Bard W24G2DB, W36G2DB, W30G2DC, W36G2DA, W24G2DC Installation Instructions Manual

...

INSTALLATION INSTRUCTIONS

WG SERIES WALL MOUNTED GAS/ELECTRIC

WITH DEHUMIDIFICATION

Models:

W24G2DA

W24G2DB

W24G2DC

W30G2DA

W30G2DB

W30G2DC

W36G2DA

W36G2DB

W36G2DC

W42G2DA

W42G2DB

W42G2DC

WARNING

READ ALL INSTRUCTIONS CAREFULLY BEFORE

BEGINNING THE INSTALLATION.

THE INSTALLATION MUST COMPLY WITH THESE

INSTRUCTIONS AND THE REQUIREMENTS OF

ALL GOVERNING CODES AND ORDINANCES FOR

THE INSTALLATION LOCATION.

IT IS THE RESPONSIBILITY OF INSTALLER

TO KNOW AND UNDERSTAND ALL OF THESE

REQUIREMENTS.

W48G2DA

W48G2DB

W48G2DC

W60G2DA

W60G2DB

W60G2DC

FAILURE TO DO SO COULD CREATE A HAZARD

RESULTING IN PROPERTY DAMAGE, BODILY

INJURY, OR DEATH.

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual No.: 2100-592C

Supersedes: 2100-592B

Date: 5-4-15

Page 1 of 69

CONTENTS

Page

Getting Other Information and Publications ... 4

Wall Mount Gas/Electric General Information

W**G Series Model Nomenclature ..................... 5

Ventilation Options .......................................... 5

Air Conditioning Module Options ....................... 6

1. Important ....................................................... 6

2. Application ..................................................... 6

3. Duct Work ....................................................... 6

4. High Altitude Applications .............................. 10

5. Transportation Damage ................................... 10

6. General Information ....................................... 10

7. Wall Mounting Information ............................. 11

8. Mounting the Unit ......................................... 11

9. Clearances .................................................... 17

10. Vent Terminal and Combustion Inlet Hood ........ 18

11. Optional Vertical Venting ................................ 18

12. Vent Resizing Instructions .............................. 19

13. Fresh Air Intake ............................................. 19

14. Condensate Drain .......................................... 19

15. Wiring – Main Power ...................................... 20

16. Wiring – Low Voltage Wiring ............................ 21

17. Thermostats .................................................. 22

18. Gas Supply and Piping ................................... 27

19. Manifold Pressure Adjustment ........................ 28

20. Checking Gas Input Rate ................................ 28

.. 5

Page

21. Standard Orifice Sizing and High

Altitude Derate .............................................. 30

22. Conversion of Gas Input BTUH from High

to Low Rating ................................................ 33

23. Measuring Air Temperature Rise ...................... 33

24. Filters .......................................................... 34

25. Compressor Control Module ............................ 34

26. Phase Monitor ............................................... 35

27. Lighting and Shutdown Instructions ................ 36

28. Service Agency Procedures ............................. 37

29. Maintaining Unit in Good Working Order .......... 37

30. Replacement Parts ........................................ 38

31. Sequence of Operation – Heating .................... 39

32. Sequence of Operation – Cooling..................... 39

33. Indoor Blower Operation ................................. 41

34. W**G Dehumidification Relay Logic Board ....... 49

35. Pressure Service Ports ................................... 50

36. Dehumidification Circuit ................................ 50

37. Refrigerant Charge ......................................... 51

38. Fan Blade Setting Dimensions ........................ 52

39. Low NOx Burner Assembly "N" Suffix

Models Only – U.S. Installations Only .............. 52

Index – Wiring Diagrams and Ladder Diagrams ....... 53

Wiring Diagrams and Ladder Diagrams ................... 54

Manual 2100-592C

Page 2 of 69

Page

FIGURES

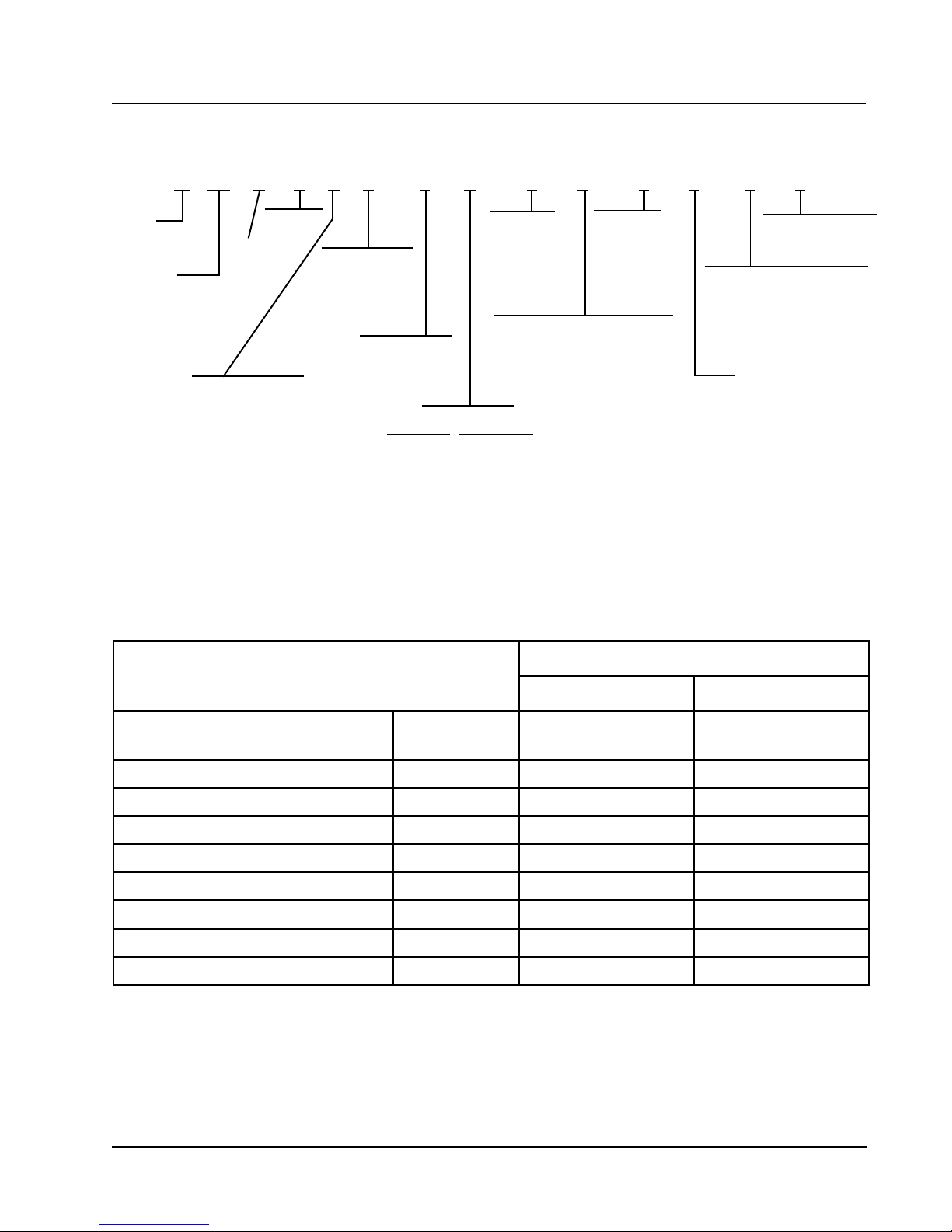

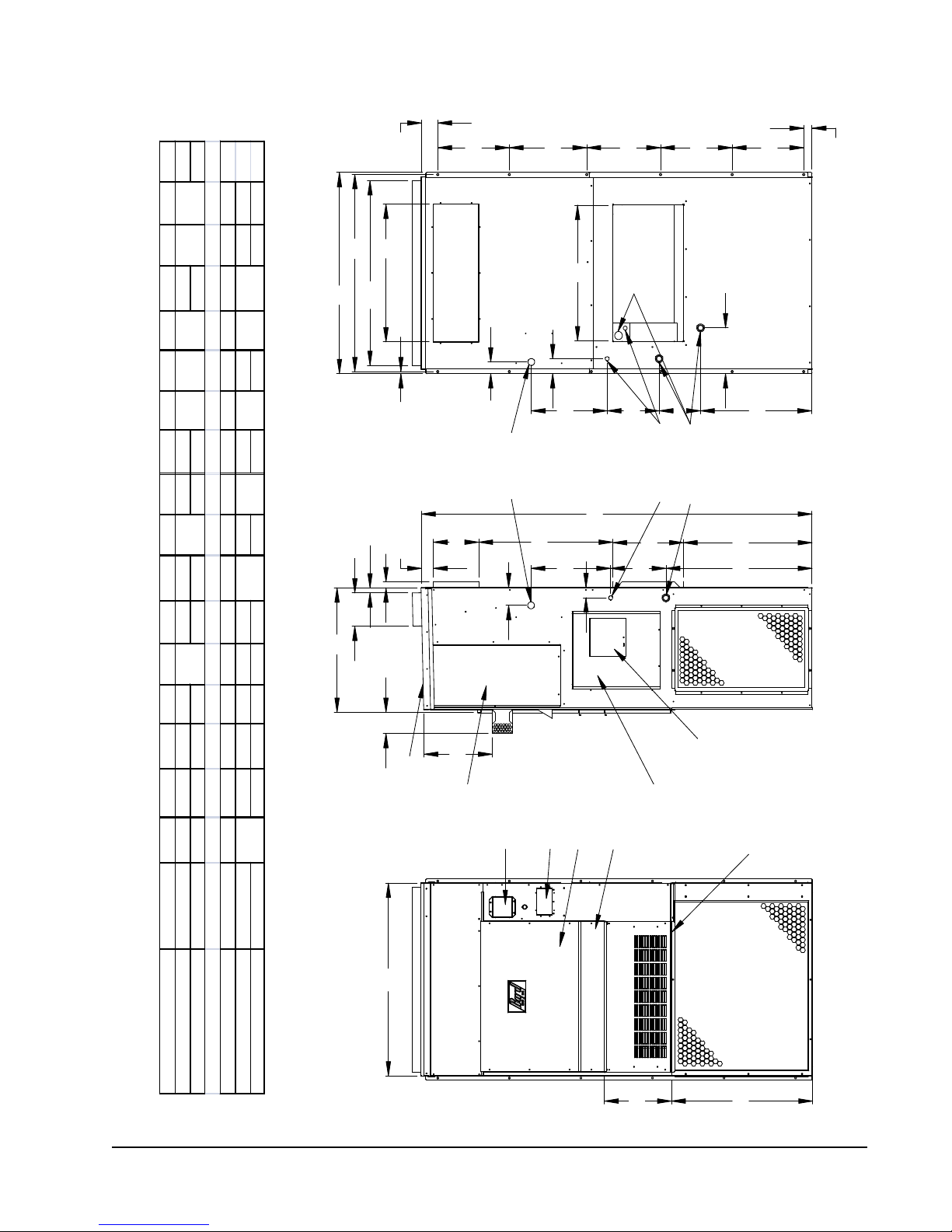

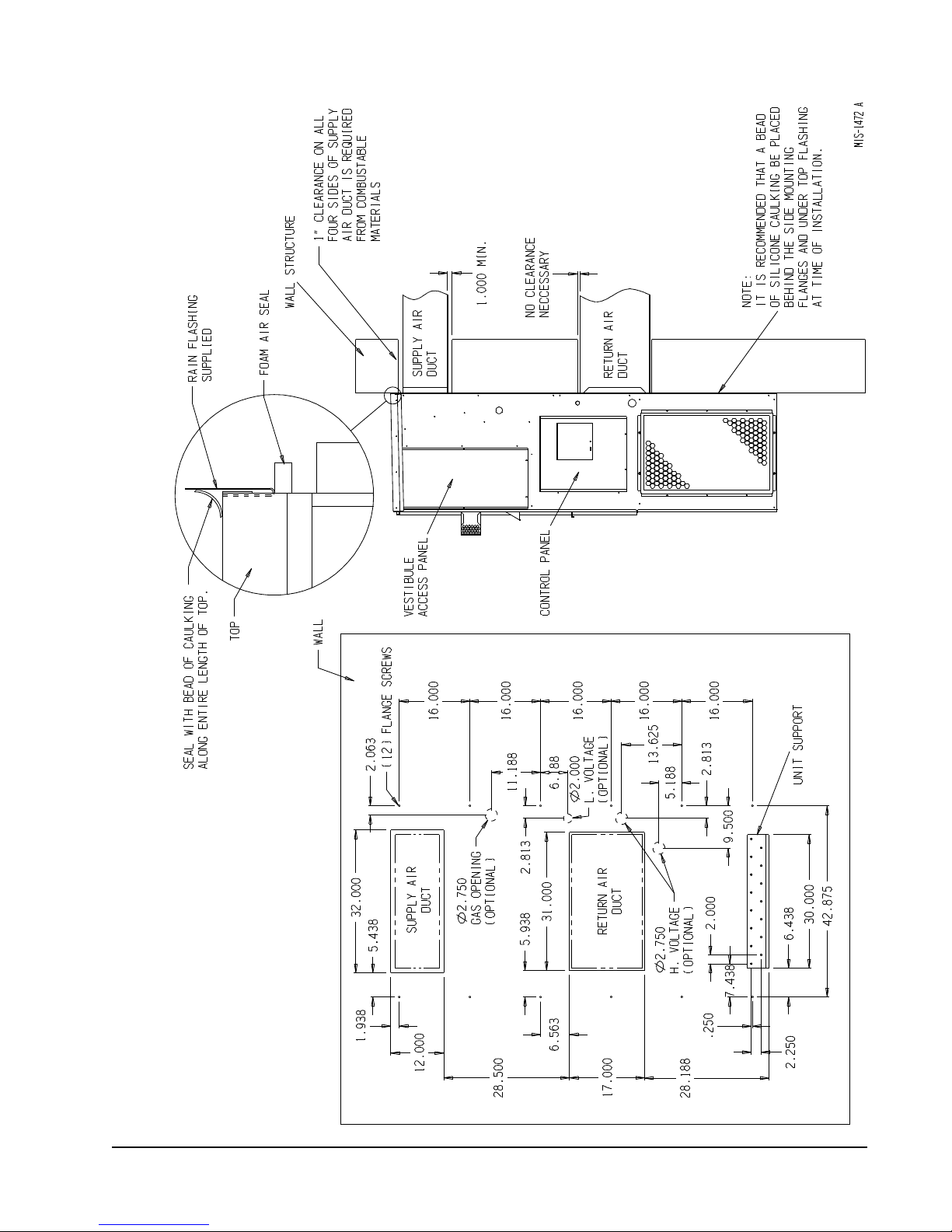

Figure 1 Unit Dimensions .................................. 9

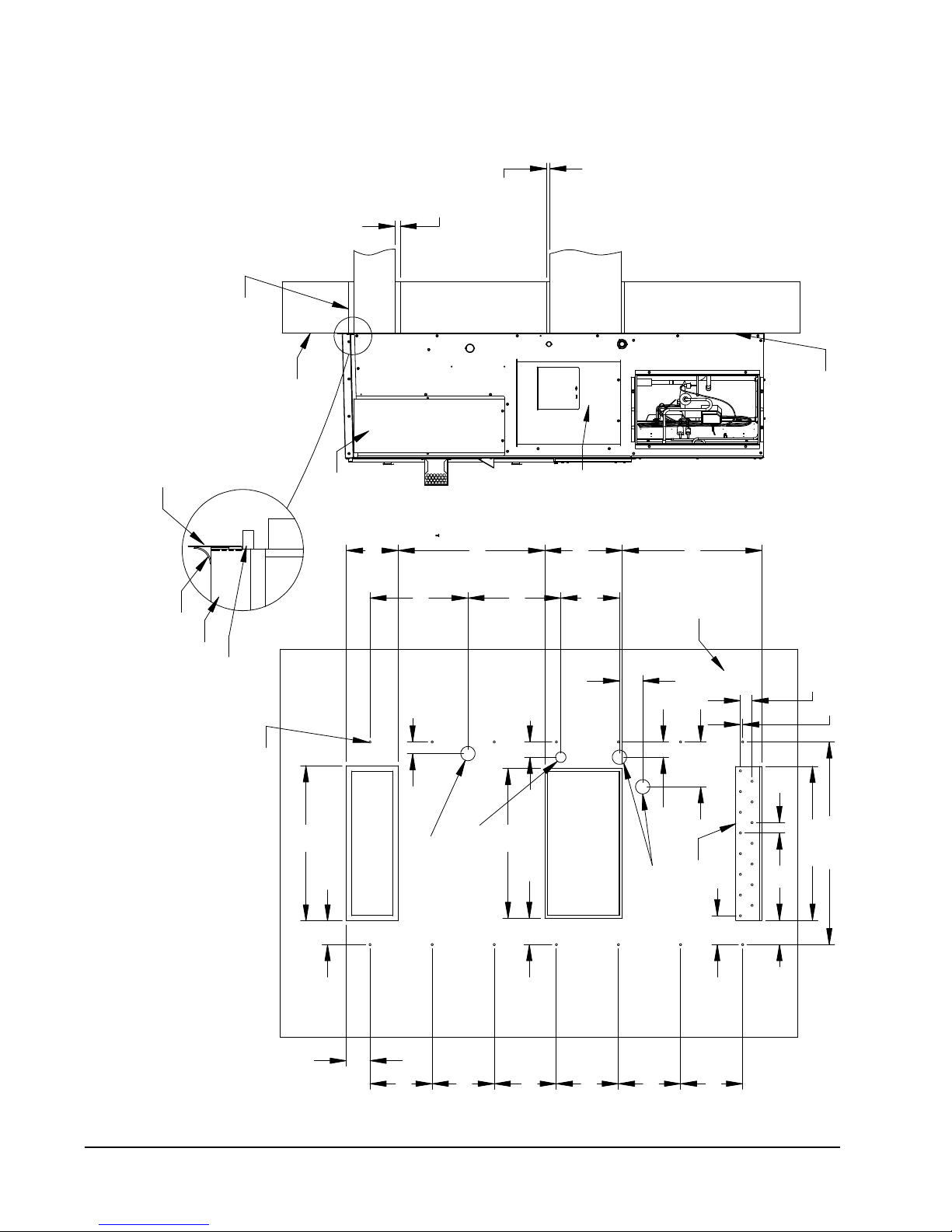

Figure 2 Mounting Instructions – W24G-36G ..... 12

Figure 2A Mounting Instructions – W42G-60G ..... 13

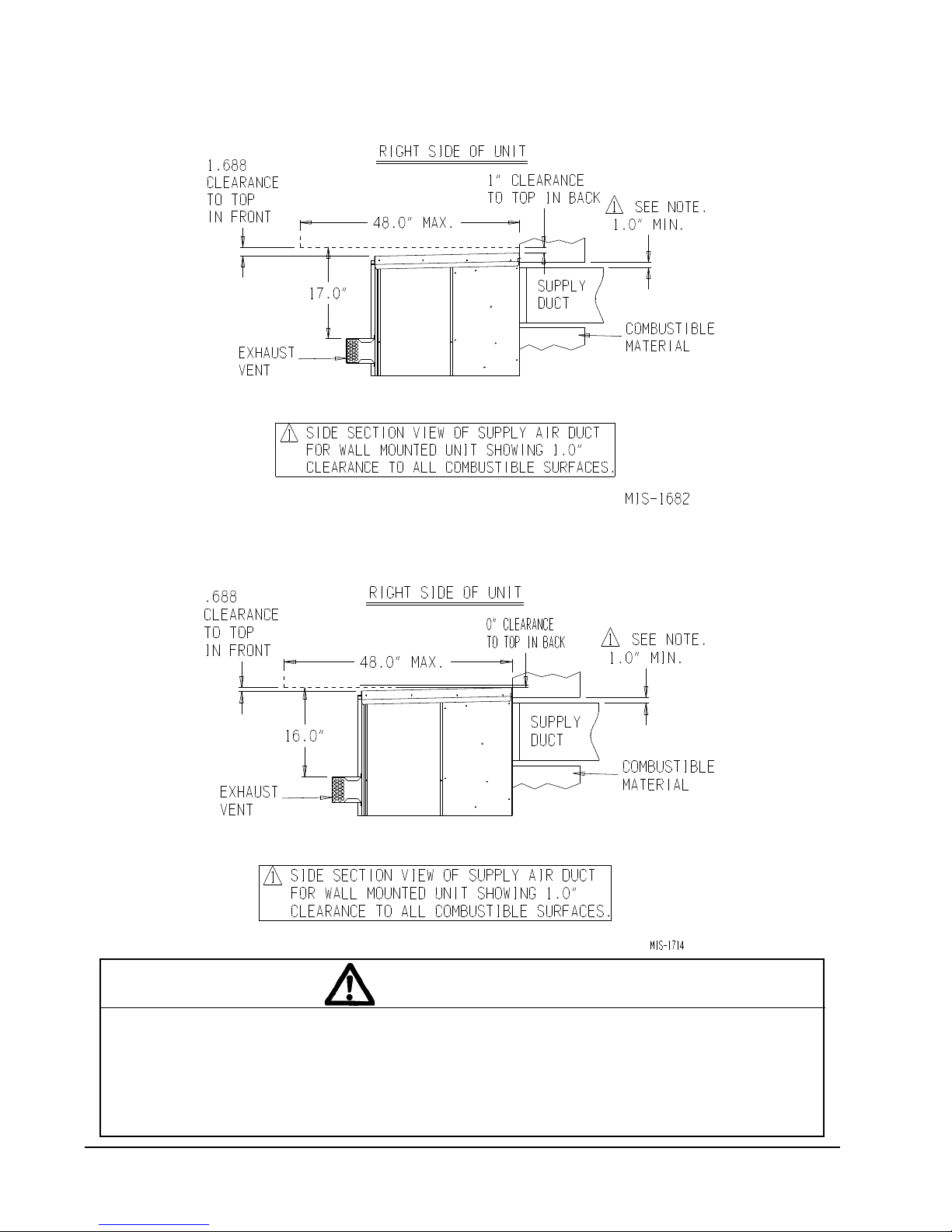

Figure 3 Combustible Clearance – W24G-36G ... 14

Figure 3A Combustible Clearance – W42G-60G.... 14

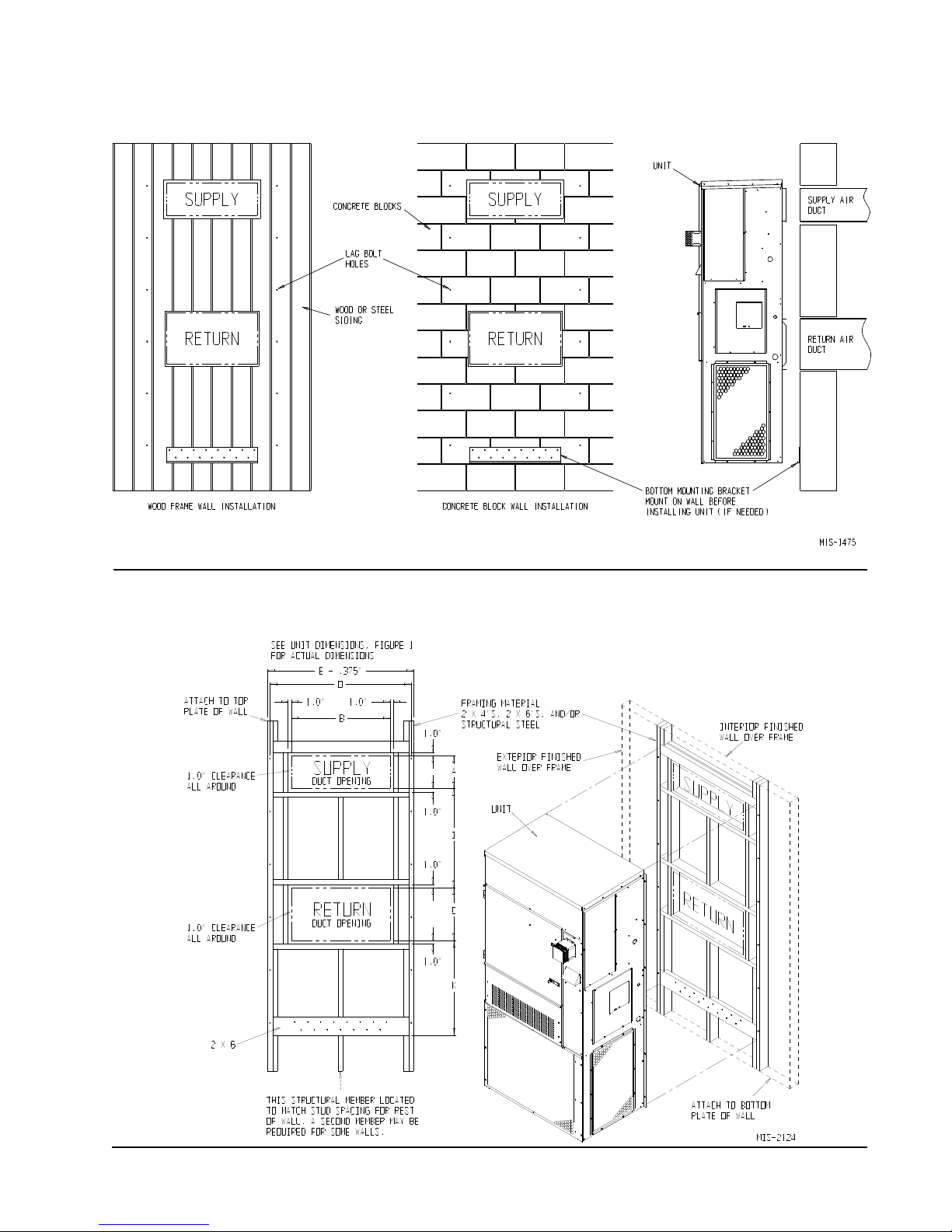

Figure 4 Wall Mounting Instructions .................. 15

Figure 5 Wall Mounting Instructions .................. 15

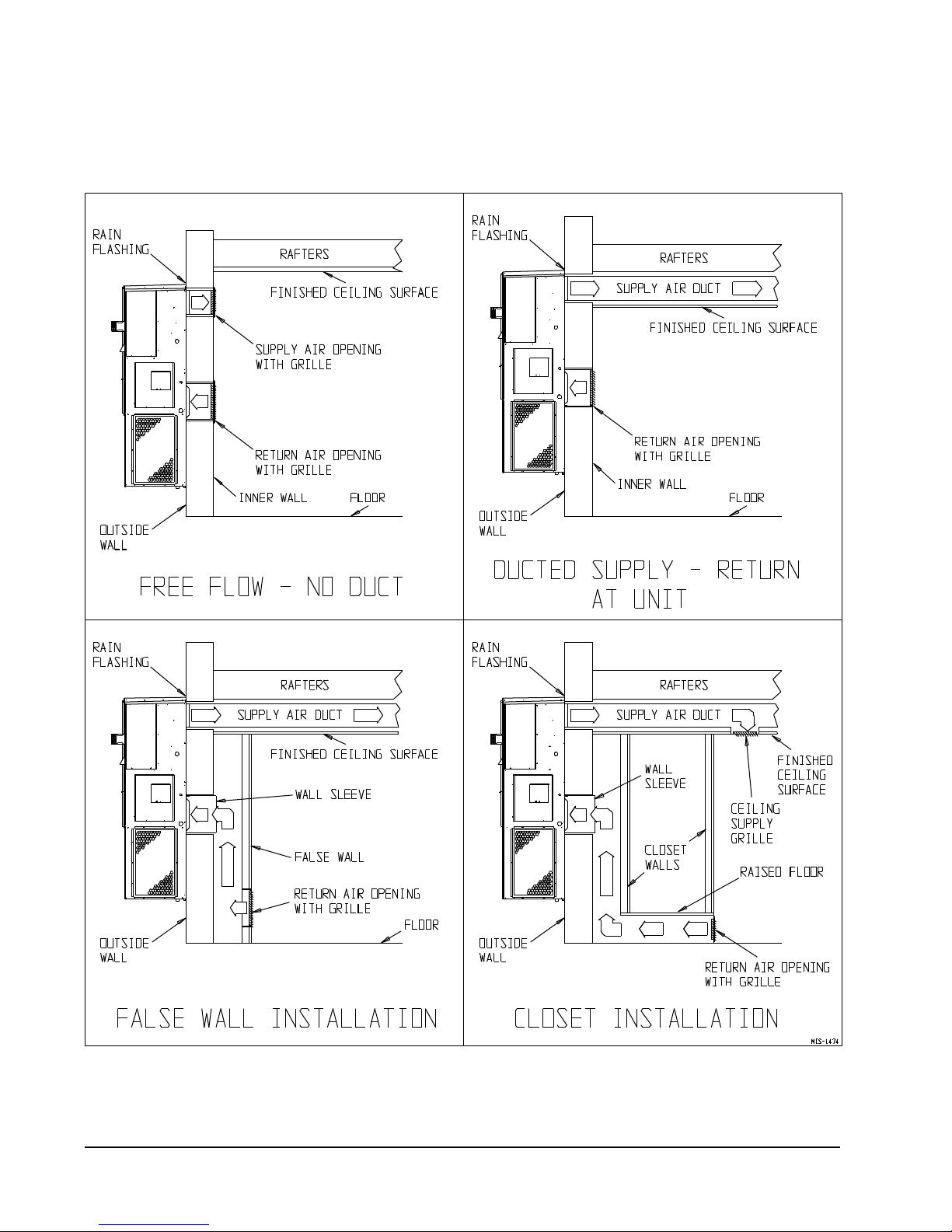

Figure 6 Common Wall Mounting Installations .... 16

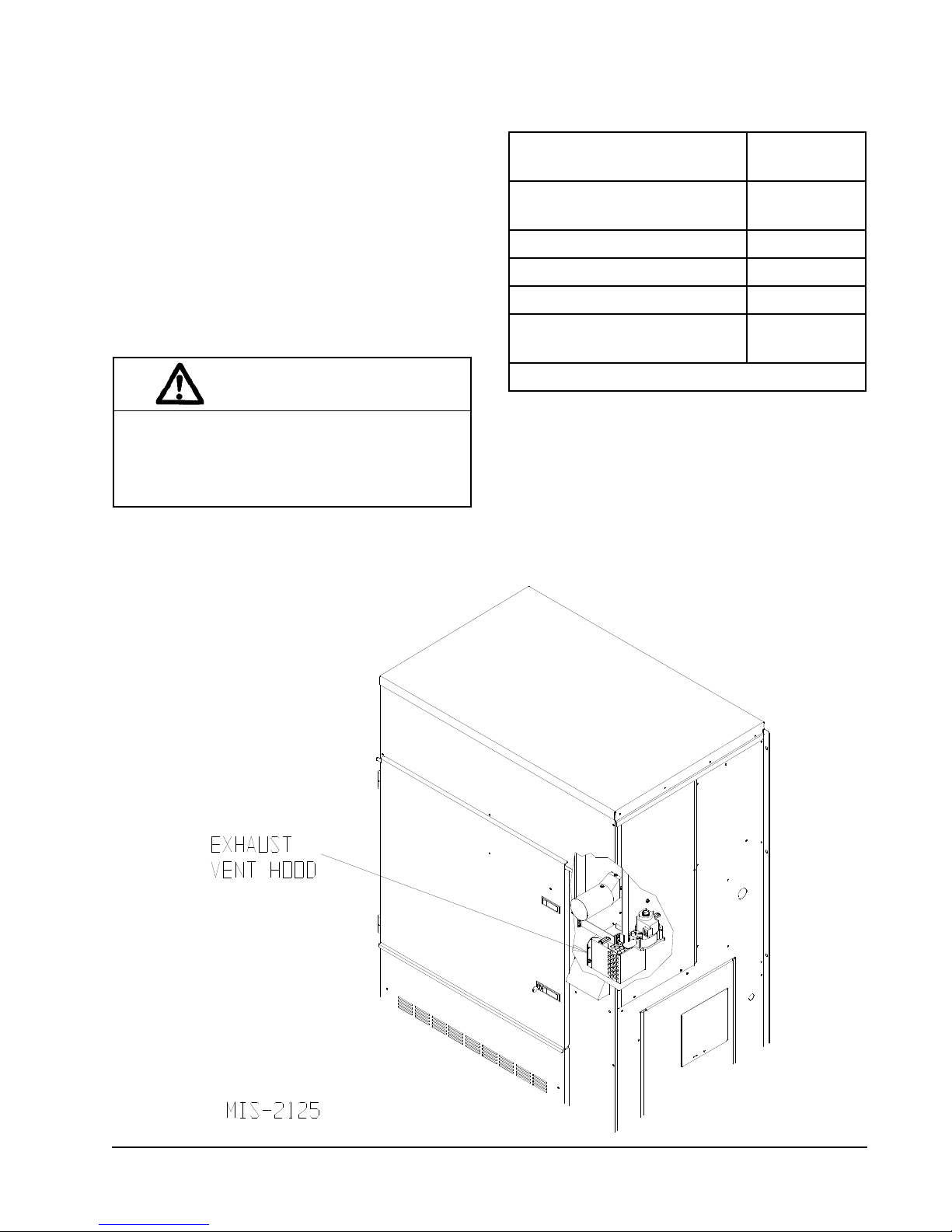

Figure 7 Location of Vent Terminal in Shipping .. 17

Figure 8 Vent Terminal and Combustion

Air Intake .......................................... 18

Figure 9 Fresh Air Damper ............................... 19

Figure 10 Installation of Flexible Conduit ............ 21

Figure 11A Thermostat Connection using

Combination Temperature and

Humidity Controller ............................ 23

Figure 11B Thermostat Using Separate

Temperature and Humidity Controllers .. 24

Figure 11C MFAD, Classroom Ventilation Spring

and Power and ERV Low Voltage

Connections ....................................... 25

Figure 11D Economizer Low Voltage Connections ... 25

Figure 12 Gas Pipe Connection ........................... 26

Figure 13 Proper Piping Practice ........................ 27

Figure 14 Access Internal Filter Through

Upper Service Door ............................. 34

Figure 15 Lighting and Shutdown Instruction

Label ................................................ 36

Figure 16 Top View of Gas Control ...................... 37

Figure 17 Sequence of Operation – Electronic

Blower Control ................................... 40

Figure 18 Furnace Control Board and

Blower Control ................................... 41

Figure 19 Circuit Diagrams ................................ 50

Figure 20 Fan Blade .......................................... 52

Figure 21 Low NOx Insert .................................. 52

Page

TABLES

Table 1 Specifications – W24G-36G Models ......... 7

Table 1A Specifications – W42G-60G Models ......... 8

Table 2 Minimum Installation Clearances ........... 17

Table 3 Thermostat Wire Size ............................22

Table 4A Wall Thermostat ................................... 22

Table 4B Humidistat ..........................................22

Table 5 Length of Standard Pipe Threads ........... 27

Table 6 Gas Pipe Sizes – Natural Gas ................ 27

Table 7 Natural Gas Derate Capacities

for All Models ...................................... 30

Table 8 Natural Gas Orifice Tables – W24G-36G ... 31

Table 8A Natural Gas Orifice Tables – W42G-60G . 32

Table 9 Motor Speed Taps ................................ 41

Table 10 W24G Indoor Blower Performance .........42

Table 11 W30G Indoor Blower Performance .........43

Table 12 W36G Indoor Blower Performance .........44

Table 13 W42G Indoor Blower Performance ........45

Table 14 W48G Indoor Blower Performance .........46

Table 15 W60G Indoor Blower Performance .........47

Table 16 Integrated Furnace and Blower

Control Operation ................................. 48

Table 17 Dehumidification Relay Logic Board ....... 49

Table 18 Refrigerant Charge-Pressure Tables ........ 51

Table 19 Fan Blade Dimension ...........................52

Manual 2100-592C

Page 3 of 69

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help when installing the

furnace. They can usually be found at the local library

or purchased directly from the publisher. Be sure to

consult the current edition of each standard.

National Fuel Gas Code ............ANSI Z223.1/NFPA 54

National Electrical Code .......................ANSI/NFPA 70

Standard for the Installation ..............ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air ...................... ANSI/NFPA 90B

Heating and Air Conditioning Systems

Standard for Chimneys, ............................. NFPA 211

Fireplaces, Vents, and Solid Fuel Burning Appliances

Load Calculation for ........................... ACCA Manual J

Residential Winter and Summer Air Conditioning

Duct Design for Residential .............. ACCA Manual D

Winter and Winter Air Conditioning and Equipment

Selection

Canadian Electrical Code ...........................CSA C22.1

For more information, contact these

publishers:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue, NW

Washington, DC 20009

Telephone: (202) 483-9370

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, NE.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

CSA Canadian Standards Association

178 Rexdale Boulevard

Rexdale, Ontario

Canada. M9W 1R3

Telephone: (416) 447-4044

Canadian Installation Code……………CAN/CGA B149

Manual 2100-592C

Page 4 of 69

BARD MANUFACTURING COMPANY, INC.

BRYAN, OHIO 43506 USA

WALL MOUNT GAS/ELECTRIC GENERAL INFORMATION

MODEL NUMBER NOMENCLATURE

W 42 G 2 D A X C X X X X X X

MODEL

Wall Mount

COOLING

CAPACITY

24 = 2 ton

30 = 2½ ton

36 = 3 ton

42 = 3½ ton

48 = 4 ton

60 = 5 ton

REVISION

GAS/ELECTRIC

FEATURE

D = Dehumidification

VENT

(See Table Below)

VOLTAGE

A = 230/208-60-1

B = 230/208-60-3

C = 460-60-3

FILTER

EMISSIONS

X = Standard

N = NOx Certified

HEATING INPUT

2 – 3 Ton

A = 45,000

B = 67,500

C = 90,000

*125,000 BTU input model is not NOx certified.

X = 2" Pleated MERV 8 (Standard)

W = 1" Washable

3½ – 5 Ton

B = 75,000

C = 100,000

D = 125,000

Ventilation Options

COLOR

X = Beige

(Standard)

4 = Buckeye Gray

8 = Dark Bronze

CONTROL OPTIONS

(See Table page 6)

COIL OPTIONS

X = Standard

1 = Phenolic coated evaporator

2 = Phenolic coated condenser

3 = Phenolic coated both coils

OUTLET

X = Front (Standard)

T = Top

Models

W24G, W30G, W36G W42G, W48G, W60G

Description

Factory Installed

Code No.

Field Installed

Part No.

Field Installed

Part No.

Barometric Fresh Air Damper X WGBFAD-3 WGBFAD-5

Blank-Off Plate B WGBOP-3 WGBOP-5

Motorized Fresh Air Damper M WGMFAD-3A WGMFAD-5A

Commercial Ventilator – Spring Return V WGCRVS-3A WGCRVS-5A

Commercial Ventilator – Power Return P WGCRVP-3A WGCRVP-5A

Economizer – Fully Modulating

E WGEIFM-3C WGEIFM-5C

Energy Recovery Ventilator – 230 Volt R WGERV-A3B WGERV-A5B

Energy Recovery Ventilator – 460 Volt R WGERV-C3B WGERV-C5B

Low ambient control is required with economizer for low temperature compressor operation.

Manual 2100-592C

Page 5 of 69

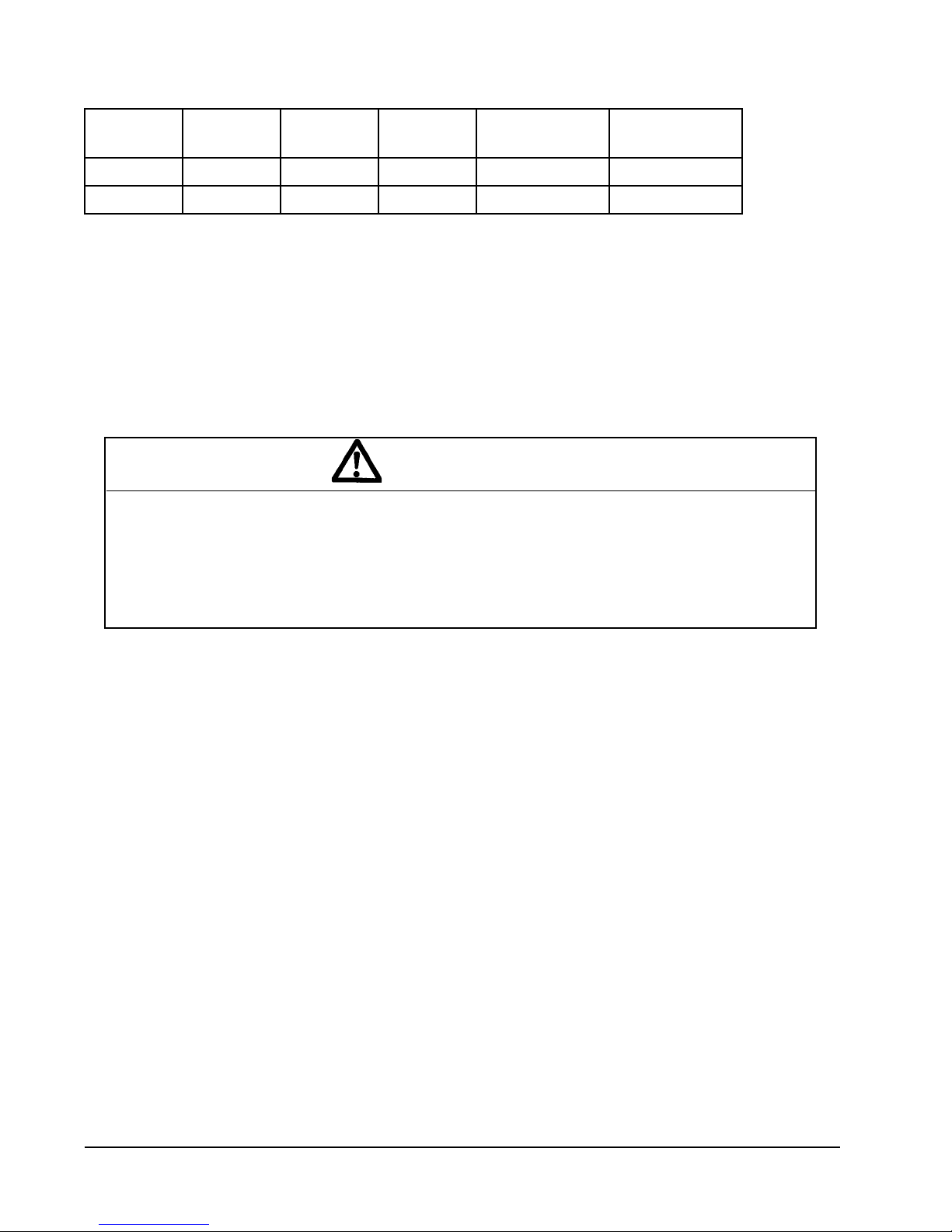

Air Conditioning Module Options

CCM

STD STD STD X N/A

STD STD STD • H CMA-28

STD – Standard equipment.

CCM Compressor control module has adjustable 30 second to 5 minute delay-on-break timer. On initial power up, or any

time the power is interrupted, the delay-on-make will be 2 minutes plus 10% of the delay-on-break setting. There is no

delay-on-make during routine operation of the unit. The module also provides the lockout feature (with 1 retry) for high

and/or low pressure controls, and a 2-minute timed bypass for low pressure control.

HPC High pressure control is auto reset. Always used with compressor control module (CCM) which is included. See Note

HPC

LPC

LAC

Factory-Installed

Code

Field-Installed

Part

.

LPC Low pressure control is auto reset. Always used with compressor control module (CCM) which is included. See Note

LAC Low ambient control permits cooling operation down to 0°F.

CAUTION

During the initial ring of the burners there will probably be some amount of smoke issued to the

circulating air stream as the result of residual oil burning off of the heat exchanger tubes. This oil

is required during the forming process of the stainless steel heat exchanger tubes to facilitate the

bending. OSHA or the National Toxicology Program does not list the oil as a carcinogen. In vapor

form this may be irritating to the eyes or could cause headaches. This is a one time occurrence, and

ventilation of the space may be required depending upon the space being conditioned.

.

1. IMPORTANT

The equipment covered in this manual is to be

installed by trained, experienced service and

installation technicians. All duct work or portions

thereof not in the conditioned space should be properly

insulated in order to both conserve energy and prevent

condensation or moisture damage.

2. APPLICATION

This is a fan-assisted forced air gas furnace with

electric air conditioning for outdoor installation. A

fan-assisted furnace is equipped with an integral

mechanical means to draw products of combustion

through the combustion chamber and heat exchanger.

The furnace installation must conform with local

building codes and ordinances or, in their absence,

with the National Fuel Gas Code ANSI Z223.1 or CAN/

CGA-B149.1, latest edition, and the National Electrical

Code ANSI/NFPA-7 or CSA C22.1, latest edition. It

is the personal responsibility and obligation of the

purchaser to contact a qualified installer to assure that

installation is adequate and is in conformance with

governing codes and ordinances.

3. DUCT WORK

The unit is designed for use with or without duct

work. See WARNING on Page 10. Flanges are

provided for attaching the supply and return ducts.

These instructions explain the recommended method

to install the air cooled self-contained electric air

conditioning and gas heating unit and the electrical

wiring connections and gas piping to the unit. The

refrigerant system is completely assembled and

charged. All internal wiring is complete.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

heating/cooling system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

All duct work, supply and return, must be properly

sized for the design airflow requirement of the

equipment. Air Conditioning Contractors of America

(ACCA) is an excellent guide to proper sizing.

Refer to tables later in this manual for maximum static

pressure available for duct design.

Manual 2100-592C

Page 6 of 69

TABLE 1

Specifications

W24G, W30G and W36G Models

Models W24G2DA W24G2DB W24G2DC W30G2DA W30G2DB W30G2DC W36G2DA W36G2DB W36G2DC

Operating Voltage Range 197-253 197-253 414-506 197-253 197-253 414-506 197-253 197-253 414-506

Minimum Circuit Ampacity 21 16 9 23 17 11 28 25 11

* Field Wire Size 10 10 14 8 10 14 8 8 14

Electrical Rating – 60 Hz 230/208-60-1 230/208-60-3 460-60-3 230/208-60-1 230/208-60-3 460-60-3 230/208-60-1 230/208-60-3 460-60-3

Ground Wire Size 10 12 14 10 12 14 10 10 14

** Delay Fuse Max. 30 25 15 35 25 15 45 40 15

Compressor

Compressor Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Volts 230/208 230/208 460 230/208 230/208 460 230/208 230/208 460

Rated Load Amps 9.9/10.9 6.4/7.1 3.9 11.8/12.9 7.5/8.2 4.7 15.3/16.7 13.3/14.6 5.1

Branch Circuit Selection Current 12.8 8.3 5.1 14.1 9.0 5.6 17.9 15.6 6.0

Lock Rotor Amps 64 58 28 77 71 38 112 110 44

Fan Motor – HP/RPM/SPD 1/5-1050-1 1/5-1050-1 1/5-1050-1 1/5-1050-1 1/5-1050-1 1/5-1050-1 1/5-1050-1 1/5-1050-1 1/5-1050-1

Fan Motor – Amps 1.5 1.5 0.8 1.5 1.5 0.8 1.5 1.5 0.8

Fan Motor and Compressor

Fan – DIA/CFM 20” – 1900 20” – 1900 20” – 1900 20” – 1900 20” – 1900 20” – 1900 20” – 1900 20” – 1900 20” – 1900

Blower Motor – HP/RPM/SPD 1/4-950-3 1/4-950-3 1/4-950-3 1/3-1075-3 1/3-1075-3 1/3-1075-3 1/3-1075-3 1/3-1075-3 1/3-1075-3

Blower Motor – Amps 1.8 1.8 0.8 2.2 2.2 1.1 2.2 2.2 1.1

Motor and Evaporator

CFM Cooling and E.S.P. 800 – .25 800 – .25 800 – .25 1000 – .35 1000 – .35 1000 – .35 1100 – .25 1100 – .25 1100 – .25

Filter Size (Inches) 20 x 25 x 2 20 x 25 x 2 20 x 25 x 2 20 x 25 x 2 20 x 25 x 2 20 x 25 x 2 20 x 25 x 2 20 x 25 x 2 20 x 25 x 2

Charge (R-410A oz.) 94 94 94 96 96 96 100 100 100

* 75° C Copper wire size

** Maximum time delay fuse or circuit breaker

Manual 2100-592C

Page 7 of 69

TABLE 1A

Specifications

W42G, W48G and W60G Models

Models W42G2DA W42G2DB W42G2DC W48G2DA W48G2DB W48G2DC W60G2DA W60G2DB W60G2DC

Operating Voltage Range 197-253 197-253 414-506 197-253 197-253 414-506 197-253 197-253 414-506

Electrical Rating – 60 Hz 230/208-60-1 230/208-60-3 460-60-3 230/208-60-1 230/208-60-3 460-60-3 230/208-60-1 230/208-60-3 460-60-3

Minimum Circuit Ampacity 32 23 11 34 25 12 40 28 14

* Field Wire Size 6 8 14 6 8 14 6 8 12

Ground Wire Size 10 10 14 10 10 14 10 10 12

** Delay Fuse – Max. 50 35 15 50 35 15 60 40 20

Manual 2100-592C

Page 8 of 69

Compressor Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Volts 230/208 230/208 460 230/208 230/208 460 230/208 230/208 460

Compressor

Rated Load Amps 15.5/17.5 10.2/11.5 4.8 19.3/21.4 13.1/14.5 6.4 21.6/24.7 12.8/14.7 7.8

Lock Rotor Amps 109 83.1 41 135 98 55 134 110 52

Branch Circuit Selection Current 19.9 13.1 6.1 21.4 14.5 6.4 26.3 15.6 7.8

Fan Motor – HP/RPM/SPD 1/3-850-2 1/3-850-2 1/3-850-1 1/3-850-2 1/3-850-2 1/3-850-1 1/3-850-2 1/3-850-2 1/3-850-1

Fan Motor – Amps 2.5 2.5 1.3 2.5 2.5 1.3 2.5 2.5 1.3

Fan Motor and Compressor

Fan – DIA/CFM 24” – 2700 24” – 2700 24” – 2700 24” – 2700 24” – 2700 24” – 2700 24” – 2700 24” – 2700 24” – 2700

Blower Motor – HP/RPM/SPD 1/2-1050-3 1/2-1050-3 1/2-1050-3 1/2-1050-3 1/2-1050-3 1/2-1050-3 1/2-1050-3 1/2-1050-3 1/2-1050-3

Blower Motor – Amps 3.4 3.4 1.5 3.4 3.4 1.5 3.4 3.4 1.5

Motor and Evaporator

CFM Cooling and E.S.P. 1300 – .35 1300 – .35 1300 – .35 1550 – .38 1550 – .38 1550 – .38 1650 – .30 1650 – .30 1650 – .30

Filter Size (Inches) 20 x 30 x 2 20 x 30 x 2 20 x 30 x 2 20 x 30 x 2 20 x 30 x 2 20 x 30 x 2 20 x 30 x 2 20 x 30 x 2 20 x 30 x 2

Charge (R-410A oz.) 129 129 129 158 158 158 161 161 161

* 75° C Copper wire size

** Maximum time delay fuse or circuit breaker

F

G

N

P

D

DD

FF

GG

HH

A

M

I

C

KJ

L

H

R

S

S

S

S

S

T

V

Y

AA

X

U

Z

CC

BB

B

EE

O

E

B

II

Q

W

COMBUSTION

AIR INTAKE

CONTROL

RIGHT SIDE

ENTRANCES

GAS

RETURN OPENING

4 DEG. PITCH IN TOP

PANEL DOOR

DOOR

LOW VOLTAGE

SUPPLY OPENING

PANEL

BACK

DISCONNECT ACCESS

VESTIBULE

PANEL (LOCKABLE)

CONDENSER

AIR INLETS

CONDENSER

VENT OPTION

AIR OUTLET

AIR EXHAUST

COMBUSTION

ENTRANCES

FRONT

CIRCUIT BREAKER/

MIS-3239

HIGH VOLTAGE

ENTRANCES

FRONT DOOR

FILTER

SERVICE

DOOR

UNIT A B C D E F G H I J K L M N O P QR

W24G-W30G-W 36G 7.88 27.88 13.88 24.25 40 25.63 81.63 27.38 27.5 39.25 5.88

W42G-W48G-W 60G

9.88

15.88

43.81

31.63

UNIT S T U V W X Y Z AA BB CC DD EE FF GG HH II

W24G-W30G-W 36G 12 - 7 HOLES 2.88 22.9 38 17.84 4.44 11.44 9 36.25 2 0.38

W42G-W48G-W 60G

3.88

24.9

42

8.44

10

40.25

2.75

1.257.25 1.133.75 2.25 3.25

15.31 4.5 2.514.88 30 14.12 15.44

FIGURE 1

Unit Dimensions

Manual 2100-592C

Page 9 of 69

4. HIGH ALTITUDE APPLICATIONS

WARNING

In all cases, there must be a metal duct

connection made to the supply air ange,

and a 1" clearance to combustibles must be

maintained to this duct connection.

For free blow applications, a metal sleeve

must be used in the wall opening itself, again

maintaining a 1" clearance to combustibles.

Failure to use the sheet metal can cause re

resulting in property damage, injury, or death.

See Figure 3 and clearance information in Section 9

and Table 2 for additional information.

Design the duct work according to methods given by

the Air Conditioning Contractors of America (ACCA).

When duct runs through unheated spaces, it should

be insulated with a minimum of 1" of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect

the duct work to the equipment in order to keep the

noise transmission to a minimum.

A 1" clearance to combustible material for the first 3'

of duct attached to the outlet air frame is required.

See Wall Mounting Instructions and Figures 2, 2A, 3

and 3A for further details.

Ducts through the walls must be insulated and all

joints taped or sealed to prevent air or moisture

entering the wall cavity.

Some installations may not require any return air duct.

A metallic return air grille is required with installations

not requiring a return air duct. The spacing between

louvers on the grille shall not be larger than 5/8".

Any grille that meets with the 5/8" louver criteria may

be used. It is recommended that Bard Return Air Grille

or Return Filter Grille be installed when no return duct

is used. Contact distributor or factory for ordering

information. If using a return air filter grille, filters

must be of sufficient size to allow a maximum velocity

of 400 fpm.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

Ratings of gas utilization equipment are based on

sea level operation and need not be changed for

operation at elevations up to 6,000'. For operation at

elevations above 6,000' and in the absence of specific

recommendations from the local authority having

jurisdiction, equipment ratings shall be reduced as

specified in Section 21.

5. TRANSPORTATION DAMAGE

All units are packed securely in shipping container.

All units should be carefully inspected upon arrival

for damage. In the event of damage, the consignee

should:

1. Note on delivery receipt of any damage to

container.

2. Notify carrier promptly, and request an inspection.

3. In case of concealed damage, the carrier must be

notified as soon as possible within 15 days after

delivery.

4. Claims for any damage, apparent or concealed,

should be filed with the carrier, using the following

supporting documents:

A. Original Bill of Lading, certified copy, or

indemnity bond.

B. Original paid freight bill of indemnity in lieu

thereof.

C. Original invoice or certified copy thereof

showing trade and other discounts or

deductions.

D. Copy of the inspection report issued by

carrier’s representative at the time damage is

reported to carrier.

6. GENERAL INFORMATION

Size of unit for proposed installation should be based

on heat loss/heat gain calculations made according to

methods of Air Conditioning Contractors of America

(ACCA). The air duct should be installed in accordance

with the Standards of the National Fire Protection

Association for the Installation of Air Conditioning and

Ventilating Systems of Other Than Residence Type,

NFPA No. 90A, and Residence Type Warm Air Heating

and Air Conditioning Systems, NFPA No. 90B. Where

local regulations are at a variance with instructions,

installer should adhere to local codes.

Manual 2100-592C

Page 10 of 69

7. WALL MOUNTING INFORMATION

1. Two holes for the supply and return air openings

must be cut through the wall as detailed in Figure

4.

2. On wood frame walls, the wall construction must

be strong and rigid enough to carry the weight of

the unit without transmitting any unit vibration.

3. Concrete block walls must be thoroughly inspected

to insure that they are capable of carrying the

weight of the installed unit.

8. MOUNTING THE UNIT

1. These units are secured by wall mounting brackets

which secure the unit to the outside wall surface at

both sides. A bottom mounting bracket is provided

for ease of installation but is not required.

CAUTION

If the bottom bracket is used, be certain the

bracket is secured to the outside wall surface in

a way sufcient to support the entire weight of

the unit during installation until side mounting

brackets are secured.

2. The W42G, W48G and W60G models are suitable

for 0 clearance on the installation mounting wall

and to the top. For all models the supply air duct

flange and the first 3' of supply air duct require a

minimum of 1" clearance to combustible material.

The W24G, W30G and W36G models are suitable

for 0 clearance on the installation mounting wall,

but require 1" clearance to the top if combustible

material overhang projects above the unit. See

Figure 3 and 3A. If a combustible wall, use a

minimum of Figure 1 “A” dimension plus 2" and

“B” dimension plus 2". See Figures 4 and 5 for

details.

WARNING

Failure to provide the 1" clearance between the

supply duct and a combustible surface for the

rst 3' of duct can result in re causing damage,

injury or death.

3. Locate and mark lag bolt locations and bottom

mounting bracket location.

4. Mount bottom mounting bracket.

5. Hook top rain flashing under back bend of top. Top

rain flashing is shipped secured to the right side of

the back.

6. Position unit in opening and secure with 5/16

lag bolts; use 7/8" diameter flat washers on the

lag bolts. Use lag bolts long enough to support

the unit’s weight when mounted to the structure.

This length may be dependant on the type of

construction.

7. Secure rain flashing to wall and caulk across entire

length of top (see Figures 2 and 2A).

8. On side-by-side installations, maintain a minimum

of 20" clearance on right side to allow access to

control panel and burner compartment, and to

allow proper airflow to the outdoor coil. Additional

clearance may be required to meet local or

national codes.

Manual 2100-592C

Page 11 of 69

39 3/16"

29 3/4"

4 11/16"

12"

12"

12"

12"

12"

12"

2"

2 1/4"

10"

28 5/16"

15"

27"

17 15/16"

11 5/16"

8 5/8"

2 15/16"

2 1/4"

30"

29"

5 1/16"

7/16"

5 9/16"

4 9/16"

4 1/2"

2 15/16"

18 15/16"

4 9/16"

SUPPLY

AIR DUCT

RETURN

AIR DUCT

Ø2 3/4" GAS

OPENING

(OPTIONAL)

Ø2 3/4" HIGH

VOLTAGE

(OPTIONAL)

Ø2" LOW VOLTAGE

(OPTIONAL)

(12) FLANGE

SCREWS

UNIT SUPPORT

1" MIN.

NECCESSARY

NO CLEARANCE

SUPPLY

AIR DUCT

RETURN

AIR DUCT

CONTROL

PANEL

VESTIBULE

DOOR

WALL

STRUCTURE

(OUTSIDE)

1" CLEARANCE ON ALL

FOUR SIDES OF SUPPLY

AIR DUCT IS REQUIRED FROM

COMBUSTABLE MATERIALS

NOTE: IT IS RECOMMENDED THAT A BEAD

OF SILICONE CAULKING BE PLACED BEHIND

THE SIDE MOUNTING FLANGES AND UNDER

TOP FLASHING AT TIME OF INSTALLATION

RIGHT SIDE

VIEW WITH UNIT

OUTSIDE WALL WITH

UNIT REMOVED

RAIN FLASHING

SUPPLIED

SEAL WITH BEAD OF CAULKING

ALONG ENTIRE LENGTH OF TOP

TOP

FOAM AIR SEAL

WALL

MIS-1681

FIGURE 2

Mounting Instructions

for W24G, W30G and W36G

Manual 2100-592C

Page 12 of 69

FIGURE 2A

Mounting Instructions

for W42G, W48G and W60G

Manual 2100-592C

Page 13 of 69

FIGURE 3

Combustible Clearance

for W24G, W30G and W36G Models

FIGURE 3A

Combustible Clearance

for W42G, W48G and W60G Models

WARNING

A minimum of one (1) inch clearance must be maintained between the supply air duct and

combustible materials. This is required for the rst three (3) feet of ducting.

It is important to insure that the one (1) inch minimum spacing is maintained at all points.

Failure to do this could result in overheating the combustible material and may result in a re causing

damage, injury or death.

Manual 2100-592C

Page 14 of 69

FIGURE 4

Wall Mounting Instructions

FIGURE 5

Wall Mounting Instructions

Manual 2100-592C

Page 15 of 69

FIGURE 6

Common Wall Mounting Installations

Manual 2100-592C

Page 16 of 69

9. CLEARANCES

Minimum clearances, as specified in Table 2, must

be maintained from adjacent structures to provide

adequate fire protection, adequate combustion air, and

room for service personnel.

While minimum clearances are acceptable for safety

reasons, they may not allow adequate air circulation

around the unit for proper operation in the cooling

mode. Whenever possible, it is desirable to allow

additional clearance, especially around the condenser

inlet and discharge openings. DO NOT install the unit

in a location that will permit discharged air from the

condenser to recirculate to the condenser inlet.

WARNING

Clearances from combustible materials must

be maintained as specied. Failure to maintain

clearances could cause re resulting in

property damage, injury, or death.

TABLE 2

Minimum Installation Clearances

Outlet Duct

(from combustible materials)

Vent Terminal

(from combustible materials)

Condenser Inlet 20"

Top See Figure 3

Burner Service 20"

Combustible Base (Wood or Class A,

B or C roof covering material)

* See Figures 3 and 3A

1" first 3'

* 17"

0"

FIGURE 7

Location of Vent Terminal in Shipping

Manual 2100-592C

Page 17 of 69

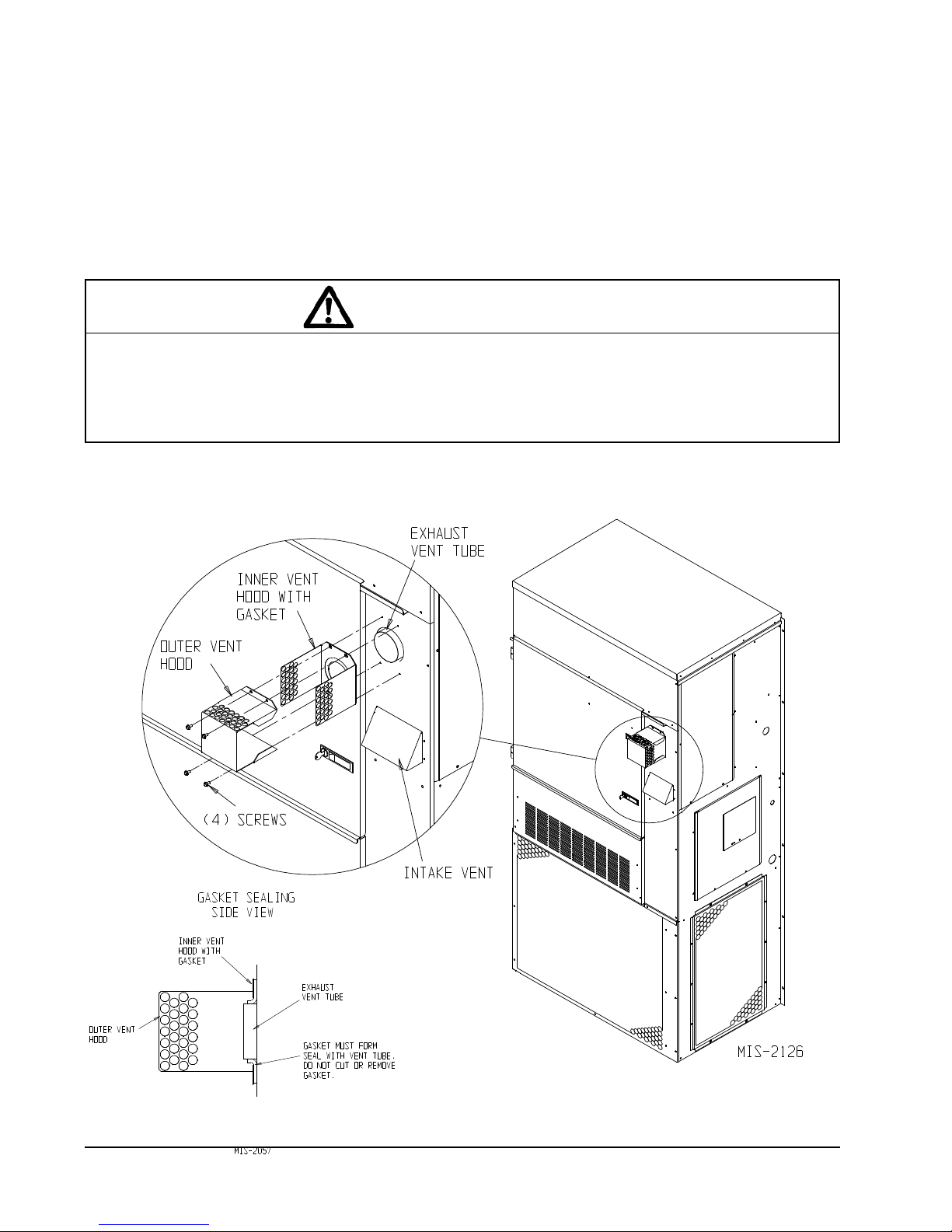

10. VENT TERMINAL AND

COMBUSTION AIR INLET HOOD

The vent terminal is shipped in the burner

compartment (see Figure 7). Remove the two shipping

screws and separate the two-piece assembly. Install

the vent terminal by using the four screws provided.

Make sure gasket is in place (see Figure 8). The

combustion air intake hood is factory installed.

11. OPTIONAL VERTICAL VENTING

With the optional vertical venting kit (VVK-5), this unit

may be vented vertically through a roof or overhang.

The kit includes a stainless steel transition drain tee,

silicone sealant and drain tubing.

If unit is installed with vertical vent kit, annually

inspect the vent system and drain. Replace any portion

of the vent system that shows signs of deterioration.

Make sure drain is open and free of obstruction.

CAUTION

Vent terminal must be installed as shown in Figure 8 for proper operation of the heating system.

NOTE: The inner vent hood gasket is designed to stretch over and seal around the combustion air

blower outlet. This is a very critical seal to prevent water and ue products from entering the unit.

Care must be taken to ensure this gasket is in place and sealing properly.

FIGURE 8

Vent Terminal and Combustion Air Intake

Manual 2100-592C

Page 18 of 69

12. VENT RESIZING INSTRUCTIONS

When an existing furnace is removed from a venting

system servicing other appliances, the venting system

is likely to be too large to properly vent the remaining

attached appliances.

The following steps shall be followed with each of

the appliances remaining connected to the common

venting system, placed in operation one at a time

while the other appliances remaining connected to the

common venting system are not in operation.

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and

horizontal pitch, as required in the National

Fuel Gas code, ANSI Z223.1 or the CAN/CGA

B149 Installation Codes and these instructions.

Determine that there is no blockage or restriction,

leakage, corrosion and other deficiencies which

could cause an unsafe condition.

3. In so far as is practical, close all building doors

and windows and all doors between the space

in which the appliance(s) connected to the

venting system are located and other spaces of

the building. Turn on clothes dryers and any

appliances not connected to the venting system.

Turn on any exhaust fans, such as range hoods

and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Place the

appliance being inspected in operation. Adjust

thermostat so appliance shall operate continuously.

5. Test for draft hood equipped appliance spillage at

the draft hood relief opening after 5 minutes of

main burner operation. Use the flame of a match

or candle.

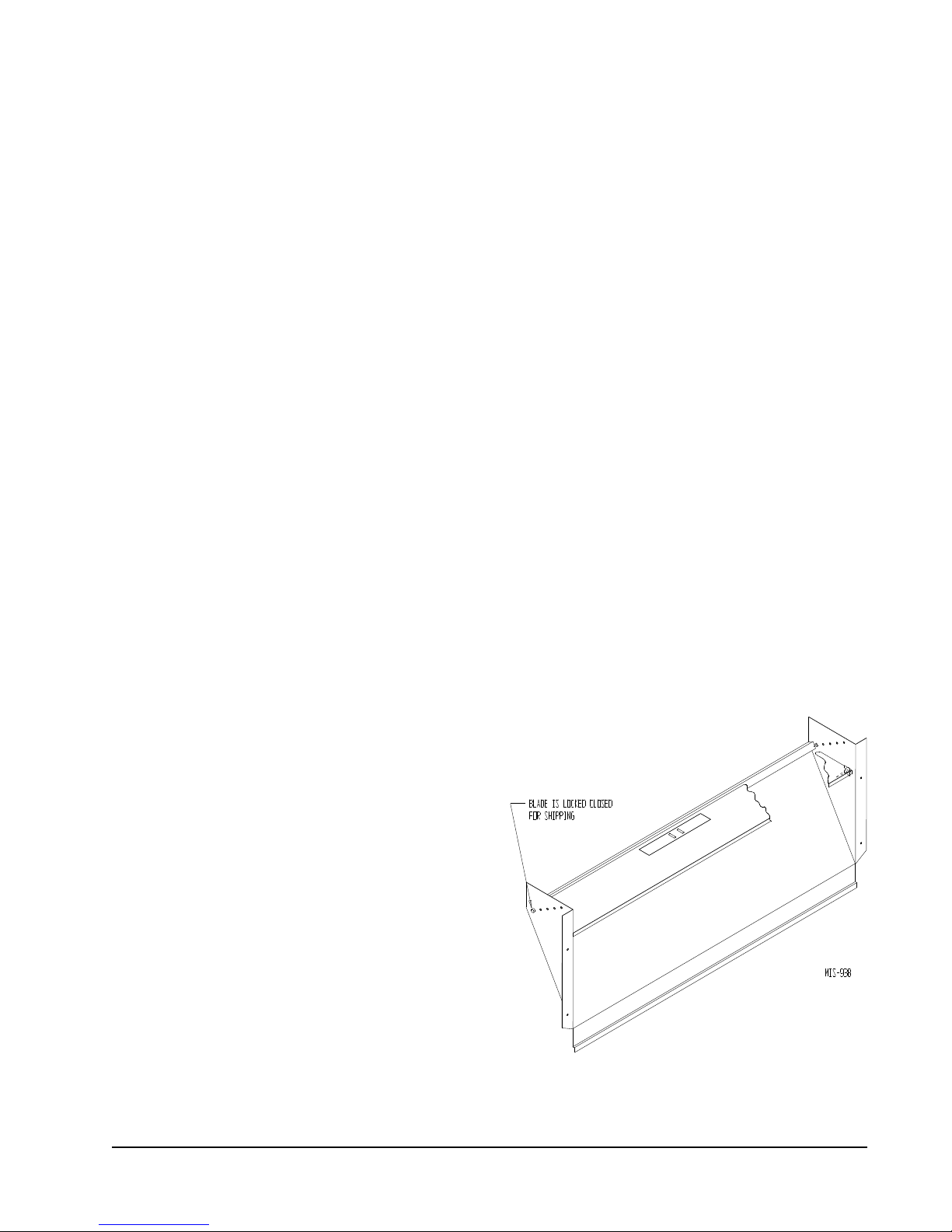

13. FRESH AIR INTAKE

All units are built with fresh air inlet slots punched in

the service panel.

If the unit is equipped with a fresh air damper

assembly, the assembly is shipped already attached

to the unit. The damper blade is locked in the

closed position. To allow the damper to operate, the

maximum and minimum blade position stops must be

installed (see Figure 9).

All capacity, efficiency and cost of operation

information as required for Department of Energy

“Energyguide” Fact Sheets is based upon the fresh

air blank-off plate in place and is recommended for

maximum energy efficiency.

The blank-off plate is available upon request from the

factory and is installed in place of the fresh air damper

shipped with each unit.

One of several other ventilation options may be

installed. Refer to model number and/or supplemental

installation instructions.

14. CONDENSATE DRAIN

A plastic drain hose extends from the drain pan at

the top of the unit down to the unit base. There are

openings in the unit base for the drain hose to pass

through. In the event the drain hose is connected to

a drain system of some type, it must be an open or

vented type system to assure proper drainage.

FIGURE 9

Fresh Air Damper

6. After it has been determined that each appliance

connected to the venting system properly vents

when tested as outlined above, return doors,

windows, exhaust fans, fireplace dampers and

any other gas-burning appliances to their previous

conditions of use.

7. If improper venting is observed during any of the

above tests, the venting system must be corrected.

Manual 2100-592C

Page 19 of 69

15. WIRING – MAIN POWER

WARNING

For personal safety, turn off electric power

at service entrance panel before making any

electrical connections. Failure to do so could

result in electric shock or re.

Refer to unit rating plate for wire sizing information and

maximum fuse or circuit breaker size. Each outdoor

unit is marked with a “Minimum Circuit Ampacity”.

This means that the field wiring used must be sized to

carry that amount of current. All models are suitable

only for connection with copper wire. Each unit and/or

wiring diagram will be marked “Use Copper Conductors

Only”. These instructions must be adhered to. Refer

to the National Electrical Code (NEC) for complete

current carrying capacity data on the various insulation

grades of wiring material. All wiring must conform to

NEC and all local codes.

The electrical data lists fuse and wire sizes (75° C

copper) for all models.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or circuit breaker that is to be used with

the equipment. The correct size must be used for

proper circuit protection and also to assure that there

will be no nuisance tripping due to the momentary high

starting current of the compressor motor.

The disconnect access door on this unit may be locked

to prevent unauthorized access to the disconnect. To

convert for the locking capability, bend the tab located

in the bottom left hand corner of the disconnect

opening under the disconnect access panel straight

out. This tab will now line up with the slot in the door.

When shut, a padlock may be placed through the hole

in the tab preventing entry.

See “Start Up” section for important information on

three phase scroll compressor start ups.

Electrical Grounding

When installed, the furnace must be electrically

grounded in accordance with local codes or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or Canadian Electrical Code,

CSA22.1, latest edition. Use a copper wire from green

ground wire on the furnace to a grounded connection

in the service panel or a properly driven and electrically

grounded ground rod. See Table 1 for proper ground

wire size.

WARNING

Failure to provide a proper electrical ground

could result in electric shock or re.

Field-Installed Equipment

Wiring to be done in the field between the furnace

and devices not attached to the furnace, or between

separate devises which are field installed and located,

shall conform with the temperature limitation for

Type T wire {63° F rise (36° C)} when installed in

accordance with the manufacturer’s instructions.

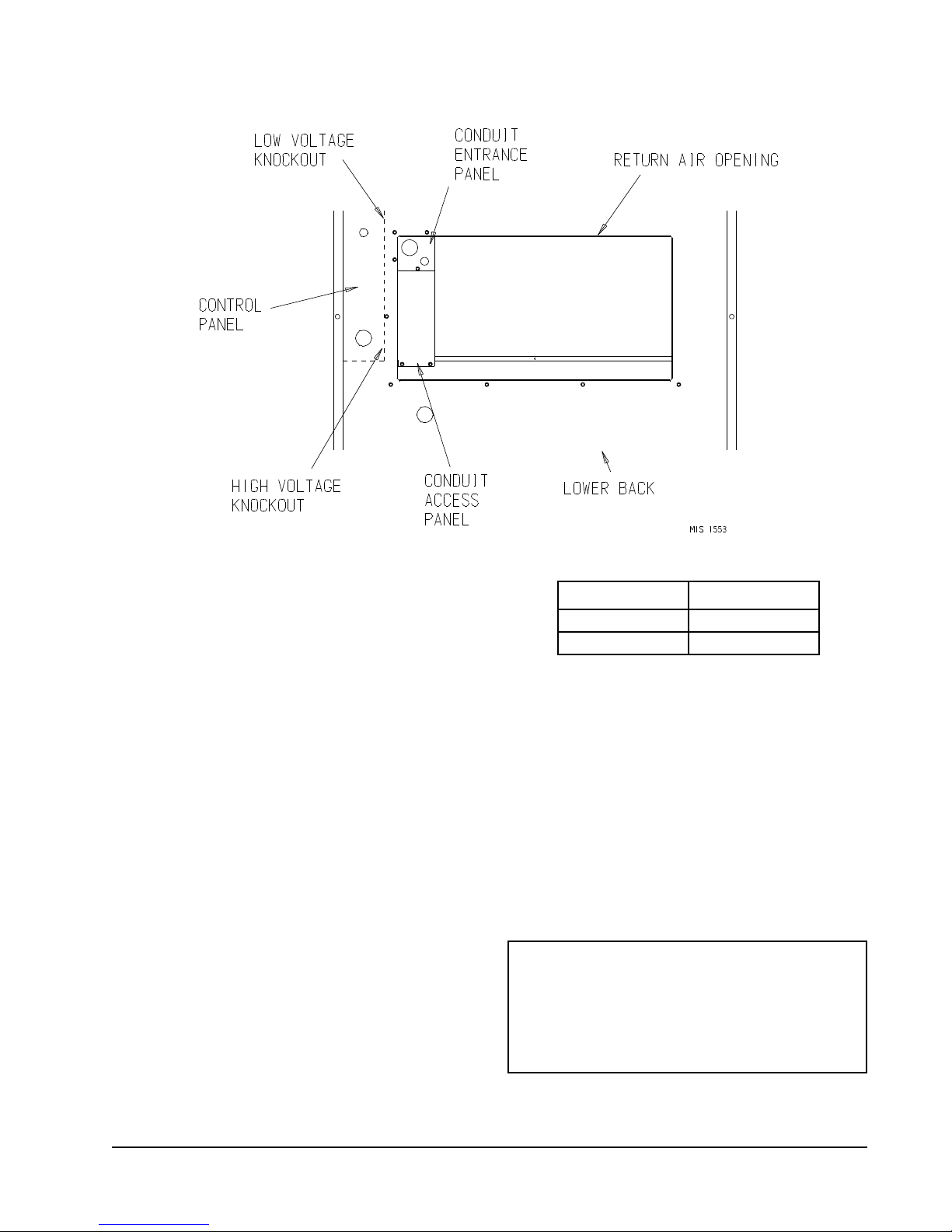

Installation of Flexible Conduit Through Return Air

Opening

NOTE: To allow proper clearance between the control

panel and any vent options, 90° conduit

fittings must be used on the back of the

control panel.

Installing Conduit (See Figure 10)

1. Remove conduit access panel if required to gain

access to area behind control panel.

2. Remove low voltage and high voltage knockouts

located in rear of control panel.

3. Run low voltage conduit through 7/8 bushing

located in conduit entrance plate and secure to low

voltage opening in rear of control panel.

WARNING

Failure to provide an electrical power supply

shut off means could result in electric shock or

re.

Manual 2100-592C

Page 20 of 69

4. Run high voltage conduit through 1-3/4 bushing

located in conduit entrance plate and secure to

high voltage opening in rear of control panel.

5. Replace conduit access panel if required to

complete installation.

6. Seal around conduit in conduit entrance plate.

FIGURE 10

Installation of Flexible Conduit

16. WIRING – LOW VOLTAGE WIRING

Low Voltage Connection

These units use a 24-volt AC low voltage circuit.

The “R” terminal is the hot terminal and the “C”

terminal is grounded.

“G” terminal is the fan input.

“Y1” terminal is the compressor input.

“R” terminal is 24 VAC hot.

“C” terminal is 24 VAC grounded.

“A” terminal is the ventilation input. This terminal

energizes any factory or field installed vent option.

“2” terminal is the “L” input back to the thermostat if

compressor control module is tripped.

“3” terminal is the dehumidification input.

This energizes compressor, blower and 3-way

dehumidification valve.

“W1” terminal is the heating input.

230/208 Volt Units

All models are equipped with dual primary voltage

transformers. All equipment leaves the factory wired

on 240V tap. For 208V operation, reconnect from

240V to 208V tap. The acceptable operating voltage

range for the 240V and 208V taps are:

Tap Range

240 253 – 206

208 220 – 187

NOTE: The voltage should be measured at the field

power connection point in the unit and while

the unit is operating at full load (maximum

amperage operating condition).

460 Volt Units

All models are equipped with single primary voltage

transformers and no rewiring is required.

Direct Digital Controls (DDC)

For total and proper control using DDC, a total of 5

controlled outputs are required (4 if no ventilation is

installed).

LOW VOLTAGE CONNECTIONS FOR DDC CONTROL

Fan Only Energize G

Cooling Mode Energize G, Y1

Heating Mode Energize W1

Ventilation Energize G, A

Dehumidification Energize 3

Manual 2100-592C

Page 21 of 69

Loading...

Loading...