Bard FC085V42A, FH110V60A, FC085V42A,FH085V42A,FH110V48A,FH110V60A, FH085V42A, FH110V48A Installation Instructions Manual

...Page 1

OIL FURNACE

INSTALLATION INSTRUCTIONS

MODELS

FC085V42A FH085V42A FH110V48A

FH110V60A FLF085V42A FLF110V48A

FLF110V60A FLR085V42A FLR110V48A

FLR110V60A FLR140V60A

WARNING

READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION.

THIS INSTALLATION MUST COMPLY WITH THESE INSTRUCTIONS AND THE REQUIREMENTS

OF ALL GOVERNING CODES AND ORDINANCES FOR THE INSTALLATION LOCATION.

IT IS THE RESPONSIBILITY OF INSTALLER TO KNOW AND UNDERSTAND ALL OF THESE

REQUIREMENTS.

FAILURE TO DO SO COULD CREATE A HAZARD RESULTING IN PROPERTY DAMAGE, BODILY

INJURY OR DEATH.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

IMPORTANT NOTICE

THIS FURNACE IS NOT INTENDED FOR USE AS A CONSTRUCTION HEATER. USE OF THIS

FURNACE DURING CONSTRUCTION AND FINISHING PHASES OF A STRUCTURE IS

CONSIDERED AS "OPERATION IN A CORROSIVE ATMOSPHERE" AND "UNUSUAL,

NEGLIGENT OR IMPROPER USE" AND AS SUCH ARE CONSIDERED EXCLUSIONS BY THE

BARD MANUFACTURING COMPANY LIMITED WARRANTY.

WARNING

CARBON MONOXIDE POISONING HAZARD

FAILURE TO FOLLOW THIS WARNING COULD RESULT IN PERSONAL INJURY OR DEATH.

Carbon Monoxide is invisible, orderless and toxic! Bard Manufacturing recommends a carbon

monoxide alarm in your home, even if you do not own a gas appliance. Locate the carbon

monoxide alarm in the living area of your home and away from doorways to attached garages.

Follow the alarm manufacturer’s instructions included with the alarm.

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

Manual: 2100-540D

Supersedes: 2100-540C

File: VOL. I, TAB 3

Date: 04-24-13

Manual 2100-540D

Page 1 of 45

Page 2

CONTENTS

Getting Other Information and Publications ........ 3

Installation and Operating Instructions

Equipment Selection............................................. 4

Locating the Furnace ............................................ 4

Installing the Furnace ........................................... 8

Duct Work ............................................................. 8

Installing a Cooling Unit ........................................ 8

Wiring .............................................................. 9

Oil Line Piping..................................................... 12

Beckett AFG Oil Burner .............................. 12 & 13

Beckett “CleanCut” Oil Pump.............................. 13

Beckett Solid State Igniter................................... 13

Beckett GeniSys 7505 ...........................14 & 16-17

Burner States, Reset Button Op., Priming the Pump, Cad

Cell Resistance Indicator, Reset Restricted Lockout

Troubleshooting GE ECM2.3......................... 21-23

Burner Setup and Adjustments ...................... 24-26

Short Form Adjustment Procedure ..................... 26

Combustion Air Requirements ............................ 30

Louvers and Grilles............................................. 35

Venting Options .................................................. 35

Thermostat.......................................................... 35

T ABLES

Table 1 Minimum Clearances.............................4

Table 2 Dimensions FLF/R Models ................... 5

Table 3 Electrical Data........................................9

Table A Reset Button Operation ....................... 15

Table B Status Lights ........................................15

Table C Heating Tap Select Settings................. 19

Table D Cooling Tap Select Settings .................19

Table E Adjustment Tap Selects ....................... 20

Table F Heating Delay Profile Taps .................. 20

Troubleshooting GE ECM2.3............... 21

Table 4 Furnace Data.......................................24

Table 5 Correlation of % of CO

Reserve Air .......................................... 29

, O2 and

2

Table 6 No. 2 Fuel Oil Efficiency Chart.............29

Table 7 Recommended Start-Up Settings ........29

Table 8 Sq.Ft. Required as

Unconfined Sp ace ............................... 32

Table 9 Minimum Ventilation Openings ............33

Table 10 Temperature Rise Ranges, Limit

Control Settings, and

Heating Blower Speeds ....................... 36

Table 11 Filter Sizes for Oil Furnaces ................ 37

Manual 2100-540D

Page 2 of 45

Filters

Lo-Boy Models – Filter Locations.................37-38

Maintenance

Lubrication .......................................................... 39

Inspect Air Filter .................................................. 39

Final Inspection and Test .................................... 39

Service Hints....................................................... 39

Combination Combustion Chamber/Burner

Mounting System ................................................ 40

To Remove Burner Only ..................................... 41

To Remove Entire Combustion Chamber

Mounting System ................................................ 41

Common Causes of Trouble............................... 42

Care of Finish ..................................................... 42

Cleaning of the Heat Exchanger......................... 42

Wiring Diagrams ............................................43-45

FIGURES

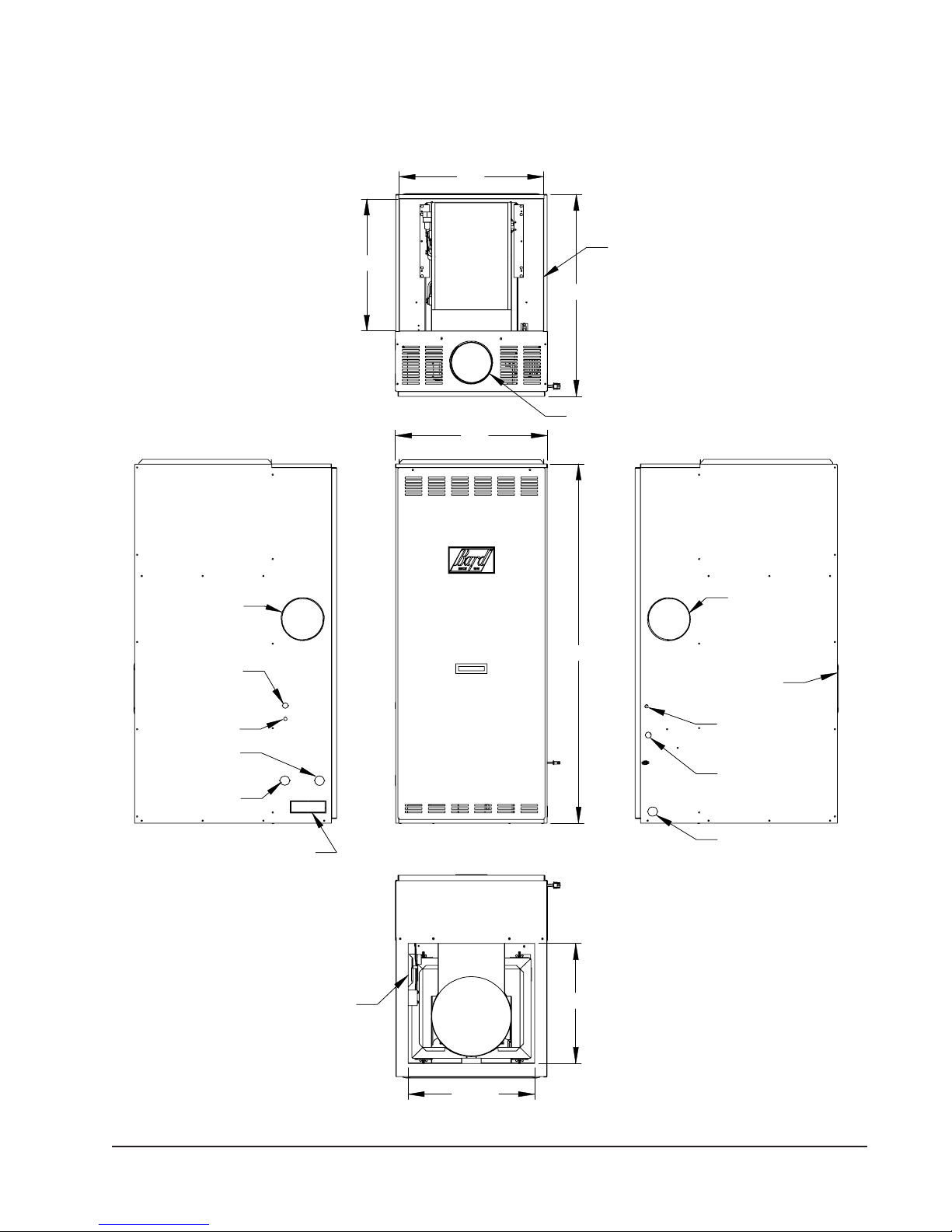

Figure 1 FLF/R Models Dimensions ................ 5

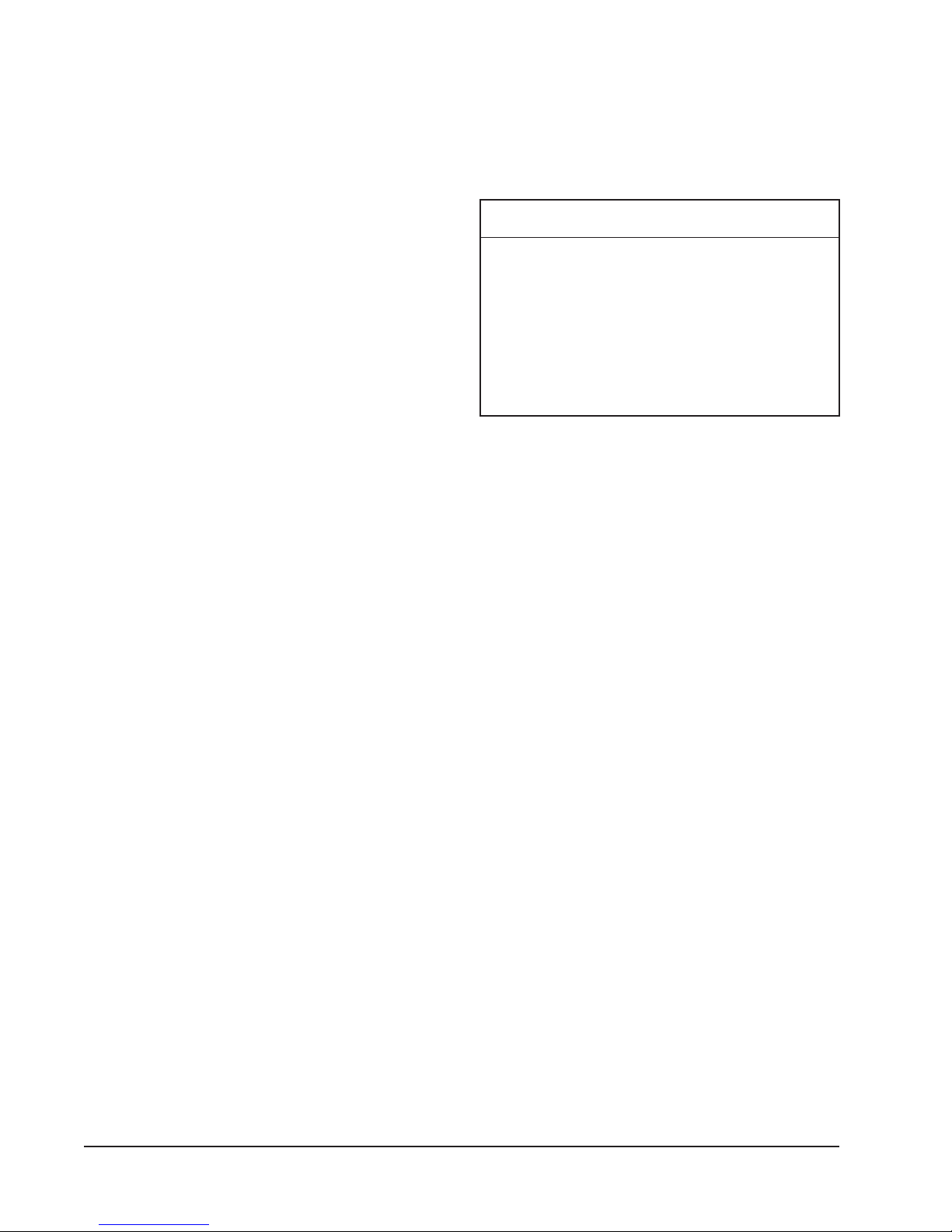

Figure 2 FH Models Dimensions .....................6

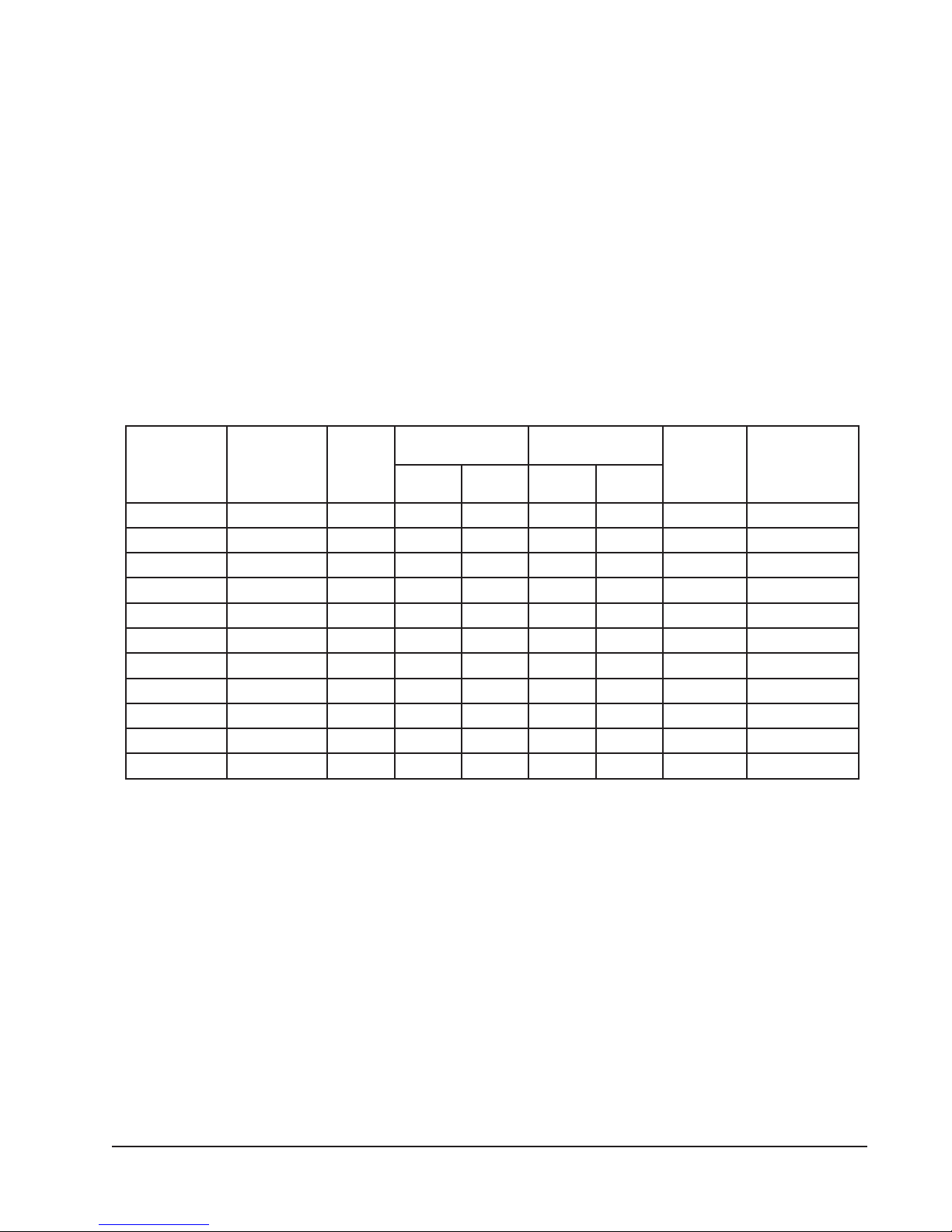

Figure 3 FC Models Dimensions .....................7

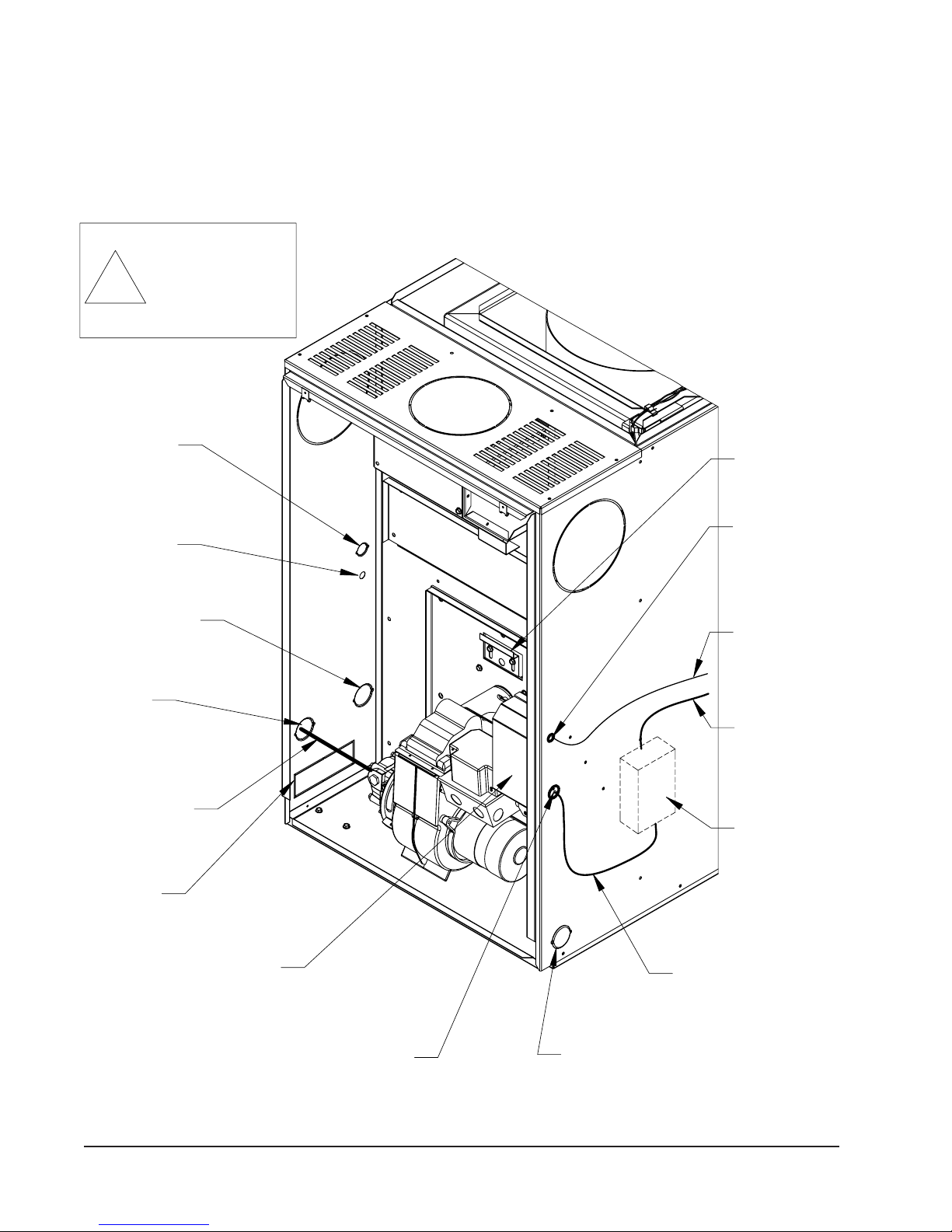

Figure 4 Typical Unit Setup - FLF..................10

Figure 5 Typical Flue Inst allation

Requirements - FLF ........................ 11

Figure 6 Typical Single Inside

Tank Installation............................... 12

Figure 7 Electronic Blower Control ................18

Figure 8 Control Disassembly .......................23

Figure 9 Winding Test....................................23

Figure 10 Drip Loop......................................... 23

Figure 11 Typical Smoke-CO

Characteristic .. 27

2

Figure 12 Pressure Gauge Connection to

Bleed Port ....................................... 28

Figure 13A Electrode Adjustments-AFG............30

Figure 13B Electrode Adjustments-NX .............. 30

Figure 14 Combustion Air Boot Assembly .......31

Figure 15 All Air From Inside Building ............. 32

Figure 16 All Air From Outdoors ...................... 33

Figure 17 All Air From Outdoors Through

Ventilated Attic.................................34

Figure 18 All Air From Out doors - Inlet Air

From Ventilated Crawl Space and

Outlet Air to Ventilated Attic .............34

Figure 19 Typical Installation of FR26 and FR27.

Filter Rack ....................................... 37

Figure 20 Typical Inst allation of FR25 Filter

Kit ....................................................37

Figure 21 Filter Installation - Lo-Boy Models ... 38

Figure 22 Removal of Burner Only ..................40

Figure 23 Removal of Entire Combustion

Chamber Mounting System.............41

Page 3

GETTING OTHER INFORMATION and PUBLICATIONS

These publications can help you install the furnace. You

can usually find these at your local library or purchase

them directly from the publisher. Be sure to consult

current edition of each standard.

National Fuel Gas Code.............. ANSI Z223.1/NFPA54

National Electrical Code.........................ANSI/NFPA 70

Standard for the Installation................. ANSI/NFPA 90A

of Air Conditioning and Ventilating Systems

Standard for Warm Air ........................ ANSI/NFPA 90B

Heating and Air Conditioning Systems

Standard for Chimneys, Fireplaces, Vents...... NFPA 211

and Solid Fuel Burning Appliances

Load Calculation for ..............................ACCA Manual J

Residential Winter and Summer Air Conditioning

FOR MORE INFORMATION, CONTACT THESE

PUBLISHERS:

ACCA Air Conditioning Contractors of America

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

ANSI American National Standards Institute

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

ASHRAE American Society of Heating Refrigerating,

and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

Duct Design for Residential................. ACCA Manual D

Winter and Summer Air Conditioning

and Equipment Selection

NFPA National Fire Protection Association

Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-540D

Page 3 of 45

Page 4

INSTALLATION and OPERATING INSTRUCTIONS

EQUIPMENT SELECTION

An accurate heating load calculation must be conducted

using American Society of Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE) or Air

Conditioning Contractors of America (ACCA)

manuals. Do not add a large safety factor above the

calculated value. If the calculated heating load

requirement exceeds the heating capacity rating of a

given model, use only the next larger size available.

Never increase by any more than absolutely necessary

based upon available equipment heating capacities.

Always select based upon heat capacity (output), never

use input capacities.

NOTE: It is the personal responsibility and obligation

of the purchaser to contract a qualified

installer to assure that installation is adequate

and is in conformance with governing codes

and ordinances.

LOCATING THE FURNACE

When installing the furnace be sure to provide adequate

space for easy service and maintenance. Locate the

furnace as close to the chimney as practical, giving

consideration to the accessibility of the oil burner,

controls, and blower for service. Allow a minimum of

24 inches at front of furnace for servicing oil burner.

Allow adequate room for filter and blower

maintenance. Clearance from combustible material as

stated on the furnace and repeated in Table 1 must be

maintained. For damp basement installations, a raised

concrete pad is recommended. This will help keep the

bottom of the furnace dry and reduce the risk of rusting.

An oil burner must have a generous supply of

combustion air to operate properly. The flow of

combustion and ventilating air must not be obstructed

from reaching the furnace. See “Combustion Air

Requirements” section.

The furnace area must be kept clear and free of

combustible materials, gasoline and other flammable

vapors and liquids.

This unit is not designed for mobile home or trailer

installations. Always install furnace in a level position.

TABLE 1

MINIMUM CLEARANCES

sehcnI—secanraelCnoitallatsnImuminiM

1

ledoM

A24V580CF 6 122229CN ** 42——

A24V580HF

A84V011HF

A06V011HF

4V011FLF

1

For the first three (3) feet from plenum. After three (3) feet, no clearance required.

C

Combustible flooring

NC

Noncombustible floor

*

Maintained on one side or the other to achieve filter access and/or blower service.

**

Floor must be noncombustible. For furnace only installation can be installed on combustible

flooring only when installed on special base part no. CFB7 available from factory. When air

conditioning coil cabinet DCB23-22 is used then use special base part no. CFB23.

4

4

4

A24V580FLF

6

A8

6

6

A06V011FLF

6

A24V580RLF

6

A84V011RLF

A06V011RLF

6

A06V041RLF

6

1

1

1

0

0

0

81

81

81

81

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

tcuD

2

2

2

2

2

2

2

2

2

2

eulF

epiProolFtnorFkcaBsediSpoTsediStnorFkcaBsediS

—

9

9

9

9

9

9

9

9

9

9

C

C

C

CN

CN

CN

CN

CN

CN

CN

42

—

42

—

42

42

42

42

42

42

42

42

42

42

42

42

42

42

42

ecivreSmuminiM

secnaraelCecanruFmunelP

—

—

—

*81

*81

*81

*81

*81

*81

*81

Manual 2100-540D

Page 4 of 45

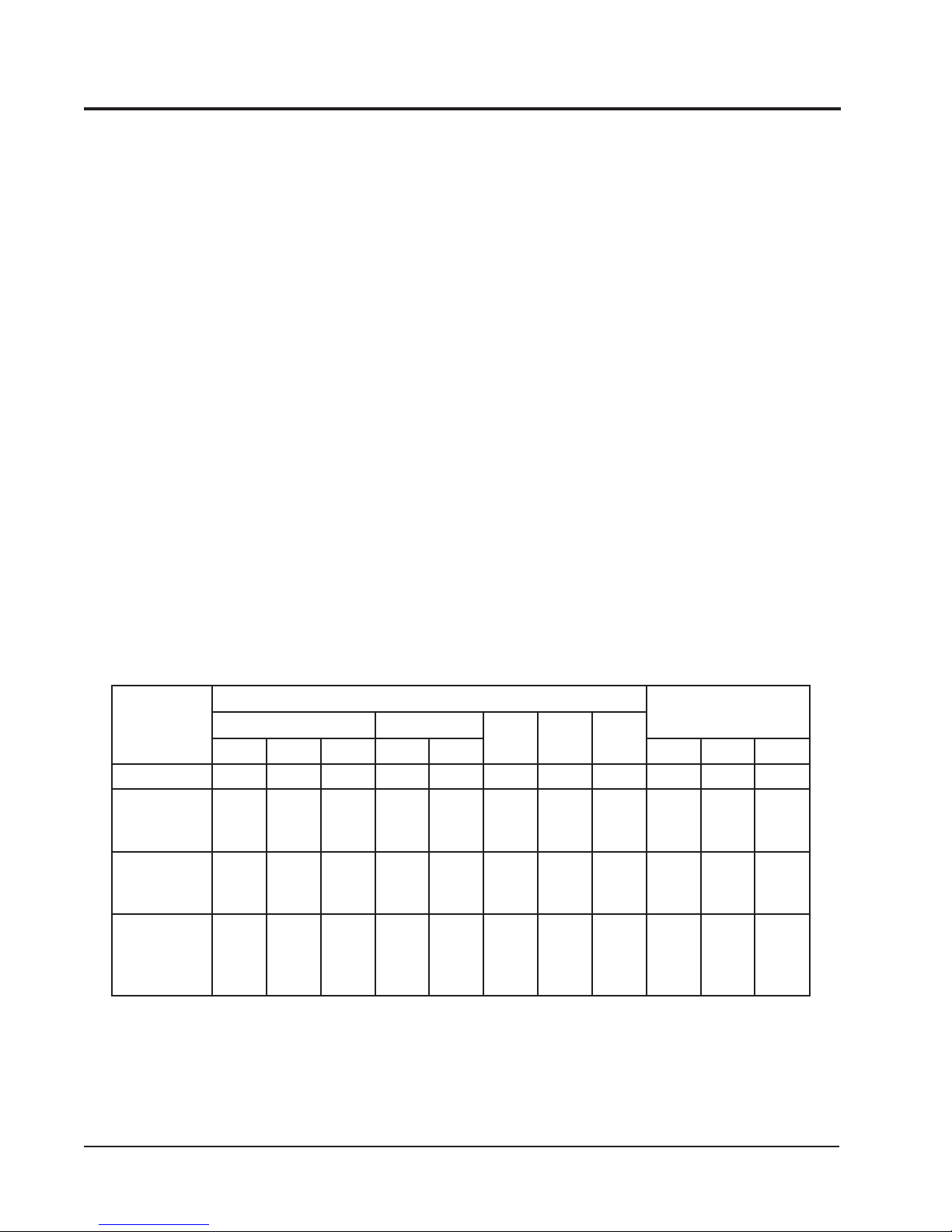

Page 5

Washable type filter 1” nom. thickness

ledoM

rebmuN

tenibaC

munelP

sgninepOnoitcennoCeulFsretliFriA 1

A

htdiW

B

htpeD

C

thgieH

ExD

ylppuS

FxD

nruteRnoitacoL

G

.aiDH

J eziS

.oN

desU

A24V580FLF

A24V580RLF

32

32

521.84

521.84

526.63

526.63

02x22

02x22

41x22

41x22

tnorF

raeR

6

6

526.13

526.13

521.5

521.5

1x02x61

1x02x61

1

1

A84V011FLF

A06V011FLF

A84V011RLF

A06V011RLF

323232

32

521.84

521.84

521.84

521.84

526.04

526.04

526.04

526.04

02x22

02x22

02x22

02x22

41x22

41x22

41x22

41x22

tnorF

tnorF

raeR

raeR

666

6

526.53

526.53

526.53

526.53

521.5

521.5

521.5

521.5

1x02x02

1x02x02

1x02x02

1x02x02

111

1

A06V041RLF62052.05526.7402x5261x52raeR6

521.24— 1x52x021

1

B

MIS-1815 A

RIGHT SIDE VIEWFRONT VIEWLEFT SIDE VIEW

TABLE 2

FLF/R MODELS DIMENSIONS (INCHES)

"FLF" FLUE

KNOCKOUT

LOW VOLTAGE

ENTRANCE

ENTRANCE

HIGH VOLTAGE

C

OPTIONAL

OIL ENTRANCE

FIGURE 1

A

FLF/R MODELS DIMENSIONS

SPECIFICATION SHEET

FLF/FLR 085, 110 AND 140

J

DUCT

SUPPLY

TOP VIEW

DUCT

RETURN

"FLF" FLUE

KNOCKOUT

EF

OIL

OPTIONAL

"FLF" FLUE

KNOCKOUT

G

D

REAR FLUE

OPTIONAL

ENTRANCE

HIGH VOLTAGE

ON "FLR" MODELS

ENTRANCE

LOW VOLTAGE

H

OIL

OPTIONAL

ENTRANCE

FILTER

ENTRANCE

FRESH AIR

KNOCKOUT

DOOR

Manual 2100-540D

Page 5 of 45

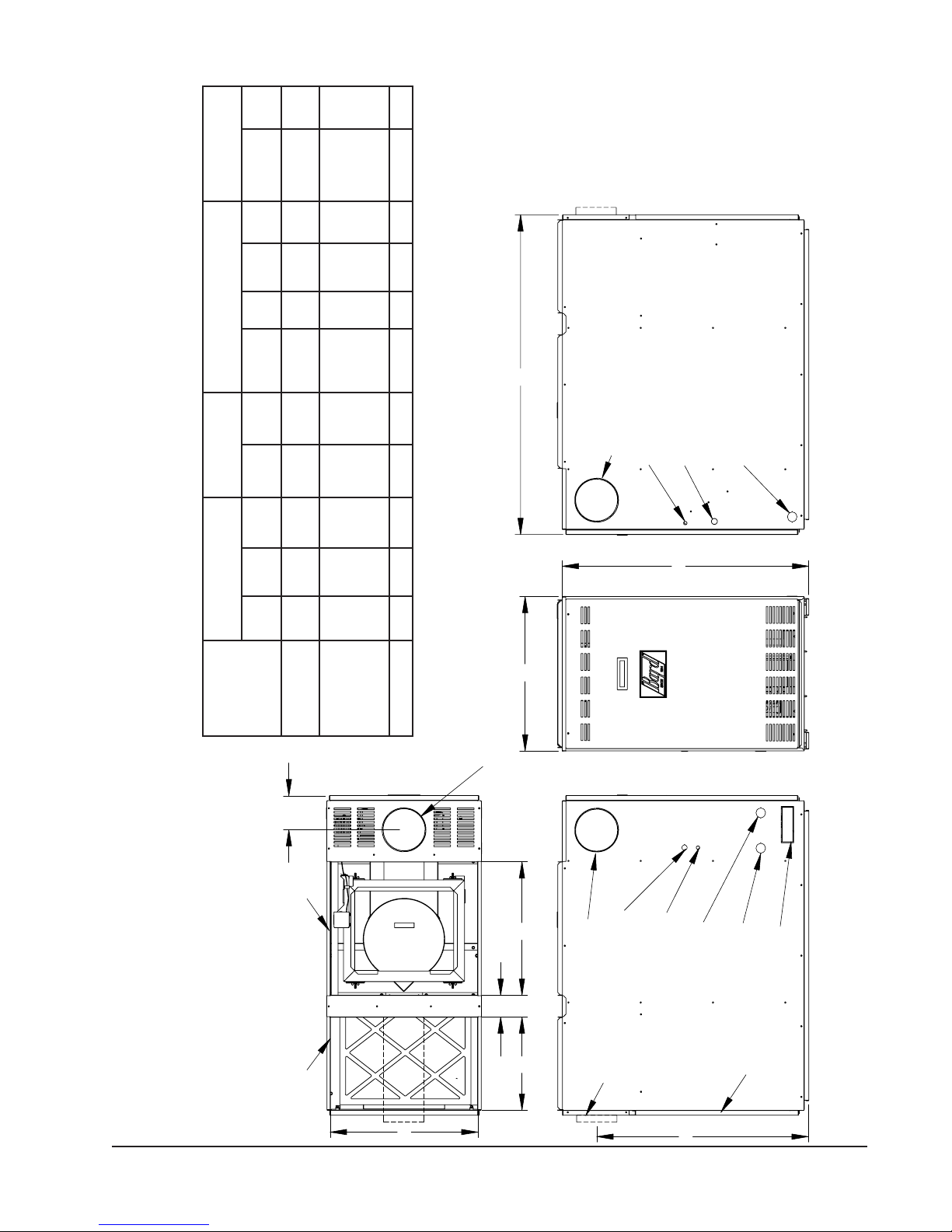

Page 6

FH085 AND FH110

SPECIFICATION SHEET

RETURN

OPENING

(CUT OUT)

MIS-1814 A

RIGHT SIDE VIEW

SUPPLY

OPENING

FIGURE 2

21 7/8"

FH MODELS DIMENSIONS

19 7/8"

TOP VIEW

30 1/2"

FLUE

KNOCKOUT

23"

FLUE

FLUE

KNOCKOUT

KNOCKOUT

OPTIONAL

HIGH VOLTAGE

HIGH

DOOR

REAR CLEANOUT

ENTRANCE

VOLTAGE

OPTIONAL

ENTRANCE

LOW VOLTAGE

ENTRANCE

53" (FH085)

OIL

OPTIONAL

ENTRANCE

LOW VOLTAGE

59" (FH110)

OIL

ENTRANCE

OPTIONAL

ENTRANCE

FRESH AIR

KNOCKOUT

OIL

ENTRANCE

DOOR

VESTIBULE

FRONT VIEW

Manual 2100-540D

Page 6 of 45

19 1/4"

RETURN

OPENING

(CUT OUT)

16"

LEFT SIDE VIEW

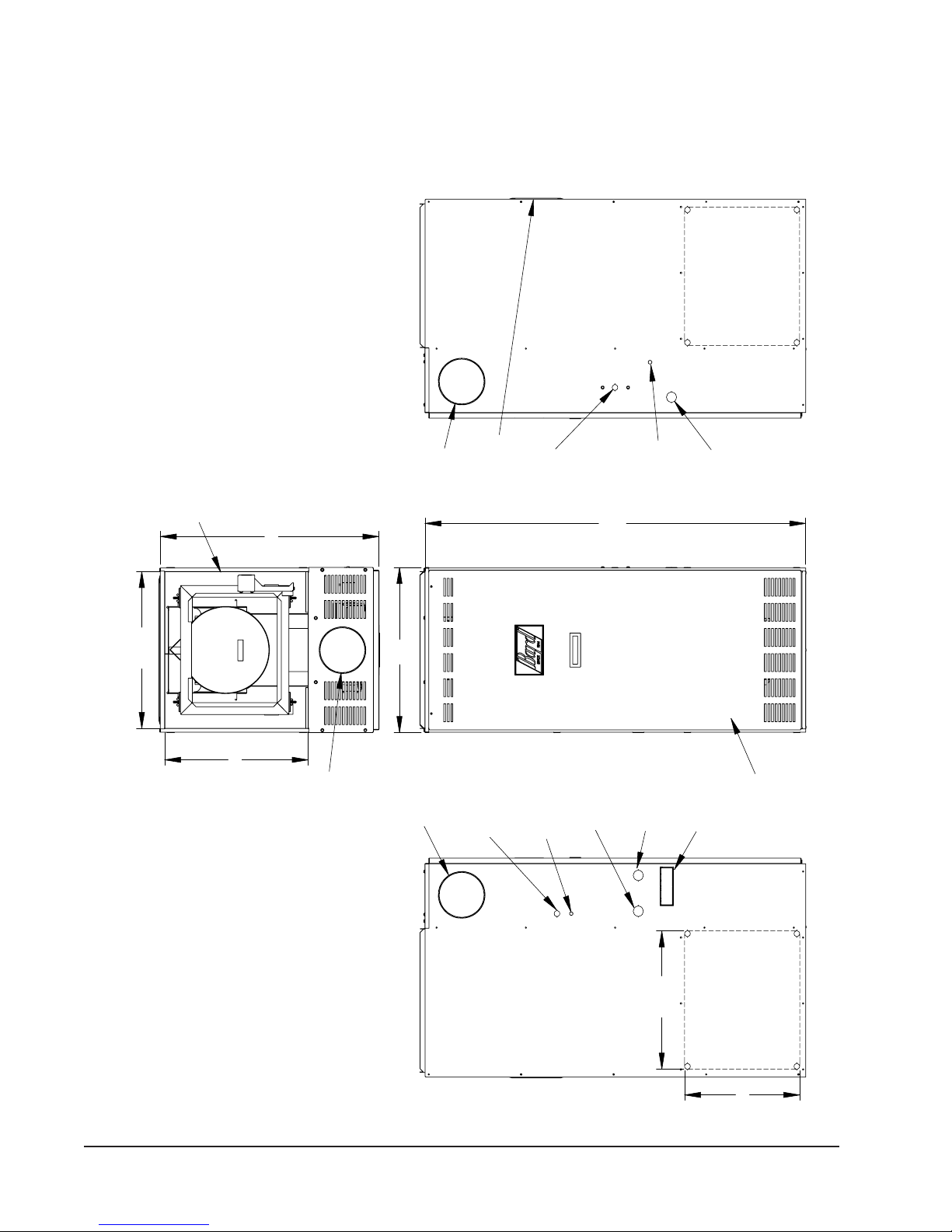

Page 7

COUNTERFLOW

FIGURE 3

FC085 MODEL DIMENSIONS

22"

20"

RETURN

OPENING

SPECIFICATION

SHEET

FLUE

KNOCKOUT

OPTIONAL

HIGH VOLTAGE

ENTRANCE

OPTIONAL

LOW VOLTAGE

ENTRANCE

OIL ENTRANCE

OPTIONAL

OIL ENTRANCE

23"

30 5/8"

TOP VIEW

FLUE

KNOCKOUT

54 1/4"

FLUE

KNOCKOUT

REAR

CLEANOUT

DOOR

LOW VOLTAGE

ENTRANCE

HIGH VOLTAGE

ENTRANCE

FRESH AIR

KNOCKOUT

LEFT SIDE VIEW

SUPPLY

OPENING

BOTTOM VIEW

FRONT VIEW

19 1/8"

OPTIONAL

OIL ENTRANCE

RIGHT SIDE VIEW

18 1/8"

MIS-1826 A

Manual 2100-540D

Page 7 of 45

Page 8

INSTALLING THE FURNACE

INSTRUMENTS REQUIRED FOR PROPER

SETUP OF THE FURNACE

It is important that a set of instruments capable of the

following requirements be used for the setup of this

furnace to ensure proper and safe operation:

1. Oil pump pressure gauge that measures up to

150 PSI.

2. Smoke gun to pull smoke samples from flue.

3. Draft gauge that will measure -.02" water column

(W.C.)

4. Duct static pressure gauge 0-1.0" W.C. range.

5. Temperature gauge that can read from 50° F up to

700° F.

6. A gauge to measure CO2 or O2.

DUCT WORK

The air distribution system should be designed and

installed in conformance with manuals published by

Air Conditioning Contractors of America (ACCA) as

set forth in Manual D, or ASHRAE publications.

IMPORTANT

When a furnace is installed so that supply

ducts carry air circulated by the furnace to

areas outside the space containing the

furnace, the return air must also be handled

by a duct(s) sealed to the furnace casing and

terminating outside the space containing the

furnace This is to prevent drawing possible

hazardous combustion products into the

circulated air.

INSTALLATION

A typical installation is shown in Figures 4 and 5. All

parts of the furnace installation (furnace, oil tank and

piping systems, combustion and ventilation air, venting,

etc.) must comply with NFPA31, Installation of Oil

Burning Equipment -- latest edition. This drawing

shows the typical connecting parts needed to correctly

install this furnace. Make sure that all parts of the

heating system comply with the local codes.

Check the furnace and your load calculation to verify

that the unit is properly sized. (Refer to “Equipment

Selection” section on Page 4.)

The correct size of unit needed may be substantially

smaller than the unit being replaced due to home

improvements and technology advancements since the

initial installation.

INADEQUATE SUPPLY AIR and/or RETURN

AIR DUCT SYSTEMS

Short cycling because of limit control operation can be

created by incorrectly designed or installed supply and/

or return air duct systems.

The duct systems must be designed using ASHRAE or

ACCA design manuals and the equipment CFM and

external static pressure ratings to ensure proper air

delivery capabilities.

On replacement installations, particularly if equipment

is oversized, the duct systems can easily be undersized.

Modifications may be required to assure that the

equipment is operating within the approved

temperature rise range when under full rated input

conditions, and that no short cycling on limit controls is

occurring.

INSTALLING A COOLING UNIT

When the furnace is used in connection with a cooling

unit*, the furnace shall be installed parallel with or on

the upstream side of the cooling unit to avoid

condensation in the heating element. With a parallel

flow arrangement, the dampers or other means used to

control flow of air shall be adequate to prevent chilled

air from entering the furnace, and if manually operated,

must be equipped with means to prevent operation of

either unit, unless the damper is in the full heat or cool

position.

* A cooling unit is an air conditioning coil, heat

pump coil or chilled water coil.

When installing a cooling unit above an FH or FL

(below on an FC) series furnace, the coil must be

spaced far enough from the furnace outlet to assure

proper operation of the furnace. Bard supplied coils,

when used with Bard supplied coil cabinets, are

automatically positioned.

For top discharge FH and FL models, when coils are

installed without using Bard coil cabinets or coils of

another brand are used, the coil drain pan should be

located a minimum of four (4) inches above the top of

the furnace cabinet. If a greater clearance is specified

by the coil manufacturer then it would apply.

NOTE: IF DRAIN PAN IS ANYTHING OTHER

THAN A STEEL PAN PARTICULAR

ATTENTION MUST BE GIVEN TO THE

INSTALLATION INSTRUCTIONS FOR

THE COIL TO MAKE SURE IT IS

ACCEPTABLE FOR USE WITH THESE

OIL FURNACES HAVING MAXIMUM

OUTLET AIR TEMPERATURE OF 200° F.

See Cooling Tap Select Table D (Page 19) for CFM at

static pressures for additional information.

Manual 2100-540D

Page 8 of 45

Page 9

WIRING

FACTORY WIRING

All units are fully factory wired. Multispeed blowers

are factory wired on high speed for cooling/manual fan

operation. Heating speeds are wired for the largest

input and may need lower speed for field installed low

input nozzle. If replacement wire is necessary, use 105

degrees C minimum. See electrical data, Table 3.

ELECTRICAL DATA

FIELD WIRING

All wiring must conform to the National Electrical

Code and all local codes. A separate fuse or breaker

should be used for the furnace.

TABLE 3

rotoMrewolBrotoMrenruB

latoT

ledoMHP-ZH-stloV

A24V580CF1-06-5116.82/19.67/17.13.0151

A24V580HF1-06-5116.82/19.67/17.13.0151

A84V011HF1-06-5113.014/36.87/17.15.2151

A06V011HF1-06-5112.511

A24V580FLF1-06-5116.82/19.67/17.13.0151

A84V011FLF1-06-5113.014/36.87/17.15.2151

A06V011FLF1-06-5112.511

A24V580RLF1-06-5116.82/19.67/17.13.0151

A84V011RLF1-06-5113.014/36.87/17.15.2151

A06V011RLF1-06-5112.511

A06V041RLF1-06-5115.4118.217/17.17.7102

spmA

PHALFPHALF

5.317/17.16.8102

5.317/17.16.8102

5.317/17.16.8102

muminiM

tiucriC

yticapmA

emiT.xaM

esuFyaleD

RCAHro

rekaerBtiucriC

Manual 2100-540D

Page 9 of 45

Page 10

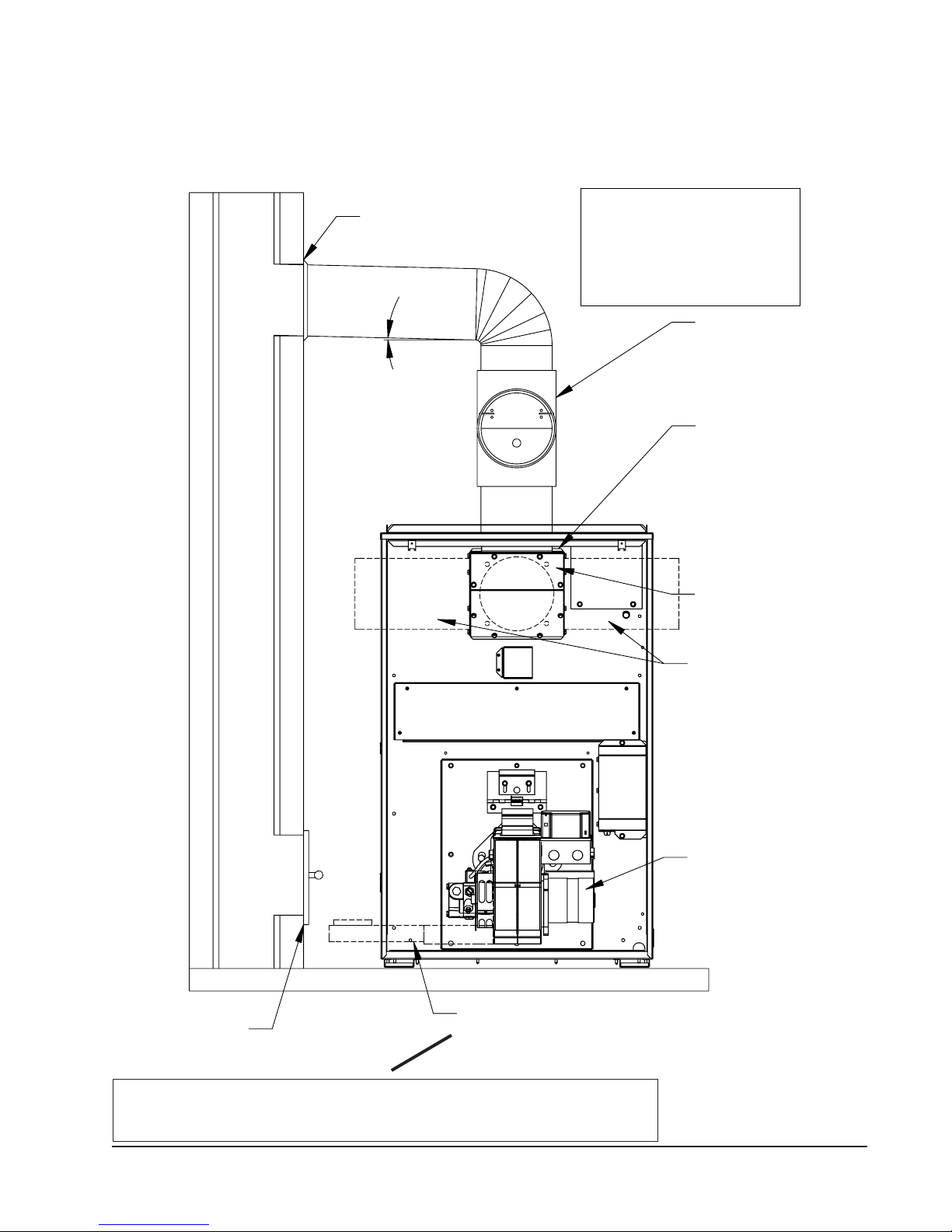

FIGURE 4

TYPICAL UNIT SETUP

FLF UNIT SHOWN

WARNING

ALL WIRING MUST

CONFORM TO THE

NATIONAL ELECTRIC

!

CODE AND ALL LOCAL

Left side

high voltage

(unit power)

entrance

Left side

low voltage

(thermostat)

entrance

Left side oil

line entrance

for opt. air boot

Left side

oil line

entrance

CODES.

TYPICAL UNIT

SETUP

(FLF UNIT SHOWN)

Inspection

door

Right side

low voltage

(thermostat)

entrance

To thermostat

and optional

A/C unit

Oil line

(see burner

pump inst. for

hookup info.)

Air Boot

knockout

(optional)

Control panel

(junction box

in FH units)

Manual 2100-540D

Page 10 of 45

Right side

high voltage

(unit power)

entrance

Right side

oil line

entrance

To power

source

Shut off switch

(if not fused,

power line must

include fuse or

circuit breaker)

Power Wires:

Black (HOT)

White (NEUTRAL)

Green (GROUND)

MIS-1836

Page 11

FIGURE 5

TYPICAL FLUE INSTALLATION REQUIREMENTS

FRONT FLUE LO-BOY MODEL SHOWN

(REPRESENTS ALL MODELS)

L

i

n

e

d

C

h

i

m

n

Thimble

1/4 inch per

1 foot rise

INSTALLER NOTE:

Follow all appropriate

standards for installing

needed venting system.

Draft Regulator

(Be sure to follow

installation inst.

supplied with

regulator).

90° Rotatable

Flue Box on front

flue models

(remove appropriate

cabinet knockout).

Mounting screws

located under flue

box cover.

Flue Box

Cover

Optional

Flue

Locations

e

y

Clean-out Door

(keep closed)

∨

∨∨

∨∨

Note: This accessory is not currently available for Bard Models:

FH110V48A, FH110V60A, FLF110V48A, FLF110V60A with NX Burners

Optional Fresh

Air Boot (remove

rect. knockout).

Oil Burner

MIS-1825

Manual 2100-540D

Page 11 of 45

Page 12

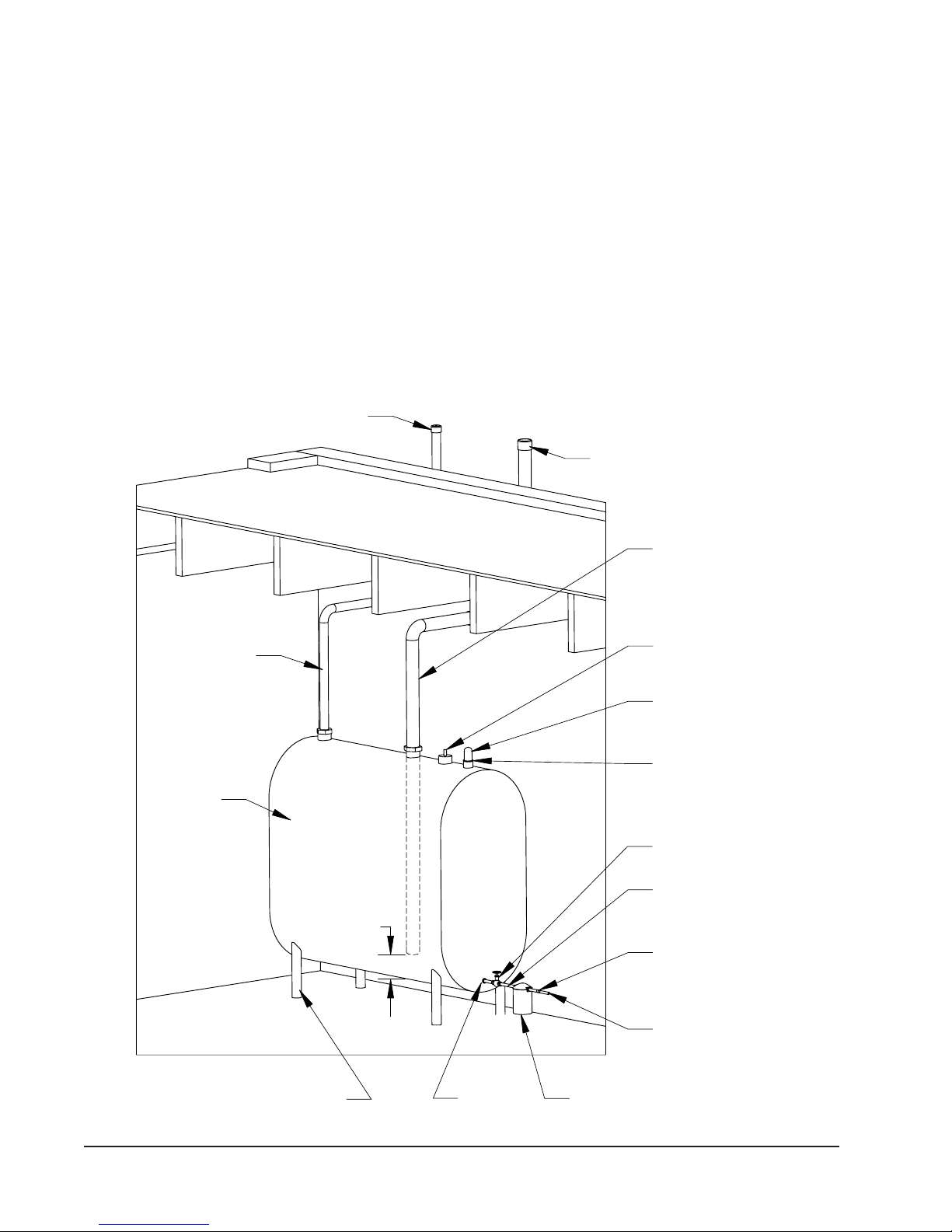

OIL LINE PIPING

First determine whether the pipe system is to be a

single line system or a two line system. All

connections must be absolutely air tight or you will

have a malfunction of the burner. When installing the

piping, a good oil filter should be installed close to the

burner. A single line system is recommended for

gravity feed.

A typical single inside tank installations shown in

Figure 6. For installation details for this and other tank

configurations, refer to NFPA31 -- latest edition. All

tank and pipe setups must comply with NFPA31.

TYPICAL SINGLE INSIDE TANK INSTALLATION

Vent Cap

BECKETT AFG OR NX OIL BURNER

This furnace is equipped with a high static Beckett AFG

or Beckett NX oil burner which is designed to produce

adequate draft in nearly any vertically vented

application. The burner employs the latest time tested

controls of the highest quality. The controls consist of a

high voltage Beckett solid state igniter, a Beckett

“CleanCut” oil pump with an integral solenoid valve,

and a Genisys 7505 primary control.

FIGURE 6

2" Cap

1-1/4"

Vent Pipe

Oil

Tank

2" Fill Pipe

Return Line

Guage

Bushing,

2" x 1-1/2" or

1-1/4"

Gate Valve

3/8" x 4"

nipple

6"

3/8" x 3/8"

Adapter

Legs (either 1-1/4"x10"

or 1-1/2"x10" nipples)

Manual 2100-540D

Page 12 of 45

Bushing

Oil Filter

3/8" O.D. Copper

Fuel Tubing

MIS-1823

Page 13

These controls were selected for their proven high

quality, dependability, and serviceability. With proper

maintenance this burner assembly will provide many

years of reliable service.

All units are shipped with the oil burner installed, and

with high rate oil nozzle installed designed for use with

No. 1 or No. 2 fuel oil. Inspect firepot refractory

before firing to be sure it has not been jarred out of

position in shipment. Burner air tube must not

extend beyond inside surface of firepot. Burner

head should be centered on the combustion chamber

opening.

WARNING

Never attempt to use gasoline in your

furnace. Gasoline is more combustible than

fuel oil and could result in a serious explosion

causing damage, injury or death.

BECKETT SOLID STATE IGNITER

This igniter differs from the traditional iron core

transformer in that it produces a 14,000 volt spark

instead of a 10,000 volt spark of the iron core

transformer. This hotter spark provides for cleaner,

faster ignitions. Being solid state technology this

igniter is less susceptible to problems caused by voltage

variations. It also has a greater ability to ignite cold

and/or inconsistent oil. The solid state igniter is wired

to the primary control the same as an iron core

transformer.

GENISYS 7505 PRIMARY CONTROL

The Genisys 7505 Interrupted Electronic Oil Primary is

a line voltage, safety rated, interrupted ignition oil

primary control for residential oil burners. The Genisys

7505 used with a cad cell flame sensor, operates the oil

burner and oil valve. The primary controls fuel oil,

senses flame, controls ignition spark and is designed to

notify a remote alarm circuit before going into lockout

when equipped with a flame monitoring system.

The following is a detailed explanation of each control

included in the Beckett AFG Oil Burner, how each

operates, how to set up the burner, and how to

troubleshoot problems should they occur.

BECKETT “CLEANCUT” OIL PUMP

This oil pump is equipped with an oil solenoid valve

installed in the pump housing. This feature provides

quick cutoffs resulting in reduction in smoke after the

burner shuts down. This is a time proven pump design

and is capable of both one and two pipe systems. All

installation and set up instructions are outlined in the

“Oil Pump Specification” section of the installation

instructions manual.

This primary control possesses the latest technology, is

a very simple control to operate and provides additional

troubleshooting features to ease service and reduce

down time. The operational guide for the Genisys 7505

primary control is provided following on Page 14.

Manual 2100-540D

Page 13 of 45

Page 14

BECKETT GENISYS

MODEL 7505

MIS-2491

PRIMARY OPERATIONAL GUIDE

BECKETT GENISYS 7505

Sequence of Operation

BURNER STATES

1. Standby: The burner is idle, waiting for a call

for heat.

2. Valve-On Delay (Prepurge): The igniter and

motor are on while the control delays turning on

the oil solenoid valve for the programmed time.

3. Trial for Ignition: The fuel valve is opened. A

flame should be established within the factory

set trial for ignition time (“lockout time”).

4. Lockout: The control has shut the burner down

for one of the following safety reasons:

• The trial for ignition (lockout) time expires

without flame being established.

• The cad cell detects flame during Valve-On

Delay.

• The Recycle mode 30-second time budget

expires (see “Recycle” section for complete

explanation of recycle time budget).

If the control locks out three times without

completing a successful call for heat, the control

enters Restricted (Hard) Lockout, and must be reset

by a technician. Hold the reset button for 15

seconds until the red light shuts off to reset from

Restricted Lockout.

5. Ignition Carryover: Once flame is established,

the igniter remains on for 10 additional seconds

to ensure flame stability.

6. Run: The flame is sustained until the call for

heat is satisfied. The burner is then sent to

Motor-Off Delay (Postpurge), if applicable, or it

is shut down and sent to Standby.

7. Recycle: If the flame is lost while the burner is

firing, the control shuts down the burner, enters

a 60-second recycle delay and then repeats the

ignition sequence. The control will continue to

Recycle each time the flame is lost until the

accumulated oil-flow-without-flame time

reaches 30 seconds, at which point the control

will go into lockout. This feature prevents

excessive accumulation of oil in the appliance

firing chamber.

8. Motor-Off Delay: If applicable, the fuel valve is

closed and the control delays turning the motor

off for the set motor-off delay time before the

control returns to standby.

9. Pump Prime: The igniter and motor are on with

the oil valve open for up to 4 minutes. During

Pump Prime mode, the cad cell is disregarded,

allowing the technician to prime the pump

without having to jumper the cad cell.

RESET BUTTON OPERATION

• Table A explains what action the control

will take when the reset button is pressed for

different lengths of time during the various

burner operating states.

Manual 2100-540D

Page 14 of 45

Page 15

TABLE A

RESET BUTTON OPERATION

ehtnisirenrubehtfI

:etatswoleb

kcilCnottuB

)dnoces1<sserp(

tuokcoLtuokcoLtfoSmorfteseR tuokcoL)draH(detcirtseRmorfteseR

,yaleDno-evlaV

,noitingIroflairT

revoyrraCnoitingI

)ffotuhssiretingi(nuR

ybdnatS,yaleDffO-rotoMnoitcaoN

emirPpmuPnoitcaoNybdnatSotnruterdnaedomemirPpmuPtixE

emirPpmuPotoG

)woleBees(

otsehsalfDELwolleY

.ecnatsiserllecdacetacidni

ecnatsiseRlleCdaC"eeS

foelbatrof"rotacidnI

.seulavecnatsiser

dloHnottuB

)dnoces1>sserp(

:renruBehtelbasiD

,gninnursirenrubehtemitynA

nottubteserehtdlohdnasserp

.renrubehtelbasidot

saffoniamerlliwrenrubehT

.dlehsinottubehtsagnol

TABLE B

STATUS LIGHTS

:lliwnottubteseRehtgnihsuP

dloHnottuB

)sdnoces+51sserp(

:gnimirPpmuPselbanE

rofdlehneebsahnottubteserehtretfA

ebnehtnacnottubeht,sdnoces51

ecneuqesnoitingitxenehtgniruddeppat

.edomemirPpmuPretneot

DEL

roloC

ylsuounitnoCnOgnihsalF

deRtuokcoL)drah(detcirtseRtuokcoLtfoS

neerG)thgilyartsroemalfebdluoC(detceteDemalFelcyceR

wolleY

edomemirPpmuPnisilortnoC ro

sdnoces+51rofdlehyltnerrucnottubteseR

"rotacidnIecnatsiseRlleCdaC"eeS.ecnatsiserlleCdaC

.seulavecnatsiserfoelbatrofnoitces

Manual 2100-540D

Page 15 of 45

Page 16

PRIMING THE PUMP

WARNING

Hot Gas Puff-Back & Heavy Smoke Hazard

Failure to bleed the pump properly could

result in unstable combustion, hot gas puffback and heavy smoke.

• Do not allow oil to spray into a hot combustion

chamber while bleeding air from the pump.

• Install a gauge in the nozzle discharge port

tubing or fully open the pump bleed valve to

prevent oil spray from accumulating in the

combustion chamber during the air bleed

procedure.

• Ensure that all bubbles and froth are purged

from the oil supply system before tightening the

pump air bleed valve.

5. At burner start up, tap the reset button within

the first 10 seconds of the ignition cycle. This

will transition the control to a dedicated Pump

Prime mode, during which the motor, igniter

and valve are powered for four minutes. The

yellow LED will be on.

6. Bleed the pump until all froth and bubbles are

purged. If desired, hold the reset button for at

least one second to exit Pump Prime mode and

return to Standby.

7. At the end of 4 minutes, the yellow LED will

turn off and the control will automatically return

to standby mode.

8. If prime is not established during the four

minute pump prime mode, return to step 5 to

re-enter Pump Prime mode. Repeat steps 5

through 7 until the pump is fully primed and the

oil is free of bubbles.

9. Terminate the call for heat, and the control will

resume normal operation.

1. Prepare the burner for priming by fully opening

the pump bleed port and attaching a clear

plastic hose over the bleed port fitting. Use a

suitable container to collect purged oil.

2. Initiate a call for heat.

3. After the burner starts, press and hold the reset

button for 15 seconds until the yellow LED

turns on. This indicates that the button has

been held long enough.

4. Release the reset button. The yellow LED will

turn off and the burner will start up again.

CAD CELL RESISTANCE INDICATOR

• During the burner Run state, tap the reset button

(less than 1 second) to check the cad cell

resistance range. The yellow LED will flash 1 to 4

times depending on the amount of light detected

by the cad cell. See chart below:

sehsalFDELwolleYegnaRnoitceteDemalF

1)smho004-0(lamroN

2)smho008-004(lamroN

3)smho0061-008(lamroN

4)tuokcoL-smho0061(detimiL

Manual 2100-540D

Page 16 of 45

Page 17

RESETTING FROM RESTRICTED LOCKOUT

• If the control locks out three times without a

satisfied call for heat, or due to other significant

events such as a relay contact weld, the Lockout

becomes restricted in order to prevent repetitious

resetting by the homeowner.

CAUTION

Before resetting the control from restricted

lockout state, troubleshoot the heating

system for the root cause(s) of lockout and

make necessary repairs or adjustment to

ensure a safe start condition.

• Then, to reset, hold the button down for 15

seconds until the red light turns off and the yellow

LED turns on. Observe at least one full control

sequence of operation from startup to shutdown.

Simulate a flame failure lockout by following the

procedure (within this manual). If the operation is

erratic, or not to specifications, then replace the

control. Always verify the control functions

according to all specifications before leaving the

installation site.

DISABLE FUNCTION

• Any time the burner is running, press and hold the

reset button to disable the burner. The burner will

remain off as long as the button is held.

Electronic Blower Control Interface

This furnace is equipped with an Electronic Blower

Control Interface, which through its set points

determines what the blower does with the 24 VAC

inputs from the home thermostat.

There are dip switches that control the ECM motor for:

1. Heating Airflow

2. Cooling Airflow

3. Heating On/Off Delay

4. A

+10% adjustment for heating airflows.

(See to Figure 7 for the location of these switches.)

The Electronic Blower Control Interface also

performs the additional functions of having a

diagnostic light, which indicates a safety limit is

open, and also has a relay which isolates the T-T

signal from the oil primary control.

Required 24 VAC inputs for various functions:

Continuous Blower: “R” to “G”

Heating with Oil Furnace: “R” to “W”

Cooling Single Stage: “R” to “G”, “Y1” & “Y2”

Cooling Two-Stage, Part Load: “R” to “G” & “Y1”

Cooling Two-Stage, Full Load: “R” to “G”, “Y1” & “Y2”

Heat Pump Single Stage: “R” to “G”, “Y1”, “Y2” & “O”

Heat Pump Two-Stage, Part Load: “R” to “G”, “Y1” & “O”

Heat Pump Two-Stage, Full Load: “R” to “G”, “Y1”, “Y2” & “O”

Burner Option – Flame Quality Monitor

This control is trained to recognize and remember a

good flame based on initial burner set up. Control

then monitors the flame via the CAD cell signal for

deviation in the combustion characteristics of the

burner. If the control senses a deviation on the high

side or on the low side from the original set up

condition for three consecutive cycles, it will trigger

an alarm circuit which can be tied to an audible local

device to signal the home owner or into the home

security system. Upon being notified of the alarm,

the security agency will notify the dealer of choice

based upon information supplied by the home

owner. The system will also be capable of being

connected to a phone line that will contact the dealer

directly with the alarm. This alarm will typically

sound 3 to 5 days prior to the primary control going

into lockout giving the service agency a prior notice

before a sooting condition or other failure can occur

resulting in untold savings. This monitor system is

available through your local distributor under the

Honeywell Part #QS7100F.

Manual 2100-540D

Page 17 of 45

Page 18

FIGURE 7

ELECTRONIC BLOWER CONTROL

COOLING SPEED

TAP SELECT

SWITCHES

HEATING SPEED

TAP SELECT

SWITCHES

HEATING BLOWER

DELAY SELECT

SWITCHES

+/- ADJUSTMENT

TAP SELECT

SWITCHES

CFM BLINK LIGHT

(100 CFM/BLINK)

LINE VOLTAGE

"HOT"

LINE VOLTAGE

"NEUTRAL"

CONNECTION

HUMIDIFIER 120 VAC

LINE VOLTAGE OUTPUT

TERMINAL (ENERGIZES

WITH OIL BURNER MOTOR)

TRANSFORMER

24V SECONDARY

CONNECTIONS

3 AMP FUSE

LIMIT LIGHT

REMOVE FACTORY INSTALLED

JUMPER WIRE FOR 2-STAGE AIR

CONDITIONER OR HEAT PUMP

INPUT SIGNAL

LIGHTS

THERMOSTAT CONNECTIONS

MIS-2869

Manual 2100-540D

Page 18 of 45

Page 19

TABLE C

HEATING TAP SELECT SETTINGS BY MODEL

ledoMtupnIHPGretteLpaT1#hctiwS2#hctiwS

A24V580CF

A24V580HFBNOFFO5301

A24V580FLF56.0CFFONO039

A24V580RLF55.0DNONO097

A84V011HF

A84V011FLF

A84V011RLFDNONO0601

A06V011HF

A06V011FLF

A06V011RLFDNONO0601

A06V041RLF

57.0

00.1

58.0

00.1

58.0

52.1

01.1

A FFO FFO 5701

A FFO FFO 0821

BNOFFO5221

CFFONO0601

A FFO FFO 0821

BNOFFO5221

CFFONO0601

A FFO FFO 0681

BNOFFO0971

CFFONO5461

DNONO5461

TABLE D

COOLING TAP SELECT SETTINGS BY MODEL

MFCgnitaeH

).P.S.E"5.0-"0(

COLUMN A COLUMN B COLUMN C

HPG

ledoM

A24V580CF

A24V580HFBNOFFO3 0021058006

A24V580FLF56.0C FFONO5.20001527005

A24V580RLF55.0D NONO2 008575004

A84V011HF

A84V011FLF

A84V011RLFDNONO5.20001527005

A06V011HF

A06V011FLF

A06V011RLFDNONO3 0021058006

A06V041RLF

paT

tupnI

57.0

00.1

58.0

00.1

58.0

52.1

01.1

retteL1#hctiwS2#hctiwS

A FFO FFO 5.3 0041 0001 007

A FFO FFO 4 0061 0511 008

BNOFFO5.300410001007

CFFONO3 0021058006

A FFO FFO 5 0002 0541 0001

BNOFFO4 00610511008

CFFONO5.300410001007

A FFO FFO 5 0002 0541 0001

BNOFFO4 00610511008

CFFONO5.300410001007

DNONO3 0021058006

lanimoN

gnilooC

egannoT

gnilooC

MFCdaoLlluF

).P.S.E"5.0-"0(

gnilooC

MFCdaoLtraP

).P.S.E"5.0-"0(

MFC

Note: Part Load Airflow for 2-stage A/C or HP systems is achieved when removing the factory installed jumper

wire on the Electronic Blower Control Interface Board that is (installed) between the thermostat connection

screws “Y2” and “Y1” dependent upon the tap selected. This allows for 2-stage A/C or HP systems to be installed

with this product. (See Figure 7 or the Wiring Diagrams.)

ylnOrewolB

lanimreT"G"

For 1-stage compressor systems requiring lower airflow than shown in Column A, remove “Y1-Y2” jumper to

achieve Column B airflow delivery.

Manual 2100-540D

Page 19 of 45

Page 20

TABLE E

ADJUSTMENT TAP SELECTS

ledoMretteLpaT1#hctiwS2#hctiwSnoitcnuF

AFFOFFOegnahCoN

LLA

BNOFFOwolfriAgnitaeH%01+

CFFONOwolfriAgnitaeH%01-

DNONOegnahCoN

TABLE F

HEATING DELAY PROFILE TAPS

nuR-erP

paT

ledoM

LLA

retteL1#hctiwS2#hctiwS

AFFOFFO030060500328

BNOFFO0300605042001

CFFONO540 0210500388

DNONO0600 001081001

yaleDnO

sdnoceS

yaleDnO

MFC%

emiT

sdnoceS

nuR-erP

MFC%

yaleDffO

sdnoceS

yaleDffO

MFC%

Manual 2100-540D

Page 20 of 45

Page 21

,gnitaeHpmuP

taeHegatS-2

daoLlluF

2

,gnitaeHpmuP

taeHegatS-2

daoLtraP

2

egatSelgniS

pmuPtaeH

gnitaeH

1

pmuPtaeHegatS-2

,gnilooC

daoLlluF

2

,gnilooCpmuP

taeHegatS-2

daoLtraP

2

XXXXX

TROUBLESHOOTING GE ECM 2.3™ MOTORS

egatSelgniS

pmuPtaeH

gnilooC

1

,gnilooC

daoLlluF

egatS-2

2

,gnilooC

daoLtraP

egatS-2

2

gnilooC

elgniS

egatS

1

ecanruF

liO

suounitnoC

rewolB

FFO

tatsomrehT

noitarepO

foedoM

.dezigrenEsyawlA;langiS)nommoC("C"CAV42

— "G" "W" "1Y","G" "1Y","G" "2Y","1Y","G" "O","1Y","G" "O","1Y","G" "O","2Y","1Y","G" "O","1Y","G" "O","1Y","G" "O","2Y","1Y","G"

tupnICAV42

slangiS

1#niP

.dezigrenEsyawlA;langiS)nommoC("C"CAV42

2#niPX

3#niP

.)egannoT(sgnitteSnopUdesaBslangiSevaW-flaHdeiraV;selbaTtceleSpaTlooC

.sgnitteSnopUdesaBslangiSevaW-flaHdeiraV;seliforPpaTtnemtsujdA

.sgnitteSnopUdesaBslangiSevaW-flaHdeiraV;seliforPpaTyaleD

.MFCotnoitalerroCtceriDnituptuO"-"stloVCD

XXXXXXXXX

4#niP

5#niP

6#niP

7#niP

8#niP

9#niP X

.egannoTnopUdesaBslangiSevaW-flaHdeiraV;selbaTtceleSpaTtaeH

XXXXX

.noitcnuFrofdemmargorPyltnerruCtoN;esUerutuF

.dezigrenEsyawlA;langiS"R"toHCAV42

.sruccOpirTtimiLnehWdezigrenE

11#niP

01#niP

21#niP

31#niP

41#niPX

.MFCotnoitalerroCtceriDnituptuO"+"stloVCD

51#niP X XXXXXXXXX

61#niP

16-PIN BLOWER TAP SELECT CONTROLS - OUTPUTS BASED UPON MODE

1 .ecafretnIrewolBdetargetnInodellatsnieriwrepmuj"2Y"ot"1Y"seriuqeR

2 .ecafretnIlortnoCrewolBcinortcelEnoeriwrepmuj"2Y"ot"1Y"dellatsnIyrotcaFfolavomerseriuqeR

Manual 2100-540D

Page 21 of 45

Page 22

TROUBLESHOOTING GE ECM 2.3

™

MOTORS

CAUTION:

Disconnect power from unit before removing or replacing

connectors, or servicing motor. To avoid electric shock

from the motor’s capacitors, disconnect power and wait at

least 5 minutes before opening motor.

Symptom Cause/Procedure

Motor rocks slightly • This is normal start-up for ECM

when starting

Motor won’t start • Check blower turns by hand

• No movement

• Motor rocks, • Check for loose or compliant motor mount

but won’t start

Motor oscillates up • It is normal for motor to oscillate with no

load & down while being on shaft

tested off of blower

Motor starts, but

runs erratically

• Varies up and down • Check line voltage for variation or “sag”

or intermittent • Check low voltage connections

• “Hunts” or “puffs” at • Does removing panel or filter reduce

high CFM (speed) “puffing”?

• Stays at low CFM • Check low voltage (Thermostat) wires and

despite system call connections

for cool or heat CFM • Verify fan is not in delay mode; wait until

• Stays at high CFM • “R” missing/not connected at motor

• Blower won’t shut off •

Excessive noise • Determine if it’s air noise, cabinet, duct or

• Air noise • High static creating high blower speed?

• Check power at motor

• Check low voltage (24 Vac R to C) at motor

• Check low voltage connections

(G, Y, W, R, C) at motor

• Check for unseated pins in connectors on

motor harness

• Test with a temporary jumper between R - G

• Check motor for tight shaft

• Perform motor/control replacement check

• Perform Moisture Check

• Make sure blower wheel is tight on shaft

• Perform motor/control replacement check

(G, Y, W, R, C) at motor, unseated pins in

motor harness connectors

• Check “Bk” for erratic CFM command (in

variable-speed applications)

• Check out system controls, Thermostat

• Perform Moisture Check

- Reduce restriction

- Reduce max airflow

delay complete

• “R” missing/not connected at motor

• Perform motor/control replacement check

• Is fan in delay mode? - wait until delay time

complete

• Perform motor/control replacement check

Current leakage from controls into G, Y or W?

Check for Triac switched thermostat or solid state relay

motor noise; interview customer, if necessary

- Is airflow set properly?

- Does removing filter cause blower to slow

down? Check filter

- Use low-pressure drop filter

- Check/correct duct restrictions

Symptom Cause/Procedure

• Noisy blower or cabinet • Check for loose blower housing, panels, etc.

• “Hunts” or “puffs” at • Does removing panel or filter reduce

high CFM (speed)

Evidence of Moisture

• Motor failure or • Replace motor and

malfunction has occurred

and moisture is present

• Evidence of moisture • Perform Moisture Check

present inside air mover

• High static creating high blower speed?

- Check for air whistling through seams in

ducts, cabinets or panels

- Check for cabinet/duct deformation

“puffing”?

- Reduce restriction

- Reduce max. airflow

Perform Moisture Check

Do Don’t

• Check out motor, controls, • Automatically assume the motor is bad.

wiring and connections

thoroughly before replacing

motor

• Orient connectors down so • Locate connectors above 7 and 4 o’clock

water can’t get in positions

- Install “drip loops”

• Use authorized motor and • Replace one motor or control model # with

model #’s for replacement another (unless an authorized replacement)

• Keep static pressure to a • Use high pressure drop filters some have

minimum: H20 drop!

- Recommend high • Use restricted returns

efficiency, low static filters

- Recommend keeping filters

clean.

- Design ductwork for min.

static, max. comfort

- Look for and recommend

ductwork improvement,

where necessary

• Size the equipment wisely • Oversize system, then compensate with low

• Check orientation before • Plug in power connector backwards

inserting motor connectors • Force plugs

airflow

Moisture Check

• Connectors are oriented “down” (or as recommended by equipment

manufacturer)

• Arrange harness with “drip loop” under motor

• Is condensate drain plugged?

• Check for low airflow (too much latent capacity)

• Check for undercharged condition

• Check and plug leaks in return ducts, cabinet

Comfort Check

• Check proper airflow settings

• Low static pressure for lowest noise

• Set low continuous-fan CFM

• Use humidistat and 2-speed cooling units

• Use zoning controls designed for ECM that regulate CFM

• Thermostat in bad location?

½"

Manual 2100-540D

Page 22 of 45

Page 23

TROUBLESHOOTING GE ECM

™

MOTORS CONT’D.

Replacing ECM Control Module

To replace the control module for the GE variable-speed indoor blower

motor you need to take the following steps:

1. You MUST have the correct replacement module. The controls are

factory programmed for specific operating modes. Even though they look

alike, different modules may have completely different functionality.

USING THE WRONG CONTROL MODULE VOIDS ALL PRODUCT

WARRANTIES AND MAY PRODUCE UNEXPECTED RESULTS.

2. Begin by removing AC power from the unit being serviced. DO NOT

WORK ON THE MOTOR WITH AC POWER APPLIED. To avoid

electric shock from the motor’s capacitors, disconnect power and wait at

least 5 minutes before opening motor.

3. It is not necessary to remove the motor from the blower assembly, nor

the blower assembly from the unit. Unplug the two cable connectors to the

motor control assembly. There are latches on each connector. DO NOT

PULL ON THE WIRES. The plugs remove easily when properly

released.

4. Locate the screws that retain to t

sheet metal of the unit and remove them. Remove two (2) nuts that

retain the control to the bracket and then remove two (2) nuts that

retain sheet metal motor control end plate. Refer to Figure 8.

5. Disconnect the three (3) wires interior of the motor control by

using your thumb and forefinger squeezing the latch tab and the

opposite side of the connector plug, gently pulling the connector. DO

NOT PULL ON THE WIRES, GRIP THE PLUG ONLY. Refer to

Figure 8.

6. The control module is now completely detached from the motor.

Verify with a standard ohmmeter that the resistance from each motor

lead (in the motor plug just removed) to the motor shell is >100K

ohms. Refer to Figure 9. (Measure to unpainted motor end plate.) If

any motor lead fails this test, do not proceed to install the control

module. THE MOTOR IS DEFECTIVE AND MUST BE

REPLACED. Installing the new control module will cause it to fail

also.

he motor control bracket to the

7. Verify that the replacement control is correct for your

application. Refer to the manufacturer's authorized replacement list.

USING THE WRONG CONTROL WILL RESULT IN

IMPROPER OR NO BLOWER OPERATION. Orient the control

module so that the 3-wire motor plug can be inserted into the socket in

the control. Carefully insert the plug and press it into the socket until

it latches. A SLIGHT CLICK WILL BE HEARD WHEN

PROPERLY INSERTED.

8. Reverse the steps #5, 4, 3 to reconnect the motor control to the

motor wires, securing the motor control cover plate, mounting the

control to the bracket, and mounting the motor control bracket back

into the unit. MAKE SURE THE ORIENTATION YOU SELECT

FOR REPLACING THE CONTROL ASSURES THE

CONTROL'S CABLE CONNECTORS WILL BE LOCATED

DOWNWARD IN THE APPLICATION SO THAT WATER

CANNOT RUN DOWN THE CABLES AND INTO THE

CONTROL. DO NOT OVERTIGHTEN THE BOLTS.

9. Plug the 16-pin control plug into the motor. The plug is keyed.

Make sure the connector is properly seated and latched.

10. Plug the 5-pin power connector into the motor. Even though

the plug is keyed, OBSERVE THE PROPER ORIENTATION. DO

NOT FORCE THE CONNECTOR. It plugs in very easily when

properly oriented. REVERSING THIS PLUG WILL CAUSE

IMMEDIATE FAILURE OF THE CONTROL MODULE.

11.

Final installation check. Make sure the motor is installed as follows:

a. Motor connectors should be oriented between the 4 o’clock

and 8 o’clock positions when the control is positioned in its

final location and orientation.

b. Add a drip loop to the cables so that water cannot enter the

motor by draining down the cables. Refer to Figure 10.

The installation is now complete. Reapply the AC power to the

HVAC equipment and verify that the new motor control module is

working properly. Follow the manufacturer's procedures for

disposition of the old control module.

Only remove

Hex Head Bolts

ECM 2.0

Note:

Use the shorter

bolts and

alignment pin

supplied when

replacing an

ECM 2.0

control.

Figure 8

Figure 3

Control Disassembly

Push until

Latch Seats

Over Ramp

ECM

2.3/2.5

Hex-head Screws

From Motor

Circuit

Board

Motor

Motor Conne c tor

(3-pin)

Control Connector

(16-pin)

Power Connector

(5-pin)

Motor Connector

(3-pin)

Back of

Control

Figure 9

Figure 4

Winding Test

Motor OK when

R > 100k ohm

Figure 10

Figure 5

Drip Loop

Connector Orientation

Between 4 and 8 o'clock

Drip Loop

Manual 2100-540D

Page 23 of 45

Page 24

TABLE 4

FURNACE DATA

ledoM

rebmuN

A24V580CF

A24V580HF

A84V011HF

A06V011HF

A24V580FLF

A84V011FLF

A06V011FLF

A24V580RLF

A84V011RLF

A06V011RLF

A06V041RLF

renruB

epyT

GFAwolfretnuoC

GFAyoB-iH

XNyoB-iH

XNyoB-iH

GFAyoB-oL

XNyoB-oL

XNyoB-oL

GFAyoB-oL

GFAyoB-oL

GFAyoB-oL

GFAyoB-oL

ecanruF

epyT

eziSepyTerusserPpmuP

57.0 *

56.0000,19000,67

55.0000,77000,46

57.0 *

56.0000,19000,67

55.0000,77000,46

58.0 *

57.0000,911000,99

58.0 *

57.0000,911000,99

57.0 *

56.0000,19000,67

55.0000,77000,46

58.0 *

57.0000,911000,99

58.0 *

57.0000,911000,99

57.0 *

56.0000,19000,67

55.0000,77000,46

00.1 *

58.0000,911000,99

00.1 *

58.0000,911000,99

52.1 *

01.1000,451000,721

elzzoN

wolloH°07GISP001

wolloH°07GISP001

diloS°06GISP051

diloS°06GISP051

wolloH°07GISP001

diloS°06GISP051

diloS°06GISP051

wolloH°07GISP001

wolloH°07GISP001

wolloH°07GISP001

wolloH°07GISP001

gnitaeH

tupnI

HUTB

000,501 000,78

000,501 000,78

000,041 000,611

000,041 000,611

000,501 000,78

000,041 000,611

000,041 000,611

000,501 000,78

000,041 000,611

000,041 000,611

000,571 000,541

gnitaeH

tuptuO

HUTB

* Factory Installed Nozzle. Also shown are optional approved nozzle size/type.

BURNER SETUP AND ADJUSTMENT

PROCEDURES

All oil burner installations should be performed by a

qualified installer in accordance with regulations of the

National Fire Protection Standard for Oil-Burning

Equipment, NFPA31 -- latest edition, and in complete

compliance with all local codes and authorities having

jurisdiction. A qualified installer is an individual or

agency who is responsible for the installation and

adjustments of the heating equipment and who is

properly licensed and experienced to install oil-burning

equipment in accordance with all codes and ordinances.

The proper installation and adjustment of any oil burner

requires technical knowledge and the use of combustion

test instruments. The following procedure must be

followed to correctly adjust the burner to match the

specific characteristics of the installation.

Manual 2100-540D

Page 24 of 45

IMPORTANT

Always use combustion test instruments when

making burner adjustments and draft gauge

when setting the barometric damper. It is

virtually impossible to make accurate and

reliable adjustments using the “eyeball” method.

Check all oil lines and connections for leaks.

Connect pressure gauge by removing bleed fitting and

screwing in pressure gauge. See Figure 12.

Page 25

1. PREPARATION STEPS

A. Calibrate and Check Operation of

Measuring Equipment Follow

manufacturer’s recommended procedures for

calibration and equipment check out.

B. Prepare Heating Unit for Testing Drill two

1/4 inch holes in the flue between the heating

plant and the barometric draft regulator. If

space permits, the holes should be located in a

straight section of the flue, at least two flue

diameters from the elbow in the flue pipe and

at least one diameter from the draft regulator.

The purpose of the two holes in the flue pipe is

to speed up testing and reduce instrument

handling.

C. Clean and Seal Heating Plant Make sure the

burner blast tube, fan housing, and blower

wheel are clear of dirt and lint. Seal any air

leaks into the combustion chamber.

D. Nozzle Inspection Annual replacement of

nozzle is recommended. The nozzle size

should match the design load. DO NOT

OVERSIZE. (Determination of oversizing can

be determined prior to your adjustment. If the

firing rate should be reduced refer to Table 4.)

Short cycles and low percent “on” time result

in higher overall pollutant emissions and lower

thermal efficiency. An in-line oil filter will

reduce service problems due to nozzle

clogging.

The filter should be located as close as possible

to the oil burner. Care should be taken to

prevent air leakage in the oil suction line. Use

continuous runs of copper tubing and use

minimum number of joints and fittings.

Always use flare fittings.

E. Adjustment of Electrodes Adjust ignition

electrodes as specified in Figures 13A & 13B.

F. Operate Burner Operate burner, adjust air

setting for good flame by visual observation,

and run for at least 10 minutes or until

operation has stabilized.

G. Check Burner Pressure Bleed air from

pump and nozzle piping. Check pump

pressure and adjust to nameplate pump

pressure, if necessary.

2. COMBUSTION ADJUSTMENT STEPS

H. Set Draft Check the draft reading over the

fire with a draft gauge through a hole in the

inspection door. The hole is above the flame

level. Adjust the barometric draft regulator on

the flue to give the over fire of -.02" W.C.

I. Check Smoke Readings After burner has

been operating 5 or 10 minutes, take a smoke

measurement in the flue, following the smoke

tester instructions. Oily or yellow smoke spots

on the filter paper are usually a sign of

unburned fuel, indicating very poor combustion

(and likely high emissions of carbon monoxide

and unburned hydrocarbons). This condition

can sometimes be caused by too much air, or by

other factors. If this condition cannot be

corrected, major renovation or even burner

replacement may be necessary.

J. Develop Smoke - CO2 Curve Record

measurements of smoke and CO

Then establish the smoke - CO

from the flue.

2

curve by taking

2

readings over a range of air settings, as shown

in Figure 11.

To do this, start with the air gate set at nearly

full open and then take smoke and CO

readings at progressively lower air settings, as

necessary to visualize the general shape of the

curve. (The CO2 readings will increase as the

air setting is decreased, unless combustion is

incomplete.) Do not set the air gate to give a

smoke reading above No. 4 or No. 5. Plot the

points on graph paper, as in Figure 11. Usually

3 or 4 readings are enough to establish the

curve.

In adjusting each air setting, it is helpful to note

the various positions of air gate at which

measurements are made so that the final setting

can be located quickly.

K. Adjust Air Setting Examine the smoke - CO

plot and, keeping in mind the curve of Figure 11,

note the location of the “knee” where the smoke

number begins to rise sharply. Noting the air

gate position marks, adjust the air setting to a

CO2 level 1/2 to 1 percent lower than the CO

level at the “knee”. (This provides a tolerance

against possible shifts in the setting over a

period of time.) Do not increase the air setting

any more than necessary on the lower portion

of the curve below the “knee”.

The characteristic curve for some burners may

not yield a distinct “knee” in the curve. In such

cases, the setting should be made near the

minimum smoke, (using judgement).

Lock the air adjustment and repeat draft,

CO2 and smoke measurements to make sure

the setting has not shifted.

3. COMBUSTION DIAGNOSIS

L. Check Performance A well-matched and

well-tuned burner should be capable of

operation with smoke not greater than No. 2

and at a CO2 level not less than 10%.

If this cannot be reached, check the following:

2

2

2

Manual 2100-540D

Page 25 of 45

Page 26

1. Air leaks into the combustion chamber or

heat exchanger can dilute the combustion

gases and prevent normal CO

readings.

2

Such leaks should be sealed with furnace

cement or other high-temperature sealant.

To check for dilution by leakage, measure

the CO2 at as high a point as possible over

the fire, using a stainless steel tube

inserted through the fire door sample hole

(as described earlier for overfire draft

measurements), and compare this with the

CO2 measured in the flue. A difference of

more than 1 percent CO2 between the flue

and overfire reading usually indicates air

entry through leaks that have not been

properly sealed.

Seal between the probe and inspection door

sample hole during test. The inspection

door hole should be sealed when not being

used to avoid leakage of air through it.

(See Step H.)

2. If the CO2 level of 10% cannot be reached

without exceeding No. 2 smoke, poor

mixing of air and fuel is likely.

It may be necessary to replace the

combustion head or try different settings.

4. FINAL CHECKS

M. Measure Stack Temperature Operating the

unit at an excessive firing rate will generate

more heat than the heat exchanger can utilize

and result in unnecessary heat loss up the

chimney. Other causes of excessive heat loss

are badlysooted heat exchanger surfaces and

excessive draft. The temperature of the flue gas

provides an indication of these heat losses.

SHORT FORM ADJUSTMENT

PROCEDURE

Some burner service organizations may wish to

perform a shorter procedure for the adjustment of oil

burners. The following is an example of such a short

form prepared by the National Association of Oil Heat

Service Managers.

1. SERVICE AND CLEAN BURNER

Follow company procedure to complete the

cleaning and servicing. Operate burner for ten

minutes while tools are gathered and are cleaned.

2. CHECK DRAFT

Set draft regulator, if necessary. Regulator should

be adjusted to achieve a -.02" W.C. over fire

condition. The more restricted and lengthy the

flue, the higher the draft necessary to obtain the

accepted over fire conditions.

3. SMOKE TEST

Follow the instructions of the manufacturer of the

smoke tester and take a smoke sample. Adjust the

air to obtain a preliminary reading of about No. 3

spot. Then readjust the air to obtain the lowest

possible reading, but do not open the air adjustment

more than absolutely necessary to obtain a trace or

No. 0 spot.

4. CO2 TEST

Check CO2 levels. This level should be between

10% and 12%.

Measure flue temperature by subtracting the

room air temperature from the thermometer

reading. Excessive stack loss is indicated if the

net stack temperature during steady operation

exceeds 600°F.

N.

Check Ignition Check operation over repeated

cycles to ensure prompt ignition on starting.

O. Check Pump Cutoff Slow pump cutoff at the

end of a firing cycle can cause smoke and other

pollutant emissions. Check for prompt pump

cutoff by observing flame or by testing smoke

at shutdown. If poor cutoff is observed, make

sure air is purged from the pump and nozzle

line. Air trapped in the pump or nozzle line

will expand when heated, thus causing oil to

drip into the combustion chamber after

shutdown. If poor cutoff persists, repair or

replace pump. Also make sure the pump

solenoid is working - if not replace.

Manual 2100-540D

Page 26 of 45

Page 27

TYPICAL SMOKE – CO

FIGURE 11

CHART WITH ADJUSTMENT RANGE

2

High

8

6

Normal

adjustment

4

range

Tolerance

Bacharach Smoke Number

to "knee"

"Best" air

2

setting

Plotted point

0

6

8

Air Settings

Plotted point

"Knee"

10

Percent CO in Flue Gas

2

12

CO Curve

from plotted

points

Plotted point

Low

2

14

8

6

4

Bacharach Smoke Number

2

0

6

810

12

Percent CO in Flue Gas

2

Technician's

plotting area

14

MIS-1827

Manual 2100-540D

Page 27 of 45

Page 28

FIGURE 12

PRESSURE GAUGE CONNECTION TO BLEED PORT

Remove Bleed

Port to attach

pressure guage.

Manual 2100-540D

Page 28 of 45

Pressure Gauge

MIS-1660

Page 29

TABLE 5 — CORRELATION OF PERCENT OF CO2, O2 AND RESERVE AIR

edixoiDnobraCnegyxO).xorppA(riAevreseR

4.51

0.51

5.41

0.41

5.31

0.31

5.21

0.21

5.11

0.11

5.01

0.01

0.0

6.0

2.1

0.2

6.2

3.3

0.4

6.4

3.5

0.6

7.6

4.7

0.0

0.3

0.6

0.01

0.51

0.02

0.52

0.03

0.53

0.04

0.54

0.05

TABLE 6 — NO. 2 FUEL OIL EFFICIENCY CHART (NET STACK TEMP. DEGREES F)

2

O%

16.984.883.782.681.580.489.287.186.085.974.873.772.677.41

24.982.880.789.587.486.384.282.181.089.877.776.674.570.41

32.989.787.685.583.481.389.187.084.972.870.778.576.472.31

49.887.784.681.588.386.283.180.087.875.772.679.476.375.21

57.883.780.686.483.380.286.083.979.776.673.579.376.277.11

64.880.785.581.487.283.189.975.870.776.572.478.274.170.11

70.885.680.585.380.285.080.975.770.675.470.375.170.073.01

002052003053004054005055006056007057008O%

2

TABLE 7 — RECOMMENDED START-UP SETTINGS

ledoM

rebmuN

A24V580CF

A24V580HF

A84V011HF

A06V011HF

A24V580FLF

A84V011FLF

A06V011FLF

A24V580RLF

A84V011RLF

A06V011RLF

A06V041RLF

elytSrenruB

.oNtraP

eziSepyTerusserPpmuP

57.0 *

040-0209/GFA

56.005—

55.005—

57.0 *

040-0209/GFA

56.005—

55.005—

58.0 *

440-0209/XN

57.0——3

58.0 *

440-0209/XN

57.0——3

57.0 *

040-0209/GFA

56.005—

55.005—

58.0 *

440-0209/XN

57.0——3

58.0 *

440-0209/XN

57.0——3

57.0 *

140-0209/GFA

56.005—

55.005—

00.1 *

240-0209/GFA

58.008—

00.1 *

240-0209/GFA

58.008—

52.1 *

340-0209/GFA

01.106—

elzzoN

wolloH°07GISP001

wolloH°07GISP001

diloS°06GISP051

diloS°06GISP051

wolloH°07GISP001

diloS°06GISP051

diloS°06GISP051

wolloH°07GISP001

wolloH°07GISP001

wolloH°07GISP001

wolloH°07GISP001

0 6 —

0 6 —

— — 57.3

— — 57.3

0 6 —

— — 57.3

— — 57.3

0 6 —

2 01 —

2 01 —

0 8 —

dnaBriA

gnitteS

riA

rettuhS

gnitteS

riA

tnemtsujdA

etalP

gnitteS

* Factory Installed Nozzle. Also shown are optional approved nozzle size/type.

Manual 2100-540D

Page 29 of 45

Page 30

SPACING OF ELECTRODES

The electrodes should be spaced 5/32" apart. They

should extend 1/16" beyond the end and 5/16" above the

center of the nozzle tip as shown in Figures 13A & 13B.

GUN ASSEMBLY ADJUSTMENT

The gun assembly can be adjusted in the slot inside of

fan housing by loosening screw holding slot cover in

position. Nozzle tip should ordinarily be located 1-1/8"

behind the front face of the cone.

REMOVING GUN ASSEMBLY

Disconnect the oil line at the fan housing and remove

lock nuts on copper tube fitting. Loosen igniter hold

down clamps, then swing igniter up and backward. Gun

assembly can now be removed through this opening.

FIGURE 13A

ELECTRODE ADJUSTMENTS — AFG BURNERS

COMBUSTION AIR REQUIREMENTS

This furnace must be installed in a location where a

sufficient supply of combustion air is available for the

complete combustion of the fuel oil. Keep in mind that a

certain amount of excess air is required as well to ensure

complete combustion of the fuel oil.

When structures are constructed too tightly to supply

sufficient combustion air, air from outside the structure

is required to be brought in directly to the furnace. This

furnace has been conveniently designed to accept a

combustion air boot which is attached directly to the

outdoors by means of a 4" pipe. This pipe can be rigid or

flexible, but it is recommended that a metallic material

be used. Refer to Figure 14. The air boot used for this

design is a Field Controls model number CAS-2B-90E

that can be purchased through your local distributor.

Follow all installation procedures as specified in the

instructions packaged with the air boot kit.

NOTE - This accessory is not currently available for

Bard Models: FH110V48A, FH110V60A,

FLF110V48A and FLF110V60A with NX burners.

ELECTRODE ADJUSTMENTS — NX BURNERS

Manual 2100-540D

Page 30 of 45

FIGURE 13B

Page 31

FIGURE 14

KNOCKOUT

AIR BOOT

FOR OIL LINE

BOOT AND SECURE

INSERT OUTER AIR

USE THIS

ASSEMBLE INNER

FLANGE TO UNIT

FOR AIR BOOT.

ACCORDING TO MANUAL

IN LEFT SIDE

REMOVE KNOCKOUT

MAKE ALL SETTINGS

REMOVE PUMP TO

INTAKE

AIR

TUBE

MIS-1833

AFG BURNER

COMBUSTION

AIR BOOT

ASSEMBLY

AFG

BURNER

ASSEMBLY

COMBUSTION AIR BOOT ASSEMBLY

Note: This accessory is not currently available for Bard Models:

FH110V48A, FH110V60A, FLF110V48A, FLF110V60A with NX Burners

Manual 2100-540D

Page 31 of 45

Page 32

APPLIANCES LOCATED IN CONFINED

SPACES

In unconfined spaces in buildings, infiltration may be

adequate to provide air for combustion, ventilation, and

dilution of flue gases. However, in buildings of

unusually tight construction, additional air shall be

provided using the method described under “All Air

From Outdoors” in Figure 16.

An unconfined space (such as an open basement) must

have a minimum volume of 50 cubic feet per 1,000

BTUH of total of all appliances in area. Adjoining

rooms may be counted as one area only if there are not

doors between the rooms.

Shown in Table 8 are the required minimum areas in

square feet to qualify as an unconfined space for

various total BTUH input ratings. The table is based

on a room(s) with 8 foot ceiling heights.

If the unconfined space is within a building having

insufficient air because of tight construction, the air for

combustion and ventilation shall be obtained from

outdoors or from spaces freely communicating with the

outdoors. Under these conditions a permanent opening

or openings have a total free area of not less than one

square inch per 5,000 BTU per hour (28 square inches

per hour ) of total input rating of all appliances shall be

provided. For combustion air options see “Combustion

Air Requirements”.

FIGURE 15

APPLIANCES LOCATED

IN CONFINED SPACES

ALL AIR FROM INSIDE THE BUILDING

TABLE 8

SQUARE FEET REQUIRED TO

QUALIFY AS UNCONFINED SPACE

latoT

HUTB

tupnI

000,06

000,08

000,58

000,501

000,511

000,021

000,041

000,541

000,061

000,002

573

005

135

656

917

057

578

609

0001

0521

ecapSdenifnocnU

nIaerAmuminiM

teeFerauqS

thgieHgnilieC'8

ALL AIR FROM INSIDE BUILDING

The confined space shall be provided with two

permanent openings, one near the top of the enclosure

and one near the bottom. Each opening shall have a

free area of not less than one square inch per 1,000

BTU per hour (140 square inches per gallon per hour)

of the total input rating of all appliances in the

enclosure freely communicating with interior areas

having in turn adequate infiltration from the outside.

(See Figure 15.) Also see Table 9 on the following

page for specific ventilation opening requirements for

the furnace only.

Manual 2100-540D

Page 32 of 45

The flow of combustion and ventilating air must not

be obstructed from reaching the furnace.