Page 1

INSTALLATION INSTRUCTIONS

FUSION-TEC™/LV1000

Free Cooling Unit System

FUSION-TEC™

Wall-Mount Air Conditioner

Models:

HR36APA HR36APB

HR58APA HR58APB

LV1000-100 Lead/Lag Controller

NOTE: LV1000 Controller is required for operation when

multiple HR**AP* units are used.

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-674A

Supersedes: 2100-674

Date: 7-13-17

Page 1 of 41

Page 2

CONTENTS

List of Necessary Materials/Tools ....................6

Site Preparation ...................................................7

Model Identification .......................................... 7

New Shelter Installation vs. Retrofit Installation .. 7

Minimum Clearance .......................................... 8

Clearance to Combustibles ................................ 8

Wall-Mount Unit Mounting ..............................10

Mounting the Units ......................................... 10

Supply Air Grill Installation .................................... 10

Wall-Mount Unit Wiring ...................................16

Main Power Wiring .......................................... 16

Unit Voltage Wiring ......................................... 17

Preliminary Start Up .........................................19

Running in Stand Alone (Orphan) Mode ............ 19

LV1000 Controller Installation ........................20

LV1000 Controller .......................................... 21

Mounting the LV Controller ........................ 21

Installing Remote Indoor

Temperature/Humidity Sensor(s) ................ 22

FIGURES AND TABLES

Figure 1 FUSION-TEC Model Nomenclature ........... 7

Figure 2 Dimensions ............................................ 9

Figure 3 Prefilling Traps on Indoor Drain Pan

Hoses

Figure 4 Hanging Front Access Panel to Allow

Access to Control Panel

Figure 5 Fold-Out Diverter .................................. 12

Figure 6 Downward Curved Diverter Blades .......... 12

Figure 7 View of Installed Grille .......................... 12

Figure 8 Mounting Instructions ........................... 13

Figure 9 Electric Heat Clearance ......................... 14

Figure 10 Wall Mounting Instructions ....................14

Figure 11 Wall Mounting Instructions ....................15

Figure 12 Common Wall Mounting Installations ......15

Figure 13 Wire Routing ........................................17

Figure 14 WIRING: VAC Supply Wiring

Landing Points .....................................17

Figure 15 Adjusting the 230/208 VAC

Transformer ..........................................18

Figure 16 Cool and Heat Setpoints ........................19

Figure 17 Typical LV1000 Component Location ......20

Figure 18 LV1000 Fused Power Supply Terminal ....21

Figure 19 Remote Indoor Temperature/Humidity

Sensor Installation ................................22

Figure 20 Additional Remote Sensor Installation ....23

Figure 21 Communication Wiring (Daisy Chain) ......25

Figure 22 Communication Wiring (Alt. Method) ......25

Figure 23 Placement of Communication Filters ......26

Figure 24 Communication Wiring: Termination

at the Controller ...................................27

Figure 25 Communication Wiring: Termination

at the First Wall-Mount Unit ..................28

Figure 26 Communication Wiring: Termination

at Additional Wall-Mount Units ..............29

....................................................

.........................

11

11

Additional LV1000 Connections ................. 24

Communication Wiring .............................. 25

LV1000 Supply Wiring .............................. 30

System Set Up ....................................................33

TEC-EYE Hand-Held Diagnostic Tool ................ 33

Setting Up Wall-Mount Units for Operation ....... 34

1. Address Each Wall-Mount Unit .............. 34

2. Execute a Run Test on Each Unit ........... 35

3. Clear Unit Alarm Logs ........................... 35

Setting Up LV1000 for Operation ..................... 35

4. Set LV Controller Timezone and

Date/Time ............................................ 36

5. Configure Sensors................................. 37

6. Enter Total Number of Units .................. 38

7. Verify Units are Online .......................... 39

8. Clear Controller Alarm Logs ................... 39

9. Complete Installation ............................ 39

Additional Information ....................................40

Figure 27 LV1000-100 Controller Supply Wiring ....30

Figure 28 Controller Grounding Posts ....................30

Figure 29 WIRING: LV1000 Wiring Diagram...........32

Figure 30 TEC-EYE Connection to Unit Control ......33

Figure 31 TEC-EYE Display and Interface ..............33

Figure 32 Changing Unit Setup Values ..................34

Figure 33 Changing Economizer Control Type .........35

Figure 34 Executing Run Test ...............................35

Figure 35 Clearing Unit Alarm Logs .......................35

Figure 36 LV1000 Controller Display/Interface .......36

Figure 37 Changing Timezone ...............................36

Figure 38 Setting Controller Date and Time ............36

Figure 39 Configuring Indoor Humidity 1 Sensor ....37

Figure 40 Configuring Indoor Humidity 2 Sensor ....37

Figure 41 Configuring Indoor Humidity 3 Sensor ....37

Figure 42 Configuring Indoor Temp 1 Sensor ..........38

Figure 43 Configuring Indoor Temp 2 Sensor ..........38

Figure 44 Configuring Indoor Temp 3 Sensor ..........38

Figure 45 Entering Total Number of Units ..............39

Figure 46 Verifying Units .....................................39

Figure 47 Clearing LV1000 Alarm Logs .................39

Figure 48 Adjusting Sensor Offset Value ................40

Figure 49 Restoring Factory Default Settings..........40

Table 1 Clearance Required for Service Access

and Adequate Condenser Airflow ..............8

Table 2 Minimum Clearance Required to

Combustible Materials ............................8

Table 3 Electrical Specification .........................16

Table 4 LV1000-100 Terminal Block Index .........31

Table 5 LV1000/TEC-EYE Passwords (Default) ....33

Table 6 Unit Status Messages ...........................41

Table 7 LV1000 Status Messages ......................41

Manual 2100-674A

Page 2 of 41

Page 3

GENERAL INFORMATION

Free Cooling Unit System

This Bard Free Cooling Unit System is composed of

FUSION-TEC wall-mounted air conditioners matched

with an LV1000 lead/lag controller. The wall mounts

are specifically engineered for telecom/motor control

center rooms.

NOTE: The LV1000 lead/lag controller and FUSION-

TEC wall-mount units are designed specifically

to work together. The controller cannot run

other Bard models or other brands of systems,

nor can other controllers run the FUSION-TEC

wall-mount units. They are a complete system,

and must be used together.

Wall-Mount Air Conditioner Units

The FUSION-TEC units operate on VAC power.

units will supply 100% of rated cooling airflow in free

cooling mode with ability to exhaust the same amount

through the unit itself without any additional relief

openings in the shelter.

Each of these units are fully charged with refrigerant

and may have optional auxiliary heat.

The

Controller

LV1000 controller and accessories included shown

below.

General

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use without duct work. Flanges

are provided for transition from unit to wall grilles. A

field-supplied wall sleeve may be necessary between

the supply and return flanges and grilles.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly any tags

and/or labels attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation

is made. See Additional Publications on page 4 for

information on codes and standards.

LV1000 Series

TEC-EYETM Hand-Held

Diagnostic Tool

Bard P/N 8301-059

LV1000 Series

Programmable Logic

Controller

Remote Temperature/

Humidity Sensor*

(with 35' shielded cable)

Bard P/N 8403-079

* One remote temperature/humidity sensor and 35' of 5-wire shielded cable with drain are included with

the LV1000 controller. Up to two additional remote temperature/humidity sensors can be purchased and

installed. Temperature-only sensors (Bard P/N 8301-058) may be used instead of the additional temperature/

humidity sensors, but will also need to be purchased separately. Temperature-only sensors require fieldsupplied 2-wire shielded cable with drain.

Communication

EMI Filters

Bard P/N 8301-055

Manual 2100-674A

Page 3 of 41

Page 4

Sizing of systems for proposed installation should be

based on heat loss and heat gain calculations made

according to methods of Air Conditioning Contractors of

America (ACCA). The supply flange should be installed

in accordance with the Standards of the National

Fire Protection Association for the Installation of Air

Conditioning and Ventilating Systems of Other Than

Residence Type, NFPA No. 90A, and Residence Type

Warm Air Heating and Air Conditioning Systems, NFPA

No. 90B. Where local regulations are at a variance with

instructions, installer should adhere to local codes.

Shipping Damage

Upon receipt of equipment, the cartons should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

These units must remain in upright position at all

times.

Additional Publications

These publications can help when installing the

furnace. They can usually be found at the local library

or purchased directly from the publisher. Be sure to

consult the current edition of each standard.

ANSI Z535.5 Definitions:

DANGER: Indicate[s] a hazardous situation which, if

not avoided, will result in death or serious injury. The

signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

WARNING: Indicate[s] a hazardous situation which,

if not avoided, could result in death or serious injury.

WARNING [signs] should not be used for property

damage hazards unless personal injury risk appropriate

to this level is also involved.

CAUTION: Indicate[s] a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION [signs] without a safety alert symbol may be

used to alert against unsafe practices that can result in

property damage only.

NOTICE: [this header is] preferred to address practices

not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an

alternative to “NOTICE” the word “CAUTION” without

the safety alert symbol may be used to indicate a

message not related to personal injury.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation of Air Conditioning

and Ventilating Systems ...................ANSI/NFPA 90A

Standard for Warm Air Heating

and Air Conditioning Systems ............ANSI/NFPA 90B

Load Calculation for Residential Winter

and Summer Air Conditioning ............. ACCA Manual J

For more information, contact these publishers:

Air Conditioning Contractors of America (ACCA)

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370 Fax: (202) 234-4721

American National Standards Institute (ANSI)

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900 Fax: (212) 302-1286

American Society of Heating, Refrigeration and Air

Conditioning Engineers, Inc. (ASHRAE)

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400 Fax: (404) 321-5478

National Fire Protection Association (NFPA)

Batterymarch Park

P. O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555 Fax: (617) 984-7057

Manual 2100-674A

Page 4 of 41

Page 5

!

WARNING

!

WARNING

Electrical shock hazard.

Have a properly trained individual perform

these tasks.

Failure to do so could result in electric shock

or death.

!

WARNING

Fire hazard.

Maintain minimum 1/4" clearance between the

supply ange and combustible materials.

Failure to do so could result in re causing

damage, injury or death.

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

!

CAUTION

Cut hazard.

Wear gloves to avoid contact with sharp

edges.

Failure to do so could result in personal injury.

Manual 2100-674A

Page 5 of 41

Page 6

LIST OF NECESSARY MATERIALS/TOOLS

Additional hardware and miscellaneous supplies are needed for installation. These items are field supplied and must

be sourced before installation. This list also includes tools needed for installation.

List of Materials/Tools

• Personal protective equipment/safety devices/ antistatic wrist straps

• SGR-5W Supply Grille and RGR-5W Return Grille

• Field-fabricated sleeves (if necessary)

• Bottom mounting bracket #113-140 (optional)

• Fasteners sufficient for mounting the units such as

5/16" diameter anchor/lag bolts

• 7/8" diameter washers

• Fasteners appropriate for the shelter wall

construction to attach the controller to the wall

• Commercial grade outdoor silicone sealant

• Miscellaneous hand and power tools and jobsite or

shop materials

• Lifting equipment with the necessary capacity and

rigging to safely move/install the systems

• Water to prime drain traps

• Electrical supplies

- Various size circuit breakers for the shelter AC

breaker box (see Table 3 on page 16)

- High-voltage wire of various gauges

(see Table 3)

- 16 gauge minimum, 14 gauge maximum

power wire to connect controller to shelter

power source

- 5-wire, 18 gauge shielded cable with drain

for remote temperature and humidity sensors

(2-wire, 18 gauge shielded cable with drain for

temperature-only sensors)

- Communication wire: 2-wire, 18 gauge,

shielded with drain

- 18 gauge non-shielded wire for connecting

smoke detector, hydrogen detector and/or

generator, if applicable, to controller

-

- Miscellaneous electrical supplies including

CAT 6 Ethernet cable of field-determined length

(for remote communication, if applicable)

rigid/flexible conduit and fittings, 2" x 4"

junction boxes (one per temperature/humidity

sensor), wire connectors and supports

The following is required and must be sourced prior

to installation of these units.

• One (1) 5A circuit breaker for the shelter DC

power plant (for the controller)

Circuit breakers for Emerson Network Power (ENP)

power plants (used in most telecomm shelters built

today) are available directly through the following

distributors:

• Emerson Network Power: 440.288.1122

• Master Electronics: 888.473.5297 or

www.onlinecomponents.com

Emerson Network Power (ENP) Part Number

• 5A circuit breaker: P/N 101598

Always confirm the application before ordering.

Manual 2100-674A

Page 6 of 41

Page 7

SITE PREPARATION

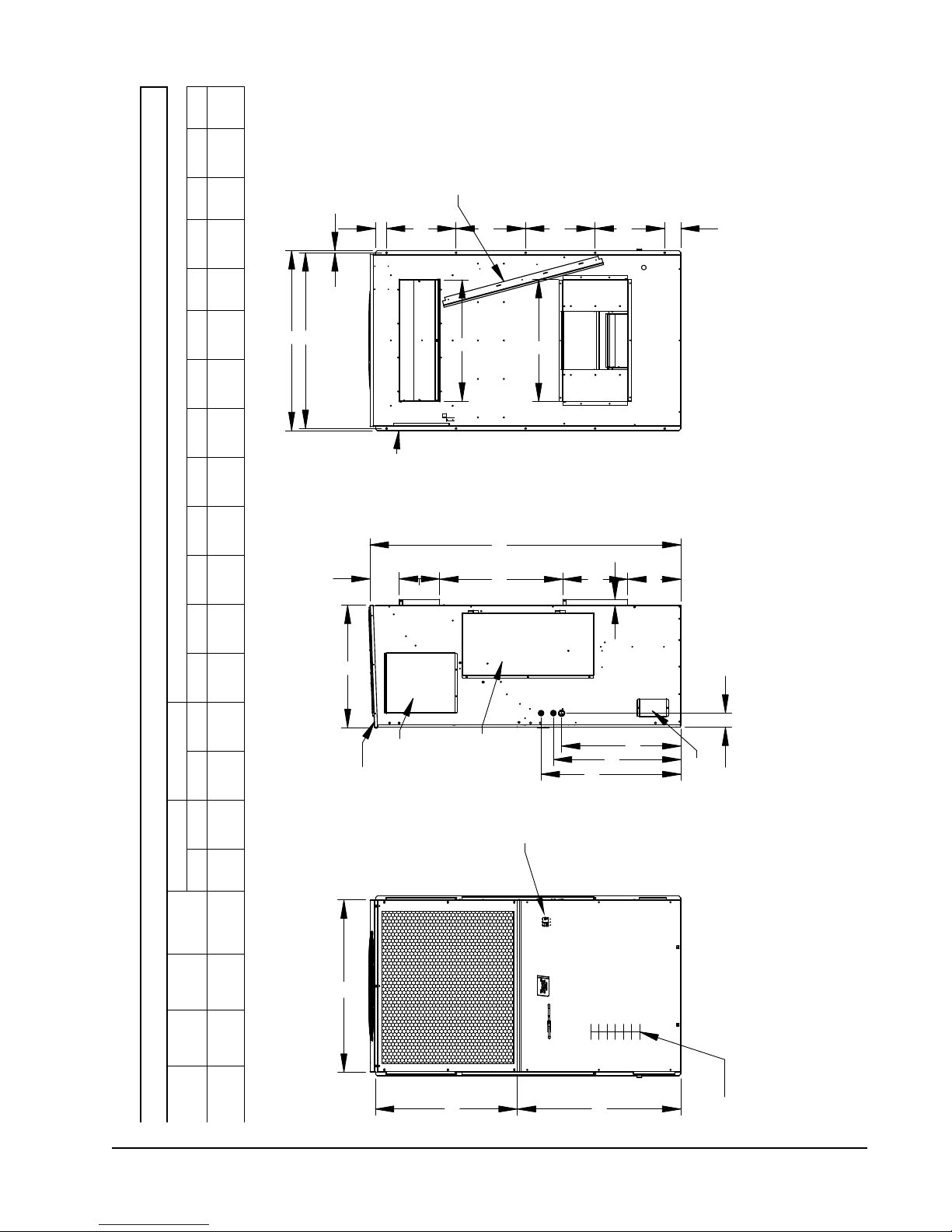

Model Identification

Identify the specific model using the model

nomenclature information found in Figure 1 and

the model/serial tag found on the unit. See Figure

2 on page 9 for dimensions and critical installation

requirements.

New Shelter Installation vs. Retrofit

Installation

These installation instructions cover both new shelter

installations and retrofit installations. Each installation

FIGURE 1

FUSION-TEC Wall-Mount Unit Model Nomenclature

HR 58 A P A 0Z E P X X X X

UNIT SERIES

MAXIMUM SENSIBLE CAPACITY

36 – 3 Ton 2 Stage Step Capacity

58 – 5 Ton 2 Stage Step Capacity

REVISION

A – Revision Level

CONTROL LOGIC AND CLIMATE OPTIONS

0Z – O kW with Circuit Breaker

01 – 1.5 kW with Circuit Breaker

05 – 5 kW with Circuit Breaker

5 – Internal and External Cabinet Component Coating, Coated Evaporator Coil, Coated Condenser Coil

P – Programmable Logic Board

VOLTS & PHASE

A – 230/208/60/1

B – 230/208/60/3

MZ – O kW with Circuit Breaker and Inverter

M1 – 1.5 kW with Circuit Breaker and Inverter

M5 – 5 kW with Circuit Breaker and Inverter

E – Factory-Installed Economizer (All Units)

P – MERV8 Disposable Pleated Filter

X – Copper/Aluminum Evaporator Coil, Copper/Aluminum Condenser Coil

4 – Condenser Section Component Coating, Coated Evaporator Coil, Coated Condenser Coil

X – Standard accessories including airflow sensor, dirty filter sensor, pressure transducers, crankcase heater

S – All standard accessories plus additional Bard Guard

is unique and may require special accommodations and

modifications. Although Bard Manufacturing follows a

long-established tradition of manufacturing equipment

using industry standard dimensions for building

penetration, it is occasionally necessary to move or

enlarge supply and return openings when replacing

non-standardized equipment in a retrofit application.

IMPORTANT: All retrofit installations require any

existing supply and return grilles be removed and

discarded. This is a counterflow unit and requires

specified grilles to ensure proper system performance.

ELECTRIC HEAT

VENT PACKAGE

FILTER

COLOR AND CABINET FINISH

X – Beige Baked Enamel Finish

1 – White Baked Enamel Finish

4 – Buckeye Gray Baked Enamel Finish

5 – Desert Brown Baked Enamel Finish

8 – Dark Bronze Baked Enamel Finish

PLACEHOLDER

X – Future Use

COIL AND UNIT COATING OPTIONS

1 – Coated Evaporator Coil

3 – Coated Evaporator Coil, Coated Condenser Coil

2 – Coated Condenser Coil

ACCESSORIES AND CONTROLS OPTIONS

TM

security features and security frame

Manual 2100-674A

Page 7 of 41

Page 8

Minimum Clearance

Counter flow wall-mount air conditioner models have

a removable lower front service panel that allows

access to the control panel, blower, compressor, circuit

breakers and heat strip. There is a hinged access panel

on both sides for filter change and evaporator coil

service.

The upper side panel is removable to allow access

to condenser fan, condenser coil and filter drier. The

design allows for installations to place units within

close proximity without complicating maintenance and

repair.

To maintain full serviceability, side-by-side installations

require 15" of clearance between units.

The condenser discharge air exits through the top

of the unit. Although this reduces the potential for

recirculation, it is still critical to system performance

that any obstruction, shrubbery or structure adhere to

minimum clearances listed (see Table 1).

For overhangs not exceeding 12" from exterior wall,

minimum allowable clearance from top of unit

to bottom of overhang should be no less than 5".

For overhangs greater than 12" from exterior wall,

minimum allowable clearance from top of unit to

bottom of overhang should be no less than 10".

Clearance to Combustibles

The unit itself is suitable for 0" clearance, but the

supply air flange requires a minimum of 1/4" clearance

to combustible material. However, it is generally

recommended that a 1" clearance is used for ease of

installation and maintaining the required clearance

to combustible material. See Figure 8 on page 13 for

details on opening sizes.

!

WARNING

Fire hazard.

Maintain minimum 1/4" clearance between the

supply ange and combustible materials.

Failure to do so could result in re causing

damage, injury or death.

TABLE 1

Clearance Required for Service Access and Adequate Condenser Airflow

Model Side(s)

HR36 15" 5" 10"

HR58 15" 5" 10"

Discharge (Top)

Overhang 12" or less

Discharge (Top)

Overhang

Exceeding 12"

TABLE 2

Minimum Clearances Required to Combustible Materials

Model Supply Air Flange Cabinet

HR36 1/4" 0"

HR58 1/4" 0"

Intake (Base) Front of Unit

15" from

Snowline

15" from

Snowline

36" 24"

36" 24"

Shelter

Equipment from

Supply Grille

Manual 2100-674A

Page 8 of 41

Page 9

2° Pitch

Rain Hood

Access Panel

Condenser

Built In

Service Port

Cover

K

N

D

7.125

I

1.500

C

A

H

J

L

M

Q

R

E

B

B

.500

P

Q

Q

Q

O

MIS-3894

HR58

UNIT

Side View

Front View

Electric

Heat

Back View

F

W

G

Circuit

Breaker

Disconnect

Filter

Access

Panel

Side Wall

Mounting

Flanges

(Built in)

Top Rain Flashing

Shipping Location

(Remove before

installing unit)

FIGURE 2

Return Supply

A B C B E F G I J K L M N O P Q R

(H)

(D)

(W)

Model

42.00 30.00 76.00 9.88 29.88 14.25 29.88 44.00 40.00 34.13 30.00 29.13 13.00 31.13 34.13 3.50 43.00 2.69 17.00 3.88

HR36

HR58

All dimensions are in inches. Dimensional drawings are not to scale.

Height

Depth

Width

Dimensions of Basic Unit for Architectural and Installation Requirements (Nominal)

Sizes:

.875" (2)

Knockout

1.093" (1)

Manual 2100-674A

Page 9 of 41

Page 10

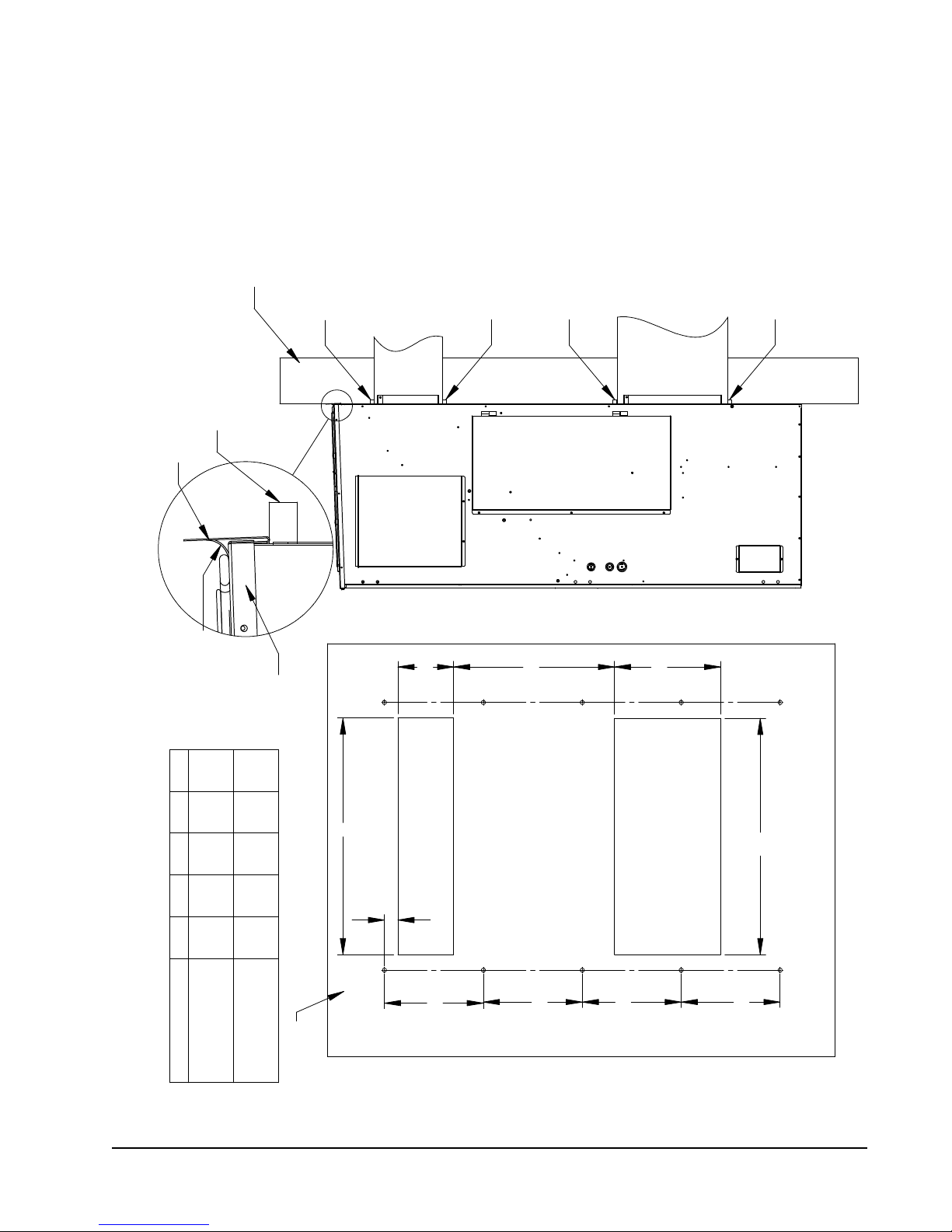

WALL-MOUNT UNIT MOUNTING

Mounting the Units

!

WARNING

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

NOTE: It may be best to spot some electrical knockouts

(such as those located on the sides of the

wall-mount unit) before units are mounted and

access is unavailable or limited (see Figure 2 to

locate pre-punched knockouts).

Two holes for the supply and return air openings must

be cut through the wall as shown in Figure 8 on page

13. On wood frame walls, the wall construction must

be strong and rigid enough to carry the weight of the

unit without transmitting any unit vibration. All walls

must be thoroughly inspected to ensure that they are

capable of carrying the weight of the installed unit.

In retrofit (unit replacement) installations, the openings

cut for the original equipment may not line up exactly

with needs of this installation. Modifications may need

to be made, such as increasing or decreasing the size

of the wall cutouts. The existing bolt placement may

not line up in which case the original bolts would need

to be removed or cut away.

These units are secured by full-length mounting flanges

built into the cabinet on each side. An optional bottom

mounting bracket (purchased separately) is available,

but not required.

The unit itself is suitable for 0" clearance, but the

supply air flange requires a minimum of 1/4" clearance

to combustible material. However, it is generally

recommended that a 1" clearance is used for ease of

installation and maintaining the required clearance

to combustible material. See Figure 8 for details on

opening sizes.

IMPORTANT: When removing the shipping pallet from

beneath the wall unit, do not loosen or remove any of

the screws from either side of the unit.

1. Locate and mark lag bolt locations on both sides

and location for optional bottom mounting bracket,

if desired (see Figure 8).

NOTE: Top rain flashing is attached to back of unit

for shipping purposes. Be sure to remove this

flashing before installing unit.

2. If desired, hook top rain flashing under back bend

of top.

3. Position unit in opening and secure with fasteners

sufficient for the application such as 5/16" lag/

anchor bolts; use 7/8" diameter flat washers on

the lag bolts. It is recommended that a bead of

commercial grade outdoor silicone sealant caulk be

placed behind the side mounting flanges.

NOTE: Opening and removing the filter access door

from each side may make fastening unit to wall

easier.

4. Secure optional rain flashing to wall and caulk

around entire unit (see Figure 8).

5. For additional mounting rigidity, the return air

and supply air frames or collars can be drilled

and screwed or welded to the structural wall itself

(depending upon wall construction). Be sure to

observe required clearance if combustible wall.

6. Four plastic drain hoses extend from the condenser

and evaporator drain pans. The drain hoses are

secured to fittings mounted to the unit base.

NOTE: At the time of installation, Bard highly

recommends prefilling of the traps on both of

the indoor drain pan hoses to ensure proper unit

drainage at start. The water traps can easily

be seen with the front service panel removed.

To fill traps, pour water into both sides of

evaporator drain pan until the drain hoses are

visibly full (see Figure 3).

A unique feature of the FUSION-TEC is the ability to

hang the front service panel on the unit in a position

that allows full access to the control panel (see

Figure 4) while the unit remains fully functional for

troubleshooting and testing. To do this, remove the

panel and hook top lip of panel into bottom channel

of control panel. For added front panel stability, use

several of the screws that were removed to temporarily

connect the panel to the unit.

Manual 2100-674A

Page 10 of 41

Page 11

FIGURE 3

Prefilling Traps on Indoor Drain Pan Hoses

Evaporator Drain Pan Left Side Drain Hose Evaporator Drain Pan Right Right Drain Hose

Pour water into evaporator drain pan directly above left and right drain

fittings until coiled drain tubes in blower section are visibly full.

FIGURE 4

Hanging Front Access Panel to Allow

Access to Control Panel

Manual 2100-674A

Page 11 of 41

Page 12

Supply Air Grill Installation

Bard model SGR-5W grille is custom designed for

utilization with Bard wall-mount unit HR**AP* for

optimizing the air flow pattern and distribution to

minimize recirculation issues, and optimizing airflow

patterns within the shelter. It is engineered to ensure

that the distributed air is forced in a downward and

outward direction to eliminate obstructions and such

from causing the distributed air from stratifying close

to the unit and getting drawn back into the return air

opening. With the optimized air pattern, the shelter

should experience distributed air at the opposite end of

the room.

To accomplish this, the grille has two special features:

1. The grille has a specialty fold-out diverter on

the backside of the grille that directs the supply

airflow in an outward pattern, thereby eliminating

the potential for the obstruction of supply air if

FIGURE 5

Fold-Out Diverter

equipment would be directly mounted in front of

the unit. The rear deflectors must be folded out and

secured by the installer with the supplied screws

(see Figure 5).

2. The grille is also equipped with downward curved

diverter blades to ensure a smooth and efficient

means of directing the air pattern in a downward

pattern, and away from being drawn back into

the return air opening. The curved diverter blades

are shipped in the flat position and need to be

folded out to between 75-90° (best tuned to each

individual structure). See Figures 6 and 7.

FIGURE 6

Downward Curved Diverter Blades

Rear deflectors as shipped

Rear deflectors raised and secured together

Manual 2100-674A

Page 12 of 41

Diverter blades as shipped (left), and after raising (right)

FIGURE 7

View of Installed Grille (as seen from above)

Page 13

MIS-3898

Wall Structure

During Installation

Foam Air Seal To Support Rain Flashing

Rain Flashing

Supplied

FIGURE 8

Mounting Instructions

Entire Length Of Top

Of Calking Along

Seal With Bead

Foam Seal

Foam Seal

Air

Return

Foam Seal

Supply Air

Opening

Foam Seal

NOTES:

IT IS RECOMMENDED THAT A BEAD OF

SILICONE CAULKING BE PLACED BEHIND

THE SIDE MOUNTING FLANGES AND UNDER

TOP FLASHING AT TIME OF INSTALLATION

Right Side View

"

B

E

16.25

Top Of Unit

A B C D E

32 12 5 1/2 2 29

30 1/2 10 1/2 6 1/4 2 3/4 29 3/4

WALL

MATERIALS

COMBUSTIBLE MATERIALS

FROM COMBUSTIBLE

CLEARANCE FROM

MAINTAIN 1/4" MIN.

REQUIRED DIMENSIONS TO

MAINTAIN 1" MIN. CLEARANCE

REQUIRED DIMENSIONS TO

A

A

Return Air Opening

Supply Air Opening

D

Wall Opening and Hole Location View

17"

17"

17"

17"

Manual 2100-674A

Page 13 of 41

Page 14

Electric Heat Clearance

Typical Building

Outside Sheeting

FIGURE 9

Wall Frame

Inside Sheeting

Wall Mounting Instructions

See FIGURE 2 – Mounting Instructions

Supply Air Duct

Flange of Wall

1/4" Min.

FIGURE 10

1/4" Min.

SUPPLY GRILLE

FACTORY SUPPLIED

RAIN FLASHING.

MOUNT ON UNIT

BEFORE INSTALLATION

MIS-3897

WALL STRUCTURE

RETURN AIR

OPENING

SUPPLY AIR

OPENING

CONCRETE BLOCK WALL INSTALLATION WOOD FRAME WALL INSTALLATION

Manual 2100-674A

Page 14 of 41

RETURN AIR

OPENING

SUPPLY AIR

OPENING

WOOD OR STEEL SIDING

SIDE VIEW

RETURN AIR

OPENING

SUPPLY AIR

OPENING

MIS-3896

Page 15

FIGURE 11

Wall Mounting Instructions

MIS-3895

FRAMING MATERIAL

2 x 4'S, 2 x 6'S &/OR

STRUCTURAL STEEL

ATTACH TO TOP

PLATE OF WALL

1.000" CLEARANCE

ALL AROUND DUCT

IF REQUIRED

INTERIOR FINISHED WALL

OVER FRAME

1.000" CLEARANCE

ALL AROUND DUCT

IF REQUIRED

EXTERIOR FINISH WALL

OVER FRAME

ATTACH TO BOTTOM

PLATE OF WALL

45.00

29.88

RETURN DUCT

OPENING

SUPPLY DUCT

OPENING

2 x 6

1.000

9.88

30.00

14.25

13.00

C

L

THIS STRUCTURAL MEMBER

LOCATED TO MATCH STUD

SPACING FOR REST OF WALL.

A SECOND MEMBER MAY BE

REQUIRED FOR SOME WALLS.

RAIN

FLASHING

OUTSIDE

WALL

FIGURE 12

Common Wall Mounting Installation

RAFTERS

FINISHED CEILING SURFACE

RETURN AIR WALL SLEEVE

RETURN AIR DUCT

FIELD SUPPLIED

W/ GRILLE

W/ GRILLE

SUPPLY AIR WALL SLEEVE

SUPPLY AIR

FIELD SUPPLIED

OPENING W/ GRILLE

W/ GRILLE

FREE AIR FLOW

NO DUCT

MIS-3899

Manual 2100-674A

Page 15 of 41

Page 16

WALL-MOUNT UNIT WIRING

!

WARNING

Electrical shock hazard.

Have a properly trained individual perform

these tasks.

Failure to do so could result in electric shock

or death.

Main Power Wiring

Refer to the unit rating plate or Table 3 for wire sizing

information and maximum fuse or circuit breaker size.

Each outdoor unit is marked with a “Minimum Circuit

Ampacity”. The field wiring used must be sized to carry

that amount of current. Depending on the installed KW

of electric heat, there may be two field power circuits

required. If this is the case, the unit rating plate will

so indicate. All models are suitable only for connection

with copper wire. Each unit and/or wiring diagram

will be marked “Use Copper Conductors Only”. These

instructions must be adhered to. Refer to the National

Electrical Code (NEC) for complete current carrying

capacity data on the various insulation grades of wiring

material. All wiring must conform to NEC and all local

codes.

The unit rating plate and Table 3 list fuse and wire

sizes (75°C copper) for all models including the most

commonly used heater sizes. Also shown are the

number of field power circuits required for the various

models with heaters.

The unit rating plate lists a maximum circuit breaker or

fuse that is to be used with the equipment. The correct

size must be used for proper circuit protection and also

to ensure that there will be no nuisance tripping due to

the momentary high starting current of the compressor

motor.

The main unit circuit breaker disconnect access is

located on the front panel of the unit. Located at the

upper right corner of this panel is the rubber circuit

TABLE 3

Electrical Specifications

Single Circuit

Model

HR36 A0Z

HR36 B0Z

HR58 A0Z

HR58 B0Z

Maximum size of the time delay fuse or circuit breaker for protection of field wiring conductors.

Based on 75°C copper wire. All wiring must conform to the National Electrical Code and all local codes.

These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National

Electrical code (latest version), Article 310 for power conductor sizing.

CAUTION: When more than one field power circuit is run through one conduit, the conductors must be derated. Pay

IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly sized fuses

Rated Volts

& Phase

A01

230/208-1

A05

B01

230/208-3

B05

A01

230/208-1

A05

B01

230/208-3

B05

special attention to Note 8 of Table 310 regarding Ampacity Adjustment Factors when more than three current

carrying conductors are in a raceway.

and conductor wires in accordance with the National Electrical Code and all local codes.

No. Field

Power

Circuits

1

1

1

1

1

1

1

1

1

1

1

1

Minimum Circuit

Ampacity

26

26

30

25

25

25

43

43

43

30

30

30

Maximum

External Fuse or

Circuit Breaker

35

35

35

30

30

30

60

60

60

45

45

45

Field Power

Wire Size

8

8

8

10

10

10

8

8

8

8

8

8

Ground Wire

10

10

10

10

10

10

10

10

10

10

10

10

Manual 2100-674A

Page 16 of 41

Page 17

breaker boot. This allows unit power to be disconnected

without panel removal.

Route all field wires in channel under the control panel

as shown in Figure 13.

See Figure 14 to reference VAC landing points.

When running wires to unit from shelter, be careful to

not place wiring and conduit where it will interfere with

opening filter access doors.

FIGURE 13

Wire Routing

Unit Control Voltage Wiring

230/208V 1 phase and 3 phase equipment use dual

primary voltage transformers. All equipment leaves the

factory wired on 240V tap. It is very important that

the correct voltage tap is used. For 208V operation,

reconnect from 240V to 208V tap (see Figure 15 on

page 18). The acceptable operating voltage range for

the 240 and 208V taps are: 240V Tap (253 – 216)

and 208 Tap (220 – 197).

NOTE: The voltage should be measured at the field

power connection point in the unit and while

the unit is operating at full load (maximum

amperage operating condition.

FIGURE 14

VAC Supply Wiring Landing Points

Manual 2100-674A

Page 17 of 41

Page 18

FIGURE 15

Adjusting the 230/208 VAC Transformer

230/208V 1 phase and 3 phase equipment use dual primary voltage transformers. All equipment leaves the factory wired on

240V tap. It is very important that the correct voltage tap is used. For 208V operation, reconnect from 240V to 208V tap.

The acceptable operating voltage range for the 240 and 208V taps are: 240V Tap (253 – 216) and 208 Tap (220 – 197).

1. Verify incoming AC voltage: Multimeter set to VAC

60

230VAC

Shelter supply

breaker in ON position

Bard system

breaker in OFF position

230V/208V Single Phase Voltage Range:

197VAC – 253VAC

230V/208V Three Phase Voltage Range:

197VAC – 253VAC

(not shown)

2. If incoming AC voltage is 220VAC or above...

...do not adjust transformer

3. If incoming AC voltage is below 220VAC...

...shut off AC breaker to unit

and move factory "240V" wire to "208V" terminal

Manual 2100-674A

Page 18 of 41

Page 19

PRELIMINARY START UP

Running in Stand Alone (Orphan) Mode

With the AC breakers turned on, each FUSION-TEC

wall-mount unit has the capability to run without the

LV1000 controller attached—this feature is called

stand alone or orphan mode. This keeps the shelter

between 60°F and 79°F (factory default settings) by

the use of the factory-installed return air sensor in

each wall-mount unit. In stand-alone mode, the wall

unit uses a continuous blower setting to circulate room

air into the return air inlet and uses the return air

temperature sensor to control room temperature.

The wall-mount unit can be turned on and off with

the TEC-EYE hand-held diagnostic tool. When ON is

chosen, the wall unit will heat or cool. The blower will

continue to run when OFF is chosen. If the wall unit is

turned OFF by the TEC-EYE while in stand alone mode

and power is interrupted, when repowered the blower

will not run until the wall unit is turned back ON by the

TEC-EYE.

To turn the unit on or off with TEC-EYE:

1. Connect the TEC-EYE diagnostic tool to the control

board located in the unit.

2. Press MENU key to go to the Main Menu screen.

3. Press UP or DOWN keys and ENTER key to enter

USER password 2000.

4. Press UP or DOWN keys to scroll to On/Off; press

ENTER key.

5. Press UP or DOWN keys to change value from On

to Off or from Off to On.

6. Press ESCAPE key several times to return to Main

Menu screen.

To verify or change the wall-mount unit cooling and

heating setpoints in stand alone mode:

1. Connect the TEC-EYE diagnostic tool to the control

board located in the unit.

2. From the Status screen, press UP or DOWN key

until Quick Menu displays Setpoints (SET) icon.

Press ENTER key.

3. Press ENTER key to scroll to the selected choice

(see Figure 16).

4. Press UP or DOWN key on desired value until value

displays correctly.

5. Press ENTER key to save and scroll to next

parameter.

6. Press ESCAPE key until Main Menu screen is

displayed.

FIGURE 16

Cool and Heat Setpoints

During installation, the ability to run in stand alone

mode allows deactivation of one of the existing, older

wall-mount units, while keeping the shelter cool with

the other unit still operating. Once the first of the Bard

FUSION-TEC wall-mount units is installed, orphan

mode can be enabled early in the installation—keeping

the climate inside the shelter stable and the installers

comfortable while the remainder of the older equipment

is removed and the remaining Bard FUSION-TEC wallmount units and LV1000 controller are installed.

To ensure units will go into stand alone mode,

disconnect the plug marked R-T-/R+T+/GND on the

control board located in the wall-mount unit. Be sure

to reconnect the plug before operating the wall-mount

unit as part of the Bard Free Cooling Unit System.

Additionally, should any or all of the FUSION-TEC

wall-mount units lose communication with the LV1000

controller (such as during maintenance), they will

continue to serve the shelter’s needs until a repair can

be made.

NOTE: Screenshots shown in this manual reflect

default settings (when applicable).

Manual 2100-674A

Page 19 of 41

Page 20

LV1000 CONTROLLER INSTALLATION

FIGURE 17

Typical LV1000 Component Location

RJ11 Cable

to Display

-48VDC to 24V

Power Supply

Control Board

Power Loss Relay

Power Supply

Connections

Manual 2100-674A

Page 20 of 41

USB

Connection

Terminal Block

Page 21

!

WARNING

Electrical shock hazard.

Disconnect VAC and VDC power supplies

before servicing.

Failure to do so could result in electric shock

or death.

IMPORTANT: When working with circuit board

components,

an anti-static wrist strap to prevent static

electricity shorts to electronic controls.

Bard recommends the use of

LV1000 Controller

The LV1000 controller is part of the Free Cooling

Unit system by Bard. It is used to control up to four

(4) wall-mount air conditioners from one controller.

The microprocessor control provides an easy-to-read

interface with large LCD graphical display. It provides

control for redundancy for the structure and equal wear

on all units. The LV1000 controller is configured for

first on/next on sequence.

Conduit is recommended for all wiring. Route

communication wiring and power supply wiring in their

own separate conduits.

The LV1000 controller is not weatherproof and is

intended for use in weathertight structure.

Mounting the LV1000 Controller

The dimensions of the LV controller are 16" by 12" by

6".

Because the LV1000 controller utilizes a remote

temperature sensor as opposed to one located in the

controller box, the controller itself can be installed in

any indoor location that is suitable, preferably at eye

level. Four (4) mounting holes are provided for mounting

to the wall and holes for conduit connection are provided

in both the base, sides and top of the controller.

Ground case before doing any work or do not connect

power (48VDC) to unit until earth ground is connected.

The LV1000 controller includes a fused power supply

terminal in the terminal block. Before connecting wires

to the terminal block, confirm that the fuse in the fuse

holder is in the proper position (active) as shown in

Figure 18.

FIGURE 18

LV1000 Fused Power Supply Terminal

Fuse in Active Position

Shipping Position

Manual 2100-674A

Page 21 of 41

Page 22

Installing Remote Indoor Temperature/Humidity Sensor(s)

One remote indoor temperature/humidity sensor and 35' of 18 gauge 5-conductor shielded cable is included with the

controller. This sensor must be installed for proper operation. Mount the temperature/humidity sensor in a location

least likely to be affected by open doors, rack-mounted fans, radiant heat sources, etc. Location height should be

approximately 60" above the floor. The sensor should be installed on a 2" x 4" junction box to allow for control wire

conduit (see Figure 19). Use shielded cable to connect to controller.

FIGURE 19

Remote Indoor Temperature/Humidity Sensor Installation

1. Connect wires from the 18 gauge shielded cable to terminals #24, #25, #18, #19 and #30.

TB# Sensor Description

24 NTC OUT Indoor Temperature 1 B6

25 NTC OUT Ground GND

18 OUT H Indoor Humidity 1 Signal: 0-1 VDC B2

19 M (G) Indoor Humidity 1 Common GND

30 + (G) Indoor Humidity 1 Power +VDC

LV1000 Terminal Block

4 5 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 466

Wire

Mark

2. Connect the other end of the shielded cable to the sensor

terminals. Be sure wires are connected to proper terminals

as shown in table above. Sensor jumpers need to be

positioned for 0-1 V. With sensor oriented as shown in

image to right, move both jumpers to left position (DP1 and

DP2 set to OFF).

This applies to all temperature/humidity sensors connected

to the LV controller.

Sensor is best mounted on a junction box, and it is

recommended that the cable be in conduit.

Manual 2100-674A

Page 22 of 41

Jumper

DP1

DP2

Page 23

Up to two additional temperature and humidity sensors can be purchased and installed. Alternately, temperatureonly sensors can be purchased and installed instead of the combination sensors.

Use shielded cable to connect

additional sensors to controller.

FIGURE 20

Additional Remote Temperature and Temperature/Humidity Sensor Installation

Up to two additional temperature/humidity sensors may be added. Be sure the sensors are connected to the proper

terminals on the terminal block and sensor as listed below. See page 22 for information on correct sensor jumper

position.

LV1000 Terminal Block

12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

3 3

2

3

2

2

3

2

2

3

TB# Sensor Description

26 NTC OUT Indoor Temperature 2 B7

27 NTC OUT Ground GND

2

Optional Remote

Temperature/Humidity Sensor

Terminals 26, 27, 20, 21 & 31

3

Optional Remote

Temperature/Humidity Sensor

Terminals 28, 29, 22, 23 & 32

Temperature-only sensors can be used in place of the additional temperature/humidity sensors. #2 temperature-only sensor

will connect to TB# 26 and 27. #3 temperature-only sensor will connect to TB# 28 and 29. The wire connections for the

temperature-only sensors are not polarity sensitive.

20 OUT H Indoor Humidity 2 Signal: 0-1 VDC B3

21 M (G) Indoor Humidity 2 Common GND

31 + (G) Indoor Humidity 2 Power +VDC

TB# Sensor Description

28 NTC OUT Indoor Temperature 3 B8

29 NTC OUT Ground GND

22 OUT H Indoor Humidity 3 Signal: 0-1 VDC B4

23 M (G) Indoor Humidity 3 Common GND

32 + (G) Indoor Humidity 3 Power +VDC

Wire

Mark

Wire

Mark

Manual 2100-674A

Page 23 of 41

Page 24

Additional LV1000 Connections

There are factory-installed jumpers across terminals #8 and #9 (smoke detector), #10 and #11 (hydrogen detector)

and #12 and #13 (generator run). Remove the factory-installed jumpers before connecting to the detectors and/or

generator (if applicable).

INPUTS

Smoke

Hydrogen

Generator

Anti-Theft

Power Loss

Humidifier

HVAC Fail

HVAC Maintenance

Anti-Theft

LV1000 Connections Sensor Connections

Wire Mark Terminal Terminal

DI1 8

GND 9 Ground

DI2 10 Hydrogen Detector Input

GND 11 Ground

DI3 12 Generator Run Input

GND 13 Ground

DI4 14 9 (BG1000) Anti-Theft Device

GND 15 10 (BG1000) Ground

Relay - A1

Relay - A2 230VAC Power Loss Relay

Varies

Varies

Description

Smoke Detector Input

230VAC Power Loss Relay

OUTPUTS

LV1000 Connections

Wire Mark Terminal Terminal

NO1 34

C1 35 Common

NO2 36 Alarm Relay – HVAC Fail

C1 37 Common

NO3 38

C1 39 Common

NO4 40 Alarm Relay – Anti-Theft

C2 41 Common

External

Connections

Varies

Description

Humidifier Output

Alarm Relay –

HVAC Maintenance

LV1000 Connections

Wire Mark Terminal Terminal

Fieldbus 1*

Fieldbus 2*

Ground FB-2 (–) 46 Drain Drain for Daisy Chain

FB-1 (–) 42 2 Wall Unit Daisy Chain

FB-1 (+) 43 1 Wall Unit Daisy Chain

FB-2 (–) 44 – IPv6 SNMP Board

FB-2 (+) 45 + Ground

* Polarity Sensitive

Manual 2100-674A

Page 24 of 41

COMMUNICATIONS

External

Connections

Description

Page 25

Communication Wiring

Connect the communication wiring from the wall-mount units to the controller in the manner shown in Figures 21,

22 or 23 (page 26). The daisy chain does not need to follow the addressing order. The communication wire should

be 2-wire, 18 gauge shielded cable with drain. Any color can be used. Be sure to match "+" and "-" symbols on

controller terminal blocks to prewired unit control terminal block (see Figures 25 and 26 on pages 28 and 29).

Attach communication wire filters as shown in Figures 21, 22 or 23. Filters go inside the unit or controller box; they

are shown out of unit for identification purposes only. Do not run communication wiring in same conduit as supply

wiring. Route communication wiring and power supply wiring in their own separate conduits.

FIGURE 21

Communication Wiring (Daisy Chain Method)

Wall-Mount Unit

Filter

Wall-Mount Unit

Filter

LV1000 Controller

In addition to the "daisy chain" method of connecting the communication wiring shown in Figure 21, the wall-mount

units can also be connected in the manner shown in Figure 22. If connecting wall-units this way, be sure to place

the communication wire filters in the positions shown in Figure 22. See Figure 23 for more information on the

correct placement of the communication wire filters depending on the wiring method used.

FIGURE 22

Communication Wiring (Alternate Method)

Wall-Mount Unit

LV

Controller

Filter

Filter

Wall-Mount Unit

Manual 2100-674A

Page 25 of 41

Page 26

FIGURE 23

Placement of Communication Wire Filters (Daisy Chain and Alternate Methods)

Daisy Chain Wiring (up to four units)

Place filter here

LV1000

Place filter here

Place filter here

Unit 1 Unit 2 Unit 3 Unit 4

Alternate Wiring (up to four units)

Place filter here

Unit 1 Unit 2 Unit 3 Unit 4

NOTE: Line filters can be on either the unit or controller, whichever device is on the end of the chain. No matter

how many units there are, the two end devices will only have ONE communication cable, whereas the

center devices will all have TWO (as shown above). Filters go inside the unit or controller; shown out of

unit above for identification only.

Manual 2100-674A

Page 26 of 41

LV1000*

Page 27

The steps outlined on the following pages show how to connect the communication wiring using the daisy chain

- +

G

method shown in Figure 21 If using the alternate method (as shown in Figure 22), the connections to the controller

and each wall-mount unit will be the same but the filters need to be placed in the positions shown in Figure 23.

FIGURE 24

Communication Wiring: Termination at the Controller

1. Using the field-provided shielded cable, make a small service loop after entering the controller and attach the provided

EMI filter at the intersection of the loop.

2. Connect one wire to terminal #42 (NEGATIVE), the other wire to terminal #43 (POSITIVE) and the drain wire to

ground terminal #46.

20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

LV1000 Terminal Block

+

–

To Wall-Mount Unit 1

Control Board RS485

NOTE: The drain only gets grounded one time,

anywhere in the chain.

Manual 2100-674A

Page 27 of 41

Page 28

FIGURE 25

Communication Wiring: Termination at the First Wall-Mount Unit

1 2 4 5 7 9 108 12 14 16 173 6

Unit 1 Terminal Block

13 15

11

– +

From LV1000

Controller

1. From the controller, extend the shielded cable through a separate conduit

and route to the provided terminal block next to the wall-mount control

board.

These connections are polarity-sensitive. Two-wire communication from

control board is prewired to terminal block. Make sure to match "+" and "-"

symbols on controller terminal block.

Wall-Mount Unit 1

2. Connect the wires matching the terminal

designations (+/-) of the controller

terminals. Leave the drain wire loose.

3. Connect another cable in a similar

fashion (“daisy chain”) to route in

conduit to the second wall-mount unit.

Connect both drain wires with wire nut.

1 2 4 5 7 9 108 12 14 16 173 6

– +

1 2 4 5 7 9 108 12 14 16 173 6

– +

13 15

Unit 1 Terminal Block

Unit 1 Terminal Block

11

From LV1000

Controller

13 15

11

From LV1000

Controller

To Wall-Mount Unit 2

Manual 2100-674A

Page 28 of 41

Page 29

FIGURE 26

Communication Wiring: Termination at Additional Wall-Mount Units

1 2 4 5 7 9 108 12 14 16 173 6

Unit 2 Terminal Block

13 15

11

–+

From Wall-Mount

Unit 1

1. Route the cable from the first wall-mount unit to the

terminal block of the second wall-mount unit. If this is

the last unit to be connected, make a small service loop

and attach EMI filter as shown.

2. Connect the wires matching the terminal

designations (+/-) of the controller terminals.

Cap the loose drain with a wire nut or

electrical tape.

1 2 4 5 7 9 108 12 14 16 173 6

–+

Wall-Mount Unit 2

13 15

Unit 2 Terminal Block

11

From Wall-Mount

Unit 1

3. Continue daisy chaining units by connecting

"+" to "+", "-" to "-" and wire nutting drain

together until last unit which is capped with

a wire nut. Attach EMI filter as shown above

at last unit. Up to four wall-mount units can

be connected and controlled by one LV1000

controller.

Manual 2100-674A

Page 29 of 41

Page 30

LV1000 Supply Wiring

1 2 3 4 5 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 466

The LV1000 controller is powered by -48VDC from the shelter. A field-supplied 5 amp DC circuit breaker is required.

Field-supplied supply wiring should be minimum 16 gauge, maximum 14 gauge (see Figure 27). A reliable earth

ground must be connected in addition to any grounding from conduit. Grounding posts are included with the

controller for this purpose; install as shown in Figure 28. Failing to ground the controller box properly could result in

damage to the equipment.

FIGURE 27

LV1000-100 Controller Supply Wiring

The controller requires a separate -48VDC power supply, an additional 5-amp DC breaker (field supplied) and minimum 16

gauge supply wire.

-48VDC termination at controller: Bring the -48VDC power supply wires through conduit to the controller box. Land the

positive (+) 48VDC wire to terminal #1 and the negative (-) 48VDC wire to terminal #2.

NOTE: If the DC wiring is not terminated correctly on the specific polarity-indicated terminals of the

block, the controller will not activate and will not function. Verify polarity of connections and wait to

initialize controller until "system start up."

+

–

FIGURE 28

Controller Grounding Posts

A reliable earth ground must be connected in

addition to any grounding from conduit. Attach

earth ground to dedicated lugs on side of controller

box. Failing to ground the controller box properly

could result in damage to the equipment or

personal injury.

Manual 2100-674A

Page 30 of 41

Page 31

TABLE 4

LV1000 Terminal Block Index

TB#

10 DI2 Hydrogen Detector Input

11 GND Hydrogen Detector Common

12 DI3 Generator Run Input

13 GND Generator Run Common

14 DI4 Anti Theft Input

15 GND Anti Theft Common

16 - RESERVED FOR POWER LOSS INPUT

17 GND

18 B2 Humidity Sensor 1

19 GND Ground

20 B3 Humidity Sensor 2

21 GND Ground

22 B4 Humidity Sensor 3

23 GND Ground

Wire

Mark

1 48+ 48VDC +Input

2 48– 48VDC – Input

3 - Ground

4 - 24VDC +

5 - 24VDC –

6 24+ 24VDC +

7 24– 24VDC –

8 DI1 Smoke Detector Input

9 GND Smoke Detector Common

RESERVED FOR POWER LOSS INPUT –

COMMON

Description

TB#

24 B6 Temperature Sensor 1

25 GND Ground

26 B7 Temperature Sensor 2

27 GND Ground

28 B8 Temperature Sensor 3

29 GND Ground

30 VDC+ Sensor Power Distribution

31 VDC+ Sensor Power Distribution

32 VDC+ Sensor Power Distribution

33 VDC+ Sensor Power Distribution

34 NO1 Humidifier Output Relay

35 C1 Common

36 NO2 HVAC Fail

37 C1 Common

38 NO3 HVAC Maintenance

39 C1 Common

40 NO4 HVAC Anti Theft

41 C2 Common

42 FB1R- RS485 RX- / TX- (Fieldbus 1)

43 FB1R+ RS485 RX+ / TX+ (Fieldbus 1)

44 FB2R- RS485 RX- / TX- (Fieldbus 2)

45 FB2R+ RS485 RX+ / TX+ (Fieldbus 2)

46 - Ground Communication Shield

Wire

Mark

Description

Manual 2100-674A

Page 31 of 41

Page 32

FIGURE 29

LV1000 Wiring Diagram

Manual 2100-674A

Page 32 of 41

Page 33

SYSTEM SET UP

The LV1000 controller and TEC-EYE hand-held

diagnostic tool will both be used to set up the Bard

Free Cooling Unit system.

TABLE 5

LV/TEC-EYE Passwords (Defaults)

User 2000

Technician 1313

Engineer 9254

Use UP or DOWN keys and ENTER key to enter password

TEC-EYETM Hand-Held Diagnostic Tool

The microprocessor control used in the FUSION-TEC

wall-mount air conditioners allows for complete control

and monitoring through the use of the provided TECEYE hand-held monitor.

The menu driven interface provides users the ability

to scroll through two menu levels: Quick Menu and

Main Menu. The menus permit the user to easily view,

control and configure the unit. See FUSION-TEC

Service Manual 2100-670 for more information on

using the TEC-EYE.

The TEC-EYE connects to the wall-mount unit control

board via an RJ11 modular phone connector as shown

in Figure 30.

When not being used, the TEC-EYE hand-held

diagnostic tool should be stored inside or near the

LV1000 controller. Do not let the TEC-EYE leave the

shelter.

FIGURE 30

TEC-EYE Connection to Unit Control

Modular Phone Connector for

TEC-EYE Hand-Held Diagnostic Tool

TM

TEC-EYE

(Bard P/N 8301-059) Display and Interface (Status Screen Shown)

ALARM KEY

MENU KEY

ESCAPE KEY

ALARM KEY

Allows viewing of active alarms

Silences audible alarms

Resets active alarms

MENU KEY

Allows entry to Main Menu

ESCAPE KEY

Returns to previous menu level

Cancels a changed entry

FIGURE 31

UP KEY

ENTER KEY

DOWN KEY

UP KEY

Steps to next screen in the display menu

Changes (increases) the value of a modifiable field

ENTER KEY

Accepts current value of a modifiable field

Advances cursor

DOWN KEY

Steps back to previous screen in the display menu

Changes (decreases) the value of a modifiable field

Manual 2100-674A

Page 33 of 41

Page 34

TEC-EYE Status Screen

The Status screen is the default start-up screen and

also the return screen after 5 minutes of no activity.

The screen can be accessed any time by pressing the

ESCAPE key repeatedly.

The wall-mount unit address is displayed in the upper

right corner on the Status screen (see Figure 31). The

Status screen also shows the current date, time, return

air temperature, mixed air temperature, outdoor air

temperature, outdoor humidity and outdoor dew point

conditions. Blower, damper and unit status are also

displayed. See Table 6 on page 41 for wall-mount unit

status messages.

NOTE: Screenshots shown in this manual reflect

default settings (when applicable).

Setting Up Wall-Mount Units for

Operation

The TEC-EYE hand-held diagnostic tool is needed to

set up the wall-mount unit(s).

1. Address Each Wall-Mount Unit

Each unit must have a unique address for the

system to operate correctly with th LV controller

(Ex: 1, 2, 3, 4 depending on the number of units).

The unit only needs the address to be changed for

the communication to work properly.

The wall-mount unit address is displayed in the

upper right corner on the Status screen on the

TEC-EYE display (see Figure 31).

To change the unit address:

1) Press MENU key to access the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter USER password 2000.

3) Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4) Press UP or DOWN keys to scroll to Unit Setup

(A1) screen.

5) Press ENTER key to scroll to Controller

Address (see Figure 32).

6) Press UP or DOWN keys to change the address

to a value between 1 and 4.

NOTE: Each unit must have a unique address for the

communication to work properly. Bard also

recommends labeling each unit for ease in

identification.

FIGURE 32

Changing Unit Setup Values

In addition to setting up the address, the user may

also want to set the unit of measure (UOM) and

economizer control type.

To change these settings:

1) Press MENU key to access the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter USER password 2000.

3) Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4) Press UP or DOWN keys to scroll to Unit Setup

(A1) screen.

5) Press ENTER key to scroll to UOM (see Figure

32).

6) If desired, press UP or DOWN keys to change

the value from USA to SI, NC, LON, CAN or

UK. Units are preconfigured for each selection.

7) Press ENTER key to save and move the cursor

back to the top left position.

8) Press DOWN key to navigate to Economizer

Setup (A2) screen.

9) Press ENTER key to scroll to Type (see Figure

33).

10) Press UP or DOWN keys to change economizer

type to None, Drybulb, Temperature and

Humidity or Enthalpy.

11) Press ENTER key to save.

Basic wall unit parameter settings are now set and

the unit is ready to communicate with the LV.

Manual 2100-674A

Page 34 of 41

Page 35

FIGURE 33

Changing Economizer Control Type

2. Execute a Run Test on Each Unit

Execute a run test on each unit to verify the

equipment is functioning correctly. The run test

parameters are not adjustable.

1) Press MENU key to access the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter USER password 2000.

3) Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4) Press UP key to scroll to Run Test (A10)

screen.

5) Press ENTER key to scroll to Run Test Enable

parameter (see Figure 34).

6) Press UP or DOWN key to change value to ON.

The run test will begin.

FIGURE 34

Executing Run Test

Run Test Approximate Timings (in Minutes)

0:00 • Blower starts.

• Damper begins to open to damper test volts

parameter. To verify damper operation, open

unit side door. Inspect upper and lower blades.

2:30 • Damper closes. Compressor Stage 1 turns on.

Condenser fan may also turn on depending on

ambient conditions.

3:00 • Compressor Stage 2 turns on.

3:30 • Compressor turns off. Condenser fan turns off

(if applicable).

• Heat turns on.

4:30 • Heat turns off.

5:30 • Blower turns off.

3. Clear Unit Alarm Logs on Each Unit

To clear the wall-mount unit alarm logs:

1) Press MENU key to go to the Main Menu

screen.

2) Use UP or DOWN keys and ENTER key to

enter USER password 2000.

3) Press UP or DOWN keys to scroll to Settings;

press ENTER key.

4) Press UP or DOWN keys to scroll to

Initialization; press ENTER key.

5) Press ENTER key to scroll to Delete Alarm

Logs? (see Figure 35).

6) Press UP or DOWN key to value to YES; press

ENTER key.

7) Press ESCAPE key several times to return to

Main Menu screen.

FIGURE 35

Clearing Unit Alarm Logs

Parameter Description

Damper Test Volts: This is the control voltage applied to

the actuator during opening sequence for damper.

Damper Time: This is the time (in seconds) allowed for

both the opening sequence and closing sequence.

Heat/Cool Time: This is the time (in seconds) allowed

for cooling sequence and heating sequence.

After each of the wall-mount units have been

addressed, had a run test performed and had the alarm

logs cleared, the rest of the system set up can proceed.

Manual 2100-674A

Page 35 of 41

Page 36

FIGURE 36

LV1000 Controller Display and Interface (Status Screen Shown)

ALARM KEY

MENU KEY

ESCAPE KEY

LV1000 interface key functions are the same as those shown for the TEC-EYE

in Figure 32 on page 34.

Setting Up LV1000 for Operation

The LV1000 controller will be used for the remaining

steps in the set up process.

LV1000 Status Screen

The Status screen is the default start-up screen and

also the return screen after 5 minutes of no activity on

both the LV1000. The screen can be accessed any time

by pressing the ESCAPE key repeatedly.

The Status screen on the LV1000 displays the current

date, time, indoor average temperatue and humidity,

lead unit and system status (see Figure 36). See Table

7 on page 41 for system status messages.

4. Set LV Controller Timezone and Date/Time:

1) Press MENU key to access the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter USER password 1313.

3) Press the UP or DOWN keys to scroll to the

Settings; press ENTER key.

4) Press UP or DOWN keys to scroll to Date/Time;

press ENTER key.

5) Press UP or DOWN keys to scroll to Timezone;

press ENTER key.

6) Press UP or DOWN keys to scroll through

available timezones (see Figure 37).

7) Press ENTER key to scroll to Update Timezone.

8)

9) Press ENTER key to save and scroll to top of

10) Press UP or DOWN keys to navigate to Date/

11) Press ENTER key to scroll to the desired value

Press UP or DOWN key to change value to YES.

screen.

Time change.

to be changed (see Figure 38).

UP KEY

ENTER KEY

DOWN KEY

12) Press UP or DOWN keys to change the value.

13) Press ENTER key to save.

14) Press the ESCAPE key several times to return

to Main Menu screen.

FIGURE 37

Changing Timezone

FIGURE 38

Setting Controller Date and Time

Manual 2100-674A

Page 36 of 41

Page 37

5. Configure Sensors

The system will need to be configured for the

number of temperature and humidity sensors

installed. The system is shipped with one

combination temperature and humidity sensor.

Additional combination sensors may be purchased

or alternatively, temperature-only sensors may be

purchased instead. The LV is capable of utilizing

three temperature sensors and three humidity

sensors. The system will need to be configured for

the various configurations.

If necessary, the sensors could be calibrated at this

time too. For information on calibrating the sensors

(adjusting the offset), see page 40.

To enable/disable Indoor Humidity 1:

1) Press MENU key to go to the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter TECHNICIAN password 1313.

3) Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4) Press UP or DOWN keys to scroll to Indoor

Humidity 1 (C3).

5) Press ENTER key to scroll to Enable (see

Figure 39).

6) Press UP or DOWN key to change value to ON

to enable sensor (or change value to OFF to

disable sensor).

FIGURE 39

Configuring Indoor Humidity 1 Sensor

6) Press UP or DOWN key to change value to ON

to enable sensor (or change value to OFF to

disable sensor).

FIGURE 40

Configuring Indoor Humidity 2 Sensor

To enable/disable Indoor Humidity 3:

1) Press MENU key to go to the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter TECHNICIAN password 1313.

3) Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4) Press UP or DOWN keys to scroll to Indoor

Humidity 3 (C5).

5) Press ENTER key to scroll to Enable (see

Figure 41).

6) Press UP or DOWN key to change value to ON

to enable sensor (or change value to OFF to

disable sensor).

To enable/disable Indoor Humidity 2:

1) Press MENU key to go to the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter TECHNICIAN password 1313.

3) Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4) Press UP or DOWN keys to scroll to Indoor

Humidity 2 (C4).

5) Press ENTER key to scroll to Enable (see

Figure 40).

FIGURE 41

Configuring Indoor Humidity 3 Sensor

To enable/disable Indoor Temperature 1:

1) Press MENU key to go to the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter TECHNICIAN password 1313.

3) Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

Manual 2100-674A

Page 37 of 41

Page 38

4) Press UP or DOWN keys to scroll to Indoor

Temperature 1 (C6).

5) Press ENTER key to scroll to Enable (see

Figure 42).

6) Press UP or DOWN key to change value to ON

to enable sensor (or change value to OFF to

disable sensor).

FIGURE 42

Configuring Indoor Temperature 1 Sensor

To enable/disable Indoor Temperature 2:

1) Press MENU key to go to the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter TECHNICIAN password 1313.

3) Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4) Press UP or DOWN keys to scroll to Indoor

Temperature 2 (C7).

5) Press ENTER key to scroll to Enable (see

Figure 43).

6) Press UP or DOWN key to change value to ON

to enable sensor (or change value to OFF to

disable sensor).

FIGURE 43

Configuring Indoor Temperature 2 Sensor

To enable/disable Indoor Temperature 3:

1) Press MENU key to go to the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter TECHNICIAN password 1313.

3) Press UP or DOWN keys to scroll to IO Config;

press ENTER key.

4) Press UP or DOWN keys to scroll to Indoor

Temperature 3 (C8).

5) Press ENTER key to scroll to Enable (see

Figure 44).

6) Press UP or DOWN key to change value to ON

to enable sensor (or change value to OFF to

disable sensor).

FIGURE 44

Configuring Indoor Temperature 3 Sensor

See LV1000 Service Instructions manual 2100-

673 for information on setting up the smoke,

hydrogen, generator and power loss relays.

6. Enter Total Number of Units

1) Press MENU key to go to the Main Menu

screen.

2) Press UP or DOWN keys and ENTER key to

enter USER password 2000.

3) Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4) Press UP or DOWN keys to scroll to Unit Setup

(A1); press ENTER key.

5) Press ENTER key to scroll to Total Units (see

Figure 45).

6) Press UP or DOWN keys to adjust value to

correct number of units.

7) Press ENTER key to save value.

NOTE: The cooling and heating setpoints are

also displayed on the Unit Setup (A1)

screen. See CONTROL OPERATION in

LV1000 Service Instructions 2100-673 for

information on adjusting the cooling and

heating setpoints. Information on changing

UOM (Units of Measure) and Continuous

Manual 2100-674A

Page 38 of 41

Page 39

Fan settings can also be found in the

LV1000 Service Instructions.

8) Press the ESCAPE key several times to return

to Main Menu screen.

FIGURE 45

Entering Total Number of Units

7. Verify Units Are Online

Once a unit is uniquely addressed, communication

can be verified at the LV controller.

With the correct number of units set at the LV

controller, each unit can be remotely viewed from

the controller information screen.

To view these screens:

1) Press

2) Press UP or DOWN key until the Quick Menu in

3) Press UP or DOWN keys to scroll through the

In addition to being able to remotely view the units,

an alarm will be generated on the LV controller for

units not communicating.

ESCAPE

(May need to be pressed more than once.)

the lower right corner of the screen displays the

Information icon ( ); press ENTER key.

Information screens until the desired unit

Information screen appears (see Figure 46).

Three Info screens are available for each unit.

Unit serial number and model number and 24hour run time information can also be viewed

on these screens.

key to view the Status screen.

8. Clear Controller Alarm Logs

To clear the LV controller alarm logs:

1) Press MENU key to go to the Main Menu

screen.

2) Use UP or DOWN keys and ENTER key to

enter USER password 2000.

3) Press UP or DOWN keys to scroll to Settings;

press ENTER key.

4) Press UP or DOWN keys to scroll to

Initialization; press ENTER key.

5) Press ENTER key to scroll to Delete Alarm

Logs? (see Figure 47).

6) Press UP or DOWN key to value to YES; press

ENTER key.

7) Press ESCAPE key several times to return to

Main Menu screen.

FIGURE 47

Clearing LV1000 Alarm Logs