Bardac K340i, K680i, K1220i Application Information

340i / 680i / 1220i Applications 1

- Data – Product manuals – Technical help – Drive glossary – FAQ – Brochures – Images – Data – Product manuals

K340i, K680i, K1220i Application manual.

w w w .barda c . c o m

K340i / K680i / K1220i Applications 2

www.bardac.com

NOTE. These instructions do not purport to cover all details or variations in equipment, or to provide for every

possible contingency to be met in connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise which are not covered sufficiently for the purchaser's

purposes, the matter should be referred to the local Supplier sales office. The contents of this document shall

not become part of or modify any prior or existing agreement, commitment, or relationship. The sales contract

contains the entire obligation of Bardac Drives. The warranty contained in the contract between the parties

is the sole warranty of Bardac Drives. Any statements contained herein do not create new warranties or

modify the existing warranty.

HEALTH AND SAFETY AT WORK

Electrical devices can constitute a safety hazard. It is the responsibility of the user to ensure the compliance of

the installation with any acts or bylaws in force. Only skilled personnel should install and maintain this

equipment. If in doubt refer to the supplier.

Note. The contents of this document are believed to be accurate at the time of printing. The manufacturers,

however, reserve the right to change the content and product specification without notice. No liability is

accepted for omissions or errors. No liability is accepted for the installation or fitness for purpose or

application of the K340i / K680i / K1220i motor drive units.

1 Table of contents

1 Table of contents ....................................................................................... 2

2 340i Block Diagram and terminal listing. ............................................................ 3

3 Typical applications..................................................................................... 8

3.1 ON OFF switch with ramp to stop or coast to stop................................................................. 8

3.2 Zero reference interlock and Stop / Start pushbuttons. ......................................................... 9

3.3 Using an external 4-20mA speed signal ............................................................................ 10

3.4 Torque control ........................................................................................................... 11

3.5 Load sharing slave single direction. ................................................................................. 12

3.6 Low voltage speed feedback .......................................................................................... 12

Bardac Corporation

40 Log Canoe Circle

Stevensville, MD 21666 USA

Phone: (410)604-3400 Fax: (410)604-3500

K340i / K680i / K1220i Applications 3

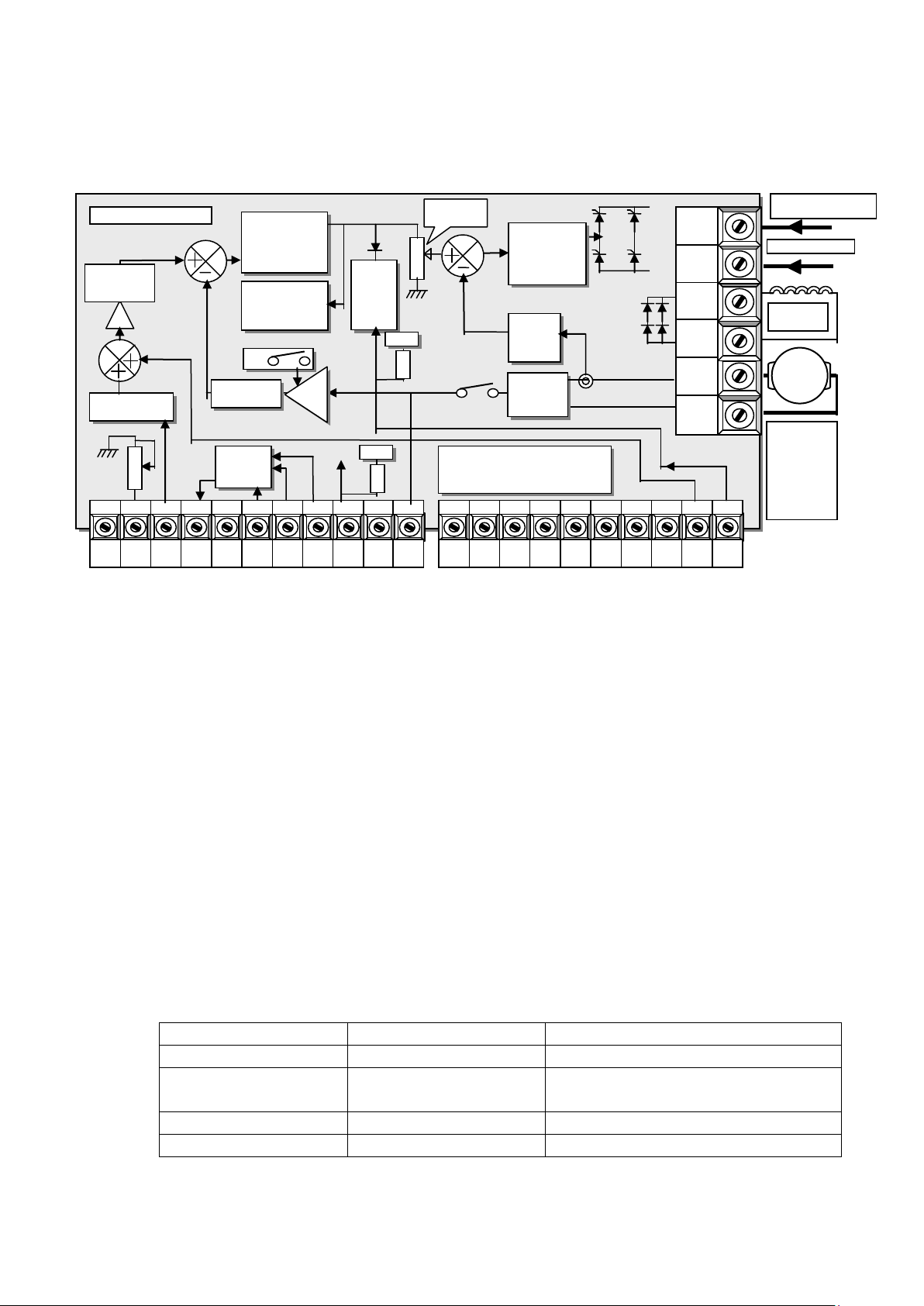

PB+ Terminal 7

PB- Terminal 8

Input T6 to output T4 mode

Closed to Common

Open circuit

Invert (+/-10.5V range)

Closed to Common

Closed to Common

Remains in prevailing mode.

Powers up in invert mode.

Open circuit

Closed to Common

Non-invert (0 to +10.5V range)

Open circuit

Open circuit

Invert (+/-10.5V range)

+10V

Min

IP

OP+/-

COM

IP+/-

PB+

PB-

RUN

COM

Tach

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

RLOP

RLIP

OVLD

TRIP

ROP

DEM

SOP

IOP

SPD

TRQ

L N F+

F -

A-

A+

Invert

Non-invert

OP IP

5

K

Up / Down Ramp

OP on T16. ROP

Speed P+I error

amplifier with

stability preset.

Output provides

current demand.

Arm Amps

Isolation

Amplifier.

IOP on T19

Max Current

Preset

Total speed

demand DEM

on T17 (-ve)

Speed Output

SOP on T18

Arm Volts

Isolation

Amplifier

X 2

30 Sec Stall timer

with logic outputs

TRIP on T15 and

Overload on T14

Current

Demand

Clamp.

0 - 5V on

T21 =

0 -100%

+12V

Centre zero comparator with window

threshold from +/-50mV to +/-10.5V

Goes high on T12 (0-10V. 10mA) if

+/- signal input T13 exceeds window.

+12V

.1

M

12

K

Current P+I error

amp with phase

angle controlled

anti-parallel

bridge.

AC 240V or 110V

Field coil

Armature.

For armatures

with a time

constant of

less than 5mS

a DC choke

must be wired

in series.

AC supply must be

semi-conductor fused.

2 K340i Block Diagram and terminal listing.

K340i/680i/1220i

1 +10V output. 10mA max. (Use a 10K Ohm pot for external speed reference).

2 MIN SPEED. (Bottom end of external pot. 5K Ohms preset to common).

3 IP. Speed input. 0 to +/-10V speed input from pot wiper. 47K internal pull down.

4 OP+/-. +/-10.5V range. Input from T6. Invert with pushbutton input T8 open. Non-

invert with pushbutton input T7. 10mA max.

5 COM. Common. (0 Volts)

6 IP+/-. Input to pushbutton controlled +/- signal channel. OP on T4. 50K Ohms

impedance for invert mode, 10M input impedance in non-invert mode.

Note. This channel can invert input signals in the range +/-10.5V. It can also buffer

(i.e. non-invert) signals in the range 0V to +10.5V. (It cannot buffer negative signals.

If you try to buffer a negative signal the output will be positive).

Note. If using a high resistance external pot for positive signals e.g. greater than

20KOhms, then this channel can be used to buffer it using the non-invert mode.

7 PB+ Pushbutton input. 47K Ohm pull up to +12V. Connect to T5 COM. Latches T4 to

buffer (non-invert) positive T6 signals when opened, provided T8 PB- is connected to

T5 COM.

8 PB- Pushbutton input. 47K Ohm pull up to +12V. Connect to T5 COM. Latches T4 to

invert T6 when opened. T7 PB+ may be open or connected to T5 COM.

See truth table below for T7 and T8 operation. See terminal 6 IP+/- for notes.

a) Hence if PB+ Terminal 7 remains open then a switch on PB- Terminal 8 can be

K340i / K680i / K1220i Applications 4

Output voltage

Typical current limit available

Typical Load resistance

10.5V

1mA

Greater than 10K Ohms

10.0V

10 mA

1000 Ohms

9.5V

15 mA

633 Ohms

9.0V

20 mA

450 Ohms

8.5V

25mA

340 Ohms

8.0V

30mA

267 Ohms

Below 8V

30 mA

Less than 267 Ohms

used to change modes.

b) If both PB+ Terminal 7 and PB- Terminal 8 remain open then the invert mode is

established.

c) If both PB+ Terminal 7 and PB- Terminal 8 are connected to common then the

desired mode can be established by momentarily opening PB+ Terminal 7 for noninvert, or PB- Terminal 8 for invert mode. The mode remains latched when the

common connection is re-established. This is useful for end of travel reversal. To

implement, connect T1 +10V to T6 IP+/- and use the T4 OP+/- as the reference to

the external max speed pot. Then connect the normally closed contacts from

microswitches on the track, to the pushbutton inputs T7 PB+ and T8 PB- such that

when the load reaches and opens the microswitch it toggles the reference in the

opposite direction.

9 RUN. Internal 12K pull up to +12V. Open to stop, close to COMMON to run. WARNING.

RUN is an electronic inhibit function. The field remains energised, and all power

terminals ‘live’. RUN must not be relied on to ensure the machine is stationary

during hazardous operations. Remove the power source to the system.

Opening T9 RUN will cause immediate drive inhibit and hence if the motor is

rotating at the time it will coast to zero speed.

10 COM. Common. (0 Volts)

11 TACH input. The tach must be opposite polarity to speed input. 1.5 MOhms.

12 RLOP. Relay driver. +10.5V active high. Flywheel diode to COM.

Note. The output is current limited. When in current limit, the output voltage

achieved, depends on the resistance of the load multiplied by the available current

limit at that voltage, according to the table below.

When driving relays, ensure the coil operating range is suitable. E. g. a 12V relay

with a coil operating range of 80-110% will energise at voltages of 9.6V and above

(80% of 12V). Hence it must have coil resistance greater than 633 Ohms for the

output to be capable of achieving the desired voltage. (See table above).

K340i / K680i / K1220i Applications 5

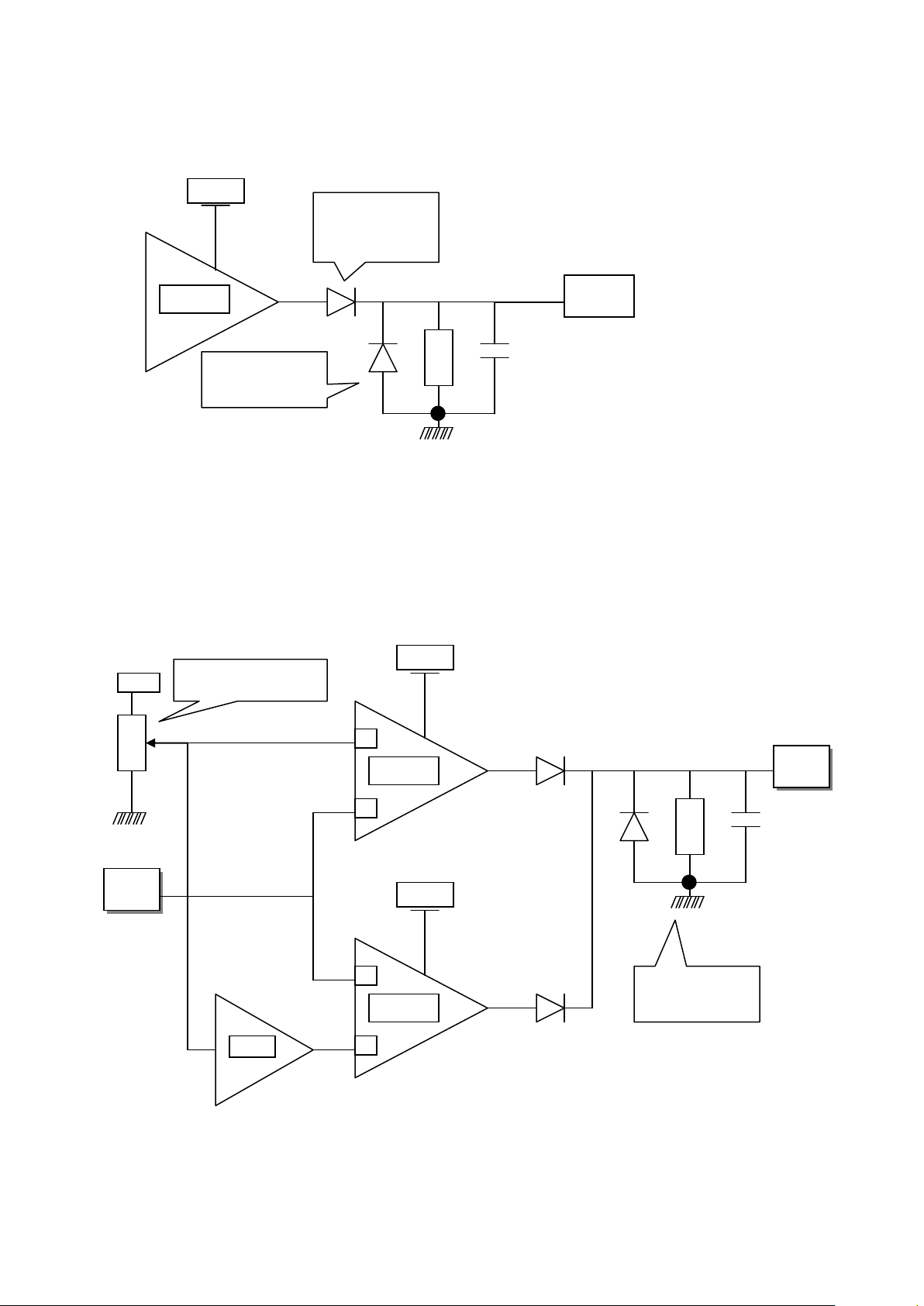

Flywheel diode,

47K resistor and

47nF capacitor

LM324

+12V

Output

This diode allows

relay outputs to

be OR'd together

if desired,

LM324

+12V

T12

RLOP

Flywheel diode,

47K resistor and

47nF capacitor

LM324

+12V

-

+

-

+

invert

10.5V

T13

RLIP

Level preset range

0.5% to 105%

Diagram of relay driver output stage

terminal

13 RLIP. Relay driver input. Accepts 0 to +/- 10.5V signal inputs. The threshold to

activate the relay driver is symmetrical around zero, and set by the RELAY preset

between +/- 0.05V and +/-10.5V. When the T13 input exceeds the positive or

negative threshold, then the T12 RELAY DRIVER OUTPUT is turned ON. Typical uses

include zero speed detector, zero current detector, stall detector etc.. The

input will accept any output provided on other control terminals. 50K Ohm pull

down to common.

Loading...

Loading...