INSTALLATION INSTRUCTIONS

MIS-3116

I-TEC SERIES

PACKAGED HEAT PUMP

Models:

I36Z1-A

I36Z1-B

I36Z1-C

I48Z1-A

I48Z1-B

I48Z1-C

I60Z1-A

I60Z1-B

I60Z1-C

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-578E

Supersedes: 2100-578D

Date: 11-10-14

Page 1 of 41

CONTENTS

Getting Other Information and Publications

For more information, contact these publishers: ........... 3

General ......................................................................... 4

ANSIZ535.5Denitions................................................ 4

I-TEC General Information

I-TEC Model Nomenclature .......................................... 5

Shipping Damage ......................................................... 8

Unit Removal From Skid ............................................... 8

Handling Unit After Removal From Skid ....................... 8

Required Steps after Final Placement ........................ 10

Minimum Installation Clearances ................................ 10

Securing Unit to Structure ........................................... 10

Seismic Considerations .............................................. 10

Rubber Mat ................................................................. 10

Duct Work ................................................................... 16

Filters .......................................................................... 16

Condensate Drain ....................................................... 17

With No Vent Option ................................................... 17

With Commercial Room Ventilator .............................. 17

Installation Instructions

Mounting the Unit ........................................................ 20

Wiring — Main Wiring .................................................. 20

Wiring — Low Voltage Wiring ...................................... 21

Low Voltage Connections ........................................... 21

Start Up

R-410A Refrigerant Required ......................................... 26

Topping Off System Charge ........................................... 26

Safety Practices.............................................................. 26

Description of Standard Equipment ................................ 26

Important Installer Note .................................................. 26

Phase Monitor ................................................................ 26

Three Phase Scroll Compressor .................................... 26

Service Hints .................................................................. 26

Sequence of Operation................................................... 27

Pressure Service Ports ................................................... 27

Defrost Cycle .................................................................. 28

I-TEC Commercial Room Ventilator System

General Description .................................................... 29

Control Wiring ............................................................. 29

Recommended Control Sequences ............................ 29

Setting the Ventilation CFM Levels ............................. 29

Annual Maintenance ..................................................... 33

Troubleshooting

Solid State HP Control Troubleshooting Procedure ....... 34

Checking Temperature Sensor ....................................... 35

Troubleshooting ECM™ 142R Motor .....................36 & 37

Replacing the Motor .......................................................37

Troubleshooting Indoor ECM™ Motor ....................38 & 39

Fan Blade Setting Dimensions ....................................... 40

Refrigerant Charge ......................................................... 40

Figures

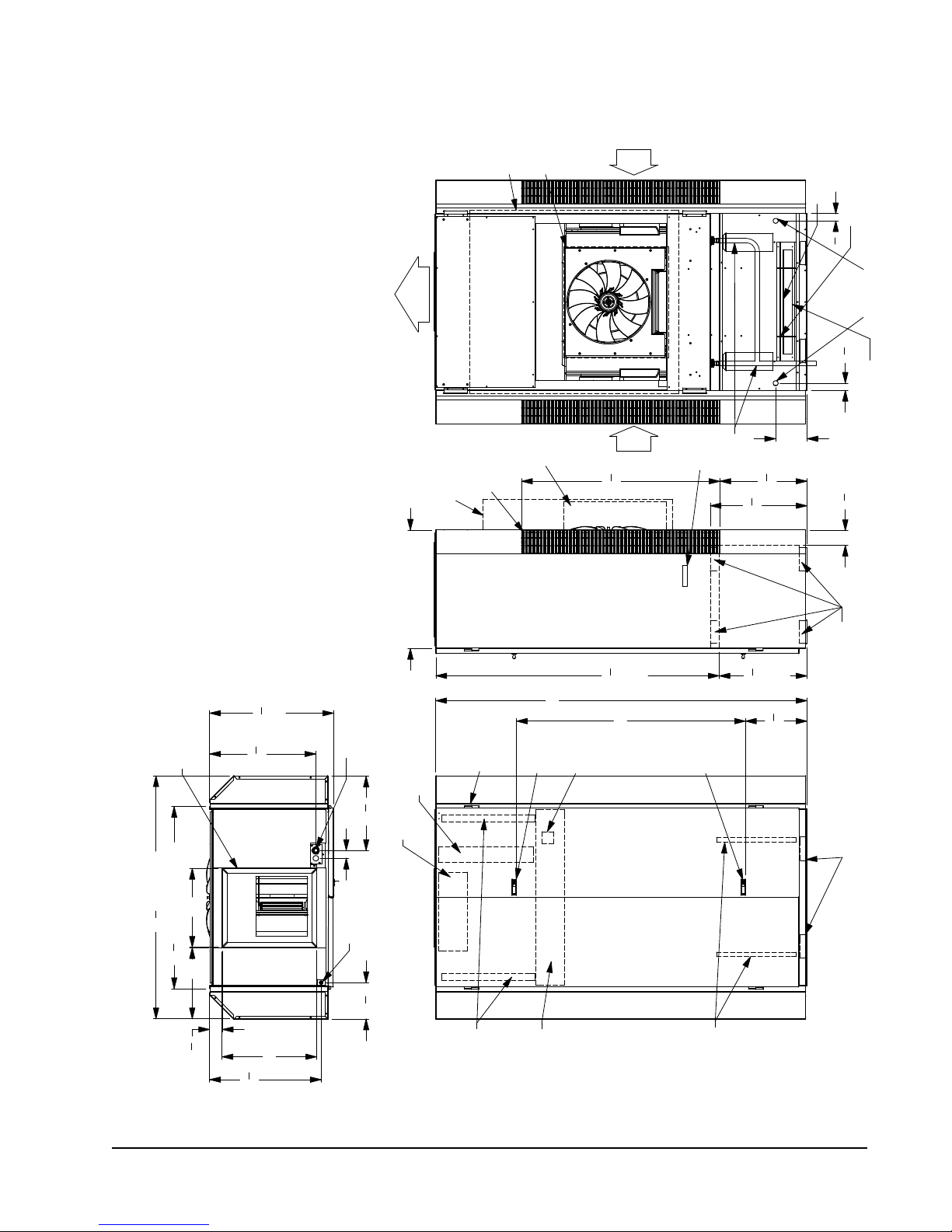

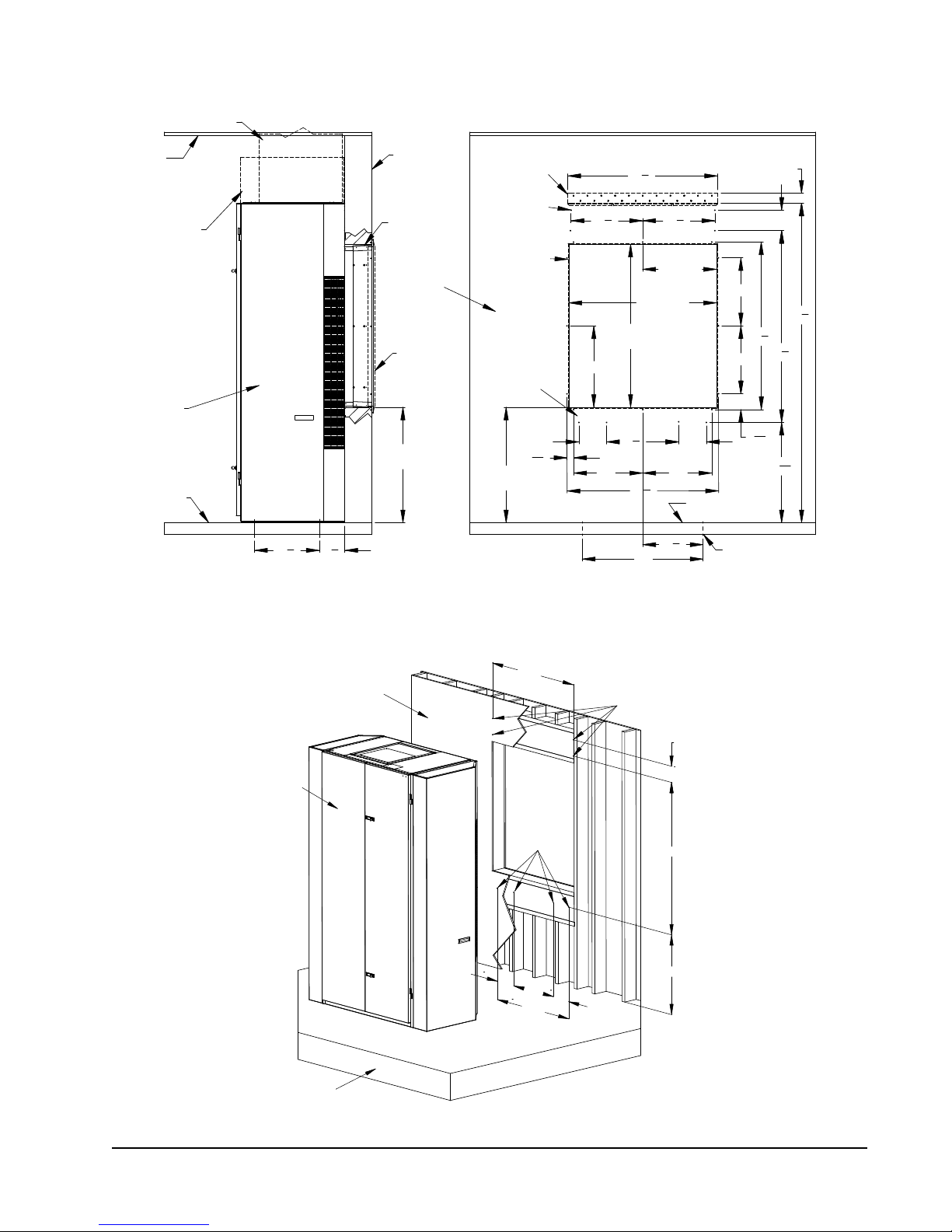

Figure 1 Unit Dimensions ........................................... 7

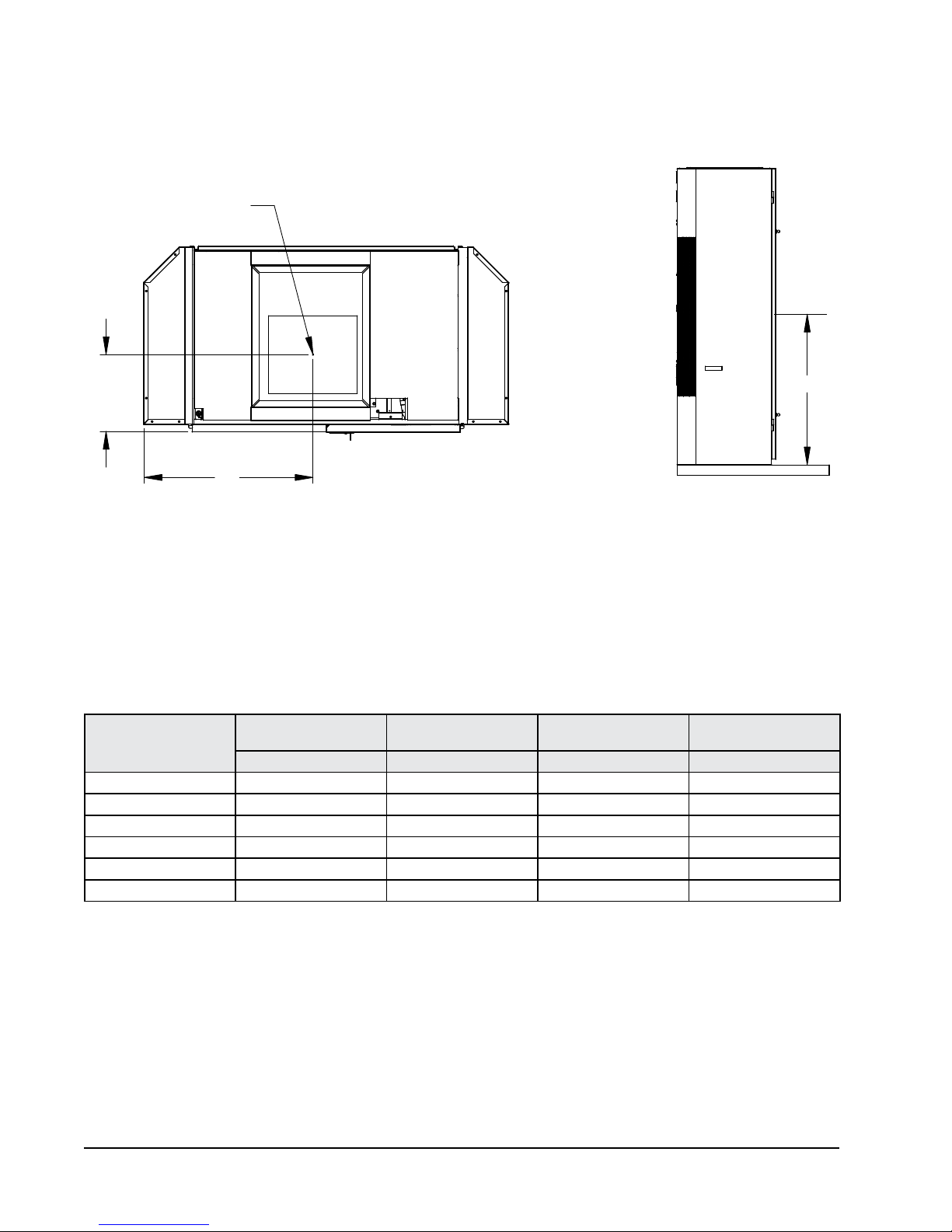

Center of Gravity .......................................... 8

Figure 2A Unit on Lift .................................................... 8

Figure 2B Unit Side....................................................... 8

Wall Mounting Bracket Location ................................... 10

Bracket Wall Sect. View & Wood Framed Install ...........11

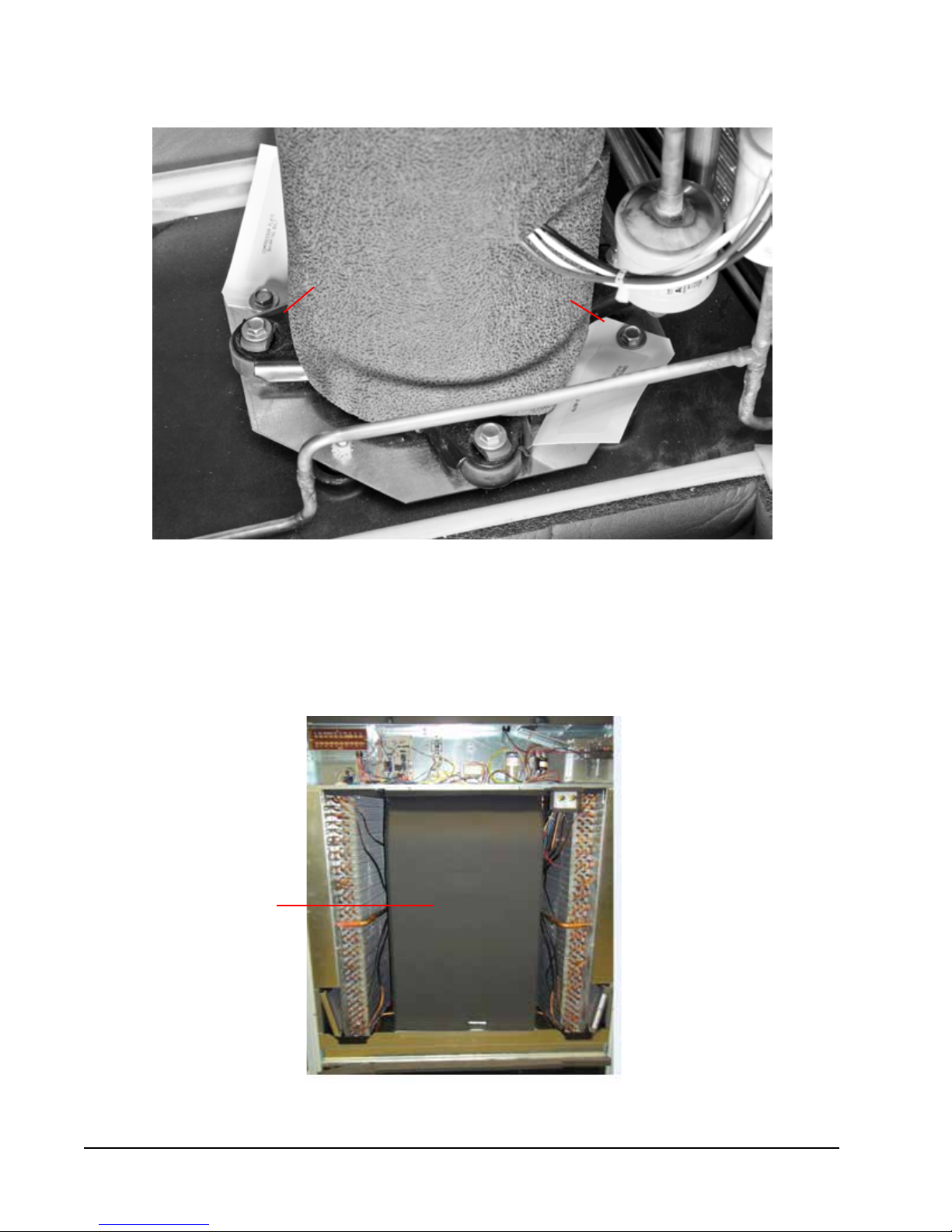

Figure 3 Compressor Shipping Bolts........................ 12

Figure 4 Removal of Air Duct ................................... 12

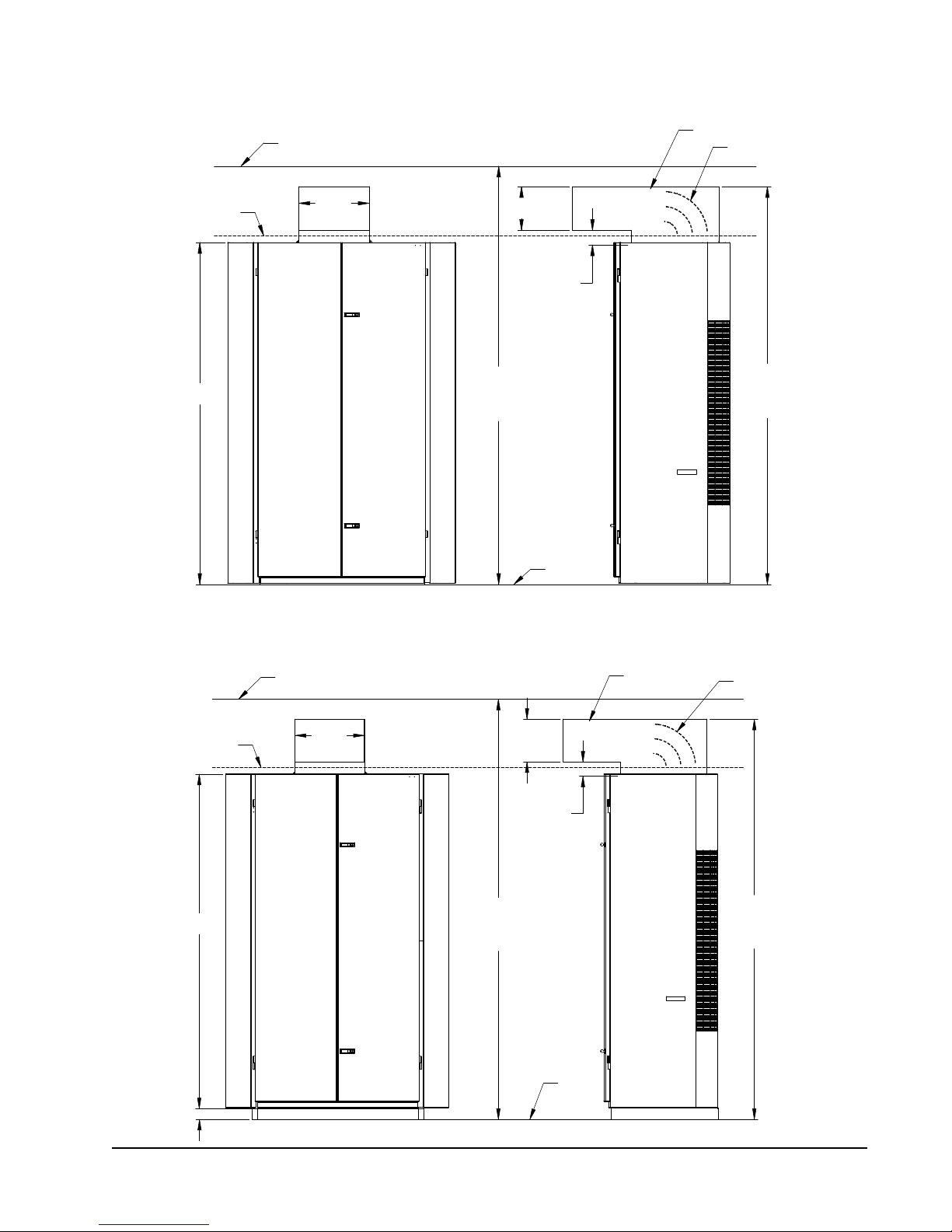

Figure 5A Ducted Application ..................................... 13

Figure 5B 3" Riser Application .................................... 13

Figure 5C 6" Riser Application .................................... 14

Figure 5D Req'd. Clearances & Rec. Access ............. 15

Figure 6 Supply Duct Connections ........................... 16

Figure 7 Filter Location............................................. 16

Figure 8 Drain Locations .......................................... 17

Figures 9A & 9B Unit Mounting ............................18 & 19

Figure 10 Component Location .................................. 20

Figure 11 Basic Heat Pump w/No Vent Pkg. .............. 22

Figure 12 Heat Pump w/CRV, without CO

Figure 13 Heat Pump with CRV & CO

Figure 14 Defrost Cycle .............................................. 28

Figure15 CRVMotorSpeed/CFMConguration ....... 30

Figure 16 CRV Speed Change Terminal Access ........ 31

Figure17 VentilationAirowDiagram ........................ 32

Figure 18 Control Disassembly .................................. 39

Figure 19 Winding Test ............................................... 39

Figure 20 Drip Loop.................................................... 39

Figure 21 Control Connector Motor Half .................... 40

Control .... 23

2

Control .......... 24

2

Tables

Table 1 Factory Built-In Electric Heat Table ............... 5

Table 1A Indoor Blower Performance........................... 5

Table2 Elec.Specications ....................................... 6

Center of Gravity Table .................................. 8

Table 3 Operating Voltage Range ............................ 21

Table 4 Wall Thermostats ......................................... 21

Table 5 Troubleshooting ........................................... 34

Table 6 Temperature vs Resistance of

Temperature Sensor .................................... 35

Table 7 Troubleshooting ECM™ 142R .................... 37

Table 8 Cooling Mode .............................................. 37

Table 9 Heat Pump Mode ........................................ 37

Troubleshooting ECM™ Blower Motors ....................... 40

Power Connector ......................................................... 40

Table 10A Pressures: Full Load Cooling

Table 10B Pressures: Full Load Heating

Table 11A Pressures: Part Load Cooling

Table 11B Pressures: Part Load Heating

I36Z-I60Z ..... 41

I36Z-I60Z ..... 41

I36Z-I60Z .... 41

I36Z-I60Z .... 41

Manual 2100-578E

Page 2 of 41

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually nd these

at your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation ...............ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air .......................ANSI/NFPA 90B

Heating and Air Conditioning Systems

Load Calculation for ..................... ACCA Manual J or

Winter and Summer Manual N

Air Conditioning

Low Pressure, Low Velocity ......... ACCA Manual D or

Duct System Design Manual Q

Winter and Summer Air Conditioning

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating, Refrigeration,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-578E

Page 3 of 41

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The I-TEC must be installed with the Bard

manufactured IWS wall sleeve and ILG louver

grille accessories. These are sold as separate

accessories. Any substitutions will void the

manufacturer’s warranty.

The unit is designed for use with or without ductwork.

For use without ductwork, Plenum Box IPBDFZ18color (18" height) or IPBDFZ12-color (12" height) is

recommended.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical connections to it.

These instructions and any instructions packaged

with any separate equipment required to make up the

entire heating and air conditioning system should be

carefully read before beginning the installation. Note

particularly “Start Procedure” and any tags and/or

labels attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation is

made. See Page 3 for information on codes and standards.

Size of unit for a proposed installation should be

based on heat loss or heat gain calculation made

according to methods of Air Conditioning Contractors

of America (ACCA). The air duct should be installed

in accordance with the Standards of the National Fire

Protection Systems of Other Than Residence Type,

NFPA No. 90A, and Residence Type Warm Air Heating

and Air Conditioning Systems, NFPA No. 90B. Where

local regulations are at a variance with instructions,

installer should adhere to local codes.

ANSI Z535.5 Denitions:

• Danger: Indicate[s] a hazardous situation which, if

not avoided, will result in death or serious injury. The

signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

• Warning: Indicate[s] a hazardous situation which,

if not avoided, could result in death or serious injury.

WARNING [signs] should not be used for property

damage hazards unless personal injury risk appropriate to

this level is also involved.

• Caution: Indicate[s] a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION [signs] without a safety alert symbol may be

used to alert against unsafe practices that can result in

property damage only.

• Notice: [this header is] preferred to address practices

not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an alternative

to “NOTICE” the word “CAUTION” without the safety

alert symbol may be used to indicate a message not

related to personal injury.

Manual 2100-578E

Page 4 of 41

I-TEC Series General Information

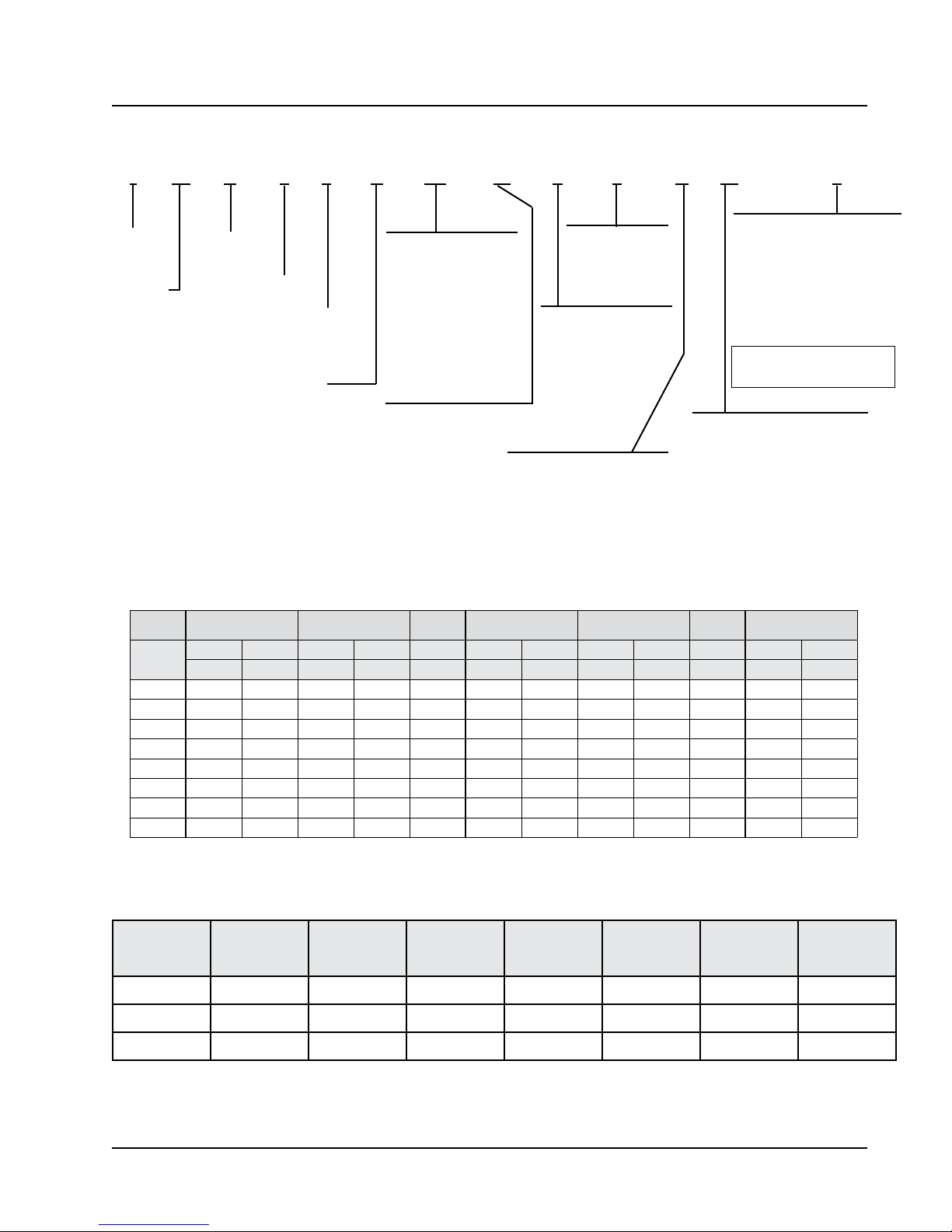

I-TEC MODEL NOMENCLATURE Z-Version (CA) 2-Stage Air Source Heat Pumps

I 36 Z 1 – A 0Z M P 1 X X 2

MODEL

SERIES

NOMINAL

CAPACITY

36 = 36,000 BTUH

48 = 48,000

60 = 60,000

SYSTEM TYPE:

H/P CA Design

REVISION

SPECIAL UNITS

(–) = Standard

C = 460V Circuit

Breaker

VOLTS & PHASE |

A = 230/208, 60-1

B = 230/208, 60-3

C = 460-60-3

ELECTRIC HEAT

0Z = No heat w/breaker

04 = 4KW 1-Phase

05 = 5KW 1-Phase

06 = 6KW 3-Phase

09 = 9KW 3-Phase

10 = 10KW 1-Phase

15 = 15KW 1 & 3-Phase

18 = 18KW 3-Phase

20 = 20KW 1-Phase

VENTILATION OPTIONS

B = Blank-Off Plate

M = Multi-Speed CRV

COLOR OPTIONS

X - Beige paint

1 - White paint

4 - Gray paint

FILTER OPTIONS

P = 2" Pleated MERV 8

M = 2" Pleated MERV 11

N = 2" Pleated MERV 13

VINYL GRAPHICS OPTIONS

X - None

A - Letter Assigned as Req'd.

CONTROLS

X = 24V Terminal Block Only w/o

CompleteStat

1 = CompleteStat THO (Temp,

Humidity & Occupancy)

2 = CompleteStat THO w/CO2

3 = CompleteStat THO w/Ethernet

4 = CompleteStat THO w/CO2 &

Ethernet

Note:CompleteStatmustbeeld

installed & wired. All units have

COIL TREATMENT

X - Std. Hydrophilic Fin Evap. &

Uncoated Alum. Cond. Coil

1 - Phenolic Coated ID Coil

2 - Phenolic Coated OD Coil

3 - Phenolic Coated ID & OD Coil

TABLE 1

FACTORY BUILT-IN ELECTRIC HEAT TABLE

Models I36Z1-A I36Z1-B I36Z1-C I48Z1-A

KW

10.0 34,130 25,598 34,130 25,598 34,130 25,598

15.0 51,195 38,396 51,195 38,396 51,195 51,195 38,396 51,195 38,396 51,195 51,195 38,396

18.0 61,434 46,076 61,434

20.0 68,260 51,195 68,260 51,195

240V-1 208V-1 240V-3 208V-3 460V-3 240V-1 208V-1 240V-3 208V-3 460V-3 240V-1 208V-1

BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH BTUH

4.0 13,652 10,239

5.0 17,065 12,799 17,065 12,799 17,065 12,799

6.0 20,478 15,359 20,478 20,478 15,359 20,478

9.0 30,717 23,038 30,717 30,717 23,038 30,717

I48Z1-B

I60Z1-B

I48Z1-C

I60Z1-C

24V terminal block.

I60Z1-A

Model Rated ESP Max. ESP

I36Z1

I48Z1

I60Z1

.15 0.50 600 1150 850 700 1400

.20 0.50 725 1500 1050 700 1400

.20 0.50 850 1700 1200 700 1400

Motor will deliver consistent CFM through voltage supply range with no deterioration.

kContinuous fan CFM is the total air being circulated during continuous fan mode.

lWilloperateatratedFullLoadAirowwhenoperatingwithHeatPump.

mWill occur automatically with a call for "W3" or "Emergency Heat" signal from the thermostat (Heat Pump Operation is terminated at this condition).

TABLE 1A

INDOOR BLOWER PERFORMANCE

k

Continuous

CFM

Rated 2nd

Stage CFM

Rated 1st

Stage CFM

l

5 - 9 KW

CFM

13.5 - 18

KW CFM

Manual 2100-578E

Page 5 of 41

m

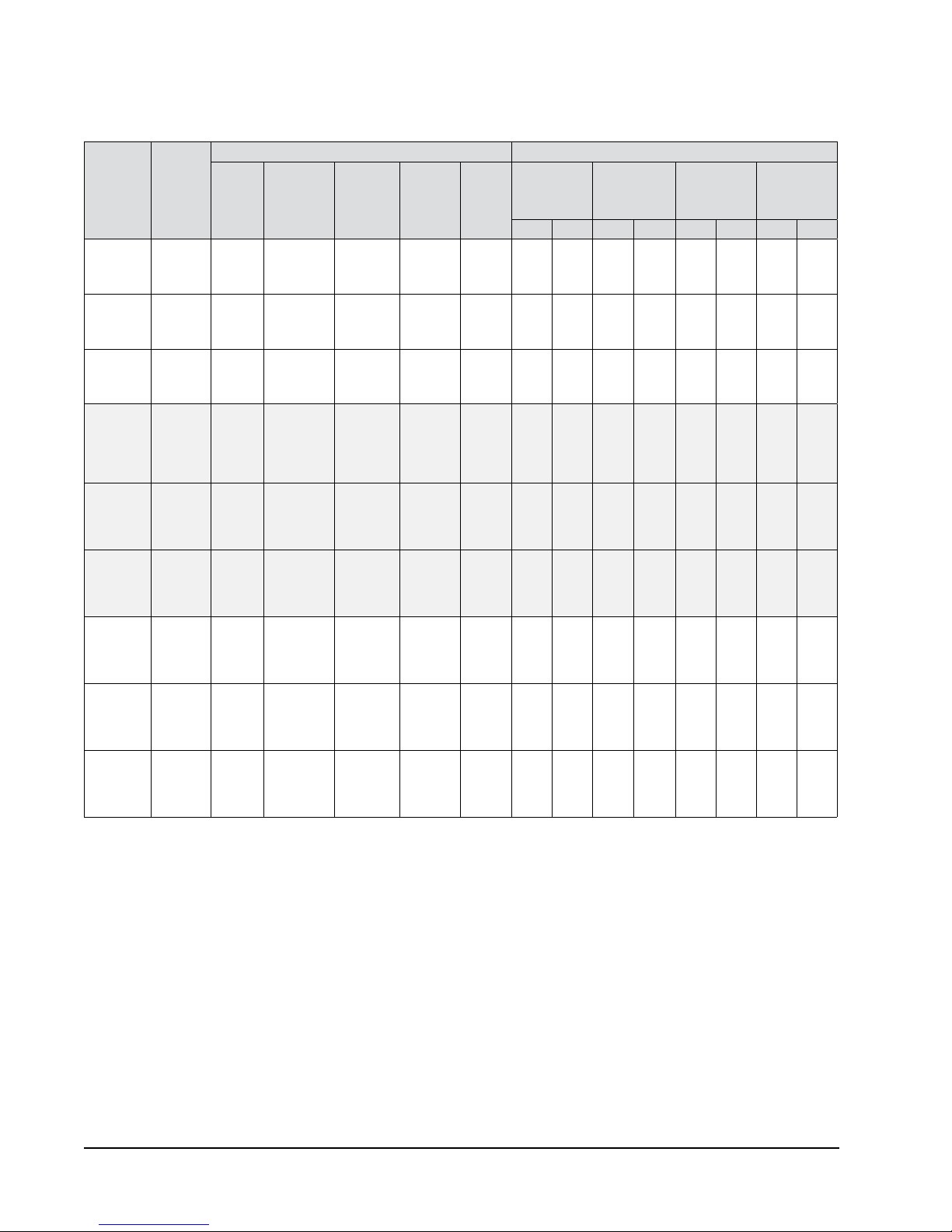

TABLE 2

ELECTRICAL SPECIFICATIONS

Single Circuit Multiple Circuit

Rated

MODEL

Volts,

Hertz &

Phase

I36Z1-A0Z

A05

230/208-1

A10

A15

I36Z1-B0Z

B06

230/208-3

B09

B15

I36Z1-C0Z

C06

460-3

C09

C15

I48Z1-A0Z

A04

A05

230/208-1

A10

A15

A20

I48Z1-B0Z

B06

230/208-3

B09

B15

B18

I48Z1-C0Z

C06

230/208-1

C09

C15

C18

I60Z1-A0Z

A05

230/208-1

A10

A15

A20

I60Z1-B0Z

B06

230/208-3

B09

B15

B18

I60Z1-C0Z

C06

460-3

C09

C15

C18

These“MinimumCircuitAmpacity”valuesaretobeusedforsizingtheeldpowerconductors.RefertotheNationalElectricCode(latestrevision),Article310forpowerconductorsizing.

Caution: Whenmorethanoneeldpowerconductorcircuitisrunthroughoneconduit,theconductorsmustbederated.Payspecialattentiontonote8oftable310regarding

Ampacity Adjustment Factors when more than three (3) current carrying conductors are in a raceway.

MaximumsizeofthetimedelayfuseorHVACtypecircuitbreakerforprotectionofeldwiringconductors.

Based on 75°C copper wire. All wiring must conform to the National Electrical Code and all local codes.

Maximum KW that can operate with the heat pump is 10KW for 1-Phase and 9KW for 3-Phase.

Represents Electric Heat only. Electric Control Circuit will lock-out Heat Pump Operation.

No.

Field

Power

Circuits

1

1

1 or 2

1 or 2

1

1

1

1

1

1

1

1

1

1

1 or 2

1 or 2

1 or 2

1 or 2

1

1

1

1

1

1

1

1

1

1

1

1 or 2

1 or 2

1 or 2

1 or 2

1

1

1

1

1 or 2

1

1

1

1

1

Minimum

Circuit

Ampacity

26

52

78

84

22

40

49

51

11

20

24

28

34

54

59

85

85

110

26

44

53

53

53

15

25

29

29

29

44

70

96

96

112

31

49

58

58

63

15

25

29

29

29

Maximum

External

Fuse or

Ckt. Brkr.

40

60

80

90

30

45

50

60

15

20

25

30

50

60

70

90

90

110

35

50

60

60

60

20

30

30

30

30

60

80

100

100

120

45

60

60

60

70

20

30

30

30

30

Field

Power

Wire

Size

8

6

4

4

10

8

8

6

14

12

10

10

8

6

6

3

3

2

8

8

6

6

6

12

10

10

10

10

8

4

3

3

2

8

8

6

6

6

12

10

10

10

10

Ground

Wire

10

10

10

10

10

10

14

12

10

10

10

10

10

10

10

10

10

12

10

10

10

10

10

10

10

10

10

12

10

10

10

10

Minimum

Circuit

Ampacity

Ckt. A Ckt. B Ckt. A Ckt. B Ckt. A Ckt. B Ckt. A Ckt. B

8

26265252404060

8

8

35

8

35

8

35

6

59

8

44

8

44

8

44

6

60

8 31 54 45 60 8 6 10 10

26

52

52

52

26

52

52

52

Maximum

External

Fuse or Ckt.

Breaker

60

45

30

45

60

45

60

60

60

60

30

60

60

60

60

60

60

Field Power

Wire Size

8

6

8

6

8

10

8

6

8

6

6

6

8

10

8

6

8

6

6

6

Ground Wire

Size

101010

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

Manual 2100-578E

Page 6 of 41

Back View

Air

Supply

Sleeve

Outer

Inner

Sleeve

Air

Return

RUBBER MATT

PART #5451-027

MIS-3114 A

WIRE TIES

PART #7950-031

"

3

4

1

(2) Opt.

Unit Drain

Entrances

"

4

3

1

Unit Specification Sheet

"

3

8

31

FIGURE 1 — UNIT DIMENSIONS

20" x 24" Supply Frame

"

7

26

Total Depth

8

Right Side View

High Voltage

Entrance

"

4

3

18

2"

Sides Removed

30" With Doors and

Wire Channel

Electric Heat

Outer

Sleeve

Openings

(2) Return

Hinges

(4) Lift-Off

Inner

Sleeve

94"

Locking

Door Latch

Return

Electrical

Disconnect

Air

" 50

1

4

"

3

4

71

Upper

Section

(2) Side

Handles

Drains

(2) Unit

58"

Door Latch

Locking

8"

"

8

1

22

"

1

2

24

"

1

4

22

Lower

Section

" 15

5

8

RUBBER MATT &

FRONT TRIM LOCATION

"

3

4

3

(Remove Sides)

Side Forklift Holes

Front Forklift Holes

(Remove Front Trim)

2

20" 18"

61 " Total Width

" With Sides Removed

1

8

46

"

1

4

3

Top View

24"

"

4

1

28

Entrance

Low Voltage

"

1

4

9

Front View

Filters

Return Air

(2) 2"x24"x30"

Control Panel

Air Filters

(2) 16" x 25"

Vent Exhaust

Manual 2100-578E

Page 7 of 41

CENTER OF GRAVITY

CENTER OF GRAVITY

"X"

"Y"

FRONT OF UNIT

Unit Tested

I36Z1-A, B 13½" 31" 43½" 47"

I36Z1-C 13½" 31½" 43½" 47"

I48Z1-A, B 13½" 31" 43½" 47"

I48Z1-C 13½" 31½" 43½" 47"

I60Z1-A, B 13½" 31" 43½" 47"

I60Z1-C 13½" 31½" 43½" 47"

DOOR TO CENTER

"X" Dimension "Y" Dimension "Z" Dimension "Z" Dimension

LEFT SIDE

TO CENTER

FLOOR TO CENTER

CRV & ERV

FLOOR TO CENTER

NO VENT

"Z"

MIS-3268

Manual 2100-578E

Page 8 of 41

SHIPPING DAMAGE

Upon receipt of equipment, the unit should be checked

for external signs of shipping damage. The skid must

remain attached until the unit is ready for installation.

If damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

UNIT REMOVAL FROM SKID

WARNING

This unit is heavy and requires more than one person

to handle during installation and removal from the

skid. Extreme caution must be taken to prevent injury

to personnel and damage to the unit. Use appropriate

safety equipment, including gloves when handling.

Failure to do so may result in serious injury.

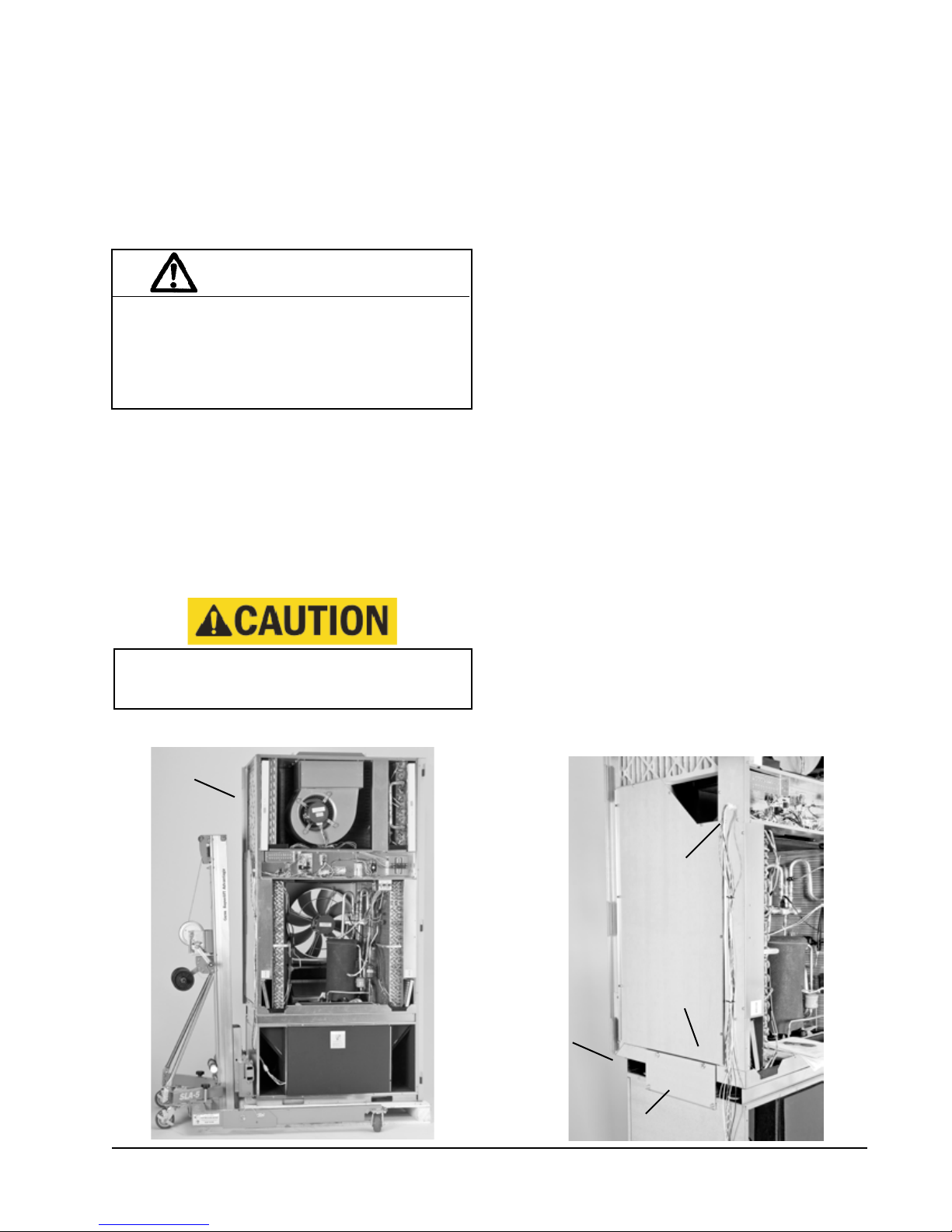

A forklift or a lift rated for the load (Figure 2A) is

required to lift the unit off from the skid. This unit is

top heavy and should never be tipped while moving it.

The I-TEC is designed to be lifted off the skid from the

front or rear of the unit without having to remove any

doors or side panels. See Figure 1 for fork openings.

The shipping brackets on front and rear of the unit must

be removed and discarded. The unit can now be lifted

straight up and the skid can be slid out from underneath.

Tip unit from left side only.

Failure to do so may result in injury due to unit

top-heaviness or compressor damage!

HANDLING UNIT AFTER REMOVAL FROM SKID

If a wide and tall opening exists, the I-TEC can be moved as a

complete assembled unit. If not, use the following directions for

dis-assembly to allow it to pass through a 36" wide door.

1. Depress and release both top & bottom door latches and

open doors.

2. Remove doors by lifting straight up & off from the hinge pins.

3. Remove cabinet sides by rst removing the four (4) sheet metal

screws from the front (leading edge) of the side panel. The panel

will not fall off. Swing the panel away from the chassis 20-30

degrees & then pull forward from the two (2) tabs supporting

the rear edge. At this point, the unit can be tipped on its left

side enough to get dolly carts under it. Use dolly carts to

move unit into installation area. Use care not to damage

vent wire harness. This method is not suggested due to unit

weight and if a forklift or unit lift is available, continue with

the following steps for separation of top section & bottom base.

4. On each side of the unit is a tie plate that secures the top &

bottom sections with four (4) cap bolts. Using a ½" wrench

or socket, remove these screws from both plates & set aside.

5. If the unit is equipped with a CRV, you must unplug the

wire harness on the left-hand side of the control box.

6. A forklift or a lift rated for the load is required to lift the

top section off from the bottom base. Do not attempt to

do this manually! Failure to do so could result in the

unit tipping over & causing bodily injury &/or damage to

the unit.

7. The top section can be forked from either the RH or LH

side. See Figure 1 for fork openings.

8. Carefully lift the top section straight up avoiding tipping.

9. Move the top section through the doorway & place on at

surface free of debris.

10. The bottom base can now be moved through the doorway

the same way.

11. Reassemble the unit by reversing this procedure.

FIGURE 2A UNIT ON LIFT

LEFT

SIDE

of

UNIT

FIGURE 2B UNIT SIDE

CRV

(4) CAP BOLTS

FORK OPENING

(Visible after

removing tie plate)

HARNESS CONNECTION

(Covers entire width; shortened for illustration

purposes to show Fork Openings)

TIE PLATE

Manual 2100-578E

Page 9 of 41

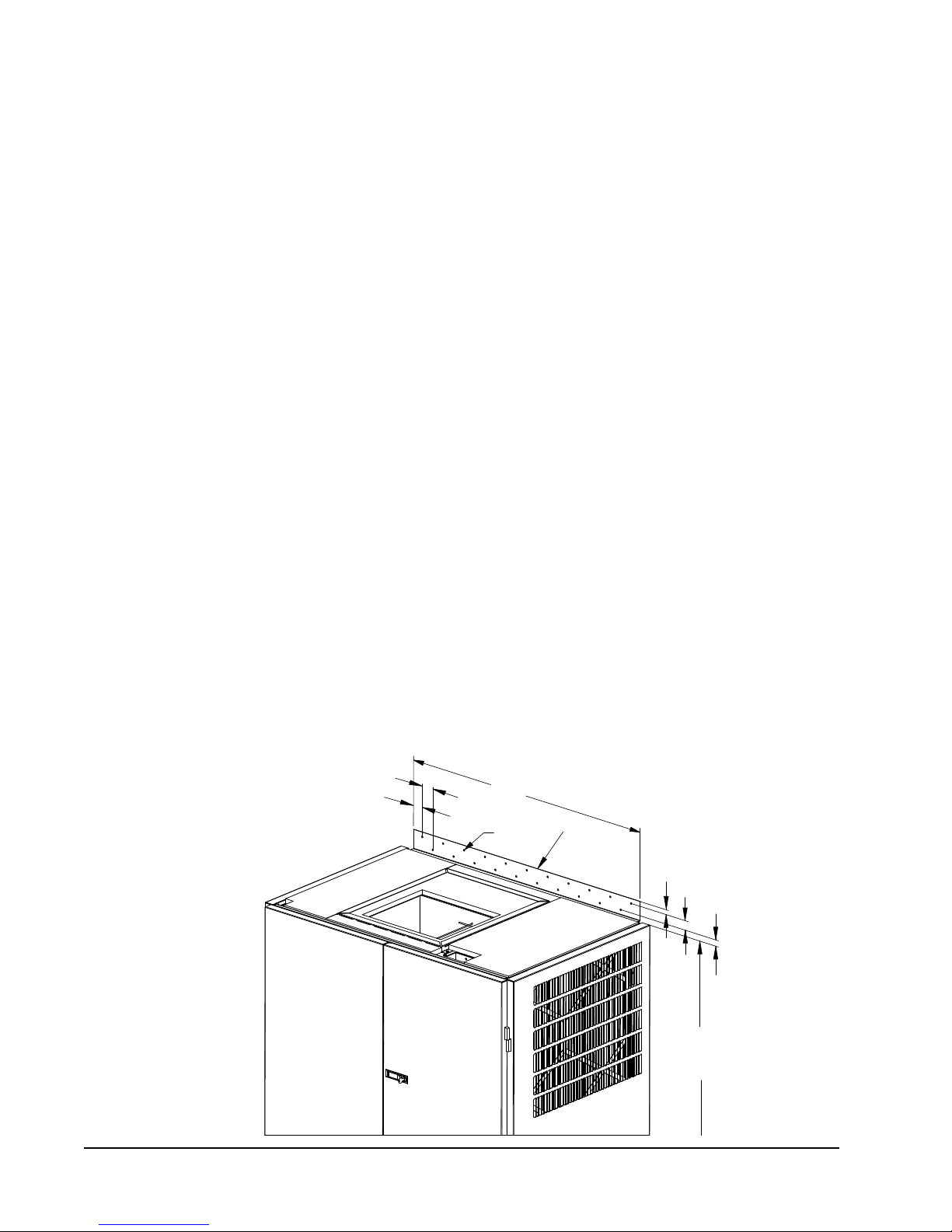

REQUIRED STEPS AFTER FINAL PLACEMENT

MIS-3029

2"

1 11/16"

43 3/8"

Ø1/4"

94" FROM BOTTOM

OF BRACKET TO

FLOOR WITHOUT

RISER KIT

7/8"

3/4"

1 1/2"

BRACKET

The compressor is secured to the base with two (2) bolts

for shipping. Although the unit will perform as designed

with the shipping bolts in place, there may be noticeable

additional noise and vibration noted. To obtain the lowest

noise and vibration levels, remove the shipping bolts after

the unit is in its nal operating location. To gain access

to the compressor, the compressor access panel must be

removed (Figure 7). Once this panel is removed, the CRV

air duct must be removed. See Figure 4.

The air duct is removed by pulling it straight toward you;

there are no screws securing it in place. Both the top and

bottom slide toward you at the same time (pull hard).

Once removed, the compressor is visible as well as the

tags on the shipping bolts (Figure 3).

After the compressor shipping bolts have been removed,

the CRV air duct can be slid back in place and the

compressor access panel attached.

MINIMUM INSTALLATION CLEARANCES

The minimum installation height to the bottom of the

roof or xed ceiling for ducted applications is 9 ft. 7 in.

This provides enough clearance to install the duct work.

See Figure 5A.

The IWS Series wall sleeve has a built-in vertical

adjustment to t window sill heights from 31-34 inches.

If additional height is required, two riser platform

accessories are available. The IRZ3 increases the

unit height by 3 inches (Figure 5B) and the IRZ6 by 6

inches (Figure 5C).

Several construction options are available for unit

installation of the IZ Series. Serviceability and lter

access must be considered before installing. See Figure

5D for required clearances and recommended service

access dimensions.

SECURING UNIT TO STRUCTURE

Shipped with the I-TEC unit is a wall mounting bracket

(screwed to shipping skid on backside of unit). This bracket

can be utilized to secure the top portion of the unit to the

wall using the appropriate eld supplied hardware based

upon the material you are fastening to. (There are several

offset holes, sized to accept up to a 1/4" diameter fastener

that will easily allow you to hit studs on a framed wall.) See

BRACKET SECTION VIEW (Page 10) for locating this top

wall bracket which will need to be applied after the unit is

located in the nal position.

Additional/optional mounting holes for up to a 3/8"

diameter fastener are also available in the backside and

base of the unit. These can be accessed by:

• removing the air lters (uppermost set)

• removing the compressor section service door (lower set)

• removing vent door and vent partitions (base set)

Refer to WOOD FRAMED INSTALLATION (Page 10) for

additional framing required to secure unit to wall.

The additional/optional mounting holes will require a

long extension to drive the fasteners.

SEISMIC CONSIDERATIONS

The I-TEC product features several locations for product

securement but all site conditions are different. Consult

with a licensed Seismic Engineer to advise of particular

needs when attaching the I-TEC unit to the structure.

RUBBER MAT

Unit rests on rubber mat placed under base rails during

installation. Place mat on oor ush with wall and

centered over wall opening.

WALL MOUNTING

BRACKET LOCATION

Manual 2100-578E

Page 10 of 41

35"

17

1

2

"

"

3

4

18 7

3

8

"

(4) optional Unit

Mounting holes

C

L

C

L

Mounting holes

(4) optional Unit

Bracket

*

** Separate telescoping sleeves available for different wall thicknesses.

Centered on

Optional Top

*

* Higher Sill Heights Acheivable With Base Kit.

Opening

Wall

Room Floor Level

Outside

Sleeve Mounting

Hole Locations

FLOOR MOUNTING HOLE

& CENTERLINES

8

20

7

6"

8

20 "

2

32

1

7

"

"29

"

17

8"

56

8"

20

7

8

"

8

""94

1

31" Min.

20"

34" Max.

3"

1

48-1/2" Max.

48" Min.

3

Centered

8

Centered

43-1/4" Max.

"

49

16

8

"

20"

20"

20"

43

7

42-3/4" Min.

"

16

11

15

4

43

3

8

"

Duct

Grille

Floor

Optional

Outside

Ceiling

Wall Sleeve**

Telescoping

Wall

Unit

Optional

Trim or

Supply Duct

Box

31" Min.

34" Max.

C

L

Wall Section View

Right Side View

Front (Wall Only) View

C

L

MIS-3196 A

6.00

41.75

56.50

29.568.00

8.0036.88

20.88

MIS-3197

(4) lower fastener

holes

Floor

riser kit. If unit uses riser kit add

appropriate dimension to height.

Inner wall

Unit

*

(4) Upper

fastener holes

* Height dimension shown without

BRACKET WALL SECTION VIEW

WOOD FRAMED INSTALLATION (for Wall Attachment)

Manual 2100-578E

Page 11 of 41

COMPRESSOR SHIPPING BOLTS

COMPRESSOR

SHIPPING BOLT

FIGURE 3

COMPRESSOR

SHIPPING BOLT

CRV

AIR DUCT

FIGURE 4

REMOVAL OF AIR DUCT

Manual 2100-578E

Page 12 of 41

INSTALLATION

9'-5"

MINIMUM

REQUIRED

HEIGHT

9'-10" MINIMUM

CLEARANCE

RECOMMENDED TO

BOTTOM OF ROOF

OR FIXED CEILING

3" RISER

FIELD SUPPLIED DUCT

MIS-3199

TURNING VANES

RECOMMENDED

MINIMUM

12"

4" MINIMUM FROM

TOP OF UNIT TO

DUCT BOTTOM

BOTTOM OF ROOF

FLOOR

OR FIXED CEILING

SUSPENDED

CEILING

20"

MINIMUM

7'-9 3/4"

UNIT HEIGHT

9'-7" MINIMUM

CLEARANCE

RECOMMENDED TO

BOTTOM OF ROOF

OR FIXED CEILING

9'-2"

MINIMUM

REQUIRED

INSTALLATION

HEIGHT

BOTTOM OF ROOF

FLOOR

OR FIXED CEILING

SUSPENDED

CEILING

20"

MINIMUM

7'-9 3/4"

UNIT HEIGHT

FIELD SUPPLIED DUCT

MIS-3198

TURNING VANES

RECOMMENDED

MINIMUM

12"

4" MINIMUM FROM

TOP OF UNIT TO

DUCT BOTTOM

FIGURE 5A

DUCTED APPLICATION – BASIC UNIT

FIGURE 5B

3" RISER APPLICATION

Manual 2100-578E

Page 13 of 41

INSTALLATION

9'-8"

MINIMUM

REQUIRED

HEIGHT

10'-1" MINIMUM

CLEARANCE

RECOMMENDED TO

BOTTOM OF ROOF

OR FIXED CEILING

6" RISER

FIELD SUPPLIED DUCT

MIS-3200

TURNING VANES

RECOMMENDED

MINIMUM

12"

4" MINIMUM FROM

TOP OF UNIT TO

DUCT BOTTOM

FLOOR

OR FIXED CEILING

BOTTOM OF ROOF

SUSPENDED

CEILING

20"

MINIMUM

7'-9 3/4"

UNIT HEIGHT

FIGURE 5C

6" RISER APPLICATION

Manual 2100-578E

Page 14 of 41

12" MIN.

REQUIRED CLEARANCES & RECOMMENDED ACCESS

WING WALL CONSTRUCTION TOP VIEW

FIGURE 5D

12"

MIN.

61 1/2"

CLOSET CONSTRUCTION TOP VIEW

61 1/2"

12" MIN.

48" MIN.

LEFT CORNER CONSTRUCTION TOP VIEW

12" MIN.

12" MIN.

31 3/8"

12"

MIN.

12" MIN.

FOR LEFT

SIDE

ACCESS

RECOMMENDED SERVICE

ACCESS DIMENSIONS

FILTERS

24" MIN.

24" MIN.

12" MIN.

FOR RIGHT

SIDE

ACCESS

0" REQUIRED

12" RECOMMENDED

RIGHT CORNER CONSTRUCTION TOP VIEW

0" REQUIRED

12" RECOMMENDED

48"

MIN. FOR

FILTER ACCESS

Unit can be located in corner

with 0" clearance as long as

other side is unobstructed

MIS-3230

Manual 2100-578E

Page 15 of 41

DUCT WORK

MIS-2959

SUPPLY DUCT AND

FASTENERS TO BE

FIELD SUPPLIED

24"

20"

BEND THE PROVIDED

SUPPLY FRAME FLANGES

UP FOR DUCT INSTALLATION

Any heat pump is more critical of proper operating

charge and an adequate duct system than a straight air

conditioning unit. All duct work must be properly sized

for the design airow requirement of the equipment.

Air Conditioning Contractors of America (ACCA) is

an excellent guide to proper sizing. All duct work or

portions thereof not in the conditioned space should be

properly insulated in order to both conserve energy and

prevent condensation or moisture damage. When duct

runs through unheated spaces, it should be insulated

with a minimum of one inch of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect the

duct work to the equipment in order to keep the noise

transmission to a minimum.

The I-TEC series heat pump has provision to attach a

supply air duct to the top of the unit. Duct connection

size is 20 inches x 24 inches. The anges are shipped

at and must be bent upward using sheet metal anging

pliers. The duct work is eld supplied. See Figure 6 for

suggested attachment method.

Make sure to seal the slots in the bend-up ange at the

time of securing your ductwork to the ange. This can

be accomplished with either foil tape or caulk. Failing

to do so may cause air leakage/whistling of air.

FIGURE 6

SUPPLY DUCT CONNECTIONS

The unit is equipped with a variable speed indoor

blower motor which increases in speed with an increase

in duct static pressure. The unit will therefore deliver

proper rated airow up to the maximum ESP shown

in Table 1A. However, for quiet operation of the

air system, the duct static should be kept as low as

practical, within the guidelines of good duct design.

FILTERS

Two 2-inch throw away lters (24 x 30) and two 1-inch

throw away lters (16 x 25) are supplied with each

unit. The 2-inch lters slide into brackets on both sides

for the return air openings. If a CRV vent option is

used, there are two (2) additional 1" throw away lters

included with that option. See Figure 7 for specic

locations. The lters are serviced from the inside of

the building by opening the cabinet doors, and do not

require any tools to access.

FIGURE 7

FILTER LOCATION

24" X 30" 2"

FILTERS

INDOOR

BLOWER

ACCESS

NOTE: Unit cabinet, supply air duct and duct free

plenum are approved for “0” clearance to

combustible material.

The I-TEC series heat pumps are designed for use with

free return (non-ducted) and either duct free with the use

of IPBDFZ Series Plenum Box (18" or 12") or a duct

supply air system.

The IPBDZ Plenum Box mounts on top of the unit and

has both vertically and horizontally adjustable louvers on

the front discharge grille.

When used with a ducted supply, a Cabinet Extension

may be used to conceal the ductwork above the unit to

the ceiling. The ICX28 extends 28" above the unit for a

total height of 10'-2" or can be trimmed to any height.

Manual 2100-578E

Page 16 of 41

COMPRESSOR

ACCESS

ACCESS TO

WASHABLE

FILTERS

VENT & FLOOR

MOUNTING HOLE

ACCESS DOOR

MIS-3202

(2) Unit

Drain Entrances

Drain Area

Drains

Insulate

(2) Optional Unit

(2) Drain

Access

Locations

MIS-3115 A

(2) OPTIONAL DRAIN

HOLES IN BASE

WALL

BASE VIEW

16 1/2"

18 3/4"

7 3/16"

40 3/4"

35"

OPTIONAL FLOOR

MOUNTING HOLES

CONDENSATE DRAIN

There are two condensate drain connections from the

condenser drain pan (compressor area). These are

visible from the rear of the unit. Factory installed tubing

connects the two drains at a tee connection and then a

single drain hose with a barbed hose connector carries

the condensate to the draining option of your choice.

Enough tubing is provided to reach all drain options and

can be cut down in length.

The unit is shipped from the factory with the drain line

on the left-hand side as you look at the rear of the unit.

The tubing can be removed from the drain connections

and ipped for a right-hand drain. See Figure 8.

The drain can be routed directly through the oor or

through the wall. There are also two optional drain

locations in the lower rear back panel. See Figure 8.

The I-TEC design does not require a trap in the

condensate disposal tubing. Check your local codes to

see if a “P” trap is required.

For a stand pipe oor drain or through the wall, there is

adequate hose length to reach needed location behind the

unit. The lower rear portion of the cabinet is recessed

approximately 4 inches allowing room for a “P” trap (if

required) to be installed with the cabinet ush with the wall.

Keep in mind, the drain line must be able to be removed

from the unit if necessary to remove the unit from the wall.

Access plates are located on the rear of the unit for

servicing the drain trap. See Figure 8. If the drain line

is to be routed through an unconditioned space, it must

be protected from freezing.

The condensate drain line can also be routed back into

the unit through either the right-hand or left-hand

optional drain locations on the rear of the unit. The

hole is covered by insulation on the inside of the unit

and will have to be cut away. Located inside the unit,

about 12 inches in from the front on both the left and

right side are drain holes in the bottom of the base.

These holes are covered with insulation and are not

visible from inside vent option area. They are located

very close to the side panels and can be found by

pressing down on the insulation or looking at back of

vent option area (See Figure 8). Cut insulation away

to expose the hole. A drain trap can now be installed

inside of the cabinet, and the drain hose routed directly

through the oor.

Once the I-TEC is installed, the rear drains exiting the

condenser section can be easily serviced with removal

of the pre-painted metal sides (lift-off doors, remove

four [4] screws to remove side).

If side access is not available, the drain lines and trap

can be serviced by removing either one of the drain

access panels on the rear of the unit (in the ventialtion

package area.) See Figure 8.

After drain installation is complete, drain area must

be insulated for sound purposes with 45" x 24

piece of insulation. See Figure 8.

¾"

x 6"

WITH NO VENT OPTION

To remove the drain access panels in the rear of this

section, simply remove the front door/cover from the

box. Rear drain access panels are now visible on both

right-hand and left-hand sides in rear of box.

WITH COMMERCIAL ROOM VENTILATOR

1. Open hinged front doors.

2. Disconnect unit power to eliminate shock hazard.

3. Remove front cover/door of CRV vent package.

(Can leave lter access panels in place.)

4. Unplug wires coming in on left side from upper

unit section.

Unplug two wire harness from front (intake) blower.

5.

6. Remove two (2) screws securing front (intake)

blower and slide blower out of unit.

7. Remove four (4) screws that retian the partition

behind/beneath intake blower removed in Step #6.

8. Rear drain access panels are now visible on both

right-hand and left-hand sides in rear of box.

FIGURE 8 — DRAIN LOCATIONS

Manual 2100-578E

Page 17 of 41

D

REF.

A AND B

REF.

(4) 5/16" - 1/2" NON-TAPPING

REF.

E

REF.

(6) 5/16" - 3/4" NON-TAPPING

C

(4) 1-1/2" LONG SCREWS

REF.

E

(18) 5/16" - 3/4" SELF TAPPING

B

C

REF.

REF.

REF.

A

REF.

D

MIS-3014 A

Use (4) 1-1/2" Long

Louver Grille to

Outer Sleeve.

Screws to Attach

to Outer Sleeve

to Attach Inner Sleeve

Self Tapping Screws

Use (6) 3/4" Long

Unit Fan Shroud

Exhaust Sleeve to

Screws to Attach

Use (6) 3/4" Long

Use (12) 3/4" Long

to Attach Inner Sleeve

to Unit Back

Self Tapping Screws

Use (4) 1/2" Long

Screws to Attach

frame to Exhaust

Sleeve

Use (12) Field Supplied Concrete

or Wood Screws to Secure Outer

Sleeve to Structure.

outer sleeve.

IMPORTANT!

IMPORTANT!

between inner and

entire perimeter seam

seal between unit and sleeve.

IMPORTANT!

Doing so may compromise water

to not damage gasketing material.

Use care when inserting screws

Apply Caulk bead to

Apply liberal amount

of caulk to back of

flange before installing.

Pull Inner Frame

Out Until Flush

With Grille Mounting

Angle

FIGURE 9A

UNIT MOUNTING

Manual 2100-578E

Page 18 of 41

(SIZE VARIES)

OUTDOOR GRILLE

INSIDE WALL

AND SLEEVE

INTERIOR FLOOR

AREA BETWEEN WALL

OUTSIDE WALL

(INSULATED)

(INSULATED)

FILL INSULATION

UNIT

SLEEVE

MIS-3201 A

DRAIN AREA

(INSULATED WITH

6" BATT MATERIAL)

FIGURE 9B

UNIT MOUNTING

NOTICE: In order to achieve optimum sound reduction, the following areas need insulated:

1. Outside wall.

2. Area between sleeve and wall.

3. Drain area behind unit.

Manual 2100-578E

Page 19 of 41

INSTALLATION INSTRUCTIONS

MOUNTING THE UNIT

The wall sleeve is attached to the I-TEC unit from the

outside of the building. See Figures 9A & 9B. Refer

to wall sleeve Manual 2100-562 supplied with sleeve.

Following are the steps for attaching the I-TEC to the

wall sleeve.

1. Lift the unit into place making sure that it is

aligned side to side. Align unit with rubber mat.

2. Push the unit back until the rear panel touches

the sleeve gasket.

3. This unit must be level from side to side and

from front to back. If adjustments are necessary,

shim up under the base rails with sheets of metal

or any substance not affected by moisture.

4.

Attach the sleeve to the unit using the ten (10) ¾"

long self-tapping screws supplied with the sleeve.

5.

The exhaust sleeve has three (3) ¾" long screw slots

in each side ange. Line these up with the screw

engagement holes in the fan panel. Attach using six

(6) ¾" long pointed sheet metal screws supplied

with the sleeve. Extend the sleeve out until it is

ush with the louver grill attachment angles.

6.

Lock the sleeve in place using two (2) ½" long

pointed sheet metal screws on each side by

shooting through the slot into a pre-punched hole.

7. A bottom trim piece is shipped loose for

installation beneath the doors. Attach the trim

piece to the unit with screws provided.

8. The compressor is secured to the base with two

(2) bolts for shipping. Both bolts are identied

with a tag. Remove shipping bolts (Figure 3).

WIRING – MAIN POWER

Refer to the unit rating plate and/or Table 2 for wire sizing

information and maximum fuse or “HACR Type” circuit

breaker size. Each unit is marked with a “Minimum Circuit

Ampacity”. This means that the eld wiring used must be

sized to carry that amount of current. Depending on the

installed KW of electric heat, there may be two eld power

circuits required. If this is the case, the unit serial plate will

so indicate. All models are suitable only for connection

with copper wire. Each unit and/or wiring diagram will be

marked “Use Copper Conductors Only suitable for at least

75°C”. THESE INSTRUCTIONS MUST BE ADHERED

TO. Refer to the National Electrical Code (NEC) for

complete current carrying capacity data on the various

insulation grades of wiring material. All wiring must

conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75°C copper)

for all models, including the most commonly used heater

sizes. Also shown are the number of eld power circuits

required for the various models with heaters.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or “HACR Type” circuit breaker that is to

be used with the equipment. The correct size must be

used for proper circuit protection, and also to assure that

there will be no nuisance tripping due to the momentary

high starting current of the compressor motor.

See “START UP” section for information on three

phase scroll compressor start-ups.

The eld wiring conduit connections are located on the top

right-hand corner of the unit with a wire raceway to feed

the wires down to the circuit breaker(s). See Figure 10.

REFRIGERANT PORT

Manual 2100-578E

Page 20 of 41

ELECTRIC HEAT

INDOOR BLOWER

LOW VOLTAGE

OUTDOOR FAN

VENT OPTION

FIGURE 10

COMPONENT LOCATION

WIRE RACEWAY

EVAPORATOR COIL

CONTROL PANEL

CONDENSER COIL

COMPRESSOR

WIRING – LOW VOLTAGE WIRING

230/208V, 1 PHASE AND 3 PHASE EQUIPMENT

DUAL PRIMARY VOLTAGE TRANSFORMERS.

All Equipment leaves the factory wired on 240V tap.

For 208V operation, reconnect from 240V to 208V tap.

The acceptable operating voltage range for the 240 and

208V taps are as noted in Table 3.

TABLE 3 — OPERATING VOLTAGE RANGE

TAP RANGE

240V 253 – 216

208V 220 – 187

NOTE: The voltage should be measured at the eld power

connection point in the unit and while the unit is operating at

full load (maximum amperage operating condition).

The standard unit includes a remote thermostat connection

terminal strip. See Figures 11 through 16 for connection

diagrams. Compatible thermostats are listed in Table 4.

TABLE 4 — WALL THERMOSTATS

“W2” terminal is rst stage electric heat (if equipped).

First stage electric heat can be operated simultaneously

with the heat pump operating.

“A” terminal is the ventilation input. This terminal

energizes any factory installed ventilation option.

“W3” terminal is second stage electric heat. When

“W3” terminal is energized, it locks out compressor

operation to limit discharge air temperature and

required branch circuit ampacity.

NOTE: For total and proper control using DDC,

a minimum of 9 controlled outputs are needed

when above 10KW Electric Heat is employed with

ventilation, a total of 8 controlled outputs with below

10KW Electric Heat with Ventilation, 7 controlled

outputs below 10KW Electric Heat with no ventilation,

7 controlled outputs with no Electric Heat, but with

ventilation, and 6 controlled outputs with no electric

heat and no ventilation. If Dehumidication Model

& Vent, 10 controlled outputs are needed when above

10KW Electric Heat is employed with ventilation.

Thermostat Predominant Features

8403-060

(1120-445)

8403-067

(CDT-2W40-LCD-RLY)

CS9B-THO

CS9B-THOC

CS9BE-THO

CS9BE-THOC

3 Stage Cool; 3 Stage Heat

Programmable/Non-Programmable Electronic

HP or Conventional

Auto or Manual changeover

Carbon Dioxide Sensor with LCD for

Sensor Readings

3 Stage Heat, 3 Stage Cool, Prog/NonProg, HP or Conv,

Auto or Manual Changeover, Humidity Sensor w/

dehumidication,MotionSensorw/IntelligentLearning

Control, BACnet-compatible

3 Stage Heat, 3 Stage Cool, Prog/NonProg, HP or Conv,

Auto or Manual Changeover, Humidity Sensor w/

dehumidication,CO2Sensor,MotionSensorw/Intelligent

Learning Control, BACnet-compatible

3 Stage Heat, 3 Stage Cool, Prog/NonProg, HP or Conv,

Auto or Manual Changeover, Humidity Sensor w/

dehumidication,MotionSensor,IntelligentLearningControl,

BACnet-compatible, Ethernet-compatible

3 Stage Heat, 3 Stage Cool, Prog/NonProg, HP or Conv,

Auto or Manual Changeover, Humidity Sensor w/

dehumidication,CO2Sensor,MotionSensorw/Intelligent

Learning Control, BACnet-compatible, Ethernet-compatible

LOW VOLTAGE CONNECTIONS

These units use a grounded 24 volt AC low voltage

circuit.

“G” terminal is the fan input.

“Y1” terminal is the compressor part load input.

“Y2” terminal is the compressor full load input.

“B/W1” terminal is the reversing valve input.

The reversing valve must be energized for heating mode.

“R” terminal is 24 VAC hot.

“C” terminal is 24 VAC grounded.

“L” terminal is compressor lockout output. This

terminal is activated on a high or low pressure trip and

condensate overow trip by the electronic heat pump

control. This is a 24 VAC output.

LOW VOLTAGE CONNECTIONS FOR DDC CONTROL

Fan Only Energize G

Cooling Part Load Energize G, Y1

Cooling Full Load Energize G, Y1, Y2

HP Heating Part Load Energize G, Y1, B/W1

HP Heating Full Load Energize G, Y1, Y2, B/W1

HP Heating Full Load + Electric Heat

(up to 10KW)

Heating with Bank #1 Electric Heat Only Energize G, W2

Emergency Heat (Heat pump operation

is negated for this condition)

Ventilation Energize A

Energize G, Y1, Y2, B/W1, W2

Energize G, W2, W3

GENERAL

This unit is equipped with a variable speed ECM motor.

The motor is designed to maintain rated airow up to

the maximum static allowed. It is important that the

blower motor plugs are not plugged in or unplugged

while the power is on. Failure to remove power prior

to unplugging or plugging in the motor could result in

motor failure.

CAUTION

Do not plug in or unplug blower motor

connectors while the power is on. Failure to do

so may result in motor failure.

Manual 2100-578E

Page 21 of 41

FIGURE 11

6 4W3 A DL

B/W1

Y2Y1RT GC W2

Low

Voltage

Term. Strip

R 3

SC

W1/E

A DLO/BY2Y1

24V

G

COM

W2

Completestat

Model #CS9B-THO or

Model #CS9BE-THO

SC

SC

GND

Thermostat

W1/E

A

YO/D

LO/BY2Y1R GC W2

Bard #8403-060

Blue

Yellow

Orange

Red

1

Not needed below 15KW

Factory installed jumper. Remove jumper and connect to N.C fire alarm

2

2

2

1

3

3 Relay Provided with Completestat

White

MIS-3203 A

BASIC HEAT PUMP WITH NO VENTILATION PACKAGE

Manual 2100-578E

Page 22 of 41

FIGURE 12

6 4W3 A DL

B/W1

Y2Y1RT GC W2

Low

Voltage

Term. Strip

R 3

COM

G

24V

Y1 Y2 O/B L DA GND

SCSCSC

Completestat

Model #CS9B-THO or

Model #CS9BE-THO

W2

W1/E

Thermostat

W1/E

A

YO/D

LO/BY2Y1R GC W2

Bard #8403-060

Blue

Yellow

Orange

MIS-3204 A

1

Not needed below 15KW.

2

to N.C fire alarm circuit if emergency shutdown required.

Factory installed jumper. Remove jumper and connect

3

Connect to "G" terminal when thermostat has "Occupancy Signal".

without "Occupancy Signal" is used.

Install a jumper between "G" and "A" only when thermostat

4

3

4

CRV Wiring Harness

1

2

BROWN/WHITE

ORANGE

BLACK/WHITE

RED/WHITE

2

Red

5

5 Relay Provided with Completestat

White

HEAT PUMP WITH CRV, WITHOUT CO2 CONTROL

Manual 2100-578E

Page 23 of 41

SC

W1/E

A DLO/BY2Y1

24V

G

COM

W2

Completestat

Model #CS9B-THO or

Model #CS9BE-THO

SC

SC

GND

5

2

1

6

W1/E

A

YO/D

LO/BY2Y1R GC W2

Thermostat

Bard #8403-060

W1/E

A DLO/BY2Y1

24V

G

COM

W2

Completestat

Model #CS9B-THO or

Model #CS9BE-THO

SC

SC

SC

GND

Thermostat

W1/E

A

YO/D

LO/BY2Y1R GC W2

Bard #8403-060

Blue

Yellow

Orange

MIS-3205 A

Not needed below 15KW.

1

B/W1

2

to N.C fire alarm circuit if emergency shutdown required.

Factory installed jumper. Remove jumper and connect

3

3

4

CRV Wiring Harness

RT

Connect to "G" terminal when thermostat has "Occupancy Signal".

4

BROWN/WHITE

ORANGE

BLACK/WHITE

RED/WHITE

1

W3 A DL 4Y2Y1

GC W2

Term. Strip

R 6

2

3

Voltage

Low

directly to "A" and do not use seperate CO2 controller.

If CS9B-THOC or CS9BE-THOC is used, connect "Brown/White"

5

5

Bard #8403-067

CO2 Control

6

6

Red

2

6

Relay Provided with Completestat

White

Install a jumper between "G" and "A" only when thermostat

without "Occupancy Signal" is used.

FIGURE 13

HEAT PUMP WITH CRV AND CO2 CONTROL

NOTE: Bard 8403-060

thermostat must be in

programmed operation

mode and in programmed

fan mode for ventilation to

function.

Manual 2100-578E

Page 24 of 41

START UP

THESE UNITS REQUIRE R-410A

REFRIGERANT AND POLYOL

ESTER OIL.

GENERAL:

1. Use separate service equipment to avoid cross

contamination of oil and refrigerants.

2. Use recovery equipment rated for R-410A

refrigerant.

3. Use manifold gauges rated for R-410A (800 psi/250

psi low).

4. R-410A is a binary blend of HFC-32 and HFC-125.

5. R-410A is nearly azeotropic - similar to R-22 and

R-12. Although nearly azeotropic, charge with

liquid refrigerant.

6. R-410A operates at 40-70% higher pressure than

R-22, and systems designed for R-22 cannot

withstand this higher pressure.

7. R-410A has an ozone depletion potential of zero,

but must be reclaimed due to its global warming

potential.

8. R-410A compressors use Polyol Ester oil.

9.

Polyol Ester oil is hygroscopic; it will rapidly absorb

moisture and strongly hold this moisture in the oil.

10. A liquid line dryer must be used - even a deep

vacuum will not separate moisture from the oil.

11. Limit atmospheric exposure to 15 minutes.

12. If compressor removal is necessary, always plug

compressor immediately after removal. Purge with

small amount of nitrogen when inserting plugs.

TOPPING OFF SYSTEM CHARGE

If a leak has occurred in the system, Bard

Manufacturing recommends reclaiming, evacuating (see

criteria above), and charging to the nameplate charge.

However, if done correctly, topping off the system

charge can be done without problems.

With R-410A, there are no signicant changes in the

refrigerant composition during multiple leaks and

recharges. R-410A refrigerant is close to being an

azeotropic blend (it behaves like a pure compound

or single component refrigerant). The remaining

refrigerant charge, in the system, may be used after

leaks have occurred and then “top-off” the charge by

utilizing the charging charts on the inner control panel

cover as a guideline.

REMEMBER: When adding R-410A refrigerant,

it must come out of the charging cylinder/tank as a

liquid to avoid any fractionation, and to insure optimal

system performance. Refer to instructions for the

cylinder that is being utilized for proper method of

liquid extraction.

WARNING

Failure to conform to these practices

could lead to injury or death.

SAFETY PRACTICES:

1. Never mix R-410A with other refrigerants.

2. Use gloves and safety glasses. Polyol Ester oils

can be irritating to the skin, and liquid refrigerant

will freeze the skin.

3. Never use air and R-410A to leak check; the

mixture may become ammable.

4. Do not inhale R-410A – the vapor attacks the

nervous system, creating dizziness, loss of

coordination and slurred speech. Cardiac

irregularities, unconsciousness and ultimate death

can result from breathing this concentration.

5. Do not burn R-410A. This decomposition

produces hazardous vapors. Evacuate the area if

exposed.

6. Use only cylinders rated DOT4BA/4BW 400.

7. Never ll cylinders over 80% of total capacity.

8. Store cylinders in a cool area, out of direct

sunlight.

9. Never heat cylinders above 125°F.

10. Never trap liquid R-410A in manifold sets, gauge

lines or cylinders. R-410A expands signicantly

at warmer temperatures. Once a cylinder or line is

full of liquid, any further rise in temperature will

cause it to burst.

Manual 2100-578E

Page 25 of 41

START UP

DESCRIPTION OF STANDARD

EQUIPMENT

Solid State Electronic Heat Pump Control

Provides efcient 30, 60 or 90-minute defrost cycle.

A thermistor sensor and speed up terminal for service

along with a 8-minute defrost override are standard on

the electronic heat pump control. By default, the I-TEC

are factory shipped on the 90-minute defrost cycle.

High / Low Pressure Switch

Provides refrigerant circuit high pressure and loss

of charge protection. Includes lockout circuit built

into heat pump control that is resettable from room

thermostat.

Five Minute Compressor Time Delay

Provides short cycle protection for the compressor

which extends compressor life. Built into the electronic

heat pump control as standard.

Condensate Overow

Senses and provides system shut down if draining issue

causes water level to rise in the lower drain pan.

Low Ambient Control

The low ambient control permits cooling operation

down to 0°F outdoor ambient.

IMPORTANT INSTALLER NOTE

For improved start-up performance, wash the indoor

coil with a dishwasher detergent.

PHASE MONITOR

All units with three phase scroll compressors are

equipped with a 3 phase line monitor to prevent

compressor damage due to phase reversal.

The phase monitor in this unit is equipped with two

LEDs. If the Y signal is present at the phase monitor

and phases are correct the green LED will light and the

compressor contactor is allowed to energize.

If phases are reversed, the red fault LED will be lit and

compressor operation is inhibited.

If a fault condition occurs, reverse two of the supply

leads to the unit. Do not reverse any of the unit factory

wires as damage may occur.

THREE PHASE SCROLL COMPRESSOR

START UP INFORMATION

Scroll compressors, like several other types of

compressors, will only compress in one rotational

direction. Direction of rotation is not an issue with

single phase compressors since they will always start

and run in the proper direction.

However, three phase compressors will rotate in either

direction depending upon phasing of the power. Since

there is a 50-50 chance of connecting power in such

a way as to cause rotation in the reverse direction,

verication of proper rotation must be made.

Verication of proper rotation direction is made by

observing that suction pressure drops and discharge

pressure rises when the compressor is energized.

Reverse rotation also results in an elevated sound level

over that with correct rotation, as well as substantially

reduced current draw compared to tabulated values.

Verication of proper rotation must be made at the time

the equipment is put into service. If improper rotation

is corrected at this time there will be no negative impact

on the durability of the compressor. However, reverse

operation for even one hour may have a negative

impact on the bearing due to oil pump out.

All three phase scroll compressors used in the I-TEC

series are wired identically internally. As a result, once

the correct phasing is determined for a specic system or

installation, connecting properly phased power leads to

the same Fusite terminal should maintain proper rotation

direction. The direction of rotation of the motor may be

changed by reversing any two line connections to the unit.

SERVICE HINTS

1.

Caution user to maintain clean air lters at all

times. Also, not to needlessly close off supply air

registers. This may reduce airow through the

system, which shortens equipment service life as

well as increasing operating costs and noise levels.

2.

Switching to heating cycle at 75°F or higher outside

temperature may cause a nuisance trip of the remote

reset high pressure switch. Turn thermostat off,

then on to reset the high pressure switch.

3.

The heat pump wall thermostats perform multiple

functions. Be sure that all function switches are

correctly set for the desired operating mode before

trying to diagnose any reported service problems.

4. Check all power fuses or circuit breakers to be

sure they are the correct rating.

5.

Periodic cleaning of the outdoor coils to permit

full and unrestricted airow circulation is essential.

6. Annual maintenance is required to make sure

that all of the systems are functioning properly.

a. Check to make sure that the drains are not

obstructed in any way.

b. Remove any debris in the condenser section

of the unit.

c. Inspect and wash outdoor coils as necessary.

7. All motors are sealed and require no oiling.

Manual 2100-578E

Page 26 of 41

SEQUENCE OF OPERATION

PRESSURE SERVICE PORTS

COOLING PART LOAD – Circuit R-Y1 makes at

thermostat pulling in compressor contactor, starting the

compressor and outdoor motor. The G (indoor motor)

circuit is automatically completed on any call for

cooling operation or can be energized by manual fan

switch on subbase for constant air circulation.

COOLING FULL LOAD – Circuit R-Y1 & Y2

makes at the thermostat energizing the 2nd stage

solenoid in the compressor. The default position of

the compressor staging solenoid is non-energized. The

compressor will run at low capacity until this solenoid

is energized.

HEATING STAGE 1 – A 24V solenoid coil on

reversing valve controls heating cycle operation. Two

thermostat options, one allowing “Auto” changeover

from cycle to cycle and the other constantly energizing

solenoid coil during heating season and thus

eliminating pressure equalization noise except during

defrost, are to be used. On “Auto” option a circuit is

completed from R-B and R-Y1 on each heating “on”

cycle, energizing reversing valve solenoid and pulling

in compressor contactor starting compressor and

outdoor motor. R-G also make starting indoor blower

motor. Heat pump heating cycle now in operation.

The second option has no “Auto” changeover position,

but instead energizes the reversing valve solenoid

constantly whenever the system switch on subbase

is placed in “Heat” position, the “B” terminal being

constantly energized from R. A thermostat demand

for Stage 1 heat completes R-Y1 circuit, pulling in

compressor contactor starting compressor and outdoor

motor. R-G also make starting indoor blower motor.

High and low pressure service ports are installed on

all units so that the system operating pressures can be

observed. Pressure tables can be found later in the

manual covering all models. It is imperative to match

the correct pressure table to the unit by model number.

Upper and lower service doors must be attached to

obtain proper reading.

HEATING STAGE 2 – Circuit R-Y1 & Y2 makes at

the thermostat energizing the 2nd stage solenoid in the

compressor.

Manual 2100-578E

Page 27 of 41

DEFROST CYCLE

120*

SW1SW

2 TIME (SEC)

OFF

OFF

ON

ON

OFF

ON

OFF

ON

30

60

180

MIS-2668 A

OFF

LOW PRESSURE BYPASS TIMER SWITCH

*(FACTORY SETTING 120 SECONDS)

ACCUMULATED DEFROST TIME TIMER

(FACTORY SETTING 60 MIN.)

ON

The defrost cycle is controlled by temperature and time

on the solid state heat pump control. See Figure 14.

When the outdoor temperature is in the lower

40°F temperature range or colder, the outdoor coil

temperature is 32°F or below. This coil temperature

is sensed by the coil temperature sensor mounted near

the bottom of the outdoor coil. Once coil temperature

reaches 30°F or below, the coil temperature sensor sends

a signal to the control logic of the heat pump control and

the defrost timer will start accumulating run time.

After 30, 60 or 90 minutes of heat pump operation at

30°F or below, the heat pump control will place the

system in the defrost mode. Factory default setting is 90

minutes.

During the defrost mode, the refrigerant cycle switches

back to the cooling cycle, the outdoor motor stops,

electric heaters are energized, and hot gas passing

through the outdoor coil melts any accumulated frost.

When the temperature rises to approximately 57°F, the

coil temperature sensor will send a signal to the heat

pump control which will return the system to heating

operations automatically.

If some abnormal or temporary condition such as a high

wind causes the heat pump to have a prolonged defrost

cycle, the heat pump control will restore the system to

heating operation automatically after 8 minutes.

The heat pump defrost control board has an option of

30, 60 or 90-minute setting. All models are shipped

from the factory on the 90-minute pin. If special

circumstances require a change to another time, remove

the wire from the 90-minute terminal and reconnect to

the desired terminal.

The manufacturer’s recommendation is for 90-minute

defrost cycles. Refer to Figure 14.

There is a cycle speed up jumper on the control. This

can be used for testing purposes to reduce the time

between defrost cycle operation without waiting for

time to elapse.

Use a small screwdriver or other metallic object, or

another ¼ inch QC, to short between the SPEEDUP

terminals to accelerate the HPC timer and initiate

defrost.

Be careful not to touch any other terminals with the

instrument used to short the SPEEDUP terminals. It

may take up to 15 seconds with the SPEEDUP terminals

shorted for the speedup to be completed and the defrost

cycle to start.

As soon as the defrost cycle kicks in remove the

shorting instrument from the SPEEDUP terminals.

Otherwise the timing will remain accelerated and run

through the 1-minute minimum defrost length sequence

in a matter of seconds and will automatically terminate

the defrost sequence.

There is an initiate defrost jumper (sen jump) on the

control that can be used at any outdoor ambient during

the heating cycle to simulate a 0° coil temperature.

This can be used to check defrost operation of the unit

without waiting for the outdoor ambient to fall into the

defrost region.

By placing a jumper across the SEN JMP terminals (a

¼ inch QC terminal works best) the defrost sensor

mounted on the outdoor coil is shunted out & will

activate the timing circuit. This permits the defrost cycle

to be checked out in warmer weather conditions without

the outdoor temperature having to fall into the defrost

region.

In order to terminate the defrost test the SEN JMP

jumper must be removed. If left in place too long, the

compressor could stop due to the high pressure condition

created by operating in the cooling mode with outdoor

fan off. Pressure will rise rapidly as there is likely

no actual frost on the outdoor coil in this articial test

condition.

There is also a 5-minute compressor time delay function

built into the Heat Pump Control to protect the compressor

from short cycling conditions. The board’s LED will have a

fast blink rate when in the compressor time delay function.

In some instances, it is helpful to the service technician to

override or speed up this timing period, and shorting out

the SPEEDUP terminals for a few seconds can do this.

FIGURE 14

HEAT PUMP CONTROL

DEFROST CYCLE

(FACTORY SETTING 90 MIN.)

Manual 2100-578E

Page 28 of 41

I-TEC COMMERCIAL ROOM

5.500

2.585 2.585 2.585 .745

NO. NO.

DATE

PART

NAME

DWG.

Bryan, Ohio

DISTRIBUTION 1 2 3 4 5

MAT'L

Bard Mfg. Co.

CHECKED

DRAWN BYSCALE

PART

APPROVED

DISCONNECT ALL ELECTRICAL

IN SEVERE INJURY OR AMPUTATION.

IN SEVERE INJURY OR AMPUTATION.

7961-754-2

C

LABEL SHEET #1

REQUIRE PROPER PHASING. REFER

DISCONNECT THE REMOTE

7961-754

3 PHASE SCROLL COMPRESSORS

EXPOSED MOVING PARTS.

FAILURE TO DO SO CAN RESULT

ELECTRICAL SHOCK CAN RESULT

IN SEVERE INJURY OR AMPUTATION.

POWER BEFORE SERVICING.

EXPOSED MOVING PARTS.

WARNING

IN SERIOUS INJURY OR DEATH.

DISCONNECT THE REMOTE

7961-754-1

DISCONNECT ALL ELECTRICAL

ELECTRICAL SHOCK CAN RESULT

ELECTRIC POWER SUPPLY OR

7961-754-1

WARNING

!

HAZARD OF ELECTRICAL SHOCK.

PROPER START UP INFORMATION.

IMPORTANT

SUPPLIES BEFORE SERVICING.

IN SERIOUS INJURY OR DEATH.

1:1

11/17/2011

7961-754-8

TO INSTALLATION INSTRUCTIONS FOR

Piece

Front Trim

EXPOSED MOVING PARTS.

SUPPLIES BEFORE SERVICING.

CGB

7961-754-2

WARNING

!

HAZARD OF ELECTRICAL SHOCK.

!

WARNING

DAY RSP

WARNING

!

!

WARNING

7961-754-2

7961-754-1

DISCONNECT ALL ELECTRICAL

7961-754-9

POWER BEFORE SERVICING.

FAILURE TO DO SO CAN RESULT

POWER BEFORE SERVICING.

FAILURE TO DO SO CAN RESULT

ELECTRIC POWER SUPPLY OR

VENTILATOR SYSTEM

GENERAL DESCRIPTION

The I-TEC Commercial Room Ventilator (CRV) is

designed to be used with all Bard I-TEC models. The

only intent of this device is to provide the required

ventilation by delivering fresh air to meet I.A.Q. (Indoor

Air Quality) requirements. In the installed application,

this system also includes exhaust provisions which

are balanced with the intake air to maintain building

pressurization requirements of ASHRAE 62.1 Standard.

Ventilation is accomplished with (2) blower/

motor assemblies for maximum ventilation at low

sound levels. The intake and exhaust blowers are

programmed independently and are balanced to

maintain a slight positive pressurization in accordance

to ASHRAE 62.1 Standard.

The I-TEC CRV is also provided with lters to reduce

the required service needed and to further improve the

I.A.Q. The exhaust air blowers and intake air blowers

are protected by two (2) throw away lters. Both are

accessible without the need for tools.

CONTROL WIRING

The I-TEC CRV comes wired from the factory set to

450 CFM of ventilation. Care must be taken when

deciding how to control the operation of the ventilator.

When designing the control circuit for the ventilator, the

following requirements must be met.

1.

The indoor blower must be run whenever the I-TEC

CRV is run.

2.

Select and congure the correct CFM ventilation

level that the I-TEC CRV needs to operate and

congure the system to this level following later

instructions within this section. Over ventilating

serves no useful purpose and signicantly affects

the overall efciency of the heat pump system.

System operating costs would also increase.

3. Run the I-TEC CRV only during periods when the

conditioned space is occupied. Running the

ventilation during unoccupied periods wastes

energy, decreases the expected life of the CRV,

and can result in large moisture buildup in the

structure. Running the CRV when the structure is

unoccupied allows moisture to build up in the

structure because there is little or no cooling load.

Thus, the air conditioner is not running enough to

remove the excess moisture being brought in. Use

a control system that in some way can control the

system based upon occupancy.

Operating the I-TEC CRV during unoccupied periods can

result in a build up of excess moisture in the structure.

RECOMMENDED CONTROL SEQUENCES

Several possible scenarios are listed below:

1. Use a programmable electronic thermostat with

auxiliary terminal to control the CRV based on

daily programmed occupance periods. Bard

markets and recommends Bard Part #8403-060

programmable electronic thermostat.

2.

temperature, humidity and occupancy control with

learning capability into a single device. No

programming required.

3.

upon a room occupancy schedule to control the CRV.

4.