Bard HA4S4KA, HA5S4KA, HL4S4KA, HL5S4KA Installation Instructions Manual

INSTALLATION INSTRUCTIONS

WALL-MOUNTED

PACKAGED AIR CONDITIONER

Models:

HA4S4KA

HA5S4KA

HL4S4KA

HL5S4KA

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

MIS-2498

Manual: 2100-646

Supersedes: NEW

Date: 9-3-15

Page 1 of 26

CONTENTS

Getting Other Information and Publications

Wall Mount General Information

Air Conditioner Wall Mount Model Nomenclature

Shipping Damage

General

Duct Work

Filters

............................................................... 7

........................................................... 7

................................................................. 7

Condensate Drain

Installation

Wall Mounting Information

Mounting the Unit

Typical Installations

Wiring – Main Power

Wiring – Low V

................................................. 7

................................................ 7

............................................................... 8

.................................... 8

................................................ 8

.............................................. 8

............................................. 8

oltage Wiring ................................. 12

......................... 4

..... 4

Dirty Filter Switch and Relay ............................... 13

Economizer Fail Time Delay Relay ........................ 13

Figures

Figure 1 Unit Dimensions .................................. 5

Figure 2

Mounting Instructions .......................... 9

Figure 3 Wall Mounting Instructions ................. 10

Figure 4

Wall Mounting Instructions ................. 10

Figure 5 Common Wall Mounting Installations ... 11

Figure 6 Electric Heat Clearance ...................... 12

Figure 7 Start Up Label ................................... 17

Figure 8

Fan Blade Setting .............................. 18

Figure 9 Control Disassembly ........................... 21

Figure 10 Winding Test ...................................... 21

Figure 11 Drip Loop .......................................... 21

Figure 12 H***S4 Wiring Diagram – Top ............. 24

Figure 13

H***S4 Wiring Diagram – Bottom ........ 25

Figure 14 H***S4 Low Voltage Ladder Diagram

for Unit and MV Connections ............... 26

3

Start Up ................................................................... 14

General

Topping Off System Charge

Safety Practices

Important Installer Note

Service Hints

Sequence of Operation

High and Low Pressure Switch

Compressor Control Module

Motor Start Device

Pressure Service Ports

Crankcase Heaters

Service

Compressor Solenoid

Fan Blade Setting Dimensions

............................................................. 14

................................. 14

................................................. 14

...................................... 14

..................................................... 14

........................................ 15

............................. 15

................................. 15

.............................................. 16

........................................ 16

.............................................. 16

..................................................................... 18

.......................................... 18

............................. 18

Removal of Fan Shroud ....................................... 18

R-410A Refrigerant Charge ................................. 19

Troubleshooting GE ECM

TM

Motors ....................... 20

Optional Accessories ........................................... 21

Tables

Table 1 Electric Heat ....................................... 4

Table 2 Dimensions of Basic Unit ...................... 5

Table 3 Electrical Specifications ....................... 6

Table 4

Sequence of Operation ....................... 15

Table 5 Fan Blade Dimensions ........................ 18

Table 6 Cooling Pressure ................................ 19

Table 7 Indoor Blower Performance ................. 22

Table 8

Optional Accessories

Table 9 Optional Accessories

– RH Units .......... 22

– LH Units .............22

Manual 2100-646

Page 2 of 26

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help when installing the

furnace. They can usually be found at the local library

or purchased directly from the publisher. Be sure to

consult the current edition of each standard.

National Electrical Code

Standard for the Installation of

Air Conditioning and Ventilating

Systems .......................................... ANSI/NFPA 90A

Standard for Warm Air Heating

and Air Conditioning Systems

Load Calculation for Residential

inter and Summer

W

Air Conditioning

Low Pressure, Low Velocity

Duct System Design for

inter and Summer

W

Air Conditioning

..............ACCA Manual J or Manual N

............. ACCA Manual D or Manual Q

...................... ANSI/NFPA 70

............ANSI/NFPA 90B

For more information, contact these publishers:

ACCA

Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating, Refrigeration

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

11 West Street, 13th Floor

Manual 2100-646

Page 3 of 26

WALL MOUNT GENERAL INFORMATION

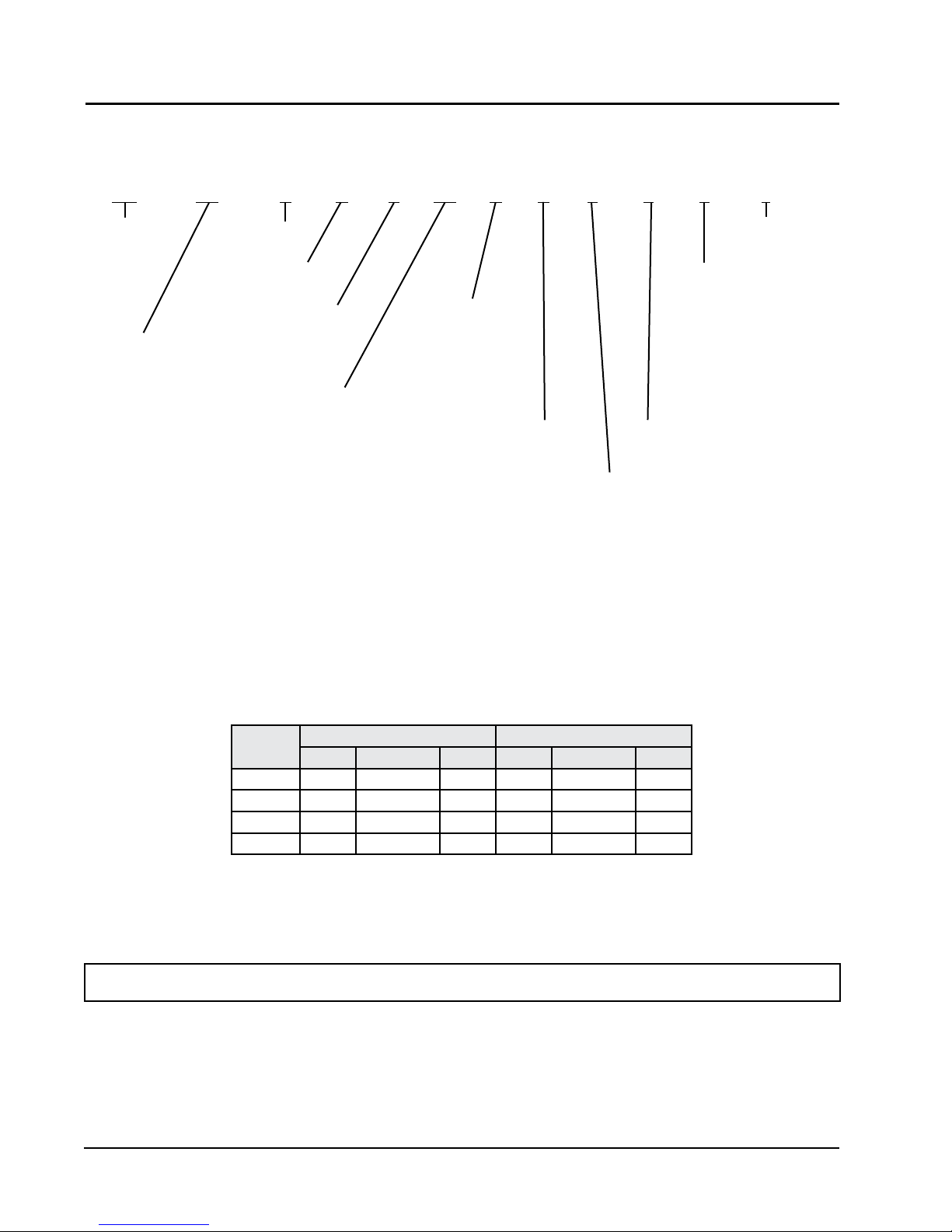

AIR CONDITIONER WALL MOUNT MODEL NOMENCLATURE

HA 4S 4 K A 05 B P X X X J

MODEL NUMBER

HA – Right Hand

HL – Left Hand

CAPACITY

4S – 4 Ton

5S – 5 Ton

REVISION

K – Accumulator

VOLTS & PHASE

A – 230/208-1

– No KW

0Z

w/Circuit Breaker

or Pull Disconnect

05 – 5 KW

08 – 8 KW

10

– 10 KW

15 – 15 KW

KW

VENTILATION OPTIONS

B – Blank-Off Plate

(No Ventilation)

Y – 100% Economizer

(Temperature)

Z – 100% Economizer

(Enthalpy)

FILTER OPTIONS

P – 2" Pleated MERV 8

CONTROL MODULES

J – Only

COIL OPTIONS

X – Standard

1

–

Phenolic Coated

Evaporator

2

–

Phenolic Coated

OUTLET OPTIONS

X – Front (Standard)

COLOR OPTIONS

X – Beige (Standard)

4 – Buckeye Gray

5 – Desert Brown

8 – Dark Bronze

A – Aluminum

S – Stainless Steel

Condenser

3

–

Phenolic Coated

Evaporator and

Condenser

TABLE 1

Electric Heat Table

Nominal

KW

5.0 5.0 20.8 17,065 3.75 18.0 12,799

8.0 8.0 33.3 27,304 6.00 28.8 20,478

10.0 10.0 41.7 34,130 7.50 36.1 25,598

15.0 15.0 62.5 51,195 11.25 54.1 38,396

These electric heaters are available in 230/208V units only.

Kw 1-Ph Amps Btuh Kw 1-Ph Amps Btuh

At 240V At 208V

See Table 3 for heater availability by model

Manual 2100-646

Page 4 of 26

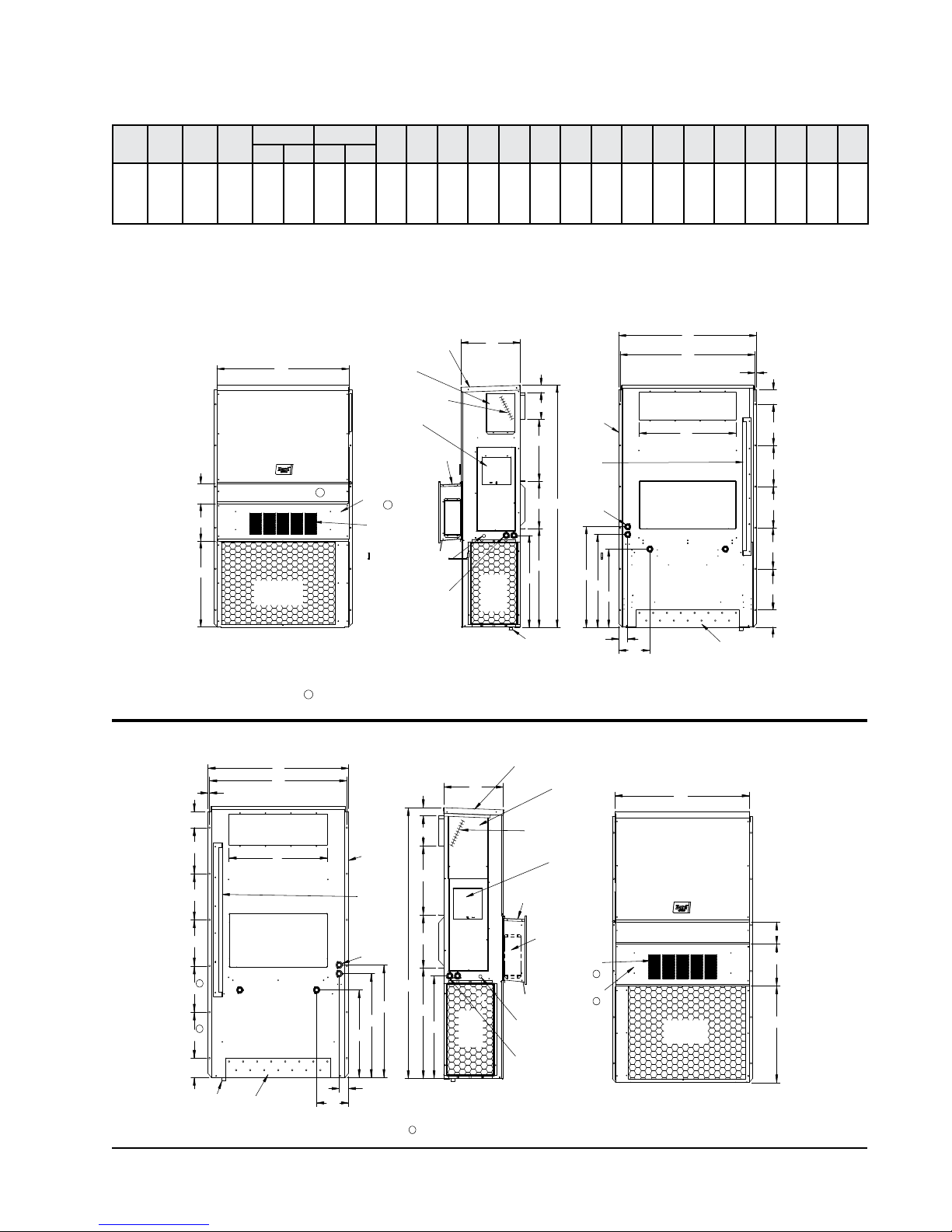

TABLE 2

1

Not used when EWM Economizer is installed. Filter access through the EWM hood

MIS-3761

Electrical

Entrances

Optional

Side Wall

Mounting

Brackets

(Built In)

Location

Shipping

Return Air Opening

Supply Air Opening

Top Rain

Flashing

Bottom Installation

Bracket

Back View

M

L

O

E

R

S1

S1

S1

S2

S2

T

.44

N

Q

P

B

Low Voltage

Electrical

Entrance

High Voltage

Electrical

Entrance

Economizer

Intake Hood

4° Pitch

(Lockable)

Rain Hood

Built In

Air

Inlet

Access

Panel

Cond.

Heater

Electric

Heat

C. Breaker/

Disconnect

Access Panel

Drain

Side View

C H

K

J

I

D

2.13

A

Vent Option

Door

1

1

Condenser

Filter Access Panel

Air Outlet

Ventilation

Air

Front View

F

G

W

5.75

Condenser

Air Outlet

I

A

C

K

2.13

H

J

N

Q

P

M

L

O

E

.44

W

5.88

F

G

R

S

S

S

S

S

T

D

B

1

High Voltage

Drain

Economizer

Inlet

Front View

Side View

1

Electrical

Cond.

Air

Back View

Door

Bottom

Installation

Bracket

Side Wall

Mounting

Brackets

Flashing

Shipping

Location

Optional

Electrical

Entrances

Panel

Air

Ventilation

Electrical

Entrance

MIS-3762

Intake Hood

Entrance

(Built In)

Top Rain

Low Voltage

Filter Access Panel

Access Panel

(Lockable)

Vent Option

Disconnect

Electric

Heat

Heater

Access

Return Air Opening

1

Rain Hood

4° Pitch

1

Supply Air Opening

C. Breaker/

Built In

Economizer Controls

Opposite Side

1

Not used when EWM economizer is installed. Filter access through the EWM hood.

Dimensions of Basic Unit for Architectural and Installation Requirements (Nominal)

WidthWDepthDHeight

Unit

HA4S4

HL4S4

42.075 22.432 94.875 9.88 29.88 15.88 29.88 43.88 19.10 41.66 30.00 42.68 36.94 44.69 42.43 3.37 43.00 33.88 10.00 1.44 16.00 21.00 1.88

HA5S4

HL5S4

All dimensions in inches. Dimensional drawings are not to scale.

Supply Return

H

E F G I J K L M N O P Q R S1 S2 TA B C B

FIGURE 1

Unit Dimensions

HA*S4

RIGHT

UNIT

HL*S4

LEFT

UNIT

Manual 2100-646

Page 5 of 26

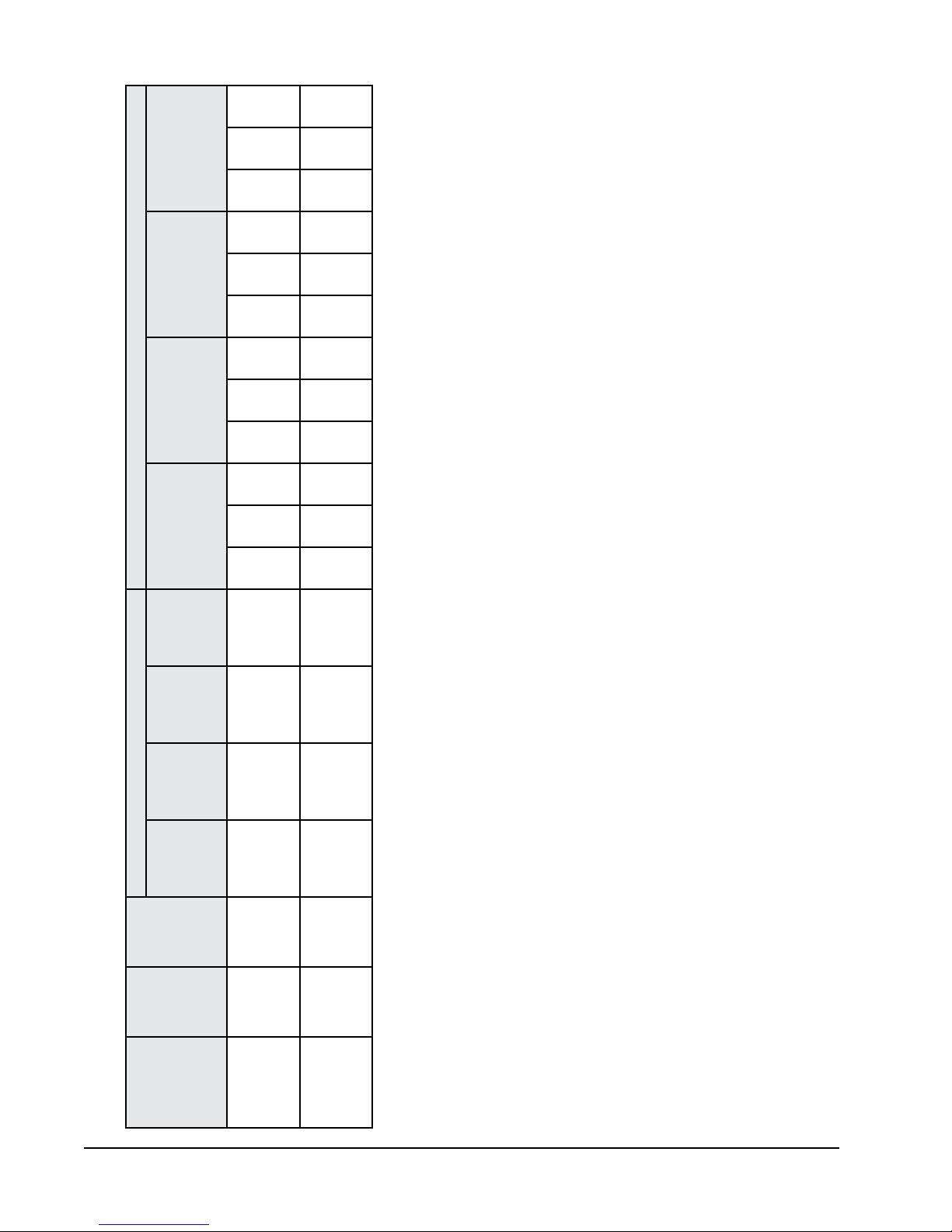

Wire

Ground

10

10

10

10

10

10

10

10

Field

Power

Wire Size

Maximum

or Ckt. Brkr.

External Fuse

Circuit

Ampacity

Minimum

Ckt. A Ckt. B Ckt. C Ckt. A Ckt. B Ckt. C Ckt. A Ckt. B Ckt. C Ckt. A Ckt. B Ckt. C

TABLE 3

Wire

Ground

Electrical Specifications

Field

Power

Wire Size

10

8

30

45

26

37

8

101010

88643

6

8

60

45

52

37

8

101010

88663

10

8

30

50

26

44

8

6

8

60

50

52

44

8

Single Circuit Multiple Circuit

Maximum

or Ckt. Brkr.

External Fuse

Circuit

Ampacity

Minimum

Power

Circuits

No. Field

Volts

Rated

and Phase

Model

4545607090

3838536389

111

1 or 2

1 or 2

230/208-1

- A05

- A08

- A10

HA/L4S4 - A0Z

- A15

5050607090

4444536389

111

HA/L5S4 - A0Z

Manual 2100-646

Page 6 of 26

1 or 2

1 or 2

230/208-1

- A05

- A08

- A10

- A15

CAUTION: When more than one filed power conductor circuit is run through one conduit, the conductors must be derated.

conductor sizing.

Pay special attention to Note * of Table 310 regarding Ampacity Adjustment Factors when more than three conductors are in a raceway.

These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electric Code (latest version), Article 310 for power

Based on 75°C copper wire. All wiring must conform to the National Electric Code (NEC) and all local codes.

Maximum size of the time delay fuse or circuit breaker for protection of field wiring conductors.

SHIPPING DAMAGE

Upon receipt of equipment, the carton should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and

return ducts.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any

national and/or local codes in any way. Authorities

having jurisdiction should be consulted before the

installation is made. See page 3 for information on

codes and standards.

Size of unit for a proposed installation should be based

on heat loss calculation made according to methods of

Air Conditioning Contractors of America (ACCA). The

air duct should be installed in accordance with the

Standards of the National Fire Protection Association

for the Installation of Air Conditioning and Ventilating

Systems of Other Than Residence Type, NFPA No.

90A, and Residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B. Where local

regulations are at a variance with instructions, installer

should adhere to local codes.

DUCT WORK

All duct work, supply and return, must be properly

sized for the design airflow requirement of the

equipment. Air Conditioning Contractors of America

(ACCA) is an excellent guide to proper sizing. All duct

work or portions thereof not in the conditioned space

should be properly insulated in order to both conserve

energy and prevent condensation or moisture damage.

Refer to Table 7 for maximum static pressure available

for duct design.

Design the duct work according to methods given by

the Air Conditioning Contractors of America (ACCA).

When duct runs through unheated spaces, it should

be insulated with a minimum of 1" of insulation. Use

insulation with a vapor barrier on the outside of the

insulation. Flexible joints should be used to connect

the duct work to the equipment in order to keep the

noise transmission to a minimum.

A 1/4" clearance to combustible material for the first

3' of duct attached to the outlet air frame is required.

See Wall Mounting Instructions and Figures 3 and 4 for

further details.

Ducts through the walls must be insulated and all joints

taped or sealed to prevent air or moisture entering the

wall cavity.

!

CAUTION

Some installations may not require any

return air duct. A return air grille is

required with installations not requiring

a return air duct. The spacing between

louvers on the grille shall not be larger

than 5/8".

Any grille that meets the 5/8" louver criteria, may be

used. It is recommended that Bard Return Air Grille

Kit RG-5 or RFG-5 be installed when no return duct

is used. Contact distributor or factory for ordering

information. If using a return air filter grille, filters

must be of sufficient size to allow a maximum velocity

of 400 fpm.

NOTE:

If no return air duct is used, applicable

installation codes may limit this cabinet to

installation only in a single story structure.

FILTERS

A 2" pleated MERV 8 filter is supplied with each unit.

The filter slides into position making it easy to service.

This filter can be serviced from the outside by removing

the filter access panel.

CONDENSATE DRAIN

A plastic drain hose extends from the drain pan at

the top of the unit down to the unit base. There are

openings in the unit base for the drain hose to pass

through. In the event the drain hose is connected to

a drain system of some type, it must be an open or

vented type system to assure proper drainage.

Manual 2100-646

Page 7 of 26

INSTALLATION

WALL MOUNTING INFORMATION

1. Two holes, for the supply and return air openings,

must be cut through the wall as shown in Figure 3.

On wood-frame walls, the wall construction must

2.

be strong and rigid enough to carry the weight of

the unit without transmitting any unit vibration.

See Figures 4 and 5.

3. Concrete block walls must be thoroughly inspected

to insure that they are capable of carrying the

weight of the installing unit.

MOUNTING THE UNIT

1. These units are secured by wall mounting brackets

which secure the unit to the outside wall surface at

both sides. A bottom mounting bracket is provided

for ease of installation.

2.

The unit itself is suitable for 0 clearance, but the

supply air duct flange and the first 3’ of supply

air duct require a minimum of 1/4” clearance to

combustible material. If a combustible wall, use

a minimum of 30-1/2” x 10-1/2” dimensions for

sizing. However, it is generally recommended that

a 1” clearance is used for ease of installation and

maintaining the required clearance to combustible

material. The supply air opening would then be

32” x 12”. See

Figures 2, 3 and 6 for details.

3. Locate and mark lag bolt locations and bottom

mounting bracket location (see Figure 4).

Mount bottom mounting bracket.

4.

5. Hook top rain flashing under back bend of top.

Top rain flashing is shipped secured to the right

side of the back.

6.

Position unit in opening and secure with 5/16"

lag bolts; use 7/8" diameter flat washers on the

lag bolts.

Secure rain flashing to wall and caulk across

7.

entire length of top (see Figure 2).

8.

For additional mounting rigidity, the return air

and supply air frames or collars can be drilled

and screwed or welded to the structural wall itself

(depending upon wall construction). Be sure to

observe required clearance if combustible wall.

9. On side-by-side installations, maintain a

minimum of 20" clearance on right side to

allow access to heat strips and control panel

and to allow proper airflow to the outdoor coil.

Additional clearance may be required to meet

local or national codes.

TYPICAL INSTALLATIONS

See Figure 5 for common ways to install the wall

mount unit.

!

WARNING

Failure to provide the 1/4" clearance

between the supply duct and a combustible

surface for the rst 3' of duct can result in

re causing damage, injury or death.

Clearances Required for Service Access

and Adequate Condenser Airflow

MODELS

HA4S4, HL4S4

HA5S4, HL5S4

NOTE: For side-by-side installation of two H**S4 models, there

must be 20" between units. This can be reduced to 15"

by using a HL*S4 model (left side compressor and controls) for the left unit and HA*S4 (right side compressor

and controls) for right unit.

See H**S4 Specification S3458.

LEFT

SIDE

20" 20" 10”

RIGHT

SIDE

DISCHARGE

SIDE

WIRING – MAIN POWER

Refer to the unit rating plate for wire sizing

information and maximum fuse or circuit breaker

size. Each outdoor unit is marked with a “Minimum

Circuit Ampacity”. This means that the field wiring

used must be sized to carry that amount of current.

Depending on the installed KW of electric heat, there

may be two field power circuits required. If this is the

case, the unit serial plate will so indicate. All models

are suitable only for connection with copper wire.

Each unit and/or wiring diagram will be marked “Use

Copper Conductors Only”. These instructions must

be adhered to. Refer to the National Electrical Code

(NEC) for complete current carrying capacity data on

the various insulation grades of wiring material. All

wiring must conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75ºC

copper) for all models, including the most commonly

used heater sizes. Also shown are the number of field

power circuits required for the various models with

heaters.

Manual 2100-646

Page 8 of 26

Loading...

Loading...