 44

AIRCRAFT 1900/1900C, UA and UB

TANK UNIT BEECH PROBE P/N MIN NOM MAX

Integral Outboard 114-389001-29, -31 26.4 29.36 32.3

Integral Inboard 114-389001-25, -27 31.2 34.68 38.1

Integral Combined 114-389001-25, -27 or –29 and -31 57.6 64.04 70.4

Leading Edge

Outboard

Leading Edge

Inboard

Box Section 114-389001-13, -15 24.4 27.19 29.9

Center Section

Outboard

114-389001-1, -3 32.1 35.65 39.2

114-389001-9, -11 40.3 44.77 49.2

114-389001-5, -7 39.1 43.46 47.8

Center Section

Inboard

Collector Tank 114-389001-17, -19 10.5 11.71 12.9

114-389001-21, -23 29.1 32.35 35.6

Table 6 Probe Capacitance Full (in pF)

AIRCRAFT 1900C/1900D, UC and UE

TANK UNIT LOCATION

WING STATION

41.85 118-389004-41 (75-134-9) 66.0 66.5 67.0

79.65 118-389004-43 (75-134-10) 48.2 48.7 49.2

124.59 118-389004-45 (75-134-11) 13.8 14.3 14.8

135.86 118-389004-13 (75-134-4) 90.5 91.0 91.5

171.29 118-389004-47 (75-134-12) 42.2 42.7 43.2

194.85 118-389004-21 (75-134-6) 43.0 43.5 44.0

223.49 118-389004-25 (75-134-7) 52.6 53.1 53.6

276.01 118-389004-49 (75-134-13) 50.5 51.0 51.5

BEECH PROBE P/N (Ragen P/N) MIN NOM MAX

Table 7 Probe Capacitance Full (in pF)

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 19 of 44

(6) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

(7) Press and hold the PRESS TO READ CAP (pF) pushbutton.

(8) If testing 1900/1900C, UA and UB, rotate the Probe Selector Unit

switch until all probes are tested.

(9) If testing a/c serial numbers UC and UE, and using Probe Selector

Unit P/N 118-389004/935, set the ALL/EACH switch to EACH, the

MAIN/AUX switch to MAIN. Then, rotate the switch through the MAIN

probe positions to take readings. To read the AUX probes, set the

ALL/EACH switch to the ALL position, the MAIN/AUX switch to the

AUX and the BOTH/EACH switch to BOTH to take readings. If also

testing individual AUX probes, set the ALL/EACH switch to EACH, the

BOTH/EACH switch to EACH and rotate the switch through the two

AUX probe positions and take readings.

(10) Verify that the value shown for each probe is within the tolerances

specified in Table 4, or Table 5 (for empty tanks) or Table 6, or Table

7 (for full tanks).

Note: If any probe capacitance is out of specifications, refer to the

A/C Maintenance Manual for proper procedures.

(11) Set the T/S ON/OFF switch to OFF.

E. Disconnecting/Reconfiguring

(1) Disconnect the test set ACFT connector from the adapter cable.

(2) Disconnect the adapter cable from the Fuel Probe Selector Unit.

(3) If testing 1900/1900C, UA and UB serial numbers, disconnect the

Fuel Probe Selector Unit from the Interconnect Fuel Line Receptacle

connector. If testing serial numbers 1900C/1900D, UC and UE serial

numbers, disconnect the Fuel Probe Selector Unit from the Main and

Aux Harness.

(4) Connect the Interconnect Fuel Line receptacle connector to the

aircraft wiring plug (1900/1900C, UA and UB or connect the Main and

Aux Harness disconnect to the aircraft wiring plugs 1900C/1900D, UC

and UE).

(5) Return the aircraft to its original configuration.

Note: If testing the opposite side of the a/c, repeat and follow same

procedure.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 20 of 44

5. INDICATOR TEST

Note: Refer to PRECAUTIONS and PRELIMINARY sections (Chapter 1).

Note: The Indicator Bench Test (Chapter 3, Section 1) may be performed in place

of the Indicator Test.

A. Aircraft Preparation

(1) Disconnect the aircraft battery.

Caution: When lowering or raising the pilot fuel panel, insure aircraft

battery is disconnected.

(2) Access the indicator.

(3) Open the appropriate circuit breakers.

(4) Disconnect the aircraft wiring plug located at the indicator.

B. Test Set Preparation

(1) Set the ON/OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(3) Set the INSULATION/SYSTEM switch to SYSTEM.

(4) Set the MAIN/TOT-AUX/NAC switch to MAIN/TOT.

(5) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

C. Connecting Test Set

(1) Determine the number of pins on connector. Connect test set as

shown in Figure 9 or Figure 10 accordingly.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 21 of 44

Figure 9 Indicator Test Set Connection

Figure 10 Indicator Test Set Connection

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 22 of 44

D. Test Procedure

(1) Set the test set ON/OFF switch to ON.

(2) Set the CAP SIM (pF) 100’s to 1. Set the 10’s thumbwheels to 5 for

all 1900 models.

(3) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain a test set reading of

156.5 pF (for UA or UB) or a reading of 159.4 pF (for UC or UE)

(4) Rotate the TEST FUNCTION switch to IND AMP.

(5) Connect the aircraft battery.

(6) Close the circuit breakers.

(7) Turn the aircraft battery ON/OFF switch ON.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

gently tap adjacent panel or rear housing of indicator before

taking readings.

(8) Verify that the indicator reads zero lbs.

(9) If reading is not zero, adjust EMP 1/E 1 or E located at rear of the

indicator.

(10) If the indicator will not give a zero reading, replace the indicator.

(11) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(12) Set the 200 (pF)/1000 (pF) switch to 1000 (pF).

(13) Set the CAP SIM (pF) 100’s thumbwheel to 2. Set the 10’s

thumbwheel to 6 (UA or UB) or to 9 (UC or UE).

(14) Push and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain a test set reading of

260.9 pF (for UA or UB) or 295 pF (UC or UE).

(15) Release the pushbutton.

(16) Rotate the TEST FUNCTION switch to IND AMP.

(17) The indicator will read 1400 lbs (UA or UB) or 1600 lbs (UC or UE).

(18) If the indicator does not show 1400 (UA or UB) or 1600 (UC or UE),

adjust FULL adjustment located at rear of the indicator.

(19) If the indicator still does not give the appropriate reading, replace the

indicator.

Note: The following “Aux Empty Adjustment” is applicable for serial

numbers UC and UE only. For serial numbers UA or UB, skip

to step 31.

(20) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(21) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

(22) Set the CAP SIM (pF) 100’s thumbwheel to “-“. Set the 10’s

thumbwheel to 6.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 23 of 44

(23) Push and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knobs. Verify that the T/S displays

64.1 pF.

(24) Release pushbutton.

(25) Set the MAIN/TOT-AUX/NAC switch to AUX/NAC.

(26) Rotate TEST FUNCTION switch to IND AMP.

(27) Verify the indicator reads 0 lbs.

(28) If reading is not 0 lbs., adjust the indicator using the EMP 2/E 2

switch located at rear of indicator.

(29) If the indicator still does not read 0, replace the indicator.

(30) Repeat steps (1) thru (29) until an accurate gage adjustment is

obtained.

(31) Set the MAIN/TOT – AUX/NAC switch to MAIN/TOT.

(32) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(33) Set the 200 (pF)/1000 (pF) switch to 1000 (pF).

(34) Set the CAP SIM (pF) 100’s thumbwheel to 1 and the 10’s

thumbwheel to 7 (UA and UB). Set 100’s and 10’s thumbwheels to 1

and 8 (UC and UE).

(35) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain a test set reading

of 178.9 pF (UA and UB) or 185.0 pF (UC and UE).

(36) Rotate the TEST FUNCTION switch to IND AMP.

(37) Verify the indicator reads 300 ±35 lbs.

(38) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(39) Set the CAP SIM (pF) 100’s thumbwheel to “2”. Set the 10’s

thumbwheel to “0” (UA and UB) or to “1” (UC and UE).

(40) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain a test display of

201.2 pF (UA and UB) or 210.0 pF (UC and UE).

(41) Rotate the TEST FUNCTION switch to IND AMP.

(42) Verify the indicator reads 600 ±35 lbs.

(43) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(44) Set the CAP SIM (pF) 100’s thumbwheels to “2”. Set the 10’s

thumbwheel to “2” (UA and UB) or to “3” (UC and UE).

(45) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain a test set display of

223.6 pF (UA and UB) or 236.0 pF (UC and UE).

(46) Rotate the TEST FUNCTION switch to IND AMP.

(47) Verify the indicator reads 900 ±35 lbs.

(48) Rotate the TEST FUCTION switch to CAP SIM CAL (NORM SYS).

(49) Set the CAP SIM (pF) 100s thumbwheel to “2”. Set the 10s

thumbwheel to “4” for the UA and UB or “6” for the UC and UE serial

numbers.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 24 of 44

(50) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain a test set display of

246.0 pF for the UA and UB or 261.0 pF for the UC and UE serial

numbers.

(51) Rotate the TEST FUNCTION switch to IND AMP.

(52) Verify the indicator reads 1200 +/-35 lbs.

(53) Set the test set ON / OFF switch to OFF.

E. Disconnecting / Reconfiguring

(1) Open the circuit breakers.

(2) Disconnect the test set ACFT connector from aircraft wiring plug or

adapter cable.

(3) Disconnect the test set IND connector from the indicator or adapter

cable.

(4) Connect the aircraft wiring plug to the indicator.

(5) Return the aircraft to its original configuration.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 25 of 44

6. PREFERRED CALIBRATION TEST (WITH DRY TANKS)

Note: See PRECAUTIONS and PRELIMINARY sections (Chapter 1).

Note: When draining facilities are not readily available, the Alternate Calibration

Test (Chapter 3, Section 2) may be used as a temporary measure.

The preferred calibration is done with dry tanks. This method is the most

accurate for calibration since the indicator zero reading is set to the actual empty

tank condition. A capacitance value, applied to system by the test set, is

substituted for an equivalent quantity of fuel in the tanks. The indicator is

adjusted to read the substituted fuel quantity.

A. Aircraft Preparation

CAUTION: Refer to the Aircraft Maintenance Manual for proper

defueling and fueling procedures. Observe all safety

precautions.

(1) Ensure aircraft is defueled. Drain sumps.

(2) Disconnect the aircraft battery.

(3) Maintain the circuit breakers open.

(4) Access the indicator.

(5) Disconnect the aircraft wiring plug from the indicator.

B. Test Set Preparation

(1) Insure the test set ON/OFF switch is OFF.

(2) Rotate theTEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(3) Set the INSULATION/SYSTEM switch to SYSTEM.

(4) Set the MAIN/TOT-AUX/NAC switch to MAIN/TOT.

(5) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

(6) Set the CAP SIM (pF) 100’s thumbwheels to “1“. Set the 10’s to "0"

for the UA & UB serial numbers and "3" for the UC and UE serial

numbers.

C. Connecting Test Set

(1) Determine number of pins on indicator connector and connect test set

as shown in Figure 9 or Figure 10 accordingly.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 26 of 44

D. Test

(1) Set test set ON/OFF switch to ON.

(2) Press and hold PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain a test set reading

according to the following table.

Aircraft Add For Full Simulator (pF)

1900/1900C,

UA and UB

1900C/1900D,

UC and UE

Table 8 Add for Full

104.0

135.9

(3) Release the pushbutton.

(4) Connect the aircraft battery.

(5) Close the circuit breakers.

Caution: Do not tap bezel of instrument to vibrate. To remove

friction, gently tap adjacent panel or rear housing of

indicator before taking readings.

(6) Verify the indicator reads slightly below zero (approximately one

needle width).

(7) If pointer position is not acceptable, use the EMP 1/E 1 or E/EMP

adjustment on rear of indicator to obtain the correct pointer position.

(8) Rotate the TEST FUNCTION switch to ADD CAP.

(9) Verify the indicator reads 1400 lbs (UA and UB) or 1600 lbs (UC and

UE).

(10) If the indicator does not give the appropriate reading, use the F/FULL

adjustment located on the rear of the indicator to obtain correct

reading.

Note: AUX calibration is applicable only for 1900C/1900D (UC

and UE). If testing 1900/1900C (UA and UB) skip to step

(16).

(11) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(12) Set the aircraft fuel panel select switch to AUX/NAC and hold.

(13) Verify the indicator shows zero lbs

(14) If pointer position is not acceptable, use the EMP 2/E 2 adjustment

located at rear of the indicator to obtain a desirable pointer position.

(15) Repeat steps (2) thru (14) until an accurate calibration is obtained.

(16) Set the test set ON/OFF switch to OFF.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 27 of 44

E. Disconnecting or reconfiguring

(1) Open the circuit breakers.

(2) Disconnect the test set ACFT connector from aircraft wiring plug or

the adapter cable.

(3) Disconnect the test set IND connector from the indicator or adapter

cable.

(4) Disconnect the adapter cable from the aircraft wiring and indicator.

(5) Connect the aircraft plug to indicator.

(6) Return the aircraft to original configuration.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 28 of 44

7. SYSTEM WIRING INTEGRITY TEST

Note: Refer to PRECAUTIONS and PRELIMINARY sections (Chapter 1).

Note: Insure that the Insulation, Capacitance, Indicator test and Preferred

Calibration have all been accomplished with satisfactory results and that the

tanks are still dry prior to attempting this test.

This test is used to determine whether there exists an inline (series) resistance

problem in the aircraft wiring. It will be accomplished by a comparison of the aircraft

empty probes capacitance versus a simulated capacitance from the Test Set to

drive the cockpit indicator to the same point. No adjustment of the Indicator should

be made during this test or based on the outcome of this test. If repairs are made to

the harness following this test, then the Preferred Calibration must be repeated and

subsequently this integrity test.

A. Aircraft Preparation

(1) Disconnect aircraft battery.

Caution: When lowering or raising the fuel panel, ensure aircraft battery

is disconnected.

(2) Access the indicator.

(3) Open the circuit breakers.

(4) Disconnect the aircraft wiring plug located at the indicator.

B. Test Set Preparation

(1) Set the test set ON / OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to PROBE(S).

(3) Set the INSULATION / SYSTEM switch to SYSTEM.

(4) Set the MAIN / TOT-AUX / NAC switch to MAIN / TOT.

(5) Set the 200 (pF)

/ 1000 (pF) switch to 200 (pF).

C. Connecting Test Set

(1) Connect the test set as shown in either Figure 3 or 4. Figure 3

depicts using Adapter Cable 101-00831 for conversion to systems

with circular style connectors.

(2) Connect the test set ACFT connector to the aircraft wiring plug

removed from indicator.

(3) Do not connect the test set IND connector.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 29 of 44

D. Test

(1) Set the test set ON / OFF switch to ON.

(2) Set the aircraft fuel panel select switch to MAIN or TOTAL.

(3) Push and hold the test set PRESS TO READ CAP (pF) pushbutton.

(4) Record the capacitance value measured.

(5) Release the pushbutton.

(6) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(7) Set the CAP SIM (pF) 100’s and the 10’s thumbwheels to the closest

approximation of the recorded value of step 4.

(8) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain the recorded value

of step 4.

(9) Set the test set ON

(10) Connect the test set to the Indicator as shown in either Figure 5 or 6.

Figure 5 depicts using Adapter Cable 101-00831 for conversion to

systems with circular style connectors.

(11) Connect the aircraft battery if not already connected.

(12) Close the circuit breakers.

(13) Turn the aircraft battery ON

(14) Set the test set ON / OFF switch to ON.

/ OFF switch to OFF.

/ OFF switch ON.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

gently tap adjacent panel or rear housing of indicator before

taking readings.

(15) Verify the indicator reads slightly below zero (approximately one

needle width).

(16) Rotate the TEST FUNCTION switch to IND AMP.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

gently tap adjacent panel or rear housing of indicator before

taking readings.

(17) Verify the indicator reads the same as in step 15 within one needle

width.

Note: Failure to obtain the correct indication may indicate the

possibility of in-line resistance in the aircraft wiring between

the Indicator and the probes. If this condition is found to

exist, disconnect and clean the wing harness connector with

contact cleaner and gently blow dry. If the condition persists

disconnect and clean the fuel panel connector behind the LH

sidewall below the fuel panel in the same manner. When

cleaning the connectors be sure to include the test sets

connectors.

(18) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 30 of 44

(19) Set the CAP SIM (pF) 100’s and the 10’s thumbwheels to the closest

approximation of the required value as per Table 4.

(20) Press and hold PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain a test set reading

according to Table.4.

(21) Release the pushbutton.

(22) Rotate the TEST FUNCTION switch to ADD CAP.

(23) Verify the indicator reads 1400 lbs. for the UA & UB serial numbers

and 1600 lbs. for the UC and UD serial numbers.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

gently tap adjacent panel or rear housing of indicator before

taking readings.

(24) Record the exact indicator reading.

(25) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(26) Set the CAP SIM (pF) 100’s and the 10’s thumbwheels to the closest

approximation of the sum of aircraft capacitance from step 4 and

value used from Table 4.

(27) Press and hold PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain the summed value.

(28) Release the pushbutton.

(29) Rotate the TEST FUNCTION switch to IND AMP.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

gently tap adjacent panel or rear housing of indicator before

taking readings.

(30) Verify the indicator reads the same as in step 24 ± 40 lbs.

Note: Failure to obtain the correct indication may indicate the

possibility of in-line resistance in the aircraft wiring between

the Indicator and the probes. If this condition is found to

exist, disconnect and clean the wing harness connector with

contact cleaner and gently blow dry. If the condition persists

disconnect and clean the fuel panel connector behind the LH

sidewall below the fuel panel in the same manner. When

cleaning the connectors be sure to include the test sets

connectors.

(31) Set the test set ON / OFF switch to OFF.

(32) For 1900 / 1900C (UA and UB) proceed to step E.(1) to disconnect

the test equipment.

(33) Turn the aircraft battery ON / OFF switch OFF.

(34) Open the circuit breakers.

(35) Disconnect the aircraft battery if previously connected.

(36) Connect the test set as shown in either Figure 3 or 4 as applicable.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 31 of 44

Note: The battery must be connected; the battery switch set to ON

position and the circuit breakers closed for this test.

(37) Rotate the TEST FUNCTION switch to PROBE(S).

(38) Set the test set ON / OFF switch to ON.

(39) Set the aircraft fuel panel select switch to AUX / NAC and hold if

applicable.

(40) Push and hold the test set PRESS TO READ CAP (pF) pushbutton.

(41) Record the capacitance value measured.

(42) Release the pushbutton.

(43) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(44) Set the CAP SIM (pF) 100’s and the 10’s thumbwheels to the closest

approximation of the recorded value of step 40.

(45) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain the recorded value

of step 40.

(46) Set the test set ON / OFF switch to OFF.

(47) Turn the aircraft battery ON / OFF switch to OFF if applicable.

(48) Disconnect the aircraft battery if previously connected.

(49) Connect the test set to the Indicator as shown in either Figure 5 or 6

as applicable.

(50) Reconnect the aircraft battery.

(51) Close the circuit breakers.

(52) Turn the aircraft battery ON / OFF switch ON.

(53) Set the test set ON / OFF switch to ON.

(54) Set the aircraft fuel panel select switch to AUX / NAC and hold, if

applicable.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

(55) Verify the indicator reads zero pounds.

(56) Rotate the TEST FUNCTION switch to IND AMP.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

(57) Verify the indicator reads the same as in step 55 within one needle

width.

Note: Failure to obtain the correct indication may indicate the

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 32 of 44

gently tap adjacent panel or rear housing of indicator before

taking readings.

gently tap adjacent panel or rear housing of indicator before

taking readings.

possibility of in-line resistance in the aircraft wiring between

the Indicator and the probes. If this condition is found to

exist, disconnect and clean the wing harness connector with

contact cleaner and gently blow dry. If the condition persists

disconnect and clean the fuel panel connector behind the LH

sidewall below the fuel panel in the same manner. When

cleaning the connectors be sure to include the test sets

connectors.

(58) Set the test set ON / OFF switch to OFF.

E. Disconnecting or reconfiguring

(1) Open the circuit breakers.

Caution: When lowering or raising the fuel panel, ensure aircraft battery

switch is OFF and this battery is disconnected.

(2) Disconnect the test set ACFT connector from aircraft wiring plug or

the adapter cable.

(3) Disconnect the test set IND connector from the indicator or adapter

cable.

(4) Disconnect the adapter cable from the aircraft wiring and indicator.

(5) Connect the aircraft plug to indicator.

(6) Return the aircraft to original configuration.

61-101-00802.EF2 (REV. G) CH. 2

January 7, 2015 Page 33 of 44

CHAPTER 3 ALTERNATE TESTS

1. PROBES BENCH TEST

Note: See PRECAUTIONS and PRELIMINARY sections (Chapter 1).

A. Test Set Preparation

(1) Set the test set ON/OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to PROBE(S).

(3) Set the INSULATION/SYSTEM switch to SYSTEM.

(4) Set the MAIN/TOT-AUX/NAC switch to MAIN/TOT.

(5) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

B. Connecting Test Set

(1) Refer to Figure 11 and connect the test set to the probe as shown.

(2) Connect the Beech probe adapter, P/N 101-00829 or 101-00814, to

the test set PROBES receptacle as shown in the Figure 11.

(3) If necessary, use the Beech made alligator clip adapters (UA and UB)

or adapter pins (UC and UE) to attach P/N 101-00829 harness to the

probes as shown in Figure 12.

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 34 of 44

Figure 11 Bench Probe Interface

(4) Determine the P/N and physical makeup of the probe-under-test.

(5) Connect the color-coded pin sockets from the probe adapter to the

matching color of the probe lead wire pins or the alligator clips or

probe threaded terminals by thread size and color as applicable.

(6) Connect the socket pin ground lead of the probe adapter to the

ground clip pigtail of the probe adapter. Attach the ground clip to the

grounding area on the probe.

ALL 1900/1900C/1900D

PROBES

C. Test

(1) Set the test set switch to ON.

(2) Press the PRESS TO READ CAP (pF) pushbutton to display probe

capacitance.

(3) Verify probe capacitance is within the tolerance referenced in Table 4

through Table 7.

(4) If value is not within tolerance, reject probe.

(5) Set the test set ON/OFF switch to OFF.

(6) Rotate the TEST FUNCTION switch to IND AMP.

(7) Set the INSULATION/SYSTEM switch to INSULATION.

(8) Disconnect the pin socket ground lead of the probe adapter from the

ground clip pigtail. Disconnect the small black wire from the ground

clip.

(9) Rotate the INS TEST POINT switch to LO-Z GND.

(10) Set the ON/OFF switch to ON.

(11) Allow time for test set display to stabilize.

(12) Verify the test set display shows less than 50nS. (Refer to Table 1.)

(13) Rotate the INS TEST POINT switch to each remaining position

except SIG/RTN and verify each time that the test set display shows

less than 50nS.

Figure 12 Probes Bench Test

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 35 of 44

(14) With the INS TEST POINT switch at SIG/RTN position, verify the test

set display shows a value between 1500 and an “over range” of 1.

Note: If testing the 1900/1900C, UA and UB, an over range also

appears when the INS TEST POINT switch is in LO-Z/RTN

position and P/N 114-389001-17 Probe (Gull Airborne) is

installed in the collector tank.

(15) Verify conductance is within specifications. If test results are outside

limits, repeat test.

(16) Set ON/OFF switch to OFF.

(17) Disconnect Probe adapter from Probe.

(18) Disconnect Probe adapter from T/S.

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 36 of 44

2. INDICATOR BENCH TEST

Note: See PRECAUTIONS and PRELIMINARY sections (Chapter 1).

Note: Failure to calibrate the system after performing the indicator bench test will

result in an inaccurate fuel quantity reading.

A. Test Set Preparation

(1) Set the ON/OFF switch to OFF.

(2) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(3) Set the INSULATION/SYSTEM switch to SYSTEM.

(4) Set the MAIN/TOT-AUX/NAC switch to MAIN/TOT.

B. Connecting Test Set

(5) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

(1) Determine the number of pins on the connector and connect the test

set as shown in Figure 13 or Figure 14.

(2) Connect the 28 VDC power supply to the test set AUX POWER jacks.

Observe polarity.

Figure 13 Indicator Bench Test Connection

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 37 of 44

Figure 14 Indicator Bench Test Connection

C. Test Procedure

(1) Set the test set ON/OFF switch to ON.

(2) Set the CAP SIM (pF) 100’s to 1. Set the 10’s thumbwheels to 5 for

all 1900 models.

(3) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain a test set reading of

156.5 pF (for UA and UB serial numbers) or 159.4 (for UC and UE

serial numbers).

(4) Release the pushbutton.

(5) Rotate the TEST FUNCTION switch to IND AMP.

(6) Set the 28 VDC power supply ON/OFF switch to ON.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

gently tap adjacent panel or rear housing of indicator before

taking readings.

(7) Verify the indicator reads zero lbs.

(8) If reading is not zero, adjust EMP 1/E 1 or E located at rear of

indicator.

(9) If the indicator will not give a zero reading, replace the indicator.

(10) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 38 of 44

(11) Set the 200 (pF)/1000 (pF) switch to 1000 (pF).

(12) Set the CAP SIM (pF) 100’s thumbwheel to 2. Set the 10’s

thumbwheel to “5” (for S/N’s UA and UB); set to 9 (for UC and UE

S/N’s).

(13) Push and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain a test set reading of

260.9 pF (for S/N’s UA and UB); 295 pF (for UC and UE S/N’s).

(14) Release the pushbutton.

(15) Rotate the TEST FUNCTION switch to IND AMP.

(16) Verify the indicator reads 1400 lbs. (for UA and UB S/N's) or 1600

lbs. (for UC and UE S/N's).

(17) If the indicator does not show 1400 lbs (for UA & UB S/N’s) or 1600

lbs (for UC and UE S/N’s), adjust the F/FULL located at rear of

indicator.

(18) If the indicator still does give the appropriate reading, replace the

indicator.

Note: AUX calibration is applicable only for 1900C/1900D, UC

and UE. If testing 1900/1900C, UA and UB, skip to step (30).

(19) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(20) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

(21) Set the CAP SIM (pF) 100’s thumbwheel to “- “. Set the 10’s

thumbwheel to 6.

(22) Push the PRESS TO READ CAP (pF) pushbutton and hold while

adjusting the CAP SIM (pF) control knob to obtain a test set display

reading of 64.1pF.

(23) Release the pushbutton.

(24) Set the MAIN/TOT-AUX/NAC switch to AUX/NAC.

(25) Rotate the TEST FUNCTION switch to IND AMP.

(26) Verify that the indicator reads 0 lbs.

(27) If the reading is not 0 lbs., adjust the indicator using the EMP 2/E 2

switch located at rear of the indicator.

(28) If the indicator still does not read 0, replace the indicator.

(29) Repeat steps (1) thru (28) until an accurate gage adjustment is

obtained.

(30) Set the MAIN/TOT – AUX/NAC switch to MAIN/TOT.

(31) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(32) Set the 200 (pF)/1000 (pF) switch to 1000 (pF).

(33) Set the CAP SIM (pF) 100’s thumbwheel to 1 for all 1900 models. Set

the 10’s thumbwheel to 7 (UA and UB) or 8 (UC and UE).

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 39 of 44

(34) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain a test set reading

of 178.9 pF (UA and UB) or 185.0 pF (UC and UE).

(35) Release pushbutton.

(36) Rotate the TEST FUNCTION switch to IND AMP.

(37) Verify the indicator reads 300 ±35 lbs.

(38) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(39) Set the CAP SIM (pF) 100’s thumbwheel to 2 for all 1900 models.

Set the 10’s thumbwheel to 0 (UA and UB) or to 1 (UC and UE).

(40) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain a test display of

201.2 pF (UA and UB) or 210.0 pF (UC and UE).

(41) Release the pushbutton.

(42) Rotate the TEST FUNCTION switch to IND AMP.

(43) Verify the indicator reads 600 ±35 lbs.

(44) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(45) Set the CAP SIM (pF) 100’s thumbwheels to 2. Set 10’s thumbwheel

to 2 (UA and UB), or to 3 (UC and UE).

(46) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain a test set display of

223.6 pF (UA and UB), or 236.0 pF (UC and UE).

(47) Release the pushbutton.

(48) Rotate the TEST FUNCTION switch to IND AMP.

(49) Verify the indicator reads 900 ±35 lbs.

(50) Rotate the TEST FUCTION switch to CAP SIM CAL (NORM SYS).

(51) Set the CAP SIM (pF) 100s thumbwheel to “2”. Set the 10s

thumbwheel to “4” for the UA and UB or “6” for the UC and UE serial

numbers.

(52) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain a test set display of

246.0 pF for the UA and UB or 261.0 pF for the UC and UE serial

numbers.

(53) Rotate the TEST FUNCTION switch to IND AMP.

(54) Verify the indicator reads 1200 +/-35 lbs.

(55) Set the 28 VDC power supply to OFF.

(56) Set the test set ON / OFF switch to OFF.

D. Disconnecting/Reconfiguring

(1) Disconnect the 28 VDC power supply.

(2) Disconnect the test set IND connector from the indicator or adapter

cable.

(3) If using a 15 pin connector, disconnect the adapter cable from the

indicator.

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 40 of 44

3. ALTERNATE CALIBRATION (WET TANKS)

Note: The Alternate Calibration should only be used as a temporary measure

when draining the facilities is not available. Recalibrate the aircraft using

the Preferred Calibration method at the first opportunity.

The Alternate Calibration applies the nominal empty tank capacitance value to

the system by test set for the indicator zero reading. A second capacitance

value, (equal to the combined value of nominal empty tank plus the equivalent

quantity of fuel in the tanks), is applied to the system. The indicator is then

adjusted to show the substituted fuel quantity.

Note: Measurements close to the Preferred Calibration, may be obtained if the

measured dry capacitance for specific serial number aircraft is known and

used instead of EMPTY values referenced in Table 2 (Tank Capacitance

Empty). The ADD FOR FULL values listed in Table 4 should be added to

the known values to obtain the CAP SIM value for FULL.

A. Aircraft Preparation

Note: See PRECAUTIONS and PRELIMINARY sections (Chapter 1).

(1) Insure the aircraft battery is disconnected.

Caution: When lowering or raising the pilot fuel panel, insure that the

aircraft battery is disconnected. Observe all safety

precautions.

(2) Access the indicator.

(3) Insure the circuit breakers are open.

(4) Insure the aircraft wiring plug at Indicator is disconnected.

B. Test Set Preparation

(1) Insure the test set switch is OFF.

(2) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(3) Set the INSULATION/SYSTEM switch to SYSTEM.

(4) Set the MAIN/TOT-AUX/NAC switch to MAIN/TOT.

(5) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

C. Connecting the Test Set

(1) Determine the number of pins on the indicator connector and connect

the test set as shown in Figure 15 or Figure 16 accordingly.

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 41 of 44

Figure 15 Alternate Calibration Test Set Setup

Figure 16 Alternate Calibration Test Set Setup

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 42 of 44

D. Test

(1) Set the test set ON/OFF switch to ON.

(2) Set the CAP SIM (pF) 100’s and the 10’s thumbwheels to the digits

necessary to adjust the test set display to a MAIN/TOTAL nominal

value listed in Table 2 for the aircraft-under-test.

(3) Press and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain a test set reading

MAIN/TOTAL Nom (nominal) value reading for the aircraft referenced

in Table 2.

(4) Close the circuit breakers.

(5) Connect the aircraft battery and turn the battery switch to ON.

(6) Rotate the TEST FUNCTION switch to IND AMP.

Caution: Do not tap bezel of instrument to vibrate. To remove friction,

(7) Verify the aircraft indicator shows a reading slightly below zero

(approximately one needle width).

(8) If pointer position is not acceptable, adjust EMP 1/E 1 or E/EMP

adjustment on rear of indicator for the pointer position.

(9) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(10) Set the 200 (pF)/1000 (pF) switch to 1000 (pF).

(11) Set the CAP SIM (pF) 100’s and the 10’s thumbwheels to the digits

required to adjust the test set display to a MAIN/TOTAL nominal

value referenced in Table 3.

(12) Push and hold the PRESS TO READ CAP (pF) pushbutton while

adjusting the CAP SIM (pF) control knob to obtain the test set reading

for the aircraft listed in Table 3.

(13) Release the pushbutton.

(14) Rotate the TEST FUNCTION switch to IND AMP.

(15) Verify the indicator reads 1400 lbs (for serial numbers UA and UB) or

1600 lbs (for UC and UE).

(16) If the indicator does not give the appropriate reading, adjust the

F/FULL at the rear of indicator to obtain the value.

Note: AUX calibration is applicable only for 1900C/1900D (SN’s UC

(17) Rotate the TEST FUNCTION switch to CAP SIM CAL (NORM SYS).

(18) Set the 200 (pF)/1000 (pF) switch to 200 (pF).

(19) Set the MAIN/TOT – AUX/NAC switch to AUX/NAC.

gently tap adjacent panel or rear housing of indicator

before taking readings.

and UE). If testing UA and UB, skip to step (26).

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 43 of 44

(20) Set the CAP SIM (pF) 100’s and the 10’s to the digits required to

adjust the test set display to an AUX/NAC nominal value referenced

in Table 2.

(21) Press and hold PRESS TO READ CAP (pF) pushbutton while

adjusting CAP SIM (pF) control knob to obtain the test set AUX/NAC

nominal value reading for the aircraft listed in Table 2.

(22) Release the pushbutton.

(23) Rotate the TEST FUNCTION switch to IND AMP.

(24) Verify the indicator shows zero lbs.

(25) If indicator reading is not acceptable, use the EMP 2/E 2 adjustment

(located at the rear of the indicator) to obtain the correct reading.

(26) Repeat steps (2) through (25) until an accurate calibration is

obtained.

(27) Set the test set switch to OFF.

E. Disconnecting or Reconfiguring

(1) Open the circuit breakers.

(2) Disconnect the test set ACFT connector from the aircraft wiring plug

or adapter cable;

(3) Disconnect the test set IND connector from the indicator or adapter

cable.

(4) If applicable, disconnect the adapter cable from the aircraft wiring.

(5) Connect the aircraft wiring plug to the indicator.

(6) Return the aircraft to its original configuration.

61-101-00802.EF2 (REV. G) CH. 3

January 7, 2015 Page 44 of 44

Loading...

Loading...