Page 1

OPERATIONS MANUAL

TELCOM

CLIMATEWATCH

SYSTEM

MODEL

TCS22-***-003

Manual: 2100-444-003A

Supersedes: 2100-444-003

File: Vol. III, Tab 19

Page 2

Table Of Contents

1.0 INTRODUCTION ...........................................................................................................1

1.1 Shipping Damage.........................................................................................................................1

1.2 Package Contents.........................................................................................................................1

1.3 Additional Requirements............................................................................................................1

1.4 Copyright Notice..........................................................................................................................1

1.5 General..........................................................................................................................................2

1.5.1 Building Points to be Monitored:...........................................................................................2

1.5.2 Wallmount Points to be Monitored for Each Unit:................................................................2

1.5.3 Building Points to be Controlled: ..........................................................................................2

1.5.4 System Points to be Controlled:.............................................................................................3

1.5.5 Wallmount Points to be Controlled: ......................................................................................3

1.5.6 Alarm Points:.........................................................................................................................3

1.6 Model Nomenclature....................................................................................................................5

2.0 SPECIFICATIONS.........................................................................................................5

2.1 Electrical Specifications...............................................................................................................5

2.2 Mechanical Specifications...........................................................................................................5

2.3 Environmental Specifications.....................................................................................................5

2.4 Sensor Specifications ...................................................................................................................6

2.4.1 Temperature Sensors..............................................................................................................6

2.4.2 Humidity Sensors...................................................................................................................6

2.4.3 Compressor Current Sensor...................................................................................................6

2.4.4 Dirty Filter Sensor..................................................................................................................6

2.4.5 Blower Airflow Switch..........................................................................................................7

3.0 INSTALLATION...........................................................................................................11

3.1 Mounting.....................................................................................................................................11

3.2 Wiring.........................................................................................................................................11

3.2.1 High Voltage Wiring............................................................................................................11

3.2.2 Wiring - Low Voltage..........................................................................................................12

2100-444-003A

Page ii

Page 3

3.2.3 Wiring - Sensors ..................................................................................................................12

3.2.4 Wiring – Inputs & Outputs...................................................................................................13

3.2.5 Wiring - Telephone Line......................................................................................................14

3.2.6 Wiring - Ethernet .................................................................................................................14

3.3 Installation Check List ..............................................................................................................18

3.4 System Startup...........................................................................................................................19

3.4.1 Wallmount Startup Checklist...............................................................................................19

3.4.2 TCS22 Startup Checklist .....................................................................................................20

4.0 OPERATION................................................................................................................21

4.1 General........................................................................................................................................21

4.2 Sequence of Operation...............................................................................................................21

4.2.1 Cooling Sequence with Economizers ..................................................................................21

4.2.2 Heating Sequence.................................................................................................................21

4.2.3 Fan Sequence.......................................................................................................................21

4.2.4 Occupied / Unoccupied Mode Sequence.............................................................................22

4.2.5 Alarm Sequence..................................................................................................................22

4.2.6 Dehumidification sequence..................................................................................................24

4.2.7 Thermal Shock Protection Sequence ...................................................................................24

4.2.8 Modem Sequence.................................................................................................................24

4.2.9 Power Management Sequence.............................................................................................24

4.2.10 Setpoints...............................................................................................................................25

5.0 DISPLAY & KEYPAD OPERATION (DAK).................................................................25

5.1 Display & Keypad Physicals.....................................................................................................25

5.2 Power Up.....................................................................................................................................26

5.3 Menu Tree...................................................................................................................................26

5.3.1 Buildings Status Screen.........................................................................................................27

5.3.1.1 Room Temperature ..............................................................................................................28

5.3.1.2 Room Humidity ...................................................................................................................28

5.3.1.3 Outdoor Temperature...........................................................................................................28

5.3.1.4 Outdoor Humidity................................................................................................................28

5.3.1.5 Active Cooling Setpoint.......................................................................................................28

5.3.1.6 Active Heating Setpoint.......................................................................................................28

5.3.1.7 Free Cooling On / Off........................................................................................................29

5.3.1.8 Room Occupied Yes/No...................................................................................................29

5.3.1.9 Outdoor Enthalpy................................................................................................................29

2100-444-003A

Page iii

Page 4

5.3.2 Unit Status Screen..................................................................................................................30

5.3.2.1 Unit #1 Economizer.............................................................................................................30

5.3.2.2 Unit #1 Compressor.............................................................................................................30

5.3.2.3 Unit #1 Heater......................................................................................................................30

5.3.2.4 Unit #1 Blower.....................................................................................................................30

5.3.2.5 Unit #1 FILTER...................................................................................................................31

5.3.2.6 Unit #1 Discharge Air Temperature.....................................................................................31

5.3.3 Alarms Menu..........................................................................................................................31

5.3.3.1 Space Temp Alarm .............................................................................................................32

5.3.3.2 Space Humidity Alarm........................................................................................................32

5.3.3.4 #1 Compressor Alarm.........................................................................................................33

5.3.3.5 #1 Filter Alarm....................................................................................................................33

5.3.3.6 Utility Power Fail................................................................................................................33

5.3.3.7 Fire Trouble .....................................................................................................................34

5.3.3.8 Fire Alarm...........................................................................................................................34

5.3.3.9 Outdoor Temp Alarm..........................................................................................................34

5.3.3.10 Outdoor Humidity Alarm.................................................................................................34

5.3.3.11 Door Alarm......................................................................................................................34

5.3.4 Setpoints Screen............................................................................................................................35

5.3.4.1 Occupied Cooling Setpoint..................................................................................................36

5.3.4.2 Unoccupied Cooling Setpoint..............................................................................................36

5.3.4.3 Occupied Heating Setpoint ..................................................................................................37

5.3.4.4 Unoccupied Heating Setpoint ..............................................................................................37

5.3.4.5 High Temperature Alarm Setpoint.......................................................................................37

5.3.4.6 Low Temperature Alarm Setpoint .......................................................................................37

5.3.4.7 High Humidity Alarm Setpoint............................................................................................37

5.3.4.8 Low Humidity Alarm Setpoint ............................................................................................37

5.3.4.9 Dehumidification Setpoint...................................................................................................37

5.3.4.10 Free Cooling Enthalpy Setpoint.......................................................................................38

5.3.4.11 Free Cooling Dry Bulb Setpoint ......................................................................................38

5.3.5 Overrides Unit #1 Screen .............................................................................................................39

5.3.5.1 #1 Blower Override..............................................................................................................40

5.3.5.2 #1 Economizer Override......................................................................................................41

5.3.5.3 #1 Compressor Override......................................................................................................41

5.3.5.4 #1 Heater Override...............................................................................................................41

5.3.5.5 Continuous Blower ..............................................................................................................42

5.3.6 Enables Menu...............................................................................................................................43

5.3.6.1 Economizer Operation .........................................................................................................44

5.3.6.2 Free Cooling Enthalpy Changeover.....................................................................................44

5.3.6.3 Dry Bulb Temperature Changeover.....................................................................................44

5.3.6.4 Daylight Savings Time.........................................................................................................44

2100-444-003A

Page iv

Page 5

5.3.6.5 50HZ Clock..........................................................................................................................44

5.3.6.6 Zone Humidity Sensor.........................................................................................................44

5.3.7 Password Operation...............................................................................................................45

5.4 Keyboard Map ...........................................................................................................................46

6.0 PC SOFTWARE OPERATION....................................................................................48

6.1 ClimateWatch System Software Overview.............................................................................48

6.2 Installation..................................................................................................................................48

6.2.1 Hardware Requirements.......................................................................................................48

6.2.2 Software Installation............................................................................................................48

6.3 ASI Expert / Bard ClimateWatch Software............................................................................49

6.3.1 Screen Overview..................................................................................................................49

6.3.2 TCS communications...........................................................................................................51

6.4 TCS Controller Information Screens.......................................................................................59

6.4.1 Main Screen Tab..................................................................................................................60

6.4.2 Set Point Tab........................................................................................................................62

6.4.3 Override #1 Tab...................................................................................................................66

6.4.4 Alarms Tab...........................................................................................................................70

6.4.5 Alarm Log Tab.....................................................................................................................74

6.4.6 Offsets Tab...........................................................................................................................75

6.4.7 Misc. Tab .............................................................................................................................76

6.4.8 Trend Tab.............................................................................................................................79

6.4.9 Dial Out Tab ........................................................................................................................80

6.4.10 Notes Tab.............................................................................................................................82

7. MAINTENANCE & TROUBLESHOOTING ........................................................................83

7.1 Routine Maintenance.................................................................................................................83

7.2 Troubleshooting.........................................................................................................................83

7.2.1 TCS22 Troubleshooting......................................................................................................83

7.2.2 Wallmount quick troubleshooting Guide.............................................................................89

2100-444-003A

Page v

Page 6

Table of Figures and Tables

Figure 1 Front Cover

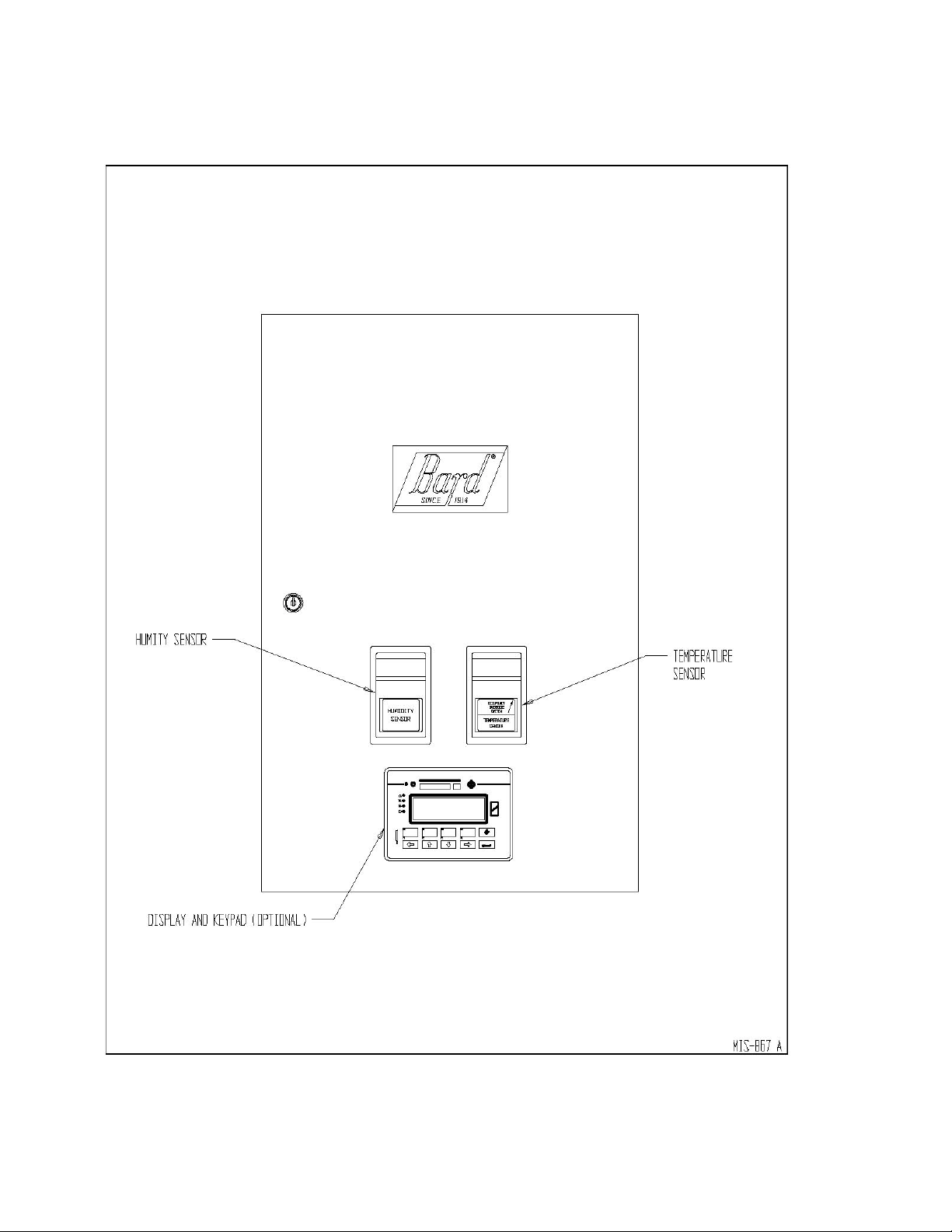

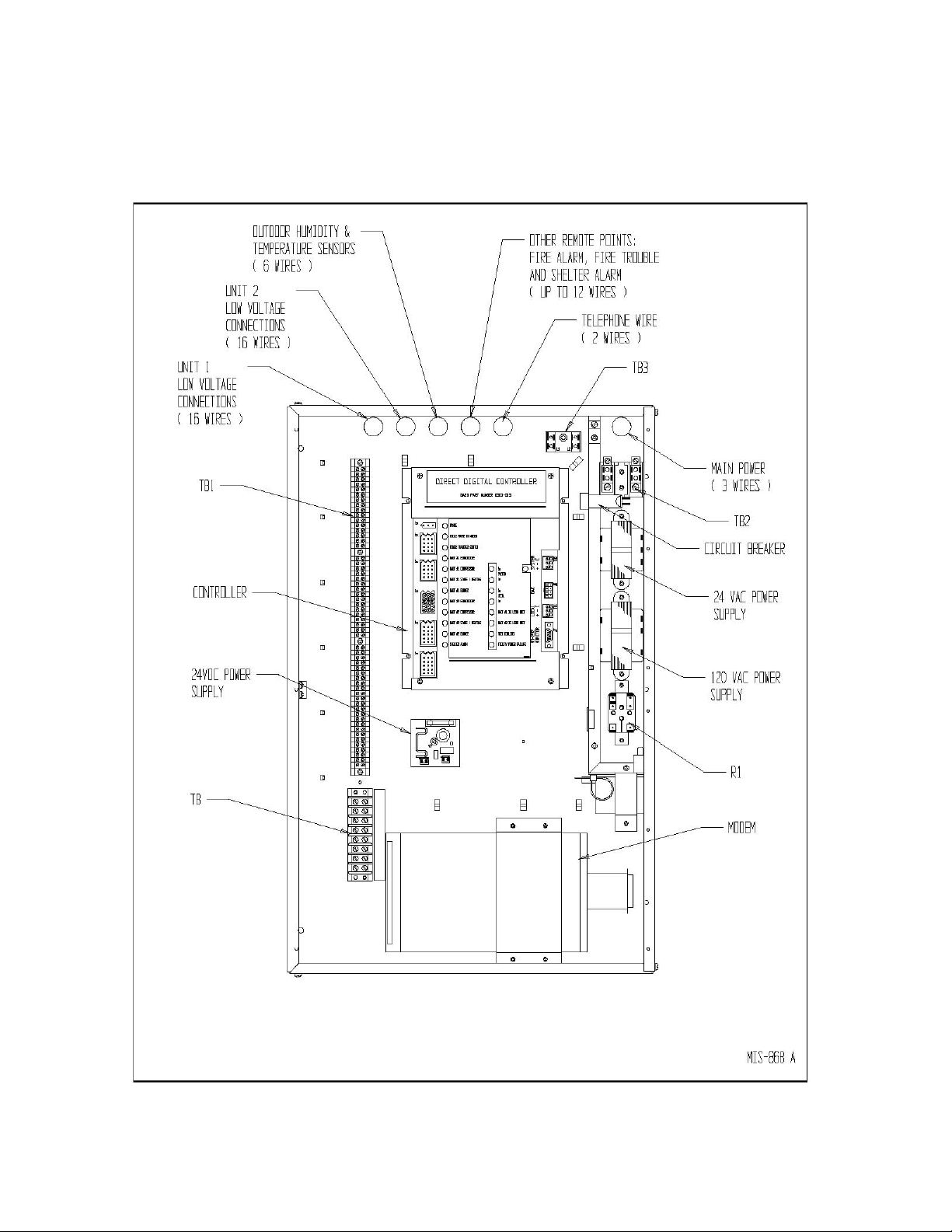

Figure 2 Control Location

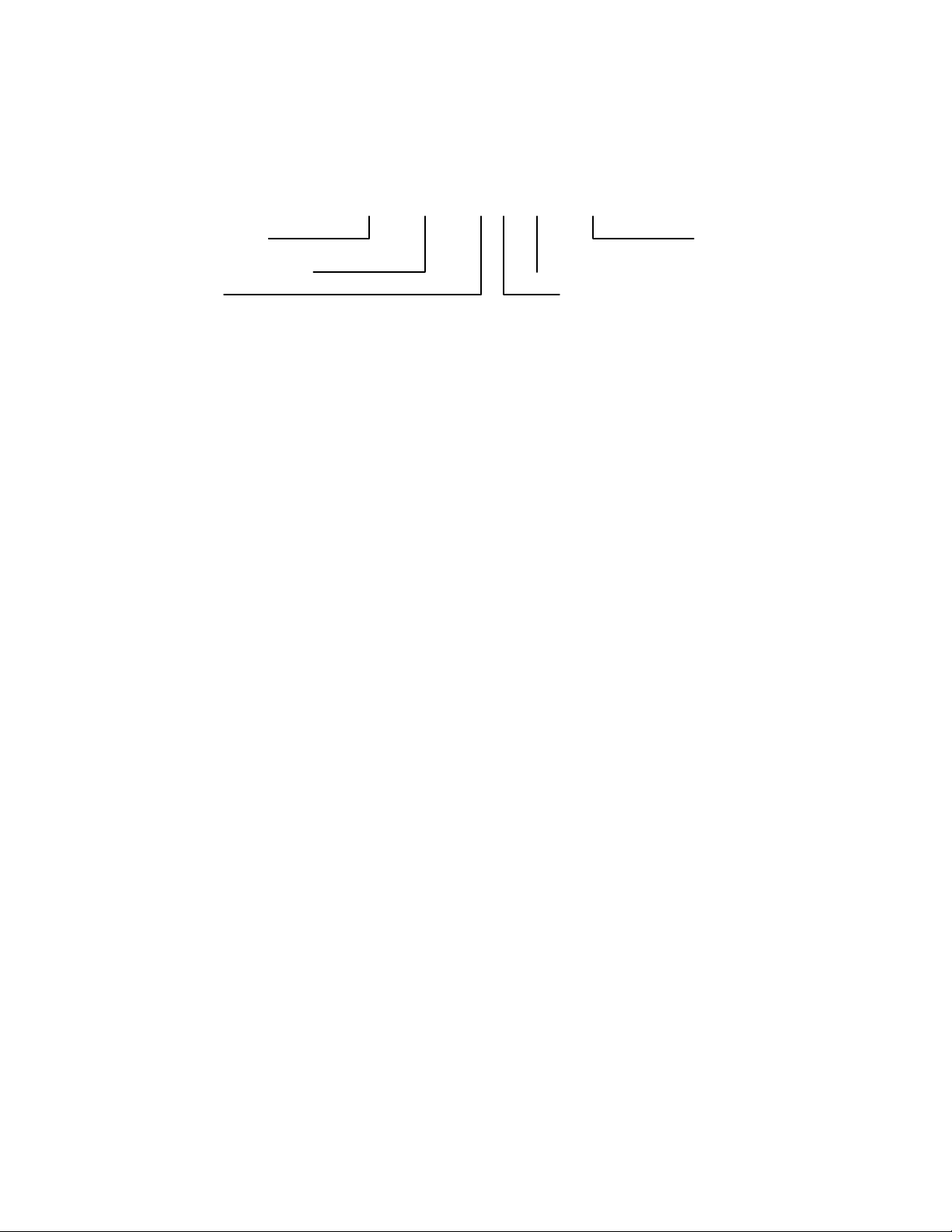

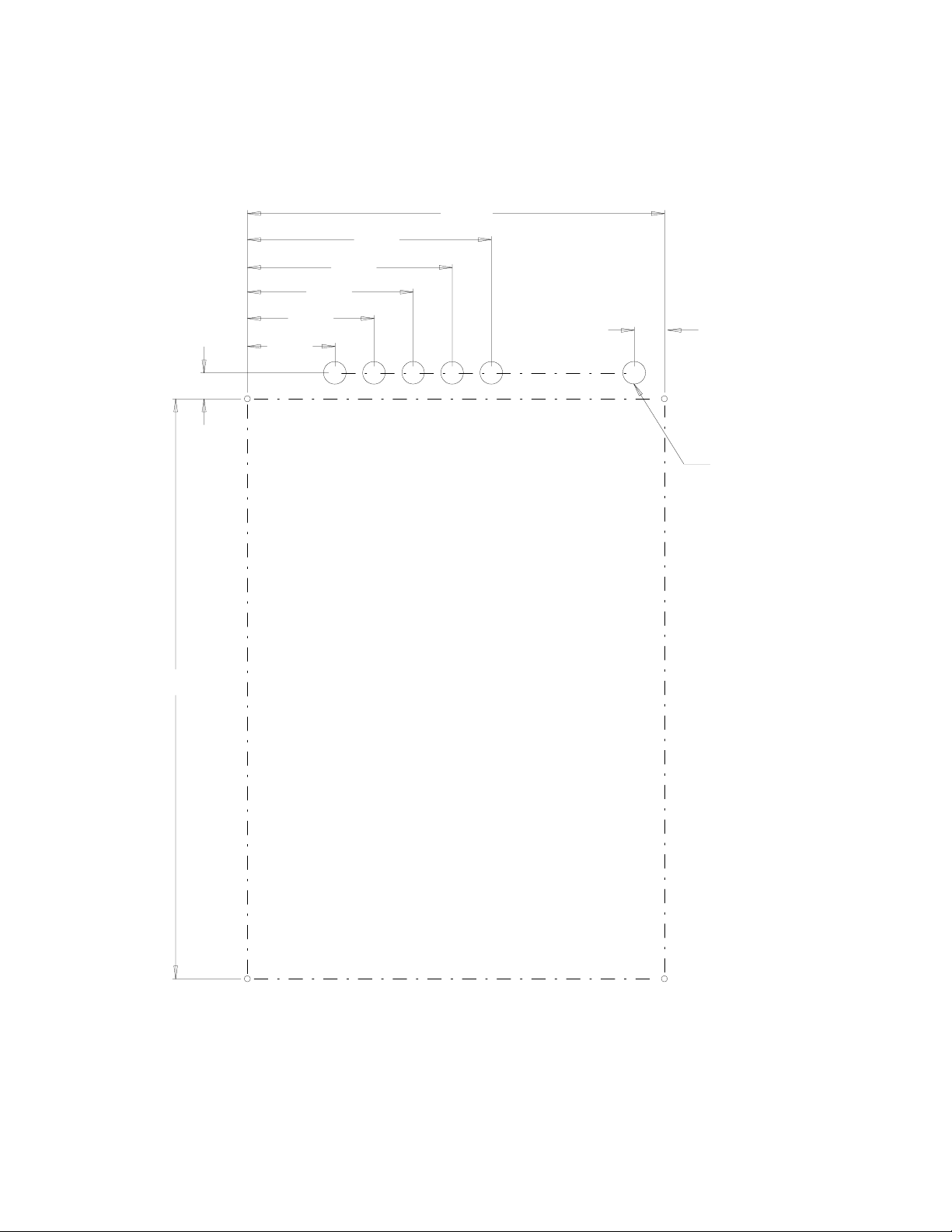

Figure 3 Mounting Template

Table 1 Low Voltage Wire Size

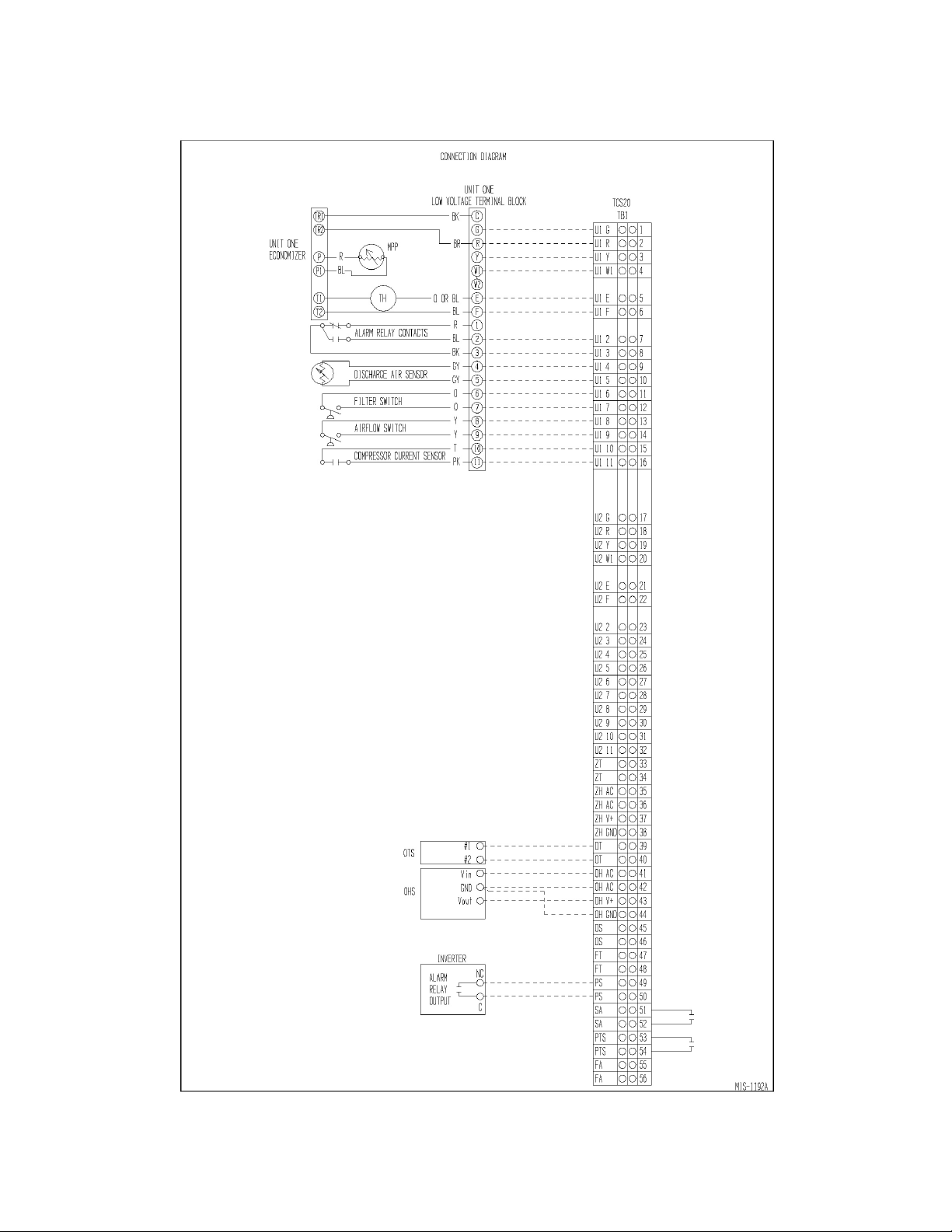

Figure 4 External Wiring

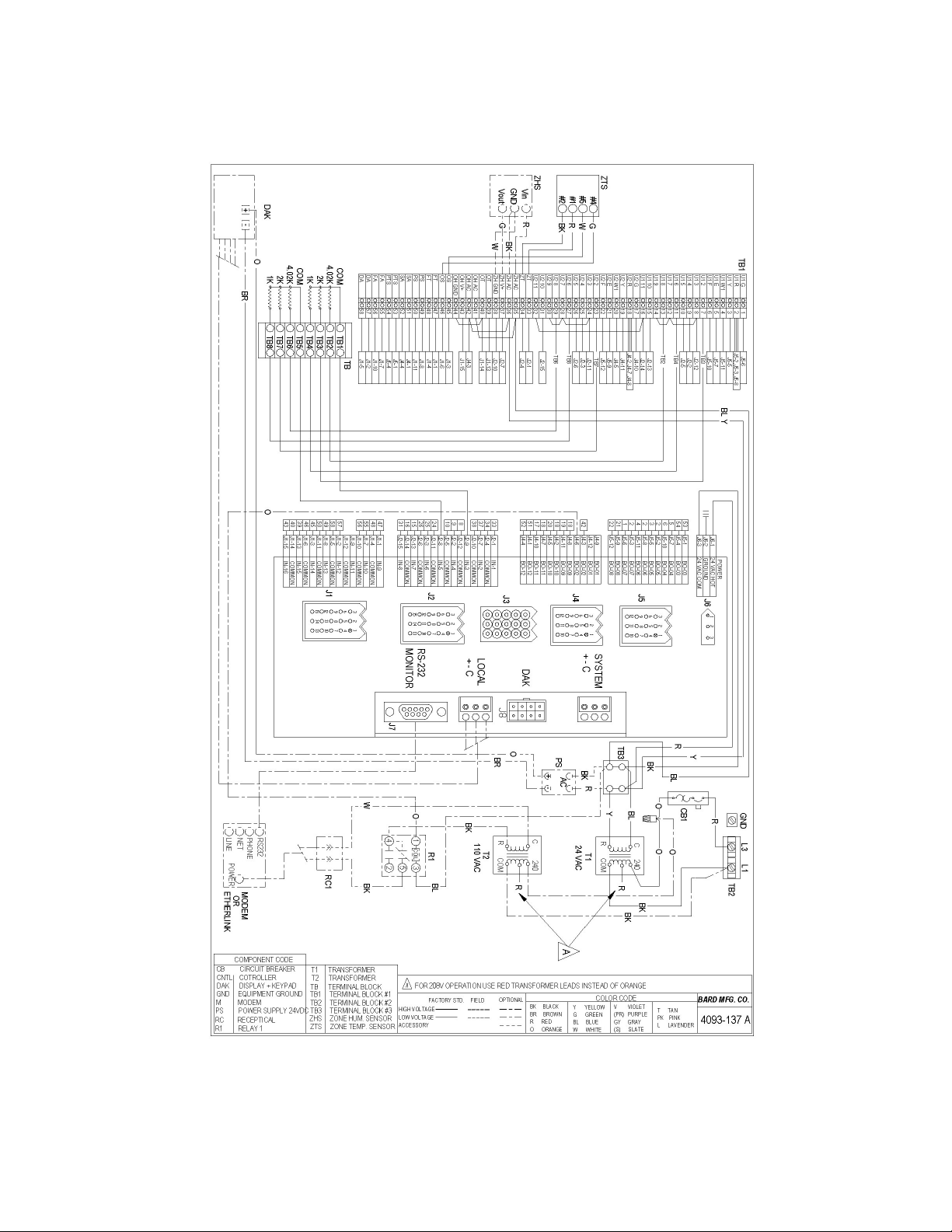

Figure 5 Internal Wiring

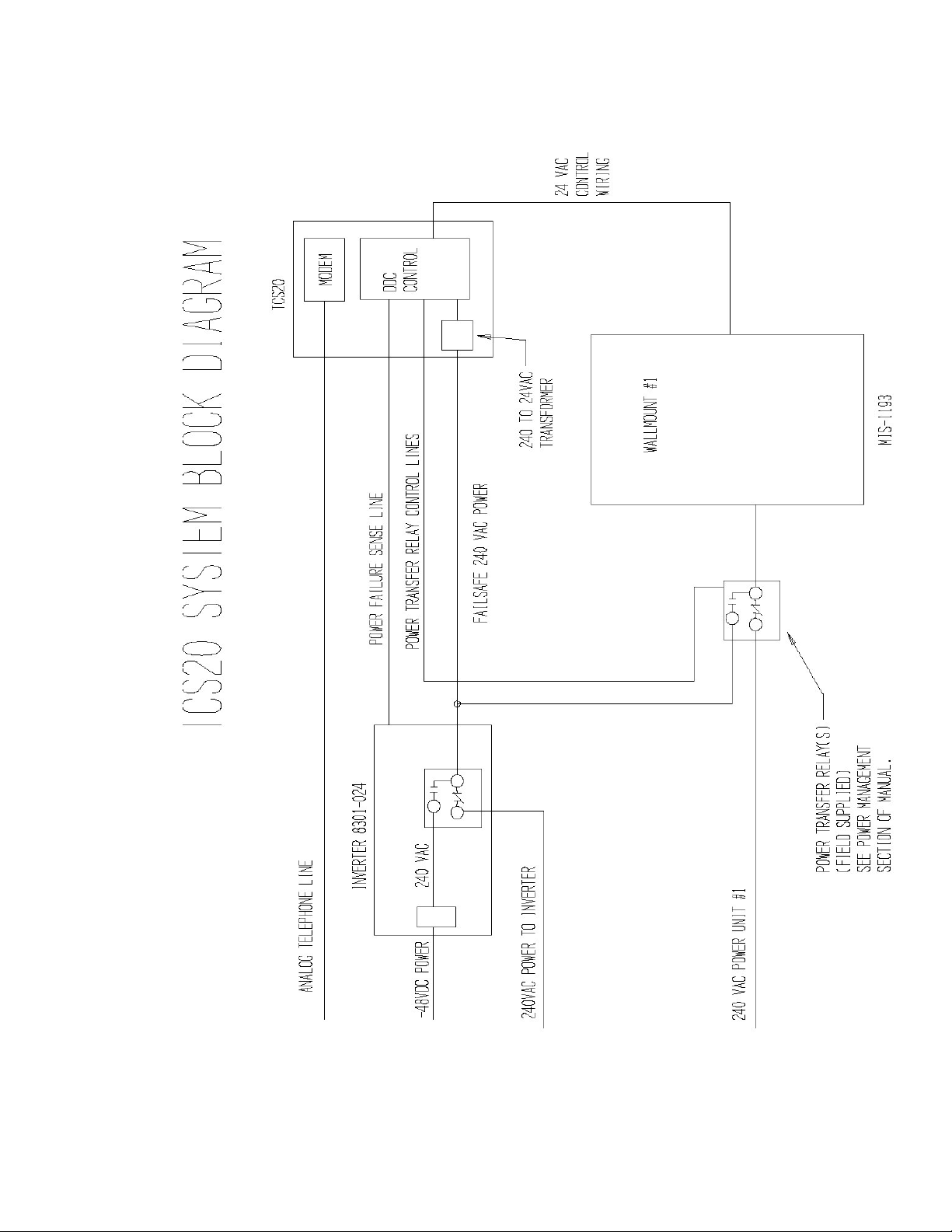

Figure 6 Power Backup System

Table 2. Enthalpy Lookup Table

Table 3 Humidity Sensor Output

......................................................................................................................8

............................................................................................................9

....................................................................................................10

..............................................................................................12

............................................................................................................15

.............................................................................................................16

..............................................................................................16

............................................................................................39

............................................................................................87

Table 4 Thermistor Resistance Vs. Temperature Table.

.............................................88

2100-444-003A

Page vi

Page 7

1.0 INTRODUCTION

1.1 Shipping Damage

Upon receipt of equipment, the carton should be checked for external signs of shipping damage.

If damage is found, the receiving party must contact the carrier immediately, preferably in writing,

requesting inspection by the carrier's agent.

1.2 Package Contents

1 - TCS22

1 - Outdoor Humidity Sensor

1 - Outdoor Temperature Sensor

1 - TCS22 Operations Manual

1 - TCS Software Package

1.3 Additional Requirements

This controller is suitable for use with 1 1/2 ton through 6 ton Bard WallMount airconditioners. The Bard WallMount must be equipped with the "V" control module for proper

operation of the TCS22. Air-conditioner model numbers used with the TCS22 should contain the letter

"V" in the 15th position of the model number.

The TCS22 can be used with or without economizers. If economizers are to be used the units

should be ordered with the “D” vent option. The air-conditioner with economizer used with the TCS22

should contain the letter "D" in the 10th position of the model number.

Additionally, to utilize the Power Failure Management portion of the controller an Inverter and

battery backup system should be installed in the shelter. This provides for ventilation of the structure in

case of utility power failure, alarming of the power failure condition, and acts as an uninterruptible

power supply for the TCS22. See Figure 6.

If the inverter and battery backup system is not used disregard the power failure management

sequence later in this manual.

The power transfer relays shown in Figure 3 are field supplied items and are needed if ventilation

of the structure is required during power outages. The field supplied power transfer relays should be

sized to handle the MCA of the unit being controlled. Single phase units will require a 4 pole contactor

with 2 normally open and 2 normally closed contacts. Three phase units will require either a six pole

contactor or two 3 pole relays with 3 normally closed and three normally open contacts. Square D, DLine or F-Line contactors or equivalent are recommended.

If ventilation of the structure is not required during power outages these may be omitted. The

TCS22 will still dial out and alarm the power failure condition although no ventilation will be provided.

1.4 Copyright Notice

All materials contained in this manual originated from and are the property of Bard

Manufacturing Co. Any reproduction of the text, drawings, or wiring diagrams contained in this manual

is forbidden without the written consent of Bard Manufacturing Co.

2100-444-003A

Page 1

Page 8

All SOFTWARE supplied with this product is the property of Bard Manufacturing Co. You may

not modify, disassemble, de-compile, reverse engineer, or create derivative works from this

SOFTWARE. Bard Manufacturing Co. licenses the purchaser of this product to use two copies of this

SOFTWARE on two computer systems, one remote computer system and one on site computer system.

If installed on a network server, additional software licenses should be purchased for each

computer on the network using the SOFTWARE.

1.5 General

The Telcom Climate Watch System (TCS) is a building monitoring and control system used in

conjunction with one (1) Bard Wall-Mount air-conditioners. The system consists of a state of the art

direct digital controller, the TSC22, one (1) Bard Wall-Mount air-conditioners, and a special "V"

control module that is added to the Bard Wall-Mount air-conditioners. This system provides the

following features.

1.5.1 BUILDING POINTS TO BE MONITORED:

Space Temperature

Space Humidity

Outdoor Temperature

Outdoor Humidity

Occupancy Override Switch

Main Power to Building

Fire Alarm Circuit

Fire Trouble Circuit

Door Alarm Circuit

1.5.2 WALLMOUNT POINTS TO BE MONITORED FOR EACH UNIT:

Blower Airflow

Discharge Air Temperature

Valid Compressor Current Sensor

Compressor Lockout Relay

Dirty Filter Sensor

1.5.3 BUILDING POINTS TO BE CONTROLLED:

Power Transfer Relay

Shelter Alarm Circuit

Door Alarm

2100-444-003A

Page 2

Page 9

1.5.4 SYSTEM POINTS TO BE CONTROLLED:

Modem Power

1.5.5 WALLMOUNT POINTS TO BE CONTROLLED:

Blower Unit #1

Economizer Unit #1

Compressor Unit #1

Heating Unit #1

Blower Unit #2

1.5.6 ALARM POINTS:

High Space Temperature

Low Space Temperature

High Space Humidity

Low Space Humidity

Blower Failure Unit #1

Compressor Lockout Unit #1

Compressor Current Failure Unit #1

Dirty Filter Unit #1

Main Power Failure

Fire Alarm

Fire Trouble

Door Alarm

2100-444-003A

Page 3

Page 10

INPUTS

1 Indoor Temperature Sensor Required (Standard in TCS22)

2 Indoor Humidity Sensor Optional (Optional in TCS22)

3 -0 Unit #1 Blower Airflow Sensor Required (Standard in "V" Module)

-1 Unit #1 Compressor Lockout Relay Required (Standard in "V" Module)

-2 Unit #1 Dirty Filter Sensor Optional (Standard in "V" Module)

4 Unit #1 Discharge Air Sensor Optional (Standard in "V" Module)

5 Spare

6 Spare

7 Unit #1 Compressor Current Switch Required (Standard in "V" Module)

8 Spare

9 Fire Trouble Optional

10 Fire Alarm Optional

11 Spare

12 Door Alarm Optional

13 Main Power Sensor Optional

14 Occupied Override Switch Required (Standard in TCS22)

15 Outdoor Temperature Sensor Required (Standard in TCS22)

16 Outdoor Humidity Sensor Required (Standard in TCS22)

OUTPUTS

1 Spare

2 Cycle Power To Modem

3 Power Transfer Switch

4 Unit #1 Economizer (Y1)

5 Unit #1 Compressor (Y2)

6 Unit #1 Heater (W1)

7 Unit #1 Blower (G)

8 Spare

9 Spare

10 Spare

11 Spare

12 Shelter Alarm Circuit

13 Unit #1 is Lead Unit

14 Spare

15 Free Cooling

16 Power Failure

2100-444-003A

Page 4

Page 11

1.6 Model Nomenclature

TCS2 2 - H D M - 001

BASIC MODEL SOFTWARE

REVISION NUMBER ---- REMOTE COMMUNICATIONS

SENSORS DISPLAY M - With

H- Humidity & Temperature D - With X - Without

T - Temperature Only X – Without E - Ethernet

2.0 SPECIFICATIONS

2.1 Electrical Specifications

Supply Voltage 208/240 VAC +/- 10% 50/60 HZ

Minimum Circuit Ampacity 3 Amp

Overcurrent Protection Internal Circuit Breaker - 3 Amp

Controller Analog Inputs 16

Resolution 8 bits/ 0.4% Full Scale

Voltage Range 0 Vdc to +10 Vdc

Current Rating 5.0 mA at +10 Vdc

Binary Relay Outputs 12

Type Form "A" Relay SPST N.O.

Contact Rating 24 VAC, 5 A Resistive

24 VAC, 2 A Inductive

2.2 Mechanical Specifications

Height 26.25 in., (667 mm.)

Width 17.00 in., (432 mm.)

Depth 5.50 in., (140 mm.)

Material 18 ga galvanized steel with Beige baked polyester enamel.

Mounting Vertical

Mounting Area Required 27 in. high by 18 in. wide, (686 mm. high by 457 mm. wide)

Weight 27 lb., (12.3 kilograms)

2.3 Environmental Specifications

Operating Temperature Range 32 to 130 o F (0 to 55o C)

Operating Humidity Range 10 to 95%, non condensing

Storage Temperature Range -35 to 180 o F (-37 to 82o C)

Storage Humidity Range 5 to 95%, non condensing

2100-444-003A

Page 5

Page 12

2.4 Sensor Specifications

2.4.1 TEMPERATURE SENSORS

Indoor and Outdoor

Type Thermistor

Ohms 3000 Ω at 77o F (25o C)

Temperature Range -40 to 302

Interchangeability .2 Deg Celsius

Discharge

Type Thermistor

Ohms 10000 Ω at 77o F (25o C)

Temperature Range -40 to 302

Interchangeability .2 Deg Celsius

2.4.2 HUMIDITY SENSORS

Type Bulk Polymer

Output 0-5 Vdc

Supply Voltage 24 Vac, +/- 15%

Accuracy +/- 5%

Sensitivity 0.1% RH

Repeatability 0.5% RH

Long Term Stability Less than 1% per year

Interchangeability +/- 3%

Temperature Range -40 to 130 o F (-40 to 76o C)

Humidity Range 0 to 99%, non condensing

o

F (-40 to 150o C)

o

F (-40 to 150o C)

2.4.3 COMPRESSOR CURRENT SENSOR

Type Solid State DC Switch

Output Form "A" solid state DC switch

Supply Voltage Self Powered

Trip Current Range 1 to 175 Amps

Maximum Load 150 mA, at 30 VDC

Temperature Range -58 to 149 o F (-50 to 65o C)

Dimensions 2.125 in. high, 3.25 in. wide, 1 in. deep

(54 mm. high, 83 mm. wide, 26 mm. deep)

2.4.4 DIRTY FILTER SENSOR

Type Mechanical Airflow Switch

Output Form "A" Contact

Supply Voltage Self Powered

Maximum Load 1.5A, at 24 VAC

Temperature Range 0 to 170 o F (-18 to 77o C)

Pressure Range 0.1 to 0.7 in. wc.

Dimensions 3 1/4 in. high, 2 1/4 in. wide, 2 in. deep

(83 mm. high, 57 mm. wide, 51 mm. deep)

2100-444-003A

Page 6

Page 13

2.4.5 BLOWER AIRFLOW SWITCH

Type Mechanical Airflow Switch

Output Form "C" Contact

Supply Voltage Self Powered

Maximum Load 300 VA, at 24 VAC

Temperature Range -40 to 180 o F (-40 to 82o C)

Pressure Range 0.07 to 0.12 in. wc

Dimensions 6.125 high, 4.125 wide, 3.188 deep

(156 mm. high, 105 mm. wide, 81 mm. deep)

2100-444-003A

Page 7

Page 14

Figure 1 Front Cover

2100-444-003A

Page 8

Page 15

Figure 2 Control Location

2100-444-003A

Page 9

Page 16

Figure 3 Mounting Template

16.000

9.356

7.856

6.356

4.856

3.356

1.000

1.288

HIGH VOLTAGE

WIRING

22.288

MIS-866

2100-444-003A

Page 10

Page 17

3.0 INSTALLATION

This section discusses mounting and wiring

of the TCS22 into the building. Also included is an

installation checklist to be completed by the

installing contractor. See installation instructions

supplied with the Bard Wall-Mount air

conditioners for information on installing the air

conditioners.

This controller should be installed and

serviced by a qualified service technician only.

3.1 Mounting

TCS22 should be mounted on a flat vertical

surface four (4) to six (6) feet from the floor of the

building. When choosing a suitable location take

into consideration that the electrical connections

can be made from the back or top of the TCS22.

See Figure 3 for rear electrical entrance locations.

The TCS22 is secured to the wall with

four (4) - 1/4 inch fasteners with flat washers.

Hollow wall anchors or lag bolts are suitable as

dictated by the wall construction. See Figure 3 for

a bolt pattern layout drawing.

! WARNING

_________________________________

•HAZARD OF ELECTRIC SHOCK.

•ELECTRIC SHOCK CAN RESULT IN

SERIOUS INJURY OR DEATH.

•DISCONNECT THE REMOTE ELECTRIC

POWER SUPPLIES BEFORE SERVICING.

3.2 Wiring

Electrical connections can be made from

the back or top of the TCS22. All wiring should

exit the TCS22 in conduit. Use the supplied wire

ties and cable holders to route unit low voltage,

communication, and sensor wiring neatly. Avoid

looping excess wire. See Figure 2 for suggested

conduit connections.

Never connect or disconnect wiring from the

controller with power connected to the controller

or to either of the Bard Wall-Mount air-

conditioners.

3.2.1 HIGH VOLTAGE WIRING

IMPORTANT: High voltage wiring must

not be run in the same conduit as low voltage

control or sensor wiring. Failure to comply with

this requirement will result in poor or no remote

communication and/or in inaccurate sensor

reading.

Supply power is 208/240 VAC, 50/60 Hz,

1 Phase at 3 amps minimum circuit ampacity. A 3

amp circuit breaker is supplied as part of the

TCS22. This circuit breaker is for internal circuit

protection only and cannot be used as a disconnect.

Supply wire size should be 18 ga. or larger. Use

Copper Conductors Only. All wiring must comply

with the applicable sections of the National

Electrical Code ( NEC) and any applicable local

codes.

The TCS22 is shipped for 240 VAC

operation . For 208 Volt operation change both

transformer primaries in the TCS22 to the 208 volt

tap. See Wiring Diagram. The acceptable operating

voltage ranges for the 240 and 208 volt taps are:

Tap Range

240 253-216

208 220-187

Connect the high voltage power supply to

Terminal Block TB2. Connect ground wire to the

ground connector provided. TCS22 must be

grounded for proper operation. Failure to ground

the controller may cause erratic controller

operation and inaccurate sensor operation. See

Figure 2 and the wiring diagram.

2100-444-003A

Page 11

Page 18

3.2.2 WIRING - LOW VOLTAGE

IMPORTANT: High voltage wiring must

not be run in the same conduit as low voltage

control or sensor wiring. Failure to comply with

this requirement will result in poor or no remote

communication and/or in inaccurate sensor

reading.

Sixteen (16) wires should be run from each

Bard Wall-Mount to the low voltage terminal

block in the TCS22. An eight pair shielded cable

with 20 gauge copper conductors, such as National

Wire & Cable Corporation NQP series cable or

equivalent, is recommended for distances up to 45

feet. See Table 1 for distances more than 45 feet.

The connection points are shown in Figure 5.

Table 1 Low Voltage Wire Size

Wire Gauge Maximum Distance

in Feet ( meter)

20 gauge, 0.50 mm2 45 (14)

18 gauge, 0.75 mm2 60 (18)

17 gauge, 1.00 mm2 75 (23)

16 gauge, 1.50 mm2 100 (30)

14 gauge, 2.50 mm2 160 (49)

12 gauge, 4.00 mm2 250 (76)

3.2.3 WIRING - SENSORS

IMPORTANT: High voltage wiring must

not be run in the same conduit as low voltage

control or sensor wiring. Failure to comply with

this requirement will result in poor or no remote

communication and/or in inaccurate sensor

reading.

3.2.3.1 Outdoor Temperature Sensor (OTS)

The Outdoor Temperature Sensor (OTS) is

supplied as part of the TCS22 package. The

Outdoor Temperature Sensor (OTS) is a thermistor

type device. The sensor is mounted in a

weatherproof junction box suitable for connection

to conduit. This sensor is a two (2) wire device.

The Outdoor Temperature Sensor (OTS)

2100-444-003A

Page 12

should be mounted on the exterior of the structure

at a height above any expected accumulation of

snow. It is recommended that the box be mounted

securely to the outside wall of the structure and all

wiring to the sensor be made through conduit. A

one (1) pair shielded cable with 20 gauge copper

conductors, such as National Wire & Cable

Corporation NQP series cable or equivalent, is

recommended for connection to the sensor for

distances up to 45 feet. See Table 1 for distances

more than 45 feet.

Use wire nuts to connect the cable to the

blue and yellow sensor leads in the sensor housing.

Polarity is not critical with this sensor. The

connection points for the sensor inside the TCS22

are shown in Figure 4.

3.2.3.2 Outdoor Humidity Sensor (OHS)

The Outdoor Humidity Sensor (OHS) is

supplied as part of the TCS22 package. The

Outdoor Humidity Sensor (OHS) is a bulk polymer

type device. The sensor is mounted in a

weatherproof junction box suitable for connection

to conduit. This sensor is a four (4) wire device, 1

to 5 Vdc output.

The Outdoor Humidity Sensor (OHS)

should be mounted on the exterior of the structure

at a height above any expected accumulation of

snow. It is recommended that the box be mounted

securely to the outside wall of the structure and all

wiring to the sensor be made through conduit. A

two (2) pair shielded cable with 20 gauge copper

conductors, such as National Wire & Cable

Corporation NQP series cable or equivalent, is

recommended for connection to the sensor for

distances up to 45 feet. See Table 1 for distances

more than 45 feet.

Connect the cable to the terminal blocks in

the sensor housing. Polarity is critical with this

sensor. The connection points for the sensor inside

the TCS22 are shown in Figure 4.

3.2.3.3 Zone Temperature Sensor (ZTS)

The Zone Temperature Sensor (ZTS) is

supplied as part of the TCS22 package. The Zone

Temperature Sensor (ZTS) is a thermistor type

device. The sensor is premounted to the front door

of the TCS22. No wiring is required.

Page 19

3.2.3.4 Zone Humidity Sensor (ZHS) (Optional)

The Zone Humidity Sensor (ZHS) is

supplied as part of the TCS22 package (Optional).

The Zone Humidity Sensor (ZHS) is a bulk

polymer type device. If so equipped, the sensor is

premounted to the front door of the TCS22. No

wiring is required.

3.2.4 WIRING – INPUTS & OUTPUTS

A shielded cable with 20 gauge copper conductors,

such as National Wire & Cable Corporation NQP

series cable or equivalent, is recommended for

connection to the inputs and outputs of the TCS22

for distances up to 45 feet. See Table 1 for

distances more than 45 feet.

3.2.4.1 Shelter Alarm Output

The Shelter Alarm Output (SA) is a

normally open set of contacts that closes whenever

an alarm condition exists as sensed by the TCS22

controller. See the alarm section of this manual for

an explanation of the various conditions that will

send a shelter alarm.

The Form "A" contacts are SPST N.O.

rated at 24 VAC, 5 A Resistive, or 24 VAC, 2 A

Inductive. These rating should not be exceeded

under any conditions.

These contacts may be used to trigger an

alarm in the shelter or a remote alarm.

3.2.4.2 Power Transfer Switch Output (PTS)

The Power Transfer Switch Output is a

normally open set of contacts that closes two (2)

minutes after a power failure is sensed by the

TCS22 controller. See the alarm section of this

manual for an explanation of the power failure

alarm.

The Form "A" contacts are SPST N.O.

rated at 24 VAC, 5 A Resistive, or 24 VAC, 2 A

Inductive. These rating should not be exceeded

under any conditions.

These contacts can be used to energize a power

transfer switch when used in conjunction with an

inverter to provide emergency ventilation of the

shelter during power failures. Consult the power

failure management sequence, section 4.2.10 and

section 1.3, for more details.

3.2.4.3 Power Failure Sense Input

The Power Failure Sense is an input into

the Controller. A normally open set of contacts is

connected across these inputs. When power is lost

to the shelter these contacts should close indicating

that the building has lost normal utility power.

These contacts can be used in conjunction with an

inverter and power transfer switch to provide

emergency ventilation of the shelter during power

failures. Consult the power failure management

sequence, section 4.2.10 and section 1.3, of this

manual for more details..

This is a dry contact input only. Do not

connect any voltage source to these terminals. Do

not connect utility power to these terminals.

3.2.4.4 Fire Alarm Input

The Fire Alarm is an input into the

Controller. A set of normally open contacts is

connected across these inputs. These contacts

should close when fire alarm system has sensed a

fire.

This is a dry contact input only. Do not

connect any voltage source to these terminals. Do

not connect utility power to these terminals.

3.2.4.5 Fire Trouble Input

The Fire Trouble is an input into the

Controller. A set of normally open contacts is

connected across these inputs. These contacts

should close when the fire alarm system senses a

problem with the fire alarm system.

This is a dry contact input only. Do not connect

any voltage source to these terminals. Do not

connect utility power to these terminals.

3.2.4.6 Door Alarm Input

The Door Alarm is an input into the

Controller. A set of normally open contacts is

connected across these inputs. These contacts

2100-444-003A

Page 13

Page 20

should close when door is closed. If a door switch

is not used a jumper should be placed across

this input.

This is a dry contact input only. Do not

connect any voltage source to these terminals. Do

not connect utility power to these terminals.

3.2.5 WIRING - TELEPHONE LINE

When the TCS22 is equipped with a

modem, an analog phone line should be connected

to the back of the modem in the jack labeled LINE.

This jack accepts a standard a RJ-11 six (6)

position modular phone plug.

3.2.6 WIRING - ETHERNET

When the TCS22 is equipped with an

Etherlink communications module, The

LAN/WAN should be connected to the back of the

module in the jack labeled Ethernet. This jack

accepts a standard a RJ-11 eight (8) position

modular phone plug.

The Etherlink communications module

requires a dedicated IP address. This must be

programmed by the end user via a computer and

RS232 cable at the time of connection to the

network. The cable is provided with the TCS22.

Specific configuration information is

provided with the EtherLink Module in a separate

document.

2100-444-003A

Page 14

Page 21

Figure 4

External Wiring

2100-444-003A

Page 15

Page 22

Figure 5

Internal Wiring

Figure 6

Power

2100-444-003A

Page 16

Page 23

Backup System

2100-444-003A

Page 17

Page 24

3.3 Installation Check List

TCS22 securely mounted to wall and all conduit connections tight.

Main power wiring is NOT in same conduit as low voltage or sensor wiring

Main power wires are copper conductors

TCS22 is grounded.

Check supply voltage. Change both transformer taps if necessary. See Sec. 3.21

Carefully recheck all low voltage wiring for correct connection points .

Carefully recheck all sensor connections for correct connection points.

Recheck analog telephone wire connection to modem if so equipped

Make sure modem power switch is on if so equipped.

Connect jumper between terminals DA if a door switch is not used.

.

2100-444-003A

Page 18

Page 25

3.4 System Startup

3.4.1 WALLMOUNT STARTUP CHECKLIST

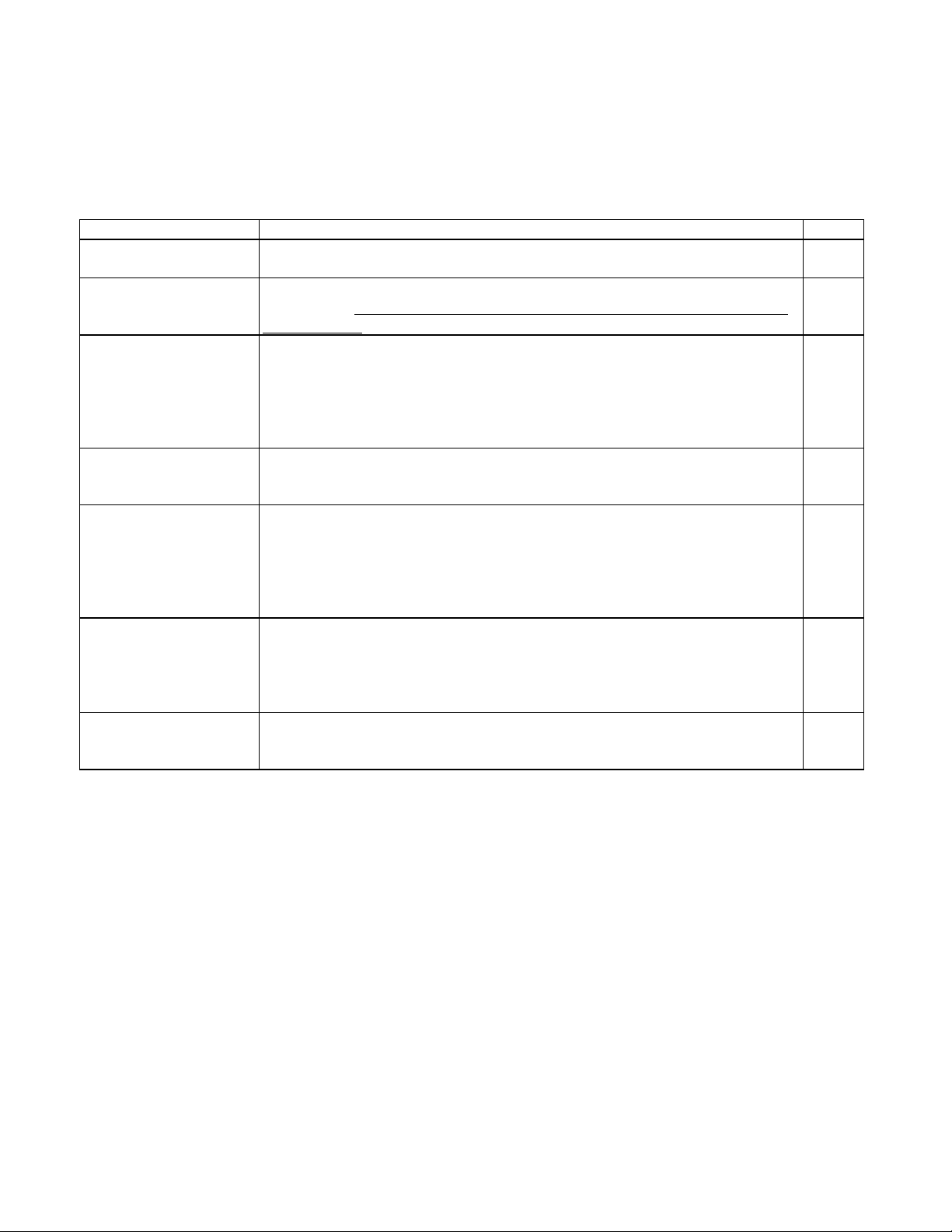

Operation Procedure

Bypassing TCS22

Controller

Apply power to both

Wall-mounts

Compressor Test Connect jumper wire on A/C unit low voltage terminals from R to Y

Blower Test Connect a jumper wire on A/C unit low voltage terminals R to G and

Economizer Test Connect a jumper wire on A/C unit low voltage terminals R to G and

Heater Test Connect a jumper wire on A/C unit low voltage terminals R to W1.

Disconnect Power to

WallMount AirConditioners

Disconnect power to the TCS22. Unplug the plug in connectors J4 and

J5 from the controller

Follow recommended startup procedure in the WallMount installation

instructions. Compressor damage could occur if startup procedures are

not followed.

and observe Compressor operation (There will be a Time delay

between the installation of the jumper and the starting of the

Compressor. The Compressor Time Delay relay will determine the

time delay period.). After the Compressor starts, the jumper wire can

be removed.

observe Blower operation (The Blower will continue to run for One (1)

minute after the jumper is removed).

observe Blower operation. After Blower operation is confirmed, the

Economizer can be tested. Leave the jumper in place from the previous

step. Connect a separate jumper on the A/C unit low voltage terminals

from E to F and observe the Economizer operation (Never connect

power to terminals E or F).

The Heating contactor will engage when the jumper is connected. The

Blower will also operate while this jumper is in place. To check the

operation of the Heater, you will have to check the Discharge Air

temperature of the A/C unit.

Disconnect power to WallMount air conditioners. Reconnect plug-in

connectors J4 and J5 to the controller. Go to TCS22 Startup Checklist

2100-444-003A

Page 19

Page 26

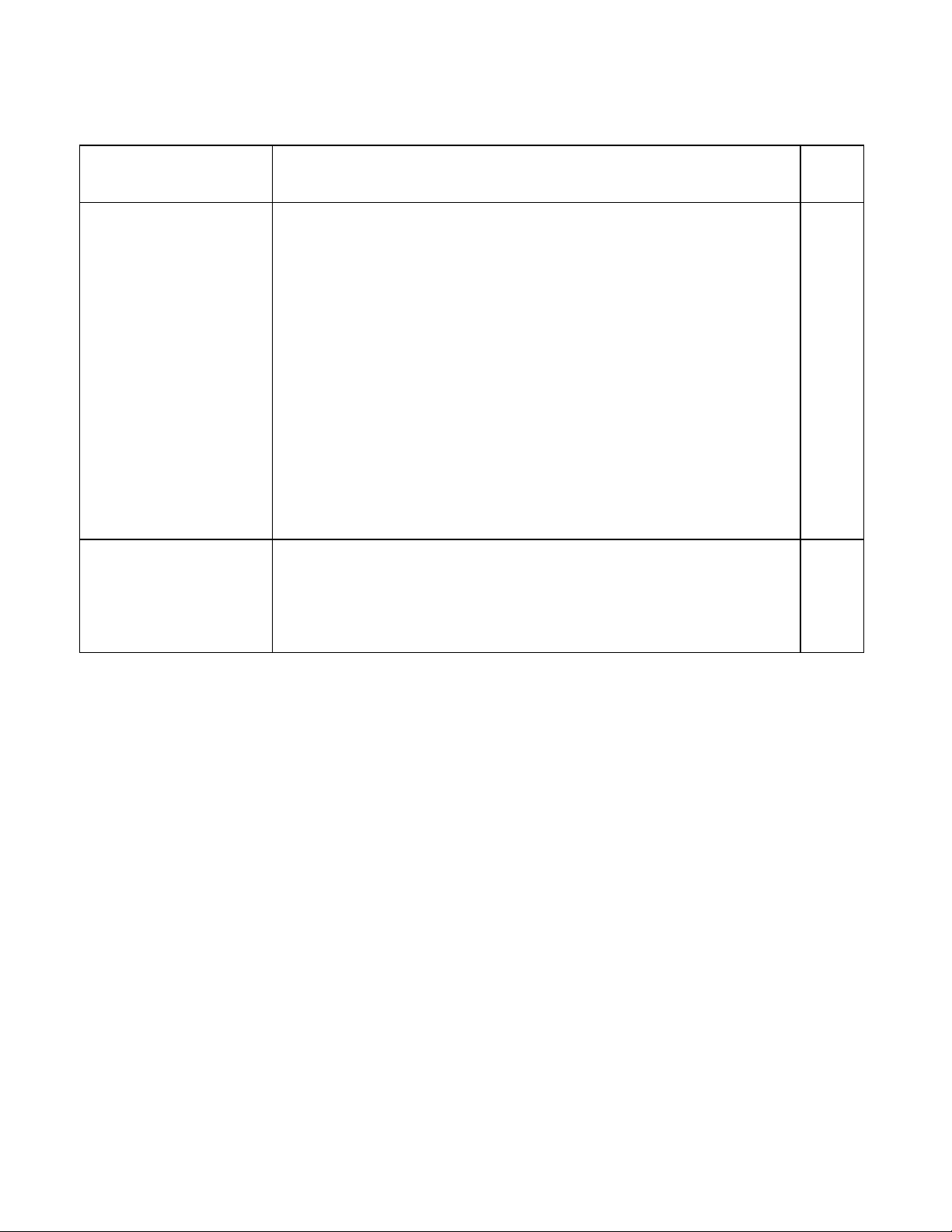

3.4.2 TCS22 STARTUP CHECKLIST

Apply power to

WallMount airConditioners

Apply power to TCS22 Apply power to TCS22 and monitor LEDs on the front of the

Connect to Controller Use the DAK or Laptop PC to connect to controller to change

Apply power to WallMount air-Conditioners. Wait two minutes for

wallmount time delays to expire.

controller. The controller performs a self test on startup. Upon

application of power, 9 LEDs will light.

System Power led will light and stay lit

Unit #1 is Lead Unit, Unit #2 is Lead Unit, Free Cooling, Power

Failure LEDs will light for 5 seconds and then resume normal

operation

System Rx and Tx and Local Rx and Tx will all flash on, flash off,

flash on and then flash off during this five seconds and will then

resume normal operation .

This completes the self test and controller will now start controlling

per the sequence of operation.

setpoints.

See Section 5.0 for DAK operation procedures.

See Section 6.0 for direct connect PC operation.

2100-444-003A

Page 20

Page 27

4.0 OPERATION

This section describes the sequence of operation of the controller. The tools available for

monitoring and controlling the air-conditioners for both on-site and remote operations are explained. The

remote trending, alarming, and site setup software are detailed.

4.1 General

This section will describe the sequence of operation of the controller. Cooling , heating,

dehumidification, and alarm sequences are explained.

4.2 Sequence of Operation

This sequence of operation is for the TCS22-002 software package. Different software packages

have different sequences of operation. Check the last three numbers of the TCS22 model number on the

serial plate to verify that the sequence installed is "002"

4.2.1 COOLING SEQUENCE WITH ECONOMIZERS

Free cooling setpoint, that is, the outdoor conditions at which cooling is handled by the

economizer, can be configured to use either enthalpy or dry bulb temperature.

Outdoor Enthalpy or Temperature is calculated from Outdoor Temperature and/or Outdoor

Humidity sensors. If the outdoor enthalpy or temperature is below the free cooling setpoint, free cooling

is enabled and Output #15, Free Cooling is lit.

Active Cooling Setpoint is compared to Space Temperature . If Space temperature is above

Active Cooling Setpoint, stage 1 cooling is enabled. If Free Cooling is enabled, Economizer and Blower

of the Unit are energized. If Free Cooling is inhibited, Compressor and Blower of the Unit are

energized.

If the Space Temperature is above Active Cooling Setpoint plus 2 deg Fo, stage 2 cooling is

enabled. If Free Cooling is enabled, Compressor and Blower of the Unit are energized.

4.2.2 HEATING SEQUENCE

Active Heating Setpoint is compared to Space Temperature. If Space temperature is below

Active Heating Setpoint , Stage 1 heating is enabled. Heater and Blower of the Unit are energized.

4.2.3 FAN SEQUENCE

The Evaporator Fan is programmed for continuous operation. Operator can change continuous

operation to cycle on demand. Lag unit fan will cycle on demand.

2100-444-003A

Page 21

Page 28

4.2.4 OCCUPIED / UNOCCUPIED MODE SEQUENCE

In heating mode, activation of the Occupancy Override Button will change the Active Heating

Setpoint from Unoccupied Heating Setpoint to Occupied Heating Setpoint for a period of two hours. In

cooling mode, activation of the Occupancy Override Button will change the Active Cooling Setpoint

from Unoccupied Cooling Setpoint to Occupied Cooling Setpoint for two hours.

4.2.5 ALARM SEQUENCE

The controller will alarm on the following failures. Modem dial-out is initiated when any of the

following alarms occur.

High Space Temperature

When Space Temperature is above High Temperature Alarm Setpoint a critical alarm is logged

in the Event List and Output 12, Shelter Alarm, is energized. This is a self clearing alarm.

Low Space Temperature

When Space Temperature is below Low Temperature Alarm Setpoint a critical alarm is logged in

the Event List and Output 12, Shelter Alarm, is energized. This is a self clearing alarm.

High Space Humidity

When Space Humidity is above High Humidity Alarm Setpoint a critical alarm is logged in the

Event List and Output 12, Shelter Alarm, is energized. This is a self clearing alarm.

Low Space Humidity

When Space Humidity is below Low Humidity Alarm Setpoint a critical alarm is logged in the

Event List and Output 12, Shelter Alarm, is energized. This is a self clearing alarm.

Blower Failure Unit #1

If Blower operation is called for the blower airflow sensor is checked. If the airflow sensor does

not confirm that there is airflow, Output 7, Unit #1 Blower, is de-energized. After 30 seconds the

blower is energized again. If airflow is not sensed, Output 7, Unit #1 Blower, is de-energized.

After another 30 seconds the blower is energized again. If airflow is not sensed, Output 7, Unit

#1 Blower, is de-energized and locked out. A critical alarm is logged in the Event List and

Output 12, Shelter Alarm, is energized. Lead unit switches to lag unit. The Output Alarm must be

cleared to resume operation.

2100-444-003A

Page 22

Page 29

Compressor Lockout Failure Unit #1

If Compressor operation is not verified because the High or Low Pressure Lockout Relay has

been energized, Output 5, Unit #1 Compressor, is de-energized and locked out. A critical alarm

is logged in the Event List and Output 12, Shelter Alarm, is energized. Lead unit switches to lag

unit .The Output Alarm must be cleared to resume operation. Verify is tried 3 times before the

output is locked out. Compressor Operation is verified by Unit #1 Compressor Lockout Relay

and Unit #1 Compressor Current Switch.

Compressor Current Failure Unit #1

If Unit #1 Compressor is on and Unit #1 Compressor Current Switch is not valid , a

critical alarm is logged in the Event List and Output 12, Shelter Alarm, is energized. Lead unit

switches to lag unit. The Output Alarm must be cleared to resume operation. Verify is tried 3

times before the output is locked out. Compressor Operation is verified by Unit #1 Compressor

Lockout Relay and Unit #1 Compressor Current Switch.

Dirty Filter Unit #1

If Unit #1 Dirty Filter Switch is closed, a low priority alarm is logged in the Event List and

Output 12, Shelter Alarm, is energized. This alarm must be reset at the unit.

Utility Power Failure

If Input #13, Power Sense, is closed indicating a utility power failure, a critical priority alarm is

logged in the Event list and Output 12, Shelter Alarm, is energized. All unit outputs are de-

energized. Two minutes after the alarm, Output #3, Power Transfer Switch, is energized . Three

minutes after the alarm, Lead Unit Blower and Lead Unit Economizer are energized

continuously until Utility Power Failure Alarm is cleared. This is a self clearing alarm.

Fire Trouble

If Input #9, Fire Trouble, is closed indicating a problem with the Fire Alarm System, a medium

priority alarm is logged in the Event list and Output 12, Shelter Alarm, is energized.

Fire Alarm

If Input #10, Fire Alarm, is closed indicating a fire in the Zone, a critical priority alarm is logged

in the Event list and Output 12, Shelter Alarm, is energized. All unit outputs are de-energized.

2100-444-003A

Page 23

Page 30

Door Alarm

If Input #9,Door Alarm, is open for more than three minutes indicating an open door, a medium

priority alarm is logged in the Event list and Output 12, Shelter Alarm, is energized. The door

must be opened continuously for more than three minutes for the alarm to be logged. This is a

self clearing alarm.

4.2.6 DEHUMIDIFICATION SEQUENCE

Dehumidification Setpoint is compared to Space Humidity. If Space Humidity is above

Dehumidification Setpoint , Stage 1 cooling is enabled. Compressor and Blower of the Unit are

energized. During dehumidification Active Heating Setpoint and Active Cooling Setpoint are changed to

70o and 72o respectively and cannot be changed. This prevents coil freeze up during dehumidification.

If Space temperature is cooled below Active Heating Setpoint by the dehumidification, Stage 1

heating is enabled. Heater and Blower of the Unit are energized.

4.2.7 THERMAL SHOCK PROTECTION SEQUENCE

The thermal shock protection sequence protects equipment in the structure from being subjected

to rapid changes in temperature after a power outage. The thermal shock routine limits the rate of change

in the zone temperature to less than 15 degrees F per hour. This is accomplished by making incremental

changes to a temporary setpoint every 8 minutes until the desired setpoint is reached. If the room

temperature is more then 6 degrees above the setpoint the thermal shock routine is active.

4.2.8 MODEM SEQUENCE

The power to the modem will be cycled off for one minute every day at midnight.

4.2.9 POWER MANAGEMENT SEQUENCE

If Input #13, Power Sense, is closed indicating a utility power failure, a critical priority alarm is

logged in the Event list and Output 12, Shelter Alarm, is energized. All unit outputs are de-energized.

Two minutes after the alarm, Output #3, Power Transfer Switch, is energized. Three minutes after the

alarm, Lead Unit Blower and Lead Unit Economizer are energized continuously until Utility Power

Failure Alarm is cleared. The economizer modulates to maintain a 55 degree F entering air temperature.

This is a self clearing alarm.

2100-444-003A

Page 24

Page 31

4.2.10 SETPOINTS

The default setpoint for all points are listed below. All setpoints are user changeable within the

ranges listed.

Occupied Heating Setpoint Default 70.0 Fo Range 60.0 - 70.0 Fo

Unoccupied Heating Setpoint Default 68.0 Fo Range 55.0 - 70.0 Fo

Occupied Cooling Setpoint Default 75.0 Fo Range 72.0 - 80.0 Fo

Unoccupied Cooling Setpoint Default 80.0 Fo Range 72.0 - 85.0 Fo

High Temperature Alarm Setpoint Default 90.0 Fo Range 80.0 - 100.0 Fo

Low Temperature Alarm Setpoint Default 56.0 Fo Range 45.0 - 67.0 Fo

High Humidity Alarm Setpoint Default 60 % RH Range 55 % - 85 %

RH

Low Humidity Alarm Setpoint Default 20 % RH Range 5 % - 35 %

RH

Changeover Hours Default 24 Hrs Range 24 - 168 Hrs

Enthalpy / Free Cooling Setpoint Default 23.0 Btu/lb Range 5.00 – 40.00

Btu/lb

Drybulb / Free Cooling Setpoint Default 48.0 F

o

Range 40.0 - 80.0 F

o

Dehumidification Setpoint Default 50 % RH Range 50 % - 70 %

RH

Dehumidification Heating Setpoint Default 70.0 F

adjustable

Dehumidification Cooling Setpoint Default 73.0 F

o

Range Fixed, Not

o

Range Fixed, Not

adjustable

5.0 DISPLAY & KEYPAD OPERATION (DAK)

The display and keypad (DAK) is used to monitor and change parameters in the controller. If

DAK is needed it must be ordered as part of the TCS22. It cannot be ordered separately at a later date.

5.1 Display & Keypad Physicals

The display and keypad (DAK) consists of a 4 line by 20 character backlit LCD display, 13 key

keypad and 5 indicating LEDs.

All messages displayed on the DAK are uploaded from the 7040 controller at power up. The

LCD display uses a simple page menu system to display all functions.

The keypad consists of keys labeled <F1 >, <F2>, <F3>, <F4>, <//>, <Left>, <Up>, <Down>,

<Right>,and <Enter>. The specific function of these keys is preprogrammed and not user configurable.

The <?>, <|>, and <I> keys are not programmed and serve no function in this application..

In general the keys have the following functions. The <Up>, <Left>, <Down>, <Right> keys

are used to navigate through the 7 screens, increment or decrement values, and choose which digit or

letter to change. The <Enter > Key is used to select a choice or accept the changes. The < F1 > key is

used to enter change mode to change setpoints, passwords, or lead/ lag units. The function of each of the

keys depends on were you are in the menu tree. The <F2> key is used to enter passwords. The <//> key

2100-444-003A

Page 25

Page 32

cancels any operation.

The double arrow LED is lit when the DAK is receiving or transmitting data normally. It will

flash if there is a communication error.

The DAK plugs into the 7040 controller through a pre-wired cord set. All communication

signals are sent through this cord set to the DAK. The display and keypad (DAK) communicates with

the 7040 controller via an RS485 communication bus using a proprietary communication protocol. The

DAK will only function when plugged into the 7040 controller. The DAK uses a separate 24VDC power

supply which has a 1 amp fuse on board.

5.2 Power Up

Upon applying power, the DAK will establish communications with the controller and begin

requesting data. The first information screen to appear Building Status screen. Each screen consists of up

32 lines of data. Each line can have up to 16 characters. The first four lines of the Building Status screen

will be displayed at power up. The current controller date and time will be displayed on the first line of

the display. Alarm status is shown on the second line. This line indicates the status of any alarms. If

there are no alarms the line will say "NO ALARMS". If one or more alarms are present it will flash

ALARM NOW.

Use the <Down> key to scroll down through the 32 lines of buiding status information. The

display will then scroll to the first display list entry of the Building Status menu. The name of the point

being displayed will on the first line of the display, in this case Zone Temperature. The current zone

temperature will be displayed in the second line of the display. This screen will also be displayed for 5

seconds and then the display will scroll back to the time & date. These two displays will continue to

scroll until a key is pressed.

12/01/03 8:45 AM

NO ALARMS

BUILDING STATUS

5.3 Menu Tree

The DAK consists of seven main screens.

Menu Screen Name

Building Status

Unit Status

Alarms

Setpoints

Overrides Unit #1

2100-444-003A

Page 26

Page 33

Enables

Each of these screens has up to 32 lines of data in it. Study the Keypad Map in section 5.4 to

become familiar with the menu tree structure. This is a handy reference and includes all keystrokes

needed to get to any display or function.

Pressing the <Right > key once from the Building Status screen will take you to the next screen,

the Unit Status screen . The screen name will be displayed on the second line. Use the right and left

arrows to scroll back and forth through the seven screens.

From this display press the <Down> key to scroll down the screen information.

Not all items in every screen are available to every user to change. Some screens are password

protected. If your password gives you the required authority level, you will be able to access the screenu

to make changes. See the Password section for a discussion of the authority levels.

UNIT STATUS

5.3.1 Buildings Status Screen

Authority Level Required to Make Changes - Does not apply. No changes can be made from this screen.

The Building Status screen displays the following information about the shelter environment.

Room Temperature Value DegF

Room Humidity Value RH

Outdoor Temperature Value DegF

Outdoor Humidity Value RH

Active Cooling Setpoint Value DegF

Active Heating Setpoint Value DegF

Free Cooling YES/NO

Shelter Power UTIL/BAT

Room Occupied YES/NO

Outdoor Enthalpy Value Btu/Lb

Pressing the <Up> or <Down> key will scroll up or

2100-444-003A

Page 27

12/01/03 8:45 AM

NO ALARMS

BUILDING STATUS

ROOM TEMP. 75.59F

ROOM RH 39.4RH

OD TEMP. 73.11F

OUTDOOR RH 40.9RH

ACTIVE CLG.SP 80.00F

ACTIVE HTG.SP 68.00F

FREE COOLING NO

LEAD UNIT 2

SHELTER POWER UTIL

ROOM OCCUPIED NO

OD ENTHALPY 25.44

Page 34

down respectively through the above screen showing four lines at a time.

5.3.1.1 ROOM TEMPERATURE

The room temperature item displays the current temperature inside the structure.

5.3.1.2 ROOM HUMIDITY

The room humidity item displays the current humidity inside the structure. This is an optional

sensor and may or may not be present in your system. The current value will read one percent, "1 %" if

no sensor is present.

5.3.1.3 OUTDOOR TEMPERATURE

The outdoor temperature item displays the current temperature outside the structure.

5.3.1.4 OUTDOOR HUMIDITY

The outdoor humidity item displays the current humidity outside the structure.

5.3.1.5 ACTIVE COOLING SETPOINT

The Active Cooling Setpoint displays the current cooling setpoint that the controller using to

determine whether cooling is required or not. If the Zone temperature is above the Active Cooling

Setpoint, Stage One Cooling will be on.

The Active Cooling Setpoint will be one of three values. If the controller is in occupied mode,

the Active Cooling Setpoint will be the same as the Occupied Cooling Setpoint. If the controller is in

unoccupied mode, the Active Cooling Setpoint will be the same as the Unoccupied Cooling Setpoint.

Occupancy is determined from the After-hours Occupancy Override Button located on the temperature

sensor on the front of the TCS22. If the controller is in Dehumidification mode, the Active Cooling

Setpoint will be 73o the same as the fixed Dehumidification Cooling Setpoint.

5.3.1.6 ACTIVE HEATING SETPOINT

The Active Heating Setpoint displays the current heating setpoint that the controller using to

determine whether heating is required or not. If the Zone Temperature is below the Active Heating

Setpoint, Stage One Heating will be on.

The Active Heating Setpoint will be one of three values. If the controller is in occupied mode, the

Active Heating setpoint will be the same as the Occupied Heating Setpoint. If the controller is in

unoccupied mode, the Active Heating Setpoint will be the same as the Unoccupied Heating Setpoint.

Occupancy is determined from the After-hours Occupancy Override Button located on the temperature

sensor on the front of the TCS22. If the controller is in Dehumidification mode, the Active Heating

2100-444-003A

Page 28

Page 35

Setpoint will be 70o the same as the fixed Dehumidification Heating Setpoint.

5.3.1.7 FREE COOLING ON / OFF

This display item indicates whether outside conditions are suitable to allow the use of outside air

to provide free cooling inside the structure. The controller calculates the either outside temperature or

enthalpy from the Outdoor Temperature and Outdoor Humidity and compares this value with the Free

Cooling Setpoint. The Free cooling setpoint can be either a dry bulb temperature or enthalpy. This is

user selectable. If outdoor temperature or enthalpy, whichever the user has selected, is less than the Free

cooling setpoint then Free Cooling is ON. If the temperature or enthalpy of the outside air is more than

the Free Cooling Setpoint then Free Cooling is Off.

5.3.1.8 ROOM OCCUPIED YES/NO

This display indicates the status of the After-hours Occupancy Override Button. If the display

shows "NO", the controller is in the unoccupied mode and the unoccupied setpoints prevail. If the

display shows "YES", the controller is in the occupied mode and the occupied setpoints prevail.

Depressing the Occupancy Override Switch on the Zone Temperature Sensor for one second triggers the

Occupied mode for two (2) hours.

5.3.1.9 OUTDOOR ENTHALPY

This outdoor enthalpy displays the calculated outdoor air enthalpy. The outdoor enthalpy is

calculated from the outdoor temperature and outdoor humidity sensors and is used to determine wether

the air is suitable for free cooling or not.

2100-444-003A

Page 29

Page 36

5.3.2 Unit Status Screen

Authority Level Required to Make Changes - Does not apply. No changes can be made from this

screen.

The Unit Status screen displays the following information about both air-conditioners.

Unit #1 Economizer On/Off

Unit #1 Compressor On/Off

Unit #1 Heater On/Off

Unit #1 Blower On/Off

Unit #1 Filter Clean/Dirty

Unit #1 Discharge Air Temperature Value DegF

Pressing the <Up> or <Down> key will scroll up or down respectively through the above screen

showing four lines at a time.

UNIT STATUS

UNIT#1 ECON. OFF

UNIT#1 COMP. OFF

UNIT#1 HEAT ON

UNIT#1 BLOWER OFF

UNIT#1FILTER CLEAN

U#1 SUPPLY AIR 90.24

5.3.2.1 UNIT #1 ECONOMIZER

This display item will show "Off" if the unit #1 economizer output of the controller is not

energized. This display item will show "On" if the unit #1 economizer output of the controller is

energized.

5.3.2.2 UNIT #1 COMPRESSOR

This display item will show "Off" if the unit #1 compressor output of the controller is not

energized. This display item will show "On" if the unit #1 compressor output of the controller is

energized.

5.3.2.3 UNIT #1 HEATER

This display item will show "Off" if the unit #1 heater output of the controller is not energized.

This display item will show "On" if the unit #1 heater output of the controller is energized.

5.3.2.4 UNIT #1 BLOWER

This display item will show "Off" if the unit #1 blower output of the controller is not energized.

This display item will show "On" if the unit #1 blower output of the controller is energized.

2100-444-003A

Page 30

Page 37

5.3.2.5 UNIT #1 FILTER

This display item will show "Clean" if the unit #1 dirty filter alarm of the controller is not

energized. This display item will show "Dirty" if the unit #1 filter alarm is energized.

5.3.2.6 UNIT #1 DISCHARGE AIR TEMPERATURE

This display will show the current discharge air temperature in the supply air duct of Unit #1 in

Fo.

5.3.3 Alarms Menu

The Alarm menu set displays the following information about the controller.

Space Temp Alarm

Space Humidity Alarm

#1 Blower Fail

#1 Compressor Alarm

#1 Filter Alarm

#2 Blower Fail

#2 Compressor Alarm

#2 Filter Fail

Utility Power Fail

Fire Trouble

Fire Alarm

Outdoor Temperature Alarm

Outdoor Humidity Alarm

Door Alarm

From this menu the current alarm status of an item is

displayed and, with the proper authorization, the alarm can be

acknowledged Acknowledging an alarm resets the shelter alarm

output so that if another alarm is registered the shelter alarm

will reenergize to indicate a new alarm. Acknowledging the

alarm does not clear the alarm. The fault condition must be

corrected before the alarm is cleared. The values displayed for

each of these points is updated every ten (10) seconds.

Pressing the <Up> or <Down> key will scroll forward or backward respectively through the

screen showing four lines at a time.

Three types of alarms are displayed. H signifies a high alarm. L signifies a low alarm. F signifies

a fault alarm.

To acknowledge an alarm , scroll up or down until the alarm that is to be acknowledged is visible

ALARMS

F1 = EDIT MODE

ENTER TO EDIT

NOP = NO OPERATION

ACK = ACKKNOWLEDGE

CRAM= CLEAR ALR RAM

ACKA= ACKKNOWLEDGE ALL

CAF = CLEAR ALR FLAG

ALARM TYP ACK A

ZONE TEMP H A -ZONE HUMID --

U1 BLOWER -U1 COMP -U1 FILTER -UTL POW FAIL -FIRE ALARM -FIRE TROUBLE -OUTDOOR TEMP F --

OUTDOOR HUM. -DOOR ALARM --

2100-444-003A

Page 31

Page 38

on the screen. Press the <F1> key. Use the <Up> key to highlight the dashes next to the alarm item to be

acknowledged. Press <Enter> to enter edit mode.

If you do not have authority to acknowledge alarms the dashes will not be highlighted. An

Engineer authority level is required to override outputs. If you have authority to dashes will be

highlighted after pressing the <F1> key.

There are five (5) actions now available, NOP = No Operation, ACK = Acknowledge the alarm,

CRAM = Clear alarm ram, ACKA = Acknowledge all alarms, CAF = Clear alarm flag. Use the <Up>

and <Down> keys to choose ACK to acknowledge the alarm. Once the desired action is displayed press

the <Enter> key to initiate the action. If the action was accepted the screen will show an A next to the

alarm type.

The display will then revert to the list item display and within 10 seconds the new action will be

updated.

5.3.3.1 SPACE TEMP ALARM

The space temperature alarm item will show one of four different alarm messages. A No alarm

message indicates that the Zone Temperature Sensor is functioning normally. A Fault alarm message

indicates that the Zone Temperature Sensor is sensing a value above 120 Fo or below -20 Fo. This

probably indicates a faulty sensor. When a Space Temperature Fault alarm is detected the Zone

Temperature value defaults to 74 degrees effectively shutting down heating and cooling until the sensor

is replaced.

An Alarm (High) or Alarm (Low) message indicates that the sensor is sensing a temperature

above or below, respectively, the High Temperature Alarm Setpoint or Low Temperature Alarm

Setpoint.

The Fault alarm takes precedence over the Alarm (High) or Alarm (Low) message. If the Sensor

is failed high or low the Alarm (High) or Alarm (Low) alarms will also be activated but only the Fault

alarm will be displayed because this is the actual condition causing the other alarms.

These are all self-clearing alarms and will reset themselves when the alarm condition no longer

exists. This is a critical alarm.

5.3.3.2 SPACE HUMIDITY ALARM

The Space Humidity Alarm item will show one of four different alarm messages. A No alarm

message indicates that the Zone Humidity Sensor is functioning normally. A Fault alarm message

indicates that the Zone Humidity Sensor is sensing a value above 99 % RH or below 2 % RH. This

probably indicates a faulty sensor. When a Space Humidity Fault alarm is detected, the Zone Humidity

value defaults to 50 % RH until the sensor is replaced.

An Alarm (High) or Alarm (Low) message indicates that the sensor is sensing humidity above or

below, respectively, the High Humidity Alarm Setpoint or Low Humidity Alarm Setpoint.

2100-444-003A

Page 32

Page 39

The Fault alarm takes precedence over the Alarm (High) or Alarm (Low) message. If the Sensor

is failed high or low the Alarm (High) or Alarm (Low) alarms will also be activated but only the Fault

alarm will be displayed because this is the actual condition causing the other alarms.

These are all self-clearing alarms and will reset themselves when the alarm condition no longer

exists. This is a medium priority alarm.

5.3.3.3 #1 BLOWER ALARM

The Blower Fail alarm item will show one of two different alarm messages. A "No Alarm"

message indicates that the blower airflow sensor contacts have closed and the blower is functioning

normally. A Fault alarm message indicates that the blower airflow sensor contacts have not closed. A

faulty blower motor, wheel or sensor could cause this alarm.

This alarm must be cleared before operation of the blower can resume. Use the Clr Verify Alr

action in the Override menu to clear the alarm. This is a critical alarm.

5.3.3.4 #1 COMPRESSOR ALARM

The Compressor Alarm item will show one of two different alarm messages. "No Alarm"

message indicates that the compressor verify circuit contacts have closed and the compressor is

functioning normally. A Fault alarm message indicates that the compressor verify circuit contacts have

not closed. A Trip on High or Low pressure, no compressor current, failed blower, or faulty compressor

current sensor could cause this alarm.

This alarm must be cleared before operation of the compressor can resume. Use the Clr Verify

Alr action in the Override menu to clear the alarm. This is a critical alarm.

5.3.3.5 #1 FILTER ALARM

The Filter alarm item will show one of two different alarm messages. "No Alarm" message

indicates that the filter is clean enough to operate. A Fault alarm message indicates that the filter is dirty

and needs replaced.

This is a self-clearing alarm and will reset itself when the alarm condition no longer exists. The

filter sensor is a manually reset device and must be reset once the filter is changed to clear the alarm

condition. This is a low priority alarm.

5.3.3.6 UTILITY POWER FAIL

The Utility Power Fail alarm item will show one of two different alarm messages. A "None"

alarm message indicates that no alarm is present and that utility power is present at the site. A "Fault"

alarm message indicates that an alarm is present and the system is operating on backup power. This

feature will operate only if the TCS22 is connected to an uninterruptible power supply.

This is a self-clearing alarm and will reset itself when the alarm condition no longer exists. This

is a critical priority alarm.

2100-444-003A

Page 33

Page 40

5.3.3.7 FIRE TROUBLE

The Fire Trouble alarm item monitors the fire alarm system in the structure. A "None" alarm

message indicates that no alarm is present and that the fire alarm system is operating normally. A "Fault"

alarm message indicates that an alarm is present and the fire alarm system is malfunctioning.

This is a self-clearing alarm and will reset itself when the alarm condition no longer exists. This

is a medium priority alarm.

5.3.3.8 FIRE ALARM

The Fire Alarm item monitors the fire alarm system in the structure. A "None" alarm message

indicates that no alarm is present and that the fire alarm system has not detected a fire. A "Fault" alarm

message indicates that an alarm is present and that the fire alarm system has detected a fire in the

structure.

This is a self-clearing alarm and will reset itself when the alarm condition no longer exists. This

is a critical priority alarm.

5.3.3.9 OUTDOOR TEMP ALARM

The Outdoor temperature alarm item will show one of two different alarm messages. A No alarm

message indicates that the Outdoor Temperature Sensor is functioning normally. A Fault alarm message

indicates that the Outdoor Temperature Sensor is sensing a value above 120 Fo or below -20 Fo. This

probably indicates a faulty sensor.

These are all self-clearing alarms and will reset themselves when the alarm condition no longer

exists. This is a critical alarm.

5.3.3.10 OUTDOOR HUMIDITY ALARM

The Outdoor Humidity Alarm item will show one of two different alarm messages. A No alarm

message indicates that the Outdoor Humidity Sensor is functioning normally. A Fault alarm message

indicates that the Outdoor Humidity Sensor is sensing a value above 99 % RH or below 2 % RH. This

probably indicates a faulty sensor. When a Outdoor Humidity Fault alarm is detected, the Outdoor

Humidity value defaults to 50 % RH until the sensor is replaced.

These are all self-clearing alarms and will reset themselves when the alarm condition no longer

exists. This is a medium priority alarm.

5.3.3.11 DOOR ALARM

The Door Alarm item monitors the door switch in the structure. A "None" alarm message

indicates that no alarm is present and that the door is closed. A "Fault" alarm message indicates that an