INSTALLATION INSTRUCTIONS

SPLIT AIR CONDITIONER

OUTDOOR SECTION

Models:

HAC181-AD040

HAC241-AD040

HAC301-AD040

HAC361-AD040

HAC421-AD040

HAC481-AD040

HAC481-BD040

HAC601-AD040

HAC601-BD040

FOR USE WITH:

MA TCHING INDOOR

BLOWER COIL UNITS

AND MA TCHING ADD

ON COIL UNITS ONLY

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914 . . . Moving ahead just as planned.

Manual No.: 2100-346C

Supersedes: 2100-346B

File: Volume 1, Tab 4

Date: 09-04-02

© Copyright 2002

CONTENTS

Split Air Conditioner General Information......... 1

Split Air Conditioner Model Nomenclature ............... 1

Application and Location ....................................4

General .................................................................... 4

Shipping Damage .................................................... 4

Application ............................................................... 4

Location ................................................................... 4

Mounting Unit Outside on Slab................................. 4

Important Installer Note............................................ 4

Installing Refrigerant Tubing..................................... 4

Sweat Style Tubin Connections: Sweat

Indoor Unit and Sweat Outdoor Unit ........................ 5

Field Fabricated Tubing Connections:

Quick Connect Indoor Unit and Sweat

Outdoor Unit Using CTO Kit..................................... 6

Wiring Instructions ..............................................9

General .................................................................... 9

Control Circuit Wiring ............................................... 9

Wall Thermostats..................................................... 9

Optional Controls ................................................... 12

Installation Instructions – CMA-5 ............................ 12

Installation Instructions – CMA-6 ............................ 12

Installation Instructions – CMA-10A........................ 13

Installation Instructions – CMA-13A........................ 14

Charging Instructions ........................................ 15

Pressure Service Ports .......................................... 15

System Start-Up (Indoor Units

without Expansion V alves....................................... 15

Service ................................................................17

Service Hints.......................................................... 17

Fan Blade Setting Dimensions ............................... 17

Pressure T ables ................................................ 20-23

FIGURES

Figure 1.................................................................... 1

Figure 2.................................................................... 4

Figure 3.................................................................... 5

Figure 4.................................................................... 5

Figure 5.................................................................. 12

Figure 6.................................................................. 12

Figure 7.................................................................. 12

Figure 8.................................................................. 13

Figure 9.................................................................. 14

TABLES

Table 1 ..................................................................... 1

Table 2 ..................................................................... 2

Table 3 ..................................................................... 3

Table 4 ..................................................................... 6

Table 6 ..................................................................... 9

Table 7 ..................................................................... 9

Table 8 ..................................................................... 9

Table 9 ................................................................... 15

Table 10 ................................................................. 15

Table 11 ................................................................. 16

Table 12 ................................................................. 17

Table 13 ................................................................. 20

Table 14 ................................................................. 20

Table 15 ................................................................. 21

Table 16 ................................................................. 21

Table 17 ................................................................. 22

Table 18 ................................................................. 22

Table 19 ................................................................. 23

SPLIT AIR CONDITIONER MODEL NOMENCLATURE

HAC 36 1 – A DXXX

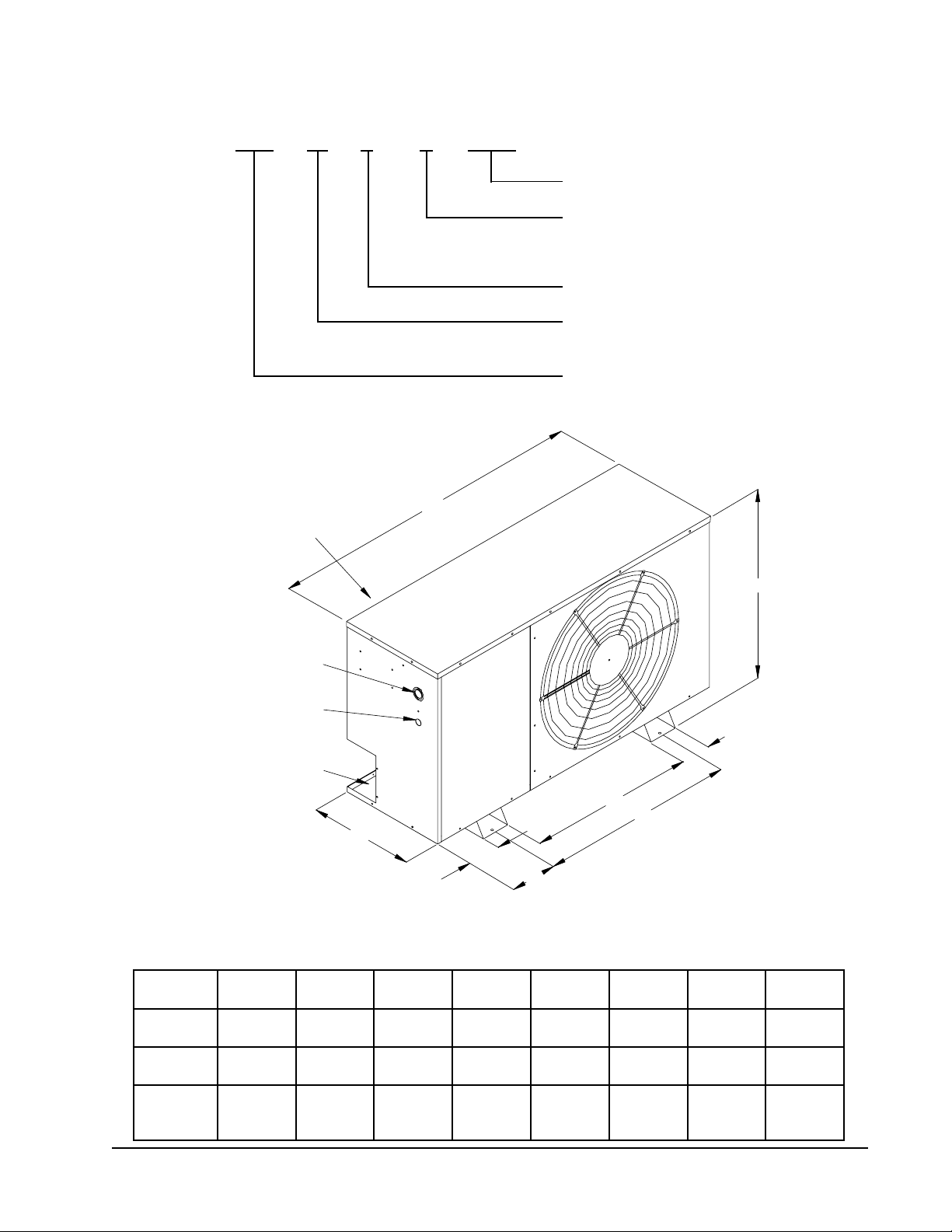

FIGURE 1

UNIT DIMENSIONAL DRAWING

Customized Unit Code

Electrical Characteristics

A – 230/208-60-1

B – 230/208-60-3

Modification Code

Capacity – 3 Ton or

approx. 36,000 BTU

Basic Model Number

ALTERNATE

ELECTRICAL

ENTRANCES

ON BACK

HIGH VOLTAGE

ENTRANCE

LOW VOLTAGE

ENTRANCE

REFRIGERANT

SHUTOFF

VALVES

D

W

H

C

B

F

A

E

MIS-1789

TABLE 1

UNIT DIMENSIONS

"W"

.oNledoM

181CAH

142CAH

103CAH

163CAH

htdiW

00.0400.5100.62521.5881.0200.4521.7881.42

00.5400.5100.62521.5881.5200.4521.7881.92

"D"

htpeD

"H"

thgieHABCEF

124CAH

184CAH

00.0500.5100.23526.6886.8200.4526.8886.23

106CAH

Manual 2100-346

Page 1

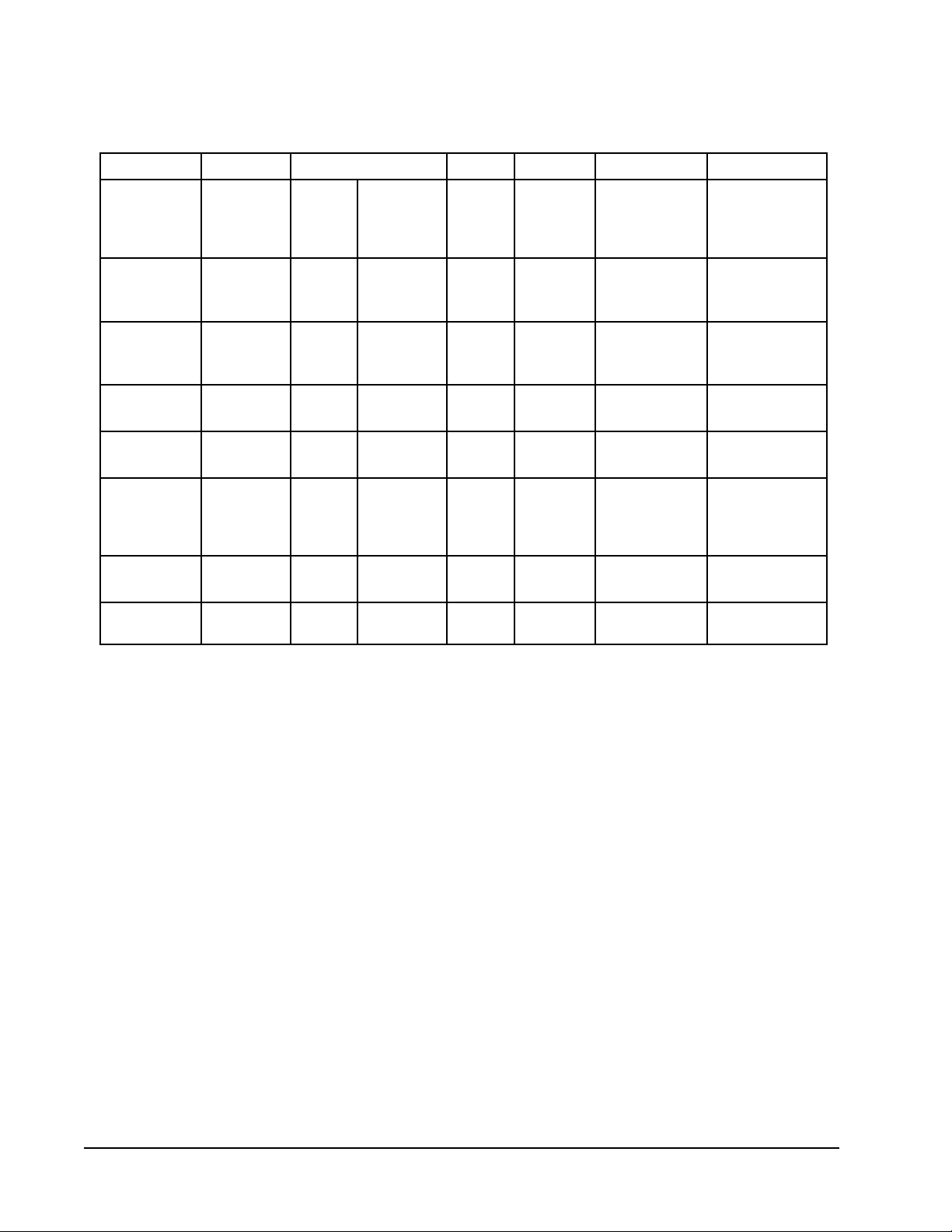

TABLE 2

RATED CFM AND AIR FLOW DATA

(WET COIL – COOLING)

wolfriAdetaR

gnisnednoC

tinU

.oNledoM

A-181CAH

A142CAH

A-103CAH

A-163CAH

A-124CAH

B-,A-184CAH

B-,A-106CAH

rotaropavE

lioC

.oNledoM

A-SA03A

A-SA42S

B42CB

A-SA03A

A-SA42S

B42CB

A-SA63A

B63CB

A-SA73A

B63CB

A-SA24A

A-SA84A

B63CB

B06CB

B-SA16A

B06CB

B-SA16A

B06CB

MFC

056

056

056

008

087

057

000,1

000,1

001,1

001,1

004,1

005,1

002,1

005,1

007,1

007,1

067,1

008,1

erusserP

O

HporD

2

51.

42.

81.

03.

02.

81.

03.

62.

82.

03.

detaR

.P.S.E

53.deM

02.hgiH

03.woL

72.hgiH

51.

83.

52.woL

82.hgiH

rotoM

deepS

paT

hgiH

woL

dednemmoceR

egnaRwolFriA

517-055

517-055

517-055

019-007

098-086

019-007

571,1-058

571,1-058

022,1-029

022,1-029

055,1-072,1

526,1-052,1

023,1-020,1

526,1-052,1

578,1-054,1

578,1-054,1

059,1-005,1

579,1-525,1

metsyS

ecifirO

deriuqeR

250.

250.

250.

550.

550.

550.

360.

360.

960.

960.

870.

870.

870.

870.

180.

180.

290.

290.

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Q Measured across the evaporator coil assembly, including drain pan.

R External static pressure available for the duct system -- supply and return. All blower coils have multispeed

motors, and value shown is at the recommended rated speed. Consult specification air flow charts with the

blower coil units for complete information at other speeds.

* IMPORT ANT INFORMA TION

Proper sized orifice is not factory installed in indoor section. Proper orifice size is shipped with outdoor unit

packaged with its installation instructions for indoor sections listed on this page. The orifice must be replaced

with the proper system orifice shown above in T able 2.

For other evaporator coil models not listed, see indoor coil installation instructions for proper orifice information.

Manual 2100-346

Page 2

!

TABLE 3

SPECIFICATIONS

SLEDOMA-181CAHA-142CAHA-103CAHA-163CAHA-124CAHA-184CAHB-184CAHA-106CAHB-106CAH

)HP/V/ZH06(gnitaRlacirtcelE1-802/0321-802/0321-802/0321-802/0321-802/0321-802/0323-802/0321-802/0323-802/032

egnaRegatloVgnitarepO352-791352-791352-791352-791352-791352-791352-781352-791352-781

yticapmAtiucriCmuminiM515191025262715312

¬

eziSeriWdleiF41412121010121801

rekaerBtiucriCromumixaMesuFyaleD020203030454520653

802/032spmAtinUlatoT6.8/9.74.11/2.010.41/4.318.51/5.416.91/1.910.12/4.914.31/8.217.62/7.222.71/3.51

ROSSERPMOC

802/032stloV802/032802/032802/032802/032802/032802/032802/032802/032802/032

spmAdaoLdetaR5.7/8.63.01/1.99.21/3.217.41/4.311.81/6.715.91/9.719.11/3.112.52/2.127.51/8.31

tnerruCnoitceleStiucriChcnarB6.83.017.317.411.815.916.213.627.51

802/032spmArotoRkcoL94/9465/6557/5728/28501/501201/20119/19531/531051/051

taeHesacknarCenoNenoNenoNenoN

RESNEDNOCdnaROTOMNAF

MPR/PH–rotoMnaF528–6/1528–6/1528–6/1528–6/1528–4/1528–4/1528–4/1528–4/1528–4/1

spmA–rotoMnaF1.11.11.11.15.15.15.15.15.1

noisremmI

epyT

noisremmI

epyT

noisremmI

epyT

enoNenoN

Manual 2100-346

Page 3

retemaiD–naF000,2–"02000,2–"02000,2–"02000,2–"02006,2–"42006,2–"42006,2–"42006,2–"42006,2–"42

METSYSTCENNOCTAEWS

DIeziSeniLnoitcuS"8/5"4/3"4/3"4/3"8/7"8/7"8/7"8/7"8/7

DIeziSeniLdiuqiL"4/1"8/3"8/3"8/3"8/3"8/3"8/3"8/3"8/3

.zO22-RegnahCyrotcaF.zo37.zo97.zo48.zo69.zo201.zo551.zo551.zo351.zo351

.SBL–THGIEWGNIPPIHS

551551081081052052052552552

APPLICATION and LOCATION

GENERAL

These instructions explain the recommended method to

install the air cooled remote type condensing unit, the

interconnecting refrigerant tubing and the electrical wiring

connections to the unit.

The condensing units are to be used in conjunction with the

matching evaporator coils or evaporator blower units for

comfort cooling applications as shown in the specification

sheet.

These instructions and any instructions packaged with any

separate equipment required to make up the entire air

conditioning system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be checked for

external signs of shipping damage. If damage is found, the

receiving part must contact the last carrier immediately,

preferably in writing, requesting inspection by the carrier’s

agent.

APPLICATION

LOCATION

The condensing unit is designed to be located outside with

free and unobstructed condenser air inlet and discharge. It

must also permit access for service and installation.

Condenser air enters the coil from the rear of the unit as

shown in Figure 2 with electrical service access.

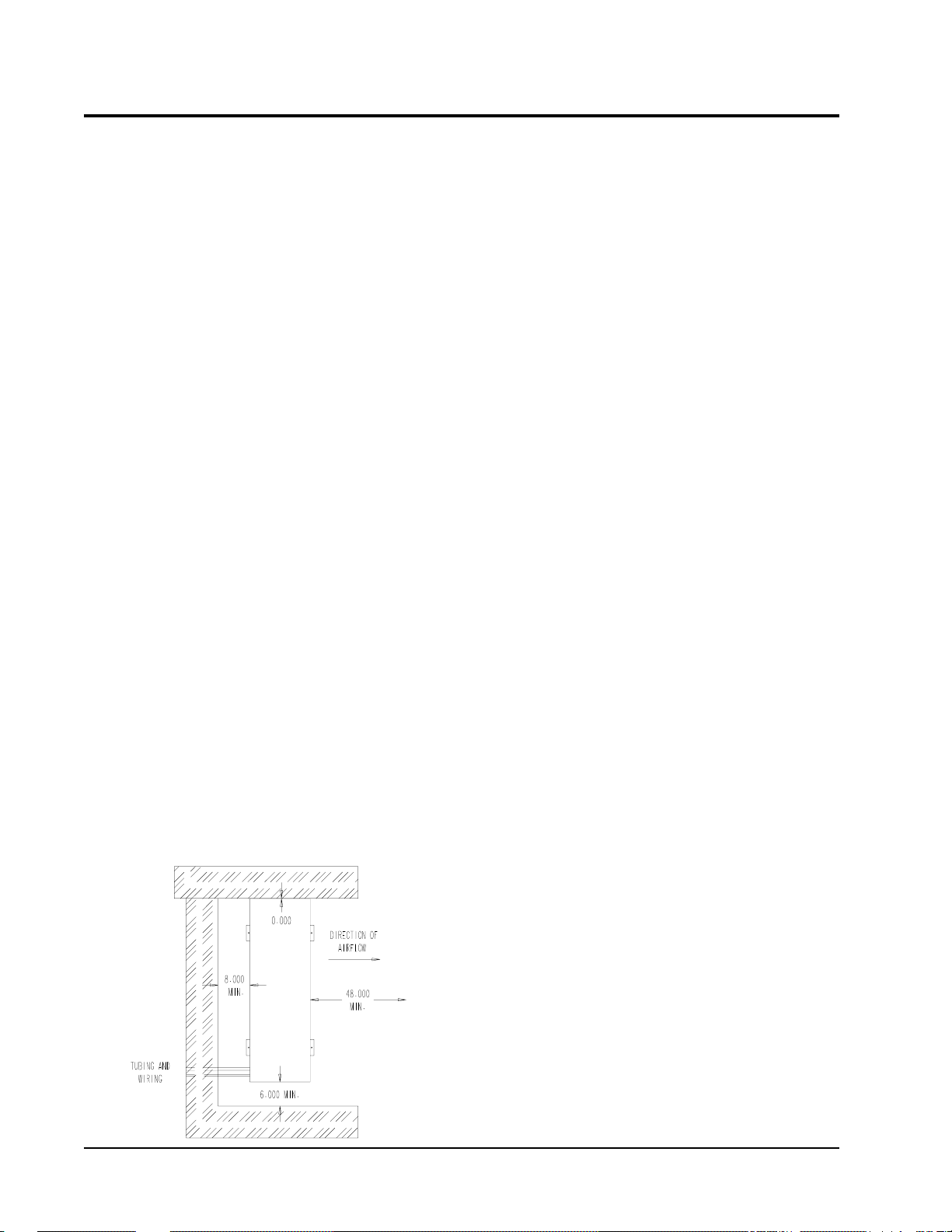

MOUNTING UNIT OUTSIDE ON SLAB

A solid level base or platform, capable to support the unit’s

weight, must be set at the outdoor unit predetermined

location. The base should be at least two inches larger than

the base dimensions of the unit and at least two inches

higher than surrounding grade level. The required unit

minimum installed clearances must be maintained as called

out in Figure 2 when locating and setting the base.

Remove the unit from its shipping carton and position the

unit on the prepared base or platform.

NOTE: These units employ internally sprung

compressors; therefore, it is not necessary to

remove or loosen the base mounting bolts on the

compressor prior to operation.

Consideration should be given to the electrical and tubing

connections when placing the unit to avoid unnecessary

bends or length of material.

Size of unit for a proposed installation should be based on

heat loss calculation and air duct sizing made according to

methods of Air Conditioning Contractors of America. The

air duct should be installed in accordance with the Standards

of the National Fire Protection Association for the

Installation of Air Conditioning and Ventilating Systems of

Other Than Residence Type, NFPA 90A, and Residence

Type Warm Air Heating and Air Conditioning Systems,

NFPA 90B. Where local regulations are at a variance with

instructions, installer should adhere to local codes.

FIGURE 2

INSTALLATION CLEARANCE

IMPORTANT INSTALLER NOTE

For improved start up performance, wash the indoor coil

with a dishwashing detergent.

INSTALLATION REFRIGERANT TUBING

The information that follows on installing refrigerant tubing

and for changing the system orifice (if required) covers

applications listed in the front of this installation instruction

only. Although other indoor units may be of similar

construction, the installation instructions for these units

should be consulted for proper installation of those units

prior to installation.

This information is provided for the field service personnel

to install refrigerant tubing in compliance with Section 608

of Title VI National Recycling and Emission Reduction

Program for the U.S. Clean Air Act effective July 1, 1992.

Consult manual 2100-002 on procedure for leak test –

evacuation – charging before installation refrigerant tubing

that requires any refrigerant recovery or system evacuation.

Manual 2100-002 is included with the unit installation

instruction package when shipped from the factory.

Manual 2100-346

Page 4

MIS-589

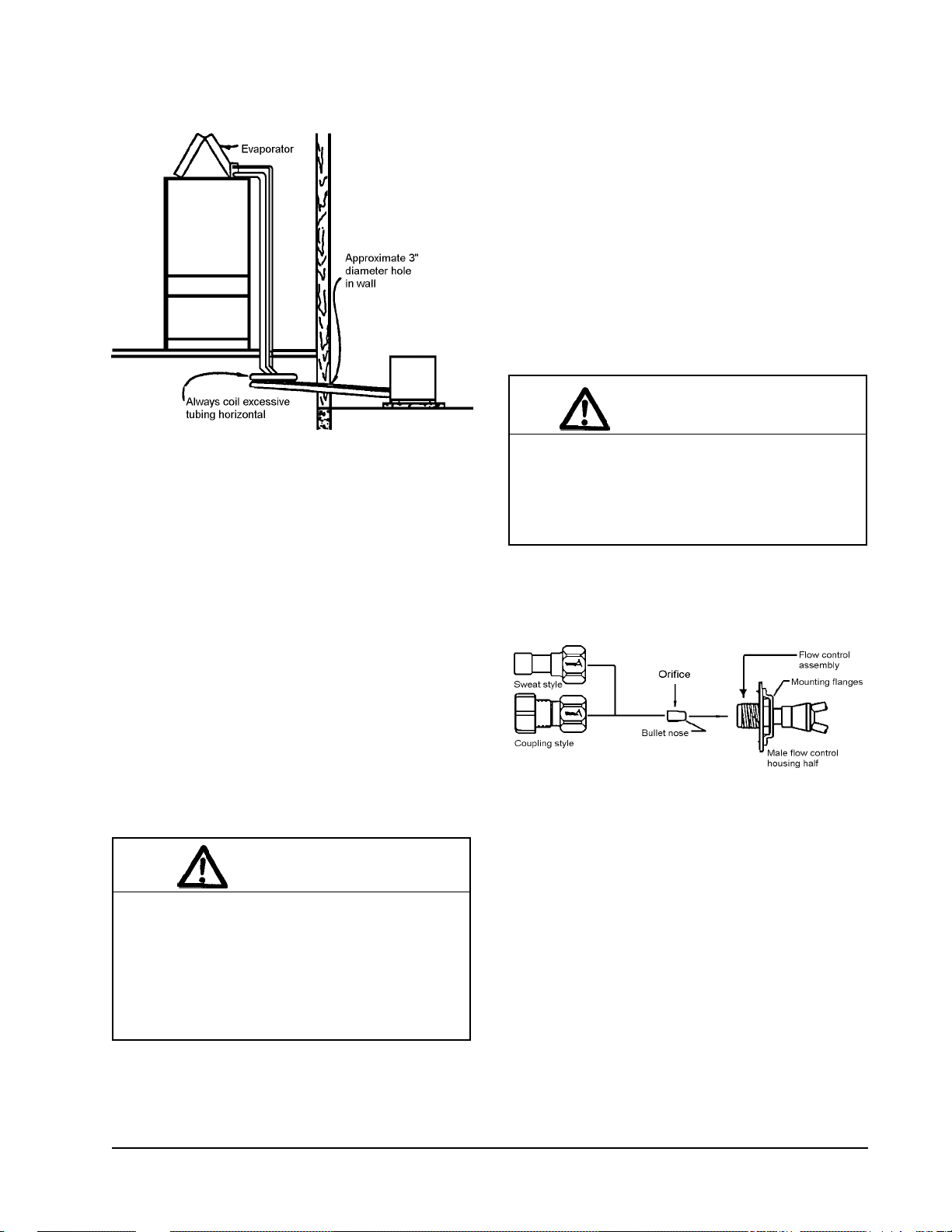

FIGURE 3

INSTALLING REFRIGERANT TUBING

NOTE:

If the orifice does not have to be changed, skip the

instructions outlined further in Step 3 and proceed to Step 8.

3. Disassemble Flow Control Assembly by turning body

4. If existing orifice has not dropped out of the body when

5. Insert proper sized orifice fully into the flow control

Do not braze line to units! If orifice needs to be

changed, change out orifice first.

hex.

disassembled, remove by using a pin or paper clip.

Discard this original orifice.

body with rounded “bullet” nose towards the unit as

shown in Figure 4. Insure the orifice stays inserted in

body before connecting mating half. See chart in the

outdoor unit installation instructions for proper size.

pp5

SWEAT STYLE TUBING CONNECTIONS: SWEAT

INDOOR UNIT and SWEAT OUTDOOR UNIT

Use only refrigeration grade (dehydrated and sealed) copper

tubing. Care must be taken to insure that the tubing is kept

clean and dry before and during installation. Do not remove

the plugs from the tubing ends, coil connections or base

valves until the connection is ready to be brazed.

The suction line must be insulated with a minimum of 3/8”

Armaflex or equivalent before cutting and making

connections.

1. Being careful not to kink, route both the suction line

and liquid line between the indoor unit and outdoor

unit. Use a tubing bender to make any necessary bends

in tubing. When necessary to bend the insulated tube

suction line, cut the insulation around its circumference

at a distance far enough beyond the point of the bend so

as to clear the tubing bender. Slip the insulation back

together and vapor seal the joint with tape. Coil any

excess tubing in a horizontal place with the slope of the

tubing toward the condensing unit. See Figure 3.

CAUTION

1. Be careful not to tear the insulation when

pushing it through hole in masonry or frame

walls. 2. When sealing the tube opening in

house wall, use a soft material to prevent tube

damage and vibration transmission. 3. Avoid

excessive bending in any one place to avoid

kinking.

2. The tubing ends should be cut square. Make sure it is

round and free of burrs at the connecting ends. Clean

the tubing to prevent contaminants from entering the

system.

CAUTION

Be sure there is no dirt introduced into the flow

control - orifice assembly . Be sure to install the

orifice with the bullet nose pointing in the proper

direction as shown in Figure 4. Failure to do so

will result in improper operation.

FIGURE 4

FLOW CONTROL ASSEMBLY

FIELD ORIFICE REPLACEMENT INSTRUCTIONS

pp5

6. Thread assembly halves together by hand to insure

proper mating of threads and tighten until bodies

“bottom” or a definite resistance is felt.

7. Using a marker pen or ink pen, mark a line lengthwise

from the union nut to the bulkhead. Then tighten an

additional 1/6 turn (or 1 hex flat). The misalignment of

the line will show the amount the assembly has been

tightened. This final 1/6 turn is necessary to insure the

formation of the leakproof joint.

8. Wrap a wet rag around the copper stub before brazing.

9. Flux the copper tube and insert into the stub. Braze the

joint using an alloy of silver or copper and phosphorus

with a melting temperature above 1,100° F for copper

to copper joints. The phosphorus will act as a flux,

therefore, no flux will be required.

Manual 2100-346

Page 5

A copper-silver alloy with a high silver content should

be used when iron or steel material is involved in the

joint. These alloys require the use of silver solder flux.

Alloys containing phosphorus should not be used with

iron or steel. Phosphorus reacts with the iron forming

iron phosphate which is extremely brittle.

FIELD FABRICATED TUBING CONNECTIONS:

QUICK CONNECT INDOOR UNIT and SWEAT

OUTDOOR UNIT USING CTO KIT

Use only refrigeration grade (dehydrated and sealed) copper

tubing. Care must be taken to insure that the tubing is kept

clean and dry before and during installation. Do not remove

the plugs from the tubing ends, coil connections or base

valves until the connection is ready to be brazed.

CAUTION

1. Brazing alloys with a melting temperature

below 700° F should not be used. 2. Leadtin or tin-antimony solders should not be used

due to their low melting point and necessity for

corrosive fluxes.

To further prevent the formation of copper oxide inside

the tubing, dry nitrogen may be purged through the

refrigerant system during brazing.

WARNING

Never purge or pressurize a system with

oxygen. An explosion and fire will result.

10. After brazing, quench with wet rag to cool the joint and

remove any flux residue.

11. Leak test all connections using an electronic leak

detector or a halide torch.

The suction line must be insulated with a minimum of 3/8”

Armaflex or equivalent before cutting and making

connections.

1. Being careful not to kink, route both the suction line and

liquid line between the indoor unit and outdoor unit. Use

a tubing bender to make any necessary bends in tubing.

When necessary to bend the insulated tube suction line,

cut the insulation around its circumference at a distance

far enough beyond the point of the bend so as to clear the

tubing bender. Slip the insulation back together and

vapor seal the joint with tape. Coil any excess tubing in

a horizontal place with the slope of the tubing toward the

condensing unit. See Figure 3.

CAUTION

1. Be careful not to tear the insulation when

pushing it through hole in masonry or frame

walls. 2. When sealing the tube opening in

house wall, use a soft material to prevent tube

damage and vibration transmission. 3. Avoid

excessive bending in any one place to avoid

kinking.

12. Evacuate suction line, liquid line and indoor unit

through outdoor unit base valves.

13. Open both the suction and liquid base valves to the

fully open position. Refer to section later in installation

instructions for details on setting proper system charge.

cisaB

gnisnednoC

ledoMtinU

181CAH"4/1"8/5"4/1"8/5"8/3"4/3

142CAH"8/3"8/5"8/3"4/3"8/3"4/3

103CAH"8/3"8/5"8/3"4/3"8/3"4/3

163CAH"8/3"8/5"8/3"4/32/1"8/7

124CAH"8/3"4/3"8/3"8/72/1"8/7

184CAH"8/3"8/7"8/3"8/72/1"8/1-1

106CAH"8/3"8/7"8/3"8/72/1"8/1-1

Manual 2100-346

Page 6

diuqiLnoitcuSdiuqiLnoitcuSdiuqiLnoitcuS

TABLE 4

TUBING CHART

).tF(htgneLeniLtnaregirfeR

02-006-12001-16

2. The tubing ends should be cut square. Make sure it is

round and free of burrs at the connecting ends. Clean

the tubing to prevent contaminants from entering the

system.

NOTE: Do not make any tubing connection at indoor unit

at this time. Make all brazing of joints and

evacuate both suction and liquid line first.

3. Wrap a wet rag around the copper stub before brazing.

4. Flux the copper tube and insert into the stub. Braze the

joint using an alloy of silver or copper and phosphorus

with a melting temperature above 1,100° F for copper

to copper joints. The phosphorus will act as a flux,

therefore, no flux will be required.

A copper-silver alloy with a high silver content should

be used when iron or steel material is involved in the

joint. These alloys require the use of silver solder flux.

Alloys containing phosphorus should not be used with

iron or steel. Phosphorus reacts with the iron forming

iron phosphate which is extremely brittle.

8. Recover charge from the indoor unit.

A. Connect the suction line only to the indoor unit as

outlined in Steps 15, 16, and 17.

B. Recover indoor unit and suction line unit charge

through service port located on outdoor unit base

valve.

9. Disassemble Flow Control Assembly by turning body

hex.

10. If existing orifice has not dropped out of the body when

disassembled, remove by using a pin or paper clip.

Discard this original orifice.

11. Insert proper sized orifice fully into the flow control

body with rounded “bullet” nose towards the unit as

shown in Figure 4. Insure the orifice stays inserted in

body before connecting mating half. See chart in the

outdoor unit installation instructions for proper size.

To further prevent the formation of copper oxide inside

the tubing, dry nitrogen may be purged through the

refrigerant system during brazing.

CAUTION

1. Brazing alloys with a melting temperature

below 700° F should not be used. 2. Lead-tin

or tin-antimony solders should not be used due

to their low melting point and necessity for

corrosive fluxes.

WARNING

Never purge or pressurize a system with

oxygen. An explosion and fire will result.

5. After brazing, quench with wet rag to cool the joint and

remove any flux residue.

6. Leak test all connections using an electronic leak

detector or a halide torch.

7. Evacuate suction line and liquid line through outdoor

unit base valves.

CAUTION

Be sure there is no dirt introduced into the flow

control – orifice assembly. Be sure to install the

orifice with the bullet nose pointing in the proper

direction as shown in Figure 4. Failure to do so

will result in improper operation.

12. Thread assembly halves together by hand to insure

proper mating of threads and tighten until bodies

“bottom” or a definite resistance is felt.

13. Using a marker pen or ink pen, mark a line lengthwise

from the union nut to the bulkhead. Then tighten an

additional 1/6 turn (or 1 hex flat). The misalignment of

the line will show the amount the assembly has been

tightened. This final 1/6 turn is necessary to insure the

formation of the leakproof joint.

14. Evacuate the suction line and indoor unit through the

outdoor unit base valve before connecting all other

tubing. Refer to section later in installation instructions

for details on setting the proper refrigerant charge.

15. Remove (remaining) protector caps and plugs (if orifice

was changed). Inspect fittings and if necessary

carefully wipe coupling seats and threaded surfaces

with a clean cloth to prevent the inclusion of dirt or any

foreign material in the system.

If orifice does not have to be changed, skip the instructions

outlined further in Step 8 and proceed to Step 15.

Manual 2100-346

Page 7

16. Lubricate male half diaphragm and synthetic rubber

seal with refrigerant oil. Thread coupling halves

together by hand to insure proper mating of threads. Be

sure to hold the coupling firmly to prevent movement of

the coupling and tubing. Failure to do so could tear out

the diaphragm causing a blockage of the system. Use

proper size wrenches (on coupling body hex and on

union nut) and tighten until coupling bodies ”bottom”

or a definite resistance is felt.

TABLE 5

COUPLINGS

eziSgnilpuoCsdnuoPteeF

6-21-01

01-54-53

11-54-53

21-56-05

CAUTION

After starting to tighten up the fitting, never try to

back it off or take it apart.

17. Using a marker or ink pen, mark a line lengthwise from

the coupling union nut to the bulkhead. Then tighten

an additional 1/4 turn. The misalignment of the line

will show the amount the coupling has been tightened.

This final 1/4 turn is necessary to insure the formation

of leakproof joint. If a torque wrench is used, the

torque values shown in Table 5 are recommended.

18. Leak test all connections using an electronic leak

detector or a halide torch.

19. When tubing is installed in attics or drop ceilings,

insulate the couplings on the larger tube thoroughly

with 3/8” wall thickness, closed cell sponge tube

insulation or equivalent. Failure to insulate will result

in water damage to ceiling since the fitting will “sweat”

and drop water on the ceiling.

Manual 2100-346

Page 8

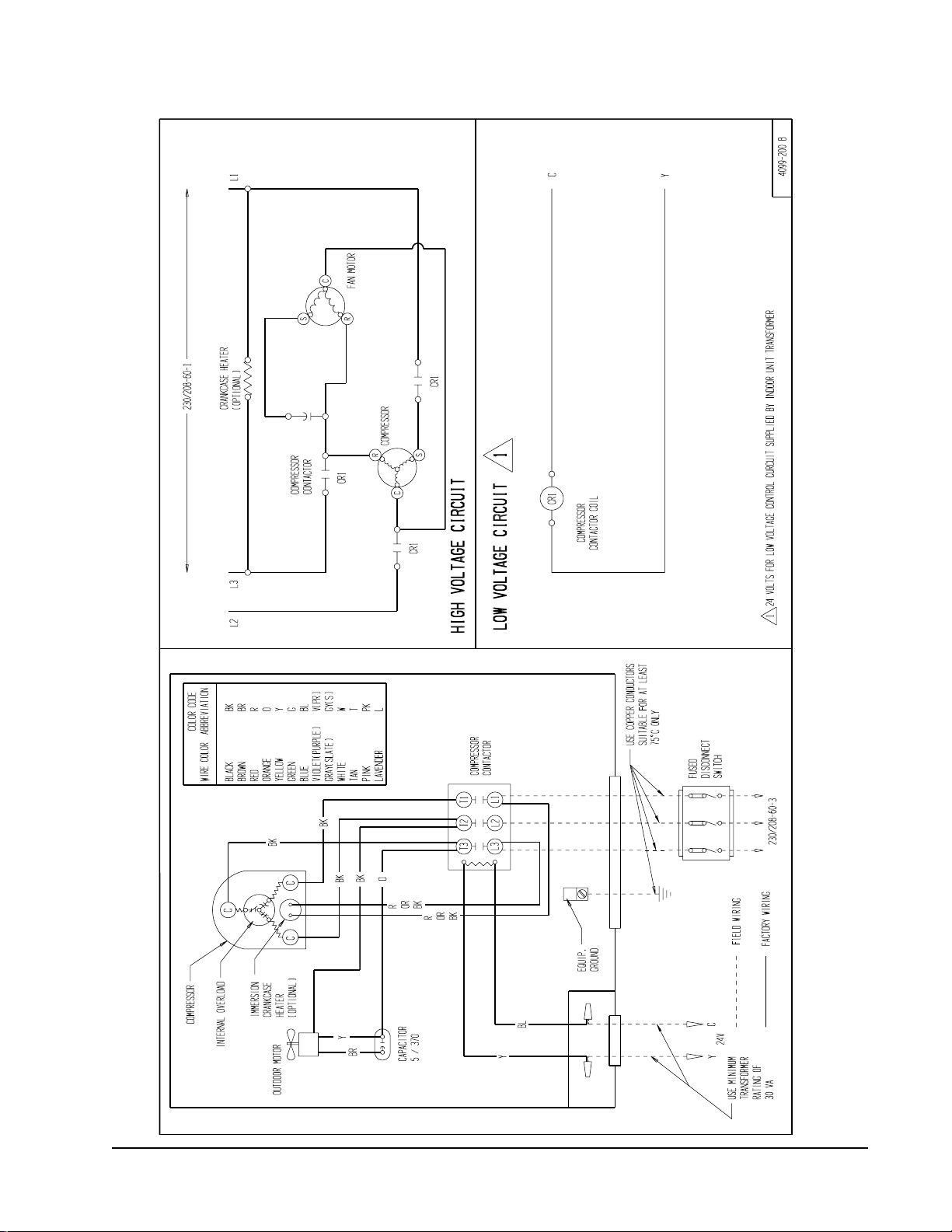

WIRING INSTRUCTIONS

GENERAL

All wiring must be installed in accordance with the National

Electrical Code and local codes. In Canada, all wiring must

be installed in accordance with the Canadian Electrical

Code and in accordance with the regulations of the

authorities having jurisdiction. Power supply voltage must

conform to the voltage shown on the unit serial plate. A

wiring diagram of the unit is attached to the inside of the

electrical cover. The power supply shall be sized and fused

according to the specification supplied. A ground lug is

supplied in the control compartment for equipment ground.

The unit rating plate lists a “Maximum Time Delay Fuse” or

HACR type” circuit breaker that is to be used with the

equipment. The correct size must be used for proper circuit

protection and also to assure that there will be no nuisance

tripping due to the momentary high starting current of the

compressor motor.

CONTROL CIRCUIT WIRING

For split systems, the minimum control circuit wiring gauge

needed to insure proper operation of all controls in both

indoor and outdoor units will depend on two factors:

1. The rated VA of the control circuit transformer.

Example: 1 . Control circuit transformer rated at 40 VA

2. Maximum total distance of control circuit

wiring 85 feet.

From Table 6, minimum of 18 gauge wire should be used in

the control circuit wiring.

For control circuit transformers rated other than those listed,

use the next lower rated transformer listed.

Example: 1 . Control circuit transformer rated at 55 VA

From table use 50VA transformer.

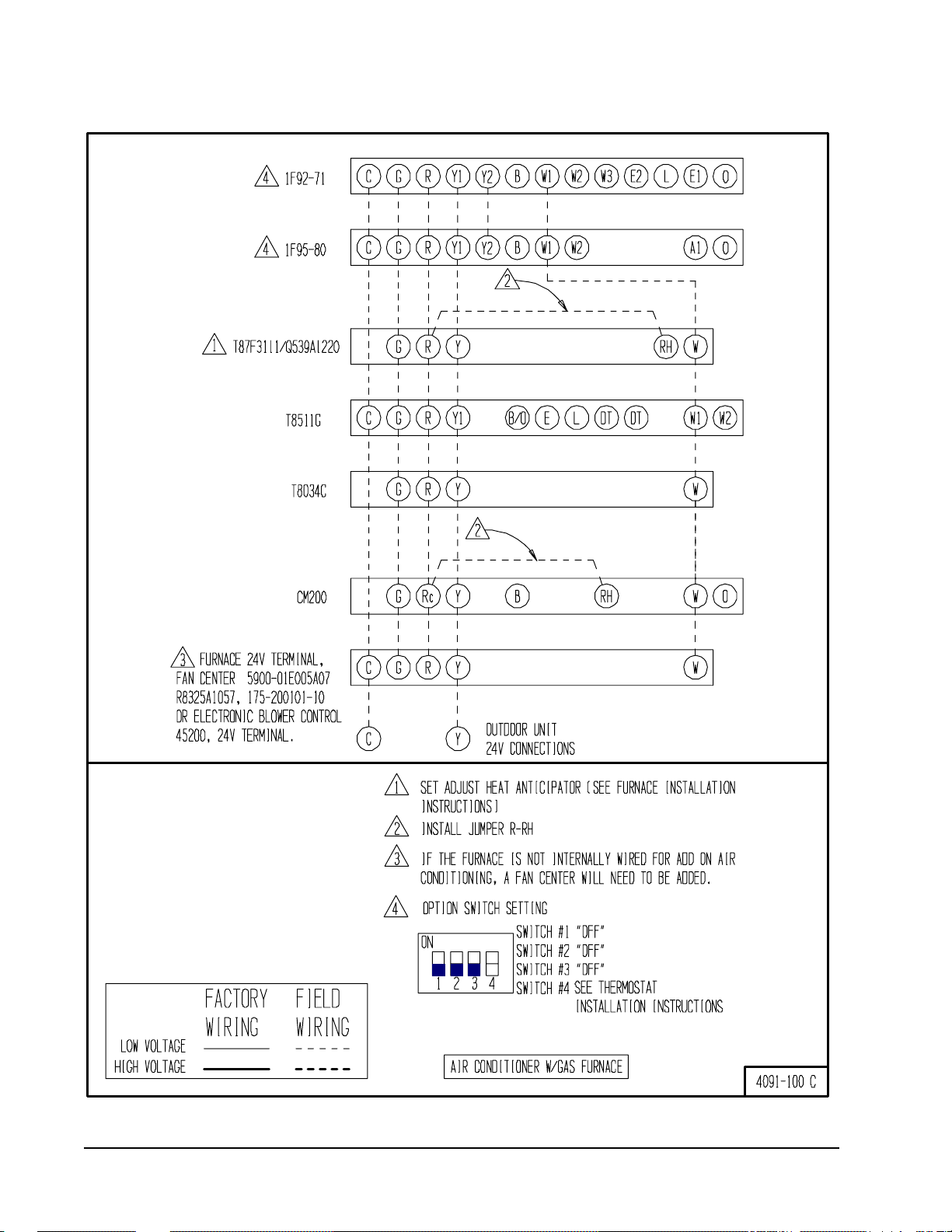

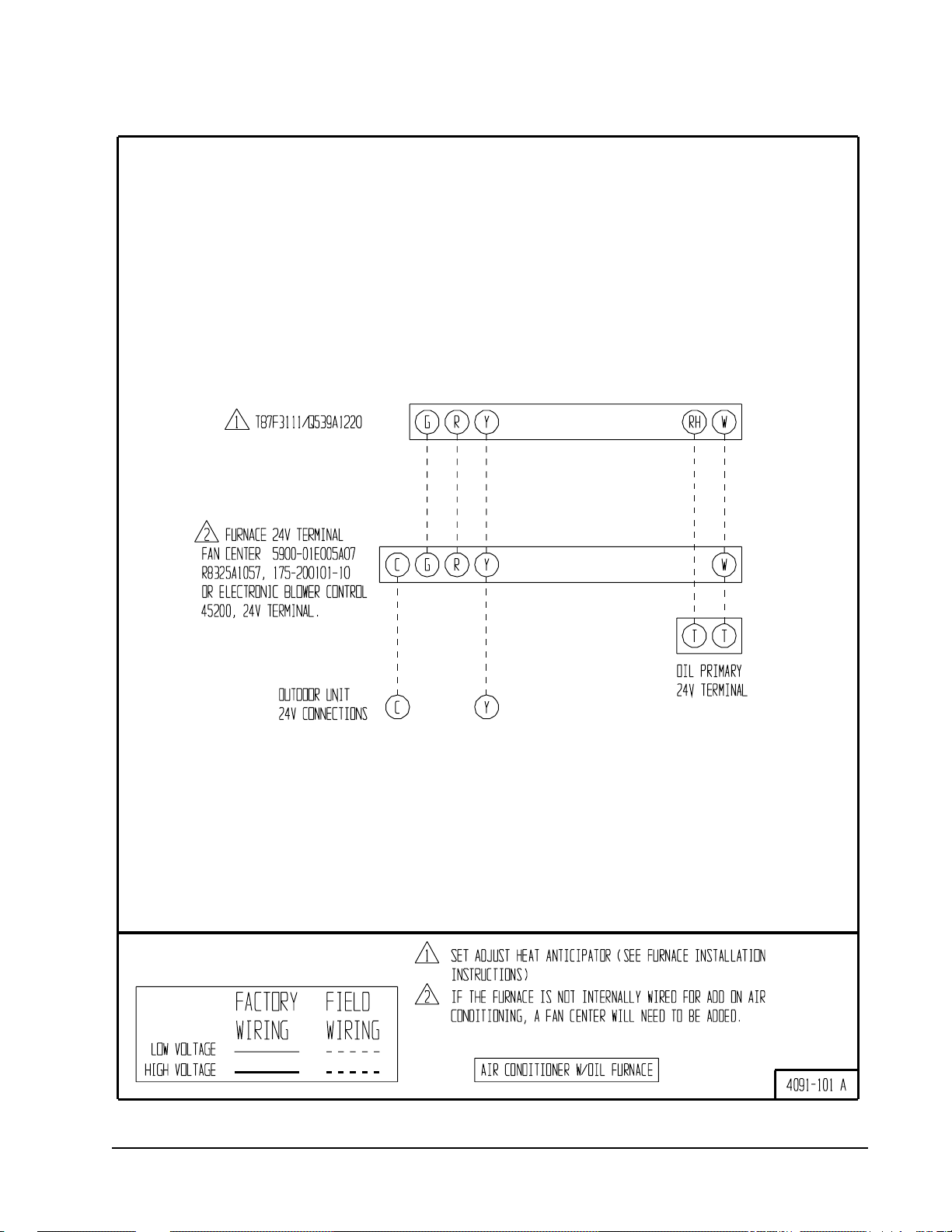

There are two (2) separate control diagrams for fossil fuel

furnaces with air conditioners.

Control diagrams for the various circuit which could be

encountered with blower coils can be found in the

installation instructions of the blower coil.

TABLE 7

CONTROL DIAGRAMS

metsyS

sledoMllA001-1904101-1904

ecanruFsaG

margaiDlortnoC

ecanruFliO

margaiDlortnoC

2. The maximum total distance of the control circuit

wiring. (This is the distance between the wall

thermostat to the indoor unit plus the distance

between the indoor unit to the outdoor unit.)

The following table should be used to determine proper

gauge of control circuit wiring required.

TABLE 6

CONTROL CIRCUIT WIRING

foAVdetaR

tiucriClortnoC

remrofsnarT

046.1

051.2

567.2

remrofsnarT

yradnoceS

V42@ALF

WALL THERMOSTATS

The following wall thermostats and subbases should be

used as indicated, depending on the application.

TABLE 8

WALL THERMOSTAT and SUBBASE

COMBINATIONS

latoTmumixM

foecnatsiD

tiucriClortnoC

teeFnigniriW

56eguag02

09eguag81

541eguag61

032eguag41

54eguag02

06eguag81

001eguag61

061eguag41

052eguag21

04eguag02

55eguag81

58eguag61

531eguag41

012eguag21

tatsomrehTesabbuSserutaeFetanimoderP

200-3048

113F78T

140-3048

C-4308T

530-3048

08-59F1

240-3048

G1158T

340-3048

002MC

720-3048

17-29F1

300-4048

0221A925Q

---

---

---

---

---

yrucreM;loocegats1,taehegats1

otua-no:naFlooc-ffo-taeh:metsyS

yrucreM;loocegats1,taehegats1

otua-no:naFlooc-ffo-taeh:metsyS

loocegats2,taehegats2

elbammargorP

cinortcelE

loocegats1,taehegats2

looc-otua-ffo-taeh:metsyS

cinortcelEotua-no:naF

loocegats1,taehegats1

otua-no:naFlooc-ffo-taeh:metsyS

noitcApanS

loocegats2,taehegats3

elbammargorP

cinortcelE

Manual 2100-346

Page 9

Manual 2100-346

Page 10

Manual 2100-346

Page 11

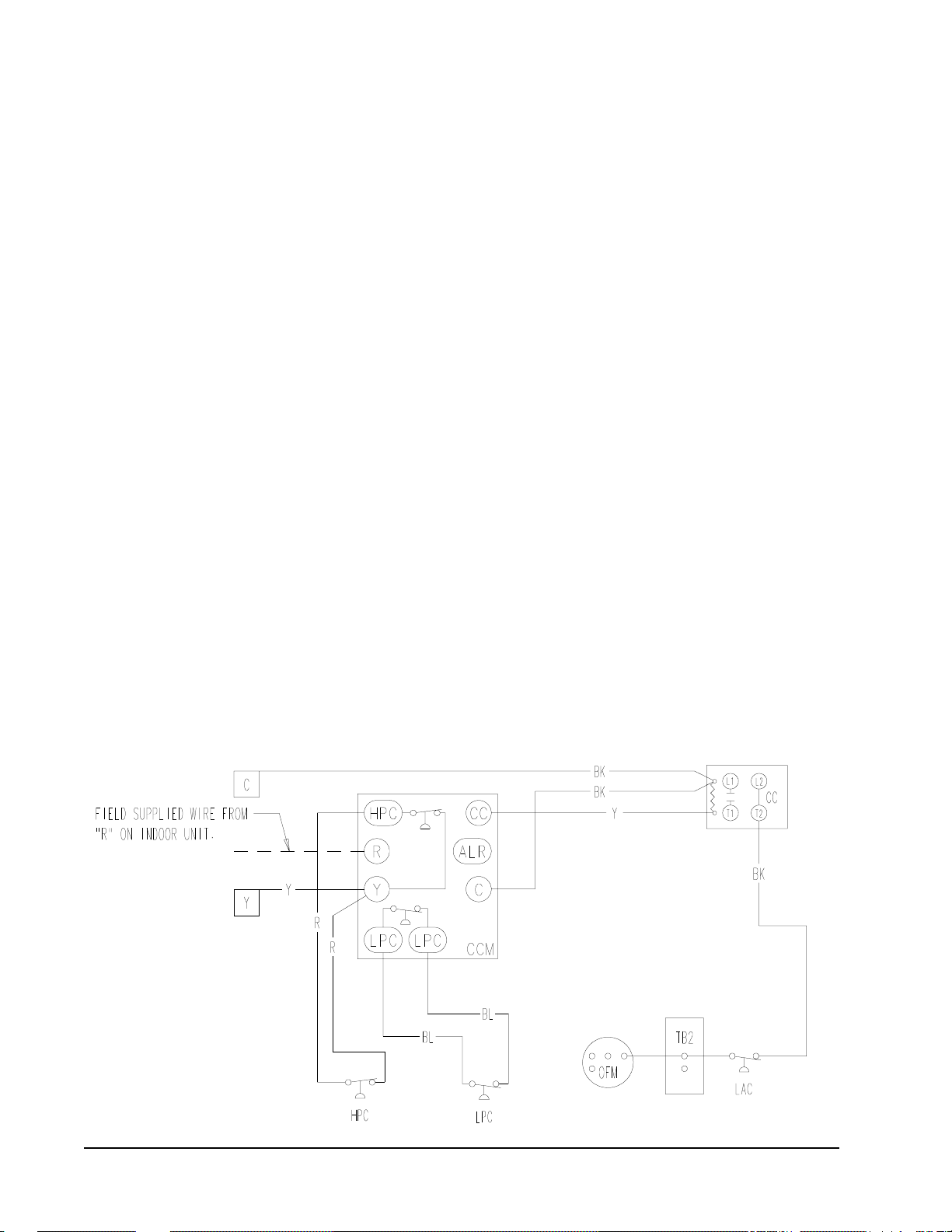

OPTIONAL CONTROLS

INSTALLATION INSTRUCTIONS — CMA-6

FIGURE 5

COMPONENT MOUNTING LOCATION

CMA-5 & CMA-13A LOW

CMA-5 COMPRESSOR

TIME DELA Y RELAY

SK109 LOW VOLTAGE

START KIT

MIS-1302

AMBIENT FAN CYCLING

CONTROL TERMINAL BLOCK

CMA-10A & CMA-13A

COMPRESSOR

CONTROL

INSTALLATION INSTRUCTIONS — CMA-5

Disconnect all power to the unit. Remove control panel

cover.

1. Mount compressor TDR in position shown in Figure 5

with screw provided.

2. Disconnect yellow low voltage (Y) wire at the

compressor contactor coil and reconnect to the Y1 or #3

terminal of the TDR.

3. Connect yellow wire from terminal (Y) of the TDR to

the (Y) terminal of the compressor contactor coil. This

is the terminal that the wire was removed from in

Step 2.

4. Recheck wiring. Refer to Figure 9. Energize unit.

Compressor should start. Remove power and reapply.

Compressor should not start until the 5 minute time

delay has expired.

Disconnect all power to unit. Remove control panel inner

and outer cover.

1. Mount terminal block in position shown in Figure 5.

2. Disconnect black high voltage outdoor motor lead from

compressor contactor and reconnect to terminal block.

3. Route low ambient control wires up through the

bushing in the bottom of the control panel. Connect the

low ambient control wires between the terminal block

and T2 of the compressor contactor.

4. Remove service port cap on discharge line. Install the

low ambient control on the discharge line with the flare

tee adapter that is brazed to the low ambient control.

Check for pressure at the flare tee dill valve after

installation to insure that the dill valve in the unit

service port was depressed by the flare tee connector.

Check for leaks at the flare tee connectors. Replace

service port cap on the flare tee service port and tighten.

5. Recheck wiring. See Figure 10. Check for proper

operation of the unit by energizing in cooling mode.

The condenser fan motor should not run until the

discharge pressure has exceeded 300 PSI. Should the

discharge pressure fall below 200 PSI while running,

the condenser fan motor will de-energize until the head

pressure builds to 300 PSI.

6. Apply “This unit equipped with CMA-6 control

module” label to the inside of the control panel cover

above the wiring diagrams.

7. Replace all panels and covers. This completes

installation.

FIGURE 7

INSTALLATION INSTRUCTIONS FOR

CMA-6 LOW AMBIENT FAN CYCLING CONTROL

5. Apply “This unit equipped with CMA-5 control

module” label to inside of the inner control panel cover

above wiring diagram.

6. Replace all panels and covers. This completes

installation.

FIGURE 6

INSTALLATION INSTRUCTIONS

FOR CMA-5 COMPRESSOR TIME DELAY RELAY

MIS-598

Manual 2100-346

Page 12

MIS-594

INSTALLATION INSTRUCTIONS – CMA-10A

Disconnect all power to unit. Remove control panel cover.

1. Screw compressor control module and terminal block

into control panel as shown in Figure 5.

2. Disconnect yellow low voltage wire form compressor

contactor and reconnect to terminal “Y” of the

compressor control module.

3. Connect the yellow wire from the compressor control

module to “Y” side of the compressors contactor coil.

This is the same terminal from which the wire was

removed in Step 2.

4. Connect the black wire form the compressor control

module to common “C” side of the compressor

contactor coil.

5. Connect a field supplied wire from “R” of the indoor

unit to “R” on the compressor control module.

6. Route the high (red) and low (blue) pressure switch

wires through the bushing in the bottom of the control

panel. Connect the low pressure switch wire to

terminals LPC of the compressor control module.

7.Remove service port caps on both the suction and

discharge lines. Install the high pressure switch on the

discharge line to the flare tee adapter that is brazed to

the controls. Install the low pressure switch on the

suction line. Check for pressure at the flare tee dill

valves after installation to insure that the dill valve in

the unit service port was depressed by the flare tee

connector. Check for leaks at the flare tee connectors.

Replace service port caps on the flare tee service ports

and tighten.

8. Adjust the compressor time delay relay to the desired

delay on break. Two minutes are recommended. This

TDR is variable form 30 seconds to 5 minutes.

9. Recheck wiring. Energize unit is first stage cooling.

Compressor should not start until the time delay has

expired. This will be 10% of the delay on break period.

Run the unit for at least 5 minutes. The unit should not

go into lockout.

10. Apply “This unit equipped with CMA-10A control

module.” label to the inside of the inner control panel

cover above the wiring diagram.

11. Replace all panels and covers. This completes

installation.

FIGURE 8

INSTALLATION INSTRUCTIONS FOR

CMA-10A DUAL PRESSURE CONTROL and

COMPRESSOR TIME DELAY RELAY

MIS-1303

Manual 2100-346

Page 13

INSTALLATION INSTRUCTIONS – CMA-13A

Disconnect all power to unit. Remove control panel cover.

1. Screw compressor control module and terminal block

into control panel as shown in Figure 5.

2. Disconnect yellow low voltage wire from compressor

contactor and reconnect to terminal “Y” of the

compressor control module.

3. Connect the yellow wire from the compressor control

module to “Y” side of the compressor’s contactor coil.

This is the same terminal from which the wire was

removed in Step 2.

4. Connect the black wire from the compressor control

module to common “C” side of the compressor

contactor coil.

5. Connect a field supplied wire from “R” of the indoor

unit to “R” on the compressor control module.

6. Route the high (red) and low (blue) pressure switch

wires through the bushing in the bottom of the control

panel. Connect the low pressure switch wire to

terminals LPC of the compressor control module.

Connect the high pressure switch wires to terminals

HPC of the compressor control module.

7. Disconnect the high voltage outdoor motor lead and

reconnect to the terminal block installed in Step 1.

8. Route the LAC (black) wires up through the busing in

the bottom of the control panel. Connect one wire to

the terminal block and the other to “T2” of the

contactor. This will be the same terminal from which

the high voltage outdoor motor lead was removed in

Step 7.

9. Remove service port caps on both the suction and

discharge lines. Install the high pressure switch and

the low ambient control on the discharge line with the

flare tee adapter that is brazed to the controls. Install

the low pressure switch on the suction line. Check for

pressure at the flare tee dill valves after installation to

insure that the dill valve in the unit service port was

depressed by the flare tee connector. Check for leaks at

the flare tee connectors. Replace service port caps on

the flare tee service ports and tighten.

10. Adjust the compressor time delay relay to the desired

delay on break. Two minutes are recommended. This

TDR is variable from 30 seconds to 5 minutes.

11. Recheck wiring. Energize unit in first stage cooling.

Compressor should not start until the time delay has

expired. This will be 10% of the delay on break period.

Run the unit for at least 5 minutes. The unit should not

go into lockout. The condenser fan motor should not

run until the discharge pressure has exceeded 300 PSI.

Should the discharge pressure fall below 200 PSI while

running the condenser fan motor will de-energize until

the head pressure builds to 300 PSI.

12. Apply “This unit equipped with CMA-13A control

module.” label to the inside of the inner control panel

cover above the wiring diagram.

13. Replace all panels and covers. This completes

installation.

FIGURE 9

INSTALLATION INSTRUCTIONS FOR

CMA-13A DUAL PRESSURE CONTROL, LOW AMBIENT FAN CYCLING CONTROL

and COMPRESSOR TIME DELAY RELAY

MIS-1304

Manual 2100-346

Page 14

CHARGING INSTRUCTIONS

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on all units

so that the system operating pressures can be observed.

Pressure tables can be found later in the manual covering all

models. It is imperative to match the correct pressure table

to the unit by model number.

SYSTEM START-UP (INDOOR UNITS

WITHOUT EXPANSION VALVES)

1. Close disconnect switch(es) and set the thermostat to

cool and the temperature to the highest setting.

2. Check for proper airflow across the indoor coil by

referring to indoor unit installation.

3. Connect the service gauges and allow the unit to run for

at least 10 minutes or until pressures are stable. Check

pressures to the system pressure table attached to the

outdoor unit service panel. For optimum system

performance, go to Step 4.

4. Install a thermometer on the suction line approximately

6" to 10" from the compressor. Optimum system

performance will occur with a refrigerant charge

resulting in a suction line superheat as determined from

the following calculations.

A. Measure outdoor air dry bulb temperature

________ ºF

B. Measure indoor air wet bulb temperature

________ ºF

C. Measure suction pressure ______PSIG

D. Measure suction line temperature ________ ºF

E. Determine optimum system superheat

from Table 9 using outdoor air dry bulb

(Step B) and indoor air wet bulb (Step A)

________ ºF

TABLE 9

SYSTEM SUPERHEAT

tneibmAroodtuO

F(erutarepmeT

)bluByrD

501

59

09

58

08

57

95367617

1

1

1

3

1

7

3

9

8

41

01

02

bluBteWF

5

)8(

41

91

52

03

TABLE 10

SATURATED SUCTION TEMPERATURE R-22

noitcuSdetarutaS

GISPerusserPnoitcuS

05

35

55

85

16

36

56

76

07

37

67

97

28

68

62

82

03

23

43

63

83

93

14

34

54

74

94

15

)F(erutarepmeT

erutarepmeTriAnruteR

02

62

33

93

24

F. Determine saturated suction temperature

from suction pressure using Table 10 ________ ºF

G. Determine system superheat:

Suction line temperature (Step D) ________ ºF

- Saturated suction temperature (Step F)

- ________ ºF

= System superheat

= ________ ºF

H. Adjust the system superheat (Step G) to the

optimum system superheat (Step E) by adding

charge to lower the superheat or removing

charge to raise the superheat.

I. Check final system operating pressures to the

system pressure tables as was done in Step 3.

Manual 2100-346

Page 15

TABLE 11

TOTAL SYSTEM OPERATING CHARGE

(Includes charge for the basic outdoor unit,

indoor coil and 25’ of interconnecting tubing.)

noitceSroodtuOnoitceSroodnI

A-SA03A

A-181CAH

A-142CAH

A-103CAH

A-163CAH

A-124CAH

B-,A-184CAH

B-,A-106CAH

A-SA42S

B42CB

A-SA03A

A-SA42S

B42CB

A-SA63A

B63CB

A-SA73A

B63CB

A-SA24A

A-SA84A

B63CB

B06CB

A-SA16A

B06CB

A-SA16A

B06CB

.zo37

.zo37

.zo87

.zo08

.zo08

.zo97

.zo48

.zo59

.zo89

.zo69

.zo201

.zo711

.zo501

.zo241

.zo551

.zo571

.zo351

.zo561

SCHEDULE FOR TABLE 11

retemaiDeniLdiuqiL.tFreP22-R.zO

"4/1

"8/3

22-RlatoT

).zO(egrahC

Installer Note: Stamp or mark the final system charge

determined above on the outdoor unit serial plate.

"2/1

52.0

06.0

02.1

Q

R

R

R

R

R

R

Includes 25’ of 1/4” diameter liquid line. For other than 25’ and

Q

other tube sizes, adjust the total charge according to the

following schedule.

Includes 25’ of 3/8” diameter liquid line. For other than 25’ and

R

other tube sizes, adjust the total charge according to the

following schedule.

Manual 2100-346

Page 16

SERVICE

ledoMAnoisnemiDsnoitacoLbuHnaF

181CAH

142CAH

103CAH

163CAH

"5B

124CAH

184CAH

106CAH

"4/3-4C

SERVICE HINTS

1. Caution homeowner to maintain clean air filters at all

times. Also, not to needlessly close off supply and

return air registers. This reduces air flow through the

system, which shortens equipment service life, as well

as, increasing operating costs.

2. Check all power fuses or circuit breakers to be sure that

they are the correct rating.

3. Periodic cleaning of the outdoor coil to permit full and

unrestricted air flow circulation is essential.

FAN BLADE SETTING DIMENSIONS

Shown in Figure 10 are the correct fan blade setting

dimensions for proper air delivery across the outdoor coil.

Any service work requiring removal or adjustment in the fan

and/or motor area will require that the dimensions below be

checked and blade adjusted in or out on the motor shaft

accordingly.

FIGURE 10

FAN BLADE

C

B

A

7960-337

TABLE 12

FAN BLADE SETTING

Manual 2100-346

Page 17

Manual 2100-346

Page 18

Manual 2100-346

Page 19

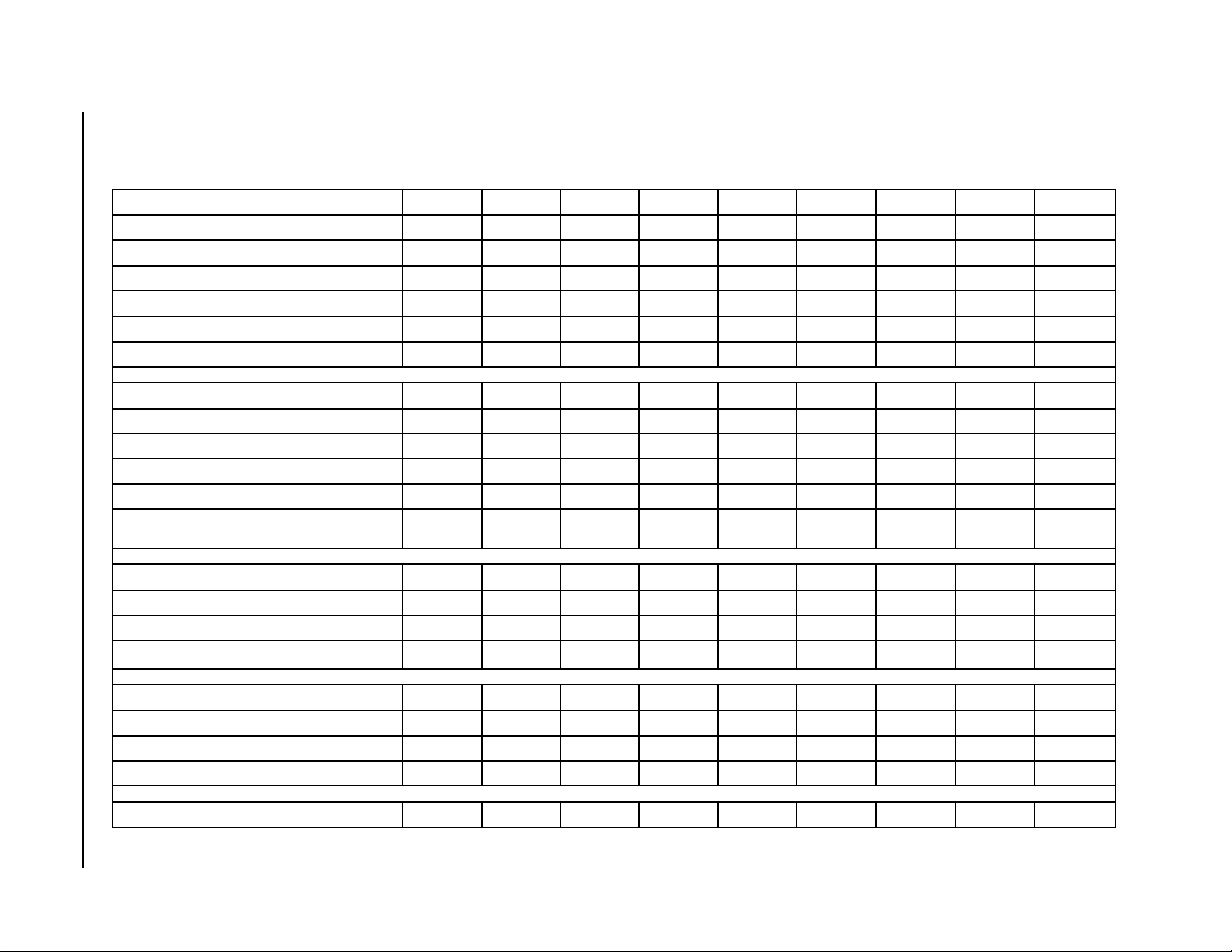

TABLE 13

PRESSURE TABLE

HAC181-A

roodnI

noitceS

A-SA03SA

A-SA42S

B42CB

Low side pressure ± 2 PSIG (suction line 8 inches from compressor)

High side pressure ± 5 PSIG (discharge line 8 inches from compressor, liquid at base valve approximately -20 PSIG from

values listed)

T ests are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct operating change being in

the system. The charge should be removed, system evacuated and recharged to serial plate instructions.

riAnruteR

.pmeTerusserP

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

56075708580959001501011511

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

86

07

27

47

67

87

08

051

071

781

302

622

442

452

07

37

67

97

18

48

68

961

381

891

312

822

442

062

67

97

28

58

78

09

29

771

191

602

55

26

86

261

871

391

77

87

87

461

081

891

67

97

28

771

191

602

122

632

252

962

37

87

902

422

08

312

032

58

78

122

632

18

48

042

652

18

28

48

642

362

09

29

252

962

lioCroodtuOgniretnEerutarepmeTriA

28

48

58

852

552

642

88

09

29

672

392

013

49

69

89

682

403

223

68

78

78

272

882

403

68

88

09

082

692

313

49

69

89

682

403

223

78

023

39

823

99

043

78

023

39

923

99

043

TABLE 14

PRESSURE TABLE

HAC241-A

roodnI

noitceS

A-SA03SA

A-SA42S

B42CB

Low side pressure ± 2 PSIG (suction line 8 inches from compressor)

High side pressure ± 5 PSIG (discharge line 8 inches from compressor, liquid at base valve approximately -20 PSIG from

values listed)

T ests are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct operating change being in

the system. The charge should be removed, system evacuated and recharged to serial plate instructions.

riAnruteR

.pmeTerusserP

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

56075708580959001501011511

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

06

46

86

17

47

67

87

271

091

702

422

142

852

572

66

07

37

67

97

771

591

312

032

742

37

67

97

28

58

581

302

022

832

752

56

96

37

77

08

971

491

902

522

07

37

57

77

97

401

251

291

522

37

67

97

28

58

581

302

022

832

652

18

38

562

282

78

98

372

28

142

752

152

962

78

372

192

38

372

18

38

082

98

192

lioCroodtuOgniretnEerutarepmeTriA

08

292

58

992

903

48

092

58

482

903

18

28

803

523

68

78

613

333

19

29

49

623

443

58

68

603

423

68

88

182

072

19

29

49

623

443

28

143

88

053

59

263

78

143

98

252

59

263

Manual 2100-346

Page 20

TABLE 15

PRESSURE TABLE

HAC301-A

roodnI

noitceS

A-SA63A

B63CB

Low side pressure ± 2 PSIG (suction line 8 inches from compressor)

High side pressure ± 5 PSIG (discharge line 8 inches from compressor, liquid at base valve approximately -20 PSIG from

values listed)

T ests are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct operating change being in

the system. The charge should be removed, system evacuated and recharged to serial plate instructions.

riAnruteR

.pmeTerusserP

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

56075708580959001501011511

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

26

56

76

96

261

381

402

422

86

07

27

47

761

881

012

032

57

77

87

08

171

491

612

832

16

56

96

27

581

76

091

47

891

102

712

432

17

47

77

702

322

932

77

08

38

512

232

842

17

37

57

442

262

082

67

87

08

052

962

782

28

48

68

852

872

792

57

77

97

052

662

282

08

28

48

652

272

982

68

88

09

562

282

992

lioCroodtuOgniretnEerutarepmeTriA

77

87

08

792

313

923

28

48

58

503

88

513

892

68

603

29

613

123

833

09

29

333

943

18

28

38

413

78

223

39

333

133

88

933

59

153

TABLE 16

PRESSURE TABLE

HAC361-A

18

443

78

353

49

563

48

743

98

653

69

863

roodnI

noitceS

A-SA73A

B63CB

Low side pressure ± 2 PSIG (suction line 8 inches from compressor)

High side pressure ± 5 PSIG (discharge line 8 inches from compressor, liquid at base valve approximately -20 PSIG from

values listed)

T ests are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct operating change being in

the system. The charge should be removed, system evacuated and recharged to serial plate instructions.

riAnruteR

.pmeTerusserP

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

56075708580959001501011511

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

66

86

07

27

47

67

87

181

791

312

032

642

262

872

17

37

57

77

97

18

38

681

202

912

532

252

862

582

77

97

191

802

36

66

871

591

66

96

481

002

27

57

881

602

18

38

58

78

98

622

342

062

872

592

86

07

27

47

67

212

822

542

262

972

27

57

87

08

28

712

432

152

962

682

87

422

18

38

68

88

242

062

872

692

lioCroodtuOgniretnEerutarepmeTriA

08

28

48

492

013

623

58

78

98

203

813

533

19

39

59

213

033

743

87

97

18

692

313

133

48

58

78

403

09

413

123

933

29

49

233

153

68

343

19

153

79

463

28

843

88

753

59

963

Manual 2100-346

Page 21

TABLE 17

PRESSURE TABLE

HAC 421-A

roodnI

noitceS

A-SA24A

B63CB

A-SA84A

B06CB

Low side pressure ± 2 PSIG (suction line 8 inches from compressor)

High side pressure ± 5 PSIG (discharge line 8 inches from compressor, liquid at base valve approximately -20 PSIG from

values listed)

T ests are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct operating change

being in the system. The charge should be removed, system evacuated and recharged to serial plate instructions.

riAnruteR

.pmeTerusserP

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

5708580959001501011511

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

46

302

96

802

37

612

37

212

77

812

38

422

76

812

27

422

77

232

47

822

97

432

58

142

07

332

57

042

08

842

67

442

18

052

78

852

27

052

77

652

38

562

77

062

38

762

98

672

47

662

97

372

58

282

97

772

58

482

19

492

67

382

28

092

78

003

18

492

78

203

39

492

lioCroodtuOgniretnEerutarepmeTriA

77

003

28

803

98

813

28

213

98

023

59

133

87

813

48

623

09

733

48

033

09

933

79

053

TABLE 18

PRESSURE TABLE

HAC481-A, HAC481-B

97

633

58

543

19

953

68

943

29

853

99

073

roodnI

noitceS

-SA16A

B

B06CB

Low side pressure ± 2 PSIG (suction line 8 inches from compressor)

High side pressure ± 5 PSIG (discharge line 8 inches from compressor, liquid at base valve approximately -20 PSIG from

values listed)

T ests are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct operating change

being in the system. The charge should be removed, system evacuated and recharged to serial plate instructions.

riAnruteR

.pmeTerusserP

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

5708580959001501011511

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

47

802

87

412

48

022

86

242

67

842

28

752

57

322

08

922

68

632

07

052

77

652

38

562

77

832

28

542

88

352

27

062

87

662

48

672

87

452

48

162

09

072

47

272

08

872

68

882

08

172

68

872

29

882

67

582

18

292

78

203

28

882

88

692

49

603

87

003

28

803

88

813

lioCroodtuOgniretnEerutarepmeTriA

38

603

09

413

69

523

97

713

48

523

09

633

58

423

19

333

79

443

08

633

58

443

19

653

78

343

39

253

99

463

18

653

78

563

39

873

Manual 2100-346

Page 22

TABLE 19

PRESSURE TABLE

HAC601-A, HAC601-B

roodnI

noitceS

-SA16A

B

B06CB

Low side pressure ± 2 PSIG (suction line 8 inches from compressor)

High side pressure ± 5 PSIG (discharge line 8 inches from compressor, liquid at base valve approximately -20 PSIG from

values listed)

T ests are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct operating change

being in the system. The charge should be removed, system evacuated and recharged to serial plate instructions.

riAnruteR

.pmeTerusserP

BD57

BW26

BD08

BW76

BD58

BW27

BD57

BW26

BD08

BW76

BD58

BW27

5708580959001501011511

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

76

722

27

232

87

042

46

322

96

032

67

732

96

342

47

942

08

852

76

932

27

642

87

552

17

062

67

662

28

672

07

752

57

462

08

372

37

672

87

482

48

392

27

572

77

382

28

392

57

392

08

103

68

113

47

592

97

303

58

413

67

013

28

813

88

923

67

613

18

523

58

633

lioCroodtuOgniretnEerutarepmeTriA

87

623

48

633

09

643

77

933

28

843

78

063

97

343

68

353

29

463

87

363

38

273

98

583

97

953

88

073

49

283

87

883

48

893

09

114

Manual 2100-346

Page 23

Loading...

Loading...