Bard PH13242-A, PH13422-A, PH13422-B, PH13422-C, PH13482-A Installation Instructions Manual

...

INSTALLATION INSTRUCTIONS

SINGLE PACKAGE

HEAT PUMPS

MODELS

PH13242-A PH13302-A

PH13363-A PH13363-B

PH13422-A PH13422-B

PH13422-C PH13482-A

PH13482-B PH13482-C

PH13602-A PH13602-B

PH13602-C

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914 . . . Moving ahead, just as planned.

Manual : 2100-468J

Supersedes: 2100-468

File: Volume II Tab 11

Date: 07-25-12

I

Manual 2100-468J

Page 1 of 29

CONTENTS

Getting Other Informations and Publications .........3

General Instructions

Important .................................................................4

Shipping Damage .....................................................4

General .................................................................4

Field-Installed Heater Packages (Optional) ..............4

Installation

Location ...............................................................10

Slab Mounting .........................................................10

Winter Installation ...................................................10

Typical Installations .........................................10 & 13

Condensate Drain Trap ...........................................13

Air Filters ...............................................................13

Thermostats ............................................................14

Wiring – Main Power ...............................................15

Wiring – 24V Low Voltage Control Circuit ...............15

Thermostat Indicator Lamps ...................................16

Emergency Heat Position .......................................16

Transformer Taps ....................................................16

Compressor Cutoff Thermostat and Outdoor ..........16

Figures

Figure 1A Unit Dimensional Drawing ........................8

Figure 1B Unit Dimensional Drawing ........................9

Figure 2 Slab Mounting at Ground Level .............. 11

Figure 3 Airow and Service Access

Clearances .............................................11

Figure 4 Elevated Mounting Platform ...................12

Figure 5 Condensate Drain Trap ..........................13

Figure 6 Low Voltage Wiring ................................15

Figure 7 Unit 24V Terminal Board (5–10 KW) ......16

Figure 8 Unit 24V Terminal Board (15–20 KW) ....17

Figure 9 Defrost Control Board ............................20

Figure 10 Fan Blade Setting ...................................24

Figure 11 Brazing Diagram ....................................27

Figure 12 Motor Connections .................................28

Figure 13 Wiring (Connections/Voltage) .................29

Start Up and Operation

General ...............................................................18

Topping Off System Charge ....................................18

Safety Practices ......................................................18

Start Up Notes ........................................................18

Three Phase Scroll Compressor Start Up

Information ..............................................................19

Sequence of Operation ...........................................19

Defrost Cycle ..................................................20 & 21

Troubleshooting

Solid State Heat Pump Control

Troubleshooting Procedure .....................................22

Troubleshooting Guide ............................................22

Checking Temperature Sensor Check Out .............23

Temperature vs. Resistance of

Temperature Sensor Chart ......................................23

Service

Service Hints ...........................................................24

Pressure Service Ports ...........................................24

R-410A Refrigerant Charge ....................................24

Fan Blade Settings .................................................24

Suction and Discharge Tube Brazing ......................27

Pressure Tables ..............................................24 & 25

Troubleshooting GE ECM Blower Motors ...28 & 29

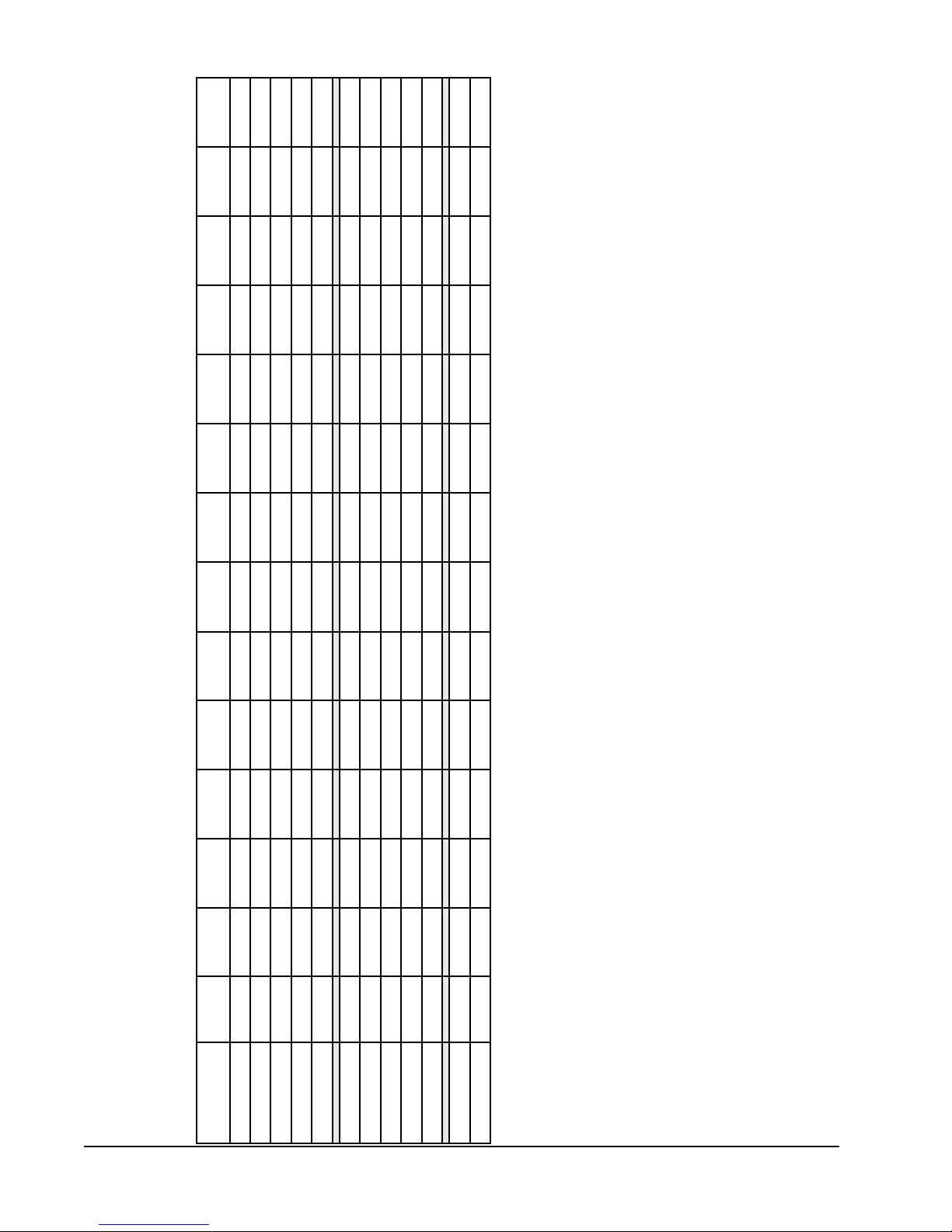

Tables

Table 1 Rated CFM and ESP ................................4

Table 2 Electrical Data ..........................................5

Table 3 Optional Field Installed Heater

Packages .................................................6

Table 4 Opt. Field Installed Elec. Heater ..............7

Table 5 Required Filters ......................................13

Table 6 Heat Pump Thermostats ........................14

Table 7 Thermostat Wire Size .............................14

Table 8 Compressor Cutoff Thermostat

Wiring (5 - 10 KW) .................................17

Table 9 Compressor Cutoff Thermostat

Wiring (15 - 20 KW) ...............................17

Table 10 Troubleshooting......................................22

Table 11 Pressure Table - Cooling & Heating .......25

Table 12 Pressure Table - Cooling & Heating .......26

Table 13 Indoor Blower Performance ...................27

Manual 2100-468J

Page 2 of 29

Getting Other Information and Publications

These publications can help you install the air conditioner

or heat pump. You can usually nd these at your local

library or purchase them directly from the publisher. Be

sure to consult current edition of each standard.

National Electrical Code ............................ANSI/NFPA 70

Standard for the Installation ....................ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard

Heating and Air Conditioning Systems

Load Calculation for

Residential Winter and Summer Air Conditioning

Duct Design for Residential ....................ACCA Manual D

Winter and Summer Air Conditioning and Equipment

Selection

for Warm Air ............................ANSI/NFPA 90B

..............................ACCA Manual J

FOr mOre InFOrmatIOn, cOntact

these PublIshers:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-468J

Page 3 of 29

General InstructIOns

ImPOrtant

The equipment covered in this manual is to be installed by

trained, experienced service and installation technicians.

Any heat pump is more critical of proper operating

charge and an adequate duct system than a straight air

conditioning unit. All duct work, supply and return ducts,

must be properly sized for the design airow requirement

of the equipment. ACCA is an excellent guide to proper

sizing. All duct work or portions thereof not in the

conditioned space should be properly insulated in order

to both conserve energy and prevent condensation or

moisture damage.

shIPPInG DamaGe

Upon receipt of equipment, the carton should be checked

for external signs of shipping damage. If damage is

found, the receiving party must contact the last carrier

immediately, preferably in writing, requesting inspection

by the carrier’s agent.

General

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions and any instructions packaged with any

separate equipment required to make up the entire heat

pump system should be carefully read before beginning

the installation. Note particularly “Starting Procedure”

and any tags and/or labels attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made.

FIelD InstalleD heater PacKaGes

(OPtIOnal)

These packaged heat pumps are manufactured without

supplementary electric heaters. Supplementary heaters are

available for simple, fast eld installation.

A separate power circuit is required for the supplementary

heaters.

IMPORTANT: Refer to Table 1 when designing duct

work for maximum available static pressure with heater

installed.

Refer to Tables 2 and 4 for proper application information

on all available heater combinations and what units they

can be used with. It also shows the applicable circuit

ampacities, fuse size, and wire size for each heater

combination.

These instructions explain the recommended method to

install the air cooled self-contained unit and the electrical

wiring connections to the unit.

rateD cFm anD external statIc Pressure (esP)

model

no.

PH1324 800 Note 0.10 0.50

PH1330 1000 Note 0.15 0.50

PH1336 1100 Note 0.15 0.50

PH1342 1450 Note 0.15 0.50

PH1348 1550 Note 0.20 0.50

PH1360 1750 Note 0.20 0.50

rated

cFm

NOTE: Motor will adjust to deliver rated airow.

table 1

recommended

Airow Range

rated

esP

max.

esP

Manual 2100-468J

Page 4 of 29

460-60-3

230/208-60-1 230/208-60-3

460-60-3

230/208-60-1 230/208-60-3

460-60-3

table 2

electrIcal Data

230/208-60-1 230/208-60-1 230/208-60-1 230/208-60-3 230/208-60-1 230/208-60-3

electric rating –

60 hz – circuit a

model Ph13242-a Ph13302-a Ph13363-a Ph13363-b Ph13422-a Ph13422-b Ph13422-c Ph13482-a Ph13482-b Ph13482-c Ph13602-a Ph13602-b Ph13602-c

Operating Voltage Range 197 - 253 197 - 253 197 - 253 187 - 253 197 - 253 187 - 253 414-506 197 - 253 187 - 253 414-506 197 - 253 187 - 253 414-506

Fan motor and condenser

Fan Motor – HP/RPM 1/6 / 825 1/6 / 825 1/6 / 825 1/6 / 825 1/4 / 825 1/4 / 825 1/4 / 825 1/4 / 825 1/4 / 825 1/4 / 825 1/4 / 825 1/4 / 825 1/4 / 825

Fan Motor Amps 1.1 1.1 1.1 1.1 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Minimum Circuit Ampacity 20 22 27 18 33 25 12 36 29 14 39 26 17

BCSC 13 14 17.5 11 21 15 8 22 14 8 26 16 9

Field Wire Size * 12 10 10 12 10 10 14 8 10 12 8 10 10

Ground Wire Size 12 10 8 12 10 10 14 8 10 14 8 10 12

Delay Fuse – Max. ** 30 30 40 25 50 35 15 50 40 20 60 40 25

Total unit Amps – 230/208 11.2/12.2 14.8/16.3 19.4/21.9 13.9/15.4 21.9/22.9 17.1/17.9 10.4 24.7/26.6 18.0/19.2 10.7 25.3/28.9 17.7/19.9 11.9

compressor – circuit a

Compressor Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Volts 230/208 230/208 230/208 230/208 230/208 230/208 460 230/208 230/208 460 230/208 230/208 460

Rated Load Amps 8/9 11/12.5 15/17.5 9.5/11 16.1/17.1 11.3/12.0 7.7 18.7/20.6 12.0/13.2 7.7 19.3/22.9 11.7/13.9 8.6

Lock Rotor Amps 58.3/58.3 73/73 79/79 88/88 115/115 115/115 50 117/117 83.1/83.1 50 134/134 110/110 52

Fan – Dia./CFM 24"/2800 24"/2600 24"2600 24"/2600 24"/3400 24"/3400 24"/3400 24"/3400 24"/3400 24"/3400 24"/3400 24"/3400 24"/3400

motor and evaporator

Blower Motor – HP/RPM 1/3 ECM 1/2 ECM 1/2 ECM 1/2 ECM 1/2 ECM 1/2 ECM 1/2 ECM 3/4 ECM 3/4 ECM 3/4 ECM 3/4 ECM 3/4 ECM 3/4 ECM

Blower Motor – Amps 2.1 2.7 3.3 3.3 3.9 3.9 3.9 4.5 4.5 4.5 5.0 5.0 5.0

CFM Cooling 800 1000 1000 1000 1450 1450 1450 1550 1550 1550 1750 1750 1750

Charge (R-410A oz.) 75 136 136 136 170 170 160 180 180 160 190 190 160

Shipping Weight (pounds) 360 410 410 410 440 440 490 440 440 500 450 450 500

* 75 degree C copper wire

** Maximum time delay fuse of HACR type circuit breaker

Manual 2100-468J

Page 5 of 29

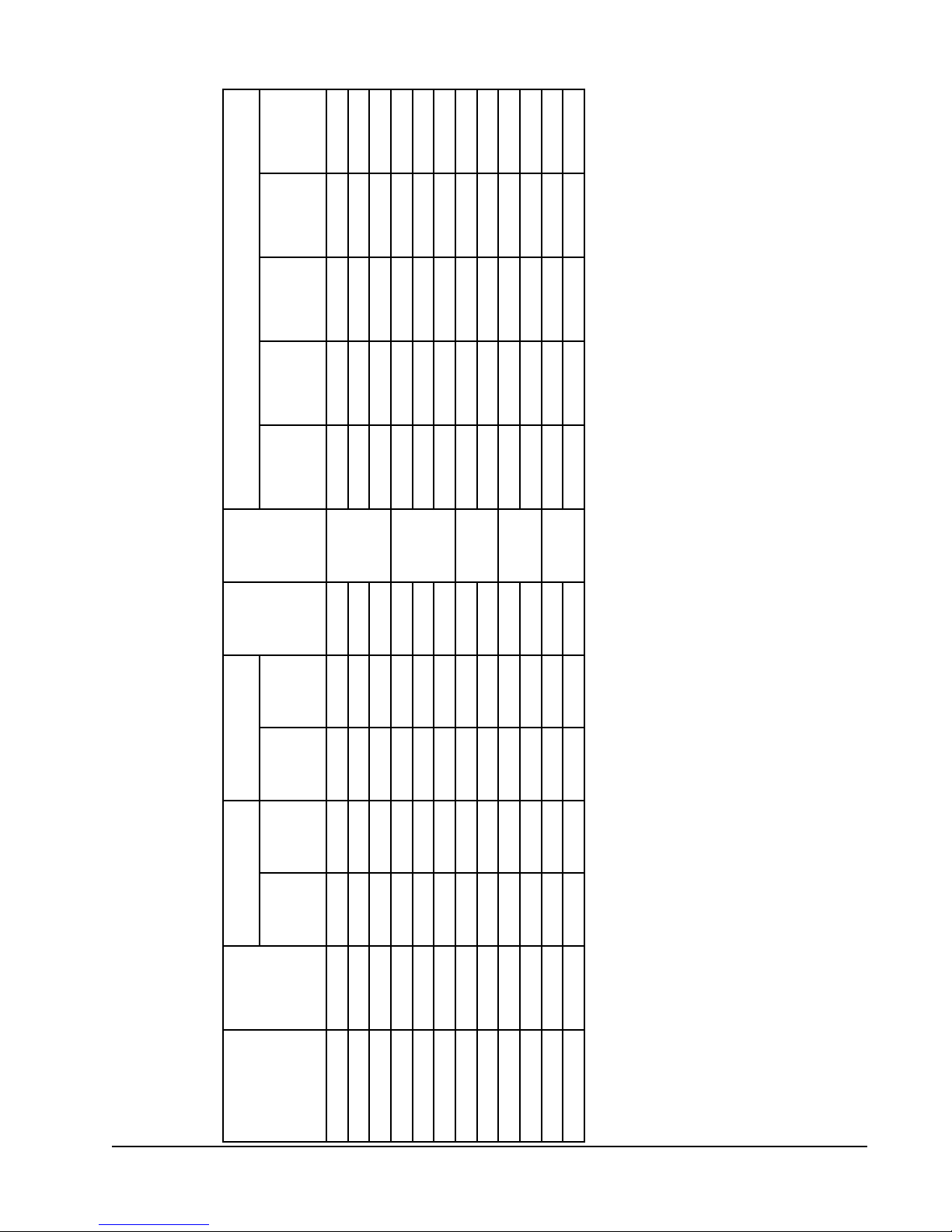

table 3

OPtIOnal FIelD InstalleD heater PacKaGes

Only tO be useD wIth the heat PumP mODels InDIcateD

X X

X X X

X X X

X

X X

Ph13242-a Ph13302-a Ph13363-a Ph13363-b Ph13422-a Ph13422-b Ph13422-c Ph13482-a Ph13482-b Ph13482-c Ph13602-a Ph13602-b Ph13602-c

Phase

Volts &

model

EHP323-A15 240/208-1

EHP323-B09 240/208-3 X

EHP323-A10 240/208-1 X X X

EHP323-A05 240/208-1 X X X

heater Package

Manual 2100-468J

Page 6 of 29

EHP323-B15 240/208-3

EHP513-A05 240/208-1 X X X

EHP513-A10 240/208-1 X X X

EHP513-A15 240/208-1

EHP513-B09 240/208-3 X X

EHP513-B15 240/208-3

EHP513-C09 460-3 X X X

EHP513-C15 460-3

Max. KW that can operate with Heat Pump on is 10 KW. 15 KW will operate during emergency heat.

Max. KW that can operate with Heat Pump on is 9 KW. 15 KW will operate during emergency heat.

Circuit B

Size

Wire

Ground

Field

Power

Wiring

Current

Protection

Max. Over

Min.

Circuit

Ampacity

table 4

OPtIOnal FIelD InstalleD electrIc heater table

Circuits

No. Field

Fuse

Heater

Internal

240/208V

Htr. Amps

@ 208 Volts

Htr. KW & Capacity

@ 240 Volts

Htr. KW & Capacity

KW BTUH KW BTUH

1 26/23 30/25 10/10 10

30/60

1 26/23 30/25 10/10 10

30/60

1 28/24 30/25 10/10 10

None

1 28/24 30/25 10/10 10

None

1 14 15 14 14

None

Phases

Unit Volts

Heater

Package

Model No.

EHP323-A05 240/208-1 5 17,100 3.75 12,800 20.8/18.1

EHP323-A10 240/208-1 10 34,100 7.50 26,000 41.6/36.2 1 53/46 60/50 6/8 10

EHP323-A15 240/208-1 15 51,200 11.25 38,400 62.5/54.1 1 79/68 80/70 4/4 8

EHP513-A05 240/208-1 5 17,100 3.75 12,800 20.8/18.1

EHP513-A10 240/208-1 10 34,100 7.50 26,000 41.6/36.2 1 53/46 60/50 6/8 10

EHP513-A15 240/208-1 15 51,200 11.25 38,400 62.5/54.1 1 79/68 80/70 4/4 8

EHP323-B09 240/208-3 9 30,700 6.75 23,000 21.7/18.7

EHP323-B15 240/208-3 15 51,200 11.25 38,400 36.2/31.2 1 46/39 50/40 8/8 10

EHP513-B09 240/208-3 9 30,700 6.75 23,000 21.7/18.7

EHP513-B15 240/208-3 15 51,200 11.25 38,400 36.2/31.2 1 46/39 50/40 8/8 10

EHP513-C09 480-3 9 30,700 10.8

EHP513-C15 480-3 15 51,200 18 1 28 30 10 12

and conductor wires in accordance with the national Electrical Code and all existing local codes.

Time delay fuses of HACR type circuit breakers must be used for 60 and smaller sizes. Standard fuses or circuit breakers are suitable for sizes 70 and

larger. 480V circuit breakers are not HACR type.

Based on wire suitable for 75 degree C. Other wiring materials must be rated for marked Minimum Circuit Ampacity or greater.

BaseduponTable250-95ofN.E.C.1993.SeeelectricdataforbasicheatpumpforCircuitAwiringspecicationrequirements.

NOTE: While this electrical data is presented as a guide, it is important to electrically connect properly sized fuses

Manual 2100-468J

Page 7 of 29

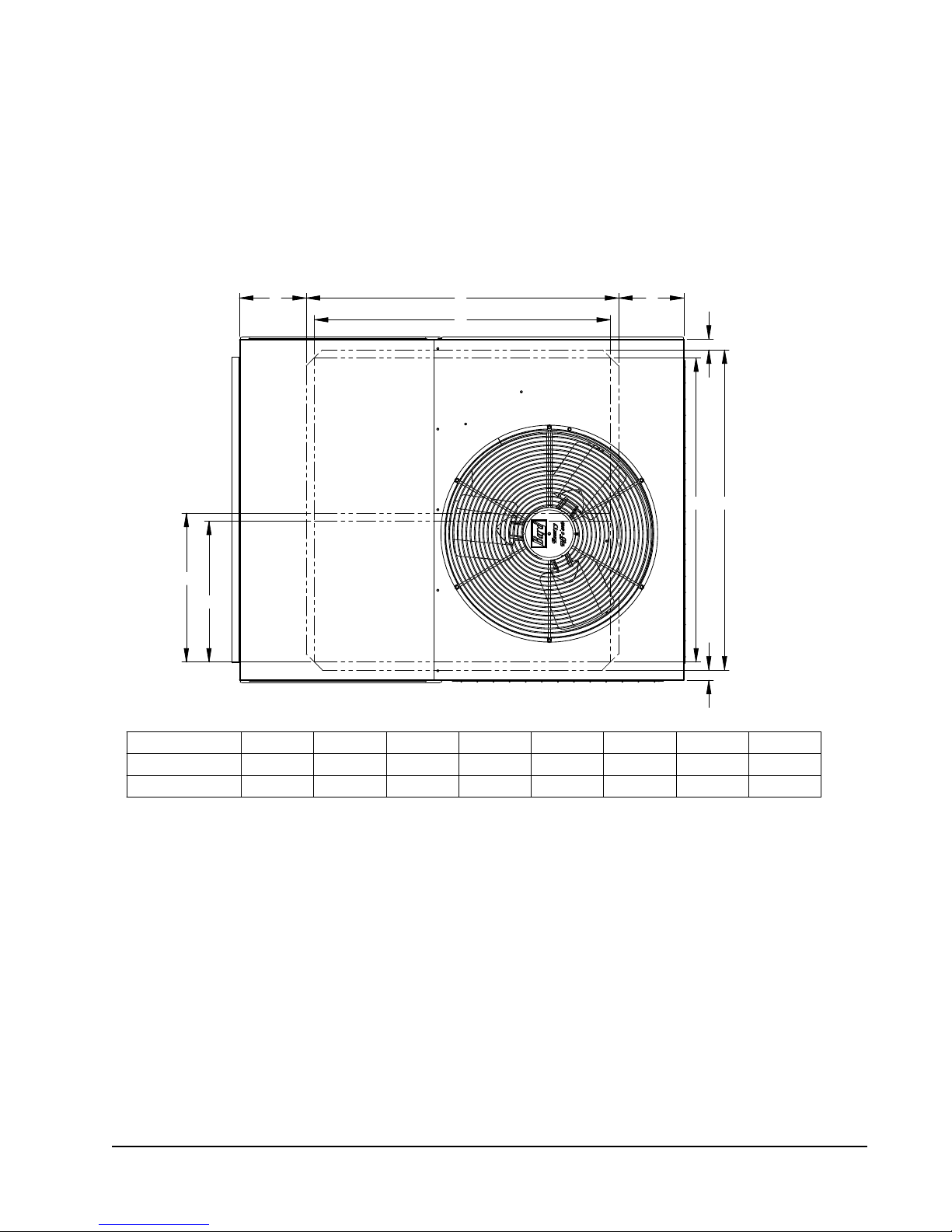

Return opening

Drain access

Supply opening

High voltage knockout

Low voltage knockout

access door

Control panel door

Heater package access panel

Compressor

Heater package knockout

A

E

C

D

L

W

B

F

Condenser air

Condenser air

intake grille

intake grille

access door

Blower motor

Condenser fan

G

47 11/16"

H

Unit Dimension Chart

MIS-2142 A

A C B C H (height) L (length) W (width) D E F G

PA/PH1324,1330,1336 5.875 32.875 13.875 32.875 26.25 53.25 38.125 23.25 1.125 1.375 35.625

PA/PH1342,1348,1360 9.875 37.875 15.875 37.875 33.25 55.25 42.375 30.25 1.5 2.375 38.125

Unit

Unit General Dimensions

Supply Size

Return Size

Unit Overall Dimensions

FIGure 1a

unIt DImensIOnal DrawInG

Manual 2100-468J

Page 8 of 29

FIGure 1b

unIt DImensIOnal DrawInG

A B

C

G

H

UNIT A B C D E F GH

PA/PH1324, 1330, 1336 7 3/16" 3813/16" 36 3/4" 1 3/8" 33 5/8" 35 1/2" 183/16" 17 1/4"

PA/PH1342, 1348, 1360 8 3/16" 3913/16" 36 3/4" 1 3/8" 37 3/4" 39 3/4" 18 1/2" 17 1/2"

A

D

FE

D

MIS-3033

Manual 2100-468J

Page 9 of 29

Loading...

Loading...