Bard W24HB-A, W30HB-A, W24HB-B, W24HB-C, W30HB-B Installation Instructions Manual

...

INSTALLATION INSTRUCTIONS

WALL MOUNTED PACKAGE

HEAT PUMP

Models:

W18HB-A W24HB-A

W24HB-B

W24HB-C

W30HB-A

W30HB-B

W30HB-C

W36HB-A

W36HB-B

W36HB-C

W24HBDA

W24HBDB

W24HBDC

W30HBDA

W30HBDB

W30HBDC

W36HBDA

W36HBDB

W36HBDC

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-703

Supersedes: NEW

Date: 8-12-19

Page 1 of 40

CONTENTS

Getting Other Information and Publications .... 3

Wall Mount General Information .........................4

Heat Pump Wall Mount Model Nomenclature .......... 4

Shipping Damage ................................................. 4

General ............................................................... 4

Duct Work ........................................................... 4

Filters ................................................................. 5

Fresh Air Intake ................................................... 5

Installation ...............................................................6

Basic Installation Design and Application Planning .. 6

Wall Construction ............................................. 6

Outdoor Area Inspection .................................... 6

Condensate Water Drainage ............................... 6

Indoor Ducted and Non-Ducted Applications ........... 6

Indoor Supply Airflow ........................................ 6

Indoor Return Airflow ........................................ 6

Ducted Applications ......................................... 7

Free Blow Applications...................................... 7

Thermostat or Indoor Temperature Sensor

Placement ....................................................... 7

Unit Installation ................................................... 8

Materials/Tool List ............................................ 8

Wall Preparation ............................................... 8

Wall Mount Installation to Wall Surface .............. 8

Wiring – Main Power ........................................... 15

Wiring – Low Voltage ........................................... 15

Low Voltage Connections ................................. 15

Unit Shutdown Feature ................................... 15

Balanced Climate

TM

Feature ............................. 15

Dehumidification Feature ................................ 16

Ventilation Features ........................................ 16

Alarm Relay Feature ....................................... 16

Dirty Filter Switch Indicator (DFS).................... 16

Start Up ................................................................... 20

General ......................................................... 20

Topping Off System Charge ................................. 20

Safety Practices ................................................ 20

Important Installer Note ..................................... 20

High and Low Pressure Switch ............................ 21

Three Phase Scroll Compressor Start Up

Information ....................................................... 21

Phase Monitor ................................................... 21

Condenser Fan Operation ................................... 21

Sequence of Operation ....................................... 21

Cooling ......................................................... 21

Heating ......................................................... 21

Balanced Climate Mode .................................. 21

Defrost Cycle ..................................................... 22

Low Pressure Switch Bypass Operation ............. 22

High Pressure Switch Operation ....................... 23

Vent Connection Plug .......................................... 23

Pressure Service Ports ........................................ 23

Service Hints ..................................................... 23

Service ..................................................................... 25

Solid State Heat Pump Control Troubleshooting

Procedure ......................................................... 25

Checking Temperature Sensor Outside

Unit Circuit ........................................................ 26

Troubleshooting Nidec SelecTech Series ECM

Motors ............................................................... 27

If the Motor Is Running ................................... 27

If the Motor Is Not Running ............................. 27

Model SelecTech Communication Diagnostics ... 28

Fan Blade Setting Dimensions ............................. 29

Removal of Fan Shroud ....................................... 29

R-410A Refrigerant Charge ................................. 29

Setting Unit Airflow ............................................ 33

Blower Speeds ............................................... 33

Speed Tap 1 – Vent/Blower Only .................. 34

Speed Tap 2 – Balanced Climate ................. 34

Speed Tap 3 – Default LO Cooling &

Heating ............................... 34

Speed Tap 4 – Optional MED Cooling &

Heating ............................... 34

Speed Tap 5 – Optional HI Cooling &

Heating ............................... 34

TABLES

Table 1 Clearance Required for Service Access

and Adequate Condenser Airflow ............. 9

Table 2 Minimum Clearances Required to

Combustible Materials ........................... 9

Table 3 Low Voltage Connections...................... 16

Table 4 Wall Thermostats ................................ 17

Table 5 Humidity Controls ............................... 17

Table 6 CO

Controller ..................................... 17

2

Table 7 Thermostat Wire Size ........................... 17

Table 8 Troubleshooting .................................. 25

Table 9 Temperature vs. Resistance .................. 26

Table 10 Fan Blade Dimension .......................... 29

Table 11A Cooling Pressure ................................. 30

Table 11B Heating Pressure ................................. 30

Table 12 Cooling Pressure – Balanced Climate

Airflow ............................................... 31

Table 13 Electrical Specifications ...................... 32

Table 14 Recommended Airflow ......................... 33

Table 15 Blower Speeds for Unit Operational

Modes ................................................ 34

Table 16 Indoor Blower Performance .................. 35

Table 17 Maximum ESP of Operation –

Electric Heat Only .............................. 36

Table 18 Electric Heat ...................................... 36

Table 19 Optional Accessories ........................... 37

Table 20 Vent and Control Options ..................... 38

Manual 2100-703

Page 2 of 40

FIGURES

Figure 1 Fresh Air Damper .................................. 5

Figure 2 Unit Dimensions ................................... 9

Figure 3A Mounting Instructions – W18H, W24H .. 10

Figure 3B Mounting Instructions – W30H, W36H .. 11

Figure 4 Electric Heat Clearance ....................... 12

Figure 5 Wall Mounting Instructions .................. 13

Figure 6 Wall Mounting Instructions .................. 13

Figure 7 Common Wall Mounting Installations .... 14

Figure 8 Programmable Thermostat Connections . 18

Figure 9 Non-Programmable Thermostat

Connections ....................................... 19

Figure 10 Defrost Control Board .......................... 24

Figure 11 Motor Connections .............................. 27

Figure 12 Motor Connections .............................. 28

Figure 13 Fan Blade Setting ............................... 29

Figure 14 Speed Taps ......................................... 33

Figure 15 Speed Taps ......................................... 33

GRAPHS

Graph 1 W18HB FAD-NE2, 3 W/O Exhaust

Ventilation Delivery ............................. 39

Graph 2 W24HB FAD-NE2, 3 W/O Exhaust

Ventilation Delivery ............................. 39

Graph 3 W30HB FAD-NE2, 3 W/O Exhaust

Ventilation Delivery ............................. 40

Graph 4 W36HB FAD-NE2, 3 W/O Exhaust

Ventilation Delivery ............................. 40

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help when installing the heat

pump. They can usually be found at the local library

or purchased directly from the publisher. Be sure to

consult the current edition of each standard.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation ..............ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air .......................ANSI/NFPA 90B

Heating and Air Conditioning Systems

Load Calculation for ......................... ACCA Manual J

Residential Winter and Summer Air Conditioning

Duct Design for Residential ............... ACCA Manual D

Winter and Summer Air Conditioning and Equipment

Selection

For more information, contact these publishers:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating, Refrigeration

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-703

Page 3 of 40

WALL MOUNT GENERAL INFORMATION

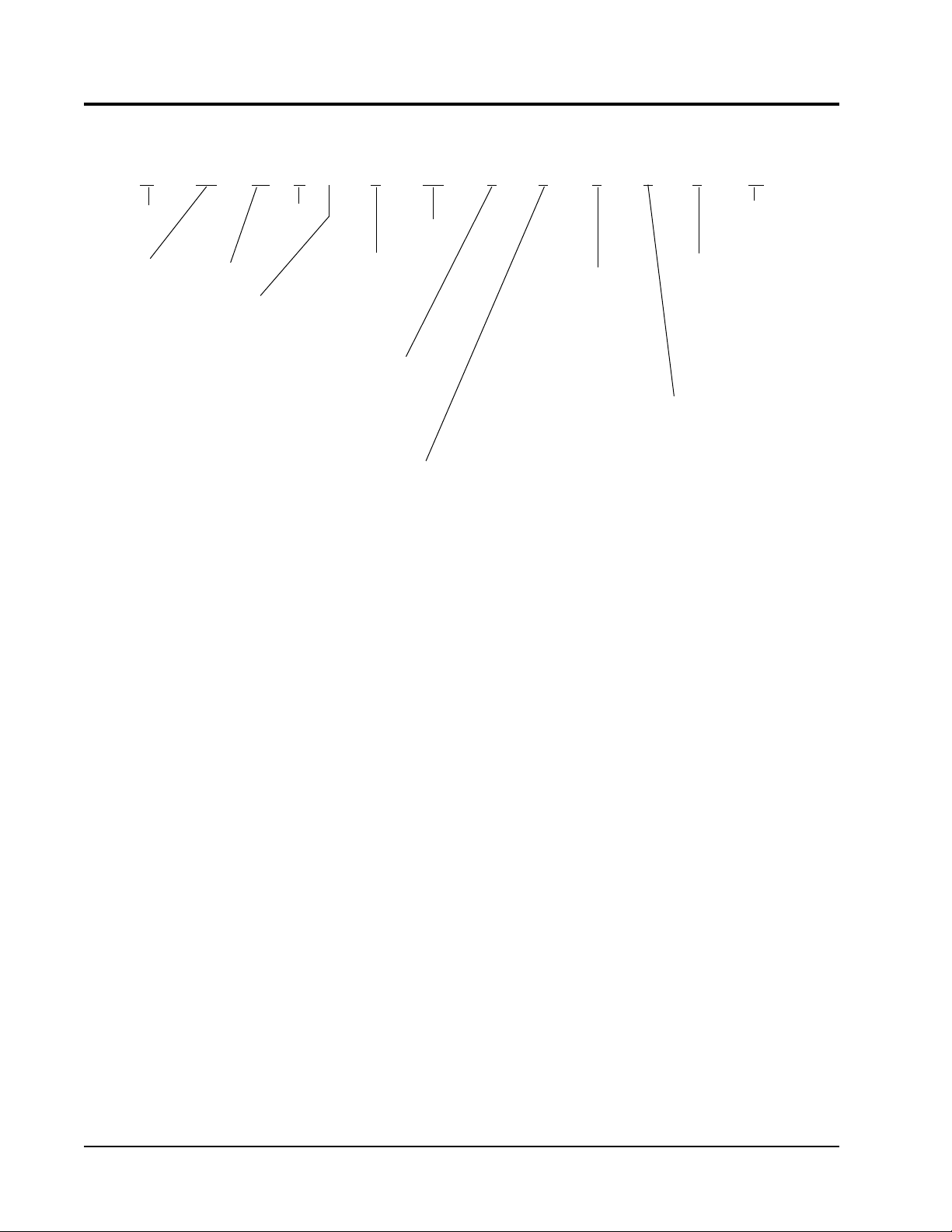

HEAT PUMP WALL MOUNT MODEL NOMENCLATURE

W 30 H B – A 10 X X X X X A

MODEL NUMBER

CAPACITY

18 - 1½ Ton

24 - 2 Ton

30 - 2½ Ton

36 - 3 Ton

Insert “D” for dehumidification with hot gas reheat. Reference latest revision of Form 7960-828 for complete details.

For 0 KW and circuit breakers (230/208 volt) or toggle disconnect (460V) applications, insert 0Z in the KW field of the model number.

NOTE: Vent options X, B and M are without exhaust capability. May require separate field-supplied barometric relief in building.

H - Heat Pump

SPECIALTY PRODUCTS

(Non-Standard)

VENTILATION OPTIONS

(See Spec. Sheet S3585)

X - Barometric Fresh Air Damper (Standard)

A - Fresh Air Damper w/Exhaust

B - Blank-Off Plate

D - Economizer, 0-10V no controls

M - Commercial Ventilator, ON/OFF

R - Energy Recovery Ventilator

S - Partial Flow Economizer, JADE

V - Commercial Ventilator,

0-10V variable

Y - Full Flow Economizer, DB

Z - Full Flow Economizer, JADE,

DB and WB

Shipping Damage

Upon receipt of equipment, the carton should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

REVISIONS

VOLTS & PHASE

A - 230/208/60/1

B - 230/208/60/3

C - 460/60/3

FILTER OPTIONS

X - 1" MERV2 Disposable Filter

W - 1" MERV2 Permanent Filter

P - 2" MERV8 Disposable Filter

M - 2" MERV11 Disposable Filter

N - 2" MERV13 Disposable Filter

KW

COLOR & CABINET

FINISH

X - Beige Baked

Enamel Finish

1 - White Baked

Enamel Finish

4 - Buckeye Gray

Baked Enamel

Finish

5 - Desert Brown

Baked Enamel

Finish

8 - Dark Bronze Baked

Enamel Finish

S - Stainless Steel

A - Aluminum

PLACEHOLDER

X - Future Use

While these instructions are intended as a general

recommended guide, they do not supersede any

national and/or local codes in any way. Authorities

having jurisdiction should be consulted before the

installation is made. See page 3 for information on

codes and standards.

CONTROL MODULES

(See Spec. Sheet S3585)

COIL OPTIONS

X - Standard

1 - Phenolic Coated Evaporator

2 - Phenolic Coated Condenser

3 - Phenolic Coated Evaporator

and Condenser

4 - Coated Coils and Condenser

Section

5 - Coated Coils, Inside and

Outside of Unit

Size of unit for a proposed installation should be

General

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and

return ducts.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

based on heat loss/gain calculation made according

to methods of Air Conditioning Contractors of America

(ACCA). The air duct should be installed in accordance

with the Standards of the National Fire Protection

Association for the Installation of Air Conditioning and

Ventilating Systems of Other Than Residence Type,

NFPA No. 90A, and Residence Type Warm Air Heating

and Air Conditioning Systems, NFPA No. 90B. Where

local regulations are at a variance with instructions,

installer should adhere to local codes.

Duct Work

All duct work, supply and return, must be properly

sized for the design airflow requirement of the

equipment. Air Conditioning Contractors of America

(ACCA) is an excellent guide to proper sizing. All duct

work or portions thereof not in the conditioned space

should be properly insulated in order to both conserve

energy and prevent condensation or moisture damage.

equipment.

Manual 2100-703

Page 4 of 40

Refer to the Maximum ESP of Operation table on page

36.

Design the duct work according to methods given by

the Air Conditioning Contractors of America (ACCA).

When duct runs through unheated spaces, it should

be insulated with a minimum of 1" of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect

the duct work to the equipment in order to keep the

noise transmission to a minimum.

Models W18 and W24 are approved for 0" clearance

to the supply duct. For models W30 and W36, a 1/4"

clearance to combustible material for the first 3' of

duct attached to the outlet air frame is required. See

Ducted Applications on page 7 and Figures 3A and 3B

(pages 10 and 11) and Figure 4 (page 12) for further

details.

Ducts through the walls must be insulated and all joints

taped or sealed to prevent air or moisture entering the

wall cavity.

Some installations may not require any return air duct.

A metallic return air grille is required with installations

not requiring a return air duct. The spacing between

louvers on the grille shall not be larger than 5/8".

Any grille that meets with 5/8" louver criteria may be

used. It is recommended that Bard Return Air Grille

Kit RG-2W through RG-5W or RFG-2W through RFG5W be installed when no return duct is used. Contact

distributor or factory for ordering information. If using a

return air filter grille, filters must be of sufficient size to

allow a maximum velocity of 400 fpm.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

Filters

A 1" throwaway filter is standard with each unit. The

filter slides into position making it easy to service. This

filter can be serviced from the outside by removing the

filter access panel. A 1" washable filter and 2" pleated

filter are also available as optional accessories. The

internal filter brackets are adjustable to accommodate

the 2" filter by bending two tabs down on each side of

the filter support bracket.

Fresh Air Intake

All units are built with fresh air inlet slots punched in

the service door.

If the unit is equipped with a fresh air damper

assembly, the assembly is shipped already attached

to the unit. The damper blade is locked in the closed

position. To allow the damper to operate, the maximum

and minimum blade position stops must be installed

(see Figure 1).

Graphs found on pages 39 and 40 give approximate

fresh air amounts based on the blade position stop

location.

All capacity, efficiency and cost of operation

information is based upon the fresh air blank-off plate

in place and is recommended for maximum energy

efficiency.

The blank-off plate is available upon request from the

factory and is installed in place of the fresh air damper

shipped with each unit.

FIGURE 1

Fresh Air Damper

BLADE IS LOCKED CLOSED

FOR SHIPPING

MIS-938

Manual 2100-703

Page 5 of 40

INSTALLATION

Basic Installation Design and

Application Planning

Successful unit installations require proper planning

and site inspection before installation begins. Before

installing the wall mount unit, make sure that all

service and airflow clearances are met and that the

unit can meet all applicable code and regulation

requirements. Provide an inspection of both the inside

and outside of the structure by reviewing floorplans and/

or visiting the installation site.

Wall Construction

The wall must be inspected to ensure that the weight

of the unit can be supported. Be sure to review all

applicable construction codes and regulations including

seismic requirements. When inspecting wood frame

walls, the wall construction must be strong and

rigid enough to carry the weight of the unit without

transmitting any unit vibration. It is important that

the side unit wall mounting lags and optional bottom

bracket are supported by structural members inside

the wall cavity. Concrete block and brick walls must be

thoroughly inspected to ensure that they are capable of

carrying the weight of the installed unit. Metal buildings

must contain structural components to support the unit

weight. If heavily corrugated siding is present, it may

need to be trimmed and flashed to provide a flat, even

surface to attach and seal the unit to the wall.

Outdoor Area Inspection

Inspect the outdoor area of the jobsite or review

construction plans and locate the area where the wall

mount is to be installed. The outdoor area must be

free from obstructions including fences, bushes and

walls that will hinder unit operation regarding outdoor

condenser airflow and unit serviceability. Do not

install units in enclosed areas that limit the amount

of ambient temperature airflow. Warm air will exit

the front condenser section of the unit, and outdoor

ambient temperature air must be able to enter side

intake condenser openings of the unit. Portable or

modular building placement must be in a way that the

wall mount units have a constant supply of outdoor air

for proper unit operation. Make sure that the service

panels of the unit are accessible. Inspect wall surfaces

for obstructions that could hinder unit installation

and servicing including outdoor electrical conduits,

junction boxes, wall drains, vent hoods, windows, doors,

overhangs and posts.

NOTE: Before mounting the heat pump unit,

consideration should be given to the

condensate removal from the outdoor coil when

in heating mode. The unit must be mounted

high enough above grade to ensure that ice

will not build up under the unit and come into

contact with the base of the unit. If allowed,

this could cause damage to the coil and other

base components. Also, be sure there are no

air obstructions to the sides or front of the

unit, such as bushes or fences, that would

inhibit condenser airflow.

Condensate Water Drainage

Review all codes and requirements for unit condensate

drainage. A clear, flexible PVC drain hose (3/4" ID, 1"

OD) extends from the drain pan in the upper section of

the unit and extends down to the unit base. An opening

is supplied towards the back of the unit base for the

drain hose to pass through, and the hose extends 1"

to 2" below the unit base. Water removed from the

indoor air (condensate) will be expelled from the unit

in large amounts during cooling operation through the

hose. Units running in cooling operation in cold outdoor

below freezing conditions can cause the condensate

to freeze after leaving the drain hose. In the event the

drain hose is connected to a drain system of some type,

it must be an open or vented type system to ensure

proper drainage throughout seasonal use.

Indoor Ducted and Non-Ducted

Applications

Air distribution inside the structure being conditioned

plays an important role in making sure the area is

a consistent temperature. Improper air distribution

can result in areas being cooler or warmer, electrical

equipment not receiving sufficient airflow or occupancy

discomfort felt inside an area. Thermostat or indoor

temperature sensor placement inside the area being

conditioned also plays an important role in indoor

climate control.

Indoor Supply Airflow

Indoor installation areas must provide a non-restrictive

path for the conditioned supply air to leave supply

grilles and registers. Inspect the area to ensure that all

indoor portions of the room or rooms will have access

to supply air. Ductwork may be used to ensure proper

air circulation and all provided ductwork guidelines and

clearances must be followed. Non-ducted applications

must use a supply louver grille installed over the supply

opening inside the room. Be sure to adjust supply

deflectors to properly disperse the conditioned supply

air to all parts of the room. Avoid closing sections of

the supply grilles which would cause unneeded supply

duct pressurization.

Indoor Return Airflow

A non-restrictive path for room air returning to the

center section of the unit must be provided inside

the room. Avoid placing objects including furniture,

electronics equipment, equipment racks and cabinets

Manual 2100-703

Page 6 of 40

directly in front of the unit return grilles and registers.

Bard recommends at least 2' between solid objects

and return grilles or registers. Ductwork may be used to

ensure proper air circulation and all provided ductwork

guidelines and clearances must be followed. Nonducted applications must use a return louver grille

installed over the return opening inside the room.

Ducted Applications

Field fabricated supply and return duct work may be

installed inside the structure being conditioned. A short

supply and/or return stub duct may be connected to the

unit supply and return flanges before unit installation to

help with duct connections inside the structure. Supply

and return ducts must be properly sized for the design

airflow requirement of the equipment. Air Conditioning

Contractors of America (ACCA) is an excellent guide

to proper sizing. All duct work or portions thereof not

in the conditioned space should be properly insulated

in order to conserve energy, reduce heat conductivity,

and prevent condensation or moisture damage. Refer to

Maximum External Static Pressure (ESP) of Operation

Table 17 on page 36. Design the duct work according

to methods given by the Air Conditioning Contractors

of America (ACCA). When duct work is installed

in unheated spaces, it should be insulated with a

minimum of 1" of insulation. Use insulation with a

vapor barrier on the outside of the insulation. Flexible

joints should be used to connect the duct work to the

equipment in order to keep the noise transmission to a

minimum. Ducts through the walls must be insulated

and all joints taped or sealed to prevent air or moisture

from entering the wall cavity.

The unit itself is suitable for 0" clearance, but the

supply air duct flange and the first 3' of supply air duct

require a minimum of 1/4" clearance to combustible

material for model series W30 and W36. However, it

is generally recommended that a 1" clearance is used

for ease of installation and maintaining the required

clearance to combustible material. See Figures 3A and

3B on pages 10 and 11 for details on opening sizes.

!

WARNING

Fire hazard.

Maintain minimum 1/4" clearance between the

supply air duct and combustible materials in

the rst 3' of ducting.

Failure to do so could result in re causing

damage, injury or death.

Free Blow Applications

Some installations may not require extensive supply

duct work throughout the structure and are referred

to as free blow applications. A short field-fabricated

supply duct must be used in the wall cavity to

transition between the supply collar on the unit and

the supply louver grille in the room. The duct must

be properly insulated in order to conserve energy,

reduce heat conductivity and prevent condensation or

moisture damage. All joints must be taped or sealed to

prevent air or moisture entering the wall cavity. Follow

all clearances including distances to combustible

materials and all instructions provided in this manual.

A non-restrictive metallic supply air grille with

deflectors is required for free blow applications. Contact

the local Bard distributor or visit www.bardhvac.com for

ordering information.

A metallic return air grille is required for non-ducted

applications. The spacing between louvers on the grille

shall not be larger than 5/8". It is recommended that a

Bard Return Air Grille Kit be installed that is designed

specifically for the wall mount product. Contact the

local Bard distributor or visit www.bardhvac.com for

ordering information. A field-supplied return grille

that meets the 5/8" louver criteria and does not cause

the unit to exceed the maximum specified external

static pressure (ESP) may be used. If using a return

air filter grille, filters must be of sufficient size to

allow a maximum velocity of 400 fpm. Filter return

air grilles do not filter air being brought into the

structure through ventilation options including fresh air

dampers, ventilators, economizers and energy recovery

ventilators. Be sure to install the return grille with the

louvers pointed downward towards the floor. This will

help ensure return air is drawn upward from the floor

and improve air circulation in the room.

NOTE: If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

Thermostat or Indoor Temperature Sensor Placement

The location and installation of the thermostat or

temperature sensor that monitors indoor temperature is

very important regarding unit operation. Avoid placing

the thermostat in an area exposed to direct sunlight

or air from doorways leading outdoors. Use a piece

of insulating material to close off conduit openings

or holes in the wall surface for wire entry into the

thermostat or temperature sensor. This will help avoid

non-conditioned air from entering the thermostat

and effecting temperature and/or humidity readings.

As common practice, the thermostat or temperature

sensor should measure the temperature of the air

being returned to the unit, and not the conditioned

air being supplied by the unit. Placing the thermostat

or temperature sensor near a return air opening will

normally result in optimal unit performance.

Manual 2100-703

Page 7 of 40

Unit Installation

Make sure to have the proper tools at the work site that

are needed for unit installation. The following steps

are provided to ensure the unit is installed properly to

the wall surface, and that the unit will provide years of

service with minimal service requirements.

Materials/Tools List

Additional hardware and miscellaneous supplies are

needed for installation. These items are field supplied

and must be sourced before installation. This list also

includes tools needed for installation.

• Appropriate safety gear including gloves and safety

glasses

• 5/16" hex bit with drill driver

• Phillips head screwdriver

• Small straight (thermostat) screwdriver

• Tape measure

• Leveling device

• Two (2) tubes of caulk and caulk gun

• Utility knife

• Tools for cutting holes in the wall surface (if

needed)

• Electrical components and wiring along with

electrical tools

• Multimeter

• Wall fasteners for side flanges, bottom mounting

bracket and top rain flashing.

• Duct tape and/or other duct sealing materials.

Wall Preparation

1. Two holes for the supply and return air openings

must be cut through the wall as shown in

Figures 3A and 3B on pages 10 and 11. Be sure

the openings are square and level. Follow all

clearances including distances to combustible

materials and all instructions provided in this

manual.

2. Review all electrical requirements provided in this

manual and plan out electrical entrances into the

building. Also plan electrical conduit routing and

thermostat placement, if necessary.

3. Install necessary duct work and prepare the

openings for unit installation.

4. Clean the exterior wall where the unit is to be

installed and make sure it is able to provide a

smooth, level, debris-free surface. Remove all

construction debris from the supply, return and

electrical hole cutting process.

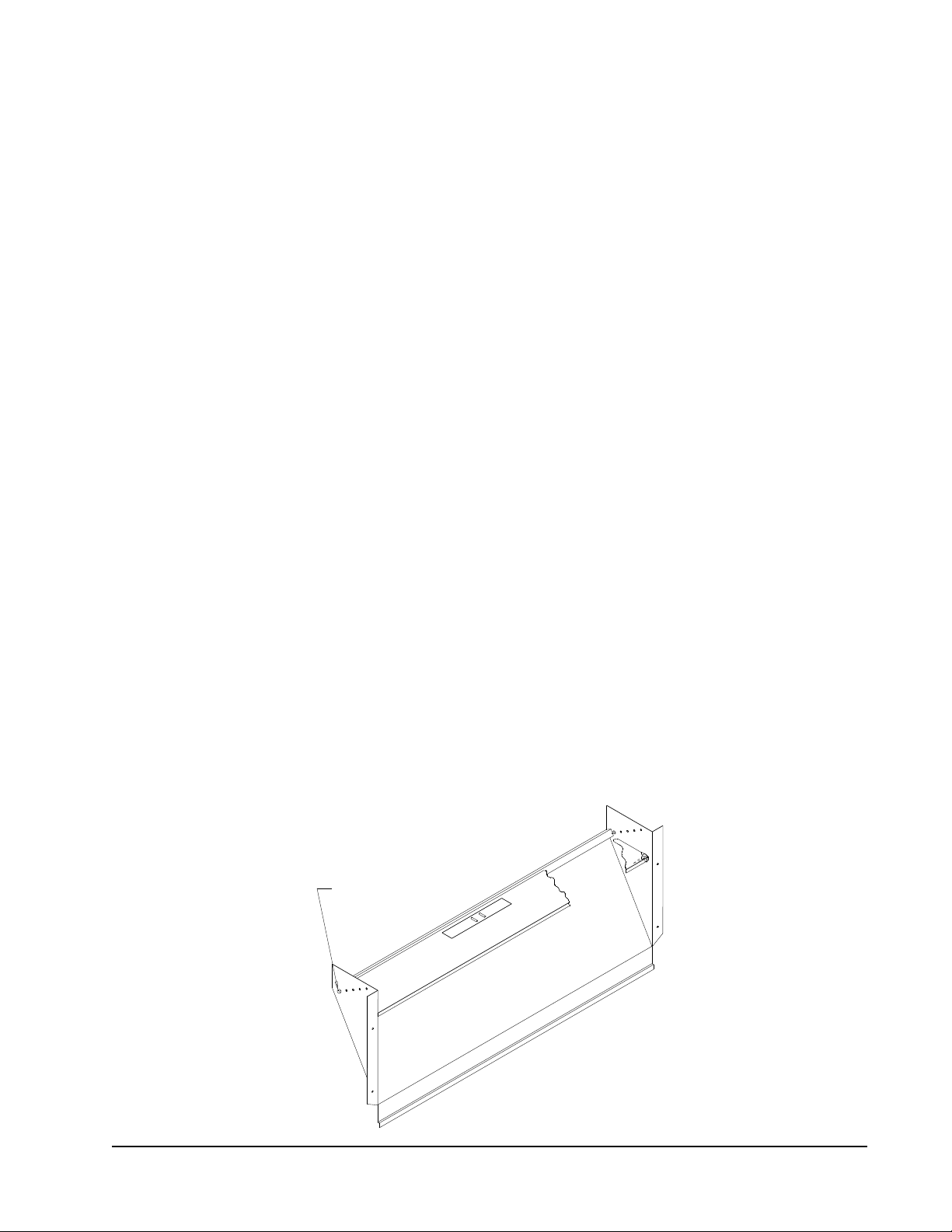

Wall Mount Installation to Wall Surface

Remove packaging from unit and make sure unit

1.

is not damaged before installation. A top rain

flashing is supplied for field use and is mounted

to the back of the unit for shipping. Remove rain

flashing before locating the unit against wall. Top

rain flashing is required to avoid water entering

the area behind the unit that is against the wall. A

bottom mounting bracket, attached to the skid for

shipping, is provided for ease of installation but is

not required. Review all requirements listed on unit

labels and on serial plate located on the side of the

unit.

2. Locate and mark bolt hole locations and bottom

mounting bracket location. Install bottom mounting

bracket with field-supplied fasteners to wall if it is

to be used (optional). Bracket must be level and

installed in the correct location to help support the

unit during the installation process (see Figures 3A

and 3B).

3. Position the wall mount unit close to the wall

surface where it will be installed. Install rain

flashing at the top of the unit facing the wall by

hooking the hem bend into the rear bend of the

unit top (see Figures 3A and 3B).

4. Apply a liberal amount of caulk on left and right

cabinet side wall mount brackets and back of

top rain flashing. Place unit back surface flush

against wall. Unit must be level to ensure proper

condensate drainage. Optional bottom bracket may

be used to help support the unit.

5. Units are secured to the wall by using fieldsupplied fasteners along each side of the wall

mount through the built-in wall mounting brackets.

It is the responsibility of the installer to select the

proper fastener to secure the unit to the wall based

on wall construction and applicable building codes.

Typical installations may include 5/16" fasteners

with 7/8" diameter flat washers. Be sure unit is

securely mounted and all weight-bearing fasteners

are attached to the weight supporting structural

members of the wall.

6. Apply a bead of caulk between the back of the unit

top and the front surface of the top rain flashing

(see Figures 3A and 3B).

7. Connect unit duct work from the inside of the

building following all clearances and instructions

provided. For additional mounting rigidity, the

return air and supply air frames or collars can be

drilled and screwed or welded to the structural wall

itself (depending upon wall construction). Be sure

to use code approved duct tape or other sealing

materials to seal the duct work to the unit.

8. On side-by-side installations, maintain a minimum

of 20" clearance on right side to allow access to

control panel and heat strips, and to allow proper

airflow to the outdoor coil. Additional clearance

may be required to meet local or national codes.

Manual 2100-703

Page 8 of 40

TABLE 1

Clearance Required for Service Access and

Adequate Condenser Airflow

TABLE 2

Minimum Clearances Required

to Combustible Materials

Model

W18H

W24H

W30H

W36H

Left

Side

15" 20"

Right

Side

Model Supply Air Duct (1st 3') Cabinet

W18H

W24H

W30H

W36H

0" 0"

1/4" 0"

1. Follow all national, state, and local codes and regulations regarding the installation of heating and cooling equipment regarding Single

Packaged Vertical Units (SPVU) including electrical access clearances.

2. Field ventilation installation with the unit installed requires 40" on the left or right side of the unit.

3. Bard recommends a minimum of 10' between the unit front condenser air outlet and solid objects including fences, walls, bushes and

other airflow obstructions.

4. Bard recommends a minimum of 15' between the condenser air outlets of two units that are facing each other.

5. Bard recommends a minimum clearance of 4" under the unit cabinet for condenser defrost drain age during heat pump operation.

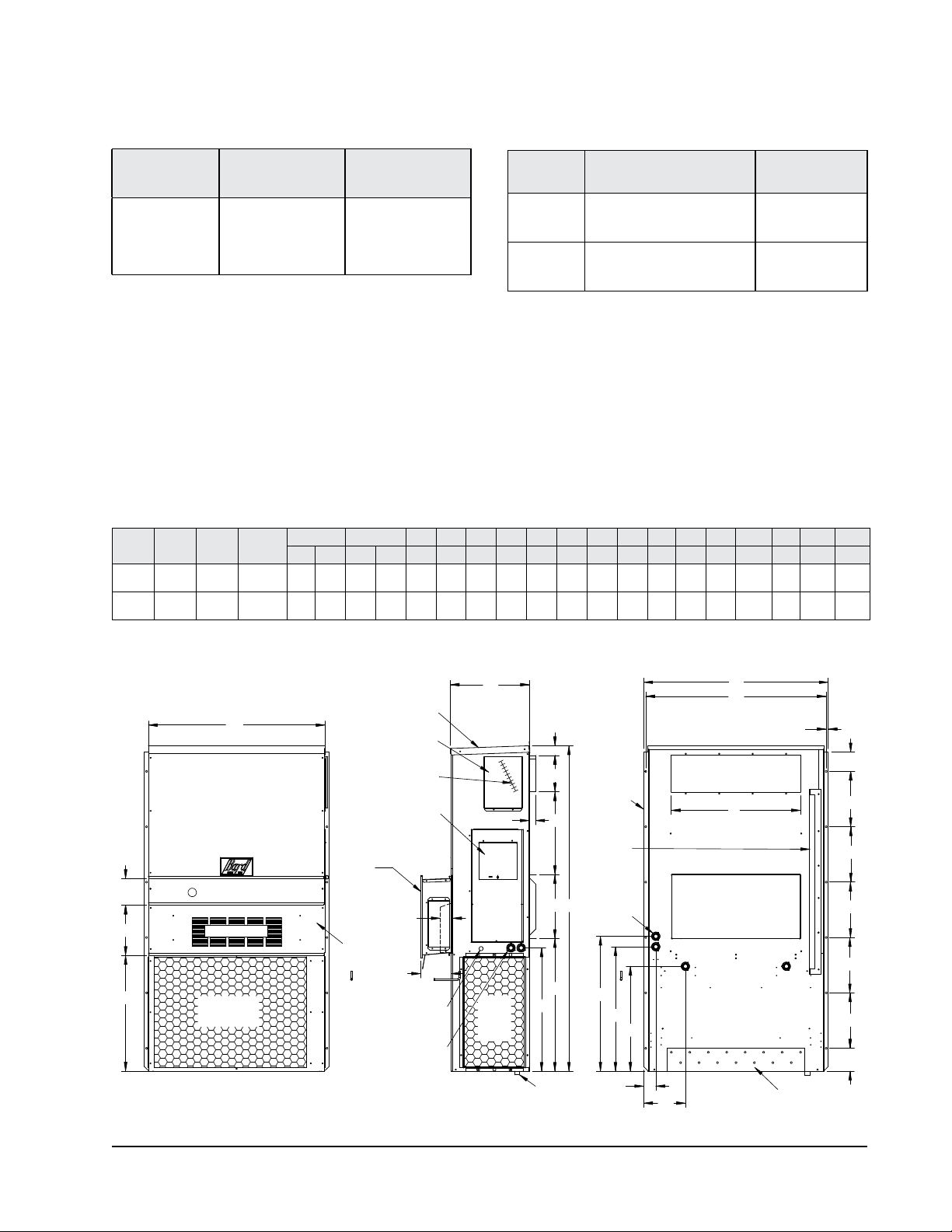

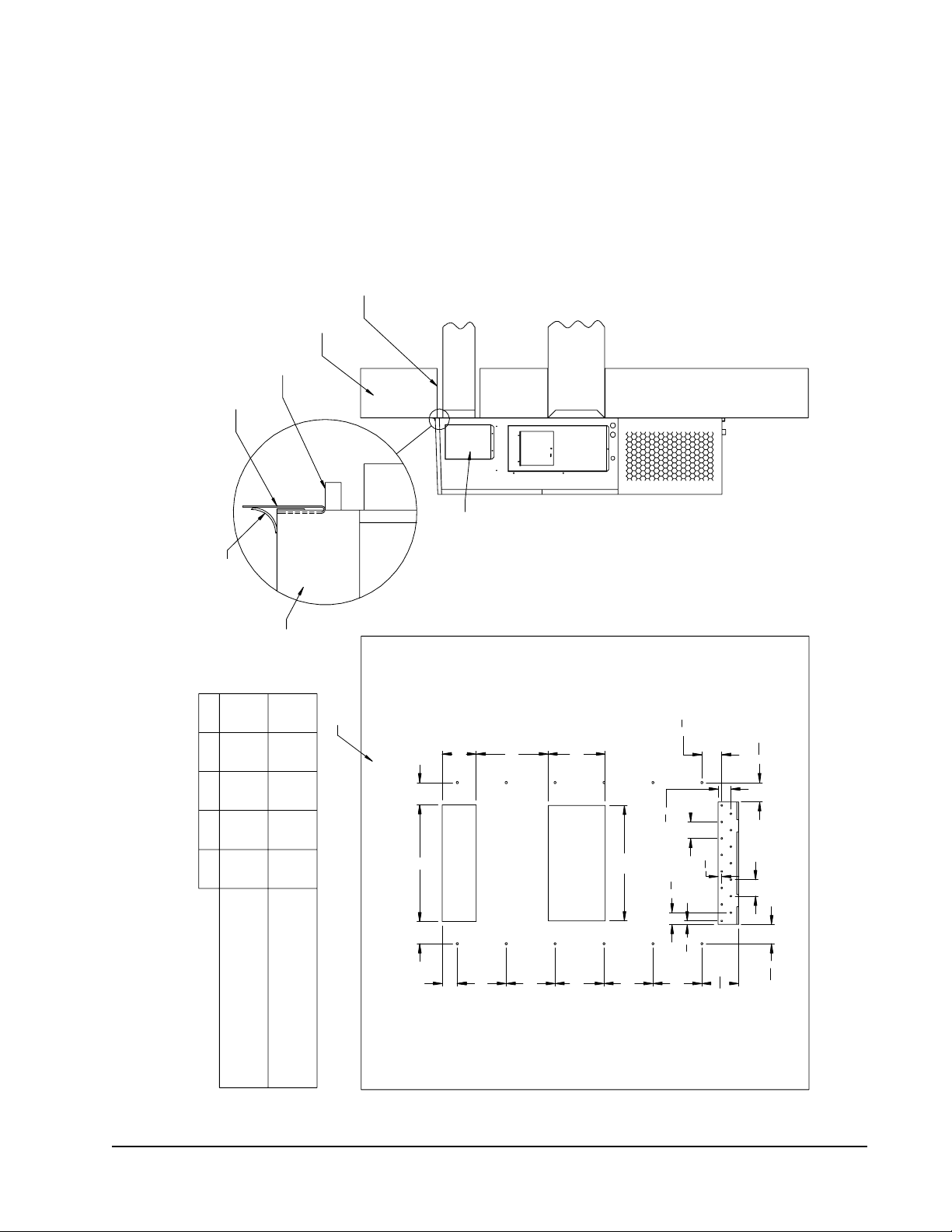

FIGURE 2

Unit Dimensions

Width

Depth

(W)

W18HB

33.300 17.125 74.563 7.88 19.88 11.88 19.88 35.00 10.88 29.75 20.56 30.75 32.06 33.25 31.00 2.63 34.13 26.06 10.55 4.19 12.00 9.00

W24HB

W30HB

38.200 17.125 74.563 7.88 27.88 13.88 27.88 40.00 10.88 29.75 17.93 30.75 32.75 33.25 31.00 2.75 39.13 26.75 9.14 4.19 12.00 9.00

W36HB

Height

(D)

All dimensions are in inches. Dimensional drawings are not to scale.

Supply Return

(H)

A B C B E F G I J K L M N O P Q R S T

5.88

F

G

W

Filter AccessPanel

1

Ventilation Air

Condenser

Air Outlet

Front View

Rain Hood

C. Breaker/

Disconnect

Access Panel

(Lockable)

Hood for CRVand

ECON models

only

Standard

flush vent

door for nonERV/CRV

Econ.

models

Low Voltage

High Voltage

Built In

4° Pitch

Heater

Access

Panel

Electric

Heat

3"

7.00

Electrical

Entrance

Electrical

Entrance

D

1.250

Cond.

Air

Inlet

Side View

2.13

J

Drain

E

O

.44

Side Wall

A

Mounting

Brackets

(Built In)

I

Top Rain

Flashing

Shipping

Location

Optional

C

Electrical

H

Entrances

K

L

M

P

N

Supply Air Opening

B

Return Air Opening

Back View

Q

Bottom Installation

Bracket

R

S

S

S

S

S

T

MIS-3796

Manual 2100-703

Page 9 of 40

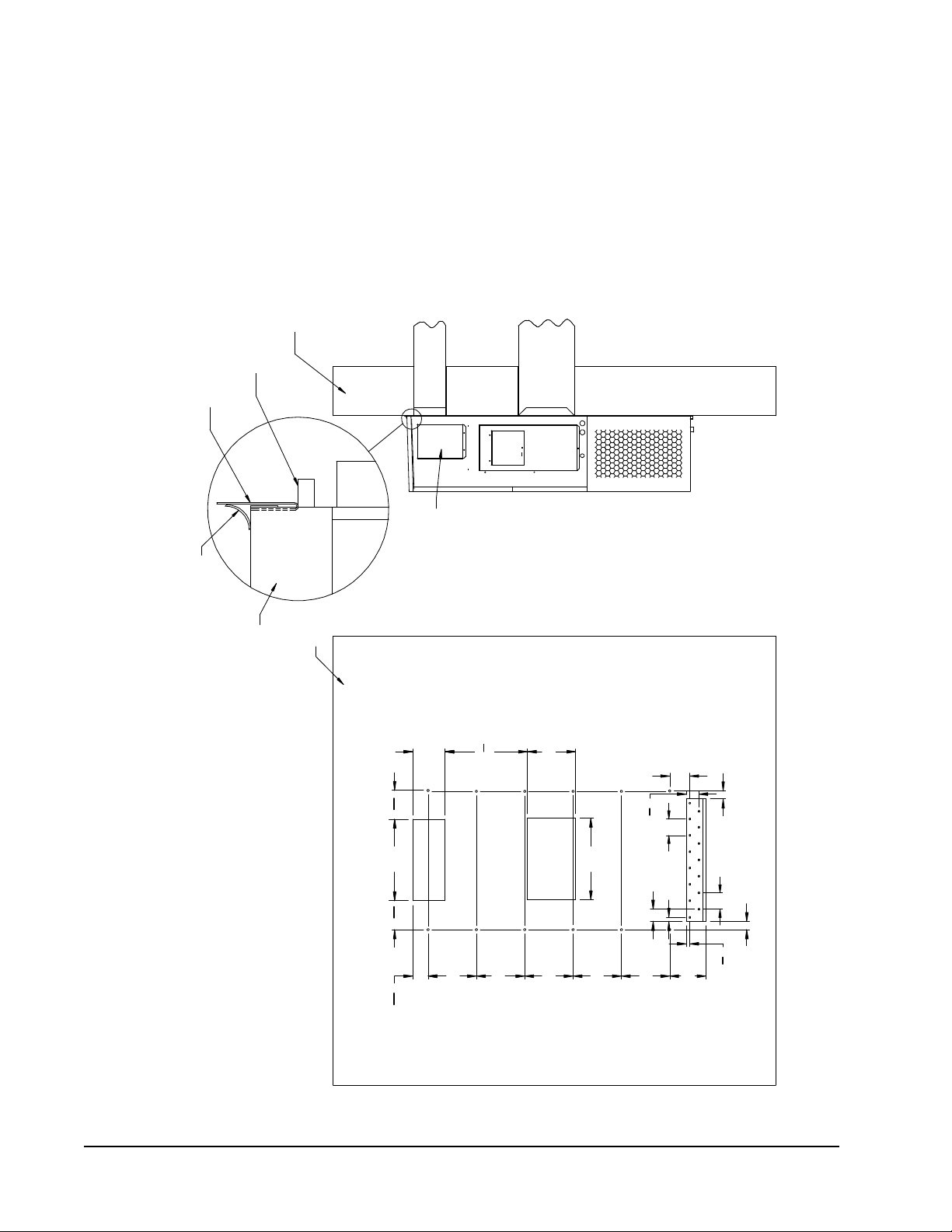

12"

12"

12"

12"

12"

20"

20"

8"

20

1

2

"

12"

3

13

16

"

2"

2"

7

1

16

" 7

1

16

"

5"

1"

3"

4"

Typ.

3

1

8

"

4"

Typ.

7

8

"

9"

NOTES:

WALL STRUCTURE

ENTIRE LENGTH OF TOP.

TOP

WALL

OF CAULKING ALONG

PANEL

FOAM AIRSEAL

DUCT

RAIN FLASHING

HEATER ACCESS

MIS-3157 A

Wall Opening and Hole Location View Right Side View

RETURN AIR

TOP FLASHING ATTIME OF INSTALLATION.

OPENING

THE SIDEMOUNTING FLANGES ANDUNDER

SEAL WITHBEAD

IT IS RECOMMENDEDTHATA BEAD OF

SILICONE CAULKING BEPLACED BEHIND

SUPPLY AIR

SUPPLIED

Return Opening

Supply Opening

J**A UNIT SHOWN, J**L UNIT

CONTROLS AND HEATERACCESS

IS ONOPPOSITE(LEFT) SIDE.

FIGURE 3A

W18H, W24H

Mounting Instructions

Manual 2100-703

Page 10 of 40

28"

A C

D

C

12"

12"

12"

12"

12"

B

E

14"

4

11

16

"

4

11

16

"

4"

Typ.

2

7

8

"

7

8

"

7

8

"

" 3

1

8

4"

Typ.

9

1

16

"

4

7

8

"

MATERIALS

RAIN FLASHING

RETURN AIR

TOP

SILICONE CAULKING BE PLACED BEHIND

SUPPLIED

ENTIRE LENGTH OF TOP.

NOTES:

OF CAULKING ALONG

PANEL

FOAM AIR SEAL

WALL STRUCTURE

FOUR SIDES OF SUPPLY

AIR DUCT IS REQUIRED

SUPPLY AIR

OPENING

MIS-3158 A

Right Side View

1/4" CLEARANCE ON ALL

DUCT

THE SIDE MOUNTING FLANGES AND UNDER

HEATER ACCESS

TOP FLASHING AT TIME OF INSTALL ATION.

FROM COMBUSTABLE

SEAL WITH BEAD

IT IS RECOMMENDED THAT A BEAD OF

WALL

Wall Opening and Hole Location View

REQUIRED DIMENSIONS TO MAINTAIN

Return Opening

16 7/84 7/164 5/89 7/829 7/8

17 5/83 11/165 3/88 3/828 3/8

EDCBA

COMBUSTIBLE MATERIALS

RECOMMENDED 1" CLEARANCE FROM

REQUIRED DIMENSIONS TO MAINTAIN

COMBUSTIBLE MATERIALS

1/4" MIN. CLEARANCE FROM

Supply Opening

J**A UNIT SHOWN, J**L UNIT

CONTROLS AND HEATER ACCESS

IS ON OPPOSITE (LEFT) SIDE.

FIGURE 3B

W30H, W36H

Mounting Instructions

Manual 2100-703

Page 11 of 40

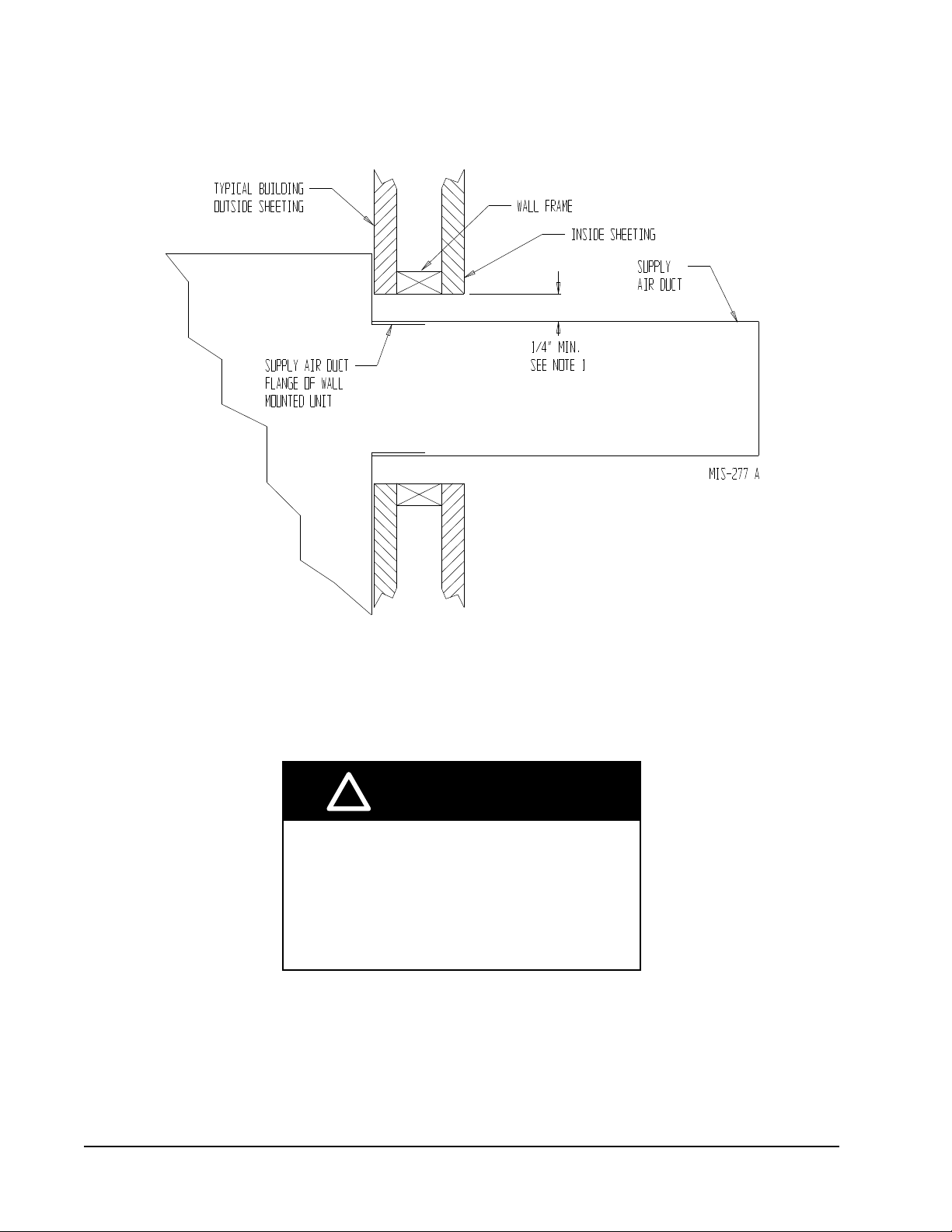

FIGURE 4

Electric Heat Clearance

W30H and W36H

SIDE SECTION VIEW OF SUPPLY AIR DUCT FOR

WALL-MOUNTED UNIT SHOWING 1/4" CLEARANCE

TO COMBUSTIBLE SURFACES.

!

WARNING

Fire hazard.

Maintain minimum 1/4" clearance between the

supply air duct and combustible materials in

the rst 3' of ducting.

Failure to do so could result in re causing

damage, injury or death.

Manual 2100-703

Page 12 of 40

Loading...

Loading...