Page 1

INSTALLATION INSTRUCTIONS

SINGLE STAGE HEAT PUMPS

LOW VOLTAGE

CONTROL CIRCUIT WIRING

MODELS

W**H W**H*D

S**H S**H*D

T**H T**H*D

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

Manual : 2100-516H

Supersedes: 2100-516G

File: Volume III Tab 16

Date: 03-28-14

Manual 2100-516H

Page 1 of 19

Page 2

Contents

Installation Instructions

Wiring – Low Voltage Wiring

Operating Voltage Range

Low Voltage Connection

Figures

Figure 1 Basic HP w/Opt. Elec. Heat .....................5

Figure 2 HP w/Opt. MFAD, CRV & ERV Vent. Pkg.

w/Programmable T-Stat ...........................6

Figure 3 HP w/Opt. MFAD, CRV & ERV Vent. Pkg.

w/Non-Programmable T-Stat ....................7

Figure 4

w/Non-Programmable Thermostat with ...

CO2 Controller .........................................8

Figure 5 Heat Pump w/Opt. Economizer

"E" Vent Option ........................................9

Figure 6 HP w/Dehumidication Sequence & No

Vent Pkg. Using T-Stat Comb. ...............10

Figure 7 HP w/Dehumidication Sequence w/

Non-Programmable T-Stat ......................... 11

Figure 8 HP w/Dehumidication Sequence & Opt.

MFAD, CRV, & ERV Vent Pkg.

Using Elec. T-Stat with Combination

Temp. & Humidity Control ......................12

Figure 9 HP w/Dehumidication Sequence & Opt.

MFAD, CRV & ERV Vent. Pkg.

Using Non-Prog. T-Stat.

(No Occupied Signal) .............................13

Figure 10

MFAD, CRV & ERV Vent. Pkg.

Using Non-Prog. T-Stat. with

CO2 Controller ........................................14

Figure 11 Heat Pump w/CS2000A* ........................15

Figure 12 W**H1 Dehum. with Economizer and

#8403-060 Thermostat (EIFM)

"E" Vent Option ......................................16

Figure 13 1-Stage HP w/Opt. Elec. Heat with or w/o

Dehum. with ECONWM* Style Economizer

"W" or "T" Vent Option ...........................17

Figure 14 HP w/Opt. CRVMP Vent Pkg. with

Programmable T-Stat .............................18

Figure 15

with Non-Programmable T-Stat ............ 19

HP w/Opt. MF AD, CRV & ERV V ent. Pkg.

HP w/Dehumidication Sequence & Opt.

HP w/Opt. MFAD, CRV & ERV Vent Pkg.

.....................................3

..........................................3

...........................................3

Wiring Diagram

Figure 11 Heat Pump w/CS2000A* ........................15

Tables

Table 1 Diagram to Use w/Unit & Vents ................3

Table 2 Operating Voltage Range .........................3

Table 3 Wall Thermostat .......................................3

Table 4 Humidity Controls .....................................4

Table 5 CO2 Controller ..........................................4

Table 6 Thermostat Wire Size ...............................4

Manual 2100-516H

Page 2 of 19

Page 3

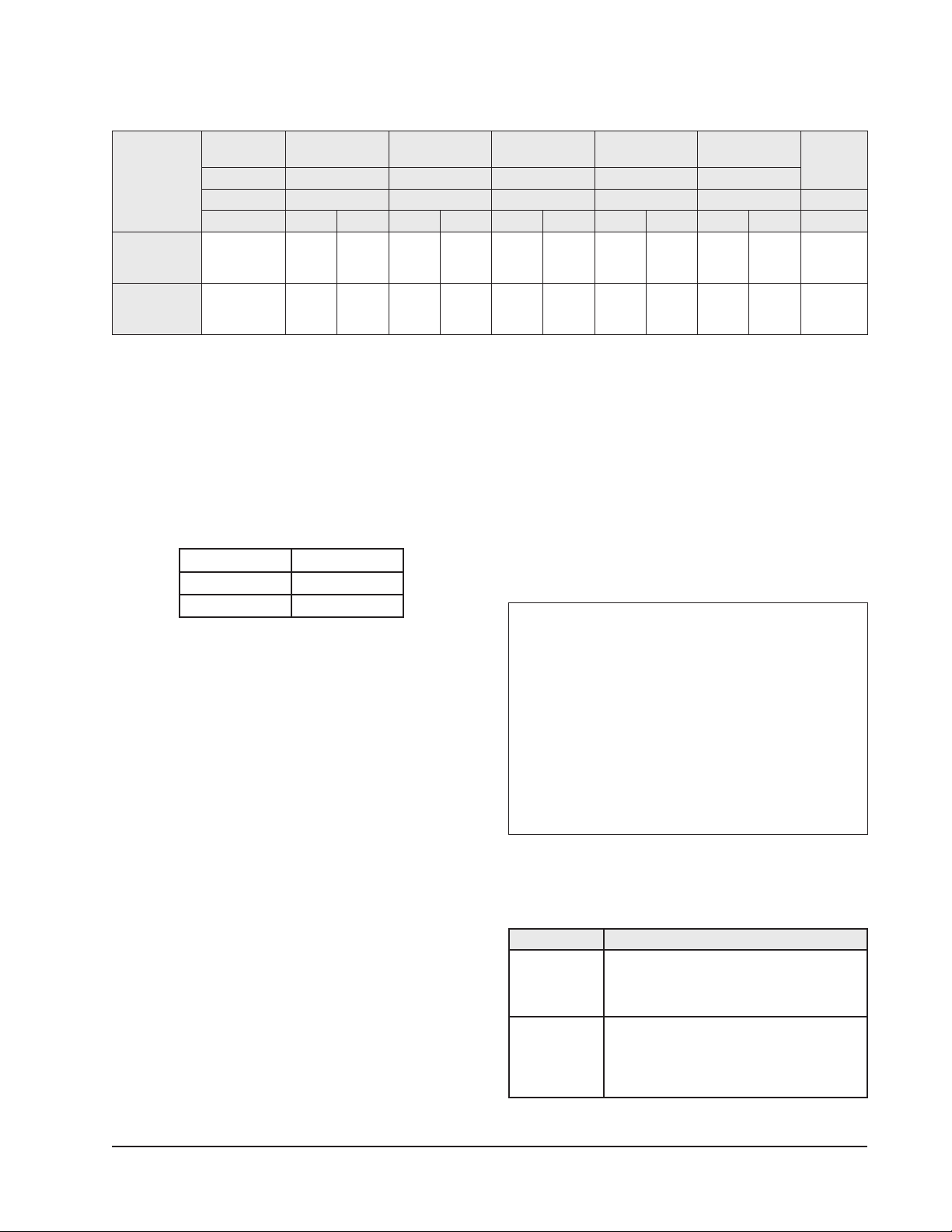

TABLE 1

DIAGRAM TO USE WITH UNIT AND VENTS

Vent None CRV, ERV, MFAD

System

Heat Pump

Heat Pump with

Dehumidication

Vent Code X R, M, V, P C E T, W, S

Thermostat Programmable Programmable Programmable Programmable Programmable All

Model Series No Yes No Yes No Yes No Yes No Yes

S**H

T**H

W**H

S**H*D

T**H*D

W**H*D

1 1 3 & 4 2 15 14 N/A 5 N/A 13 11

7 6 9 & 10 8 N/A 14 N/A 12 N/A 13 N/A

WIRING – LOW VOLTAGE WIRING

230/208V, 1 phase and 3 phase equipment dual primary

voltage transformers. All equipment leaves the factory

wired on 240V tap. For 208V operation, reconnect

from 240V to 208V tap. The acceptable operating

voltage range for the 240V and 208V taps are:

TABLE 2

OPERATING VOLTAGE RANGE

TAP RANGE

240V 253 – 216

208V 220 – 187

NOTE: Thevoltageshouldbemeasuredattheeldpower

connectionpointintheunitandwhiletheunit

isoperatingatfullload(maximumamperage

operatingcondition).

An 18 gauge copper, color-coded thermostat cable is

recommended. The connection points are shown in this

Manual. See Table above.

Low Voltage Connection

These units use a grounded 24-volt AC low voltage

circuit.

The “R” terminal is the hot terminal and the “C”

terminal is grounded.

“G” terminal is the faninput.

“Y” terminal is the compressorinput.

“B” terminal is the reversingvalveinput. The reversing

valve must be energized for heating mode.

“R” terminal is the 24 VAC hot.

“C” terminal is the 24 VAC grounded.

CRVMWH-3

CHCRV-5

EIFM

Economizer

ECONWM*

CS2000A*

“L” terminal is compressorlockoutoutput. This

terminal is activated on a high or low pressure trip by the

electronic heat pump control. This is a 24 VAC output.

“W2” terminal is second stage heat (if equipped).

“O1” terminal is the ventilationinput. This terminal

energizes any factory installed ventilation option.

“E” terminal is the

emergencyheatinput. This terminal

energizes the emergency heat relay.

“W3” terminal is the dehumidicationinput. This

terminal energizes compressor, blower and three-way

valve.

LOW VOLTAGE CONNECTIONS

FOR DDC CONTROL

Fan Only Energize G

Cooling Mode Energize Y, G

Heat Pump Heating Energize Y, G, B

2nd Stage Heating

Energize G, W2, Y, B

w/Heat Pump (if employed)

Ventilation Energize G, O1

Emergency Heat

Energize B, W2, E, G

Dehumidication EnergizeW3

TABLE 3

WALL THERMOSTAT

Part Number Predominate Features

8403-058

(TH5220D1151)

8403-060

(1120-445)

2 stage Cool, 2 stage Heat - Conventional

1 stage Cool, 2 stage Heat - Heat Pump

Electronic Non-Programmable

Auto or Manual changeover

3 stage Cool; 3 stage Heat

Programmable/Non-Programmable Electronic

HP or Conventional

Auto or Manual changeover

Dehumidication Output

Manual 2100-516H

Page 3 of 19

Page 4

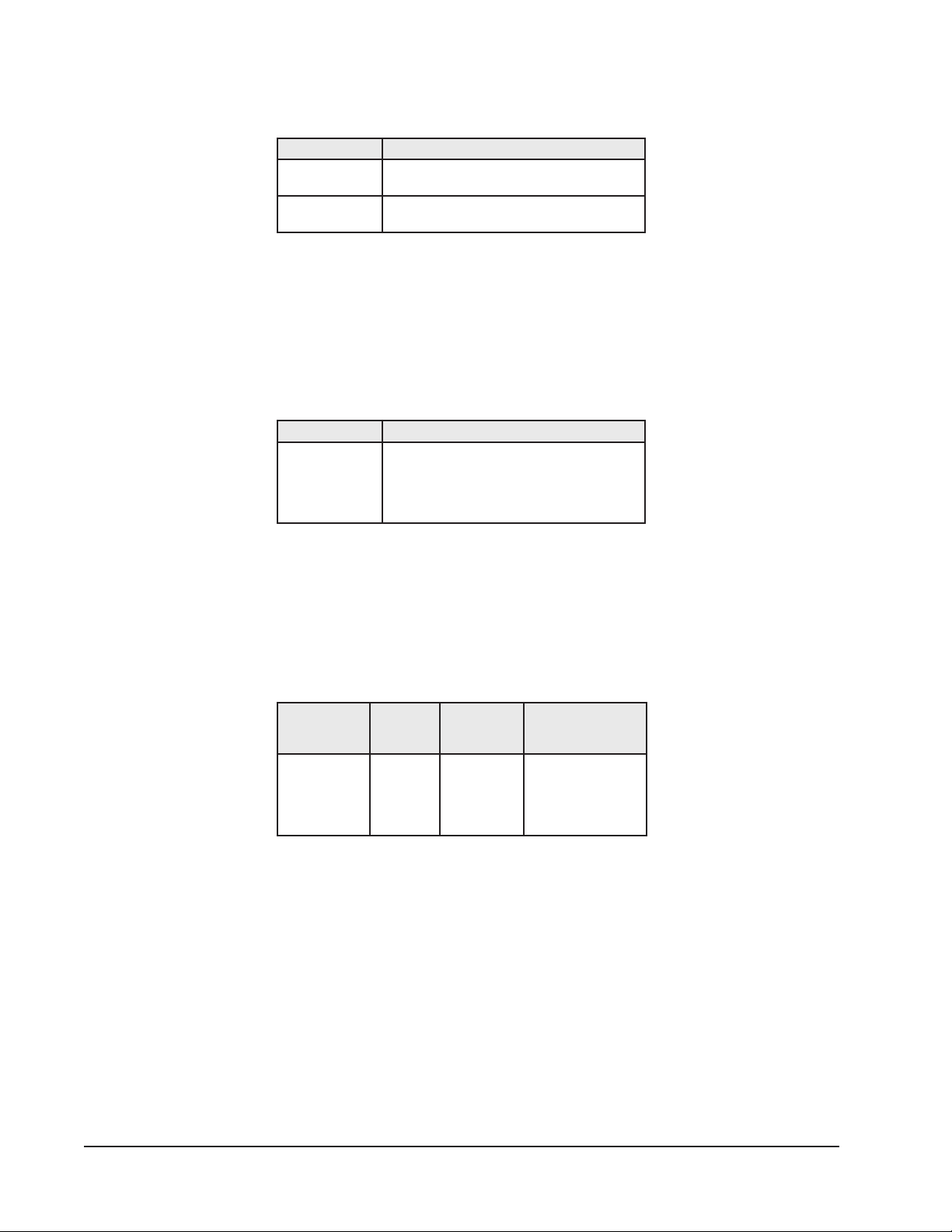

TABLE 4

HUMIDITY CONTROLS

Part Number Predominate Features

8403-038

(H600A1014)

8403-047

(H200-10-21-10)

SPDT switching, pilot duty 50VA @ 24V

Humidity range 20-80% RH

Electronic dehumidistat SPST closes-on-rise

Humidity range 10-90% with adjustable stops

TABLE 5

CO2 CONTROLLER

Part Number Predominate Features

Normally Open SPST relay closes-on-rise

8403-067

24V dual wave length sensor. Default setting

950ppm, adjustable to 0-2000ppm

Default off setting 1000ppm, adjustable to

0-200 ppm can be calibrated

Transformer

VA

55 2.3

TABLE 6

THERMOSTAT WIRE SIZE

FLA

Wire

Gauge

20 gauge

18 gauge

16 gauge

14 gauge

12 gauge

Maximum

Distance

In Feet

45

60

100

160

250

Manual 2100-516H

Page 4 of 19

Page 5

FIGURE 1

C

Factory Jumper Installed1

Unit

1

24V Low Voltage

Terminal Block

W3 E L DH O1W2W1Y1 BYRG

MIS-2645 C

Aux

Low Voltage Wiring Diagram

C G R Rc Y O/B

1

L E

W1/E

C

Bard part #8403-058

#TH5220D1151

Thermostat

2 Stage Heat

1 Stage Cool

Programmable

Electronic

Bard part #8403-060

AY2L

Y O/D

Thermostat

W2G R Y1 O/B

"L" is constant 24V output

when

thermostat is in Em Heat mode

BASIC HEAT PUMP WITH OPTIONAL ELECTRIC HEAT

NO ECONOMIZER or VENTILATION PACKAGES

Manual 2100-516H

Page 5 of 19

Page 6

FIGURE 2

1 652 4

3

3

4

if optional CO controller is used.

Unit

C G R

YEY1

W2 W1

O1

DH

L

B W3

Terminal Block

24V Low Voltage

Ventilation Packaging with Programmable Thermostat (Recommended)

Figure 2

Low Voltage Wiring Diagram

C O/BY1RG W2

Y O/D

W1/E

Heat Pump with Optional MFAD, CRV, and ERV

Bard part #8403-060

Thermostat

Programmable

L A

Y2

Red

Orange

Black

2

Brown/White

Ventilation Packages

Electronic

Red

Factory Jumper Installed

Do not connect "A" from tstat #8403-060

Black

MFAD

2

ERV

CRV

during scheduled occupied periods

set to programmed for the "A" output to function

Must be configured to programmable and fan

2

2

4

optional CO controller is used.

Connect orange wire to "G" only if

3

1

2

1

MIS-2633 C

Optional CO Controller

Bard part #8403-067

HEAT PUMP WITH OPTIONAL MFAD, CRV & ERV

VENTILATION PACKAGING WITH PROGRAMMABLE THERMOSTAT (RECOMMENDED)

Manual 2100-516H

Page 6 of 19

Page 7

FIGURE 3

E

Unit

C R

Y EY1

Low Voltage Wiring Diagram

W1 O1

Black

LB

when

DH

Bard part #8403-058

W3

24V Low Volt age

Thermostat

#TH5220D1151

R

Red

Factory Jumper Inst al led

G

ERV

Orange

Black

Brown/White

CRV

Packages

Ventilation

1

whenever blower operates.

Add jumper, ventilation will be active

3

2

Do not connect orange w ire.

MFAD

Terminal Bl ock

3

2

1

Red

O/B

C

L

Y

2 Stage Heat

1 Stage Cool

thermostat is in Em Heat mode

W2

AUX

G

Rc

"L" is constant 24V output

1

MIS-2646 C

HEAT PUMP WITH OPTIONAL MFAD, CRV and ERV VENTILATION

PACKAGING WITH NON-PROGRAMMABLE THERMOSTAT (NO OCCUPIED SIGNAL)

Manual 2100-516H

Page 7 of 19

Page 8

FIGURE 4

Unit

C G R Y EY1 W2 W1 O1DH LB W3

1

Factory Jumper Inst al led

Low Voltage Wiring Diagram

C O/B

Y

R

L

AUX

Terminal Bl ock

E

24V Low Volt age

Bard part #8403-058

MFAD

Bard part #8403-067

2 Stage Heat

1 Stage Cool

Thermostat

1

Red

1

Orange

Optional CO Controller

Brown/White

#TH5220D1151

Ventilation Packages

Black

Red

526

3

2 4

G

2

1

2

ERV

CRV

is used.

only if optional CO controller

Connect orange wi re to "G"

Rc

Black

"L" is constant 24V output

when

thermostat is in Em Heat mode

2

MIS-2634 E

HEAT PUMP WITH OPTIONAL MFAD, CRV and ERV VENTILATION

PACKAGING WITH NON-PROGRAMMABLE THERMOSTAT WITH CO2 CONTROLLER

Manual 2100-516H

Page 8 of 19

Page 9

FIGURE 5

Unit

CRB

YEY1W2

W1

O1DH

Terminal Block

LW3G

Y2 Y1

Pink

Thermostat

Orange

Yellow

C

Black

24V Low Voltage

L

Purple

YO/D

Y1

1

Factory Jumper Installed.

2

be active as first stage cooling.

Must be configured for economizer with YO/D output to

These wires are used in special control applications only.

EF

Black

2 Stage Heat

Blue

3

1

Wiring Harness

Economizer

1

Bard part #8403-060

G

R O/B

2 Stage Cool

Low Voltage Wiring Diagram

Figure 5

Heat Pump with Optional Economizer

W1/E

W2

3

2

A

MIS-2648 C

HEAT PUMP WITH OPTIONAL EIFM ECONOMIZER

“E” VENT OPTION

Manual 2100-516H

Page 9 of 19

Page 10

FIGURE 6

C

Factory Jumper Installed.

Unit

A

G O1REY1

W2

Y2

DHLW1

Electronic

B

YO/D

Terminal Block

Figure 6

Low Voltage Wiring Diagram

C

O/B

RG

L

24V Low Voltage

Bard part #8403-060

Thermostat

using Thermostat part #8403-060 Combination Temperature and Humidity Controller.

Y1

Heat Pump with Dehumidification Sequence and No Ventilation Package

Programmable

W2

W1/E

W3Y

2

1

1

MIS-2636 A

Must be configured for "No economizer"

for YO/D to be active for humidity control

2

HEAT PUMP WITH DEHUMIDIFICATION SEQUENCE AND NO VENTILATION PACKAGE

USING THERMOSTAT #8403-060 COMBINATION TEMPERATURE & HUMIDITY CONTROLLER

Manual 2100-516H

Page 10 of 19

Page 11

FIGURE 7

C

Unit

C G R YEY1

Bard part #8403-038

E

O1DHLB

Terminal B lock

#TH5220D1151

W3

24V Low Voltage

1

Mechanical Humi dist at

L

W1

Red Yellow

6 5 3

4

1 Factory Jumper Instal l ed.

Jumper needs to be added.

Bard part #8403-047

Electronic Humidistat

R Y

W2

Thermostat

2 Stage Heat

1 Stage Cool

Bard part #8403-058

AUX

G Rc

O/B

2

1

Low Voltage Wiring Diagram

2

"L" is constant 24V output

when

thermostat is in Em Heat mode

MIS-2649 B

HEAT PUMP WITH DEHUMIDIFICATION SEQUENCE

WITH NON-PROGRAMMABLE THERMOSTAT

Manual 2100-516H

Page 11 of 19

Page 12

FIGURE 8

2

G

Block

Red

during scheduled occupied periods.

Figure 8

C

C

Unit

Low Voltage Wiring Diagram

#8403-060

E

Heat Pump with

Thermostat

24V Low

3

W3

3

Dehumidification

O/B

Orange

CRV

ERV

Voltage

Y2

RG

W2

YO/D

L

Y1

W1/E

A

Ventilation Packages

when optinal CO controller is used.

LY1 DHY B W1 O1R W2

2

and fan set to programmed fan for the "A" output to function

2

2

active for humidity control. Must be configured to programmable

Red

Terminal

Black

controller is used. Connect orange wire to "G" only

Must be configured to "no economizer" to make YO/D output

3

Brown/White

Bard part

Black

MFAD

Do not connect "A" from thermostat if optional CO

Packaging using Electronic Thermostat with Combination Temperature and Humidity Control

Sequence and Optional MFAD, CRV, and ERV Ventilation

with Optional CO Controller

Heat

Cool

2 Stage

2 Stage

1

Factory Jumper Installed

2

1

4 52231 6

MIS-2637 C

Optional CO Controller

Bard part #8403-067

HEAT PUMP WITH DEHUMIDIFICATION SEQUENCE & OPTIONAL MFAD, CRV & ERV VENTILATION

PACKAGING USING ELECTRONIC THERMOSTAT WITH COMBINATION TEMPERATURE &

HUMIDITY CONTROL WITH OPTIONAL CO2 CONTROLLER

Manual 2100-516H

Page 12 of 19

Page 13

FIGURE 9

Terminal B lock

Electronic Humidistat

Low Voltage Wiring Diagram

G

O/BY

R

Y1

AUX

L

Bard part #8403-047

2

24V Low Voltage

Bard part #8403-058

Rc

Thermostat

Ventilation

2 Stage Heat

1 Stage Cool

O1

MFAD

ERV

Red

1

Black

Brown/White

CRV

Black

Red Yellow

6

Packages

1

5

Orange

1 Factory Jumper Inst al l ed.

active whenever blower operates.

Add jumper, ventilation wi ll be

3

4

3

Bard part #8403-038

Mechanical Humidi st at

2

4

Jumper needs to be added.

3

Orange wire is not connected.

Unit

C G R Y E

RED

W2

C

DH LB W3

E

4

W1

"L" is constant 24V output

when

thermostat is in Em Heat mode

MIS-2638 C

HEAT PUMP WITH DEHUMIDIFICATION SEQUENCE & OPTIONAL MFAD, CRV & ERV VENTILATION

PACKAGING USING A NON-PROGRAMMABLE THERMOSTAT (NO OCCUPIED SIGNAL)

Manual 2100-516H

Page 13 of 19

Page 14

FIGURE 10

2

Cool

Unit

24V Low Volt age

Low Voltage Wiring Diagram

Terminal Bl ock

Heat

2 Stage

Y1

1

Bard part #8403-058

Jumper needs to be added.

#TH5220D1151

1

Connect Orange wire to "G".

Mechanical Humidi st at

Black

MFAD

Thermostat

ERV

2

Red

Ventilation

CRV

1 Stage

Optional CO Controller

Bard part #8403-038

Factory Jumper Inst al led.

Bard part #8403-047

3

Electronic Humidistat

3

1

4

356

YellowRed

Brown/White

Black

Orange

Red

AUX

C G R Y

Packages

W2 W3O1DH

L

B W1

E

2

E

Rc L

G R

Y O/B

Bard part #8403-067

C

1

65432

"L" is constant 24V output

when

thermostat is in Em Heat mode

MIS-2639 E

HEAT PUMP WITH DEHUMIDIFICATION SEQUENCE & OPTIONAL MFAD, CRV & ERV VENTILATION

PACKAGING USING A NON-PROGRAMMABLE THERMOSTAT WITH CO2 CONTROLLER

Manual 2100-516H

Page 14 of 19

Page 15

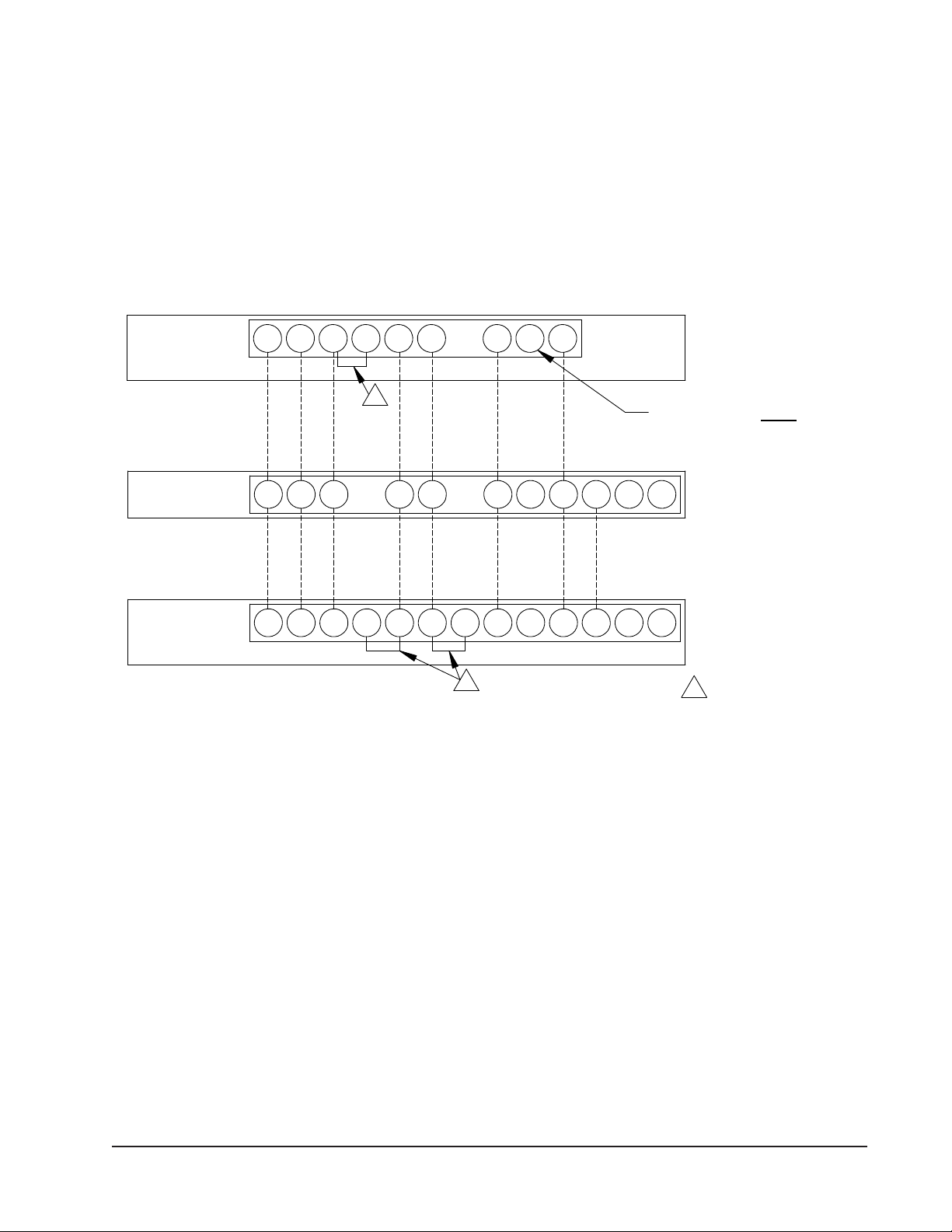

JUMPER IS FACTORY INSTALLED.

LIGHTING CONTROL CIRCUIT

IS OPTIONAL AND FIELD

SUPPLIED. LIGHTING CONTROL

RELAY REQUIRES NORMALLY

CLOSED CONTACTS AND MUST

BE SIZED ACCORDING TO

CONTROLLED LOAD.

2

1

CONTROLLER BARD P/N 8403-060

90

SEARCH-TIME

84

LIGHTS

TEMPERATURE SWITCHES

LEARN

FUNCTION SWITCHES

DEMAND 1

DEMAND 2

AUX

STAGE

N/C

RATE

MODE

PRE P

RECOMMENDED SWITCH SETTINGS SHOWN BELOW

48

54

58

62

68

65

81

78

1

TEMPERATURE/HUMIDITY

Figure 11

DO NOT CONNECT "L" UNTIL AFTER

TERMINALS

G

O/B

OPTIONAL

OR

C

E

R

E

O/B

CGR

Y

Y1 B

CRV

6

UNIT 24V

O

G

Y

W1

C

DEHUMIDSTAT

THERMOSTAT TH5220D1151

WERV

L

W1/E

ON PAGE 3

L

1

HUMIDITY CONTROLLER

L

SEARCH TIME DETAIL

TO CS2000 = YES

FACTORY JUMPER - SEE

AND ORANGE WIRES

WH/SH HEAT PUMP CONNECTION DIAGRAM

RC

CONTACTS

OPEN

NORMALLY

(OPTIONAL)

DETECTOR

MOTION

LIGHTING CONTROL

CONTROLLER

PACKAGE (OPTIONAL)

SETTINGS).

INSTALLED IN HEAT PUMP

BARD P/N 8403-058

HP WITH CS2000

OVERIDE

ENERGY MONITOR

HVAC

NO C NCDOORPRECOND

- +

REMOTE

PWR

- +

C NC

REM

W3

PWR

3

- +

AREA OCCUP.

4

VENT HVAC FAN

R

NOTE: IF FACTORY INSTALLED

5

MAN.

NO C NC

H600A1014

R

H200-10-21-10

CS2000A2

8403-060 CONTROLLER IS CONFIGURED

BARD VENTILATION

BLUE

(SEE STEP 2, FUNCTION SWITCH

CONNECTIONS USED ONLY

HUMIDITY

DISCONNECT AND TAPE RED

8403-038

CIRCUIT THAT MUST BE FACTORY

RELAY NORMALLY

FIELD SUPPLIED

CONTROL

01

8403-047

2

RED

MUST ALSO BE CONNECTED

YELLOW

FOR PRE-PURGE OPERATION

FOR OPTIONAL DEHUMIDIFICATION

Aux

W2

CLOSED CONTACTS

MANUAL SWITCH

LIGHTING

NC C NO C NC

W2

YO/D

Y1

(24 HRS)

IF OPTIONAL VENT PACKAGE IS

INSTALLED, THE "G" WIRE MUST

BE CONNECTED TO ASSURE

CONTINUOUS BLOWER DURING

OCCUPIED PERIODS WHEN VENT

SYSTEM IS "ON". THE "G" WIRE

1

4093-140 L

BK

BR/W

FIGURE 11

HEAT PUMP WITH CS2000A2

Manual 2100-516H

Page 15 of 19

Page 16

FIGURE 12

*ELECTRICAL SHOCK HAZARD

*DISCONNECT POWER BEFORE

SERVICING.

DANGER

!

1

24

56

3

1

24

56

3

Yellow

Low Voltage

Blue

W3

Black

*Thermostat Model Configuration Notes:

W**H1Dehum.with Econ.

Part #8201-062

W2

W1E

RG

C

Thermostat Part#8403-060*

W2GRCE

L O/B

YOD

Y2 Y1

L W1 O/BY

WH Unit

Y1

Vent Option

and #8403-060 Thermostat

Dehum.Relay

Heat Relay

Term.Strip

Economizer

Part #8201-062

EF

Y2 Y1

Black

Green

Red

White

Brown

Orange

Blue

Light Blue

Light Blue

Orange

Black

Blue

Pink

Purple

1.) Configured for "Heat Pump"

2.) Configured for "Multi-Stage"

3.) Configured for "No Economizer"

4.) Configured CS2000A Attached = NO

4200-001 B

RELAYS AND

ASSOCIATED WIRING

ARE FIELD INSTALLED

W**H1 DEHUM. WITH ECONOMIZER

& #8403-060 THERMOSTAT (EIFM)

“E” VENT OPTION

Manual 2100-516H

Page 16 of 19

Page 17

FIGURE 13

W1/E

Y2

1

is 10V (100%).Depending upon applicationmay require setting to lower value.

YO/D

CRB

YE

Must be configured for heat pump / multistage/ no economizer/

2

3

Low Voltage Wiring Diagram

2

Y1

W2

L

24V Low Voltage

W2

Terminal Block

W1

Wiring Harness

to enable YO/D output to be active as dehumidification output

L

W3

O1

G

Thermostat

Factory Jumper Installed.

Economizer

part #8403-060

G

R O/B

DH

C

A

3

1

Must be energized to enable minimum position. NOTE: Economizer ControlDefault Setting

Y1

Yellow

Black

Blue

Red

Yellow/red

Brown/white

Pink

Purple

Orange

Yellow/White

MIS-2981 B

1-STAGE HEAT PUMP WITH OPTIONAL ELECTRIC HEAT

WITH OR WITHOUT DEHUMIDIFICATION

WITH ECONWM STYLE ECONOMIZER

“W” OR “T” VENT OPTION

Manual 2100-516H

Page 17 of 19

Page 18

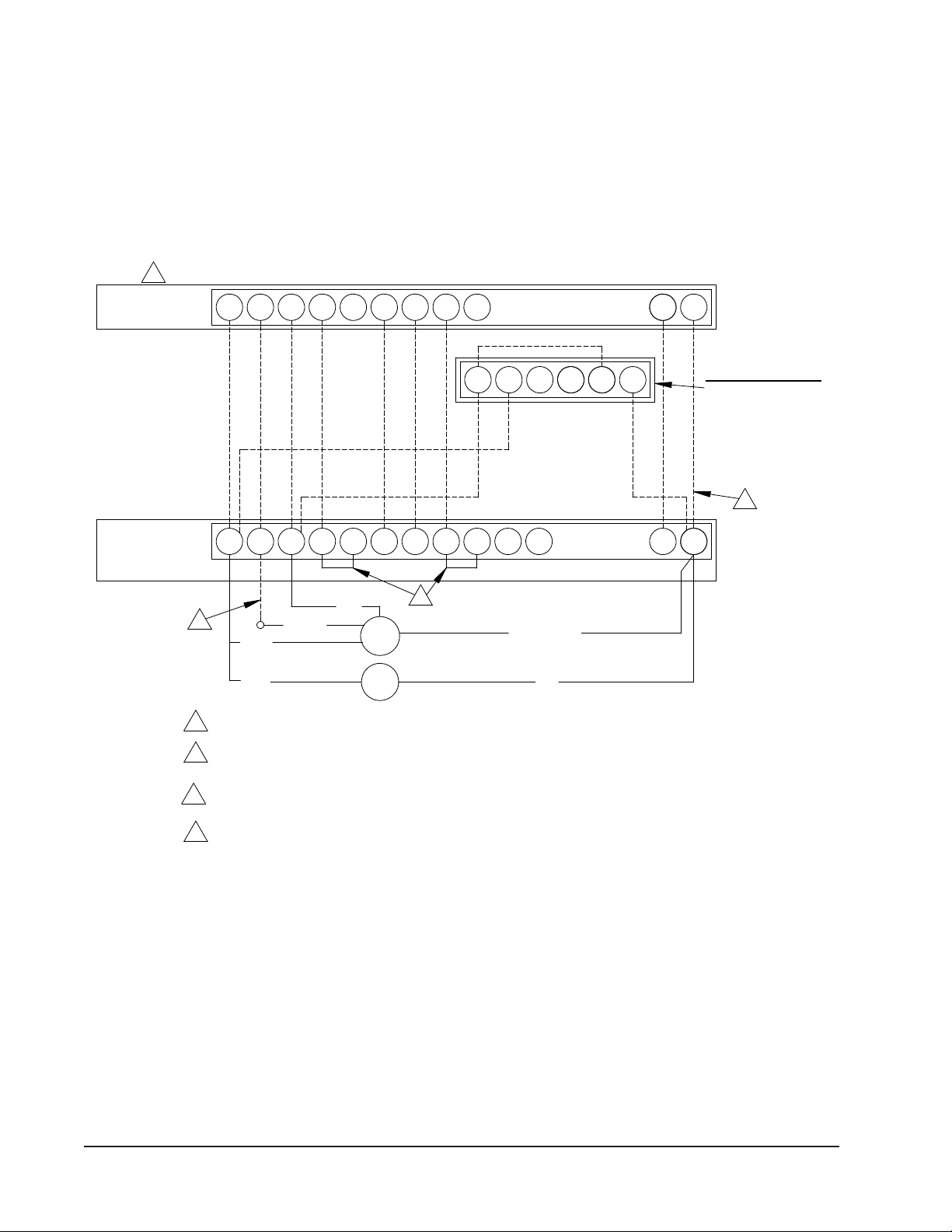

FIGURE 14

3

652 41

3

during scheduled occupied periods

set to programmed for the "A" output to function

Bard part #8403-067

Factory Jumper Installed

Unit

C G R

YEY1

W2 W1

O1

DH

L

B W3

Terminal Block

24V Low Voltage

1

Low Voltage Wiring Diagram

C O/BY1RG W2

Y O/D

W1/E

Bard part #8403-060

Thermostat

Programmable

L A

Y2

Yellow

Black

Orange

Electronic

if optional CO controller is used.

Do not connect "A" from tstat #8403-060

Must be configured to programmable and fan

2

Package

Ventilation

Wire only needed for dehumidification units

3

2

CHCRV-5

Red

CRVMWH-3

OR

4

1

2

4

Optional CO Controller

2

MIS-2997 C

HEAT PUMP WITH OPTIONAL CRVMWH-3 OR CHCRV-5

VENTILATION PACKAGING WITH PROGRAMMABLE THERMOSTAT (RECOMMENDED)

Manual 2100-516H

Page 18 of 19

Page 19

FIGURE 15

Y

L

1 Stage Cool

2 Stage Heat

Thermostat

#TH5220D1151

Bard part #8403-058

AUX

G R Rc

O/B

C

Low Voltage Wiring Diagram

E

1

Unit

C

Factory Jumper Installed

G2R

EY1W2 W1 O1DHLB

Ventilation

Y

Black

W3

Package

24V Low Voltage

Add jumper, ventilation will be active

Terminal Block

Red

1

whenever blower operates.

Orange

1

2

Yellow

CHCRV-5

OR

CRVMWH-3

MIS-2998 A

HEAT PUMP WITH OPTIONAL CRVMWH-3 OR CHCRV-5 VENTILATION

PACKAGING WITH NON-PROGRAMMABLE THERMOSTAT (NO OCCUPIED SIGNAL)

Manual 2100-516H

Page 19 of 19

Loading...

Loading...