Bardac OPTIDRIVE PLUS 3GV Sales Brochure

(

)

OPTIDRIVE PLUS 3

GV

3rd Generation Vector Control

AC Variable Speed Drive 0.37-160kW

Optidrive Plus 3GV is the natural evolution of the

Optidrive family adding ultimate motor control to

established Optidrive benchmarks of control and

ease of use.

Optidrive Plus 3

revolutionary and patented motor control strategy.

GV

3

technology delivers 100% torque at 0.0Hz

allowing this unique open loop product to be used

without any feedback device in many traditional

closed loop applications.

Only the motor name plate data is required to

achieve optimum performance, the drive

continuously and automatically determines and

tracks the key motor characteristics required for

vector control.

Optidrive Plus 3

unique Optiwand CE Plus software designed for

use on pocket pc’s. Communication takes place

without wires using infrared light to quickly and

accurately transfer data.

GV

uses 3GV technology, a

GV

can be commissioned using the

Key Benefits

x True evolution of range, maintaining same

footprint and connector arrangement as original

x Fast and accurate parameter configuration using

unique Optiwand CE Plus and Optistore Plus

x Small mechanical envelope

x Rugged industrial operation 50

x Simple mechanical & electrical installation

x Simple operation, powerful features & easy to use

x Fast setup, 14 basic parameters

x Real time motor current, motor speed and kW

indication

x Debugging using troubleshooting & P0

x 150% overload for 60 secs (175% for 2 secs)

x Keypad control

x Spin start

x 100% torque at 0.0Hz (no encoder)

x Built in PID controller for feedback control systems

x Speed regulation <1%

x Torque control

x Dual high speed serial communication interfaces

- Optical (IrDA) interface for commissioning and

low bandwidth control systems (115kbps)

- RS485/ Modbus RTU interface for high

bandwidth control

Page 2

9k6 to 115kbps

o

C ambient rating

Key Physical Features

x Pluggable control terminals

x Easy access key slots for simple installation

x Easy access contactor style power terminals for

intuitive easy wiring

x Help card for basic parameter description and terminal

layout

x Easy to use keypad with bright LED display

x IP20

x Integral rfi filter

x Integral braking transistor (not size 1)

x 3 phase line choke (size 4, 5 & 6)

Key Control I/O Features

x Programmable I/O for flexible control

x 12 bit bipolar analogue input, 8ms sample time

nd

x 2

x Positive logic digital inputs (active high), 8ms sampling

x 24V/ 100mA user supply output

x 0..10V & 4..20mA analog output, 8ms update

x Galvanically isolated and short circuit proof

analogue input for PID feedback control systems

Key Programming Features

x Silent motor running with 32kHz ultra-quiet switching

x 8 preset speeds

x Mains dip ride through

x Skip frequency

x Last 4 trips stored

x 2kHz output frequency

x Parameter lock

x Hours run & kWh meters

x Speed scaling factor for master- slave arrangements

nd

x 2

x Display scaling to show real values ie “bottles/ hour”

deceleration ramp for rapid stop

A Revolution Evolution –

st

21

Century Motor Control

Optidrive Plus 3GV’s revolutionary and patented 3

(3rd Generation Vector) vector control strategy

provides smooth, controlled full torque through zero

speed in open loop mode, without the need for motor

tacho-generators or encoders.

GV

The 3

drive for applications across the industrial spectrum.

Fast

and industrial washers. Powerful

starting torque applications like crushers and fully

loaded conveyors. Smooth

cranes.

Only motor nameplate details are required to achieve

optimum performance. Optidrive Plus 3

automatically performs an automatic tuning routine

measuring vital motor inductances, resistances,

currents and power factor with the motor at standstill.

After the initial tuning, these values are constantly

adapted in real time to ensure that performance is

maintained irrespective of changes arising out of

motor heating.

Non linearities are further corrected using highly

sophisticated measurement and compensation

techniques to give a very high quality sine wave

output. This results in smooth operation from zero up

to 2kHz

making this range of products ideal for high speed

applications such as machine tool spindles.

ultrafast torque control ensures it is the ideal

enough for pulse loads like jogging machines

enough for high

enough for hoists and

GV

output frequency, without discontinuity and

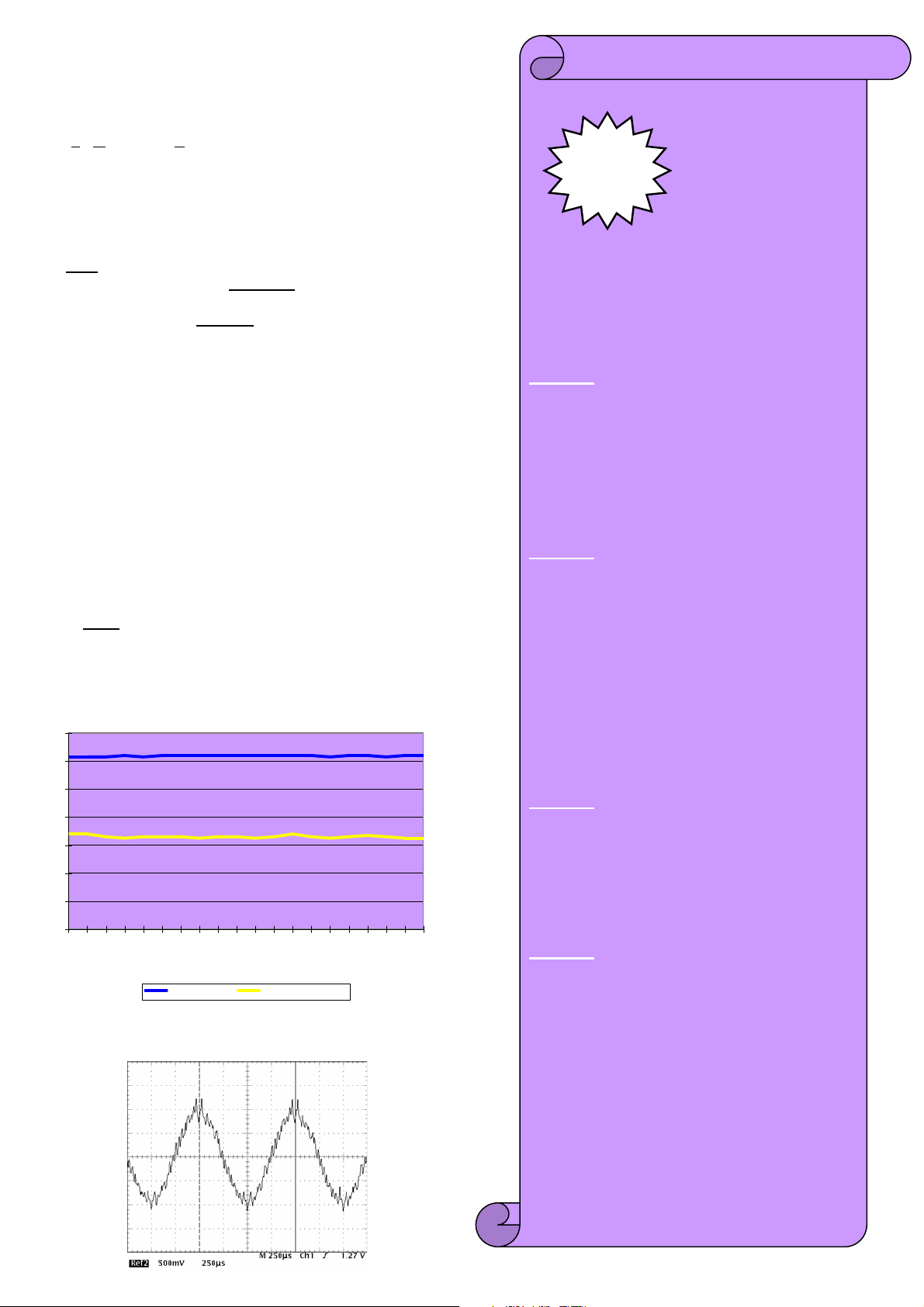

Torque vs Motor Frequency (Log Scale)

Showing Full Torque Across The Speed Range

GV

st

1

4 easy steps to

Incredible Performance

Step 1

Connect motor to drive (check

star/ delta connection) & apply

power to drive

Step 2

Input motor data from motor

name plate:

P1-07 motor rated voltage

P1-08 motor rated current

P1-09 motor rated frequency

Torque/ Current

0

1

2

3

5

8

15

25

35

Motor Frequency (Log Scale)/ Hz

Torque / Nm Motor Current /A

Ultra-smooth high frequency current waveform, ideal

for machine tool spindle applications

45

Step 3

Change mode to 3GV,

P4-01 = 0

Step 4

Autotune, P4-02 = 1

……drive performs a static

automatic tuning routine, after

which motor performance is

optimised for dynamic response,

energy saving and maximum

torque

Page 3

Loading...

Loading...