Optidrive ODV-2 User Guide Revision 2.00

www.invertekdrives.com

1

1

Introduction

User Guide

IP20

IP66 / NEMA 4X

IP55 / NEMA 12

IP40

AC Variable Speed Drives

0.75 - 160kW / 1HP - 250HP

200-480V Single and 3 Phase Input

Installation and Operating Instructions

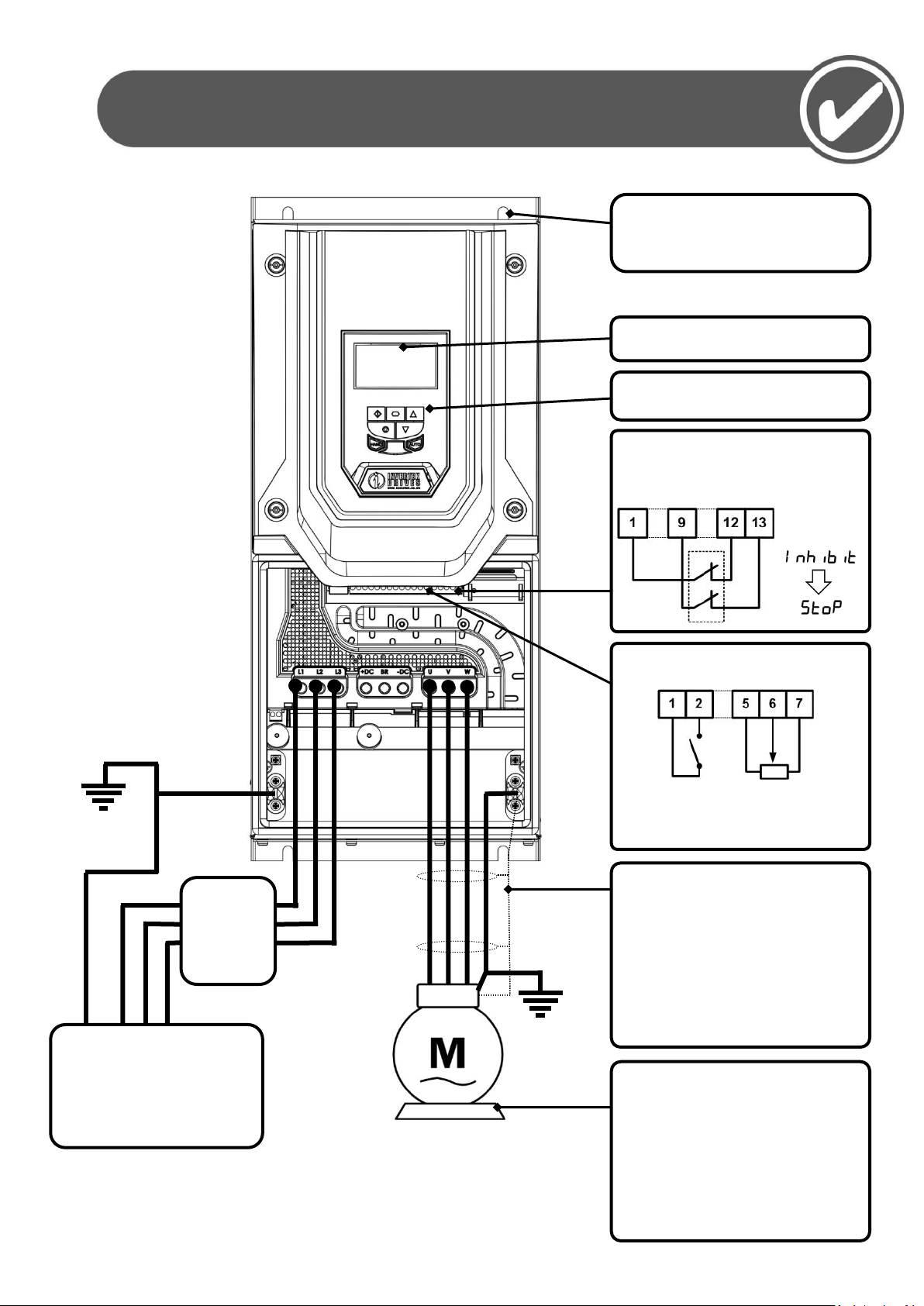

Keypad Operation can be found in

section 5.5 on page 27

Run / Stop 10K Pot

HVAC Display

(Status, Diagnostics, and Programming)

Motor Cable

For correct cable size, see Technical

Data on page 47

Observe the maximum permissible

motor cable length.

For Motor cable lengths > 50 metres, an

output filter is recommended.

Use a screened (shielded cable). The

shield should be bonded to earth at

Motor Connection

Check for Star or Delta connection

according to the motor voltage rating in

section 4.5.

Motor Nameplate Details

Motor Rated Voltage: P1-07

Motor Rated Current: P1-08

Motor Rated Frequency: P1-09

Motor Rated Speed (Optional): P1-10

Fuses or MCB

Check Drive

Rating info in

section 13.4

AC Supply Connection

200 – 240 Volts + / - 10%

380 – 380 Volts + / - 10%

Check Drive Input Voltage

Ranges on page 47

PE L1 L2 L3

Control Terminal

Configuration based on factory settings

Mechanical Mounting

Information can be found in section 3.7

on page 16

Hardware Enable Circuit

Link the terminals as shown, optionally

through contacts to enable drive

operation.

Close the switch to run (enable)

Open the switch to stop

Optidrive HVAC Start Up Guide

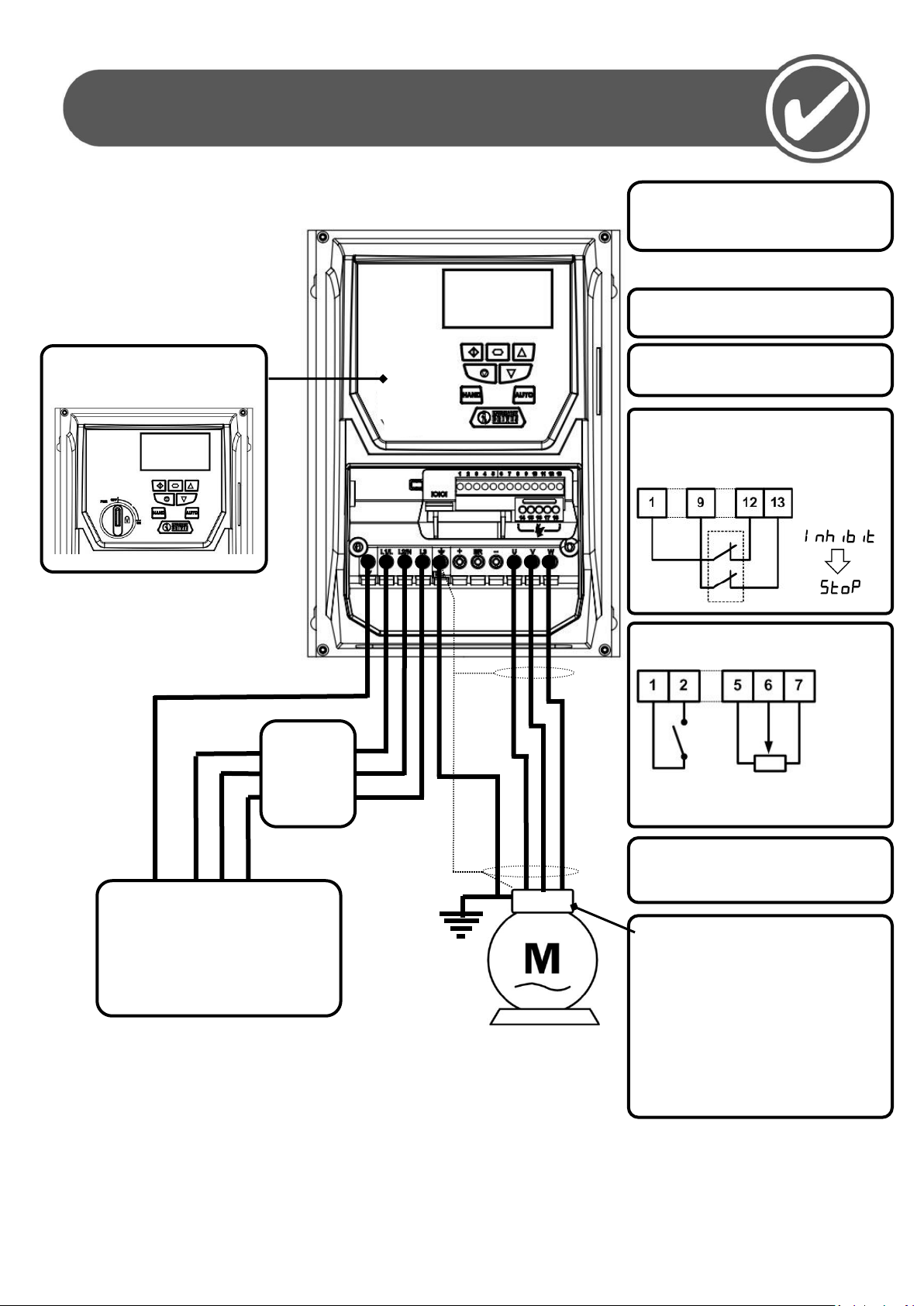

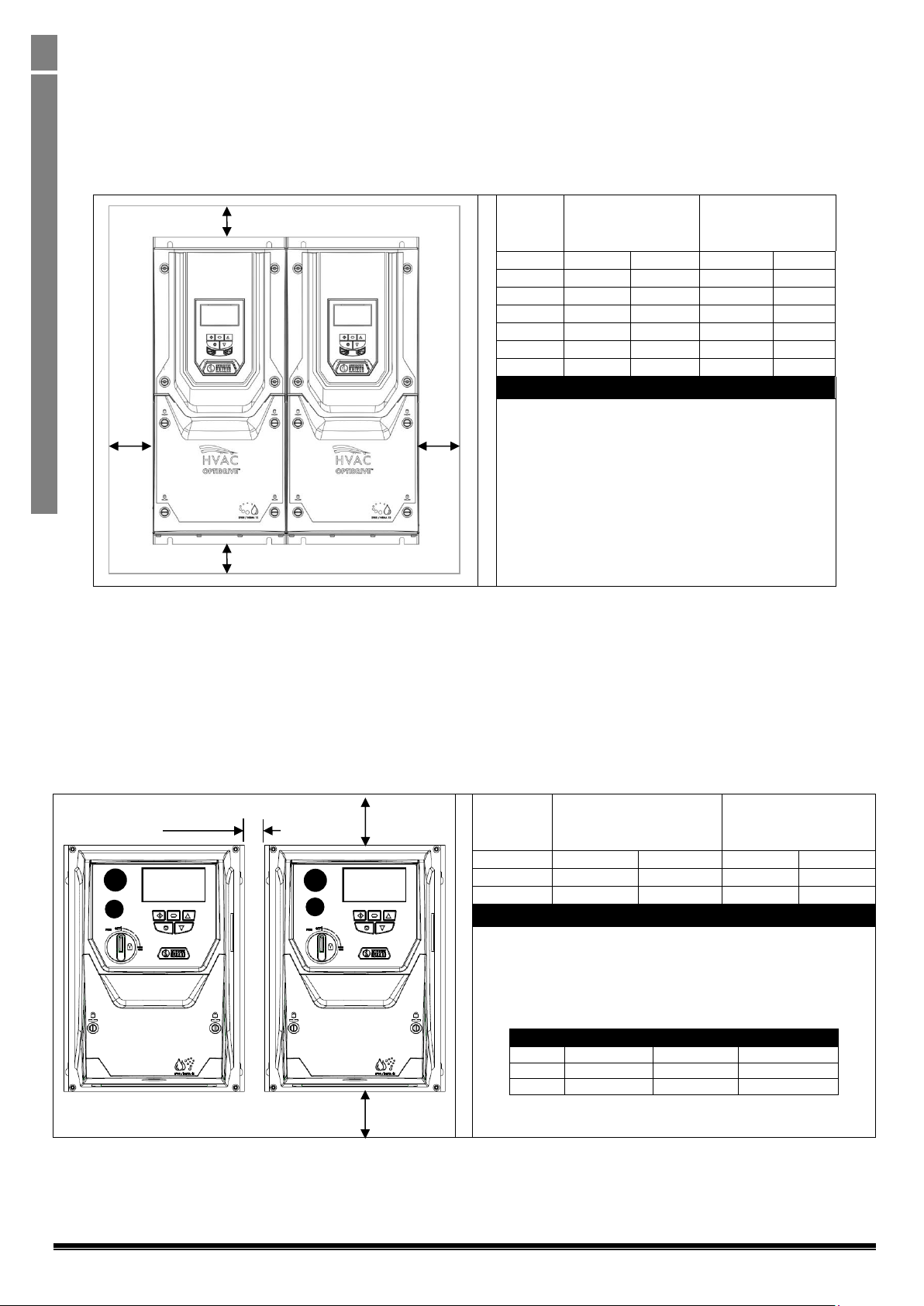

OPTIDRIVE HVAC (IP55 Enclosure).

Supply Voltage

Optidrive HVAC User Guide V2.00

Optidrive HVAC Start Up Guide

HVAC Display

(Status, Diagnostics, and Programming)

Motor Cable Sizes

Check the rating information in

section 11.3 on page 47

Motor Connections

Check for Star or Delta connection

according to the motor voltage rating –

se section 4.5 on page 23

Motor Nameplate Details

Motor Rated Voltage: P1-07

Motor Rated Current: P1-08

Motor Rated Frequency: P1-09

Motor Rated Speed (Optional): P1-10

Mechanical Mounting

Information can be found in section 3.8

on page 16

Control Terminal

Configuration based on factory settings

Hardware Enable Circuit

Link the terminals as shown, optionally

through switch contacts to enable drive

operation.

Close the switch to run (enable)

Open the switch to stop

Keypad Operation can be found in

section 5.5 on page 27

Applies to Switched version only

In-built Isolator:

Mains Power On / Off

Fuses or MCB

Check Drive

Rating info in

section 13.4.

AC Supply Connection

200 – 240 Volts + / - 10%: 1 / 3 Phase

380 – 380 Volts + / - 10%: 3 Phase

Check Drive Input Voltage Ranges on

page 47

PE L1 L2 L3

Run / Stop 10K Pot

OPTIDRIVE HVAC (IP66 Enclosure).

Optidrive HVAC User Guide V2.00

Fuses or MCB

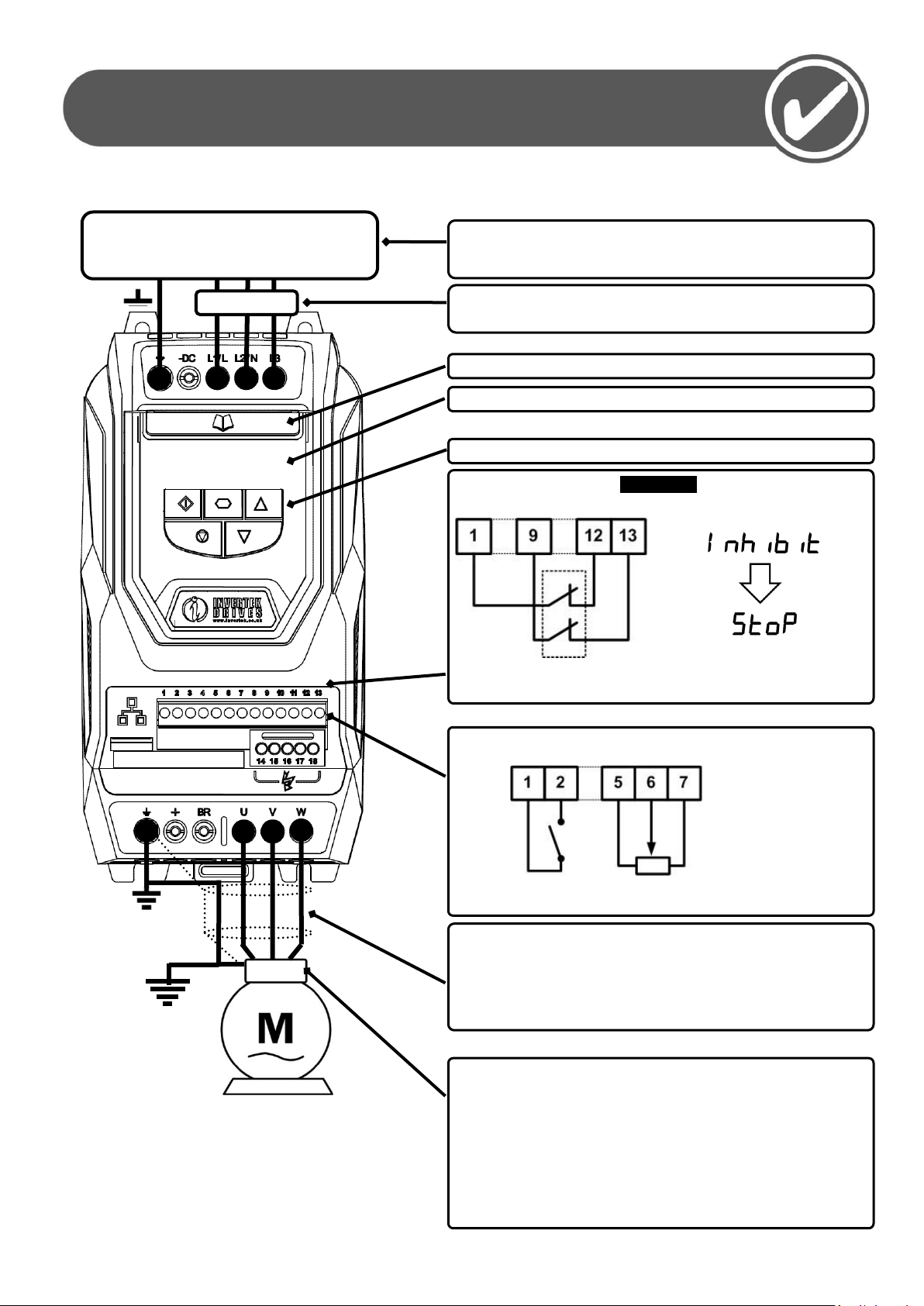

Optidrive HVAC Start Up Guide

OPTIDRIVE HVAC (IP20 Enclosure).

AC Supply Connection Supply Voltage

3 Phase Units : Connect L1 L2 L3, PE 200 – 240 Volts + / - 10%

1 Phase Units : Connect L1, L2, PE 380 – 380 Volts + / - 10%

Fuses or MCB

o Check the Technical Data in section 11 on page 47

Help Card

Display Information can be found in section 5.4 on page 26

Keypad Operation can be found in section 5.2 on page 25

IMPORTANT!

Hardware Enable Circuit

Run – Stop 10K Speed Pot

Link the terminals as shown, optionally through contacts to enable drive

operation

Control Terminals

Based on the factory default parameter settings

Close the switch to run (enable), open to stop

Motor Cable

o For correct cable size see Technical Data on page 47

o Observe the maximum permissible motor cable length

o For Motor cable lengths > 50 metres, an output filter is

recommended

o Use a screened (shielded cable)

Motor Connection

o Check for Star or Delta connection according to the motor

voltage rating - see section 4.5 on page 23

o Motor Nameplate Details

o Motor Rated Voltage : P1-07

o Motor Rated Current : P1-08

o Motor Rated Frequency : P1-09

o Motor Rated Speed (Optional) : P1-10

Optidrive ODV-2 User Guide Revision 2.00

www.invertekdrives.com

5

1

Introduction

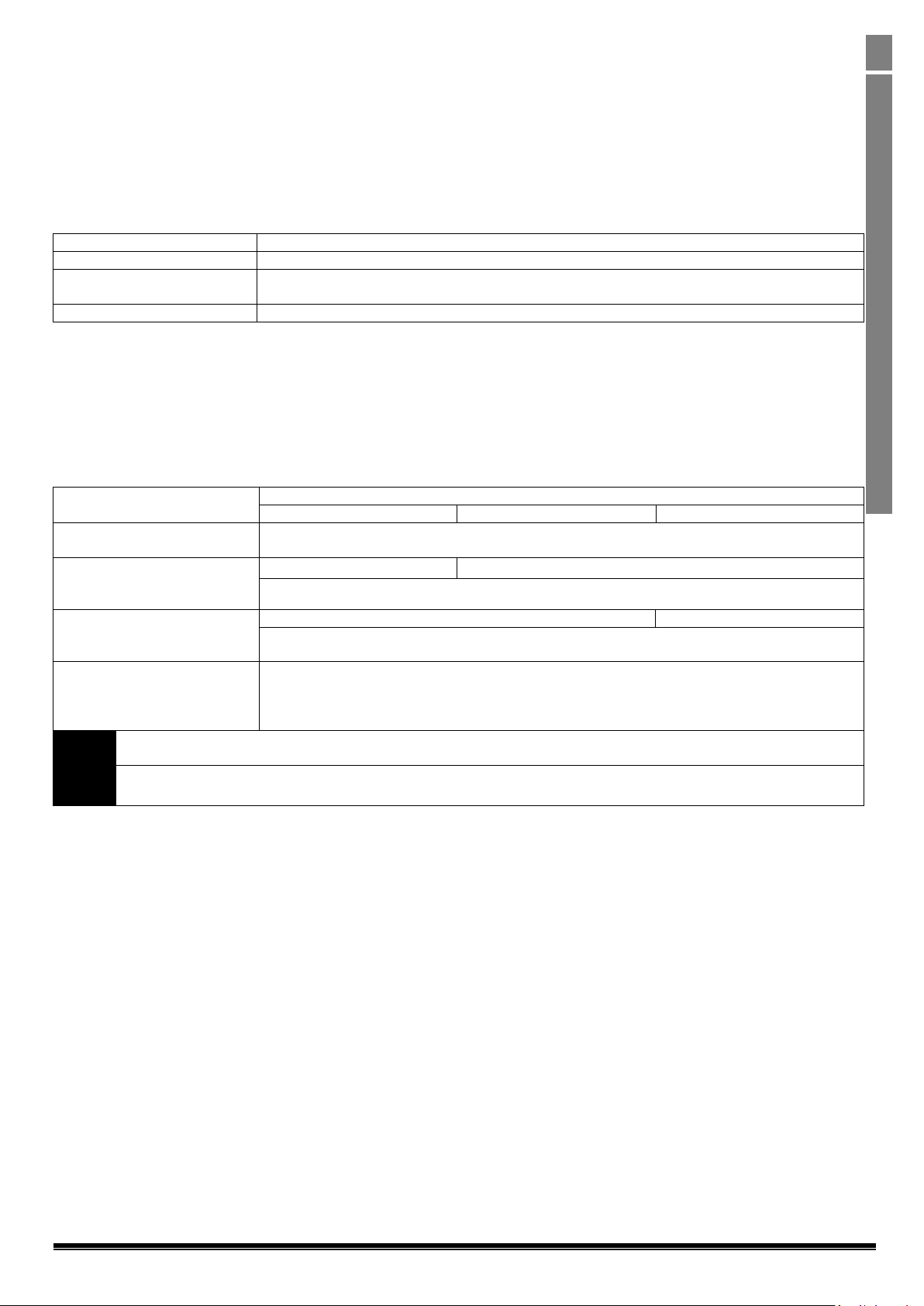

EN 61800-5-1: 2003

Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

EN 61800-3 2nd Ed: 2004

Adjustable speed electrical power drive systems. EMC requirements and specific test methods

EN 55011: 2007

Limits and Methods of measurement of radio disturbance characteristics of industrial, scientific and

medical (ISM) radio-frequency equipment (EMC)

EN60529 : 1992

Specifications for degrees of protection provided by enclosures

Drive Type / Rating

EMC Category

C1

C2

C3

1 Phase, 230 Volt Input

ODV-2-x2xxx-1xFxx-xx

No additional filtering required

Use shielded motor cable

3 Phase, 400 Volt Input

IP20 & IP66 Models

ODV-2-x4xxx-3xFxx-xx

Use Additional External Filter

No additional filtering required

Use shielded motor cable

3 Phase, 400 Volt Input

IP55 Models

ODV-2-x4xxx-3xFxN-xx

Use Additional External Filter

No Additional Filtering Required

Use shielded motor cable

3 Phase, 525 & 600 Volt Input

All Models

ODV-2-x5xxx-3x0xx-xx

ODV-2-x5xxx-3x0xx-xx

This equipment is intended for fixed installation, and is not intended to conform to the EMC Directive

without additional preventative measures being applied. Consult your Invertek Sales Partner for further

information.

Note

Compliance with EMC standards is dependent on a number of factors including the environment in which the drive is installed,

motor switching frequency, motor, cable lengths and installation methods adopted.

For motor cable lengths greater than 100m, an output dv / dt filter must be used, please refer to the Invertek Stock Drives

Catalogue for further details

Declaration of Conformity:

Invertek Drives Limited

Offas Dyke Business Park

Welshpool

Powys

UK

SY21 8JF

Invertek Drives Ltd hereby states that the Optidrive ODV-2 product range conforms to the relevant safety provisions of the Low Voltage

Directive 2006/95/EC and the EMC Directive 2004/108/EC and has been designed and manufactured in accordance with the following

harmonised European standards:

Electromagnetic Compatibility

All Optidrives are designed with high standards of EMC in mind. All versions suitable for operation on Single Phase 230 volt and Three Phase

400 volt supplies and intended for use within the European Union are fitted with an internal EMC filter. This EMC filter is designed to reduce

the conducted emissions back into the supply via the power cables for compliance with harmonised European standards.

It is the responsibility of the installer to ensure that the equipment or system into which the product is incorporated complies with the EMC

legislation of the country of use. Within the European Union, equipment into which this product is incorporated must comply with the EMC

Directive 2004/108/EC. When using an Optidrive with an internal or optional external filter, compliance with the following EMC Categories, as

defined by EN61800-3:2004 can be achieved:

All rights reserved. No part of this User Guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including photocopying, recording or by any information storage or retrieval system without permission in writing from the publisher.

Copyright Invertek Drives Ltd © 2013

All Invertek Optidrive HVAC units carry a 2 year warranty against manufacturing defects from the date of manufacture. The manufacturer

accepts no liability for any damage caused during or resulting from transport, receipt of delivery, installation or commissioning. The

manufacturer also accepts no liability for damage or consequences resulting from inappropriate, negligent or incorrect installation, incorrect

adjustment of the operating parameters of the drive, incorrect matching of the drive to the motor, incorrect installation, unacceptable dust,

moisture, corrosive substances, excessive vibration or ambient temperatures outside of the design specification.

The local distributor may offer different terms and conditions at their discretion, and in all cases concerning warranty, the local distributor

should be contacted first.

This user guide is the “original instructions” document. All non-English versions are translations of the “original instructions”.

Contents of this User Guide are believed to be correct at the time of printing. In the interest of a commitment to a policy of continuous

improvement, the manufacturer reserves the right to change the specification of the product or its performance or the contents of the User

Guide without notice.

This User Guide is for use with version 1.30 Firmware.

User Guide 2.00

Invertek Drives Ltd adopts a policy of continuous improvement and whilst every effort has been made to provide accurate and up to date

information, the information contained in this User Guide should be used for guidance purposes only and does not form the part of any

contract.

Optidrive HVAC User Guide V2.00

6

www.invertekdrives.com

1

Introduction

1. Introduction................................................................................................................................ 8

1.1. Important safety information .............................................................................................................................................. 8

2. General Information and Ratings ................................................................................................. 9

2.1. Drive model numbers .......................................................................................................................................................... 9

2.2. Identifying the Drive by Model Number ............................................................................................................................ 11

3. Mechanical Installation .............................................................................................................. 12

3.1. General .............................................................................................................................................................................. 12

3.2. Before Installation ............................................................................................................................................................. 12

3.3. UL Compliant Installation .................................................................................................................................................. 12

3.4. Mechanical dimensions and Weights ................................................................................................................................ 12

3.5. Guidelines for Enclosure mounting (IP20 Units)................................................................................................................ 15

3.6. Mounting the Drive – IP20 Units ...................................................................................................................................... 15

3.7. Guidelines for mounting IP55 Units................................................................................................................................... 16

3.8. Guidelines for mounting (IP66 Units) ............................................................................................................................... 16

3.9. Removing the Terminal Cover ........................................................................................................................................... 17

3.10. Routine Maintenance ....................................................................................................................................................... 19

3.11. Gland Plate and Lock Off ................................................................................................................................................... 19

4. Electrical Installation .................................................................................................................. 20

4.1. Grounding the Drive .......................................................................................................................................................... 20

4.2. Wiring Precautions ............................................................................................................................................................ 21

4.3. Incoming Power Connection ............................................................................................................................................. 22

4.4. Drive and Motor Connection ............................................................................................................................................. 22

4.5. Motor Terminal Box Connections ...................................................................................................................................... 23

4.6. Motor Thermal overload Protection. ................................................................................................................................ 23

4.7. Control Terminal Wiring .................................................................................................................................................... 24

4.8. Connection Diagram .......................................................................................................................................................... 24

5. Managing the Keypad ................................................................................................................ 25

5.1. Keypad Layout and Function – Standard LED Keypad (IP20 Drives) .................................................................................. 25

5.2. Changing Parameters – Standard LED Keypad (IP20 Drives) ............................................................................................. 25

5.3. Advanced Keypad Operation Short Cuts – Standard LED Keypad (IP20 Drives) ................................................................ 26

5.4. Drive Operating Displays – Standard LED Keypad (IP20 Drives) ........................................................................................ 26

5.5. Keypad Layout and Function – Standard OLED Keypad (IP55 and IP66 Drives) ................................................................ 27

5.6. Drive Operating Displays – Standard OLED Keypad (IP55 and IP66 Drives) ...................................................................... 27

5.7. Accessing and Changing Parameter Values – Standard OLED Keypad (IP55 and IP66 Drives) .......................................... 27

5.8. Resetting Parameters to Factory Default Settings – Standard OLED Keypad (IP55 and IP66 Drives)................................ 28

5.9. Resetting Parameters to User Default Settings – Standard OLED Keypad (IP55 and IP66 Drives) .................................... 28

5.10. Changing the Language on the OLED Display – Standard OLED Keypad (IP55 and IP66 Drives) ....................................... 29

5.11. Selecting between Hand and Auto Control – Standard OLED Keypad (IP55 and IP66 Drives) .......................................... 29

6. Commissioning .......................................................................................................................... 30

6.1. General .............................................................................................................................................................................. 30

7. Parameters ................................................................................................................................ 31

7.1. Parameter Set Overview .................................................................................................................................................... 31

7.2. Parameter Group 1 – Basic Parameters ............................................................................................................................ 31

8. Digital Input Functions ............................................................................................................... 33

8.1. Digital Input Configuration Parameter P1-13 .................................................................................................................... 33

9. Extended Parameters ................................................................................................................. 34

9.1. Parameter Group 2 - Extended parameters ...................................................................................................................... 34

9.2. Parameter Group 3 – PID Control ...................................................................................................................................... 38

9.3. Parameter Group 4 – High Performance Motor Control ................................................................................................... 39

9.4. Parameter Group 5 – Communication Parameters ........................................................................................................... 40

9.5. Parameter Group 8 – HVAC Function Specific Parameters ............................................................................................... 41

9.6. Parameter Group 0 – Monitoring Parameters (Read Only) ............................................................................................... 43

10. Serial communications ............................................................................................................... 45

10.1. RS-485 communications .................................................................................................................................................... 45

10.2. Modbus RTU Communications .......................................................................................................................................... 45

10.3. BACnet MS/TP Communications ....................................................................................................................................... 46

11. Technical Data ........................................................................................................................... 47

11.1. Environmental ................................................................................................................................................................... 47

11.2. Input Voltage Ranges ......................................................................................................................................................... 47

11.3. Output Power and Current ratings .................................................................................................................................... 47

11.4. Additional Information for UL Approved Installations ...................................................................................................... 49

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

7

1

Introduction

11.5. Derating Information ......................................................................................................................................................... 50

12. Troubleshooting ......................................................................................................................... 51

12.1. Fault messages .................................................................................................................................................................. 51

Optidrive HVAC User Guide V2.00

8

www.invertekdrives.com

1

Introduction

Danger : Indicates a risk of electric shock, which, if not

avoided, could result in damage to the equipment and

possible injury or death.

Danger : Indicates a potentially hazardous situation

other than electrical, which if not avoided, could

result in damage to property.

This variable speed drive product (Optidrive) is intended for professional incorporation into complete equipment or systems as

part of a fixed installation. If installed incorrectly it may present a safety hazard. The Optidrive uses high voltages and currents,

carries a high level of stored electrical energy, and is used to control mechanical plant that may cause injury. Close attention is

required to system design and electrical installation to avoid hazards in either normal operation or in the event of equipment

malfunction. Only qualified electricians are allowed to install and maintain this product.

System design, installation, commissioning and maintenance must be carried out only by personnel who have the necessary

training and experience. They must carefully read this safety information and the instructions in this Guide and follow all

information regarding transport, storage, installation and use of the Optidrive, including the specified environmental limitations.

Do not perform any flash test or voltage withstand test on the Optidrive. Any electrical measurements required should be

carried out with the Optidrive disconnected.

Electric shock hazard! Disconnect and ISOLATE the Optidrive before attempting any work on it. High voltages are present at the

terminals and within the drive for up to 10 minutes after disconnection of the electrical supply. Always ensure by using a suitable

multimeter that no voltage is present on any drive power terminals prior to commencing any work.

Where supply to the drive is through a plug and socket connector, do not disconnect until 10 minutes have elapsed after turning

off the supply.

Ensure correct earthing connections and cable selection as per defined by local legislation or codes. The drive may have a

leakage current of greater than 3.5mA; furthermore the earth cable must be sufficient to carry the maximum supply fault

current which normally will be limited by the fuses or MCB. Suitably rated fuses or MCB should be fitted in the mains supply to

the drive, according to any local legislation or codes.

Do not carry out any work on the drive control cables whilst power is applied to the drive or to the external control circuits.

Within the European Union, all machinery in which this product is used must comply with the Machinery Directive 2006/42/EC,

Safety of Machinery. In particular, the machine manufacturer is responsible for providing a main switch and ensuring the

electrical equipment complies with EN60204-1.

The level of integrity offered by the Optidrive control input functions – for example stop/start, forward/reverse and maximum

speed, is not sufficient for use in safety-critical applications without independent channels of protection. All applications where

malfunction could cause injury or loss of life must be subject to a risk assessment and further protection provided where

needed.

The driven motor can start at power up if the enable input signal is present.

The STOP function does not remove potentially lethal high voltages. ISOLATE the drive and wait 10 minutes before starting any

work on it. Never carry out any work on the Drive, Motor or Motor cable whilst the input power is still applied.

The Optidrive can be programmed to operate the driven motor at speeds above or below the speed achieved when connecting

the motor directly to the mains supply. Obtain confirmation from the manufacturers of the motor and the driven machine about

suitability for operation over the intended speed range prior to machine start up.

Do not activate the automatic fault reset function on any systems whereby this may cause a potentially dangerous situation.

IP55 and IP66 drives provide their own pollution degree 2 environments. IP20 drives must be installed in a pollution degree 2

environment, mounted in a cabinet with IP54 or better.

Optidrives are intended for indoor use only

When mounting the drive, ensure that sufficient cooling is provided. Do not carry out drilling operations with the drive in place,

dust and swarf from drilling may lead to damage.

The entry of conductive or flammable foreign bodies should be prevented. Flammable material should not be placed close to the

drive

Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and no. of phases (1 or 3 phase) correspond to the rating of the Optidrive as delivered.

Never connect the mains power supply to the Output terminals U, V, W.

Do not install any type of automatic switchgear between the drive and the motor

Wherever control cabling is close to power cabling, maintain a minimum separation of 100 mm and arrange crossings at 90

degrees

Ensure that all terminals are tightened to the appropriate torque setting

Do not attempt to carry out any repair of the Optidrive. In the case of suspected fault or malfunction, contact your local Invertek

Drives Sales Partner for further assistance.

1. Introduction

1.1. Important safety information

Please read the IMPORTANT SAFETY INFORMATION below, and all Warning and Caution information elsewhere.

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

9

2

General Information and Ratings

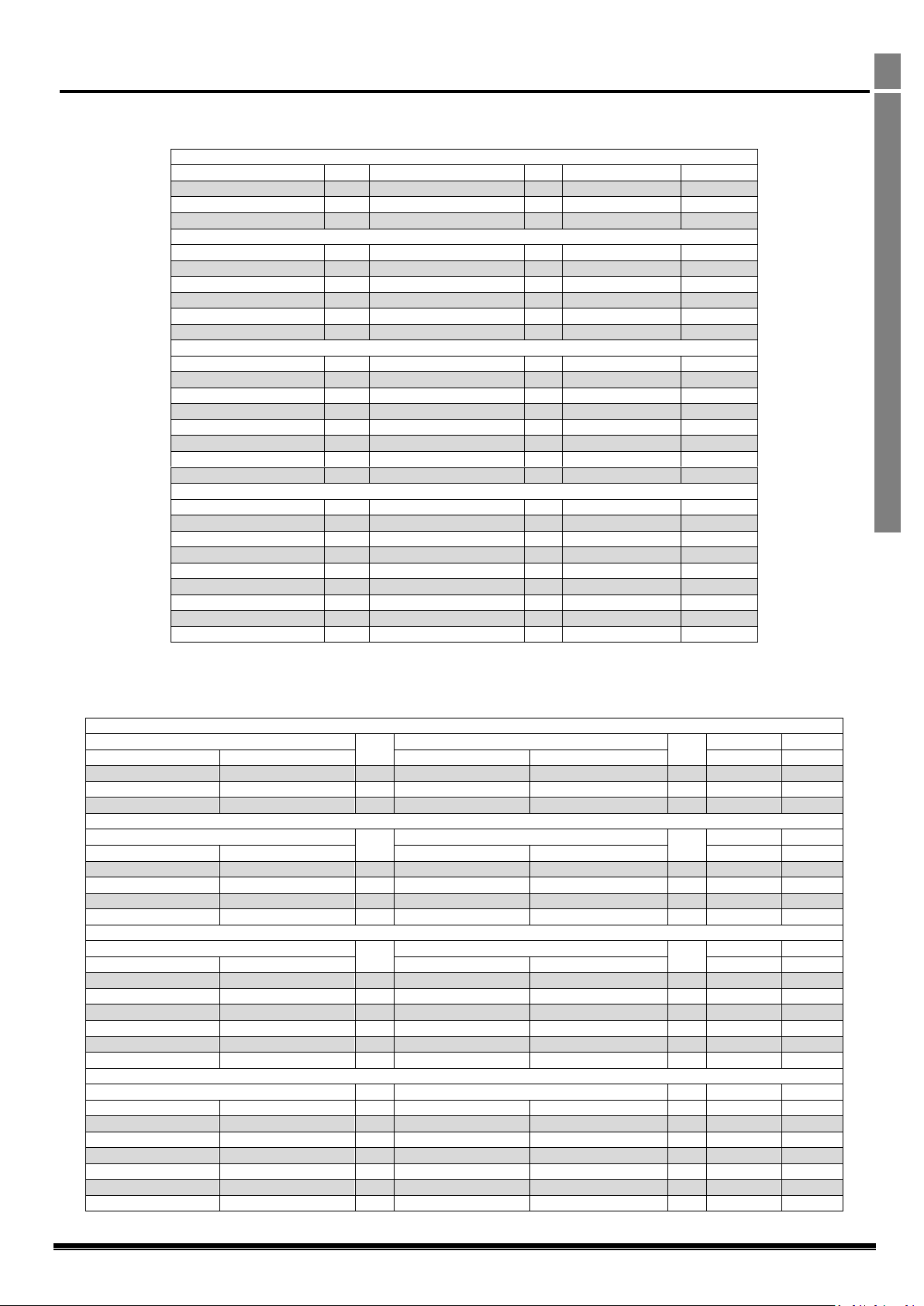

200-240V ±10% - 1 Phase Input

kW Model

kW

HP Model

HP

Output Current (A)

Frame Size

ODV-2-22075-1KF12-SN*

0.75

ODV-2-22010-1HF12-SN*

1

4.3

2

ODV-2-22150-1KF12-SN*

1.5

ODV-2-22020-1HF12-SN*

2 7 2

ODV-2-22220-1KF12-SN*

2.2

ODV-2-22030-1HF12-SN*

3

10.5

2

200-240V ±10% - 3 Phase Input

kW Model

kW

HP Model

HP

Output Current (A)

Frame Size

ODV-2-22075-3KF12-SN*

0.75

ODV-2-22010-3HF12-SN*

1

4.3

2

ODV-2-22150-3KF12-SN*

1.5

ODV-2-22020-3HF12-SN*

2 7 2

ODV-2-22220-3KF12-SN*

2.2

ODV-2-22030-3HF12-SN*

3

10.5

2

ODV-2-32040-3KF12-SN*

4

ODV-2-32050-3HF12-SN*

5

18

3

ODV-2-32055-3KF12-SN*

5.5

ODV-2-32075-3HF12-SN*

7.5

24

3

380-480V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output Current (A)

Frame Size

ODV-2-24075-3KF12-SN*

0.75

ODV-2-24010-3HF12-SN*

1

2.2

2

ODV-2-24150-3KF12-SN*

1.5

ODV-2-24020-3HF12-SN*

2

4.1

2

ODV-2-24220-3KF12-SN*

2.2

ODV-2-24030-3HF12-SN*

3

5.8

2

ODV-2-24400-3KF12-SN*

4

ODV-2-24050-3HF12-SN*

5

9.5

2

ODV-2-34055-3KF12-SN*

5.5

ODV-2-34075-3HF12-SN*

7.5

14

3

ODV-2-34075-3KF12-SN*

7.5

ODV-2-34100-3HF12-SN*

10

18

3

ODV-2-34110-3KF12-SN*

11

ODV-2-34150-3HF12-SN*

15

24

3

500 – 600V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output Current (A)

Frame Size

ODV-2-26075-3K012-SN*

0.75

ODV-2-26010-3H012-SN*

1

2.1

2

ODV-2-26150-3K012-SN*

1.5

ODV-2-26020-3H012-SN*

2

3.1

2

ODV-2-26220-3K012-SN*

2.2

ODV-2-26030-3H012-SN*

3

4.1

2

ODV-2-26400-3K012-SN*

4

ODV-2-26050-3H012-SN*

5

6.5

2

ODV-2-26055-3K012-SN*

5.5

ODV-2-26075-3H012-SN*

7.5 9 2

ODV-2-36075-3K012-SN*

7.5

ODV-2-36100-3H012-SN*

10

12

3

ODV-2-36110-3K012-SN*

11

ODV-2-36150-3H012-SN*

15

17

3

ODV-2-36150-3K012-SN*

15

ODV-2-36200-3H012-SN*

20

22

3

200-240V ±10% - 1 Phase Input

kW Model

kW

HP Model

HP

Output

Frame

Non Switched

Switched

Non Switched

Switched

Current (A)

Size

ODV-2-22075-1KF1X-TN*

ODV-2-22075-1KF1D-TN*

0.75

ODV-2-22010-1HF1X-TN*

ODV-2-22010-1HF1D-TN*

1

4.3

2

ODV-2-22150-1KF1X-TN*

ODV-2-22150-1KF1D-TN*

1.5

ODV-2-22020-1HF1X-TN*

ODV-2-22020-1HF1D-TN*

2 7 2

ODV-2-22220-1KF1X-TN*

ODV-2-22220-1KF1D-TN*

2.2

ODV-2-22030-1HF1X-TN*

ODV-2-22030-1HF1D-TN*

3

10.5

2

200-240V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output

Frame

Non Switched

Switched

Non Switched

Switched

Current (A)

Size

ODV-2-22075-3KF1X-TN*

ODV-2-22075-3KF1D-TN*

0.75

ODV-2-22010-3HF1X-TN*

ODV-2-22010-3HF1D-TN*

1

4.3

2

ODV-2-22150-3KF1X-TN*

ODV-2-22150-3KF1D-TN*

1.5

ODV-2-22020-3HF1X-TN*

ODV-2-22020-3HF1D-TN*

2 7 2

ODV-2-22220-3KF1X-TN*

ODV-2-22220-3KF1D-TN*

2.2

ODV-2-22030-3HF1X-TN*

ODV-2-22030-3HF1D-TN*

3

10.5

2

ODV-2-32040-3KF1X-TN*

ODV-2-32040-3KF1D-TN*

4

ODV-2-32050-3HF1X-TN*

ODV-2-32050-3HF1D-TN*

5

18

3

380-480V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output

Frame

Non Switched

Switched

Non Switched

Switched

Current (A)

Size

ODV-2-24075-3KF1X-TN*

ODV-2-24075-3KF1D-TN*

0.75

ODV-2-24010-3HF1X-TN*

ODV-2-24010-3HF1D-TN*

1

2.2

2

ODV-2-24150-3KF1X-TN*

ODV-2-24150-3KF1D-TN*

1.5

ODV-2-24020-3HF1X-TN*

ODV-2-24020-3HF1D-TN*

2

4.1

2

ODV-2-24220-3KF1X-TN*

ODV-2-24220-3KF1D-TN*

2.2

ODV-2-24030-3HF1X-TN*

ODV-2-24030-3HF1D-TN*

3

5.8

2

ODV-2-24400-3KF1X-TN*

ODV-2-24400-3KF1D-TN*

4

ODV-2-24050-3HF1X-TN*

ODV-2-24050-3HF1D-TN*

5

9.5

2

ODV-2-34055-3KF1X-TN*

ODV-2-34055-3KF1D-TN*

5.5

ODV-2-34075-3HF1X-TN*

ODV-2-34075-3HF1D-TN*

7.5

14

3

ODV-2-34075-3KF1X-TN*

ODV-2-34075-3KF1D-TN*

7.5

ODV-2-34100-3HF1X-TN*

ODV-2-34100-3HF1D-TN*

10

18

3

500-600V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output

Frame

Non Switched

Switched

Non Switched

Switched

Current (A)

Size

ODV-2-26075-3K01X-TN*

ODV-2-26075-3K01D-TN*

0.75

ODV-2-26010-3H01X-TN*

ODV-2-26010-3H01D-TN*

1

2.1

2

ODV-2-26150-3K01X-TN*

ODV-2-26150-3K01D-TN*

1.5

ODV-2-26020-3H01X-TN*

ODV-2-26020-3H01D-TN*

2

3.1

2

ODV-2-26220-3K01X-TN*

ODV-2-26220-3K01D-TN*

2.2

ODV-2-26030-3H01X-TN*

ODV-2-26030-3H01D-TN*

3

4.1

2

ODV-2-26400-3K01X-TN*

ODV-2-26400-3K01D-TN*

4

ODV-2-26050-3H01X-TN*

ODV-2-26050-3H01D-TN*

5

6.5

2

ODV-2-26550-3K01X-TN*

ODV-2-36550-3K01D-TN*

5.5

ODV-2-26075-3H01X-TN*

ODV-2-26075-3H01D-TN*

7.5 9 2

ODV-2-36075-3K01X-TN*

ODV-2-36075-3K01D-TN*

7.5

ODV-2-36100-3H01X-TN*

ODV-2-36100-3H01D-TN*

10

12

3

2. General Information and Ratings

2.1. Drive model numbers

2.1.1. IP20 Enclosed Units

* Note : The final two characters of the model number relate to available factory build options as follows

-SN Standard Seven Segment LED Display, standard PCB coating

-SC Standard Seven Segment LED Display, additional PCB conformal coating

2.1.2. IP66 Enclosed Units

Optidrive HVAC User Guide V2.00

10

www.invertekdrives.com

2

General Information and Ratings

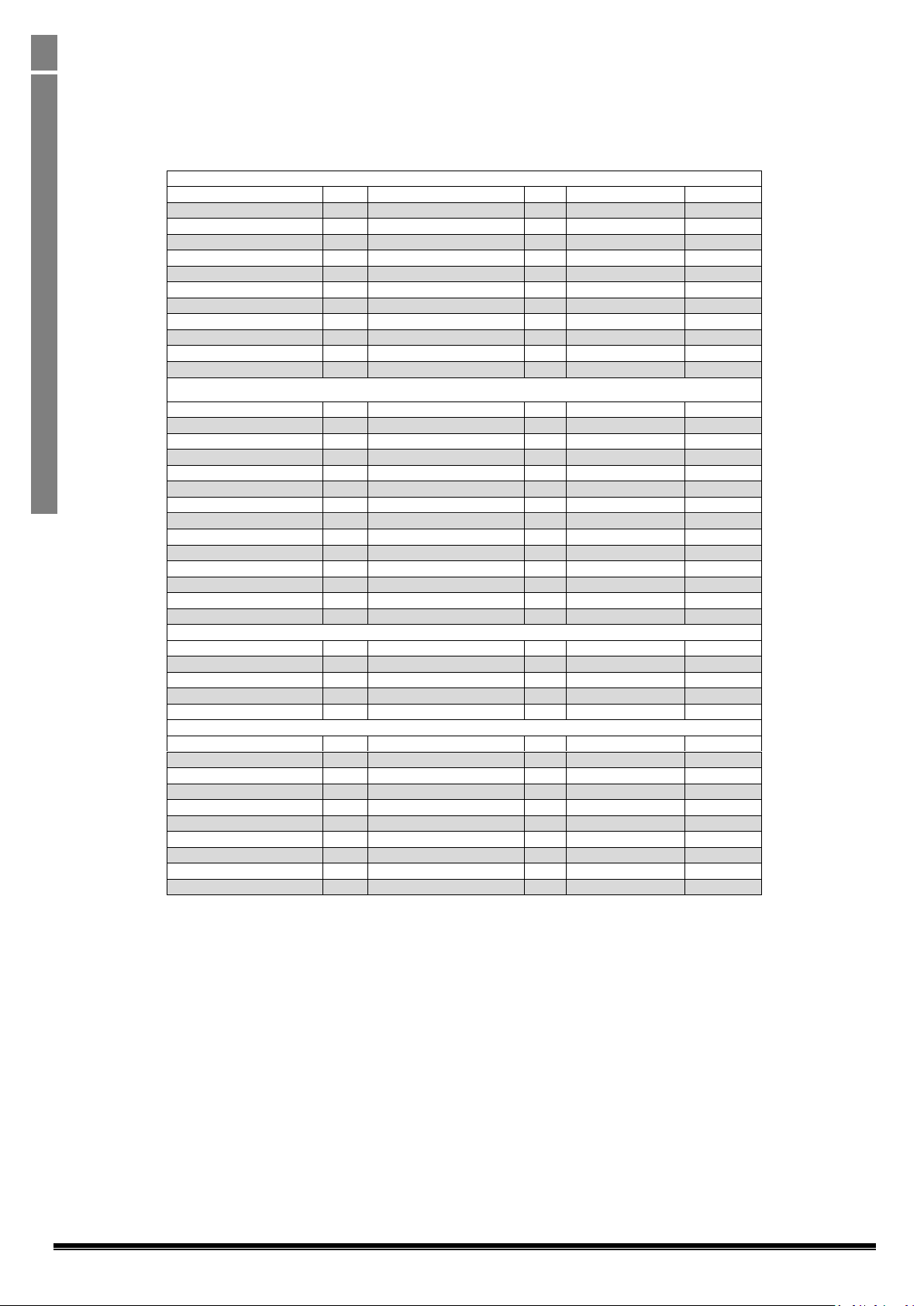

200-240V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output Current (A)

Frame Size

ODV-2-42055-3KF1N-TN*

5.5

ODV-2-42075-3HF1N-TN*

7.5

24

4

ODV-2-42075-3KF1N-TN*

7.5

ODV-2-42100-3HF1N-TN*

10

30

4

ODV-2-42110-3KF1N-TN*

11

ODV-2-42150-3HF1N-TN*

15

46

4

ODV-2-52150-3KF1N-TN*

15

ODV-2-52020-3HF1N-TN*

20

61

5

ODV-2-52185-3KF1N-TN*

18.5

ODV-2-52025-3HF1N-TN*

25

72

5

ODV-2-62022-3KF1N-TN*

22

ODV-2-62030-3HF1N-TN*

30

90

6

ODV-2-62030-3KF1N-TN*

30

ODV-2-62040-3HF1N-TN*

40

110

6

ODV-2-62037-3KF1N-TN*

37

ODV-2-62050-3HF1N-TN*

50

150

6

ODV-2-62045-3KF1N-TN*

45

ODV-2-62060-3HF1N-TN*

60

180

6

ODV-2-72055-3KF1N-TN*

55

ODV-2-72075-3HF1N-TN*

75

202

7

ODV-2-72075-3KF1N-TN*

75

ODV-2-72100-3HF1N-TN*

100

248

7

380-480V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output Current (A)

Frame Size

ODV-2-44110-3KF1N-TN*

11

ODV-2-44150-3HF1N-TN*

15

24

4

ODV-2-44150-3KF1N-TN*

15

ODV-2-44200-3HF1N-TN*

20

30

4

ODV-2-44185-3KF1N-TN*

18.5

ODV-2-44250-3HF1N-TN*

25

39

4

ODV-2-44220-3KF1N-TN*

22

ODV-2-44300-3HF1N-TN*

30

46

4

ODV-2-54300-3KF1N-TN*

30

ODV-2-54040-3HF1N-TN*

40

61

5

ODV-2-54370-3KF1N-TN*

37

ODV-2-54050-3HF1N-TN*

50

72

5

ODV-2-64045-3KF1N-TN*

45

ODV-2-64060-3HF1N-TN*

60

90

6

ODV-2-64055-3KF1N-TN*

55

ODV-2-64075-3HF1N-TN*

75

110

6

ODV-2-64075-3KF1N-TN*

75

ODV-2-64120-3HF1N-TN*

120

150

6

ODV-2-64090-3KF1N-TN*

90

ODV-2-64150-3HF1N-TN*

150

180

6

ODV-2-74110-3KF1N-TN*

110

ODV-2-74175-3HF1N-TN*

175

202

7

ODV-2-74132-3KF1N-TN*

132

ODV-2-74200-3HF1N-TN*

200

240

7

ODV-2-74160-3KF1N-TN*

160

ODV-2-74250-3HF1N-TN*

250

302

7

480-525V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output Current (A)

Frame Size

ODV-2-75132-3K01N-TN*

132

185

7

ODV-2-75150-3K01N-TN*

150

205

7

ODV-2-75185-3K01N-TN*

185

255

7

ODV-2-75200-3K01N-TN*

200

275

7

500-600V ±10% - 3 Phase Input

kW Model Number

kW

HP Model Number

HP

Output Current (A)

Frame Size

ODV-2-46185-3K01N-TN*

18.5

ODV-2-46250-3H01N-TN*

25

28

4

ODV-2-46220-3K01N-TN*

22

ODV-2-46300-3H01N-TN*

30

34

4

ODV-2-56300-3K01N-TN*

30

ODV-2-56400-3H01N-TN*

40

43

5

ODV-2-56370-3K01N-TN*

37

ODV-2-56050-3H01N-TN*

50

54

5

ODV-2-56450-3K01N-TN*

45

ODV-2-56060-3H01N-TN*

60

65

5

ODV-2-66055-3K01N-TN*

55

ODV-2-66075-3H01N-TN*

75

78

6

ODV-2-66075-3K01N-TN*

75

ODV-2-66100-3H01N-TN*

100

105

6

ODV-2-66090-3K01N-TN*

90

ODV-2-66125-3H01N-TN*

125

130

6

ODV-2-66110-3K01N-TN*

110

ODV-2-66150-3H01N-TN*

150

150

6

* Note : The final two characters of the model number relate to available factory build options as follows

-TN OLED Text Display, standard PCB coating

-TC OLED Text Display, additional PCB conformal coating

2.1.3. IP55 Enclosed Units

* Note : The final two characters of the model number relate to available factory build options as follows

-TN OLED Text Display, standard PCB coating

-TC OLED Text Display, additional PCB conformal coating

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

11

2

General Information and Ratings

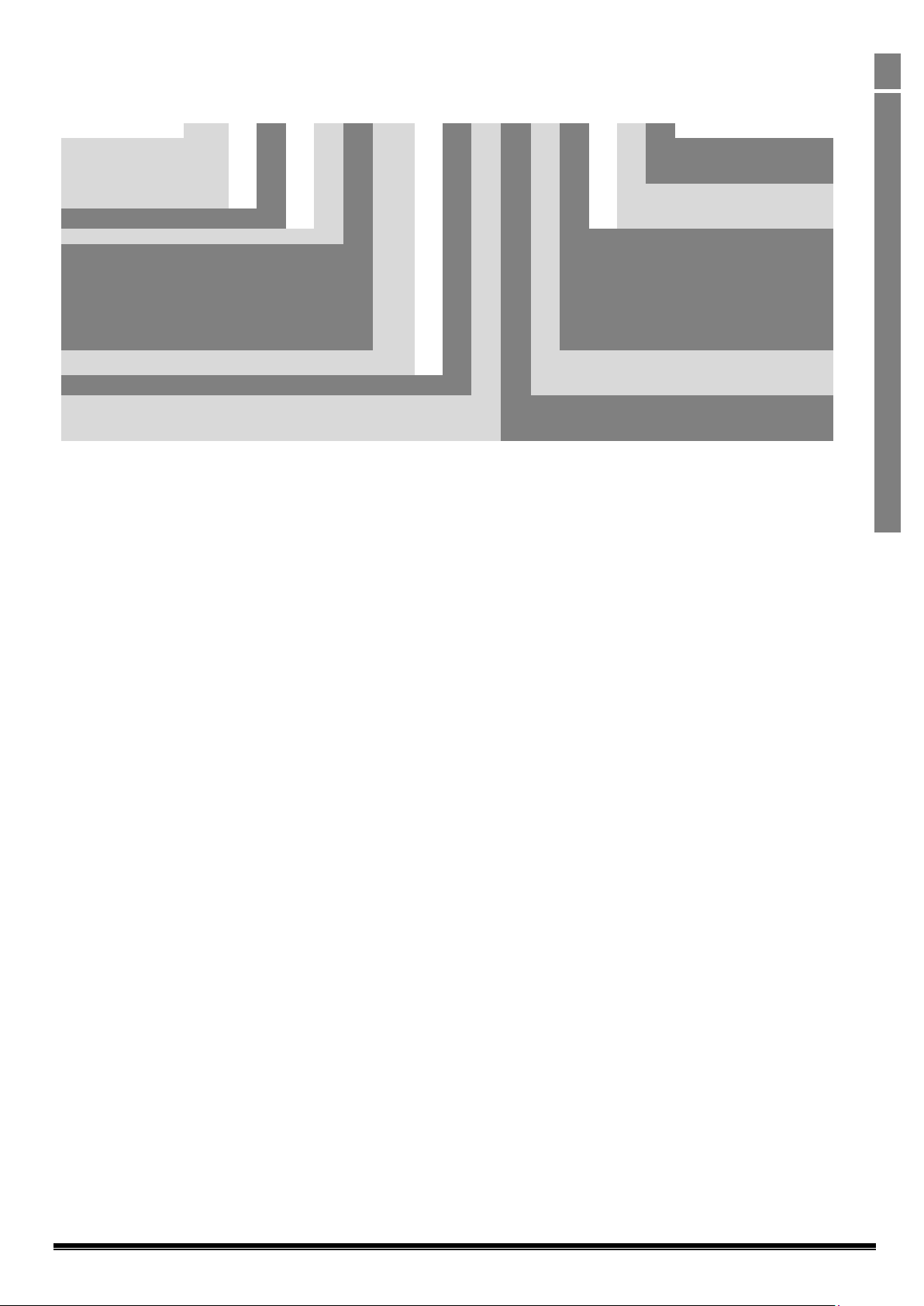

ODV - 2 - 2 4 400 - 3 K F 1 2 - S N

Product Family

ODE : E Series

ODP : Optidrive Plus Series

ODV : HVAC Product Series

PCB Coating

N : Standard Localised Coating

C : Full Conformal Coating

Display

S : 7 Segment LED Display

T : OLED Text Display

Generation

Frame Size

Enclosure

2 : IP20

4 : IP40

D : IP66 with Internal Disconnect

N : IP55 Non Switched

S : IP55 Switched

X : IP66 Non Switched

Y : IP66 Switched

Voltage Code

1 : 110 Volt

2 : 230 Volt

4 : 400 Volt

5 : 525 Volt

6 : 600 Volt

Three Digit Power Rating

Brake Chopper

1 : No Brake Chopper

4 : Internal Brake Chopper

Input Phases

Power Type

K : kW Rated

H : HP Rated

EMC Filter

0 : No Internal Filer

F : Internal EMC Filter

2.2. Identifying the Drive by Model Number

Each drive can be identified by its model number, shown below. The model number is on the shipping label and the drive nameplate. The

model number includes the drive and factory fitted options.

Note

Optidrive HVAC drives are not available with brake chopper / transistor

All IP20 Optidrive HVAC drives are available with 7 Segment LED Display only

All IP55 & IP66 Optidrive HVAC drives are available with OLED Text Display only

All 230 & 400 Volt drives have an internal EMC filter fitted as standard

All 525 & 600 Volt drives have no internal EMC filter

Optidrive HVAC User Guide V2.00

12

www.invertekdrives.com

3

Mechanical Installation

Drive

Size

A B C D E F G H I J Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

Ib

2

221

8.70

207

8.15

137

5.39

209

8.23

5.3

0.21

185

7.28

112

4.41

63

2.48

5.5

0.22

10

0.39

1.8

4

3

261

10.28

246

9.69 - -

247

9.72 6 0.24

205

8.07

131

5.16

80

3.15

5.5

0.22

10

0.39

3.5

7.7

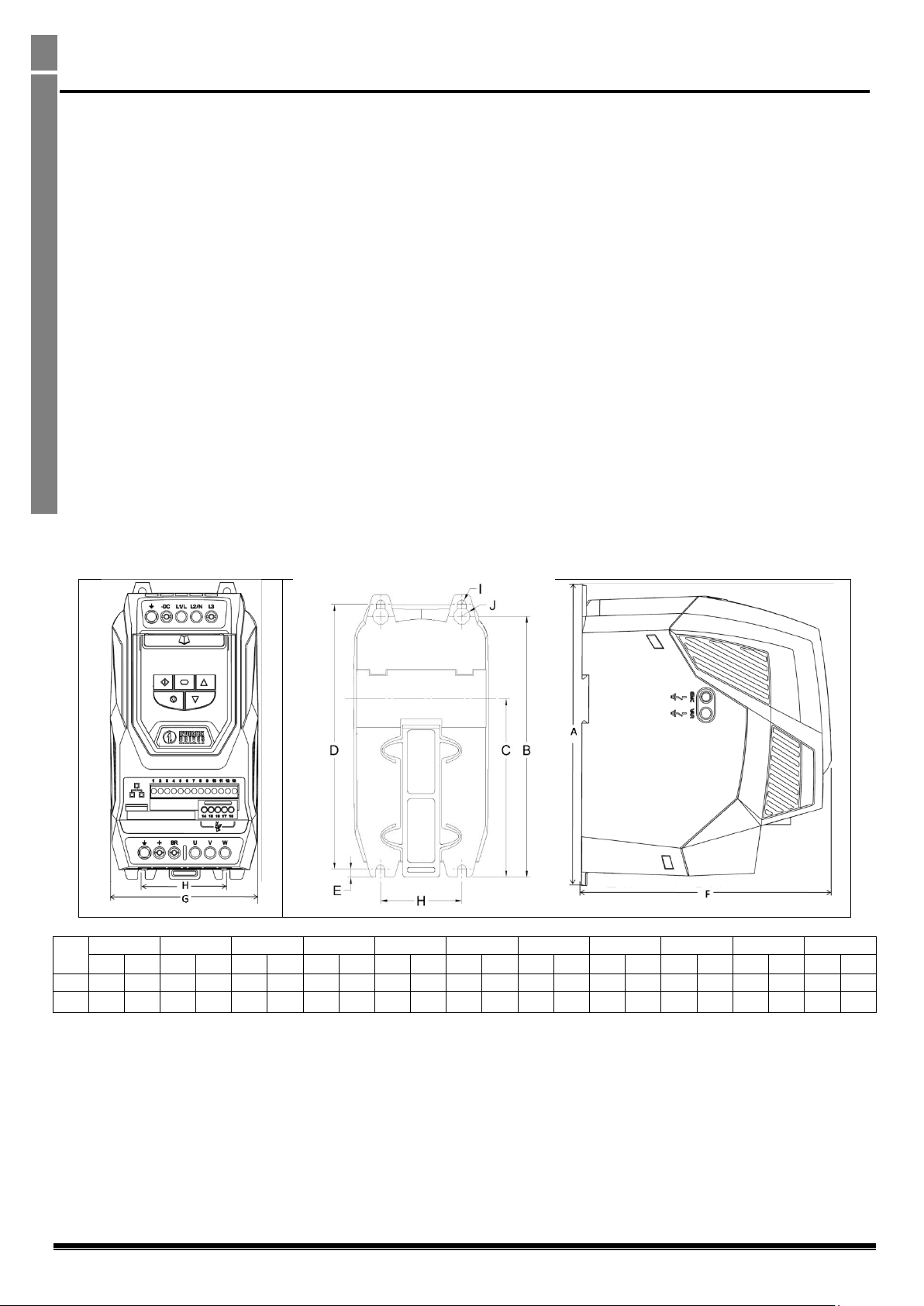

3. Mechanical Installation

3.1. General

The Optidrive should be mounted in a vertical position only, on a flat, flame resistant, vibration free mounting using the integral

mounting holes or DIN Rail clip (Frame Size 2 only).

The Optidrive must be installed in a pollution degree 1 or 2 environment only.

Do not mount flammable material close to the Optidrive

Ensure that the minimum cooling air gaps, as detailed in sections 3.6, 3.7 and 3.8 are left clear

Ensure that the ambient temperature range does not exceed the permissible limits for the Optidrive given in section 11.1

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the Optidrive

3.2. Before Installation

Carefully Unpack the Optidrive and check for any signs of damage. Notify the shipper immediately if any exist.

Check the drive rating label to ensure it is of the correct type and power requirements for the application.

To prevent accidental damage always store the Optidrive in its original box until required. Storage should be clean and dry and

within the temperature range –40°C to +60°C

3.3. UL Compliant Installation

Note the following for UL-compliant installation:

For an up to date list of UL compliant products, please refer to UL listing NMMS.E226333

The drive can be operated within an ambient temperature range as stated in section 11.1

For IP20 & IP40 units, installation is required in a pollution degree 1 environment

For IP55 & IP66 units, installation in a pollution degree 2 environment is permissible

UL Listed ring terminals / lugs must be used for all bus bar and grounding connections

Refer to section 11.4 on page 49 for Additional Information for UL Approved Installations

3.4. Mechanical dimensions and Weights

3.4.1. IP20 Units

Mounting Bolts

All Frame Sizes : 4 x M5 (#10)

Tightening Torques

Control Terminal Torque Settings : All Sizes : 0.8 Nm (7 lb-in)

Power Terminal Torque Settings : All Sizes : 1 Nm (8.85 lb-in)

www.invertekdrives.com

13

3

Mechanical Installation

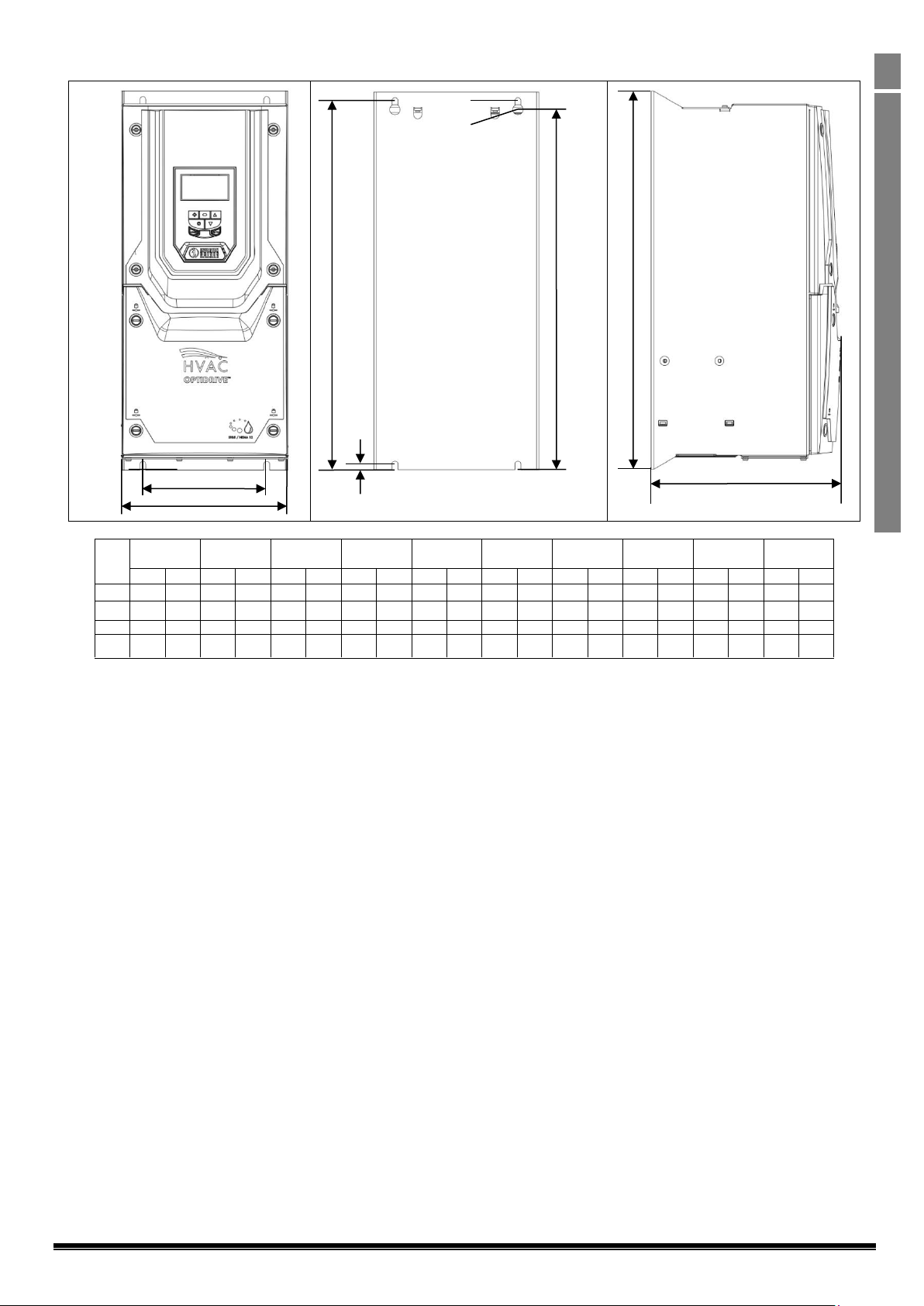

3.4.2. IP55 Units

Drive

Size

A B C D E F G H I

Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

Ib

4

450

17.32

428

16.46

433

16.65 8 0.31

252

9.92

171

6.73

110

4.33

4.25

0.17

7.5

0.30

11.5

25.4

5

540

21.26

515

20.28

520

20.47 8 0.31

270

10.63

235

9.25

175

6.89

4.25

0.17

7.5

0.30

22.5

49.6

6

865

34.06

830

32.68

840

33.07

10

0.39

330

12.99

330

12.99

200

7.87

5.5

0.22

11

0.43

50

110.2

7

1280

50.39

1245

49.02

1255

49.41

10

0.39

360

14.17

330

12.99

200

7.87

5.5

0.22

11

0.43

80

176.4

G F A B C D E

ØH

ØI

Optidrive HVAC User Guide V2.00

Mounting Bolts

Frame Size 4 : M8 (5/16 UNF)

Frame Size 5 : M8 (5/16 UNF)

Frame Size 6 : M10 (3/8 UNF)

Frame Size 7 : M10 (3/8 UNF)

Tightening Torques

Control Terminal Torque Settings : All Sizes : 0.8 Nm (7 lb-in)

Power Terminal Torque Settings : Frame Size 4 : 4 Nm (3 lb-ft)

Frame Size 5 : 15 Nm (11.1 lb-ft)

Frame Size 6 : 20 Nm (15 lb-ft)

Frame Size 7 : 20 Nm (15 lb-ft)

Optidrive HVAC User Guide V2.00

14

www.invertekdrives.com

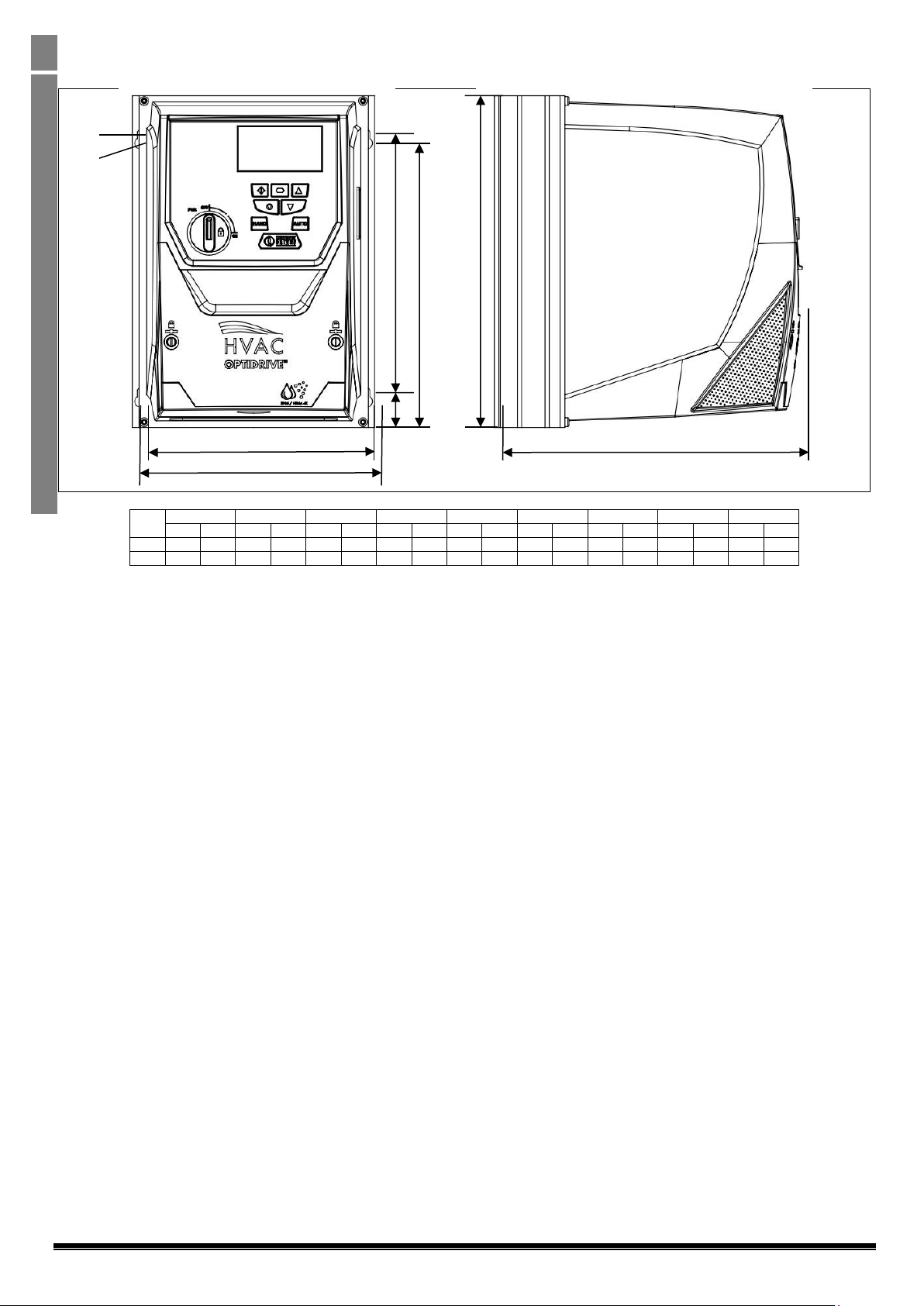

3

Mechanical Installation

Drive

Size

A B D F G H I J Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

Ib 2 257

10.12

220

8.66

200

7.87

239

9.41

188

7.40

176

6.93

4.2

0.17

8.5

0.33

4.8

10.6 3 310

12.20

277

10.89

252

9.90

251

9.88

211

8.29

198

7.78

4.2

0.17

8.5

0.33

7.3

16.1

A F G H D B E

ØH

ØI

3.4.3. IP66 Units

Mounting Bolt Sizes

All Frame Sizes 4 x M4 (#8)

Tightening Torques

Control Terminal Torque Settings : All Sizes : 0.8 Nm (7 lb-in)

Power Terminal Torque Settings : Frame Size 2 : 1.2 – 1.5 Nm (10 – 15 lb-in)

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

15

3

Mechanical Installation

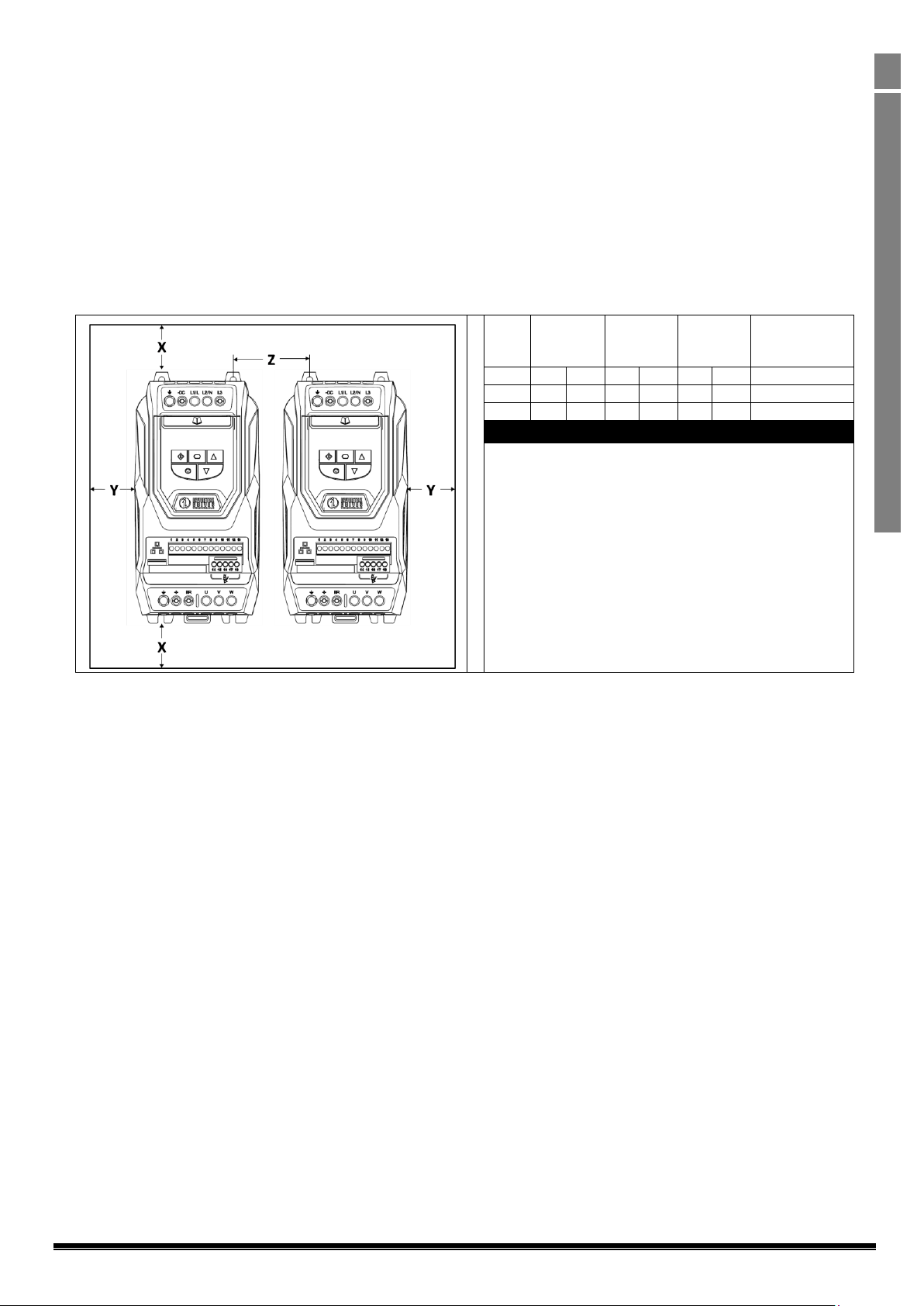

Drive

Size X Above &

Below

Y

Either

Side

Z

Between

Recommended

airflow

mm

in

mm

in

mm

in

CFM (ft3/min)

2

75

2.95

50

1.97

46

1.81

11

3

100

3.94

50

1.97

52

2.05

26

Note :

Dimension Z assumes that the drives are mounted side-byside with no clearance.

Typical drive heat losses are 3% of operating load conditions.

Above are guidelines only and the operating ambient

temperature of the drive MUST be maintained at all times.

3.5. Guidelines for Enclosure mounting (IP20 Units)

IP20 drives are suitable for use in pollution degree 1 environments, according to IEC-664-1. For pollution degree 2 or higher

environments, drives should be mounted in a suitable control cabinet with sufficient ingress protection to maintain a pollution

degree 1 environment around the drive.

Enclosures should be made from a thermally conductive material.

Ensure the minimum air gap clearances around the drive as shown below are observed when mounting the drive.

Where ventilated enclosures are used, there should be venting above the drive and below the drive to ensure good air circulation.

Air should be drawn in below the drive and expelled above the drive.

In any environments where the conditions require it, the enclosure must be designed to protect the Optidrive against ingress of

airborne dust, corrosive gases or liquids, conductive contaminants (such as condensation, carbon dust, and metallic particles) and

sprays or splashing water from all directions.

High moisture, salt or chemical content environments should use a suitably sealed (non-vented) enclosure.

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate through

the drive heatsink. Invertek Drives recommend the following minimum sizes for drives mounted in non-ventilated metallic enclosures:-

3.6. Mounting the Drive – IP20 Units

IP20 Units are intended for installation within a control cabinet.

When mounting with screws

o Using the drive as a template, or the dimensions shown above, mark the locations for drilling

o Ensure that when mounting locations are drilled, the dust from drilling does not enter the drive

o Mount the drive to the cabinet backplate using suitable M5 mounting screws

o Position the drive, and tighten the mounting screws securely

When Din Rail Mounting (Frame Size 2 Only)

o Locate the DIN rail mounting slot on the rear of the drive onto the top of the DIN rail first

o Press the bottom of the drive onto the DIN rail until the lower clip attaches to the DIN rail

o If necessary, use a suitable flat blade screw driver to pull the DIN rail clip down to allow the drive to mount securely on

the rail

o To remove the drive from the DIN rail, use a suitable flat blade screwdriver to pull the release tab downwards, and lift the

bottom of the drive away from the rail first

Optidrive HVAC User Guide V2.00

16

www.invertekdrives.com

3

Mechanical Installation

Drive

Size X Above &

Below

Y

Either

Side

mm

in

mm

in

2 (IP66)

150

5.9

10

0.394

3 (IP66)

150

5.9

10

0.394

4 (IP55)

200

7.9

10

0.394

5 (IP55)

200

7.9

10

0.394

6 (IP55)

200

7.9

10

0.394

7 (IP55)

200

7.9

10

0.394

Note :

Typical drive heat losses are 3% of operating load

conditions.

Above are guidelines only and the operating ambient

temperature of the drive MUST be maintained at all

times.

Y

X

X

Drive

Size X Above &

Below

Y

Either

Side

mm

in

mm

in

2

200

7.87

10

0.39

3

200

7.87

10

0.39

Note :

Typical drive heat losses are approximately 3% of operating load

conditions.

Above are guidelines only and the operating ambient temperature

of the drive MUST be maintained at all times.

Cable Gland Sizes

Frame

Power Cable

Motor Cable

Control Cables

2

M25 (PG2*

M25 (PG2*

M20 (PG13.5)

3

M25 (PG2*

M25 (PG2*

M20 (PG13.5)

X

X

Y

Y

3.7. Guidelines for mounting IP55 Units

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 11.1

The drive must be mounted vertically, on a suitable flat surface

The minimum mounting clearances as shown in the table below must be observed

The mounting site and chosen mountings should be sufficient to support the weight of the drives

IP55 units do not require mounting inside an electrical control cabinet; however they may be if desired.

Using the drive as a template, or the dimensions shown above, mark the locations required for drilling

Suitable cable glands to maintain the IP protection of the drive are required. Gland sizes should be selected based on the number

and size of the required connection cables. Drives are supplied with a plain, undrilled gland plate to allow the correct hole sizes to

be cut as required. Remove the gland plate from the drive prior to drilling.

3.8. Guidelines for mounting (IP66 Units)

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 11.1

The drive must be mounted vertically, on a suitable flat surface

The minimum mounting clearances as shown in the table below must be observed

The mounting site and chosen mountings should be sufficient to support the weight of the drives

Using the drive as a template, or the dimensions shown above, mark the locations required for drilling

Suitable cable glands to maintain the ingress protection of the drive are required. Gland holes for power and motor cables are pre-

moulded into the drive enclosure, recommended gland sizes are shown above. Gland holes for control cables may be cut as

required.

www.invertekdrives.com

17

3

Mechanical Installation

3.9. Removing the Terminal Cover

3.9.1. Frame Size 2

3.9.2. Frame Size 3

3.9.3. Frame Size 4

3.9.4. Frame Size 5

Using a suitable flat

blade screwdriver,

rotate the two

retaining screws

indicated until the

screw slot is vertical.

Using a suitable flat

blade screwdriver,

rotate the four

retaining screws

indicated until the

screw slot is vertical.

Terminal Cover Release Screws

Using a suitable flat

blade screwdriver,

rotate the two

retaining screws

indicated until the

screw slot is vertical

Using a suitable flat

blade screwdriver,

rotate the two

retaining screws

indicated until the

screw slot is vertical

Optidrive HVAC User Guide V2.00

Optidrive HVAC User Guide V2.00

18

www.invertekdrives.com

3

Mechanical Installation

3.9.5. Frame Size 6

3.9.6. Frame Size 7

Using a suitable flat

blade screwdriver,

rotate the two

retaining screws

indicated until the

screw slot is vertical

Using a suitable flat

blade screwdriver,

rotate the four

retaining screws

indicated until the

screw slot is vertical

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

19

3

Mechanical Installation

The use of a suitable gland system is required to maintain the appropriate IP / Nema rating. Cable entry holes will need to be drilled to suit

this system. Some guidelines sizes are defined below:

Please take care when drilling to avoid leaving any particles within the product.

Cable Gland recommended Hole Sizes & types:

Min Gland Rating

Hole Size

Imperial

Metric

Size 2

IP66

3 x 22mm

3 PG13.5

3 x M20

Size 3

IP66

1 x 22mm and 2 x 28mm

1 PG13.5 and 2 PG16

1 x M20 and 2 x M25

UL rated ingress protection ("Type " ) is only met when cables are installed using a UL recognized bushing or fitting for a flexible-

conduit system which meets the required level of protection ("Type")

For conduit installations the conduit entry holes require standard opening to the required sizes specified per the NEC

Not intended for rigid conduit system

Power Isolator Lock Off – IP66 with Built in Isolator Option

On the switched models the main power isolator switch can be locked in the ‘Off’ position using a 20mm standard shackle padlock (not

supplied).

IP66 / Nema 12 Unit Lock Off

IP66 / Nema 4X Unit Lock Off

3.10. Routine Maintenance

The drive should be included within the scheduled maintenance program so that the installation maintains a suitable operating environment,

this should include:

Ambient temperature is at or below that set out in the “Environment” section.

Heat sink fans freely rotating and dust free.

The Enclosure in which the drive is installed should be free from dust and condensation; furthermore ventilation fans and air filters

should be checked for correct air flow.

Checks should also be made on all electrical connections, ensuring screw terminals are correctly torqued; and that power cables have no signs

of heat damage.

3.11. Gland Plate and Lock Off

20

www.invertekdrives.com

4

Electrical Installation

4. Electrical Installation

This manual is intended as a guide for proper installation. Invertek Drives Ltd cannot assume responsibility for the compliance

or the non-compliance to any code, national, local or otherwise, for the proper installation of this drive or associated

equipment. A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

This Optidrive contains high voltage capacitors that take time to discharge after removal of the main supply. Before working

on the drive, ensure isolation of the main supply from line inputs. Wait ten (10) minutes for the capacitors to discharge to safe

voltage levels. Failure to observe this precaution could result in severe bodily injury or loss of life.

Only qualified electrical personnel familiar with the construction and operation of this equipment and the hazards involved

should install, adjust, operate, or service this equipment. Read and understand this manual and other applicable manuals in

their entirety before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

Whenever possible use Shielded motor cablesmaintaining shield as far as possible along the cable.

=/>100mm

Twisted-Pair shielded cables for analog/communications

control and motor feedback signals.

Ensure Filter chassis is making metal-metal contact with

Mounting panel.

RFI Filter

Option

Site Ground Bus-Bar bonded to Metal Back-Panel

panel which is bonded to main power ground.

Metal Back-Panel

U V W

PE

U V W

PE

360° bonding

EMC cable gland

(Best-Practice)

(Shield to Motor

Chassis)

X

On Installations that do not permit this method or

if a metal backplate is not used then an

alternative shield-bonding method should be

adopted, e.g. suitable EMC cable bracket or 360°

bonding EMC cable gland.

Do not run Power and

signal cables in parallel

4.1. Grounding the Drive

4.1.1. Recommended installation for EMC compliance.

Optidrive HVAC User Guide V2.00

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

21

4

Electrical Installation

Remove the screws as indicated below

Internal

EMC

Filter

Internal

Surge

Protection

Earth

4.1.2. Grounding Guidelines

The ground terminal of each Optidrive should be individually connected DIRECTLY to the site ground bus bar (through the filter if installed).

Optidrive ground connections should not loop from one drive to another, or to, or from any other equipment. Ground loop impedance must

confirm to local industrial safety regulations. To meet UL regulations, UL approved ring crimp terminals should be used for all ground wiring

connections.

The drive Safety Ground must be connected to system ground. Ground impedance must conform to the requirements of national and local

industrial safety regulations and/or electrical codes. The integrity of all ground connections should be checked periodically.

4.1.3. Protective Earth Conductor

The Cross sectional area of the PE Conductor must be at least equal to that of the incoming supply conductor.

4.1.4. Safety Ground

This is the safety ground for the drive that is required by code. One of these points must be connected to adjacent building steel (girder, joist),

a floor ground rod, or bus bar. Grounding points must comply with national and local industrial safety regulations and/or electrical codes.

4.1.5. Motor Ground

The motor ground must be connected to one of the ground terminals on the drive.

4.1.6. Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist. The Optidrive is designed to produce the minimum possible leakage current whilst

complying with worldwide standards. The level of current is affected by motor cable length and type, the effective switching frequency, the

earth connections used and the type of RFI filter installed. If an ELCB (Earth Leakage Circuit Breaker) is to be used, the following conditions

apply: -

A Type B Device must be used

The device must be suitable for protecting equipment with a DC component in the leakage current

Individual ELCBs should be used for each Optidrive

Drives with an EMC filter have an inherently higher leakage current to Ground (Earth). For applications where tripping occurs the EMC filter

can be disconnected (on IP20 units only) by removing the EMC screw on the side of the product.

The Optidrive product range has input supply voltage surge suppression components fitted to protect the drive from line voltage transients,

typically originating from lightning strikes or switching of high power equipment on the same supply.

4.1.7. Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the motor cable shield. The motor cable shield connected to this terminal (drive

end) should also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to the safety

ground terminal.

4.2. Wiring Precautions

Connect the Optidrive according to section 4.3 and 4.4, ensuring that motor terminal box connections are correct. There are two connections

in general: Star and Delta. It is essential to ensure that the motor is connected in accordance with the voltage at which it will be operated. For

more information, refer to section 4.5 Motor Terminal Box Connection.

It is recommended that the power cabling should be 4-core PVC-insulated screened cable, laid in accordance with local industrial regulations

and codes of practice.

Optidrive HVAC User Guide V2.00

22

www.invertekdrives.com

4

Electrical Installation

4.3. Incoming Power Connection

For a single phase supply, power should be connected to L1/L, L2/N.

For 3 phase supplies power should be connected to L1, L2, and L3. Phase sequence is not important.

For compliance with CE and C Tick EMC requirements, a symmetrical shielded cable is recommended.

A fixed installation is required according to IEC61800-5-1 with a suitable disconnecting device installed between the Optidrive and

the AC Power Source. The disconnecting device must conform to the local safety code / regulations (e.g. within Europe, EN60204-1,

Safety of machinery).

The cables should be dimensions according to any local codes or regulations. Guideline dimensions are given in section13.4.

Suitable fuses to provide wiring protection of the input power cable should be installed in the incoming supply line, according to the

data in section 13.4. The fuses must comply with any local codes or regulations in place. In general, type gG (IEC 60269) or UL type

T fuses are suitable; however in some cases type aR fuses may be required. The operating time of the fuses must be below 0.5

seconds.

Where allowed by local regulations, suitably dimensioned type B MCB circuit breakers of equivalent rating may be utilised in place

of fuses, providing that the clearing capacity is sufficient for the installation.

When the power supply is removed from the drive, a minimum of 30 seconds should be allowed before re-applying the power. A

minimum of 10 minutes should be allowed before removing the terminal covers or connection.

The maximum permissible short circuit current at the Optidrive Power terminals as defined in IEC60439-1 is 100kA.

An optional Input Choke is recommended to be installed in the supply line for drives where any of the following conditions occur:-

o The incoming supply impedance is low or the fault level / short circuit current is high

o The supply is prone to dips or brown outs

o An imbalance exists on the supply (3 phase drives)

o The power supply to the drive is via a bus-bar and brush gear system (typically overhead Cranes).

In all other installations, an input choke is recommended to ensure protection of the drive against power supply faults. Refer to

your local Invertek sales partner for available options

Optidrive HVAC models in frame sizes 4 to 8 are factory fitted with an Input choke as standard.

4.4. Drive and Motor Connection

The drive inherently produces fast switching of the output voltage (PWM) to the motor compared to the mains supply, for motors

which have been wound for operation with a variable speed drive then there is no preventative measures required, however if the

quality of insulation is unknown then the motor manufacturer should be consulted and preventative measures may be required.

The motor should be connected to the Optidrive U, V, and W terminals using a suitable 3 or 4 core cable. Where a 3 core cable is

utilised, with the shield operating as an earth conductor, the shield must have a cross sectional area at least equal to the phase

conductors when they are made from the same material. Where a 4 core cable is utilised, the earth conductor must be of at least

equal cross sectional area and manufactured from the same material as the phase conductors.

The motor earth must be connected to one of the Optidrive earth terminals.

For compliance with the European EMC directive, a suitable screened (shielded) cable should be used. Braided or twisted type

screened cable where the screen covers at least 85% of the cable surface area, designed with low impedance to HF signals are

recommended as a minimum. Installation within a suitable steel or copper tube is generally also acceptable.

The cable screen should be terminated at the motor end using an EMC type gland allowing connection to the motor body through

the largest possible surface area

Where drives are mounted in a steel control panel enclosure, the cable screen may be terminated directly to the control panel using

a suitable EMC clamp or gland, as close to the drive as possible.

For IP55 drives, connect the motor cable screen to the internal ground clamp

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

23

4

Electrical Installation

Incoming Supply Voltage

Motor Nameplate Voltages

Connection

230

230 / 400

Delta

400

400 / 690

600

600 / 1050

400

230 / 400

Star

600

340 / 600

Additional Information

Compatible Thermistor : PTC Type, 2.5kΩ trip level

Use a setting of P1-13 that have Input 5 function as External Trip, e.g.

P1-13 = 6. Refer to section 8.1 for further details.

4.5. Motor Terminal Box Connections

Most general purpose motors are wound for operation on dual voltage supplies. This is indicated on the nameplate of the motor

This operational voltage is normally selected when installing the motor by selecting either STAR or DELTA connection. STAR always gives the

higher of the two voltage ratings.

4.6. Motor Thermal overload Protection.

4.6.1. Internal Thermal overload protection.

The drive has an in-built motor thermal overload function; this is in the form of an “I.t-trP” trip after delivering >100% of the value set in P108 for a sustained period of time (e.g. 110% for 60 seconds).

4.6.2. Motor Thermistor Connection

Where a motor thermistor is to be used, it should be connected as follows :-

Optidrive HVAC User Guide V2.00

24

www.invertekdrives.com

4

Electrical Installation

4.8.1. Power Terminal Designations

Incoming Mains Power

Supply

For 1 Phase Supply, connect

to L1/L and L2/N terminals.

For 3 Phase Supply, connect

to L1, L2 & L3 terminals.

Phase sequence is not

important.

Motor Connections

Connect the motor to the U, V & W

terminals.

The motor earth must be connected

to the drive

Protective Earth / Ground

connection.

The drive must be Earthed /

Grounded

4.8.2. Control Terminal Connections & Factory Settings

Open

Closed

+24V Supply (100mA) / External Input

+24V 1

Digital Input 1

Stop

Run (Enable)

DIN1 2

Digital Input 2

Analog Input Ref

Preset Speed 1

DIN2 3

Digital Input 3

Analog Input 1

Ref

Analog Input 2

Ref

DIN3 4

Digital Inputs : 8 – 30 Volt DC

+ 10 Volt, 10mA Output

+10V 5

Analog Input 1

AIN1 6

0V 7 0V

Output Speed

Analog Output : 0 – 10 Volt / 4-20mA, 20mA Max

8 AOUT1

0 Volt Supply / External Input

0V 9 0V

Output Current

Analog Input 2

AIN2

10

Analog Output : 0 – 10 Volt / 4-20mA, 20mA Max

11

AOUT2

External Hardware Enable Circuit

EN+

12

EN-

13

Relay Contacts

250VAC / 30VDC

5A Maximum

14

RL1-C

Healthy

/ Fault

15

RL1-NO

16

RL1-NC

17

RL2-A

Running

18

RL2-B

4.7. Control Terminal Wiring

All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other

Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC, should not be routed in the same cable.

Maximum control terminal tightening torque is 0.5Nm

Control Cable entry conductor size: 0.05 – 2.5mm2 / 30 – 12 AWG.

4.8. Connection Diagram

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

25

5

Managing the Keypad

NAVIGATE

Used to display real-time information, to

access and exit parameter edit mode and to

store parameter changes

UP

Used to increase speed in real-time mode or to

increase parameter values in parameter edit

mode

DOWN

Used to decrease speed in real-time mode or

to decrease parameter values in parameter

edit mode

RESET /

STOP

Used to reset a tripped drive.

When in Keypad mode is used to Stop a

running drive.

START

When in keypad mode, used to Start a stopped

drive or to reverse the direction of rotation if

bi-directional keypad mode is enabled

Procedure

Display shows...

Power on Drive

Press and hold the for >2 seconds

Press the Key

The and can be used to select the desired parameter

etc..

Select the required parameter, e.g. P1-02

Press the button

.

Use the and keys to adjust the value, e.g. set to 10

.

Press the key

The parameter value is now adjusted and automatically stored. Press the key for >2 seconds to return to

operating mode

5. Managing the Keypad

The drive is configured and its operation monitored via the built in keypad and display.

IP20 Drives:

IP20 rated drives are supplied with a 7 Segment LED display and a five button keypad (Start, Stop, Navigate, Up, Down)

IP55 and IP66 Drives:

IP55 and IP66 rated drives are supplied with an OLED multi-line text display and a seven button keypad (Start, Stop,

Navigate, Up, Down, Hand, Auto)

Commissioning and operation of the drive with the two different Keypads and displays is detailed below.

5.1. Keypad Layout and Function – Standard LED Keypad (IP20 Drives)

5.2. Changing Parameters – Standard LED Keypad (IP20 Drives)

Optidrive HVAC User Guide V2.00

26

www.invertekdrives.com

5

Managing the Keypad

Function

When Display shows...

Press...

Result

Example

Fast Selection of

Parameter Groups

Note : Parameter Group

Access must be enabled

P1-14 = 101

xxx

+

The next highest

Parameter group is

selected

Display shows

Press +

Display shows

xxx

+

The next lowest

Parameter group is

selected

Display shows

Press +

Display shows

Select lowest Group

Parameter

xxx

+

The first parameter of a

group is selected

Display shows

Press +

Display shows

Set Parameter to

minimum value

Any numerical value

(Whilst editing a

parameter value)

+

The parameter is set to

the minimum value

When editing P1-01

Display shows .

Press +

Display shows.

Adjusting individual

digits within a parameter

value

Any numerical value

(Whilst editing a

parameter value)

+

Individual parameter

digits can be adjusted

When editing P1-10

Display shows

Press +

Display shows

Press

Display shows

Press +

Display shows

Press

Display shows

Etc...

Display

Status

Drive mains power applied, but no Enable or Run signal applied

Motor Autotune in progress.

x.x

Drive running, display shows output frequency (Hz)

Whilst the drive is running, the following displays can be

selected by briefly pressing the button on the drive.

Each press of the button will cycle the display through to the

next selection.

x.x

Drive running, display shows motor current (Amps)

x.x

Drive Running, display shows motor power (kW)

x.x

Drive Running, display shows customer selected units, see

parameters P2-21 and P2-22

Drive mains power not present, external 24 Volt control power supply present only

Output power hardware enable circuit open. External links are required to the STO inputs (terminals 12 and 13) as shown in

section 4.8 Connection Diagram

Parameters reset to factory default settings

Parameters reset to User default settings

For drive fault code displays, refer to section 12.1

5.3. Advanced Keypad Operation Short Cuts – Standard LED Keypad (IP20 Drives)

5.4. Drive Operating Displays – Standard LED Keypad (IP20 Drives)

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

27

5

Managing the Keypad

OLED Display

Main Displayed Parameter

Shows which of the selectable

parameters is currently being shown on

the main display, e.g. Motor Speed,

Motor Current etc.

Operating Information

Provides a real time display of key

operating information, e.g. output

current and power

Start Button

When in Hand mode, used to Start the

drive.

Stop / Reset Button

Used to reset a tripped drive.

When in Hand mode, used to Stop the

drive.

Hand Button

Used to place drive in Hand (keypad)

mode.

Control Keypad

Provides access to the drive parameters,

and also allows control of the drive

when Hand operation is selected.

Navigate Button

Used to display real-time information, to

access and exit parameter edit mode

and to store parameter changes

Up Button

Used to increase speed in real-time

mode or to increase parameter values in

parameter edit mode

Down Button

Used to decrease speed in real-time

mode or to decrease parameter values

in parameter edit mode

Auto Button

Used to place drive in Auto (Remote)

mode.

Displayed when the hardware

enable circuit is open

Displayed when the drive power

is applied, motor stopped

Drive operating, display showing

output information

Drive trip display showing trip

condition

Hold navigate button in for >1

sec

Use up and down keys to scroll to

required parameter.

Presss / release navigate button

when required parameter shown

Use up and down keys to edit

parameter value.

5.5. Keypad Layout and Function – Standard OLED Keypad (IP55 and IP66 Drives)

5.6. Drive Operating Displays – Standard OLED Keypad (IP55 and IP66 Drives)

5.7. Accessing and Changing Parameter Values – Standard OLED Keypad (IP55 and IP66 Drives)

Optidrive HVAC User Guide V2.00

28

www.invertekdrives.com

5

Managing the Keypad

Hold down the Up, Down, Start and

Stop keys for >2s

The display shows P-Def. Drive is

returned to factory settings. Press

the Stop key

Hold down the Up, Down, and Stop

keys for >2s

The display shows P-Def. Drive is

returned to User Standard settings.

Press the Stop key

5.8. Resetting Parameters to Factory Default Settings – Standard OLED Keypad (IP55 and IP66 Drives)

Note: Parameters cannot be defaulted whilst P2-39=1 (parameter set locked).

5.9. Resetting Parameters to User Default Settings – Standard OLED Keypad (IP55 and IP66 Drives)

The current parameter settings of the drive can be stored internally within the drive as the standard default settings. This does not affect the

procedure for returning the drive to factory default settings as described above.

P6-29 (Save user parameters as default) can be enabled (set to * to invoke a parameter save of the current parameter values as the standard

defaults for the drive. Parameter menu group 6 can only be accessed with advanced security level access (Default P1-14=20*.

Note: Parameters cannot be defaulted whilst P2-39=1 (parameter set locked).

Optidrive HVAC User Guide V2.00

www.invertekdrives.com

29

5

Managing the Keypad

Hold down the Start, Navigate, and

Up keys for >1s

Use the Up and Down arrows to

select a language.

Press the Navigate button to select

Language.

The active control source is shown on the

OLED display.

Use the Hand and Auto buttons on the

keypad to switch between control sources

Hand mode permits drive control directly

from the drive keypad.

Auto mode control source is configured

with Parameter P1-12 (Control Mode)

A = Auto

H = Hand

5.10. Changing the Language on the OLED Display – Standard OLED Keypad (IP55 and IP66 Drives)

5.11. Selecting between Hand and Auto Control – Standard OLED Keypad (IP55 and IP66 Drives)

Optidrive HVAC User Guide V2.00

30

www.invertekdrives.com

6

Commissioning

6. Commissioning

6.1. General

The following guidelines apply to all applications

6.1.1. Entering the motor nameplate information