Bardac K340i, K680i, K1220i Users Manual

Model K340i / K680i / K1220i DC drive product manual 1

EXTERNAL CONTROLS

INSTALLATION

MAXIMUM OUTPUT

AC SUPPLY INPUT

SPEED RANGE

USER ADJUSTMENTS

CONTROL ACTION

POWER RATING

K340i / K680i / K1220i

DC Motor Controller

Product Manual

This drive is an isolated single direction

speed controller for shunt wound or permanent magnet motors. It utilises speed feedback from the armature

voltage (Avf), or from a shaft mounted tachogenerator. It incorporates a fully controlled thyristor bridge with a

current loop to protect the drive and motor. It can be used in speed or current control modes. The drive can

motor forward and will regenerate for reverse rotation by an external force. Please obtain expert help if you are

not qualified to install this equipment. Make safety a priority.

This component is hazardous. (All specifications in this document are nominal).

K340i 0.55KW (0.5 HP) at 180 Volts DC, 3.4 Amps

K680i 0.75KW (1.0 HP) at 180 Volts DC, 6.8 Amps

K1220i 1.80KW (2.0 HP) at 180 Volts DC, 12.2 Amps

(The KW / HP ratings are typical motor ratings at or below the available terminal rating of Watts= Varm x Iarm)

Versions that work from 60V / 30V AC supply are also available.

K340i / LV60, K680i / LV60, K1220i / LV60. For motors rated up to 48V DC

Armature: 200 Volts DC. or 50V DC for LV60 models

Models K340i / K680i / K1220i 3.4/ 6.8/ 12.2 Amps.

Field: Volts DC=0.9 x AC supply volts. 1 Amp Max.

(0.45 x AC for field connected to F- and N). 1 Amp Max.

110V AC or 240V AC +/-10%, 50–60 Hz.

30V AC or 60V AC +/-10%, 50-60Hz for LV60 models.

Speed range 0–100%. (motor dependant)

Load Regulation typically 0.2% tach, 2% Arm Volts.

Presets accessible under lift up cover.

Clockwise rotation for linear increase in parameter.

Relay driver Threshold (Level) +/-(0.5% to 105%). (+/-10.5V) Symmetrical about zero.

Maximum Speed (Max spd) 40V-200V span with Spd x 2 switch. (Avf/Tach fb volts)

LV60 models have an Avf range 10 - 50V.

Minimum Speed (Min spd) 0 to 30% of maximum speed. (With 10K external pot).

Up Ramp (Ramp) 20 to 1 seconds up ramp rate. (For 0 to +10V)

Down Ramp (Ramp) 20 to 1 seconds down ramp rate (For +10 to 0V)

Stability (Stab) Gain 1 to 10

Maximum Current (I max) 0 to 100% current limit.

IR compensation (IR comp) 0 to 25%

Speed setpoint from external 10K Ohms pot.

External RUN contact for electronic STOP/START.

Built in functions are +/- channel with pushbutton control inputs, and

relay driver with variable threshold. There is a pot kit available with graduated dial and knob.

Speed loop: Full P+I armature voltage or tach feedback.

Current loop: Full P+I isolated current feedback.

Use correctly rated cable minimum 600V AC,

1.5 times armature current.

DOC# HG502078 iss 14, 05/07/12.

2 Model K340i / K680i / K1220i DC drive product manual

FUSING REQUIREMENT

MECHANICAL

PRESET POT settings

CONTROL SIGNALS

MOTOR

AC SUPPLY

POWER ON

RAMP and MIN SPEED

Semi-conductor fuse parts.

K340i DIN Mount Fuse Kit FLN-6.3, FLL-6.3

K680i DIN Mount Fuse Kit FLN-20, FLL-20

K1220i DIN Mount Fuse Kit FLN-20, FLL-20

Suitable for use on a circuit capable of delivering not more than 5000A RMS symmetrical amperes when protected

by an aR class fuse.

WARNING The drive can only be protected by fitting an external

AC supply semi-conductor fuse with an I2t rating below 150 A2s.

Control signals are isolated from the supply, and the unit may be

connected to other isolated instruments.

The unit is designed to clip onto a DIN rail. Avoid vibration and ambient

temperatures outside –10 and +40C. Protect the unit from pollutants.

Ensure there is an adequate supply of clean cool air to ventilate the unit

and the enclosure it is mounted in. (Dissipation in Watts = 5 x Armature Amps).

Foot mounted motors must be level and secure. Protect motors from

ingress of foreign matter during installation.Ensure accurate alignment

of motor shaft with couplings. Do not hammer pulleys or couplings onto

the motor shaft.

Before running motor, complete the following check list. (Warning isolate the supply first).

1) Correct insulation between all motor windings and earth. Disconnect all drive cables.

2) Check inside connection box for foreign objects, damaged terminals etc.

3) Check that brushes are in good condition, correctly seated and free to move in brush

boxes. Check correct action of brush springs.

4) Motor vents must be freed of any obstruction or protective covers prior to running.

Please note that this drive does not provide motor over-temperature protection. If required, equip your

motor with a thermal sensor device that can remove the supply when activated by over-temperature.

To avoid damage, ensure the supply selection jumper on the drive

matches the incoming supply. 110V or 240V AC.

For models with LV60 suffix 30V AC or 60V AC.

Set the I max (Max Current) preset to approximately match the motor

armature rating. Fully clockwise is 100% drive rating.

(K340i 3.4A, K680i 6.8A, K1220i 12.2A). Fully anticlockwise is 0%. E. g. for a

K340i unit a midway setting is 50% i.e. 1.7A. More accurate setting requires a suitable current meter in series with

the armature. Set the Stab preset midway. (Clockwise rotation of the stab preset increases gain, excessive

rotation may lead to instability).

et all the other presets anticlockwise to start off with. (Note LV60 models avf range 10-50V )

S

The preferred strategy for initial commissioning is in armature voltage feedback mode described as follows. Set

Avf/Tach switch ON (left) for armature voltage feedback (Avf) and Spd x 2 switch OFF (right) for 40V max

feedback. For systems utilising tach feedback, remove the terminal 11 tach connection and temporarily make

wire end safe until later.

Check that the Power lamp lights. Close the run contact.

Increase the external speed pot slowly to maximum.

The motor should slowly ramp up to around 40V on the motor armature. (10V for LV60 models). Now set the

correct 100% armature voltage and hence speed by using the Spd x 2 switch (ON (left) for speed X 2) and the Max

spd preset (Clockwise to increase). Note, if you change the Spd x 2 switch position whilst running, the speed will

undergo an immediate step change.

The up / down ramps can now be set between 20 and 1 seconds, and the

Min spd adjusted up to 30%.

(Note, down ramp becomes up ramp for negative input).

Model K340i / K680i / K1220i DC drive product manual 3

IR COMP

TACH FEEDBACK

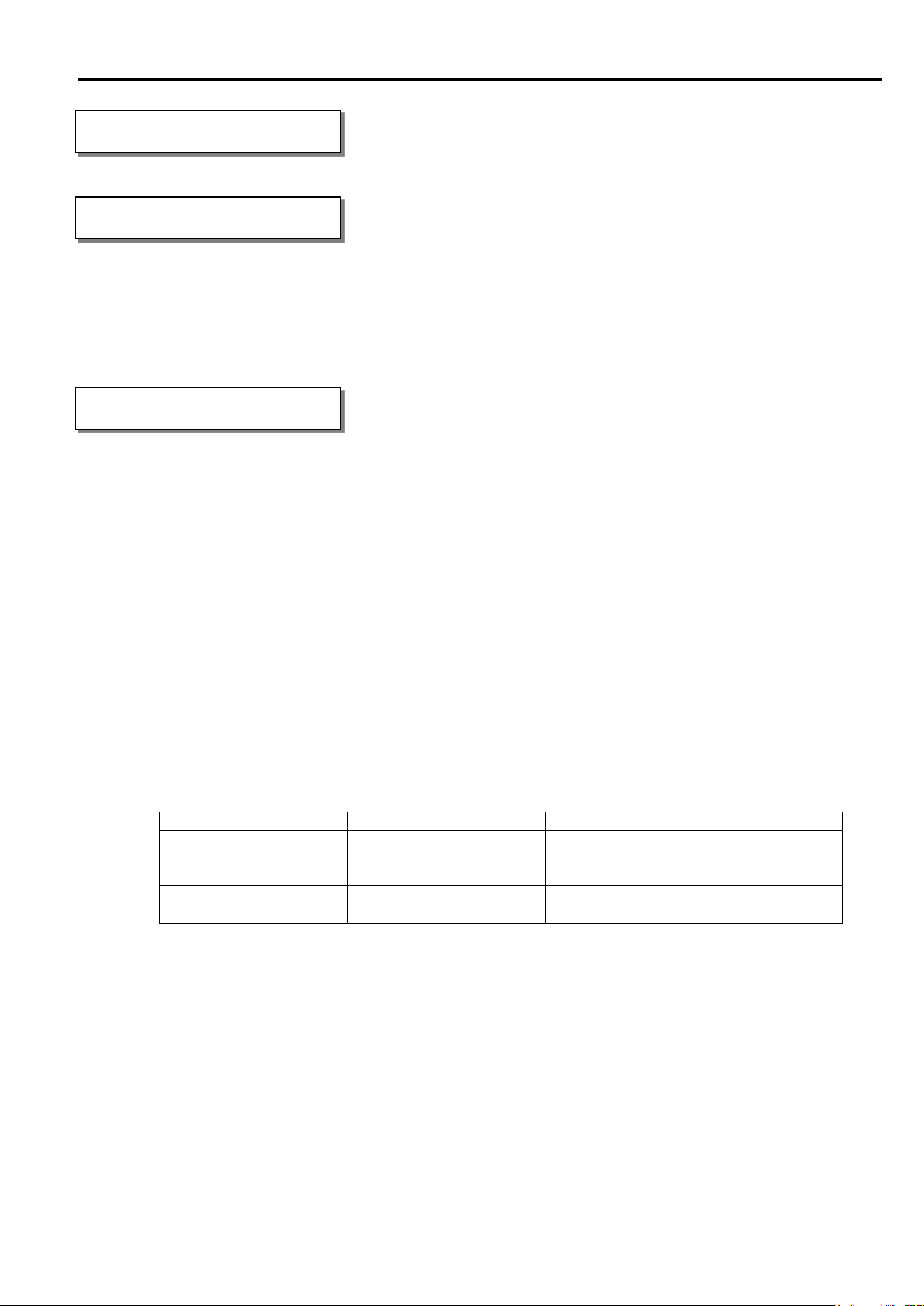

PB+ Terminal 7

PB- Terminal 8

Input T6 to output T4 mode

Closed to Common

Open circuit

Invert (+/-10.5V range)

Closed to Common

Closed to Common

Remains in prevailing mode.

Powers up in invert mode.

Open circuit

Closed to Common

Non-invert (0 to +10.5V range)

Open circuit

Open circuit

Invert (+/-10.5V range)

TERMINAL LISTING

Speed droop on heavy loads may occur when armature voltage feedback

is used. This is compensated for by clockwise rotation of IR comp.

Excessive rotation may lead to instability.

Note, IR comp is not used with tach feedback, leave preset anticlockwise.

The tach feedback signal on terminal 11 must be negative with respect

to terminal 10 COMMON for a positive speed demand input.

Whilst still in AVF mode and running at 100% speed, measure the tach

volts on the wire intended for T11. (Warning, possible high voltage). This is the tach full speed voltage. Make a

note of it to assist in selecting the speed range. Stop the motor and turn off the supply.

Set Avf/tach switch OFF (right) to disconnect AVf and then re-connect the tach wire to T11. By using the tach

voltage reading just obtained, you can adjust the full speed with the Spd x 2 switch and/or Max spd preset.

With Spd x 2 switch OFF (right) the Max spd range = 40 to 100V.

With Spd x 2 switch ON (left) the Max spd range = 80 to 200V

To do this re-start and adjust Max spd as required within the selected range, suggest starting anticlockwise.

1 +10V output. 10mA max. (Use a 10K Ohm pot for external speed reference).

2 MIN SPEED. (Bottom end of external pot. 5K Ohms preset to common).

3 IP. Speed input. 0 to +/-10V speed input from pot wiper. 47K internal pull down.

4 OP+/-. +/-10.5V range. Input from T6. Invert with pushbutton input T8 open. Non-invert with pushbutton

input T7 open. 10mA max.

5 COM. Common. (0 Volts)

6 IP+/-. Input to pushbutton controlled +/- signal channel. OP on T4. 50K Ohms impedance for invert mode,

10M input impedance in non-invert mode. The operating mode is controlled by PB+ on T7 and PB- on T8.

Note. This channel can invert input signals in the range +/-10.5V. It can also buffer (i.e. non-invert) signals

in the range 0V to +10.5V. (It cannot buffer negative signals. If you try to buffer a negative signal the

output will be positive).

Note. If using a high resistance external pot for positive signals e.g. greater than 20KOhms, then this

channel can be used to buffer it using the non-invert mode.

7 PB+ Pushbutton input. 47K Ohm pull up to +12V. Connect to T5 COM. When opened it latches T4 to buffer

(non-invert) mode for positive T6 input signals, provided T8 PB- is connected to T5 COM.

8 PB- Pushbutton input. 47K Ohm pull up to +12V. Connect to T5 COM. When opened it latches T4 to (invert)

mode for positive and negative T6 input signals.

Note. The PB- function will operate when T7 PB+ is either open, or connected to T5 COM.

See truth table below for T7 and T8 operation. See terminal 6 IP+/- for notes.

a) Hence if PB+ Terminal 7 remains open then a switch on PB- Terminal 8 can be

used to change modes.

b) If both PB+ Terminal 7 and PB- Terminal 8 remain open then the invert mode is established.

c) If both PB+ Terminal 7 and PB- Terminal 8 are connected to common then the desired mode can be

established by momentarily opening PB+ Terminal 7 for non-invert, or PB- Terminal 8 for invert mode.

The mode remains latched when the common connection is re-established.

9 RUN. Internal 12K pull up to +12V. Open to stop, close to COMMON to run. WARNING. RUN is an electronic

inhibit function. The field remains energised, and all power terminals ‘live’. RUN must not be relied

on to ensure the machine is stationary during hazardous operations. Remove the power source to the

system.

Opening T9 RUN will cause immediate drive inhibit and hence if the motor is rotating at the time it will

coast to zero speed.

Loading...

Loading...