Bard PH1230, PH1236, PH1224 User Manual

INST ALLA TION INSTRUCTIONS

SINGLE P ACKAGE

HEA T PUMPS

MODELS

PH1224

PH1230

PH1236

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914...Moving ahead, just

as planned.

Manual : 2100-344

File: Volume II Tab 11

Date: 08-21-98

© Copyright 1998

Contents

Getting Other Informations and Publications ........ 1

General Instructions................................................. 3

Important ................................................................ 3

Shipping Damage .................................................... 3

General ................................................................ 3

Field-Installed Heater Packages (Optional).............. 3

Installation................................................................. 5

Location ................................................................ 5

Typical Installations .................................................. 5

Condensate Drain Trap............................................ 8

Air Filters ................................................................ 8

Wiring – Main Power................................................ 9

Wiring – 24V Low Voltage Control Circuit................ 9

Thermostats........................................................... 10

Thermostat Indicator Lamps ...................................1 1

Emergency Heat Position .......................................1 1

Transformer Taps....................................................1 1

Compressor Cut-Off Thermostat and Outdoor

Thermostat Wiring ..................................................11

Start Up and Operation .......................................... 12

Three Phase Scroll Compressor Start Up

Information............................................................. 12

Sequence of Operation.......................................... 12

Defrost Cycle ......................................................... 12

Start Up Notes ....................................................... 12

Service and Troubleshooting ................................ 14

Service Hints.......................................................... 14

Pressure Service Ports .......................................... 14

Refrigerant Charge ................................................ 14

Fan Blade Settings................................................. 14

Solid State Heat Pump Control

Troubleshooting Procedure.................................... 14

Troubleshooting Guide ........................................... 15

Checking T emperature Sensor Check Out............. 16

Temperature vs. Resistance of

Temperature Sensor Chart..................................... 16

Suction and Discharge Tube Brazing..................... 17

Pressure T ables ..................................................... 18

Wiring Diagrams ............................................. 19 - 21

Figures

Figure 1 Prefabricated Rood Curb

Specifications .......................................... 4

Figure 2 Field Fabricated Curbing......................... 4

Figure 3 Elevated Mounting Platforms .................. 6

Figure 4 Airflow and Service Access

Clearances .............................................. 6

Figure 5 Roof Top Application ............................... 7

Figure 6 Slab Mounting at Ground Level ............... 7

Figure 7 Condensate Drain Trap ........................... 8

Figure 8 Low Voltage Wiring ................................. 9

Figure 9 Compressor Cut-Off Thermostat

Wiring (5 and 10 KW) ............................11

Figure 10 Compressor Cut-Off Thermostat

Wiring )15 KW ONLY) ...........................11

Figure 11 Heat Pump Control Board..................... 13

Figure 12 Fan Blade Setting Dimensions .............. 14

Figure 13 Brazing Diagram ................................... 17

Tables

Table 1 Electrical Data......................................... 2

T able 2 Optional Field Installed Heater

Packages ................................................ 2

T able 3 Optional Field Installed Heater Table....... 2

Table 4 Rated CFM and Rated ESP.................... 3

Table 5 Air Filter Area and Size ........................... 8

Table 6 Thermostat Wire Size ............................. 9

Table 7 Heat Pump Thermostats ....................... 10

Table 8 V olts, KW and Phase - Compressor

Cut-Off Wiring (5 and 10 KW)...............11

Table 9 V olts, KW and Phase - Compressor

Cut-Off Wiring (15 KW ONLY0 .............11

Table 10 Refrigerant Charge ............................... 14

T able 1 1 Pressure T able - Cooling ....................... 18

T able 12 Pressure Table - Heating....................... 18

Getting Other Information and Publications

These publications can help you install the air conditioner or

heat pump. You can usually find these at your local library

or purchase them directly from the publisher. Be sure to

consult current edition of each standard.

National Electrical Code ........................... ANSI/NFPA 70

Standard for the Installation...................... ANSI/NFPA 90A

of Air Conditioning and

Ventilating Systems

Standard for Warm Air .............................ANSI/NFPA 90B

Heating and Air

Conditioning Systems

Load Calculation for .................................ACCA Manual J

Residential Winter and

Summer Air Conditioning

Duct Design for Residential......................ACCA Manual D

Winter and Summer Air Conditioning

and Equipment Selection

For more information, contact these

publishers:

ACCA — Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI — American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE — American Society of Heating

Refrigerating, and

Air Conditioning Engineers, Incorporated

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

Commercial Low Pressure, ....................... ACCA Manual Q

Low Velocity Duct System Design

Load Calculation For Commercial ............ACCA Manual N

Summer and Winter Air Conditioning

NFPA — National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-344

Page 1

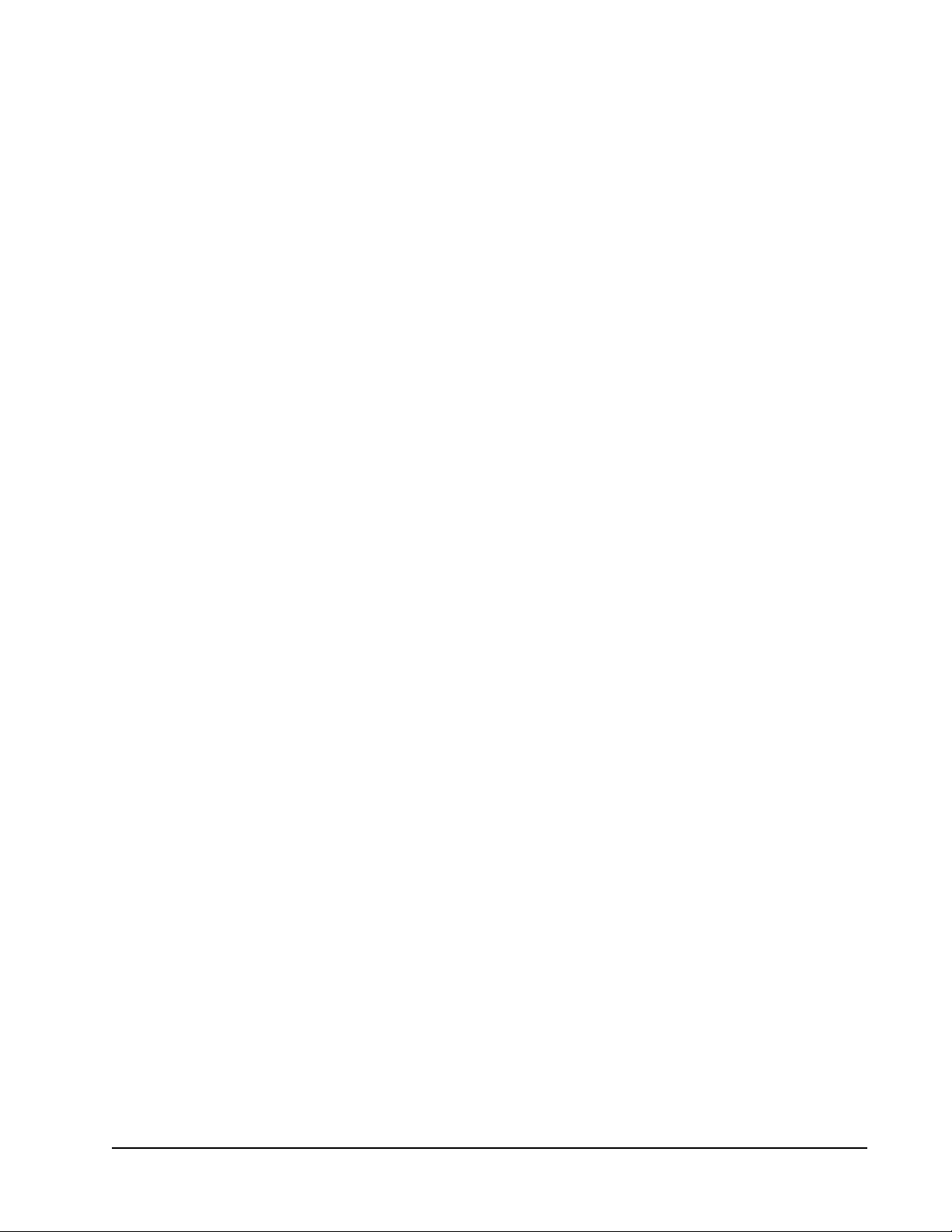

TABLE 1

ELECTRICAL DATA

Q

mumixaM

lanretxE

detaR

&stloV

ledoM

sesahP

gnitarepO

egatloV

egnaR

mumixaM

spmAtinU

rosesuF

.krB.tkC

A.tkCA.tkCA.tkCA.tkC

muminiM

tiucriC

yticapmA

4221HP1-802/032352-7914.4152810101

0321HP1-802/032352-7917.7103220101

6321HP1-802/032352-7918.12047288

B-6321HP3-802/032352-7916.5152910101

Maximum time delay fuse or HACR type circuit breaker. HACR type not applicable to 460 volt.

Q

75 degree C cooper wire size, basic unit only.

R

TABLE 2

OPTIONAL FIELD INSTALLED HEATER PACKAGES

ONLY TO BE USED WITH THE HEAT PUMP MODELS INDICATED

R

dleiF

rewoP

gniriW

R

dnuorG

eziSeriW

egakcaPretaeH

.oNledoM

50A-CP3HE

01A-BP3HE

01A-CP3HE

51A-CP3HE

90B-BP3HE

51B-BP3HE

dnastloV

esahP4221HP0321HP6321HPB-6321HP

X

1/042

X

X

X

X

X

X

X

3/042

X

X

TABLE 3

OPTIONAL FIELD-INSTALLED ELECTRIC HEATER TABLE

&WK.rtH

yticapaC

@

retaeH

ledoM.gkP

.oN

01A-BP3HE

50A-CP3HE

01A-CP3HE

51A-CP3HE

90B-BP3HE

51B-BP3HE

Q

R

S

stloVtinU

esahP

1-802/04201001,4305.7000,627.1413506601

1-802/042

5

1-802/042

01

1-802/042

51

3-802/042

9

3-802/042

51

Time delay fuses or “HACR” type circuit breakers must be used for 60 and smaller sizes. Standard fuses

or circuit breakers are suitable for sizes 70 and larger. 480V circuit breakers are not “HACR” type.

Based on wire suitable for 75° C. Other wiring materials must be rated for marked “Minimum Circuit

Ampacity” or greater.

Based upon T able 250-95 of N.E.C. 1993. See electrical data for basic heat pump for Circuit A wiring

specification requirements.

ro(V042

fiV084

)elbacilppa

@

001,71

001,43

002,15

007,03

002,15

&WK.rtH

@

yticapaC

stloV802

57.3

05.7

52.11

57.6

52.11

008,21

000,62

004,83

000,32

004,83

V042

saV084ro

elbacilppa

spmA.rtH

8.02

7.14

5.2606/03

7.12

2.63

retaeH

.oN

lanretnI

dleiF

sesuF

.stkC

1

1

1

1

1

muminiM

tiucriC

yticapmA

62

35

97

82

64

Q

BtiucriC

R

mumixaM

tnerrucrevO

noitcetorP

03

06

08

03

05

6

4

8

S

dleiF

rewoP

gniriW

01

01

dnuorG

eriW

eziSWKHUTBWKHUTB

01

01

8

01

01

IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly size fuses

and conductor wires in accordance with the National Electrical Code and all existing local codes.

Manual 2100-344

Page 2

GENERAL INSTRUCTIONS

IMPORTANT

The equipment covered in this manual is to be installed by

trained, experienced service and installation technicians.

Any heat pump is more critical of proper operating charge

and an adequate duct system than a straight air conditioning

unit. All duct work, supply and return ducts, must be

properly sized for the design air flow requirement of the

equipment. ACCA is an excellent guide to proper sizing.

All duct work or portions thereof not in the conditioned

space should be properly insulated in order to both conserve

energy and prevent condensation or moisture damage.

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be checked for

external signs of shipping damage. If damage is found, the

receiving party must contact the last carrier immediately,

preferably in writing, requesting inspection by the carrier’s

agent.

GENERAL

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method to

install the air cooled self-contained unit and the electrical

wiring connections to the unit.

These instructions and any instructions packaged with any

separate equipment required to make up the entire heat

pump system should be carefully read before beginning the

installation. Note particularly “Starting Procedure” and any

tags and/or labels attached to the equipment.

FIELD INSTALLED HEATER PACKAGES

(OPTIONAL)

These packaged heat pumps are manufactured without

supplementary electric heaters. Supplementary heaters

EH3P series (to fit PH1224, PH1230, and PH1236) are

available for simple, fast, field installation.

A separate field power circuit is required for the

supplementary heaters.

IMPORTANT: Refer to Table 4 when designing duct

work for maximum available static

pressure with heater installed.

Refer to the electrical data shown on pages 2 and 3 for

proper application information on all available heater

combinations and what units they can be used with. It also

shows the applicable circuit ampacities, fuse size, and wire

size for each heater combination.

Refer to the installation instructions packed with the heater

for details on how to insert it into the basic unit.

TABLE 4

RATED CFM AND

EXTERNAL STATIC PRESSURE (ESP)

WET COIL (COOLING)

detaR

ledoM

4221HP00802.MFC088-086

0321HP000103.MFC0011-577

6321HP001102.MFC0121-577

MFC

detaR

PSE

dednemmoceR

egnaRwolFriA

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made.

Manual 2100-344

Page 3

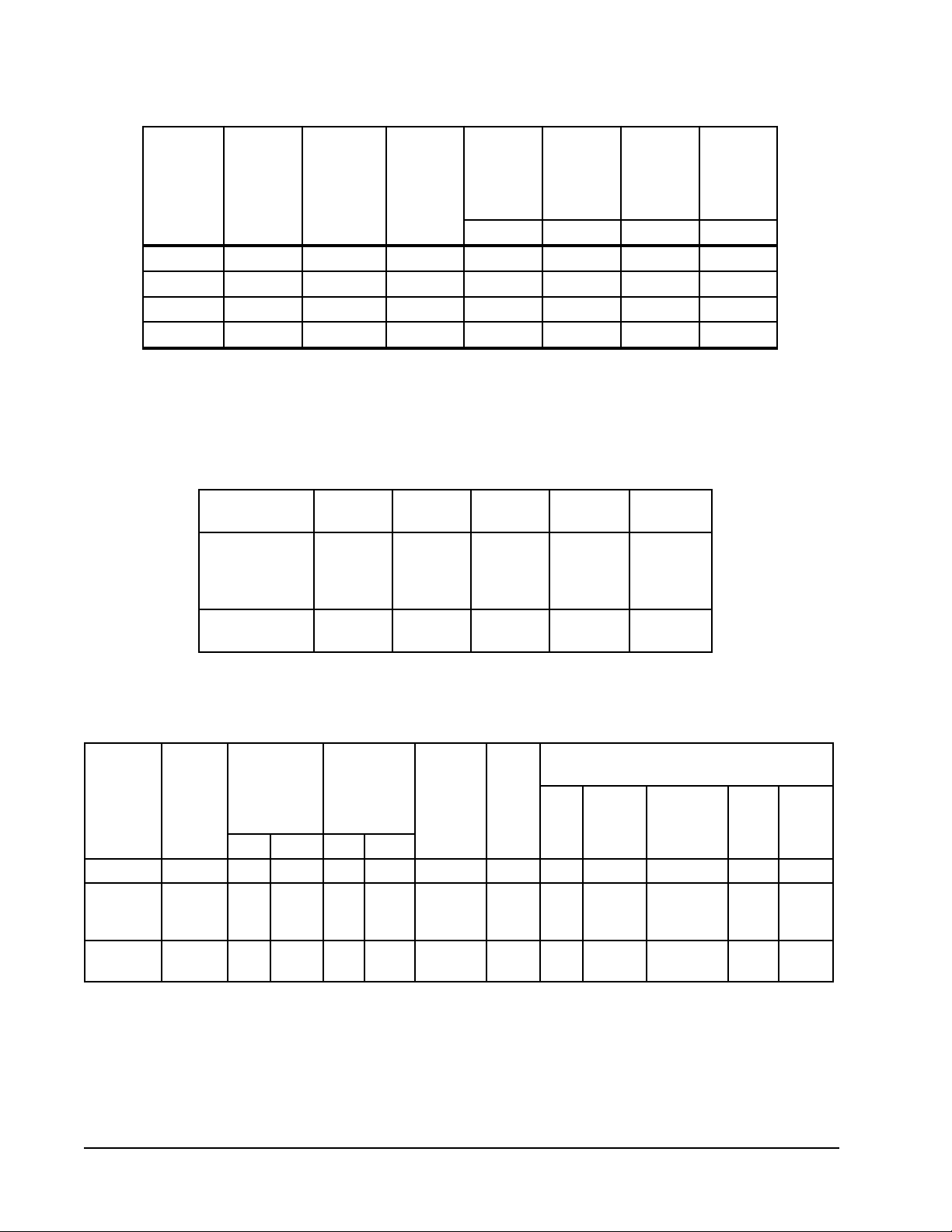

MIS-1177

FIGURE 1

PREFABRICATED ROOF CURB SPECIFICATIONS

HEAVY GAUGE GALVANIZED WITH WOOD NAILING STRIP, WELDED/LEAKPROOF

ONE PIECE CONSTRUCTION – READY TO INSTALL

CURB AND ROOF DETAILS

fooR

bruCAB*CDEF *J*H

300-24098/3-084/1-044/1-738/3-838/3-53244/3-418/1-9106EHR

*Duct Sizing Information

Return Air Dimension “C” is length Supply Air Dimension “C” is length

Return Air Dimension “H” is width Supply Sir Dimension “J” is width

FIGURE 2

FIELD FABRICATED CURBING

dooHfooR

ledoM

dooHfooR

ledoM

tinU

ledoM

gninoitidnoCriA

stinU

,0321HP,4221HP

6321HP

E

4221HP

63EHR

0321HP

14

6321HP

MIS-1178

Manual 2100-344

Page 4

INSTALLATION

LOCATION

GENERAL

The unit must be located outside, or in a well ventilated

area. It must not be in the space being heated or cooled. A

sound absorbing material should be considered if the unit is

to be installed in such a position or location that might cause

transmission of sound or vibration to the living area or

adjacent buildings.

SLAB MOUNTING

In areas where winter temperatures DO NOT go below

32° F for periods over twelve hours, the unit may be slab

mounted at grade level. When installing unit at grade level,

install on a concrete slab at least four inches above finished

grade level. Slab should have a slope tolerance away from

the building structure of at lease 1/4 inch per foot, while

being level from side to side. This will prevent ice buildup

under the unit during defrost cycles. Place slab in a location

where runoff water from higher ground will not collect

around unit. See Figure 3.

A minimum of 18 inches should be provided between the

coil inlet and any building surfaces. Provide at least four

feet between coil outlet and any building wall, fences or

other vertical structures. Provide a minimum of three feet

clearance on the service access side of the unit. See

Figure 4

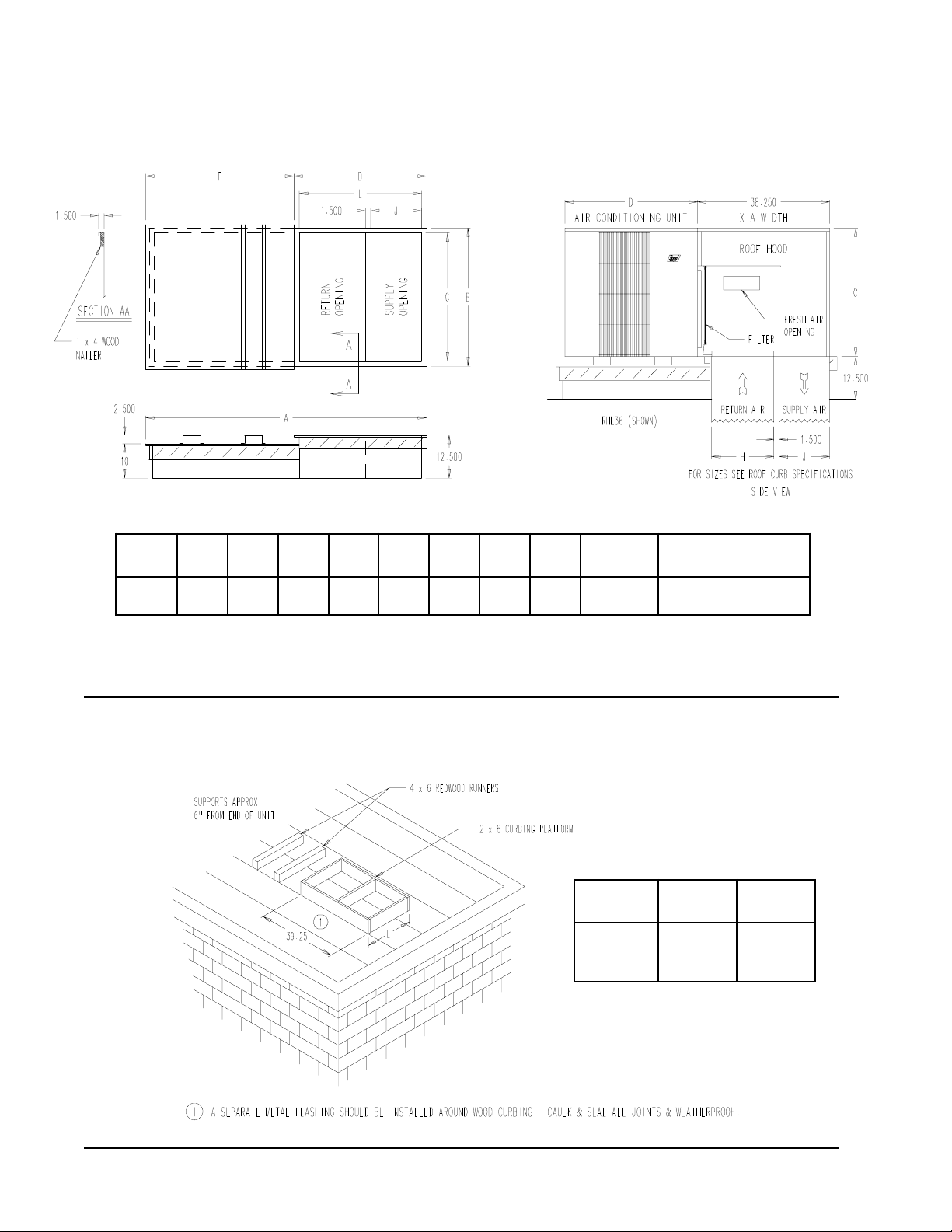

ROOF MOUNTING

When a unit is installed in areas where low ambient

temperatures or strong winter winds exist, it should be

placed so prevailing winter winds are not in direct line with

the heat pump coil. If this is not possible, a wind barrier

should be constructed. Place barrier 24 inches from the coil

inlet side of the unit and in the direction of prevailing winds.

Size barrier at least the same height and width as the unit.

This may be necessary on ground level installations, also.

See Figure 5.

WINTER INSTALLATION BELOW 32°F

In areas where winter conditions go below 32°F for

extended periods, the unit must be elevated above the

mounting surface to prevent snowfall or defrost ice

accumulation from interfering with the operation of the unit.

A minimum of twelve inch elevation is recommended, while

greater elevation may be required for areas of high snow

accumulation. Poured concrete, steel framework, brick,

cement block, etc., can be utilized to construct a suitable

raised mounting platform. See Figure 6.

DUCT WORK

Refer to Tables 4, 5 and 5A when designing duct work for

maximum static pressure available with the specific model

and heater package being installed. Unit duct work is

suitable for 0” clearance to combustible materials.

TYPICAL INSTALLATIONS

1.

ROOF MOUNTED

sturdy base on the roof of the building. Return air to the

unit is brought through a single return grille (grilles with

built-in filters are best since they enable easy access for

filter changing). Return air ducts are attached to the

lower section of the front panel. Supply air is brought

from the unit to attic duct work or to a furred down hall.

Supply air duct is attached to the top of the front panel.

CAUTION: All outdoor duct work must be thoroughly

insulated and weatherproofed. All attic duct work

must be thoroughly insulated. Two inch thick

insulation with suitable vapor barrier is

recommended for both outdoor and attic runs.

In roof top installation, as in all installations, the heat

pump must be level from side to side. However, the unit

should have a pitch along the length to assure complete

external drainage of precipitation and of defrost

condensate.

CRAWL SPACE

2.

space must be well insulated and provided with a vapor

barrier. In addition, the crawl space must be thoroughly

ventilated and provided with a good vapor barrier as a

ground cover. It is most desirable to install the unit

outdoors rather than inside the crawl space, so that it

will be readily accessible for service. In addition, it is

necessary to dispose of the condensate from the outdoor

coil on the heating cycle, and this is virtually impossible

with the unit installed inside the crawl space.

3.

SLAB MOUNTED AT GROUND LEVEL

type installation is ideal for homes with a slab floor

construction where a roof mounted unit is not desired.

The supply and return duct work can be run through a

furred closet space.

4.

THROUGH THE WALL

requires a suitable framework to be fabricated capable of

withstanding the unit weight. Normally the unit will be

insulated so as to minimize supply and return duct work.

5.

OTHER INSTALLATIONS

installations are possible with the packaged heat pump.

No matter what the installation, always consider the

following facts:

A. Insure that the discharge air is not obstructed in any

way so as to cause operation difficulties.

B. The indoor coil drain pan is equipped with a

coupling that must be piped through a condensate

drain trap to a suitable drain.

C. Always mount the unit is such a position that it may

be easily reached for servicing and maintenance.

D. Insure that the unit is clear so that proper air flow

over the outdoor coil will be maintained.

If this unit is operated in cooling below a 65° outdoor

ambient temperature, the installation of low ambient

controls (CMA-6) to unit is required.

– The unit is mounted on a

– Duct work installed in crawl

– This

– This type installation

– Many other

Manual 2100-344

Page 5

Loading...

Loading...