INSTALLATION

INSTRUCTIONS

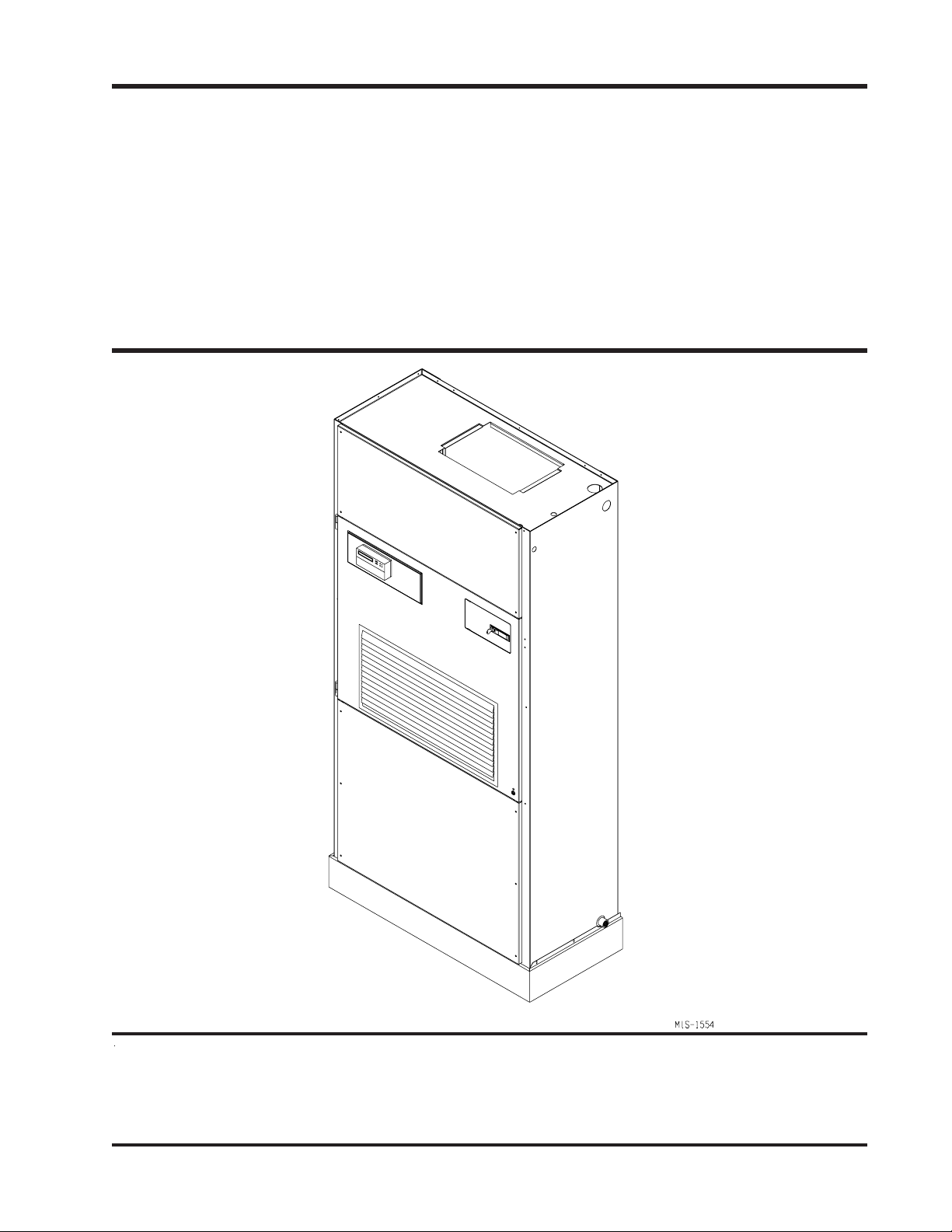

Q-TEC SERIES

PACKAGED HEAT PUMP

Models:

Q24H1 Q30H1

Q36H1 Q42H1

Q48H1 Q60H1

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914 . . . Moving ahead, just as planned.

Manual: 2100-519C

Supersedes: 2100-519B

File: Vol. II Tab 14

Date: 02-17-12

Manual 2100-519C

Page 1 of 42

CONTENTS

Getting Other Information and Publications

For more information, contact these publishers: .......... 3

Q-TEC General Information

EC Model Nomenclature ......................................... 4

Q-T

Shipping Damage ......................................................... 7

Unit Removal From Skid .............................................. 7

Handling Unit After Removal From Skid ....................... 8

General ......................................................................... 8

Minimum Installation Height ......................................... 8

Duct Work .................................................................. 10

Filters .......................................................................... 10

Fresh Air Intake .......................................................... 11

Service Light ............................................................... 11

Condensate Drain ...................................................... 11

Optional Rear Drain Kits............................................. 11

Installation Instructions

Mounting the Unit ....................................................... 18

Wiring — Main Power ................................................. 19

Wiring — Low Voltage Wiring ..................................... 19

Low Voltage Connections ........................................... 20

Figures

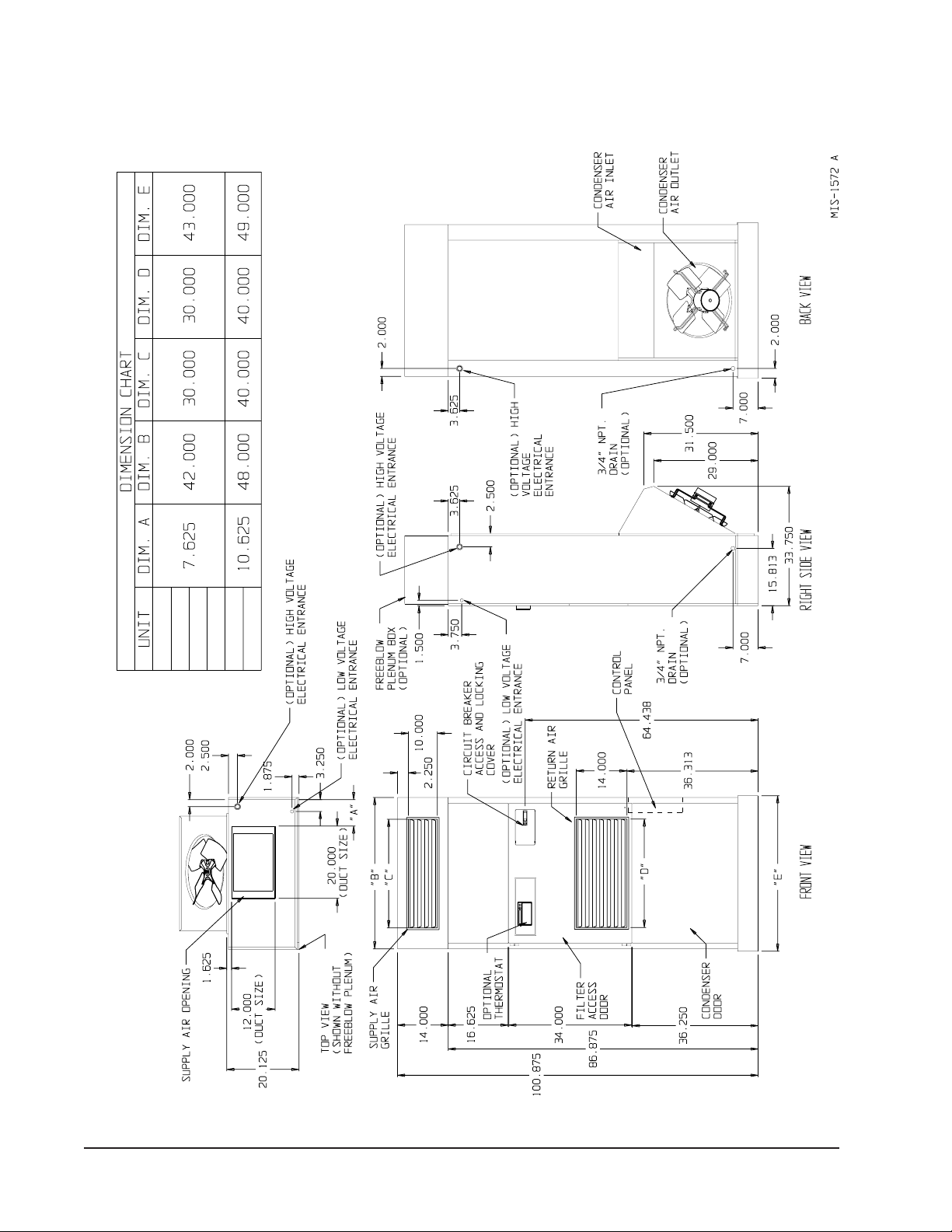

Figure 1 Unit Dimensions .......................................... 6

Figure 2 Air Seal on Bottom of Unit ........................... 7

Figure 3 Removal of Unit From Skid ......................... 7

Figure 4 Unit on Appliance Cart for Moving ............... 8

Figure 5 Installation With Free Blow Plenum ............ 9

Figure 6 Ducted Application ....................................... 9

Figure 7 Supply Duct Connections .......................... 10

Figure 8 Filter Location ............................................ 10

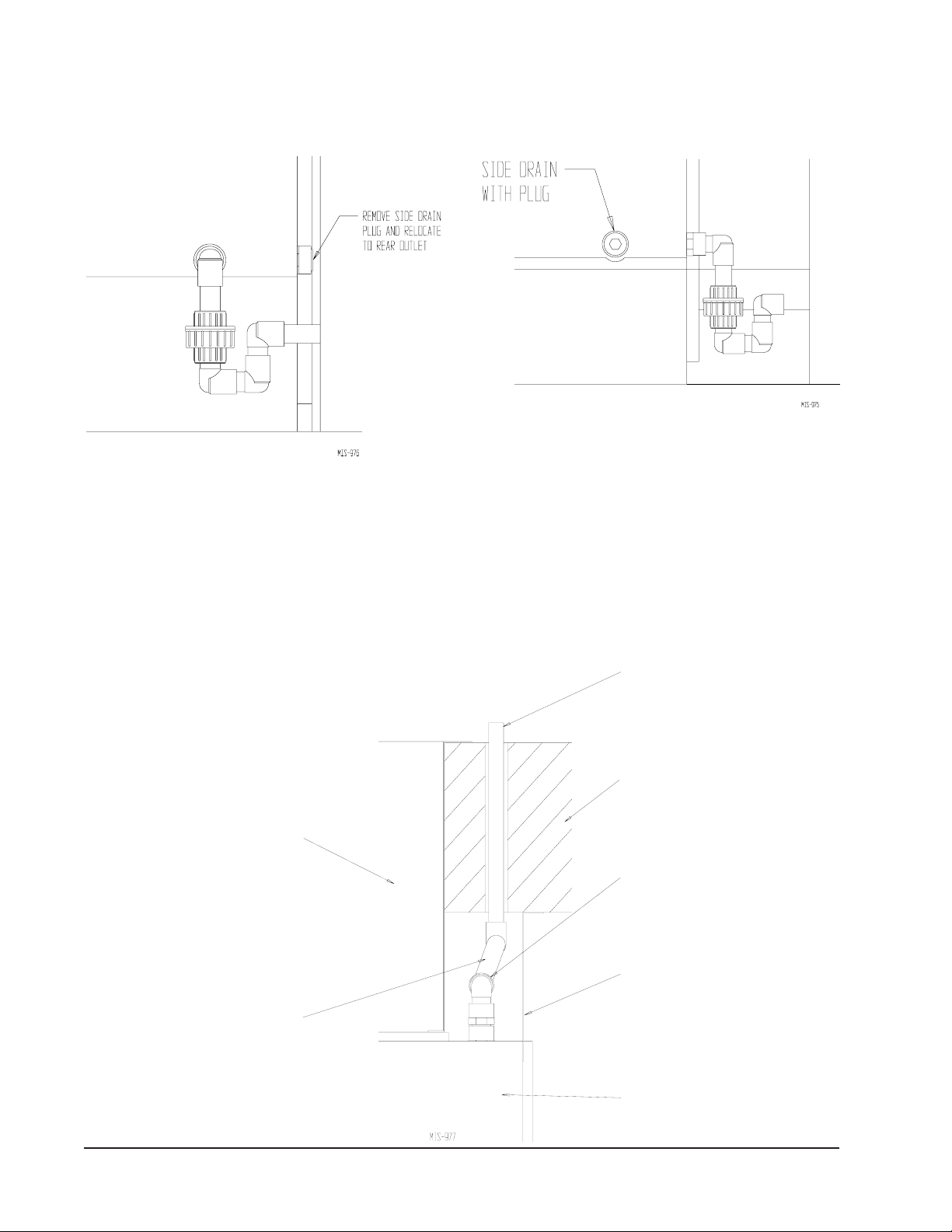

Figure 9 Optional Side Drain ................................... 12

Figure 10 Standard Rear Drain .................................. 12

Figure 11 Rear Drain (Top View) ............................... 12

Figure 12A

Figure 12B

Figure 12C

Figure 12D

Figure 13A Unit Mounting - Method 1 .......................... 17

Figure 13B Unit Mounting - Method 2 .......................... 17

Figure 14 Removing Locking Screws from Wheels ... 18

Figure 15 Component Location ................................. 19

Figure 16 Thermostat Plug Terminals ........................ 21

Figure 17A T-Stat Wiring Diagram "X" Option .............. 22

Figure 17B T-Stat Wiring Diagram "X" Option w/Demand 23

Figure 18 Thermostat Wiring Diagram "A" Option .... 24

Figure 19 Thermostat Wiring Diagram "D" Option ... 25

Figure 20 Thermostat Wiring Diagram "H" Option .... 26

Figure 21 Fresh Air Damper Removal ....................... 31

Figure 22 QERV Removal ......................................... 32

Figure 23 CO

Figure 24 Defrost Control Board ................................ 35

Figure 25 Control Disassembly ................................. 39

Figure 26 Winding Test .............................................. 39

Figure 27 Drip Loop ................................................... 39

Figure 28 Fan Blade Setting ...................................... 40

Optional Rear Drain Kit ............................. 13

Optional Rear Drain Kit ............................. 14

Optional Rear Drain Kit ............................. 15

Optional Rear Drain Kit ............................. 16

Controller ........................................... 33

2

Start Up

R-410A Refrigerant Required ........................................ 27

Topping Off System Charge ........................................... 27

Safety Practices ............................................................. 27

Description of Standard Equipment ............................... 28

Optional CFM (Q36, Q42, Q48 & Q60 Only) ................. 28

Important Installer Note.................................................. 28

Phase Monitor ................................................................ 28

Three Phase Scroll Compressor Start Up

Information ................................................................ 28

Service Hints .................................................................. 29

Mist Eliminator Service .................................................. 29

Vent Options .................................................................. 30

Sequence of Operation .................................................. 33

Optional Climate Controls Sequence

of Operation .............................................................. 33

Pressure Service Ports .................................................. 34

Defrost Cycle ................................................................. 34

Troubleshooting

Solid State Heat Pump Control Troubleshooting

Procedure ...................................................................... 36

Checking Temperature Sensor ...................................... 37

Troubleshooting GE ECM™ Blower Motors............. 38-39

Fan Blade Setting Dimensions ...................................... 40

Refrigerant Charge ........................................................ 40

Pressure Charts ...................................................... 41 - 42

Tables

Table 1 Factory Built-In Electric Heat Table .............. 4

Table 2 Electrical Specifications ................................ 5

Table 3 Operating Voltage Range ........................... 19

Table 4 Wall Thermostats ........................................ 21

Table 5 Troubleshooting .......................................... 36

Table 6 Temperature vs Resistance of

Temperature Sensor ................................... 37

Table 7 Fan Blade Dimensions ............................... 40

Table 8 Indoor Blower Performance ........................ 40

Table 9 Cooling Pressure ........................................ 41

Table 10 Heating Pressure ........................................ 42

Manual 2100-519C

Page 2 of 42

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually find these at

your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code ..................... ANSI/NFPA 70

Standard for the Installation ............. ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air ...................... ANSI/NFPA 90B

Heating and Air Conditioning Systems

Load Calculation for .......................ACCA Manual J or

Winter and Summer Manual N

Air Conditioning

Low Pressure, Low Velocity ........ ACCA Manual D or

Duct System Design Manual Q

Winter and Summer Air Conditioning

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating, Refrigeration,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-519C

Page 3 of 42

Q-T

EC

Series General Information

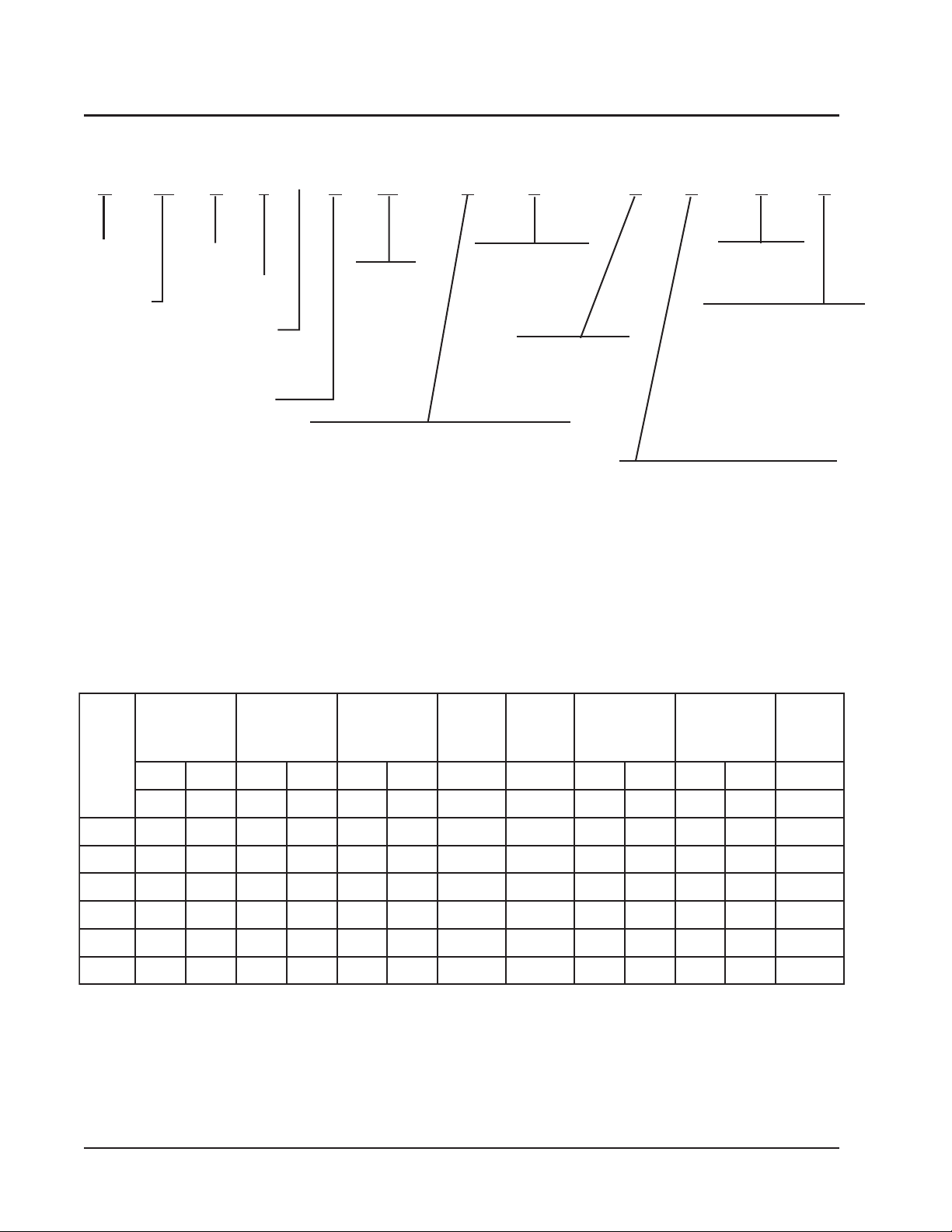

Q-TEC MODEL NOMENCLATURE

Q 36 H 1–A 10 X X V X X X

MODEL

NUMBER

Q - Q-TEC

CAPACITY |

24 - 2 Ton

30 - 2½ Ton

36 - 3 Ton

42 - 3½ Ton

48 - 4 Ton

60 - 5 Ton

sledoM

HEAT

PUMP

REVISION

SPECIAL UNITS |

L - Low Ampacity

Circuit

VOLTS & PHASE |

A - 230/208/60/1

B - 230/208/60/3

C - 460/60/3

FILTER OPTIONS

KW

0Z - 0KW

05 - 5KW

06 - 6KW

09 - 9KW

10 - 10KW

12 - 12KW

15 - 15KW

VENTILATION OPTIONS

X - Barometric Fresh Air Damper (Standard)

B - Blank-off Plate

V - Commercial Ventilator - Motorized w/Exhaust

Spring Return

P - Commercial Ventilator - Motorized w/Exhaust

Power Return

R - Energy Recovery Ventilator w/Exhaust

X - 1-Inch Fiberglass

(Standard)

F - 2-Inch Fiberglass

P - 2-Inch Pleated

COLOR OPTIONS

V - Platinum w/Slate

Front (Vinyl)

X - Beige paint

4 - Gray paint

CLIMATE CONTROL OPTIONS

X - None

A - Electronic/Non Prog/Man C/O

D - Electronic/Prog/Man/Auto

H - Electronic/Prog/Man/Auto with CO

COIL OPTIONS

X - Standard

I

NTERNAL CONTROLS

X - Standard

• High Pressure Switch

• Low Pressure Switch

• Compressor Time Delay

E - Low Ambient Control

Q - Outdoor Thermostat

R - Low Ambient Control &

Outdoor Thermostat

TABLE 1

FACTORY BUILT-IN ELECTRIC HEAT TABLE

A-1H63Q

A-1H42Q

A-1H03QB-1H42QB-1H03QC-1H42QC-1H03Q

1-V0421-V8021-V0421-V8021-V0421-V8023-V0843-V0841-V0421-V8021-V0421-V8023-V084

A-1H24Q

A-1H84Q

A-1H06Q

B-1H63Q

B-1H24Q

B-1H84Q

B-1H06Q

2

C-1H63Q

C-1H24Q

C-1H84Q

C-1H06Q

WKHUTBHUTBHUTBHUTBHUTBHUTBHUTBHUTBHUTBHUTBHUTBHUTBHUTB

0.5083,61092,21 083,61092,21

0.6005,02063,51005,02063,51005,02005,02005,02063,51005,02

0.9007,03000,32007,03000,32007,03007,03007,03000,32007,03

0.01076,23075,42 076,23075,42

0.21000,14007,03000,14

0.51 051,94068,63051,94068,63051,94

Manual 2100-519C

Page 4 of 42

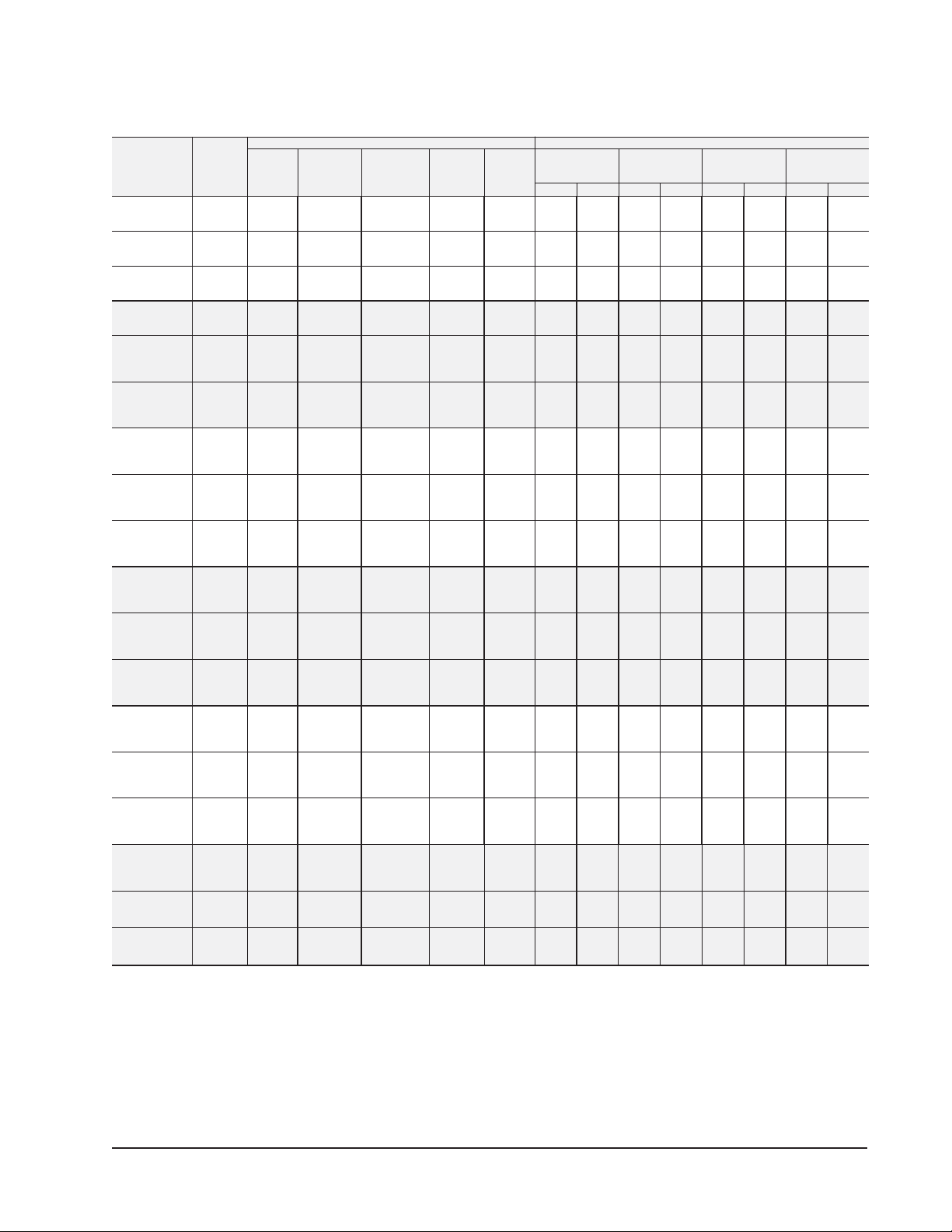

TABLE 2

ELECTRICAL SPECIFICATIONS

tiucriCelgniS tiucriClauD

ledoM

Z0A-1H42Q

50A

01A

Z0B-1H42Q

60B

90B

Z0C-1H42Q

60C

90C

Z0A-1H03Q

50A

01A

Z0B-1H03Q

60B

90B

21B

Z0C-1H03Q

60C

90C

21C

Z0A-1H63Q

50A

01A

4 51A

Z0B-1H63Q

60B

90B

5 51B

Z0C-1H63Q

60C

90C

5 51C

Z0A-1H24Q

50A

01A

4 51A

Z0B-1H24Q

60B

90B

5 51B

Z0C-1H24Q

60C

90C

5 51C

Z0A-1H84Q

50A

01A

4 51A

Z0B-1H84Q

60B

90B

5 51B

Z0C-1H84Q

60C

90C

5 51C

Z0A-1H06Q 1 54 06 8 01 - - - - - - - 50A

01A

5 51A

Z0B-1H06Q 1 13 54 8 01 - - - - - - - 90B

5 51B

Z0C-1H06Q 1 71 52 01 01 - - - - - - - 90C

5 51C

detaR

stloV

esahPdna

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

1-802/032

3-802/032

3-064

1-802/032

3-802/032 1

3-064 1

3 muminiM

dleiF.oN

rewoP

stiucriC

1

1

2ro1

1

1

1

1

1

1

1

1

2ro1

1

1

1

1

1

1

1

1

1

1

2ro1

2ro1

1

1

1

1

1

1

1

1

1

1

2ro1

2ro1

1

1

1

1

1

1

1

1

1

2ro1

2ro1

2ro1

1

1

1

1

1

1

1

1

2ro1

2ro1

2ro1

1

1

1 mumixaM

tiucriC

yticapmA

22

74

27

71

53

44

01

91

32

52

05

57

81

73

54

55

21

12

52

03

13

65

18

38

52

34

25

35

21

12

62

72

43

95

48

48

52

34

25

35

31

22

62

72

83

36

88

88

92

74

65

65

51

42

82

82

07

59

59

85

85

13

13

03

05

08

02

53

54

51

02

52

53

05

08

52

04

54

06

51

52

52

03

54

06

09

09

03

05

06

06

51

52

03

03

05

06

09

09

53

05

06

06

51

52

03

03

05

07

09

09

04

05

06

06

02

52

03

03

09

06

06

53

53

2 dleiF

esuFlanretxE

.rkrB.tkCro

001

001

2 dnuorG

rewoP

eziSeriW

01

8

4

21

8

8

41

21

01

8

8

4

01

8

8

6

41

01

01

01

8

6

4

4

01

8

6

6

41

01

01

01

8

6

4

4

8

8

6

6

41

01

01

01

8

6

3

3

8

8

6

6

21

01

01

01

4

3

3

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

8

3 muminiM

tiucriC

eriW

01

01

21

01

01

41

21

01

01

01

01

01

01

01

41

01

01

01

01

01

01

01

01

01

41

01

01

01

01

01

01

01

01

01

41

01

01

01

01

01

01

01

01

21

01

01

01

01

01

01

01

yticapmA

A.tkC B.tkC A.tkC B.tkC A.tkC B.tkC A.tkC B.tkC

-

22

-

-

-

-

-

-

-

52

-

-

-

-

-

-

-

-

-

13

33

-

-

-

-

-

-

-

-

-

-

43

43

-

-

-

-

-

-

-

-

-

83

83

83

-

-

-

-

-

-

-

-

54

54

54

-

-

-

-

1 mumixaM

esuFlanretxE

-

-

05

-

-

-

-

-

-

-

05

-

-

-

-

-

-

-

-

-

05

05

-

-

-

-

-

-

-

-

-

05

05

-

-

-

-

-

-

-

-

52

05

05

-

-

-

-

-

-

-

52

05

05

-

-

-

-

-

-

-

03

05

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

03

05

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

54

05

54

05

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

54

05

54

05

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

05

52

05

05

05

05

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

06

52

06

05

06

05

-

-

-

-

-

-

-

-

2 dleiF

rekaerB.tkCro

rewoP

eziSeriW

-

01

-

-

-

-

-

-

-

01

-

-

-

-

-

-

-

-

-

-

8

8

-

-

-

-

-

-

-

-

-

-

8

8

-

-

-

-

-

-

-

-

-

8

8

8

-

-

-

-

-

-

-

-

8

8

8

-

-

-

-

2 dnuorG

eziSeriW

-

-

8

-

-

-

-

-

-

-

8

-

-

-

-

-

-

-

-

-

8

8

-

-

-

-

-

-

-

-

-

8

8

-

-

-

-

-

-

-

-

01

8

8

-

-

-

-

-

-

-

01

8

8

-

-

-

-

-

-

-

01

01

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

01

01

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

01

01

01

01

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

01

01

01

01

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

01

01

01

01

01

01

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

01

01

01

01

01

01

-

-

-

-

-

-

-

-

1 Maximum size of the time delay fuse or HACR type circuit breaker for protection of field wiring conductors.

2 Based on 75°C copper wire. All wiring must conform to the National Electrical Code and all local codes.

3 These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electric Code (latest

revision), article 310 for power conductor sizing.

Caution: When more than one field power conductor circuit is run through one conduit, the conductors must be derated. Pay special

attention to note 8 of table 310 regarding Ampacity Adjustment Factors when more than three conductors are in a raceway.

4 Maximum KW that can operate with heat pump on is 10KW. Other 5KW energizes during emergency heat only.

5 Maximum KW that can operate with heat pump on is 9KW. Other 6KW energizes during emergency heat only.

Manual 2100-519C

Page 5 of 42

FIGURE 1

Q24H1

UNIT DIMENSIONS

Q30H1

Q36H1

Q48H1

Q42H1

Q60H1

Manual 2100-519C

Page 6 of 42

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be

checked for external signs of shipping damage. The

skid must remain attached to the unit until the unit is

ready for installation. If damage is found, the receiving

party must contact the last carrier immediately,

preferably in writing, requesting inspection by the

carrier’s agent.

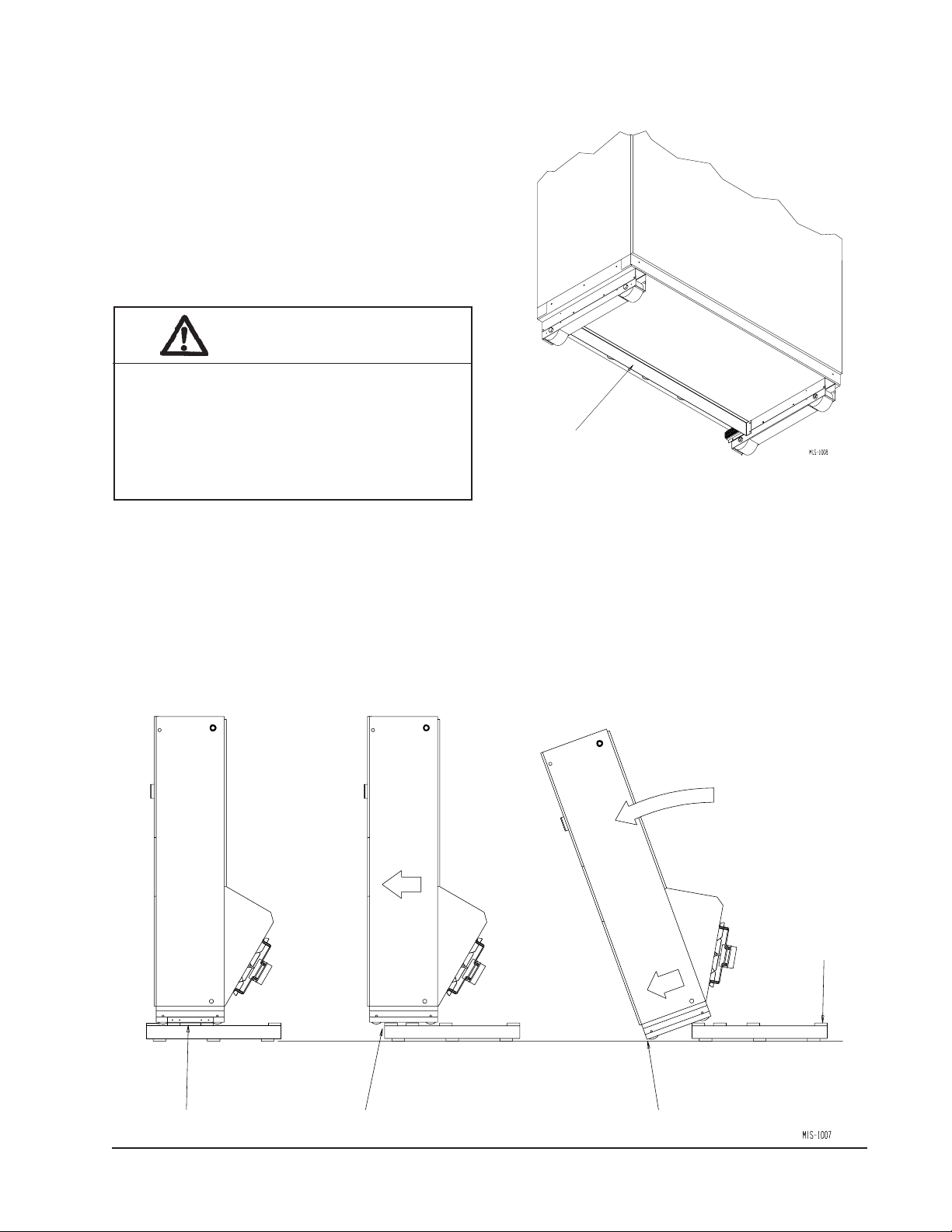

UNIT REMOVAL FROM SKID

WARNING

This unit is heavy and requires more than one

person to handle and remove from the skid.

Check unit wheels to ensure that wheels are

locked before removing from skid. Extreme

caution must be taken to prevent injury to

personnel and damage to the unit.

FIGURE 2

AIR SEAL UNDER QT

Air Seal

EC

UNIT

It is recommended that the unit not be removed from the

skid with a forklift since the air seal under the unit could

be damaged. See Figure 2.

The shipping brackets on each side of the unit must be

removed and discarded. See Figure 3-A. The return air

grille panel can be removed to provide a place to hold

the unit. The unit can be slid forward on the skid until

REMOVAL OF UNIT FROM SKID

the front wheels hang over the edge of the skid. See

Figure 3-B. The unit can be tipped forward and slid

down the edge of the skid until the front wheels touch

the ground. See Figure 3-C. The wheels will not roll.

They are shipped from the factory locked so they will

not roll. The back of the skid will have to be held down

to keep it from tipping up. The skid can be slid out from

under the unit. The unit can then be set upright.

FIGURE 3

Hold

Skid

Down

A Shipping Brackets B Front Wheels Over Edge C Front Wheels On Floor

Manual 2100-519C

Page 7 of 42

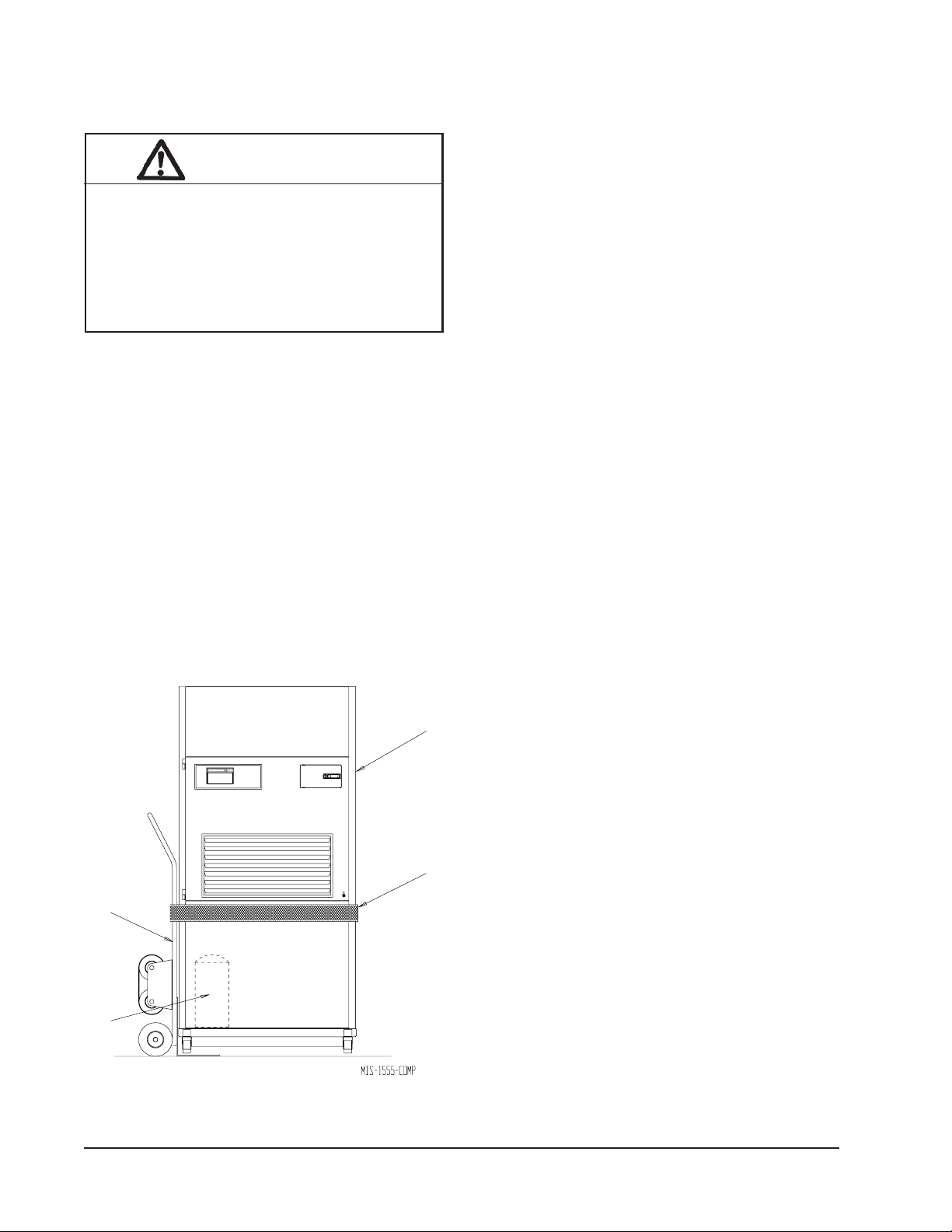

HANDLING UNIT AFTER REMOVAL

FROM SKID

WARNING

Exercise extreme caution when pushing the

unit on the rollers. Handle and push from the

lower 1/3 of the unit. Insure that debris is not

on the floor where the unit is to be moved on

the rollers. Failure to do so could result in the

unit tipping over and causing bodily injury and/

or damage to the unit.

The blade of the appliance cart should be slid under the

wheels of the unit. The strap of the appliance cart

should be placed around the unit and strapped tightly.

Help will be required to tip the unit back onto the cart.

The unit can be leaned far enough back to be rolled

through the door. Be careful when setting the unit back

up to keep from damaging the unit.

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The unit will have to be turned sideways and removed

from the skid to fit through a 36" doorway. If the door

height allows, the unit can be slid sideways through the

door.

If the unit cannot be slid through the door, then the unit

will have to be put on a cart and tipped down to roll

through the door. It is recommended that an appliance

cart be used with a strap to hold the unit on the cart.

The wheels of the unit must be locked. If the wheels

were allowed to roll, the unit could roll off the cart. The

unit should always be carted from the left side. This is

the side where the compressor is located. See Figure 4.

FIGURE 4

UNIT ON APPLIANCE CART

Q-TEC UNIT

(Right Side)

STRAP

APPLIANCE

CART

A QWS-Series wall sleeve supplied as a separate

accessory must be ordered and installed with Q-Tec unit.

The unit is designed for use with or without duct work.

For use without duct work, Plenum Box QPB42 is

recommended.

These instructions explain the recommended method to

install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly “Start

Procedure” and any tags and/or labels attached to the

equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Page 3 for information on codes and

standards.

Size of unit for a proposed installation should be based

on heat loss calculation made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Systems of

Other Than Residence Type, NFPA No. 90A, and

Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

should adhere to local codes.

COMPRESSOR

Manual 2100-519C

Page 8 of 42

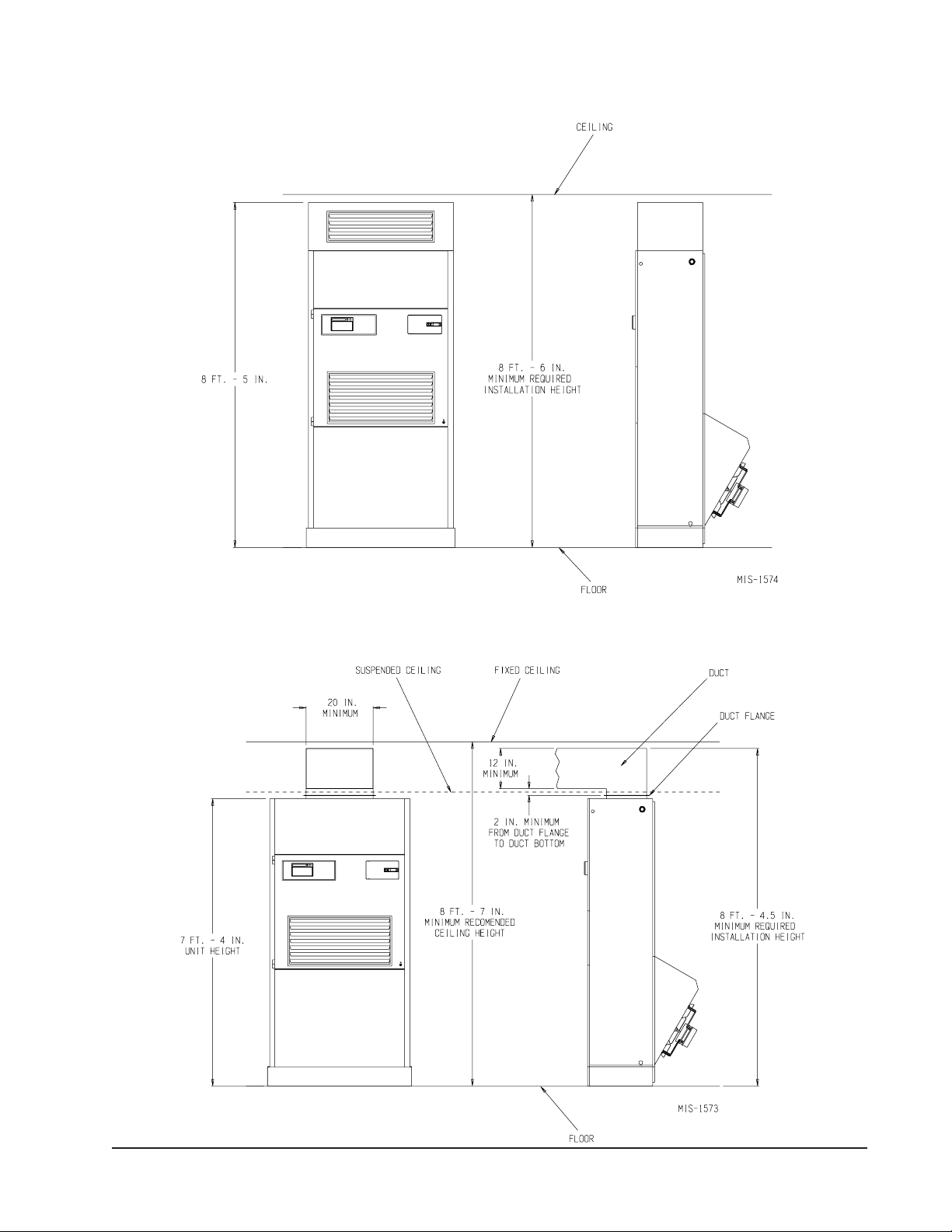

MINIMUM INSTALLATION HEIGHT

The minimum installation height of the unit with a Free

Blow Plenum is 8 ft. 6 in. This provides enough

clearance for the plenum to be removed. See Figure 5.

The minimum installation height for ducted applications

is 8 ft. 4½ in. This provides enough clearance to install

the duct work. See Figure 6.

FIGURE 5

INSTALLATION WITH FREE BLOW PLENUM

FIGURE 6

DUCTED APPLICATION

Manual 2100-519C

Page 9 of 42

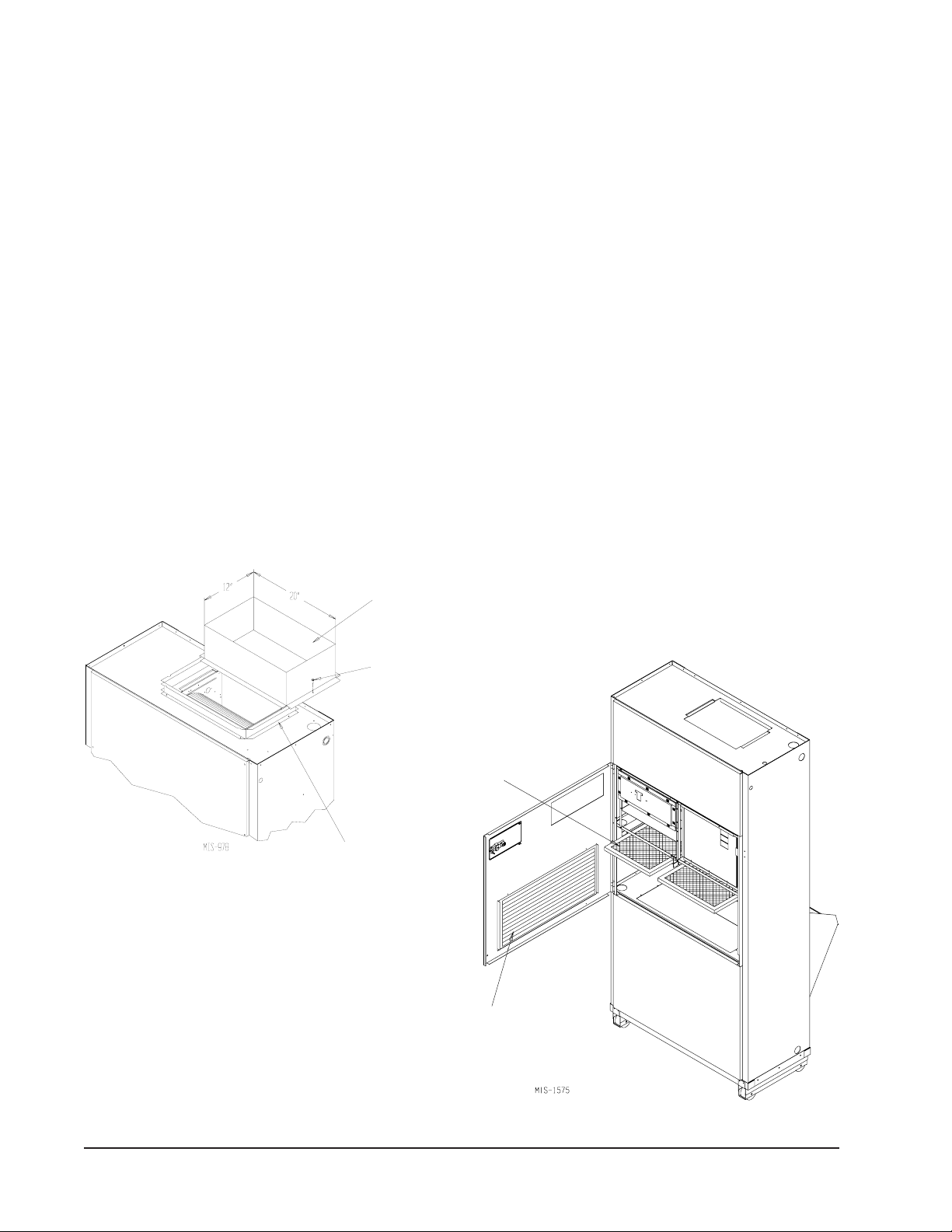

DUCT WORK

Any heat pump is more critical of proper operating

charge and an adequate duct system than a straight air

conditioning unit. All duct work must be properly sized

for the design airflow requirement of the equipment.

Air Conditioning Contractors of America (ACCA) is an

excellent guide to proper sizing. All duct work or

portions thereof not in the conditioned space should be

properly insulated in order to both conserve energy and

prevent condensation or moisture damage. When duct

runs through unheated spaces, it should be insulated

with a minimum of one inch of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect the

duct work to the equipment in order to keep the noise

transmission to a minimum.

The Q-TEC series heat pump has provision to attach a

supply air duct to the top of the unit. Duct connection

size is 12 inches x 20 inches. The duct work is field

supplied and must be attached in a manner to allow for

ease of removal when it becomes necessary to slide the

unit out from the wall for service. See Figure 7 for

suggested attachment method.

FIGURE 7

SUPPLY DUCT CONNECTIONS

SUPPLY DUCT

TO BE FIELD

SUPPLIED

ATTACHMENT

SCREWS TO

BE FIELD

SUPPLIED

For hot water coil option a QPBHWxx-F for free blow

or QPBHWxx-D for ducted airflow is used.

When used with a ducted supply, a QCX Cabinet

Extension can be used to conceal the duct work above

the unit to the ceiling. This extends 20" above the unit

for a total height above the floor of 10'-7/8". The unit is

equipped with a variable speed indoor blower motor

which increases in speed with an increase in duct static

pressure. The unit will therefore deliver proper rated air

flow up to the maximum ESP shown in Table 9.

However, for quiet operation of the air system, the duct

static should be kept as low as practical, within the

guidelines of good duct design.

FILTERS

Two 1-inch throw away filters [(1) 16x16 and (1)

16x20] are supplied with each unit. The filters slide into

filter brackets. Refer to Figure 8.

The filters are serviced from the inside of the building

by opening the hinged door. This door is attached by

T-25 torx screw and one locking latch.

The internal filter brackets are adjustable to

accommodate 2-inch filters. The tabs for the 1-inch

filters must be bent down to allow the 2-inch filters to

slide in place.

FIGURE 8

FILTER LOCATION

ROOM SIDE

EC UNIT

OF Q-T

DUCT FLANGE

PROVIDED WITH

UNIT

NOTE: Unit cabinet, supply air duct and free blow

plenum are approved for “0” clearance to

combustible material.

The Q-T

EC

series heat pumps are designed for use with

free return (non-ducted) and either free blow with the

use of QPB Plenum Box or a duct supply air system.

The QPB and QPBHW Plenum Box mounts on top of

the unit and has both vertically and horizontally

adjustable louvers on the front discharge grille.

Manual 2100-519C

Page 10 of 42

FILTERS

RETURN AIR

GRILLE

FRESH AIR INTAKE

This unit is equipped with a fresh air damper assembly.

The damper blade is locked in the closed position when

the unit is shipped from the Factory. To allow the

damper to operate remove the two plastic locking pins,

one on each end of the blade. This will allow for

maximum fresh airflow. The damper blade will now

open when the indoor blower is operating. If less than

maximum fresh airflow is required, reinsert the plastic

pins to limit damper blade opening to desired level.

Two extra pins are provided (taped to the inside of the

assembly) which may be used to hold the blade in some

position other than minimum or maximum position.

This fresh air assembly is located in the rear of the unit

and to gain access to make these adjustments remove

the air filter service door.

All capacity, efficiency and cost of operation

information as required for Department of Energy

“Energyguide” Fact Sheets are based upon the fresh air

blank-off plate in place and is recommended for

maximum energy efficiency.

The blank-off plate is available upon request from the

factory and is installed in place of the fresh air damper

shipped with each unit.

For details on energy recovery ventilation see Page 30.

SERVICE LIGHT

The unit is equipped with a service light which signals

the user that service is required. The light is located in

the upper control panel and is visible only when the

hinged service/filter access door is open.

The Service Unit light indicates that the unit has been

shut off by a high or low pressure device. This indicates

that the unit needs to be serviced. See Page 33 for details.

CONDENSATE DRAIN

There are two drain connections on the unit. The rear

drain is the primary drain, and is located on the right

lower rear panel of the unit. The optional side drain is

located on the bottom right side of the unit. The side

drain is shipped with a plug installed.

The rear drain can be used with wall thickness of up to

10 inches where a water trap can be installed between

the unit and the interior wall. See Figure 10. The trap

cannot extend beyond the edge of the unit or it will

interfere with the wall mounting bracket. The drain can

be routed through the floor or through the wall. If the

drain is routed through the wall, the drain line must be

positioned such that it will not interfere with the sleeve

flange or the grille. See Figure 11. If the drain is to be

routed through an unconditioned space, it must be

protected from freezing.

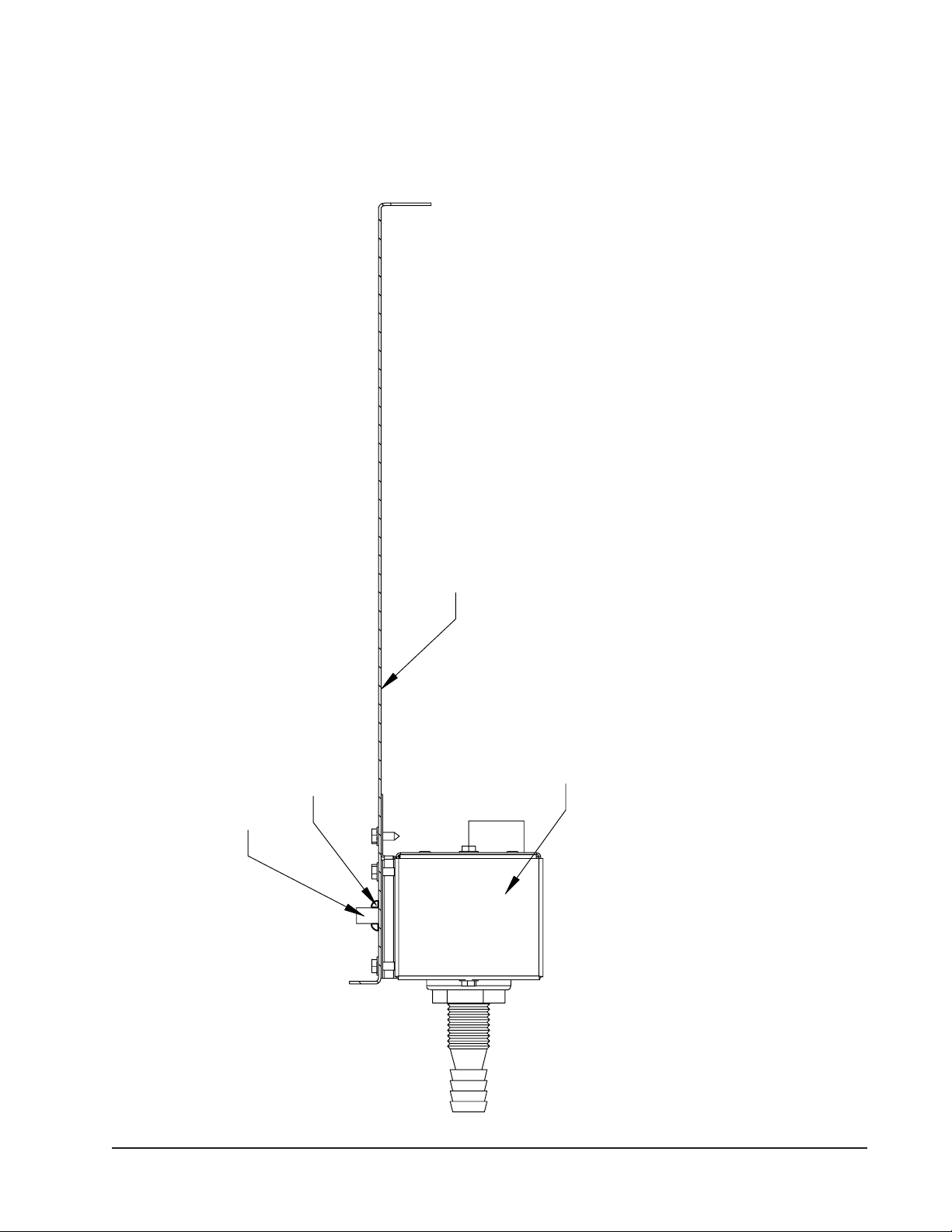

OPTIONAL REAR DRAIN KITS

Optional Rear Drain Kit, Bard Model QCDS48A, is

also available for these products. The optional rear

drain kit offers multiple benefits that include the

following:

• Allows unit to be rolled away from the sleeve

without having to disconnect any hard plumbing

connections.

• Allows indoor coil condensate to be easily

connected to Rear Drain Box while bypassing the

outdoor coil drain pan. This aids in minimizing the

potential for biological growth to occur by

minimizing the standing water and exposing it to

warm temperatures.

See Figures 12A, 12B, 12C and 12D.

The drain box permanently mounts onto the wall sleeve

and is then either piped directly outdoors, or can be

piped vertically. The Q-Tec unit is then equipped with

fittings on the rear of the unit that slide into the drain

box as it is wheeled towards the wall sleeve.

NOTE: On models equipped with a refrigerant

subcooler in the lower drain pan may experience a 23% decrease in cooling performance and efficiency

when the indoor condensate is routed around the

outdoor coil drain pan/subcooler assembly. Unit rated

performance and efficiency are with the indoor

condensate routed to the outdoor coil pan.

There is also a heated version of the rear drain box

available (Model #QCDS48H) for installation in

northern climates where freezing may occur.

The side drain requires a water trap for proper drainage.

See Figure 9. The drain can be routed through the floor

or through the wall. If the drain is to be routed through

an unconditioned space, it must be protected from

freezing. The drain line must be able to be removed from

the unit if it is necessary to remove the unit from the wall.

When the side drain is used, the plug must be removed

and installed in the rear drain outlet.

Manual 2100-519C

Page 11 of 42

FIGURE 9

OPTIONAL SIDE DRAIN (SIDE VIEW)

INSTALLATION

Q-TEC UNIT

FIGURE 10

STANDARD REAR DRAIN

SLEEVE

WATER

TRAP

FIGURE 11

REAR DRAIN (TOP VIEW)

DRAIN LINE

WALL (MAXIMUM 10"

FOR REAR DRAIN)

COUPLINGS NOT

SHOWN BUT

RECOMMENDED

FOR EASE OF

REMOVABILITY

FOR SERVICE.

WALL

BRACKET

Manual 2100-519C

Page 12 of 42

UNIT

WALL SLEEVE

MIS-2469

FIGURE 12A

OVERFLOW TUBE

CAULK AROUND TUBE

DRAIN BOX

Manual 2100-519C

Page 13 of 42

PLUG INSTALLED IN

SIDE Q/Tec DRAIN

FIGURE 12B

REAR DRAIN CONNECTION IN

Q/Tec PRODUCT

3/4" PLASTIC PIPE NIPPLE

SUPPLIED WITH DRAIN BOX KIT

(APPLY TEFLON TAPE TO

THREADS)

IMPORTANT !

1/2" SLIP X 1/2" SLIP X 3/4" NPT

TEE SUPPLIED WITH DRAIN BOX KIT

(TIGHTEN THREADS SO TEE IS

HORIZONTAL TO FLOOR)

MIS-2470

Manual 2100-519C

Page 14 of 42

FIGURE 12C

REMOVE KNOCK-OUT FOR

INDOOR DRAIN HOSE CONNECTOR

(If Used)

MIS-2471

Manual 2100-519C

Page 15 of 42

FIGURE 12D

MOVE HOSE FROM ATTACHMENT IN

LOWER DRAIN PAN AND SLIDE ONTO

DRAIN BOX BARB FITTING, SECURING

WITH SUPPLIED CLAMP IF OUTDOOR

PAN IS BYPASSED. ( WILL REDUCE RISK

OF ALGAE GROWTH IN THE OUTDOOR

PAN BUT AT A SLIGHT COOLING

PERFORMANCE REDUCTION OF 2-3% )

Manual 2100-519C

Page 16 of 42

DRAIN HOSE FROM INDOOR

DRAIN PAN.

MIS-2472

FIGURE 13A

UNIT MOUNTING - METHOD 1

ENLARGED VIEW OF MOUNTING

BRACKET SHOWING SLEEVE TO

CABINET ATTACHMENT

BOTTOM

TRIM

PIECE

BOTTOM TRIM

EXTENSION

SIDE TRIM

(2 PCS.)

QWS Series

Wall Sleeve

SIDE TRIM

(2 PCS.)

MOUNTING

BRACKET

#8 SCREW

PROVIDED

(LIGHT COLOR)

CABINET

SIDE PANEL

FIGURE 13B

UNIT MOUNTING - METHOD 2

MOUNTING BRACKET

WALL

SLEEVE

#10 HEX

HEAD SCREW

PROVIDED

Sleeve

Washer

Return Grille

Stud

Nut

Condenser

Door (Removed)

MIS-2689

Lower Control Panel

Manual 2100-519C

Page 17 of 42

INSTALLATION INSTRUCTIONS

MOUNTING THE UNIT

When installing a Q-TEC unit near an interior wall on the

left side, a minimum of 8 inches is required; 12 inches is

preferred.

When installing a Q-TEC unit near an interior wall on the

right side, a minimum of 18 inches is required as

additional space is required to connect the side drain. If

the rear condensate drain kit QCDS48 is used the

minimum can be reduced to 8 inches.

This clearance is required to allow for the attachment of

the unit to the sleeve and side trim pieces to the wall.

This unit is to be secured to the wall sleeve with

mounting brackets provided. The unit itself, the supply

duct and the free blow plenum are suitable of “0”

clearance to combustible material.

Following are the steps for mounting the Q-TEC. For

reference see Figure 13A for external mounting bracket

or 13B for internal bolt secured bracket (recommended).

1. Attach mounting brackets to the wall sleeve with

screws provided. Either use external mounting

bracket (Fig. 13A) or internal bolt bracket (Fig. 13B).

2. Position the unit in front of the sleeve with the

condenser section toward the sleeve.

3. Remove the locking screws from the wheels.

Refer to Figure 14.

4. Roll the unit into the sleeve. Make sure to check

both sides of the unit as it is being rolled to keep

it centered in the sleeve. Also check the

alignment to the mounting brackets. This unit

must be level from side to side. If adjustments

are necessary, shim up under the rollers with

sheets of steel or any substance that is not

affected by moisture.

5. Make sure the gasket on the rear of the unit is

touching the sleeve across the top and down both

sides. This is a rain water seal.

6. Secure the mounting brackets to the unit with

screws provided, #10 hex head sheet metal

screws (Figure 13A) or use nut and washer to

secure sleeve (Figure 13B).

7. Bottom trim extensions are provided for use when

wall is less than 14 inches but greater than 10.5

inches. Secure to wall with screws (not provided).

8. Attach the bottom trim piece to the unit with the

screws provided (dark colored).

9. Position side trim pieces to wall and attach with

field supplied screws. There are two long pieces

and two short pieces supplied. The long pieces

are to enclose the gap behind the unit. The short

pieces are to fill the gap behind the cabinet

extension or the free blow plenum box. They

may be cut to suit your ceiling height or overlap

the unit side trim. There is sufficient length to

trim up to a 10'2" ceiling.

NOTE: If the exterior wall thickness is between 5

inches to 10.5 inches, a side trim extension

piece kit, model QSTX42, is available.

Manual 2100-519C

Page 18 of 42

FIGURE 14

REMOVING LOCKING SCREWS FROM WHEELS

REMOVE SCREWS FROM

WHEELS BEFORE

ROLLING INTO PLACE

WIRING – MAIN POWER

Refer to the unit rating plate and/or Table 2 for wire

sizing information and maximum fuse or “HACR Type”

circuit breaker size. Each unit is marked with a

“Minimum Circuit Ampacity”. This means that the

field wiring used must be sized to carry that amount of

current. Depending on the installed KW of electric

heat, there may be two field power circuits required. If

this is the case, the unit serial plate will so indicate. All

models are suitable only for connection with copper

wire. Each unit and/or wiring diagram will be marked

“Use Copper Conductors Only”. These instructions

MUST BE adhered to. Refer to the National Electrical

Code (NEC) for complete current carrying capacity data

on the various insulation grades of wiring material. All

wiring must conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75°C

copper) for all models, including the most commonly

used heater sizes. Also shown are the number of field

power circuits required for the various models with

heaters.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or “HACR Type” circuit breaker that is to

be used with the equipment. The correct size must be

used for proper circuit protection, and also to assure that

there will be no nuisance tripping due to the momentary

high starting current of the compressor motor.

The disconnect access door on this unit may be locked

to prevent unauthorized access to the disconnect.

FIGURE 15

COMPONENT LOCATION

SIDE FIELD WIRE

ELECTRIC

HEATERS

UNIT

MOUNTED

THERMOSTAT

LOCATION

DEHUMIDIFICATION

CONTROL

(OPTIONAL)

BREAKER PANEL

& CONTROLS

ENTRANCE

REMOTE

THERMOSTAT

TERMINAL

BLOCK

I

NDOOR

BLOWER

CIRCUIT

LOWER

CONTROL

PANEL

See Start Up section for information on three phase

scroll compressor start-ups.

The field wiring connections are located behind the top

and hinged panel in the circuit breaker panel. See

Figure 15.

WIRING – LOW VOLTAGE WIRING

230/208V, 1 PHASE AND 3 PHASE EQUIPMENT

DUAL PRIMARY VOLTAGE TRANSFORMERS.

All Equipment leaves the factory wired on 240V tap.

For 208V operation, reconnect from 240V to 208V tap.

The acceptable operating voltage range for the 240 and

208V taps are as noted in Table 3.

TABLE 3

OPERATING VOLTAGE RANGE

PATEGNAR

V042612–352

V802781–022

NOTE: The voltage should be measured at the field

power connection point in the unit and while

the unit is operating at full load (maximum

amperage operating condition).

The standard Climate Control Option X is a remote

thermostat connection terminal block. See Figure 17A

for wiring diagram. Compatible thermostats are listed

in Table 4. See Fig. 17B for Remote CO2 Sensor

Connection.

The Climate Control Option A is an electronic, nonprogrammable manual or auto changeover thermostat.

The subbase of the thermostat is factory wired to the

front panel of the unit. See Figure 18 for wiring

diagram. Compatible for use with Bard CS2000A*

Controller and Energy Recovery Ventilator.

The Climate Control Option D is an electronic,

programmable thermostat. The subbase of the

thermostat is factory wired to the front panel of the unit.

See Figure 19 for wiring diagram. Compatible for use

with Energy Recovery Ventilator or Economizer.

The Climate Control Option H is an electronic,

programmable thermostat and a CO2 controller. The

subbase of the thermostat and CO2 controller are factory

wired to the front panel of the unit. See Figure 20 for

wiring diagram.

NOTE: On option X or A the CS2000A* (or other field

provided means to control ventilation) must be

used if any of the motorized ventilation options

are installed.

Manual 2100-519C

Page 19 of 42

LOW VOLTAGE CONNECTIONS

These units use a grounded 24 volt AC low voltage

circuit.

The “R” terminal is the hot terminal and the “C”

terminal is grounded.

“G” terminal or pins 6 and 1 of P2 are the fan inputs.

Both must be energized for proper fan operation. This

is done automatically in the factory installed climate

control options. If the climate control option is

abandoned and connections are made directly to P2 both

pins 6 and 1 of P2 must be energized for proper

operation.

“Y” terminal or pin 7 of P2 is the compressor input.

“B” terminal or pin 8 of P2 is the reversing valve input.

The reversing valve must be energized for heating

mode.

“R” terminal or pin 10 of P2 is 24 VAC hot.

“C” terminal or pin 11 of P2 is 24 VAC grounded.

“L” terminal or pin 12 of P2 is compressor lockout

output

pressure trip by the electronic heat pump control. This

is a 24 VAC output.

. This terminal is activated on a high or low

NOTE: For total and proper control using DDC, a total

of 6 controlled outputs are required (5 if no

ventilation system is installed). For proper

system operation under Emergency Heat

conditions. Where the compressor needs to be

deactivated, the B-W2-E outputs need to be

energized. Removing the Y (compressor) signal

alone turns the compressor off, but does not

activate the additional circuitry embedded in

the heat pump for proper and complete

operation.

ROFSNOITCENNOCEGATLOVWOL

LORTNOCCDD

ylnOnaFGezigrenE

edoMgnilooCG,YezigrenE

gnitaeHpmuPtaeHB,G,YezigrenE

gnitaeHegatSdn2

)deyolpmefi(

noitalitneV1O,GezigrenE

taeHycnegremEE,2W,BezigrenE

2W,GezigrenE

“W2” terminal or pin 9 of P2 is second stage heat (if

equipped). If the unit is equipped with an optional hot

water coil plenum box or electric heat these will be

energized by this terminal.

“O1” terminal of pin 5 of P2 is the ventilation input.

This terminal energizes any factory installed ventilation

option.

“E” terminal or pin 3 of P2 is the emergency heat input.

This terminal energizes the emergency heat relay.

GENERAL

This unit is equipped with a variable speed ECM motor.

The motor is designed to maintain rated airflow up to

the maximum static allowed. It is important that the

blower motor plugs are not plugged in or unplugged

while the power is on. Failure to remove power prior

to unplugging or plugging in the motor could result in

motor failure.

CAUTION

Do not plug in or unplug blower motor

connectors while the power is on. Failure to do

so may result in motor failure.

Manual 2100-519C

Page 20 of 42

TABLE 4

WALL THERMOSTATS

tatsomrehTserutaeFtnanimoderP

060-3048

)544-0211(

850-3048

)1511D0225HT(

650-3048

)8001A2327C(

FIGURE 16

taeHegats3;looCegats3

cinortcelEelbammargorP-noN/elbammargorP

lanoitnevnoCroPH

revoegnahclaunaMrootuA

taeHegats2;looCegats2

elbammargorP-noNcinortcelE

lanoitnevnoCroPH

revoegnahclaunaMrootuA

rofDCLhtiwrosneSedixoiDnobraC

sgnidaeRrosneS

MIS-1285

Manual 2100-519C

Page 21 of 42

FIGURE 17A

REMOTE THERMOSTAT WIRING DIAGRAM

“X” THERMOSTAT OPTION

REMOTE THERMOSTAT WIRING DIAGRAM

"X" THERMOSTAT OPTION

Thermostat

Bard Part #8403-060

G

W1/E

L

A

Y1

O/B

W2

C

Thermostat #TH522001151

Bard Part #8403-058

G

E

Y

O/B

Aux

RR

Rc

C

1

Low Voltage

Terminal Block

G

E

L

O1

W1

Y

B

W2

R

C

W3

Orange

Red/Yellow

Brown/White

Yellow

Blue

Brown

Red/White

Black/White

Plug #2

Orange

1

2

3

4

5

6

7

8

9

10

11

12

Factory installed jumper.

1

NOTE: On option X or A the CS2000A* (or other field

provided means to control ventilation) must be

used if any of the motorized ventilation options

are installed.

Manual 2100-519C

Page 22 of 42

MIS-2687

VENTILATOR OR DAMPER

“X” THERMOSTAT OPTION WITH DEMAND VENTILATION

Optional

CO2 Controller

#C7232A1008

Bard Part #8403-056

24VAC

Analog

Out

FIGURE 17B

REMOTE THERMOSTAT WIRING DIAGRAM

Red

Black

Yellow

Brown

Orange

Green

1

3

2

5

4

Relay

Part #8201-062

3

2

Plug #2

G

W1/E

L

A

Y1

O/B

W2

C

Thermostat

Bard Part #8403-060

G

E

Y

O/B

Aux

RR

Rc

1

C

Thermostat #TH522001151

Bard Part #8403-058

G

E

L

O1

W1

Y

B

W2

R

C

W3

Low Voltage

Terminal Block

Orange

Red/Yellow

Brown/White

Yellow

Brown

Red/White

Black/White

Blue

Orange

1

2

3

4

5

6

7

8

9

10

11

12

Factory installed jumper.

1

Mount relay in low voltage terminal block compartment.

2

Relay is field installed and required if demand ventilation

3

control does not supply blower "G" signal when ventilation

signal "O1" is supplied.

MIS-2688

Manual 2100-519C

Page 23 of 42

UNIT MOUNTED THERMOSTAT WIRING DIAGRAM

“A” THERMOSTAT OPTION

Temp. and Humidity

FIGURE 18

Plug #2

Controller

PART #8403-060

W1/E

G

Y1

O/B

W2

Orange

1

Brown/White

2

Red/Yellow

3

4

5

Orange

6

Yellow

7

Blue

8

Brown

9

R

C

L

NOTE: On option X or A the CS2000A* (or other field

provided means to control ventilation) must be used

if any of the motorized ventilation options are

installed.

Manual 2100-519C

Page 24 of 42

Red/White

10

Black/White

11

Pink

12

4102-062 A

UNIT MOUNTED THERMOSTAT WIRING DIAGRAM

“D” THERMOSTAT OPTION

Temp. and Humidity

FIGURE 19

Plug #2

Controller

PART #8403-060

W1/E

A Brown/White

G

Y1

O/B

W2

Orange

1

2

Red/Yellow

3

4

5

Orange

6

Yellow

7

Blue

8

Brown

9

R

C

Red/White

10

Black/White

11

12

4102-060

Manual 2100-519C

Page 25 of 42

FIGURE 20

UNIT MOUNTED THERMOSTAT WIRING DIAGRAM

“H” THERMOSTAT OPTION

CO2 Controller

Part #8403-056

Temp. and Humidity

Controller

Part #8403-060

4102-059

Red Red/White

24VAC

Analog

Out

Black

Yellow

Brown

Black/White

5321

4

Orange

Red/White

Green

W1/E

Black/White

Brown/White

ABrown/White

G

Y1

O/B

W2

R

C

Orange

Yellow

Blue

Brown

Red/White

Black/White

Relay

Part #8201-062

Orange

Orange

Red/Yellow

Plug #2

1

2

3

4

5

6

7

8

9

10

11

12

Manual 2100-519C

Page 26 of 42

START UP

THESE UNITS REQUIRE R-410A

REFRIGERANT AND POLYOL

ESTER OIL.

GENERAL:

1. Use separate service equipment to avoid cross

contamination of oil and refrigerants.

2. Use recovery equipment rated for R-410A

refrigerant.

3. Use manifold gauges rated for R-410A (800 psi/250

psi low).

4. R-410A is a binary blend of HFC-32 and HFC-125.

5. R-410A is nearly azeotropic - similar to R-22 and

R-12. Although nearly azeotropic, charge with

liquid refrigerant.

6. R-410A operates at 40-70% higher pressure than

R-22, and systems designed for R-22 cannot

withstand this higher pressure.

7. R-410A has an ozone depletion potential of zero,

but must be reclaimed due to its global warming

potential.

8. R-410A compressors use Polyol Ester oil.

9. Polyol Ester oil is hygroscopic; it will rapidly absorb

moisture and strongly hold this moisture in the oil.

10. A liquid line dryer must be used - even a deep

vacuum will not separate moisture from the oil.

11. Limit atmospheric exposure to 15 minutes.

12. If compressor removal is necessary, always plug

compressor immediately after removal. Purge with

small amount of nitrogen when inserting plugs.

TOPPING OFF SYSTEM CHARGE

If a leak has occurred in the system, Bard Manufacturing

recommends reclaiming, evacuating (see criteria above),

and charging to the nameplate charge. If done correctly,

topping off the system charge can be done without

problems.

With R-410A, there are no significant changes in the

refrigerant composition during multiple leaks and

recharges. R-410A refrigerant is close to being an

azeotropic blend (it behaves like a pure compound or

single component refrigerant). The remaining

refrigerant charge, in the system, may be used after

leaks have occurred and then “top-off” the charge by

utilizing the pressure charts on the inner control panel

cover as a guideline.

REMEMBER: When adding R-410A refrigerant, it

must come out of the charging cylinder/tank as a liquid

to avoid any fractionation, and to insure optimal system

performance. Refer to instructions for the cylinder that

is being utilized for proper method of liquid extraction.

WARNING

Failure to conform to these practices

could lead to damage, injury or death.

SAFETY PRACTICES:

1. Never mix R-410A with other refrigerants.

2. Use gloves and safety glasses. Polyol Ester oils can

be irritating to the skin, and liquid refrigerant will

freeze the skin.

3. Never use air and R-410A to leak check; the

mixture may become flammable.

4. Do not inhale R-410A – the vapor attacks the

nervous system, creating dizziness, loss of

coordination and slurred speech. Cardiac

irregularities, unconsciousness and ultimate death

can result from breathing this concentration.

5. Do not burn R-410A. This decomposition

produces hazardous vapors. Evacuate the area if

exposed.

6. Use only cylinders rated DOT4BA/4BW 400.

7. Never fill cylinders over 80% of total capacity.

8. Store cylinders in a cool area, out of direct

sunlight.

9. Never heat cylinders above 125°F.

10. Never trap liquid R-410A in manifold sets, gauge

lines or cylinders. R-410A expands significantly

at warmer temperatures. Once a cylinder or line is

full of liquid, any further rise in temperature will

cause it to burst.

Manual 2100-519C

Page 27 of 42

START UP

DESCRIPTION OF STANDARD

EQUIPMENT

Solid State Electronic Heat Pump Control

Provides efficient 30-minute defrost cycle. A thermistor

sensor and speed up terminal for service along with a

10-minute defrost override are standard on the electronic

heat pump control.

High / Low Pressure Switch

Provides refrigerant circuit high pressure and loss of

charge protection. Includes lockout circuit that is

resettable from room thermostat.

Five Minute Compressor Time Delay

Provides short cycle protection for the compressor

which extends compressor life. Built into the electronic

heat pump control as standard.

Service Light

One service light indicates when service is required.

• Check System – detects high or low pressure

switch operation for compressor protection.

OPTIONAL CFM (Q36H1, Q42H1, Q48H1

AND Q60H1 ONLY)

These units are shipped from the factory set to operate at

the optional CFM level shown in Table 9. This provides

lower operating sound levels for non-ducted, free

discharge applications. This CFM level will reduce the

system capacity performance by approximately 2% at

the same energy efficiency.

Rated CFM is required for ducted applications for

maximum performance rating. To obtain full CFM on

these models, connect jumper wire as follows:

1. Disconnect all power to the unit. Failure to do so

may result in damage to the motor.

2. Open return air service panel

3. Open inner control panel cover

4. Locate low voltage terminal strip. There is a pink

jumper wire with both ends attached to terminal

marked “G2”. Move one end of this jumper to

terminal “Y”.

5. Reverse steps to reassemble.

IMPORTANT INSTALLER NOTE

For improved start-up performance, wash the indoor coil

with a dishwasher detergent.

PHASE MONITOR

All units with three phase scroll compressors are

equipped with a 3 phase line monitor to prevent

compressor damage due to phase reversal.

The phase monitor in this unit is equipped with two

LEDs. If the Y signal is present at the phase monitor

and phases are correct the green LED will light and the

compressor contactor is allowed to energize.

If phases are reversed, the red fault LED will be lit and

compressor operation is inhibited.

If a fault condition occurs, reverse two of the supply

leads to the unit. Do not reverse any of the unit factory

wires as damage may occur.

THREE PHASE SCROLL COMPRESSOR

START UP INFORMATION

Scroll compressors, like several other types of

compressors, will only compress in one rotational

direction. Direction of rotation is not an issue with

single phase compressors since they will always start

and run in the proper direction.

However, three phase compressors will rotate in either

direction depending upon phasing of the power. Since

there is a 50-50 chance of connecting power in such a

way as to cause rotation in the reverse direction,

verification of proper rotation must be made.

Verification of proper rotation direction is made by

observing that suction pressure drops and discharge

pressure rises when the compressor is energized.

Reverse rotation also results in an elevated sound level

over that with correct rotation, as well as, substantially

reduced current draw compared to tabulated values.

Verification of proper rotation must be made at the

time the equipment is put into service. If improper

rotation is corrected at this time there will be no

negative impact on the durability of the compressor.

However, reverse operation for even one hour may

have a negative impact on the bearing due to oil pump

out.

All three phase scroll compressors used in the QT

series are wired identically internally. As a result, once

the correct phasing is determined for a specific system

or installation, connecting properly phased power leads

to the same Fusite terminal should maintain proper

rotation direction. The direction of rotation of the motor

may be changed by reversing any two line connections

to the unit.

EC

Manual 2100-519C

Page 28 of 42

SERVICE HINTS

1. Caution user to maintain clean air filters at all

times. Also, not to needlessly close off supply air

registers. This may reduce airflow through the

system, which shortens equipment service life as

well as increasing operating costs and noise

levels.

2. Switching to heating cycle at 75°F or higher

outside temperature may cause a nuisance trip of

the remote reset high pressure switch. Turn

thermostat off, then on to reset the high pressure

switch.

3. The heat pump wall thermostats perform multiple

functions. Be sure that all function switches are

correctly set for the desired operating mode

before trying to diagnose any reported service

problems.

4. Check all power fuses or circuit breakers to be

sure they are the correct rating.

g. Remove screws that attach the duct work to

the unit flanges.

This unit is equipped with four rollers

mounted to the base. For ease of pulling unit

out from the wall, you may want to remove

the bottom service door which requires

removal of the return air panel, and grip the

front flange of the base pan then pull straight

out.

7. Annual maintenance is required to make sure that

all of the systems are functioning properly.

a. Check to make sure that the drains are not

obstructed in any way.

b. Remove any debris in the condenser section of

the unit.

c. Inspect and clean mist eliminator as described

below.

d. Inspect and wash outdoor coil as necessary.

5. Periodic cleaning of the outdoor coil to permit

full and unrestricted airflow circulation is

essential.

6. Some service requires the need to remove the unit

from the wall including replacement of the indoor

coil and/or the outdoor coil. Also, servicing the

outdoor fan motor or fan blade will require

removing the unit from the wall if the unit is

installed at a height that is not easily accessible

from the outside of the building.

In order to remove the unit from the wall the

following procedure must be used:

a. Turn off power to the unit at the remote

location. Some units may have more than one

power supply.

b. Disconnect field wiring at unit terminal block

and remove from unit.

c. Disconnect condensate drain.

d. Remove the lower skirting around the unit.

e. Remove wall mounting brackets from wall on

each side of the unit and/or remove the

internal bolts in the lower section securing unit

to wall sleeve.

f. If unit is attached to duct work, remove upper

cabinet extension by removing the top center

screw only from the cabinet side panel.

MIST ELIMINATOR SERVICE

A mist eliminator is supplied with the wall sleeve. The

mist eliminator is constructed of an aluminum frame

and mesh. The mist eliminator is located in the top

section of the wall sleeve and can be removed from the

inside of the building without removing the unit from

the wall. This requires that the ventilation package be

removed.

It is recommended that the mist eliminator be inspected

annually and serviced as required. The mist eliminator

can be inspected from the outside of the building by

looking through the outdoor grille. The mist eliminator

can be serviced from the outside by using a vacuum

cleaner. The outdoor grille must be removed. Use the

vacuum to remove dirt and debris from the surface of

the mist eliminator. If additional cleaning is required,

the mist eliminator will have to be removed from the

sleeve.

The ventilation package will have to be removed to gain

access to the mist eliminator. If the blank off plate

option is used, it is not necessary to service the mist

eliminator. The steps necessary to remove each of the

vent options are listed on the following pages.

The mist eliminator can be cleaned by washing with

soap and water. The excess water should be shaken off

the mist eliminator before it is reinstalled.

Manual 2100-519C

Page 29 of 42

VENT OPTIONS

BAROMETRIC FRESH AIR DAMPER

(Standard)

Before starting, make sure the power has been turned

off. The return air grille panel must be removed. The

fresh air damper assembly can be seen on the back of

the unit. See Figure 21.

Q-TEC ENERGY RECOVERY VENTILATOR

(Option)

Before starting, make sure that the power has been

turned off. The return air grille panel must be removed.

The energy recovery ventilator (QERV) can be seen

after the panel has been removed. To gain access to the

mist eliminator, the QERV must be removed. See

Figure 22.

1. The fresh air damper is attached to the back of

the unit with one screw on either side of the

assembly. Both of the screws must be removed.

2. Once the mounting screws are removed, tilt the

assembly down and lift it out.

The mist eliminator can be seen through the opening.

The mist eliminator must be raised up and the bottom

can be pulled toward the front of the unit.

COMMERCIAL ROOM VENTILATOR (Option)

Before starting, make sure the power has been turned

off. The return air grille panel must be removed. The

commercial room ventilator (CRV) can be seen after

the panel has been removed. The CRV must be

removed to gain access to the mist eliminator.

1. The two mounting screws in the front of the

CRV must be removed.

2. The power connectors for the CRV (located on

the right side of the unit) must be disconnected.

Squeeze the tabs on the sides of the connector

and pull straight out. Unplug both of the

connectors.

1. The front fill plate of the QERV must be removed.

There is one screw on either side of the plate.

Remove these screws and remove the plate.

2. On either side of the QERV there are mounting

screws that hold the QERV in place. Remove both of

these screws.

3. Underneath the heat recovery cassette there is a

power connector for the lower blower assembly. To

disconnect this plug, the tabs on both sides of the

plug must be squeezed to release the plug. While

squeezing the tabs, pull the plug out of the socket.

4. The QERV is plugged into the unit in the right side

of the unit. Both of these plugs must be disconnected

to remove the QERV. Squeeze the tabs on the sides

of the connector and pull straight out.

5. Slide the QERV assembly straight out of the unit,

being careful not to let the cassette slide out of the

QERV.

The mist eliminator can be seen through the opening in

the back of the unit. The mist eliminator must be raised

up and the bottom can be pulled toward the front of the

unit and removed.

3. Slide the CRV straight out of the unit.

The mist eliminator can be seen through the opening in

the back of the unit. The mist eliminator must be raised

up and the bottom can be pulled toward the front of the

unit and removed.

Manual 2100-519C

Page 30 of 42

FIGURE 21

FRESH AIR DAMPER REMOVAL

MOUNTING

SCREW

Manual 2100-519C

Page 31 of 42

FIGURE 22

QERV REMOVAL

MOUNTING

SCREWS

POWER

CONNECTORS

LOWER

BLOWER

ASSEMBLY

POWER

CONNECTOR

Manual 2100-519C

Page 32 of 42

FRONT FILL

SEQUENCE OF OPERATION

"SW1" SET TO ON "OUT" SET TO 20-100%

"SW2" SET TO ON

OFF

ON

ON

OFF

0-100%

20-100%

VOLTAGE

CURRENT

SW2SW1OU T AN

"AN" SET TO VOLTAGE

MIS-2667

COOLING –

compressor contactor, starting the compressor and

outdoor motor. The G (indoor motor) circuit is

automatically completed on any call for cooling

operation or can be energized by manual fan switch on

subbase for constant air circulation.

HEATING –

controls heating cycle operation. Two thermostat

options, one allowing “Auto” changeover from cycle to

cycle and the other constantly energizing solenoid coil

during heating season, and thus eliminating pressure

equalization noise except during defrost, are to be used.

On “Auto” option a circuit is completed from R-W1 and

R-Y on each heating “on” cycle, energizing reversing

valve solenoid and pulling in compressor contactor

starting compressor and outdoor motor. R-G also make

starting indoor blower motor. Heat pump heating cycle

now in operation. The second option has no “Auto”

changeover position, but instead energizes the reversing

valve solenoid constantly whenever the system switch on

subbase is placed in “Heat” position, the “B” terminal

being constantly energized from R. A Thermostat

demand for heat completes R-Y circuit, pulling in

compressor contactor starting compressor and outdoor

motor. R-G also make starting indoor blower motor.

High / Low Pressure control provides protection for the

compressor. In the event system pressures go above 600

PSI or below 15 PSI in either cooling or heating mode,

the compressor will be stopped. This will activate the

red light located in the control panel. The lockout

circuit will hold compressor off line. When the system

problem is corrected, the unit operation can be restored

by turning of the main power supply off and then back

on, or reset the room thermostat. The low pressure

control has a bypass to eliminate nuisance lockout on

cold start up.

Circuit R-Y makes at thermostat pulling in

A 24V solenoid coil on reversing valve

The Climate Control Option “D” is an electronic,

programmable thermostat. The thermostat can be set in

the heat, cool or automatic mode. When the thermostat

is set in the heat mode, it can heat only to maintain the

temperature set on the thermostat. When the thermostat

is set in the cool mode, it can cool only to maintain the

temperature set on the thermostat. When the thermostat

is set in the automatic mode, the thermostat can change

automatically to the heat or cool modes to maintain the

temperature set on the thermostat.

The Climate Control Option “H” is an electronic,

programmable thermostat and a CO

controller. The

2

thermostat can be set in the heat, cool or automatic

mode. When the thermostat is set in the heat mode, it

can heat only to maintain the temperature set on the

thermostat. When the thermostat is set in the cool

mode, it can cool only to maintain the temperature set

on the thermostat. When the thermostat is set in the

automatic mode, the thermostat can change

automatically to the heat or cool modes to maintain the

temperature set on the thermostat.

The CO

controller will energize the vent option and the

2

ID blower when the room CO2 levels rise over set level.

Default CO2 set point is 1000 ppm. See Figure 23.

FIGURE 23

CO2 CONTROLLER – FACTORY SET TO 1000

PPM

The bypass timer should be set to 120 seconds and this

is to assure there is no nuisance tripping of the lowpressure control during startup in heating mode under

cold weather conditions. See Defrost Control Board Figure 24.

OPTIONAL CLIMATE CONTROLS

SEQUENCE OF OPERATION

The Climate Control Option “A” is an electronic, nonprogrammable manual or auto changeover thermostat.

The thermostat may be manually set to heat or cool

mode. The thermostat will maintain the temperature set

on the thermostat in the mode in which it is set.

Manual 2100-519C

Page 33 of 42

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on all units

so that the system operating pressures can be observed.

Pressure tables can be found later in the manual covering all

models. It is imperative to match the correct pressure table

to the unit by model number. Upper and lower service

doors must be attached to obtain proper reading.

DEFROST CYCLE

The defrost cycle is controlled by temperature and time on

the solid state heat pump control.

When the outdoor temperature is in the lower 40°F

temperature range or colder, the outdoor coil temperature is

32°F or below. This coil temperature is sensed by the coil

temperature sensor mounted near the bottom of the outdoor

coil. Once coil temperature reaches 30°F or below, the coil

temperature sensor sends a signal to the control logic of the

heat pump control and the defrost timer will start

accumulating run time.

After 30, 60 or 90 minutes of heat pump operation at 30°F

or below, the heat pump control will place the system in

the defrost mode.

During the defrost mode, the refrigerant cycle switches

back to the cooling cycle, the outdoor motor stops, electric

heaters are energized, and hot gas passing through the

outdoor coil melts any accumulated frost. When the

temperature rises to approximately 57°F, the coil

temperature sensor will send a signal to the heat pump

control which will return the system to heating operations

automatically.

If some abnormal or temporary condition such as a high

wind causes the heat pump to have a prolonged defrost

cycle, the heat pump control will restore the system to

heating operation automatically after 8 minutes.

The heat pump defrost control board has an option of 30,

60 or 90-minute setting. By default, this unit is shipped

from the factory with the defrost time on the 30 minute pin.

If circumstances require a change to another time, remove

the wire from the 30-minute terminal and reconnect to the

desired terminal. Refer to Figure 24.

There is a cycle speed up jumper on the control. This can

be used for testing purposes to reduce the time between

defrost cycle operation without waiting for time to elapse.

Use a small screwdriver or other metallic object, or another

¼ inch QC, to short between the SPEEDUP terminals to

accelerate the HPC timer and initiate defrost.

Be careful not to touch any other terminals with the

instrument used to short the SPEEDUP terminals. It may

take up to 10 seconds with the SPEEDUP terminals shorted

for the speedup to be completed and the defrost cycle to

start.

As soon as the defrost cycle kicks in remove the shorting

instrument from the SPEEDUP terminals. Otherwise the

timing will remain accelerated and run through the 1minute minimum defrost length sequence in a matter of

seconds and will automatically terminate the defrost

sequence.

There is an initiate defrost jumper (sen jump) on the

control that can be used at any outdoor ambient during the

heating cycle to simulate a 0° coil temperature.

This can be used to check defrost operation of the unit

without waiting for the outdoor ambient to fall into the

defrost region.

By placing a jumper across the SEN JMP terminals (a

¼ inch QC terminal works best) the defrost sensor mounted

on the outdoor coil is shunted out & will activate the

timing circuit. This permits the defrost cycle to be checked

out in warmer weather conditions without the outdoor

temperature having to fall into the defrost region.

In order to terminate the defrost test the SEN JMP jumper

must be removed. If left in place too long, the compressor

could stop due to the high pressure control opening

because of high pressure condition created by operating in

the cooling mode with outdoor fan off. Pressure will rise

fairly fast as there is likely no actual frost on the outdoor

coil in this artificial test condition.

There is also a 5-minute compressor time delay function built

into the HPC. This is to protect the compressor from short

cycling conditions. The board’s LED will have a fast blink

rate when in the compressor time delay. In some instances, it

is helpful to the service technician to override or speed up this

timing period, and shorting out the SPEEDUP terminals for a

few seconds can do this.

Low Pressure Switch Bypass Operation - The control has a

selectable (SW1) low pressure switch bypass set up to ignore

the low pressure switch input during the first (30, 60, 120 or

180 seconds) of “Y” operation.

After this period expires, the control will then monitor the low

pressure switch input normally to make sure that the switch is

closed during “Y” operation.

High Pressure Switch Operation - The control has a built-in

lockout system that allows the unit to have the high pressure

switch trip up to two times in one hour and only encounter a

“soft” lockout. A “soft” lockout shuts the compressor off and

waits for the pressure switch to reset, which at that point then

allows the compressor to be restarted as long as the 5-minute

short cycle timer has run out. If the high pressure switch trips

a third time within one hour, the unit is in “hard” lockout