Page 1

SERVICE AND INSTALLATION

INSTRUCTIONS

WITH REPLACEMENT PARTS LIST

LC6000-200 CONTROLLER

Part of the Bard Cooling System

NOTE: LC6000-200 controller is required for operation when

multiple MULTI-TEC

MEGA-TECTM wall-mount units are used.

Additional information regarding the installation and setup

of the LC6000-200 controller and software is included in

the system installation instructions located inside the wallmount unit control panel.

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

®, FUSION-TEC® WR Series and/or

Manual : 2100-669F

Supersedes: 2100-669E

Date: 3-18-19

Page 1 of 37

Page 2

CONTENTS

LC6000 Controller Installation ................................... 5

LC6000 Controller .................................................. 6

Mounting the LC6000 Controller ....................... 6

Supply Wiring .................................................. 7

Installing Remote Indoor Temperature/Humidity

Sensor(s) ......................................................... 8

Emergency Off, Emergency Vent and Generator

Run Connections ............................................ 11

Communication Wiring .................................... 12

Installing Outdoor Temperature/Humidity Sensor ..

10

Alarms .................................................................15

Alarm Adjustment ...............................................15

Acknowledging/Clearing Alarms ......................15

Low Temperature Alarm .................................15

High Temperature Alarm ................................15

High Temperature 2 Alarm .............................16

Emergency Off Alarm .................................... 16

Generator Alarm ...........................................17

Emergency Vent Alarm ..................................18

Zone Unit Alarm ........................................... 18

Humidity Alarm ............................................19

Control Operation .............................................21

Temperature Control ............................................21

Indoor Temperature Averaging ........................21

Comfort Mode ..............................................21

Staging ............................................................21

FIFO (First In First Out) .................................21

LIFO (Last In First Out) ................................. 21

Demand Staging ...........................................21

Staging Delay ...............................................22

Maximum Number of Units Running...............22

Rotation ......................................................22

Demand .......................................................23

Humidity Control .................................................23

Dehumidification ..........................................23

Humidification .............................................24

Enabling Humidifier ...............................24

Continuous Blower ..............................................25

Continuous Blower Custom Configuration ........ 25

Additional Information ....................................26

LC6000 Menus/Screens ......................................26

Main Menu ..................................................26

Status Screen ..............................................26

Quick Menu .................................................26

Alarm Log .............................................26

Info ......................................................26

Setpoints ..............................................26

Menu Screens and Password Levels ................27

Additional Programming ......................................27

Changing to Celsius ......................................27

Configuring Number of Units .........................27

Calibrating Sensors .......................................28

Clearing Alarm Logs ...................................... 28

Configuring Free Cooling ...............................28

Enabling High Sensible Operation .................. 28

Troubleshooting ................................................30

8403-079 Remote Indoor Temp/Humidity Sensor ..30

8301-090 Outdoor Temp/Humidity Sensor ............33

LC6000 Replacement Parts List ......................37

FIGURES AND TABLES

Figure 1

Figure 2 LC6000 Fused Power Supply Terminals ....6

Figure 3 LC6000 Controller Supply Wiring .............7

Figure 4 Controller Grounding Posts ......................7

Figure 5 Remote Indoor Temperature/Humidity

Sensor Installation .................................. 8

Figure 6

Figure 7 Remote Outdoor Temperature/Humidity

Sensor Installation ................................ 10

Figure 8 Emergency Off, Emergency Vent and

Generator Run Connections ...................11

Figure 9 Communication Wiring: Termination at

the Controller ....................................... 12

Figure 10 Communication Wiring (Daisy Chain) ......13

Figure 11 Communication Wiring (Alt. Method) ......13

Figure 12 Placement of Communication Filters ......14

Figure 13 Adjust Alarm Setpoints .........................15

Figure 14 Adjust Alarm Remote Notification Relay

Output Direction ................................... 15

Figure 15 Adjust Emergency Off, Emergency Vent

or Generator Alarm Input Direction .........16

Figure 16 Adjust Alarm Remote Notification Relay

Output Direction ................................... 17

Figure 17 Adjust Units Running When Generator

Is Active ..............................................17

Figure 18 Adjust Zone Alarm Configuration ............19

Figure 19 Adjust Humidity Alarm Setpoints ...........20

Figure 20 Change Indoor Temperature Averaging

Type ....................................................21

Figure 21 Adjust Staging Settings .........................22

Figure 22 Staging Maximum Number of Units

Running ..............................................22

Figure 23 Rotation ..............................................23

Figure 24 Humidity Control Setpoints ....................24

Figure 25 Dehumidification Types .........................24

Figure 26 Enabling Humidifier ..............................24

Figure 27 Continuous Blower Status ......................25

Figure 28

Figure 29 MULTI-TEC Unit Info Screen .................26

Figure 30

Figure 31 MEGA-TEC Unit Info Screen ..................26

Figure 32 Changing to Celsius ..............................27

Figure 33 Clearing LC6000 Alarm Logs .................28

Figure 34 Configuring Free Cooling .......................28

Figure 35 Enabling High Sensible Operation ..........29

Figure 36 8403-079 Sensor .................................30

Figure 37 8301-090 Sensor .................................33

Figure 38 LC6000-200 Wiring Diagram .................36

Table 1 LC6000 Passwords (Defaults) ................27

Table 2 LC6000 Status Messages ......................27

Table 3 8403-079 Sensor: Temp/Resistance.......31

Table 4 8403-079 Sensor: Voltage/Humidity ......32

Table 5 8301-090 Sensor: Temp/Resistance.......33

Table 6 LC6000-200 Terminal Block Index ........34

Table 7

Typical LC6000-200 Component Location ..

Additional Remote Sensor Installation .......

Continuous Blower Custom Configuration ..

FUSION-TEC WR Series Unit Info Screen ..

LC6000-200 to Sensor Connection Index ..

5

9

25

26

35

Manual 2100-669F

Page 2 of 37

Page 3

GENERAL INFORMATION

Cooling System

This Bard cooling system is composed of MULTI-TEC, FUSION-TEC WR Series and/or MEGA-TEC wall-mounted

air conditioners matched with an LC6000 controller or Bard th-Tune stand-alone controller (th-Tune can only be

used with MULTI-TEC units). If only one wall-mounted air conditioner is being used, it can be matched with either

the LC6000 or a th-Tune stand-alone controller (if applicable). If more than one wall-mount unit is installed, the

LC6000 controller must be matched with the air conditioning units. The wall-mount units are specifically engineered

for equipment cooling applications.

NOTE: The LC6000 controller and MULTI-TEC, FUSION-TEC WR Series and MEGA-TEC wall-mount units are

designed specifically to work together. The controller cannot run other brands of systems, nor can other

controllers run the MULTI-TEC, FUSION-TEC WR Series or MEGA-TEC wall-mount units. They are a

complete system, and must be used together.

LC6000-200 Series Controller and Accessories Included with Controller

(1) TEC-EYETM Hand-Held Diagnostic Tool

Bard P/N 8301-059

(1) LC6000 Programmable Logic

Controller

Outside Air

Temperature/Humidity Sensor

Bard P/N 8301-090

+

Optional Sensors:

Remote

Temperature/Humidity Sensor

Bard P/N 8403-079

(1) Remote Temperature/Humidity Sensor1

Bard P/N 8403-079

(1) 35' 5-Wire 18 Gauge Shielded Cable

(2) Communication EMI Filters

Bard P/N 8301-055

1

Temperature Only Sensor

Remote

Bard P/N 8301-058

1

One remote temperature/humidity sensor is included with the LC6000 controller. If the site in which the LC6000

controller will be used has more than one zone (maximum three zones per LC6000), additional remote temperature/

humidity sensors (one sensor per zone) will need to be purchased and installed in the additional zones. One

additional temperature-only sensor (Bard P/N 8301-058) may also be used in Zone 1 but will also need to be

purchased separately. Additional temperature/humidity sensors require field-supplied 5-wire 18 gauge shielded

cable. Temperature-only sensors require field-supplied 2-wire 18 gauge shielded cable.

Manual 2100-669F

Page 3 of 37

Page 4

The equipment covered in this manual is to be installed

by factory trained and certified, experienced service and

installation technicians.

These instructions should be carefully read before

beginning the installation. Note particularly any tags

and/or labels attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Additional Publications for information

on codes and standards.

Shipping Damage

Upon receipt of equipment, the cartons should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

Additional Publications

These publications can help when installing the air

conditioner. They can usually be found at the local

library or purchased directly from the publisher. Be

sure to consult the current edition of each standard.

ANSI Z535.5 Definitions:

DANGER: Indicate[s] a hazardous situation which, if

not avoided, will result in death or serious injury. The

signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

WARNING: Indicate[s] a hazardous situation which,

if not avoided, could result in death or serious injury.

WARNING [signs] should not be used for property

damage hazards unless personal injury risk appropriate

to this level is also involved.

CAUTION: Indicate[s] a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION [signs] without a safety alert symbol may be

used to alert against unsafe practices that can result in

property damage only.

NOTICE: [this header is] preferred to address practices

not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an

alternative to “NOTICE” the word “CAUTION” without

the safety alert symbol may be used to indicate a

message not related to personal injury.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation of Air Conditioning

and Ventilating Systems ...................ANSI/NFPA 90A

Standard for Warm Air Heating

and Air Conditioning Systems ............ANSI/NFPA 90B

Load Calculation for Residential Winter

and Summer Air Conditioning ............. ACCA Manual J

Duct Design for Residential Winter and Summer

Air Conditioning and Equipment Selection

....................................................... ACCA Manual D

For more information, contact these publishers:

Air Conditioning Contractors of America (ACCA)

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370 Fax: (202) 234-4721

American National Standards Institute (ANSI)

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900 Fax: (212) 302-1286

American Society of Heating, Refrigeration and Air

Conditioning Engineers, Inc. (ASHRAE)

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400 Fax: (404) 321-5478

National Fire Protection Association (NFPA)

Batterymarch Park

P. O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555 Fax: (617) 984-7057

NOTICE

It is important to check the software version

during installation to ensure that the latest

version has been installed. Current software

versions, change log and installation

instructions are available on the Bard website at

http://www.bardhvac.com/software-download/

Manual 2100-669F

Page 4 of 37

Page 5

RJ11 Cable

to Display

Transformer

LC6000 CONTROLLER INSTALLATION

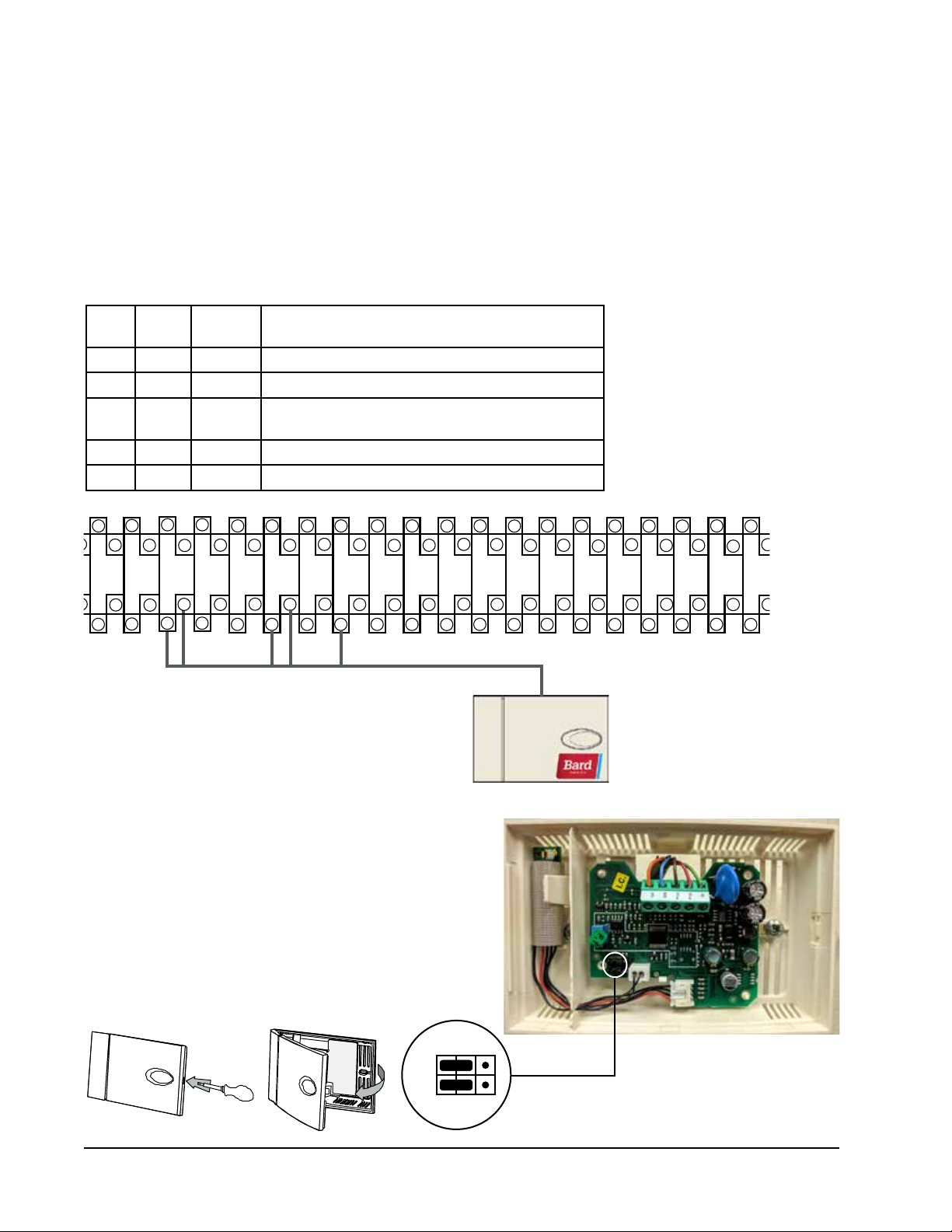

FIGURE 1

Typical LC6000-200 Component Location

Ethernet Cable

Connection

Four Fused

Power Supply

Terminals

Emergency Off

Alarm Jumper

Emergency Vent

Alarm Jumper

Generator Run

Alarm Jumper

Control Board

USB Male A

to Micro Male

B Cable

Terminal Block

Manual 2100-669F

Page 5 of 37

Page 6

!

WARNING

Electrical shock hazard.

Disconnect VAC power supplies before

servicing.

Failure to do so could result in electric shock

or death.

IMPORTANT: When working with circuit board

components,

an anti-static wrist strap to prevent static

electricity shorts to electronic controls.

Bard recommends the use of

LC6000 Controller

The LC6000 controller is part of this air conditioning

system. It is used to control up to 14 wall-mount air

conditioners from one controller. The microprocessor

control provides an easy-to-read interface with

large LCD graphical display. It provides control for

redundancy for the structure and equal wear on all

units.

Conduit is recommended for all wiring. Route

communication wiring and power supply wiring in their

own separate conduits.

The LC6000 controller is not weatherproof and is

intended for use in a weathertight structure.

IMPORTANT: When connecting this product from a

remote location, ensure that the network

connection is secure and reliable.

Mounting the LC6000 Controller

The dimensions of the LC controller are 16" x 12" x 6".

Because the LC6000 controller utilizes a remote

temperature sensor as opposed to one located in the

controller box, the controller itself can be installed in

any indoor location that is suitable, preferably at eye

level. Four (4) mounting holes are provided for mounting

to the wall and holes for conduit connections are provided

in the base, sides and top of the controller.

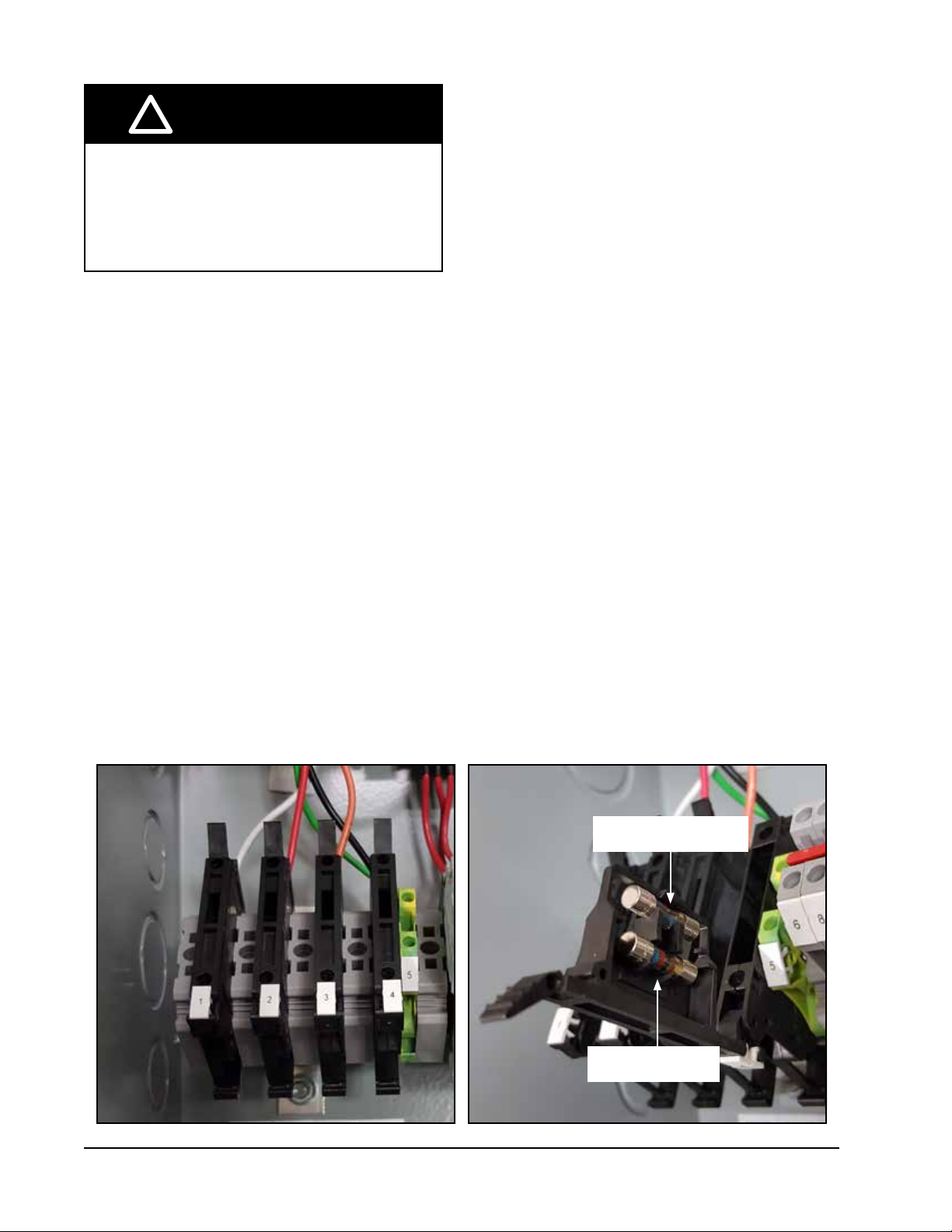

The LC6000 controller includes four fused power

supply terminals in the terminal block. Before

connecting wires to the terminal block, confirm that the

fuse in each of the four fuse holders is in the proper

position (active) as shown in Figure 2.

Manual 2100-669F

Page 6 of 37

FIGURE 2

LC6000 Fused Power Supply Terminals

Fuse in Active Position

Shipping Position

Page 7

Supply Wiring

19

21

25

23

18

20

22 24

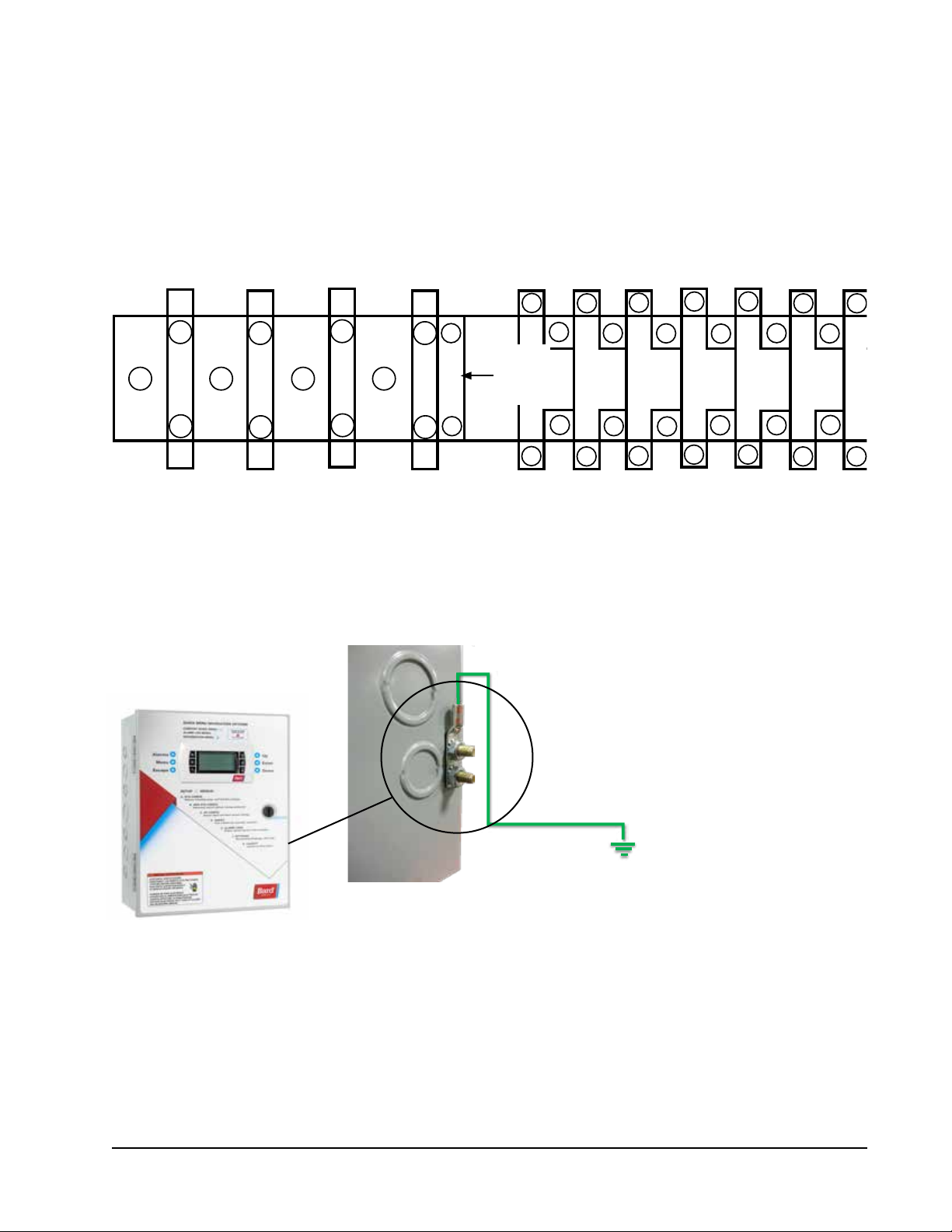

The LC6000 controller is powered by 120, 208 or 240 volts from the shelter. Field-supplied supply wiring should

be minimum 16 gauge, maximum 14 gauge (see Figure 3). A reliable earth ground must be connected in addition

to any grounding from conduit. Grounding bolts and nuts are included with the controller for this purpose; a 2 hole

grounding lug must be field supplied. Install as shown in Figure 4. Failing to ground the controller box properly could

result in damage to the equipment.

FIGURE 3

LC6000 Controller Supply Wiring

Power

1

2

3

4

5

Input

6

Ground

9

8 10 12

7

11 13

14

15

16

17

120

VAC

Input

(L1)

208V

VAC

Input

(L1)

240V

VAC

Input

(L1)

Power

Input

Common

(L2 or N)

FIGURE 4

Controller Grounding Posts

A reliable earth ground must be connected in

addition to any grounding from conduit. Attach

earth ground to side of controller box using bolts

and nuts supplied with controller and fieldsupplied 2 hole grounding lug. Failing to ground

the controller box properly could result in damage

to the equipment.

Manual 2100-669F

Page 7 of 37

Page 8

Installing Remote Indoor Temperature/Humidity Sensor(s)

47 51

49 53

55

59

57

60

48

50 52

54

56

58

One remote indoor temperature/humidity sensor and 35' of 18 gauge 5-conductor shielded cable is included with the

controller. This sensor must be installed for proper operation. Mount the temperature/humidity sensor in a location

least likely to be affected by open doors, rack-mounted fans, radiant heat sources, etc. Locating the sensor between

both return grilles is often the best location, but every installation is unique. Location height should be approximately

60" above the floor. The sensor should be installed on a 2" x 4" junction box to allow for control wire conduit. Use

shielded cable to connect to controller.

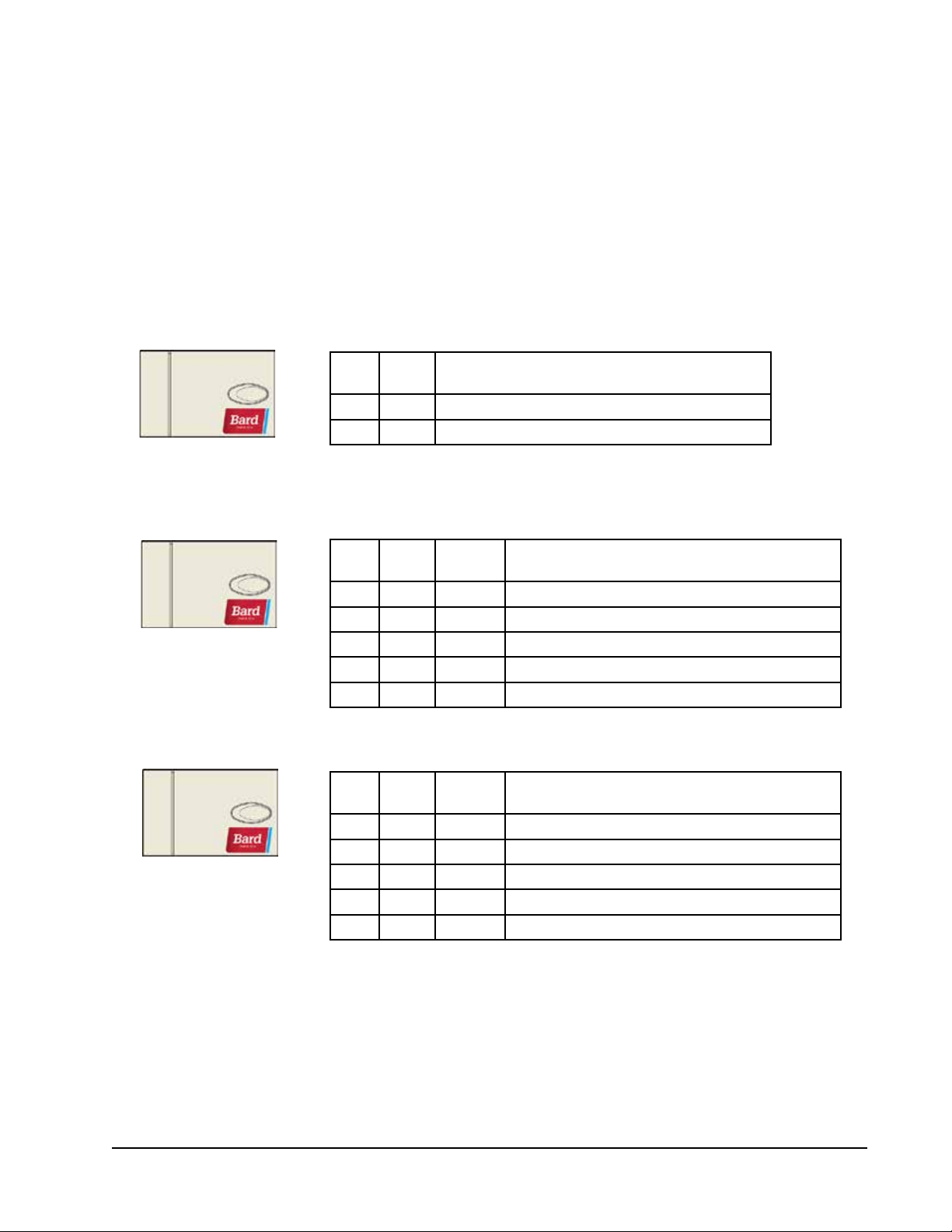

FIGURE 5

Remote Indoor Temperature/Humidity Sensor Installation

1. Connect wires from the 18 gauge shielded cable to terminals #12, #13, #18, #19 and #22.

TB#

Wire

Mark

Sensor Description

18 B6 NTC OUT Indoor Remote Sensor (Zone 1)

19 GND NTC OUT Ground

12 B2 OUT H Remote Indoor Humidity Sensor: 0-1 VDC (Zone 1)

13 GND M (GO) Ground

22 +VDC + (G) Power for B2

212523

11 13

9

8 10 12

14

16 18

15

17

19

20

22 24

26

27

28

29

30 32 34 36

313533

37

40

39 4341 45

38

42 44

46

2. Connect the other end of the shielded cable to the sensor

terminals. Be sure wires are connected to proper terminals

as shown in table above.

Sensor jumpers need to be positioned for 0-1 V. With sensor

oriented as shown in image to right, move both jumpers

to left position (DP1 and DP2 set to OFF). This applies

to all temperature/humidity sensors connected to the LC

controller.

Sensor is best mounted on a junction box, and it is

recommended that the cable be in conduit.

Jumper

DP1

DP2

Manual 2100-669F

Page 8 of 37

Page 9

For proper operation, the remote indoor temperature/humidity sensor (and any additional sensors) must be

configured properly with the controller as shown in Step 2 on page 8. An additional remote indoor temperature-

only sensor can be purchased and installed in Zone 1. If the site in which the LC6000 controller will be used has

more than one zone (maximum three zones per LC6000), additional remote temperature/humidity sensors (one per

zone) will need to be purchased and installed in the additional zones. All installed sensors must be enabled in the

controller menu (see Configure Sensors in system installation instructions included with the wall-mount unit).

FIGURE 6

Additional Remote Temperature and Temperature/Humidity Sensor Installation

One additional temperature sensor can be added to Zone 1 and additional temperature/humidity sensors may be

added to Zones 2 and 3 (one per zone). Be sure the sensors are connected to the proper terminals on the terminal

block and sensor as listed below.

Zone 1:

Optional Remote

Temperature Sensor

Terminals 20 & 21*

Zone 2:

Optional Remote

Temperature/Humidity Sensor

Terminals 26, 27, 14, 15 & 23

IMPORTANT: Note jumper

position in Figure 14

Zone 3:

Optional Remote

Temperature/Humidity Sensor

Terminals 28, 29, 16, 17 & 24

IMPORTANT: Note jumper

position in Figure 14

TB#

20 B7 Indoor Remote Sensor (Zone 1 – optional)

21 GND Ground

* The two wire connections for the optional remote temperature sensor

are not polarity sensitive.

TB#

26 B8 NTC OUT Indoor Remote Sensor (Zone 2)

27 GND NTC OUT Ground

14 B3 OUT H Remote Indoor Humidity Sensor: 0-1 VDC (Zone 2)

15 GND M (GO) Ground

23 +VDC + (G) Power for B3

TB#

28 B9 NTC OUT Indoor Remote Sensor (Zone 3)

29 GND NTC OUT Ground

16 B4 OUT H Remote Indoor Humidity Sensor: 0-1 VDC (Zone 3)

17 GND M (GO) Ground

24 +VDC + (G) Power for B4

Wire

Mark

Wire

Mark

Wire

Mark

Description

Sensor Description

Sensor Description

Zones 2 and 3 can also use temperature-only sensors in place of the temperature/humidity sensors. Zone 2 will connect

to TB# 26 and 27. Zone 3 will connect to TB# 28 and 29. The wire connections for the temperature-only sensors are not

polarity sensitive.

Manual 2100-669F

Page 9 of 37

Page 10

Installing Optional Outdoor Temperature/Humidity Sensor

One optional outdoor temperature/humidity sensor (8301-090) can be installed. Follow the manufacturer's mounting

instructions. Use 18 gauge 5-conductor shielded cable to connect to controller.

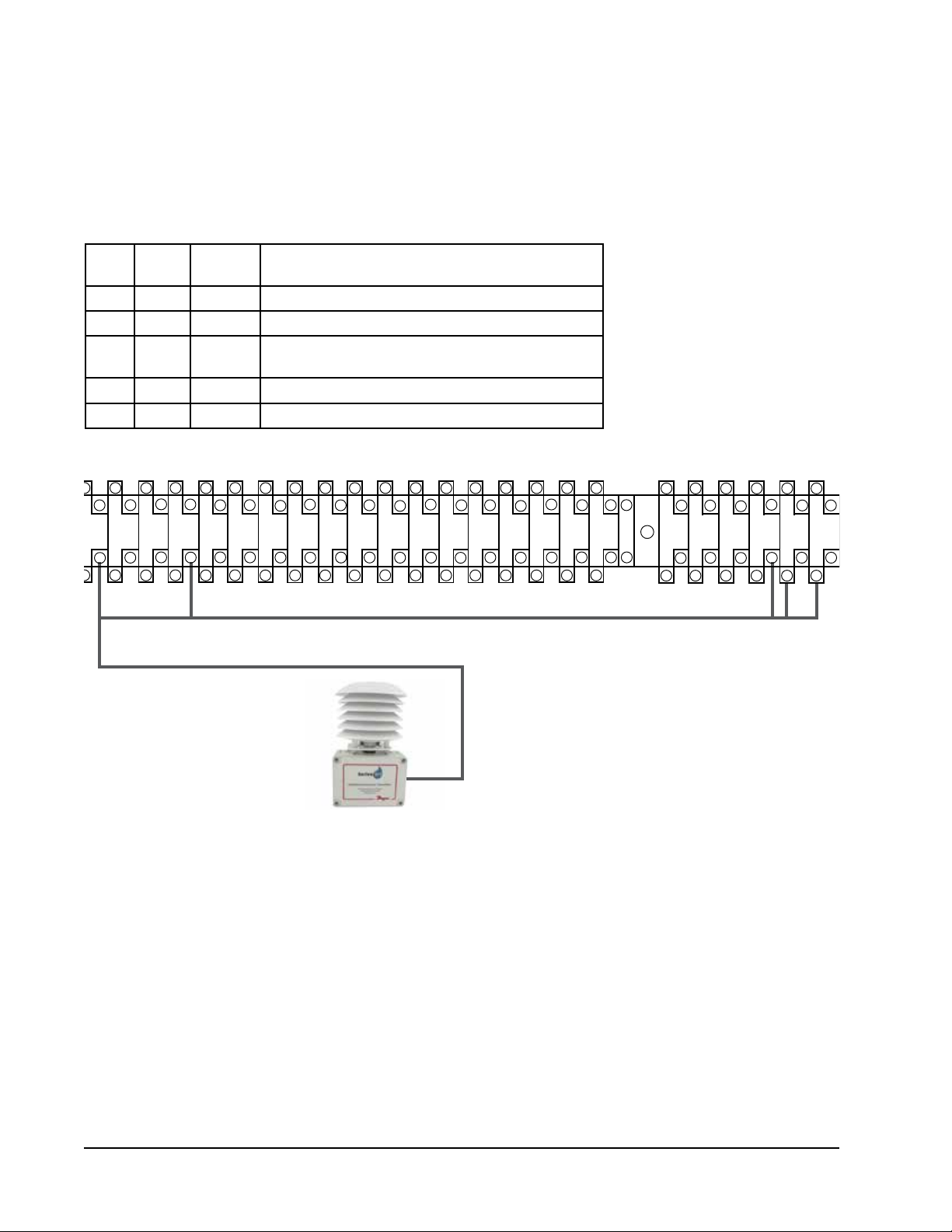

FIGURE 7

Remote Outdoor Temperature/Humidity Sensor Installation

1. Connect wires from the 18 gauge shielded cable to terminals #65, #66, #67, #70 and #71.

TB#

Wire

Mark

Sensor Description

70 B12 4 Remote Outdoor Temperature Sensor

71 ND 5 Ground

67 B11 1 Remote Outdoor Humidity Sensor: 0-10 VDC

66 GND 3 Ground

65 +VDC 2 +VDC

28

25

26

27

29

30 32 34 36

313533

37

40

38

39 4341 45

42 44

47 51

46 48

49 53

50 52

54

55

56

57

58

59

60

62

61 65

64 66

63

68

67

70

69

72

71

2. Connect the other end of the shielded cable to the sensor terminals. Be sure wires are connected to proper terminals

as shown in table above.

Manual 2100-669F

Page 10 of 37

Page 11

Emergency Off, Emergency Ventilation and Generator Run Connections

27

29

31

33

26

28

30 32 34 36

The LC6000-200 controller is shipped with emergency off, emergency ventilation and generator run contacts. There

are factory-installed jumpers across terminals #6 and #7 (emergency off), #8 and #9 (emergency ventilation) and

#10 and #11 (generator run). Remove the factory-installed jumpers before making the connections.

FIGURE 8

LC6000-200 Series Connection for Emergency Off, Emergency Ventilation and Generator Run (If Applicable)

3

4

5

7

6

9

8 10 12

11 13

14

Generator Run*

Emergency Ventilation*

Emergency Off*

* Normally closed (NC) contacts required.

By default:

Closed = No Alarm

Open = Alarm

17

16 18

15

19

20

21

23

22 24

25

Manual 2100-669F

Page 11 of 37

Page 12

- +

G

63

61 65

67

62

64 66

68

Communication Wiring

The steps outlined on the following pages show how to connect the communication wiring to the LC controller.

Communication wire connections to the wall-mount unit vary with the different units. See the system installation

instructions included with the wall-mount unit for information on connecting the communication wiring to the wallmount unit(s).

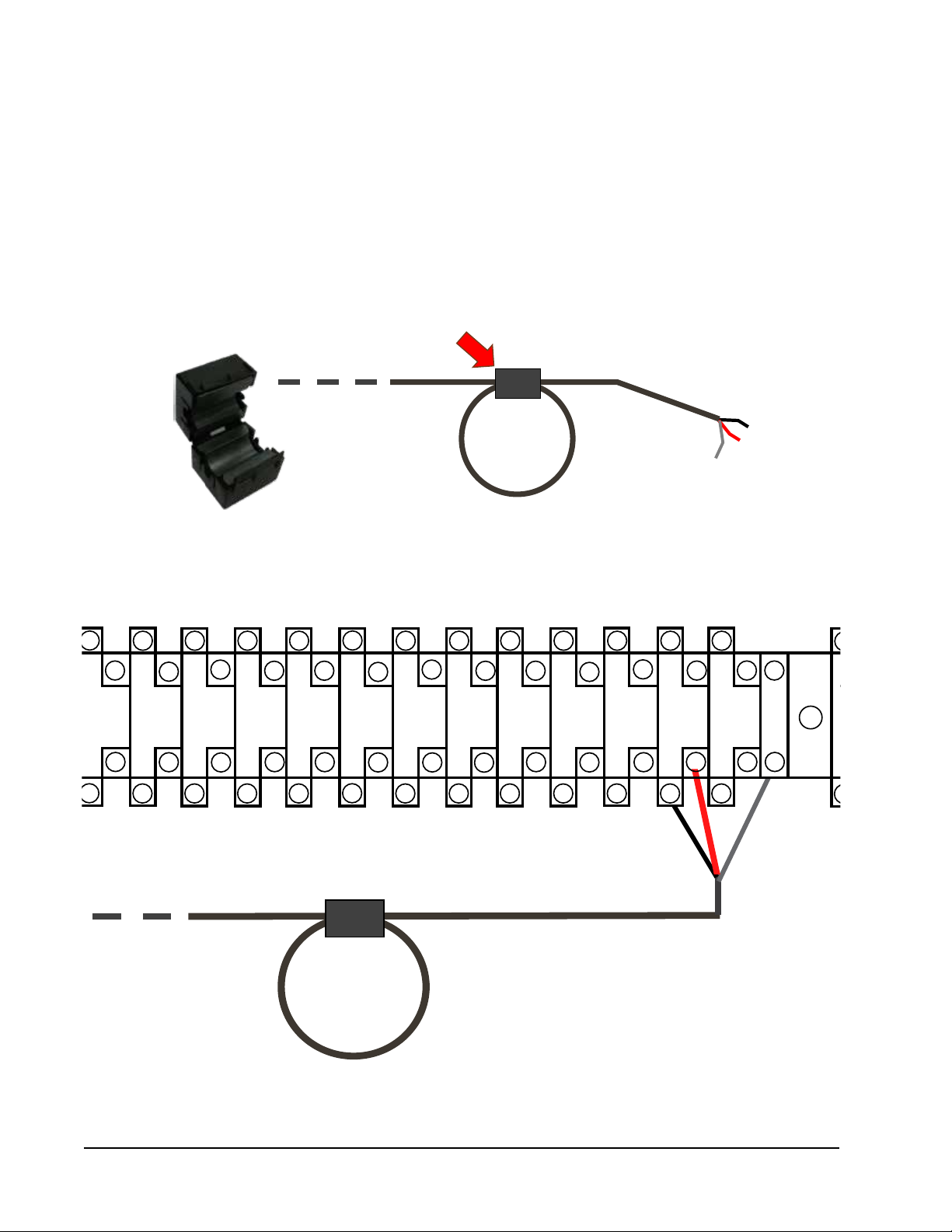

FIGURE 9

Communication Wiring: Termination at the Controller

1. Using the field-provided shielded cable, make a small service loop after entering the controller and attach the provided

EMI filter at the intersection of the loop.

2. Connect one wire to terminal #56 (negative), the other wire to terminal #57 (positive) and the drain wire to ground

terminal #60.

36

37

38

40

39 4341 45

42 44

47 51

46 48

49 53

50 52

54

55

56

57

58

59

60

35

+

–

To Wall-Mount Unit 1

Manual 2100-669F

Page 12 of 37

Page 13

Connect the communication wiring from the controller to the wall-mount units in the manner shown in Figures 10,

11 or 12. The daisy chain does not need to follow the addressing order. The communication wire should be 2-wire,

18 gauge shielded cable with drain. Any color can be used. Be sure to match "+" and "-" symbols on controller

terminal blocks to prewired unit control terminal block. Attach communication wire filters as shown in Figures 10,

11 or 12. Do not run communication wiring in same conduit as supply wiring.

Route communication wiring and

power supply wiring in their own separate conduits.

The wall-mount units may not look the same as those depicted in the figures but these directions apply to all

units connected to the LC6000-200 controller.

FIGURE 10

Communication Wiring (Daisy Chain Method)

Filter

Filter

Wall-Mount Unit Wall-Mount Unit

LC6000 Controller

In addition to the "daisy chain" method of connecting the communication wiring shown in Figure 10, the wall-mount

units can also be connected in the manner shown in Figure 11. If connecting wall-units this way, be sure to place

the communication wire filters in the positions shown in Figure 11. See Figure 12 on page 14 for more information

on the correct placement of the communication wire filters depending on the wiring method used.

FIGURE 11

Communication Wiring (Alternate Method)

Wall-Mount Unit

LC

Controller

Filter

Filter

Wall-Mount Unit

Manual 2100-669F

Page 13 of 37

Page 14

FIGURE 12

Placement of Communication Wire Filters (Daisy Chain and Alternate Methods)

Place filter here

Place filter here

(end unit)

LC6000

Daisy Chain Wiring

Unit 1 Unit 2 Unit 3 Unit 4 Unit 5

Alternate Wiring

LC6000*

Place filter here

(end unit)

... up to 14 units

Place filter here

(end unit)

Unit 1 Unit 2

Unit 3 Unit 4 Unit 5

... up to 14 units

* LC6000 can be in any position other than start and end

NOTE: Line filters can be on either the unit or controller, whichever device is on the end of the chain. No matter

how many units there are, the two end devices will only have ONE communication cable, whereas the

center devices will all have TWO (as shown above). Maximum two wires in each terminal. Filters go inside

the unit or controller; shown out of unit above for identification only.

Manual 2100-669F

Page 14 of 37

Page 15

ALARMS

NOTE: Screenshots shown in this manual reflect

default settings (when applicable).

Alarm Adjustment

Acknowledging/Clearing Alarms

Alarm conditions activate a red LED indicator that

backlights the ALARM function key. As an option, an

alarm condition may also be enunciated by an audible

alarm signal. An alarm is acknowledged by pressing the

ALARM key. This calls up alarm display screen(s) that

provide a text message detailing the alarm condition(s).

After an alarm condition is corrected, the alarm can be

cleared by pressing the ALARM key for 3 seconds.

Low Temperature Alarm

If the lowest temperature sensor value in a zone is

below the low temperature setpoint, an alarm will be

generated for that zone. Additionally, a relay output will

be actuated from the LC controller to provide remote

notification of the event.

NOTE: This alarm is per zone. If each zone is meant to

operate within the same alarm parameters, each

zone will need to be set accordingly.

To adjust the low temperature alarm setpoint:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Alarm

Setpoints A2-9 (Zone 1), Alarm Setpoints A3-9

(Zone 2) or Alarm Setpoints A4-9 (Zone 3).

6. Press ENTER key to scroll to the variable labeled

Low Temp (see Figure 13).

7. Press UP or DOWN keys to adjust setpoint.

FIGURE 13

Adjust Alarm Setpoints

To change the direction of the remote notification relay

output:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital Out

Config C3.

Press ENTER key to scroll to the variable in the table

5.

that intersects LoTemp and Dir (see Figure 14).

6. Press UP or DOWN key to change direction.

The low temperature notification relay has dry contacts.

The Dir, direction, is the position of the relay without

a low temperature event. NO is normally open; NC is

normally closed.

When the Val (value) is OFF, the relay is not in an alarm

condition. When the Val (value) is ON, the relay is in

an alarm condition. The relay connections for the low

indoor temperature alarm are on the LC6000 terminal

block; see Table 6 on page 34 for terminal block index.

FIGURE 14

Adjust Alarm Remote Notification

Relay Output Direction

High Temperature Alarm

If the highest temperature sensor value in a zone is

above the high temperature setpoint, an alarm will be

generated for that zone. When this alarm is present,

emergency cooling in this zone will become active.

There are two high temperature alarm setpoints. This

is the first and there is no remote notification for this

alarm.

NOTE: This alarm is per zone. If each zone is meant to

operate within the same alarm parameters, each

zone will need to be set accordingly.

To adjust the high temperature alarm setpoint:

1. Press MENU key to go to the Main Menu screen.

Manual 2100-669F

Page 15 of 37

Page 16

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Alarm

Setpoints A2-8 (Zone 1), Alarm Setpoints A3-8

(Zone 2) or Alarm Setpoints A4-8 (Zone 3).

6. Press ENTER key to scroll to the variable labeled

High Temp (see Figure 13).

7. Press UP or DOWN keys to adjust setpoint.

High Temperature 2 Alarm

If the highest temperature sensor value in a zone is

above the high temperature 2 setpoint, an alarm will

be generated for that zone. When this alarm is present,

the units will emergency cool in this zone. Additionally,

a relay output will be actuated from the LC to provide

remote notification of the event.

NOTE: This alarm is per zone. If each zone is meant to

operate within the same alarm parameters, each

zone will need to be set accordingly.

To adjust the high temperature 2 alarm setpoint:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Alarm

Setpoints A2-9 (Zone 1), Alarm Setpoints A3-9

(Zone 2) or Alarm Setpoints A4-9 (Zone 3).

6. Press ENTER key to scroll to the variable labeled

High Temp 2 (see Figure 13).

7. Press UP or DOWN keys to adjust setpoint.

To change the direction of the remote notification relay

output:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital Out

Config C3.

Press ENTER key to scroll to the variable in the

5.

table that intersects HiTemp and Dir (see Figure

14).

6. Press UP or DOWN key to change direction.

When the Val (value) is OFF, the relay is not in an

alarm condition. When the Val (value) is ON, the relay

is in an alarm condition. The relay connections for the

high indoor temperature 2 alarm are on the LC6000

terminal block; see Table 6 on page 34 for terminal

block index.

Emergency Off Alarm

If the LC gets an input from a smoke detector or similar

device, an alarm will be generated and all units will be

shut down. Additionally, a relay output will be actuated

from the LC to provide remote notification of the event.

The emergency off input can be configured to accept

either normally open or normally closed inputs. The

controller is defaulted to normally open and a jumper is

placed across the terminals of the input (#6 and #7).

When this jumper is removed, the alarm will become

active.

To change the direction of the emergency off input:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital In

Config C1.

Press ENTER key to scroll to the variable in the

5.

table that intersects EM Off and Dir (see Figure 15).

6. Press UP or DOWN key to change direction.

Emergency Off (EM Off) Dir (direction) is the position

of the smoke detector contacts in the event of smoke.

NO is normally open; NC is normally closed.

EM Off En (enable) allows the LC controller to monitor

the smoke detector when set to ON. When set to OFF,

the LC controller ignores the smoke detector.

EM Off Val (value) of ON indicates a smoke event. A

Val (value) of OFF indicates no smoke event.

Smoke detector connections (emergency off input) are

on the LC6000 terminal block; see Table 6 on page 34

for terminal block index.

FIGURE 15

Adjust Emergency Off, Emergency Vent or

Generator Alarm Input Direction

Manual 2100-669F

Page 16 of 37

Page 17

To change the direction of the remote notification relay

output:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital Out

Config C2.

Press ENTER key to scroll to the variable in the table

5.

that intersects EMG Off and Dir (see Figure 16).

6. Press UP or DOWN key to change direction.

The smoke alarm notification relay has dry contacts.

The Dir (direction) is the position of the relay without

a smoke event. NO is normally open; NC is normally

closed.

When the Val (value) is ON, the relay is in an alarm

condition. The relay connections (smoke alarm) are on

the LC6000 terminal block; see Table 6 on page 34 for

terminal block index.

FIGURE 16

Adjust Alarm Remote Notification Relay

Output Direction

Generator Alarm

If the LC detects a generator running event (through a

digital input), an alarm will be generated. Additionally,

a relay output will be actuated from the LC to provide

remote notification of the event. The end user will be

able to configure which units are permitted to run during

this event. Default will be to not allow any units to run.

The generator alarm input can be configured to accept

either normally open or normally closed inputs. The

controller is defaulted to normally open and a jumper

is placed across the terminals of the input (#10 and

#11). When this jumper is removed, the alarm will

become active.

To change the direction of the generator input:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital In

Config C1.

5. Press ENTER key to scroll to the variable in the

table that intersects Gen and Dir (see Figure 15).

6. Press UP or DOWN key to change direction.

Gen Dir (direction) is the position of the generator

input contacts in the event of a need for generator

operation. NO is normally open; NC is normally closed.

Gen En (enable) allows the LC controller to monitor

the generator input contacts when set to ON. When set

to OFF, the LC controller ignores the generator input

contacts.

Gen Val (value) of ON indicates the generator is in

operation. A Val (value) of OFF indicates the generator

is not operating.

Generator connections (generator run input) are on the

LC6000 terminal block; see Table 6 on page 34 for

terminal block index.

While the generator is running, the system will

only allow selected units to run. This selection is

customizable by the end user. This limitation is in

place to match the unit power requirements to the

shelter generator capacity.

The default is to not allow any units to run during a

generator event. This can be adjusted to allow specific

units to run during a generator event.

To change which units run when the generator run

input is active:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

TECHNICIAN password 1313.

3. Press UP or DOWN keys to scroll to Adv System

Config; press ENTER key.

4. Press UP or DOWN keys to scroll to Generator

Disable B13. This screen displays units 1-6 (as

applicable).

5. Press ENTER key to scroll to 01 (see Figure 17).

FIGURE 17

Adjust Units Running When Generator Is Active

Manual 2100-669F

Page 17 of 37

Page 18

6. Press UP or DOWN key to change Disable to

Enable.

7. Press ENTER key to save the value and move

cursor to 04.

8. Press UP or DOWN keys and ENTER key to change

units to Enable as needed.

9. Press ENTER key to scroll back to top line.

The Generator Disable B13 screen displays units 1-6.

To enable/disable units 7-14, press UP or DOWN

keys to scroll to Generator Disable B14 and follow the

directions provided above.

To change the direction of the remote notification relay

output:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital Out

Config C2.

5. Press ENTER key to scroll to the variable in the

table that intersects Gen and Dir (see Figure 16 on

page 17).

6. Press UP or DOWN key to change direction.

The generator alarm notification relay has dry contacts.

The Dir (direction) is the position of the relay without

generator operation. NO is normally open; NC is

normally closed.

When the Val (value) is ON, the relay is in an alarm

condition. The relay connections (generator alarm) are

on the LC6000 terminal block; see Table 6 on page 34

for terminal block index.

Emergency Vent Alarm

If the emergency vent terminals are activated by a

hydrogen detector or similar device, an alarm will

be generated and the wall units will all be put into

emergency ventilation by the LC. Additionally, a relay

output will be actuated from the LC to provide remote

notification of the event. The end user will be able to

configure which zones ventilate during this event.

Units with economizers will operate in emergency vent

mode. The dampers will open at 100% and the blower

will come on at full speed until the alarm is reset.

Units without economizers located in the same zone

will only bring on the blower at full speed.

The emergency vent alarm input can be configured to

accept either normally open or normally closed inputs.

The controller is defaulted to normally open and a

jumper is placed across the terminals of the input (#8

and #9). When this jumper is removed, the alarm will

become active.

To change the direction of the emergency vent input:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital In

Config C1.

5. Press ENTER key to scroll to the variable in the

table that intersects EM Vent and Dir (see Figure

15 on page 16).

6. Press UP or DOWN key to change direction.

Emergency Vent (EM Vent) Dir (direction) is the

position of the emergency vent contacts in the event

of hydrogen being sensed. NO is normally open; NC is

normally closed.

EM Vent En (enable) allows the LC controller to monitor

the hydrogen detector when set to ON. When set to

OFF, the LC controller ignores the hydrogen detector.

EM Vent Val (value) of ON indicates a hydrogen event.

A Val (value) of OFF indicates no hydrogen event.

Emergency vent connections (hydrogen detector input)

are on the LC6000 terminal block; see Table 6 on page

34 for terminal block index.

To change the direction of the remote notification relay

output:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital Out

Config C2.

Press ENTER key to scroll to the variable in the

5.

table that intersects EMG Vent and Dir (see Figure

16 on page 17).

6. Press UP or DOWN key to change direction.

The emergency vent alarm notification relay has dry

contacts. The Dir (direction) is the position of the relay

without a hydrogen event. NO is normally open; NC is

normally closed.

When the Val (value) is ON, the relay is in an alarm

condition. The relay connections (emergency vent

alarm) are on the LC6000 terminal block; see Table 6

on page 34 for terminal block index.

Zone Unit Alarm

By default, if any of the units communicate a high

pressure or low pressure alarm to the LC, the LC will

actuate a relay output to provide remote notification

of the event. A relay output will be actuated from the

Manual 2100-669F

Page 18 of 37

Page 19

LC to provide remote notification of the event for each

zone.

To change the direction of the remote notification relay

output:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital Out

Config C3.

5. Press ENTER key to scroll to the variable in the

table that intersects Z1Alm and Dir, Z2Alm and

Dir, or Z3Alm and Dir (see Figure 14 on page 15).

6. Press UP or DOWN key to change direction.

When the direction is set to NO, the relay output will

be closed when the alarm is active and open when

not active. When the direction is set to NC, the relay

output will be open when alarm is active and closed

when not active.

The zone alarms can be configured to actuate based on

15 alarms communicated from each wall unit. These

items can be selected for each zone.

To select which wall unit alarms actuate zone alarms:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

TECHNICIAN password 1313.

3. Press UP or DOWN keys to scroll to Adv Sys

Config; press ENTER key.

4. Press UP or DOWN keys to scroll to Zone Alarm

Config B4, Zone Alarm Config B5 and Zone Alarm

Config B6. The 15 alarms are divided between

these three screens.

5. Press ENTER key to scroll to the variable in the

table that intersects with each alarm and zone

number (see Figure 18).

6. Press UP or DOWN key to change value (N or Y).

If a value of Y is entered, the wall unit alarm will

trigger the zone alarm relay output. If a value of N

is entered, the wall unit alarm will not trigger the

zone alarm relay output.

NOTE: By default, only 'no temperature sensors' and

high and low pressure actuate the alarms.

NOTE: Power Loss group is also affected by

communication loss.

NOTE: If no temperature sensors are detected by the

controller for a given zone, that zone alarm

output will be actuated. This is nonconfigurable.

FIGURE 18

Adjust Zone Alarm Configuration

Humidity Alarm

When the LC detects a high indoor humidity or low

indoor humidity event in a selected zone (through an

analog input from a remote sensor), an alarm will be

generated. Additionally, a relay output will be actuated

from the LC to provide remote notification of the event.

The end user can configure the alarm to be actuated

when the measurement is high, low or both high and low.

To adjust the humidity alarm setpoints:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone

2 or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Alarm

Setpoints A2-10 (Zone 1), Alarm Setpoints A3-10

(Zone 2) or Alarm Setpoints A4-10 (Zone 3).

Manual 2100-669F

Page 19 of 37

Page 20

6. Press ENTER key to scroll to Low Humidity, High

Humidity or Alarm Delay (delay in seconds from

the time the alarm is sensed until the alarm is

displayed). See Figure 19.

7. Press UP and DOWN keys to adjust setpoints or

delay.

FIGURE 19

Adjust Humidity Alarm Setpoints

To adjust the direction of the remote notification relay

output:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Digital Out

Config C3.

5. Press ENTER key to scroll to the variable in the

table that intersects HumAl and Dir (see Figure 14

on page 15).

6. Press UP or DOWN key to change direction.

When the direction is set to NO, the relay output will

be closed when the alarm is active and open when not

active. When the direction is set to NC, the relay output

will be open when alarm is active and closed when not

active.

Manual 2100-669F

Page 20 of 37

Page 21

CONTROL OPERATION

NOTE: Screenshots shown in this manual reflect

default settings (when applicable).

Temperature Control

Indoor Temperature Averaging

The LC has the ability to average all of the zone

temperature sensors connected to the LC and the

return air temperature sensors connected to the wallmount unit, use only the zone temperature sensors, or

use the LC sensors and any unit which has its blower

run continuously. This can be set differently for each

zone. This value will then be used as a zone indoor

temperature for the LC and wall-mount unit control

functions.

There are three possible sensor averaging selections:

• LC Only

This configuration only averages the zone

temperature sensors connected to the LC and

enabled within the specific zone.

• Blower On

This configuration averages any temperature

sensors connected to the LC that are enabled and

the return air temperature sensor of any wallmount unit set to run in continuous blower within

the specific zone.

• All Sensors

This configuration averages the zone temperature

sensors connected to the LC that are enabled and

all the return air temperature sensors of all wallmount units within the specific zone, regardless of

blower operation.

To change the indoor temperature averaging type:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone

2 or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Zone Temp A2-

11 (Zone 1), Zone Temp A3-11 (Zone 2) or Zone

Temp A4-11 (Zone 3).

6. Press ENTER key to scroll to Selection (see Figure

20).

7. Press UP and DOWN keys to adjust.

FIGURE 20

Change Indoor Temperature Averaging Type

Comfort Mode

If comfort mode is activated, all of the zone setpoints

will be set to 72°F for cooling and 70°F (comfort

setpoint -2) for heating. This setpoint will be active for

60 minutes.

To enable comfort mode:

1. Press UP or DOWN key while on the Status screen

to select Setpoints ( ) from the Quick Menu

options; press ENTER key.

2. Press ENTER key to scroll to Comfort Mode.

3. Press UP or DOWN keys to change the duration of

comfort mode.

4. Press ENTER key to scroll to Comfort Setpoint.

5. Press UP and DOWN keys to change the cooling

setpoint for comfort mode.

6. Press ENTER key to scroll to Comfort Enable.

7. Press UP or DOWN key to change value from OFF

to ON; press ENTER key.

The system is now in comfort mode and will cool or heat

to the comfort setpoint for the 60-minute duration.

Staging

Each zone is capable of three different staging

methods.

FIFO (First in First Out)

The unit that is first in rotation will be the first one

turned off.

LIFO (Last in First Out)

The unit that is last in rotation will be the first one

turned off.

Demand Staging

While in cooling operation, the unit with the highest

return temperature will be brought on first. The unit

with the lowest return temperature will be turned off

first. While in heating mode, the unit with the lowest

Manual 2100-669F

Page 21 of 37

Page 22

return air temperature will be brought on first and the

unit with the highest return temperature will be turned

off first.

To change the staging method type:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Staging A2-5

(Zone 1), A3-5 (Zone 2) or A4-5 (Zone 3).

6. Press ENTER key to scroll to the variable labeled

Type (see Figure 21).

7. Press UP or DOWN keys to adjust.

FIGURE 21

Adjust Staging Settings

Maximum Number of Units Running

The maximum number of units that will be staged

on can be configured for each zone. The number is

defaulted at the total number of units capable so that

they are fully utilized by default. This is configurable

for economizer, cooling and heating independently.

To adjust the maximum number of units running:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Staging A2-6

(Zone 1), Staging A3-6 (Zone 2) or Staging A4-6

(Zone 3).

6. Press ENTER key to scroll to the variable for

Freecooling, Cooling or Heating (see Figure 22).

7. Press UP or DOWN keys to adjust number of units.

FIGURE 22

Staging Maximum Number of Units Running

Staging Delay

A delay on and off can be set for economizer (FC),

cooling (CL) and heating (HT) independently for each

zone. This will limit how fast the units can be staged

on or off.

To adjust the on and off delay times:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Staging A2-5

(Zone 1), Staging A3-5 (Zone 2) or Staging A4-5

(Zone 3).

6. Press ENTER key to scroll to the variable in the

table that intersects FC, CL or HT and Delay On or

Delay Off (see Figure 21).

7. Press UP or DOWN keys to adjust.

Rotation

The units in each zone can be rotated based on

a configurable number of days (1-7). The time is

defaulted to 7 days. In addition to time based, a

manual rotation can be triggered for troubleshooting.

To change the rotation variables:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Rotation A2-7

(Zone 1), Rotation A3-7 (Zone 2) or Rotation A4-7

(Zone 3).

Manual 2100-669F

Page 22 of 37

Page 23

6. Press ENTER key to scroll to Time Based (see

Figure 23). The changeover time is 12 am.

7. Press UP or DOWN key to change ON to OFF.

8. Press ENTER key to scroll to Num. of Days.

9. Press UP or DOWN keys to adjust the number of

days.

10. Press ENTER key to scroll to Manual.

11. Press UP or DOWN key to change OFF to ON.

FIGURE 23

Rotation

Demand

The system will compare the zone temperature

(determined by zone averaging selection) to the

zone cooling and heating setpoint. A demand will be

calculated to determine how many units are required.

For cooling, the zone temperature will be compared

to the cooling setpoint. The controller will calculate a

demand based on how far above the setpoint and how

long it has been above the setpoint. The demand value

(0-100%) will then be split and applied to free cooling

and cooling separately shown as two demands both

ranged 0-100% applied to all of the available cooling

methods for that zone. For example, if the demand is

at 50% and there are 10 available stages of cooling in

that zone, there would be 5 stages active (50% x 10

= 5). The system will prioritize free cooling stages over

compressor stages. Adding to the example, if 5 of the

10 stages for cooling are economizer, 5 units would

be running economizer and no compressors running.

The demand is calculated for the cooling application.

However, for display purposes, the demand is split

so that the user can see demand separately for free

cooling and compressor.

For heating, the zone temperature will be compared

to the heating setpoint. The controller will calculate a

demand based on how far below the setpoint and how

long it has been below the setpoint. The demand value

0-100% will the be applied to all of the available stages

of heating in that zone. For example, if the demand is

at 50% and there are 5 available stages of heating in

that zone, there would be 2 stages active (50% x 5 =

2.5 and a half of a stage cannot be turned on).

Humidity Control

The LC can be configured to control up to three

humidifiers (field supplied) with relay outputs and

up to 14 units equipped with dehumidification. The

indoor humidity level for each zone is compared to the

dehumidification setpoint and humidification setpoint

for each zone.

Dehumidification

The LC6000 controller will monitor the indoor relative

humidity of each zone and compare the value to

three setpoints for each zone. The three setpoints

will be described as dehumidification off, passive

dehumidification and active dehumidification. The

default value for these setpoints will be 60% RH, 70%

RH and 80% RH, respectively.

When the humidity level inside the shelter falls to the

dehumidification off setpoint, the system will stop

attempting to dehumidify the space.

When the humidity level rises to the passive

dehumidification setpoint, all units with economizers

will disable the use of economizers for cooling calls.

This will act as passive dehumidification by forcing the

use of compressor for space cooling. Availability for

passive dehumidification will be determined by model

number. All units with economizers will be considered.

When the humidity level rises to the active

dehumidification setpoint, the controller will activate

staged dehumidification. The controller will then

calculate a dehumidification demand based on how

far above the setpoint and how long the RH level

has been above the setpoint. The demand will then

utilize all of the units with active dehumidification

capabilities to reduce the indoor humidity level. The

units will be staged on based on the existing cooling

rotation for the units in the zone up to an optional

maximum number of units running value. Availability

for active dehumidification will be determined by

model number. Units with concurrent electric reheat

or mechanical dehumidification will be considered.

NOTE: Only one type of dehumidification unit will

be considered depending upon configuration of the

LC6000 controller. Unit capability is determined by the

model number.

To change the dehumidification setpoints:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Setpoints A2-2

(Zone 1), Setpoints A3-2 (Zone 2) or Setpoints

A4-2 (Zone 3).

Manual 2100-669F

Page 23 of 37

Page 24

6. Press ENTER key to scroll to Dehumidification Off,

Passive On or Active On (see Figure 24).

7. Press UP and DOWN keys to change

dehumidification setpoints to desired values.

FIGURE 24

Humidity Control Setpoints

In addition to the setpoint configuration for

dehumidification, each zone must be configured for the

type of active dehumidification.

To change the dehumidification type:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Setpoints A2-3

(Zone 1), Setpoints A3-3 (Zone 2) or Setpoints

A4-3 (Zone 3).

6. Press ENTER key to scroll to Type (see Figure 25).

7. Press UP and DOWN keys to change to desired

value. Dehumidification type choices are None,

Electric Reheat, Mechanical Reheat or Cycling

Reheat. The units in the zone being configured will

need to have the capability of the setting being

selected (see unit model number).

FIGURE 25

Dehumidification Types

Humidification

If the humidity level is below 45% RH (Humidification

Setpoint), the LC will enable humidification for

that zone. Once the humidity level rises to 55%

RH (humidification setpoint plus 10% RH), the

humidification for that zone will be disabled.

NOTE: Humidifiers are field supplied.

To change the humidification setpoint:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Setpoints A2-2

(Zone 1), Setpoints A3-2 (Zone 2) or Setpoints

A4-2 (Zone 3).

6. Press ENTER key to scroll to Humidification (see

Figure 24).

7. Press UP and DOWN keys to change humidification

setpoint to desired value.

Enabling Humidifier

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to General; press

ENTER key.

5. Press ENTER key to scroll to Humidifiers (see

Figure 26).

6. Press UP or DOWN keys to change value to NONE,

Zone 1, Z1 & Z2 or Z1, Z2, & Z3.

7. Press ENTER to scroll to Humidifier Type.

8. Press UP or DOWN keys to change value to Relay

from Comm.

FIGURE 26

Enabling Humidifier

Manual 2100-669F

Page 24 of 37

Page 25

Continuous Blower

The LC will has the option in each zone to operate in

continous blower. The options are None, Lead, All and

Custom. When None is selected, continuous blower

will be disabled on all units in that zone. When Lead is

selected, only the lead unit will have continuous blower

activated. When All is selected, continuous blower will

be enabled on all units in that zone. When Custom is

selected, only units specifically commanded on by the

end user will run in that zone.

Precedence for continuous blower will be given to

the LC or stand-alone controller in instances where

communication with LC is lost.

To change the continuous blower status of each zone:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Cont. Blower

A2-8 (Zone 1), Cont. Blower A3-8 (Zone 2) or

Cont. Blower A4-8 (Zone 3).

6. Press ENTER key to scroll to Selection (see Figure

27).

7. Press UP and DOWN keys to change to desired

choice.

4. Press UP or DOWN keys to scroll to Cont. Blower

Cust. B10, Cont. Blower Cust. B11 or Cont. Blower

Cust. B12. The wall-mount units are divided

between these three screens.

5. Press ENTER key to scroll to the variable in the

Enable column that represents the desired wall

mount unit (see Figure 28).

6. Press UP or DOWN key to change value from No

to Yes (to enable that unit for continuous blower)

or Yes to No (to disable that unit for continuous

blower).

7. Press ENTER key to save.

FIGURE 28

Continuous Blower

FIGURE 27

Continuous Blower

Continuous Blower Custom Configuration

When Custom is selected, only unit specifically

commanded on by the end user will run in that zone.

To select the units to run in continuous blower:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

TECHNICIAN password 1313.

3. Press UP or DOWN keys to scroll to Adv Sys

Config; press ENTER key.

Manual 2100-669F

Page 25 of 37

Page 26

ADDITIONAL INFORMATION

LC6000 Menus/Screens

Main Menu

Press the MENU key from any screen to return to the

Main Menu. Press the UP or DOWN keys to scroll

through the available menus. When the desired menu

is highlighted, press the ENTER key to access that

menu. Press the ESCAPE key or MENU key to return to

the Status screen from the Main Menu.

Status Screen

The Status screen is the default start-up screen and

also the return screen after 5 minutes of no activity.

The screen can be accessed any time by pressing the

ESCAPE button repeatedly. The LC6000 Status screen

displays the current date, time, unit displayed, zone

and system status.

Quick Menu

The Quick Menu is available on the Status screen. Use

UP or DOWN keys while on the Status screen to scroll

between the three Quick Menu options; press ENTER

key.

Alarm Log

The alarm log displays the record number, time of

alarm event, date of alarm event, description of alarm

event and whether the entry is the beginning or end

of event. The alarm log will have as many screens as

events occurred.

Info

The information menu groups all information by unit

address. The LC6000 controller is capable of operating

MULTI-TEC, FUSION-TEC WR Series and MEGATEC wall-mount units. The screens will automatically

show the relevant information for each unit. For

example, the FUSION-TEC WR Series and MEGATEC wall-mount units are equipped with a supply air

temperature sensor while the MULTI-TEC units are not.

The supply temperature measurement will only show

when displaying information from a FUSION-TEC WR

Series or MEGA-TEC wall-mount unit. Additionally,

FUSION-TEC WR Series units are equipped with an

electronic expansion valve (EEV). When connected to

a FUSION-TEC WR Series unit, an additional screen

will show pressures and temperatures affecting the

air conditioning system. MEGA-TEC wall-mount units

are equipped with two electronic expansion valves

with additional screens that show pressures and

temperatures for each EEV.

The last of the wall-mount unit’s information screens

will display the model number, serial number and

software version of the unit (see Figures 29, 30 and

31). This information is very important and could be

needed when referencing technical documentation

online or contacting Bard Technical Services.

FIGURE 29

MULTI-TEC Unit Information Screen

FIGURE 30

FUSION-TEC WR Series Unit Information Screen

FIGURE 31

MEGA-TEC Unit Information Screen

Setpoints

Setpoints allows setting and enabling of comfort mode.

Manual 2100-669F

Page 26 of 37

Page 27

Menu Screens and Password Levels

A System Config

General: User (2000)

Zone 1: User (2000)

Zone 2: User (2000)

Zone 3: User (2000)

B Adv Sys Config: Technician (1313)

C I-O Config: Technician (1313)

D On/Off: User (2000)

E Alarm Logs: User (2000)

F Settings

Date/Time: Technician (1313)

Language: User (2000)

Network Config: Technician (1313)

Serial Ports: Technician (1313)

Initialization

Clear Logs: User (2000)

System Default: Engineer (9254)

Restart: User (2000)

Parameter Config: Engineer (9254)

Alarm Export: User (2000)

Logout: Used to log out of the current password level.

G

Entering back into the menu requires a password.

Additional Programming

Changing to Celsius

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to General

Settings (A1-1); press enter key.

5. Press ENTER key to scroll to UOM (see Figure 32).

6. Press UP and DOWN keys to change value to SI.

FIGURE 32

Changing to Celsius

TABLE 1

LC6000 Passwords (Defaults)

User 2000

Technician 1313

Engineer 9254

Use UP or DOWN keys and ENTER key to enter password

TABLE 2

LC6000 Status Messages

Message Description

On The system is on

Off by Alarm

Off by BMS

Off by Keypad

Emergency

Cooling

The system has a major fault and is

disabled

The system has been disabled by

network supervisor

The system has been turned off by

local user

The system has detected a high

temperature alarm and one or more

zones are emergency cooling

Configuring Number of Units

The LC is capable of operating up to 14 wall-mount

units in up to 3 zones. This includes MULTI-TEC,

FUSION-TEC WR Series and MEGA-TEC units. Add all

units up for total number of units. Example: If there

are three MULTI-TEC units in Zone 1, two FUSION-TEC

WR units in Zone 2 and one MEGA-TEC unit in Zone 3,

the total number of units should be set to 6.

To configure the total number of units:

1. Press MENU key to go to the Main Menu screen.

2. Press UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to General

Settings (A1-1); press enter key.

5. Press ENTER key to scroll to Total Units (see

Figure 32).

6. Press UP or DOWN keys to adjust value to correct

number of units.

7. Press ENTER key to save value.

Emergency Vent

The system has detected hydrogen

and one or more zones are in

emergency ventilation

Manual 2100-669F

Page 27 of 37

Page 28

Calibrating Sensors

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to I/O Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to sensor to be

adjusted.

5. Press ENTER key to scroll to Offset.

6. Press UP or DOWN keys to add or subtract to the

sensor offset value.

7. Press ENTER key to save.

Clearing Alarm Logs

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Settings; press

ENTER key.

4. Press UP or DOWN keys to scroll to Initialization;

press ENTER key.

5. Press ENTER key to scroll to Delete Alarm Logs?

(see Figure 33).

6. Press UP or DOWN key to change value to YES;

press ENTER key.

in the respective zone will operate. These settings will

be communicated to the wall units while connected to

the LC6000 to ensure all units operate the same.

To make changes to the free cooling settings:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Zone FC

Settings A2-4 (Zone 1), Zone FC Settings A3-4

(Zone 2) or Zone FC Settings A4-4 (Zone 3).

6. Press ENTER key to scroll to Type, Enable Temp,

Enable Hum or Enable Dewp (see Figure 34).

7. Press UP and DOWN keys to adjust free cooling

values.

FIGURE 34

Configuring Free Cooling

FIGURE 33

Clearing LC6000 Alarm Logs

Configuring Free Cooling

Each zone can be configured to operate the

economizers with different considerations. For more

information on the economizer enable setpoints, please

reference the most recent version of the corresponding

wall-mount unit service manual. For MULTI-TEC, see

Service Manual 2100-665. For FUSION-TEC WR

Series, see Service Manual 2100-688. For MEGA-TEC,

see Service Manual 2100-671.

The type of consideration can be changed to none,

drybulb, temperature and humidity, or enthalpy. The

temperature, humidity and dewpoint parameters can be

changed to affect at what conditions the economizers

Enabling High Sensible Operation

The LC6000 has the option to operate the wall units in

a high sensible mode that will adjust blower speeds to

enhance the sensible cooling capacity of the units. This

option is not enabled by default and will automatically

turn off when the indoor humidity raises to the passive

dehumidification setpoint. High sensible operation will

resume once the indoor humidity has lowered to the

dehumidification off setpoint.

NOTE:

To enable high sensible operation:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

3. Press UP or DOWN keys to scroll to Sys Config;

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

This mode available only on the FUSION-TEC WR

Series and MEGA-TEC wall-mount units. It is not

available on the MULTI-TEC wall-mount units.

USER password 2000.

press ENTER key.

or Zone 3; press ENTER key.

Manual 2100-669F

Page 28 of 37

Page 29

5. Press UP or DOWN keys to scroll to Blower Profile

A2-12 (Zone 1), Blower Profile A3-12 (Zone 2) or

Blower Profile A4-12 (Zone 3).

6. Press ENTER key to scroll to Enable (see Figure

35).

7. Press UP or DOWN key to change value to YES;

press ENTER key.

FIGURE 35

Enabling High Sensible Operation

Manual 2100-669F

Page 29 of 37

Page 30

TROUBLESHOOTING

8403-079 Remote Indoor Temperature/Humidity Sensor

Troubleshooting the temperature/humidity sensor is necessary if the temperature or humidity reading for a zone is

inaccurate. Always start sensor troubleshooting by verifying connections at the sensor board and at the LC6000

terminal blocks. Improper connection will cause inaccurate readings. Next, verify continuity at both ends of wires