Bard I36Z1-A, I36Z1-B, I36Z1-C, I48Z1-A, I48Z1-B Installation Instructions Manual

...

INSTALLATION INSTRUCTIONS

MIS-3116

I-TEC SERIES

PACKAGED HEAT PUMP

Models:

I36Z1-A

I36Z1-B

I36Z1-C

I48Z1-A

I48Z1-B

I48Z1-C

I60Z1-A

I60Z1-B

I60Z1-C

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-578E

Supersedes: 2100-578D

Date: 11-10-14

Page 1 of 41

CONTENTS

Getting Other Information and Publications

For more information, contact these publishers: ........... 3

General ......................................................................... 4

ANSIZ535.5Denitions................................................ 4

I-TEC General Information

I-TEC Model Nomenclature .......................................... 5

Shipping Damage ......................................................... 8

Unit Removal From Skid ............................................... 8

Handling Unit After Removal From Skid ....................... 8

Required Steps after Final Placement ........................ 10

Minimum Installation Clearances ................................ 10

Securing Unit to Structure ........................................... 10

Seismic Considerations .............................................. 10

Rubber Mat ................................................................. 10

Duct Work ................................................................... 16

Filters .......................................................................... 16

Condensate Drain ....................................................... 17

With No Vent Option ................................................... 17

With Commercial Room Ventilator .............................. 17

Installation Instructions

Mounting the Unit ........................................................ 20

Wiring — Main Wiring .................................................. 20

Wiring — Low Voltage Wiring ...................................... 21

Low Voltage Connections ........................................... 21

Start Up

R-410A Refrigerant Required ......................................... 26

Topping Off System Charge ........................................... 26

Safety Practices.............................................................. 26

Description of Standard Equipment ................................ 26

Important Installer Note .................................................. 26

Phase Monitor ................................................................ 26

Three Phase Scroll Compressor .................................... 26

Service Hints .................................................................. 26

Sequence of Operation................................................... 27

Pressure Service Ports ................................................... 27

Defrost Cycle .................................................................. 28

I-TEC Commercial Room Ventilator System

General Description .................................................... 29

Control Wiring ............................................................. 29

Recommended Control Sequences ............................ 29

Setting the Ventilation CFM Levels ............................. 29

Annual Maintenance ..................................................... 33

Troubleshooting

Solid State HP Control Troubleshooting Procedure ....... 34

Checking Temperature Sensor ....................................... 35

Troubleshooting ECM™ 142R Motor .....................36 & 37

Replacing the Motor .......................................................37

Troubleshooting Indoor ECM™ Motor ....................38 & 39

Fan Blade Setting Dimensions ....................................... 40

Refrigerant Charge ......................................................... 40

Figures

Figure 1 Unit Dimensions ........................................... 7

Center of Gravity .......................................... 8

Figure 2A Unit on Lift .................................................... 8

Figure 2B Unit Side....................................................... 8

Wall Mounting Bracket Location ................................... 10

Bracket Wall Sect. View & Wood Framed Install ...........11

Figure 3 Compressor Shipping Bolts........................ 12

Figure 4 Removal of Air Duct ................................... 12

Figure 5A Ducted Application ..................................... 13

Figure 5B 3" Riser Application .................................... 13

Figure 5C 6" Riser Application .................................... 14

Figure 5D Req'd. Clearances & Rec. Access ............. 15

Figure 6 Supply Duct Connections ........................... 16

Figure 7 Filter Location............................................. 16

Figure 8 Drain Locations .......................................... 17

Figures 9A & 9B Unit Mounting ............................18 & 19

Figure 10 Component Location .................................. 20

Figure 11 Basic Heat Pump w/No Vent Pkg. .............. 22

Figure 12 Heat Pump w/CRV, without CO

Figure 13 Heat Pump with CRV & CO

Figure 14 Defrost Cycle .............................................. 28

Figure15 CRVMotorSpeed/CFMConguration ....... 30

Figure 16 CRV Speed Change Terminal Access ........ 31

Figure17 VentilationAirowDiagram ........................ 32

Figure 18 Control Disassembly .................................. 39

Figure 19 Winding Test ............................................... 39

Figure 20 Drip Loop.................................................... 39

Figure 21 Control Connector Motor Half .................... 40

Control .... 23

2

Control .......... 24

2

Tables

Table 1 Factory Built-In Electric Heat Table ............... 5

Table 1A Indoor Blower Performance........................... 5

Table2 Elec.Specications ....................................... 6

Center of Gravity Table .................................. 8

Table 3 Operating Voltage Range ............................ 21

Table 4 Wall Thermostats ......................................... 21

Table 5 Troubleshooting ........................................... 34

Table 6 Temperature vs Resistance of

Temperature Sensor .................................... 35

Table 7 Troubleshooting ECM™ 142R .................... 37

Table 8 Cooling Mode .............................................. 37

Table 9 Heat Pump Mode ........................................ 37

Troubleshooting ECM™ Blower Motors ....................... 40

Power Connector ......................................................... 40

Table 10A Pressures: Full Load Cooling

Table 10B Pressures: Full Load Heating

Table 11A Pressures: Part Load Cooling

Table 11B Pressures: Part Load Heating

I36Z-I60Z ..... 41

I36Z-I60Z ..... 41

I36Z-I60Z .... 41

I36Z-I60Z .... 41

Manual 2100-578E

Page 2 of 41

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually nd these

at your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation ...............ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air .......................ANSI/NFPA 90B

Heating and Air Conditioning Systems

Load Calculation for ..................... ACCA Manual J or

Winter and Summer Manual N

Air Conditioning

Low Pressure, Low Velocity ......... ACCA Manual D or

Duct System Design Manual Q

Winter and Summer Air Conditioning

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating, Refrigeration,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-578E

Page 3 of 41

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The I-TEC must be installed with the Bard

manufactured IWS wall sleeve and ILG louver

grille accessories. These are sold as separate

accessories. Any substitutions will void the

manufacturer’s warranty.

The unit is designed for use with or without ductwork.

For use without ductwork, Plenum Box IPBDFZ18color (18" height) or IPBDFZ12-color (12" height) is

recommended.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical connections to it.

These instructions and any instructions packaged

with any separate equipment required to make up the

entire heating and air conditioning system should be

carefully read before beginning the installation. Note

particularly “Start Procedure” and any tags and/or

labels attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Page 3 for information on codes and standards.

Size of unit for a proposed installation should be

based on heat loss or heat gain calculation made

according to methods of Air Conditioning Contractors

of America (ACCA). The air duct should be installed

in accordance with the Standards of the National Fire

Protection Systems of Other Than Residence Type,

NFPA No. 90A, and Residence Type Warm Air Heating

and Air Conditioning Systems, NFPA No. 90B. Where

local regulations are at a variance with instructions,

installer should adhere to local codes.

ANSI Z535.5 Denitions:

• Danger: Indicate[s] a hazardous situation which, if

not avoided, will result in death or serious injury. The

signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

• Warning: Indicate[s] a hazardous situation which,

if not avoided, could result in death or serious injury.

WARNING [signs] should not be used for property

damage hazards unless personal injury risk appropriate to

this level is also involved.

• Caution: Indicate[s] a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION [signs] without a safety alert symbol may be

used to alert against unsafe practices that can result in

property damage only.

• Notice: [this header is] preferred to address practices

not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an alternative

to “NOTICE” the word “CAUTION” without the safety

alert symbol may be used to indicate a message not

related to personal injury.

Manual 2100-578E

Page 4 of 41

I-TEC Series General Information

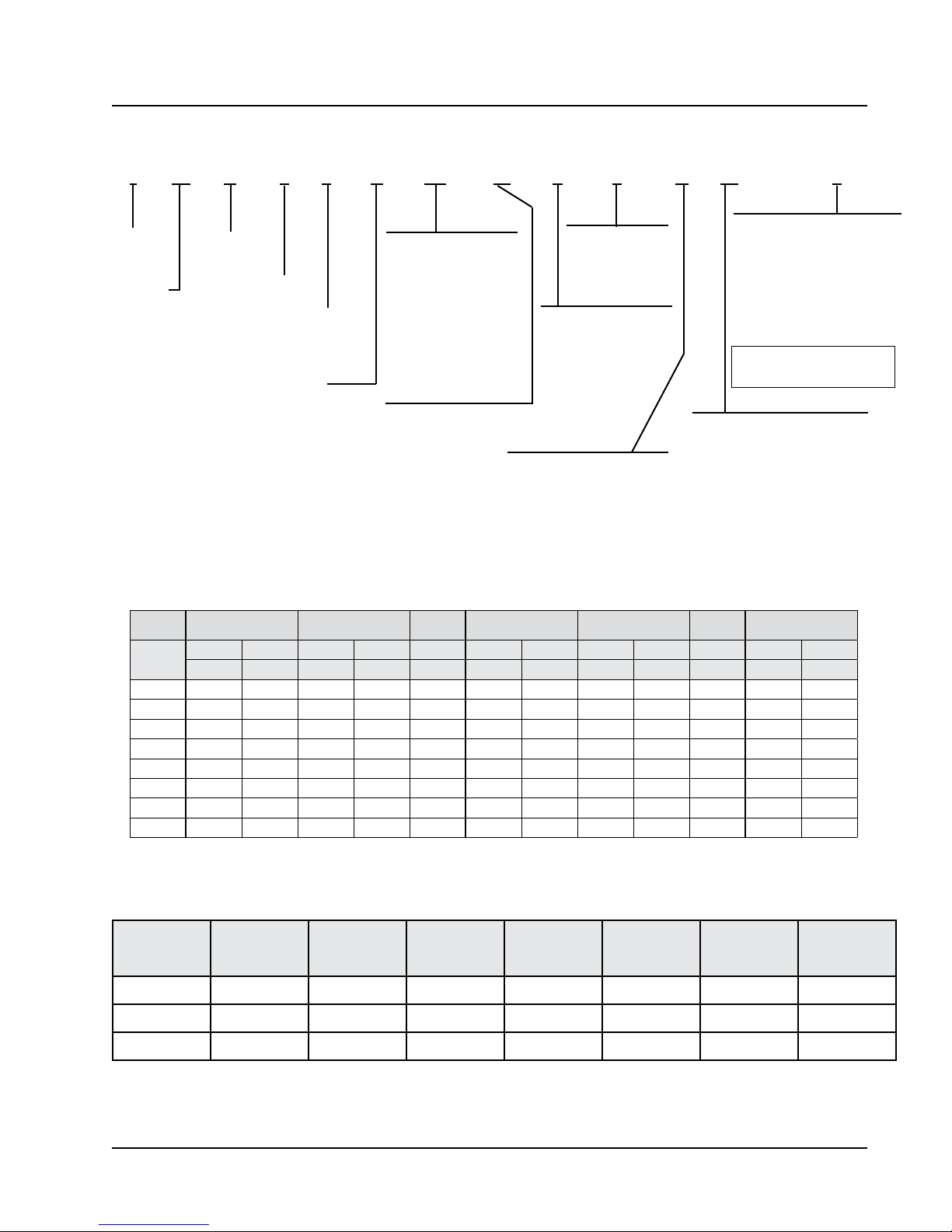

I-TEC MODEL NOMENCLATURE Z-Version (CA) 2-Stage Air Source Heat Pumps

I 36 Z 1 – A 0Z M P 1 X X 2

MODEL

SERIES

NOMINAL

CAPACITY

36 = 36,000 BTUH

48 = 48,000

60 = 60,000

SYSTEM TYPE:

H/P CA Design

REVISION

SPECIAL UNITS

(–) = Standard

C = 460V Circuit

Breaker

VOLTS & PHASE |

A = 230/208, 60-1

B = 230/208, 60-3

C = 460-60-3

ELECTRIC HEAT

0Z = No heat w/breaker

04 = 4KW 1-Phase

05 = 5KW 1-Phase

06 = 6KW 3-Phase

09 = 9KW 3-Phase

10 = 10KW 1-Phase

15 = 15KW 1 & 3-Phase

18 = 18KW 3-Phase

20 = 20KW 1-Phase

VENTILATION OPTIONS

B = Blank-Off Plate

M = Multi-Speed CRV

COLOR OPTIONS

X - Beige paint

1 - White paint

4 - Gray paint

FILTER OPTIONS

P = 2" Pleated MERV 8

M = 2" Pleated MERV 11

N = 2" Pleated MERV 13

VINYL GRAPHICS OPTIONS

X - None

A - Letter Assigned as Req'd.

CONTROLS

X = 24V Terminal Block Only w/o

CompleteStat

1 = CompleteStat THO (Temp,

Humidity & Occupancy)

2 = CompleteStat THO w/CO2

3 = CompleteStat THO w/Ethernet

4 = CompleteStat THO w/CO2 &

Ethernet

Note:CompleteStatmustbeeld

installed & wired. All units have

COIL TREATMENT

X - Std. Hydrophilic Fin Evap. &

Uncoated Alum. Cond. Coil

1 - Phenolic Coated ID Coil

2 - Phenolic Coated OD Coil

3 - Phenolic Coated ID & OD Coil

TABLE 1

FACTORY BUILT-IN ELECTRIC HEAT TABLE

Models I36Z1-A I36Z1-B I36Z1-C I48Z1-A

KW

10.0 34,130 25,598 34,130 25,598 34,130 25,598

15.0 51,195 38,396 51,195 38,396 51,195 51,195 38,396 51,195 38,396 51,195 51,195 38,396

18.0 61,434 46,076 61,434

20.0 68,260 51,195 68,260 51,195

240V-1 208V-1 240V-3 208V-3 460V-3 240V-1 208V-1 240V-3 208V-3 460V-3 240V-1 208V-1

BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH

4.0 13,652 10,239

5.0 17,065 12,799 17,065 12,799 17,065 12,799

6.0 20,478 15,359 20,478 20,478 15,359 20,478

9.0 30,717 23,038 30,717 30,717 23,038 30,717

I48Z1-B

I60Z1-B

I48Z1-C

I60Z1-C

24V terminal block.

I60Z1-A

Model Rated ESP Max. ESP

I36Z1

I48Z1

I60Z1

.15 0.50 600 1150 850 700 1400

.20 0.50 725 1500 1050 700 1400

.20 0.50 850 1700 1200 700 1400

Motor will deliver consistent CFM through voltage supply range with no deterioration.

kContinuous fan CFM is the total air being circulated during continuous fan mode.

lWilloperateatratedFullLoadAirowwhenoperatingwithHeatPump.

mWill occur automatically with a call for "W3" or "Emergency Heat" signal from the thermostat (Heat Pump Operation is terminated at this condition).

TABLE 1A

INDOOR BLOWER PERFORMANCE

k

Continuous

CFM

Rated 2nd

Stage CFM

Rated 1st

Stage CFM

l

5 - 9 KW

CFM

13.5 - 18

KW CFM

Manual 2100-578E

Page 5 of 41

m

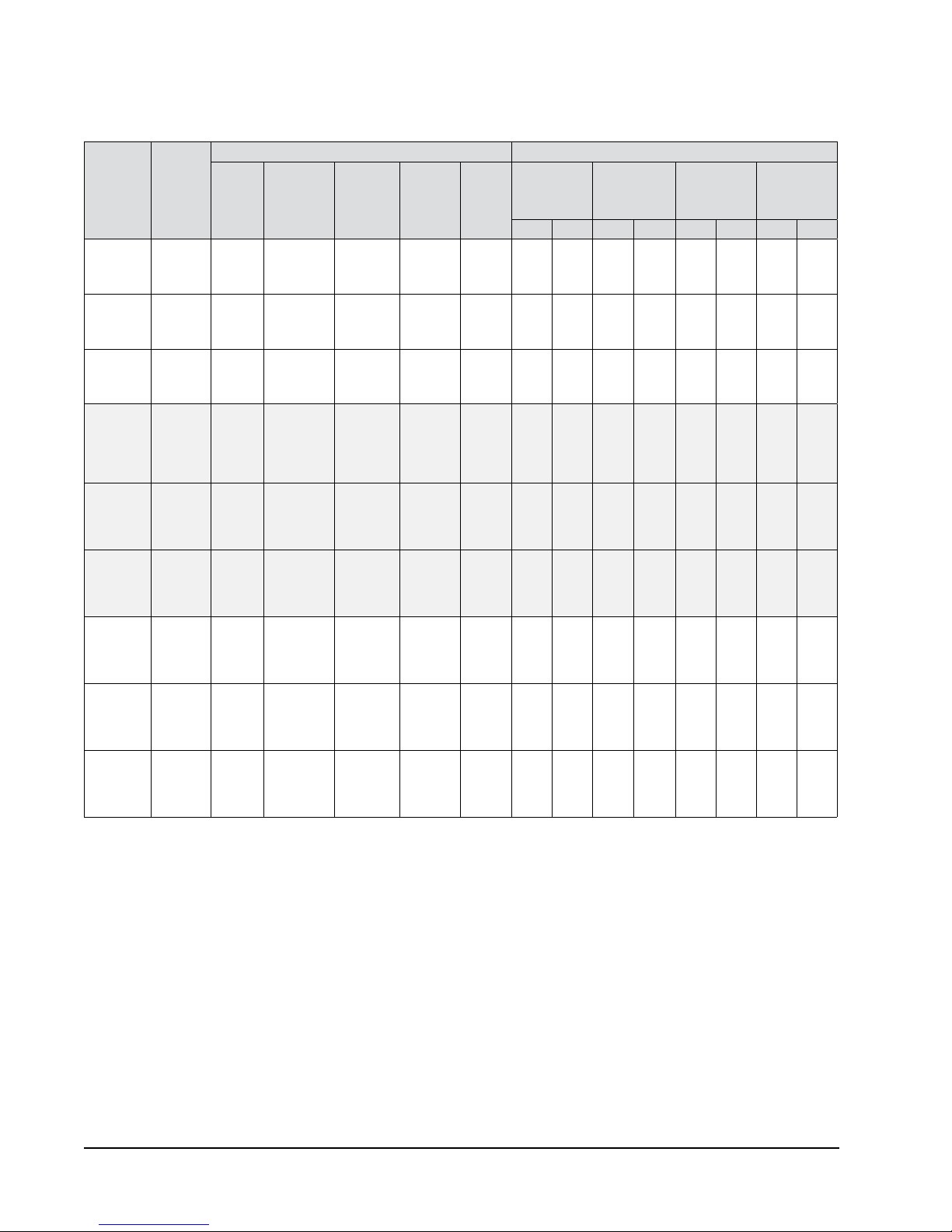

TABLE 2

ELECTRICAL SPECIFICATIONS

Single Circuit Multiple Circuit

Rated

MODEL

Volts,

Hertz &

Phase

I36Z1-A0Z

A05

230/208-1

A10

A15

I36Z1-B0Z

B06

230/208-3

B09

B15

I36Z1-C0Z

C06

460-3

C09

C15

I48Z1-A0Z

A04

A05

230/208-1

A10

A15

A20

I48Z1-B0Z

B06

230/208-3

B09

B15

B18

I48Z1-C0Z

C06

230/208-1

C09

C15

C18

I60Z1-A0Z

A05

230/208-1

A10

A15

A20

I60Z1-B0Z

B06

230/208-3

B09

B15

B18

I60Z1-C0Z

C06

460-3

C09

C15

C18

These“MinimumCircuitAmpacity”valuesaretobeusedforsizingtheeldpowerconductors.RefertotheNationalElectricCode(latestrevision),Article310forpowerconductorsizing.

Caution: Whenmorethanoneeldpowerconductorcircuitisrunthroughoneconduit,theconductorsmustbederated.Payspecialattentiontonote8oftable310regarding

Ampacity Adjustment Factors when more than three (3) current carrying conductors are in a raceway.

MaximumsizeofthetimedelayfuseorHVACtypecircuitbreakerforprotectionofeldwiringconductors.

Based on 75°C copper wire. All wiring must conform to the National Electrical Code and all local codes.

Maximum KW that can operate with the heat pump is 10KW for 1-Phase and 9KW for 3-Phase.

Represents Electric Heat only. Electric Control Circuit will lock-out Heat Pump Operation.

No.

Field

Power

Circuits

1

1

1 or 2

1 or 2

1

1

1

1

1

1

1

1

1

1

1 or 2

1 or 2

1 or 2

1 or 2

1

1

1

1

1

1

1

1

1

1

1

1 or 2

1 or 2

1 or 2

1 or 2

1

1

1

1

1 or 2

1

1

1

1

1

Minimum

Circuit

Ampacity

26

52

78

84

22

40

49

51

11

20

24

28

34

54

59

85

85

110

26

44

53

53

53

15

25

29

29

29

44

70

96

96

112

31

49

58

58

63

15

25

29

29

29

Maximum

External

Fuse or

Ckt. Brkr.

40

60

80

90

30

45

50

60

15

20

25

30

50

60

70

90

90

110

35

50

60

60

60

20

30

30

30

30

60

80

100

100

120

45

60

60

60

70

20

30

30

30

30

Field

Power

Wire

Size

8

6

4

4

10

8

8

6

14

12

10

10

8

6

6

3

3

2

8

8

6

6

6

12

10

10

10

10

8

4

3

3

2

8

8

6

6

6

12

10

10

10

10

Ground

Wire

10

10

10

10

10

10

14

12

10

10

10

10

10

10

10

10

10

12

10

10

10

10

10

10

10

10

10

12

10

10

10

10

Minimum

Circuit

Ampacity

Ckt. A Ckt. B Ckt. A Ckt. B Ckt. A Ckt. B Ckt. A Ckt. B

8

26265252404060

8

8

35

8

35

8

35

6

59

8

44

8

44

8

44

6

60

8 31 54 45 60 8 6 10 10

26

52

52

52

26

52

52

52

Maximum

External

Fuse or Ckt.

Breaker

60

45

30

45

60

45

60

60

60

60

30

60

60

60

60

60

60

Field Power

Wire Size

8

6

8

6

8

10

8

6

8

6

6

6

8

10

8

6

8

6

6

6

Ground Wire

Size

101010

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

Manual 2100-578E

Page 6 of 41

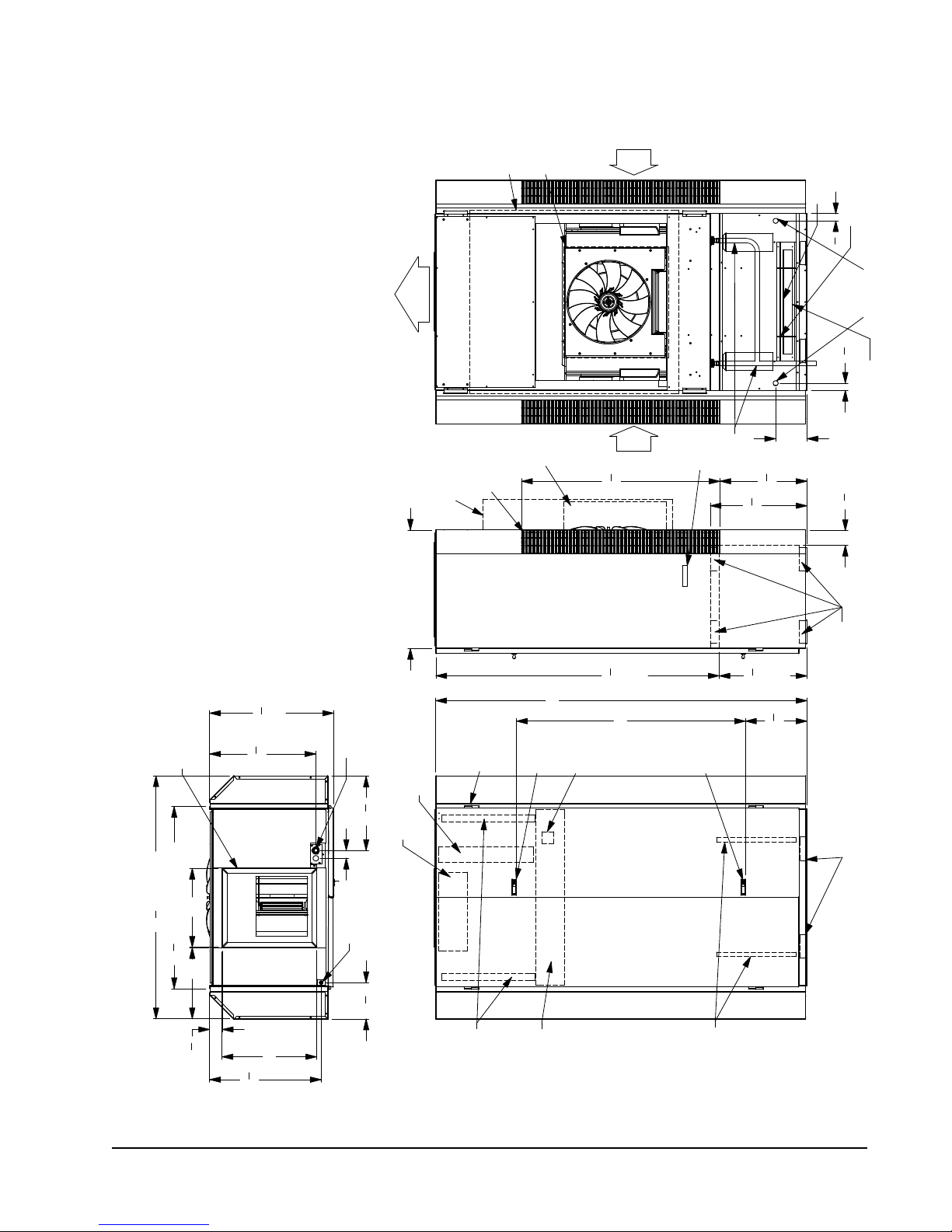

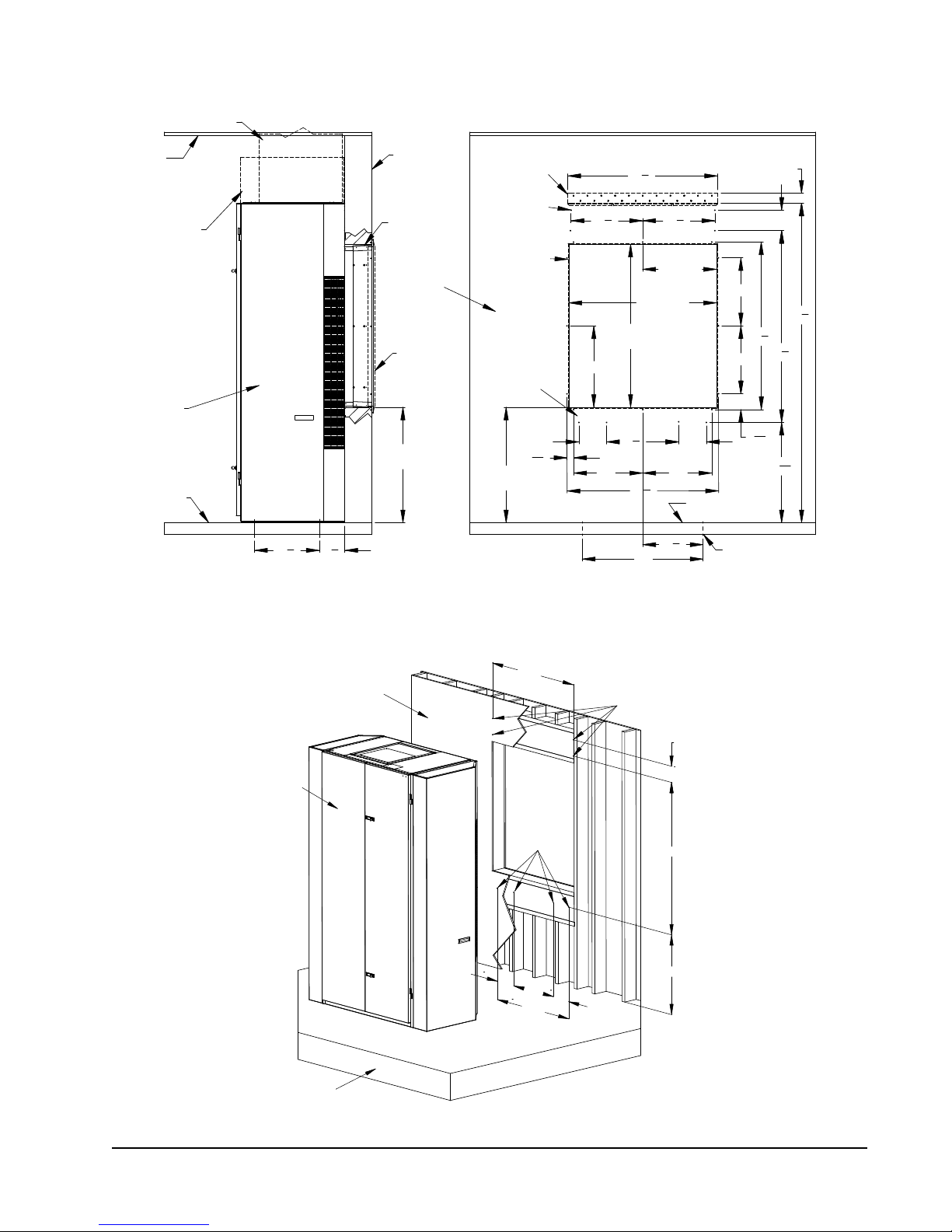

Back View

Air

Supply

Sleeve

Outer

Inner

Sleeve

Air

Return

RUBBER MATT

PART #5451-027

MIS-3114 A

WIRE TIES

PART #7950-031

"

3

4

1

(2) Opt.

Unit Drain

Entrances

"

4

3

1

Unit Specification Sheet

"

3

8

31

FIGURE 1 — UNIT DIMENSIONS

20" x 24" Supply Frame

"

7

26

Total Depth

8

Right Side View

High Voltage

Entrance

"

4

3

18

2"

Sides Removed

30" With Doors and

Wire Channel

Electric Heat

Outer

Sleeve

Openings

(2) Return

Hinges

(4) Lift-Off

Inner

Sleeve

94"

Locking

Door Latch

Return

Electrical

Disconnect

Air

" 50

1

4

"

3

4

71

Upper

Section

(2) Side

Handles

Drains

(2) Unit

58"

Door Latch

Locking

8"

"

8

1

22

"

1

2

24

"

1

4

22

Lower

Section

" 15

5

8

RUBBER MATT &

FRONT TRIM LOCATION

"

3

4

3

(Remove Sides)

Side Forklift Holes

Front Forklift Holes

(Remove Front Trim)

2

20" 18"

61 " Total Width

" With Sides Removed

1

8

46

"

1

4

3

Top View

24"

"

4

1

28

Entrance

Low Voltage

"

1

4

9

Front View

Filters

Return Air

(2) 2"x24"x30"

Control Panel

Air Filters

(2) 16" x 25"

Vent Exhaust

Manual 2100-578E

Page 7 of 41

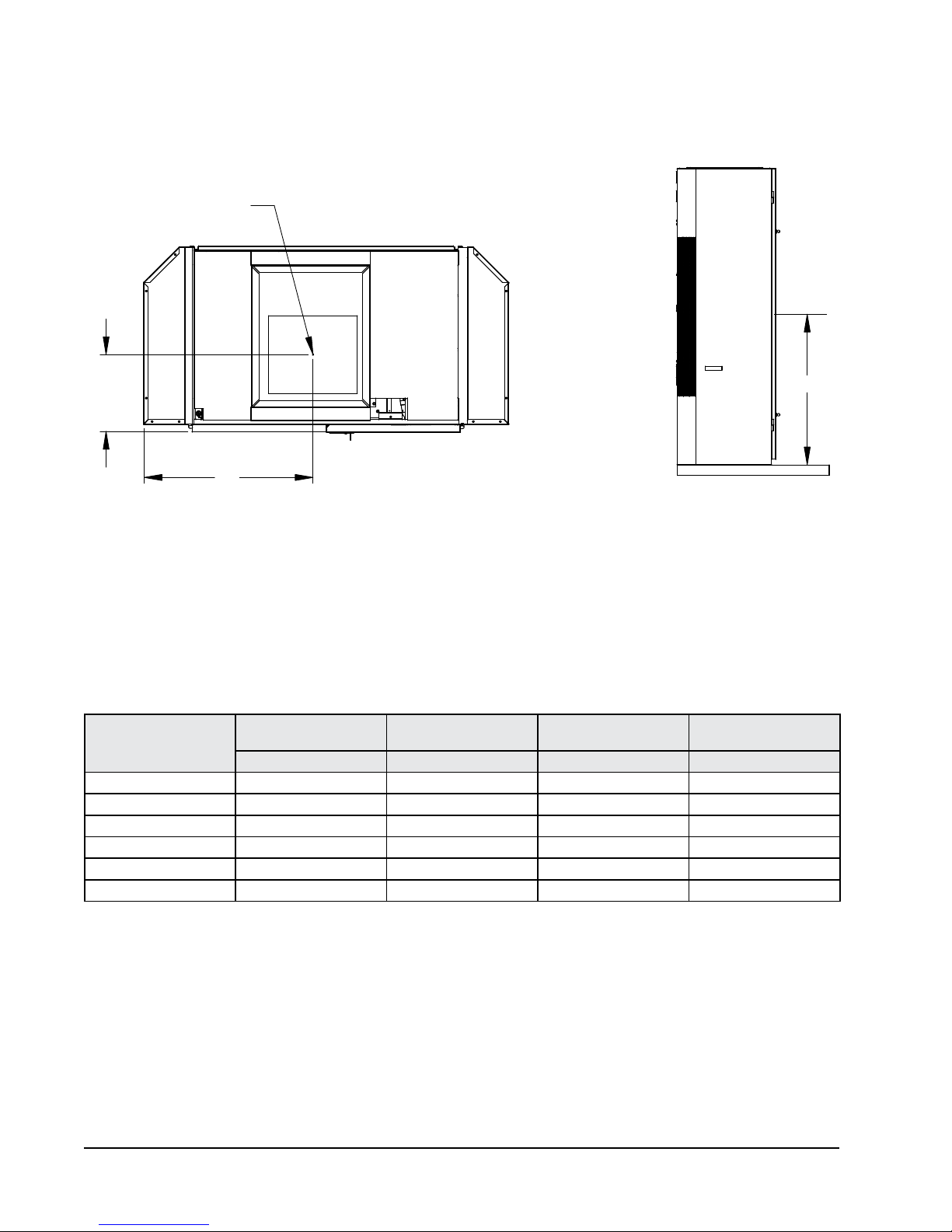

CENTER OF GRAVITY

CENTER OF GRAVITY

"X"

"Y"

FRONT OF UNIT

Unit Tested

I36Z1-A, B 13½" 31" 43½" 47"

I36Z1-C 13½" 31½" 43½" 47"

I48Z1-A, B 13½" 31" 43½" 47"

I48Z1-C 13½" 31½" 43½" 47"

I60Z1-A, B 13½" 31" 43½" 47"

I60Z1-C 13½" 31½" 43½" 47"

DOOR TO CENTER

"X" Dimension "Y" Dimension "Z" Dimension "Z" Dimension

LEFT SIDE

TO CENTER

FLOOR TO CENTER

CRV & ERV

FLOOR TO CENTER

NO VENT

"Z"

MIS-3268

Manual 2100-578E

Page 8 of 41

SHIPPING DAMAGE

Upon receipt of equipment, the unit should be checked

for external signs of shipping damage. The skid must

remain attached until the unit is ready for installation.

If damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

UNIT REMOVAL FROM SKID

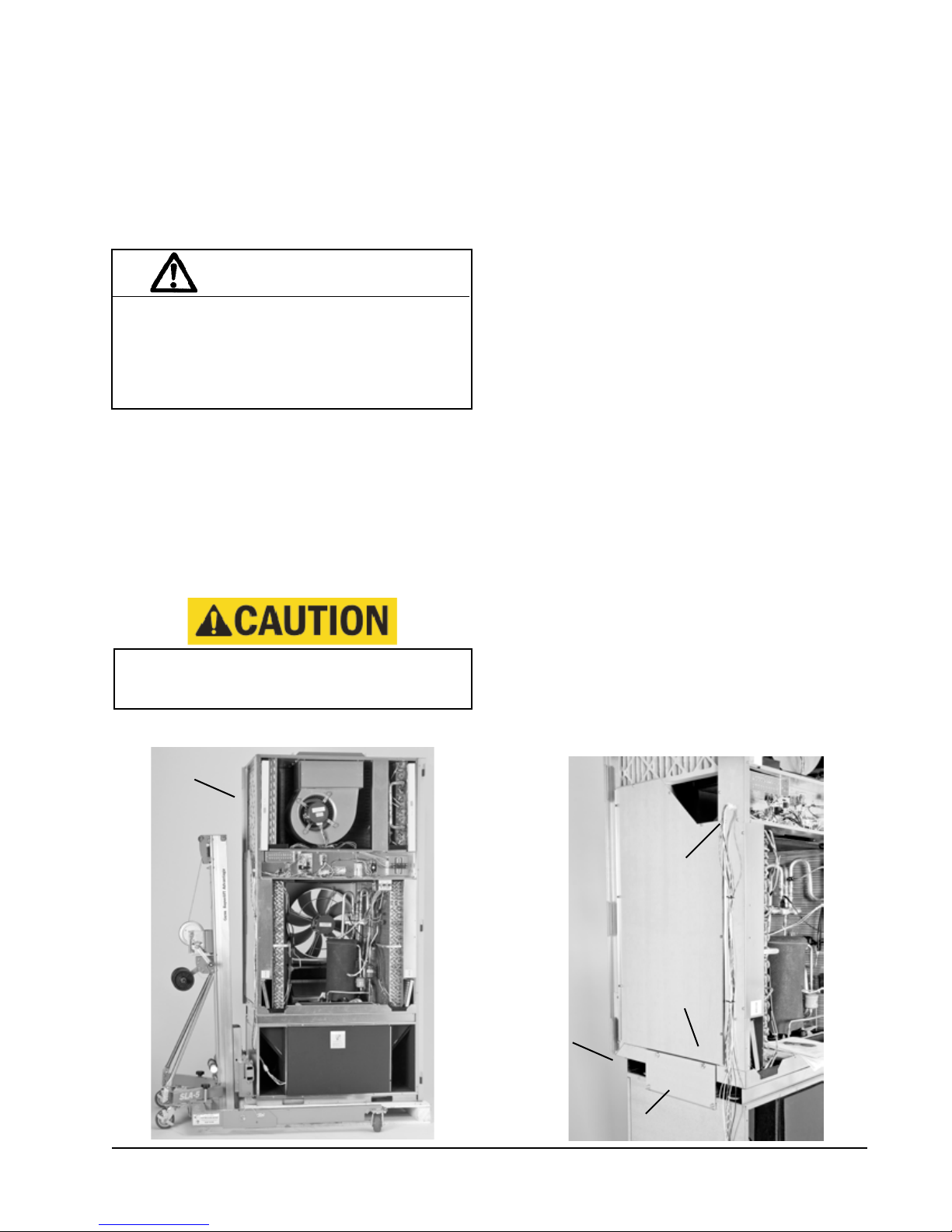

WARNING

This unit is heavy and requires more than one person

to handle during installation and removal from the

skid. Extreme caution must be taken to prevent injury

to personnel and damage to the unit. Use appropriate

safety equipment, including gloves when handling.

Failure to do so may result in serious injury.

A forklift or a lift rated for the load (Figure 2A) is

required to lift the unit off from the skid. This unit is

top heavy and should never be tipped while moving it.

The I-TEC is designed to be lifted off the skid from the

front or rear of the unit without having to remove any

doors or side panels. See Figure 1 for fork openings.

The shipping brackets on front and rear of the unit must

be removed and discarded. The unit can now be lifted

straight up and the skid can be slid out from underneath.

Tip unit from left side only.

Failure to do so may result in injury due to unit

top-heaviness or compressor damage!

HANDLING UNIT AFTER REMOVAL FROM SKID

If a wide and tall opening exists, the I-TEC can be moved as a

complete assembled unit. If not, use the following directions for

dis-assembly to allow it to pass through a 36" wide door.

1. Depress and release both top & bottom door latches and

open doors.

2. Remove doors by lifting straight up & off from the hinge pins.

3. Remove cabinet sides by rst removing the four (4) sheet metal

screws from the front (leading edge) of the side panel. The panel

will not fall off. Swing the panel away from the chassis 20-30

degrees & then pull forward from the two (2) tabs supporting

the rear edge. At this point, the unit can be tipped on its left

side enough to get dolly carts under it. Use dolly carts to

move unit into installation area. Use care not to damage

vent wire harness. This method is not suggested due to unit

weight and if a forklift or unit lift is available, continue with

the following steps for separation of top section & bottom base.

4. On each side of the unit is a tie plate that secures the top &

bottom sections with four (4) cap bolts. Using a ½" wrench

or socket, remove these screws from both plates & set aside.

5. If the unit is equipped with a CRV, you must unplug the

wire harness on the left-hand side of the control box.

6. A forklift or a lift rated for the load is required to lift the

top section off from the bottom base. Do not attempt to

do this manually! Failure to do so could result in the

unit tipping over & causing bodily injury &/or damage to

the unit.

7. The top section can be forked from either the RH or LH

side. See Figure 1 for fork openings.

8. Carefully lift the top section straight up avoiding tipping.

9. Move the top section through the doorway & place on at

surface free of debris.

10. The bottom base can now be moved through the doorway

the same way.

11. Reassemble the unit by reversing this procedure.

FIGURE 2A UNIT ON LIFT

LEFT

SIDE

of

UNIT

FIGURE 2B UNIT SIDE

CRV

(4) CAP BOLTS

FORK OPENING

(Visible after

removing tie plate)

HARNESS CONNECTION

(Covers entire width; shortened for illustration

purposes to show Fork Openings)

TIE PLATE

Manual 2100-578E

Page 9 of 41

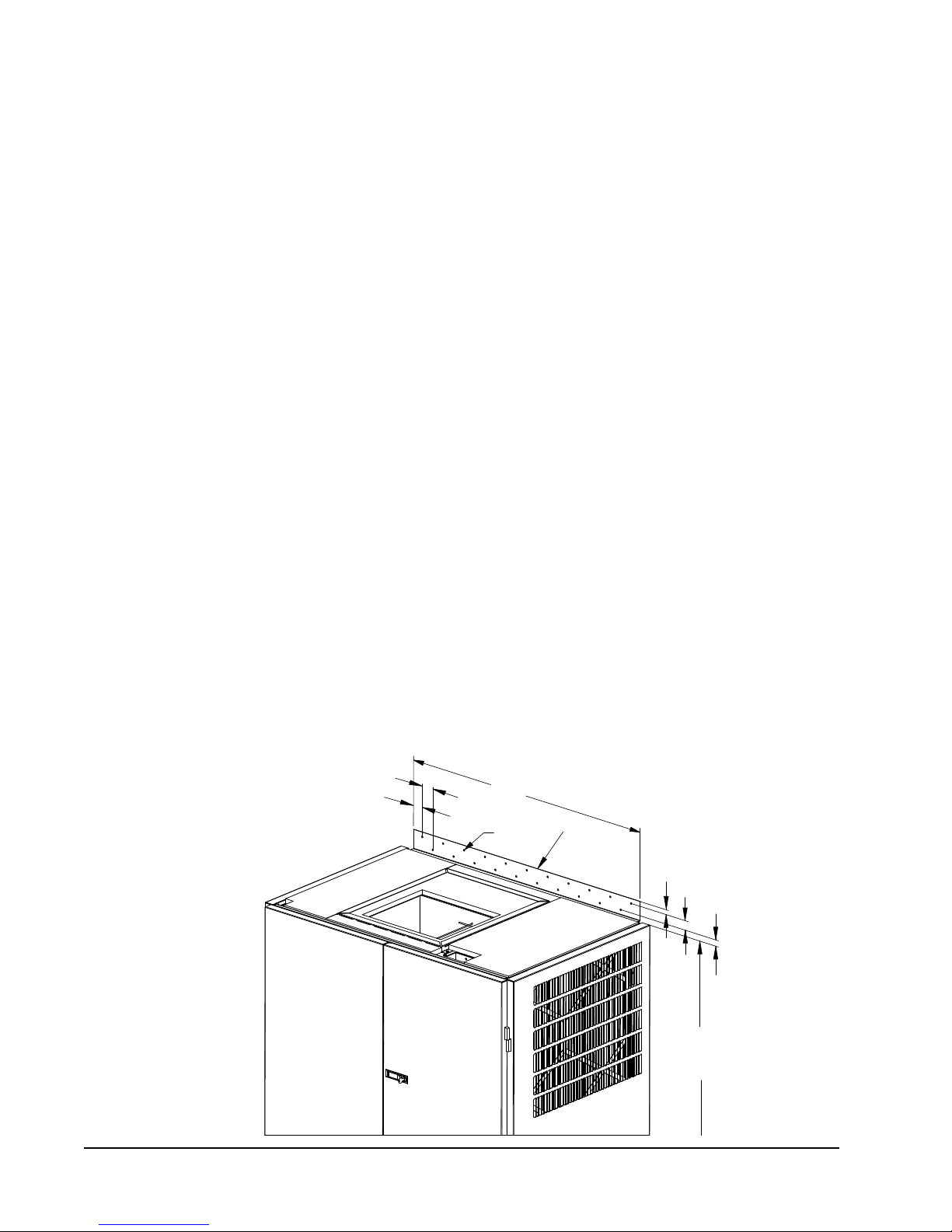

REQUIRED STEPS AFTER FINAL PLACEMENT

MIS-3029

2"

1 11/16"

43 3/8"

Ø1/4"

94" FROM BOTTOM

OF BRACKET TO

FLOOR WITHOUT

RISER KIT

7/8"

3/4"

1 1/2"

BRACKET

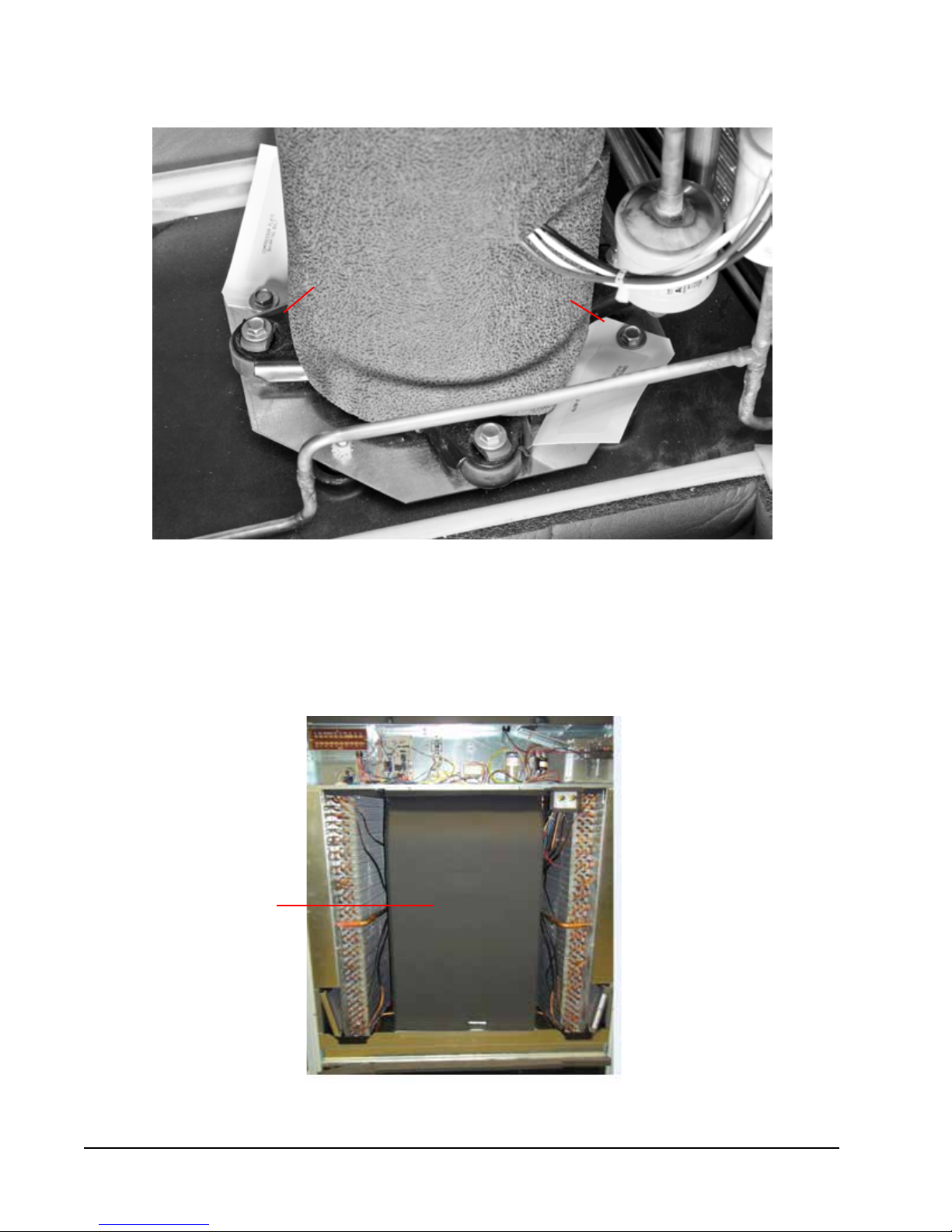

The compressor is secured to the base with two (2) bolts

for shipping. Although the unit will perform as designed

with the shipping bolts in place, there may be noticeable

additional noise and vibration noted. To obtain the lowest

noise and vibration levels, remove the shipping bolts after

the unit is in its nal operating location. To gain access

to the compressor, the compressor access panel must be

removed (Figure 7). Once this panel is removed, the CRV

air duct must be removed. See Figure 4.

The air duct is removed by pulling it straight toward you;

there are no screws securing it in place. Both the top and

bottom slide toward you at the same time (pull hard).

Once removed, the compressor is visible as well as the

tags on the shipping bolts (Figure 3).

After the compressor shipping bolts have been removed,

the CRV air duct can be slid back in place and the

compressor access panel attached.

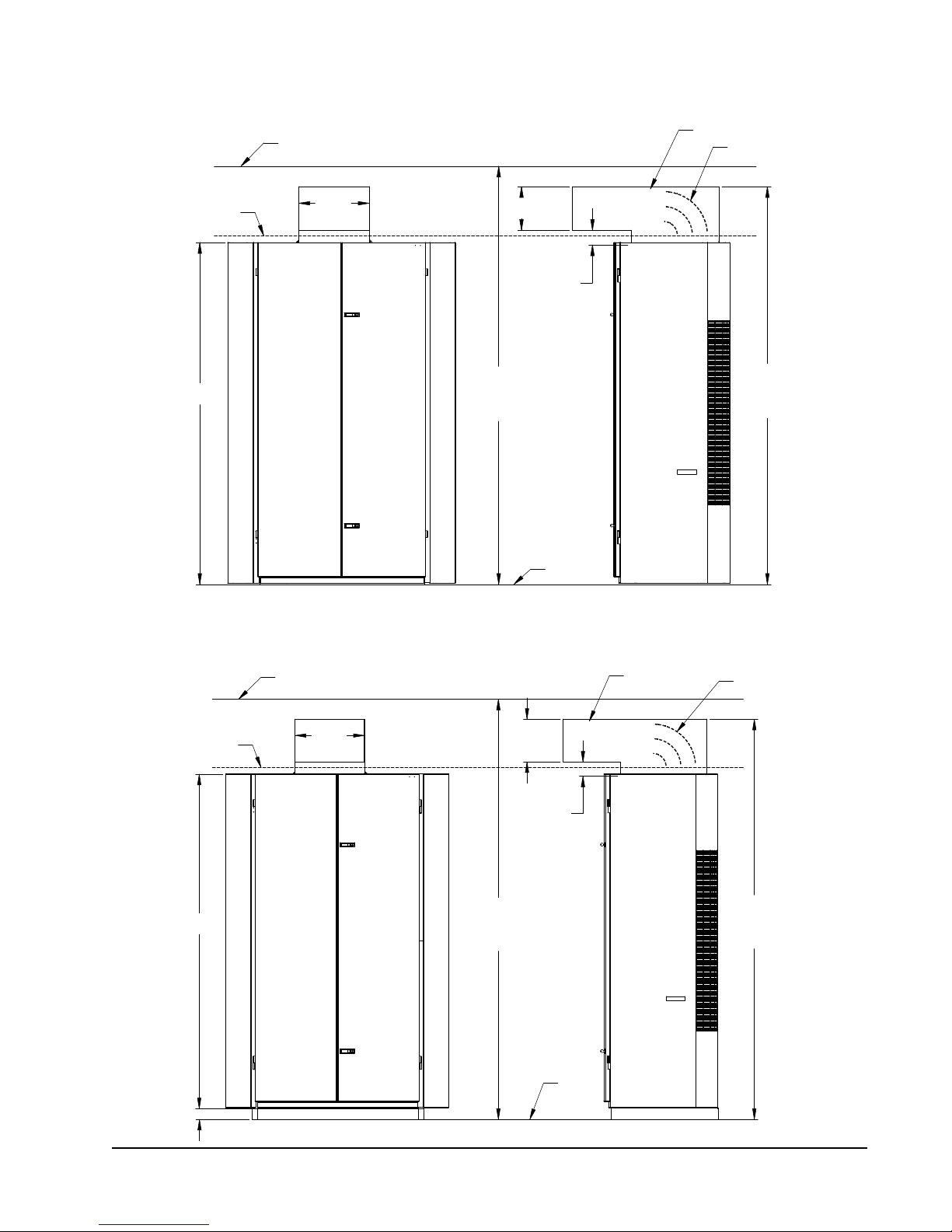

MINIMUM INSTALLATION CLEARANCES

The minimum installation height to the bottom of the

roof or xed ceiling for ducted applications is 9 ft. 7 in.

This provides enough clearance to install the duct work.

See Figure 5A.

The IWS Series wall sleeve has a built-in vertical

adjustment to t window sill heights from 31-34 inches.

If additional height is required, two riser platform

accessories are available. The IRZ3 increases the

unit height by 3 inches (Figure 5B) and the IRZ6 by 6

inches (Figure 5C).

Several construction options are available for unit

installation of the IZ Series. Serviceability and lter

access must be considered before installing. See Figure

5D for required clearances and recommended service

access dimensions.

SECURING UNIT TO STRUCTURE

Shipped with the I-TEC unit is a wall mounting bracket

(screwed to shipping skid on backside of unit). This bracket

can be utilized to secure the top portion of the unit to the

wall using the appropriate eld supplied hardware based

upon the material you are fastening to. (There are several

offset holes, sized to accept up to a 1/4" diameter fastener

that will easily allow you to hit studs on a framed wall.) See

BRACKET SECTION VIEW (Page 10) for locating this top

wall bracket which will need to be applied after the unit is

located in the nal position.

Additional/optional mounting holes for up to a 3/8"

diameter fastener are also available in the backside and

base of the unit. These can be accessed by:

• removing the air lters (uppermost set)

• removing the compressor section service door (lower set)

• removing vent door and vent partitions (base set)

Refer to WOOD FRAMED INSTALLATION (Page 10) for

additional framing required to secure unit to wall.

The additional/optional mounting holes will require a

long extension to drive the fasteners.

SEISMIC CONSIDERATIONS

The I-TEC product features several locations for product

securement but all site conditions are different. Consult

with a licensed Seismic Engineer to advise of particular

needs when attaching the I-TEC unit to the structure.

RUBBER MAT

Unit rests on rubber mat placed under base rails during

installation. Place mat on oor ush with wall and

centered over wall opening.

WALL MOUNTING

BRACKET LOCATION

Manual 2100-578E

Page 10 of 41

35"

17

1

2

"

"

3

4

18 7

3

8

"

(4) optional Unit

Mounting holes

C

L

C

L

Mounting holes

(4) optional Unit

Bracket

*

** Separate telescoping sleeves available for different wall thicknesses.

Centered on

Optional Top

*

* Higher Sill Heights Acheivable With Base Kit.

Opening

Wall

Room Floor Level

Outside

Sleeve Mounting

Hole Locations

FLOOR MOUNTING HOLE

& CENTERLINES

8

20

7

6"

8

20 "

2

32

1

7

"

"29

"

17

8"

56

8"

20

7

8

"

8

""94

1

31" Min.

20"

34" Max.

3"

1

48-1/2" Max.

48" Min.

3

Centered

8

Centered

43-1/4" Max.

"

49

16

8

"

20"

20"

20"

43

7

42-3/4" Min.

"

16

11

15

4

43

3

8

"

Duct

Grille

Floor

Optional

Outside

Ceiling

Wall Sleeve**

Telescoping

Wall

Unit

Optional

Trim or

Supply Duct

Box

31" Min.

34" Max.

C

L

Wall Section View

Right Side View

Front (Wall Only) View

C

L

MIS-3196 A

6.00

41.75

56.50

29.568.00

8.0036.88

20.88

MIS-3197

(4) lower fastener

holes

Floor

riser kit. If unit uses riser kit add

appropriate dimension to height.

Inner wall

Unit

*

(4) Upper

fastener holes

* Height dimension shown without

BRACKET WALL SECTION VIEW

WOOD FRAMED INSTALLATION (for Wall Attachment)

Manual 2100-578E

Page 11 of 41

COMPRESSOR SHIPPING BOLTS

COMPRESSOR

SHIPPING BOLT

FIGURE 3

COMPRESSOR

SHIPPING BOLT

CRV

AIR DUCT

FIGURE 4

REMOVAL OF AIR DUCT

Manual 2100-578E

Page 12 of 41

INSTALLATION

9'-5"

MINIMUM

REQUIRED

HEIGHT

9'-10" MINIMUM

CLEARANCE

RECOMMENDED TO

BOTTOM OF ROOF

OR FIXED CEILING

3" RISER

FIELD SUPPLIED DUCT

MIS-3199

TURNING VANES

RECOMMENDED

MINIMUM

12"

4" MINIMUM FROM

TOP OF UNIT TO

DUCT BOTTOM

BOTTOM OF ROOF

FLOOR

OR FIXED CEILING

SUSPENDED

CEILING

20"

MINIMUM

7'-9 3/4"

UNIT HEIGHT

9'-7" MINIMUM

CLEARANCE

RECOMMENDED TO

BOTTOM OF ROOF

OR FIXED CEILING

9'-2"

MINIMUM

REQUIRED

INSTALLATION

HEIGHT

BOTTOM OF ROOF

FLOOR

OR FIXED CEILING

SUSPENDED

CEILING

20"

MINIMUM

7'-9 3/4"

UNIT HEIGHT

FIELD SUPPLIED DUCT

MIS-3198

TURNING VANES

RECOMMENDED

MINIMUM

12"

4" MINIMUM FROM

TOP OF UNIT TO

DUCT BOTTOM

FIGURE 5A

DUCTED APPLICATION – BASIC UNIT

FIGURE 5B

3" RISER APPLICATION

Manual 2100-578E

Page 13 of 41

Loading...

Loading...