Page 1

INST ALLA TION INSTRUCTIONS

SINGLE P ACKAGE

HEA T PUMPS

MODELS

PH1224

PH1230

PH1236

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914...Moving ahead, just

as planned.

Manual : 2100-344

File: Volume II Tab 11

Date: 08-21-98

© Copyright 1998

Page 2

Contents

Getting Other Informations and Publications ........ 1

General Instructions................................................. 3

Important ................................................................ 3

Shipping Damage .................................................... 3

General ................................................................ 3

Field-Installed Heater Packages (Optional).............. 3

Installation................................................................. 5

Location ................................................................ 5

Typical Installations .................................................. 5

Condensate Drain Trap............................................ 8

Air Filters ................................................................ 8

Wiring – Main Power................................................ 9

Wiring – 24V Low Voltage Control Circuit................ 9

Thermostats........................................................... 10

Thermostat Indicator Lamps ...................................1 1

Emergency Heat Position .......................................1 1

Transformer Taps....................................................1 1

Compressor Cut-Off Thermostat and Outdoor

Thermostat Wiring ..................................................11

Start Up and Operation .......................................... 12

Three Phase Scroll Compressor Start Up

Information............................................................. 12

Sequence of Operation.......................................... 12

Defrost Cycle ......................................................... 12

Start Up Notes ....................................................... 12

Service and Troubleshooting ................................ 14

Service Hints.......................................................... 14

Pressure Service Ports .......................................... 14

Refrigerant Charge ................................................ 14

Fan Blade Settings................................................. 14

Solid State Heat Pump Control

Troubleshooting Procedure.................................... 14

Troubleshooting Guide ........................................... 15

Checking T emperature Sensor Check Out............. 16

Temperature vs. Resistance of

Temperature Sensor Chart..................................... 16

Suction and Discharge Tube Brazing..................... 17

Pressure T ables ..................................................... 18

Wiring Diagrams ............................................. 19 - 21

Figures

Figure 1 Prefabricated Rood Curb

Specifications .......................................... 4

Figure 2 Field Fabricated Curbing......................... 4

Figure 3 Elevated Mounting Platforms .................. 6

Figure 4 Airflow and Service Access

Clearances .............................................. 6

Figure 5 Roof Top Application ............................... 7

Figure 6 Slab Mounting at Ground Level ............... 7

Figure 7 Condensate Drain Trap ........................... 8

Figure 8 Low Voltage Wiring ................................. 9

Figure 9 Compressor Cut-Off Thermostat

Wiring (5 and 10 KW) ............................11

Figure 10 Compressor Cut-Off Thermostat

Wiring )15 KW ONLY) ...........................11

Figure 11 Heat Pump Control Board..................... 13

Figure 12 Fan Blade Setting Dimensions .............. 14

Figure 13 Brazing Diagram ................................... 17

Tables

Table 1 Electrical Data......................................... 2

T able 2 Optional Field Installed Heater

Packages ................................................ 2

T able 3 Optional Field Installed Heater Table....... 2

Table 4 Rated CFM and Rated ESP.................... 3

Table 5 Air Filter Area and Size ........................... 8

Table 6 Thermostat Wire Size ............................. 9

Table 7 Heat Pump Thermostats ....................... 10

Table 8 V olts, KW and Phase - Compressor

Cut-Off Wiring (5 and 10 KW)...............11

Table 9 V olts, KW and Phase - Compressor

Cut-Off Wiring (15 KW ONLY0 .............11

Table 10 Refrigerant Charge ............................... 14

T able 1 1 Pressure T able - Cooling ....................... 18

T able 12 Pressure Table - Heating....................... 18

Page 3

Getting Other Information and Publications

These publications can help you install the air conditioner or

heat pump. You can usually find these at your local library

or purchase them directly from the publisher. Be sure to

consult current edition of each standard.

National Electrical Code ........................... ANSI/NFPA 70

Standard for the Installation...................... ANSI/NFPA 90A

of Air Conditioning and

Ventilating Systems

Standard for Warm Air .............................ANSI/NFPA 90B

Heating and Air

Conditioning Systems

Load Calculation for .................................ACCA Manual J

Residential Winter and

Summer Air Conditioning

Duct Design for Residential......................ACCA Manual D

Winter and Summer Air Conditioning

and Equipment Selection

For more information, contact these

publishers:

ACCA — Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI — American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE — American Society of Heating

Refrigerating, and

Air Conditioning Engineers, Incorporated

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

Commercial Low Pressure, ....................... ACCA Manual Q

Low Velocity Duct System Design

Load Calculation For Commercial ............ACCA Manual N

Summer and Winter Air Conditioning

NFPA — National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-344

Page 1

Page 4

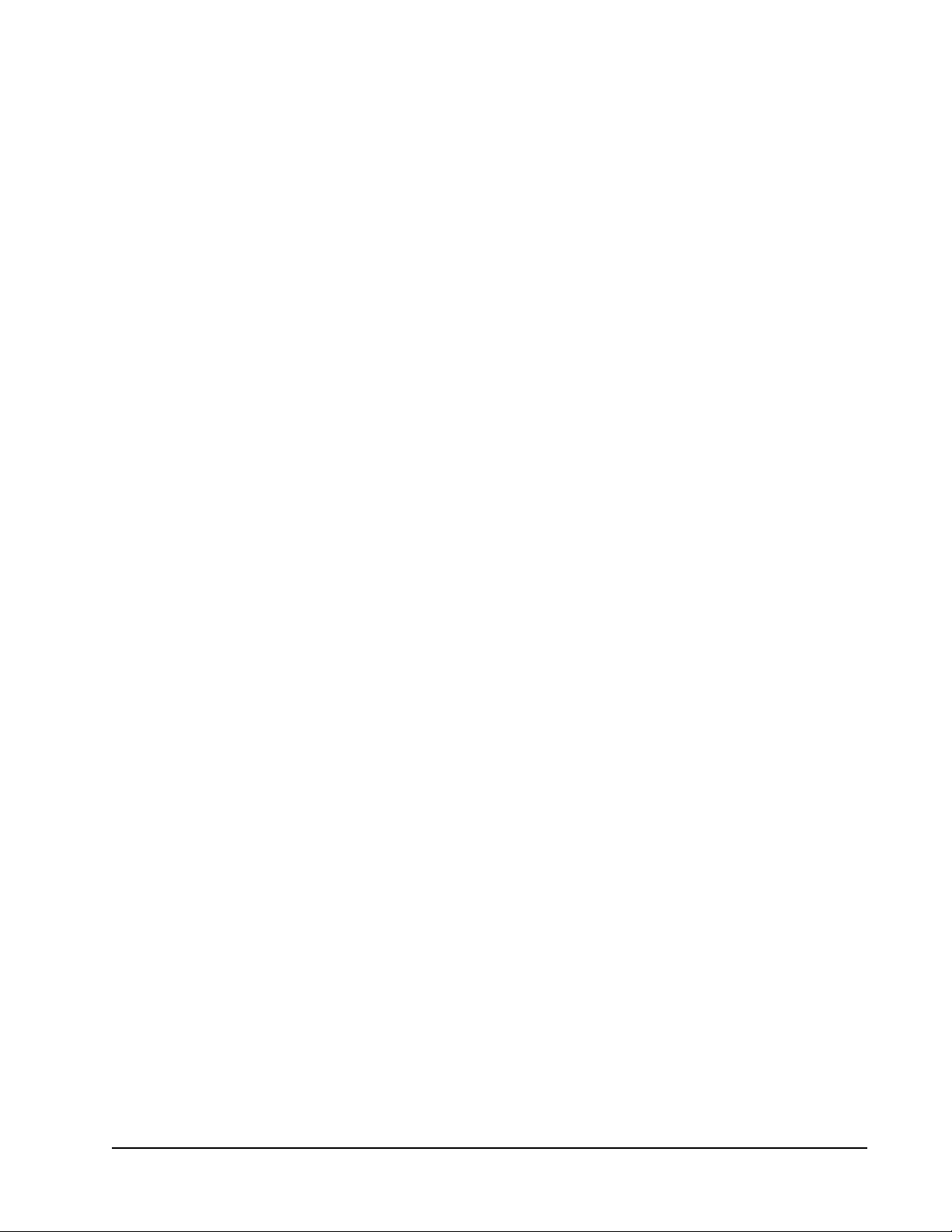

TABLE 1

ELECTRICAL DATA

Q

mumixaM

lanretxE

detaR

&stloV

ledoM

sesahP

gnitarepO

egatloV

egnaR

mumixaM

spmAtinU

rosesuF

.krB.tkC

A.tkCA.tkCA.tkCA.tkC

muminiM

tiucriC

yticapmA

4221HP1-802/032352-7914.4152810101

0321HP1-802/032352-7917.7103220101

6321HP1-802/032352-7918.12047288

B-6321HP3-802/032352-7916.5152910101

Maximum time delay fuse or HACR type circuit breaker. HACR type not applicable to 460 volt.

Q

75 degree C cooper wire size, basic unit only.

R

TABLE 2

OPTIONAL FIELD INSTALLED HEATER PACKAGES

ONLY TO BE USED WITH THE HEAT PUMP MODELS INDICATED

R

dleiF

rewoP

gniriW

R

dnuorG

eziSeriW

egakcaPretaeH

.oNledoM

50A-CP3HE

01A-BP3HE

01A-CP3HE

51A-CP3HE

90B-BP3HE

51B-BP3HE

dnastloV

esahP4221HP0321HP6321HPB-6321HP

X

1/042

X

X

X

X

X

X

X

3/042

X

X

TABLE 3

OPTIONAL FIELD-INSTALLED ELECTRIC HEATER TABLE

&WK.rtH

yticapaC

@

retaeH

ledoM.gkP

.oN

01A-BP3HE

50A-CP3HE

01A-CP3HE

51A-CP3HE

90B-BP3HE

51B-BP3HE

Q

R

S

stloVtinU

esahP

1-802/04201001,4305.7000,627.1413506601

1-802/042

5

1-802/042

01

1-802/042

51

3-802/042

9

3-802/042

51

Time delay fuses or “HACR” type circuit breakers must be used for 60 and smaller sizes. Standard fuses

or circuit breakers are suitable for sizes 70 and larger. 480V circuit breakers are not “HACR” type.

Based on wire suitable for 75° C. Other wiring materials must be rated for marked “Minimum Circuit

Ampacity” or greater.

Based upon T able 250-95 of N.E.C. 1993. See electrical data for basic heat pump for Circuit A wiring

specification requirements.

ro(V042

fiV084

)elbacilppa

@

001,71

001,43

002,15

007,03

002,15

&WK.rtH

@

yticapaC

stloV802

57.3

05.7

52.11

57.6

52.11

008,21

000,62

004,83

000,32

004,83

V042

saV084ro

elbacilppa

spmA.rtH

8.02

7.14

5.2606/03

7.12

2.63

retaeH

.oN

lanretnI

dleiF

sesuF

.stkC

1

1

1

1

1

muminiM

tiucriC

yticapmA

62

35

97

82

64

Q

BtiucriC

R

mumixaM

tnerrucrevO

noitcetorP

03

06

08

03

05

6

4

8

S

dleiF

rewoP

gniriW

01

01

dnuorG

eriW

eziSWKHUTBWKHUTB

01

01

8

01

01

IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly size fuses

and conductor wires in accordance with the National Electrical Code and all existing local codes.

Manual 2100-344

Page 2

Page 5

GENERAL INSTRUCTIONS

IMPORTANT

The equipment covered in this manual is to be installed by

trained, experienced service and installation technicians.

Any heat pump is more critical of proper operating charge

and an adequate duct system than a straight air conditioning

unit. All duct work, supply and return ducts, must be

properly sized for the design air flow requirement of the

equipment. ACCA is an excellent guide to proper sizing.

All duct work or portions thereof not in the conditioned

space should be properly insulated in order to both conserve

energy and prevent condensation or moisture damage.

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be checked for

external signs of shipping damage. If damage is found, the

receiving party must contact the last carrier immediately,

preferably in writing, requesting inspection by the carrier’s

agent.

GENERAL

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method to

install the air cooled self-contained unit and the electrical

wiring connections to the unit.

These instructions and any instructions packaged with any

separate equipment required to make up the entire heat

pump system should be carefully read before beginning the

installation. Note particularly “Starting Procedure” and any

tags and/or labels attached to the equipment.

FIELD INSTALLED HEATER PACKAGES

(OPTIONAL)

These packaged heat pumps are manufactured without

supplementary electric heaters. Supplementary heaters

EH3P series (to fit PH1224, PH1230, and PH1236) are

available for simple, fast, field installation.

A separate field power circuit is required for the

supplementary heaters.

IMPORTANT: Refer to Table 4 when designing duct

work for maximum available static

pressure with heater installed.

Refer to the electrical data shown on pages 2 and 3 for

proper application information on all available heater

combinations and what units they can be used with. It also

shows the applicable circuit ampacities, fuse size, and wire

size for each heater combination.

Refer to the installation instructions packed with the heater

for details on how to insert it into the basic unit.

TABLE 4

RATED CFM AND

EXTERNAL STATIC PRESSURE (ESP)

WET COIL (COOLING)

detaR

ledoM

4221HP00802.MFC088-086

0321HP000103.MFC0011-577

6321HP001102.MFC0121-577

MFC

detaR

PSE

dednemmoceR

egnaRwolFriA

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made.

Manual 2100-344

Page 3

Page 6

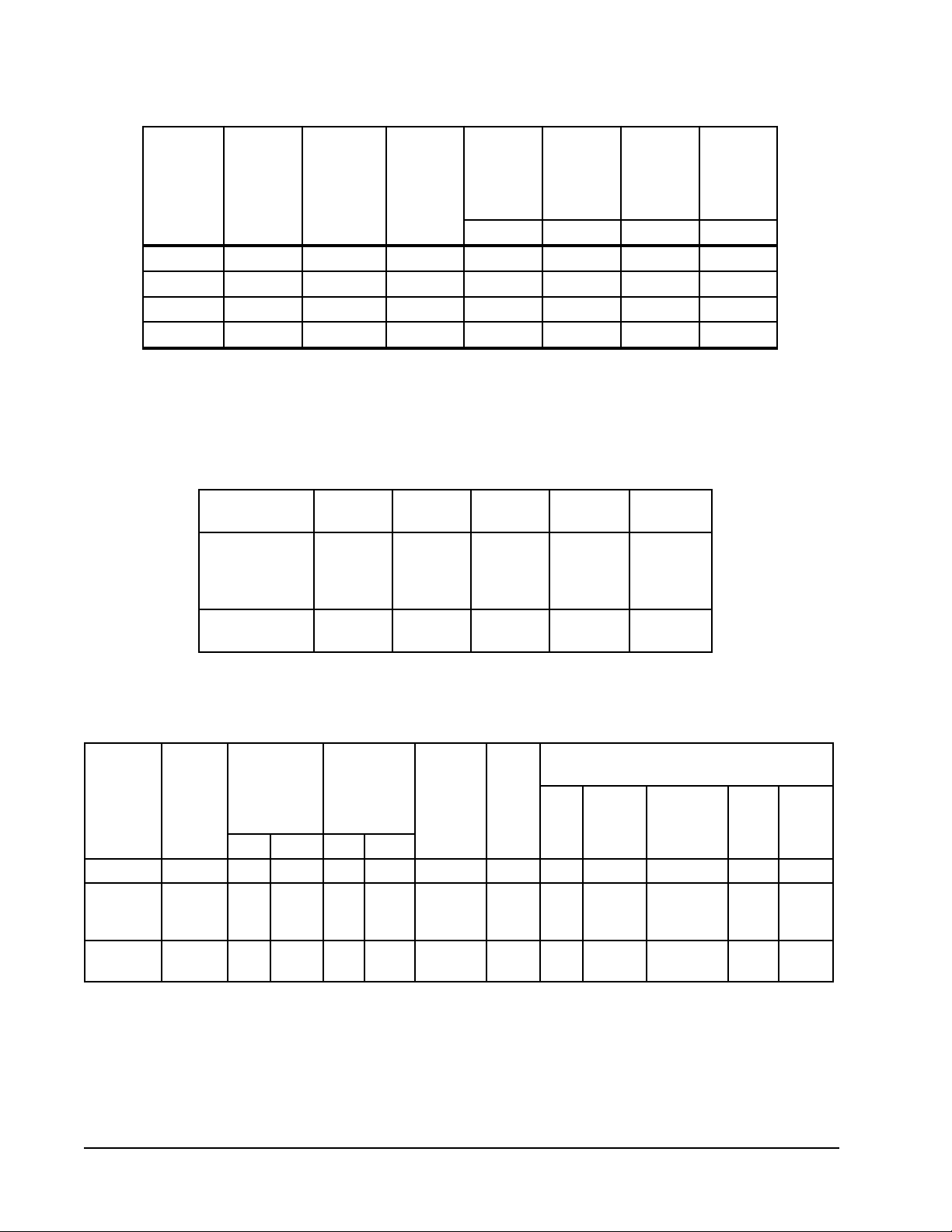

MIS-1177

FIGURE 1

PREFABRICATED ROOF CURB SPECIFICATIONS

HEAVY GAUGE GALVANIZED WITH WOOD NAILING STRIP, WELDED/LEAKPROOF

ONE PIECE CONSTRUCTION – READY TO INSTALL

CURB AND ROOF DETAILS

fooR

bruCAB*CDEF *J*H

300-24098/3-084/1-044/1-738/3-838/3-53244/3-418/1-9106EHR

*Duct Sizing Information

Return Air Dimension “C” is length Supply Air Dimension “C” is length

Return Air Dimension “H” is width Supply Sir Dimension “J” is width

FIGURE 2

FIELD FABRICATED CURBING

dooHfooR

ledoM

dooHfooR

ledoM

tinU

ledoM

gninoitidnoCriA

stinU

,0321HP,4221HP

6321HP

E

4221HP

63EHR

0321HP

14

6321HP

MIS-1178

Manual 2100-344

Page 4

Page 7

INSTALLATION

LOCATION

GENERAL

The unit must be located outside, or in a well ventilated

area. It must not be in the space being heated or cooled. A

sound absorbing material should be considered if the unit is

to be installed in such a position or location that might cause

transmission of sound or vibration to the living area or

adjacent buildings.

SLAB MOUNTING

In areas where winter temperatures DO NOT go below

32° F for periods over twelve hours, the unit may be slab

mounted at grade level. When installing unit at grade level,

install on a concrete slab at least four inches above finished

grade level. Slab should have a slope tolerance away from

the building structure of at lease 1/4 inch per foot, while

being level from side to side. This will prevent ice buildup

under the unit during defrost cycles. Place slab in a location

where runoff water from higher ground will not collect

around unit. See Figure 3.

A minimum of 18 inches should be provided between the

coil inlet and any building surfaces. Provide at least four

feet between coil outlet and any building wall, fences or

other vertical structures. Provide a minimum of three feet

clearance on the service access side of the unit. See

Figure 4

ROOF MOUNTING

When a unit is installed in areas where low ambient

temperatures or strong winter winds exist, it should be

placed so prevailing winter winds are not in direct line with

the heat pump coil. If this is not possible, a wind barrier

should be constructed. Place barrier 24 inches from the coil

inlet side of the unit and in the direction of prevailing winds.

Size barrier at least the same height and width as the unit.

This may be necessary on ground level installations, also.

See Figure 5.

WINTER INSTALLATION BELOW 32°F

In areas where winter conditions go below 32°F for

extended periods, the unit must be elevated above the

mounting surface to prevent snowfall or defrost ice

accumulation from interfering with the operation of the unit.

A minimum of twelve inch elevation is recommended, while

greater elevation may be required for areas of high snow

accumulation. Poured concrete, steel framework, brick,

cement block, etc., can be utilized to construct a suitable

raised mounting platform. See Figure 6.

DUCT WORK

Refer to Tables 4, 5 and 5A when designing duct work for

maximum static pressure available with the specific model

and heater package being installed. Unit duct work is

suitable for 0” clearance to combustible materials.

TYPICAL INSTALLATIONS

1.

ROOF MOUNTED

sturdy base on the roof of the building. Return air to the

unit is brought through a single return grille (grilles with

built-in filters are best since they enable easy access for

filter changing). Return air ducts are attached to the

lower section of the front panel. Supply air is brought

from the unit to attic duct work or to a furred down hall.

Supply air duct is attached to the top of the front panel.

CAUTION: All outdoor duct work must be thoroughly

insulated and weatherproofed. All attic duct work

must be thoroughly insulated. Two inch thick

insulation with suitable vapor barrier is

recommended for both outdoor and attic runs.

In roof top installation, as in all installations, the heat

pump must be level from side to side. However, the unit

should have a pitch along the length to assure complete

external drainage of precipitation and of defrost

condensate.

CRAWL SPACE

2.

space must be well insulated and provided with a vapor

barrier. In addition, the crawl space must be thoroughly

ventilated and provided with a good vapor barrier as a

ground cover. It is most desirable to install the unit

outdoors rather than inside the crawl space, so that it

will be readily accessible for service. In addition, it is

necessary to dispose of the condensate from the outdoor

coil on the heating cycle, and this is virtually impossible

with the unit installed inside the crawl space.

3.

SLAB MOUNTED AT GROUND LEVEL

type installation is ideal for homes with a slab floor

construction where a roof mounted unit is not desired.

The supply and return duct work can be run through a

furred closet space.

4.

THROUGH THE WALL

requires a suitable framework to be fabricated capable of

withstanding the unit weight. Normally the unit will be

insulated so as to minimize supply and return duct work.

5.

OTHER INSTALLATIONS

installations are possible with the packaged heat pump.

No matter what the installation, always consider the

following facts:

A. Insure that the discharge air is not obstructed in any

way so as to cause operation difficulties.

B. The indoor coil drain pan is equipped with a

coupling that must be piped through a condensate

drain trap to a suitable drain.

C. Always mount the unit is such a position that it may

be easily reached for servicing and maintenance.

D. Insure that the unit is clear so that proper air flow

over the outdoor coil will be maintained.

If this unit is operated in cooling below a 65° outdoor

ambient temperature, the installation of low ambient

controls (CMA-6) to unit is required.

– The unit is mounted on a

– Duct work installed in crawl

– This

– This type installation

– Many other

Manual 2100-344

Page 5

Page 8

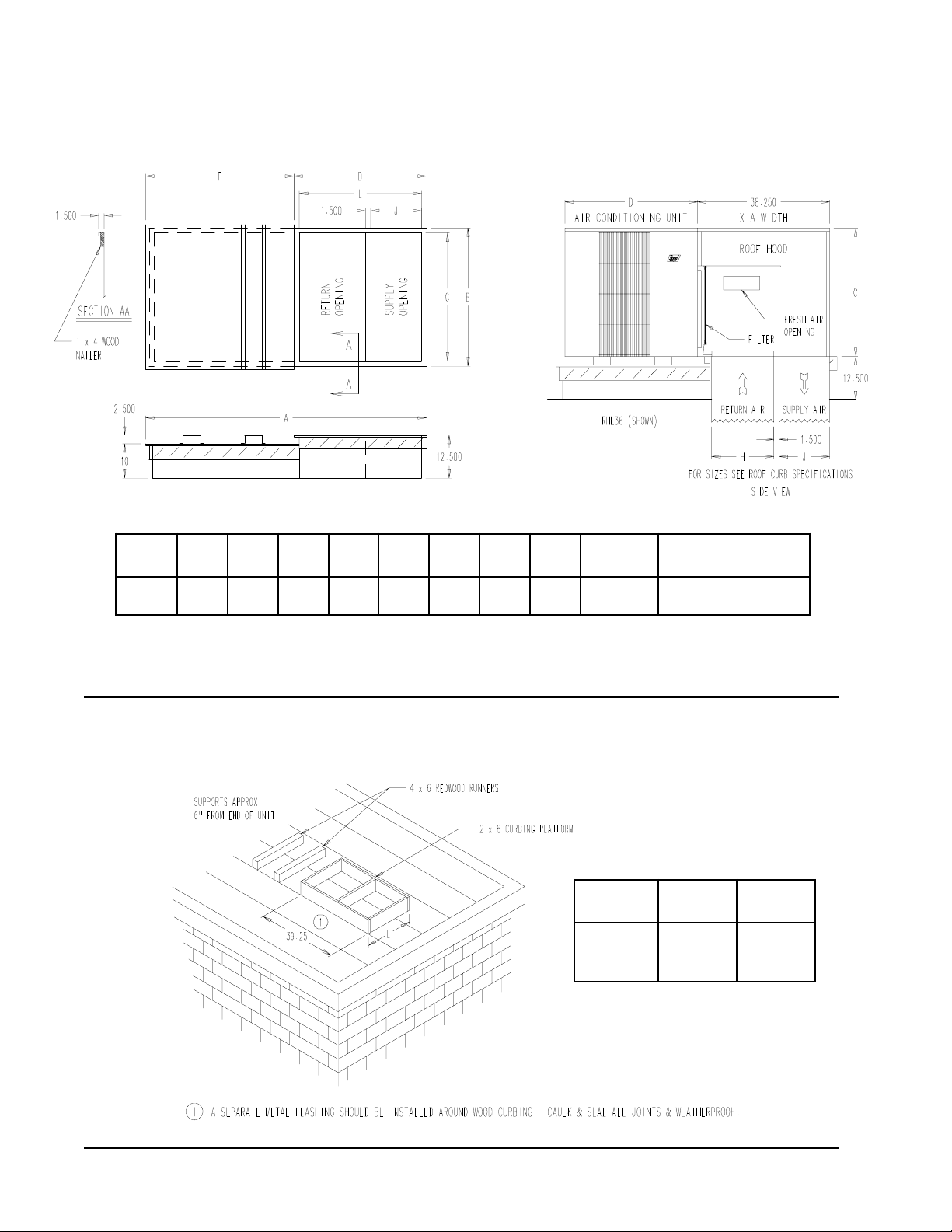

FIGURE 3

ELEVATED MOUNTING PLATFORMS

MIS-1183

FIGURE 4

AIRFLOW and SERVICE ACCESS CLEARANCES

Manual 2100-344

Page 6

MIS-1185

Page 9

FIGURE 5

ROOF TOP APPLICATION

(May also be required for ground level installations.)

MIS-1176

FIGURE 6

SLAB MOUNTING AT GROUND LEVEL

(Above 32° F Outside Temperature)

MIS-1184

Manual 2100-344

Page 7

Page 10

CONDENSATE DRAIN TRAP

It is very important to provide a trap in the condensate drain

line to allow a positive liquid seal in the line and assure

correct drainage from the coil condensate pan.

Install condensate drain trap shown in Figure 7. Use drain

connection size or larger. Do not operate unit without trap.

Unit must be level or slightly inclined toward drain. With a

trap installed on a unit located in an unconditioned area,

water in the trap may freeze. It is recommended that the trap

material be of a type that will allow for expansion of water

when it freezes.

AIR FILTERS

Air filters for the return air side of the system are not

provided as part of the various types of applications for these

models, and must be field supplied and installed as part of

the final installation.

maintained for proper operation. If this is not done,

excessive energy use, poor performance, and multiple

service problems will result. It is impossible to oversize air

filters. Generous sizing will result in cleaner air and coils

as well as lower operating costs and extend the time

between required changes. Table 6 shows minimum filter

areas and recommended filter sizes. Actual filter sizes can

vary with the installation due to single or multiple returns

utilizing a filter/grille arrangement or being placed

immediately ahead of the indoor coil face in the return air

duct.

TABLE 5

retliFmuminiM

ledoM

4221HP

0321HP

6321HP

saerA

sehcnierauqs264

)teeferauqs12.3(

dednemmoceR

eziS

1x8/5-03x51

Prior thought should be given to return air location and

placement of the air filter(s). The air filter(s) must be of

adequate size and readily accessible to the operator of the

equipment. Filters must be adequate in size and properly

CONDENSATE DRAIN TRAP

NOTE: If roof hood accessory is to be used, information

on air filters may be found under that heading in this

manual. Air filters are supplied as part of that package.

FIGURE 7

Manual 2100-344

Page 8

MIS-136

Page 11

remrofsnarT

AV

ALF

eriW

eguaG

htgneLmumixaM

teeFnI

553.202

81

61

41

21

54

06

001

061

052

WIRING – MAIN POWER

Refer to the unit rating plate for wire sizing information and

maximum fuse size. Each outdoor unit is marked with a

“Minimum Circuit Ampacity”. This means that the field

wiring used must be sized to carry that amount of current. If

field installed heaters are added to the basic unit, a second

separate power supply circuit will be required. The heater

rating plate located adjacent to the basic unit rating plate

will show the appropriate circuit ampacity fuse size, etc.

(Also see “Electrical Data” on pages 2.) All models are

suitable for connection with copper wire only. These

instructions must be adhered to. Refer to the National

Electrical Code for complete current carrying capacity data

on the various insulation grades of wiring material.

The electrical specifications on page 2 lists fuse and wire

sizes (75° F copper) for all models including the most

commonly used heater sizes.

The unit rating plate lists a “Maximum Time Delay Fuse” or

“HACR” type circuit breaker that is to be used with the

equipment. The correct size must be used for proper circuit

protection and also to assure that there will be no nuisance

tripping due to the momentary high starting current of the

compressor.

WIRING – 24V LOW VOLTAGE CONTROL

CIRCUIT

Ten (10 ) wires should be run from thermostat subbase to

the 24V terminal board in the unit. A ten conductor,

18 gauge copper, color-coded thermostat cable is

recommended. The connection points are shown in

Figure 8.

FIGURE 8 – LOW VOLTAGE WIRING

MIS-1187

TABLE 6 – THERMOSTAT WIRE SIZE

Manual 2100-344

Page 9

Page 12

THERMOSTATS

See specific wiring information for the different models, heater KWs, and voltages.

TABLE 7

HEAT PUMP THERMOSTATS

TATSOMREHTESABBUSNOITPIRCSED

540-3048

)1671A148T(

710-3048

)9211R478T(

810-3048

)4201N478T(

240-3048

)0701G1158T(

430-3048

)08-49F1(

720-3048

)17-29F1(

fotraP

tatsomrehT

900-4048

1811L476Q

010-4048

1621F476Q

fotraP

tatsomrehT

fotraP

tatsomrehT

fotraP

tatsomrehT

taeHmE-kcehC:spmaLgnitacidnI

taeHmE-kcehC:spmaLgnitacidnI

revoegnahclaunamrocitamotuA

revoegnahclaunaM;blubyruceM;taehegats2,loocegats1

looC-ffO-taeH-taeHmE:hctiwSmetsyS;nO-otuA:hctiwSnaF

taeHxuA-taeHmE-kcehC:spmaLgnitacidnI

revoegnahclaunaM;blubyrucreM;taehegats2,loocegats1

looC-ffO-taeH-taeHmE:hctiwSmetsyS;nO-otuA:hctiwSnaF

revoegnahcotuA;blubyrucreM;taehegats2,loocegats1

xuA-flaM-pmuP-remE:spmaLgnitacidnI

xuA-flaM-pmuP-remE:spmaLgnitacidnI

Q

R

looC-otuA-taeH-taeHmE-ffO:hctiwSmetsyS;nO-otuA:hctiwSnaF

)deriuqeryrettabon(elbammargorp-nonlatigiD;taehegats2,loocegats1

taeH/looCrootuA-taeHmE-ffO:hctiwSmetsyS;nO-otuA:hctiwSnaF

taeHxuA-taeHmE:noitacidnIyalpsiDkcehC:spmaLgnitacidnI

pukcabyrettaB;)yad7(elbammargorplatigiD;taehegats2,loocegats2

sruoh42repdoirepkcab-tes/pu-tes1;revoegnahclaunamrocitamotuA

yrevocerygrenerorezimonoceroflanimretnoitalitnevelbammargorP

taeH/looCrootuA-taeHmE-ffO:hctiwSmetsyS;nO-otuA:hctiwSnaF

pukcabyrettaB;)yad2/yad5(elbammarforplatigiD;taehegats3,loocegats2

sruoh42repsdoirepkcab-tes/spu-tes4:revoegnahclaunamrocitamotuA

taeH/looCrootuA-taeHmE-ffO:hctiwSmetsyS;nO-otuA:hctiwSnaF

No automatic changeover position – must be manually placed in heat or cool. Reversing valve remains energized

Q

at all times system switch is in heat position (except during defrost cycle). No pressure equalization noise when

thermostat is satisfied on either heating or cooling.

Allows thermostat to control both heating and cooling operation when set in “AUTO” position. Reversing valve de-

R

energizes at end of each “ON” heating cycle.

Manual 2100-344

Page 10

Page 13

THERMOSTAT INDICATOR LAMPS

The red lamp marked “EM. HT.” comes on and stays on

whenever the system switch is placed in Em. Ht. position.

The green lamp marked “Check” will come on if there is any

problem that prevents the compressor from running when it

is supposed to be.

COMPRESSOR CUTOFF THERMOSTAT

WIRING (5 and 10 KW)

FIGURE 9

UNIT 24V TERMINAL BOARD

EMERGENCY HEAT POSITION

The operator of the equipment must manually place the

system switch in this position. This is done when there is a

known problem with the outdoor section, or when the green

“Check” lamp comes on indicating a problem.

TRANSFORMER TAPS

230/208V, 1 phase and 3 phase equipment employ dual

primary voltage transformers. All equipment leaves the

factory wired on 240V tap. For 208V operation, reconnect

from 240V to 208V tap. The acceptable operating voltage

range for the 240 and 208V taps are:

TAP RANGE

240 253 – 216

208 220 – 187

NOTE: The voltage should be measured at the field power

connection point in the unit and while the unit is

operating at full load (maximum amperage

operating condition).

COMPRESSOR CUTOFF THERMOSTAT

and OUTDOOR THERMOSTAT WIRING

Heat pump compressor operation at outdoor temperatures

below 0° F are neither desirable nor advantageous in terms

of efficiency. Since most equipment at time of manufacture

is not designated for any specific destination of the county

and most of the equipment is installed in areas not

approaching the lower outdoor temperature range, the

compressor cutoffs are not factory installed.

Outdoor thermostats are available to hold off various banks

of electric heat until needed as determined by outdoor

temperature. The set point of either type of thermostat is

variable with geographic region and sizing of the heating

equipment to the structure. Utilization of the Heating

Application Data and the heat loss calculation of the

building are useful in determining the correct set points.

REMOVE FACTORY

JUMPER Y-Y1

MIS-1188

ledoMWKstloVesahP

4221HP01,5,00321

0321HP01,5,00321

6321HP01,5,00321

OUTDOOR THERMOSTAT

USED AS COMPRESSOR CUTOFF

TABLE 8

5 and 10 KW

COMPRESSOR CUTOFF THERMOSTAT

WIRING (15 KW ONLY)

FIGURE 10

UNIT 24V TERMINAL BOARD

REMOVE FACTORY

JUMPER Y-Y1

MIS-1189

OUTDOOR THERMOSTAT

USED AS COMPRESSOR CUTOFF

TABLE 9

15 KW ONLY

ledoMWKstloVesahP

0321HP510321

6321HP510321

Manual 2100-344

Page 11

Page 14

START UP AND OPERATION

THREE PHASE SCROLL COMPRESSOR

START UP INFORMATION

Scroll compressors, like several other types of compressors,

will only compress in one rotational direction. Direction of

rotation is not an issue with single phase compressors since

they will always start and run in the proper direction.

However, three phase compressors will rotate in either

direction depending upon phasing of the power. Since there

is a 50-50 chance of connecting power in such a way as to

cause rotation in the reverse direction, verification of proper

rotation must be made. Verification of proper rotation

direction is made by observing that suction pressure drops

and discharge pressure rises when the compressor is

energized. Reverse rotation also results in an elevated

sound level over that with correct rotation, as well as,

substantially reduced current draw compared to tabulated

values.

Verification of proper rotation must be made at the time

the equipment is put into service. If improper rotation is

corrected at this time there will be no negative impact on the

durability of the compressor. However, reverse operation for

over one hour may have a negative impact on the bearing

due to oil pump out.

NOTE: If compressor is allowed to run in reverse

rotation for several minutes the compressor’s

internal protector will trip.

All three phase ZR*3 compressors are wired identically

internally. As a result, once the correct phasing is

determined for a specific system or installation, connecting

properly phased power leads to the same Fusite terminals

should maintain proper rotation direction.

The direction of rotation of the motor may be changed by

reversing any two line connections to the unit.

SEQUENCE OF OPERATION

COOLING

compressor contactor starting the compressor and outdoor

motor. The G (indoor motor) circuit is automatically

completed on any call for cooling operation, or can be

energized by manual fan switch on subbase for constant air

circulation.

HEATING

controls heating cycle operation. Two thermostat options,

one allowing “AUTO” changeover from cycle to cycle and

the other constantly energizing solenoid coil during heating

season and thus eliminating pressure equalization noise

except during defrost, are to be used. On “AUTO” option, a

circuit is completed from R-W1 and R-Y on each heating

“On” cycle energizing reversing valve solenoid and pulling

in compressor contactor starting compressor and outdoor

motor. R-G also make starting indoor blower motor. Heat

pump heating cycle now in operation. The second energizes

– Circuit R-Y makes at thermostat pulling in

– A 24V solenoid coil on reversing valve

the reversing valve solenoid constantly whenever the system

switch on subbase is placed in “Heat” position, the “B”

terminal being constantly energized from R. A thermostat

demand for heat completes R-Y circuit, pulling in

compressor contactor starting compressor and outdoor

motor. R-G also make starting indoor blower motor.

DEFROST CYCLE

The defrost cycle is controlled by temperature and time on

the solid state heat pump control.

When the outdoor temperature is in the lower 40° F

temperature range or colder, the outdoor coil temperature is

32°F or below. This temperature is sensed by the coil

sensor mounted near the bottom of the outdoor coil. Once

the coil temperature reaches 32°F or below, the coil sensor

sends a signal to the control logic of the heat pump control

and defrost timer will start.

After 60 (90 or 30) minutes at 32°F or below, the heat pump

control will place the system in the defrost mode.

During the defrost mode, the refrigerant cycle switches back

to the cooling cycle, the outdoor motor stops, electric heaters

are energized, and hot gas passing through the outdoor coil

melts any accumulated frost. When the temperature rises to

approximately 57° F, the coil sensor will send a signal to the

heat pump control which will return the system to heating

operations automatically.

If some abnormal or temporary condition such as a high

wind causes the heat pump to have a prolonged defrost

cycle, the heat pump control will restore the system to

heating operation automatically after 10 minutes.

There are three settings on the heat pump control -- 30

minutes, 60 minutes, and 90 minutes. Most models are

shipped wired on the 60 minutes setting for greatest

operating economy. If special circumstances require a

change to another time, remove wire connected to terminal

60 and reconnect to desired terminal. (See Figure 11.)

There is a cycle speed up jumper on the control. This can be

used to reduce the time between defrost cycle operation

without waiting for time to elapse.

There is an initial defrost (sen jmp) jumper on the control

that can be used at any outdoor ambient during the heating

cycle to simulate a 0° coil temperature. This can be used to

check defrost operation of the unit without waiting for the

outdoor ambient to fall into the defrost region.

START UP NOTES

For improved start up performance, wash the indoor coil

with dishwasher detergent

Manual 2100-344

Page 12

Page 15

FIGURE 11

HEAT PUMP CONTROL BOARD

MIS-1191

Manual 2100-344

Page 13

Page 16

SERVICE AND TROUBLESHOOTING

SERVICE HINTS

1. Caution homeowner to maintain clean air filters at all

times. Also, not to needlessly close off supply and

return air registers. This reduces air flow through the

system which shortens equipment service life as well as

increasing operating costs.

2. Switching to heating cycle at 75° F or higher outside

temperature may cause a nuisance trip of the manual

reset high pressure switch.

3. The heat pump wall thermostats perform multiple

functions. Be sure that all function switches are

correctly set for the desired operating mode before

trying to diagnose any reported service problems.

4. Check all power fuses or circuit breakers to be sure that

they are the correct rating.

5. Periodic cleaning of the outdoor coil to permit full and

unrestricted airflow circulation is essential.

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on all units

so that the system operating pressures can be observed.

Pressure tables can be found in Tables 11 and 12 in this

manual covering all models on both cooling and heating

cycles. It is imperative to match the correct pressure table to

the unit by model number.

FIGURE 12

FAN BLADE SETTING DIMENSIONS

ledoMAnoisnemiD

4221HP

0321HP

6321HP

MIS-1190

"00.1

"57.

"57.

SOLID STATE HEAT PUMP CONTROL

TROUBLESHOOTING PROCEDURE

1. Turn on AC power supply to indoor and outdoor units.

2. Turn thermostat blower switch to fan on. The indoor

blower should start. (If it doesn’t, troubleshoot indoor

unit and correct problem.)

REFRIGERANT CHARGE

The correct system R-22 charge is shown on the unit rating

plate. Optimum unit performance will occur with a

refrigerant charge resulting in a suction line temperature

(6” from compressor) as shown in Table 10.

TABLE 10

FeergeD59

detaR

ledoM

4221HP

0321HP

6321HP

The above suction line temperatures are based upon 80° F

dry bulb/67° F wet bulb (50% RH) temperature and rated

airflow across the evaporator during cooling cycle.

wolfriA

008

0001

0011

DO

erutarepmeT

65-65

65-65

25-05

FeergeD28

DO

erutarepmeT

26-16

06-85

45-25

FAN BLADE SETTINGS

Shown in Figure 12 are the correct fan blade setting

dimensions for proper air delivery across the outdoor coil.

Any service work requiring removal or adjustment in the fan

and/or motor area will require that the dimensions in

Figure 12 be checked and blade adjusted in or out on the

motor shaft accordingly.

3. Turn thermostat blower switch to Auto position. Indoor

blower should stop.

4. Set system switch to heat or cool. Adjust thermostat to

call for heat or cool. The indoor blower, compressor,

and outdoor fan should start.

NOTE: If there is no power to 24 volt transformer, the

compressor and outdoor fan motor will not start

for 5 minutes. This is because of the compressor

short cycle protection.

Manual 2100-344

Page 14

Page 17

TROUBLE SHOOTING GUIDE

motpmySsesuaCelbissoPkcehCottahWriapeRrokcehCotwoH

rotcatnocrosserpmoC

ezigrenetonseod

)gniloocrognitaeh(

noitcetorp

evitcefed

rotomroodtuonaF

nurtonseod

gnitaehrognilooc(

)tsorfedgnirudtpecxe

evitcefed

seodevlavgnisreveR

ezigreneton

)ylnognitaeh(

evitcefed

otniogtonlliwtinU

tsorfed

)ylnognitaeh(

tuoemoctonlliwtinU

tsorfedfo

)ylnognitaeh(

evitcefed

evitcefedrotoMdetrohsroneporofkcehC

evitcefedlioc

.evitcefed

gniriwtiucriclitnoCtinutanoitcennocRrofkcehC

tuokcolrosserpmoCneewtebV42rofkcehC.1

elcyctrohsrosserpmoC

lortnocpmuptaeH

evitcefedrotcatnoCdetrohsroneporofkcehC

evitcefedroticapacrotoM.gnitarroticapackcehC

lortnocpmuptaeH

dionelosevlovgnisreveR

lortnocpmuptaeH

rorosneserutarepmeT

lortnocpmuptaeh

rorosneserutarepmeT

lortnocpmuptaeh

taehrewopottinuroodtuootnoitcennocRnuR

.C-Rneewtebtlov42dna

lortnocpmuptaehnoC-1L

hgihssorcakcehC.2

.hctiwserusserp

C-CCneewtebV42rofkcehC

pmuptaehnoC-Ydna

.lortnoc

elbissoprehtollakcehC

.560-0012launaM.sesuac

.gnidniwlioc

.gnidniwrotom

detrohsroneporofkcehC

.roticapac

noyalernafssorcakcehC

)CN-moC(.lortnocpmuptaeh

detrohsroneporofkcehC

.lioc

C-VRneewtebV42rofkcehC

.C-Bdna

erutarepmettcennocsiD

dnadraobmorfrosnes

pudeepsssorcarepmuj

pmujnesdnaslanimret

esuacdluohssihT.slanimret

ahguorhtogottinueht

enonihtiwelcyctsorfed

.etunim

pudeepsssorcarepmuJ

esuacdluohssihT.slanimret

tsorfedfotuoemocottinueht

.etunimenonihtiw

.lortnocpmup

ffotatsomrehtnrut,C-1LneewtebegatlovonfI.1

.hctiwserusserphgihteserotniaganodna

,tesertonlliwdnaneposihctiwserusserphgihfI.2

.hctiwserusserphgihecalper

pudeepsrepmuj,C-CCneewtebegatlovonfI

dluohsrewopsdnoces01nihtiwdna,lanimret

repmujpudeepsevomeR.C-CCneewtebraeppa

.sdnoces01retfa

.lortnocpmuptaehecalpeR

.rotcatnocecalpeR

.rotomecalpeR

.roticapacecalpeR

.lortnocpmuptaehecalpeR

.liocdionelosecalpeR

.gniriwtiucriclortnockcehC.1

lortnocpmuptaehecalpeR.2

ecalper,elcyctsorfedhguorhtseogtinufI.1

.rosneserutarepmet

ecalper,elcyctsorfedhguorhtogtonseodtinufI.2

.lortnocpmuptaeh

ecalper,elcyctsorfedfotuosemoctinufI.1

.rosneserutarepmet

,elcyctsorfedfotuoemoctonseodtinufI.2

.lortnocpmuptaehecalper

Manual 2100-344

Page 15

Page 18

CHECKING TEMPERATURE SENSOR

CHECK OUT

1. Disconnect temperature sensor from board and from

outdoor coil.

2. Use an ohmmeter and measure the resistance of the

sensor. Also use ohmmeter to check for short or open.

TEMPERATURE F vs RESISTANCE R OF TEMPERATURE SENSOR

FR FR FR FR

0.52-1786910.51046350.55434710.591356

0.42-9900910.61150250.65489610.693836

0.32-5853810.71415050.75745610.799326

0.22-8137710.81820940.85221610.898906

0.12-9821710.91095740.95017510.991695

0.02-7845610.02002640.06013510.0017285

0.91-4099510.12558440.16129410.1017965

0.81-9254510.22455340.26445410.2010755

0.71-5539410.32592240.36771410.3016445

0.61-4734410.42770140.46028310.4016235

0.51-6759310.52898930.56474310.5018025

0.41-6594310.62757830.66731310.5014905

0.31-6050310.72256730.76018210.7012894

0.21-9126210.82385630.86294210.8013784

0.11-9802210.92845530.96381210.9017674

0.01-8018110.03545430.07388110.0113664

0.9-2724110.13475330.17195110.1112654

0.8-5750110.23436230.27703110.2114644

0.7-0107010.33327130.37130110.3117634

0.6-4753010.43048030.47267010.4114724

0.5-0620010.53689920.57105010.5112814

0.4-460790.63751920.67742010.6113904

0.3-189390.73553820.77000010.7116004

0.2-800190.83775720.8706790.8111293

0.1-931880.93328620.9762590.9118383

0.0173580.04290620.0899290.0217573

0.1996280.14383520.1877090.1218763

0.2121080.24696420.2826880.2211063

0.3236770.34030420.3835680.3216253

0.4032570.44483320.4894480.4212543

0.5019270.54857220.580528

0.6076070.64051220.687508

0.7705860.74165120.789687

0.8814660.84989020.886867

0.9993460.94534020.987057

0.01944260.05698910.094337

0.11565060.15473910.195617

0.21547850.25768810.290007

0.31589650.35573810.390486

0.41482550.45898710.493866

3. Check resistance reading to chart of resistance; use

sensor ambient temperature. (Tolerance of part is

± 10%.)

4. If sensor resistance reads very low, then sensor is

shorted and will not allow proper operation of the heat

pump control.

5. If sensor is out of tolerance, shorted, open, or reads very

low ohms then it should be replaced.

Manual 2100-344

Page 16

Page 19

SUCTION AND DISCHARGE TUBE

BRAZING

Compliant Scroll compressors have copper plated steel

suction and discharge tubes. These tubes are far more

rugged and less prone to leaks than copper tubes used on

other compressors. Due to different thermal properties of

steel and copper, brazing procedures may have to be

changed from those commonly used.

• To disconnect: heat joint Areas 2 and 3 slowly and

uniformly until braze material softens and the tube can

be pulled out of suction fitting. (See Figure 10.)

BRAZING DIAGRAM

• To connect:

– Recommended brazing materials: silfos with

minimum 5% silver or silver braze material with

flux.

– Reinsert tube into fitting.

– Heat tube uniformly in Area 1 moving slowly to

Area 2. When joint reaches brazing temperature,

apply brazing material. (See Figure 10.)

– Heat joint uniformly around the circumference to

flow braze material completely around the joint.

– Slowly move torch into Area 3 to draw braze

material into joint. (See Figure 10.)

– Do not overheat joint.

FIGURE 13

MIS-1179

Manual 2100-344

Page 17

Page 20

COOLING

PRESSURE TABLES

TABLE 11

Air T emperature Entering Outdoor Coil Degrees F

riAnruteR

ledoM

4221HP

0321HP

6321HP

erutarepmeTerusserP5708580959001501011511

BD.ged57

BW.ged26

BD.ged08

BW.ged76

BD.ged58

BW.ged27

BD.ged57

BW.ged26

BD.ged08

BW.ged76

BD.ged58

BW.ged27

BD.ged57

BW.ged26

BD.ged08

BW.ged76

BD.ged58

BW.ged27

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

37

57

67

87

97

08

18

28

191

502

912

432

152

762

582

303

87

08

691

012

18

38

302

712

37

57

802

222

87

08

312

822

18

38

022

632

27

47

112

522

77

97

612

08

28

422

932

18

38

48

88

78

88

522

042

752

472

292

48

68

78

98

09

332

842

662

482

203

67

87

97

97

732

452

072

882

703

18

38

48

58

78

342

062

772

592

513

48

68

78

88

09

252

962

782

503

623

57

77

87

242

852

672

08

28

38

132

842

562

382

38

58

68

752

472

392

97

08

492

413

48

68

203

223

78

98

313

333

113

19

223

18

28

623

88

433

19

643

18

333

78

243

09

453

38

323

98

133

29

343

48

643

09

553

39

763

28

553

88

463

19

773

TABLE 12

HEATING

Air T emperature Entering Outdoor Coil Degrees F

nruteR

ledoM

4221HPged07

0321HPged07

6321HPged07

Low side pressure ± 2 PSIG

High side pressure ± 5 PSIG

T ables are based upon rated CFM (airflow across the evaporator coil and should be found under section titled “Refrigerant Charge” elsewhere

in manual. If there is any doubt as to correct operating charge being in the system, the charge should be removed, system evacuated, and

recharged to serial plate instructions.

pmeTriA

.

erusserP

05 015171025203530454740555

ediSwoL

22

42

72

03

13

33

73

14

54

05

65

ediShgiH

471

281

091

891

102

502

312

122

922

732

542

ediSwoL

12

32

52

82

92

13

43

83

34

84

35

ediShgiH

761

071

471

871

971

281

781

291

791

302

012

ediSwoL

42

52

62

82

82

03

33

73

24

74

35

ediShgiH

491

591

791

102

202

502

112

812

622

532

642

85

26

86

842

352

162

55

95

56

312

712

422

65

06

86

052

752

072

Manual 2100-344

Page 18

Page 21

Wiring Diagram (4098-123) printed

from CAD to get size needed

Manual 2100-344

Page 19

Page 22

Wiring Diagram (4098-124) printed

from CAD to get size needed

Manual 2100-344

Page 20

Page 23

Wiring Diagram (4098-211) printed

from CAD to get size needed

Manual 2100-344

Page 21

Loading...

Loading...