Bard D28A2PA, D36A2PA, D35A2PA, D28A2PB, D36A2PB Installation And Service Instructions Manual

...Page 1

INSTALLATION AND

SERVICE INSTRUCTIONS

DUAL-TEC™

WALL-MOUNT PACKAGE

AIR CONDITIONER

Models:

D25A2PA

D28A2PA

D28A2PB

D35A2PA

D35A2PB

D36A2PA

D36A2PB

D42A2PA

D42A2PB

D48A2PA

D48A2PB

D60A2PA

D60A2PB

D25L2PA

D25L2PB

D28L2PA

D28L2PB

D35L2PA

D35L2PB

D36L2PA

D36L2PB

Part of the Bard DC Free Cooling Unit System

NOTE: LC Series Controllers must be used with

D-Series Wall-Mount Units

D42L2PA

D42L2PB

D48L2PA

D48L2PB

D60L2PA

D60L2PB

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-643C

Supersedes: 2100-643B

Date: 7-28-16

Page 1 of 59

Page 2

CONTENTS

SECTION 1: Installation Instructions ......................................................................................................... 5

List of Necessary Materials/Tools .........................................................................................................................6

Site Preparation .................................................................................................................................................7

Wall-Mount Unit Installation ...............................................................................................................................9

Wall-Mount Unit Supply Wiring ..........................................................................................................................15

Preliminary Start-Up .........................................................................................................................................19

SECTION 2: Service Instructions ............................................................................................................... 21

General Refrigerant Information .........................................................................................................................22

Sequence of Operation .....................................................................................................................................24

Using the TEC-EYE

Componentry Specifications ..............................................................................................................................30

Maintenance and Troubleshooting ......................................................................................................................38

SECTION 3: Appendix .................................................................................................................................. 45

Wall-Mount Unit Architecture ............................................................................................................................46

FIGURES AND TABLES

Figure 1.1 Wall-Mount Unit Model Nomenclature ......6

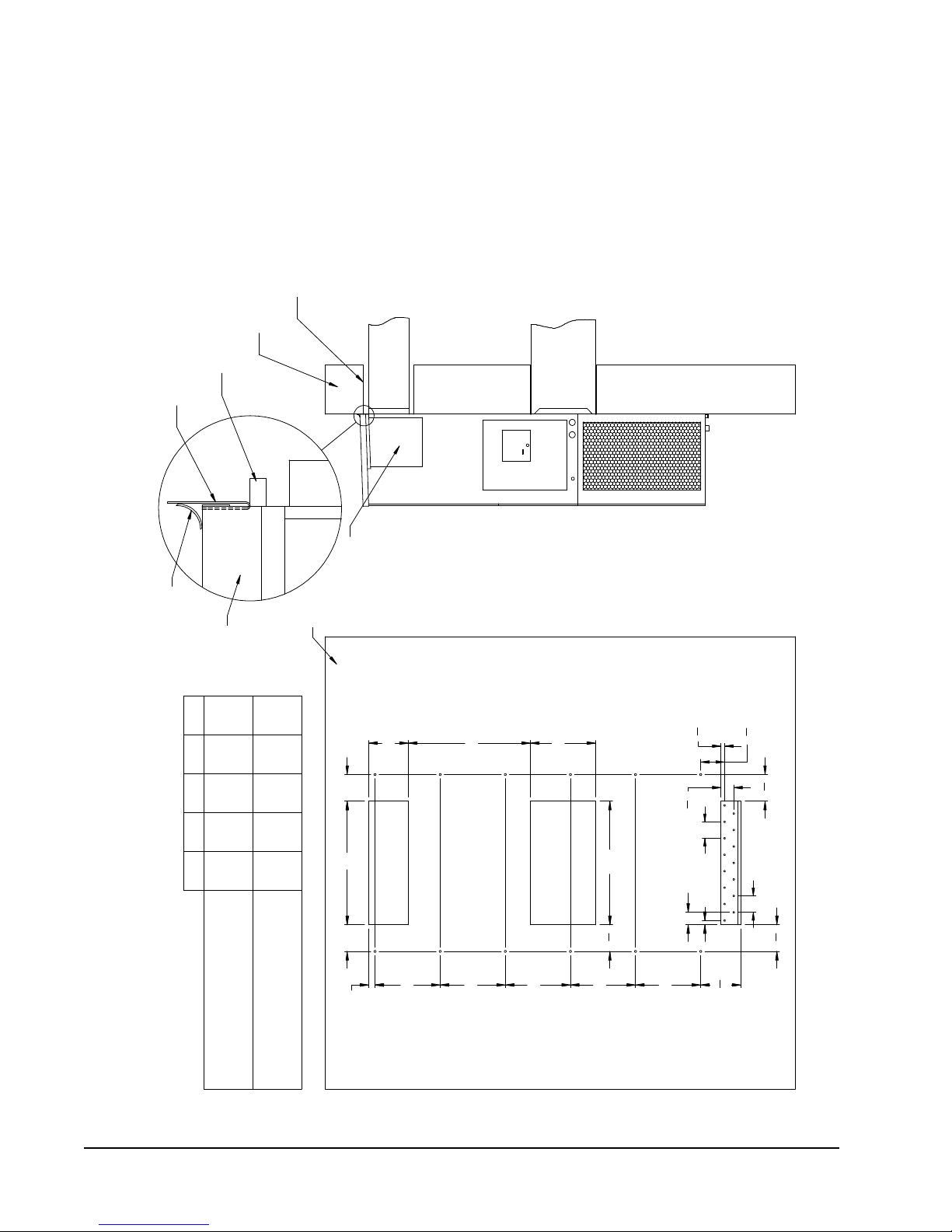

Figure 1.2 Dimensions ............................................8

Figure 1.3A D25A, D25L, D35A, D35L

Mounting Instructions ...........................10

Figure 1.3B D28A, D28L, D36A, D36L, D42A, D42L,

Mounting Instructions ...........................11

Figure 1.3C D48A, D48L, D60A, D60L

Mounting Instructions ...........................12

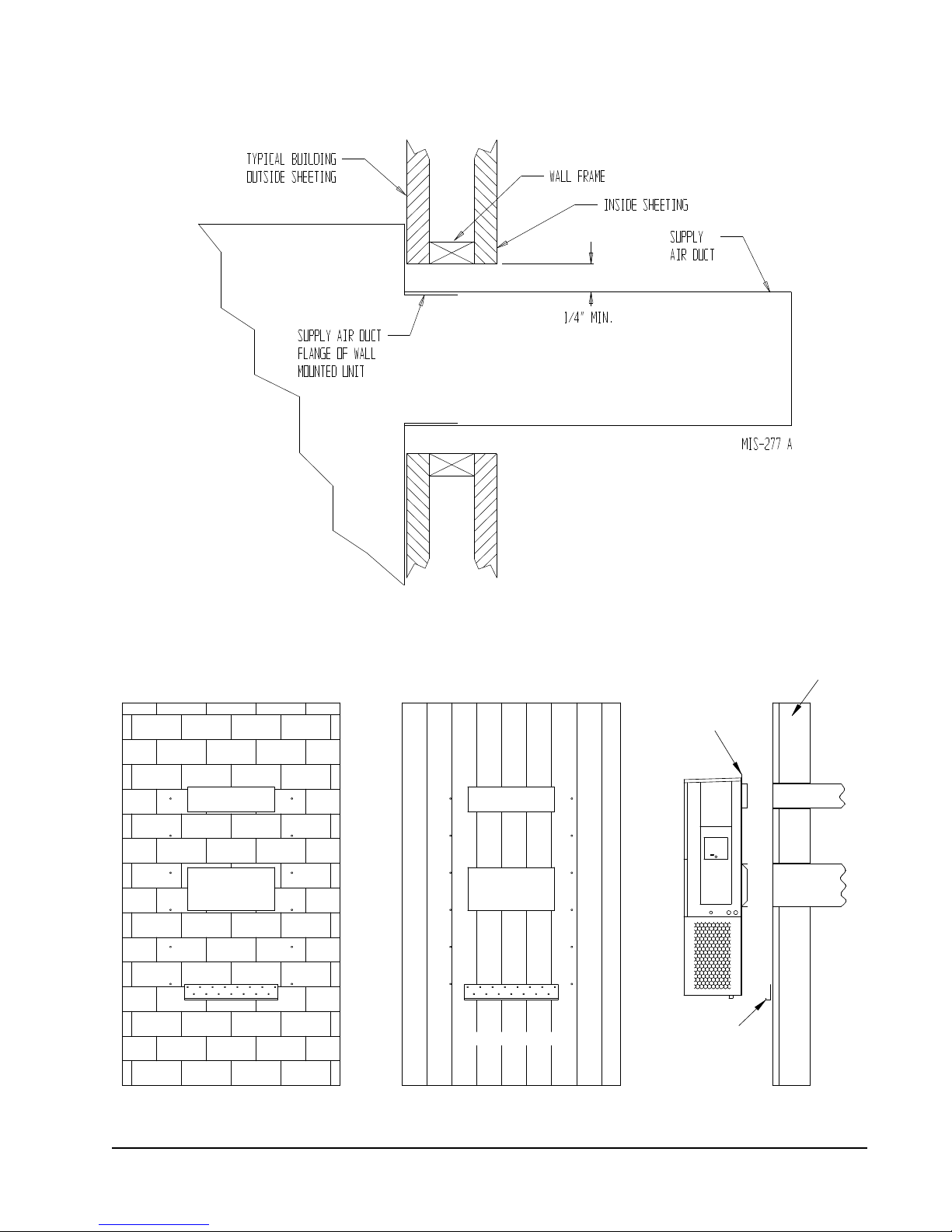

Figure 1.4 Electric Heat Clearance .........................13

Figure 1.5 Wall Mounting Instructions ....................13

Figure 1.6 Wall Mounting Instructions ....................14

Figure 1.7 Common Wall Mounting Installations ......14

Figure 1.8 Circuit Routing Label ............................15

Figure 1.9 WIRING: VAC and VDC Supply Wiring

Landing Points .....................................17

Figure 1.10 Adjusting the 230/208VAC Transformer ..17

Figure 1.11 Bard Polarity-Voltage Monitor .................18

Figure 2.1 Refrigerant Sight Glass .........................23

Figure 2.2 Wall-Mount Unit Control Board ..............25

Figure 2.3 TEC-EYE

Figure 2.4 TEC-EYE

Figure 2.5 TEC-EYE

Figure 2.6 Fan Blade Setting .................................32

Figure 2.7 Dirty Filter Switch .................................32

Figure 2.8 Power Loss Relay Circuit .......................33

Figure 2.9 High Pressure Relay Circuit ...................33

Figure 2.10 Blower Motor Start Relay Circuit ............33

Figure 2.11 D25A/L, D35A/L Unit Control Panel .......34

Figure 2.12 D28A/L, D36A/L, D42A/L, D48A/L,

D60A/L Unit Control Panel ....................35

Figure 2.13 WIRING: D25A/L, D35A/L

Unit Wiring Diagram .............................36

Figure 2.14 WIRING: D28A/L, D36A/L, D42A/L, ..........

D48A/L, D60A/L Unit Wiring Diagram ....37

Figure 2.15 Troubleshooting Motor Power Supply ......39

Figure 2.16 Troubleshooting Motor Start Command ...40

Figure 2.17 Troubleshooting Speed Voltage ...............40

Figure 2.18 VDC Polarity Check ...............................41

Figure 2.19 Verifying Incoming Voltage: VDC .............42

TM

........................................................................................................................................27

Table 1.1 Electrical Specifications ..........................16

Table 2.1 Nominal Pressures ..................................23

Table 2.2 Blower Speed Voltage Chart .....................24

Table 2.3 Temp vs. Resistance of Temp Sensor. ........31

Table 2.4 Indoor Blower Performance ......................32

Table 2.5 Troubleshooting 48VDC Blower Motor ........39

Table 2.6 Blower Speed Voltage Chart .....................40

TM

Display ................................27

TM

Connection to Unit Control ....27

TM

Status Display......................28

Manual 2100-643C

Page 2 of 59

Page 3

GENERAL INFORMATION

DC FREE COOLING UNIT SYSTEM

The Bard DC Free Cooling Unit system is composed

of two (2) D-Series DUAL-TEC™ wall-mount air

conditioners matched with one (1) LC Series lead/lag

controller. The D-Series, specifically engineered for the

telecom market, can provide outdoor air cooling during

power loss situations through the use of onsite -48VDC

positive ground battery banks.

NOTE: The LC Series lead/lag controller and the

D-Series wall-mount units are designed

specifically to work together. The controller

cannot run other Bard models or other brands

of systems, nor can other controllers or

thermostats run the D-Series wall-mount units.

They are a complete system, and must be used

together.

WALL-MOUNT AIR CONDITIONER

UNITS

The D-Series units operate on both VAC and VDC power

under normal power supply conditions. If there is loss

of VAC power supply (shore and/or back-up generator)

the unit will continue to operate as free cooling or

ventilation system using the shelter’s VDC power. The

indoor blower and free cooling unit operate from -48VDC

and no inverter is required.

The units will supply 100% of rated cooling airflow

in free cooling mode with ability to exhaust the same

amount through the unit itself without any additional

relief openings in the shelter.

Each of these units are fully charged with refrigerant

and have auxilliary heat installed.

GENERAL

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly any tags

and/or labels attached to the equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation

is made. See ADDITIONAL PUBLICATIONS for

information on codes and standards.

Sizing of systems for proposed installation should

be based on heat loss calculation made according to

methods of Air Conditioning Contractors of America

(ACCA). The air duct should be installed in accordance

with the Standards of the National Fire Protection

Association for the Installation of Air Conditioning and

Ventilating Systems of Other Than Residence Type,

NFPA No. 90A, and Residence Type Warm Air Heating

and Air Conditioning Systems, NFPA No. 90B. Where

local regulations are at a variance with instructions,

installer should adhere to local codes.

SHIPPING DAMAGE

Upon receipt of equipment, the cartons should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

These units must remain in upright position at all

times.

ADDITIONAL PUBLICATIONS

These publications can help when installing the air

conditioning system. They can usually be found at the

local library or purchased directly from the publisher.

Be sure to consult the current edition of each standard.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation of Air Conditioning

and Ventilating Systems ...................ANSI/NFPA 90A

Standard for Warm Air Heating

and Air Conditioning Systems ............ANSI/NFPA 90B

Load Calculation for Residential Winter

and Summer Air Conditioning ............. ACCA Manual J

Duct Design for Residential Winter and Summer

Air Conditioning and Equipment Selection

....................................................... ACCA Manual D

For more information, contact these publishers:

Air Conditioning Contractors of America (ACCA)

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370 Fax: (202) 234-4721

American National Standards Institute (ANSI)

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900 Fax: (212) 302-1286

Manual 2100-643C

Page 3 of 59

Page 4

American Society of Heating, Refrigeration and Air

Conditioning Engineers, Inc. (ASHRAE)

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400 Fax: (404) 321-5478

National Fire Protection Association (NFPA)

Batterymarch Park

P. O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555 Fax: (617) 984-7057

ANSI Z535.5 Definitions:

Danger: Indicate[s] a hazardous situation which, if

not avoided, will result in death or serious injury. The

signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

Warning: Indicate[s] a hazardous situation which, if

not avoided, could result in death or serious injury.

WARNING [signs] should not be used for property

damage hazards unless personal injury risk appropriate

to this level is also involved.

Caution: Indicate[s] a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION [signs] without a safety alert symbol may be

used to alert against unsafe practices that can result in

property damage only.

Notice: [this header is] preferred to address practices

not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an

alternative to “NOTICE” the word “CAUTION” without

the safety alert symbol may be used to indicate a

message not related to personal injury.

!

WARNING

Electrical shock hazard.

Have a properly trained individual perform

these tasks.

Failure to do so could result in electric shock

or death.

!

WARNING

Fire hazard.

Maintain minimum 1/4” clearance between the

supply air duct and combustible materials in

the rst 3’ feet of ducting.

Failure to do so could result in re causing

damage, injury or death.

!

WARNING

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

Manual 2100-643C

Page 4 of 59

!

CAUTION

Cut hazard.

Wear gloves to avoid contact with sharp

edges.

Failure to do so could result in personal injury.

Page 5

SECTION 1:

INSTALLATION

INSTRUCTIONS

Manual 2100-643C

Page 5 of 59

Page 6

LIST OF NECESSARY MATERIALS/TOOLS

Additional hardware and miscellaneous supplies are needed for installation. These items are field supplied and must

be sourced before installation. This list also includes tools needed for installation.

LIST OF MATERIALS/TOOLS

• Personal protective equipment/safety devices

• Supply/return grilles

• Field-fabricated sleeves (if necessary)

• Fasteners sufficient for mounting the units such as

5/16" diameter anchor/carriage/lag bolts

• 7/8" diameter washers

• Caulking materials

• Miscellaneous hand and power tools and jobsite or

shop materials

• Lifting equipment with the necessary capacity and

rigging to safely move/install the systems

• Electrical supplies:

- Two (2) 20A circuit breakers for the shelter DC

power plant (one per wall-mount unit)

- Two (2) various size circuit breakers for

the shelter AC breaker box (see Table 1.1:

Electrical Specifications on page 16)

- High-voltage wire of various gauges (see Table

1.1)

- Communication wire: 2-wire, 18 gauge,

shielded with drain

- Miscellaneous electrical supplies including

rigid/flexible conduit and fittings, junction

boxes, wire connectors and supports

The following are required and must be sourced

prior to installation of these units.

• Two (2) 20A circuit breakers for the shelter DC

power plant (one per wall-mount unit)

Circuit breakers for Emerson Network Power (ENP)

power plants (used in most telecomm shelters built

today) are available directly through the following

distributors:

• Emerson Network Power: 440.288.1122

• Master Electronics: 888.473.5297 or

www.onlinecomponents.com

Emerson Network Power (ENP) Part Number

• 20A circuit breaker: P/N 101601

Always confirm the application before ordering.

FIGURE 1.1

D-Series DUAL-TEC™ Wall-Mount Unit Model Nomenclature

D 25 A 2 P A 05 4 P X X X J

MODEL

SERIES

CAPACITY

25 – 2 Ton

28 – 2½ Ton

35 – 3 Ton

36 – 3 Ton

Manual 2100-643C

Page 6 of 59

42 – 3½ Ton

48 – 4 Ton

60 – 5 Ton

A – Right Hand

L – Left Hand

REVISION

PLC

VOLTS & PHASE

A – 230/208-60-1

B – 230/208-60-3

KW

0Z – 0 KW

05 – 5 KW

06 – 6 KW

-48VDC

Free Cooling

Unit

COIL OPTIONS

X – Standard

3 – Phenolic Coated Evaporator and

Condenser

SPECIAL FEATURES

COLOR OPTIONS

X – Beige

1 – White

4 – Buckeye Gray

FILTER OPTIONS

P – 2-Inch Pleated (MERV 8)

M – 2-Inch Pleated (MERV 11)

CONTROL MODULES

J – High Pressure Switch, Low Pressure

Switch, Compressor Control Module,

Low Ambient Control, Alarm Contacts,

Start Assist

C – J Module + Compressor Crankcase

Heater

Page 7

SITE PREPARATION

NEW SHELTER INSTALLATION VS.

RETROFIT INSTALLATION

These installation instructions cover both new shelter

installations and retrofit installations. Each installation

is unique and may require special accomodations and

modifications. Although Bard Manufacturing follows a

long-established tradition of manufacturing equipment

using industry standard dimensions for building

penetration, it is occasionally necessary to move or

enlarge supply and return openings when replacing

non-standardized equipment in a retrofit application.

MINIMUM CLEARANCE

D-Series wall-mount air conditioners are available in

both right-hand access models and left-hand access

models. Right-hand access models have the heat strip

access panel, external circuit breakers access panel

and internal controls access panel on the right side of

the unit. Left-hand access models are a mirror image

of the right-hand access models, and allow two wallmount units to be placed in relatively close proximity

and yet still allow complete access for maintenance

and repair.

On side-by-side installations, maintain a minimum of

26" clearance on control side to allow access to control

panel and heat strips, and to allow proper airflow to the

outdoor coil. For installations where units are installed

with both control panels facing each other (inward),

maintain a minimum of 36" clearance to allow access.

Additional clearance may be required to meet local or

national codes.

Care should be taken to ensure that the recirculation

and obstruction of condenser discharge air does not

occur. Recirculation of condenser discharge air can

be from either a single unit or multiple units. Any

object such as shrubbery, a building or a large object

can cause obstructions to the condenser discharge air.

Recirculation or reduced airflow caused by obstructions

will result in reduced capacity, possible unit pressure

safety lockouts and reduced unit service life.

For units with blow through condensers, such as the

D-Series units, it is recommended there be a minimum

distance of 10' between the front of the unit and

any barrier or 20' between the fronts of two opposing

(facing) units.

CLEARANCE TO COMBUSTIBLES

!

WARNING

Fire hazard.

Maintain minimum 1/4" clearance between the

supply air duct and combustible materials in

the rst 3' of ducting.

Failure to do so could result in re causing

damage, injury or death.

The unit itself is suitable for 0" clearance, but the

supply air duct flange and the first 3' of supply air duct

require a minimum of 1/4" clearance to combustible

material. However, it is generally recommended that

a 1" clearance is used for ease of installation and

maintaining the required clearance to combustible

material. See Figures 1.3A-C on pages 10-12 for

details on opening sizes.

Minimum Clearances Required to

Combustible Materials

MODELS

All covered by this

manual

SUPPLY AIR DUCT

FIRST 3'

1/4" 0"

CABINET

MODEL IDENTIFICATION

Identify the specific model using the model

nomenclature information found in Figure 1.1 and/

or model/serial tag found on the unit on the opposite

side of the control and access panels. See Figure 1.2

on page 8 for dimensions and critical installation

requirements.

Clearances Required for Service Access

and Adequate Condenser Airflow

MODELS LEFT SIDE RIGHT SIDE

All covered by this manual 26" 26"

Units with control panels

facing each other (inward)

36" between units

Manual 2100-643C

Page 7 of 59

Page 8

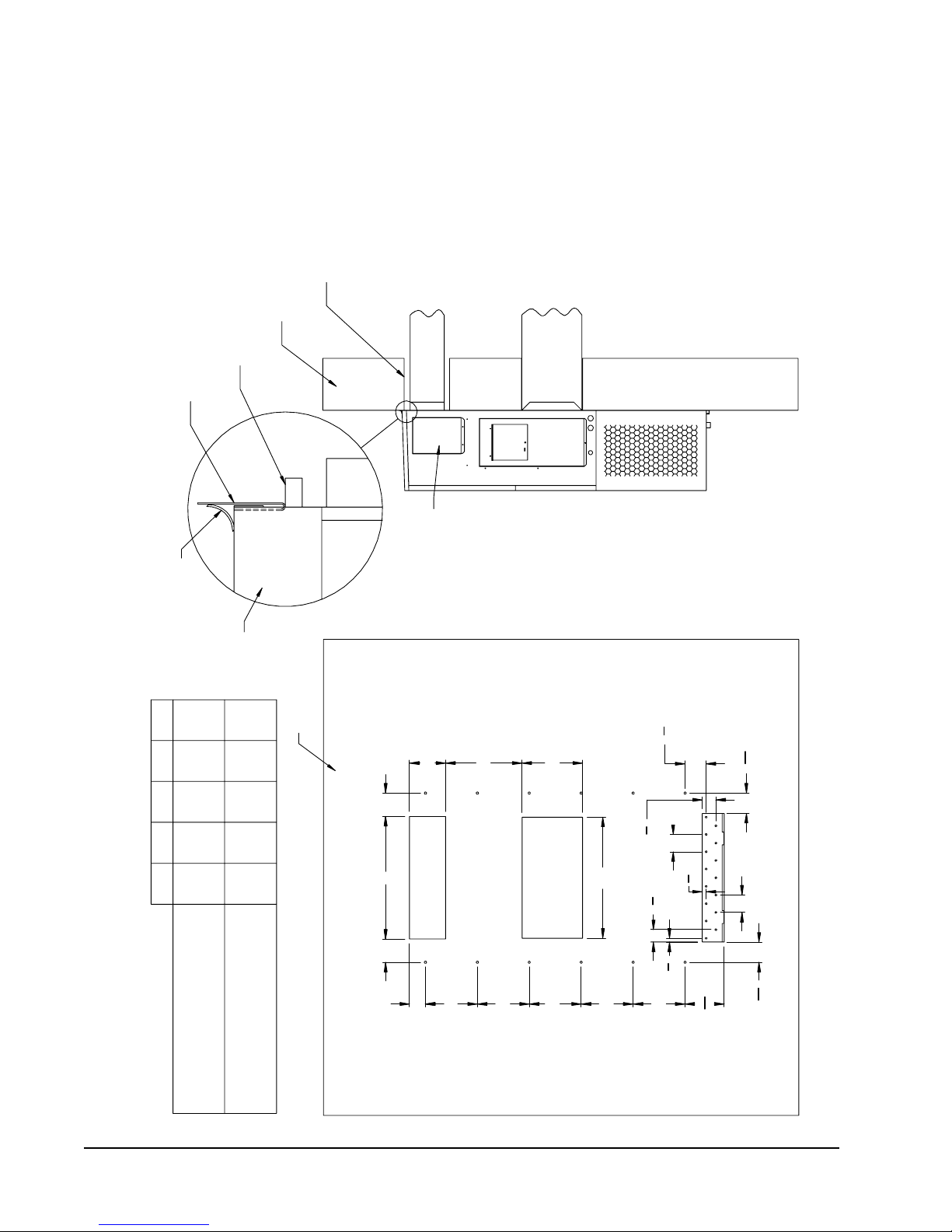

FIGURE 1.2

Dimensions of Basic Unit for Architectural and Installation Requirements (Nominal)

Width

Depth

Model

D25A/L

D35A/L

D28A/L

D36A/L

D42A/L

D48A/L

D60A/L

(W)

38.200 17.125 74.563 7.88 27.88 13.88 27.88 40.00 10.88 29.75 17.93 30.75 32.75 33.25 31.00 2.75 39.13 26.75 9.14 4.19 12.00 9.00

42.075 22.432 84.875 9.88 29.88 15.88 29.88 43.88 13.56 31.66 30.00 32.68 26.94 34.69 32.43 3.37 43.00 23.88 10.00 1.44 16.00 1.88

42.075 22.432 93.000 9.88 29.88 15.88 29.88 43.88 13.56 37.00 30.00 40.81 35.06 42.81 40.56 3.37 43.00 31.00 10.00 1.44 16.00 10.00

Height

(D)

Supply Return

(H)

A B C B E F G I J K L M N O P Q R S T

All dimensions are in inches. Dimensional drawings are not to scale.

Side View

Built In

Rain Hood

4° Pitch

D

1.250

Cond.

Air

Inlet

D

1.250

2.13

J

Drain

Electric

Heat

A

I

C H

K

Heater

Access

Panel

C. Breaker/

Disconnect

Access Panel

(Lockable)

Econ. Hood

Side Wall

Mounting

Brackets

(Built In)

Top Rain

Flashing

Shipping

Location

Optional

Electrical

Entrances

L

M

N

E

O

Supply Air Opening

B

Return Air Opening

P

Back View

Q

W

D**A

RIGHT

HAND

UNIT

D**L

LEFT

HAND

UNIT

Built In

Rain Hood

W

ECON Hood

F

Ventilation Air

Cond.

G

Air

Outlet

4° Pitch

Heater

Access

Panel

Electric

Heat

C. Breaker/

Disconnect

Access Panel

(Lockable)

7.000

Low Voltage

Electrical

Entrance

High Voltage

Electrical

Entrance

Front View

E

.44

R

S

S

O

Supply Air Opening

B

Side Wall

Mounting

Brackets

(Built In)

Top Rain

Flashing

Shipping

Location

2.13

A

I

.44

Bottom Installation

Bracket

MIS-3849

R

S

S

S

S

S

T

S

S

S

T

Drain

Return Air Opening

Bottom

Installation

Bracket

Back View

Manual 2100-643C

Page 8 of 59

Optional

Electrical

Entrances

M

P

N

Q

C

Ventilation Air

H

K

L

Cond.

J

Air

Inlet

7.000

Low Voltage

Electrical

Entrance

High Voltage

Electrical

Entrance

Condenser

Air Outlet

Front ViewSide View

F

G

MIS-3848

Page 9

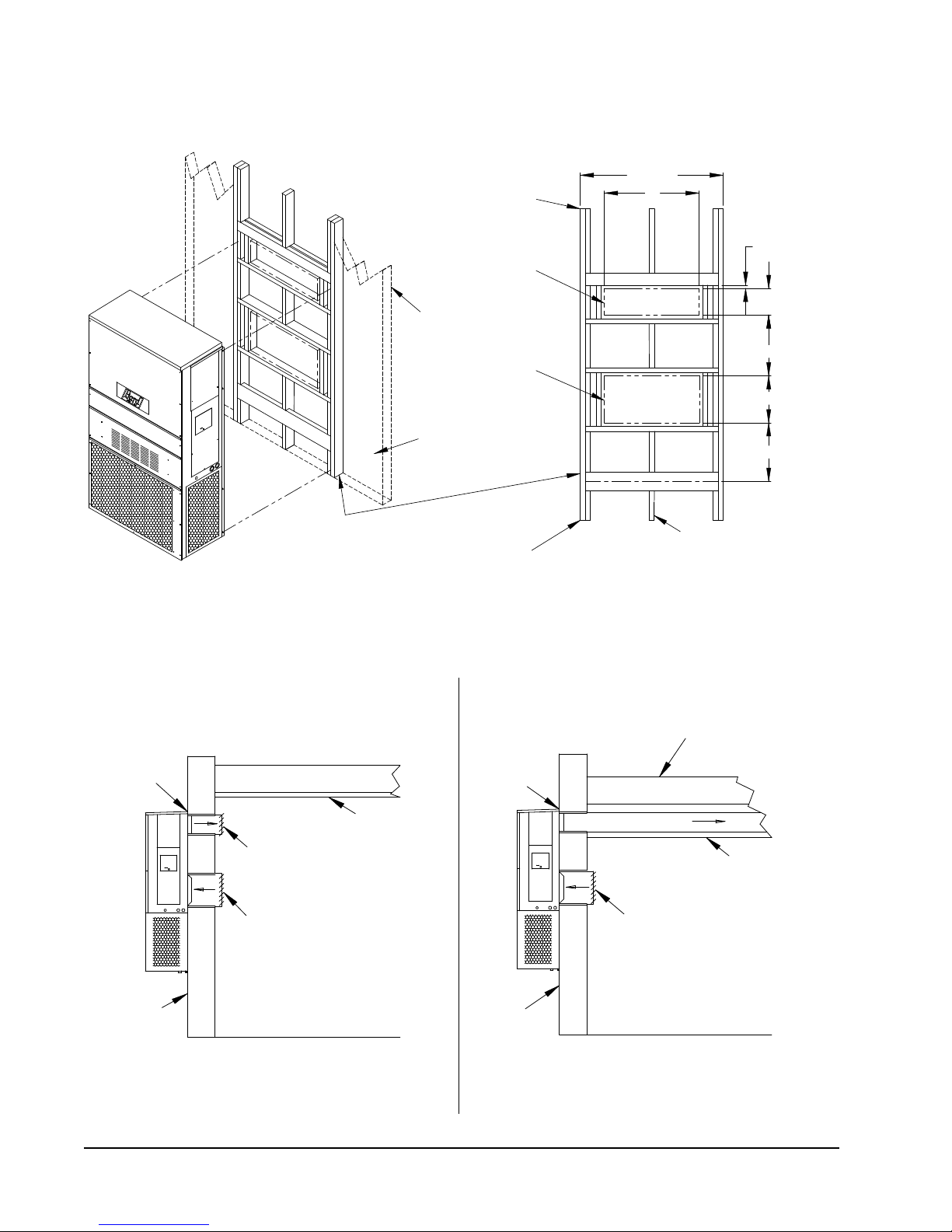

WALL-MOUNT UNIT INSTALLATION

MOUNTING THE UNITS

!

WARNING

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

NOTE: It may be best to spot some electrical knockouts

(such as those located on the back of the wallmount unit) before units are mounted and access is

unavailable or limited (see Figure 1.2 to locate prepunched knockouts).

Two holes for the supply and return air openings must

be cut through the wall as shown in Figures 1.3AC on pages 10-12. On wood frame walls, the wall

construction must be strong and rigid enough to carry

the weight of the unit without transmitting any unit

vibration. Concrete block walls must be thoroughly

inspected to insure that they are capable of carrying

the weight of the installed unit.

In retrofit (unit replacement) installations, the openings

cut for the original equipment may not line up exactly

with needs of this installation. Modifications may need

to be made, such as increasing or decreasing the size

of the wall cutouts. The existing bolt placement may

not line up in which case the original bolts would need

to be removed or cut away.

1. These units are secured by wall mounting flanges

which secure the unit to the outside wall surface at

both sides. A bottom mounting bracket, attached

to skid for shipping, is provided for ease of

installation, but is not required.

2. The unit itself is suitable for 0" clearance, but the

supply air duct flange and the first 3' of supply

air duct require a minimum of 1/4" clearance to

combustible material. However, it is generally

recommended that a 1" clearance is used for

ease of installation and maintaining the required

clearance to combustible material. See Figures

1.3A-C for details on opening sizes.

3. Locate and mark lag bolt locations and location for

optional bottom mounting bracket, if desired (see

Figures 1.3A-C).

4. Mount bottom mounting bracket (if used).

5. If desired, hook top rain flashing (attached to frontright of supply flange for shipping) under back

bend of top.

6. Position unit in opening and secure with fasteners

sufficient for the application such as 5/16" lag/

anchor/carriage bolts; use 7/8" diameter flat washers

on the bolts. It is recommended that a bead of

silicone caulking be placed behind the side

mounting flanges.

7. Secure optional rain flashing to wall and caulk

across entire length of top (see Figures 1.3A-C).

8. For additional mounting rigidity, the return air

and supply air frames or collars can be drilled

and screwed or welded to the structural wall itself

(depending upon wall construction). Be sure to

observe required clearance if combustible wall.

9. A plastic drain hose extends from the drain pan at

the top of the unit down to the unit base. There are

openings in the unit base for the drain hose to pass

through. In the event the drain hose is connected

to a drain system of some type, it must be an open

or vented type system to assure proper drainage.

Manual 2100-643C

Page 9 of 59

Page 10

FOUR SIDES OF SUPPLY

Wall Opening and Hole Location View

1/4" MIN. CLEARANCE FROM

COMBUSTIBLE MATERIALSCRECOMMENDED 1" CLEARANCE FROM

REQUIRED DIMENSIONS TO MAINTAIN

COMBUSTIBLE MATERIALS

REQUIRED DIMENSIONS TO MAINTAIN

AIR DUCT IS REQUIRED

1/4" CLEARANCE ON ALL

FROM COMBUSTABLE

MIS-3820

MATERIALS

FOAM AIR SEAL

SUPPLIED

RAIN FLASHING

SEAL WITH BEAD

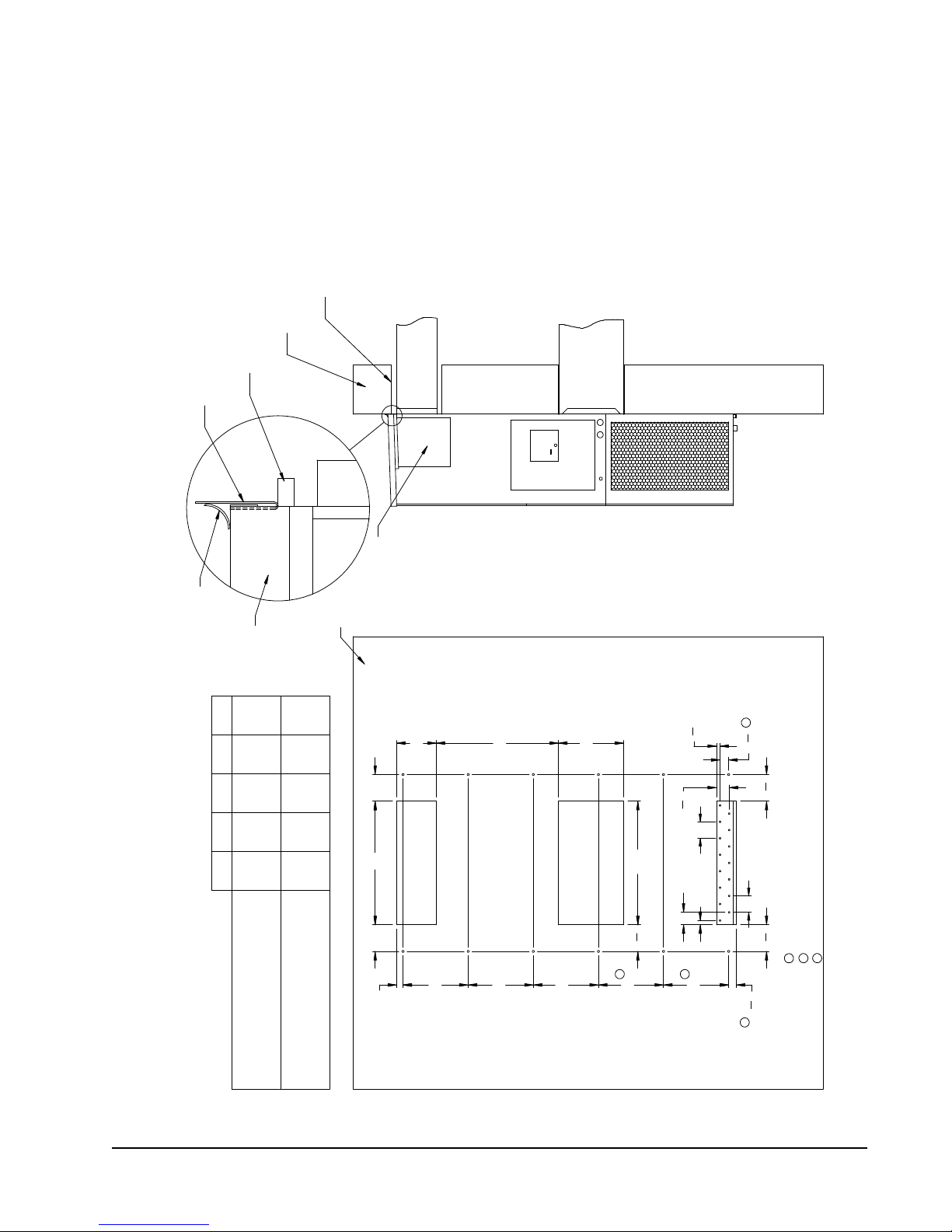

FIGURE 1.3A

OF CAULKING ALONG

Mounting Instructions

ENTIRE LENGTH OF TOP.

D25A, D25L, D35A, D35L

ED

17 5/8

3 11/16

TOP

4 7/16

WALL STRUCTURE

WALL

SUPPLY AIR

DUCT

PANEL

HEATER ACCESS

B

TOP FLASHING AT TIME OF INSTALLATION.

IT IS RECOMMENDED THAT A BEAD OF

THE SIDE MOUNTING FLANGES AND UNDER

RETURN AIR

OPENING

NOTES:

SILICONE CAULKING BE PLACED BEHIND

W**A UNIT SHOWN, W**L UNIT

CONTROLS AND HEATER ACCESS

IS ON OPPOSITE (LEFT) SIDE.

Right Side View

"

7

8

4

E

14"

"

16

11

4

5 3/8

B

8 3/8A9 7/829 7/8

4 5/8 16 7/8

28 3/8

Manual 2100-643C

Page 10 of 59

C

A

Supply Opening

Return Opening

28"

C

D

12"

12"

12"

12"

4"

"

Typ.

1

8

3

"

7

8

"

7

8

2

"

7

8

12"

4"

Typ.

"

1

16

9

"

16

11

4

Page 11

D

16"

16"

16"

16"

16"

1

7

8

"

6

1

2

" 6

1

2

"

2

1

8

"

7

8

"

1"

3"

4"

Typ.

4"

Typ.

6

1

2

"

30"

E

16"

A CC

3

1

8

"

B

Wall Opening and Hole Location View

RETURN AIR

1

REQUIRED DIMENSIONS TO MAINTAIN

1/4" MIN. CLEARANCE FROM

COMBUSTIBLE MATERIALS

REQUIRED DIMENSIONS TO MAINTAIN

29

DUCT

COMBUSTIBLE MATERIALS

A B C DE

30 1/2

10 1/2

6 1/4 1 1/4 29 3/4

32 12 5 1/2

2

NOTES:

WALL STRUCTURE

1

SUPPLY AIR

IT IS RECOMMENDED THAT A BEAD OF

OPENING

Right Side View

RAIN FLASHING

SILICONE CAULKING BE PLACED BEHIND

RECOMMENDED 1" CLEARANCE FROM

THE SIDE MOUNTING FLANGES AND UNDER

TOP FLASHING AT TIME OF INSTALLATION.

TOP.

PANEL

HEATER ACCESS

FOUR SIDES OF SUPPLY

AIR DUCT IS REQUIRED

FROM COMBUSTABLE

WALL

1/4" CLEARANCE ON ALL

MATERIALS

Supply Opening

FOAM AIR SEAL

SUPPLIED

SEAL WITH BEAD

OF CAULKING ALONG

ENTIRE LENGTH OF

TOP

1

Return Opening

MIS-416 E

Dimension is 21" on 95" tall units.

2

Dimension is 10" on T48H1 & T60H1.

2

Dimension is 6" on T48H1 & T60H1.

3

3

FIGURE 1.3B

Mounting Instructions

D28A, D28L, D36A, D36L, D42A, D42L

Manual 2100-643C

Page 11 of 59

Page 12

D

16"

16"

16"

16"

16"

2

"6

8

" 5

8 97

"

1"

3"

Typ.

1

4"

4"

Typ.

6

1

2

"

30"

E

16"

A CC

"

7

8

3

B

"

8

7

1

1

2

"6

1 1/430 1/2

1/4" CLEARANCE ON ALL

SUPPLIED

FOAM AIR SEAL

A

Supply Opening

SILICONE CAULKING BE PLACED BEHIND

DUCT

FOUR SIDES OF SUPPLY

FROM COMBUSTABLE

1/4" MIN. CLEARANCE FROM

COMBUSTIBLE MATERIALS

REQUIRED DIMENSIONS TO MAINTAIN

OPENING

COMBUSTIBLE MATERIALS

B D E

PANEL

AIR DUCT IS REQUIRED

32

10 1/2

Right Side View

SUPPLY AIR

RECOMMENDED 1" CLEARANCE FROM

MIS-3789

RAIN FLASHING

REQUIRED DIMENSIONS TO MAINTAIN

12

TOP.

MATERIALS

5 1/2

WALL STRUCTURE

2

6 1/4

29

29 3/4

IT IS RECOMMENDED THAT A BEAD OF

THE SIDE MOUNTING FLANGES AND UNDER

WALL

C

Wall Opening and Hole Location View

NOTES:

TOP FLASHING AT TIME OF INSTALLATION.

HEATER ACCESS

RETURN AIR

SEAL WITH BEAD

OF CAULKING ALONG

ENTIRE LENGTH OF

TOP

Return Opening

FIGURE 1.3C

Mounting Instructions

D48A, D48L, D60A, D60L

Manual 2100-643C

Page 12 of 59

Page 13

FIGURE 1.4

DUCT

OPENING

RETURN AIR

SUPPLY AIR

WOOD FRAME WALL INSTALLATION

OPENING

WALL BEFORE

MOUNT ON UNIT

OPENING

BEFORE INSTALLATION

BOTTOM MOUNTING

CONCRETE BLOCK WALL INSTALLATION

BRACKET. MOUNT ON

OPENING

WOOD OR STEEL SIDING

OPENING

INSTALLING UNIT.

RETURN AIR

WALL STRUCTURE

RETURN AIR

SUPPLY AIR

FACTORY SUPPLIED

RAIN FLASHING.

SUPPLY AIR

MIS-548 A

SIDE VIEW

Electric Heat Clearance

Wall Mounting Instructions

See FIGURE 2 – Mounting Instructions

FIGURE 1.5

Manual 2100-643C

Page 13 of 59

Page 14

FIGURE 1.6

I

A

C

K

E + 1.000

B

1.000

SUPPLY DUCT

OVER FRAME

INTERIOR FINISHED WALL

ALL AROUND DUCT

FRAMING MATERIAL

EXTERIOR FINISH WALL

OPENING

FOR ACTUAL DIMENSIONS.

2 x 4'S, 2 x 6'S &/OR

STRUCTURAL STEEL

ATTACH TO TOP

1.000" CLEARANCE

1.000" CLEARANCE

PLATE OF WALL

C

SEE UNIT DIMENSIONS, FIGURE 2,

OPENING

RETURN DUCT

2 x 6

ATTACH TO BOTTOM

OVER FRAME

PLATE OF WALL

L

THIS STRUCTURAL MEMBER

LOCATED TO MATCH STUD

SPACING FOR REST OF WALL.

A SECOND MEMBER MAY BE

REQUIRED FOR SOME WALLS.

MIS-549 B

ALL AROUND DUCT

SUPPLY DUCT MAY BE LOCATED IN AN ATTIC

OPENING W/ GRILLE

SUPPLY AIR DUCT

RAFTERS

RAFTERS

RETURN AIR

OPENING W/ GRILLE

DUCTED SUPPLY

OR BELOW CEILING RAFTERS AS SHOWN

FINISHED CEILING SURFACE

RAIN

FLASHING

RAIN

FLASHING

RETURN AT UNITNO DUCT

RETURN AIR

FINISHED CEILING SURFACE

FREE AIR FLOW

OUTSIDE

WALL

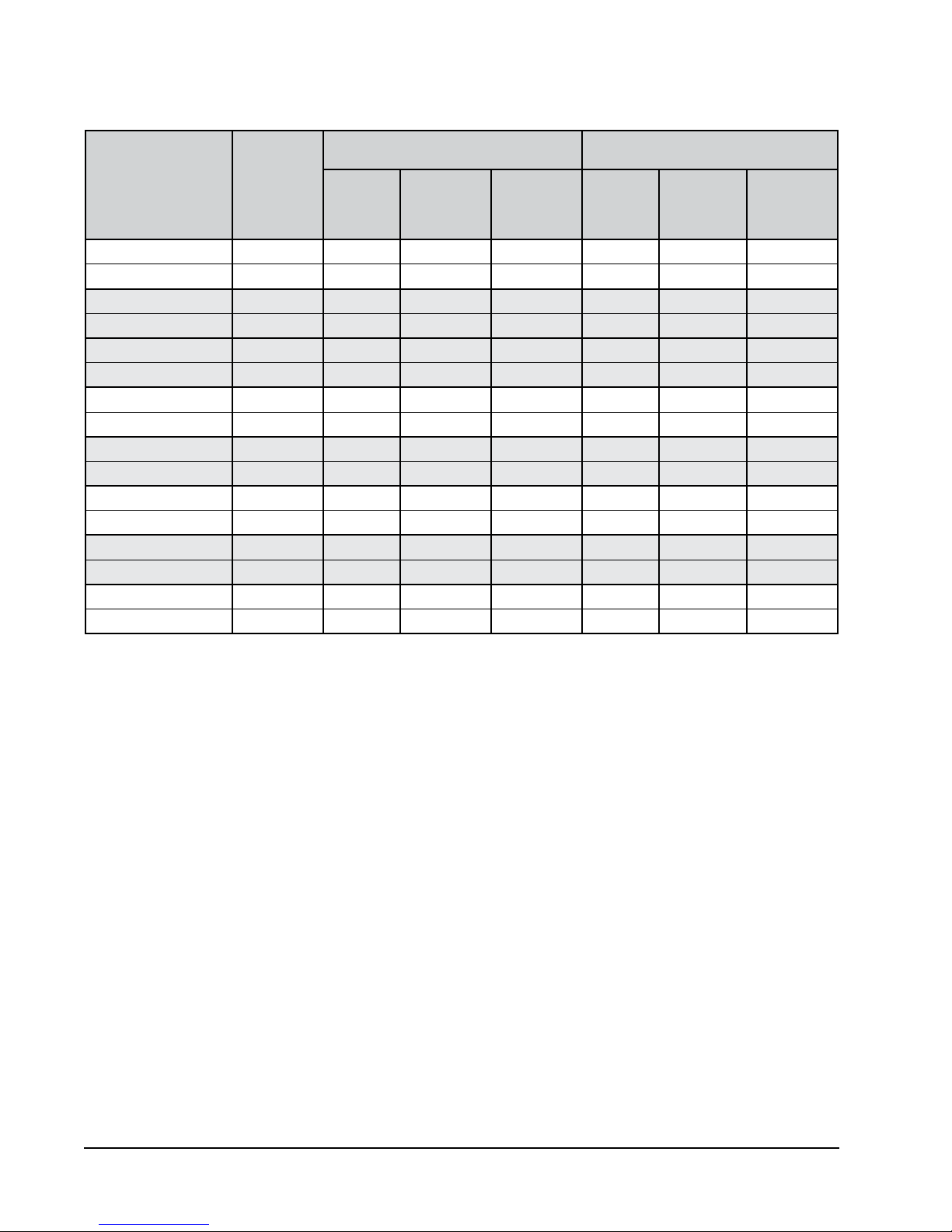

OUTSIDE

WALL

SUPPLY AIR DUCT

W/ GRILLE

Wall Mounting Instructions

SEE UNIT DIMENSIONS, FIGURE 1-2,

FOR ACTUAL DIMENSIONS

FIGURE 1.7

Common Wall Mounting Installations

Manual 2100-643C

Page 14 of 59

Page 15

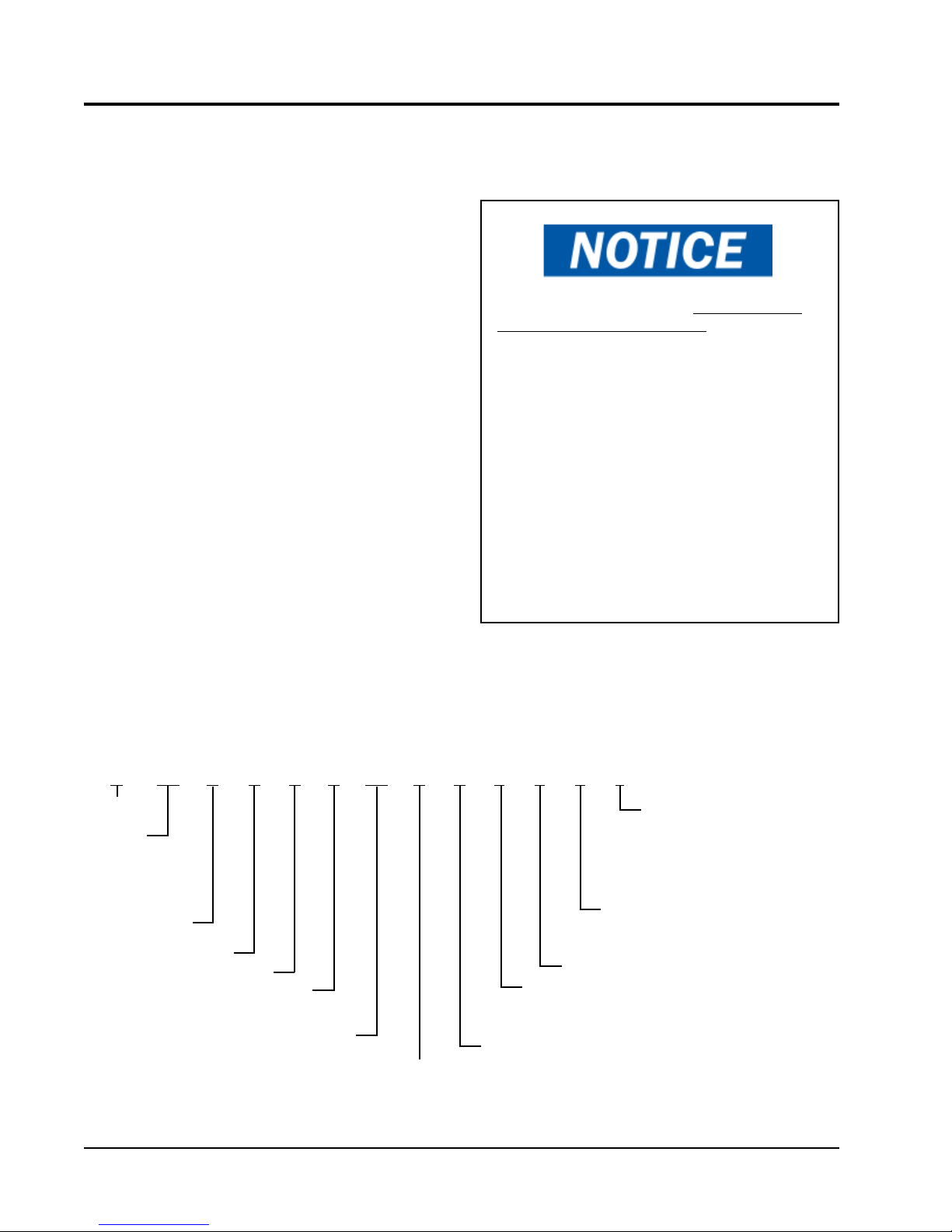

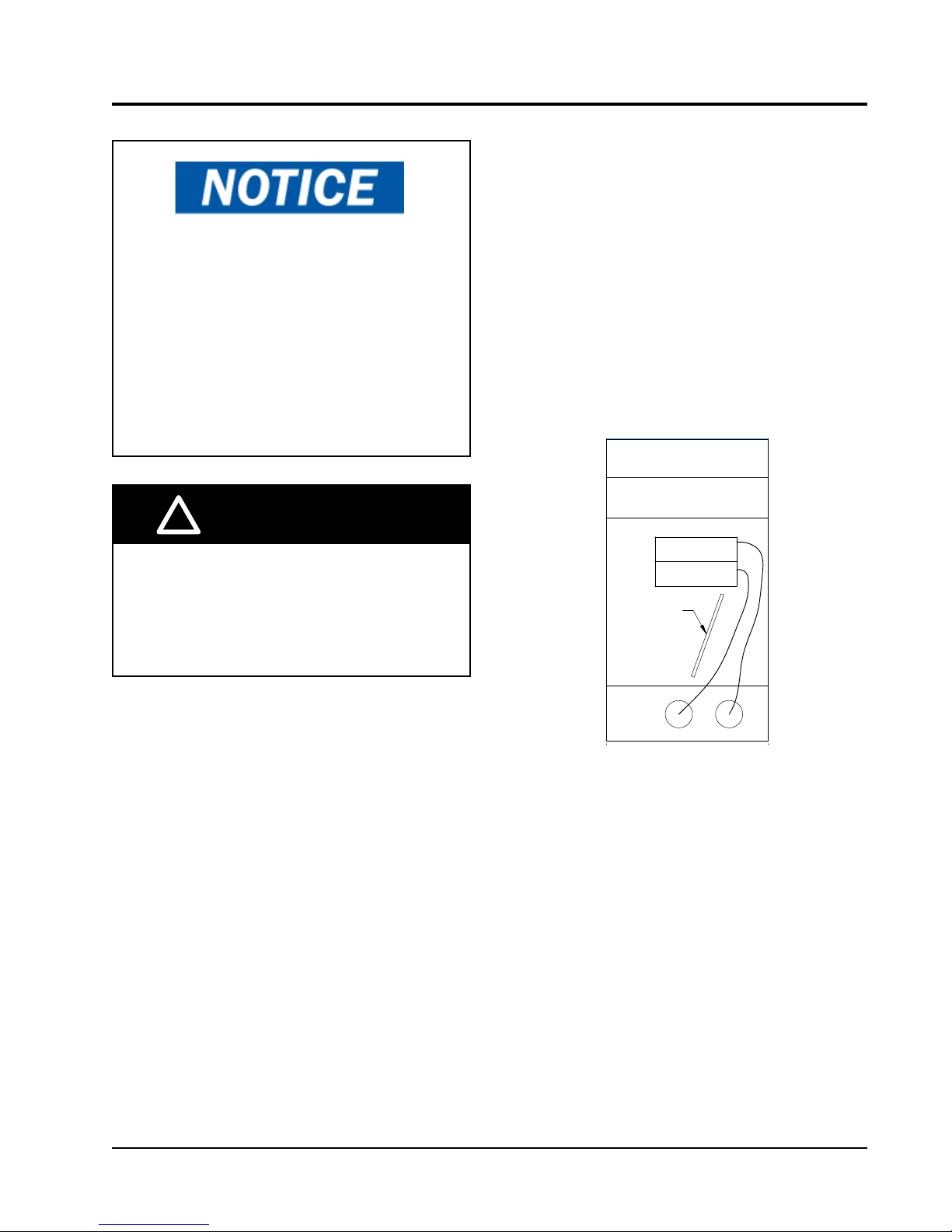

WALL-MOUNT UNIT SUPPLY WIRING

NOTICE / AVIS

ROUTE ALL HIGH VOLTAGE FIELD

WIRES TO THE RIGHT OF THE WIRE

SHIELD AS SHOWN

ACHEMINER LES FILS HAUTE

TENSION SUR LA DROITE VERS LA

PROTECTION, COMME INDIQUÉ

VAC CIRCUIT BREAKER

/DISJONCTEUR

WIRE SHIELD /

PROTECTION

WHITE 3/16" LETTERING

7961-807

VDC CIRCUIT BREAKER

/DISJONCTEUR

All models covered by this installation

instruction require dual power sources:

VAC utility power to run the compressor, heat

and outdoor fan motor and -48 VDC power

to operate the indoor blower and DC free

cooling damper.

These units require a positive ground

-48 VDC copper conductor field wire

connection. Refer to the unit wiring diagram

for more information.

!

WARNING

Route all field wires to the right of the wire shield as

shown in the circuit routing label found in Figure 1.8

(and also on the wall-mount units).

Run communication wires in separate conduit

whenever possible. If a unique installation occurs

where it is not possible to isolate the communication

wires, it is permissible to run communication wires

in a conduit which contains a dedicated VDC voltage

line. In all cases, the communication wires must be

shielded, twisted wire and utilize proper filtration at the

main communications board. It is never permissible to

run communication wires with VAC voltage lines.

FIGURE 1.8

Circuit Routing Label

Electrical shock hazard.

Have a properly trained individual perform

these tasks.

Failure to do so could result in electric shock

or death.

Refer to the unit rating plate or Table 1.1 on page

16 for wire sizing information and maximum fuse or

circuit breaker size. Each outdoor unit is marked with

a “Minimum Circuit Ampacity”. The field wiring used

must be sized to carry

models are suitable only for connection with copper

wire. Each unit and/or wiring diagram will be marked

“Use Copper Conductors Only”. These instructions

must be adhered to. Refer to the National Electrical

Code (NEC) for complete current carrying capacity data

on the various insulation grades of wiring material. All

wiring must conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75°C

copper) for all models including the most commonly

used heater sizes. Also shown are the number of field

power circuits required for the various models with

heaters.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or circuit breaker that is to be used with

the equipment. The correct size must be used for

proper circuit protection and also to assure that there

will be no nuisance tripping due to the momentary high

starting current of the compressor motor.

that amount of current. All

See Figure 1.9 on page 17 to reference VAC and VDC

supply wiring landing points.

IMPORTANT: 230/208V 1 phase and 3 phase

equipment use dual primary voltage transformers. All

equipment leaves the factory wired on 240V tap. It is

very important that the correct voltage tap is used. For

208V operation, reconnect from 240V to 208V tap (see

Figure 1.10). The acceptable operating voltage range

for the 240 and 208V taps are: 240V Tap (253 – 216)

and 208 Tap (220 – 197).

The disconnect access door on this unit may be locked

to prevent unauthorized access to the disconnect. To

convert for the locking capability, bend the tab located

in the bottom left-hand corner of the disconnect

opening under the disconnect access panel straight

out. This tab will now line up with the slot in the door.

When shut, a padlock may be placed through the hole

in the tab preventing entry.

Manual 2100-643C

Page 15 of 59

Page 16

TABLE 1.1

Electrical Specifications

AC POWER CIRCUIT DC POSITIVE GROUND POWER CIRCUIT

Model

D25A2PA0Z/D25L2PA0Z 208/230-60-1 19 30 10/10 15.6 20 12

D25A2PA05/D25L2PA05 208/230-60-1 26 30 8/10 15.6 20 12

D35A2PA0Z/D35L2PA0Z 208/230-60-1 24 40 8/10 15.6 20 12

D35A2PA05/D35L2PA05 208/230-60-1 26 40 8/10 15.6 20 12

D35A2PB0Z/D35L2PB0Z 208/230-60-3 19 25 10/10 15.6 20 12

D35A2PB06/D35L2PB06 208/230-60-3 19 25 10/10 15.6 20 12

D28A2PA05/D28L2PA05 208/230-60-1 26 30 10/10 15.6 20 12

D28A2PB06/D28L2PB06 208/230-60-3 18 20 12/12 15.6 20 12

D36A2PA05/D36L2PA05 208/230-60-1 26 40 8/10 15.6 20 12

D36A2PB06/D36L2PB06 208/230-60-3 18 25 10/10 15.6 20 12

D42A2PA05/D42L2PA05 208/230-60-1 26 40 8/10 15.6 20 12

D42A2PB06/D42L2PB06 208/230-60-3 20 25 10/10 15.6 20 12

D48A2PA05/D48L2PA05 208/230-60-1 30 50 8/10 15.6 20 12

D48A2PB06/D48L2PB06 208/230-60-3 20 30 10/10 15.6 20 12

D60A2PA05/D60L2PA05 208/230-60-1 36 60 6/10 15.6 20 12

D60A2PB06/D60L2PB06 208/230-60-3 30 40 8/10 15.6 20 12

Rated Volts,

Hertz & Phase

Minimum

Circuit

Ampacity

Maximum

External Fuse or

Ckt. Breaker

Field Power/

Ground Wire

Size

Minimum

Circuit

Ampacity

Maximum

External Fuse

or Ckt. Breaker

Field Power/

Ground Wire

Size

These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electric Code (latest

version), Article 310 for power conductor sizing.

CAUTION: When more than one field power circuit is run through one conduit, the conductors must be derated. Pay special attention

to note 8 of Table 310 regarding Ampacity Adjustment Factors when more than three current carrying conductors are in a

raceway.

Maximum size of the time delay fuse or circuit breaker for protection of field wiring conductors.

Based on 75°C copper wire. All wiring must conform to the National Electric Code and all local codes.

Manual 2100-643C

Page 16 of 59

Page 17

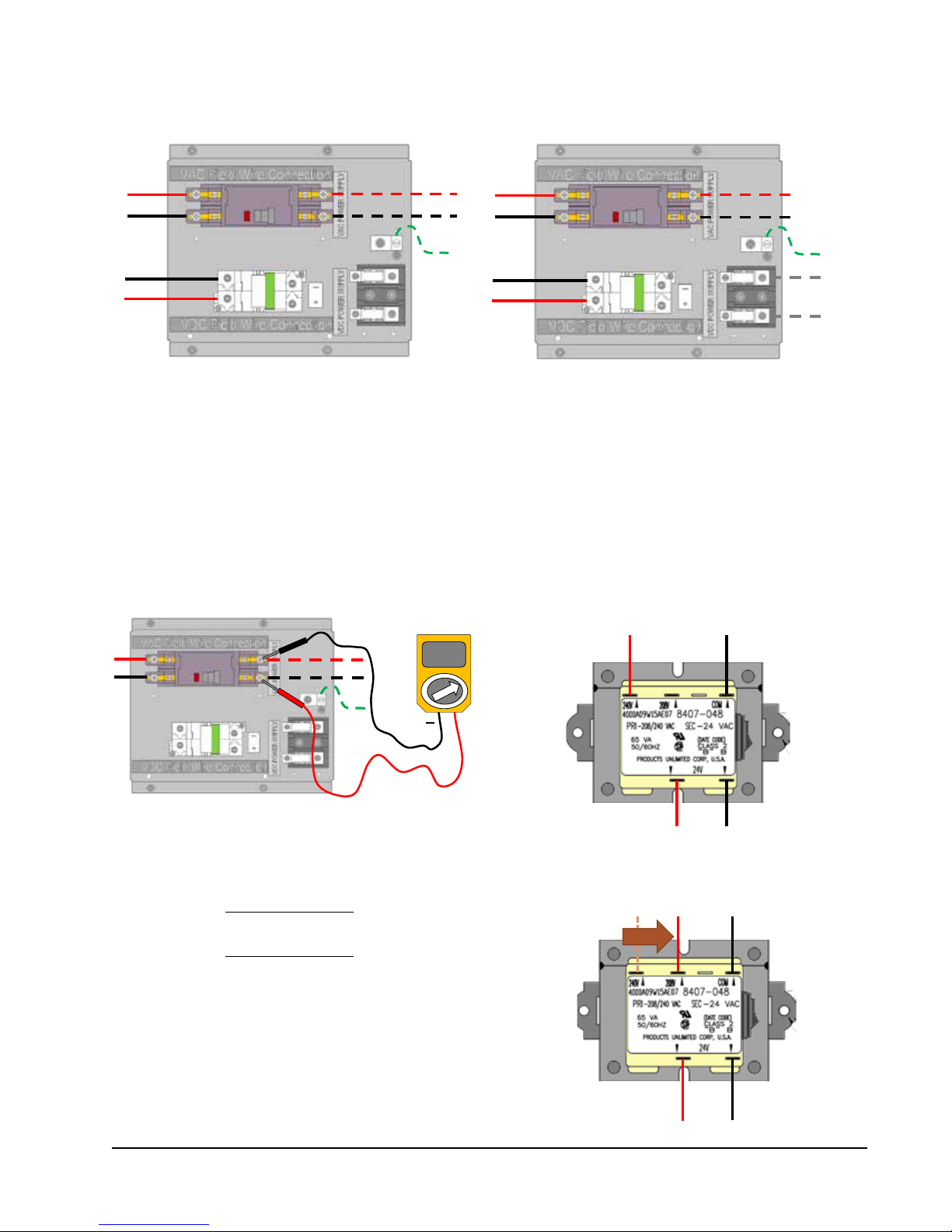

FIGURE 1.9

VAC and VDC Supply Wiring Landing Points

.

Field

Wiring

VDC

.

.

-

Factory

Wiring

VAC

Field Wiring

Factory

+

NOTE: Right-hand access model wiring landing points

are shown here; left-hand access models will

mirror this image.

Wiring

NOTE: Right-hand access model wiring landing points

are shown here; left-hand access models will

mirror this image.

FIGURE 1.10

Adjusting the 230/208 VAC Transformer

230/208V 1 phase and 3 phase equipment use dual primary voltage transformers. All equipment leaves the factory wired on

240V tap. It is very important that the correct voltage tap is used. For 208V operation, reconnect from 240V to 208V tap.

The acceptable operating voltage range for the 240 and 208V taps are: 240V Tap (253 – 216) and 208 Tap (220 – 197).

1. Verify incoming AC voltage: Multimeter set to VAC

2. If incoming AC voltage is 220VAC or above...

...do not adjust transformer

.

Shelter supply breaker in ON position

Bard system breaker in OFF position

230V/208V Single Phase Voltage Range:

197VAC – 253VAC

230V/208V Three Phase Voltage Range:

197VAC – 253VAC

(not shown)

230VAC

+

3. If incoming AC voltage is below 220VAC...

...shut off AC breaker to unit

and move factory "240V" wire to "208V" terminal

Manual 2100-643C

Page 17 of 59

Page 18

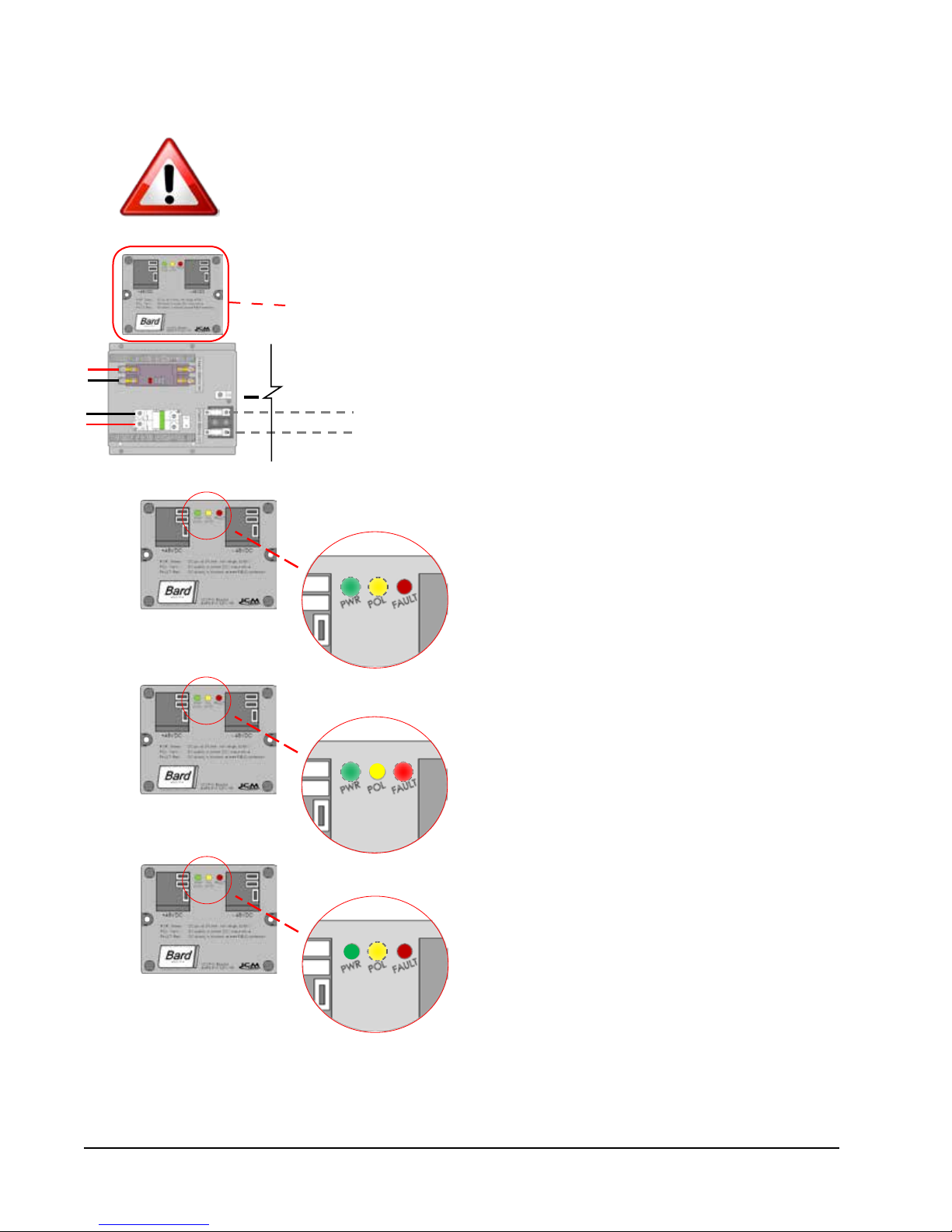

FIGURE 1.11

Bard Polarity-Voltage Monitor

If the VDC wiring is not terminated correctly on the specific polarity-indicated

terminals of the VDC terminal block, the VDC controls and motors will not activate

and the wall-mounted unit will not function.

The Bard Polarity-Voltage Monitor continually monitors for correct polarity and

voltage. If field wiring is connected improperly, or the voltage is outside of the

system parameters, the Polarity-Voltage Monitor will not allow any VDC voltage to

enter the system, protecting the internal controls and equipment.

+

When field wiring is correct in voltage and polarity, the

green power (PWR) LED and yellow polarity (POL) LED

will light, and system will operate normally.

If field wiring is incorrect in polarity, the red FAULT

LED will light, and the monitor will not allow VDC

voltage into the system.

If field wiring is correct in polarity but outside of the

required 40VDC – 56VDC, the green PWR LED will not

illuminate and the monitor not allow VDC voltage into

the system.

If the Polarity-Voltage Monitor is showing a problem with polarity and/or voltage, see pages 41 and 42 of the Service

section of this manual for instructions on checking VDC polarity and verifying incoming VDC voltage.

Manual 2100-643C

Page 18 of 59

Page 19

PRELIMINARY START-UP

RUNNING IN STAND ALONE (ORPHAN) MODE

With both AC and DC breakers turned on, each D-Series wall-mount system has the capability to run without the

controller attached—this feature is called Stand Alone or Orphan Mode, and it basically keeps the shelter between

60°F and 78°F by the use of the factory-installed return air sensor in each wall-mount unit.

During installation, this allows deactivation of one of the two existing, older wall-mount units, while keeping the

shelter cool with the other unit still operating. Once the first of the two Bard wall-mount units is installed, Orphan

Mode can be enabled early in the installation—keeping the climate inside the shelter stable and the installers

comfortable while the remainder of the older equipment is removed and the second Bard wall-mount unit and

controller are installed.

Additionally, should either or both D-Series wall-mount units lose communication with the controller (such as during

maintenance), they will continue to serve the shelter's needs until a repair can be made.

See the LC Series controller manual for information on connecting the communication wiring from the controller to

the two wall-mount units and operating the DC free cooling unit system.

Manual 2100-643C

Page 19 of 59

Page 20

Manual 2100-643C

Page 20 of 59

Page 21

SECTION 2:

SERVICE

INSTRUCTIONS

Manual 2100-643C

Page 21 of 59

Page 22

GENERAL REFRIGERANT INFORMATION

REMEMBER: When adding R-410A refrigerant, it must

come out of the charging cylinder/tank as a liquid to

avoid any fractionation and to insure optimal system

performance. Refer to instructions for the cylinder that

These units require R-410A refrigerant and

polyol ester oil.

GENERAL

1. Use separate service equipment to avoid cross

contamination of oil and refrigerants.

2. Use recovery equipment rated for R-410A

refrigerant.

3. Use manifold gauges rated for R-410A (800

psi/250 psi low).

R-410A is a binary blend of HFC-32 and HFC-125.

4.

5. R-410A is nearly azeotropic—similar to R-22 and

R-12. Although nearly azeotropic, charge with

liquid refrigerant.

6. R-410A operates at 40-70% higher pressure than

R-22, and systems designed for R-22 cannot

withstand this higher pressure.

7. R-410A has an ozone depletion potential of zero,

but must be reclaimed due to its global warming

potential.

8. R-410A compressors use polyol ester oil.

9. Polyol ester oil is hygroscopic; it will rapidly absorb

moisture and strongly hold this moisture in the oil.

10. A liquid line dryer must be used—even a deep

vacuum will not separate moisture from the oil.

11. Limit atmospheric exposure to 15 minutes.

12. If compressor removal is necessary, always plug

compressor immediately after removal. Purge with

small amount of nitrogen when inserting plugs.

TOPPING OFF SYSTEM CHARGE

If a leak has occurred in the system, Bard

Manufacturing recommends reclaiming, evacuating

(see criteria above) and charging to the nameplate

charge. If done correctly, topping off the system charge

can be done without problems.

With R-410A, there are no significant changes in the

refrigerant composition during multiple leaks and

recharges. R-410A refrigerant is close to being an

azeotropic blend (it behaves like a pure compound

or single component refrigerant). The remaining

refrigerant charge in the system may be used after

leaks have occurred. “Top-off” the charge by utilizing

the pressure charts on the inner control panel cover as

a guideline.

is being utilized for proper method of liquid extraction.

SAFETY PRACTICES

1. Never mix R-410A with other refrigerants.

2. Use gloves and safety glasses. Polyol ester oils can

be irritating to the skin, and liquid refrigerant will

freeze the skin.

3. Never use air and R-410A to leak check; the

mixture may become flammable.

4. Do not inhale R-410A—the vapor attacks

the nervous system, creating dizziness, loss

of coordination and slurred speech. Cardiac

irregularities, unconsciousness and ultimately

death can result from breathing this concentration.

5. Do not burn R-410A. This decomposition produces

hazardous vapors. Evacuate the area if exposed.

6. Use only cylinders rated DOT4BA/4BW 400.

7. Never fill cylinders over 80% of total capacity.

8. Store cylinders in a cool area, out of direct

sunlight.

9. Never heat cylinders above 125°F.

10. Never trap liquid R-410A in manifold sets, gauge

lines or cylinders. R-410A expands significantly at

warmer temperatures. Once a cylinder or line is full

of liquid, any further rise in temperature will cause

it to burst.

R410-A REFRIGERANT CHARGE

This unit was charged at the factory with the quantity

of refrigerant listed on the serial plate. AHRI capacity

and efficiency ratings were determined by testing with

this refrigerant charge quantity.

The pressure table found on the following page

shows nominal pressures for the units. Since many

installation specific situations can affect the pressure

readings, this information should only be used by

certified technicians as a guide for evaluating proper

system performance. They shall not be used to adjust

charge. If charge is in doubt, reclaim, evacuate and

recharge the unit to the serial plate charge.

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on

all units so that the system operating pressures can be

observed. A pressure table covering all models can be

found on page 23. It is imperative to match the correct

pressure table to the unit by model number.

Manual 2100-643C

Page 22 of 59

Page 23

This unit employs high-flow Coremax valves instead of

the typical Shrader type valves.

WARNING! Do NOT use a Schrader valve core removal

tool with these valves. Use of such a tool could result

in eye injuries or refrigerant burns!

TABLE 2.1

Nominal Pressures

To change a Coremax valve without first removing the

refrigerant, a special tool is required which can be

obtained at www.fastestinc.com/en/SCCA07H. See the

replacement parts manual for replacement core part

numbers.

Model

D25A/L

D28A/L

D35A/L

D36A/L

D42A/L

D48A/L

D60A/L

Return Air

Temperature

75° DB

62° WB

80° DB

67° WB

85° DB

72° WB

75° DB

62° WB

80° DB

67° WB

85° DB

72° WB

75° DB

62° WB

80° DB

67° WB

85° DB

72° WB

75° DB

62° WB

80° DB

67° WB

85° DB

72° WB

75° DB

62° WB

80° DB

67° WB

85° DB

72° WB

75° DB

62° WB

80° DB

67° WB

85° DB

72° WB

75° DB

62° WB

80° DB

67° WB

85° DB

72° WB

Pressure

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side

High Side

Low Side Pressure ±4 PSIG

High Side Pressure ±10PSIG

Air Temperature Entering Outdoor Coil, Degree °F

75 80 85 90 95 100 105 110 115 120

132

133

134

136

137

138

140

142

144

292

141

299

146

309

137

279

146

286

151

296

118

327

126

335

130

347

133

313

142

321

147

332

131

315

140

323

145

334

133

325

142

333

147

345

129

353

138

362

143

375

308

142

316

147

327

137

299

146

307

151

318

120

349

128

358

132

371

135

327

144

335

149

347

132

331

141

339

146

351

136

341

145

350

150

362

130

362

139

371

144

384

327

143

335

148

347

137

321

147

329

152

341

122

371

131

381

136

394

137

342

146

351

151

363

134

348

143

357

148

369

137

360

147

369

152

382

132

374

141

384

146

397

347

145

356

150

368

139

342

149

351

154

363

125

396

134

406

139

420

138

361

148

370

153

383

136

368

145

377

150

390

139

379

149

389

154

403

133

390

142

400

147

414

369

146

378

151

391

140

366

150

375

155

388

127

421

136

432

141

447

139

382

149

392

154

406

137

388

147

398

152

412

141

401

151

411

156

425

134

410

143

420

148

435

392

148

402

153

416

141

389

151

399

156

413

129

448

138

459

143

475

141

406

151

416

156

431

139

410

149

421

154

436

142

424

152

435

157

450

136

432

145

443

150

459

417

150

428

155

443

143

413

153

424

158

439

132

475

141

487

146

504

143

432

153

443

158

459

142

435

152

446

157

462

144

449

154

461

159

477

137

458

146

470

151

486

445

152

456

157

472

144

439

154

450

159

466

134

504

143

517

148

535

145

461

155

473

160

490

144

461

154

473

159

490

145

477

155

489

160

506

137

488

147

501

152

519

474

154

486

159

503

146

464

156

476

161

493

136

533

145

547

150

566

147

492

157

505

162

523

146

489

156

502

161

520

147

505

157

518

162

536

139

522

149

535

154

554

147

505

157

518

162

536

148

491

158

504

164

522

137

565

147

579

152

599

149

527

159

540

165

559

149

520

159

533

165

552

148

535

158

549

164

568

140

559

150

573

155

593

FIGURE 2.1

Refrigerant Sight Glass

Capacitors

Part No. Ratings

8552-050

8552-002

8552-055

8552-005

8552-052

8552-002

8552-079

8552-005

8552-079

8552-005

8552-089

8552-005

8552-058

8552-005

1 Ø, 240V

40+15/370

3 Ø, 240V

5/370

1 Ø, 240V

40+.10/370

3 Ø, 240V

10/370

1 Ø, 240V

45+15/370

3 Ø, 240V

5/370

1 Ø, 240V

45+10/370

3 Ø, 240V

10/370

1 Ø, 240V

45+10/370

3 Ø, 240V

10/370

1 Ø, 240V

70+10/370

3 Ø, 240V

10/370

1 Ø, 240V

80+10/440

3 Ø, 240V

10/370

The refrigerant sight glass installed in this unit is not a

charging indicator. The sight glass is for moisture reference

only. If charge is in doubt, reclaim, evacuate and recharge

the unit to the serial plate charge.

Manual 2100-643C

Page 23 of 59

Page 24

SEQUENCE OF OPERATION

D-SERIES WALL-MOUNT UNIT

SEQUENCE OF OPERATION

Overview

This product is designed to function like a typical

telecom air conditioning system with an outdoor aircooling damper. However, the DC Free Cooling Unit

system does have some special features, like a control

board which allows for advanced alarming and a “DC

Free Cooling” feature that allows for forced emergency

ventilated cooling anytime “shore power” VAC power

from the utility company is lost. The internal controls

within this unit automatically recognize a loss of shore

power, energizing the indoor blower motor and powering

the actuator to open the damper to bring in outdoor air.

The power utilized during this time is the stored battery

power from the equipment shelter.

Indoor Blower

The indoor blower is a 48VDC motor, completely

separate from the VAC circuit(s). For the blower to

activate, two separate actions must take place:

1. 24VDC from terminal N07 (Blower Motor Start

Relay)

2. 0-10VDC signal from terminal Y1 (Speed Voltage)

While the 24VDC from N07 will always stay the

same, the 0-10VDC signal from terminal Y1 will vary

depending upon the mode. See Table 2.2.

DC Free Cooling Damper

This controller is enabled for dewpoint control,

specifically examining the combination of temperature

and relative humidity to determine the proper control

of cooling. The system will utilize free cooling when the

following conditions are true:

1. The outdoor temperature is below 70°F

2. The dewpoint of the outdoor air is below 60°F

3. The outdoor humidity is below 80% RH

4. The indoor humidity is below 60% RH

To signal the 24VDC damper actuator to open, a

2-10VDC signal must come from the Y2 terminal.

Additionally, while other modes get only a single speed

from the indoor blower, free cooling mode will get two:

one for outdoor air temperature above 40°F (faster), and

another for those below 40°F (slower). See Table 2.2.

Cooling Call

When a call for cooling generates from the controller,

the system will first determine which mode of cooling

to employ based on the outdoor temperature, the

outdoor humidity and the indoor temperature.

• If the outdoor temperature and humidity ratio are

conducive to free cooling, the control board will

send:

1. 2-10VDC Signal from Y2 (Damper Signal)

- Modulates damper to achieve 55°F at

supply air temperature sensor

2. 24VDC from terminal N07 (Blower Motor Start

Relay)

3. 0-10VDC signal from terminal Y1 (Speed

Voltage)

• If the outdoor conditions are conducive to free

cooling, but a 2nd stage cooling call is generated,

the board will additionally add 24VAC signal

from the N02 terminal to the CCM, activating the

compressor. The damper will limit outdoor air to

keep supply air temperature at 55°F.

Model Blower Only

D25A/D25L

D28A/D28L 800/2.8 1100/3.8 1800/7.0

D35A/D35L 1100/3.0 1100/4.0 1100/4.0

D36A/D36L 800/2.8 1100/3.8 1800/7.0

D42A/D42L 950/3.1 1250/4.7 1800/7.0

D48A/D48L 1100/3.8 1600/6.3 1800/7.0

D60A/D60L 1100/3.8 1600/6.3 1800/7.0

Manual 2100-643C

Page 24 of 59

Same as

Free Cooling

Mode

Free Cooling Mode

TABLE 2.2

Blower Speed Voltage Chart

Free Cooling Mode

(CFM/VDC

Speed Voltage)

1500/6.0

Below 40°F

(CFM/VDC

Speed Voltage)

900/2.0 900/2.0 1100/4.0

Cooling

(CFM/VDC

Speed Voltage)

Electric Heat

Page 25

• If conditions outside are not conducive to free

cooling, the control board will send:

1. 24VAC signal from N02 to CCM (Compressor)

2. 24VDC from terminal N07 (Blower Motor Start

Relay)

3. 0-10VDC signal from Y1 (Speed Voltage)

Heating Call

When a call for heating generates from the controller,

the control board will send:

1. 24VAC signal from terminal N04 to heat strip

contactor.

2. 24VDC from terminal N07 (Blower Motor Start

Relay)

3. 0-10VDC signal from terminal Y1 (Motor Speed)

FIGURE 2.2

Wall-Mount Unit Control Board

Loss of Utility Power

When AC power is lost to the unit (no shore power,

no generator), the AC power loss relay will send a

digital input to terminal DI 1, alerting the board. If

the temperature outside is warmer than the shelter

internal temperature, the units will remain static. If

the temperature outside is cooler than the internal

temperature and there is a generated cooling call, the

control board will send:

1. 2-10VDC Signal from terminal Y2 (Damper Signal)

- Modulates damper to achieve 55°F at supply

air temperature sensor

2. 24VDC from terminal N07 (Blower Motor Start

Relay)

3. 0-10VDC signal from terminal Y1 (Motor Speed)

High Pressure/Comp Control Module

Low Pressure Switch

Damper Blade Switch

Common

0-10VDC Indoor Blower Speed Signal

2-10VDC Free-Cooling Damper Signal

Power Loss Relay

Dirty Filter Switch

Common

Common

24VDC to OA Humidity Sensor

Ground

Freezestat Sensor 10kΩ

OA Hum Sensor 4-20mA

RA Temp Sensor 10kΩ

OA Temp Sensor 10kΩ

Supply Air Sensor 10kΩ

–24VDC from Power Converter

+24VDC from Power Converter

24VDC from 48VDC-24VDC Converter

24VDC Output to Blower Motor Start Relay

24VAC Heating Output

24VAC Input

– Communication Wire

+ Communication Wire

24VAC Input

24VAC Compressor Output

Manual 2100-643C

Page 25 of 59

Page 26

Special Considerations

• Compressor Run Time – Once activated, the

compressor will run for a minimum of 5 minutes,

regardless of setpoint (control board programming)

• Compressor Off Time – Once deactivated, the

compressor will not start again for a minimum of 2

minutes.

• High Pressure Situation – The high pressure switch

routes through the compressor control module

(CCM), which allows one switch opening followed

by a delay (soft lockout) of at least 2 minutes

before trying again. If the switch is still open—or

opens again on the same call—the CCM locks out

the compressor and outdoor fan. Additionally, the

CCM will send 24V to the high pressure alarm

relay, which will then send a digital input to the DI

3 terminal.

• Low Pressure Situation – The low pressure switch

is connected directly to DI 4:

1. On a call for cooling, the board ignores the

low pressure switch status for 2 minutes (OAT

above 50°F) or 3 minutes (OAT below 50°F).

2. If the switch is still open, the compressor

will shut down and the controller will wait an

additional 2 minutes.

3. If the switch is still open, the controller will

notify of an alarm and lock out the compressor.

However, if the switch closes during this time,

the compressor will start again and wait for 2

minutes (OAT above 50°F) or 3 minutes (OAT

below 50°F).

4. If the low pressure switch is open at this time,

the compressor will lock out and the controller

will notify of an alarm.

• High Temperature 2 Alarm – Should the shelter

controller see 90°F, both free-cooling dampers will

open (regardless of outdoor temperature) to cool

the building.

• Smoke Alarm – Should the smoke detector send

an alarm signal to the controller, all blower,

compressor and ventilations functions cease.

• Hydrogen Alarm – Should the hydrogen detector

send an alarm signal to the controller, both

free cooling dampers will open (regardless of

temperature) to dilute the shelter air.

• Freezestat – If the coil temperature is below 30°F

for 120 seconds, the compressor will deactivate for

5 minutes, or until the sensor sees 55°F, whichever

comes first.

• Generator Run – During generator operation, the

system may limit compressor operation to only one

unit providing that a specific jumper was removed

from the LC controller terminal block and the

alarm wires were connected to a generator-run

relay (please refer to the Installation section of this

manual regarding alarms and wiring).

Manual 2100-643C

Page 26 of 59

Page 27

FIGURE 2.3

TEC-EYETM Display

USING THE TEC-EYE

TM

ALARM KEY

MENU KEY

ESCAPE KEY

ALARM KEY

Allows viewing of active alarms

Silences audible alarms

Resets active alarms

MENU KEY

Allows entry to Main Menu

ESCAPE KEY

Returns to previous menu level

Cancels a changed entry

UP KEY

Steps to next screen in the display menu

Changes (increases) the value of a modifiable field

ENTER KEY

Accepts current value of a modifiable field

Advances cursor

DOWN KEY

Steps back to previous screen in the display menu

Changes (decreases) the value of a modifiable field

TEC-EYETM HAND-HELD DIAGNOSTIC

TOOL

The microprocessor control used in this wall mount

air conditioning system allows for complete control

and monitoring through the use of the provided TEC-

TM

EYE

hand-held monitor. This comprehensive service

tool utilizes the latest in state-of-the-art technology

including a large, easy-to-read backlit LCD graphic

display.

The menu driven interface provides users the ability

to scroll through three menu levels: Info, Control and

Service. The menus permit the user to easily view,

control and configure the unit.

The controller is completely programmed at the factory;

therefore, most applications will require no field set-up.

However, the default setpoints and their ranges are

easily viewed and adjusted from the TEC-EYE

The program and operating parameters are permanently

stored on FLASH-MEMORY in case of power failure.

The controller is designed to manage temperature

levels to a user-defined setpoint via control output

signals to the wall mount air conditioning system.

TM

The TEC-EYE

connects to the wall-mount unit control

board via an RJ11 modular phone connector as shown

in Figure 2.4.

TM

display.

UP KEY

ENTER KEY

DOWN KEY

The TEC-EYETM hand-held diagnostic tool should be

stored somewhere inside the shelter, preferably close to

TM

the controller. The TEC-EYE

has integrated magnets

on the back of the tool, so it can be attached to the

front, sides, bottom or top of the control box.

FIGURE 2.4

TEC-EYETM Connection to Unit Control

Modular Phone Connector for

TM

TEC-EYE

Hand-Held Diagnostic Tool

Manual 2100-643C

Page 27 of 59

Page 28

TEC-EYETM Menu Structure

On/Off Unit

Setpoints

Clock/Scheduler

Input/Output

Analog Inputs

Digital Inputs

Relay Outputs

Analog Outputs

Alarm History

Technician

Information

Working Hours

Service Settings

Control Loops

Probe Adjustment

Manual Management

Analog Inputs

Digital Inputs

Relay Outputs

Analog Outputs

Factory

Configuration

I/O Configuration

Factory Settings

In addition to the menu structure above, there are also

Status and Alarm screens.

Status Screen

The STATUS screen is the default start-up screen and

also the return screen after 5 minutes of no activity.

The screen can be accessed any time by pressing the

ESCAPE button repeatedly.

The STATUS screen displays the current date, time,

return air temperature, supply air temperature, outdoor

air temperature, outdoor humidity and dewpoint

conditions. It also indicates the current system

operating status for Unit 1 (U1) or Unit 2 (U2). The

screen displays whether the blower is off or on and

what percentage the damper is open.

FIGURE 2.5

TEC-EYETM Status Display

TM

TEC-EYE

Acronyms

SAT – Supply air temperature

RAT – Return air temperature

OAT – Outdoor air temperature

OAH – Outdoor air humidity

Sp – Temperature setpoint

Space – Space temperature

U1 – Unit 1

U2 – Unit 2

F – Indoor blower status

D – DC free cooling damper position status

EM – Emergency ventilation mode

C1 – Compressor activate status

HT – Heater status

OA Dew Point – Calculated outdoor dew point

FC – DC free cooling status

RN – Component run time in minutes in last hour

ST – Number of start requests in last hour

Press the MENU key to access the Main Menu

screen. Press the UP or DOWN keys to scroll through

the available menus. When the desired menu is

highlighted, press the ENTER key to access that menu.

Press the ESCAPE key or MENU key to return to the

STATUS screen from the Main Menu.

For the following items, press the MENU key to access

programming.

Executing a Run Test

Execute a run test on each unit to verify the equipment

is functioning correctly.

1. Go to Technician menu, press ENTER key.

2. Press UP or DOWN arrow keys to get to Service

Settings menu, press ENTER key.

3. Press UP or DOWN arrow keys to get to Control

Loops menu, press ENTER key.

4. Cursor will be flashing in upper left corner of

screen. Press DOWN arrow key to scroll through

screens to Run Test.

5. Press ENTER key to scroll to Enable. Press UP or

DOWN arrow keys to change No to Yes. Unit will

begin the run test.

Run Test Approximate Timings (in Minutes)

Blower On: 0:00

Damper Open: 0:00 – 2:40

Closed: 2:41 – 4:57

Compressor On: 4:58

Off: 6:00

Heat On: 6:01

Off: 7:10

Blower Off: 8:19

Manual 2100-643C

Page 28 of 59

Page 29

Identifying a Unit Address

1. Go to Setpoints menu, press ENTER key.

2. Press UP or DOWN arrow keys to get to Fieldbus

Address, press ENTER key. The wall-mount unit's

current address value will display.

NOTE: This value can be changed if there was an error

with the Auto Address sequence or the user would like

to manually set the address of the unit.

Manual Override Outputs

Blower

1. Go to Technician menu, press ENTER key.

2. Go to Manual Management, press ENTER key.

3. Go to Relay Outputs, press the DOWN arrow to get

to Blower Relay Output. Move the cursor to the

selected choice by pressing the ENTER key. Press

UP or DOWN arrow keys to change the Manual

Relay and Manual Position to “ON.”

4. Press ESCAPE key, go to Analog Outputs.

5. Go to Blower Motor Analog Output, press Enter

key to move the cursor to Mode. Change to Hand

by pressing the UP arrow key. Press ENTER key.

Next change the Manual Value to test blower speed

voltage for the unit model and press ENTER key.

Refer to the unit blower speed voltages provided in

Table 2.6 on page 40; do not exceed the maximum

speed voltage (VDC) for the unit model.

DC Free Cooling Damper

1. Go to Technician menu, press ENTER key.

2. Go to Manual Management, press ENTER key.

3. Go to Analog Outputs, press ENTER key.

4. Press DOWN arrow key to scroll screens to Analog

Output 2 Damper.

5. Press ENTER key to scroll to Mode line. Press

DOWN key to change Auto to Hand.

6. Press ENTER key to scroll to Manual Value line;

Press UP or DOWN arrow keys to change the

manual value to a desired value (maximum is

10VDC) to perform damper test.

7. Verify damper operation.

Compressor

1. Go to Technician menu, press ENTER key.

2. Go to Manual Management, press ENTER key.

3. Go to Relay Output, press ENTER key.

4. Go to Relay Output Cooling Stage. Press UP or

DOWN arrow keys to change Manual Relay to

“ON”; press ENTER key. Press UP or DOWN arrow

keys to change manual position to “ON” and press

ENTER key.

5. Verify compressor is running.

Heat

1. Go to Technician menu, press ENTER key.

2. Go to Manual Management, press ENTER key.

3. Go to Relay Output, press ENTER key.

4. Go to Relay Output Heating, press ENTER key.

5. Press UP or DOWN arrow keys to change Manual

Relay and Manual Position to “ON” and press

ENTER key.

6. Verify heater “ON” status.

The Bard DC Free Cooling Unit System has been pre-programmed with what is widely

considered to be the best settings for efficiency and operation. Any changes to internal

programming through the LC Series Controller or the TEC-EYE

manual may cause the systems to operate improperly, cause internal damage to the

HVAC units, cause the shelter to overheat or other very serious consequences. Although

complete controller programming architecture for both the LC Controller and TEC-

TM

EYE

has been provided, going outside the boundaries of what has been covered in

this manual is not recommended.

CAUTION

TM

not covered within this

Manual 2100-643C

Page 29 of 59

Page 30

COMPONENTRY SPECIFICATIONS

OUTDOOR TEMPERATURE/HUMIDITY

!

WARNING

Electrical shock hazard.

Disconnect both VAC and VDC power supplies

before servicing.

Failure to do so could result in electric shock

or death.

LOW PRESSURE SWITCH

Cut-out pressure: 40psi (+/- 4 psi)

Cut-in pressure: 55psi (+/- 4psi)

HIGH PRESSURE SWITCH

Cut-out pressure: 650psi (+/- 10 psi)

Cut-in pressure: 520psi (+/- 15psi)

LOW AMBIENT CONTROL

Modulating head-pressure control that allows full

speed at pressures above 315psi. Below 315psi, the

control will slow fan speed—following internal head

pressures—until a minimum RPM is reached (approx

300 RPM). Below this point, the control will shut the

fan completely off until internal pressures rise. The

control is preset from the factory, but should adjustment

become necessary, there is an adjustment screw located

on the bottom of the control behind a weatherproof cap.

One full turn clockwise equals approximately +48 psi.

REMOTE INDOOR TEMPERATURE

SENSOR

White, decorative plastic casing, Bard logo, fieldinstalled in shelter: 10k ohm resistance, see Table 2.3.

DISCHARGE TEMP SENSOR

4.75” stainless probe factory mounted in supply

opening of wall-mount unit: 10k ohm resistance, see

Table 2.3.

RETURN TEMPERATURE SENSOR

Exposed thermistor-element style with copper-coated

steel clip, attached in return opening of wall-mount

unit: 10k ohm resistance, see Table 2.3.

EVAPORATOR TEMP SENSOR

(FREEZESTAT)

Exposed thermistor-element style with copper-coated

steel clip, attached to evaporator coil of wall-mount unit:

10k ohm resistance, see Table 2.3.

SENSOR

Gray, weather-proof octagonal case with dip tube,

located in condenser section of wall-mount unit.

• Temperature sensor: 10k ohm resistance, see Table

• Humidity sensor: 4-20mA.

COMPRESSOR CONTROL MODULE

Compressor protection device that has an adjustable

30-second to 5-minute timer (red-dial). This module

features a delay-on-make for initial start-up (or anytime

power is interrupted) for a minimum 2 minutes plus

10% of the red-dial setting. There is no delay during

routine operation of the unit. The compressor control

module (CCM) also monitors the high pressure switch,

and will allow one automatic retry (after soft lockout

delay) before disabling the compressor in a hard

lockout (requires manual reset). If hard lockout does

occur, the ALR terminal on the CCM will become active

with 24V, which will power the high pressure relay

within the wall-mount unit, breaking a digital input to

the control board—signaling a high-pressure situation

to the system.

PHASE MONITOR

Used only on 3-phase equipment, the phase

monitor is a compressor protection device that will

prohibit operation of the compressor if the device

senses a possible reverse-rotation situation due to

incorrect phasing. On a call for compressor (and only

compressor), the device will check incoming phase,

check for severe voltage imbalance and check for

proper frequency. Under nominal conditions, a green

LED light will show on the face of the monitor. If there

is improper phasing, voltage imbalance or frequency

deviation, the device will show a red LED light and

prohibit compressor operation.

TRANSFORMER