Bard W30AAPC, W24AAPA, W36AAPA, W36AAPB, W36AAPC Installation Instructions Manual

...

INSTALLATION INSTRUCTIONS

MULTI-TEC®/th-TUNE

Free Cooling Unit System

MULTI-TEC® Wall-Mount Air Conditioner

Models:

W18AAPA

W24AAPA

W24AAPB

W24AAPC

W30AAPA

W30AAPB

W30AAPC

W36AAPA

W36AAPB

W36AAPC

W42AAPA

W42AAPB

W42AAPC

W48AAPA

W48AAPB

W48AAPC

W48AAPQ

W60AAPA

W60AAPB

W60AAPC

W60AAPQ

W72AAPA

W72AAPB

W72AAPC

W72AAPQ

W18LAPA

W24LAPA

W24LAPB

W30LAPA

W30LAPB

W30LAPC

W36LAPA

W36LAPB

W36LAPC

W42LAPA

W42LAPB

W42LAPC

W48LAPA

W48LAPB

W48LAPC

W48LAPQ

W60LAPA

W60LAPB

W60LAPC

W60LAPQ

W72LAPA

W72LAPB

W72LAPC

W72LAPQ

th-Tune Single Unit Controller

NOTE: The th-Tune can be used as a replacement for the LC6000

controller for operation when a single W***AP* unit is used.

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-678

Supersedes: NEW

Date: 9-20-17

Page 1 of 24

CONTENTS

General Information ...........................................3

List of Necessary Materials/Tools ....................5

Wall-Mount Unit Site Preparation ....................6

Model Identification .......................................... 6

New Shelter Installation vs. Retrofit Installation .. 6

Minimum Clearance .......................................... 6

Clearance to Combustibles ................................ 6

Wall-Mount Unit Installation ............................8

Mounting the Unit ............................................ 8

Wall-Mount Unit Supply Wiring ...................... 16

Main Power Wiring .......................................... 16

Low Voltage Wiring ......................................... 16

Wall-Mount Unit Preliminary Start Up ..........19

Running in Stand Alone (Orphan) Mode ............ 19

th-Tune Controller Installation ......................20

Mounting th-Tune Controller to Wall ................. 20

Power and Communication Wiring .................... 20

Power Wiring ........................................... 20

Communications Wiring ............................ 21

th-Tune Operation ........................................... 22

On/Off ..................................................... 22

Heat/Cool Operation ................................. 22

Auto Mode......................................... 22

Heat Mode ........................................ 22

Cool Mode ......................................... 22

Staging of Free Cooling and

Mechanical Cooling ............................ 22

Changing the Setpoint .............................. 22

Changing the Clock .................................. 23

Blower Operation ...................................... 23

th-Tune Setup Options Using the TEC-EYE . 23

Comfort Range ................................... 23

Alarms and Troubleshooting....................... 23

Alarms .............................................. 23

Troubleshooting ................................. 23

FIGURES AND TABLES

Figure 1 MULTI-TEC Model Nomenclature .............5

Figure 2 Dimensions ............................................ 7

Figure 3 Outdoor Sensor Installation

Figure 4A W18A, W18L, W24A, W24L

Mounting Instructions

Figure 4B W30A, W30L, W36A, W36L

Mounting Instructions

Figure 4C W42A, W42L, W48A, W48L

Mounting Instructions

Figure 4D W60A, W60L, W72A, W72L

Mounting Instructions

Figure 5 Electric Heat Clearance ......................... 13

Figure 6 Wall Mounting Instructions .................... 13

Figure 7 Wall Mounting Instructions .................... 14

Figure 8 Common Wall Mounting Installations ...... 15

Figure 9 Circuit Routing Label ............................ 16

Figure 10 WIRING: VAC Supply Wiring

Landing Points .....................................16

Figure 15 th-Tune Power and Communication

Connections .........................................21

Figure 16 Wall Unit and th-Tune Power and

Communications Connections ................21

Figure 17 Proper Communication Connector

Placement ...........................................21

Figure 18 Change Setpoint ...................................22

Figure 19 Comfort Range .....................................22

Figure 20 MULTI-TEC Status Screen ..................... 23

Figure 21 Comfort Range Setup ............................23

Figure 22 th-Tune Buttons Overview ...................... 24

Figure 23 th-Tune Icons Overview .........................24

Table 1 Electrical Specifications –

W**AAP Series .....................................17

Table 2 Electrical Specifications –

W**LAP Series .....................................18

......................

..............................

............................

............................

............................

8

9

10

11

12

Manual 2100-678

Page 2 of 24

GENERAL INFORMATION

Free Cooling Unit System

This Bard Free Cooling Unit System is composed of

MULTI-TEC wall-mounted air conditioners matched

with an LC6000 lead/lag controller or Bard th-Tune

single unit controller. If only one wall-mounted air

conditioner is being used, it can be matched with

either the LC6000 lead/lag controller or a th-Tune

single unit controller. If more than one wall mount

is installed, the LC6000 lead/lag controller must be

matched with the air conditioning units. The wall

mounts are specifically engineered for telecom/motor

control center rooms.

NOTE: The LC6000 lead/lag controller (or th-Tune

single unit controller) and MULTI-TEC wallmount units are designed specifically to work

together. These controllers cannot run other

Bard models or other brands of systems, nor

can other controllers run the MULTI-TEC wallmount units. They are a complete system, and

must be used together.

Wall-Mount Air Conditioner Units

The

MULTI-TEC

units will supply 100% of rated cooling airflow in free

cooling mode with ability to exhaust the same amount

through the unit itself without any additional relief

openings in the shelter.

Each of these units are fully charged with refrigerant

and may have optional auxiliary heat.

units operate on VAC power.

The

Controller

A th-Tune single unit controller (Bard P/N 8403-

088) can be used in place of the LC6000 controller

when only one MULTI-TEC wall-mount air conditioner

is being controlled. If using a th-Tune stand-alone

controller instead of the LC6000 controller, the alarm

logging and remote communication capabilities of

the LC6000 controller will not be available. A TEC-

TM

hand-held diagnostic tool is required to program

EYE

the wall-mount unit for th-Tune single unit controller

operation. The th-Tune controller and TEC-EYE

diagnostic tool are available as a kit (Bard P/N 8620-

264).

General

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly any tags

and/or labels attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation

is made. See Additional Publications below for

information on codes and standards.

Sizing of systems for proposed installation should be

based on heat loss and heat gain calculations made

according to methods of Air Conditioning Contractors of

America (ACCA). The supply flange should be installed

in accordance with the Standards of the National

Fire Protection Association for the Installation of Air

Conditioning and Ventilating Systems of Other Than

Residence Type, NFPA No. 90A, and Residence Type

Warm Air Heating and Air Conditioning Systems, NFPA

No. 90B. Where local regulations are at a variance with

instructions, installer should adhere to local codes.

Shipping Damage

Upon receipt of equipment, the cartons should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

These units must remain in upright position at all

times.

Additional Publications

These publications can help when installing the

furnace. They can usually be found at the local library

or purchased directly from the publisher. Be sure to

consult the current edition of each standard.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation of Air Conditioning

and Ventilating Systems ...................ANSI/NFPA 90A

Standard for Warm Air Heating

and Air Conditioning Systems ............ANSI/NFPA 90B

Load Calculation for Residential Winter

and Summer Air Conditioning ............. ACCA Manual J

For more information, contact these publishers:

Air Conditioning Contractors of America (ACCA)

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370 Fax: (202) 234-4721

Manual 2100-678

Page 3 of 24

American National Standards Institute (ANSI)

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900 Fax: (212) 302-1286

American Society of Heating, Refrigeration and Air

Conditioning Engineers, Inc. (ASHRAE)

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400 Fax: (404) 321-5478

National Fire Protection Association (NFPA)

Batterymarch Park

P. O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555 Fax: (617) 984-7057

ANSI Z535.5 Definitions:

DANGER: Indicate[s] a hazardous situation which, if

not avoided, will result in death or serious injury. The

signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

WARNING: Indicate[s] a hazardous situation which,

if not avoided, could result in death or serious injury.

WARNING [signs] should not be used for property

damage hazards unless personal injury risk appropriate

to this level is also involved.

CAUTION: Indicate[s] a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION [signs] without a safety alert symbol may be

used to alert against unsafe practices that can result in

property damage only.

NOTICE: [this header is] preferred to address practices

not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an

alternative to “NOTICE” the word “CAUTION” without

the safety alert symbol may be used to indicate a

message not related to personal injury.

!

WARNING

Electric shock hazard.

Have a properly trained individual perform

these tasks.

Failure to do so could result in electric shock

or death.

!

WARNING

Fire hazard.

Maintain minimum 1/4" clearance between the

supply ange and combustible materials.

Failure to do so could result in re causing

damage, injury or death.

!

WARNING

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

!

CAUTION

Cut hazard.

Wear gloves to avoid contact with sharp

edges.

Failure to do so could result in personal injury.

Manual 2100-678

Page 4 of 24

LIST OF NECESSARY MATERIALS/TOOLS

Additional hardware and miscellaneous supplies are needed for installation. These items are field supplied and must

be sourced before installation. This list also includes tools needed for installation.

LIST OF MATERIALS/TOOLS

• Personal protective equipment/safety devices/anti-

static wrist straps

• Supply and return grilles

• Field-fabricated sleeves (if necessary)

• Fasteners sufficient for mounting the units such as

5/16” diameter anchor/lag bolts

• 7/8” diameter washers

• Fasteners appropriate for the shelter wall

construction to attach the controller to the wall

• Commercial grade outdoor silicone sealant

• Miscellaneous hand and power tools and jobsite or

shop materials

• Lifting equipment with the necessary capacity and

rigging to safely move/install the systems

• Electrical supplies

- Various size circuit breakers for the shelter AC

breaker box (see Tables 1 and 2 on pages 17

and 18)

- High-voltage wire of various gauges

(see Tables 1 and 2)

- Communication wire: 3-wire, 20 gauge

shielded cable

- Miscellaneous electrical supplies including

rigid/flexible conduit and fittings, junction

boxes, wire connectors and supports

MODEL SERIES

18 – 1½ Ton

24 – 2 Ton

30 – 2½ Ton

36 – 3 Ton

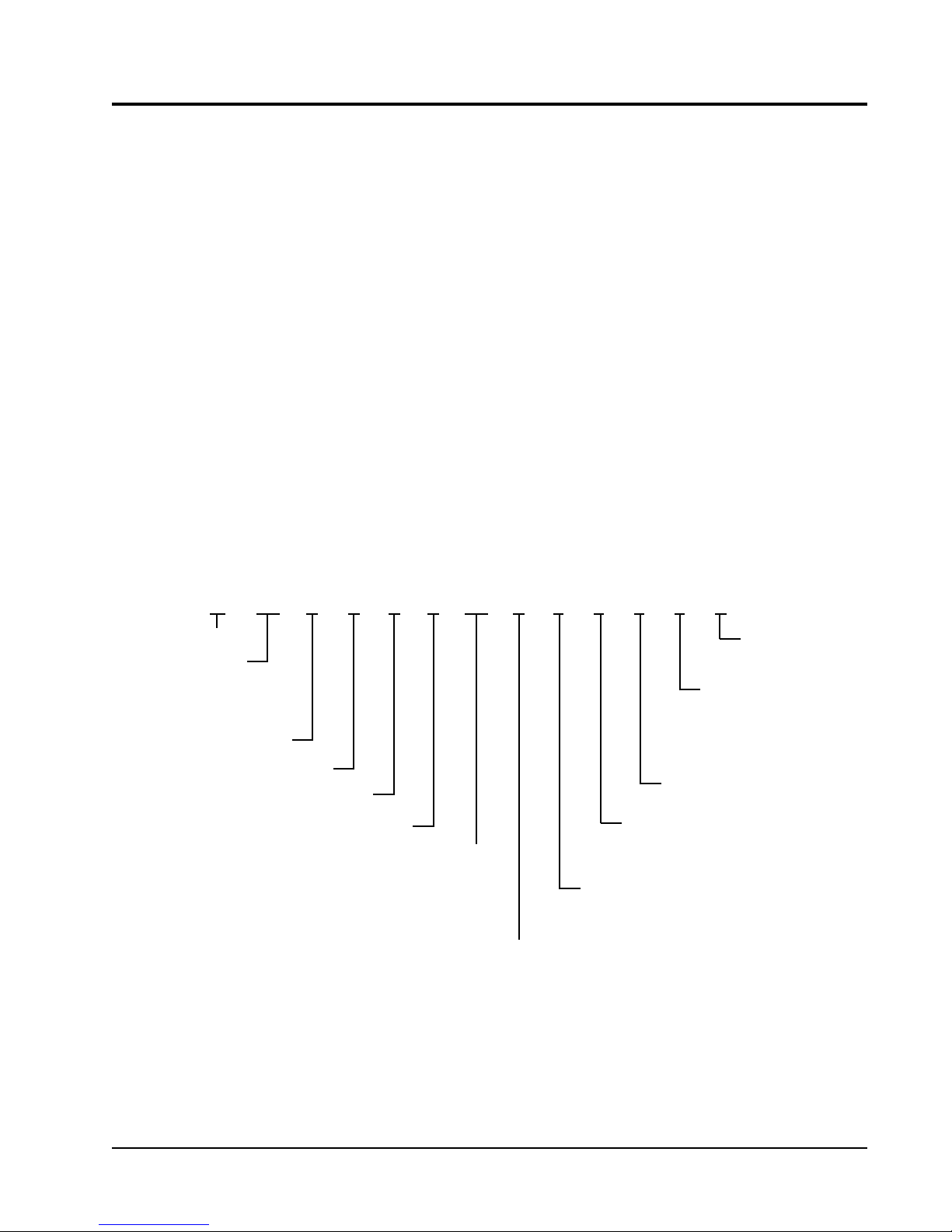

FIGURE 1

MULTI-TEC Wall-Mount Unit Model Nomenclature

W 36 A A P A 10 5 X X X X E

CAPACITY

42 – 3½ Ton

48 – 4 Ton

60 – 5 Ton

72 – 6 Ton

A – Right Hand

L – Left Hand

A – 230/208/60/1

B – 230/208/60/3

C – 460/60/3

D – 240/220/50/1

REVISION

P – PLC Logic Board

VOLTS & PHASE

E – 240/220/50/3

or 220/200/50/3

F – 415/380/50/3

Q – 575/60/3

KW

FILTER OPTIONS

X – 1" Throwaway (Standard)

W – 1" Washable

P – 2" Pleated (MERV 8)

VENTILATION OPTIONS

B – Blank-off Plate

5 – Economizer: Default Enthalpy Convert to DB Only

COLOR OPTIONS

X – Beige (Standard)

1 – White

4 – Buckeye Gray

COIL OPTIONS

X – Standard

1 – Phenolic Coated Evaporator

2 – Phenolic Coated Condenser

3 – Phenolic Coated Evaporator

and Condenser

SUPPLY AIR OUTLET

X – Front (Standard)

CONTROL MODULES

E – LAC

C – LAC & CCH

Manual 2100-678

Page 5 of 24

WALL-MOUNT UNIT SITE PREPARATION

Model Identification

Identify the specific model using the model

nomenclature information found in Figure 1 and the

model/serial tag found on the unit on the opposite side

of the control and access panels. See Figure 2 on page

8 for dimensions and critical installation requirements.

New Shelter Installation vs. Retrofit

Installation

These installation instructions cover both new shelter

installations and retrofit installations. Each installation

is unique and may require special accomodations and

modifications. Although Bard Manufacturing follows a

long-established tradition of manufacturing equipment

using industry standard dimensions for building

penetration, it is occasionally necessary to move or

enlarge supply and return openings when replacing

non-standardized equipment in a retrofit application.

Minimum Clearance

Wall-mount air conditioners are available in both righthand access models and left-hand access models.

Right-hand access models have the heat strip access

panel, external circuit breakers access panel and

internal controls access panel on the right side of the

unit. Left-hand access models are a mirror image of the

right-hand access models, and allow two wall-mount

units to be placed in relatively close proximity and yet

still allow complete access for maintenance and repair.

On side-by-side installations, maintain a minimum of

20" clearance on control side to allow access to control

panel and heat strips, and to allow proper airflow to the

outdoor coil. For installations where units are installed

with both control panels facing each other (inward),

maintain a minimum of 36" clearance to allow access.

Additional clearance may be required to meet local or

national codes.

Care should be taken to ensure that the recirculation

and obstruction of condenser discharge air does not

occur. Recirculation of condenser discharge air can

be from either a single unit or multiple units. Any

object such as shrubbery, a building or a large object

can cause obstructions to the condenser discharge air.

Recirculation or reduced airflow caused by obstructions

will result in reduced capacity, possible unit pressure

safety lockouts and reduced unit service life.

For units with blow through condensers, such as

these wall-mount units, it is recommended there be

a minimum distance of 10' between the front of the

unit and any barrier or 20' between the fronts of two

opposing (facing) units.

Clearances Required for Service Access and

Adequate Condenser Airflow

LEFT

MODELS

W18A, W24A, W30A, W36A 15" 20" 10'

W18L, W24L, W30L, W36L 20" 15" 10'

W42A, W48A, W60A, W72A 20" 20" 10'

W42L, W48L, W60L, W72L 20" 20" 10'

NOTE: For side-by-side installation of two units there must be

20" between units. This can be reduced to 15" by using a W**L

model (left side compressor and controls) for the left unit and

W**A (right side compressor and controls) for right unit.

See Specifications Sheet S3532.

SIDE

RIGHT

SIDE

DISCHARGE

SIDE

Clearance to Combustibles

!

WARNING

Fire hazard.

Maintain minimum 1/4" clearance between the

supply air duct and combustible materials in

the rst 3' of ducting.

Failure to do so could result in re causing

damage, injury or death.

The unit itself is suitable for 0" clearance, but the

supply air duct flange and the first 3' of supply air duct

require a minimum of 1/4" clearance to combustible

material. However, it is generally recommended that

a 1" clearance is used for ease of installation and

maintaining the required clearance to combustible

material. See Figures 4A-D on pages 9-12 for details

on opening sizes.

Minimum Clearances Required to

Combustible Materials

MODELS

W18A, L

W24A, L

W30A, L

W36A, L

W42A, L

W48A, L

W60A, L

W72A, L

SUPPLY AIR DUCT

FIRST 3'

0" 0"

1/4" 0"

1/4" 0"

CABINET

Manual 2100-678

Page 6 of 24

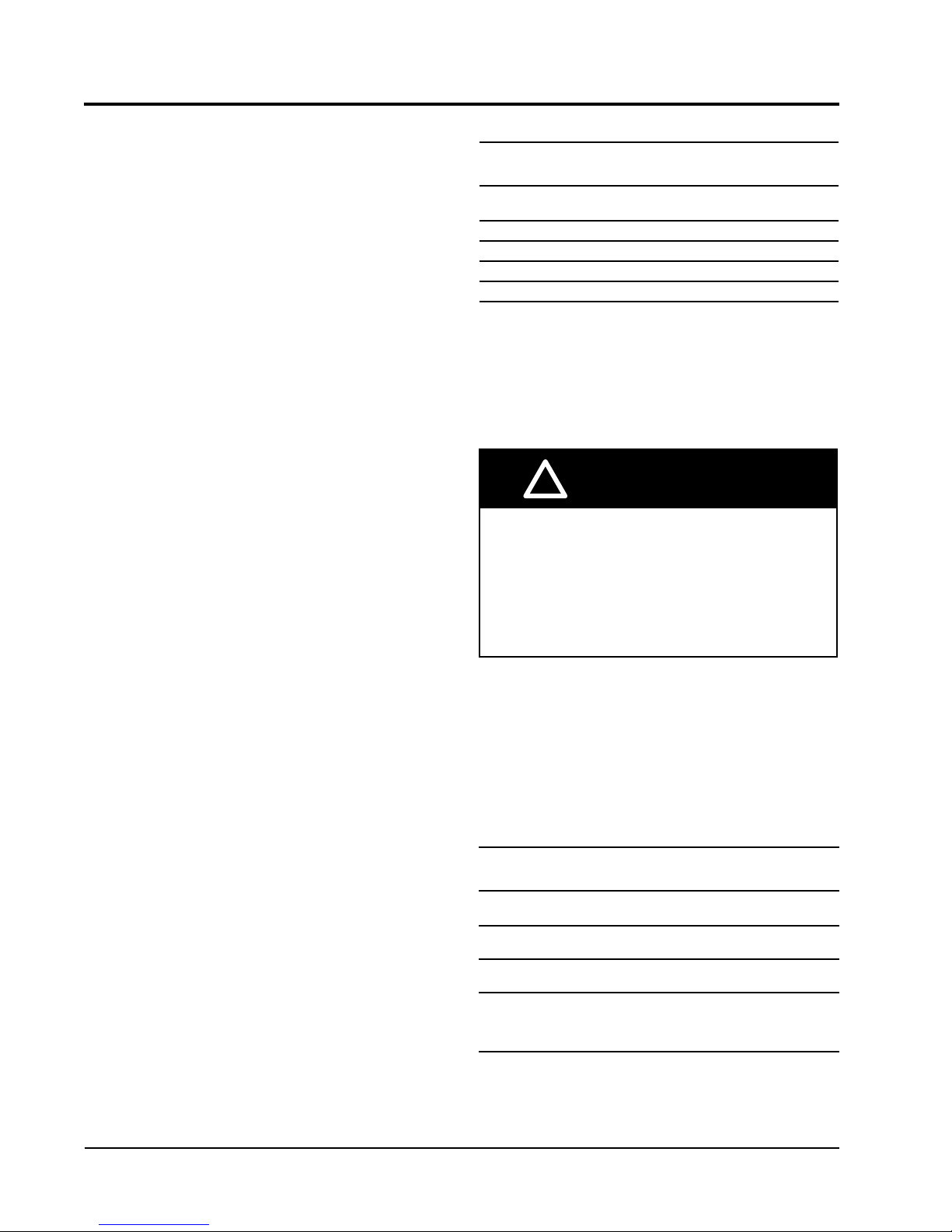

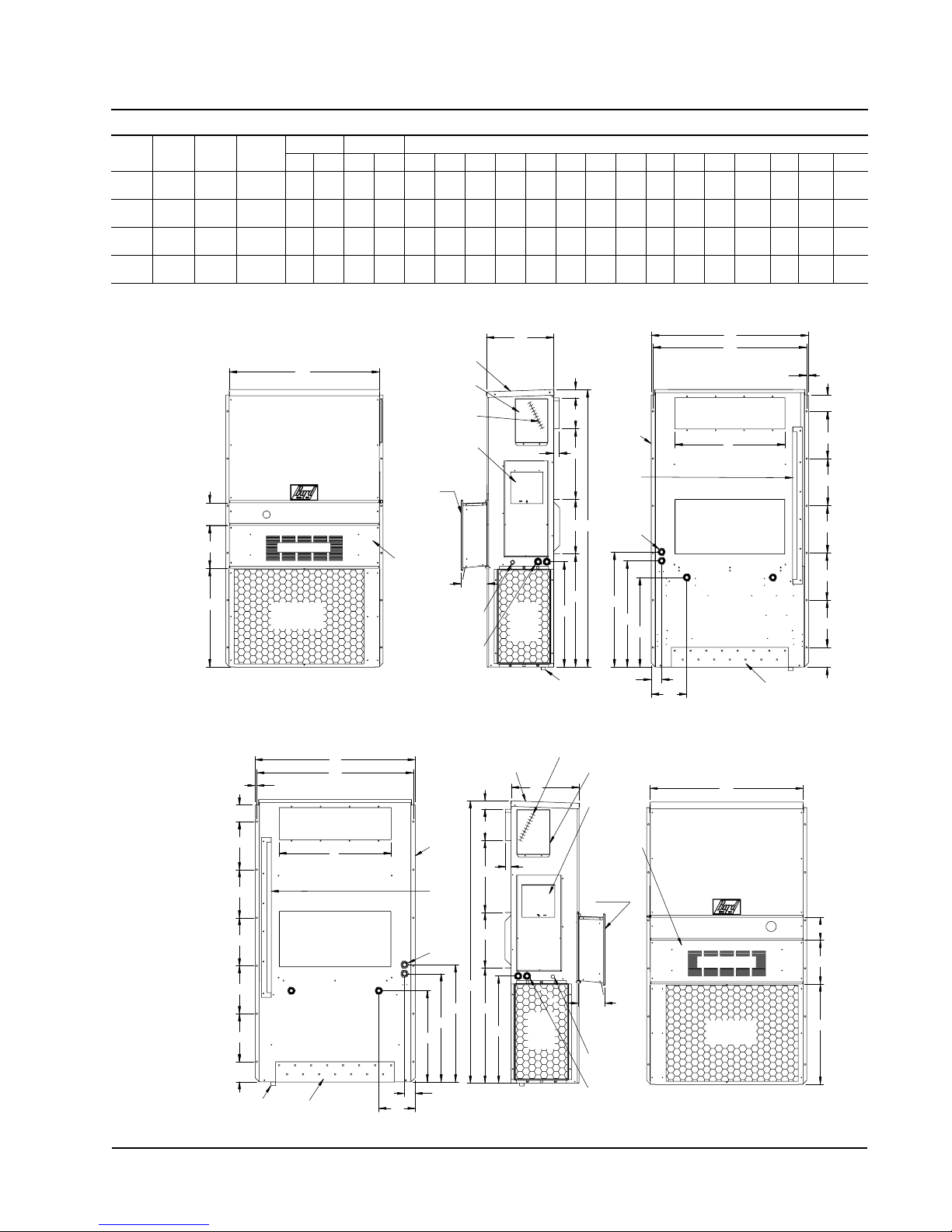

FIGURE 2

Dimensions of Basic Unit for Architectural and Installation Requirements (Nominal)

WIDTH

DEPTH

MODEL

W18*A

W24*A

W30*A

W36*A

W42*A

W48*A

W60*A

W72*A

(W)

33.300 17.125 74.563 7.88 19.88 11.88 19.88 35.00 10.88 29.75 20.56 30.75 32.06 33.25 31.00 2.63 34.13 26.06 10.55 4.19 12.00 9.00

38.200 17.125 74.563 7.88 27.88 13.88 27.88 40.00 10.88 29.75 17.93 30.75 32.75 33.25 31.00 2.75 39.13 26.75 9.14 4.19 12.00 9.00

42.075 22.432 84.875 9.88 29.88 15.88 29.88 43.88 13.56 31.66 30.00 32.68 26.94 34.69 32.43 3.37 43.00 23.88 10.00 1.44 16.00 1.88

42.075 22.432 93.000 9.88 29.88 15.88 29.88 43.88 13.56 37.00 30.00 40.81 35.06 42.81 40.56 3.37 43.00 31.00 10.00 1.44 16.00 10.00

HEIGHT

(D)

All dimensions are in inches. Dimensional drawings are not to scale.

SUPPLY RETURN

(H)

A B C B E F G I J K L M N O P Q R S T

W**A

RIGHT

UNIT

W**L

LEFT

UNIT

5.88

E

O

Supply Air Opening

B

Return Air Opening

Back View

MIS-3889

W

Filter Access Panel

Ventilation Air

Condenser

Air Outlet

Front View

.44

Bottom Installation

Bracket

MIS-3889

1

5.88

F

G

MIS-3890

MIS-3890

R

S

S

S

S

S

T

Built In

Rain Hood

4° Pitch

2.13

A

I

C

K

D

1.250

Cond.

Air

Inlet

Side View

J

D

1.250

Cond.

Air

Inlet

Side View

2.13

A

C

K

J

Drain

Electric

Heat

I

Side Wall

Mounting

Brackets

(Built In)

Top Rain

Flashing

Shipping

Location

Optional

Electrical

H

Entrances

L

Heater

Access

Panel

C. Breaker/

Disconnect

Access Panel

(Lockable)

Standard flush

vent door for

non-ERV/CRV

Econ. models

Hood for

ECON models

only

7.000

Low Voltage

Electrical

Entrance

High Voltage

Electrical

Entrance

M

P

N

Q

Built In

Rain Hood

W

Hood for ECON

models only

Filter Access Panel

1

Standard

F

G

Ventilation Air

Condenser

flush vent

door for nonERV/CRV

Econ.

models

Air Outlet

4° Pitch

Heater

Access

Panel

Electric

Heat

C. Breaker/

Disconnect

Access Panel

(Lockable)

7.00

Low Voltage

Electrical

Entrance

High Voltage

Electrical

Entrance

Front View

E

O

Supply Air Opening

B

Return Air Opening

Back View

Side Wall

Mounting

Brackets

(Built In)

Top Rain

Flashing

Shipping

Location

Optional

Electrical

Entrances

H

L

M

P

N

Q

R

S

S

S

S

S

T

Drain

.44

Bottom

Installation

Bracket

Manual 2100-678

Page 7 of 24

WALL-MOUNT UNIT INSTALLATION

Mounting the Units

!

WARNING

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

NOTE: It may be best to spot some electrical knockouts

(such as those located on the back of the wallmount unit) before units are mounted and access is

unavailable or limited (see Figure 2 to locate prepunched knockouts).

Two holes for the supply and return air openings must

be cut through the wall as shown in Figures 4A-D on

pages 9-12. On wood frame walls, the wall construction

must be strong and rigid enough to carry the weight

of the unit without transmitting any unit vibration. All

walls must be thoroughly inspected to insure that they

are capable of carrying the weight of the installed unit.

In retrofit (unit replacement) installations, the openings

cut for the original equipment may not line up exactly

with needs of this installation. Modifications may need

to be made, such as increasing or decreasing the size

of the wall cutouts. The existing bolt placement may

not line up in which case the original bolts would need

to be removed or cut away.

1. These units are secured by wall mounting flanges

which secure the unit to the outside wall surface at

both sides. A bottom mounting bracket, attached

to skid for shipping, is provided for ease of

installation, but is not required.

2. The unit itself is suitable for 0" clearance, but the

supply air duct flange and the first 3' of supply

air duct require a minimum of 1/4" clearance to

combustible material. However, it is generally

recommended that a 1" clearance is used for

ease of installation and maintaining the required

clearance to combustible material. See Figures

4A-D for details on opening sizes.

3. Locate and mark lag bolt locations and location for

optional bottom mounting bracket, if desired (see

Figures 4A-D).

4. Mount bottom mounting bracket (if used).

5. If desired, hook top rain flashing (attached to frontright of supply flange for shipping) under back

bend of top.

6. Position unit in opening and secure with fasteners

sufficient for the application such as 5/16" lag/

anchor/carriage bolts; use 7/8" diameter flat washers

on the lag bolts. It is recommended that a bead

of silicone caulking be placed behind the side

mounting flanges.

7. Secure optional rain flashing to wall and caulk

across entire length of top (see Figures 4A-D).

8. For additional mounting rigidity, the return air

and supply air frames or collars can be drilled

and screwed or welded to the structural wall itself

(depending upon wall construction). Be sure to

observe required clearance if combustible wall.

9. A plastic drain hose extends from the drain pan at

the top of the unit down to the unit base. There are

openings in the unit base for the drain hose to pass

through. In the event the drain hose is connected

to a drain system of some type, it must be an open

or vented type system to assure proper drainage.

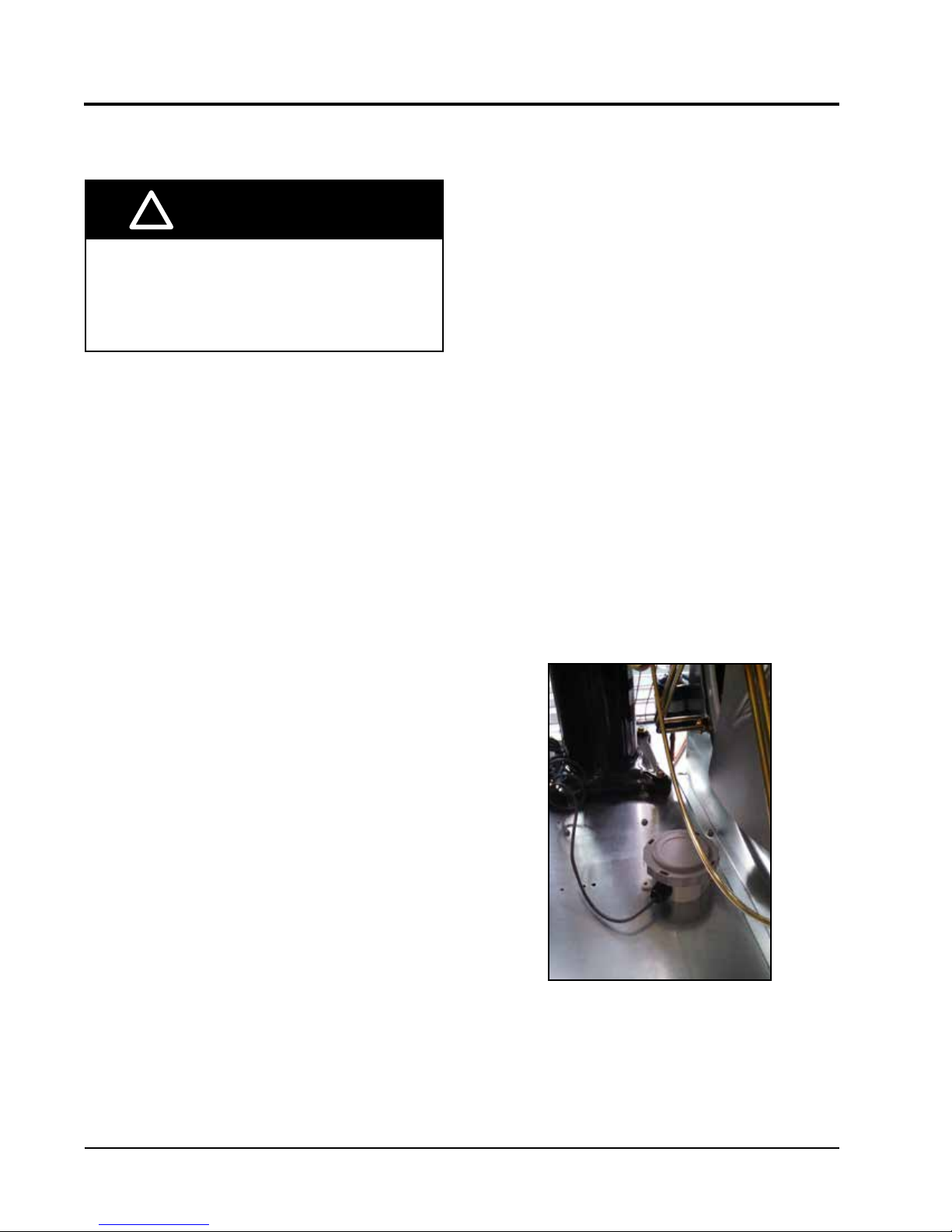

10. Install outdoor temperature/humidity sensor (see

Figure 3). Remove grommet from base and sensor.

Discard shipping bracket. Place sensor extension

through hole in base under condenser fan and

secure to base with screw.

FIGURE 3

Outdoor Sensor Installation

Manual 2100-678

Page 8 of 24

Loading...

Loading...