Optidrive Plus 3

AC Variable Speed Drive

0.37 – 160kW (0.5 – 250HP)

User Guide

GV

Installation and Operating Instructions

Optidrive Plus 3GV User Guide

EN 61800-5-1: 2003

Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

EN 61800-3 2nd Ed: 2004

Adjustable speed electrical power drive systems. EMC requirements and specific test methods

EN 55011: 2007

Limits and Methods of measurement of radio disturbance characteristics of industrial, scientific and

medical (ISM) radio-frequency equipment (EMC)

EN60529 : 1992

Specifications for degrees of protection provided by enclosures

Drive Type / Rating

EMC Category

Cat C1

Cat C2

Cat C3

1 Phase, 230 Volt

Input

ODP-x2xxx

No additional filtering required

Use shielded motor cable

3 Phase, 400 Volt

Input

ODP-x4xxx

Use External Filter OD-Fx34x

No additional filtering required

Use screened motor cable

Note

For motor cable lengths greater than 100m, an output dv / dt filter must be used (part number OD-OUTFx, please refer to the

Invertek Stock Drives Catalogue for further details)

For Frame Size 5 and 6 drives, a ferrite ring must be installed on the output motor cable, with all three phases of the motor cable

being wrapped one turn around the ferrite ring.

Vector Speed and Torque control modes may not operate correctly with long motor cables and output filters. It is recommended to

operate in V/F mode only for cable lengths exceeding 50m

Declaration of Conformity:

Invertek Drives Ltd hereby states that the Optidrive Plus 3GV product range conforms to the relevant safety provisions of the Low Voltage

Directive 2006/95/EC and the EMC Directive 2004/108/EC and has been designed and manufactured in accordance with the following

harmonised European standards:

Electromagnetic Compatibility

All Optidrives are designed with high standards of EMC compliance in mind. All versions suitable for operation on Single Phase 230 volt and

Three Phase 400 volt supplies and intended for use within the European Union are fitted with an internal EMC filter. This EMC filter is designed

to reduce the conducted emissions back into the supply via the power cables for compliance with harmonised European standards.

It is the responsibility of the installer to ensure that the equipment or system into which the product is incorporated complies with the EMC

legislation of the country of use. Within the European Union, equipment into which this product is incorporated must comply with the EMC

Directive 2004/108/EC. When using an Optidrive with an internal or optional external filter, compliance with the following EMC Categories, as

defined by EN61800-3:2004 can be achieved:

All rights reserved. No part of this User Guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including photocopying, recording or by any information storage or retrieval system without permission in writing from the publisher.

Copyright Invertek Drives Ltd © 2007

All Invertek Optidrive Plus 3GV units carry a 2 year warranty against manufacturing defects from the date of manufacture. The manufacturer

accepts no liability for any damage caused during or resulting from transport, receipt of delivery, installation or commissioning. The

manufacturer also accepts no liability for damage or consequences resulting from inappropriate, negligent or incorrect installation, incorrect

adjustment of the operating parameters of the drive, incorrect matching of the drive to the motor, incorrect installation, unacceptable dust,

moisture, corrosive substances, excessive vibration or ambient temperatures outside of the design specification.

The local distributor may offer different terms and conditions at their discretion, and in all cases concerning warranty, the local distributor

should be contacted first.

The contents of this User Guide are believed to be correct at the time of printing. In the interest of a commitment to a policy of continuous

improvement, the manufacturer reserves the right to change the specification of the product or its performance or the contents of the User

Guide without notice.

This User Guide is for use with V3.10 Firmware.

User Guide Issue 3.11 10/09

Invertek Drives Ltd adopts a policy of continuous improvement and whilst every effort has been made to provide accurate and up to date

information, the information contained in this User Guide should be used for guidance purposes only and does not form the part of any

contract.

2 www.invertek.co.uk

Optidrive Plus 3GV User Guide

1. INTRODUCTION .............................................................................................................................................. 4

1.1. Important safety information ....................................................................................................... 4

2. GENERAL INFORMATION AND RATINGS ........................................................................................................... 5

2.1. Drive model numbers ................................................................................................................... 5

3. MECHANICAL INSTALLATION ........................................................................................................................... 6

3.1. Mechanical dimensions and mounting ......................................................................................... 6

3.2. General .......................................................................................................................................... 8

3.3. Enclosure mounting ...................................................................................................................... 8

4. POWER AND CONTROL CONNECTIONS ............................................................................................................ 9

4.1. Grounding the Drive ...................................................................................................................... 9

4.2. Wiring Precautions ........................................................................................................................ 9

4.3. Mains Power Supply ...................................................................................................................... 9

4.4. Connection Diagram ................................................................................................................... 10

4.5. Motor connections ...................................................................................................................... 10

4.6. Motor Terminal Box Connections ............................................................................................... 10

4.7. Control terminal connections ..................................................................................................... 11

5. OPERATION .................................................................................................................................................. 12

5.1. Managing the keypad ................................................................................................................. 12

5.2. Changing Parameters .................................................................................................................. 12

5.3. Advanced Keypad Operation Short Cuts ..................................................................................... 13

5.4. Reset All Parameters to Factory Default Settings ....................................................................... 14

5.5. Terminal Control ......................................................................................................................... 14

5.6. Keypad Control............................................................................................................................ 14

5.7. Motor Autotuning ....................................................................................................................... 15

5.8. Operating in Sensorless Vector Speed Control Mode ................................................................. 15

5.9. Sensorless Vector Torque Control Mode .................................................................................... 15

5.10. Operation of Three Phase drives on Single Phase Supplies ........................................................ 15

6. PARAMETERS ................................................................................................................................................ 16

6.1. Parameter Group 1 – Basic Parameters ...................................................................................... 16

6.2. Parameter Group 2 - Extended parameters ................................................................................ 17

6.3. Parameter Group 3 – PID Control ............................................................................................... 20

6.4. Parameter Group 4 – High Performance Motor Control ............................................................ 20

6.5. Parameter Group 0 – Monitoring Parameters (Read Only) ........................................................ 21

7. ANALOG AND DIGITAL INPUT CONFIGURATIONS ........................................................................................... 22

7.1. Terminal mode (P1-12 =0) .......................................................................................................... 22

7.2. Keypad mode (P1-12 = 1 or 2)..................................................................................................... 23

7.3. User PI control mode (P1-12 = 3) ................................................................................................ 24

7.4. Modbus Control Mode (P1-12=4) ............................................................................................... 25

8. TROUBLESHOOTING ...................................................................................................................................... 26

8.1. Fault messages ............................................................................................................................ 26

9. TECHNICAL DATA .......................................................................................................................................... 27

9.1. Environmental ............................................................................................................................. 27

9.2. Rating tables ............................................................................................................................... 27

9.3. Maximum supply ratings for UL compliance:.............................................................................. 30

9.4. Recommended Maintenance ...................................................................................................... 30

10. MODBUS COMMUNICATIONS ....................................................................................................................... 31

10.1. Introduction ................................................................................................................................ 31

10.2. Modbus RTU Specification .......................................................................................................... 31

10.3. RJ11 Connector Configuration .................................................................................................... 31

10.4. Modbus Telegram Structure ....................................................................................................... 31

10.5. Modbus Register Map ................................................................................................................. 32

11. IP55 ENCLOSED DRIVE ................................................................................................................................... 33

11.1. Overview ..................................................................................................................................... 33

11.2. Models and Ratings ..................................................................................................................... 33

11.3. Power and Motor Cable Installation ........................................................................................... 33

11.4. Dimensions and Mounting .......................................................................................................... 34

11.5. Removing the Terminal Cover ..................................................................................................... 34

11.6. Control Terminal Wiring – None Switched Version .................................................................... 34

11.7. IP55 / Nema 12K Switched Version - Wiring diagram for in-built switches ................................ 35

11.8. Settings for typical Run / Stop switch configurations (Switched Version) .................................. 35

www.invertek.co.uk 3

Optidrive Plus 3GV User Guide

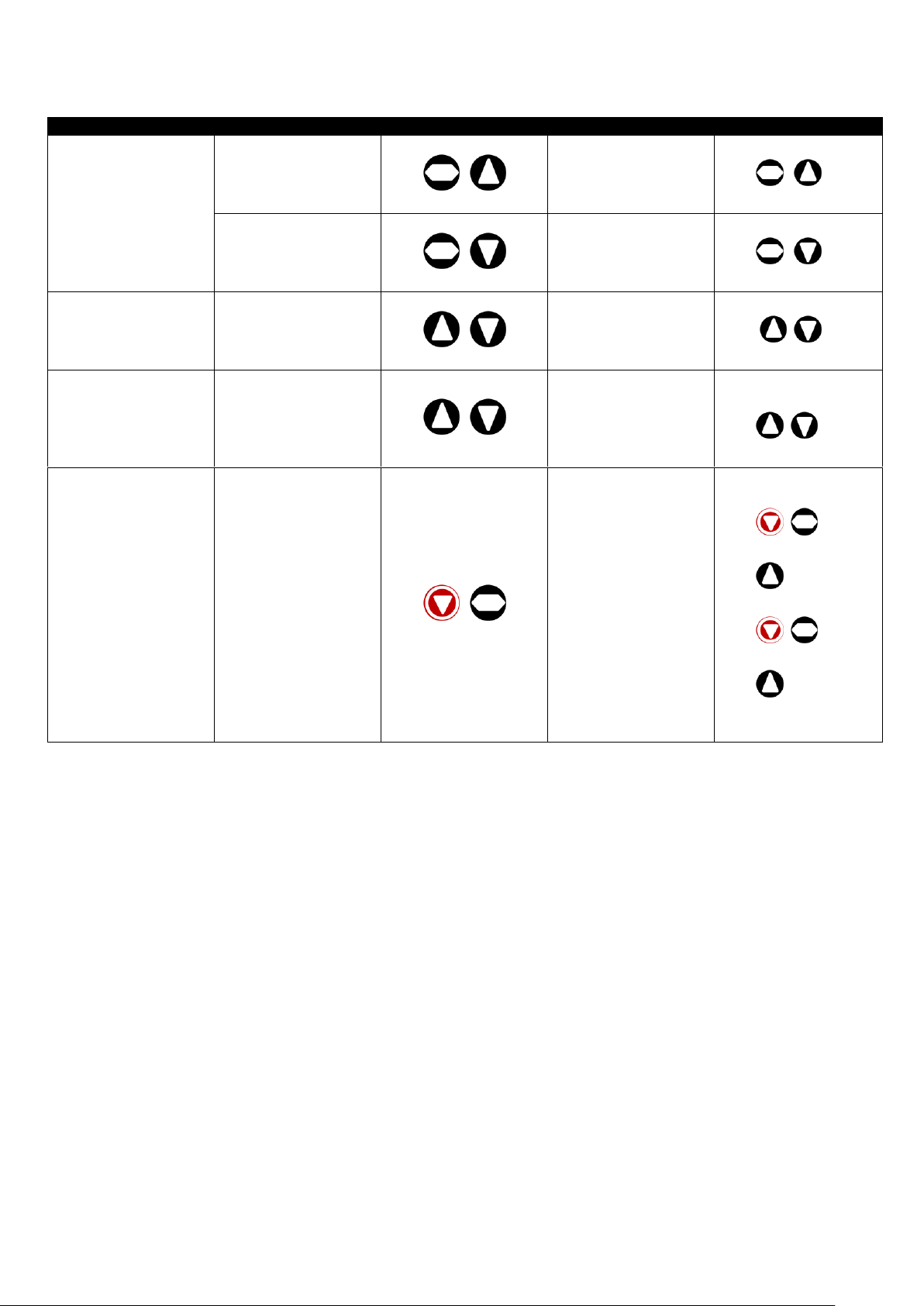

Indicates a potentially hazardous situation which, if not

avoided, could result in injury or death.

Indicates a potentially hazardous situation which, if

not avoided, could result in damage to property.

This variable speed drive product (Optidrive) is intended for professional incorporation into complete equipment or systems as part

of a fixed installation. If installed incorrectly it may present a safety hazard. The Optidrive uses high voltages and currents, carries a

high level of stored electrical energy, and is used to control mechanical plant that may cause injury. Close attention is required to

system design and electrical installation to avoid hazards in either normal operation or in the event of equipment malfunction.

System design, installation, commissioning and maintenance must be carried out only by personnel who have the necessary

training and experience. They must carefully read this safety information and the instructions in this Guide and follow all

information regarding transport, storage, installation and use of the Optidrive, including the specified environmental limitations.

The level of integrity offered by the Optidrive control functions – for example stop/start, forward/reverse and maximum speed, is

not sufficient for use in safety-critical applications without independent channels of protection. All applications where malfunction

could cause injury or loss of life must be subject to a risk assessment and further protection provided where needed.

Within the European Union, all machinery in which this product is used must comply with Directive 98/37/EC, Safety of Machinery.

In particular, the machine manufacturer is responsible for providing a main switch and ensuring the electrical equipment complies

with EN60204-1.

The driven motor can start at power up if the enable input signal is present.

The STOP function does not remove potentially lethal high voltages. ISOLATE the drive and wait 10 minutes before starting any

work on it.

Electric shock hazard! Disconnect and ISOLATE the Optidrive before attempting any work on it. High voltages are present at the

terminals and within the drive for up to 10 minutes after disconnection of the electrical supply.

Where supply to the drive is through a plug and socket connector, do not disconnect until 10 minutes have elapsed after turning off

the supply.

Ensure correct earthing connections. The earth cable must be sufficient to carry the maximum supply fault current which normally

will be limited by the fuses or MCB. Suitably rated fuses or MCB should be fitted in the mains supply to the drive.

Flammable material should not be placed close to the drive

Parameter P1-01 can be set to operate the motor at up to 120,000 rpm, hence use this parameter with care.

If it is desired to operate the drive at any frequency/speed above the rated speed (P1-09/ P1-10) of the motor, consult the

manufacturers of the motor and the driven machine about suitability for over-speed operation.

Carefully inspect the Optidrive before installation to ensure it is undamaged

The Optidrive Plus 3GV has an Ingress Protection rating of IP20 or IP55 depending on the model. IP20 units must be installed in a

suitable enclosure.

Optidrives are intended for indoor use only.

Do not perform any flash test or voltage withstand test on the Optidrive. Any electrical measurements required should be carried

out with the Optidrive disconnected.

The entry of conductive or flammable foreign bodies should be prevented

Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and no. of phases (1 or 3 phase) correspond to the rating of the Optidrive as delivered.

Never connect the mains power supply to the Output terminals U, V, W.

Do not install any type of automatic switchgear between the drive and the motor

Wherever control cabling is close to power cabling, maintain a minimum separation of 100 mm and arrange crossings at 90 degrees

Ensure that all terminals are tightened to the appropriate torque setting

1. Introduction

1.1. Important safety information

Please read the IMPORTANT SAFETY INFORMATION below, and all Warning and Caution information elsewhere.

4 www.invertek.co.uk

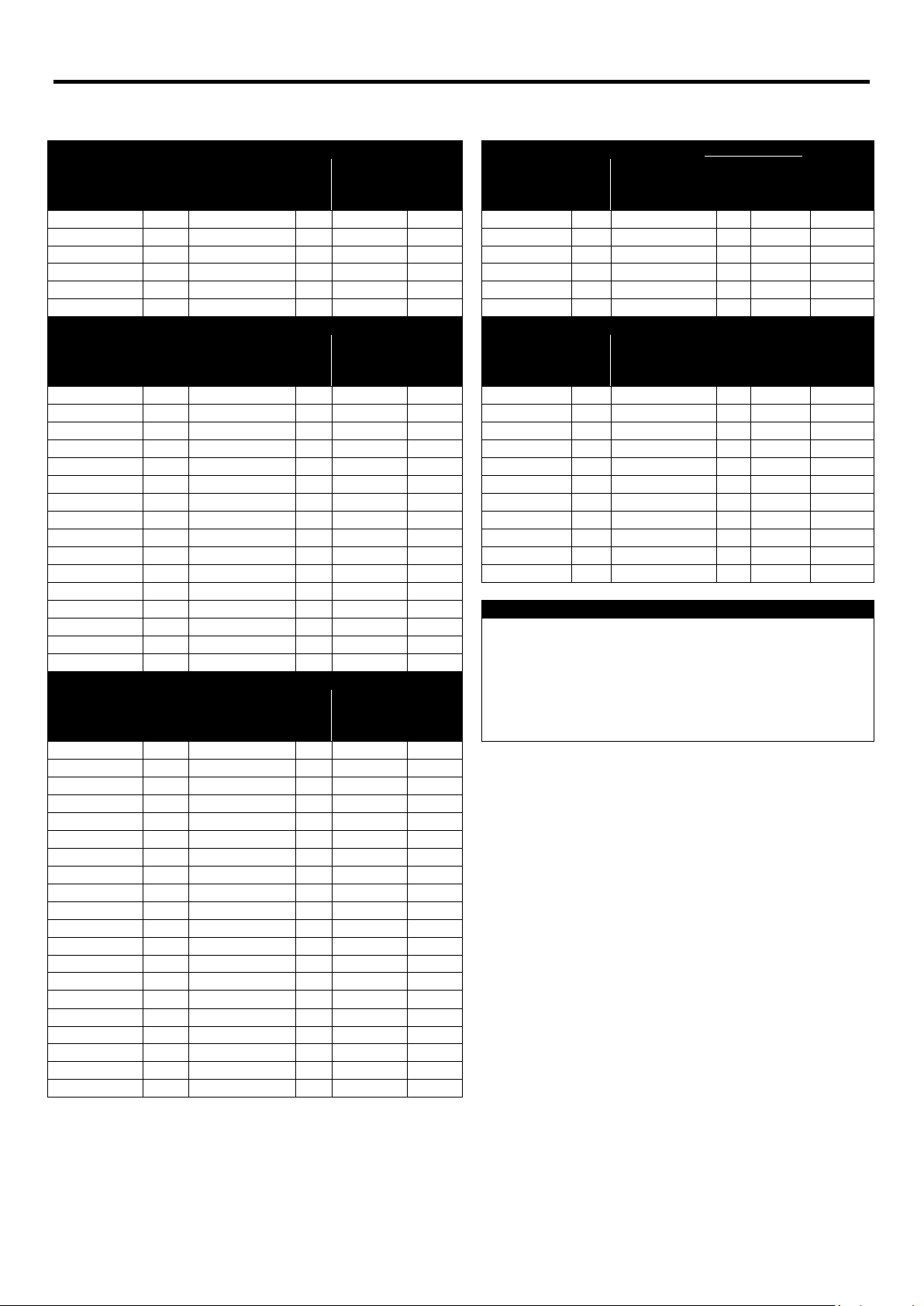

2. General Information and Ratings

200-240V ±10% - 1 Phase Input

480-525V ±10% 3 Phase Input (Note : Not UL Approved)

kW Model

Number

kW

HP Model

Number

HP

Output

Current

(A)

Frame

Size

kW Model

Number

kW

HP Model

Number

HP

Output

Current

(A)

Frame

Size

ODP-12037-xx

0.37

ODP-12005-USA

0.5

2.3

1 ODP-55550-xx

55

N/A

90 5 ODP-12075-xx

0.75

ODP-12010-USA

1

4.3

1 ODP-55750-xx

75

N/A

110

5

ODP-12150-xx

1.5

ODP-12020-USA

2 7 1 ODP-55900-xx

90

N/A

150 5 ODP-22150-xx

1.5

ODP-22020-USA

2 7 2 ODP-65132-xx

132

N/A

202

6

ODP-22220-xx

2.2

ODP-22030-USA

3

10.5

2 ODP-65160-xx

160

N/A

240

6

ODP-65200-xx

200

N/A

270

6

200-240V ±10% - 3 Phase Input

500-600V ±10% - 3 Phase Input

kW Model

Number

kW

HP Model

Number

HP

Output

Current

(A)

Frame

Size

kW Model

Number

kW

HP Model

Number

HP

Output

Current

(A)

Frame

Size

ODP3-22150-xx

1.5

ODP3-22020-USA

2 7 2 ODP-25075-xx

0.75

ODP-25010-USA

1

1.7

2

ODP3-22220-xx

2.2

ODP3-22030-USA

3

10.5 ( 9)

2 ODP-25150-xx

1.5

ODP-25020-USA

2

3.1 2 ODP-32030-xx

3.0

ODP-32040-USA

4

14

3 ODP-25220-xx

2.2

ODP-25030-USA

3

4.1

2

ODP-32040-xx

4.0

ODP32050-USA

5

18

3 ODP-25370-xx

3.7

ODP-25050-USA

5

6.1 2 ODP-32055-xx

5.5

ODP-32075-USA

7.5

25 (24)

3 ODP-25550-xx

5.5

ODP-25075-USA

7.5

9.0

2

ODP-42075-xx

7.5

ODP-42100-USA

10

39

4 ODP-35075-xx

7.5

ODP-35100-USA

10

14 3 ODP-42110-xx

11

ODP-42150-USA

15

46

4 ODP-35110-xx

11

ODP-35150-USA

15

18

3

ODP-42150-xx

15

ODP-42200-USA

20

61

4 ODP-35150-xx

15

ODP-35200-USA

20

24

3

ODP-42185-xx

18.5

ODP-42250-USA

25

72

4 ODP-45220-xx

22

ODP-45300-USA

30

39 4 ODP-52220-xx

22

ODP-52300-USA

30

90

5 ODP-45300-xx

30

ODP-45400-USA

40

46

4

ODP-52300-xx

30

ODP-52400-USA

40

110

5 ODP-45450-xx

45

ODP-45600-USA

60

62 4 ODP-52370-xx

37

ODP-52500-USA

50

150

5

ODP-52450-xx

45

ODP-52600-USA

60

180

5

Notes

ODP-62055-xx

55

ODP-62075-USA

75

202

6

Output current values shown in brackets are the maximum values

for UL conformance

An Input line choke must be fitted for all size 2 500 – 600 Volt

units

1

Model not UL Listed

2

Model has 110% overload capacity only

ODP-62075-xx

75

ODP-62100-USA

100

240

6 ODP-62090-xx

90

ODP-62120-USA

120

300

6

380-480V ±10% - 3 Phase Input

kW Model

Number

kW

HP Model

Number

HP

Output

Current

(A)

Frame

Size

ODP-24075-xx

0.75

ODP-24010-USA

1

2.2

2

ODP-24150-xx

1.5

ODP-24020-USA

2

4.1

2

ODP-24220-xx

2.2

ODP-24030-USA

3

5.8

2

ODP-24400-xx

4

ODP-24050-USA

5

9.5

2

ODP-34055-xx

5.5

ODP-34075-USA

7.5

14

3

ODP-34075-xx

7.5

ODP-34100-USA

10

18

3

ODP-34110-xx

11

ODP-34150-USA

15

25 (24)

3

ODP-34150-xx

1

15

ODP-34200-USA

1

20

30

3

ODP-44185-xx

18.5

ODP-44250-USA

25

39

4

ODP-44220-xx

22

ODP-44300-USA

30

46

4

ODP-44300-xx

30

ODP-44400-USA

40

61

4

ODP-44370-xx

37

ODP-44500-USA

50

72

4

ODP-44450-xx

2

45

ODP-44600-USA

2

60

90

4

ODP-54450-xx

45

ODP-54600-USA

60

90

5

ODP-54550-xx

55

ODP-54750-USA

75

110

5

ODP-54750-xx

75

ODP-54100-USA

100

150

5

ODP-54900-xx

90

ODP-54120-USA

150

180

5

ODP-64110-xx

110

ODP-64150-USA

160

202

6

ODP64132-xx

132

ODP-64175-USA

200

240

6

ODP-64160-xx

160

ODP-64210-USA

250

300

6

2.1. Drive model numbers

Optidrive Plus 3GV User Guide

www.invertek.co.uk 5

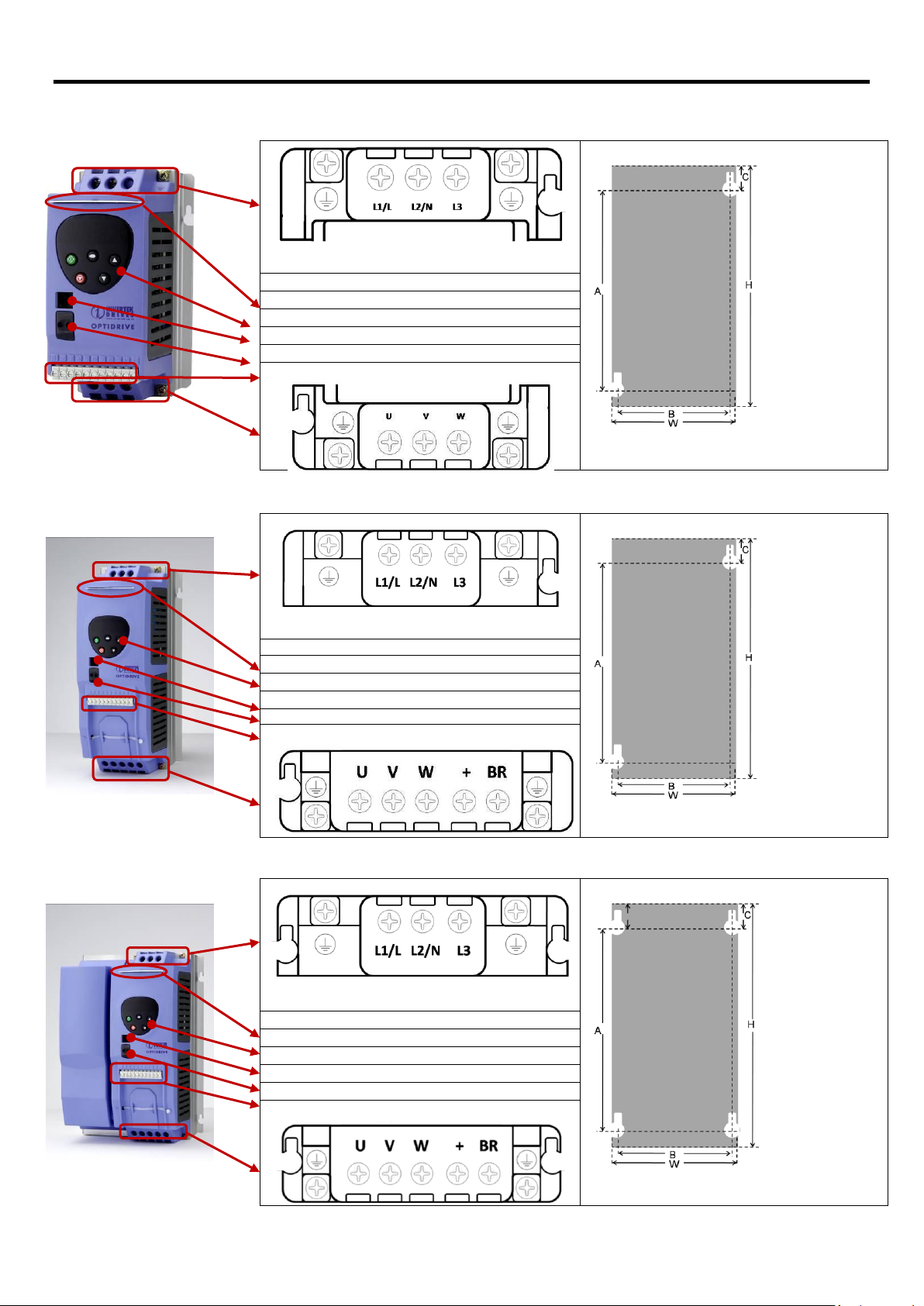

3. Mechanical Installation

Overall Dimensions

Height

155mm

Width

80mm

Depth

130mm

A

105mm

B

72mm

Incoming Power Terminals

C

25mm

Help Card

Keypad & Display – See Section 0 on page 11

Footprint View

RJ11 Connector – See Section 10.3 on page 31

Infra Red Interface

Weight : 1.1Kg

Control Terminals – See Section 4.7 on page 11

Motor Connection Terminals

Fixings : 2 x M4 Keyhole slots

Power Terminals Torque Setting : 1Nm

Overall Dimensions

Height

260mm

Width

100mm

Depth

175mm

A

210mm

B

92mm

Incoming Power Terminals

C

25mm

Help Card

Keypad & Display – See Section 0 on page 11

Footprint View

RJ11 Connector – See Section 10.3 on page 31

Infra Red Interface

Weight : 2.6Kg

Control Terminals – See Section 4.7 on page 11

Motor & Brake Resistor Connection Terminals

Fixings : 2 x M4 Keyhole slots

Power Terminals Torque Setting : 1Nm

Overall Dimensions

Height

260mm

Width

171mm

Depth

175mm

A

210mm

B

163mm

Incoming Power Terminals

C

25mm

Help Card

Keypad & Display – See Section 0 on page 11

Footprint View

RJ11 Connector – See Section 10.3 on page 31

Infra Red Interface

Weight : 5.3Kg

Control Terminals – See Section 4.7 on page 11

Motor & Brake Resistor Connection Terminals

Fixings : 4 x M4 Keyhole slots

Power Terminals Torque Setting : 1Nm

3.1. Mechanical dimensions and mounting

3.1.1. Frame Size 1

Optidrive Plus 3GV User Guide

3.1.2. Frame Size 2

3.1.3. Frame Size 3

6 www.invertek.co.uk

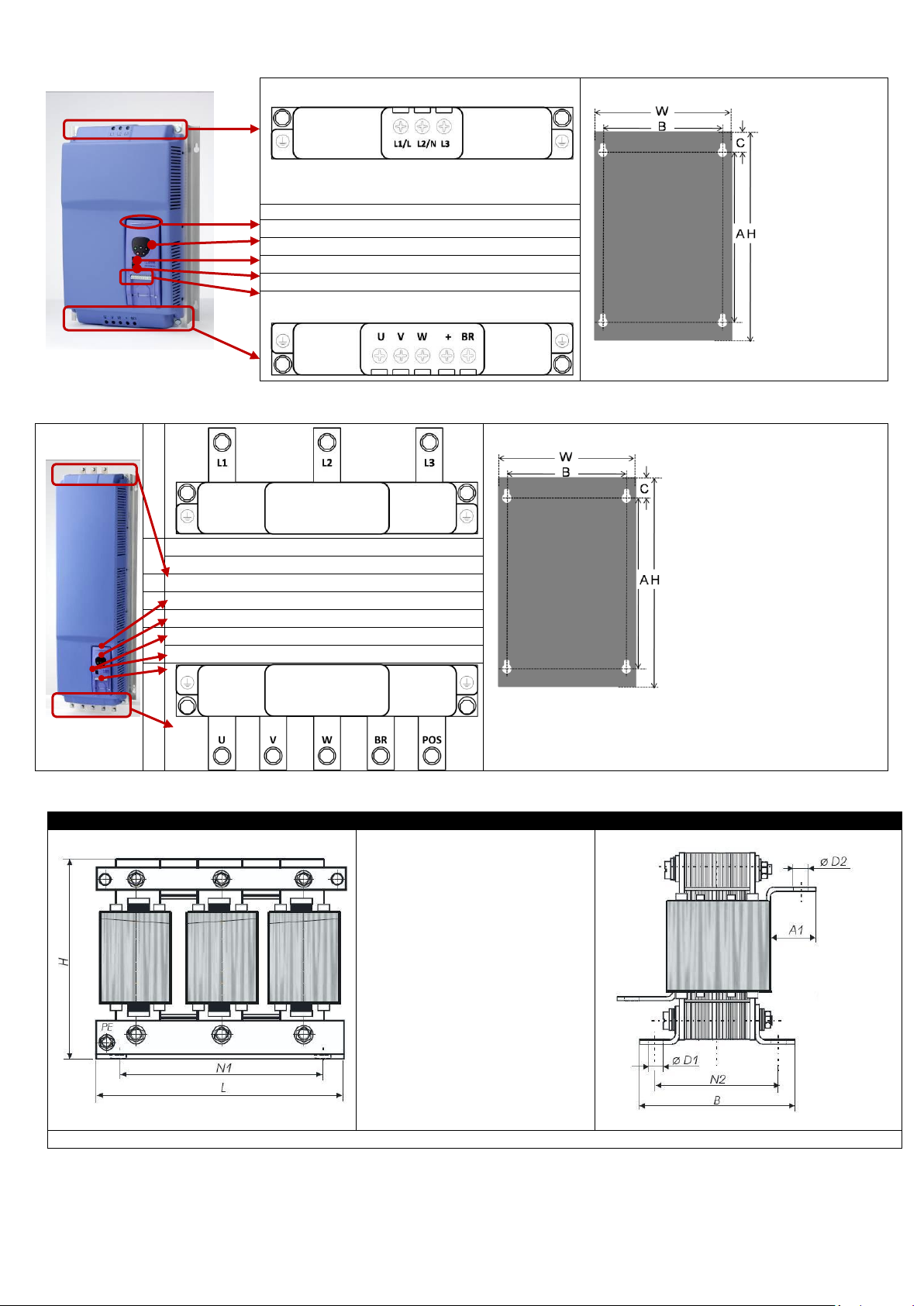

Optidrive Plus 3GV User Guide

Overall Dimensions

Height

520mm

Width

340mm

Depth

220mm

A

420mm

B

320mm

Incoming Power Terminals

C

50mm

Help Card

Keypad & Display – See Section 0 on page 11

Footprint View

RJ11 Connector – See Section 10.3 on page 31

Infra Red Interface

Weight : 28Kg

Control Terminals – See Section 4.7 on page 11

Motor & Brake Resistor Connection Terminals

Fixings : 4 x M8 Keyhole slots

Power Terminals Torque Setting : 4Nm

Overall Dimensions

Height

1100mm

Width

340mm

Depth

230 (=<75kW)

330mm (>=90kW)

A

945mm

Incoming Power Terminals

B

320mm

Help Card

C

50mm

Keypad & Display – See Section 5.1

RJ11 Connector

Footprint View

Infra Red Interface

Control Terminals – See Section 4.7

Motor & Brake Resistor Connection Terminals

Weights :

Size 5 : 67Kg

Size 6 : 55Kg

(+ 27Kg Choke)

Fixings : 4 x M8 Keyhole slots

Power Terminals Torque Setting : 8Nm

Optidrive Plus Frame Size 6 is supplied complete with an external Input Choke, which must be installed in the supply line to the drive

Overall Dimensions

Height H

230mm

Length L

240mm

Depth B

250mm

Mounting Holes

Centres N1

160mm

Centres N2

105mm

Slots D1

8.5 x 22mm

Busbar Connections

Length A1

40mm

Connection

Diameter D2

9mm

Note: The choke is always supplied with the drive, and MUST be used.

3.1.4. Frame Size 4

3.1.5. Frame Sizes 5 & 6

3.1.6. Frame Size 6 Additional Input Choke

www.invertek.co.uk 7

Optidrive Plus 3GV User Guide

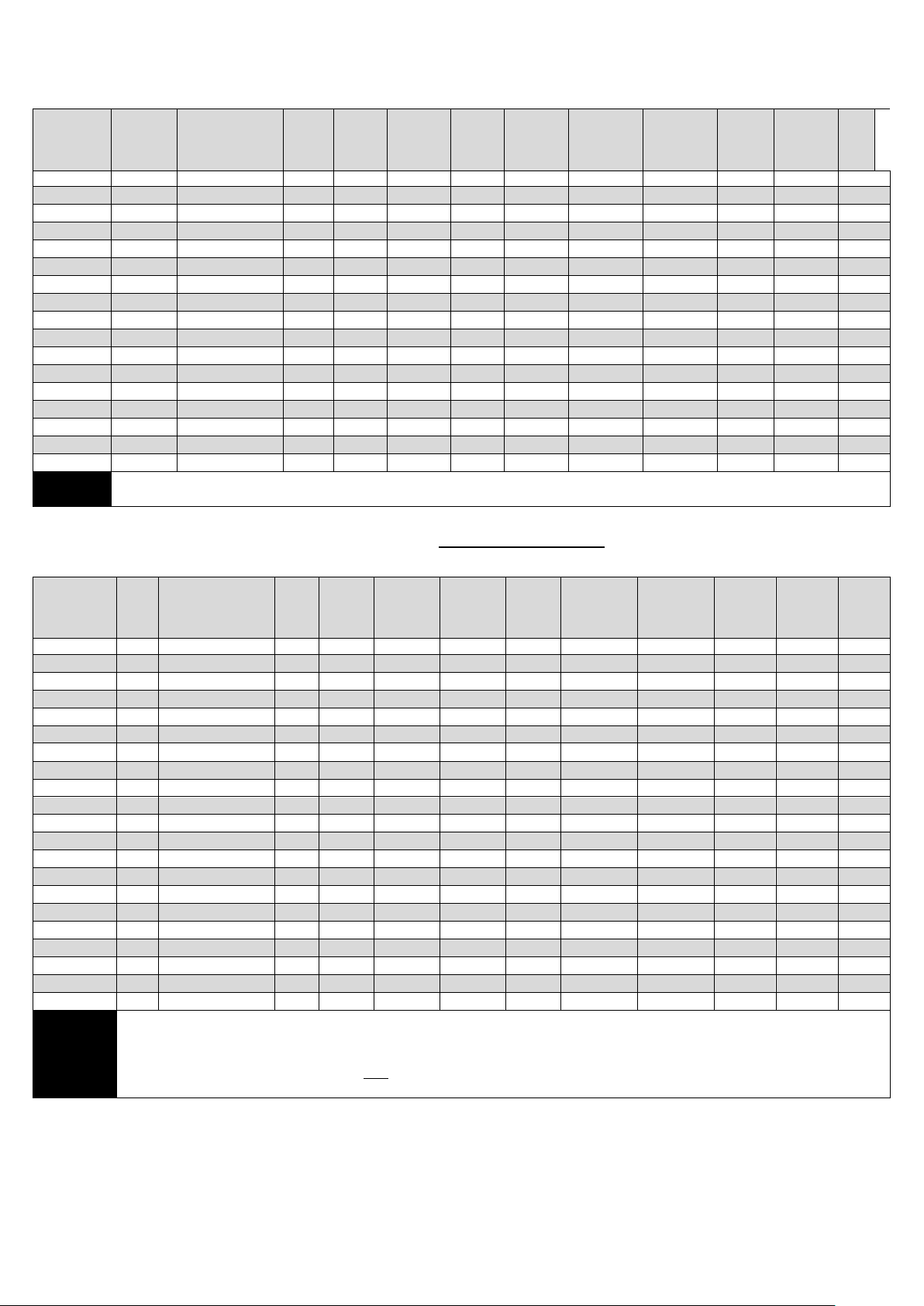

Enclosure Front View

Enclosure Side View

Enclosure Minimum Dimensions

Drive Power rating

L W D

G

Size 1 0.75kW 230V

300

250

200

50

Size 1 1.5kW 230V

400

300

250

75

Size 2 1.5kW 230V / 2.2kW 400V

400

300

300

60

Size 2 2.2kW 230V / 4kW 400V

600

450

300

100

Drive Power

Rating

Free-Vented unit

Force-vented unit

L W D G L W D G

Air Flow

Size 1 1.5 kW

400

300

150

75 275

150

150

50

> 15m3 /h

Size 2 4 kW

600

400

250

100 320

200

200

75

> 45m3 /h

Size 3 15 kW

800

600

300

150 400

250

200

100

> 80m3 /h

Size 4 22 kW

100

0

600

300

200 800

500

250

130

> 300m3 /h

Size 4 37 kW

- - - -

800

500

250

130

> 300m3 /h

Size 5 90 kW

- - - -

1500

600

400

200

> 900m3 /h

Size 6 160 kW

- - - -

1600

600

400

250

>1000m3 /h

3.2. General

Store the Optidrive in its box until required. Storage should be clean and dry and within the temperature range –40°C to +60°C

The Optidrive must be installed in a pollution degree 1 or 2 environment

3.3. Enclosure mounting

For applications that require a higher IP rating than the IP20 offered by the standard drive, the drive must be mounted in a suitable metallic

enclosure. The following guidelines should be observed for these applications:

Carefully inspect the Optidrive prior to commencing to ensure it is undamaged

Install the Optidrive on a flat, vertical, flame-resistant, vibration-free mounting.

For IP20 Optidrives, install in a suitable enclosure, according to EN60529 if specific Ingress Protection ratings are required.

Enclosures should be made from a thermally conductive material

Do not mount flammable material close to the Optidrive

Where vented enclosures are used, there should be venting above and below the drive to ensure good air circulation – see the

diagram below. Air should be drawn in below the drive and expelled above the drive.

In any environments where the conditions require it, the enclosure must be designed to protect the Optidrive against ingress of

airborne dust, corrosive gases or liquids, conductive contaminants (such as condensation, carbon dust, and metallic particles) and

sprays or splashing water from all directions.

High moisture, salt or chemical content environments should use a suitably sealed (non-vented) enclosure.

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate through the

drive heatsink. Invertek Drives recommend the following minimum sizes for drives mounted in non-ventilated metallic enclosures:-

For drives mounted in free ventilated enclosures of force ventilated enclosures, Invertek Drives recommend the following minimum sizes and

airflow requirements:-

8 www.invertek.co.uk

Optidrive Plus 3GV User Guide

This manual is intended as a guide for proper installation. Invertek Drives Ltd cannot assume responsibility for the compliance or

the non-compliance to any code, national, local or otherwise, for the proper installation of this drive or associated equipment. A

hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

This Optidrive contains high voltage capacitors that take time to discharge after removal of the mains supply. Before working on

the drive, ensure isolation of the mains supply from line inputs. Wait ten (10) minutes for the capacitors to discharge to safe

voltage levels. Failure to observe this precaution could result in severe bodily injury or loss of life.

Only qualified electrical personnel familiar with the construction and operation of this equipment and the hazards involved

should install, adjust, operate, or service this equipment. Read and understand this manual and other applicable manuals in their

entirety before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

4. Power and Control Connections

4.1. Grounding the Drive

Grounding Guidelines

The ground terminal of each Optidrive should be individually connected DIRECTLY to the site ground bus bar (through the filter if installed).

Optidrive ground connections should not loop from one drive to another, or to, or from any other equipment. Ground loop impedance must

confirm to local industrial safety regulations. To meet UL regulations, UL approved ring crimp terminals should be used for all ground wiring

connections.

The drive Safety Ground must be connected to system ground. Ground impedance must conform to the requirements of national and local

industrial safety regulations and/or electrical codes. The integrity of all ground connections should be checked periodically.

Safety Ground

This is the safety ground for the drive that is required by code. One of these points must be connected to adjacent building steel (girder, joist),

a floor ground rod, or bus bar. Grounding points must comply with national and local industrial safety regulations and/or electrical codes.

Motor Ground

The motor ground must be connected to one of the ground terminals on the drive.

Ground Fault Monitoring

If a system ground fault monitor is to be used; only Type B devices should be used to avoid nuisance tripping.

Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the motor cable shield. The motor cable shield should be connected to this terminal

(drive end) and also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to the safety

ground terminal.

When shielded cable is used for control and signal wiring, the shield should be grounded at both ends of the cable.

4.2. Wiring Precautions

Connect the Optidrive according to section 4.4 Connection Diagram, ensuring that motor terminal box connections are correct. There are two

connections in general: Star and Delta. It is essential to ensure that the motor is connected in accordance with the voltage at which it will be

operated. For more information, refer to section 4.6 Motor Terminal Box Connections.

For recommended cabling and wiring sizing, refer to section 9.2 Rating tables.

It is recommended that the power cabling should be 3-core or 4-core PVC-insulated screened cable, laid in accordance with local industrial

regulations and codes of practice.

4.3. Mains Power Supply

For 1 phase supply power should be connected to L1/L, L2/N.

For 3 phase supplies power should be connected to L1, L2, and L3. Phase sequence is not important.

The Optidrive should be connected to a fixed supply using a suitable disconnecting device between the Optidrive and the AC Power

Source. The disconnecting device must conform to the local safety code / regulations.

The cables should be dimensions according to any local codes or regulations. Guideline dimensions are given in section 9.2.

Suitable fuses to provide wiring protection should be installed in the incoming supply line, according to the data in section 9.2. The

fuses must comply with any local codes or regulations in place. In general, IEC type gG or UL type T fuses are suitable. The operating

time of the fuses must be below 0.5 seconds.

Where allowed by local regulations, suitably dimensioned circuit breakers may be utilised in place of fuses. Thermal overload

protection is not required, as the Optidrive provides thermal protection for the motor and motor cable. Guideline dimensions are

given in section 9.2.

When the power supply is removed from the drive, a minimum of 30 seconds should be allowed before re-applying the power. A

minimum of 10 minutes should be allowed before removing the terminal covers or connection.

The maximum permissible short circuit current at the Optidrive Power terminals as defined in IEC60439-1 is 100kA.

An Input Choke should be installed in the supply line for frame size 1 to 3 Optidrives where any of the following conditions occur:-

o The incoming supply impedance is low or the fault level / short circuit current is high

o The supply is prone to dips or brown outs

o An imbalance exists on the supply (3 phase drives)

o All installations of Frame Size 2 drives on 575 Volt Supply

In all other installations, an input choke is recommended to ensure protection of the drive against power supply faults. The

recommended chokes can be found in the Invertek Stock Drives Catalogue

For compliance with CE and C Tick EMC requirements, a symmetrical shielded motor cable is recommended.

www.invertek.co.uk 9

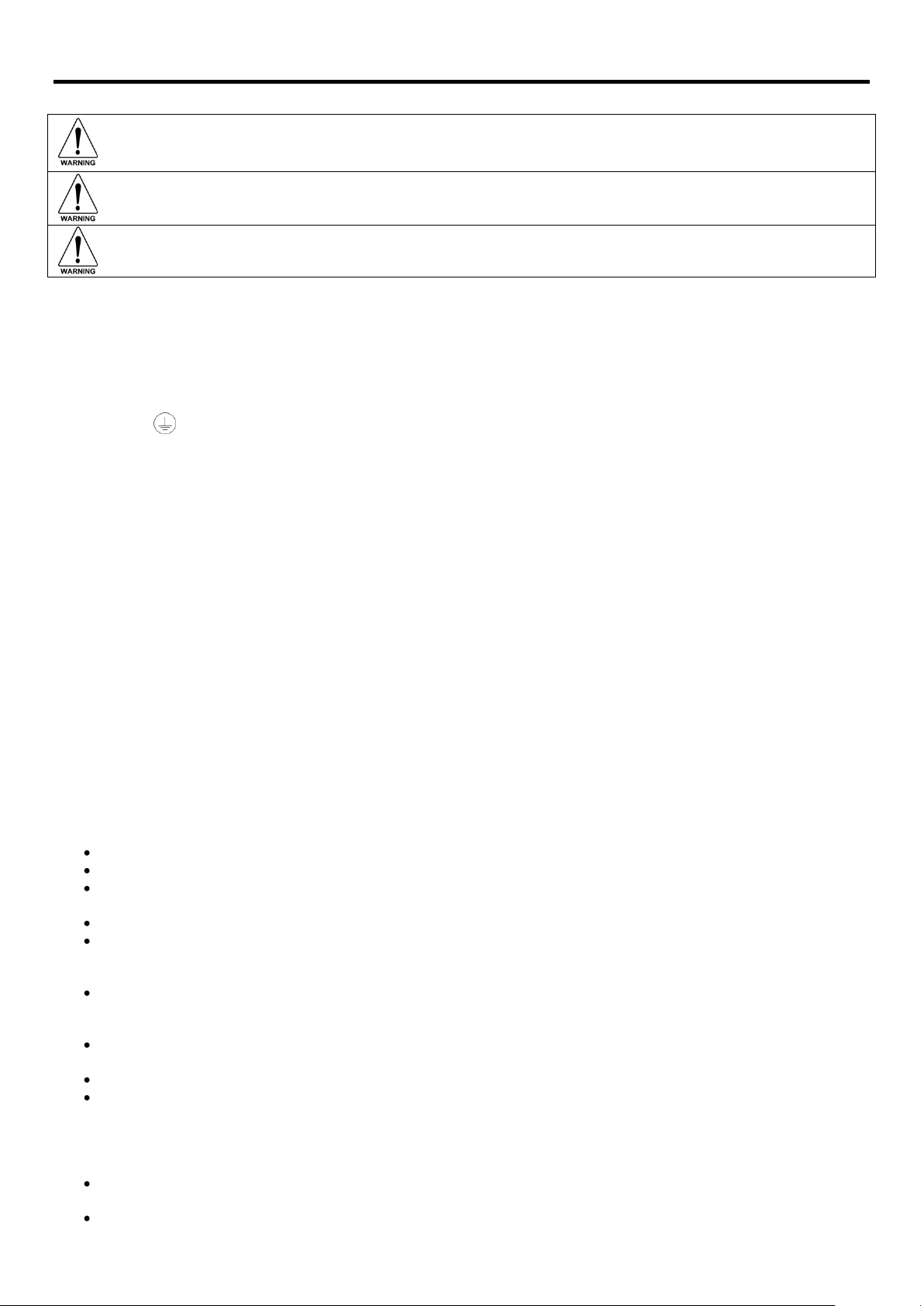

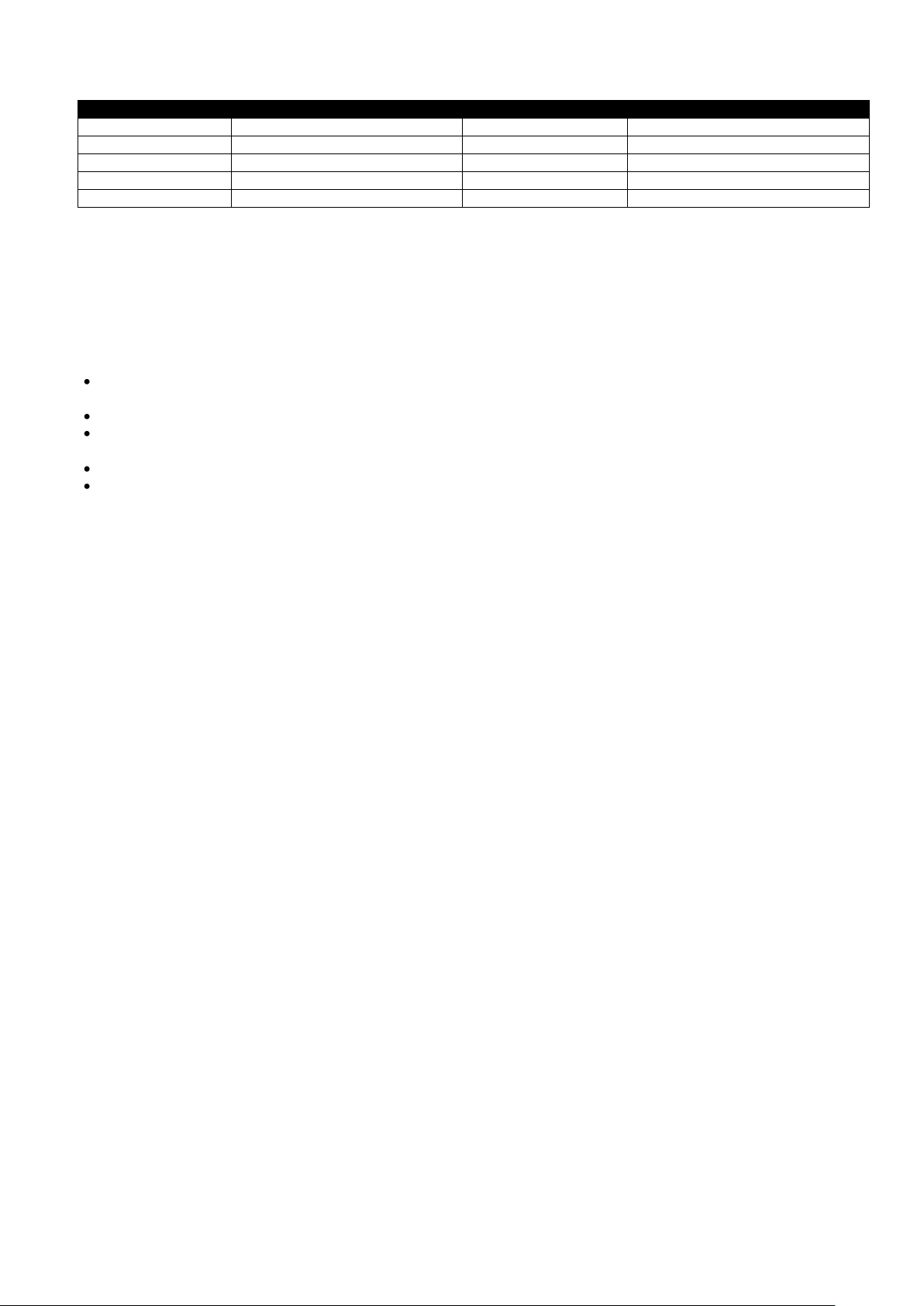

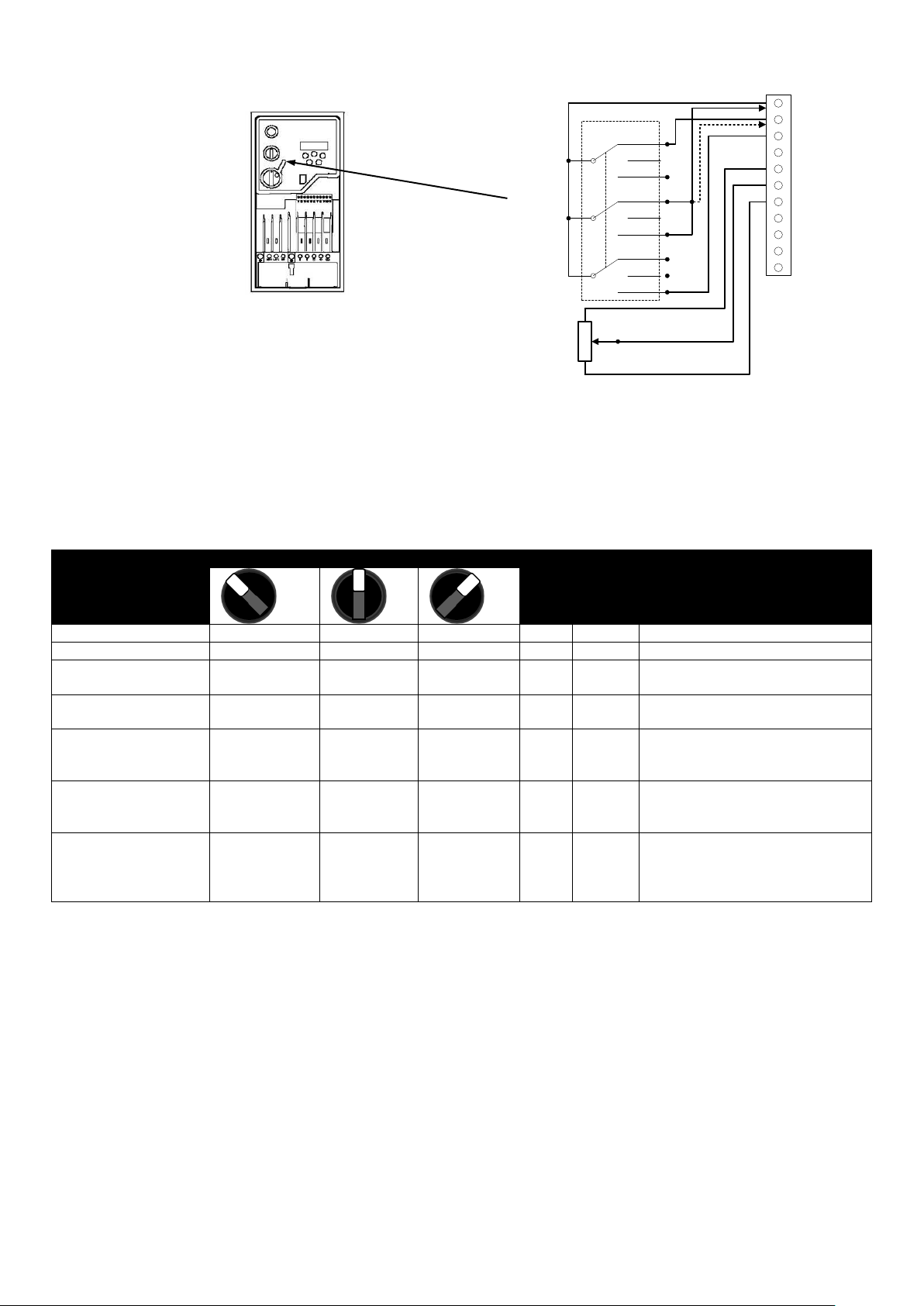

4.4. Connection Diagram

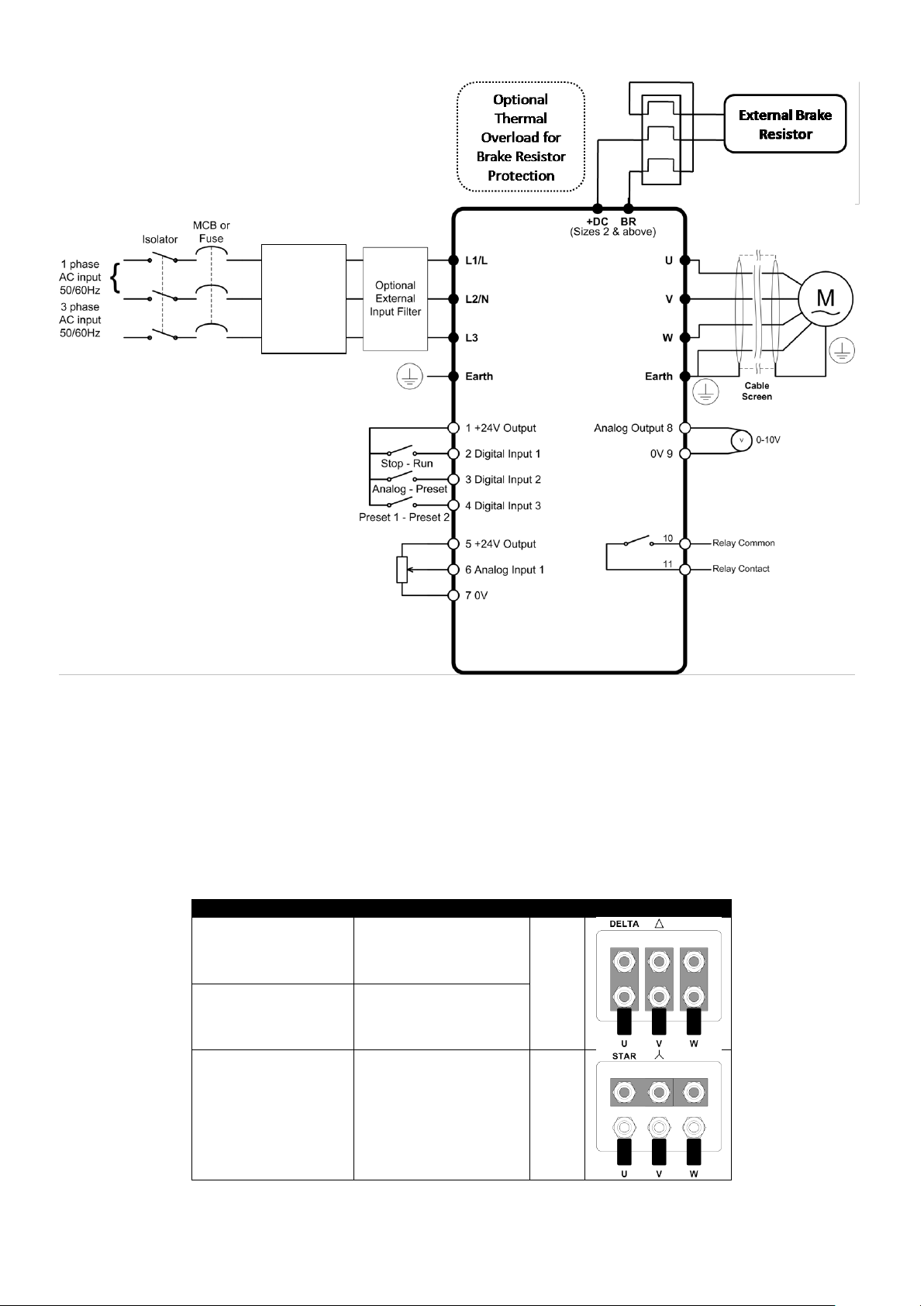

Incoming Supply Voltage

Motor Nameplate Voltages

Connection

230

230 / 400

Delta

400

400 / 690

400

230 / 400

Star

FS 6

External

Input Choke

(Optional

on FS 1 – 5)

Default Analog and Digital

Input Connections

Optidrive Plus 3GV User Guide

4.5. Motor connections

The motor should be connected to U, V, and W

For drives that have a dynamic brake transistor, an optional external braking resistor can be connected to +DC and BR when required. The

brake resistor circuit should be protected by a suitable thermal protection circuit that disconnects the AC supply to the drive in the event of a

trip. Further information can be found in the Advanced User Guide.

4.6. Motor Terminal Box Connections

Most general purpose motors are wound for operation on dual voltage supplies; this is indicated on the nameplate of the motor.

This operational voltage is normally selected when installing the motor by selecting either STAR or DELTA connection. STAR always gives the

higher of the two voltage ratings.

10 www.invertek.co.uk

Optidrive Plus 3GV User Guide

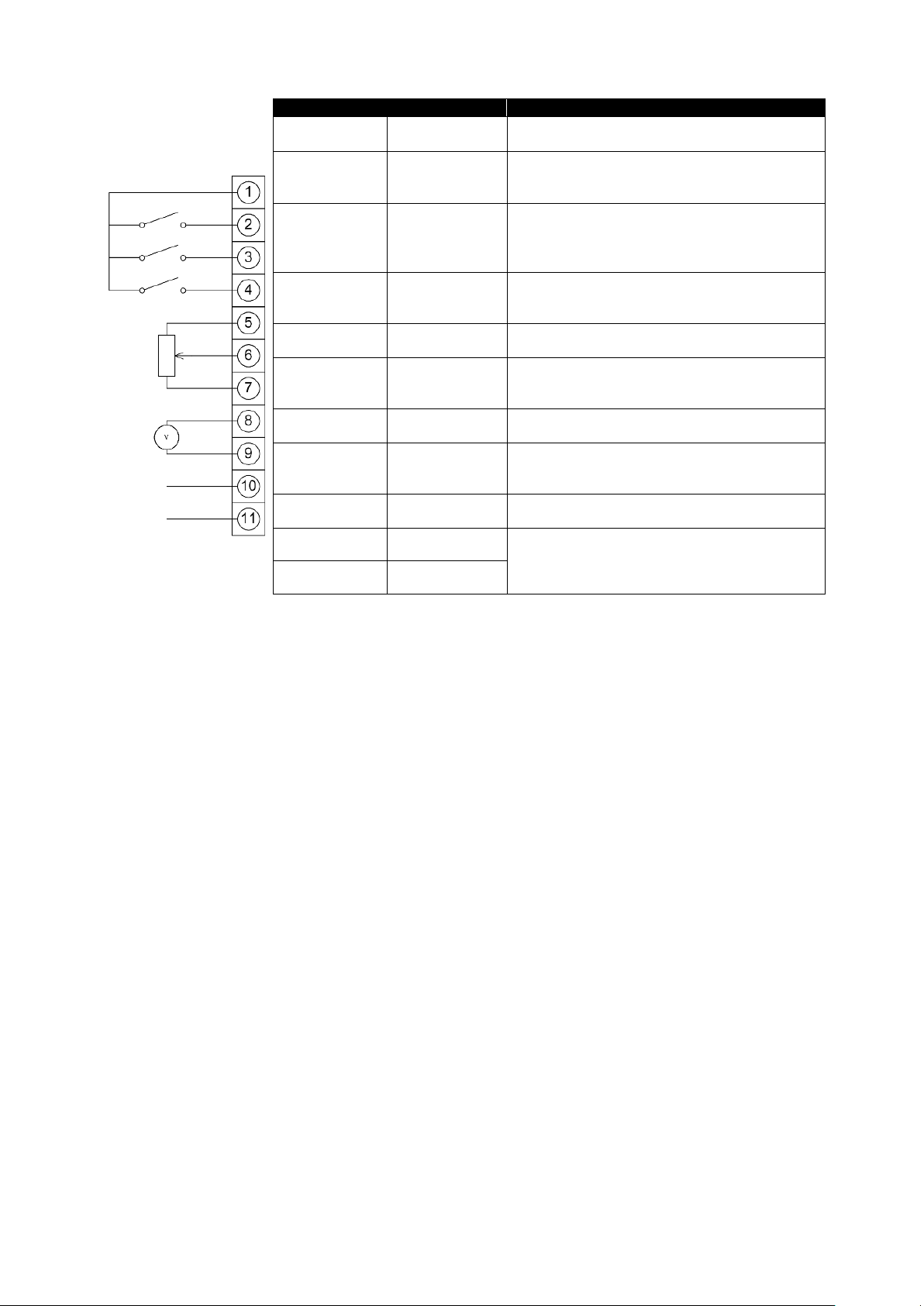

Default Connections

Control Terminal

Signal

Description

1

+24V User

Output,

+24V, 100mA user control output

2

Digital Input 1

Positive logic

“Logic 1” input voltage range: 8V … 30V DC

“Logic 0” input voltage range: 0V … 8V DC

3

Digital Input 2 /

Digital Output 3

Input : Positive logic

“Logic 1” input voltage range: 8V … 30V DC

“Logic 0” input voltage range: 0V … 8V DC

Output : 24V 10mA Max ‘Drive Healthy’ Output

4

Digital Input 3 /

Analog Input 2

Digital : “Logic 1” input voltage range : 8 to 30V DC

“Logic 0” input voltage range : 0 to 8 V DC

Analog: 0 to 10V, 0 to 20mA or 4 to 20mA

5

+24V User Output

+24V, 100mA, 1kΩ minimum

6

Bipolar analog

Input /

Digital Input 4

Digital : “Logic 1” input voltage range : 8 to 30V DC

“Logic 0” input voltage range : 0 to 8 V DC

Analog: 0 to 24V, 0 to 10V, -10 to +10V, -24 to + 24V

7

0V

User ground, connected to terminal 9

8

Analog Output /

Digital Output

Analog: 0 to 10V DC, 10 to 0 V DC, 20mA Maximum

4 to 20mA, 20 to 4 mA

Digital: 0 to 24V DC, 20mA Maximum

9

0V

User ground, connected to terminal 7

10

Relay Common

Volt free contacts. Maximum load should not exceed

250Vac, 6A / 30Vdc, 5A

11

Relay NO Contact

4.7. Control terminal connections

www.invertek.co.uk 11

Optidrive Plus 3GV User Guide

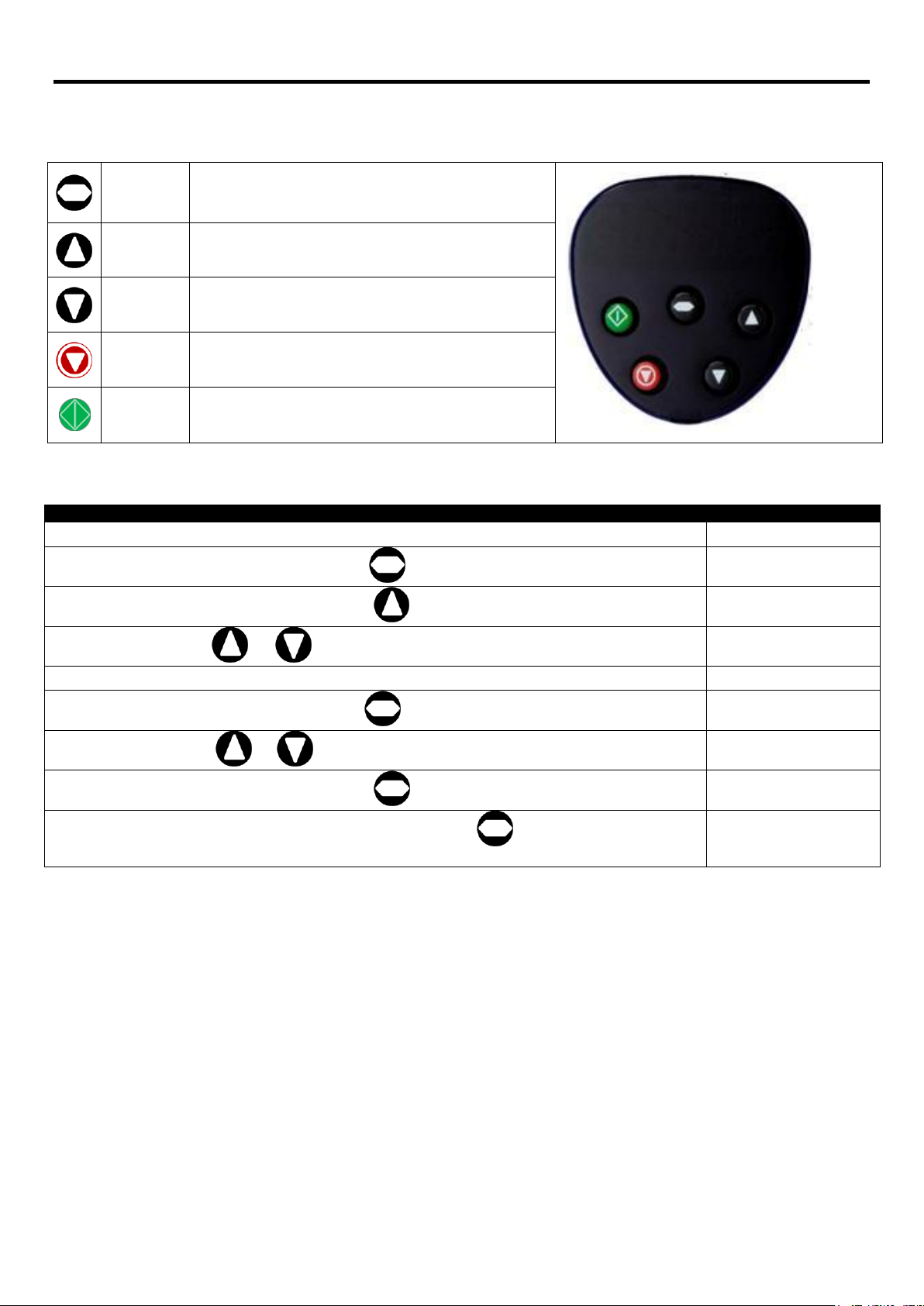

NAVIGATE

Used to display real-time information, to access and exit

parameter edit mode and to store parameter changes

UP

Used to increase speed in real-time mode or to increase

parameter values in parameter edit mode

DOWN

Used to decrease speed in real-time mode or to decrease

parameter values in parameter edit mode

RESET /

STOP

Used to reset a tripped drive.

When in Keypad mode is used to Stop a running drive.

START

When in keypad mode, used to Start a stopped drive or to

reverse the direction of rotation if bi-directional keypad

mode is enabled

Procedure

Display shows...

Power on Drive

Press and hold the for >2 seconds

Press the Key

The and can be used to select the desired parameter

etc...

Select the required parameter, e.g. P1-02

Press the button

.

Use the and keys to adjust the value, e.g. set to 10

.

Press the key

The parameter value is now adjusted and automatically stored. Press the key for >2 seconds to return to

operating mode

5. Operation

5.1. Managing the keypad

The drive is configured and its operation monitored via the keypad and display.

5.2. Changing Parameters

12 www.invertek.co.uk

Optidrive Plus 3GV User Guide

Function

When Display shows...

Press...

Result

Example

Fast Selection of

Parameter Groups

Note : Parameter Group

Access must be enabled

P1-14 = 101

xxx

+

The next highest

Parameter group is

selected

Display shows

Press +

Display shows

xxx

+

The next lowest

Parameter group is

selected

Display shows

Press +

Display shows

Select lowest Group

Parameter

xxx

+

The first parameter of a

group is selected

Display shows

Press +

Display shows

Set Parameter to

minimum value

Any numerical value

(Whilst editing a

parameter value)

+

The parameter is set to

the minimum value

When editing P1-01

Display shows .

Press +

Display shows.

Adjusting individual digits

within a parameter value

Any numerical value

(Whilst editing a

parameter value)

+

Individual parameter

digits can be adjusted

When editing P1-10

Display shows

Press +

Display shows

Press

Display shows

Press +

Display shows

Press

Display shows

Etc...

5.3. Advanced Keypad Operation Short Cuts

www.invertek.co.uk 13

Optidrive Plus 3GV User Guide

5.4. Reset All Parameters to Factory Default Settings

To reset all drive parameters to factory default settings, press + + + for >2s. The display shows . Press the

button to acknowledge and reset the drive.

5.5. Terminal Control

When delivered, the Optidrive is in the factory default state, meaning that it is set to operate in terminal control mode and all parameters have

the default values as indicated in section 6 Parameters.

Connect the drive to the supply, ensuring the correct voltage and fusing / circuit breaker protection – see section 9.2 on page 27.

Connect the motor to the drive, ensuring the correct star/delta connection for the voltage rating - see section 4.6 on page 10.

Enter the motor data from motor nameplate; P1-07 = motor rated voltage, P1-08 = motor rated current, P1-09 = motor rated

frequency.

Connect a control switch between the control terminals 1 and 2 ensuring that the contact is open (drive disabled).

Connect a potentiometer (1kΩ min to 10 kΩ max) between terminals 5 and 7, and the wiper to terminal 6.

With the potentiometer set to zero, switch on the supply to the drive. The display will show .

Close the control switch, terminals 1-2. The drive is now ‘enabled’ and the output frequency/speed are controlled by the

potentiometer.

On first enable from factory default parameters, the Optidrive will carry out an Autotune, and the display shows . Leave the

control switch closed an allow this to complete.

Following completion of the Autotune, the display shows zero speed in Hz (.) with the potentiometer turned to minimum.

Turn the potentiometer to maximum. The motor will accelerate to 50Hz, (60Hz for USA drives), the default value of P1-01, under the

control of the acceleration ramp time P1-03. The display shows 50Hz (.) at max speed.

If the potentiometer is turned to minimum, the motor will decelerate to 0Hz, the default minimum speed set in P1-02, under the

control of the deceleration ramp P1-04. The output speed can be adjusted anywhere between minimum and maximum speed using

the potentiometer.

To display motor current (Amps), briefly press the (Navigate) key.

Press again to display the motor power.

Press again to return to speed display.

To stop the motor, disable the drive by opening the control switch (terminals 1-2).

If the enable/disable switch is opened the drive will decelerate to stop at which time the display will show .

5.6. Keypad Control

To allow the Optidrive to be controlled from the keypad in a forward direction only, set P1-12 =1:

Connect the supply and motor as for terminal control above.

Enable the drive by closing the switch between control terminals 1 & 2. The display will show .

Press the key. If this is the first enable from factory default parameters, the drive will carry out an Autotune as described

above. On completion of the Autotune, the display shows ..

Press to increase speed.

The drive will run forward, increasing speed until is released.

Press to decrease speed. The drive will decrease speed until is released. The rate of deceleration is limited by the setting

in P1-04

Press the key. The drive will decelerate to rest at the rate set in P1-04.

The display will finally show at which point the drive is disabled

To preset a target speed prior to enable, press the key whilst the drive is stopped. The display will show the target speed, use

the & keys to adjust as required then press the key to return the display to .

Pressing the key will start the drive accelerating to the target speed.

To allow the Optidrive to be controlled from the keypad in a forward and reverse direction, set P1-12 =2:

Operation is the same as when P1-12=1 for start, stop and changing speed.

Press the key. The display changes to ..

Press to increase speed

The drive will run forward, increasing speed until is released. Acceleration is limited by the setting in P1-03. The maximum

speed is the speed set in P1-01.

To reverse the direction of rotation of the motor, press the key again.

14 www.invertek.co.uk

Optidrive Plus 3GV User Guide

Whilst the autotune procedure does not drive or spin the motor, the motor shaft may still turn. It is not normally necessary to

uncouple the load from the motor; however the user should ensure that no risk arises from the possible movement of the

motor shaft.

The autotune will begin immediately when P4-02 is set to 1, and no external enable signal is required. During the autotune

procedure, the motor shaft may turn. It is not normally necessary to uncouple the load from the motor; however the user

should ensure that no risk arises from the possible movement of the motor shaft.

The autotune will begin immediately when P4-02 is set to 1, and no external enable signal is required. During the autotune

procedure, the motor shaft may turn. It is not normally necessary to uncouple the load from the motor; however the user

should ensure that no risk arises from the possible movement of the motor shaft.

5.7. Motor Autotuning

Optidrive Plus uses a sophisticated Voltage Vector Control Method as a factory default setting to ensure best possible motor operation. This

control method requires the Optidrive to carry out an autotune to measure certain motor parameters prior to operation, to ensure this

function operates correctly, and reduce the risk of nuisance tripping.

Autotune after Factory Reset or from Factory Set Parameters

Following a factory reset (See section 5.4), the correct data from the motor nameplate should be entered in P1-07 (Motor Rated Voltage), P108 (Motor Rated Current) and P1-09 (Motor Rated Frequency). Providing that P1-08 is adjusted from the factory default setting, the Optidrive

will automatically carry out an autotune on the motor the first time it is enabled. During the autotune, the display will show . The test

procedure may take several minutes to complete depending on the motor. Once the autotune is completed, the drive will operate as normal,

and no further autotuning will be required unless the motor or drive control mode is changed (P4-01).

User Selected Autotune

The user can program the drive to carry out an autotune if required, as follows:Ensure the motor nameplate values are correctly entered as described above.

Set P1-14 = 101 to allow access to Parameter Groups 2, 3 and 4

Set P4-02 = 1 and press the button.

5.8. Operating in Sensorless Vector Speed Control Mode

Optidrive Plus can be programmed by the user to operate in Sensorless Vector mode, which provides enhanced low speed torque, optimum

motor speed regulation regardless of load and accurate control of the motor torque. In most applications, the default Voltage Vector control

mode will provide adequate performance, however if Sensorless Vector operation is required, the following procedure should be followed:Ensure the motor nameplate values are correctly entered in P1-07 (Motor Rated Voltage), P1-08 (Motor Rated Current) and P1-09 (Motor

Rated Frequency)

Set P1-14 = 101 to allow access to parameter groups 2, 3 and 4

The Motor Rated Power Factor from the motor nameplate MUST be entered in P4-05. If this data is not available, consult the motor

manufacturer for guidance.

Set P4-01 = 0 to select Sensorless Vector Speed Control

Set P4-02 = 1 to carry out an motor autotune

Parameters P4-03 and P4-04 have a significant effect on the behaviour of the motor when operating in vector mode, see section 6.4 for further

details, or the Optidrive Advanced User Guide.

5.9. Sensorless Vector Torque Control Mode

For applications which require the drive to control motor torque as opposed to motor speed, the Optidrive Plus can be programmed to

operate in Torque Control mode. When operating this way, the drive internal ramp times (P1-03 and P1-04) are disabled except during starting

and stopping. Please refer to the Optidrive Plus Advanced User Guide for further information on this.

5.10. Operation of Three Phase drives on Single Phase Supplies

Applies to: - Optidrive Plus, 230 Volt Supply versions, Size 3 and above

Optidrive Plus, 400 Volt Supply versions, Size 2 and above

It is possible to operate the above drive units from a single phase supply of the same rated voltage. When used in this way, the maximum

output current capacity is reduced by 50%. In order to operate on a single phase supply, the supply MUST be connected to the L1 and L2

terminals of the drive. The user must then press + + for >2s. The display will show , and all parameters will be reset to

factory default settings. Press the button to acknowledge and reset the drive. The maximum motor rated current setting in P1-08 will

now be limited to 50% of its original value, and the Phase Loss and Phase Imbalance Protection features will be disabled.

www.invertek.co.uk 15

6. Parameters

NOTE

Default parameter values for Horse Power rated drives are shown in brackets

Par.

Description

Range

Units

Default

Explanation

P1-01

Maximum

Frequency / Speed

P1-02 to 5*P1-09 (max 500Hz)

Hz

Rpm

50.0

(60.0)

Maximum speed limit – Hz or rpm.

If P1-10 >0, the value entered is in Rpm

P1-02

Minimum

Frequency / Speed

0.0 to P1-01

Hz

Rpm

0.0

Minimum speed limit – Hz or rpm.

If P1-10 >0, the value entered is in Rpm

P1-03

Acceleration ramp

time

0.0 to 3000.0

seconds

5.0

Acceleration ramp time from 0 to base speed (P1-

09) in seconds

P1-04

Deceleration ramp

time

0.0 to 3000.0

seconds

5.0

Deceleration ramp time from base speed (P1-09)

to standstill in seconds. When set to zero, fastest

possible ramp time without trip is activated

P1-05

Stop mode select

0 : Ramp to stop with brownout ride-through on mains loss

1 : Coast to stop

2 : Ramp to stop with ‘fast

stop’ on mains loss

-

0

0 : When the drive enable signal is removed, the

drive will ramp to stop at the rate set in P1-04. If

the mains supply is lost, the drive will try to

continue running by reducing the speed of the

load using the load as a generator.

1 : When the enable signal is removed from the

drive, the motor will coast (freewheel) to stop

2 : When the drive enable signal is removed, the

drive will ramp to stop at the rate set in P1-04. If

the mains supply is lost, the drive will ramp to stop

using the P2-25 decel ramp time

P1-06

Energy Optimiser

0: Disabled

1: Enabled

-

0

When enabled, automatically reduces applied

motor voltage on light load. Minimum value is 50%

of nominal rated voltage (P1-07)

P1-07

Motor rated

voltage

0, 20 to 250

0, 20 to 500

Volts

230

400

(460)

Rated (nameplate) voltage of the motor (Volts).

Value limited to 250V for low voltage drives.

P1-08

Motor rated

current

25% -100% of drive rated

current

Amps

Drive

rating

Enter the rated (nameplate) current of the motor.

This value is used for overload protection

P1-09

Motor rated

frequency

25Hz to 500Hz

Hz

50

(60)

Enter the rated (nameplate) frequency of the

motor

P1-10

Motor rated speed

0 to 60 000 rpm

Rpm

0

When non-zero, all speed related parameters are

displayed in rpm. Enter the motor rated

(nameplate) speed if this is required.

P1-11

Preset Speed 1

-P1-01 to P1-01

Hz / Rpm

50.0

(60.0)

Sets the speed the drive runs at when Preset

Speed 1 is selected

P1-12

Terminal / Keypad /

PID

Drive Control Mode

Selection

0 : Terminal control

1 : Keypad control – fwd only

2 : Keypad control fwd and

rev

3 : PID Control

4 : Modbus RTU Control

-

0

Primary Control Mode of the drive.

0 : Terminal control

1 : Uni-directional keypad control. Keypad START

button does not reverse direction.

2 : Bi-directional keypad control. Keypad START

button toggles between forward and reverse.

3 : User PID control with external feedback signal

4 : Modbus RTU Control. See section 10

P1-13

Trip log

Last four trips stored

-

Read only

Previous 4 trips stored in order of occurrence, with

the most recent first.

Press UP or DOWN to step through all four.

The most recent trip is always displayed first.

UV trip is only stored once.

P1-14

Extended menu

access

Code 0 to 30000

-

0

Set to “101” (default) for extended menu access.

Change code in P2-37 to prevent unauthorised

access to the Extended Parameter Set

6.1. Parameter Group 1 – Basic Parameters

Optidrive Plus 3GV User Guide

Following a factory reset, or when installing a drive for the first time, only Group 1 Parameter access is available. To allow access to Parameters

Groups 0, 2, 3 and 4, Parameters P1-14 and P2-37 must contain the same value. The factory set value for P2-37 = 101

16 www.invertek.co.uk

Optidrive Plus 3GV User Guide

Par.

Description

Range

Units

Default

Explanation

P2-01

Digital input function

select

0 to 22 - 0

Defines the function of the digital inputs

depending on the control mode setting in P1-

12. See section 7 Analog and Digital Input

Configurations for more information.

P2-02

Preset Speed 2

-P1-01 to P1-01

Hz / Rpm

0.0

Sets jog / preset speed 2

P2-03

Preset Speed 3

-P1-01 to P1-01

Hz / Rpm

0.0

Sets jog / preset speed 3

P2-04

Preset Speed 4

-P1-01 to P1-01

Hz / Rpm

0.0

Sets jog / preset speed 4

P2-05

Preset Speed 5

-P1-01 to P1-01

Hz / Rpm

0.0

Sets jog /preset speed 5

P2-06

Preset Speed 6

-P1-01 to P1-01

Hz / Rpm

0.0

Sets jog / preset speed 6

P2-07

Preset speed 7

-P1-01 to P1-01

Hz / Rpm

0.0

Sets jog / preset speed 7

P2-08

Preset speed 8

-P1-01 to P1-01

Hz / Rpm

0.0

Sets jog / preset speed 8

P2-09

Skip frequency

P1-02 to P1-01

Hz / Rpm

0.0

Centre point of skip frequency band set up in

conjunction with P2-10

P2-10

Skip frequency band

0 to P1-01

Hz / Rpm

0.0

Width of skip frequency band centred on

frequency set in P2-09

P2-11

Analog output /

Digital Output 1

Function select

Digital output mode

0 : Drive enabled

1 : Drive healthy

2 : Motor at target speed

3 : Motor Speed >0

4 : Motor speed >= limit

5 : Motor torque >= limit

6 : 2nd Analog Input >= limit

Analog Output Mode

7 : Motor speed

8 : Motor torque

9 : Motor power

10 : Motor current

7

Digital Output Mode. Logic 1 = +24V DC

0 : Logic 1 when the drive is enabled (Running)

1: Logic 1 When no Fault condition exists on the

drive

2 : Logic 1 when the motor speed matches the

setpoint speed

3 : Logic 1 when the motor runs above zero

speed

Options 4 to 6 : the Digital output is enabled

using the level set in P2-12h and P2-12L

Analog Output Mode

7 : Motor Speed, 0 to 10V = 0 to P-01

8 : Motor torque, 0 to 10V = 0 to 200% of

motor rated torque

9 : Motor power, 0 to 10V = 0 to 150% of drive

rated power

10 : Motor Current, 0 to 10V = 0 to 200% of P108

P2-12h

Digital Output Control

High Limit

0.0 to 200.0

%

100.0

With P2-11 = 4 to 6, Digital Output 1 is set to

Logic 1 (+24V DC) when the value set in P2-12h

is exceeded, and returns to Logic 0 (0V) when

the selected value reduces below the limit set

in P2-12L

P2-12L

Digital Output Control

Low Limit

0.0 to P2-12h

%

100.0

P2-13

User Relay Output

Function Select

0 : Drive enabled

1 : Drive healthy

2 : Motor at target speed

3 : Motor Speed >0

4 : Motor speed >= limit

5 : Motor torque >= limit

6 : 2nd Analog Input >= limit

1

Selects the function assigned to the relay

output.

0 : Logic 1 when the drive is enabled (Running)

1: Logic 1 When no Fault condition exists on the

drive

2 : Logic 1 when the motor speed matches the

setpoint speed

3 : Logic 1 when the motor runs above zero

speed

Options 4 to 6 : the Digital output is enabled

using the level set in P2-14h and P2-14L

P2-14h

Relay Output Control

High Limit

0.0 to 200.0

%

100.0

With P2-13 = 4 to 6, the User Relay Output is

set to Logic 1 (+24V DC) when the value set in

P2-14h is exceeded, and returns to Logic 0 (0V)

when the selected value reduces below the

limit set in P2-12L

P2-14L

Relay Output Control

Low Limit

0.0 to P2-14h

%

100.0

P2-15

Relay Output Mode

0 : Normally Open

1 : Normally Closed

-

0

Inverts the operating status of the User Relay

0 : Logic 1 = Relay Contacts Closed

1 : Logic 1 = Relay Contacts Open

The drive must be powered for the contacts to

close

P2-16

Zero Speed Holding

Time

0.0 to 60.0

seconds

0.2

Determines the time for which the drive output

is held at zero speed when stopping, before the

drive output is disabled

6.2. Parameter Group 2 - Extended parameters

www.invertek.co.uk 17

Optidrive Plus 3GV User Guide

Par.

Description

Range

Units

Default

Explanation

P2-17

Start Mode Select

to

-

Auto-0

Edge-r : Following Power on or reset, the drive

will not start if Digital Input 1 remains closed.

The Input must be closed following a power on

or reset to start the drive.

Auto-0 : Following a Power On or Reset, the

drive will automatically start if Digital Input 1 is

closed.

Auto 1 to 5 : Following a Fault, the drive will

make up to 5 attempts to restart at 20 second

intervals. The drive must be powered down to

reset the counter

P2-18

Spin Start Enable

0 : Disabled

1 : Enabled

-

0

When enabled, on start up the drive will

attempt to determine if the motor is already

rotating, and will begin to control the motor

from its current speed. A short delay may be

observed when starting motors which are not

turning

P2-19

Keypad Restart Mode

0 : Minimum Speed, Edge-r

1 : Previous Speed, Edge-r

2 : Minimum Speed, Auto-r

3: Previous Speed, Auto-r

-

1

Active when P1-12 = 1 or 2

0 : Following a stop and restart, the drive will

run at minimum speed

1 : Following a stop and restart, the drive will

run at the last setpoint speed

2 : As per setting 0, except that the Run

command will be determined by the status of

Digital Input 1, and the user is not required to

press the keypad start button

3 : As per setting 1, except that the Run

command will be determined by the status of

Digital Input 1, and the user is not required to

press the keypad start button

P2-20

Standby Mode

0.0 : Disabled

0.1 to 60.0

seconds

0.0

When P2-20 >0, the drive enters standby mode

if the minimum speed is maintained for the

time period set in P2-20.

Note : P2-16 must be set to zero for standby

mode to operate

P2-21

Display Scaling Factor

0.000 to 30.000

-

0.000

Disabled if P2-21 is set to 0.

If P2-21 is set >0, the variable selected in P2-22

is multiplied by the factor entered in P2-21, and

displayed whilst the drive is running

P2-22

Display Scaling Source

0 : 2nd Analog Input

1 : Motor Speed

2 : Motor Torque

3 : Motor Current

-

0

P2-23

Brake Circuit Enable

0 : Disabled

1: Enabled, Low Duty

2: Enabled, High Duty

3 : Enabled, No Protection

-

0

Enables the internal brake chopper on Size 2

and above drives. Settings 1 and 2 provide

software monitoring of the braking power

consumption. Setting 3 disables the protection,

and externally monitoring must be used

P2-24

Effective Switching

Frequency

4 to 16 / 24 / 32 / Auto

Drive Power Rating

Dependent

kHz

16

8

4

Effective power stage switching frequency.

Higher frequencies reduce the audible ‘ringing’

noise from the motor, and improve the output

current waveform, at the expense of increased

drive losses

P2-25

2nd Deceleration Ramp

time

0.0 to 3000.0

seconds

0.0

Deceleration 2nd ramp down time

Selected Automatically on mains power loss if

P1-05 = 2

Can also be selected by digital inputs,

dependent on P2-01 setting.

When set to 0, the drive decelerates as quickly

as possible, whilst preventing an overvoltage

trip

P2-26

Modbus

Communication Baud

Rate

t9.6, t19.2, t38.4, t57.6,

t115.2

r9.6, r19.2, r38.4, r57.6,

r115.2

kbaud

t115.2

Modbus RTU serial data link communication

Baud Rate. A ‘t’ Prefix indicates the drive will

trip if communication with the network master

is lost, after a preset time period. An ‘r’ Prefix

indicates that the Optidrive will Ramp to stop in

the event of a loss of communication with the

network master, after a preset time period .

P2-27

Drive Communication

Address

0: Disabled

1 to 63

-

1

Sets the communication address for the drive

when connected on an Optibus or Modbus

Network

18 www.invertek.co.uk

Optidrive Plus 3GV User Guide

Par.

Description

Range

Units

Default

Explanation

P2-28

Master / Slave Mode

Select

0 : Slave Mode

1 : Master Mode

-

0

When in Master Mode, the drive transmits its

operational status via the serial data link. All

drives on the data link must have unique

addresses. Only one drive can be programmed

as a Master

P2-29

Digital / Slave speed

reference scaling factor

0 to 500.0

%

100.0

Scaling factor applied to any speed reference

on the serial data link, e.g. in Master / Slave

operation, a Slave drive will apply this scaling

factor to the transmitted Master speed

reference

P2-30

Bipolar analog input

format

= 0 - 24V DC

= 0 - 10V DC

-10 to + 10V DC

= -24 to + 24V DC

-

Configures the analog input signal to match the

reference connected to terminal 6. Only

voltage signals can be directly connected, mA

reference signals require an external 500R

resistor connection.

P2-31

Bipolar analog input

scaling

0.0 to 500.0

%

100.0

Scales the analog input by this factor, e.g. if P230 is set for 0 – 10V, and the scaling factor is

set to 200.0%, a 5 volt input will result in the

drive running at maximum speed (P1-01)

P2-32

Bipolar analog input

offset

-500.0 to 500.0

%

0.0

Sets an offset, as a percentage of the full scale

range of the input, which is applied to the

analog input signal

P2-33

2nd analog input format

= Digital

= 0 to 10V DC

= 4 to 20mA

= 0 to 20mA

-

Selects the format for the 2nd analog input

Selecting sets the input up as a digital

input.

P2-34

2nd analog input scaling

0 to 500.0

%

100.0

Scales the 2nd analog input by the factor set in

this parameter

P2-35

Digital speed reference

scaling control

0 : Disabled (No Scaling)

1 : Scaled by P2-29

2 : Scaled by P2-29, then

bipolar analog input added as

an offset

3 : Scaled by P2-29 and by

bipolar analog input

-

0

Active in Keypad mode (P1-12 = 1 or 2) and

Master / Slave mode only.

1 : Actual Speed = Digital Speed x P2-29

2: Actual Speed = (Digital Speed x P2-29) +

bipolar analog reference

3 : Actual Speed = Digital Speed x P2-29 x

bipolar analog reference

P2-36

Analog output format

= 0 to 10V

= 4 to 20mA

= 10 to 0V

= 20 to 4mA

-

Selects the analog output signal format

P2-37

Extended menu access

code

0 to 9999

-

101

Defines the access code which must be entered

in P1-14 to access parameter groups above

Group 1

P2-38

Parameter Lock

0 : Unlocked

1 : Locked

-

0

When locked, all parameter changes are

prevented

P2-39

Hours Run Counter

0 to 65535

Hours

Read

Only

Indicates the number of hours for which the

drive has run

P2-40

Drive Type / Rating

N/A

-

Read

Only

Read only parameter, showing the drive type

and power rating

www.invertek.co.uk 19

6.3. Parameter Group 3 – PID Control

Par.

Description

Range

Units

Default

Explanation

P3-01

Proportional

gain

0.1 to 30.0

-

2.0

PID Controller Proportional Gain. Higher values provide a greater

change in the drive output frequency in response to small changes

in the feedback signal. Too high a value can cause instability

P3-02

Integral time

constant

0.0 to 30.0

seconds

1.0

PID Controller Integral Time. Larger values provide a more damped

response for systems where the overall process responds slowly

P3-03

Differential time

constant

0.00 to 1.0

seconds

0.00

PID Differential Time Constant

P3-04

PID operating

mode

0 : Direct

1 : Inverse

-

0

Direct operation – Motor speed increases with an increase in the

feedback signal

Inverse Operation – Motor speed decreases with an increase in the

feedback signal

P3-05

PID Setpoint /

reference select

0 : Digital

1 : Analog

-

0

Selects the source for the PID Reference / Setpoint

0 : P3-06 is used

1 : Bipolar analog input is used

P3-06

PID digital

reference

0.0 to 100.0

%

0.0

Sets the preset digital PID reference / setpoint

P3-07

PID controller

high limit output

P3-08 to 100.0

%

100

Limits the maximum value output from the PID controller

P3-08

PID controller

low limit output

0 to P3-07

%

0

Limits the minimum output from the PID controller

P3-09

User PID output

limit / function

control

0 : Digital output limits

1 : Analog Upper Limit

2: Analog Lower Limit

3 : PID added to

Bipolar analog input

reference

-

0

0 : PID output range limited by P3-07 & P3-08

1 : PID maximum output limited by the signal applied to the bipolar

analog input

2: PID minimum output limited by the signal applied to the bipolar

analog input

3: PID output is added to the speed reference applied to the bipolar

analog input

P3-10

PID feedback

source select

0 : 2nd Analog Input

1 : Bipolar analog

input

-

0

Selects the source of the PID feedback signal

Par.

Description

Range

Units

Default

Explanation

P4-01

Control Mode

0 : Vector Speed Control

1 : Vector Torque Control

2 : V/f Speed Control

-

2

Selects the motor control method. An autotune must be

performed following a change, see section 6.4

P4-02

Motor parameter

autotune

0 : Disabled

1 : Enabled

-

0

When set to 1, the drive immediately carries out a nonrotating autotune to measure the motor parameters for

optimum control and efficiency

P4-03

Speed controller

proportional gain

1 to 4096

-

300

Sets the proportional gain value for the speed controller.

Too high a value may cause overshoot when accelerating to

setpoint speed, or instability of the motor output speed.

P4-04

Speed controller

integral time

0.010 to 1.000

seconds

0.050

Set the integral time for the speed controller. Smaller values

provide a faster response in reaction to motor load changes,

at the risk of introducing instability

P4-05

Motor power factor

0, 0.50 to 1.00

-

-

Motor nameplate power factor, which must be entered for

Vector operation (P4-01 = 0 or 1)

P4-06

Torque reference

source select

0 : Preset Value

1 : Bipolar analog input

2 : 2nd analog input

3 : Modbus RTU

4 : Master / Slave

-

0

When operating in vector mode (P4-01 = 0 or 1), selects the

source of the torque reference

P4-07

Maximum torque

limit / torque

reference

0.0 to 200.0

%

200.0

If P4-01 = 1 and P4-06 = 0, sets the preset torque reference

If P4-01 = 0, sets the maximum torque limit

P4-08

Minimum torque

limit

0.0 to 150.0

%

0.0

Sets a minimum torque limit, see the warning below

P4-09

V/f characteristic

adjustment

frequency

0 to P1-09

Hz

0.0

When operating in V/f mode (P4-01 = 2), sets a frequency

point at which the voltage applied in P4-10 is applied to the

motor. Care must be taken to avoid overheating and

damaging the motor when using this feature

P4-10

V/f characteristic

adjustment voltage

0 to P1-07

-

0

In conjunction with P4-09, in V/f mode (P4-01 = 2), sets the

voltage applied to the motor at the adjustment frequency

set in P4-09

Incorrect adjustment of parameters in menu group 4 can cause unexpected behaviour of the motor and any connected machinery. It

is recommended that these parameters are only adjusted by experienced users.

Optidrive Plus 3GV User Guide

6.4. Parameter Group 4 – High Performance Motor Control

20 www.invertek.co.uk

Optidrive Plus 3GV User Guide

Par.

Description

Display range

Units

Explanation

P0-01

Bipolar analog input value

-100 to 100

%

100% = max input voltage

P0-02

2nd Analog input value

0 to 100

%

100% = max input voltage

P0-03

Post Ramp Speed Reference

-500 to 500

%

100% = P1-09

P0-04

Digital speed reference

-P1-01 to P1-01

Hz / Rpm

Digital speed reference

P0-05

Torque controller reference

0 to 200

%

Torque reference setpoint

P0-06

PID Reference

0 to 100

%

PID reference / setpoint

P0-07

PID Feedback

0 to 100

%

PID controller feedback value

P0-08

PID error

0 to 100

%

Actual PID error

P0-09

PID P Term

0 to 100

%

Proportional component

P0-10

PID I term

0 to 100

%

Integral component

P0-11

PID D term

0 to 100

%

Differential component

P0-12

PID Output

0 to 100

%

Output from PID controller

P0-13

Output Torque

0 to 200

%

100% = motor rated torque

P0-14

Magnetising current

Drive dependent

A

Motor rms magnetising current

P0-15

Rotor Current

Drive dependent

A

Rotor rms current

P0-16

Field Strength

0 to 100

%

Magnetic field strength

P0-17

Stator resistance

Drive dependent

Ohms

Phase to phase stator resistance

P0-18

Stator Inductance

Drive dependent

H

Stator inductance

P0-19

Rotor resistance

Drive dependent

Ohms

Calculated rotor resistance

P0-20

DC Bus Voltage

0 to 1000

Volts

Internal DC Bus voltage

P0-21

Drive Temperature

0 to 120

ºC

Measured heatsink temperature

P0-22

Supply voltage L1 – L2

Drive dependent

Volts

Phase to phase supply voltage

P0-23

Supply voltage L2 – L3

Drive dependent

Volts

Phase to phase supply voltage

P0-24

Supply voltage L3 – L1

Drive dependent

Volts

Phase to phase supply voltage

P0-25

Estimated rotor speed

Drive dependent

Hz / Rpm

In vector mode, estimated speed of motor

P0-26

kWh meter

0 to 999.9

kWh

Cumulative energy consumption

P0-27

MWh meter

0 to 60,000

MWh

Cumulative energy consumption

P0-28

Software ID – IO Processor

Drive dependent

-

Version number & checksum

P0-29

Software ID – Motor Control

Drive dependent

-

Version number & checksum

P0-30

Drive serial number

Drive dependent

-

Unique drive serial number

6.5. Parameter Group 0 – Monitoring Parameters (Read Only)

www.invertek.co.uk 21

Optidrive Plus 3GV User Guide

P2-01

Digital input 1 (T2)

Digital input 2 (T3)

Digital input 3 (T4)

Analog input (T6)

0

Open: Stop (disable)

Closed: Run (enable)

Open : Bipolar analog speed ref

Closed : Preset speed ref

Open : Preset Speed 1

Closed : Preset Speed 2

Bipolar analog input

1

Open: Stop (disable)

Closed: Run (enable)

Open: Preset Speed 1

Closed: Preset speed 2

Open: Preset speed 1 / 2

Closed: Preset speed 3

Open : Preset Speed 1 / 2 / 3

Closed : Preset Speed 4

2

Open: Stop (disable)

Closed: Run (enable)

Digital Input 2

Digital Input 3

Bipolar analog input

Speed Setpoint

Open

Open

Open

Preset Speed 1 1

Closed

Open

Open

Preset Speed 2 1

Open

Closed

Open

Preset Speed 3 1

Closed

Closed

Open

Preset Speed 4 1

Open

Open

Closed

Preset Speed 5 1

Closed

Open

Closed

Preset Speed 6 1

Open

Closed

Closed

Preset Speed 7 1

Closed

Closed

Closed

Preset Speed 8 1

3

Open: Stop (disable)

Closed: Run (enable)

Open : Forward

Closed : Reverse