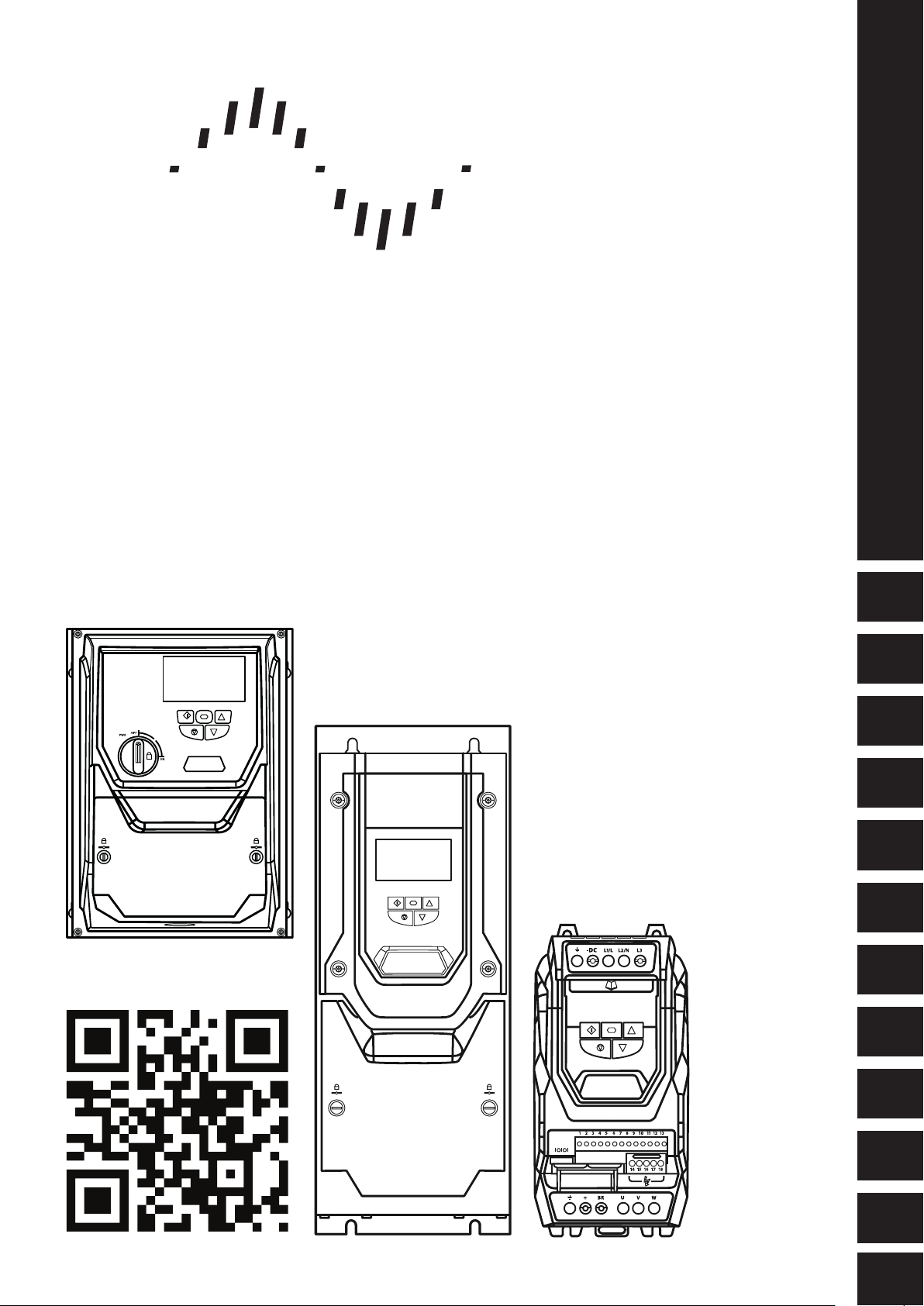

Bardac IP66, IP20, IP55 User Manual

P2 Series

drives

AC Vector Drive

For Precision Industrial Motor Speed & Torque Control

User Guide

0.75 - 160kW / 1HP - 250HP

200 - 480V 1 / 3 Phase Input

Quick Start Up

General Information

and Ratings

Mechanical Installation

Electrical Installation

Keypad and Display Operation

Parameters

Control Terminal

Functions

1

2

3

4

5

6

7

Extended

Parameters

Serial

Communications

Technical Data

Troubleshooting

8

9

10

11

1. Quick Start Up

............................

4

5. Keypad and Display Operation

......................

31

1.1. Important Safety Information

1.2. Quick Start Process

2. General Information and Ratings

2.1. Identifying the Drive by Model Number

2.2. Product Rating Label Location

2.3. Understanding the Rating Label

2.4. Drive Model Numbers – IP20

2.5. Drive Model Numbers – IP55

2.6. Drive Model Numbers – IP66

3. Mechanical Installation

3.1. General

3.2. Before Installation

3.3. UL Compliant Installation

3.4. Installation Following a Period of Storage

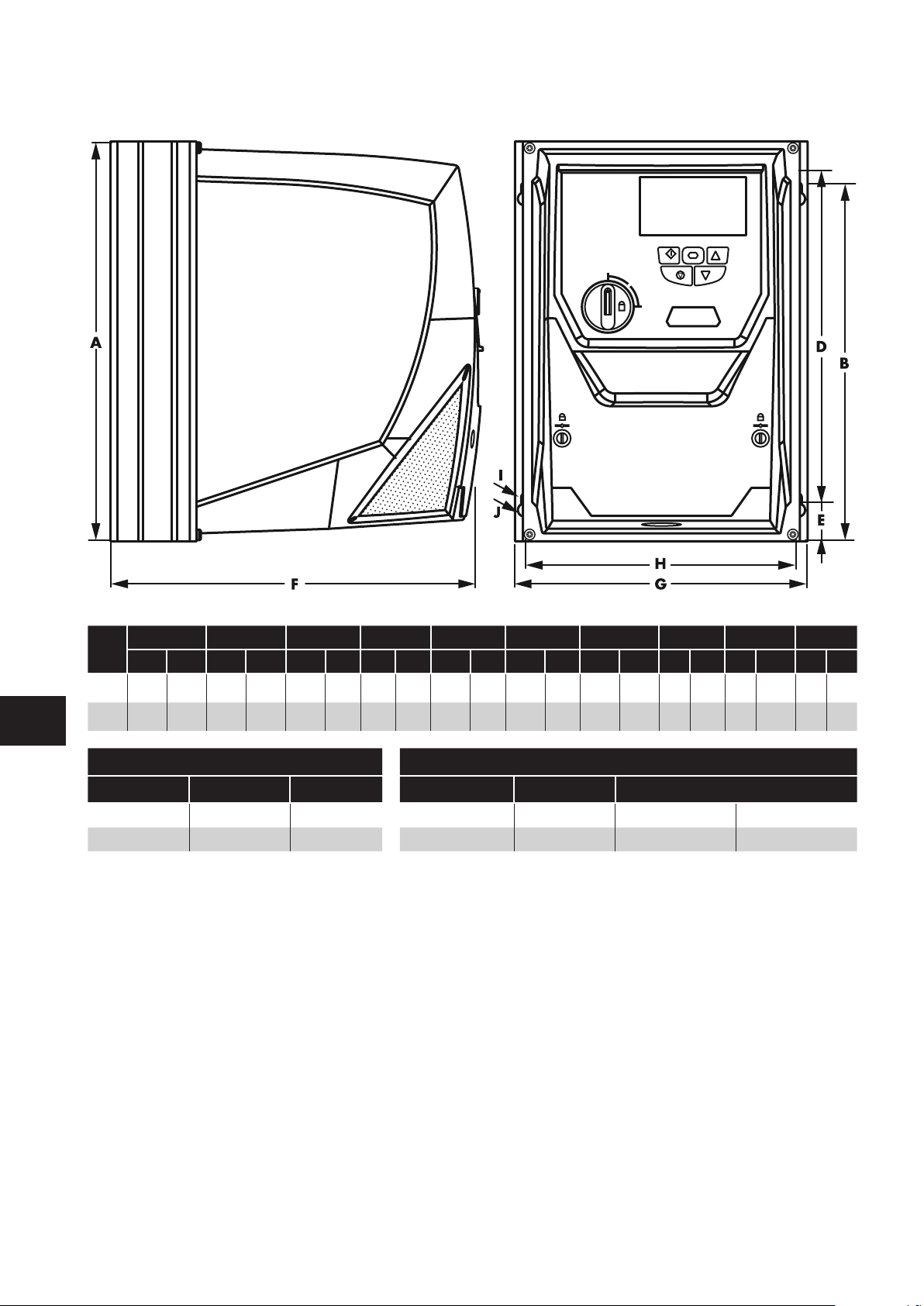

3.5. Mechanical Dimensions and Weight

3.6. Guidelines for Enclosure Mounting (IP20 Units) .....

......................................

.............................

....................

............................

...........

...................

.................

..................

..................

..................

....................

.......................

............

..........

........

4

5

6

6

7

7

7

9

10

11

11

11

11

11

12

15

5.1. OLED Keypad and Display Layout

5.2. LED Keypad and Display Layout

5.3. Selecting the Language on the OLED Display

5.4. Additional Display Messages

5.5. Changing Parameters

5.6. Parameter Factory Reset / User Reset

5.7. Resetting the Drive Following a Trip

5.8. Keypad Short Cuts

6. Parameters

6.1. Parameter Set Overview ...................................

6.2. Parameter Group 1 – Basic Parameters ......................

7. Control Terminal Functions ...........................

7.1. Control Source Selection

7.2. Digital Input Configuration Parameter P1-13. . . . . . . . . . . . . . . . . . .

7.3. Example Connection Schematics ............................

8. Extended Parameters

.......................................

....................................

.......................................

..................................

..............................

.........................

..........................

...............

.............................

......................

.........................

31

31

31

32

33

33

33

34

35

35

35

38

38

39

41

44

3.7. Mounting the Drive – IP20 Units. . . . . . . . . . . . . . . . . . .

3.8. Guidelines for Mounting (IP55 Units)

3.9. Guidelines for Mounting (IP66 Units)

3.10. Removing the Terminal Cover

3.11. Routine Maintenance

4. Electrical Installation

4.1. Connection Diagram

4.2. Protective Earth (PE) Connection

4.3. Incoming Power Connection

4.4. Operation of 3 Phase drives from a Single Phase

Supply

...........................................

4.5. Operation with DC Power Supply or Common DC

Bus

..............................................

4.6. Motor Connection

4.7. Motor Terminal Box Connections

4.8. Connecting a Brake Resistor

4.9. Control Terminal Wiring

4.10. Control Terminal Connections

..........................

.......................

...........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........................

............

............

...................

.................

....................

................

....................

..................

16

16

17

18

19

20

20

21

22

22

22

23

23

23

23

24

8.1. Parameter Group 2 - Extended Parameters ....................

8.2. Parameter Group 3 – PID Control ...........................

8.3. Parameter Group 5 – Communication Parameters .............

8.4. Advanced Parameters .....................................

8.5. Parameter Group 0 – Monitoring Parameters (Read Only) ......

9. Serial Communications ........................... 61

9.1. RJ45 Connector Pin Assignment

9.2. Modbus RTU Communications ..............................

9.3. CAN Open Communication ...............................

10. Technical Data ................................. 68

10.1. Environmental ...........................................

10.2. Input/Output Power and Current Ratings ....................

10.3. Additional Information for UL Approved Installations ...........

10.4. Derating Information .....................................

10.5. Internal EMC Filter and Varistors – Disconnection Procedure ....

11. Troubleshooting ................................ 74

11.1. Fault Messages ..........................................

............................

44

49

53

56

59

61

61

63

68

68

71

72

72

74

4.11. IP66 Switched Version Integrated Control Switch

and Potentiometer Wiring

4.12. Motor Thermal Overload Protection

4.13. EMC Compliant Installation

4.14. Safe Torque Off

P2 Series User Guide | Version 3.01 www.bardac.com

..........................

.............

....................

..............................

25

25

26

27

Declaration of Conformity

Bardac Corporation hereby states that the P2 Series product range conforms to the relevant safety provisions of the following council

directives:

2014/30/EU (EMC) and 2014/35/EU (LVD)

Designed and manufacture is in accordance with the following harmonised European standards:

EN 61800-5-1: 2007

EN 61800-3: 2004 /A1 2012 Adjustable speed electrical power drive systems. EMC requirements and specific test methods

EN 55011: 2007 Limits and Methods of measurement of radio disturbance characteristics of industrial, scientific and

EN60529: 1992 Specifications for degrees of protection provided by enclosures

Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

medical (ISM) radio-frequency equipment (EMC)

Safe Torque OFF (“STO”) Function

The P2 incorporates a hardware STO (Safe Torque Off) Function, designed in accordance with the standards listed below.

Standard Classification Independent Approval

EN 61800-5-2:2007 Type 2

EN ISO 13849-1:2006 PL “d”

EN 61508 (Part 1 to 7) SIL 2

EN60204-1 Uncontrolled Stop “Category 0”

EN 62061 SIL CL 2

*TUV

Electromagnetic Compatibility

All P2 drives are designed with high standards of EMC in mind. All versions suitable for operation on Single Phase 230 volt and Three Phase

400 volt supplies and intended for use within the European Union are fitted with an internal EMC filter. This EMC filter is designed to reduce

the conducted emissions back into the mains supply via the power cables for compliance with the above harmonised European standards.

It is the responsibility of the installer to ensure that the equipment or system into which the product is incorporated complies with the

EMC legislation of the country of use, and the relevant category. Within the European Union, equipment into which this product is

incorporated must comply with the EMC Directive 2004/108/EC. This User Guide provides guidance to ensure that the applicable

standards may be achieved.

Copyright Bardac Corporation © 2018

All rights reserved. No part of this User Guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including photocopying, recording or by any information storage or retrieval system without permission in writing from the publisher.

2 Year Warranty

All P2 Series drives units carry a 2 year warranty against manufacturing defects from the date of manufacture. The manufacturer

accepts no liability for any damage caused during or resulting from transport, receipt of delivery, installation or commissioning. The

manufacturer also accepts no liability for damage or consequences resulting from inappropriate, negligent or incorrect installation,

incorrect adjustment of the operating parameters of the drive, incorrect matching of the drive to the motor, incorrect installation,

unacceptable dust, moisture, corrosive substances, excessive vibration or ambient temperatures outside of the design specification.

The local distributor may offer different terms and conditions at their discretion, and in all cases concerning warranty, the local

distributor should be contacted first.

This user guide is the “original instructions” document. All non-English versions are translations of the

“original instructions”.

The contents of this User Guide are believed to be correct at the time of printing. In the interest of a commitment to a policy of

continuous improvement, the manufacturer reserves the right to change the specification of the product or its performance or the

contents of the User Guide without notice.

This User Guide is for use with version 2.30 Firmware. User Guide Revision 3.01.

Bardac Corporation adopts a policy of continuous improvement and whilst every effort has been made to provide accurate and up

to date information, the information contained in this User Guide should be used for guidance purposes only and does not form the

part of any contract.

This manual is intended as a guide for proper installation. Bardac cannot assume responsibility for the compliance or the

non-compliance to any code, national, local or otherwise, for the proper installation of this drive or associated equipment. A

hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

This drive contains high voltage capacitors that take time to discharge after removal of the main supply. Before working on

the drive, ensure isolation of the main supply from line inputs. Wait ten (10) minutes for the capacitors to discharge to safe

voltage levels. Failure to observe this precaution could result in severe bodily injury or loss of life.

Only qualified electrical personnel familiar with the construction and operation of this equipment and the hazards involved

should install, adjust, operate, or service this equipment. Read and understand this manual and other applicable manuals

in their entirety before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

Version 3.01 | P2 Series User Guide | 3www.bardac.com

Quick Start Up

1

1. Quick Start Up

1.1. Important Safety Information

Please read the IMPORTANT SAFETY INFORMATION below, and all Warning and Caution information elsewhere.

Danger: Indicates a risk of electric shock, which,

if not avoided, could result in damage to the

equipment and possible injury or death.

This variable speed drive product (drive) is intended for

professional incorporation into complete equipment or systems

as part of a fixed installation. If installed incorrectly it may present

a safety hazard. The drive uses high voltages and currents,

carries a high level of stored electrical energy, and is used to

control mechanical plant that may cause injury. Close attention

is required to system design and electrical installation to avoid

hazards in either normal operation or in the event of equipment

malfunction. Only qualified electricians are allowed to install and

maintain this product.

System design, installation, commissioning and maintenance must

be carried out only by personnel who have the necessary training

and experience. They must carefully read this safety information

and the instructions in this Guide and follow all information

regarding transport, storage, installation and use of the drive,

including the specified environmental limitations.

Do not perform any flash test or voltage withstand test on the

drive. Any electrical measurements required should be carried out

with the drive disconnected.

Electric shock hazard! Disconnect and ISOLATE the drive

before attempting any work on it. High voltages are present

at the terminals and within the drive for up to 10 minutes after

disconnection of the electrical supply. Always ensure by using a

suitable multimeter that no voltage is present on any drive power

terminals prior to commencing any work.

Where supply to the drive is through a plug and socket connector,

do not disconnect until 10 minutes have elapsed after turning off

the supply.

Ensure correct earthing connections and cable selection as

per defined by local legislation or codes. The drive may have

a leakage current of greater than 3.5mA; furthermore the earth

cable must be sufficient to carry the maximum supply fault current

which normally will be limited by the fuses or MCB. Suitably rated

fuses or MCB should be fitted in the mains supply to the drive,

according to any local legislation or codes.

Do not carry out any work on the drive control cables whilst

power is applied to the drive or to the external control circuits.

The “Safe Torque Off” Function does not prevent high voltages

from being present at the drives power terminals.

Within the European Union, all machinery in which this product is used

must comply with the Machinery Directive 2006/42/EC, Safety of

Machinery. In particular, the machine manufacturer is responsible for

ensuring that the electrical equipment complies with EN60204-1 and

providing a disconnecting device which must be one of the following

types:

A switch-disconnector, utilization category AC-23B (EN 60947-3).

A circuit breaker suitable for isolation in accordance with

For installation in other regions, conformance with local electrical

regulations and codes of practice must be adhered to.

The level of integrity offered by the drive control input functions – for

example stop/start, forward/reverse and maximum speed, is not

sufficient for use in safety-critical applications without independent

channels of protection. All applications where malfunction could cause

injury or loss of life must be subject to a risk assessment and further

protection provided where needed.

The driven motor can start at power up if the enable input signal is present.

The STOP function does not remove potentially lethal high voltages.

ISOLATE the drive and wait 10 minutes before starting any work on it.

Never carry out any work on the Drive, Motor or Motor cable whilst

the input power is still applied.

The drive can be programmed to operate the driven motor at speeds

above or below the speed achieved when connecting the motor

directly to the mains supply. Obtain confirmation from the manufacturers

of the motor and the driven machine about suitability for operation over

or under the intended speed range prior to machine start up.

Do not activate the automatic fault reset function on any systems

whereby this may cause a potentially dangerous situation.

IP55 and IP66 drives provide their own pollution degree 2

environments. IP20 drives must be installed in a pollution degree 2

environment, mounted in a cabinet with IP54 or better.

The drives are intended for indoor use only.

When mounting the drive, ensure that sufficient cooling is provided. Do

not carry out drilling operations with the drive in place, dust and swarf

from drilling may lead to damage.

The entry of conductive or flammable foreign bodies should be

prevented. Flammable material should not be placed close to the drive.

Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and no. of phases (1 or 3

phase) correspond to the rating of the drive as delivered.

Never connect the mains power supply to the Output terminals U, V, W.

Do not install any type of automatic switchgear between the drive and

the motor.

Wherever control cabling is close to power cabling, maintain a

minimum separation of 100 mm and arrange crossings at 90 degrees.

Ensure that all terminals are tightened to the appropriate torque setting.

Do not attempt to carry out any repair of the drive. In the case of

suspected fault or malfunction, contact your local Bardac Sales Partner

for further assistance.

Do not operate the drive with any of the enclosure covers removed.

Danger: Indicates a potentially hazardous situation

other than electrical, which if not avoided, could

result in damage to property.

EN 60947-2.

A disconnector with an integrated auxiliary contact that ensures under

all circumstances the switching devices break the load circuit prior to

opening of the main contacts of the disconnector (EN 60947-3).

P2 Series User Guide | Version 3.01 www.bardac.com

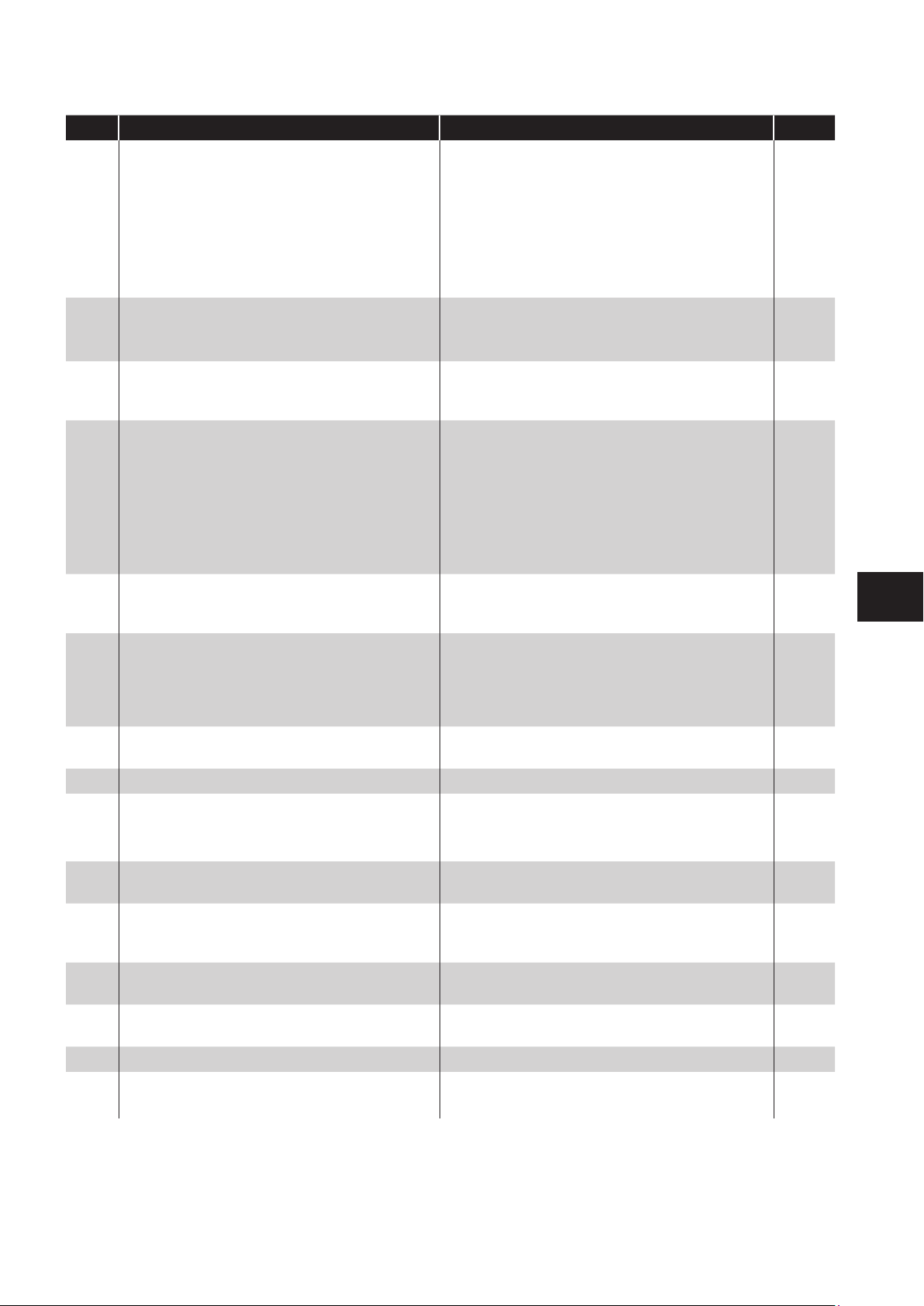

1.2. Quick Start Process

Step Action See Section Page

1 Identify the Model Type and ratings of your drive

from the model code on the label. In particular:

- Check the voltage rating suits the incoming supply

- Check the output current capacity meets or

exceeds the full load current for the intended

motor

- Check the enclosure type is suitable for the

intended mounting location.

2 Unpack and check the drive.

Notify the supplier and shipper immediately of any

damage.

3 Ensure correct ambient and environmental conditions

for the drive are met by the proposed mounting

location.

4 Install the drive in a suitable cabinet (IP20 Units),

ensuring suitable cooling air is available.

Mount the drive to the wall or machine (IP55 &

IP66).

5 Select the correct power and motor cables

according to local wiring regulations or code, noting

the maximum permissible sizes.

6 For IT Supply network, or any power supply type

where the phase – earth voltage may exceed

the phase – phase voltage (such as ungrounded

supplies), disconnect the EMC filter before

connecting the supply.

7 Check the supply cable and motor cable for faults or

short circuits.

8 Route the cables

9 Check that the intended motor is suitable for use,

noting any precautions recommended by the supplier

or manufacturer.

2.1. Identifying the Drive by Model Number

2.3. Understanding the Rating Label

2.4. Drive Model Numbers – IP20

2.5. Drive Model Numbers – IP55

2.6. Drive Model Numbers – IP66

3.1. General

10.1. Environmental 68

3.1. General

3.2. Before Installation

3.5. Mechanical Dimensions and Weight

3.6. Guidelines for Enclosure Mounting (IP20 Units)

3.7. Mounting the Drive – IP20 Units

3.8. Guidelines for Mounting (IP55 Units)

3.9. Guidelines for Mounting (IP66 Units)

10.2. Input/Output Power and Current Ratings 68

10.5. Internal EMC Filter and Varistors – Disconnection

Procedure

4.6. Motor Connection

8.2.3. Parameter Group 4 – High Performance Motor

Control

6

7

7

9

10

11

Quick Start Up

11

11

12

15

16

16

17

1

72

23

50

10 Check the motor terminal box for correct Star or

Delta configuration where applicable.

11 Ensure correct wiring protection is providing, by

installing a suitable circuit breaker or fuses in the

incoming supply line.

12 Connect the power cables, especially ensuring the

protective earth connection is made.

13 Connect the control cables as required for the

application.

14 Thoroughly check the installation and wiring.

15 Commission the drive parameters. 5.5. Changing Parameters

4.7. Motor Terminal Box Connections 23

4.3.3. Fuse / Circuit Breaker Selection 22

4.1. Connection Diagram 20

4.10. Control Terminal Connections 24

6. Parameters

Version 3.01 | P2 Series User Guide | 5www.bardac.com

33

35

2. General Information and Ratings

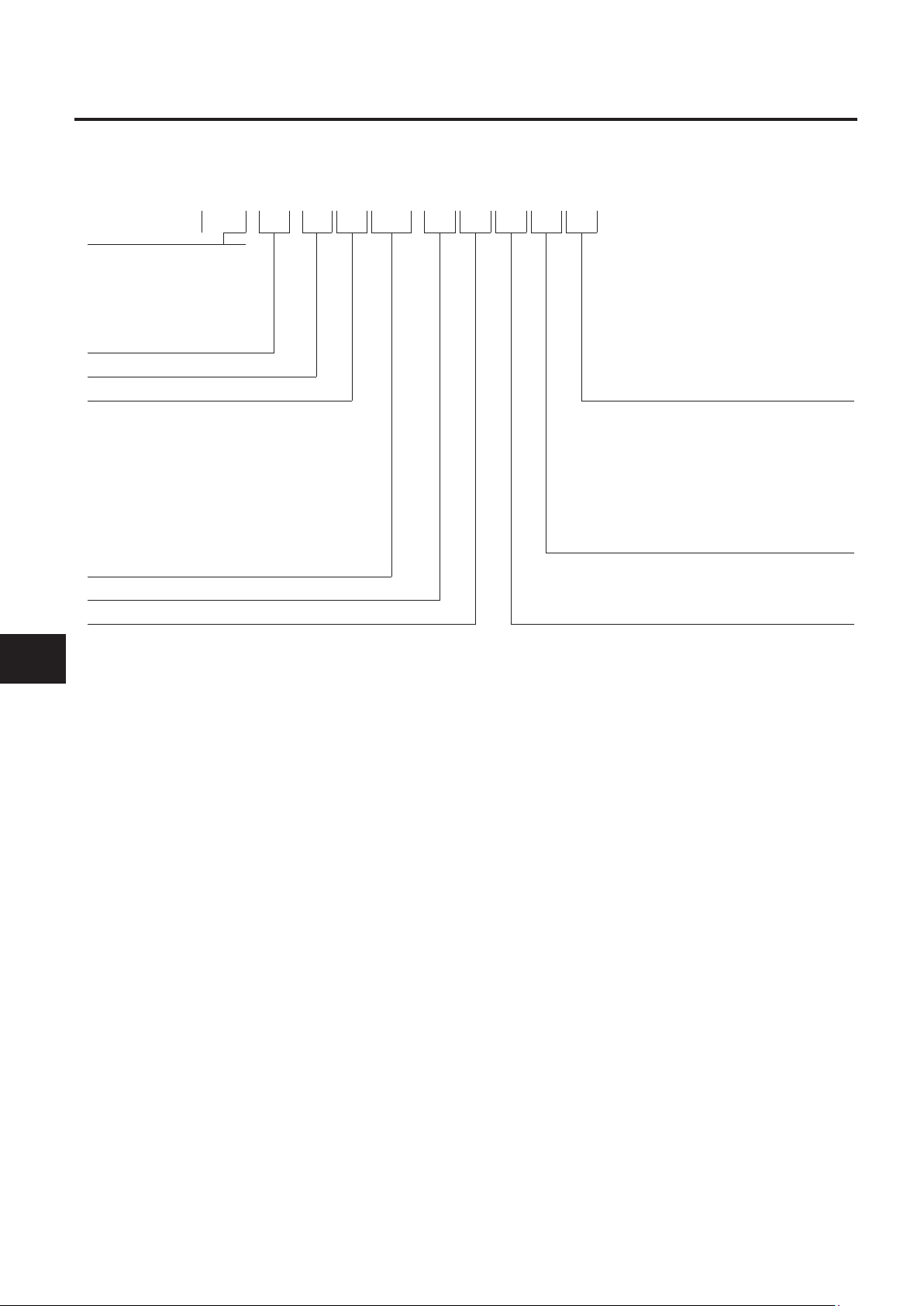

2.1. Identifying the Drive by Model Number

The model number of each P2 drive is constructed according to the following system:

P 2 - 2 4 400 - 3 K F 4 2 -

General Information & Ratings

Product Family

E: E Series

P: P Series

V: HVAC Product Series

Generation

Frame Size

Voltage Code

1 : 110 Volt

2 : 230 Volt

4 : 400 Volt

5 : 525 Volt

6 : 600 Volt

Three Digit Power Rating

Input Phases

Power Type

2

K : kW Rated

H : HP Rated

PCB Coating

Standard Localised Coating

C : Full Conformal Coating

Display

Standard 7 Segment LED Display

T : OLED Text Display

Enclosure

2 : IP20

4 : IP40

D : IP66 with Internal Disconnect

N : IP55 Non Switched

S : IP55 Switched

X : IP66 Non Switched

Y : IP66 Switched

Brake Chopper

1 : No Brake Chopper

4 : Internal Brake Chopper

EMC Filter

0 : No Internal Filer

F : Internal EMC Filter

P2 Series User Guide | Version 3.01 www.bardac.com

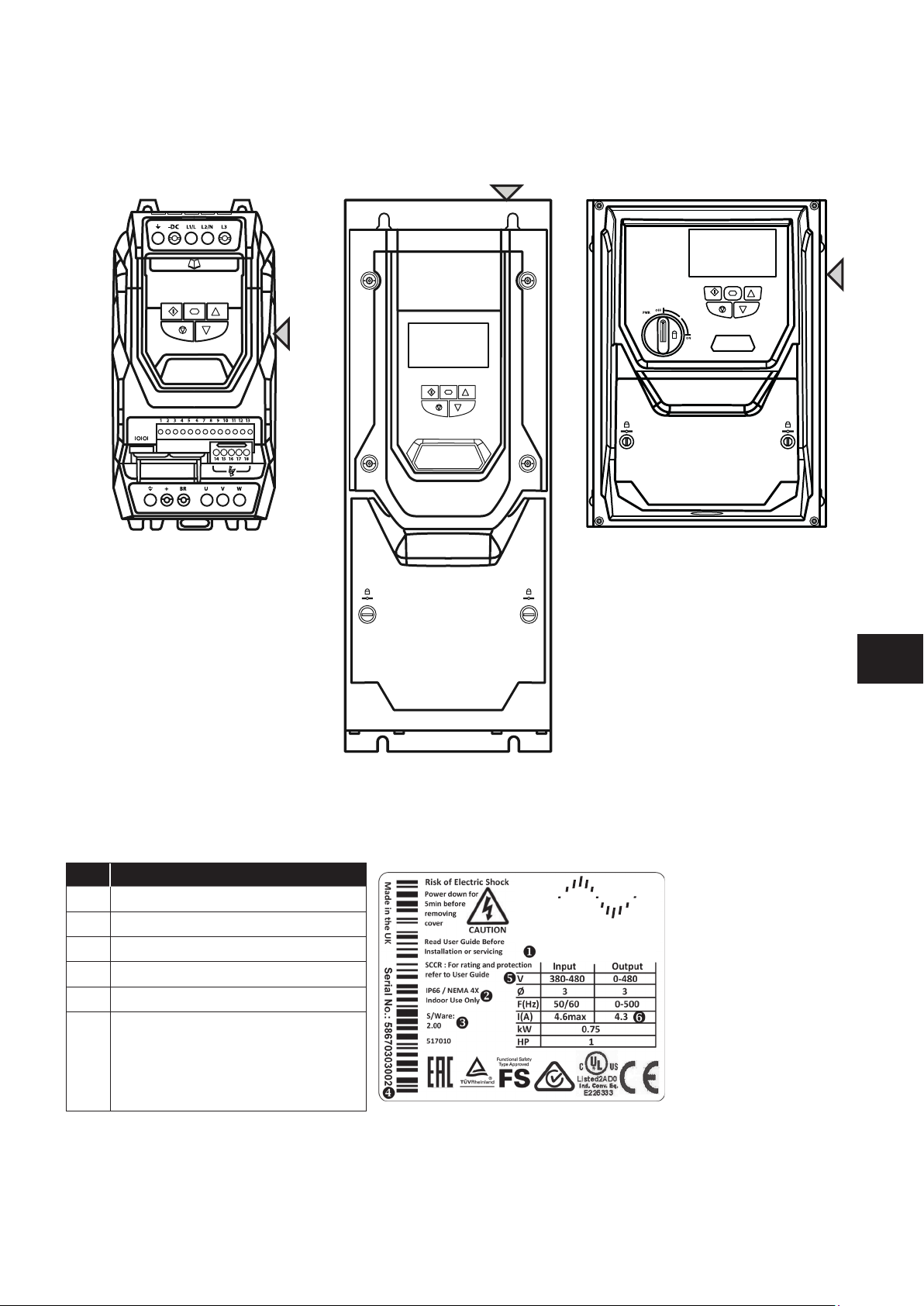

2.2. Product Rating Label Location

drives

All P2 models carry a rating label, which can be located as follows:

IP20 Models IP55 Models IP66 Models

General Information & Ratings

On right hand side when viewed from the

front.

On the top surface.

2.3. Understanding the Rating Label

The product rating label provides the following information.

Key

1 Model Code

2 Enclosure Type and IP Rating

3 Firmware Version

4 Serial Number

5 Technical Data – Supply Voltage

6 Technical Data – Maximum continuous

output current

On right hand side when viewed from the

front.

2

Bardac

P2-24010-3HF42

Version 3.01 | P2 Series User Guide | 7www.bardac.com

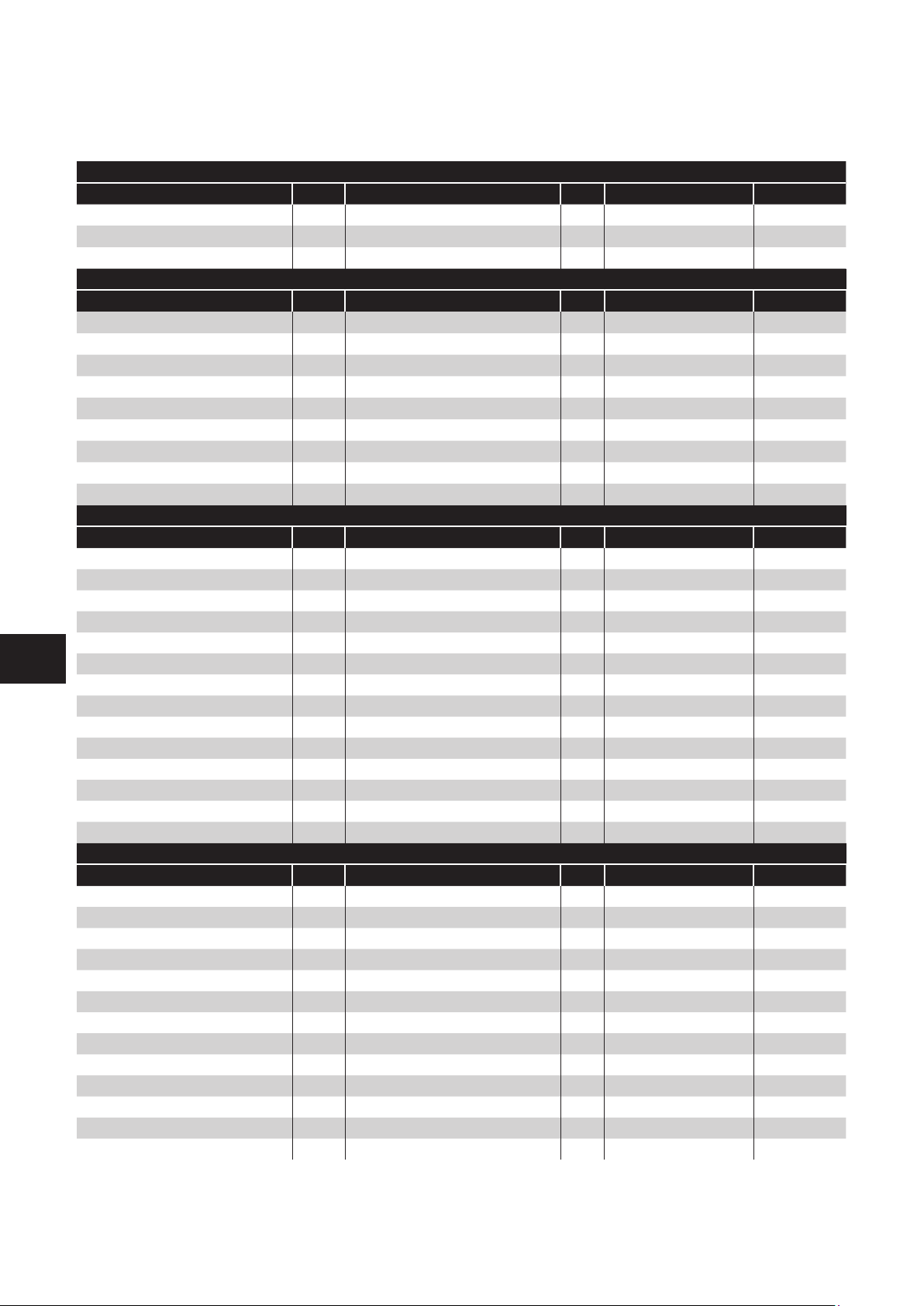

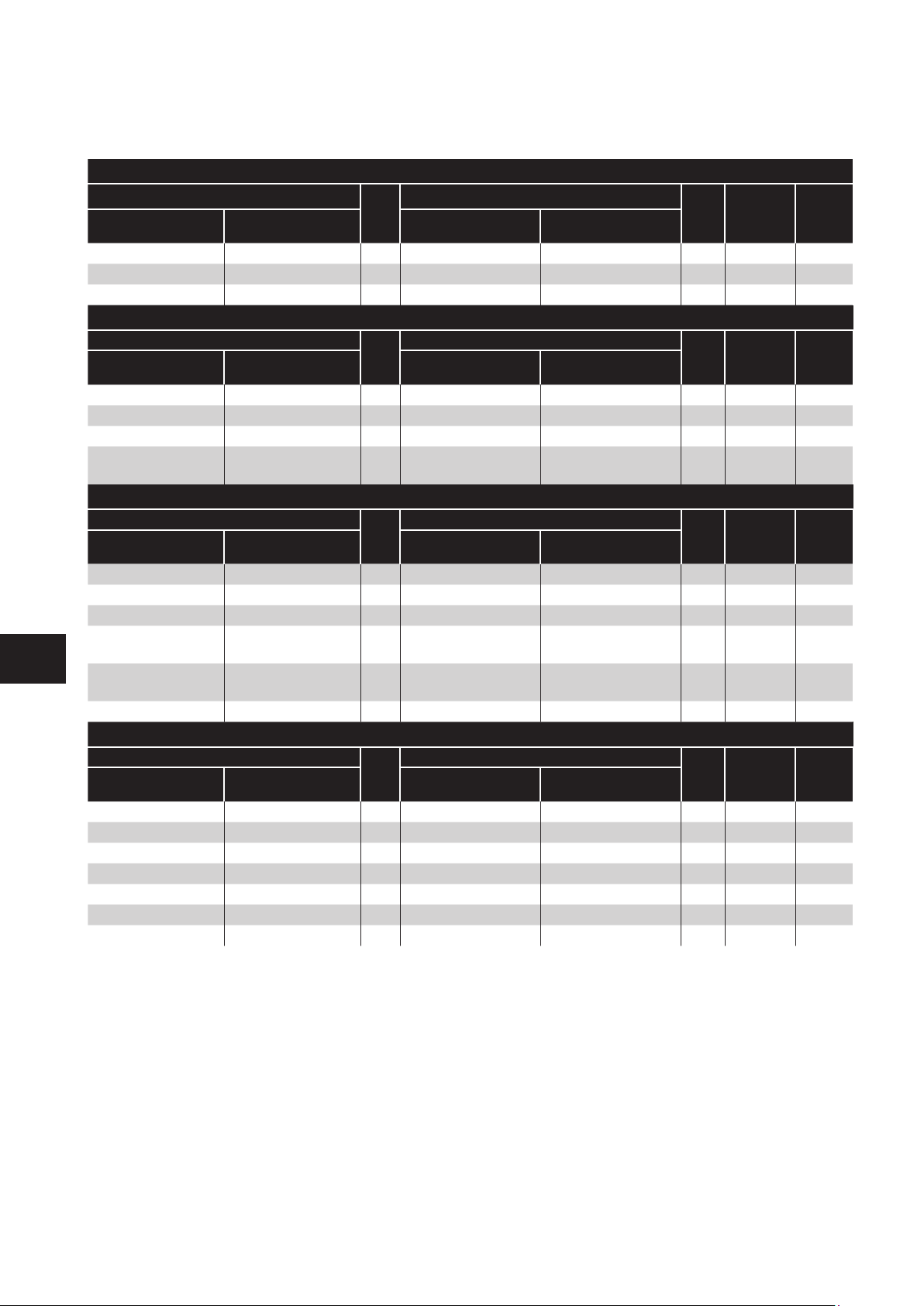

2.4. Drive Model Numbers – IP20

Mechanical Dimensions and Mounting information are shown from section 3.5.1. IP20 Units on page 12.

Electrical Specifications are shown in section 10.2. Input/Output Power and Current Ratings on page 68.

200-240V ±10% - 1 Phase Input

kW Model kW HP Model HP Output Current (A) Frame Size

P2-22075-1KF42 0.75 P2-22010-1HF42 1 4.3 2

General Information & Ratings

2

P2-22150-1KF42 1.5 P2-22020-1HF42 2 7 2

P2-22220-1KF42 2.2 P-2-22030-1HF42 3 10.5 2

200-240V ±10% - 3 Phase Input

kW Model kW HP Model HP Output Current (A) Frame Size

P2-22075-3KF42 0.75 P2-22010-3HF42 1 4.3 2

P2-22150-3KF42 1.5 P2-22020-3HF42 2 7 2

P2-22220-3KF42 2.2 P2-22030-3HF42 3 10.5 2

P2-32040-3KF42 4 P2-32050-3HF42 5 18 3

P2-32055-3KF42 5.5 P2-32075-3HF42 7. 5 24 3

P2-42075-3KF42 7. 5 P2-42100-3HF42 10 30 4

P2-42110-3KF42 11 P2-42150-3HF42 15 46 4

P2-52150-3KF42 15 P2-52020-3HF42 20 61 5

P2-52185-3KF42 18.5 P2-52025-3HF42 25 72 5

380-480V ±10% - 3 Phase Input

kW Model kW HP Model HP Output Current (A) Frame Size

P2-24075-3KF42 0. 75 P2-24010-3HF42 1 2.2 2

P2-24150-3KF42 1.5 P2-24020-3HF42 2 4.1 2

P2-24220-3KF42 2.2 P2-24030-3HF42 3 5.8 2

P2-24400-3KF42 4 P2-24050-3HF42 5 9.5 2

P2-34055-3KF42 5.5 P2-34075-3HF42 7. 5 14 3

P2-34075-3KF42 7. 5 P2-34100-3HF42 10 18 3

P2-34110-3KF42 11 P2-34150-3HF42 15 24 3

P2-44150-3KF42 15 P2-44200-3HF42 20 30 4

P2-44185-3KF42 18.5 P2-44250-3HF42 25 39 4

P2-44220-3KF42 22 P2-44300-3HF42 30 46 4

P2-54300-3KF42 30 P2-54040-3HF42 40 61 5

P2-54370-3KF42 37 P2-54050-3HF42 50 72 5

P2-84200-3KF42 200 P2-84300-3HF42 300 370 8

P2-84250-3KF42 250 P2-84350-3HF42 350 450 8

500-600V ±10% - 3 Phase Input

kW Model kW HP Model HP Output Current (A) Frame Size

P2-26075-3K042 0.75 P2-26010-3H042 1 2.1 2

P2-26150-3K042 1.5 P2-26020-3H042 2 3.1 2

P2-26220-3K042 2.2 P2-26030-3H042 3 4.1 2

P2-26400-3K042 4 P2-26050-3H042 5 6.5 2

P2-26550-3K042 5.5 P2-26075-3H042 7. 5 9 2

P2-36075-3K042 7. 5 P2-36100-3H042 10 12 3

P2-36110-3K042 11 P2-36150-3H042 15 17 3

P2-36150-3K042 15 P2-36200-3H042 20 22 3

P2-46185-3K042 18.5 P2-46250-3H042 25 28 4

P2-46220-3K042 22 P2-46300-3H042 30 34 4

P2-46300-3K042 30 P2-46400-3H042 40 43 4

P2-56370-3K042 37 P2-56050-3H042 50 54 5

P2-56450-3K042 45 P2-56060-3H042 60 65 5

P2 Series User Guide | Version 3.01 www.bardac.com

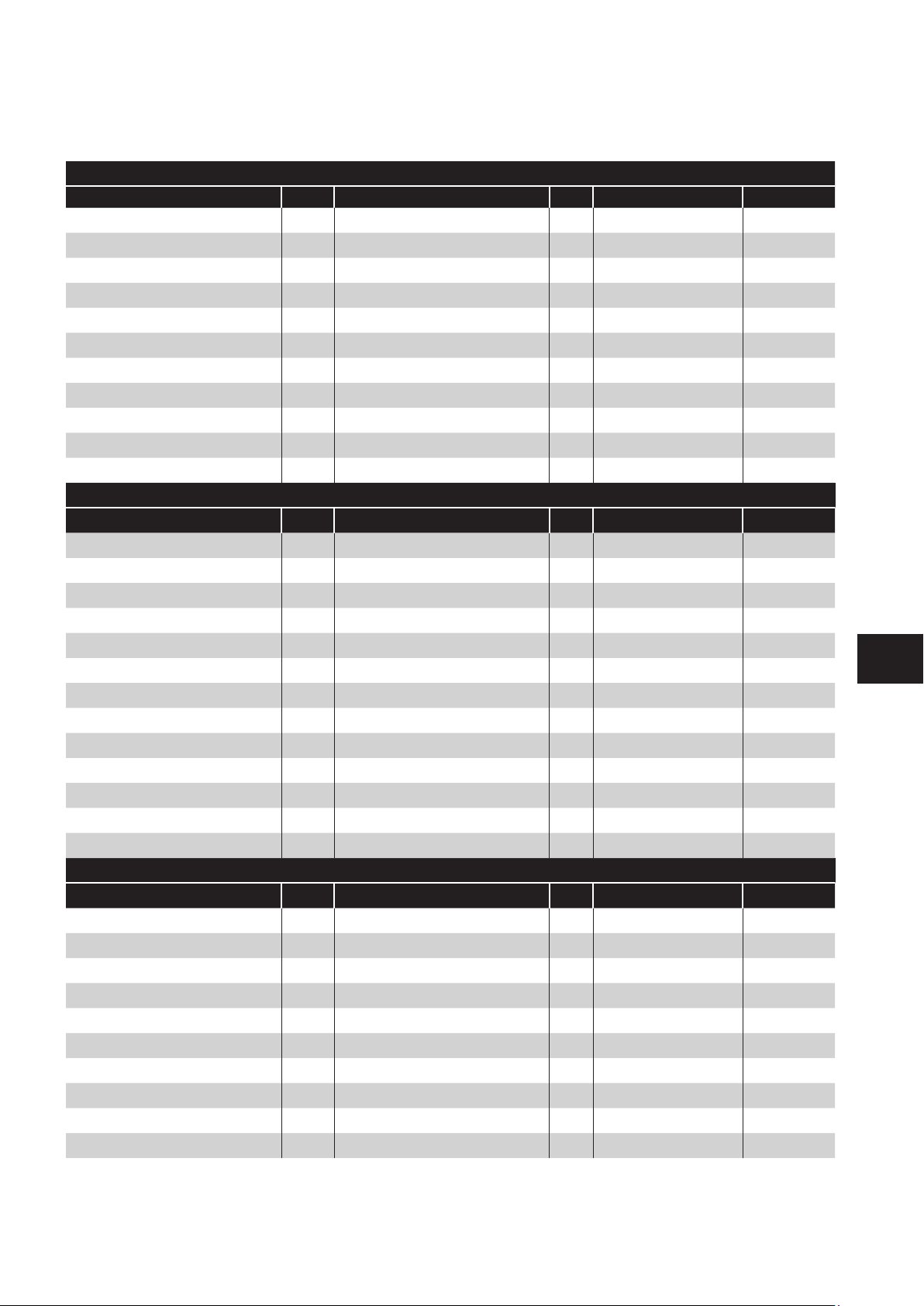

2.5. Drive Model Numbers – IP55

Mechanical dimensions and mounting information are shown from section 3.5.2. IP55 Units on page 13.

Electrical specifications are shown in section 10.2. Input/Output Power and Current Ratings on page 68.

200-240V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

P2-42055-3KF4N 5.5 P2-42075-3HF4N 7. 5 24 4

P2-42075-3KF4N 7. 5 P2-42100-3HF4N 10 39 4

P2-42110-3KF4N 11 P2-42150-3HF4N 15 46 4

P2-52150-3KF4N 15 P2-52020-3HF4N 20 61 5

P2-52185-3KF4N 18.5 P2-52025-3HF4N 25 72 5

P2-62022-3KF#N 22 P2-62030-3HF#N 30 90 6

P2-62030-3KF#N 30 P2-62040-3HF#N 40 11 0 6

P2-62037-3KF#N 37 P2-62050-3HF#N 50 15 0 6

P2-62045-3KF#N 45 P2-62060-3HF#N 60 18 0 6

P2-72055-3KF#N 55 P2-72075-3HF#N 75 202 7

P2-72075-3KF#N 75 P2-72100-3HF#N 10 0 248 7

380-480V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

P2-44110-3KF4N 11 P2-44150-3HF4N 15 24 4

P2-44150-3KF4N 15 P2-44200-3HF4N 20 30 4

P2-44185-3KF4N 18.5 P2-44250-3HF4N 25 39 4

P2-44220-3KF4N 22 P2-44300-3HF4N 30 46 4

P2-54300-3KF4N 30 P2-54040-3HF4N 40 61 5

P2-54370-3KF4N 37 P2-54050-3HF4N 50 72 5

P2-64045-3KF#N 45 P2-64060-3HF#N 60 90 6

P2-64055-3KF#N 55 P2-64075-3HF#N 75 11 0 6

P2-64075-3KF#N 75 P2-64120-3HF#N 12 0 15 0 6

P2-64090-3KF#N 90 P2-64150-3HF#N 15 0 18 0 6

P2-74110-3KF#N 11 0 P2-74175-3HF#N 175 202 7

P2-74132-3KF#N 13 2 P2-74200-3HF#N 200 240 7

P2-74160-3KF#N 16 0 P2-74250-3HF#N 250 302 7

500-600V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

P2-46150-3K04N 15 P2-46200-3H04N 20 22 4

P2-46185-3K04N 18.5 P2-46250-3H04N 25 28 4

P2-46220-3K04N 22 P2-46300-3H04N 30 34 4

P2-46300-3K04N 30 P2-46400-3H04N 40 43 4

P2-56370-3K04N 37 P2-56050-3H04N 50 54 5

P2-56450-3K04N 45 P2-56060-3H04N 60 65 5

P2-66055-3K0#N 55 P2-66075-3H0#N 75 78 6

P2-66075-3K0#N 75 P2-66100-3H0#N 10 0 10 5 6

P2-66090-3K0#N 90 P2-66125-3H0#N 12 5 13 0 6

P2-66110-3K0#N 11 0 P2-66150-3H0#N 15 0 15 0 6

General Information & Ratings

2

Version 3.01 | P2 Series User Guide | 9www.bardac.com

2.6. Drive Model Numbers – IP66

Mechanical dimensions and mounting information are shown from section 3.5.3. IP66 Units on page 14.

Electrical specifications are shown in section 10.2. Input/Output Power and Current Ratings on page 68.

200-240V ±10% - 1 Phase Input

kW Model

General Information & Ratings

2

Non Switched Switched Non Switched Switched

P2-22075-1KF4X-TN P2-22075-1KF4Y-TN 0 . 75 P2-22010-1HF4X-TN P2-22010-1HF4Y-TN 1 4.3 2

P2-22150-1KF4X-TN P2-22150-1KF4Y-TN 1.5 P2-22020-1HF4X-TN P2-22020-1HF4Y-TN 2 7 2

P2-22220-1KF4X-TN P2-22220-1KF4Y-TN 2.2 P2-22030-1HF4X-TN P2-22030-1HF4Y-TN 3 10.5 2

kW Model

Non Switched Switched Non Switched Switched

P2-22075-3KF4X-TN P2-22075-3KF4Y-TN 0 . 75 P2-12010-3HF4X-TN P2-22010-3HF4Y-TN 1 4.3 2

P2-22150-3KF4X-TN P2-22150-3KF4Y-TN 1.5 P2-22020-3HF4X-TN P2-22020-3HF4Y-TN 2 7 2

P2-22220-3KF4X-TN P2-22220-3KF4Y-TN 2.2 P2-22030-3HF4X-TN P2-22030-3HF4Y-TN 3 10.5 2

P-32040-3KF4X-TN

kW Model

Non Switched Switched Non Switched Switched

P2-24075-3KF4X-TN P2-24075-3KF4Y-TN 0.75 P2-24010-3HF4X-TN P2-24010-3HF4Y-TN 1 2.2 2

P2-24150-3KF4X-TN P2-24150-3KF4Y-TN 1.5 P2-24020-3HF4X-TN P2-24020-3HF4Y-TN 2 4 .1 2

P2-24220-3KF4X-TN P2-24220-3KF4Y-TN 2.2 P2-24030-3HF4X-TN P2-24030-3HF4Y-TN 3 5.8 2

P2-24400-3KF4X-TNP2-24400-3KF4Y-

P2-34055-3KF4X-TNP2-34055-3KF4Y-

P2-34075-3KF4X-TN P2-34075-3KF4Y-TN 7. 5 P2-34100-3HF4X-TN P2-34100-3HF4Y-TN 10 18 3

kW Model

Non Switched Switched Non Switched Switched

P2-26075-3K04X P2-26075-3K04Y 0 . 75 P2-26010-3H04X P2-26010-3H04Y 1 2 .1 2

P2-26150-3K04X P2-26150-3K04Y 1.5 P2-26020-3H04X P2-26020-3H04Y 2 3 .1 2

P2-26220-3K04X P2-26220-3K04Y 2.2 P2-26030-3H04X P2-26030-3H04Y 3 4 .1 2

P2-26400-3K04X P2-26400-3K04Y 4 P2-26050-3H04X P2-26050-3H04Y 5 6.5 2

P2-26550-3K04X P2-26550-3K04Y 5.5 P2-26075-3H04X P2-26075-3H04Y 7. 5 9 2

P2-36075-3K04X P2-36075-3K04Y 7. 5 P2-36100-3H04X P2-36100-3H04Y

P2-36110-3K04X P2-36110-3K04Y 11 P2-36150-3H04X P2-36150-3H04Y

P2-32040-3KF4Y-

TN

TN

TN

kW

200-240V ±10% - 3 Phase Input

kW

4 P2-32050-3HF4X-TN P2-32050-3HF4Y-TN 5 18 3

380-480V ±10% - 3 Phase Input

kW

4 P2-24050-3HF4X-TN P2-24050-3HF4Y-TN 5 9.5 2

5.5 P2-34075-3HF4X-TN P2-34075-3HF4Y-TN 7. 5 14 3

500-600V ±10% - 3 Phase Input

kW

HP Model

HP Model

HP Model

HP Model

Output

HP

Current

(A)

Output

HP

Current

(A)

Output

HP

Current

(A)

Output

HP

Current

(A)

10 12 3

15 17 3

Frame

Size

Frame

Size

Frame

Size

Frame

Size

P2 Series User Guide | Version 3.01 www.bardac.com

3. Mechanical Installation

3.1. General

The drive should be mounted in a vertical position only, on a flat, flame resistant, vibration free mounting using the integral mounting

holes or DIN Rail clip (Frame Size 2 only).

The drive must be installed in a pollution degree 1 or 2 environment only.

Do not mount flammable material close to the drive.

Ensure that the minimum cooling air gaps, as detailed in sections 3.6. Guidelines for Enclosure Mounting (IP20 Units),

3.8. Guidelines for Mounting (IP55 Units) and 3.9. Guidelines for Mounting (IP66 Units) are left clear.

Ensure that the ambient temperature range does not exceed the permissible limits for the drive given in section 10.1. Environmental.

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the drive.

3.2. Before Installation

Carefully Unpack the drive and check for any signs of damage. Notify the shipper immediately if any exist.

Check the drive rating label to ensure it is of the correct type and power requirements for the application.

To prevent accidental damage always store the drive in its original box until required. Storage should be clean and dry and within

the temperature range –40°C to +60°C.

3.3. UL Compliant Installation

Note the following for UL-compliant installation:

For an up to date list of UL compliant products, please refer to UL listing NMMS.E226333.

The drive can be operated within an ambient temperature range as stated in section 10.1. Environmental.

For IP20 units, installation is required in a pollution degree 1 environment.

For IP55 & IP66 units, installation in a pollution degree 2 environment is permissible.

UL Listed ring terminals / lugs must be used for all bus bar and grounding connections.

Refer to section 10.3. Additional Information for UL Approved Installations on page 71.

Mechanical Installation

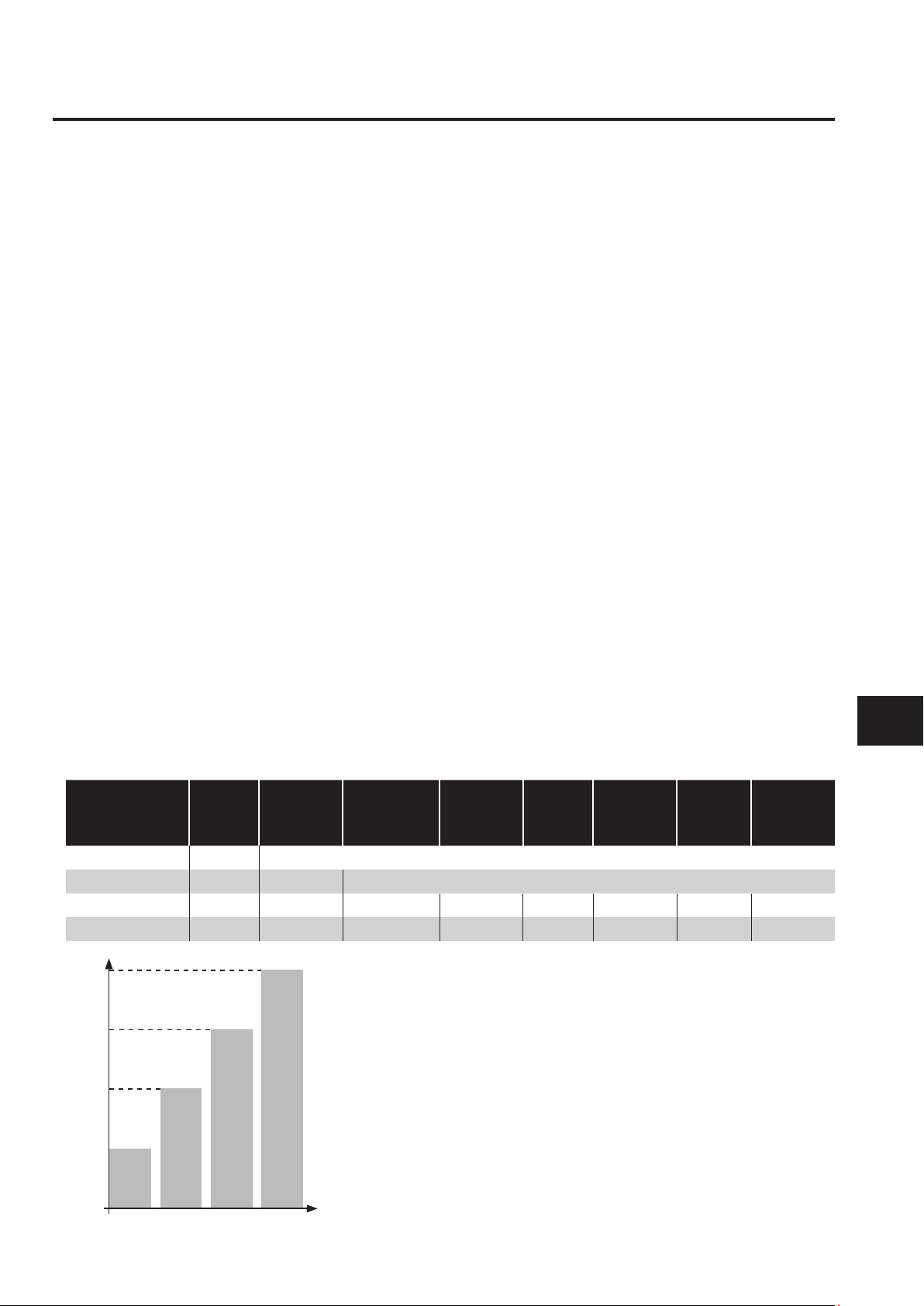

3.4. Installation Following a Period of Storage

Where the drive has been stored for some time prior to installation, or has remained without the main power supply present for an

extended period of time, it is necessary to reform the DC capacitors within the drive according to the following table before operation.

For drives which have not been connected to the main power supply for a period of more than 2 years, this requires a reduced

mains voltage mains voltage to be applied for a time period, and gradually increased prior to operating the drive. The voltage levels

relative to the drive rated voltage, and the time periods for which they must be applied are shown in the following table. Following

completion of the procedure, the drive may be operated as normal.

Storage Period

/Power-OFF

Period

Up to 1 Year 100% N/A

1 – 2 Years 100% 1 Hour N/A

2 – 3 Years 25% 30 Minutes 50% 30 Minutes 75 % 30 Minutes 100% 30 Minutes

More than 3 Years 25% 2 Hours 50% 2 Hours 75% 2 Hours 100% 2 Hours

100%

75%

50%

Initial

Input

Voltage

Level

Time

Period T1

Secondary

Input

Voltage

Level

Time

Period T2

Third

Input

Voltage

Level

Time

Period T3

Final

Input

Voltage

Level

Time

Period T4

3

25%

T1 T2 T3 T4

Version 3.01 | P2 Series User Guide | 11www.bardac.com

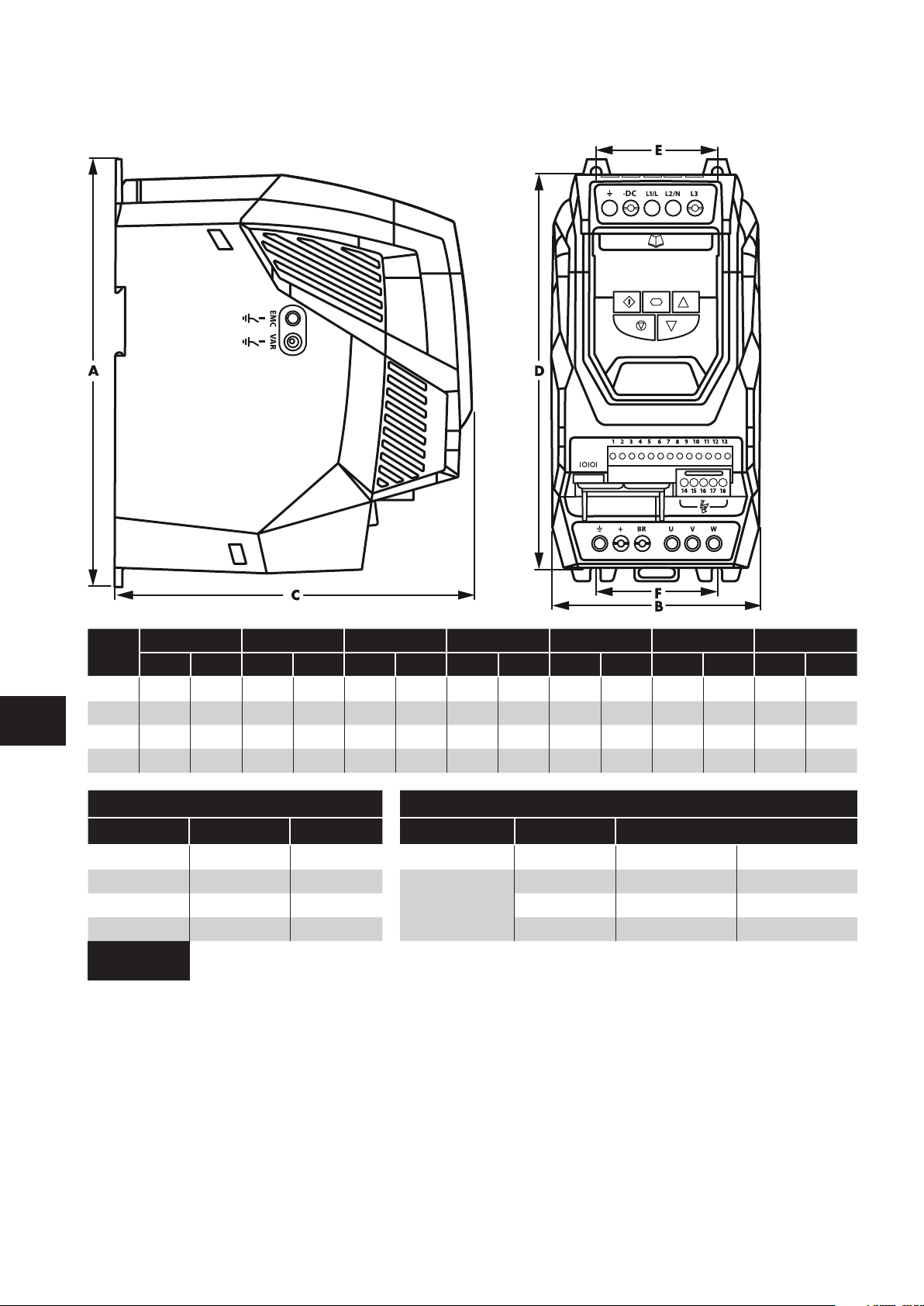

3.5. Mechanical Dimensions and Weight

3.5.1. IP20 Units

Mechanical Installation

3

Drive

Size

2 221 8. 70 11 0 4.33 18 5 7.28 209 8.23 63 2.48 63 2.48 1.8 4.0

3 261 10.28 131 5.16 205 8.07 247 9.72 80 3 .15 80 3 .15 3.5 7. 7

4 418 16.46 16 0 6.30 240 9.45 400 15 . 75 12 5 4.92 125 4.92 9.2 20.3

5 486 19.13 222 8 .74 260 10.24 460 18.11 175 6.89 175 6.89 18.1 39.9

Frame Size Metric UNF Frame Size Required Torque

2 M4 #8 Control Terminals All 0.5 Nm 4.5 lb-in

3 M4 #8

4 M8 5/16 4 2 Nm 18 lb-in

5 M8 5/16 5 4 Nm 35.5 lb-in

NOTE

A B C D E F Weight

mm in mm in mm in mm in mm in mm in Kg Ib

Mounting Bolts Tightening Torques

2 & 3 1 Nm 9 lb-in

Power Terminals

*The IP20 Frame Size 4 Chassis can obstruct the rotation (tightening) of a bolt or screw with a hex head, a fixing with a round

head will be most suitable for the mounting of this unit.

P2 Series User Guide | Version 3.01 www.bardac.com

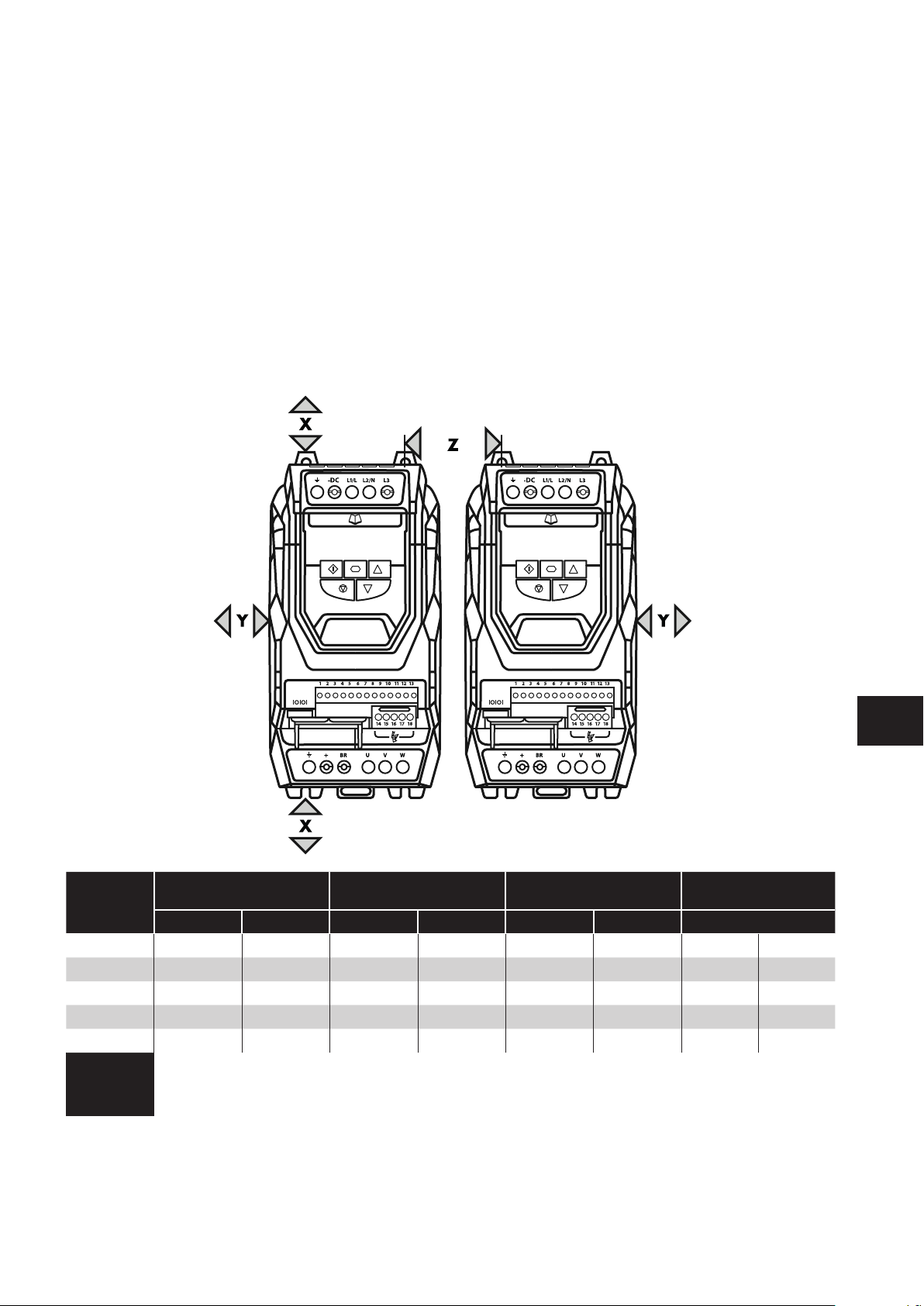

3.5.2. IP55 Units

Mechanical Installation

Drive

Size

4 450 17. 72 428 16.85 433 17.05 8 0.31 252 9.92 171 6.73 11 0 4.33 4.25 0.17 7. 5 0.30 11 . 5 25.4

5 540 21.26 515 20.28 520

6 865 34.06 830 32.68 840 33.07 10 0.39 330 12.99 330 12.99 200 7. 87 5.5 0.22 11 0.43 55 121 .2

7 1280 50.39 124 5 49.02 125 5 49.41 10 0.39 360 14 .17 330 12.99 200 7. 87 5.5 0.22 11 0.43 89

Frame Size Metric UNF Frame Size Required Torque

A B C D E F G H I Weight

mm in mm in mm in mm in mm in mm in mm in mm in mm in kg Ib

20.47

Mounting Bolts Tightening Torques

4 M8 #8

5 M8 #8

6 M10 5/16

7 M10 5/16

8 0.31 270 10.63 235 9.25 175 6.89 4.25 0.17 7. 5 0.30 23 50.7

Control Terminals All 0.5 Nm 4.5 lb-in

4 2 Nm 18 lb-in

Power Terminals

5 4 Nm 35.5 lb-in

6 15 Nm 11 lb-ft

7 15 Nm 11 lb-ft

3

196.2

Version 3.01 | P2 Series User Guide | 13www.bardac.com

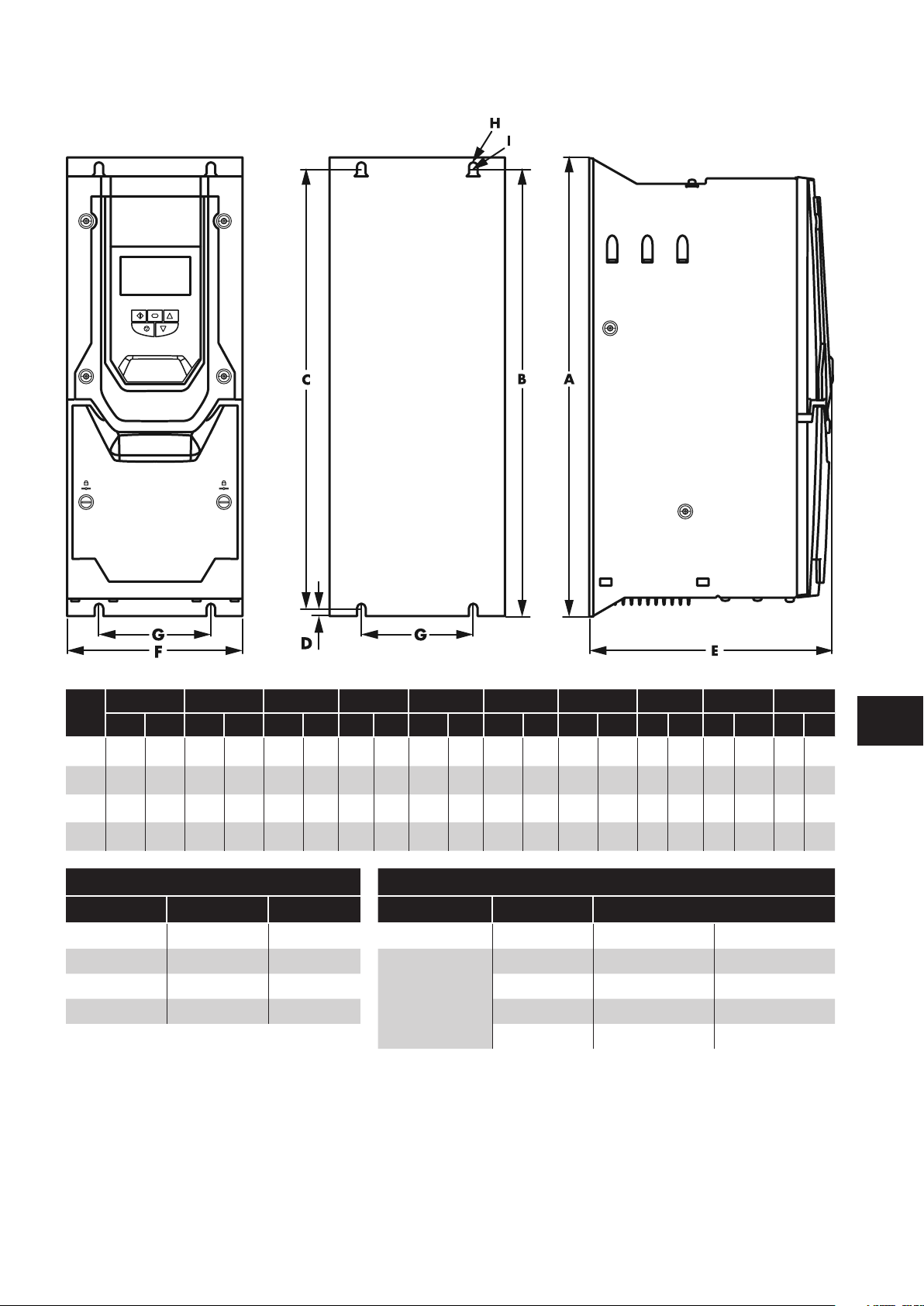

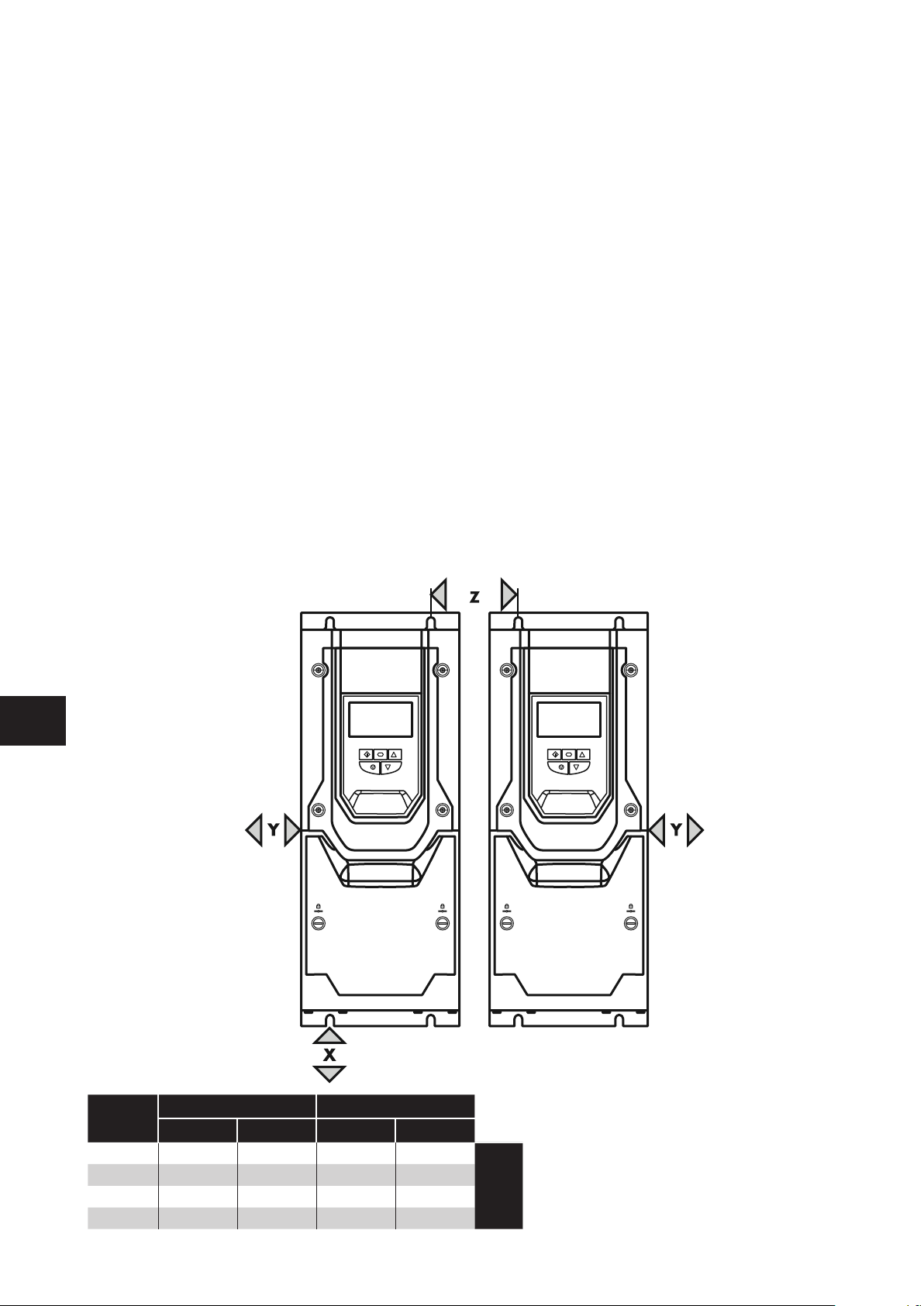

3.5.3. IP66 Units

Mechanical Installation

OFF

PWR

ON

3

Drive

Size

A B D E F G H I J Weight

mm in mm in mm in mm in mm in mm in mm in mm in mm in kg Ib

2 257 10 .12 220 8.66 200 7. 87 29 1 .12 239 9 . 41 18 8 7.40 178 7. 01 4.2 0 .17 8.5 0.33 4.8 10.6

9.90

3 310 12.20 277 10.89 252

33 1.31 266 10.47 211 8.29 200 7. 87 4.2 0.17 8.5 0.33 7. 7 16.8

Mounting Bolts Tightening Torques

Frame Size Metric UNF Frame Size Required Torque

2 M4 #8 Control Terminals All 0.5 Nm 4.5 lb-in

3 M4 #8 Power Terminals 2 & 3 1 Nm 9 lb-in

P2 Series User Guide | Version 3.01 www.bardac.com

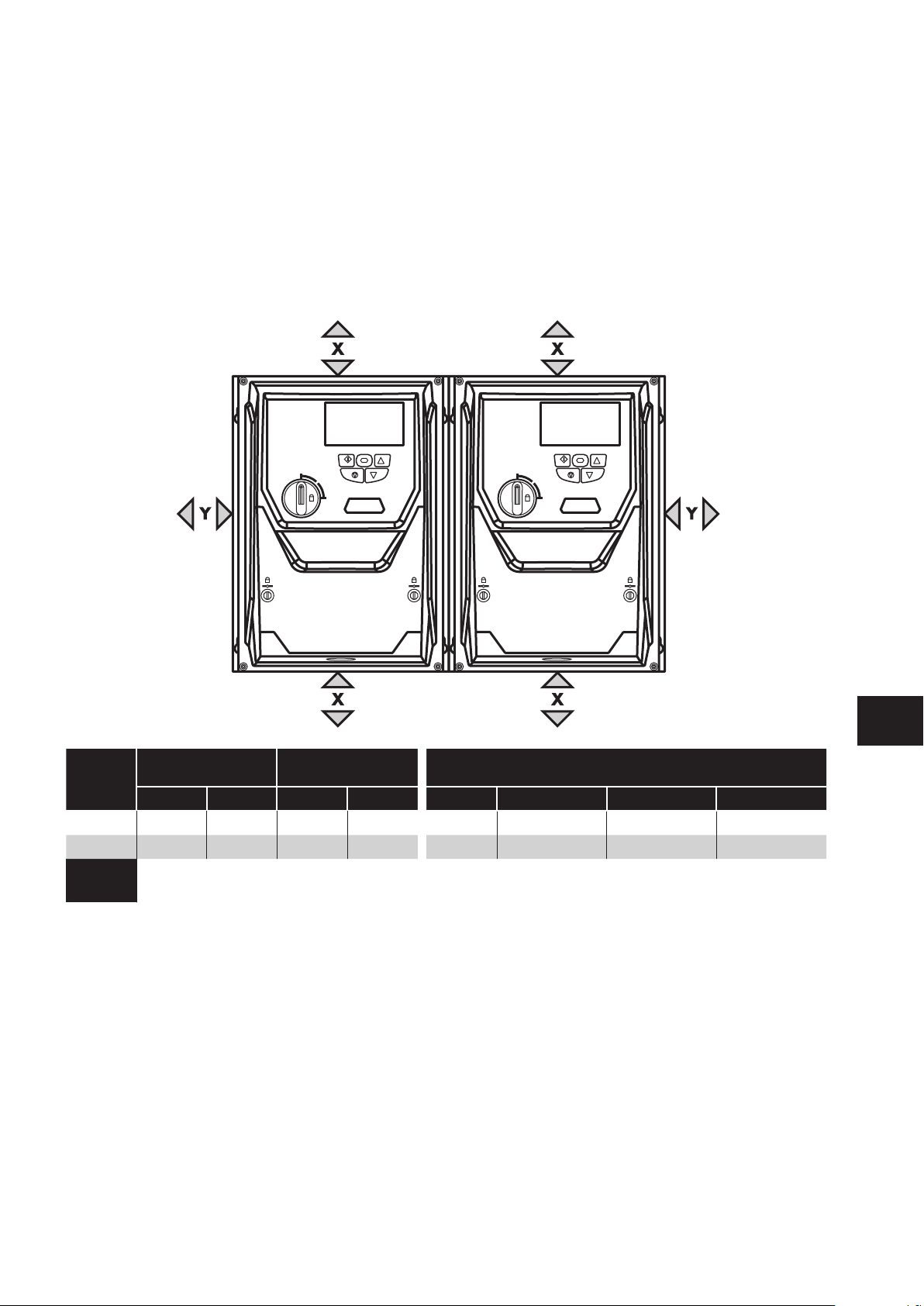

3.6. Guidelines for Enclosure Mounting (IP20 Units)

IP20 drives are suitable for use in pollution degree 1 environments, according to IEC-664-1. For pollution degree 2 or higher

environments, drives should be mounted in a suitable control cabinet with sufficient ingress protection to maintain a pollution

degree 1 environment around the drive.

Enclosures should be made from a thermally conductive material.

Ensure the minimum air gap clearances around the drive as shown below are observed when mounting the drive.

Where ventilated enclosures are used, there should be venting above the drive and below the drive to ensure good air circulation.

Air should be drawn in below the drive and expelled above the drive.

In any environments where the conditions require it, the enclosure must be designed to protect the drive against ingress of airborne

dust, corrosive gases or liquids, conductive contaminants (such as condensation, carbon dust, and metallic particles) and sprays or

splashing water from all directions.

High moisture, salt or chemical content environments should use a suitably sealed (non-vented) enclosure.

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate

through the drive heatsink. Bardac recommend the following minimum sizes for drives mounted in non-ventilated metallic enclosures:

Mechanical Installation

X

Drive Size

2 75 2.95 10 0.39 46 1. 81 0.3 11

3 100 3.94 10 0.39 52 2.05 0.9 31

4 200 7. 87 25 0.98 70 2 . 76 1.7 62

5 200 7. 87 25 0.98 70 2 . 76 2.9 104

8 300 11 . 81 100 3.94 20 705

NOTE

Above & Below

mm in mm in mm in m3/min CFM

Dimension Z assumes that the drives are mounted side-by-side with no clearance.

Typical drive heat losses are <3% of operating load conditions.

Above are guidelines only and the operating ambient temperature of the drive MUST be maintained at all times.

Y

Either Side

Z

Between

Recommended

airflow

3

Version 3.01 | P2 Series User Guide | 15www.bardac.com

3.7. Mounting the Drive – IP20 Units

IP20 Units are intended for installation within a control cabinet.

When mounting with screws:

o Using the drive as a template, or the dimensions shown above, mark the locations for drilling.

o Ensure that when mounting locations are drilled, the dust from drilling does not enter the drive.

o Mount the drive to the cabinet backplate using suitable M5 mounting screws.

o Position the drive, and tighten the mounting screws securely.

When Din Rail Mounting (Frame Size 2 Only):

o Locate the DIN rail mounting slot on the rear of the drive onto the top of the DIN rail first.

o Press the bottom of the drive onto the DIN rail until the lower clip attaches to the DIN rail.

o If necessary, use a suitable flat blade screw driver to pull the DIN rail clip down to allow the drive to mount securely on the rail.

o To remove the drive from the DIN rail, use a suitable flat blade screwdriver to pull the release tab downwards, and lift the

bottom of the drive away from the rail first.

3.8. Guidelines for Mounting (IP55 Units)

Mechanical Installation

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 10.1. Environmental on page 68.

The drive must be mounted vertically, on a suitable flat surface.

The minimum mounting clearances as shown in the table below must be observed.

The mounting site and chosen mountings should be sufficient to support the weight of the drives.

IP55 units do not require mounting inside an electrical control cabinet; however they may be if desired.

Using the drive as a template, or the dimensions shown above, mark the locations required for drilling.

Suitable cable glands to maintain the IP protection of the drive are required. Gland sizes should be selected based on the number

and size of the required connection cables. Drives are supplied with a plain, undrilled gland plate to allow the correct hole sizes to

be cut as required. Remove the gland plate from the drive prior to drilling.

3

Drive

Size

4 200 7. 8 7 10 0.39

5 200 7. 8 7 10 0.39

6 200 7. 8 7 10 0.39

7 200 7. 8 7 10 0.39

X –Above & Below Y –Either Side

mm in mm in

NOTE

Typical drive heat losses are approximately 3% of operating

load conditions.

Above are guidelines only and the operating ambient

temperature of the drive MUST be maintained at all times.

P2 Series User Guide | Version 3.01 www.bardac.com

3.9. Guidelines for Mounting (IP66 Units)

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 10.1. Environmental.

The drive must be mounted vertically, on a suitable flat surface.

The minimum mounting clearances as shown in the table below must be observed.

The mounting site and chosen mountings should be sufficient to support the weight of the drives.

Using the drive as a template, or the dimensions shown below, mark the locations required for drilling.

Suitable cable glands to maintain the ingress protection of the drive are required. Gland holes for power and motor cables are

pre-moulded into the drive enclosure, recommended gland sizes are shown above. Gland holes for control cables may be cut as

required.

Mechanical Installation

OFF

PWR

ON

Cable Gland Sizes

Drive

Size

OFF

PWR

ON

X

Above & Below

Y

Either Side

mm in mm in Frame Power Cable Motor Cable Control Cables

2 200 7. 87 10 0.39 2 M25 (PG21) M25 (PG21) M20 (PG13.5)

3 200 7. 87 10 0.39 3 M25 (PG21) M25 (PG21) M20 (PG13.5)

NOTE

Typical drive heat losses are approximately 3% of operating load conditions.

Above are guidelines only and the operating ambient temperature of the drive MUST be maintained at all times.

3

Version 3.01 | P2 Series User Guide | 17www.bardac.com

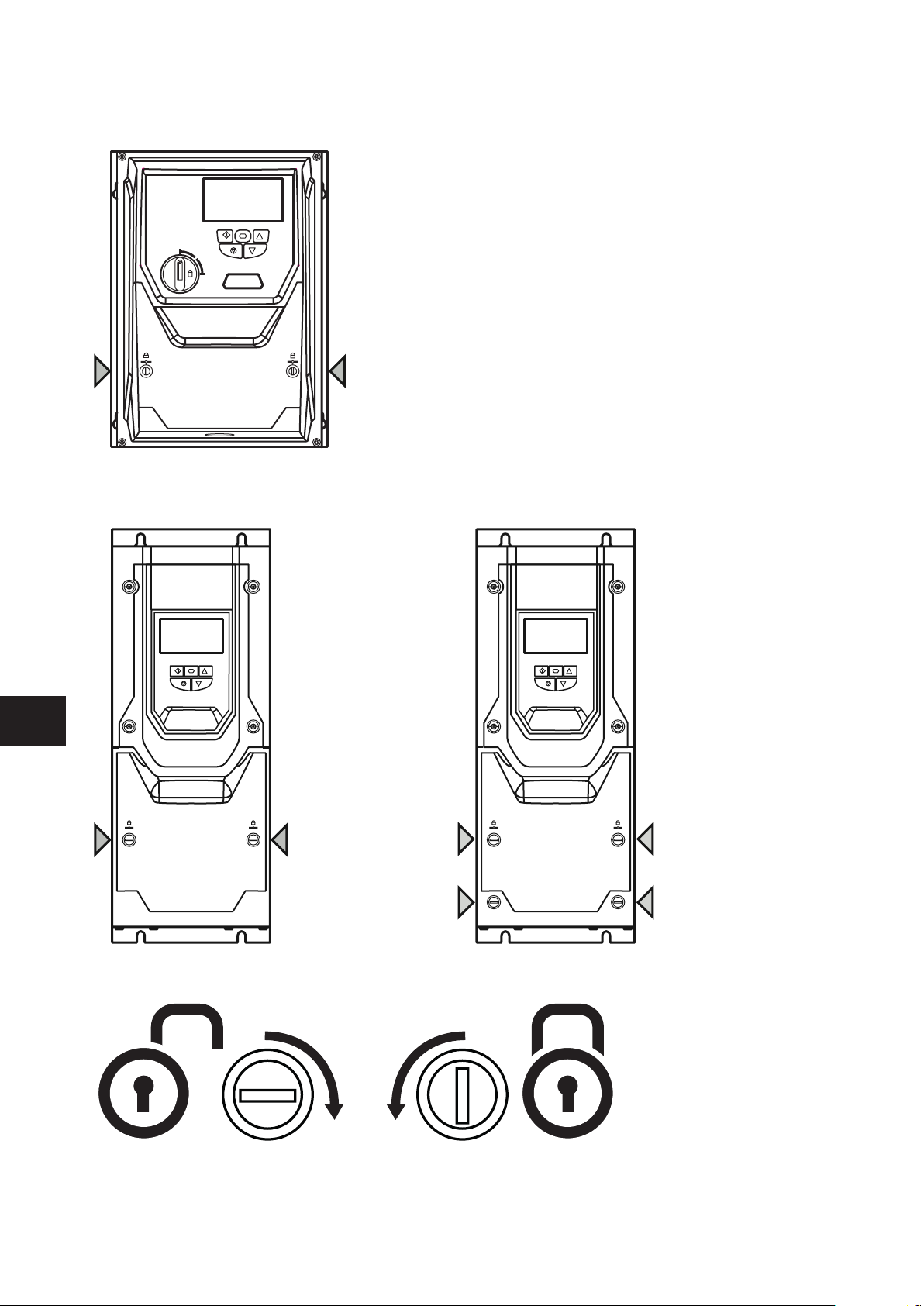

3.10. Removing the Terminal Cover

3.10.1. Frame Sizes 2 & 3

OFF

PWR

ON

Mechanical Installation

3.10.2. Frame Size 4 3.10.3. Frame Size 5

Using a suitable flat blade screwdriver, rotate the two retaining

screws indicated until the screw slot is vertical.

3

Terminal Cover Release Screws

Using a suitable flat

blade screwdriver,

rotate the two retaining

screws indicated

until the screw slot is

vertical.

Using a suitable flat

blade screwdriver,

rotate the four retaining

screws indicated

until the screw slot is

vertical.

P2 Series User Guide | Version 3.01 www.bardac.com

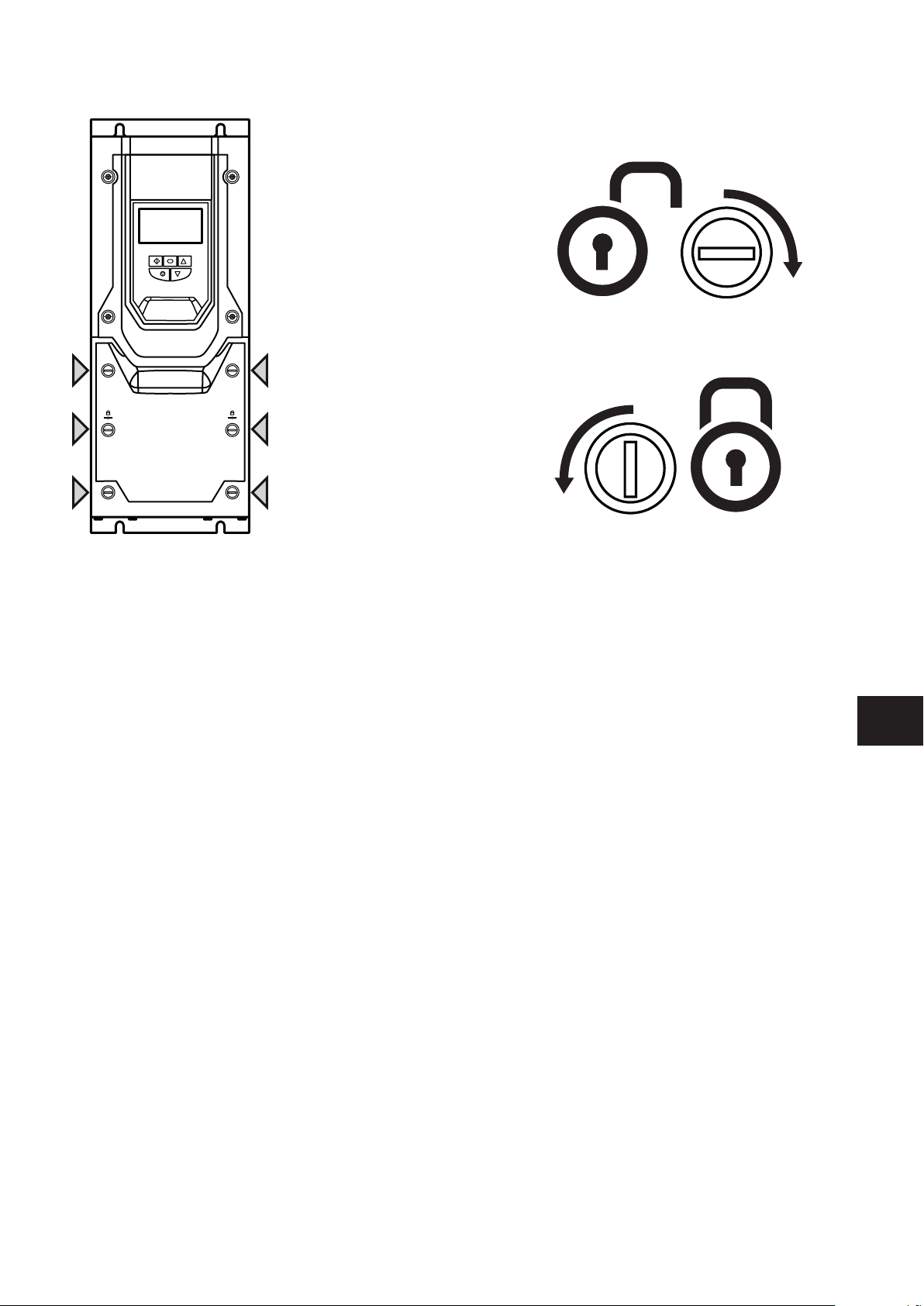

3.10.4. Frame Sizes 6 & 7

Using a suitable flat blade

screwdriver, rotate the six retaining

screws indicated until the screw slot

is vertical.

Mechanical Installation

3.11. Routine Maintenance

The drive should be included within the scheduled maintenance program so that the installation maintains a suitable operating

environment, this should include:

Ambient temperature is at or below that set out in section 10.1. Environmental.

Heat sink fans freely rotating and dust free.

The Enclosure in which the drive is installed should be free from dust and condensation; furthermore ventilation fans and air filters

should be checked for correct air flow.

Checks should also be made on all electrical connections, ensuring screw terminals are correctly torqued; and that power cables

have no signs of heat damage.

3

Version 3.01 | P2 Series User Guide | 19www.bardac.com

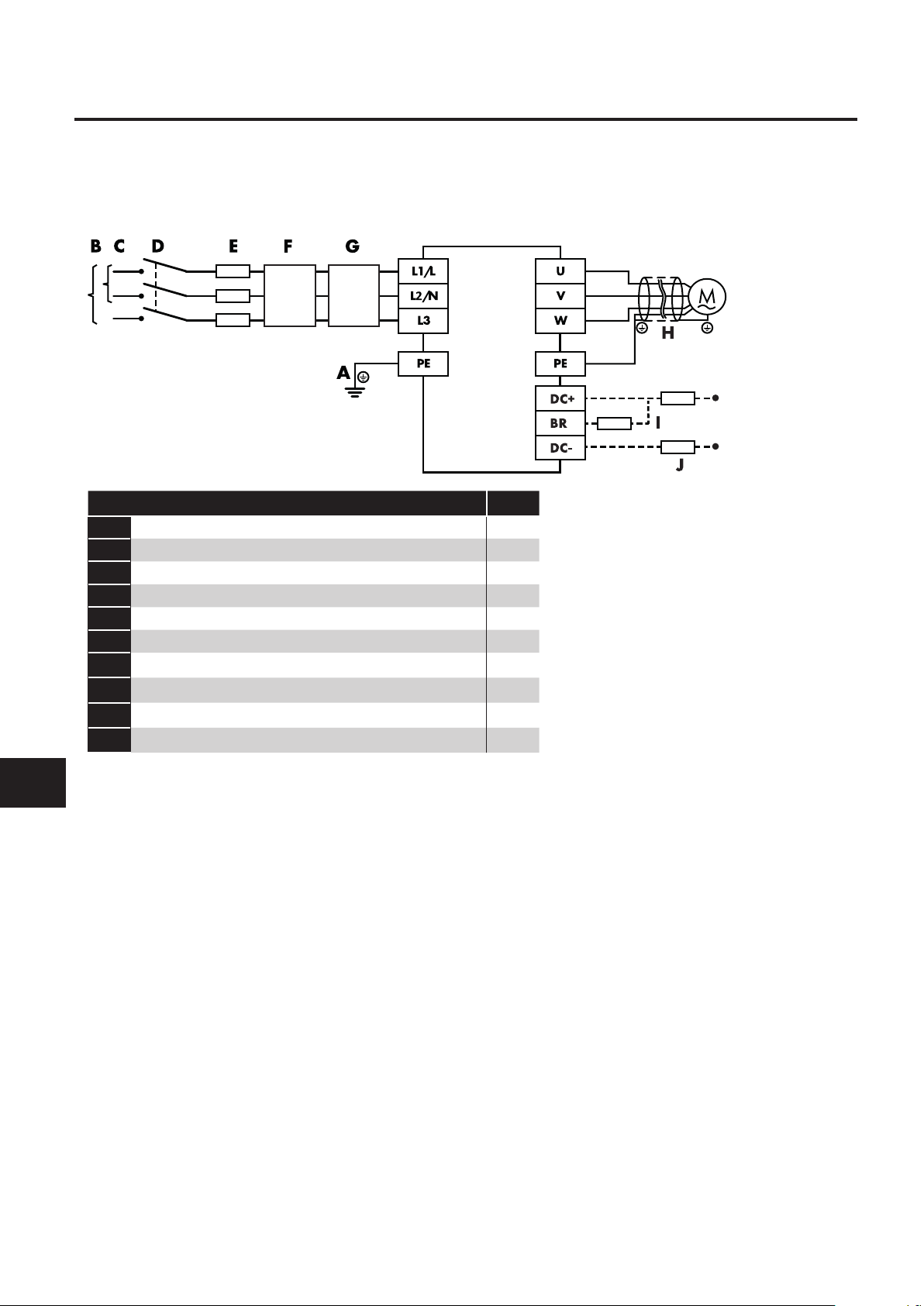

4. Electrical Installation

4.1. Connection Diagram

All power terminal locations are marked directly on the product. IP20 Frame Size 2 – 4 units have AC/DC power input located at the

top with the motor and brake resistor connections located at the bottom. All other units have power terminals located at the bottom.

4.1.1. Electrical Power Connections

Electrical Installation

A 4.2. Protective Earth (PE) (Ground) Connection 21

B 4.3. Incoming Power Connection 22

C 4.3. Incoming Power Connection 22

D External Isolator / Disconnect -

E 4.3.3. Fuse / Circuit Breaker Selection 22

F 4.3.4. Optional Input Choke 22

G 4.13. EMC Compliant Installation 26

H 4.6. Motor Connection 23

I 4.8. Connecting a Brake Resistor 23

J 4.5. Operation with DC Power Supply or Common DC Bus 22

Key Page

4

P2 Series User Guide | Version 3.01 www.bardac.com

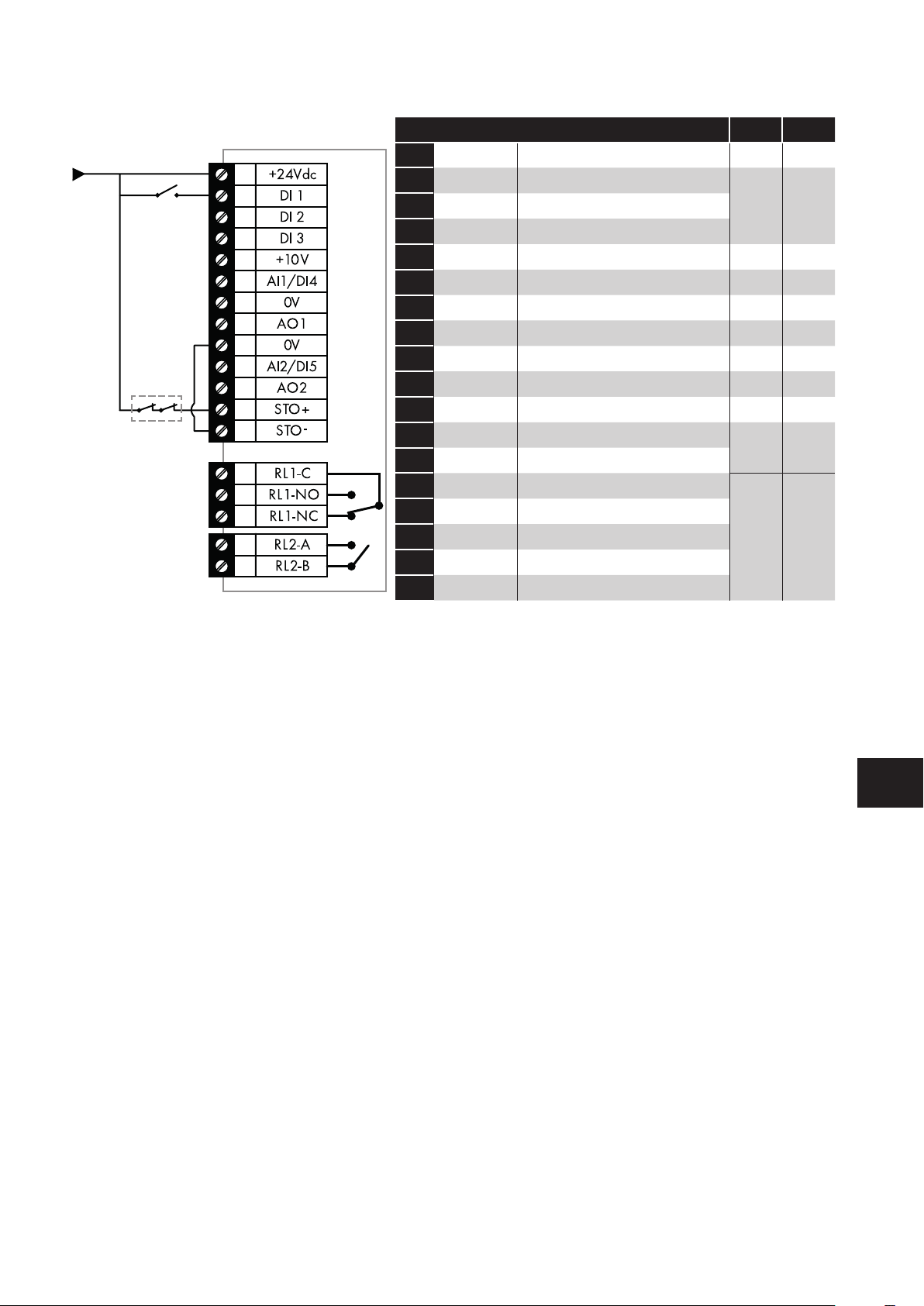

4.1.2. Control Connections

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Key Sec. Page

1 +24V 24 Volt DC Input / Output

2 DI1 Digital Input 1 (Run Enable)

3 DI2 Digital Input 2

4 DI3 Digital Input 3

5 +10V +10Volt DC Output

6 AI1 / DI4 Analog Input 1 / Digital Input 4

7 0V 0 Volt Common

8 AO1 Analog Output 1

9 0V 0 Volt Common

10 AI2 / DI5 Analog Input 2 / Digital Input 5

11 AO2 Analog Output 2

12 STO- STO 0 Volt Connection

13 STO+ STO + 24VDC Connection

14 RL1-C Relay Output 1 Common

15 RL1-NO Relay Output 1 Normally Open

16 RL1-NC Relay Output 2 Normally Closed

17 RL2-A Relay Output 2

18 RL2-B Relay Output 2

4.10 .1 24

4.10.2 24

4.10.3 24

4.10.4 24

4.10.3 24

4.10.4 24

4 .14 27

4.10.5 24

Electrical Installation

4.2. Protective Earth (PE) (Ground) Connection

4.2.1. Grounding Guidelines

Adequate safety earthing must be provided in accordance with local wiring rules and codes of practice. The ground terminal of each

drive should be connected back to the common safety earth bar to maintain touch potentials within safe limits. The ground terminal of

each drive should be individually connected DIRECTLY to the site ground bus bar (through the EMC filter if installed). The drive ground

connections should not loop from one drive to another, or to, or from any other equipment. Ground impedance must conform to local

industrial safety regulations and/or electrical codes.

To meet UL regulations, UL approved ring crimp terminals should be used for all ground wiring connections.

The integrity of all ground connections should be checked periodically.

4.2.2. Protective Earth Conductor

The Cross sectional area of the PE Conductor must be at least equal to that of the incoming supply conductors.

4.2.3. Motor Ground

The driven motor must be locally connected to a suitable ground location to maintain touch potentials within safe limits. In addition, the

motor ground must be connected to one of the ground terminals on the drive.

4.2.4. Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist. The drive is designed to produce the minimum possible leakage current

whilst complying with worldwide standards. The level of current is affected by motor cable length and type, the effective switching

frequency, the earth connections used and the type of RFI filter installed. If an ELCB (Earth Leakage Circuit Breaker) is to be used, the

following conditions apply:

A Type B Device must be used.

The device must be suitable for protecting equipment with a DC component in the leakage current.

Individual ELCBs should be used for each drive.

4

4.2.5. Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the motor cable shield. The motor cable shield connected to this terminal

(drive end) should also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to

the safety ground terminal.

Version 3.01 | P2 Series User Guide | 21www.bardac.com

4.3. Incoming Power Connection

4.3.1. Suitability

All P2 models are designed for use on a single phase or balanced three phase supply depending on the model.

For all models and ratings when working with an IT Supply network, or any power supply type where the phase to earth voltage may

exceed the phase to phase voltage (such as ungrounded supplies), the internal EMC filter and surge protection must be disconnected

before connecting the supply. Refer to section 10.5. Internal EMC Filter and Varistors – Disconnection Procedure on page 72 for

further information.

For three phase supply models, a maximum of 3% imbalance is allowed between phases.

4.3.2. Cable Selection

For 1 phase ac supply, power should be connected to L1/L, L2/N.

For a DC Supply, the main power cables should be connected to L1/L, L2/N.

For 3 phase ac supplies, the mains power cables should be connected to L1, L2, and L3. Phase sequence is not important. Neutral

connection is not required.

For compliance with CE and C Tick EMC requirements, refer to section 4.10. Control Terminal Connections on page 24.

A fixed installation is required according to IEC61800-5-1 with a suitable disconnecting device installed between the drive

and the main Power Source. The disconnecting device must conform to the local safety code / regulations (e.g. within Europe,

EN60204-1, Safety of machinery).

Electrical Installation

The cables should be dimensioned according to any local codes or regulations. Maximum dimensions for each drive model are

given in section 10.2. Input/Output Power and Current Ratings on page 68.

4.3.3. Fuse / Circuit Breaker Selection

Suitable fuses to provide wiring protection of the input power cable should be installed in the incoming supply line, according to

the data in section 10.2. Input/Output Power and Current Ratings on page 68.

The fuses must comply with any local codes or regulations in place. In general, type gG (IEC 60269) or UL type J fuses are

suitable; however in some cases type aR fuses may be required. The operating time of the fuses must be below 0.5 seconds.

Where allowed by local regulations, suitably dimensioned type B MCB circuit breakers of equivalent rating may be utilised in

place of fuses, providing that the clearing capacity is sufficient for the installation.

The maximum permissible short circuit current at the drive power terminals as defined in IEC60439-1 is 100kA.

The drive provides thermal and short circuit protection for the connected motor and motor cable.

4

4.3.4. Optional Input Choke

An optional Input Choke is recommended to be installed in the supply line for drives where any of the following conditions occur:

The incoming supply impedance is low or the fault level / short circuit current is high.

The supply is prone to dips or brown outs.

An unbalanced supply system is used (3 phase drives) where the voltage levels during on load operation exceed the designed 3%

capacity of the drive.

The power supply to the drive is via a busbar and brush gear system (typically overhead Cranes).

In all other installations, an input choke is recommended to ensure protection of the drive against power supply faults.

4.4. Operation of 3 Phase drives from a Single Phase Supply

A special function of P2 allows all drives designed for operation on 3 phase supplies to be operated on a single phase supply of the

correct rated voltage at up to 50% of the nominal capacity.

For Example, Model Number P2-64060-3HF4N can be operated on a single phase supply, 380 – 480 volts, with the maximum

output current limited to 45 Amps.

The supply must be connected to the L1 and L2 terminals of the drive.

4.5. Operation with DC Power Supply or Common DC Bus

P2 models provide terminals to directly connect to the DC Bus for applications which require this. For further information on using the

DC Bus connections, please refer to your Bardac sales Partner.

P2 Series User Guide | Version 3.01 www.bardac.com

4.6. Motor Connection

The drive inherently produces fast switching of the output voltage (PWM) to the motor compared to the mains supply, for motors

which have been wound for operation with a variable speed drive then there is no preventative measures required, however if the

quality of insulation is unknown then the motor manufacturer should be consulted and preventative measures may be required.

The motor should be connected to the drive U, V, and W terminals using a suitable 3 or 4 core cable. Where a 3 core cable is

utilised, with the shield operating as an earth conductor, the shield must have a cross sectional area at least equal to the phase

conductors when they are made from the same material. Where a 4 core cable is utilised, the earth conductor must be of at least

equal cross sectional area and manufactured from the same material as the phase conductors.

The motor earth must be connected to one of the drive earth terminals to provide a low impedance path for common mode leakage

current to return to the drive. This is best achieved in practice by using a cable with suitable shielding which provides a low impedance

path at high frequencies, and ensuring correct, low impedance earth bonding of the motor cable at both ends. For further information,

refer to section 4.13. EMC Compliant Installation on page 26.

4.7. Motor Terminal Box Connections

Most general purpose motors are wound for operation on dual voltage supplies. This is indicated on the nameplate of the motor. This

operational voltage is normally selected when installing the motor by selecting either WYE (STAR) or DELTA connection. WYE (STAR)

always gives the higher of the two voltage ratings.

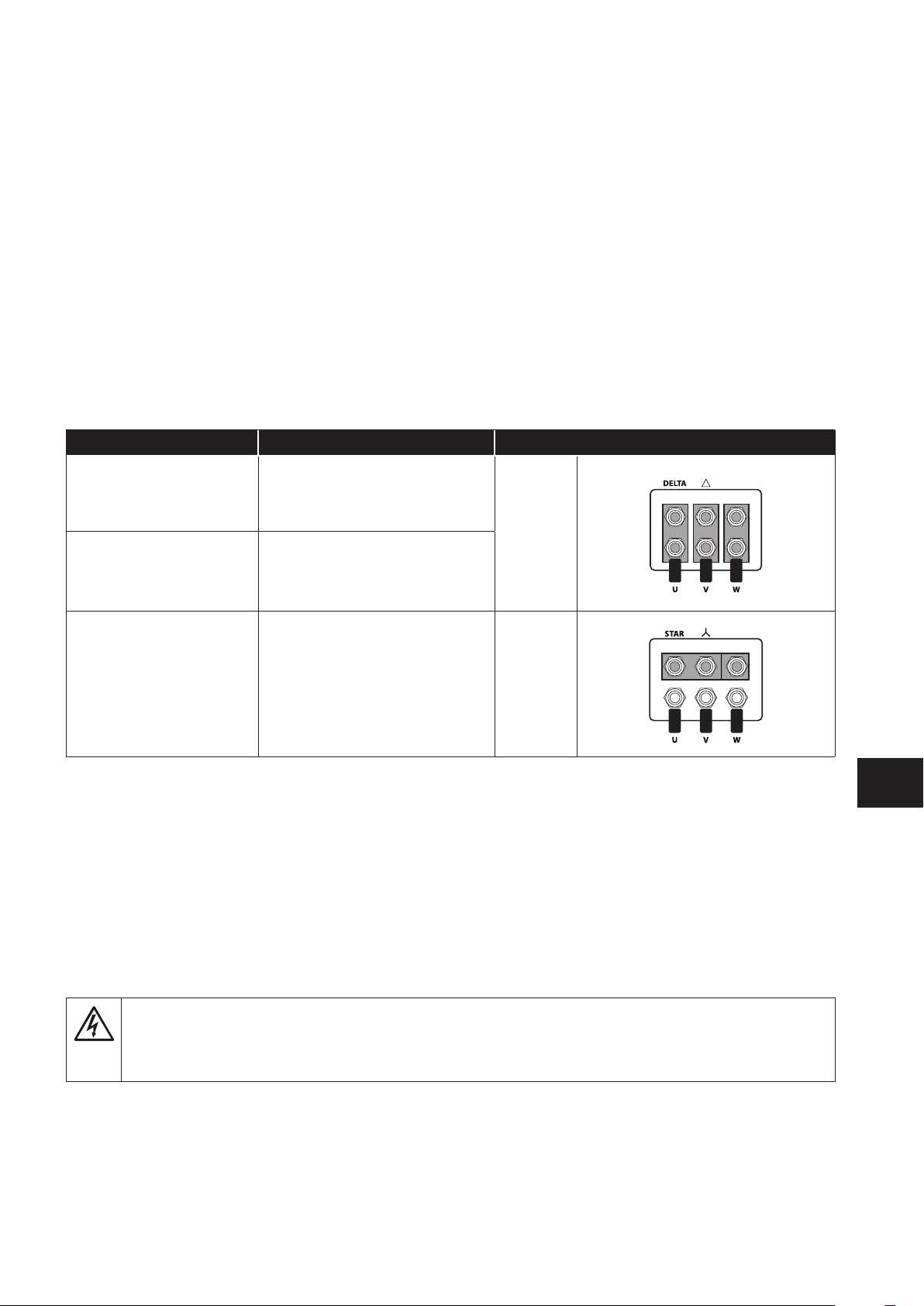

Incoming Supply Voltage Motor Nameplate Voltages Connection

230 230 / 400

Delta

400 400 / 690

400 230 / 400 WYE (Star)

4.8. Connecting a Brake Resistor

P2 units feature an internal brake transistor, fitted as standard for all models. The brake resistor should be connected to the DC+ and

BR terminals of the drive.

The brake transistor is enabled using P1-05 (Refer to section 8.1. Parameter Group 2 - Extended Parameters on page 44 for further

information).

Software protection against brake resistor overload is carried out within the drive. For correct protection of the brake resistor, the

following settings are required:

Set P1-14 = 201.

Enter the resistance of the brake resistor in P6-19 (Ohms).

Enter the power of the brake resistor in P6-20 (kW).

Electrical Installation

4

The voltage level at these terminals may exceed 800VDC.

Stored charge may be present after disconnecting the mains power.

Allow a minimum of 10 minutes discharge after power off before attempting any connection to

these terminals.

4.9. Control Terminal Wiring

All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other.

Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC, should not be routed in the same cable.

Maximum control terminal tightening torque is 0.5Nm.

Control Cable entry conductor size: 0.05 – 2.5mm

2

/ 30 – 12 AWG.

Version 3.01 | P2 Series User Guide | 23www.bardac.com

Loading...

Loading...