Bard W24AAPA, W30AAPA, W24AAPB, W24AAPC, W30AAPB Service Instructions Manual

...

SERVICE INSTRUCTIONS

WALL-MOUNT AIR CONDITIONER

Part of the Bard Free Cooling Unit System

W18AAPA

W24AAPA

W24AAPB

W24AAPC

W30AAPA

W30AAPB

W30AAPC

W36AAEA

W36AAEB

W42AAEA

W42AAEB

W42AAEC

W42AAPA

W42AAPB

W42AAPC

W48AAEA

W48AAEB

W48AAEC

MULTI-TEC

Models:

W60AAEA

W60AAEB

W60AAEC

W60AAEQ

W60AAMA

W60AAMB

W60AAMC

W60AAPA

W60AAPB

W72ABEA

W72ABEB

W72ABEC

W72ABEQ

W72ABMA

W72ABMB

W72ABMC

W72ABPA

W72ABPB

®

W18LAPA

W24LAPA

W24LAPB

W30LAPA

W30LAPB

W30LAPC

W36LAPA

W36LAPB

W36LAPC

W60LAPA

W60LAPB

W60LAPC

W60LAPQ

W72LBPA

W72LBPB

W72LBPC

W72LBPQ

W36AAEC

W36AAMA

W36AAMB

W36AAMC

W36AAPA

W36AAPB

W36AAPC

NOTE: LC6000 controller is required for operation when multiple MULTI-TEC

wall-mount air conditioners are used.

W48AAEQ

W48AAMA

W48AAMB

W48AAMC

W48AAPA

W48AAPB

W48AAPC

W48AAPQ

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

W60AAPC

W60AAPQ

W72ABPC

W72ABPQ

W42LAPA

W42LAPB

W42LAPC

W48LAPA

W48LAPB

W48LAPC

W48LAPQ

Manual : 2100-665D

Supersedes: 2100-665C

Date: 3-5-18

Page 1 of 26

CONTENTS

General Information ...........................................3

Free Cooling Unit System .......................................3

Wall-Mount Air Conditioner Units ............................3

General ................................................................3

Shipping Damage ..................................................4

Additional Publications ..........................................4

Using the TEC-EYETM ...........................................6

TEC-EYE Hand-Held Diagnostic Tool .......................6

TEC-EYE Menu Structure ......................... 7

TEC-EYE Acronyms ................................. 7

Status Screen ......................................... 7

Quick Menu............................................ 8

Setpoints: Local Col and Heat/

Current Cool and Heat ....................... 8

Information ...................................... 8

Data (Alarm) Log ............................... 8

Menu Screens and Password Levels .......... 8

Additional Features ................................. 8

Model/Serial Number Retain Feature .. 8

Time/Date/Timezone Sync .................. 9

Executing a Run Test............................... 9

Run Test Approximate Timings ........... 9

Parameter Description ....................... 9

Identifying a Unit Address ....................... 9

Changing Freecooling Type ....................... 9

Alarms .................................................................10

Acknowledging/Clearing Alarms .................... 10

Clearing Alarms .................................... 10

Clearing Alarm Logs .............................. 11

Alarm Adjustment ....................................... 11

Mixed Air Alarm .................................... 11

Refrigerant Low Pressure ....................... 11

Refrigerant High Pressure ...................... 12

Economizer Damper .............................. 12

Freezestat ............................................ 12

Control Operation .............................................13

On/Off Control ............................................ 13

Fan Control ................................................ 13

Temperature Control .................................... 13

Zone Selection...................................... 13

Cooling Sequence – Economizer Available

.. 13

Cooling Sequence –

Economizer Not Available ...................... 13

Heating Sequence ................................. 14

Freecooling ................................................ 15

Economizer Disable ............................... 15

Economizer Enable ............................... 15

None ............................................. 15

Drybulb Only .................................. 15

Temperature and Humidity (Default) . 15

Enthalpy ........................................ 15

Economizer Modulation ......................... 15

Compressor ................................................ 16

Enable ................................................. 16

Delays and Run Time............................. 16

Electric Reheat Dehumidification ................. 16

Mechanical Dehumidification ....................... 16

General Refrigerant Information ...................18

General ..................................................... 18

Topping Off System Charge .......................... 18

Safety Practices .......................................... 18

R410A Refrigerant Charge ........................... 18

Componentry .....................................................20

High Pressure Switch .................................. 20

Three Phase Scroll Compressor

Start Up Information ................................... 20

Phase Monitor ............................................ 20

Condenser Fan Operation ............................. 20

Low Ambient Control ................................... 20

Compressor Control Module ......................... 20

Pressure Service Ports ................................. 21

Outdoor Fan Motor ...................................... 21

Maintenance and Troubleshooting ...............24

Standard Maintenance Procedures ............... 24

Removal of Fan Shroud ............................... 24

Troubleshooting Nidec SelecTech ECM Motors

.. 25

FIGURES AND TABLES

Figure 1 MULTI-TEC Wall-Mount Unit Model

Nomenclature ........................................3

Figure 2 TEC-EYE Display and Interface ................6

Figure 3 TEC-EYE Connection to Unit Control ........6

Figure 4 Quick Menu Icons ...................................7

Figure 5 Local Cool/Heat and

Current Cool/Heat Setpoints.....................8

Figure 6 Alarm Log Screen Breakdown ..................8

Figure 7 Executing Run Test .................................9

Figure 8 Alarm Screen Breakdown.......................10

Figure 9 Clearing Alarms ....................................10

Figure 10 Clearing Alarm Logs ..............................11

Figure 11 Adjusting Mixed Air Alarm Values ...........11

Figure 12 Adjusting Damper Alarm Values .............12

Figure 13 LC6000 Status Screen Showing

Control Values ......................................13

Manual 2100-665D

Page 2 of 26

Figure 14 Wall-Mount Unit Cooling Staging ............13

Figure 15 Adjusting Cooling Differential Values ......14

Figure 16 Adjusting Heating Differential Values ......14

Figure 17 Wall-Mount Unit Heating Staging ...........14

Figure 18 Economizer A4 Screen ..........................15

Figure 19 Economizer A5 Screen ..........................15

Figure 20 Adjusting Damper Modulation Value .......16

Figure 21 Dehumidification Control .......................17

Figure 22 Wall-Mount Unit Control Board ..............17

Figure 23 Fan Blade Setting .................................21

Figure 24 Motor Connections ................................25

Figure 25 Motor Connections ................................26

Table 1 Wall-Mount Unit Status Messages ............7

Table 2 LC1000/TEC-EYE Passwords (Defaults) ....8

Table 3 Wall-Mount Unit Alarm Index .................10

Table 4 Cooling Pressures .................................19

Table 5A Optional Accessories – Right Hand .........22

Table 5B Optional Accessories – Left Hand ...........23

GENERAL INFORMATION

Free Cooling Unit System

The Bard Free Cooling Unit system is composed of

MULTI-TEC wall-mounted air conditioners matched

with an LC6000 supervisory controller or Bard thTune stand-alone controller. If only one wall-mounted

air conditioner is being used, it can be matched with

either the LC6000 supervisory controller or a th-Tune

stand-alone controller. If more than one wall-mount

unit is installed, the LC6000 controller must be

matched with the air conditioning units. The wall

mounts are specifically engineered for telecom/motor

control center rooms.

NOTE: The LC6000 supervisory controller and MULTI-

TEC wall-mount units are designed specifically

to work together. The controller cannot

run other brands of systems, nor can other

controllers run the MULTI-TEC wall-mount

units. They are a complete system, and must

be used together.

Wall-Mount Air Conditioner Units

The MULTI-TEC units operate

rated cooling airflow in free cooling mode with ability

to exhaust the same amount through the unit itself

without any additional relief openings in the shelter. In

the event that freecooling operation cannot satisfy the

load requirements, mechanical cooling will be utilized

to assist in cooling the shelter.

will supply 100% of

MULTI-TEC units are available with electric heat and

dehumidification options.

General

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly any tags

and/or labels attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See ADDITIONAL PUBLICATIONS on page 4

for information on codes and standards.

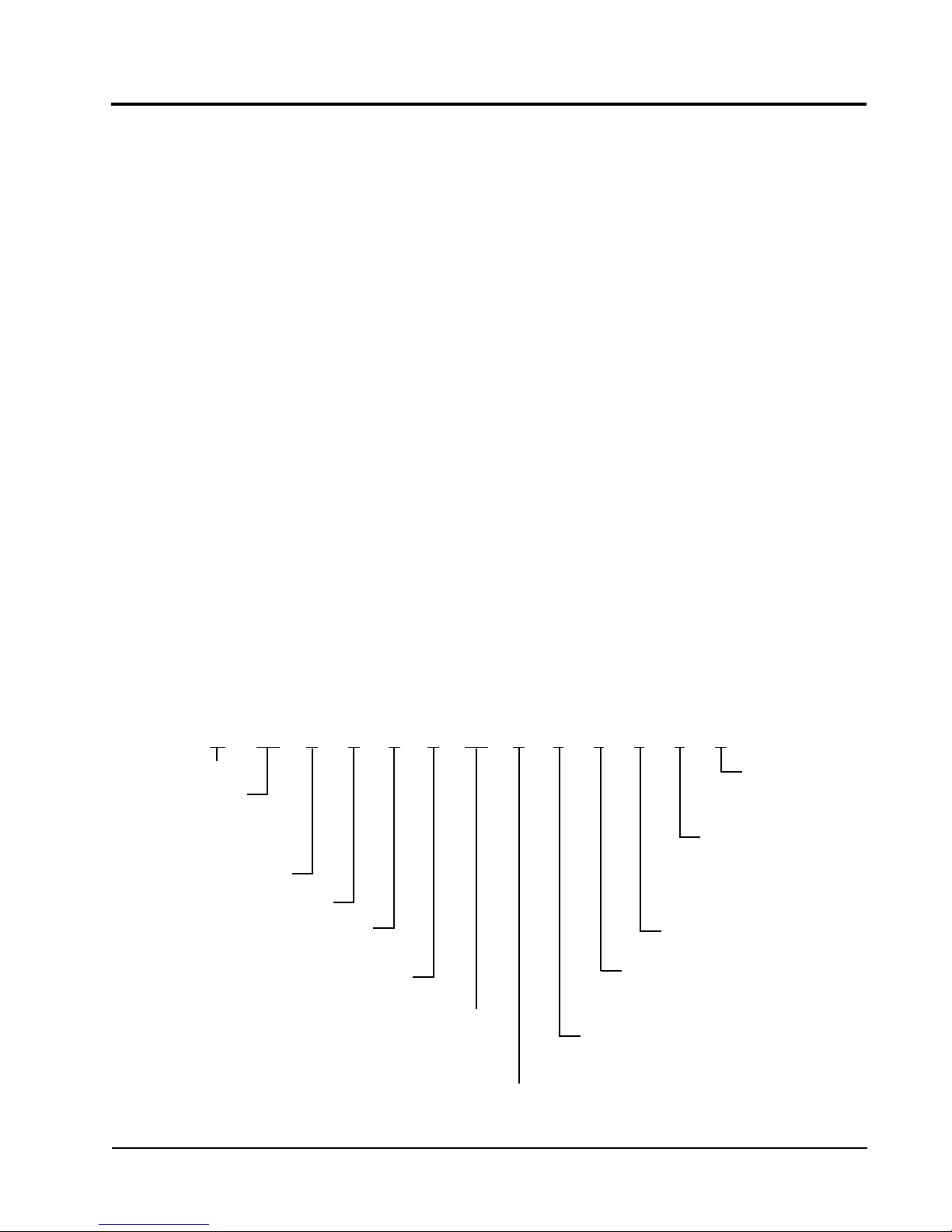

MULTI-TEC Wall-Mount Unit Model Nomenclature

W 36 A A P A 10 5 X X X X E

MODEL SERIES

CAPACITY

18 – 1½ Ton

24 – 2 Ton

30 – 2½ Ton

36 – 3 Ton

M – PLC Logic Board w/Mechanical Dehumidification

Reference Supplemental Instructions

42 – 3½ Ton

48 – 4 Ton

60 – 5 Ton

72 – 6 Ton

A – Right Hand

L – Left Hand

P – PLC Logic Board

E – PLC Logic Board w/Electric Reheat

A – 230/208/60/1

B – 230/208/60/3

C – 460/60/3

D – 240/220/50/1

7960-801 for complete details.

REVISION

VOLTS & PHASE

E – 240/220/50/3

or 220/200/50/3

F – 415/380/50/3

Q – 575/60/3

FIGURE 1

KW

VENTILATION OPTIONS

B – Blank-off Plate

5 – Economizer

CONTROL MODULES

E – Low Ambient Control

C – Low Ambient Control

& Crank Case Heater

COIL OPTIONS

X – Standard

1 – Phenolic Coated Evaporator

2 – Phenolic Coated Condenser

3 – Phenolic Coated Evaporator

and Condenser

SUPPLY AIR OUTLET

X – Front (Standard)

COLOR OPTIONS

X – Beige (Standard)

1 – White

4 – Buckeye Gray

FILTER OPTIONS

X – 1" Throwaway (Standard)

W – 1" Washable

P – 2" Pleated (MERV 8)

Manual 2100-665D

Page 3 of 26

Sizing of systems for proposed installation should be

based on heat loss and heat gain calculations made

according to methods of Air Conditioning Contractors

of America (ACCA). The air duct should be installed

in accordance with the Standards of the National

Fire Protection Association for the Installation of Air

Conditioning and Ventilating Systems of Other Than

Residence Type, NFPA No. 90A, and Residence Type

Warm Air Heating and Air Conditioning Systems, NFPA

No. 90B. Where local regulations are at a variance with

instructions, installer should adhere to local codes.

Shipping Damage

Upon receipt of equipment, the cartons should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

These units must remain in upright position at all times.

Additional Publications

These publications can help when installing the

furnace. They can usually be found at the local library

or purchased directly from the publisher. Be sure to

consult the current edition of each standard.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation of Air Conditioning

and Ventilating Systems ...................ANSI/NFPA 90A

Standard for Warm Air Heating

and Air Conditioning Systems ............ANSI/NFPA 90B

Load Calculation for Residential Winter

and Summer Air Conditioning ............. ACCA Manual J

Duct Design for Residential Winter and Summer

Air Conditioning and Equipment Selection

....................................................... ACCA Manual D

For more information, contact these publishers:

Air Conditioning Contractors of America (ACCA)

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370 Fax: (202) 234-4721

American National Standards Institute (ANSI)

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900 Fax: (212) 302-1286

American Society of Heating, Refrigeration and Air

Conditioning Engineers, Inc. (ASHRAE)

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400 Fax: (404) 321-5478

National Fire Protection Association (NFPA)

Batterymarch Park

P. O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555 Fax: (617) 984-7057

ANSI Z535.5 Definitions:

DANGER: Indicate[s] a hazardous situation which, if

not avoided, will result in death or serious injury. The

signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

WARNING: Indicate[s] a hazardous situation which,

if not avoided, could result in death or serious injury.

WARNING [signs] should not be used for property

damage hazards unless personal injury risk appropriate

to this level is also involved.

CAUTION: Indicate[s] a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION [signs] without a safety alert symbol may be

used to alert against unsafe practices that can result in

property damage only.

NOTICE: [this header is] preferred to address practices

not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an

alternative to “NOTICE” the word “CAUTION” without

the safety alert symbol may be used to indicate a

message not related to personal injury.

Manual 2100-665D

Page 4 of 26

!

WARNING

Electrical shock hazard.

Have a properly trained individual perform

these tasks.

Failure to do so could result in electric shock

or death.

!

WARNING

Fire hazard.

Maintain minimum 1/4" clearance between the

supply air duct and combustible materials in

the rst 3' feet of ducting.

Failure to do so could result in re causing

damage, injury or death.

!

WARNING

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

!

CAUTION

Cut hazard.

Wear gloves to avoid contact with sharp

edges.

Failure to do so could result in personal injury.

Manual 2100-665D

Page 5 of 26

USING THE TEC-EYE

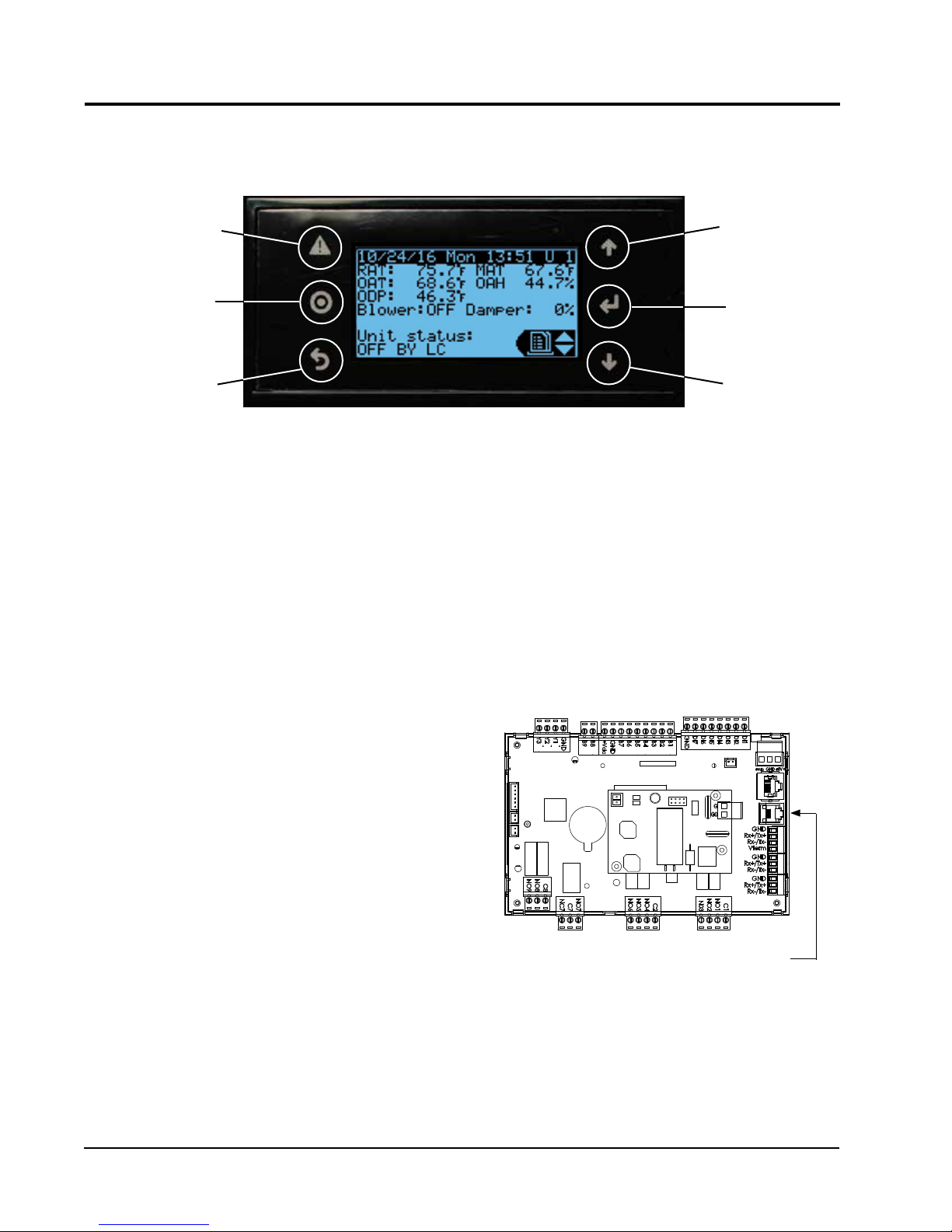

TEC-EYE (Bard P/N 8301-059) Display and Interface (Status Screen Shown)

TM

FIGURE 2

ALARM KEY

MENU KEY

ESCAPE KEY

ALARM KEY

Allows viewing of active alarms

Silences audible alarms

Resets active alarms

MENU KEY

Allows entry to Main Menu

ESCAPE KEY

Returns to previous menu level

Cancels a changed entry

TEC-EYE Hand-Held Diagnostic Tool

The microprocessor control used in the MULTI-TEC

wall-mount air conditioners allows for complete control

and monitoring through the use of the provided TECEYE hand-held monitor. This comprehensive service

tool utilizes the latest in state-of-the-art technology

including a large, easy-to-read backlit LCD graphic

display.

The menu driven interface provides users the ability

to scroll through two menu levels: Quick Menu and

Main Menu. The menus permit the user to easily view,

control and configure the unit.

The controller is completely programmed at the factory;

the default setpoints and their ranges are easily viewed

and adjusted from the TEC-EYE display. The program

and operating parameters are permanently stored

on FLASH-MEMORY in case of power failure. The

controller is designed to manage temperature levels to

a user-defined setpoint via control output signals to the

wall mount air conditioning system.

The TEC-EYE connects to the wall-mount unit control

board via an RJ11 modular phone connector as shown

in Figure 3.

UP KEY

ENTER KEY

DOWN KEY

UP KEY

Steps to next screen in the display menu

Changes (increases) the value of a modifiable field

ENTER KEY

Accepts current value of a modifiable field

Advances cursor

DOWN KEY

Steps back to previous screen in the display menu

Changes (decreases) the value of a modifiable field

FIGURE 3

TEC-EYE Connection to Unit Control

Modular Phone Connector for

TEC-EYE Hand-Held Diagnostic Tool

When not being used, the TEC-EYE hand-held

diagnostic tool should be stored inside or near the

LC6000 controller. Do not let the TEC-EYE leave the

shelter.

Manual 2100-665D

Page 6 of 26

TEC-EYE Menu Structure

Quick Menu

Data Log

Unit Information

Setpoints

Main Menu

System Configuration

Advanced System Configuration

I/O Configuration

On/Off

Alarm Logs

Settings

Logout

In addition to the menu structure above, there are also

Status and Alarm screens.

TEC-EYE Acronyms

MAT – Mixed air temperature

RAT – Return air temperature

OAT – Outdoor air temperature

OAH – Outdoor air humidity

Blower – Indoor Blower Status

Damper – Free cooling damper position status

C1 – Compressor activate status

H1 – Heater Stage 1 status

H2 – Heater Stage 2 status

ODP – Calculated outdoor dew point

FC – Free cooling status

RN – Component run time in minutes in last hour

ST – Number of start requests in last hour

Status Screen

The Status screen is the default start-up screen and

also the return screen after 5 minutes of no activity.

The screen can be accessed any time by pressing the

ESCAPE button repeatedly.

The wall-mount unit address is displayed in the upper

right corner on the Status screen (see Figure 2). The

Status screen also shows the current date, time, return

air temperature, mixed air temperature, outdoor air

temperature, outdoor humidity and outdoor dewpoint

conditions. Blower, damper and unit status are also

displayed. See Table 1 for MULTI-TEC wall-mount unit

status messages.

The Quick Menu is displayed in the bottom right corner

of the status screen (see Figure 2). Data Log, Unit

Information and Setpoints are available through the

Quick Menu. Pressing the UP or DOWN keys while on

the Status screen will change the Quick Menu icon

displayed (see Figure 4). Press the ENTER key when

the desired icon is displayed.

TABLE 1

Wall-Mount Unit Status Messages

Message Description

Stand Alone Orphan Mode Standby

th-TUNE Online th-TUNE Standby

LC Online LC Standby

Cont. Blower Continuous Blower Active

Off by th-TUNE Unit off by th-TUNE

Freecooling Freecooling Active

Optimized Cool Optimized Cooling Active

Cooling Cooling Active

Heating Heating Active

Mechanical Dehumidification or

Active Dehum

Passive Dehum

Self Test Self Test Running

Off by Alarm Unit Off by Alarm Condition

Off by BMS Unit Off by BMS

Off by LC Unit Off by LC Master

Off by Keypad Unit Off by Keypad

Emergency Vent. Emergency Vent Mode Active

Emergency Cool Emergency Cool Mode Active

Emergency Off Emergency Off Mode Active

Electric Reheat Dehumidification

Active

Economizer Disable/Enhanced

Latent Removal (if available)

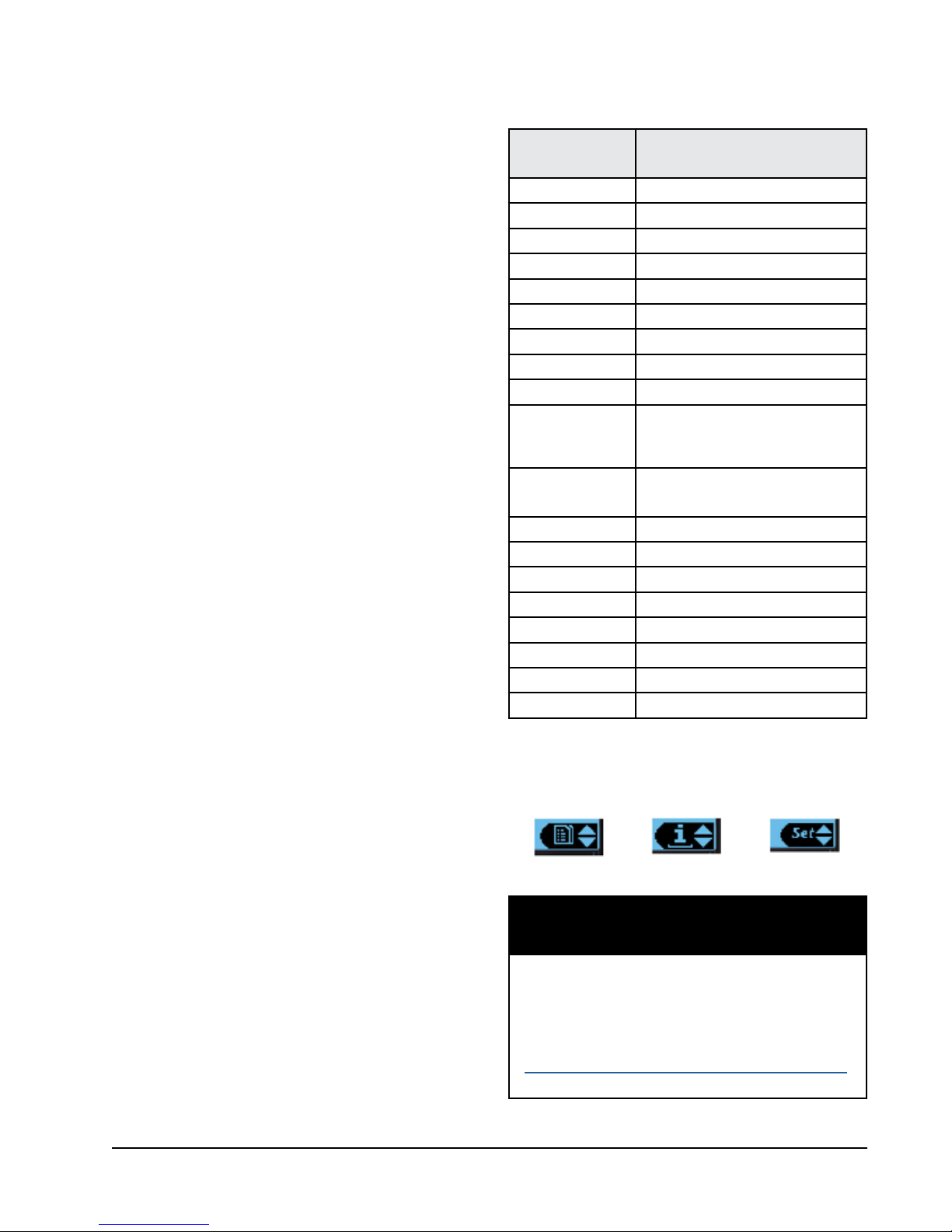

FIGURE 4

Quick Menu Icons

Data Log Unit Information

Setpoints

NOTICE

It is important to check the software version

during installation to ensure that the latest

version has been installed. Current software

versions, change log and installation

instructions are available on the Bard website at

http://www.bardhvac.com/software-download/

Manual 2100-665D

Page 7 of 26

Quick Menu

Setpoints

If at any time the unit(s) loses communication with the

LC6000 controller, the unit(s) will go to stand alone

mode. The setpoints are synced with the LC6000 when

communication is established. The unit will save and

control to these values until communication is reestablished.

To change the cooling and heating setpoints:

1. From the Status screen, press UP or DOWN key

until Quick Menu displays Setpoints icon. Press

ENTER key.

2. Press ENTER key to scroll to the selected choice

(see Figure 5).

3. Press UP or DOWN key on desired value until value

displays correctly.

4. Press ENTER key to submit value and move to next

parameter.

5. Press ESCAPE key until Main Menu screen is

displayed.

FIGURE 5

Cooling and Heating Setpoints

Information

These screens show unit demand, wall-mount unit

status, serial/model number, hours, run hours, averages

and software version information.

Data (Alarm) Log

The alarm log screens show a log of each alarm (see

Figure 6. There will be a log for when alarm occurred

and if the alarm auto clears, it will show when the

alarm cleared. See page 11 for instructions on clearing

the alarm logs.

NOTE

Screenshots shown in this manual reflect

default settings (when applicable).

FIGURE 6

Alarm Log Screen Breakdown

Alarm Log Number

Alarm Date/Time

Alarm Index

Number

Alarm Description

Alarm Event Type

(Start/Stop)

TABLE 2

LC1000/TEC-EYE Passwords (Defaults)

User 2000

Technician 1313

Engineer 9254

Use UP or DOWN keys and ENTER key to enter password

Menu Screens and Password Levels

A System Config: User (2000)

B Adv Sys Config: Technician (1313)

C I-O Config: Technician (1313)

D On/Off: User (2000)

E Alarm Logs: User (2000)

F Settings

Date/Time: Technician (1313)

Language: User (2000)

Network Config: Technician (1313)

Serial Ports: Technician (1313)

Initialization

Clear Logs: User (2000)

System Default: Engineer (9254)

Restart: User (2000)

Parameter Config: Engineer (9254)

Alarm Export: User (2000)

G Logout: Used to log out of the current password

level. Entering back into the menu requires

password.

Additional Features

Model/Serial Number Retain Feature

Model numbers and serial numbers will be retained

through most software updates. It still remains good

practice to verify the software version, model numbers

and serial numbers of any wall-mount unit after a

software update, as some functionality of the MULTITEC wall-mount unit require a specific model number.

Manual 2100-665D

Page 8 of 26

Loading...

Loading...