Bardac OD-14075-IN, OD-12075-IN, OD-12150-IN, OD-14150-IN, OD-22150-IN User Manual

...

–

A

–

p

∆

A

A

V

It is the responsibility of the installer to

ensure that the equipment or system into

which the product is incorporated complies

with the EMC legislation of the country of

use. Within the European Union, equipment

into which this product is incorporated must

comply with 89/336/EEC,Electromagnetic

Compatibility.

Bardac

OPTIDRIVE

USER GUIDE

The level of integrity offered by the

Optidrive control functions – for example

stop/start, forward/reverse and maximum

speed, is not sufficient for use in safetycritical applications without independent

channels of protection. All applications

where malfunction could cause injury or

loss of life must be subject to a risk

assessment and further protection

provided where needed. Within the

European Union, all machinery in which

this product is used must comply with

Directive 89/392/EEC, Safety of Machinery.

In particular, the electrical equipment

should comply with EN60204-1.

All Invertek Drives Ltd (IDL) products carry a

2-year warranty, valid from the date of

manufacture.

Complete Warranty Terms and Conditions

are available upon request from your IDL

Authorised Distributor.

SAFETY NOTICES

WARNING!

WARRANTY

Carefully inspect the Optidrive before

installation to ensure it is undamaged

Store the Optidrive in its box until

required. Storage should be clean and

dry Temp. Range –40oC to +60oC

Install the Optidrive on a flat, vertical,

flame-resistant vibration-free mounting

within a suitable enclosure, according to

EN60529 if specific Ingress Protection

ratings are required. Installation required

in a pollution degree 2 environment.

Flammable material should not be

placed close to the drive

The entry of conductive or flammable

foreign bodies should be prevented

Max. ambient temperature 50

5oC. Refer to table on reverse side.

Relative humidity must be less than 95%

(non-condensing).

The Optidrive is suitable for use on a

circuit capable of delivering not more

than 5KA (50Hp) / 10KA (51-200HP)

symmetrical amperes, 480V maximum.

• Supply frequency 48 to 62 Hz.

• Max. permissible 3-phase supply

imbalance 3%.

• Max. ambient temperature 50 oC.

• Max. altitude 2000 m.

• Derate above 1000 m, 1% / 100 m.

• Derate output current 5%/ oC above

max. ambient temp up to 55oC

• I x t protection above 100% output

current.

• 150% overload protection for 60 sec.

• 175% overload allowable for 2 sec.

• Storage temperature -40 to +60 oC

CAUTION

o

GENERAL TECHNICAL DAT

C, min. –

All rights reserved. No part of this User Guide may be reproduced

User Guide

or transmitted in any form or by any means, electrical or

mechanical including photocopying, recording or by any

information storage or retrieval system without permission in

writing from the publisher.

The manufacturer accepts no liability for any consequences

resulting from inappropriate, negligent or incorrect installation, or

adjustment of the optional operating parameters of the drive or

from mismatching of the drive to the motor.

The contents of this User Guide are believed to be correct at the

time of printing. In the interests of a commitment to a policy of

continuous improvement, the manufacturer reserves the right to

change the specification of the product or its performance or the

contents of the User Guide without notice.

This variable speed drive product (Optidrive) is intended for

professional incorporation into complete equipment or systems. If

installed incorrectly it may present a safety hazard. The Optidrive

uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control mechanical plant that may

cause injury. Close attention is required to system design and

electrical installation to avoid hazards in either normal operation

or in the event of equipment malfunction.

System design, installation, commissioning and maintenance

must be carried out only by personnel who have the necessary

training and experience. They must read carefully this safety

information and the instructions in this Guide and follow all

information regarding transport, storage, installation and use of

the Optidrive, including the specified environmental limitations.

Please read the IMPORTANT SAFETY INFORMATION below, and

all Warning and Caution boxes elsewhere.

WARNING is given where there is a hazard that could lead to injury

or death of personnel

CAUTION is given where there is a hazard that could lead to

damage to equipment

Copyright Invertek Drives Ltd © 2005

SAFETY

SAFETY NOTICES

Optidrives should be installed only by qualified electrical persons and in accordance with

local and national regulations and codes of practice. The Optidrive has an Ingress Protection

rating of IP20. For higher IP ratings, use a suitable enclosure.

Electric shock hazard! Disconnect and ISOLATE the Optidrive before attempting any work on

it. High voltages are present at the terminals and within the drive for up to 10 minutes after

disconnection of the electrical supply

Where supply to the drive is through a plug and socket connector, do not disconnect until 10

minutes have elapsed after turning off the supply

Ensure correct earthing connections

The earth cable must be sufficient to carry the maximum supply fault current which normally

will be limited by the fuses or MCB

The STOP function does not remove potentially lethal high voltages. ISOLATE the drive and

wait 10 minutes before starting any work on it

Parameter P-01 can be set to operate the motor at up to 60,000 rpm, hence use this

parameter with care

If it is desired to operate the drive at any frequency/speed above the rated speed (P-09/ P-10)

of the motor, consult the manufacturers of the motor and the driven machine about suitability

for over-speed operation

The fan (if fitted) to the heatsink of the Opti drive starts automatically when the heatsink

temperature reaches approximately 40ºC. When the heatsink is at room temperature the fan

will be stopped.

Ensure that the supply voltage, frequency and no. of phases (1 or 3 phase) correspond to

the rating of the Optidrive as delivered.

An isolator should be installed between the power supply and the drive.

Never connect the mains power supply to the Output terminals U,V,W.

Protect the drive by using slow-blowing HRC fuses or MCB located in the mains supply of

the drive

Do not install any type of automatic switchgear between the drive and the motor

Wherever control cabling is close to power cabling, maintain a minimum separation of 100

mm and arrange crossings at 90o

Ensure that screening or armouring of power cables is effected in accordance with the

connections diagram below

Ensure that all terminals are tightened to the appropriate torque (see table)

IMPORTANT SAFETY INFORMATION

Optidrive hardware and software are designed and tested to a high standard and failures are

unlikely.

Optidrive is designed to high standards of EMC. EMC data is provided in a separate EMC

Data Sheet, available on request. Under extreme conditions, the product might cause or

suffer disturbance due to electromagnetic interaction with other equipment. It is the

responsibility of the installer to ensure that the equipment or system into which the product

is incorporated complies with the EMC legislation of the country of use. Within the European

Union, equipment into which this product is incorporated must comply with 89/336/EEC,

Electromagnetic Compatibility.

When installed as recommended in this User Guide, the radiated emissions levels of all

Optidrives are less than those defined in the Generic radiated emissions standard EN610006-4. When correctly fitted with an Optifilter (Mains filter), the conducted emission levels are

less than those defined in the Generic radiated emissions standard EN61000-6-3 (class B)

for screened cable lengths of < 5m and with EN61000-6-4 (class A) for screened cable

lengths of < 25m.

Safety of machinery, and safety-critical applications

Electromagnetic Compatibility (EMC)

WARNING !

WARNING !

CAUTION

Bardac Corporat ion www.bardac.com

40 Log Canoe Circle, Stevensville, MD 21666 USA

USA Toll Free Phone: 1-888-667-7333 (1-888-ON SPEED)

International Phone: 410-604-3400 Fax: 410-604-3500

Made in the UK by Invertek Drives Ltd

The Optidrive conforms with the following standards

1) CE marked for low voltage directive

2) UL508C Power conversion equipment

3) IEC 664-1 Insulation coordination for equipment within low voltage systems

4) EN61800-3 Adjustable Speed electrical power drive systems – Part 3 (EMC)

5) EN 61000-6 / -2, -3, -4 Generic Immunity / Emissions standards (EMC)

STANDARDS CONFORMITY

Each drive star

∆

A

A

V

connected to system

earth point

To

other

drives

Earth

L1

L2

L3

Isolator

Contactor,

mcb or

Fuses

Optional

*

Filter

L1 L2 L3

Optidrive size 2

Optional

Braking

U V W + BR

U V W

Connect drive according to diagram (above), ensuring that

motor terminal box connections are correct (see diagram,

below).

Refer to the ELECTRICAL DATA overleaf for the sizes of

cabling and wiring.

It is recommended that the power cabling should be 3-core or

4-core PVC-insulated screened cable, laid in accordance with

local industrial regulations and codes of practice.

Resistor

Screened motor

cable connects to

motor frame earth

ELECTRICAL INSTALLATION

* If fitted, a filter should be

physically close to the Drive.

For maximum effectiveness,

the metal case of the filter

and the heat sink of the drive

should be electrically

connected, ie screw both to a

metal backplate and ensure

metal-to-metal contact.

Size 6 Input Choke

Connection – When

connecting the choke

observe the following :-

Help card

IR lens

Cable

management

tie-wrap

i) The order of the input

phases (L1,L2,L3) is not

important.

ii) The choke can be

mounted to suit the wiring,

either above the drive or

anywhere in the panel.

Either set of terminals can

be used for the Input or

Output.

iii) The choke should NOT

be connected directly to the

drive to stop any

mechanical stress on the

terminals of the drive.

OPERATION – USING THE KEYPAD

When the drive is delivered from the factory, only the Standard

Parameter Set (see overleaf) is accessible.

To access the Standard Parameter Set, press the Navigate key ⇔ for

>1 sec.

• Scroll through P-01 to P-14 (and roll over to P-01) by pressing

or

• To display the parameter value, press ⇔

• To edit the parameter value, press or

• To return to the parameter number, press ⇔

• To store a value and / or exit from edit mode, press ⇔ for >1 sec

or press no button for >20 sec.

To access the Extended Parameter Set, set P-14 = 101 and press ⇔

DISPLAY

START

RESET/ STOP

NOTE To restrict unauthorised access, make P-37 = any value from 0

to 9999.

• When in the Extended Parameter Set (except P-00), the display

will revert to normal if no button is pressed for >20 sec.

TO RESTORE ALL

DEFAULT VALUES,

stop the drive and

when display shows

StoP, press and

hold the , and

STOP keys

simultaneously for 1

second. The display

will show P-dEF.

Access code P-37

will revert to 101 but

the hours-run meter

P-39 is not affected.

Press STOP to

resume normal

operation.

MANAGING THE KEYPAD

H 5 0 . 0

CONTROL TERMINAL BLOCK -

0V

Digital I/P 1

Digital I/P 2

1234567891011

Closed: Enable; Open: Disable

Closed: Preset 1; Open: Analog I/P

Default Status

0-10V

4-20mA

nalog I/P

Digital I/P 3

+10V O/P

0V

500

Ω

0-10V

min.

analog

O/P

Relay ratings

30V dc, 5A

240V ac, 5A

Analog I/P - Closed: A; Open :

nalog O/P

0V

DOWN

Relay contact

Relay common

NAVIGATE

UP

Refer to the

Digital Inputs

table overleaf

for details of

the digital input

functions 1 to 3

If screened

cabling is used

for the control

wiring, connect

the cable

screen to 0V of

drive, terminals

1,7 or 9.

OPERATING IN KEYPAD MODE

Set P-12 = 1(this allows the Optidrive to be

controlled from the keypad):

Enable the drive by closing digital input

1. The display will show StoP.

Press the START key. The display shows

H 0.0.

Press to increase speed

The drive will run forward, increasing

speed until is released. CAUTION: the

rate of acceleration is controlled by the

setting of P-03, check this before starting.

Either Press to decrease speed

The drive will decrease speed until τ is

released. The rate of deceleration is

limited by the setting in P-04

Or Press the STOP key. The drive will

decelerate to rest at the rate set in P-04.

The display will finally show StoP at

which point the drive is disabled

To preset a target speed prior to enable

press the stop key whilst the drive is

stopped. The display will show the target

speed, use the and to adjust as

required then press the Stop key to return

the display to StoP. Pressing the START

key will start the drive accelerating to the

target speed.

With P-12 set to 2:

Press the START key. The display

changes to H 0.0.

Press to increase speed

The drive will run forward, increasing

speed until is released. Acceleration is

limited by the setting in P-03. The

maximum speed is the speed set in P-01.

Press the START key again. The motor

will reverse its direction of rotation.

The operation of the keypad can be duplicated

using remote pushbuttons connected to the

control terminals, see Application Note AN21.

In this mode, if P30 is set to Auto-0..4, then

the drive will run as soon as the drive enable

is applied (terminal 1 & 2 is closed).

TO SAVE CHANGES to Parameter settings,

switch the power supply off and wait for the

drive to power down (screen blank) before

switching on.

NOTE that this assumes P-38 = 0 (default). If

P-38 = 1, changes are not saved.

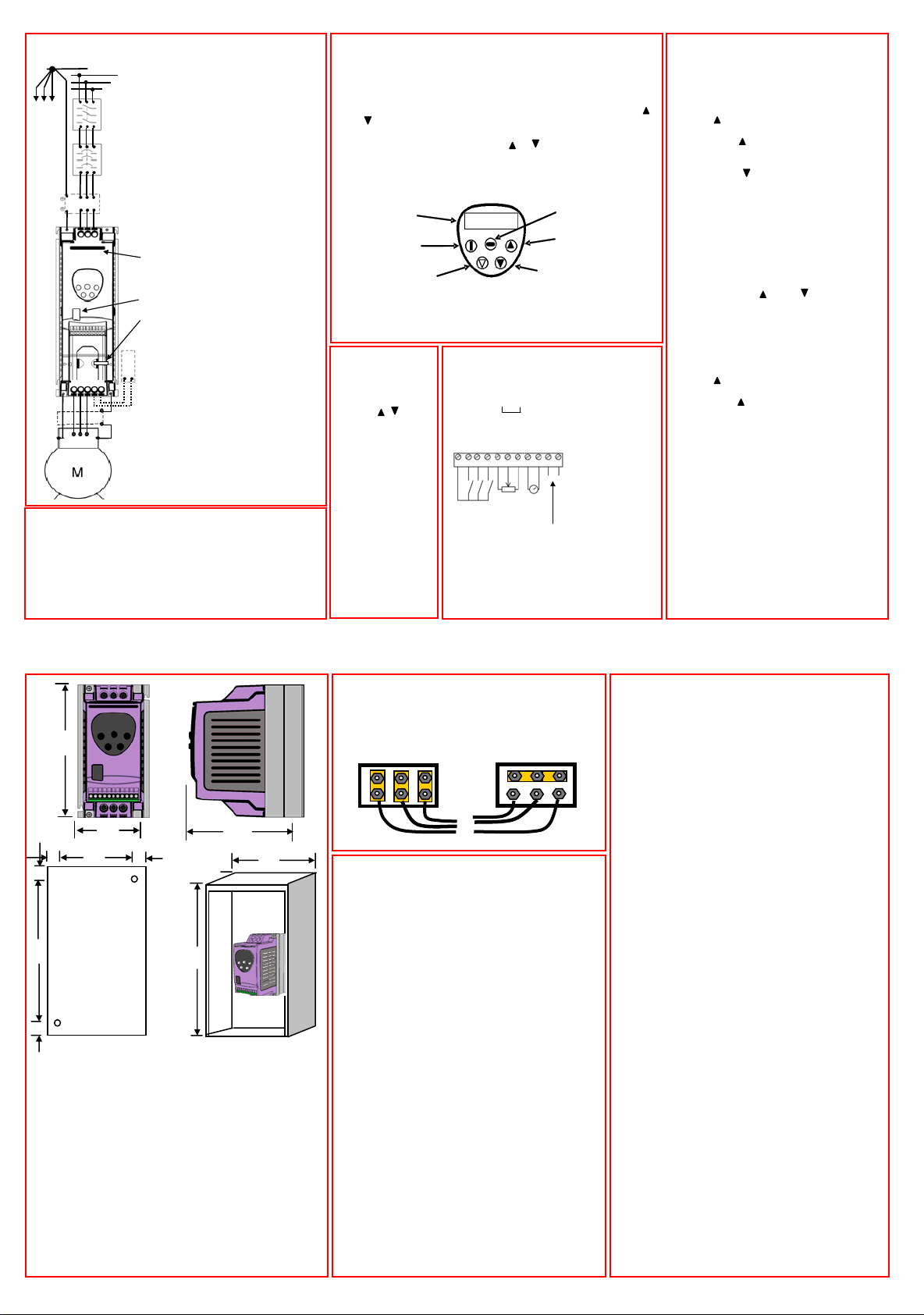

W

A

B

C

B

D

D

D

HOLE

POSITIONS

FOR

MOUNTING

H

C

Optidrives can be installed side-by-side with their heatsink

flanges touching. This gives adequate ventilation space between

them. If the Optidrive is to be installed above another drive or

any other heat-producing device, the minimum vertical spacing

is 100mm. The enclosure should either be force-ventilated or

large enough to allow natural cooling (allow 0.1 m

drive rating).

The ground terminal of each Optidrive should be individually

connected DIRECTLY to the site earth (ground) busbar (through

the filter if installed) as shown. Optidrive ground connections

should not loop from one drive to another, or to, or from any

other equipment. Ground loop impedance must conform to local

industrial safety regulations. To meet UL regulations, UL

approved ring crimp terminals should be used for all earth wiring

connections.

MECHANICAL INSTALLATION

GROUNDING (EARTHING)

ENCLOSURE

W

3

per kW of

OPERATION – BASICS + GETTING STARTED

MOTOR TERMINAL BOX CONNECTIONS

Motors are connected in either STAR or DELTA. The motor

rating plate will indicate the voltage rating for the method

of connection, ensure that this matches the Optidrive

operating voltage.

(DELTA) connection

Υ (STAR) connection

U V W Wires from Optidrive

When delivered, the Optidrive is in the default state,

meaning that it is set to operate in terminal mode and

all parameters (P-xx) have the default values as

shown overleaf.

Connect a control switch between the control

terminals 1 and 2.

Connect a potentiometer (500 Ω min to 10 kΩ max)

between terminals 5 and 7, and wiper to terminal 6.

Set the control switch between pins 1 and 2 open

so that the drive is ‘disabled’.

With the potentiometer set to zero, switch on the

supply to the drive. The display will show StoP.

Close the control switch, terminals 1-2. The drive is

now ‘enabled’ and the output frequency/speed are

controlled by the potentiometer. The display shows

zero speed in Hz (H 0.0) with the potentiometer

turned to minimum.

Turn the potentiometer to maximum. The motor will

accelerate to 50Hz (the default value of P-01) under

the control of the accelerating ramp time P-03. The

display shows H 50.0 (50Hz) at max speed.

To display motor current (A), briefly press the

Navigate key ⇔.

Press ⇔ again to return to speed display.

To stop the motor, either turn the potentiometer back

to zero or disable the drive by opening the control

switch (terminals 1-2).

If the enable/disable switch is opened the drive will

decelerate to stop at which time the display will show

StoP. If the potentiometer is turned to zero and the

enable/disable is closed the display will show 0.0Hz, if

left like this for 20 seconds the drive will go into

standby mode, display shows Stndby, waiting for a

EASY START-UP

speed reference.

SIMPLE PARAMETER ADJUSTMENTS

The factory-set default parameter values may give satisfactory

performance, however certain adjustments may be beneficial.

Maximum and Minimum Speeds P-01 & P-02

Set P-01 to the maximum speed and P-02 to the minimum speed for

your application. These limits are mirrored for negative speeds. If a

non-zero minimum speed is set in P-02, the motor will ramp (P-03) to

this minimum speed as soon as the drive is enabled.

Acceleration and Deceleration P-03 & P04

Ramps which are too short will cause the drive to deliver currents in

excess of full load current and may result in it tripping out or the

motor stalling

Stop Mode P-05

Select method of stopping required when drive is disabled. Ramp to

stop (P-05 = 0) decelerates the motor at the rate set by deceleration

ramp time P-04. Freewheel/ Coast to stop (P-05=1) disables the drive

output immediately, allowing the motor to decelerate naturally due

to friction or under the control of a mechanical brake

Torque/Speed Characteristic P-06

Certain loads such as fans and centrifugal pumps need very little

torque at low speed. Set P-06=1 to reduce power loss at low speeds

for this load type.

Rated Current, Rated Frequency and Rated Speed P-08, P-09, P-10.

Parameters P-08 and P-09 should to be set to correspond with the

rated current and frequency shown on the motor rating plate.

Parameter P-10 is optional. If this parameter is set to zero (default

state), speed will be displayed in Hz; if speed indication is required

in rpm, enter the motor rated speed (speed at full load) from the

motor rating plate.

Voltage Boost P-11

Any load which is ‘sticky’ to start will benefit from a voltage boost

on starting. P-11 permits a boost of up to 25% of full motor voltage

to be applied.

NOTE: Use of this parameter increases motor heating at low speeds

Terminal or Keypad Control P-12

Terminal control (P-12=0) is used when the drive needs to be

controlled from some remote point, such as a control panel

interface or machine system.

Keypad control (P12=1 or 2) is used for local, manual control and

commissioning

Extended Parameter Set P15 to P-40 and P-00

The Extended Parameter Set is intended for use by specialist drives

engineers and technicians and will not generally be required for

• Provides a read only window into the motor control software

allowing

key internal values to be viewed. This is useful for following

signals

through the drive control system when troubleshooting.

• Access, scroll, change and exit are as for any other parameter.

The selected variable is at the left hand side of the display.

• There are 9 different windows listed below:

1 Unscaled analog input (%)

2 Speed ref. via scaled analog input (Hz)

3 Pre-ramp speed ref. (Hz)

4 Post-ramp speed ref. (Hz)

5 Not used

6 Stator field frequency (Hz)

7 Applied motor voltage (V)

8 DC bus voltage (V)

9 Internal thermistor (NTC) value

simple applications.

PARAMETER ZERO

Loading...

Loading...