Page 1

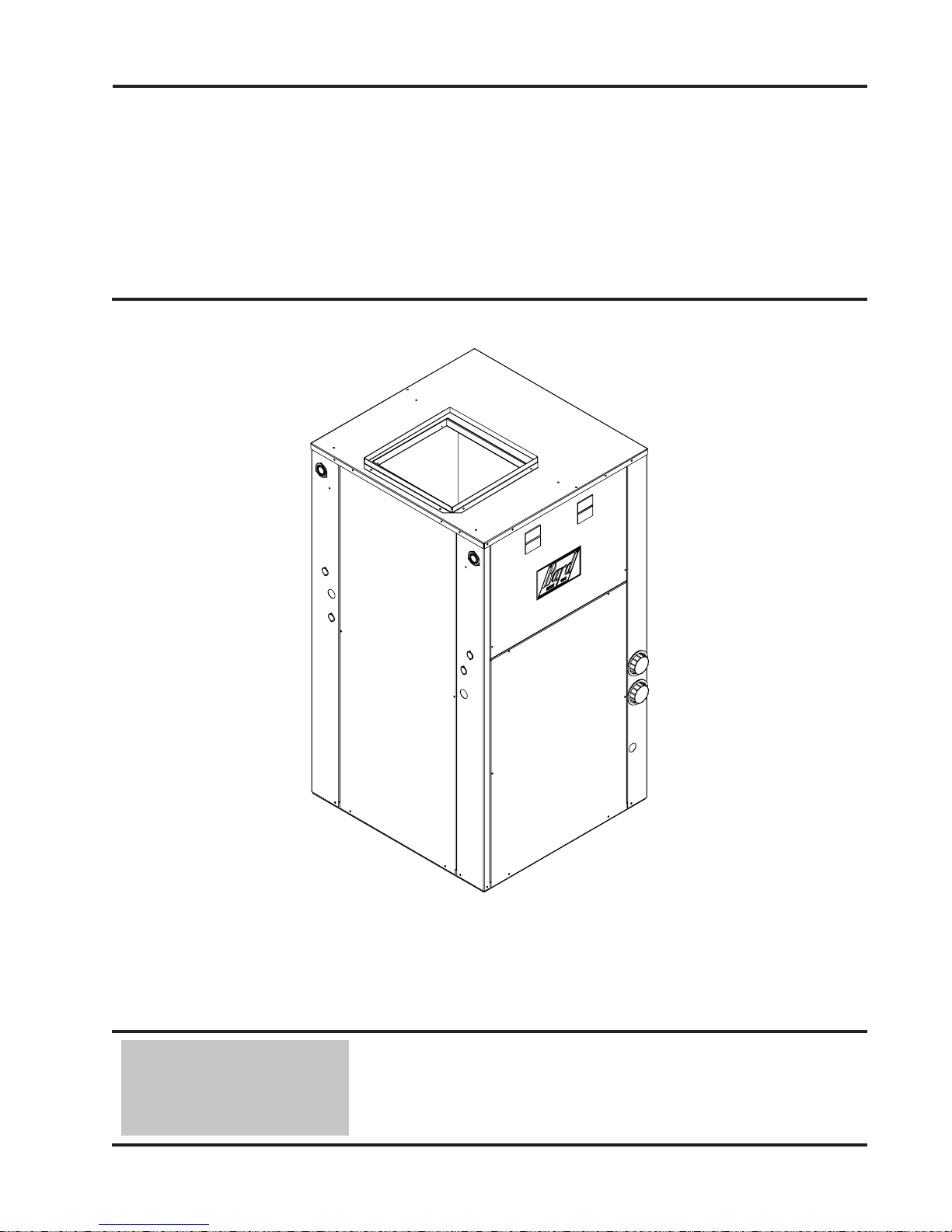

INSTALLATION

INSTRUCTIONS

WATER SOURCE

HEAT PUMPS

Models:

GV27S1-A, GV38S1-A

GV51S1-A, GV61S1-A

GV71S1-A

Ground Water Temperatures 45° - 75°

MIS-2615

Earth Loop Fluid

Temperatures 25° - 110°

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead, just as planned.

Manual: 2100-510E

Supersedes: 2100-510D

File: Volume I, Tab 8

Date: 08-04-09

Manual 2100-510E

Page 1 of 38

Page 2

CONTENTS

Getting Other Informations and Publications ........ 3

General Information

Water Source Nomenclature ................................... 4

Heater Package Nomenclature ............................... 8

Application and Location

General ................................................................ 9

Shipping Damage .................................................... 9

Application ............................................................... 9

Location ................................................................ 9

Ductwork ................................................................ 9

Filters ............................................................... 11

Condensate Drain ................................................... 11

Piping Access to Unit..............................................11

Wiring Instructions

General .............................................................. 14

Control Circuit Wiring ............................................ 14

Wall Thermostats................................................... 14

Thermostat Indicators ............................................ 14

Emergency Heat Mode .......................................... 14

Ground Loop (Earth Coupled Water Loop Applications)

Note .............................................................. 16

Circulation System Design .................................... 16

Start Up Procedure for Ground Loop System ........ 17

Ground Water (Well System Applications)

Note .............................................................. 19

Water Connections ................................................ 19

Well Pump Sizing .......................................... 19 & 20

Start Up Procedure for Ground Water System ...... 21

Water Corrosion ............................................ 21 & 22

Remedies of Water Problems................................ 22

Lake and/or Pond Installations ...................... 22 & 23

Sequence of Operation

Blower .............................................................. 24

Part Load Cooling .................................................. 24

Full Load Cooling ................................................... 24

Part Load Heating .................................................. 24

Full Load Heating .................................................. 24

Supplementary Electric Heat ................................. 24

Emergency Heat Mode .......................................... 24

Compressor Control Module .................................. 25

Pressure Service Ports .......................................... 25

System Start Up..................................................... 25

Pressure Tables ............................................. 28 & 29

Quick Reference Troubleshooting Chart ............... 30

Service

Service Hints ......................................................... 31

Unbrazing System Components ............................ 31

Compressor Solenoid ............................................ 31

Troubleshooting GE X13-Series Motors ........ 32 & 33

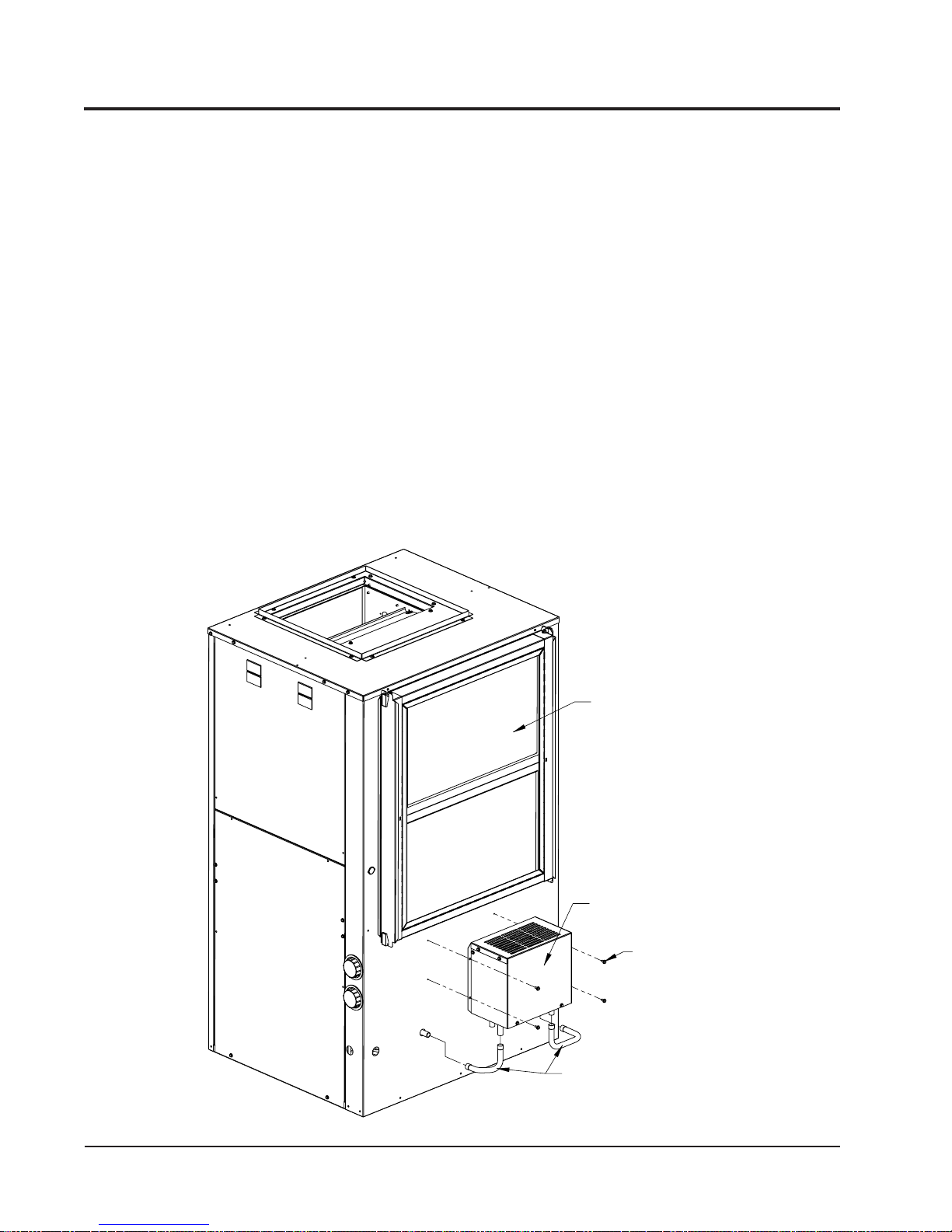

Accessories

Add-On GVDM-26 Pump Module Kit ..................... 34

General .............................................................. 34

Installation ............................................................. 34

Ground Source Heat Pump

Performance Report .......................................... 35-36

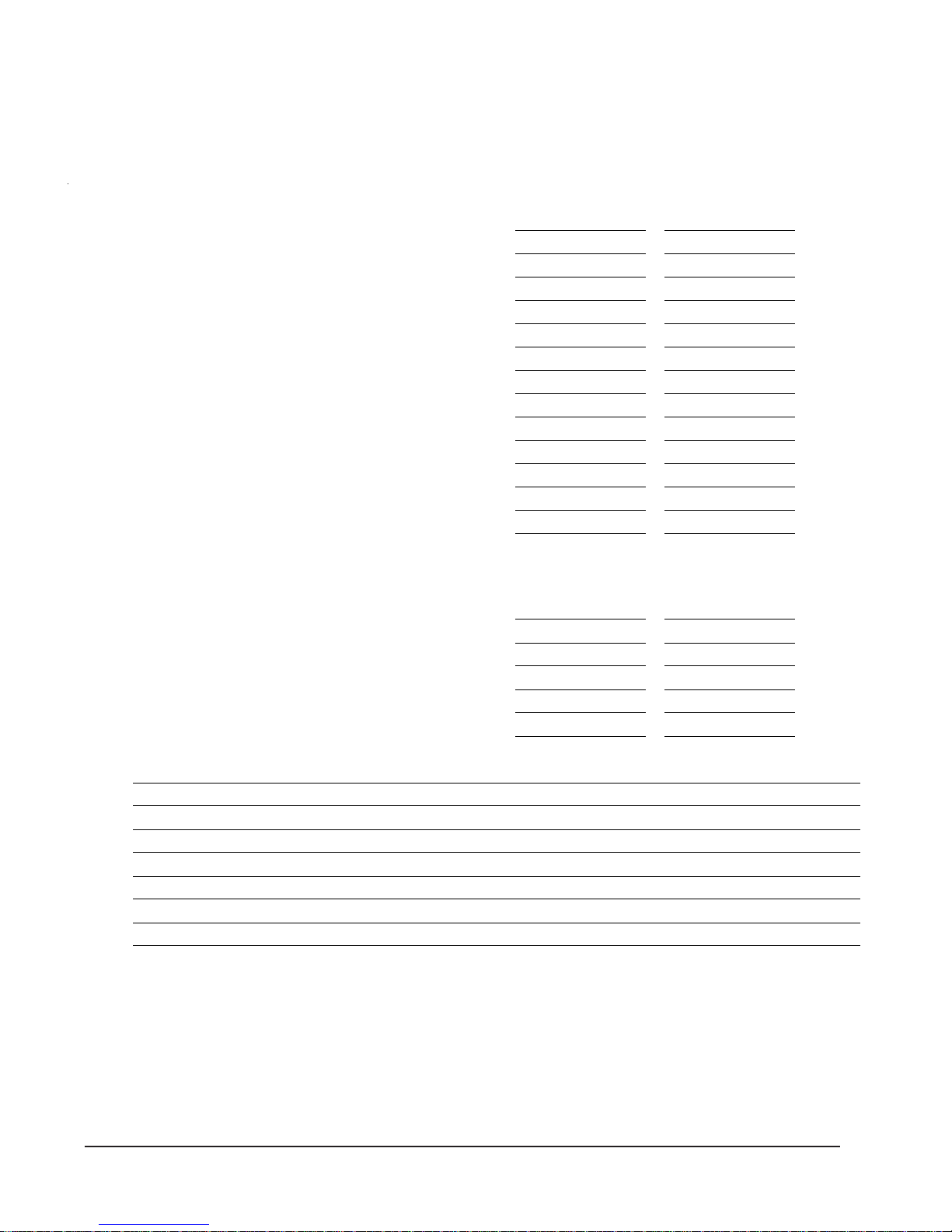

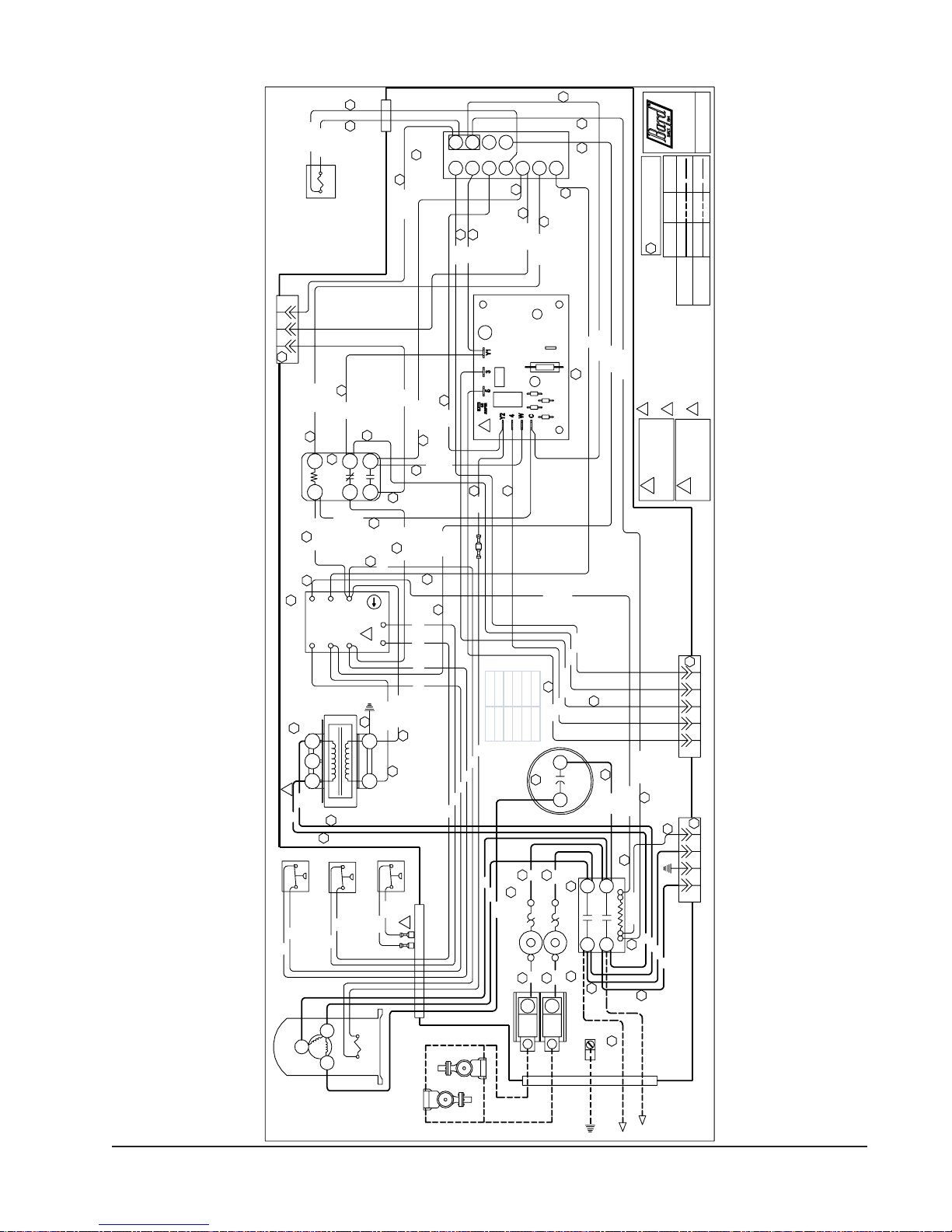

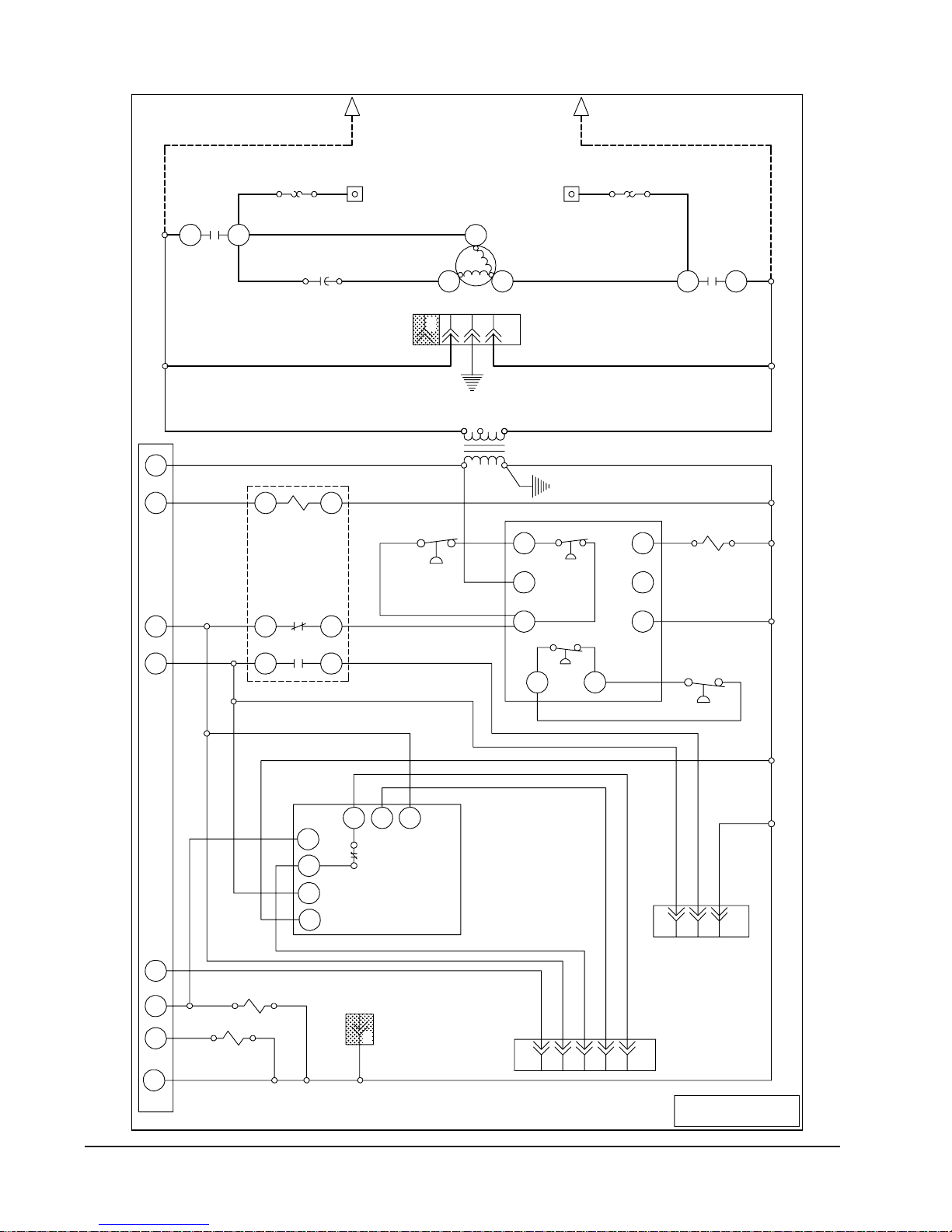

Wiring Diagrams ................................................ 37-38

Figures

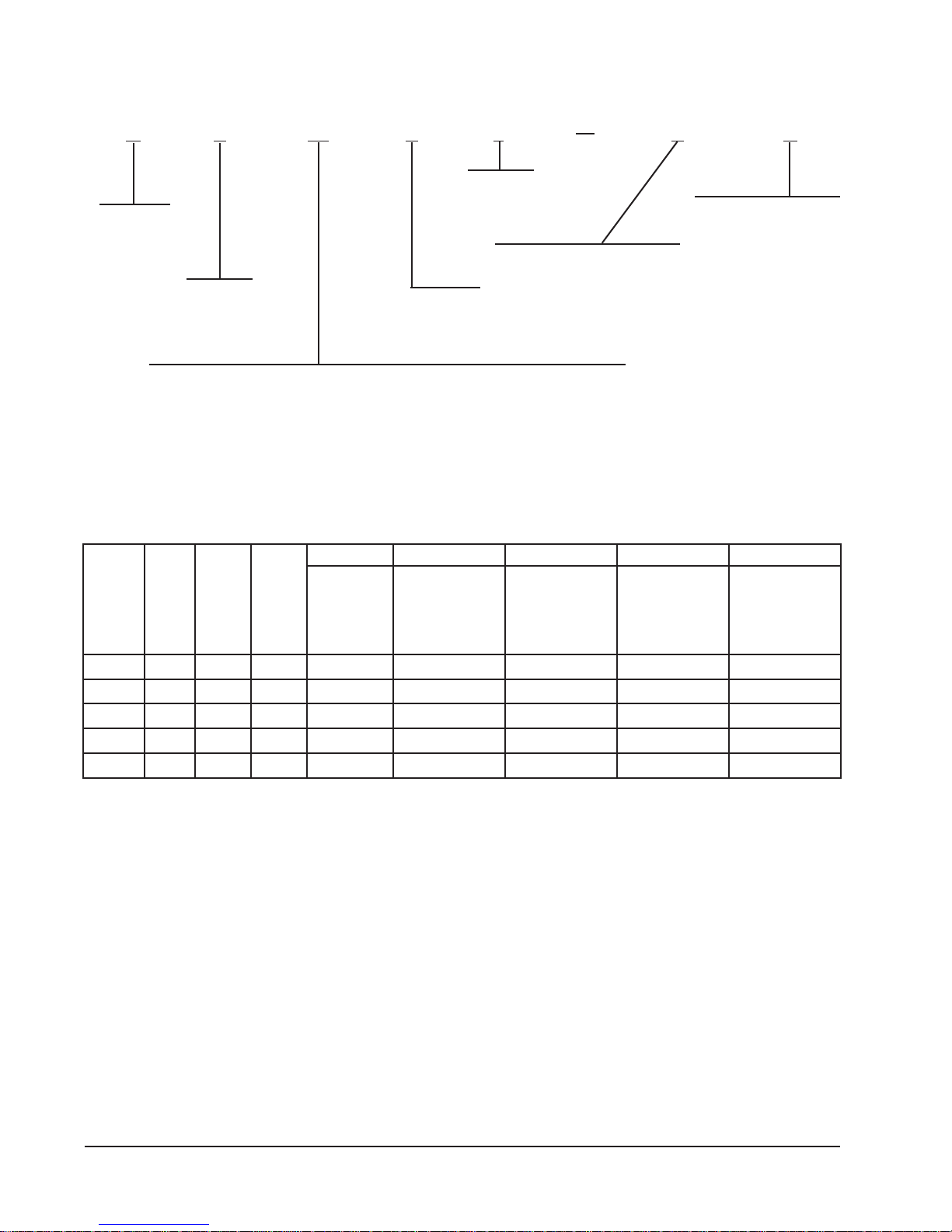

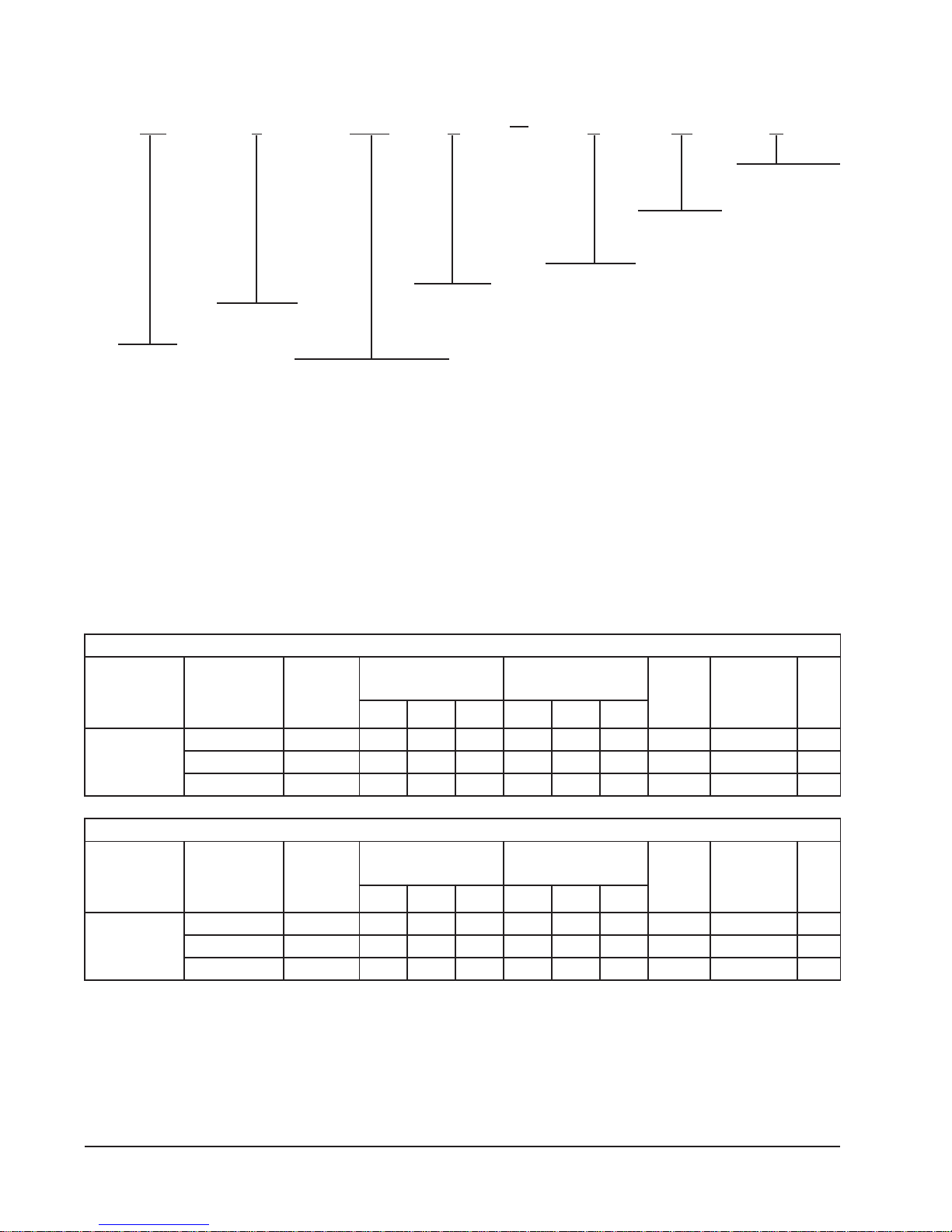

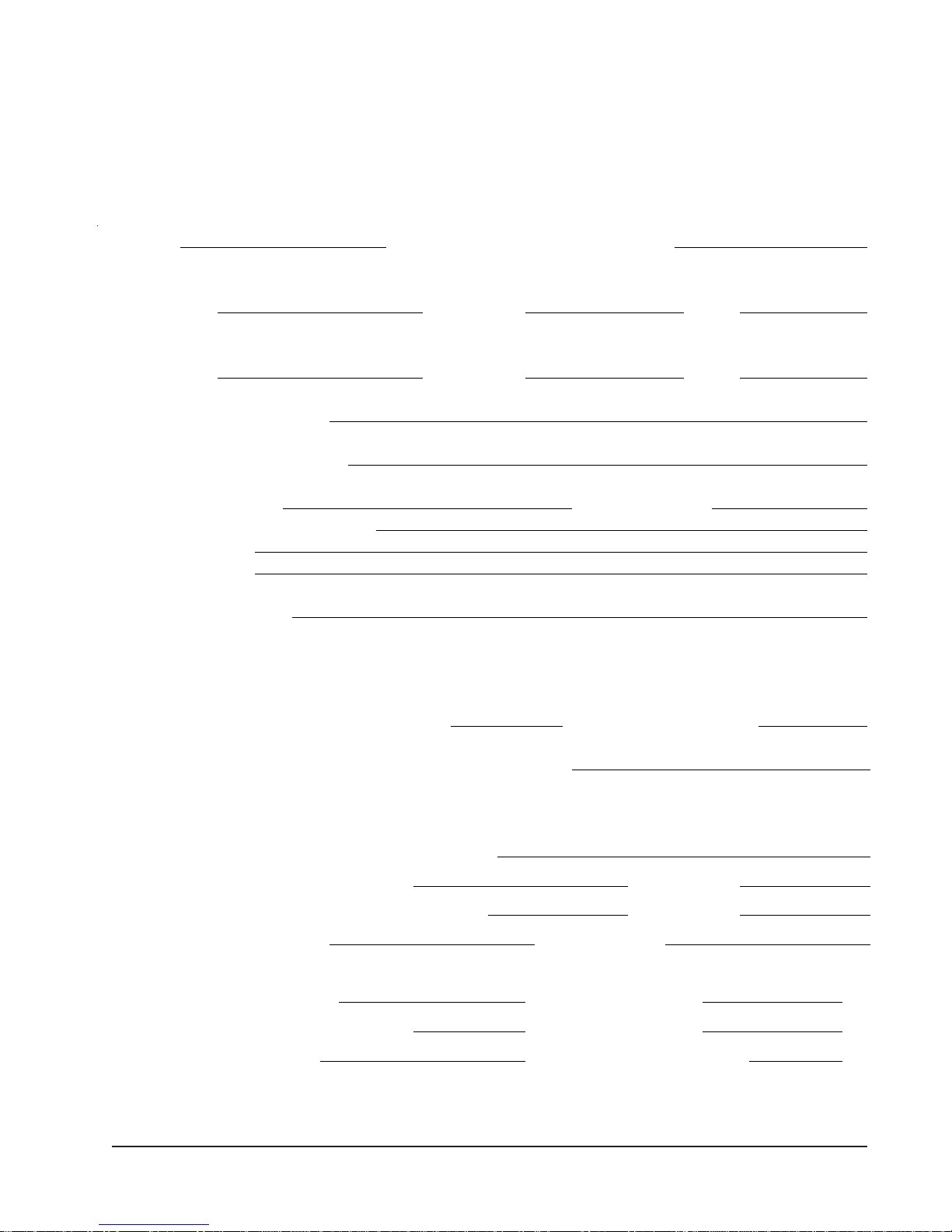

Figure 1 Unit Dimensions ...................................... 7

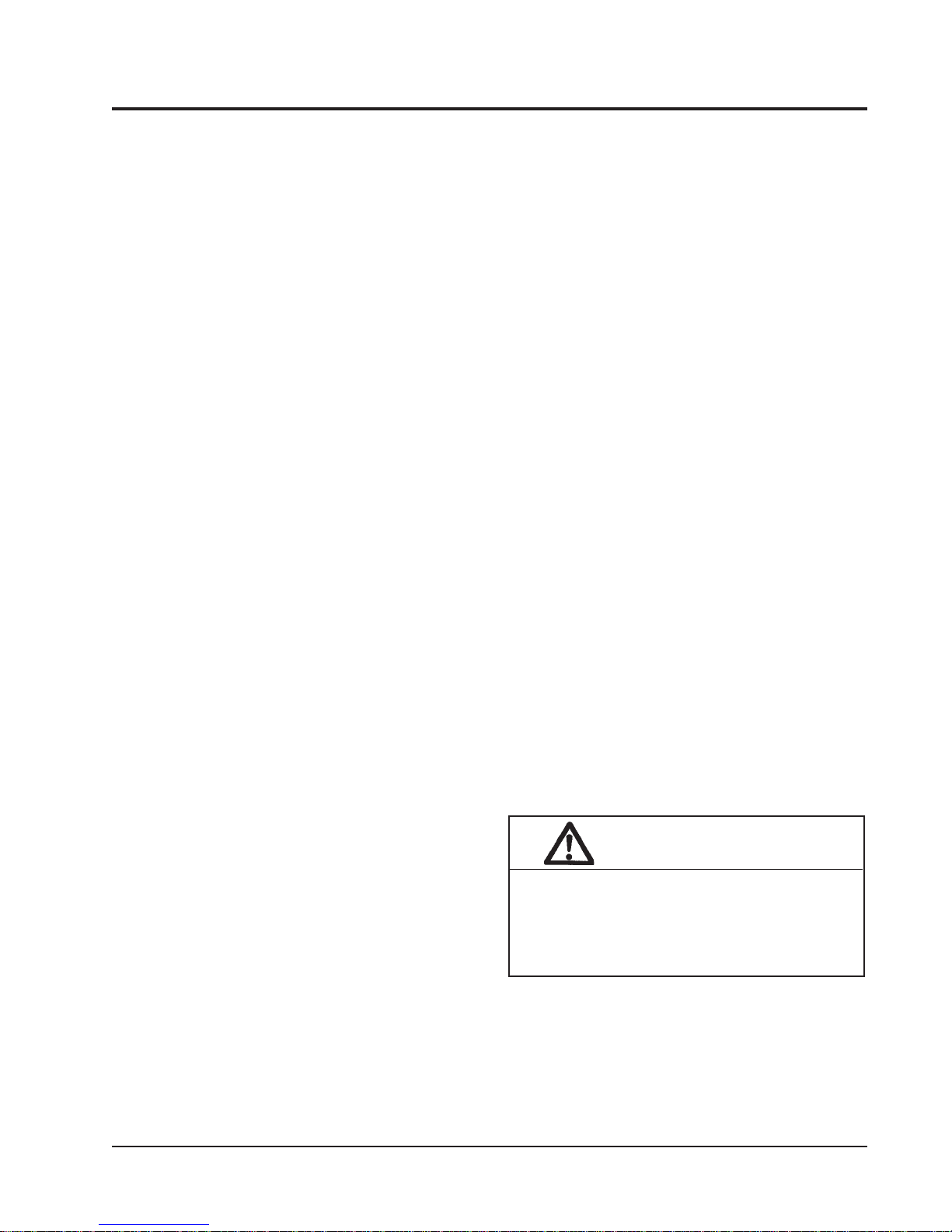

Figure 2 Field-Conversion to Left Hand Return .. 10

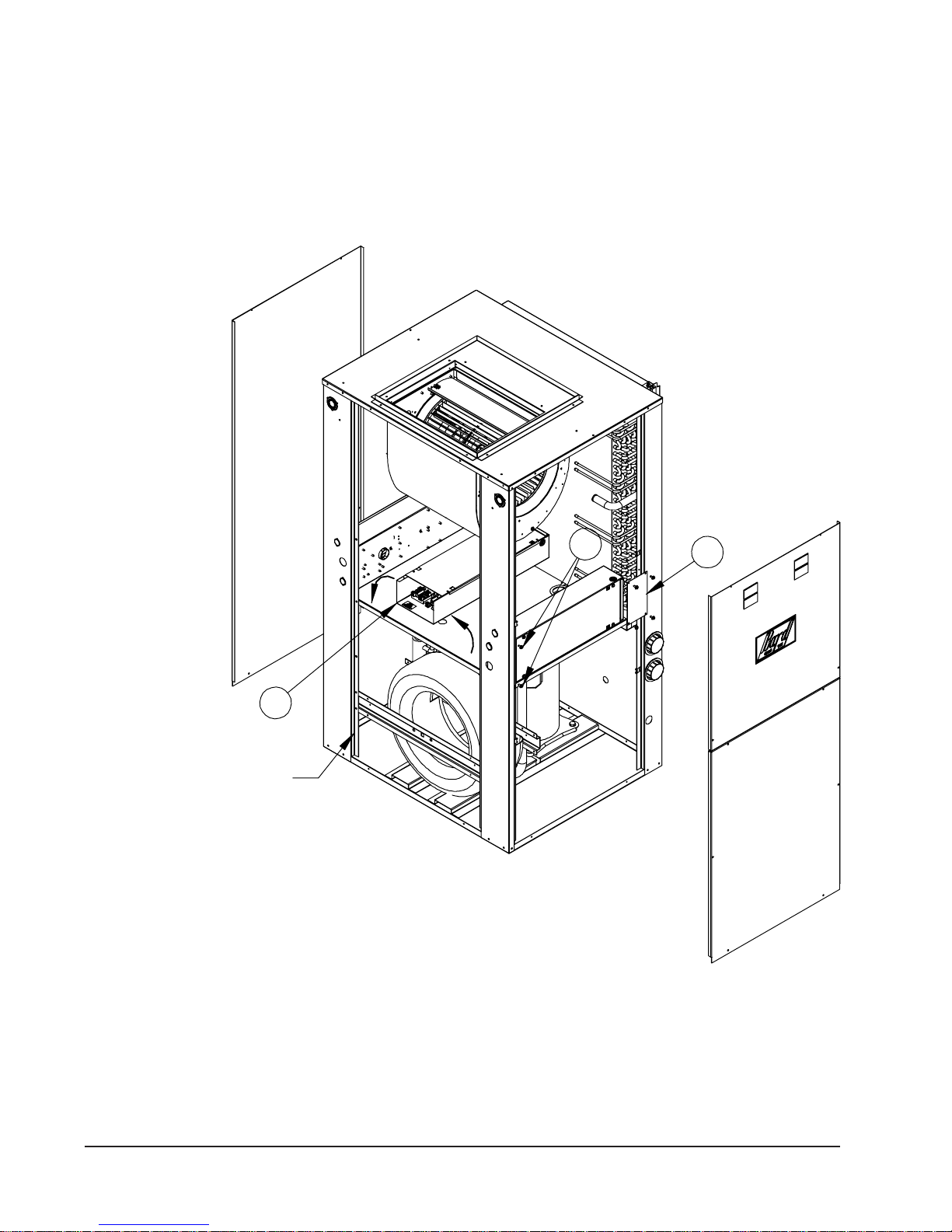

Figure 3 Filter Rack Configuration ...................... 12

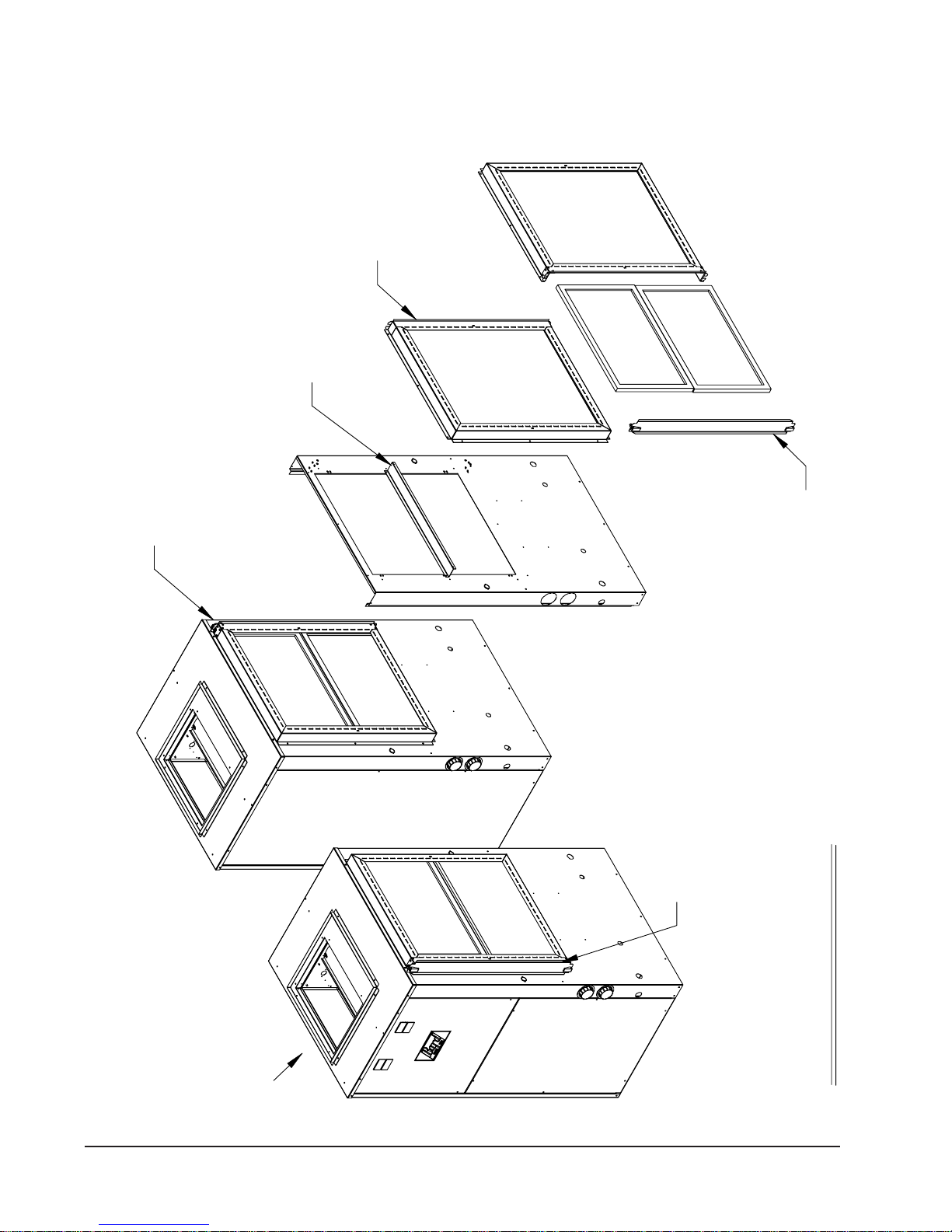

Figure 4 Piping Access ....................................... 13

Figure 5 Thermostat Wiring ................................ 15

Figure 6 Circulation System Design .................... 16

Figure 7 Temperature & Pressure Measurement ... 18

Figure 8 Model DORFC-1 Flow Center ............... 18

Figure 9 Model DORFC-2 Flow Center ............... 18

Figure 10 Water Connection Components ............ 20

Figure 11 Cleaning Water Coil .............................. 22

Figure 12 Lake or Pond Installation ...................... 23

Figure 13 Component Location ............................. 26

Figure 14 Control Panel ........................................ 26

Figure 15 Refrigerant Flow Diagrams ................... 27

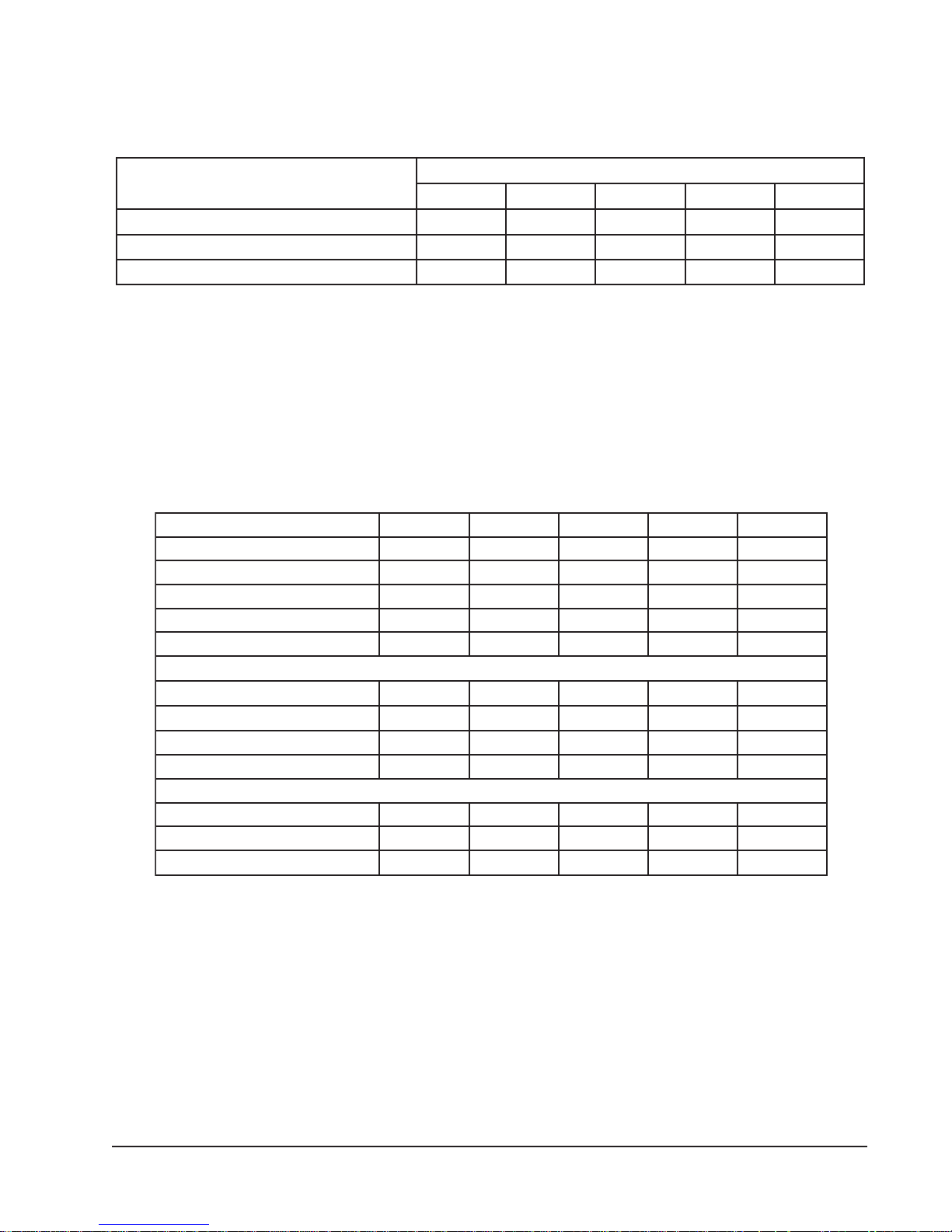

Figure 16A Pressure Tables ....................................... 28

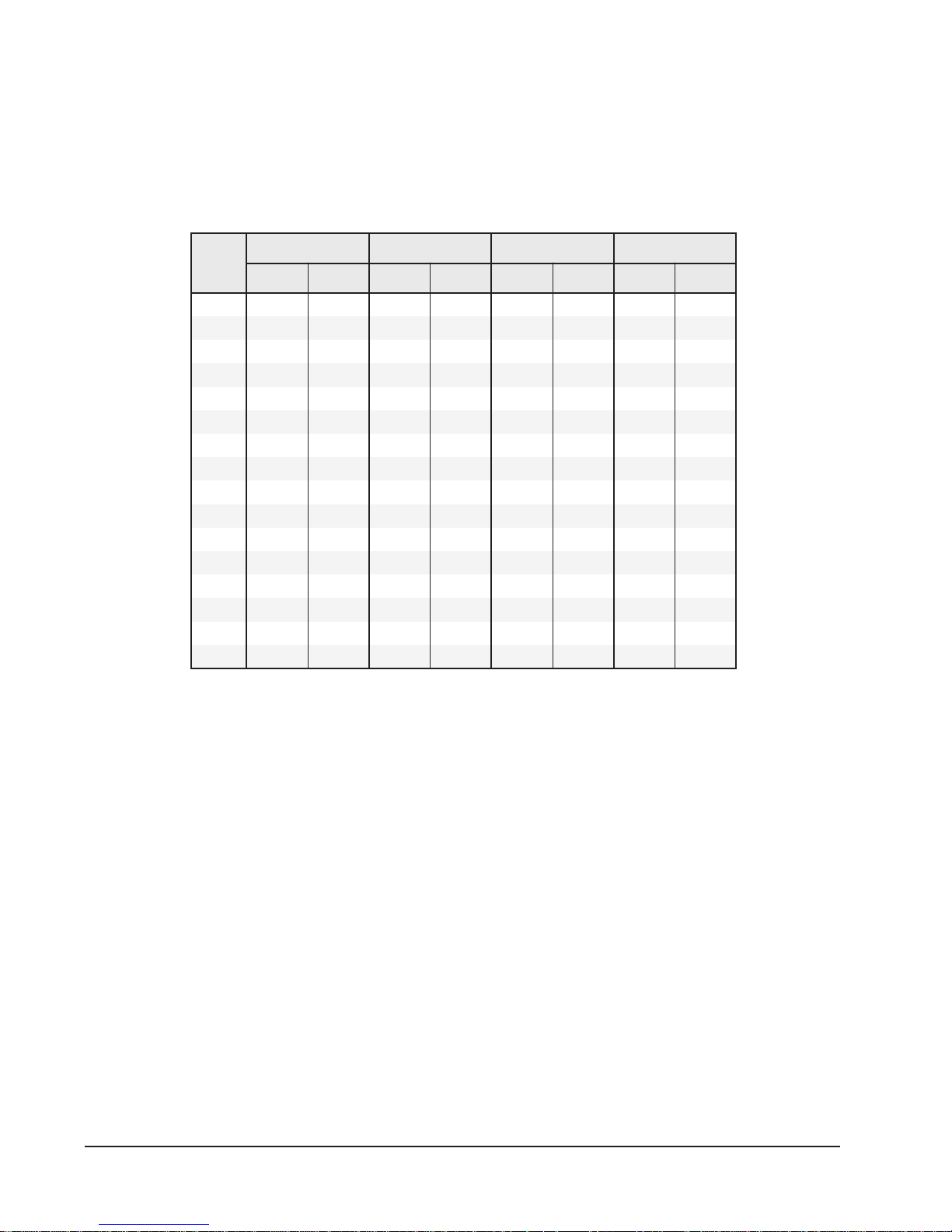

Figure 16B Pressure Tables ....................................... 29

Figure 17 Motor Connections ................................ 32

Figure 18 Motor Connections ................................ 33

Figure 19 Typical Pump Kit Connection ................ 34

Manual 2100-510E

Page 2 of 38

Tables

Table 1 Indoor Blower Performance .................... 4

Table 2 Flow Rates for Various Fluids ................. 5

Table 3 Specifications .......................................... 5

Table 4 Water Coil Pressure Drop ....................... 6

Table 5 Electrical Specifications Optional Field

Installed Heater Package ........................ 8

Table Air Filter Table ........................................11

Table 6 Control Circuit Wiring ............................ 14

Table 7 Wall Thermostat .................................... 14

Table 8 Constant Flow Valves ........................... 19

Page 3

GETTING OTHER INFORMATION AND PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually find these at

your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation .............. ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air ...................... ANSI/NFPA 90B

Heating and Air Conditioning Systems

Load Calculation for Residential ....... ACCA Manual J

Winter and Summer Air Conditioning

Duct Design for Residential ............. ACCA Manual D

Winter and Summer Air Conditioning and Equipment

Selection

Closed-Loop/Ground Source Heat Pump ........ IGSHPA

Systems Installation Guide

Grouting Procedures for Ground-Source ......... IGSHPA

Heat Pump Systems

Soil and Rock Classification for ...................... IGSHPA

the Design of Ground-Coupled Heat Pump Systems

Ground Source Installation Standards ............. IGSHPA

Closed-Loop Geothermal Systems .................. IGSHPA

– Slinky Installation Guide

FOR MORE INFORMATION, CONTACT

THESE PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Avenue

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

IGSHPA International Ground Source

Heat Pump Association

490 Cordell South

Stillwater, OK 74078-8018

Manual 2100-510E

Page 3 of 38

Page 4

WATER SOURCE PRODUCT LINE NOMENCLATURE

G V 38 S 1 A C

Revision

Level

Ground

Source

Electrical 230/208V 1-Phase

C = Copper Water Coil

N = Cupronickel

Vertical

Step

Capacity

38 = Nominal heating capacity in thousands @ 50° water - Full Load

Nominal cooling capacity in thousands @ 77° brine - Full Load

TABLE 1

INDOOR BLOWER PERFORMANCE (RATED CFM)

1#deepS2#deepS3#deepS4#deepS5#deepS

2

LEDOM

1S72VG3/151.005.00050560080090001

1S83VG2/151.005.005652700957110031

1S15VG2/102.005.0057529051105310051

1S16VG4/302.005.00080501003105410061

1S17VG4/352.005.05780511054157510571

rotoM

PH

3

detaR

PSE

XAM

PSE

4

suounitnoC

wolfriA

5

rehtaeWdliM

ts

1ninoitarepO

gnilooCegatS

).niM-5(edoM

6

daoLtraP

noitarepO

wolfriA

1

7

daoLlluF%01-

wolfriA

)lanoitpO(

8

daoLlluF

dnawolfriA

taeHcirtcelE

edoM

1 Motor will automatically step through the various airflows with thermostatic control

2 ESP = External Static Pressure (inches of water)

3 Maximum allowable duct static

4 Continuous airflow is the CFM being circulated with manual fan operation without any additional function occurring.

5 Will occur automatically for first 5 minutes of Part Load Cooling Operation.

6 Will occur automatically after five minutes of Part Load Cooling Operation.

7 This is a field option for noisy installations to de-rate Full Load airflow (requires change in control panel).

8 Will occur automatically with control signal input (will not be defeated for electric heat operation).

Manual 2100-510E

Page 4 of 38

Page 5

TABLE 2

FLOW RATES FOR VARIOUS FLUIDS

SDIULFSUOIRAV

retawhserfMPGderiuqeretarwolF 1 5679 01

edirolhCmuidoS%51MPGderiuqeretarwolF7

4SG%52MPGderiuqeretarwolF79215161

1 Rated Flow

TABLE 3

SPECIFICATIONS

LEDOM*A-1S72VG*A-1S83VG*A-1S15VG*A-1S16VG*A-1S17VG

)HP1/ZH06(gnitaRlacirtcelE1-802/0321-802/0321-802/0321-802/0321-802/032

egnaRegatloVgnitarepO791-352791-352791-352791-352791-352

yticapmAtiucriCmuminiM 1 7162238314

eziSeriWdleiF+ 1 21#01#8#6#6#

.rkB.tkCro.xaMesuFyaleD++ 1 0203040505

ROSSERPMOC

stloV802/032802/032802/032802/032802/032

802/032spmAdaoLdetaR1.01/4.85.41/4.216.02/4.714.72/4.225.82/7.42

tnerruCnoitceleS.tkChcnarB2.017.612.124.725.82

802/032spmArotoRkcoL26/2628/2869/69811/811051/051

ROTAROPAVEDNAROTOMREWOLB

epyT/deepS/PH-rotoMrewolBMCE/5/3/1MCE/5/2/1MCE/5/2/1MCE/5/4/3MCE/5/4/3

spmA-rotoMrewolB6.1/5.159.2/5.20.3/8.21.4/8.32.4/1.4

hcnIrePsniF/woR/.tF.qSaerAecaF11/4/61.311/4/61.311/3/33.511/4/33.501/5/33.5

+75°C copper wire ++ HACR type circuit breaker

* C - for copper / N for Cupro-Nickel water coil

1 Heat pump only. Optional field-installed heaters are separate circuit.

SLEDOM

S72VGS83VGS15VGS16VGS17VG

9215161

Manual 2100-510E

Page 5 of 38

Page 6

TABLE 4

WATER COIL PRESSURE DROP

ledoM

MPG

31.032.0

4 5.0 51.1 9.0 80.2

52.177.24.132.3

6 7.1 29.3 3.2 13.5

73.213.52.383.7216.4

8 1.3 51.7 1.4 64.9 5.2 77.5 2 16.4

91.464.91.577.112.383.74.245.5

01 1.6 70.41 9.3 00.9 8.2 64.6

111.783.617.448.014.348.7

21 2.8 29.81 5.5 96.21 9.3 00.9

314.996.124.667.415.483.01

41 6.01 54.42 3.7 48.61 2.5 00.21

511.896.819.516.31

61 9 67.02 7.6 64.51

719.948.224.770.71

81 4.8 83.91

1S72VG 1S15VG/1S83VG 1S16VG 1S17VG

DISP .dH.tF DISP .dH.tF DISP .dH.tF DISP .dH.tF

Manual 2100-510E

Page 6 of 38

Page 7

BACK VIEW

Y

MIS-2616

X

W

U

V

FIGURE 1 – UNIT DIMENSIONS

61/7-22/1-18/7-254/1-238/5-12/1-22/1-34/3-9261/31-6261/1-861/5-9161/5-5161/1-28/7-98/5-5261/7-0361/5-1

FILTER RACK

RETURN AIR

I

B

E

RIGHT SIDE VIEW

SUPPLY AIR

J

OPTIONAL

H

HEATER

PACKAGE

ELECTRICAL

LOW

VOLTAGE

G

NOTE A

SEE

VOLTAGE

LOW

ENTRANCE

Y

ENTRANCE

WATER CONNECTIONS

DOMESTIC HOT WATER

HEAT EXCHANGER

C

ENTRANCE

FLOW CENTER

ELECTRICAL

ENTRANCE

DRAIN LOCATION

CONDENSATE

S

NOTE A

SEE

UNIT

ELECTRICAL

ENTRANCE

R

T

R

WATER

CONNECTIONS

CONDENSATE

DRAIN LOCATION

F

TOP VIEW

ylppuSnruteR

tcuDegnalFhtdiWthgieH

8/5-7262848/7-318/7-31814/3-228/7-661/7-22/1-14/1-548/5-138/5-14/1-24/1-361/1-9261/31-5261/3-82/1-912/1-5161/1-28/3-78/1-3261/7-524/1-1

htdiWhtpeDthgieH

8/5-23728/5-558/7-718/7-712/1-328/7-927

ABCDE FGHIJKLMNOP Q RS T UVWXY

1S83-72VG

1S17-15VG

stinU

D

A

FRONT VIEW

LEFT SIDE VIEW

N

M

G

SEE

NOTE A

C

O

Q

P

L

K

R

T

S

NOTE A: PANELS ARE REVERSIBLE ALONG WITH

CONTROL PANELS FOR HEAT PUMP AND

ELECTRIC HEATER PACKAGE FOR BEST

INSTALLATION POSITION.

WATER

CONNECTIONS

CONDENSATE

DRAIN LOCATION

Manual 2100-510E

Page 7 of 38

Page 8

HEATER PACKAGE NOMENCLATURE

EH 3 GSV A A 14 C

3 = 3 Ton

5 = 5 Ton

Electric

Heater

Ground Source Vertical

Circuit Breaker

Nominal KW

240/208-1-60

Modification

Code

TABLE 5

ELECTRICAL SPECIFICATIONS

segakcaPretaeHdellatsnI-dleiFlanoitpO-snoitacificepSlacirtcelE

esUroF

sledoMhtiw

A-1S72VG

&

A-1S83VG

esUroF

sledoMhtiw

A-1S15VG

A-1S16VG

&

A-1S17VG

+ Based on 75F copper wire. All wiring must conform to National Electrical Code (latest edition) and all local codes.

retaeH

egakcaP

.oNledoM

C50A-AVSG3HE1-802/0428.815.4543,513.6183.3525,115.325201

C90A-AVSG3HE1-802/0425.730.9096,035.2357.6810,329.64058

C41A-AVSG3HE1-802/0423.655.31530,647.8431.01345,434.07084

retaeH

egakcaP

.oNledoM

C90A-AVSG5HE1-802/0425.730.9096,035.2357.6810,329.64058

C41A-AVSG5HE1-802/0423.655.31530,647.8431.01345,434.07084

C81A-AVSG5HE1-802/0420.570.81083,169.465.31530,643.890013

retaeH

egakcaP

esahP/stloV

ZH06

retaeH

egakcaP

ZH06

SPMAWKUTBSPMAWKUTB

esahP/stloV

SPMAWKUTBSPMAWKUTB

dnaWK,spmAretaeH

stloV042@yticapaC

segakcaPretaeHdellatsnI-dleiFlanoitpO-snoitacificepSlacirtcelE

dnaWK,spmAretaeH

stloV042@yticapaC

dnaWK,spmAretaeH

stloV802@yticapaC

dnaWK,spmAretaeH

stloV802@yticapaC

muminiM

tiucriC

yticapmA

muminiM

tiucriC

yticapmA

mumixaM

RCAH

tiucriC

rekaerB

mumixaM

RCAH

tiucriC

rekaerB

dleiF

eriW

+eziS

dleiF

eriW

+eziS

Manual 2100-510E

Page 8 of 38

Page 9

APPLICATION AND LOCATION

GENERAL

Units are shipped completely assembled and internally

wired, requiring only duct connections, thermostat wiring,

230/208 volt AC power wiring, and water piping. The

equipment covered in this manual is to be installed by

trained, experienced service and installation technicians.

These instructions and any instructions packaged with any

separate equipment required to make up the entire heat

pump system should be carefully read before beginning the

installation. Note particularly any tags and/or labels

attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not in any way supersede any

national and/or local codes. Authorities having jurisdiction

should be consulted before the installation is made.

SHIPPING DAMAGE

Upon receipt of the equipment, the carton should be

checked for external signs of shipping damage. If damage

is found, the receiving party must contact the last carrier

immediately, preferably in writing, requesting inspection

by the carrier’s agent.

APPLICATION

Capacity of the unit for a proposed installation should be

based on heat loss calculations made in accordance with

methods of the Air Conditioning Contractors of America.

The air duct system should be sized and installed in

accordance with Standards of the National Fire Protection

Association for the Installation of Air Conditioning and

Venting systems of Other than Residence Type NFPA No.

90A, and residence Type Warm Air Heating and Air

Conditioning Systems, NFPA No. 90B.

Unit casing suitable for 0 inch clearance with 1-inch duct

clearance for at least the first 3 feet of duct. These units

are not approved for outdoor installation and therefore

must be installed inside the structure being conditioned.

Do not locate in areas subject to freezing in the winter or

subject to sweating in the summer.

Before setting the unit, consider ease of piping, drain and

electrical connections for the unit. Also, for units which

will be used with a field installed heat recovery unit,

consider the proximity of the unit to the water heater or

storage tank. Place the unit on a solid base, preferably

concrete, to minimize undesirable noise and vibration. DO

NOT elevate the base pan on rubber or cork vibration

eliminator pads as this will permit the unit base to act like a

drum, transmitting objectionable noise.

DUCTWORK

If the unit is to be installed in a closet or utility room which

does not have a floor drain, a secondary drain pan under

the entire unit is highly recommended.

DO NOT install the unit in such a way that a direct path

exists between any return grille and the unit. Rather, insure

that the air entering the return grille will make at least one

turn before entering the unit or coil. This will reduce

possible objectionable compressor and air noise from

entering the occupied space.

Design the ductwork according to methods given by the Air

Conditioning Contractors of America. When duct runs

through unconditioned spaces, it should be insulated with

vapor barrier. It is recommended that flexible connections

be used to connect the ductwork to the unit in order to keep

the noise transmission to a minimum.

LOCATION

The unit may be installed in a basement, closet, or utility

room provided adequate service access is insured. The unit

is shipped from the factory as a right hand return and

requires access clearance of two feet minimum to the

access panels on this side of the unit. If unit is to be field

converted to left hand return the opposite side will require

access clearance of two feet minimum.

Unit may be field converted to left hand return by

removing two (2) screws that secure the control panel

cover, removing four (4) screws that hold the control panel

in place, laying the control panel down, sliding it under the

blower and re-securing the control panel on the opposite

side of the unit. (See Figure 2.) The two (2) access doors

from the right hand return can be transferred to the lefthand return side and the one (1) left-hand panel can be

transferred to the right hand side.

WARNING

Failure to provide the 1-inch clearance

between the supply duct and a combustible

surface for the first 3 feet of duct can result in

a fire.

Manual 2100-510E

Page 9 of 38

Page 10

FIGURE 2

FIELD-CONVERSION TO LEFT HAND RETURN

3

Panel removed for clarity.

Does not need removed

to change control panel location.

1. Remove control panel fill plate.

2. Remove two screws securing control panel to unit.

3. Pass control panel through blower section rotating 180°.

4. Re-secure control panel on opposite si de in same manner

as original ly attached.

5. Move double doors t o control panel side of unit.

2

MIS-2617

1

Manual 2100-510E

Page 10 of 38

Page 11

FILTER

This unit must not be operated without a filter. It comes

equipped with 2" disposable filters, which should be

checked often and replaced if dirty. Insufficient airflow

due to undersized duct systems or dirty filters can result in

nuisance tripping of the high or low pressure controls.

Refer to Table 2 for correct airflow and static pressure

requirements.

NOTE: The filter rack is installed on the unit as shipped

for right-hand return. If you require left-hand return, you

will need to remove the filter access door and remove the

screws holding the filter rack to the unit (slide downward

from underneath unit top). Invert the filter rack 180° to

move filter access door to the other side of the unit, and

reverse the previous steps (see Figure 3).

CONDENSATE DRAIN

Drain lines must be installed according to local plumbing

codes. It is not recommended that any condensate drain

line be connected to a sewer main.

Determine where the drain line will run and then select one

of four (4) locations for the condensate to exit the unit

casing (see Figure 4). There are knockouts in the unit

casing that can be selected for the condensate exit. Internal

of the unit, there is a clear flexible hose with a termination

fitting installed. When installed properly, this hose will

create a trap internal of the unit and will remain serviceable

if the drain system requires cleaning or service. Supplied in

the parts bag of the unit is a 3/4" PVC male adaptor that

will secure the internal drain components to the sheet metal

casing at the location you selected.

NOTE: You will need to bend the duct attachment flanges

up using duct bills or similar device, as the unit is shipped

with them collapsed.

AIR FILTERS

ledoMeziSretliFytitnauQ

S72VG

S83VG

S15VG

S16VG

S17VG

"2x"52x"021

"2x"52x"612

NOTE: This drain line will contain cold water and must be

insulated to avoid droplets of water from condensing on the

pipe and dripping on finished floors or the ceiling below

the unit.

PIPING ACCESS TO UNIT

Water piping to and from the unit enters the unit cabinet on

either side of the unit. The connection directly at the unit is

a special double o-ring fitting with a retainer nut that secures

it in place. (It is the same style fitting used for the flow

center connection on ground loop applications.) You may

come in and out either side of the unit in any combination as

the installation dictates. One side has both connections

closed off with a double o-ring plug seal with retaining caps.

One or both of these are transferred to opposite side depending upon installation requirements.

Note: All double o-ring fittings require “hand tightening

only”. Do not use wrench or pliers as retainer nut can be

damaged with excessive force.

Various fittings are available so you may then connect to

the unit with various materials and methods. These

methods include 1" barbed fittings (straight and 90°), 1"

MPT (straight and 90°), and 1-1/4" hot fusion fitting

(straight only) (see Figures 3 & 4).

Manual 2100-510E

Page 11 of 38

Page 12

frame 180°

to unit. Rotate filter rack

holding fi lter rack frame

Remove all screws

rack install ed.

Left-hand access filter

FIGURE 3

FILTER RACK – GV MODELS

install ed location.

does not need to be rotat ed. Leave in factory

Filter rack channel on GV51S1,61S1,71S1

MIS-2618

first r em ove filter rack door and filters.

To convert filter rack to left -hand access

Front of Unit

Manual 2100-510E

Page 12 of 38

Filter rack shipped for

right-hand access f rom factory.

Drawing show s dual air filter

models GV51S1,61S1,71S1.

GV27S1,38S 1 have only one air filt er.

Page 13

FIGURE 4

CONDENSATE DRAIN & PIPING ACCESS TO UNIT

Water in connection

Water out connection

Condensate drain

access (4) locations

MIS-2619

Desuperheater

Pump module connections

1/2" I.D. copper stub

Manual 2100-510E

Page 13 of 38

Page 14

WIRING INSTRUCTIONS

GENERAL

All wiring must be installed in accordance with the

National Electrical Code and local codes. In Canada, all

wiring must be installed in accordance with the Canadian

Electrical Code and in accordance with the regulations of

the authorities having jurisdiction. Power supply voltage

must conform to the voltage shown on the unit serial plate.

A wiring diagram of the unit is attached to the inside of the

electrical cover. The power supply shall be sized and fused

according to the specifications supplied. A ground lug is

supplied in the control compartment for equipment ground.

The unit rating plate lists a “Maximum Time Delay Fuse”

or “HACR” type circuit breaker that is to be used with the

equipment. The correct size must be used for proper

circuit protection and also to assure that there will be no

nuisance tripping due to the momentary high starting

current of the compressor motor.

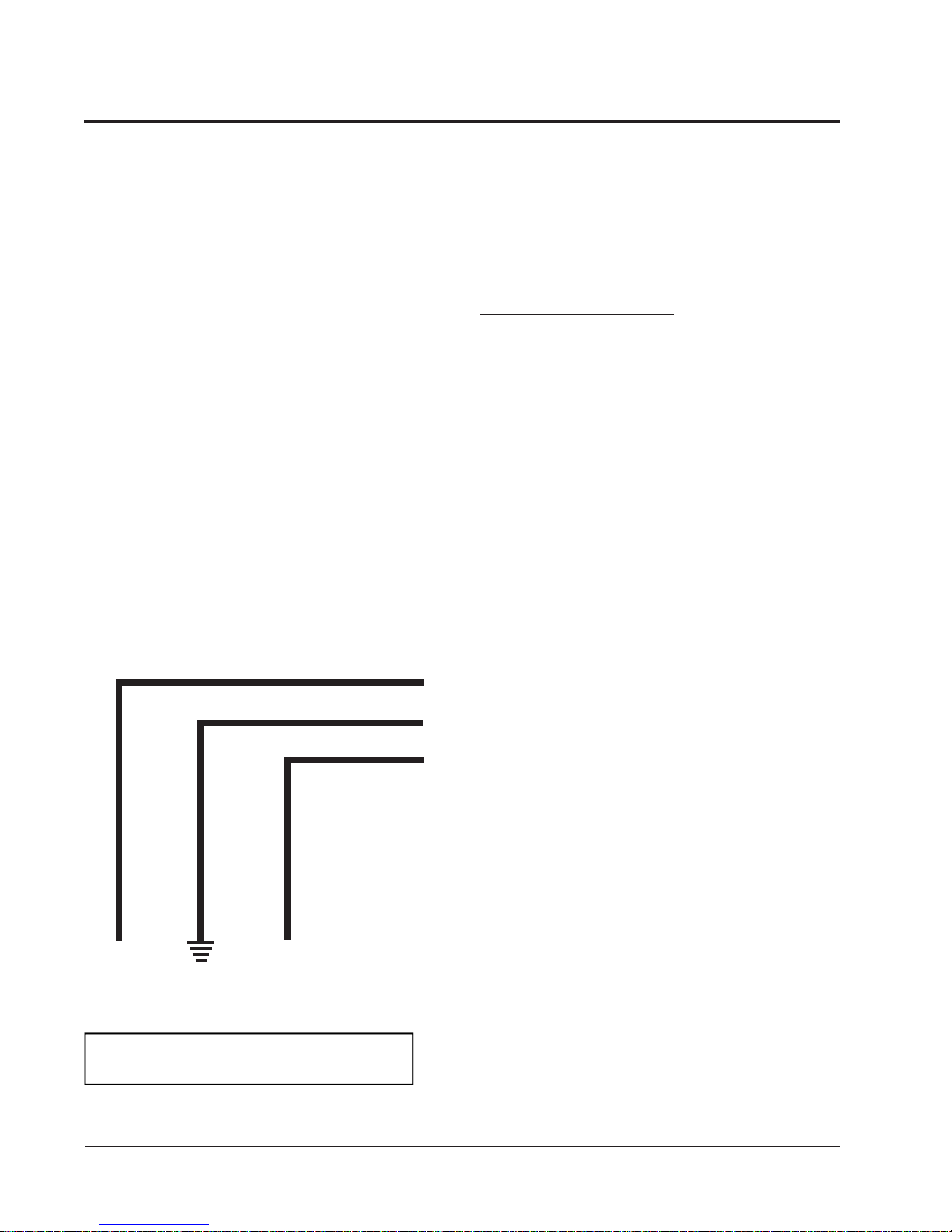

CONTROL CIRCUIT WIRING

The minimum control circuit wiring gauge needed to insure

proper operation of all controls in the unit will depend on

two factors.

1. The rated VA of the control circuit transformer.

2. The maximum total distance of the control circuit

wiring.

Table 6 should be used to determine proper gauge of

control circuit wiring required.

TABLE 6

CONTROL CIRCUIT WIRING

foAVdetaR

tiucriClortnoC

remrofsnarT

051.2

Example: 1. Control Circuit transformer rated at 50 VA

2. Maximum total distance of control circuit

wiring 85 feet.

From Table 6 minimum of 16 gauge wire

should be used in the control circuit wiring.

remrofsnarT

yradnoceS

V42@ALF

foecnatsiD

WALL THERMOSTAT

The following thermostat should be used as indicated,

depending on the application.

TABLE 7

WALL THERMOSTAT

tatsomrehTserutaeFtnanimoderP

taeHegats3;looCegats3

060-3048

)544-0211(

lanoitnevnoCroPH

revoegnahclaunaMrootuA

latoTmumixaM

tiucriClortnoC

teeFnigniriW

54-eguag02

06-eguag81

001-eguag61

061-eguag41

052-eguag21

cinortcelEelbammargorP-noN/elbammargorP

THERMOSTAT INDICATORS

8403-060 (1120-445) Temperature/Humidity Control:

In heating or cooling, the display may be black and light

gray, or backlit in blue depending on configuration. In the

event of a system malfunction such as a loss of charge or

high head pressure, the heat pump control board will issue

a signal to the thermostat causing the screen to be backlit in

RED and the display to read “Service Needed”. If this

occurs, the control will continue to function, but you will

not be able to make any adjustments until the problem is

corrected and the fault device is reset.

Manual 2100-510E

Page 14 of 38

EMERGENCY HEAT MODE

The operator of the equipment must manually place the

system switch in this mode. This is done when there is a

known problem with the unit.

When the 8403-060 (1120-445) Temperature/Humidity

Control is placed in the Emergency Heat mode, the display

will be backlit in RED to indicate that service is needed.

The display will remain backlit in red until the mode is

switched out of Emergency Heat.

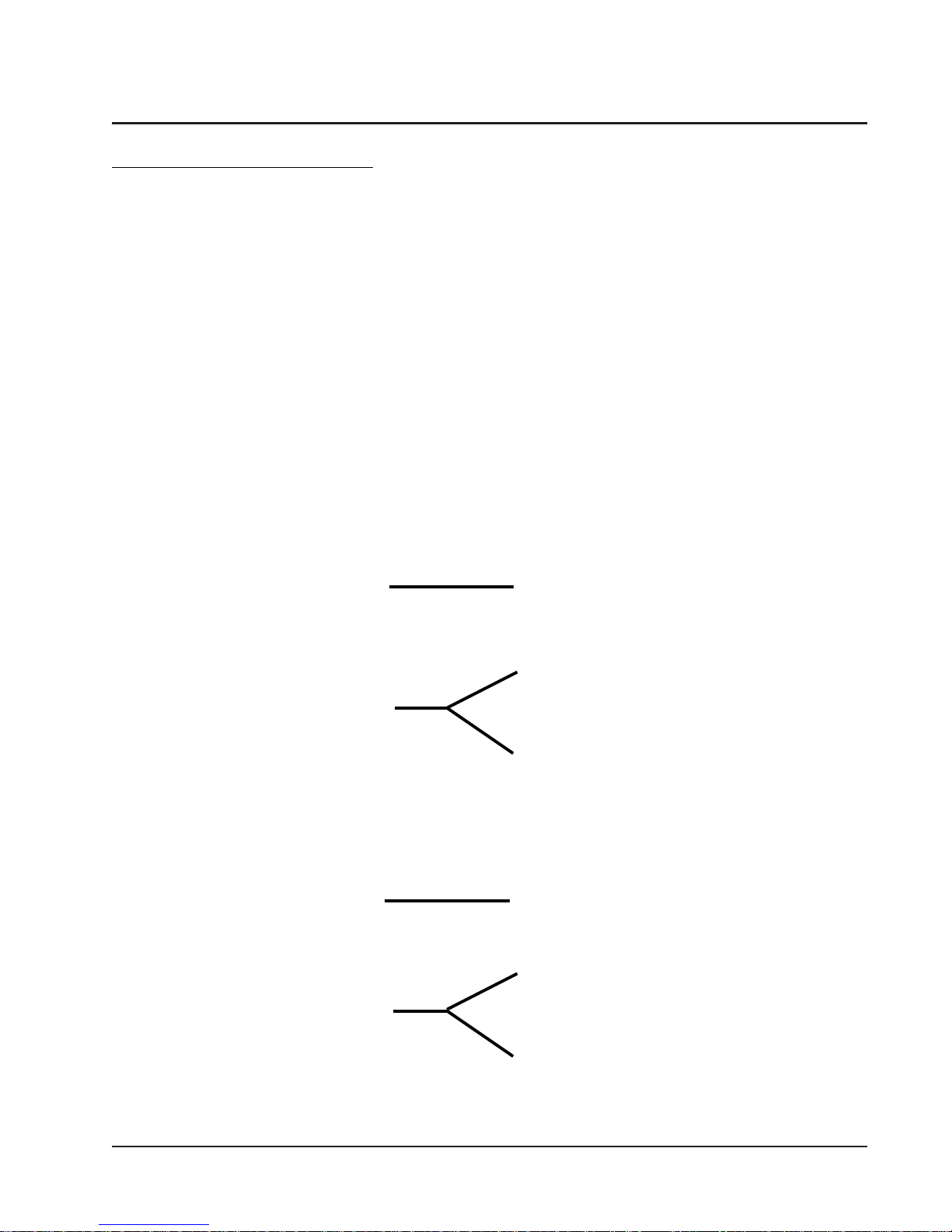

Page 15

FIGURE 5

THERMOSTAT WIRING

GROUND LOOP APPLICATIONS (when utilized with a flow center)

8403-060 (1120-445)

(See notes 1 & 2 below)

Unit 24V ter m inal strip

GROUND WATER APPLICATIONS (when installed with recom m ended m ot orized valve with end switch)

8403-060 (1120-445)

(See notes 1 & 2 below)

Unit 24V ter m inal strip

CRGY1Y2OW2

CE

Y2Y1GR

O

CRGY1Y2O L

1

2

Bard part # 8603-030

3

Motorized valve with end switch

(part of Bard GVGWK-1 Ground Water K it)

W1/E

LA

LW

W

W1/E

E

W2OY2Y1GRC

L

D/YO

D/YO

A

GROUND WATER APPLICATIONS (when installed with recom m ended m ot orized valve with end switch)

8403-060 (1120-445)

(See notes 1 & 2 below)

Unit 24V ter m inal strip

1. Will need to be programmed for multi-stage heat pump

2. Will need to be configured to energize r eversing valve for cooling mode

3. All w iring field supplied low voltage

CY1

CRGY1Y2O L

R

G

Bard part #8603-006

Solenoid valve

W2OY2

W

W1/E

E

L

A

D/YO

MIS-2620 B

Manual 2100-510E

Page 15 of 38

Page 16

GROUND LOOP

(EARTH COUPLED WATER LOOP APPLICATIONS)

NOTE:

Unit shipped from factory with 60 PSIG low pressure

switch wired into control circuit and must be rewired to

45 PSIG low pressure switch for ground loop

applications. This unit is designed to work on earth

coupled water loop systems, however, these systems

operate at entering water (without antifreeze) temperature

with pressures well below the pressures normally

experienced in water well systems.

THE CIRCULATION SYSTEM DESIGN

Equipment room piping design is based on years of

experience with earth coupled heat pump systems. The

design eliminates most causes of system failure.

The heat pump itself is rarely the cause. Most problems

occur because designers and installers forget that a

ground loop “earth coupled” heat pump system is NOT

like a household plumbing system.

Most household water systems have more than enough

water pressure either from the well pump of the

municipal water system to overcome the pressure of

CIRCULATION SYSTEM DESIGN

head loss in 1/2 inch or 3/4 inch household plumbing. A

closed loop earth coupled heat pump system, however, is

separated from the pressure of the household supply and

relies on a small, low wattage pump to circulate the

water and antifreeze solution through the earth coupling,

heat pump and equipment room components.

The small circulator keeps the operating costs of the

system to a minimum. However, the performance of the

circulator MUST be closely matched with the pressure of

head loss of the entire system in order to provide the

required flow through the heat pump. Insufficient flow

through the heat exchanger is one of the most common

causes of system failure. Proper system piping design

and circulator selection will eliminate this problem.

Bard supplies a work sheet to simplify heat loss

calculations and circulator selection. Refer to

“Circulating Pump Worksheet” section in manual

2100-099.

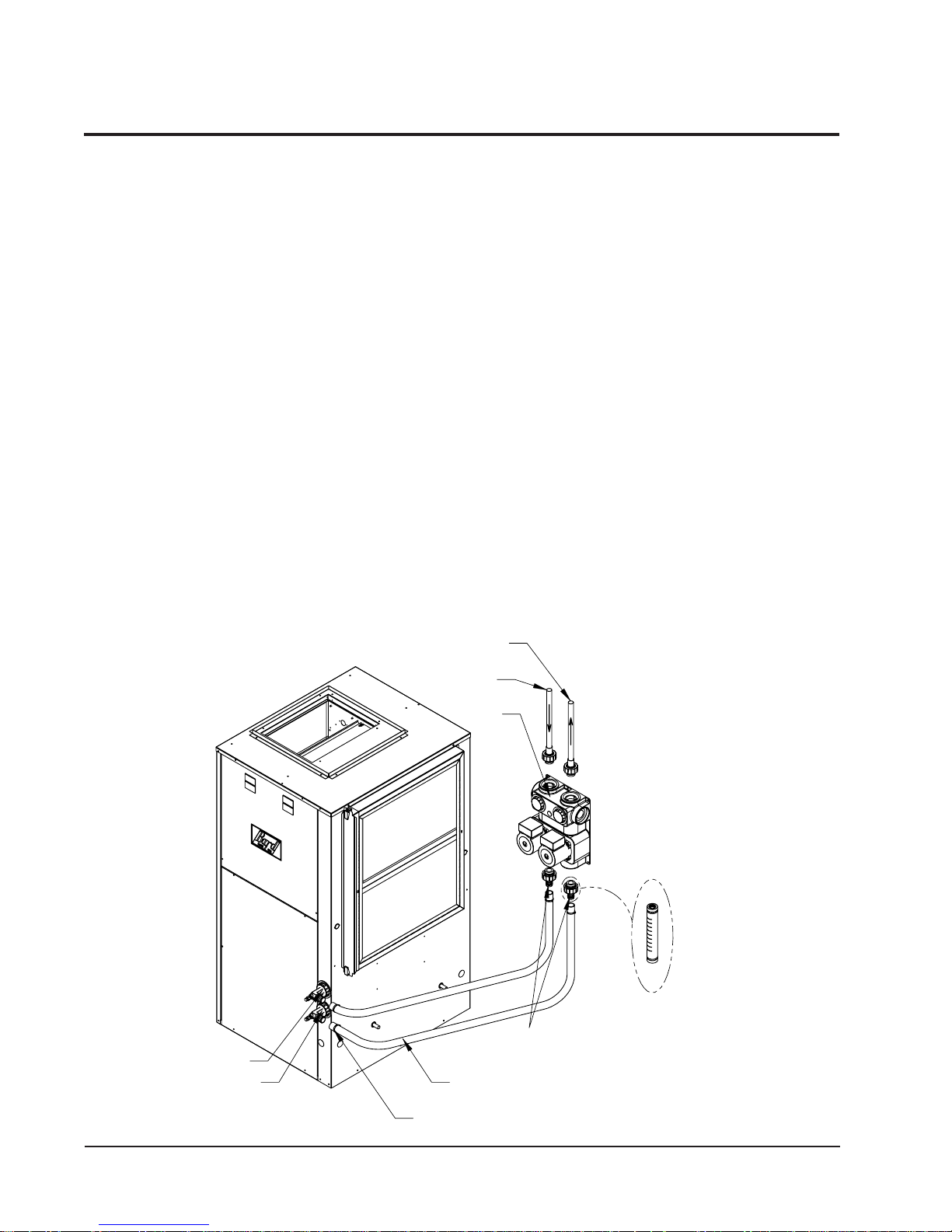

FIGURE 6

WATER IN

WATER OUT

PIPE TO GROUND LOOP

PIPE FROM

GROUND LOOP

PUMP

MODULE

1" FLEXIBLE HOSE

STRAIGHT BARBED

BRASS ADAPTERS

OPTIONAL VISUAL

FLOW METER

NOTE: IF USED

SUPPORT WITH A

FIELD-FABRICATED

WALL BRACKET

Manual 2100-510E

Page 16 of 38

HOSE CLAMPS

MIS-2621

Page 17

START UP PROCEDURE FOR GROUND

LOOP SYSTEM

1. Be sure main power to the unit is OFF at disconnect.

2. Set thermostat system switch to OFF, fan switch to

AUTO.

3. Move main power disconnect to ON. Except as

required for safety while servicing, DO NOT OPEN

THE UNIT DISCONNECT SWITCH.

4. Check system airflow for obstructions.

A. Move thermostat fan switch to ON. Blower

runs.

B. Be sure all registers and grilles are open.

C. Move thermostat fan switch to AUTO. Blowing

should stop.

5. Flush, fill and pressurize the closed loop system as

outlined in manual 2100-099.

6. Fully open the manual inlet and outlet valves. Start the

loop pump module circulator(s) and check for proper

operation. If circulator(s) are not operating, turn off

power and diagnose the problem.

7. Check fluid flow using a direct reading flow meter or a

single water pressure gauge, measure the pressure drop

at the pressure/temperature plugs across the water coil.

Compare the measurement with flow versus pressure

drop table to determine the actual flow rate. If the flow

rate is too low,

recheck the selection of the loop pump module model

for sufficient capacity. If the module selection is

correct, there is probably trapped air or a restriction in

the piping circuit.

8. Start the unit in cooling mode by moving the

thermostat switch to cool. Fan should be set for

AUTO.

9. Check the system refrigerant pressures against the

cooling refrigerant pressure table in the installation

manual for rated water flow and entering water

temperatures. If the refrigerant pressures do not match,

check for airflow problem then refrigeration system

problem.

10. Switch the unit to the heating mode by moving the

thermostat switch to heat. Fan should be set for

AUTO.

11. Check the refrigerant system pressures against the

heating refrigerant pressure table in installation manual.

Once again, if they do not match, check for airflow

problems and then refrigeration system problems.

NOTE: If a charge problem is determined (high or low):

A. Check for possible refrigerant leaks.

B. Recover all remaining refrigerant from unit and

repair leak.

C. Evacuate unit down to 29 inches of vacuum.

D. Recharge the unit with refrigerant by weight.

This is the only way to insure a proper charge.

Manual 2100-510E

Page 17 of 38

Page 18

Dial face pressure guage

with guage adaptor

50

40

30

20

10

0

Thermometer

60

70

35

FIGURE 7

80

90

100

110

120

Barbed 90° adapter

FIGURE 8

PERFORMANCE MODEL DORFC-1 FLOW CENTER

Retaining cap, hand tighten only

Pete's test plug

Test plug cap

MIS-2622

30

25

20

15

Head (Feet)

10

5

0

0 5 10 15 20 25 30 35

Flow (GPM)

FIGURE 9

PERFORMANCE MODEL DORFC-2 FLOW CENTER

70

60

50

40

30

Head (Feet)

20

10

0

0 5 10 15 20 25 30 35

Manual 2100-510E

Page 18 of 38

Flow (GPM)

Page 19

GROUND WATER

(WELL SYSTEM APPLICATIONS)

NOTE:

Unit shipped from factory with 60 PSIG low

pressure switch wired into control circuit for open loop

applications.

WATER CONNECTIONS

It is very important that an adequate supply of clean, noncorrosive water at the proper pressure be provided before

the installation is made. Insufficient water, in the heating

mode for example, will cause the low pressure switch to

trip, shutting down the heat pump. In assessing the

capacity of the water system, it is advisable that the

complete water system be evaluated to prevent possible

lack of water or water pressure at various household

fixtures whenever the heat pump turns on. All plumbing to

and from the unit is to be installed in accordance with local

plumbing codes. The use of plastic pipe, where

permissible, is recommended to prevent electrolytic

corrosion of the water pipe. Because of the relatively cold

temperatures encountered with well water, it is strongly

recommended that the water lines connecting the unit be

insulated to prevent water droplets form condensing on the

pipe surface.

Refer to piping, Figure 10. Slow open/close with End

Switch (2), 24V, provides on/off control of the water flow

to the unit. Refer to the wiring diagram for correct hookup

of the valve solenoid coil.

Constant Flow Valve (3) provides correct flow of water to

the unit regardless of variations in water pressure. Observe

the water flow direction indicated by the arrow on the side

of the valve body. Following is a table showing which

valve is the be installed with which heat pump.

Strainer (8) installed upstream of water coil inlet to collect

foreign material which would clog the flow valve orifice.

The figure shows the use of shutoff valves (4) and (5), on

the in and out water lines to permit isolation of the unit

from the plumbing system should future service work

require this. Globe valves should not be used as shutoff

valves because of the excessive pressure drop inherent in

the valve design. Instead use gate or ball valves as

shutoffs, so as to minimize pressure drop.

Hose bib (6) and (7), and tees should be included to permit

acid cleaning the refrigerant-to-water coil should such

cleaning be required. See WATER CORROSION.

Hose bib (1) provides access to the system to check water

flow through the constant flow valve to insure adequate

water flow through the unit. A water meter is used to

check the water flow rate.

WELL PUMP SIZING

Strictly speaking, sizing the well pump is the responsibility

of the well drilling contractor. It is important, however,

that the HVAC contractor be familiar with the factors that

determine what size pump will be required. Rule of thumb

estimates will invariably lead to under or oversized well

pumps. Undersizing the pump will result in inadequate

water to the whole plumbing system, but with especially

bad results to the heat pump – NO HEAT / NO COOL

calls will result. Oversized pumps will short cycle and

could cause premature pump motor or switch failures.

The well pump must be capable of supplying enough water

and at an adequate pressure to meet competing demands of

water fixtures. The well pump must be sized in such a way

that three requirements are met:

TABLE 8

CONSTANT FLOW VALVES

.oNtraP

5-VFG)1(515

6-VFG)1(516

7-VFG)1(517

9-VFG)1(519

01-VFG)1(5101

(1)

The pressure drop through the constant flow valve

will vary depending on the available pressure

ahead of the valve. Unless minimum of 15 psig

is available immediately ahead of the valve, no

water will flow.

1. Adequate flow rate in GPM.

2. Adequate pressure at the fixture.

3. Able to meet the above from the depth of the

elbaliavA.niM

GISPerusserP

etaRwolF

MPG

well-feet of lift.

Manual 2100-510E

Page 19 of 38

Page 20

The pressure requirements put on the pump are directly

affected by the diameter of pipe being used, as well as, by

the water flow rate through the pipe. The worksheet

included in Manual 2100-078 should guarantee that the

well pump has enough capacity. It should also ensure that

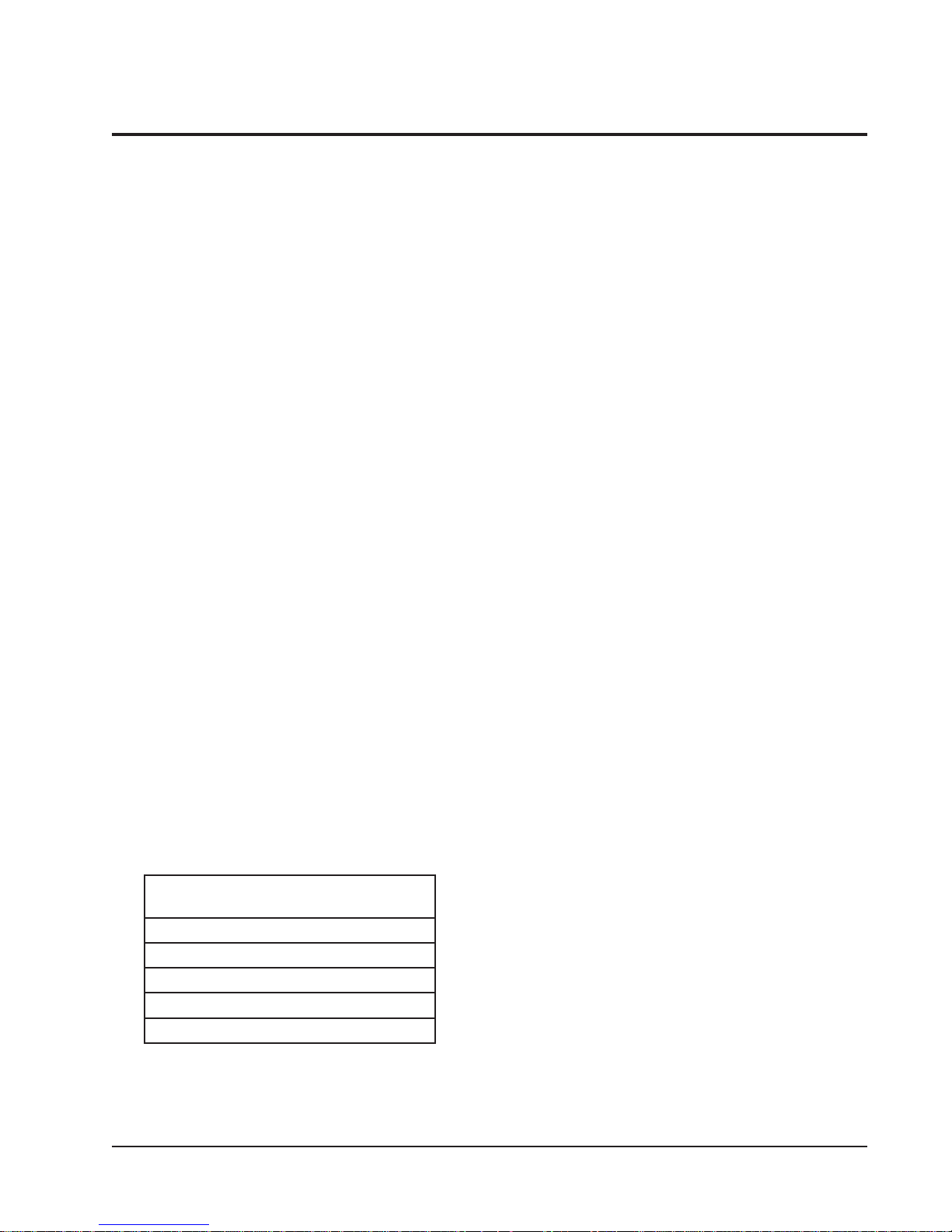

FIGURE 10

WATER CONNECTION COMPONENTS

the piping is not undersized, which would create too much

pressure due to friction loss. High pressure losses due to

undersized pipe will reduce efficiency and require larger

pumps and could also create water noise problems.

8

7

See descriptions for these

reference numbers on Page 19.

Manual 2100-510E

Page 20 of 38

MIS-2623

6

5

4

3

2

1

Page 21

SYSTEM START UP PROCEDURE FOR

GROUND WATER APPLICATIONS

1. Be sure main power to the unit is OFF at disconnect.

2. Set thermostat system switch to OFF, fan switch to

AUTO.

3. Move main power disconnect to ON. Except as required

for safety while servicing – DO NOT OPEN THE UNIT

DISCONNECT SWITCH.

4. Check system airflow for obstructions.

A. Move thermostat fan switch to ON. Blower runs.

B. Be sure all registers and grilles are open.

C. Move thermostat fan switch to AUTO. Blower

should stop.

5. Fully open the manual inlet and outlet valves.

6. Check water flow.

A. Connect a water flow meter to the drain cock

between the constant flow valve and the

solenoid valve. Run a hose from the flow meter

to a drain or sink. Open the drain cock.

B. Check the water flow rate through constant

flow valve to be sure it is the same as the unit

is rated for. (Example: 5 GPM for a GV27S1.)

C. When water flow is okay, close drain cock and

remove the water flow meter. The unit is now

ready to start.

7. Start the unit in cooling mode by moving the thermostat

switch to cool. Fan should be set for AUTO.

A. Check to see the solenoid valve opened.

8. Check the system refrigerant pressures against the

cooling refrigerant pressure table in the installation

manual for rated water flow and entering water

temperatures. If the refrigerant pressures do not match,

check for airflow problem that refrigeration system

problem.

9. Switch the unit to the heat mode by moving the

thermostat switch to heat. Fan should be set for AUTO.

A. Check to see the solenoid valve opened again.

10. Check the refrigerant system pressures against the

heating refrigerant pressure table in installation manual.

Once again, if they do not match, check for airflow

problems and then refrigeration system problems.

NOTE: If a charge problem is determined (high or low):

A. Check for possible refrigerant loss.

B. Discharge all remaining refrigerant from unit.

C. Evacuate unit down to 29 inches of vacuum.

D. Recharge the unit with refrigerant by weight.

This is the only way to insure proper charge.

WATER CORROSION

Two concerns will immediately come to light when

considering a water source heat pump, whether for ground

water or for a ground loop application: Will there be

enough water? And, how will the water quality affect the

system?

Water quantity is an important consideration and one

which is easily determined. The well driller must perform

a pump down test on the well according to methods

described by the National Well Water Association. This

test, if performed correctly, will provide information on the

rate of flow and on the capacity of the well. It is important

to consider the overall capacity of the well when thinking

about a water source heat pump because the heat pump

may be required to run for extended periods of time.

The second concern, about water quality, is equally

important. Generally speaking, if the water is not offensive

for drinking purposes, it should pose no problem for the

heat pump. The well driller or local water softening

company can perform tests which will determine the

chemical properties of the well water.

Water quality problems will show up in the heat pump in

one or more of the following ways:

1. Decrease in water flow through the unit.

2. Decreased heat transfer of the water coil (entering to

leaving water temperature difference is less).

There are four main water quality problems associated with

ground water. These are:

1. Biological Growth. This is the growth of microscopic

organisms in the water and will show up as a slimy

deposit throughout the water system. Shock treatment

of the well is usually required and this is best left up to

the well driller. The treatment consists of injecting

chlorine into the well casing and flushing the system

until all growth is removed.

2. Suspended Particles in the Water. Filtering will

usually remove most suspended particles (fine sand,

small gravel) from the water. The problem with

suspended particles in the water is that it will erode

metal parts, pumps, heat transfer coils, etc. So long as

the filter is cleaned and periodically maintained,

suspended particles should pose no serious problem.

Consult with your well driller.

3. Corrosion of Metal. Corrosion of metal parts results

from either highly corrosive water (acid water,

generally not the case with ground water) of galvanic

reaction between dissimilar metals in the presence of

water. By using plastic plumbing or dielectric unions,

galvanic reaction is eliminated. The use of corrosion

resistant materials such as the Cupronickel coil)

through the water system will reduce corrosion

problems significantly.

Manual 2100-510E

Page 21 of 38

Page 22

4. Scale Formation. Of all the water problems, the

formation of scale by ground water is by far the most

common. Usually this scale is due to the formation of

calcium carbonate but magnesium carbonate or calcium

sulfate may also be present. Carbon dioxide gas (CO2),

the carbonate of calcium and magnesium carbonate, is

very soluble in water. It will remain dissolved in the

water until some outside factor upsets the balance.

This outside influence may be a large change in water

temperature or pressure. When this happens, enough

carbon dioxide gas combines with dissolved calcium or

magnesium in the water and falls out of solution until a

new balance is reached. The change in temperature

that this heat pump produces is usually not high enough

to cause the dissolved gas to fall out of solution.

Likewise, if pressure drops are kept to a reasonable

level, no precipitation of carbon dioxide should occur.

REMEDIES OF WATER PROBLEMS

Water Treatment. Water treatment can usually be

economically justified for water loop systems. However,

because of the large amounts of water involved with a ground

water system, water treatment is generally too expensive.

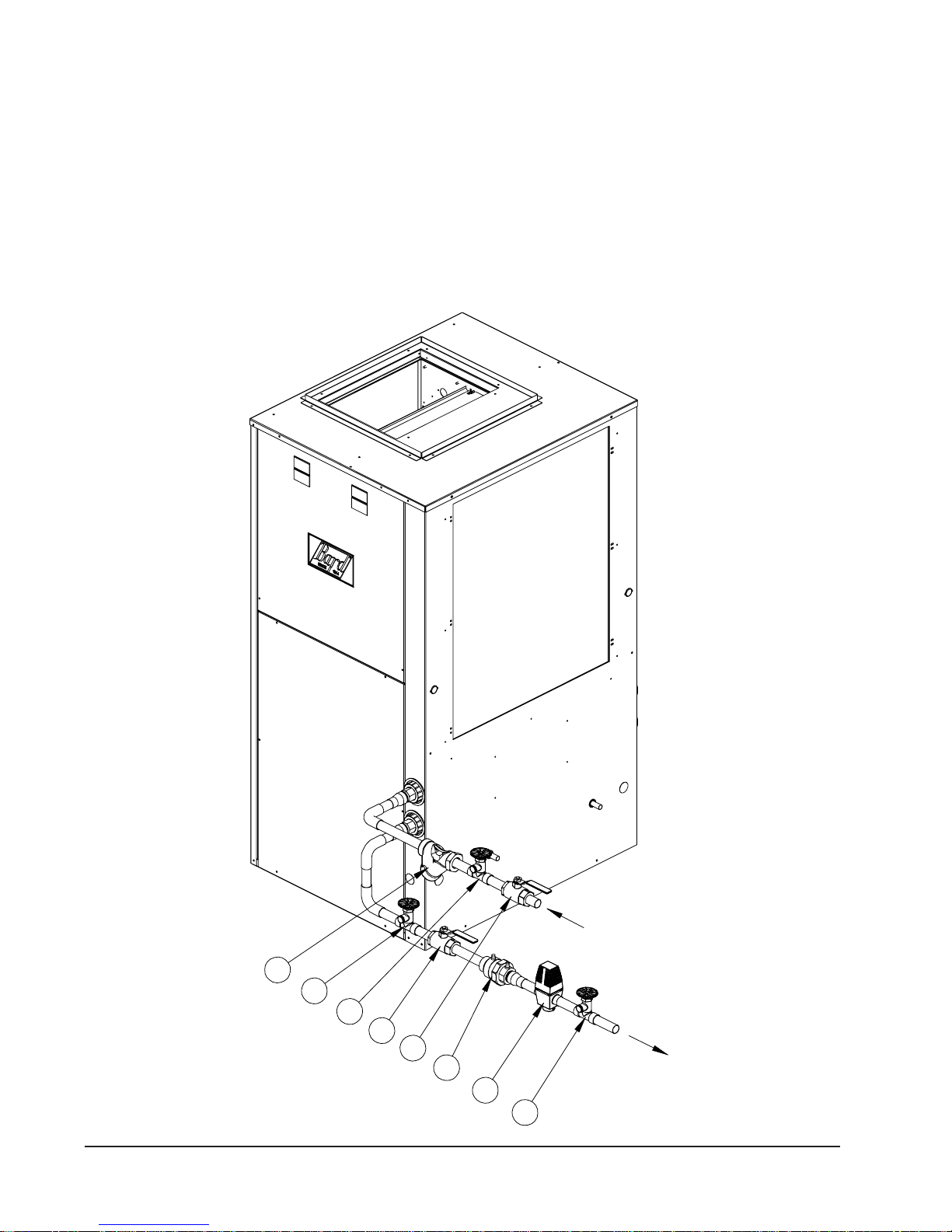

Acid Cleaning the Water Coil or Heat Pump Recovery

Unit. If scaling of the coil is strongly suspected, the coil can

be cleaned up with a solution of Phosphoric Acid (food grade

acid). Follow the manufacturer’s directions for mixing, use,

etc. Refer to the “Cleaning Water Coil”, Figure 11. The acid

solution can be introduced into the heat pump coil through the

hose bib A. Be sure the isolation valves are closed to prevent

contamination of the rest of the system by the coil. The acid

should be pumped from a bucket into the hose bib and

returned to the bucket through the other hose bib B. Follow

the manufacturer’s directions for the product used as to how

long the solution is to be circulated, but it is usually circulated

for a period of several hours.

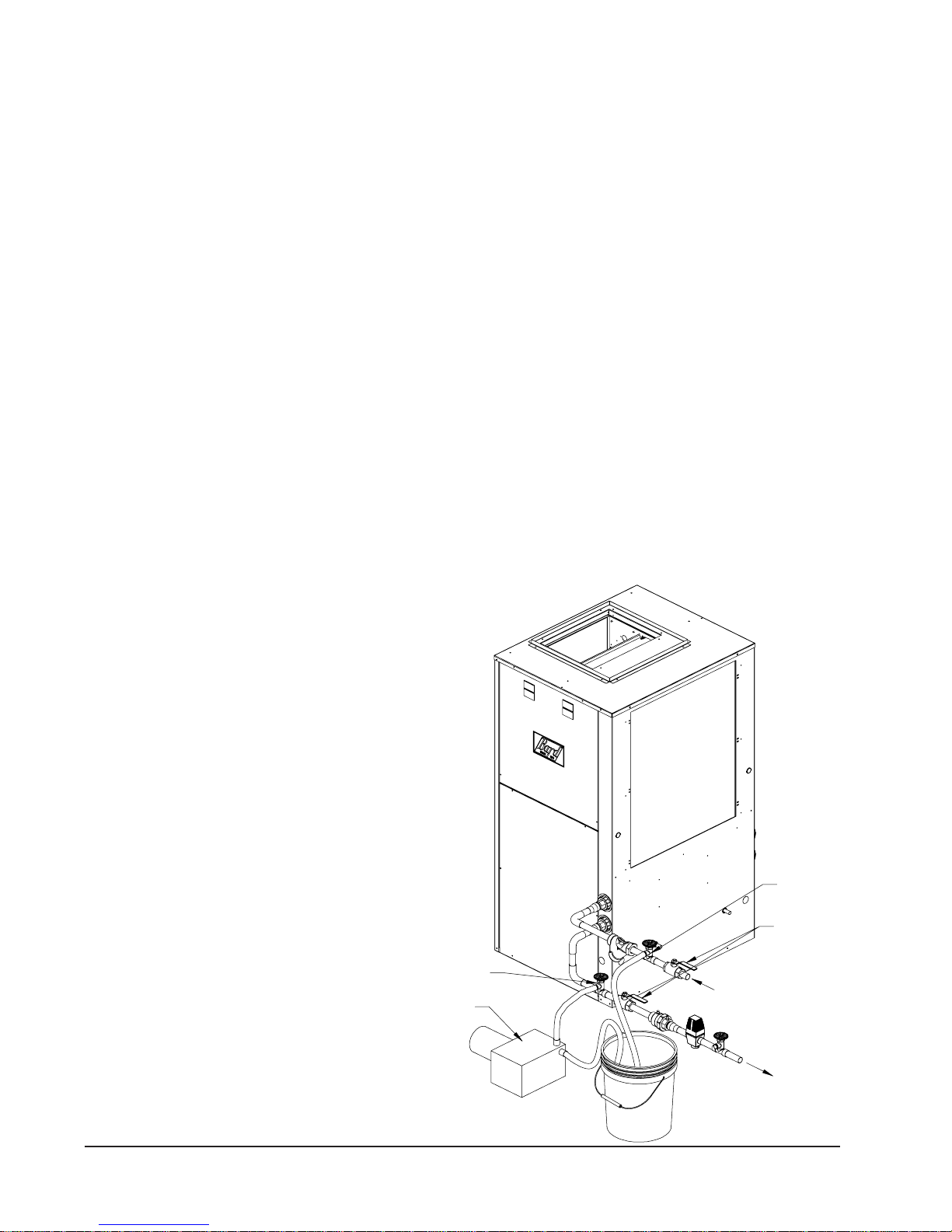

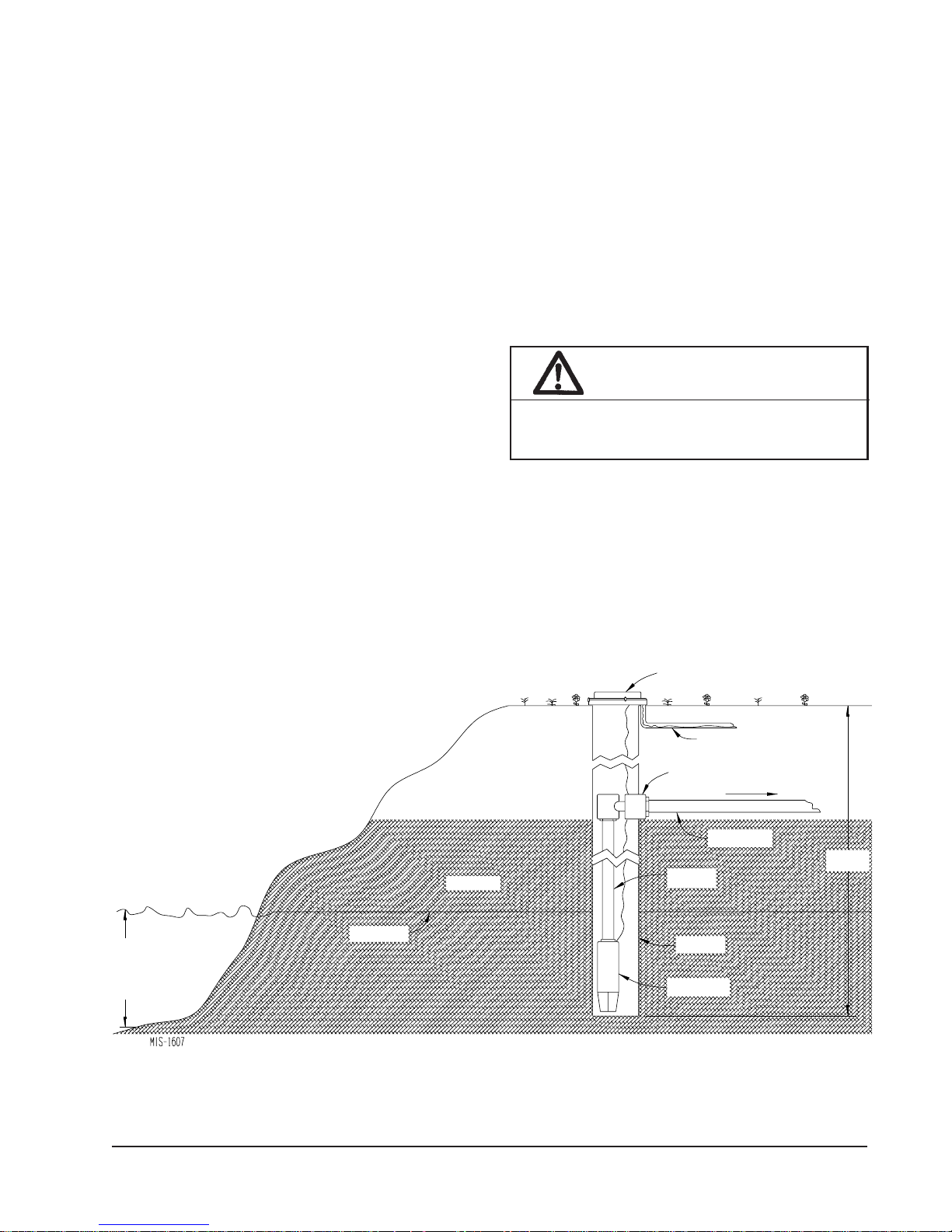

LAKE AND POND INSTALLATIONS

Lakes and ponds can provide a low cost source of water for

heating and cooling with a ground water heat pump. Direct

usage of the water without some filtration is not

recommended as algae and turbid water can foul the water to

refrigerant heat exchanger. Instead, there have been very

good results using a dry well dug next to the water line or

edge. Normal procedure in installing a dry well is to

backhoe a 15 to 20 foot hole adjacent to the body of water

(set backhoe as close to the water’s edge as possible). Once

excavated, a perforated plastic casing should be installed

with gravel backfill placed around the casing. The gravel

bed should provide adequate filtration of the water to allow

good performance of the ground water heat pump.

The following is a list of recommendations to follow when

installing this type of system:

A. A lake or pond should be at least 1 acre (40,000 a

square feet) in surface area for each 50,000 BTUs of

ground water heat pump capacity or have 2 times the

cubic feet size of the dwelling that you are trying to

heat (includes basement if heated).

B. The average water depth should be at least 4 feet and

there should be an area where the water depth is at least

12 to 15 feet deep.

FIGURE 11

CLEANING WATER COIL

Manual 2100-510E

Page 22 of 38

Hose Bib (A)

Pump

Hose Bib (B)

Isolation Valve

MIS-2624

Page 23

C. If possible, use a submersible pump suspended in the

dry well casing. Jet pumps and other types of suction

pumps normally consume more electrical energy than

similarly sized submersible pumps. Pipe the unit the

same as a water well system.

D. Size the pump to provide necessary GPM for the

ground water heat pump. A 12 GPM or greater water

flow rate is required on all models when used on this

type system.

E. A pressure tank should be installed in dwelling to be

heated adjacent to the ground water heat pump. A

pressure switch should be installed at the tank for pump

control.

F. All plumbing should be carefully sized to compensate

for friction losses, etc., particularly if the pond or lake

is over 200 feet from the dwelling to be heated or

cooled.

G. Keep all water lines below low water level and below

the frost line.

H. Most installers use 4-inch field tile (rigid plastic or

corrugated) for water return to the lake or pond.

I. The drain line discharge should be located at least 100

feet from the dry well location.

J. The drain line should be installed with a slope of 2

inches per 10 feet of run to provide complete drainage

of the line when the ground water heat pump is not

operating. This gradient should also help prevent

freezing of the discharge where the pipe terminates

above the frost line.

K. Locate the discharge high enough above high water

level so the water will not back up and freeze inside the

drain pipe.

L. Where the local conditions prevent the use of a gravity

drainage system to a lake or pond, you can instead run

standard plastic piping out into the pond below the

frost and low water level.

WARNING

Thin ice may result in the vicinity of the

discharge line.

For complete information on water well systems and lake

and pond applications, refer to Manual 2100-078 available

from your distributor.

12'

to

15'

LAKE

or

POND

FIGURE 12

LAKE OR POND INSTALLATION

GRAVEL FILL

WATER LEVEL

WELL CAP

ELECTRICAL LINE

PITLESS ADAPTER

TO PRESSURE

TANK

WATER

SUPPLY LINE

DROP

PIPE

PERFORATED

PLASTIC CASING

SUBMERSIBLE

PUMP

15' to 20'

DEEP

Manual 2100-510E

Page 23 of 38

Page 24

SEQUENCE OF OPERATION

BLOWER

Blower functions are all automatic through the thermostat

control. (See Table 1 for the specific airflows on each

speed.) Motor control inputs are all 24 VAC with line

power to motor being continuous.

On a call for “G” from the thermostat (call for manual fan),

speed tap #1 on the blower motor is energized.

On a call for “Y1” from the thermostat (heating or

cooling), speed tap #2 of the blower motor is energized

immediately. Simultaneously, the “Y1” tap of the blower

control board is also energized, and following 5 minutes,

the blower control will power speed tap #3 of the blower

motor.

On a call for “Y2” operation from the thermostat (heating

or cooling), speed tap #5 will be energized through the

blower control board.

connection on the blower control board. It comes from the

factory by default jumpering Pins #4 and #5 together to

run the blower at nominal rated full load airflow. If this is

too noisey, this jumper can be removed from Pins #4/#5 to

allow the full load airflow to be reduced by 10% (see Unit

Wiring Diagram).

On any call for “W” (electric heat operation), from the

thermostat, speed tap #5 is always energized. (It is not

affected by the #4/#5 jumper on the blower control board.)

The exception is a jumper pin

PART LOAD COOLING

When thermostat system switch is placed in COOL, it

completes a circuit from “R” to “O”, energizing the

reversing valve solenoid. On a call for cooling, the

thermostat completes a circuit from “R” to “Y1”, which

energizes the compressor contactor and blower motor on

speed tap #2 initially, then speed tap #3 after 5 minutes

(see BLOWER above).

PART LOAD HEATING (No Electric Heat)

When thermostat system switch is placed in HEAT, the

reversing valve solenoid is no longer energized. On a call

for part load heating, the thermostat completes a circuit

from “R” to “Y1”, which energizes the compressor

contactor and blower motor on speed tap #2 initially, then

speed tap #3 after 5 minutes (see BLOWER above).

FULL LOAD HEATING (No Electric Heat)

The system should already be in Part Load Heating

operation prior to Full Load Heating being energized.

Additionally what happens, the thermostat completes a

circuit from “R” to “Y2”. This sends a signal to both the

staging solenoid on the side of the compressor and

energizes either tap #5 or tap #4 of the blower motor (see

BLOWER above).

SUPPLEMENTARY ELECTRIC HEAT

The system should already be in FULL LOAD HEATING

operation (above). The thermostat completes a circuit from

“R” to “W2”, which energizes up to 9 KW of electric heat

(depends on heater package installed). 9 KW of electric

heat is the limit when operating with the heat pump and is

controlled through the emergency heat relay.

EMERGENCY HEAT MODE

When thermostat system switch is placed in EMERGENCY

HEAT MODE and the thermostat calls for heat, it

completes a circuit from “R” to “E” and from “R” to “W2”.

This will energize the heater package for all available KW

per the installed heater package. (The call from “R” to

“E” locks out compressor operation.) The blower motor is

automatically energized with this function and will run on

speed #5 (see BLOWER above).

FULL LOAD COOLING

The system should already be in Part Load Cooling

operation prior to Full Load Cooling being energized.

Additionally what happens, the thermostat completes a

circuit from “R” to “Y2”. This sends a signal to both the

staging solenoid on the side of the compressor and

energizes either tap #5 (or tap #4) of the blower motor (see

BLOWER above).

Manual 2100-510E

Page 24 of 38

Page 25

SEQUENCE OF OPERATION

COMPRESSOR CONTROL MODULE

The compressor control module is an anti-short cycle/

lockout timer with high and low pressure switch

monitoring and alarm output.

ADJUSTABLE DELAY ON MAKE AND BREAK

TIMER

On a call for compressor operation the delay on make

period begins, which will be 10% of the delay on break

setting. When the delay on make is complete and the high

pressure switch and low pressure switch are closed, the

compressor contactor is energized. Upon shutdown, the

delay on break timer starts and prevents restart until the

delay on break and delay on make periods have expired.

HIGH PRESSURE SWITCH AND LOCKOUT

SEQUENCE (Standard Feature)

If the high pressure switch opens, the compressor contactor

will de-energize immediately. The lockout timer will go

into a soft lockout and stay in soft lockout until the high

pressure switch closes and the delay on make time has

expired. If the high pressure switch opens again in the

same operating cycle, the unit will go into manual lockout

condition and the alarm relay circuit will energize.

Recycling the wall thermostat resets the manual lockout.

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on all

units so that the system operating pressures can be

observed. Pressure tables can be found later in the manual

covering all models. It is imperative to match the correct

pressure table to the unit by model number.

SYSTEM START-UP

Step 1 – Close disconnect switch(es) and set the

thermostat to cool and the temperature to the

highest setting.

Step 2 – Check for proper airflow across the indoor coil.

Step 3 – Connect the service gauges and allow the unit to

run for at least 10 minutes or until pressures are

stable. Check pressures to the system pressure

table attached to the unit service panel.

Step 4 – Fill out Ground Source Heat Pump Performance

Report.

LOW PRESSURE SWITCH, BYPASS AND

LOCKOUT SEQUENCE (Standard Feature)

If the low pressure switch opens for more than 120

seconds, the compressor contactor will de-energize and go

into a soft lockout. Regardless the state of the low pressure

switch, the contactor will reenergize after the delay on

make time delay has expired. If the low pressure switch

remains open, or opens again for longer than 120 seconds

in the same operating cycle, the unit will go into manual

lockout condition and the alarm relay circuit will energize.

Recycling the wall thermostat resets the manual lockout.

ALARM OUTPUT

Alarm terminal is output connection for applications where

alarm signal is desired. This terminal is powered whenever

compressor is locked out due to HPC or LPC sequences as

described.

Note: Both high and low pressure switch controls are

inherently automatic reset devices. The high pressure

switch and low pressure switch cut out and cut in settings

are fixed by specific air conditioner or heat pump unit

model. The lockout feature, both soft and manual, are a

function of the Compressor Control Module.

Manual 2100-510E

Page 25 of 38

Page 26

FIGURE 13

COMPONENT LOCATION

LOW PRESSURE SWITCHES

SUCTION SERVICE PORT

DISCHARGE SERVICE PORT

DESUPERHEAT COIL

HIGH VOLTAGE IN

FLOW CENTER

POWER

WATER COIL

EXPANSION VALVE

COMPRESSOR

HIGH PRESSURE SWITCH

REVERSING VALVE

TERMINAL

BLOCK

FIGURE 14

CONTROL PANEL

GROUND

BLOCK CONTROL MODULE

COMPRESSOR

CONTACTOR

CIRCUIT

BREAKER

TRANSFORMER

COMPRESSOR

COMPRESSOR

CAPACITOR

RELAY

MIS-2625

E. HEAT

PLUG

BLOWER CONTROL

TERMINAL

STRIP

MIS-2626 A

Manual 2100-510E

Page 26 of 38

Page 27

FIGURE 15

Manual 2100-510E

Page 27 of 38

Page 28

061

124

541

551

761

234

941

931

724

744

454

834

261

571

793

304

051

061

271

641

751

204

724

314

861

304

314

824

471

581

773

773

951

841

441

451

004

341

351

973

241

251

F°lioCretaWgniretnEerutarepmeTdiulF—GNILOOCDAOLLLUF

853

141

151

833

041

051

713

931

941

692

831

841

572

731

741

452

431

441

932

131

041

422

821

731

012

831

661

704

524

014

731

461

983

863

643

523

403

282

162

642

032

512

683

304

183

531

361

563

431

261

543

853

161

231

423

633

131

061

403

413

921

951

382

292

821

851

262

072

521

451

842

452

121

151

332

832

741

812

811

222

234

714

751

641

693

014

551

541

883

573

341

453

241

333

113

041

931

092

731

962

331

452

031

932

621

422

F°lioCretaWgniretnEerutarepmeTdiulF—GNITAEHDAOLLLUF

451

663

251

443

151

223

941

003

741

872

341

362

931

742

631

232

451

761

883

393

851

541

973

383

051

731

373

073

163

241

921

363

121

431

353

253

521

343

343

211

401

333

433

711

123

901

523

89

001

803

613

39

492

803

78

29

182

992

18

38

941

841

741

F°lioCretaWgniretnEerutarepmeTdiulF—GNILOOCDAOLTRAP

641

541

441

341

241

731

331

821

171

951

283

293

173

851

263

143

751

053

123

651

923

103

551

903

451

082

882

351

062

762

251

042

642

741

422

032

241

802

412

391

731

891

541

551

761

383

604

071

483

961

263

143

861

761

913

661

892

461

672

361

552

851

832

122

251

741

502

393

604

441

451

661

363

273

583

153

341

351

461

343

141

223

041

203

931

282

831

262

731

242

231

722

821

312

421

891

463

151

133

361

243

161

123

051

013

941

061

982

992

741

851

962

872

641

751

842

752

142

251

241

332

731

841

622

812

331

341

302

012

671

561

963

963

163

761

751

063

153

851

841

F°lioCretaWgniretnEerutarepmeTdiulF—GNITAEHDAOLTRAP

353

941

041

243

543

131

041

433

733

131

321

523

923

123

221

613

411

701

903

311

413

401

203

603

99

492

992

59

29

192

782

68

48

421

FIGURE 16A

PRESSURE TABLES

591

121

081

561

811

051

511

F°03 F°53 F°04 F°54 F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011

531

111

erusserP

ediShgiH

ediSwoL

erutarepmeT

riAnruteR

BW°26

BD°57

ledoM

231

331

341

002

481

031

931

621

961

531

321

351

231

831

821

911

ediShgiH

ediSwoL

ediSwoL

321

402

511

602

191

981

111

801

571

571

401

061

951

101

541

341

ediShgiH

ediShgiH

ediSwoL

612

902

102

821

491

911

421

581

971

511

021

071

461

211

451

801

941

611

ediShgiH

ediShgiH

ediSwoL

ediSwoL

riAnruteR

BW°76

BD°08

BW°26

BW°27

BD°57

BD°58

1S72VG

BW°27

BW°76

BD°58

BD°08

1S83VG

192

862

57

57

282

552

66

07

142

472

85

46

562

822

85

94

752

F°5 F°01 F°51 F°02 F°52 F°03 F°53 F°04 F°54 F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58

erusserP

512

14

25

ediShgiH

ediShgiH

ediSwoL

ediSwoL

erutarepmeT

BD°07

BD°07

1S83VG

1S72VG

ledoM

321

811

311

901

F°03 F°53 F°04 F°54 F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011

401

erusserP

ediSwoL

erutarepmeT

riAnruteR

BD°57

ledoM

141

771

231

281

161

621

561

121

641

941

031

331

611

111

411

711

ediShgiH

ediShgiH

ediSwoL

BW°26

BW°76

BD°08

1S72VG

481

881

021

921

981

831

591

171

961

631

451

031

521

831

121

911

ediShgiH

ediSwoL

421

471

331

611

551

211

801

041

401

621

ediShgiH

ediSwoL

081

461

021

951

921

441

421

941

511

921

431

111

911

ediShgiH

ediShgiH

ediSwoL

ediSwoL

riAnruteR

BW°26

BW°27

BD°58

BW°76

BD°57

BW°27

BD°08

BD°58

1S83VG

082

482

77

77

372

672

86

96

562

962

95

26

162

852

05

45

152

F°5 F°01 F°51 F°02 F°52 F°03 F°53 F°04 F°54 F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58

erusserP

452

14

74

ediShgiH

ediShgiH

ediSwoL

ediSwoL

erutarepmeT

BD°07

BD°07

1S83VG

1S72VG

ledoM

Manual 2100-510E

Page 28 of 38

Page 29

FIGURE 16B

PRESSURE TABLES

ledoM

1S15VG

1S16VG

1S17VG

ledoM

1S15VG

1S16VG

1S17VG

ledoM

1S15VG

1S16VG

1S17VG

ledoM

1S15VG

1S16VG

1S17VG

riAnruteR

erutarepmeT

BD°57

BW°26

BD°08

BW°76

BD°58

BW°27

BD°57

BW°26

BD°08

BW°76

BD°58

BW°27

BD°57

BW°26

BD°08

BW°76

BD°58

BW°27

riAnruteR

erutarepmeT

BD°07

BD°07

BD°07

riAnruteR

erutarepmeT

BD°57

BW°26

BD°08

BW°76

BD°58

BW°27

BD°57

BW°26

BD°08

BW°76

BD°58

BW°27

BD°57

BW°26

BD°08

BW°76

BD°58

BW°27

riAnruteR

erutarepmeT

BD°07

BD°07

BD°07

F°03 F°53 F°04 F°54 F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011

erusserP

ediSwoL

401

601

901

211

511

711

021

321

521

721

821

ediShgiH

141

751

371

981

502

122

632

252

862

ediSwoL

111

411

711

021

321

521

821

ediShgiH

541

161

871

491

012

ediSwoL

911

221

621

ediShgiH

051

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

erusserP

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

erusserP

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

erusserP

ediSwoL

ediShgiH

ediSwoL

ediShgiH

ediSwoL

ediShgiH

761

801

011

341

061

611

811

741

461

521

721

251

961

011

111

571

681

811

911

971

191

721

821

581

791

F°5 F°01 F°51 F°02 F°52 F°03 F°53 F°04 F°54 F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58

43

24

372

282

73

54

272

382

83

54

952

862

F°03 F°53 F°04 F°54 F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011

601

901

721

241

311

711

031

641

121

521

531

151

801

111

631

051

511

811

931

451

421

721

441

951

801

111

931

351

611

811

341

751

521

721

841

361

F°5 F°01 F°51 F°02 F°52 F°03 F°53 F°04 F°54 F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58

14

94

652

462

14

94

152

162

93

74

942

852

921

481

102

211

411

671

291

021

221

081

791

921

131

781

402

211

311

791

902

021

121

202

412

921

031

902

122

05

85

192

003

35

16

492

503

25

95

872

782

211

511

751

271

021

421

161

771

921

331

761

381

411

711

561

971

221

521

961

481

131

431

571

091

311

511

761

181

121

321

271

681

031

231

871

291

75

56

372

182

85

66

172

182

55

46

762

772

622

231

531

712

432

611

811

802

422

421

621

412

032

331

531

122

832

511

611

022

132

321

421

622

732

231

331

332

542

56

37

803

713

96

77

513

623

66

37

792

603

911

221

781

202

721

131

291

802

731

041

991

512

021

321

491

902

821

131

991

412

831

141

602

122

711

911

591

902

521

721

002

412

431

731

702

222

37

18

092

892

57

38

192

103

27

08

682

592

131

342

952

831

141

152

862

021

221

142

752

821

031

742

362

831

041

552

372

711

811

342

452

521

621

942

062

431

531

752

962

18

98

623

533

58

39

733

843

08

78

613

523

521

921

712

332

431

831

322

932

441

841

132

742

621

921

322

832

531

831

922

442

541

841

732

352

121

321

322

732

031

231

922

342

931

241

632

152

98

79

703

513

29

001

113

123

88

79

403

413

982

431

531

572

692

441

541

582

703

321

521

372

392

231

331

082

103

241

341

092

113

911

911

562

682

721

721

272

392

731

731

282

403

69

401

343

253

101

901

853

963

49

101

533

443

231

331

842

862

141

341

452

572

251

351

362

482

231

331

352

372

141

241

952

082

251

351

862

982

521

721

152

172

431

531

752

872

441

541

662

882

501

311

423

233

901

711

133

143

501

311

323

233

921

903

033

731

831

713

933

741

841

823

053

621

721

413

433

531

631

223

343

541

641

333

453

911

021

703

823

821

821

513

633

731

831

623

843

311

321

363

473

811

721

283

593

111

121

553

663

531

631

882

803

441

641

592

613

551

651

603

723

431

531

392

213

341

541

003

123

451

551

113

233

821

921

192

213

731

831

992

023

741

841

903

133

321

231

243

153

621

531

153

263

321

231

143

153

F°lioCretaWgniretnEerutarepmeTdiulF—GNILOOCDAOLLLUF

031

231

331

153

173

931

141

063

183

051

151

273

493

821

031

453

573

731

931

363

483

841

941

673

893

021

021

843

963

821

921

753

973

831

831

073

293

431

293

314

241

341

204

324

351

451

614

834

131

231

593

514

041

141

504

624

151

251

914

144

121

121

093

114

921

921

004

124

931

931

414

634

F°lioCretaWgniretnEerutarepmeTdiulF—GNITAEHDAOLLLUF

231

141

051

583

693

631

541

804

124

131

141

673

783

061

704

814

451

361

434

744

151

161

893

904

F°lioCretaWgniretnEerutarepmeTdiulF—GNILOOCDAOLTRAP

731

931

041

823

843

741

941

733

753

851

061

843

073

631

731

233

253

641

741

143

263

751

851

353

473

031

231

233

253

931

141

043

163

051

151

253

473

241

963

983

051

251

873

993

161

361

193

314

831