Bard D48L2P/BLD.10309, D36L2P/BLD.10305, D60A2P/BLD.10310, D60L2P/BLD.10303, D42A2P/BLD.10306 Installation And Service Instructions Manual

...Page 1

INSTALLATION AND SERVICE

INSTRUCTIONS

&

REPLACEMENT PARTS MANUAL

DC FREE COOLING UNIT SYSTEM

TWO (2) D-SERIES DUAL-TEC™

WALL-MOUNTED PACKAGE

AIR CONDITIONERS

&

ONE (1) BARD-LINKTM PLC

LEAD/LAG CONTROLLER

AIR CONDITIONER MODELS

D36A2P/BLD.10304 D36L2P/BLD.10305

D42A2P/BLD.10306 D42L2P/BLD.10307

D48A2P/BLD.10308 D48L2P/BLD.10309

D60A2P/BLD.10310 D60L2P/BLD.10303

CONTROLLER MODELS

LC1000-100/BLD.10293

LC1500-100/BLD.10291

NOTE: BARD-LINKTM LC1000-1000 or LC1500-100 Controllers must be used

with D-Series Wall-Mount Units

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual : 2100-620A

Supersedes: 2100-620

Date: 3-25-15

Page 1 of 107

Page 2

CONTENTS

SECTION 1: Installation Instructions ......................................................................................................... 7

List of Necessary Materials/Tools .........................................................................................................................8

Site Preparation .................................................................................................................................................9

Wall-Mount Unit Installation .............................................................................................................................11

Wall-Mount Unit Supply Wiring ..........................................................................................................................15

Preliminary Start-Up .........................................................................................................................................19

Bard-LinkTM Controller Installation .....................................................................................................................20

System Start-Up ..............................................................................................................................................36

SECTION 2: Service Instructions ............................................................................................................... 39

General Refrigerant Information .........................................................................................................................40

Sequence of Operation .....................................................................................................................................42

Advanced Programming ....................................................................................................................................49

Using the TEC-EYE ..........................................................................................................................................54

Componentry Specifications ..............................................................................................................................57

Maintenance and Troubleshooting ......................................................................................................................64

SECTION 3: Parts Manual ............................................................................................................................ 73

D-Series Wall-Mount Unit .................................................................................................................................74

Bard-LinkTM PLC Lead/Lag Controller ..................................................................................................................88

SECTION 4: Appendices .............................................................................................................................. 91

Appendix 1: LC-Series Controller Architecture .....................................................................................................92

Appendix 2: TEC-EYE Architecture ....................................................................................................................99

FIGURES AND TABLES

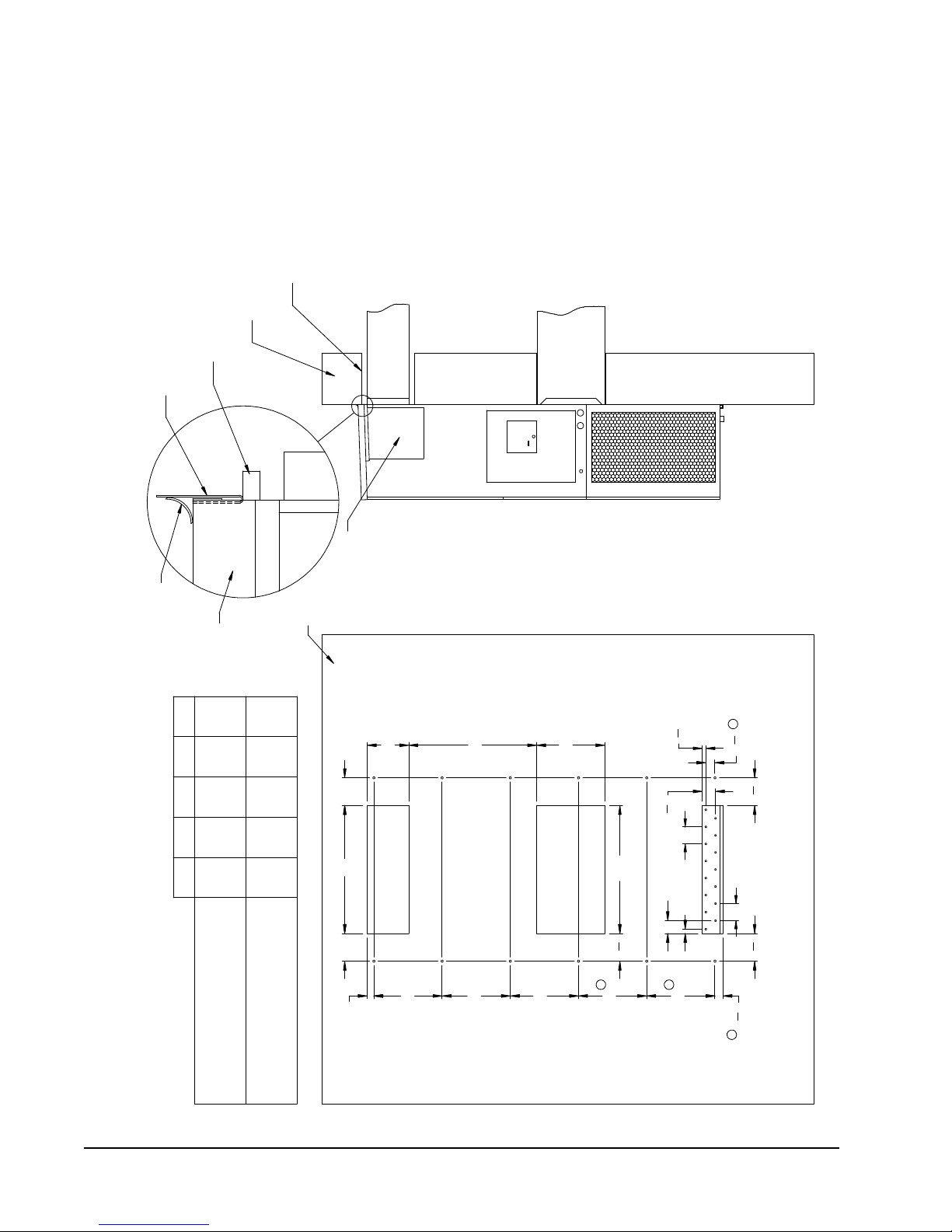

Figure 1.1 Wall-Mount Unit Model Nomenclature ......8

Figure 1.2 Dimensions ..........................................10

Figure 1.3 Mounting Instructions ...........................12

Figure 1.4 Electric Heat Clearance .........................13

Figure 1.5 Wall Mounting Instructions ....................13

Figure 1.6 Wall Mounting Instructions ....................14

Figure 1.7 Common Wall Mounting Installations ......14

Figure 1.8 Circuit Routing Label ............................16

Figure 1.9 WIRING:

Figure 1.10 Adjusting the 230/208VAC Transformer ..17

Figure 1.11 WIRING:

Figure 1.12 Bard Polarity-Voltage Monitor .................18

Figure 1.13 WIRING:

Figure 1.14 Remote Temperature Sensor Install ........22

Figure 1.15 Additional Remote Temp Sensor Install ...23

Figure 1.16 Power and Signal Connections – Smoke ..24

Figure 1.17 Power/Signal Connections – Hydrogen ....25

Figure 1.18 LC1000/LC1500 Generator Run ............25

Figure 1.19 WIRING:

Figure 1.20 WIRING:

Figure 1.21 WIRING: Communication Wiring ............28

Figure 1.22 WIRING: Communication Wiring:

Controller Termination ........................... 29

Figure 1.23 WIRING: Communication Wiring:

1st Unit Termination ............................. 30

Figure 1.24 WIRING: Communication Wiring:

2nd Unit Termination ............................ 31

Figure 1.25 Controller Circuit Install ........................32

Figure 1.26 Controller Grounding Posts ....................32

Figure 1.27 WIRING:

Figure 1.28 WIRING:

Figure 1.29 Bard-LinkTM Controller Display ...............36

Figure 1.30 Clock/Scheduler Menu ..........................36

Figure 1.31 Status Display Showing Units "Online" ....36

Figure 1.32 Executing Run Test ............................... 37

VAC Supply Wiring Landing Points . 16

VDC Supply Wiring Landing Points . 17

Typical LC1000/LC1500 Wiring .. 20

LC1000 External Alarm Wiring .. 26

LC1500 External Alarm Wiring .. 27

LC1000/LC1500 Wiring Diagram .. 34

LC1500 Punch-Down Block Wiring 35

Figure 2.1 Refrigerant Sight Glass .........................41

Figure 2.2 Wall-Mount Unit Control Board ..............43

Figure 2.3 Controller Board and Terminal Block .......45

Figure 2.4 LC Series Controller Control Board .........46

Figure 2.5 Free Cooling Damper Operation ..............48

Figure 2.6 Bard-LinkTM Controller Display ...............49

Figure 2.7 Controller Status Display .......................50

Figure 2.8 TEC-EYE Display ..................................54

Figure 2.9 TEC-EYE Connection to Unit Control ......54

Figure 2.10 TEC-EYE Status Display ........................55

Figure 2.11 Fan Blade Setting .................................59

Figure 2.12 Dirty Filter Switch .................................59

Figure 2.13 Power Loss Relay Circuit .......................60

Figure 2.14 High Pressure Relay Circuit ...................60

Figure 2.15 Blower Motor Start Relay Circuit ............60

Figure 2.16 Unit Control Panel ................................61

Figure 2.17 WIRING: Unit Wiring Diagram ................62

Figure 2.18 Low Voltage Connections .......................63

Figure 2.19 Troubleshooting Motor Power Supply ......65

Figure 2.20 Troubleshooting Motor Start Command ...66

Figure 2.21 Troubleshooting Speed Voltage ...............66

Figure 2.22 VDC Polarity Check ...............................67

Figure 2.23 Verifying Incoming Voltage .....................68

Table 1.1 Electrical Specifications ..........................15

Table 1.2 Terminal Block Index ............................... 33

Table 1.3 Controller Default Settings .......................38

Table 2.1 Nominal Pressures ..................................41

Table 2.2 Blower Speed Voltage Chart .....................42

Table 2.3 Controller Default Settings .......................48

Table 2.4 Controller Programmable Features ............52

Table 2.5 Temp vs. Resistance of Temp Sensor. ........ 58

Table 2.6 Indoor Blower Performance ......................59

Table 2.7 Troubleshooting 48VDC Blower Motor ........65

Table 2.8 Blower Speed Voltage Chart .....................66

Manual 2100-620A

Page 2 of 107

Page 3

GENERAL INFORMATION

DC FREE COOLING UNIT SYSTEM (DC-FCU)

The Bard DC Free Cooling Unit system is composed of two (2) D-Series DUAL-TEC™ wall-mounted air conditioners

matched with one (1) Bard-LinkTM PLC lead/lag controller. The D-Series, specifically engineered for the telecom

market, can provide outdoor air cooling during power loss situations through the use of onsite -48VDC positive

ground battery banks.

TM

NOTE: The Bard-Link

work together. The PLC controller cannot run other Bard models or other brands of systems, nor can other

controllers or thermostats run the D-Series wall-mount units. They are a complete system, and must be used

together.

WALL-MOUNT AIR CONDITIONER UNITS

The D-Series units operate on both VAC and VDC power under normal power supply conditions. If there is loss of VAC

power supply (shore and/or back-up generator) the unit will continue to operate as free cooling or ventilation system

using the shelter’s VDC power. The indoor blower and free cooling unit operate from -48VDC and no inverter is required.

The units will supply 100% of rated cooling airflow in free cooling mode with ability to exhaust the same amount

through the unit itself without any additional relief openings in the shelter.

Each of these units are fully charged with refrigerant and have auxilliary heat installed.

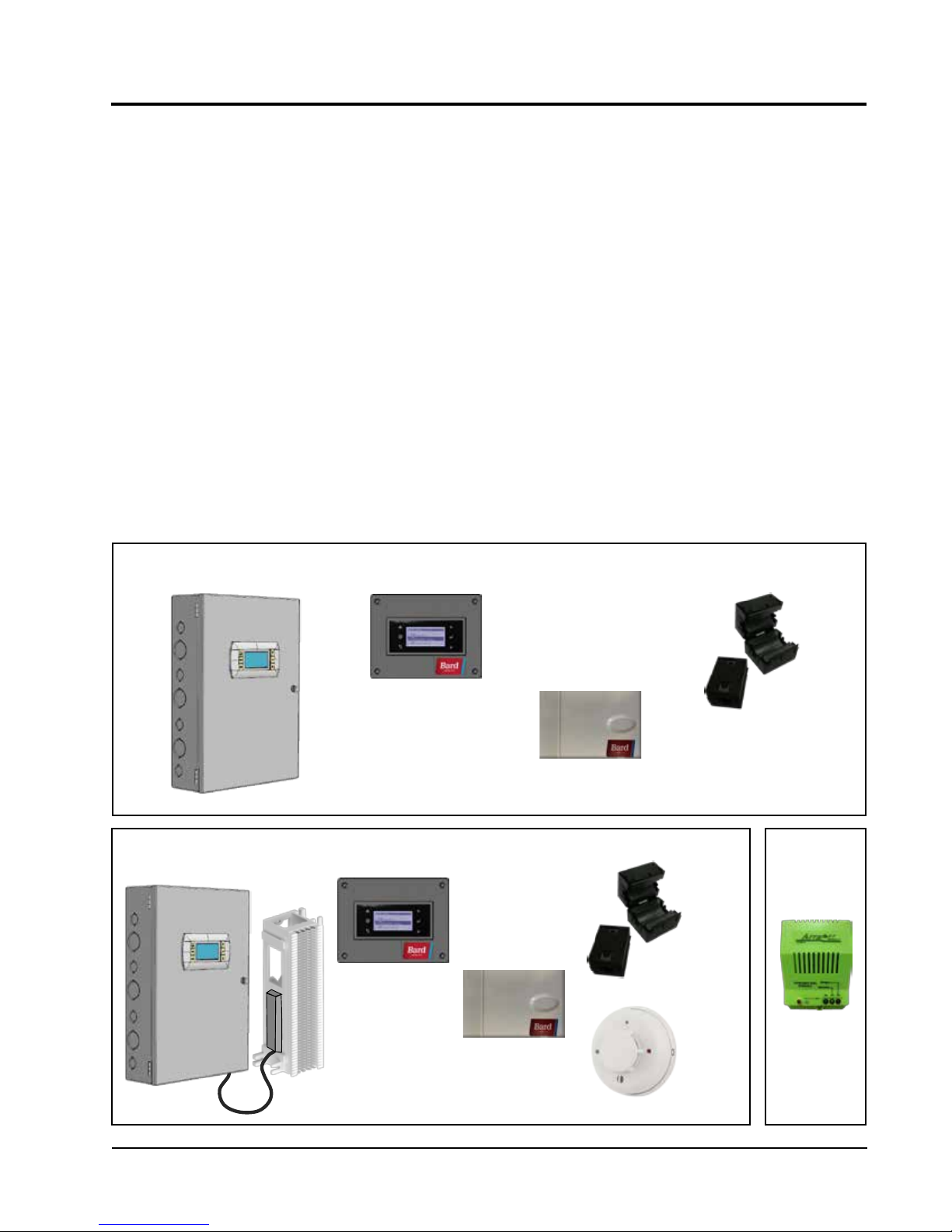

BARD-LINKTM PLC CONTROLLER

Two models: LC1000-100 and LC1500-100 (controllers and accessories included with controllers shown below).

PLC lead/lag controller and the D-Series wall-mount units are designed specifically to

LC1000-100 Series – New Shelters Only

TEC-EYE Hand-Held

Diagnostic Tool

Programmable Logic

Controller

Remote Temperature

Sensor with 35' Cable

LC1500-100 Series – EOL and All HVAC Replacement Projects

TEC-EYE Hand-Held

Diagnostic Tool

Programmable

Logic Controller

with Attached

66 Punch-Down

Block

Remote Temperature

Sensor with 35' Cable

Communication

EMI Filters

Communication

EMI Filters

VDC

Smoke

Detector

OPTIONAL

8301-061

VDC

Hydrogen

Detector

Manual 2100-620A

Page 3 of 107

Page 4

The equipment covered in this manual is to be installed

by trained, experienced service and installation

technicians.

The refrigerant system is completely assembled and

charged. All internal wiring is complete.

The unit is designed for use with or without duct work.

Flanges are provided for attaching the supply and return

ducts.

These instructions explain the recommended method

to install the air cooled self-contained unit and the

electrical wiring connections to the unit.

These instructions and any instructions packaged with

any separate equipment required to make up the entire

air conditioning system should be carefully read before

beginning the installation. Note particularly “Starting

Procedure” and any tags and/or labels attached to the

equipment.

While these instructions are intended as a general

recommended guide, they do not supersede any national

and/or local codes in any way. Authorities having

jurisdiction should be consulted before the installation

is made. See Page 3 for information on codes and

standards.

Sizing of systems for proposed installation should be

calculated by AT&T-specific methods/software using

regional climatic data and standards. The air duct

should be installed in accordance with the Standards

of the National Fire Protection Association for the

Installation of Air Conditioning and Ventilating Systems

of Other Than Residence Type, NFPA No. 90A, and

Residence Type Warm Air Heating and Air Conditioning

Systems, NFPA No. 90B. Where local regulations are at

a variance with instructions, installer should adhere to

local codes.

Shipping Damage

Upon receipt of equipment, the cartons should be

checked for external signs of shipping damage. If

damage is found, the receiving party must contact

the last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent.

These units must remain in upright position at all

times.

ADDITIONAL PUBLICATIONS

These publications can help you install the air

conditioner or heat pump. You can usually find these

at your local library or purchase them directly from the

publisher. Be sure to consult current edition of each

standard.

National Electrical Code ...................... ANSI/NFPA 70

Standard for the Installation of Air Conditioning

and Ventilating Systems ...................ANSI/NFPA 90A

Standard for Warm Air Heating

and Air Conditioning Systems ............ANSI/NFPA 90B

Load Calculation for Residential Winter

and Summer Air Conditioning ............. ACCA Manual J

Duct Design for Residential Winter and Summer

Air Conditioning and Equipment Selection

....................................................... ACCA Manual D

For more information, contact these publishers:

Air Conditioning Contractors of America (ACCA)

1712 New Hampshire Ave. N.W.

Washington, DC 20009

Telephone: (202) 483-9370

Fax: (202) 234-4721

American National Standards Institute (ANSI)

11 West Street, 13th Floor

New York, NY 10036

Telephone: (212) 642-4900

Fax: (212) 302-1286

American Society of Heating, Refrigeration and Air

Conditioning Engineers, Inc. (ASHRAE)

1791 Tullie Circle, N.E.

Atlanta, GA 30329-2305

Telephone: (404) 636-8400

Fax: (404) 321-5478

National Fire Protection Association (NFPA)

Batterymarch Park

P. O. Box 9101

Quincy, MA 02269-9901

Telephone: (800) 344-3555

Fax: (617) 984-7057

Manual 2100-620A

Page 4 of 107

Page 5

ANSI Z535.5 Definitions:

Danger: Indicate[s] a hazardous situation which, if

not avoided, will result in death or serious injury. The

signal word “DANGER” is to be limited to the most

extreme situations. DANGER [signs] should not be used

for property damage hazards unless personal injury risk

appropriate to these levels is also involved.

Warning: Indicate[s] a hazardous situation which, if

not avoided, could result in death or serious injury.

WARNING [signs] should not be used for property

damage hazards unless personal injury risk appropriate

to this level is also involved.

Caution: Indicate[s] a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION [signs] without a safety alert symbol may be

used to alert against unsafe practices that can result in

property damage only.

Notice: [this header is] preferred to address practices

not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an

alternative to “NOTICE” the word “CAUTION” without

the safety alert symbol may be used to indicate a

message not related to personal injury.

!

WARNING

Electrical shock hazard.

Have a properly trained individual perform

these tasks.

Failure to do so could result in electric shock

or death.

!

WARNING

Fire hazard.

Maintain minimum 1/4” clearance between the

supply air duct and combustible materials in

the rst 3’ feet of ducting.

Failure to do so could result in re causing

damage, injury or death.

!

WARNING

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

!

CAUTION

Cut hazard.

Wear gloves to avoid contact with sharp

edges.

Failure to do so could result in personal injury.

Manual 2100-620A

Page 5 of 107

Page 6

Manual 2100-620A

Page 6 of 107

Page 7

SECTION 1:

INSTALLATION

INSTRUCTIONS

Manual 2100-620A

Page 7 of 107

Page 8

LIST OF NECESSARY MATERIALS/TOOLS

Additional hardware and miscellaneous supplies are needed for installation. These items are field supplied and must

be sourced before installation. This list also includes tools needed for installation.

LIST OF MATERIALS/TOOLS

• Personal protective equipment/safety devices

• Supply/return grilles

• Field-fabricated sleeves (if necessary)

• 5/16" diameter anchor/carriage/lag bolts

• 7/8" diameter washers

• Caulking materials

• Miscellaneous hand and power tools and jobsite or

shop materials

• Lifting equipment with the necessary capacity and

rigging to safely move/install the systems

• Electrical supplies

- Two (2) 20A circuit breakers for the shelter DC

power plant (one per wall-mount unit)

- One (1) 5A circuit breaker for the shelter DC

power plant (for the Bard-Link

TM

controller)

- Two (2) various size circuit breakers for

the shelter AC breaker box (see Table 1.1:

Electrical Specifications on page 15)

- High-voltage wire of various gauges (see Table

1.1)

- Communication wire: 2-wire, 18 gauge,

shielded with drain

- 18 gauge non-shielded wire for connecting

smoke detector (and hydrogen detector and/or

generator, if applicable) to controller

-

CAT 6 Ethernet cable of field-determined length

(for remote communication, if applicable)

- Miscellaneous electrical supplies including

rigid/flexible conduit and fittings, junction

boxes, wire connectors and supports

The following are required and must be sourced

prior to installation of these units.

• Two (2) 20A circuit breakers for the shelter DC

power plant (one per wall-mount unit)

• One (1) 5A circuit breaker for the shelter DC

TM

power plant (for the Bard-Link

controller)

Circuit breakers for Emerson Network Power (ENP)

power plants (used in most telecomm shelters built

today) are available directly through the following

distributors:

• Emerson Network Power: 440.288.1122

• Master Electronics: 888.473.5297 or

www.onlinecomponents.com

Emerson Network Power (ENP) Part Numbers

• 20A circuit breaker: P/N 101601

• 5A circuit breaker: P/N 101598

Always confirm the application before ordering.

D-Series DUAL-TEC™ Wall-Mount Unit Model Nomenclature

D 36 A 2 P A 05 4 P X X X J

MODEL

SERIES

CAPACITY

36 – 3 Ton

42 – 3½ Ton

48 – 4 Ton

60 – 5 Ton

A – Right Hand

L – Left Hand

REVISION

PLC

VOLTS & PHASE

A – 230/208-60-1

B – 230/208-60-3

05 – 5 KW

06 – 6 KW

09 – 9 KW

10 – 10 KW

Manual 2100-620A

Page 8 of 107

KW

FIGURE 1.1

-48VDC

Free Cooling

Unit

CONTROL MODULES

J – High Pressure Switch, Low Pressure

Switch, Compressor Control Module,

Low Ambient Control, Alarm Contacts,

Start Assist

C – J Module + Compressor Crankcase

Heater

COIL OPTIONS

X – Standard

3 – Phenolic Coated Evaporator and

Condenser

SPECIAL FEATURES

COLOR OPTIONS

X – Beige

1 – White

4 – Buckeye Gray

FILTER OPTIONS

P – 2-Inch Pleated (MERV 8)

M – 2-Inch Pleated (MERV 11)

Page 9

SITE PREPARATION

NEW SHELTER INSTALLATION VS.

RETROFIT INSTALLATION

These installation instructions cover both new shelter

installations and retrofit installations. Each installation

is unique and may require special accomodations and

modifications. Although Bard Manufacturing follows a

long-established tradition of manufacturing equipment

using industry standard dimensions for building

penetration, it is occasionally necessary to move or

enlarge supply and return openings when replacing

non-standardized equipment in a retrofit application.

MINIMUM CLEARANCE

D-Series wall-mount air conditioners are available in

both right-hand access models and left-hand access

models. Right-hand access models have the heat strip

access panel, external circuit breakers access panel

and internal controls access panel on the right side of

the unit. Left-hand access models are a mirror image

of the right-hand access models, and allow two wallmount units to be placed in relatively close proximity

and yet still allow complete acess for maintenance and

repair.

On side-by-side installations, maintain a minimum of

26" clearance on control side to allow access to control

panel and heat strips, and to allow proper airflow to the

outdoor coil. For installations where units are installed

with both control panels facing each other (inward),

maintain a minimum of 36" clearance to allow access.

Additional clearance may be required to meet local or

national codes.

Care should be taken to ensure that the recirculation

and obstruction of condenser discharge air does not

occur. Recirculation of condenser discharge air can

be from either a single unit or multiple units. Any

object such as shrubbery, a building or a large object

can cause obstructions to the condenser discharge air.

Recirculation or reduced airflow caused by obstructions

will result in reduced capacity, possible unit pressure

safety lockouts and reduced unit service life.

For units with blow through condensers, such as the

D-Series units, it is recommended there be a minimum

distance of 10' between the front of the unit and

any barrier or 20' between the fronts of two opposing

(facing) units.

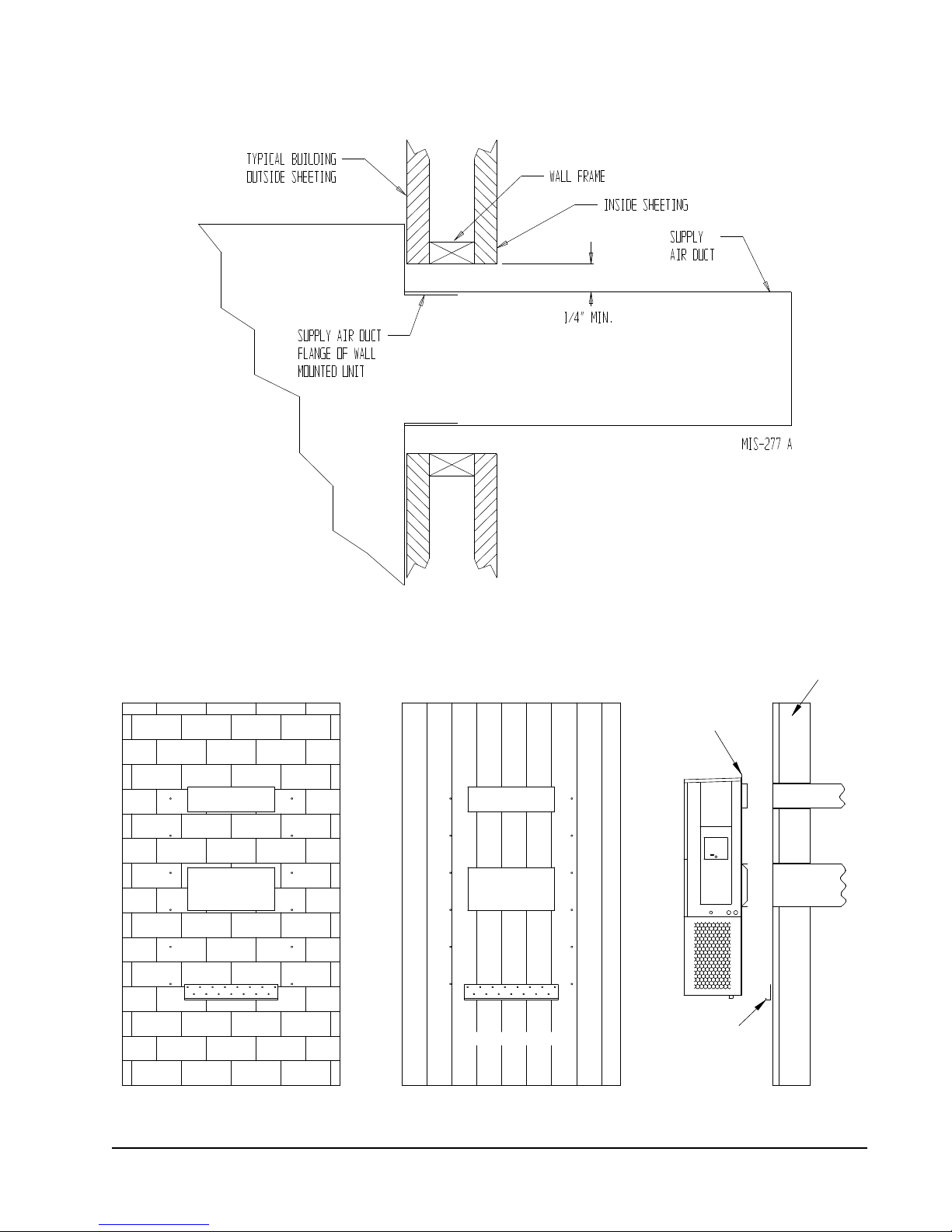

CLEARANCE TO COMBUSTIBLES

!

WARNING

Fire hazard.

Maintain minimum 1/4” clearance between the

supply air duct and combustible materials in

the rst 3’ feet of ducting.

Failure to do so could result in re causing

damage, injury or death.

The unit itself is suitable for 0" clearance, but the

supply air duct flange and the first 3' of supply air duct

require a minimum of 1/4" clearance to combustible

material. However, it is generally recommended that

a 1" clearance is used for ease of installation and

maintaining the required clearance to combustible

material. See Figure 1.3 on page 12 for details on

opening sizes.

Minimum Clearances Required to

Combustible Materials

MODELS

All covered by this

manual

SUPPLY AIR DUCT

FIRST 3'

1/4" 0"

CABINET

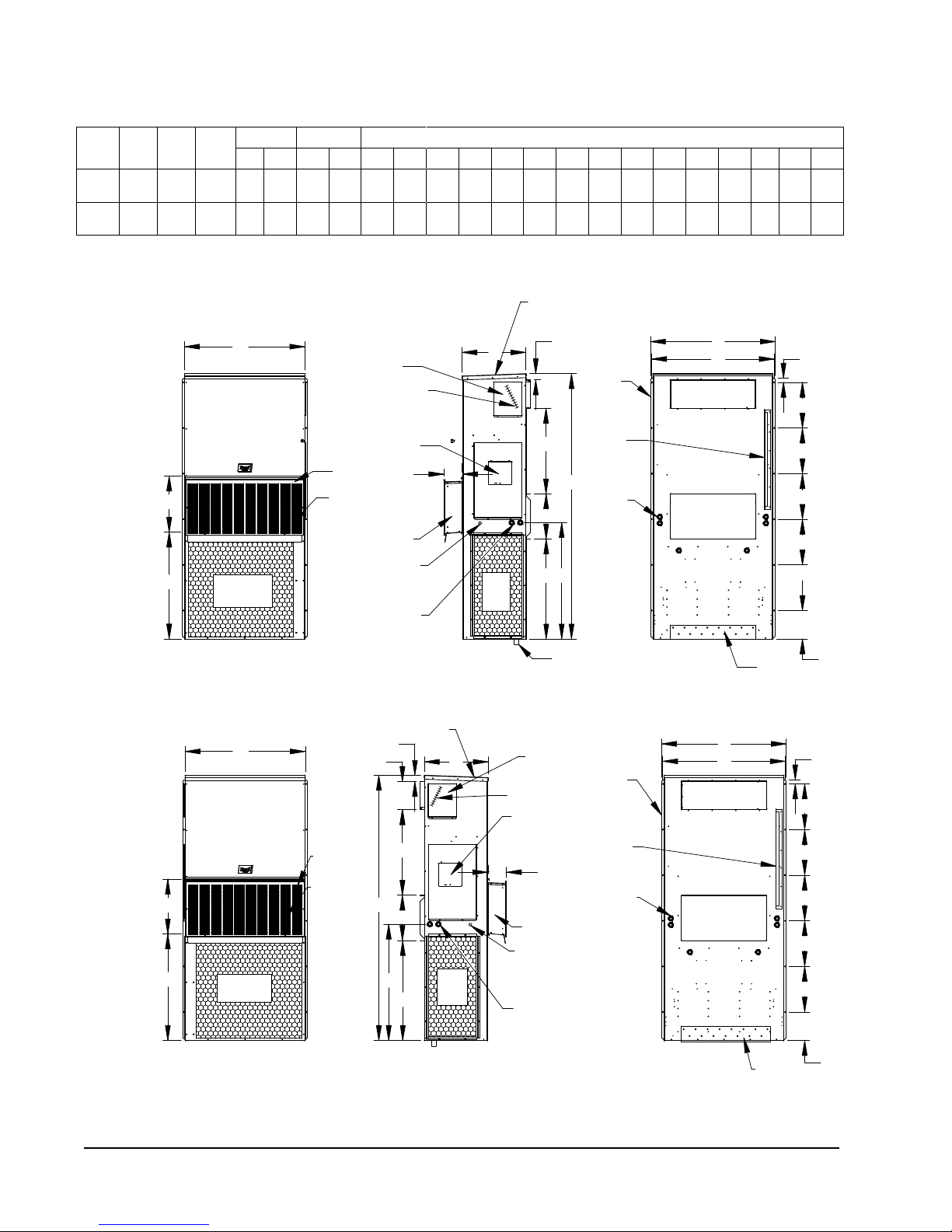

MODEL IDENTIFICATION

Identify the specific model using the model

nomenclature information found in Figure 1.1 and/

or model/serial tag found on the unit on the opposite

side of the control and access panels. See Figure 1.2

on page 10 for dimensions and critical installation

requirements.

Clearances Required for Service Access

and Adequate Condenser Airflow

MODELS LEFT SIDE RIGHT SIDE

All covered by this manual 26" 26"

Units with control panels

facing each other (inward)

36" between units

Manual 2100-620A

Page 9 of 107

Page 10

FIGURE 1.2

DRAIN

ENTRANCE

4° PITCH

RAIN HOOD

BUILT IN

PANEL

ACCESS

HEATER

(LOCKABLE)

VENT HOOD

ACCESS PANEL

DISCONNECT

ENTRANCE

ELECTRICAL

LOW VOLTAGE

C. BREAKER/

HIGH VOLTAGE

ELECTRICAL

SIDE VIEW

JDK

H

7"

C

2.13

I

ELECTRIC HEAT

Top Rain

Flashing

Shipping

Location

DOOR

AIR

VENTILIATION

VENT HOOD

Cond.

Air

Inlet

FRONT VIEW

F

G

W

SUPPLY AIR

OPENING

OPENING

RETURN AIR

Brackets

(Built In)

Mounting

Optional

Electrical

Entrances

Side Wall

BOTTOM

INSTALLATION

BRACKET

BACK VIEW

S

E

T

O

S

S

S

S

R

Air Outlet

Condenser

Dimensions of Basic Unit for Architectural and Installation Requirements (Nominal)

Width

Depth

Model

D36A/L

D42A/L

D48A/L

D60A/L

(W)

42.075 22.432 84.875 9.88 29.88 15.88 29.88 43.88 13.56 31.66 30.00 32.68 26.94 34.69 32.43 3.37 43.00 23.88 10.00 1.44 16.00 1.88

42.075 22.432 93.000 9.88 29.88 15.88 29.88 43.88 13.56 37.00 30.00 40.81 35.06 42.81 40.56 3.37 43.00 31.00 10.00 1.44 16.00 10.00

Height

(D)

Supply Return

(H)

A B C B E F G I J K L M N O P Q R S T

All dimensions are in inches. Dimensional drawings are not to scale.

D**A

RIGHT

HAND

UNIT

D**L

F

G

FRONT VIEW

W

Condenser

Air Outlet

W

HEATER

ACCESS

PANEL

ELECTRIC HEAT

C. BREAKER/

DISCONNECT

ACCESS PANEL

(LOCKABLE)

VENT HOOD

DOOR

VENTILIATION

AIR

VENT HOOD

LOW VOLTAGE

ELECTRICAL

ENTRANCE

HIGH VOLTAGE

ELECTRICAL

ENTRANCE

2.13

A

7"

BUILT IN

RAIN HOOD

4° PITCH

LEFT

HAND

UNIT

VENT HOOD

DOOR

VENTILIATION

F

G

Condenser

Air Outlet

AIR

I

H

C

J

K

D

Cond.

Air

Inlet

Cond.

Air

Inlet

SIDE VIEW

BUILT IN

RAIN HOOD

4° PITCH

2.13

I

C

JDK

DRAIN

HEATER

ACCESS

PANEL

ELECTRIC HEAT

C. BREAKER/

DISCONNECT

ACCESS PANEL

(LOCKABLE)

7"

VENT HOOD

LOW VOLTAGE

ELECTRICAL

ENTRANCE

HIGH VOLTAGE

ELECTRICAL

ENTRANCE

H

Side Wall

Mounting

Brackets

(Built In)

Optional

Electrical

Entrances

Top Rain

Flashing

Shipping

Location

Side Wall

Mounting

Brackets

(Built In)

Top Rain

Flashing

Shipping

Location

Optional

Electrical

Entrances

SUPPLY AIR

OPENING

RETURN AIR

OPENING

BACK VIEW

SUPPLY AIR

OPENING

RETURN AIR

OPENING

E

O

E

O

R

S

S

S

S

S

BOTTOM

INSTALLATION

BRACKET

S

S

S

S

S

T

R

BACK VIEW

Manual 2100-620A

Page 10 of 107

SIDE VIEW

BACK VIEW

BOTTOM

INSTALLATION

BRACKET

MIS-3618

T

Page 11

WALL-MOUNT UNIT INSTALLATION

MOUNTING THE UNITS

!

WARNING

Heavy item hazard.

Use more than one person to handle unit.

Failure to do so could result in unit damage or

serious injury.

NOTE: It may be best to spot some electrical knockouts

(such as those located on the back of the wallmount unit) before units are mounted and access is

unavailable or limited (see Figure 1.2 to locate prepunched knockouts).

Two holes for the supply and return air openings must

be cut through the wall as shown in Figure 1.3 on page

12. On wood frame walls, the wall construction must

be strong and rigid enough to carry the weight of the

unit without transmitting any unit vibration. Concrete

block walls must be thoroughly inspected to insure that

they are capable of carrying the weight of the installed

unit.

NOTICE

AT&T National Standards forbids the use of

any adaptor or transitional curbs for use in

the installation of wall-mount HVAC systems.

If existing supply and return penetrations

do not match new requirements, those

openings must be modied to meet the

needs of the new equipment.

2. The unit itself is suitable for 0" clearance, but the

supply air duct flange and the first 3' of supply

air duct require a minimum of 1/4" clearance to

combustible material. However, it is generally

recommended that a 1" clearance is used for

ease of installation and maintaining the required

clearance to combustible material. See Figure 1.3

for details on opening sizes.

3. Locate and mark lag bolt locations and location for

optional bottom mounting bracket, if desired (see

Figure 1.3).

4. Mount bottom mounting bracket (if used).

5. If desired, hook top rain flashing (attached to frontright of supply flange for shipping) under back

bend of top.

6. Position unit in opening and secure with 5/16" lag/

anchor/carriage bolts; use 7/8" diameter flat washers

on the lag bolts. It is recommended that a bead

of silicone caulking be placed behind the side

mounting flanges.

7. Secure optional rain flashing to wall and caulk

across entire length of top (see Figure 1.3).

8. For additional mounting rigidity, the return air

and supply air frames or collars can be drilled

and screwed or welded to the structural wall itself

(depending upon wall construction). Be sure to

observe required clearance if combustible wall.

9. A plastic drain hose extends from the drain pan at

the top of the unit down to the unit base. There are

openings in the unit base for the drain hose to pass

through. In the event the drain hose is connected

to a drain system of some type, it must be an open

or vented type system to assure proper drainage.

In retrofit (unit replacement) installations, the openings

cut for the original equipment may not line up exactly

with needs of this installation. Modifications may need

to be made, such as increasing or decreasing the size

of the wall cutouts. The existing bolt placement may

not line up in which case the original bolts would need

to be removed or cut away.

1. These units are secured by wall mounting flanges

which secure the unit to the outside wall surface at

both sides. A bottom mounting bracket, attached

to skid for shipping, is provided for ease of

installation, but is not required.

Manual 2100-620A

Page 11 of 107

Page 12

SUPPLIED

RAIN FLASHING

FOAM AIR SEAL

WALL STRUCTURE

1/4" CLEARANCE ON ALL

FOUR SIDES OF SUPPLY

AIR DUCT IS REQUIRED

MATERIALS

FROM COMBUSTABLE

PANEL

DUCT

SUPPLY AIR

RETURN AIR

OPENING

NOTES:

IT IS RECOMMENDED THAT A BEAD OF

SILICONE CAULKING BE PLACED BEHIND

THE SIDE MOUNTING FLANGES AND UNDER

MIS-3354

TOP FLASHING AT TIME OF INSTALLATION.

Right Side View

TOP.

FIGURE 1.3

SEAL WITH BEAD

OF CAULKING ALONG

ENTIRE LENGTH OF

Mounting Instructions

A B C D E

HEATER ACCESS

WALL

TOP

29

2

B

E

16"

6 1/4 1 1/4 29 3/4

10 1/2

30 1/2

32 12 5 1/2

A CC

Supply Opening

Return Opening

30"

"

1

2

6

"

7

8

"

1

8

3

4"

3"

3

"

1

8

2

"

1

2

Typ.

1"

4"

Typ.

" 6

1

2

6

Wall Opening and Hole Location View

1

D

16"

16"

16"

16"

1

16"

"

7

8

1

2

COMBUSTIBLE MATERIALS

1/4" MIN. CLEARANCE FROM

REQUIRED DIMENSIONS TO MAINTAIN

REQUIRED DIMENSIONS TO MAINTAIN

RECOMMENDED 1" CLEARANCE FROM

COMBUSTIBLE MATERIALS

Manual 2100-620A

Page 12 of 107

Page 13

FIGURE 1.4

DUCT

OPENING

RETURN AIR

SUPPLY AIR

WOOD FRAME WALL INSTALLATION

OPENING

WALL BEFORE

MOUNT ON UNIT

OPENING

BEFORE INSTALLATION

BOTTOM MOUNTING

CONCRETE BLOCK WALL INSTALLATION

BRACKET. MOUNT ON

OPENING

WOOD OR STEEL SIDING

OPENING

INSTALLING UNIT.

RETURN AIR

WALL STRUCTURE

RETURN AIR

SUPPLY AIR

FACTORY SUPPLIED

RAIN FLASHING.

SUPPLY AIR

MIS-548 A

SIDE VIEW

Electric Heat Clearance

Wall Mounting Instructions

See FIGURE 2 – Mounting Instructions

FIGURE 1.5

Manual 2100-620A

Page 13 of 107

Page 14

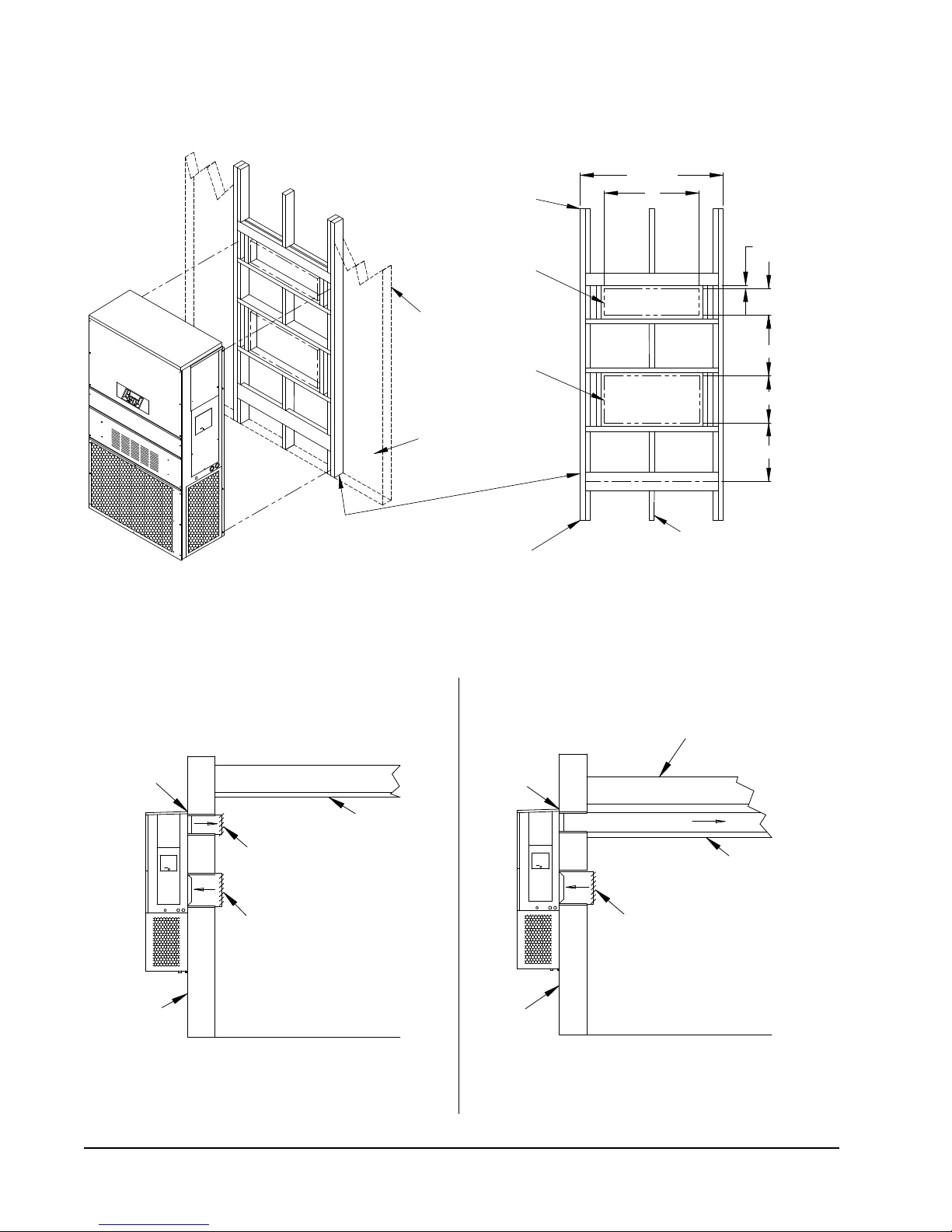

FIGURE 1.6

I

A

C

K

E + 1.000

B

1.000

SUPPLY DUCT

OVER FRAME

INTERIOR FINISHED WALL

ALL AROUND DUCT

FRAMING MATERIAL

EXTERIOR FINISH WALL

OPENING

FOR ACTUAL DIMENSIONS.

2 x 4'S, 2 x 6'S &/OR

STRUCTURAL STEEL

ATTACH TO TOP

1.000" CLEARANCE

1.000" CLEARANCE

PLATE OF WALL

C

SEE UNIT DIMENSIONS, FIGURE 2,

OPENING

RETURN DUCT

2 x 6

ATTACH TO BOTTOM

OVER FRAME

PLATE OF WALL

L

THIS STRUCTURAL MEMBER

LOCATED TO MATCH STUD

SPACING FOR REST OF WALL.

A SECOND MEMBER MAY BE

REQUIRED FOR SOME WALLS.

MIS-549 B

ALL AROUND DUCT

SUPPLY DUCT MAY BE LOCATED IN AN ATTIC

OPENING W/ GRILLE

SUPPLY AIR DUCT

RAFTERS

RAFTERS

RETURN AIR

OPENING W/ GRILLE

DUCTED SUPPLY

OR BELOW CEILING RAFTERS AS SHOWN

FINISHED CEILING SURFACE

RAIN

FLASHING

RAIN

FLASHING

RETURN AT UNITNO DUCT

RETURN AIR

FINISHED CEILING SURFACE

FREE AIR FLOW

OUTSIDE

WALL

OUTSIDE

WALL

SUPPLY AIR DUCT

W/ GRILLE

Wall Mounting Instructions

FIGURE 1.7

Common Wall Mounting Installations

Manual 2100-620A

Page 14 of 107

Page 15

WALL-MOUNT UNIT SUPPLY WIRING

All models covered by this installation

instruction require dual power sources:

VAC utility power to run the compressor, heat

and outdoor fan motor and -48 VDC power

to operate the indoor blower and DC free

cooling damper.

!

WARNING

Electrical shock hazard.

Have a properly trained individual perform

these tasks.

Failure to do so could result in electric shock

or death.

These units require a positive ground

-48 VDC copper conductor field wire

connection. Refer to the unit wiring diagram

for more information.

Refer to the unit rating plate or Table 1.1 for wire

sizing information and maximum fuse or circuit breaker

size. Each outdoor unit is marked with a “Minimum

Circuit Ampacity”. The field wiring used must be sized

to carry that amount of current. All models are suitable

only for connection with copper wire. Each unit and/or

wiring diagram will be marked “Use Copper Conductors

Only”. These instructions must be adhered to. Refer

to the National Electrical Code (NEC) for complete

current carrying capacity data on the various insulation

grades of wiring material. All wiring must conform to

NEC and all local codes.

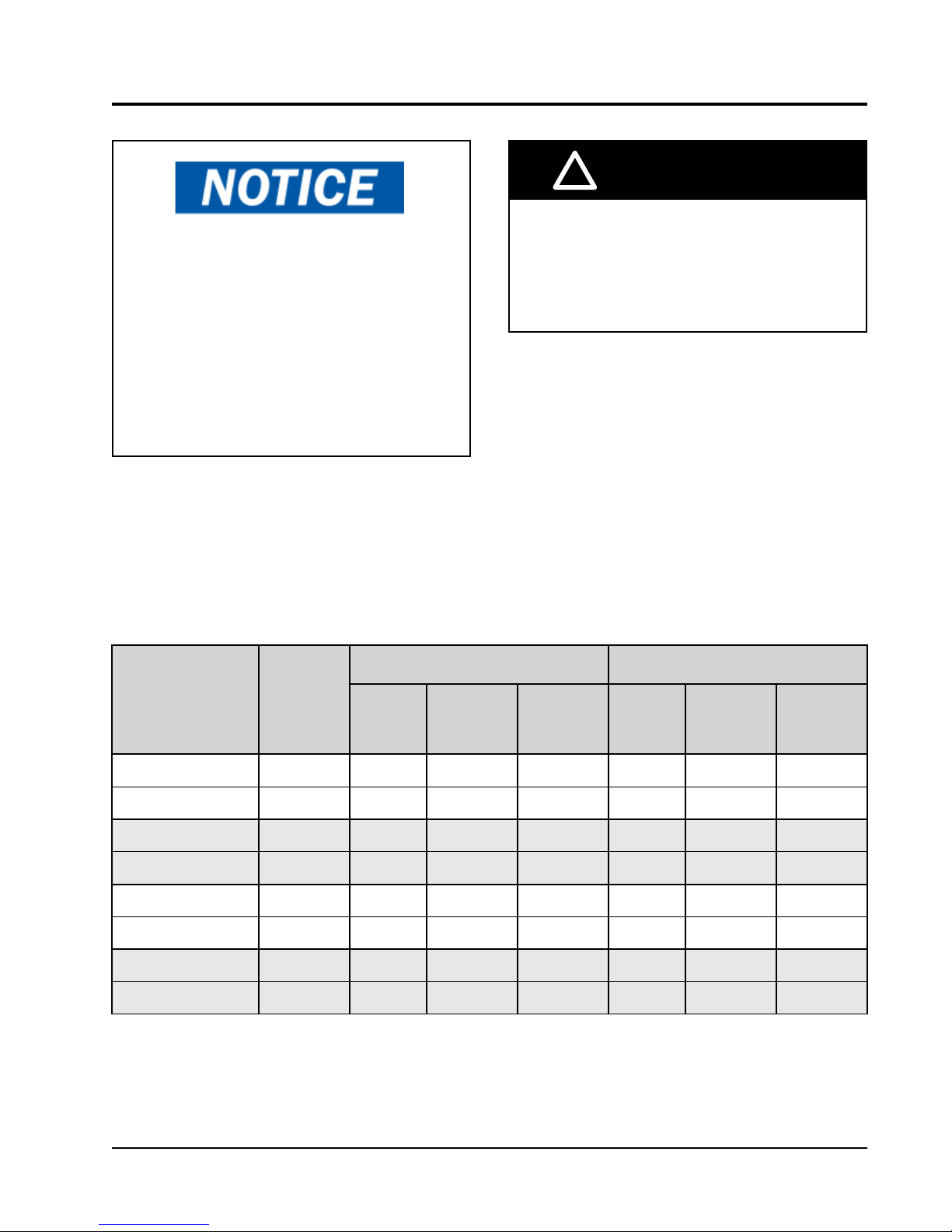

TABLE 1.1

Electrical Specifications

AC POWER CIRCUIT DC POSITIVE GROUND POWER CIRCUIT

Model

D36A2PA05/D36L2PA05

D36A2PA10/D36L2PA10

D36A2PB06/D36L2PB06

D36A2PB09/D36L2PB09

D42A2PA05/D42L2PA05

D42A2PA10/D42L2PA10

D42A2PB06/D42L2PB06

D42A2PB09/D42L2PB09

D48A2PA05/D48L2PA05

D48A2PA10/D48L2PA10

D48A2PB06/D48L2PB06

D48A2PB09/D48L2PB09

D60A2PA05/D60L2PA05

D60A2PA10/D60L2PA10

D60A2PB06/D60L2PB06

D60A2PB09/D60L2PB09

These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electric Code (latest

version), Article 310 for power conductor sizing.

CAUTION: When more than one field power circuit is run through one conduit, the conductors must be derated. Pay special attention to

note 8 of Table 310 regarding Ampacity Adjustment Factors when more than three (3) current carrying conductors are in a

raceway.

Maximum size of the time delay fuse or circuit breaker for protection of field wiring conductors.

Based on 75°C copper wire. All wiring must conform to the National Electric Code and all local codes.

Rated Volts,

Hertz & Phase

208/230-60-1

208/230-60-3

208/230-60-1

208/230-60-3

208/230-60-1

208/230-60-3

208/230-60-1

208/230-60-3

Minimum

Circuit

Ampacity

26

52

18

27.1

26

52

18.6

27.1

29

52

18.8

27.1

34.4

52

27.5

27.5

Maximum

External Fuse or

Ckt. Breaker

45

60

25

30

40

60

30

30

50

60

30

30

60

60

35

35

Field Power/

Ground Wire

Size

8

6

10

10

8

6

10

10

8

8

10

10

6

6

8

8

Minimum

Circuit

Ampacity

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

17.5

Maximum

External Fuse or

Ckt. Breaker

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

20

Field Power/

Ground Wire

Size

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

Manual 2100-620A

Page 15 of 107

Page 16

The electrical data lists fuse and wire sizes (75°C

NOTICE / AVIS

ROUTE ALL HIGH VOLTAGE FIELD

WIRES TO THE RIGHT OF THE WIRE

SHIELD AS SHOWN

ACHEMINER LES FILS HAUTE

TENSION SUR LA DROITE VERS LA

PROTECTION, COMME INDIQUÉ

VAC CIRCUIT BREAKER

/DISJONCTEUR

WIRE SHIELD /

PROTECTION

WHITE 3/16" LETTERING

7961-807

VDC CIRCUIT BREAKER

/DISJONCTEUR

copper) for all models including the most commonly

used heater sizes. Also shown are the number of field

power circuits required for the various models with

heaters.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or circuit breaker that is to be used with

the equipment. The correct size must be used for

proper circuit protection and also to assure that there

will be no nuisance tripping due to the momentary high

starting current of the compressor motor.

Route all field wires to the right of the wire shield as

shown in the circuit routing label found in Figure 1.8

(and also on the wall-mount units).

Factory

Wiring

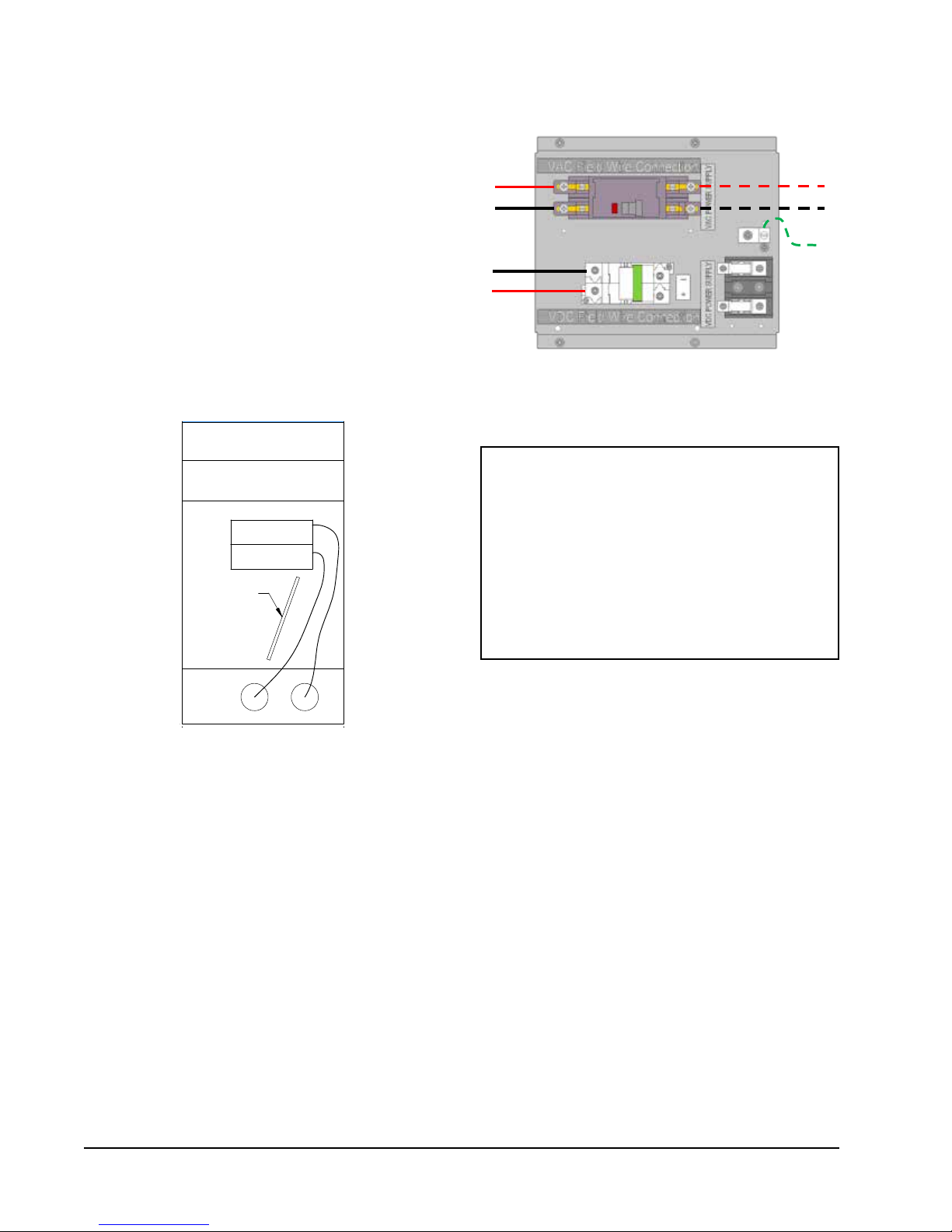

FIGURE 1.9

VAC Supply Wiring Landing Points

Field

Wiring

.

See Figure 1.9 to reference VAC landing points and

Figure 1.11 to reference VDC landing points.

The disconnect access door on this unit may be locked

to prevent unauthorized access to the disconnect. To

convert for the locking capability, bend the tab located

in the bottom left-hand corner of the disconnect

opening under the disconnect access panel straight

out. This tab will now line up with the slot in the door.

When shut, a padlock may be placed through the hole

in the tab preventing entry.

FIGURE 1.8

Circuit Routing Label

NOTE: Right-hand access model wiring landing points

are shown here; left-hand access models will

mirror this image.

IMPORTANT

230/208V 1 phase and 3 phase equipment use

dual primary voltage transformers. All equipment

leaves the factory wired on 240V tap. It is very

important that the correct voltage tap is used. For

208V operation, reconnect from 240V to 208V

tap (see Figure 1.10). The acceptable operating

voltage range for the 240 and 208V taps are:

240V Tap (253 – 216) and 208 Tap (220 – 197).

Manual 2100-620A

Page 16 of 107

Page 17

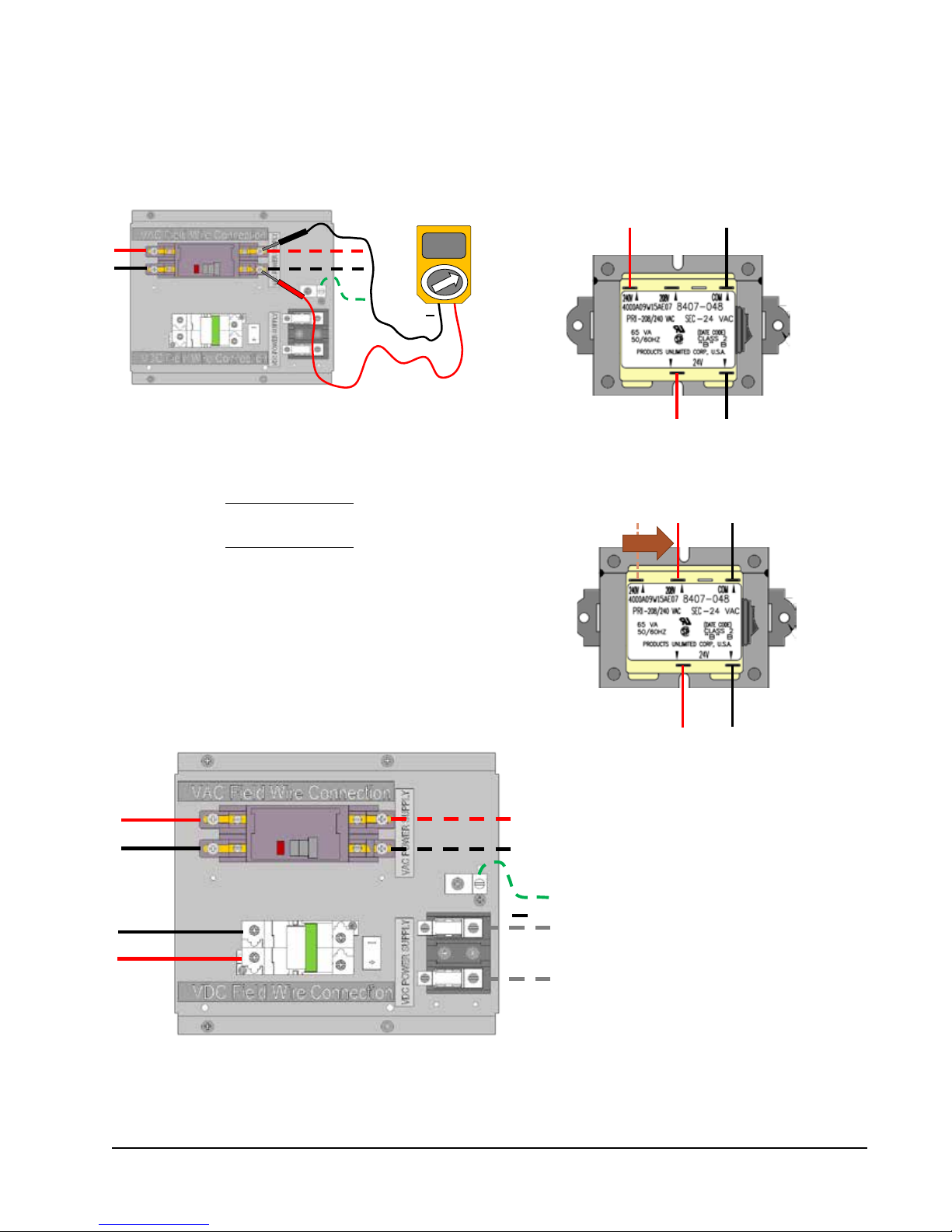

FIGURE 1.10

Adjusting the 230/208 VAC Transformer

It is very important that the correct voltage tap (240V or 208V) is used

1. Verify incoming AC voltage: Multimeter set to VAC

.

Shelter supply breaker in ON position Bard

system breaker in OFF position

230V/208V Single Phase Voltage Range:

197VAC – 253VAC

230V/208V Three Phase Voltage Range:

197VAC – 253VAC

(not shown)

2. If incoming AC voltage is 220VAC or above...

...do not adjust transformer

230VAC

+

3. If incoming AC voltage is below 220VAC...

...shut off AC breaker to unit

and move factory "240V" wire to "208V" terminal

FIGURE 1.11

VDC Supply Wiring Landing Points

.

-

Factory

Wiring

NOTE: Right-hand access model wiring landing points are

shown here; left-hand access models will mirror of

this image.

+

.

Field Wiring

+

Manual 2100-620A

Page 17 of 107

Page 18

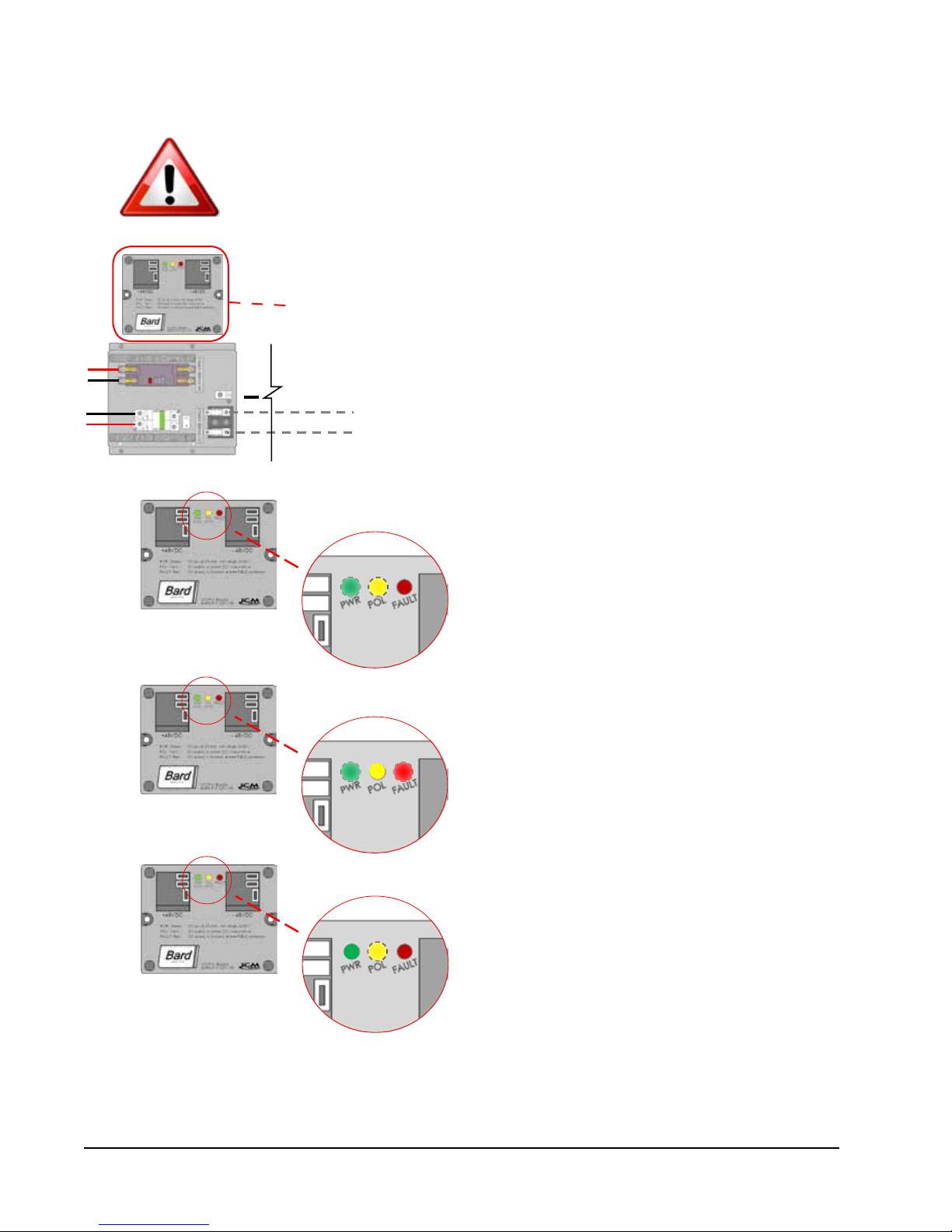

FIGURE 1.12

Bard Polarity-Voltage Monitor

If the VDC wiring is not terminated correctly on the specific polarity-indicated

terminals of the VDC terminal block, the VDC controls and motors will not activate

and the wall-mounted unit will not function.

The Bard Polarity-Voltage Monitor continually monitors for correct polarity and

voltage. If field wiring is connected improperly, or the voltage is outside of the

system parameters, the Polarity-Voltage Monitor will not allow any VDC voltage to

enter the system, protecting the internal controls and equipment.

+

When field wiring is correct in voltage and polarity, the

green power (PWR) LED and yellow polarity (POL) LED

will light, and system will operate normally.

If field wiring is incorrect in polarity, the red FAULT

LED will light, and the monitor will not allow VDC

voltage into the system.

If field wiring is correct in polarity but outside of the

required 40VDC – 56VDC, the green PWR LED will not

illuminate and the monitor not allow VDC voltage into

the system.

If the Polarity-Voltage Monitor is showing a problem with polarity and/or voltage, see pages 67 and 68 of the Service

section of this manual for instructions on checking VDC polarity and verifying incoming VDC voltage.

Manual 2100-620A

Page 18 of 107

Page 19

PRELIMINARY START-UP

RUNNING IN STAND ALONE (ORPHAN) MODE

With both AC and DC breakers turned on, each D-Series wall-mount system has the capability to run without the PLC

controller attached—this feature is called Stand Alone or Orphan Mode, and it basically keeps the shelter between

60°F and 78°F by the use of the factory-installed return air sensor in each wall-mount unit.

During installation, this allows deactivation of one of the two existing, older wall-mount units, while keeping the

shelter cool with the other unit still operating. Once the first of the two Bard wall-mount units is installed, Orphan

Mode can be enabled early in the installation—keeping the climate inside the shelter stable and the installers

comfortable while the remainder of the older equipment is removed and the second Bard wall-mount unit and PLC

controller is installed.

Additionally, should either or both D-Series wall-mount units lose communication with the PLC controller (such as

during maintenance), they will continue to serve the shelter's needs until a repair can be made.

Manual 2100-620A

Page 19 of 107

Page 20

BARD-LINKTM CONTROLLER INSTALLATION

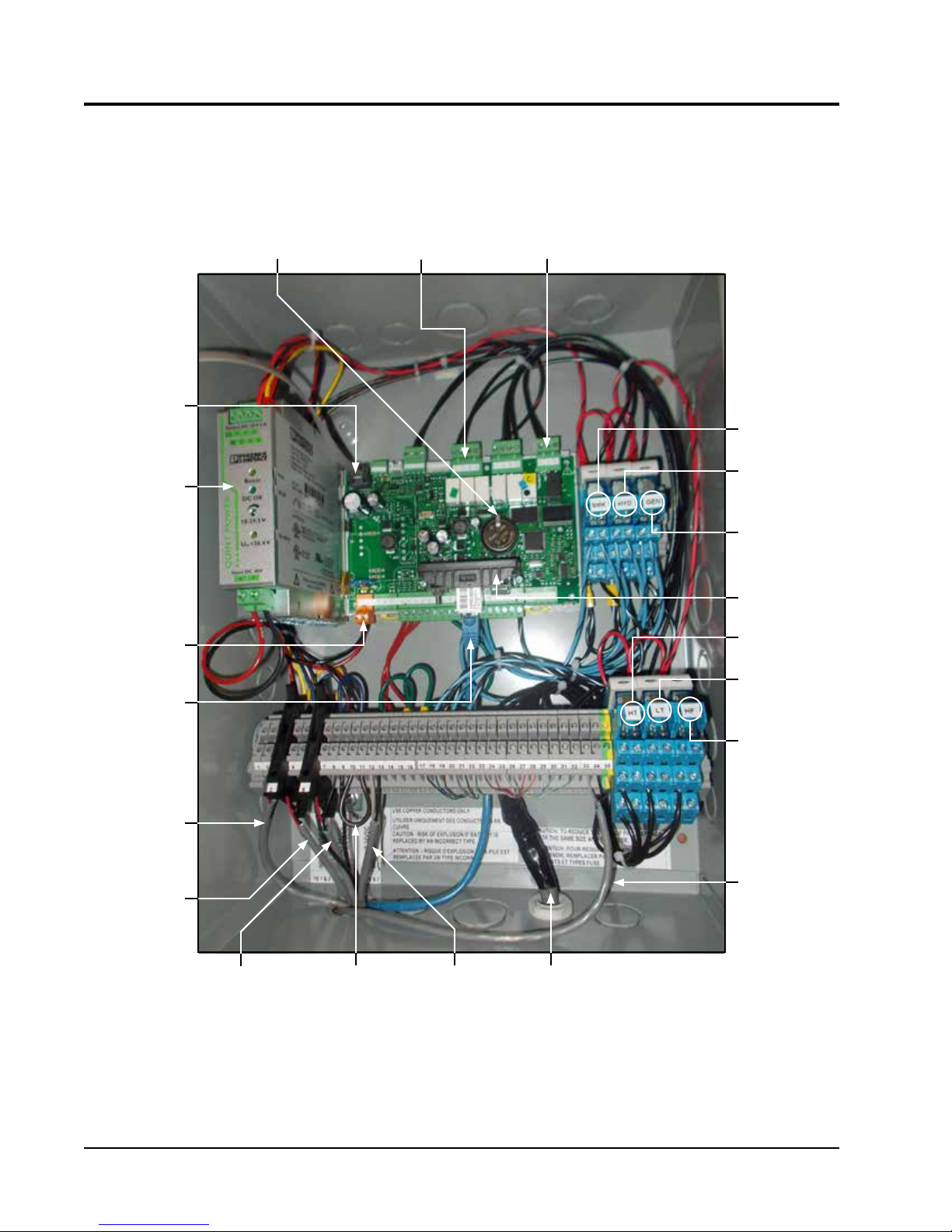

FIGURE 1.13

Typical LC1000/LC1500 Wiring

RJ11 Cable

to Display

48VDC

Power Supply

24VDC

Power

to PLC

Ethernet Cable

PLC Board

Lag Unit

Running Relay

HVAC2 Fail

Alarm Relay

Smoke

Alarm Relay

Hydrogen

Alarm Relay

Generator

Alarm Relay

Web Card

High Temp

Alarm Relay

Low Temp

Alarm Relay

-48VDC

Power Input

24VDC

Hydrogen

Power

Smoke Power

Manual 2100-620A

Page 20 of 107

24VDC

Generator

Alarm Jumper

Remote Temp

Sensor

HVAC1 Fail

Alarm Relay

RS485

Communication

Cable

Alarm Block

Wiring

Page 21

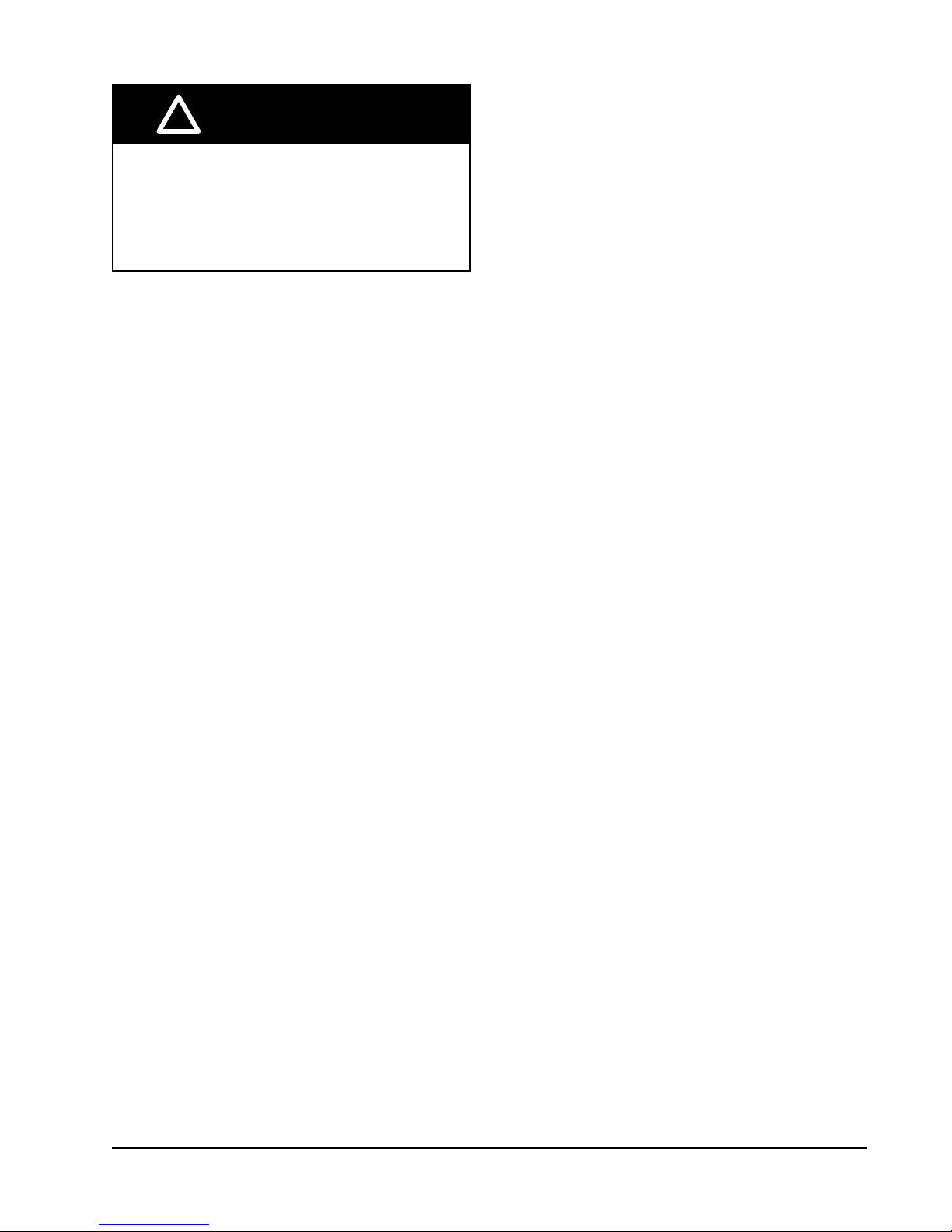

!

WARNING

Electrical shock hazard.

Disconnect both VAC and VDC power supplies

before servicing.

Failure to do so could result in electric shock

or death.

LC1000-100/LC1500-100 CONTROLLER

The Bard-LinkTM LC1000-100 (or LC1500-100)

controller is part of the DC Free Cooling Unit system. It

is used to control two wall-mount air conditioners from

one controller. The microprocessor control provides an

easy-to-read interface with large LCD graphical display.

It provides total redundancy for the structure and

equal wear on both units. The Bard-LinkTM controller is

configured for lead/lag/lead/lag sequence.

Differences Between the LC1000-100 and LC1500-100

There are two separate PLC lead-lag controllers to

choose from and each one serves a specific application.

The LC1000-100 controller comes pre-packaged with

a TEC-EYE hand-held diagnostic tool, one remote

temperature sensor and a pair of communication

EMI filters. This controller is meant for new shelter

construction only, and should never be used in the field

as a retrofit replacement. The LC1500-100 controller

comes pre-packaged with the TEC-EYE hand-held

diagnostic tool, one remote temperature sensor, a pair

of communication EMI filters and a smoke detector.

(The optional 8301-061 hydrogen detector, if ordered

from Bard, is also included with the LC1500-100

controller). The LC1500-100 has an umbilical cord

and 66 punch-down block attached. The LC1500

controller is to be used in all retrofit applications, and

all existing smoke detectors (and hydrogen detectors,

if applicable) are to be removed in lieu of the new

detectors.

Conduit is recommended for all wiring. Use separate

conduits for communication and supply wiring.

1. Mounting the Controller

TM

Because the Bard-Link

temperature sensor as opposed to one located in the

controller box, the controller itself can be installed in

any indoor location that is suitable, preferably at eye

level. Four (4) mounting holes are provided for mounting

to the wall and holes for conduit connections are provided

in both the base, sides and top of the controller. If

installing the LC1500-100, be sure to leave room to

mount the 66 punch-down block (attached with an

umbilical cord) near the controller.

controller utilizes a remote

Manual 2100-620A

Page 21 of 107

Page 22

2. Installing Remote Indoor Temperature Sensor(s)

A single remote indoor temperature sensor is included with the controller. This sensor must be installed for proper

operation. Use the included 35' shielded cable to mount the temperature sensor in a location least likely to be

affected by open doors, rack-mounted fans, radiant heat sources, etc. Locating the sensor between both return grilles

is often the best location, but every installation is unique. Location height should be approximately 48" above the

floor. The sensor should be installed on a 4" by 4" junction box to allow for control wire conduit (see Figure 1.14).

For proper operation, the remote indoor temperature sensors must be configured properly with the controller. If only

the single remote indoor temperature sensor supplied with the controller is installed, the configuration setting is

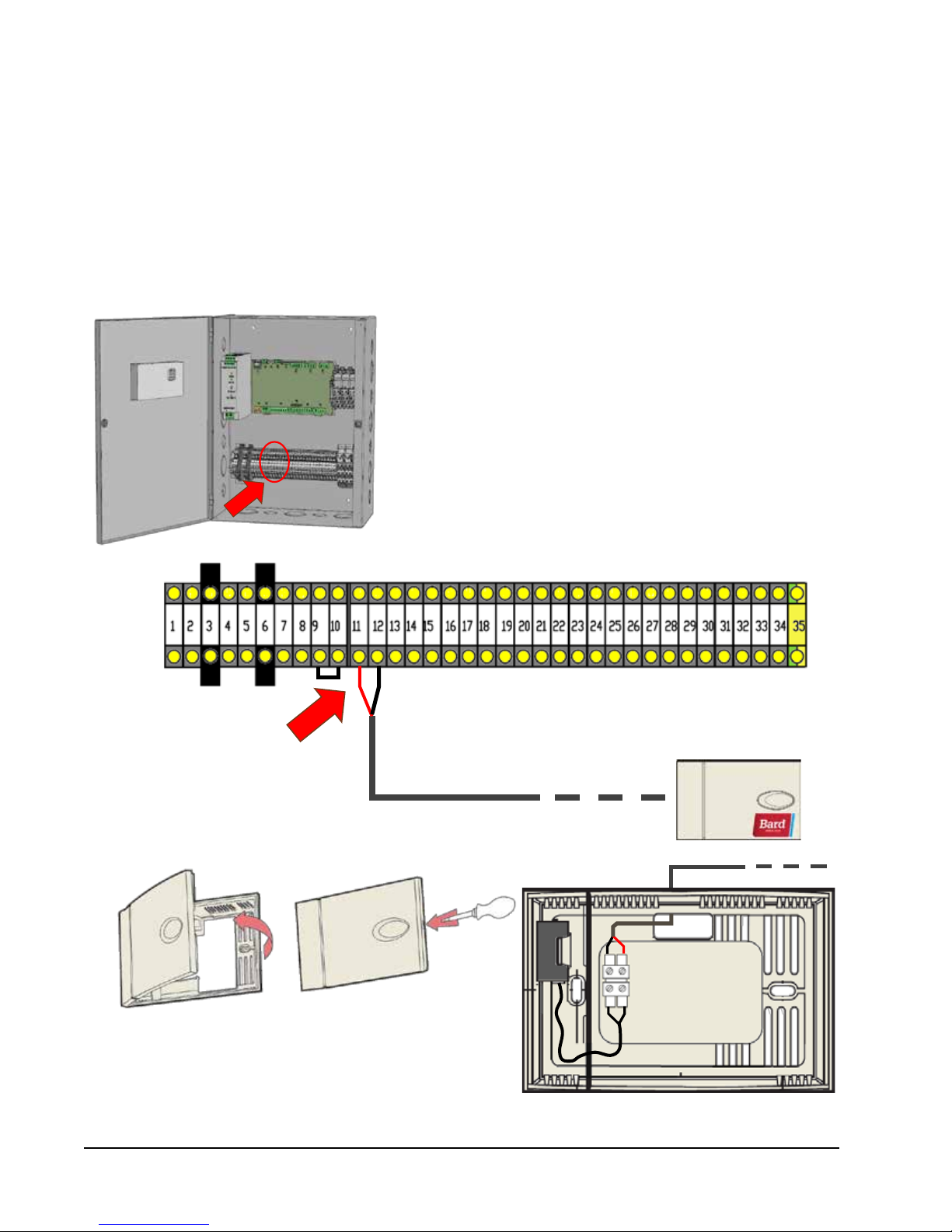

FIGURE 1.14

Remote Indoor Temperature Sensor Installation

1. Connect wires from provided 35' shielded cable to terminals

#11 and #12. The connection is not polarity-sensitive.

2. Connect the other end of the 35' shielded cable to either of

the sensor terminals. These connections are also not polarity

sensitive.

Sensor is best mounted on a junction box, and it is

recommended that the cable be in conduit.

Manual 2100-620A

Page 22 of 107

Page 23

"0". This is the default setting. For information on checking the remote indoor temperature sensor configuration, see

Configuring Additional Remote Indoor Temperature Sensors on page 51.

For unique situations involving temperature flux within the shelter, up to two (2) additional sensors may be

purchased and installed to provide temperature-averaging or highest-temperature protection (see Figure 1.15).

Please see Configuring Additional Remote Indoor Temperature Sensors on page 51 in the Service section of this

manual to set up the additional remotes.

FIGURE 1.15

Additional Remote Temperature Sensor Installation

Up to two (2) additional sensors may be purchased and installed for averaging or highest-temp mode. Use

terminals #13, #14, #15 and #16. These connections are not polarity-sensitive.

Remote Sensor

Optional Additional

Remote Sensor

Optional Additional

Remote Sensor

Manual 2100-620A

Page 23 of 107

Page 24

3. Smoke, Hydrogen and Generator Alarms

The LC1500 PLC controller is shipped with a new smoke detector (and optional hydrogen detector if ordered from

Bard) for use in existing shelters. The existing smoke detector (and hydrogen detector, if applicable) should be

removed and disposed of properly. In cases where there are no existing detectors, follow the installation instructions

provided with each detector for location and mounting practices. Both controllers have the capacity to provide power

to a 24VDC smoke detector and a 24VDC hydrogen detector through fused power supply terminals. For proper power

and alarm wiring, review the provided wiring diagrams (see Figures 1.16 and 1.17).

Please note that the provided smoke detector (and hydrogen detector, if applicable) has external testing buttons to

artificially (and temporarily) create an alarm sequence. Additionally, should the desired NC contact closure need to

be changed to the alternative contact closure, please refer to the Service section of this manual to reprogram the

PLC control.

The generator run alarm (if desired) will be signaled through an existing (or field provided) relay attached to the site

generator. The signal from the controller will route through a set of normally closed contacts. Should the generator

start, the contacts will open, triggering the alarm and initiating “Generator Run Mode” (both compressors cannot

operate concurrently). Since some sites do not have a generator present, there is a factory-installed jumper across

terminals #9 and #10. If there is no generator, no action is necessary. If generator run alarm is desired, please

remove the factory-installed jumper and wire per Figure 1.18.

FIGURE 1.16

Power and Signal Connections for Smoke Detector

-24VDC

+24VDC

See Terminal Block Index

on page 33

-24VDC Return Signal

1. Using minimum 18 gauge, non-shielded wire, supply the

new smoke detector with 24VDC from terminals 6 and 7

of the PLC controller.

2. Route a jumper wire from the -24VDC terminal on the

new smoke detector to the common terminal of the onboard relay.

3. From the normally closed contact of the relay, return the

-24VDC signal to terminal #8 of the PLC controller.

Manual 2100-620A

Page 24 of 107

Page 25

NC

COM

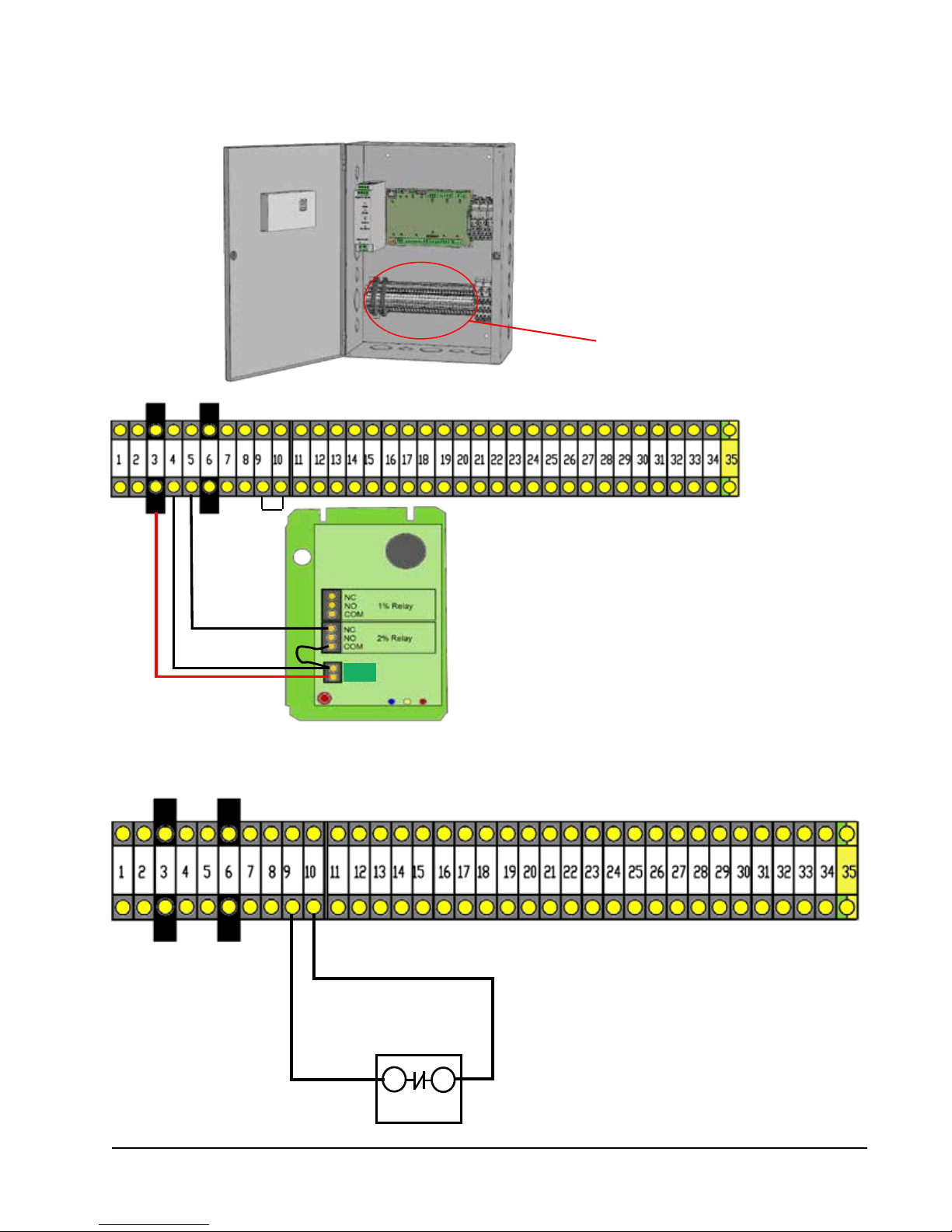

FIGURE 1.17

Power and Signal Connections for Bard-Supplied Hydrogen Detector (If Applicable)

See Terminal Block Index

on page 33

-24VDC

Return

Signal

-24VDC

+24VDC

1. Using minimum 18 gauge, non-shielded wire, supply the

new hydrogen detector with 24VDC from terminals 3 and 4

of the PLC controller.

2. Route a jumper wire from the -24VDC terminal on the new

hydrogen detector to the common terminal of the on-board

2% relay.

-24VDC

+24VDC

3. From the normally closed contact of the relay, return the

-24VDC signal to terminal #5 of the PLC controller.

FIGURE 1.18

LC1000-100 and LC1500-100 Series Generator Run

-24VDC Return Signal

-24VDC

1. If there is a generator on site, remove the factoryinstalled jumper on Terminals #9 and #10. Using

minimum 18 gauge, non-shielded wire, supply the

common terminal on the existing generator relay with

-24VDC from terminal #9 on the PLC controller.

2. From the normally closed contact of the relay, return

the -24VDC signal to terminal #10 of the PLC

controller.

Manual 2100-620A

Page 25 of 107

Page 26

4. Connecting External Alarm Points

Both the LC1000 and LC1500 PLC controls have the capability to provide NC contacts for the following eight (8)

alarms:

• Smoke

• Hydrogen

• Generator

• Lag Unit Run

• High Temp*

• Low Temp*

• HVAC 1 Fail

• HVAC 2 Fail

Before connecting the external alarm wiring, identify the model of the controller (see label inside of controller door).

The LC1000 provides contacts for alarms at the internal terminal block (see Figure 1.19).

The LC1500 PLC control has a pre-installed, pre-wired 66 punch-down block to allow easy connection to these

contacts outside of the controller box (see Figure 1.20).

FIGURE 1.19

LC1000-100 External Alarm Wiring

On the terminal strip of the LC1000 controller, there are eight (8) separate series of normally closed dry contacts for the

following alarm scenarios…

• Smoke

• Hydrogen

• Generator

• Lag Unit Run

• High Temp*

• Low Temp*

• HVAC 1 Fail

• HVAC 2 Fail

* There is no longer any need for the

electro-mechanical coiled-bulb type

thermostats—like the Johnson Penn

A19-Series—for High/Low Temperature

Alarms. Do not install in new sites, and

remove them in retrofit applications.

Lag Unit Run Alarm Common

Lag Unit Run Alarm Contact

Generator Alarm Common

Generator Alarm Contact

Hydrogen Alarm Common

Hydrogen Alarm Contact

Smoke Alarm Common

Smoke Alarm Contact

High Temp Alarm Contact

High Temp Alarm Common

Low Temp Alarm Contact

Low Temp Alarm Common

HVAC 1 Fail Alarm Contact

HVAC 1 Fail Alarm Common

HVAC 2 Fail Alarm Contact

HVAC 2 Fail Alarm Common

Manual 2100-620A

Page 26 of 107

Page 27

FIGURE 1.20

LC1500-100 External Alarm Wiring

Before connecting the external alarm wiring, identify the model of the controller (see label on inside of controller door. The

connections described below are for the LC1500-100 controller only.

The LC1500-100 has the same eight (8) separate series of normally closed dry contacts as the LC1000-100, but has a

prewired 66 punch-down block to make external connections easier.

• Smoke

• Hydrogen

• Generator

• Lag Unit Run

• High Temp*

• Low Temp*

• HVAC 1 Fail

• HVAC 2 Fail

Field wiring for alarms

48” umbilical cord allows for mounting the 66 punch-down

block to either side, top or bottom of PLC controller cox.

Bridge clips have been inserted for convenience.

* There is no longer any need for the electro-mechanical coiled-bulb type thermostats—like the Johnson Penn A19-

Series—for High/Low Temperature Alarms. Do not install in new sites, and remove them in retrofit applications.

Manual 2100-620A

Page 27 of 107

Page 28

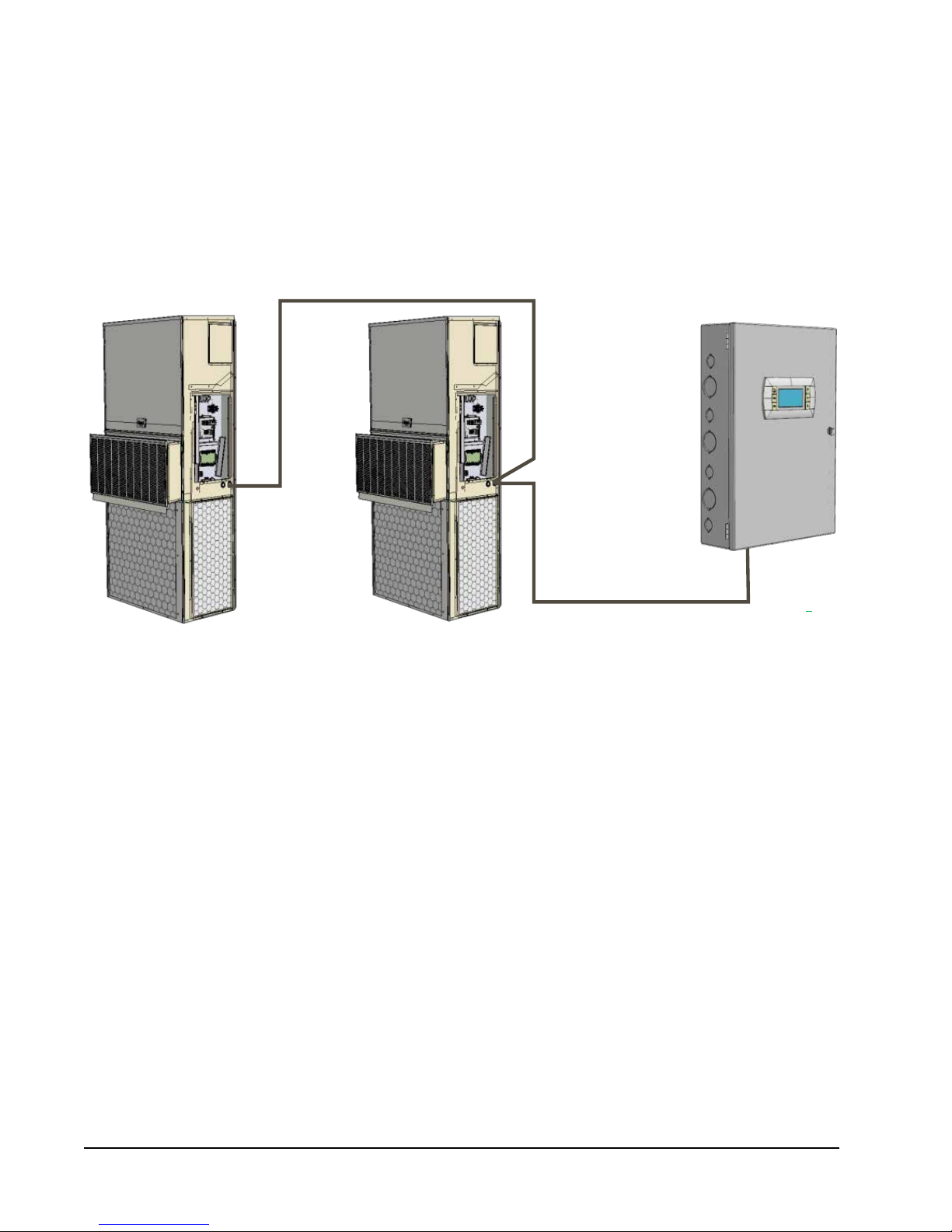

5. Communication Wiring

Connect the communication wiring from the two wall-mount units to the controller in the manner shown in Figure

1.21. The communication wire should be 2-wire, 18 gauge shielded cable with drain. Any color can be used. Be

sure to match "+" and "-" symbols on controller terminal blocks to prewired unit control terminal block (see Figures

1.23 and 1.24 on pages 30 and 31). Attach communication wire filters as shown below in Figure 1.22. Use separate

conduits for communication and supply wiring.

FIGURE 1.21

Communication Wiring

D-Series

Wall-Mount Unit

D-Series

Wall-Mount Unit

Bard-LinkTM

Controller

Manual 2100-620A

Page 28 of 107

Page 29

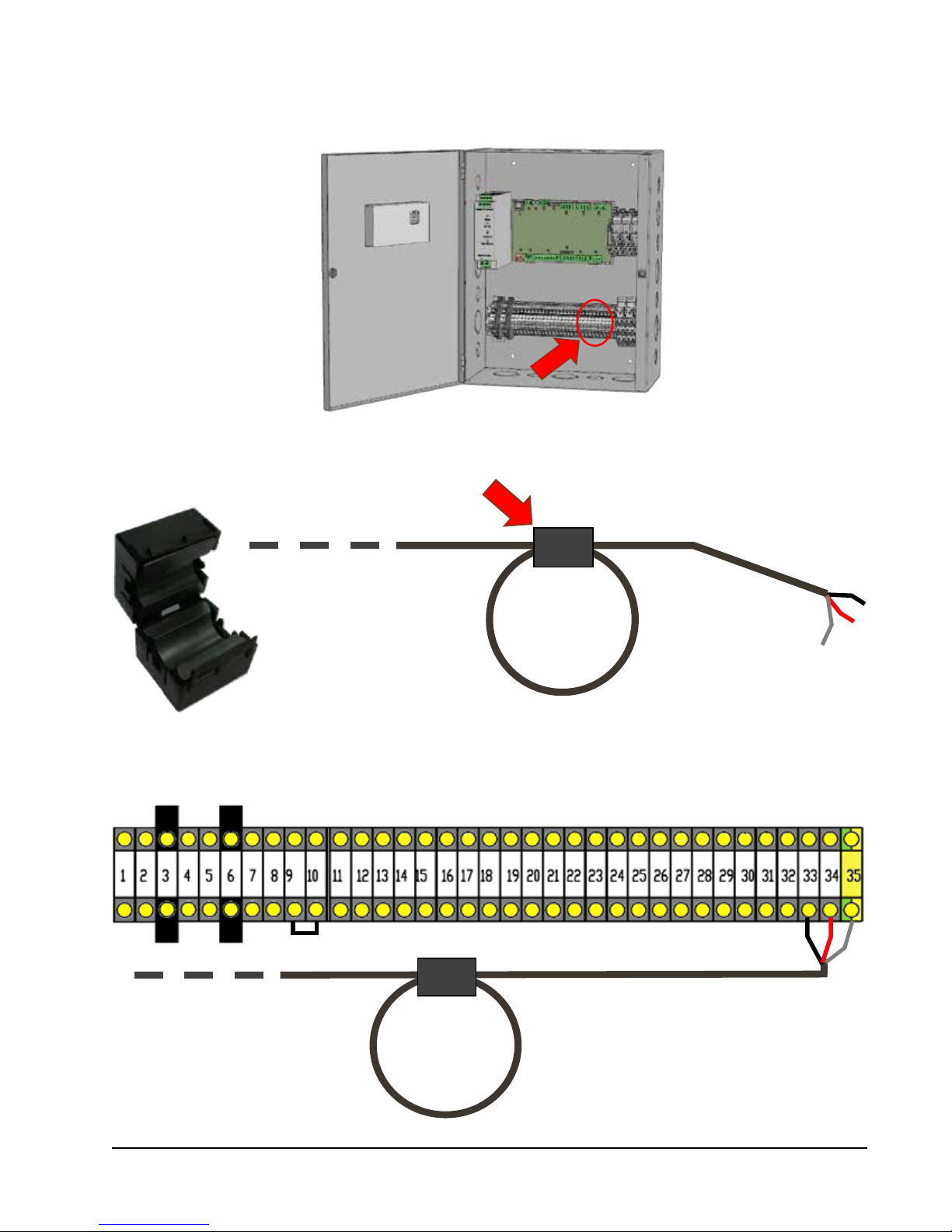

FIGURE 1.22

- +

G

Communication Wiring: Termination at the Controller

1. Using the field-provided shielded cable, make a small service loop after entering the controller and attach the provided

EMI filter at the intersection of the loop.

2. Connect one wire to terminal #33 (negative), the other wire to terminal #34 (positive) and the drain wire to ground

terminal #35.

To Wall-Mount Unit 1

Control Board RS485

Manual 2100-620A

Page 29 of 107

Page 30

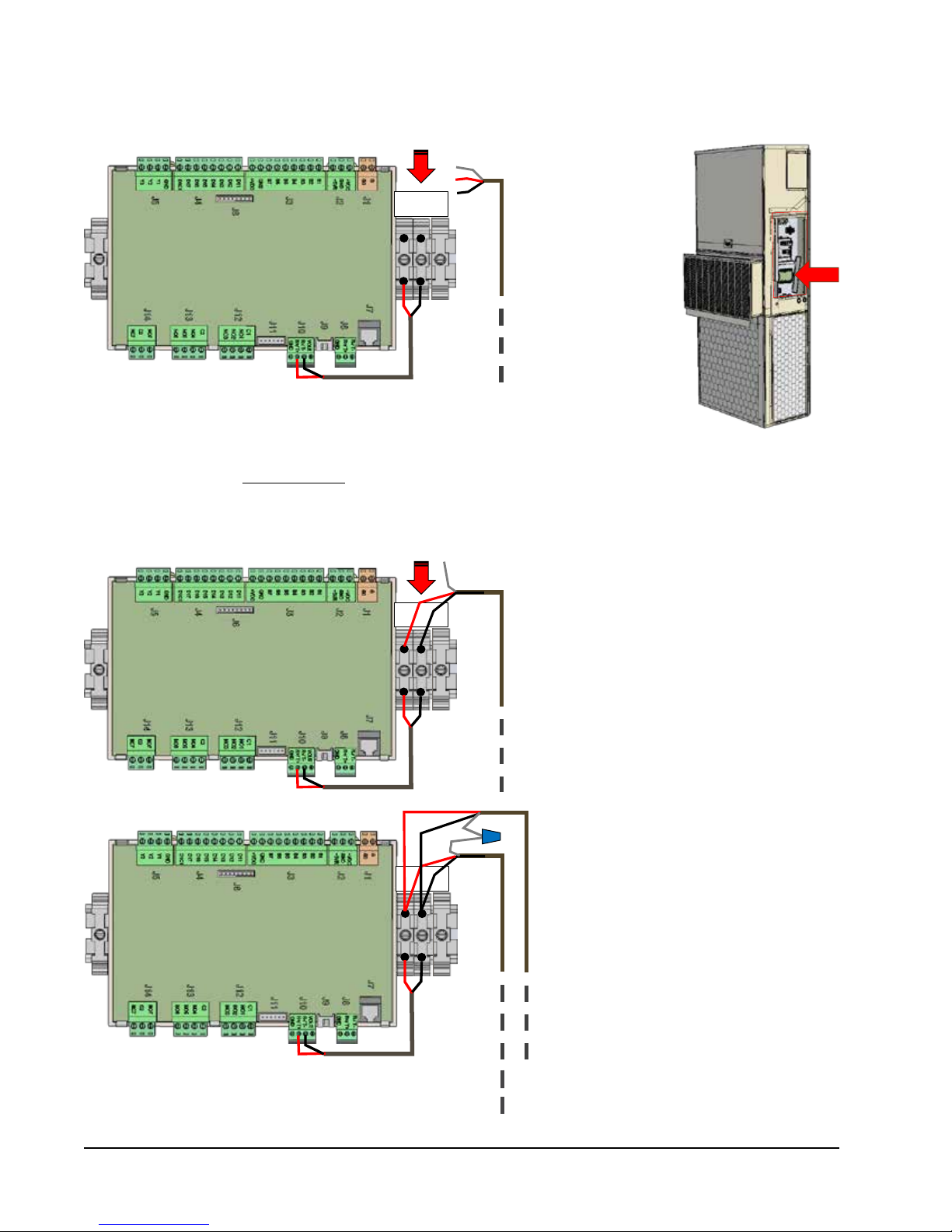

RS485

R+T+ / R-T-

FIGURE 1.23

RS485

R+T+ / R-T-

Communication Wiring: Termination at the First Wall-Mount Unit

RS485

R+T+ / R-T-

Wall-Mount Unit 1

Control Board

1. From the controller, extend the shielded cable through a separate conduit

and route to the provided terminal block next to the wall-mount control

board.

Note that the terminal block label is clearly marked “+” and “-”. These

connections are polarity-sensitive. Two-wire communication from control

board is prewired to terminal block. Make sure to match "+" and "-"

symbols on controller terminal blocks.

From LC1000-100

or LC1500-100

Controller

2. Connect the wires matching the terminal

designations (+/-) of the controller terminals.

Leave the drain wire loose.

Wall-Mount Unit 1

Control Board

From LC1000-100

or LC1500-100

Controller

Wall-Mount Unit 1

Control Board

Manual 2100-620A

Page 30 of 107

3. Connect another cable in a similar

fashion (“daisy chain”) to route in

conduit to the second wall-mount unit.

Connect both drain wires with wire nut.

From LC1000-100

or LC1500-100

Controller

To Wall-Mount Unit 2

Control Board RS485

Page 31

FIGURE 1.24

RS485

R+T+ / R-T-

Communication Wiring: Termination at the Second Wall-Mount Unit

RS485

R+T+ / R-T-

Wall-Mount Unit 2

Control Board

1. Route the cable from the first wall-mount unit to the

terminal block of the second wall-mount unit. Make a

small service loop and attach EMI filter as shown.

Wall-Mount Unit 2

Control Board

From Wall-Mount

Unit 1 RS485

2. Connect the wires matching the terminal

designations (+/-) of the controller terminals.

Cap the loose drain with a wire nut or

electrical tape.

From Wall-Mount

Unit 1 RS485

Manual 2100-620A

Page 31 of 107

Page 32

6. Supply Wiring

The LC1000-100/LC1500-100 controller is powered by -48VDC from the shelter. A field-supplied 5 amp DC circuit

breaker is required. Field-supplied supply wiring should be minimum 16 guage, maximum 14 guage (see Figure

1.25). A reliable earth ground must be connected in addition to any grounding from conduit. Grounding posts are

included with the controller for this purpose; install as shown in Figure 1.26. Failing to ground the controller box

properly could result in damage to the equipment.

FIGURE 1.25

Bard-LinkTM LC1000-100/LC1500-100 Controller Circuit Install

The Bard-LinkTM controller requires a separate -48VDC power supply, an

additional 5-amp DC breaker (field supplied) and minimum 16 gauge

supply wire.

-48VDC termination at controller: Bring the -48VDC power supply wires

through conduit to the controller box. Land the positive (+) 48VDC wire

to terminal #1 and the negative (-) 48VDC wire to terminal #2.

NOTE: If the DC wiring is not terminated correctly on the

specific polarity-indicated terminals of the PLC block, the

PLC controller will not activate and will not function. Verify

polarity of connections and wait to initialize controller until

"startup procedures."

Manual 2100-620A

Page 32 of 107

FIGURE 1.26

Controller Grounding Posts

A reliable earth ground must be connected in

addition to any grounding from conduit. Attach

earth ground to dedicated lugs on side of controller

box. Failing to ground the controller box properly

could result in damage to the equipment.

Page 33

TABLE 1.2

Terminal Block Index

Wire

TB#

Mark

1 48+ 48+ VDC Input

2 48- 48- VDC Input

3 24+ 24+VDC Input – Hydrogen

4 24- 24-VDC Input – Hydrogen

5 HA2 HA2 – Hydrogen ALR Signal Return

6 24+ 24+ VDC Input – Smoke

7 24- 24- VDC Input – Smoke

8 SA2 SA2 – Smoke ALR Signal Return

9 24- 24- VDC

10 GA2 GA2 – Generator ALR Signal Return

11 B1 Indoor Remote Sensor

12 GND GND

13 B2 Spare Remote Sensor 1

14 GND GND

15 B3 Spare Remote Sensor 2

16 GND GND

17 S24 Smoke ALR Relay Contact

18 S21 Smoke ALR Relay Contact Common

19 H24 Hydrogen ALR Relay Contact

20 H21 Hydrogen ALR Relay Contact Common

21 G24 Generator ALR Relay Contact

22 G21 Generator ALR Relay Contact Common

23 NO1 Lag Unit Run Relay Contact

24 C1 Lag Unit Run Relay Contact Common

25 HT12 High Temp ALR Relay Contact

26 HT11 High Temp ALR Relay Contact Common

27 LT12 Low Temp ALR Relay Contact

28 LT11 Low Temp ALR Relay Contact Common

29 HF12 HVAC1 Fail ALR Relay Contact

30 HF11 HVAC1 Fail ALR Relay Contact Common

31 NO7 HVAC2 Fail ALR Relay Contact

32 C3 HVAC2 Fail ALR Relay Contact Common

33 R- RS485 RX-/TX-

34 R+ RS485 RX+/TX+

35 GND Drain Shield Grounding Wire

Description NO NC

Manual 2100-620A

Page 33 of 107

Page 34

BLACK/RED

MIS-3632

TB#Wire

Mark Descripti on NO NC

1 48+ 48+VDC Input

2 48- 48- VDC Input

3 24+ 24+VDC Input - hydrogen

4 24- 24- VDC Input - hydrogen

5 HA2 HA2 - Hydrogen ALR signal return

6 24+ 24+ VDC Input - Smoke

7 24- 24- VDC Input - Smoke

8 SA2 SA2 - Smoke ALR Signalr eturn

9 24- 24- VDC

10 GA2 GA2 - Generator ALR signal return

11 B1 Indoor remote sensor

12 GND GND

13 B2 Spar e Remote sensor 1

14 GND GND

15 B3 Spar e Remote sensor 2

16 GND GND

17 S24 Smoke ALR relay contact

18 S21 Smoke ALR relay contact c ommon

19 H24 Hydrogen A LRrelay c ontact

20 H21 Hydrogen A LRrelay c ontact common

21 G24 Generator ALR relay contact

22 G21 Generator ALR relay contac t common

23

NO1 Lag un

it run relay contact

24 C1 Lag unit run relay contact c ommon

25 HT12 High Temp A LRrelay c ontact

26 HT11 High Temp A LRrelay c ontact common

27 LT12 Low Temp ALR relay contact

28 LT11 Low Temp ALR relay contact c ommon

29 HF12 HVAC1 Fail ALR relay contact

30 HF11 HVAC1 Fail ALR relay contact common

31 NO7 HVAC2 Fail ALR relay contact

32 C3 HVAC2 Fail ALR relay contact c ommon

33 R- RS485 RX- / TX-

34 R+ RS485 RX+ / TX+

35 GND Drain Shield grounding w ire

RED/BLACK

BLACK/RED

BLACK/RED

BLACK/RED

FIGURE 1.27

LC1000/LC1500 Wiring Diagram

GND

VOUT

RX-TX-

RX+TX+

GND

RX-TX-

RX+TX+

C1

C2

N02

N03

N01

N05

N04

N06

N07

C3

NC7

A1

A2 A1 A2 A1

RELAY

SMK

RELAY

HYD

RELAY

GEN

A2

24VDC

48VDC

BLUE

YELLOW

+

- +

BLACK

RED

RED/BLACK

BLACK/RED

G

G0

B1

B2B3B4

B5

B6

B7

GND

+VDC

+5 VREF

RED

RED

RED

GREEN

GND

D14

D11

D12

D13

+VDC

BLUE/BLACK

BLUE/BLACK

BLUE/BLACK

BLACK/WHITE

BLACK/WHITE

BLACK/WHITE

TO HT 11

TO LT 12

TO HT 12

12345 6 7 8 9 10 11 12 13 14 15 16 171 8 19 20 21 22 23 24 25 26 2728 29 30 31 32 3334 35

JUMPER

22

12

12

22

24

14

14

24

2111

11

21

Y2

Y3

Y1

D16

D17

D15

DIC1

GND

BLACK/WHITE

BLUE/BLACK

BLUE/BLACK

BLUE/BLACK

NC

22

12

NO

14

24

COM

11

21

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

TO LT 11

TO HF 12

TO HF 11

A1 A2 A1 A1 A2

A2

RELAY

HT

RELAY

LT

RELAY

HF

12

142124

11

12

22

22

24

14

21

11

NC

2212

NO

2414

COM

2111

TO TB 26

TO TB 25

TO TB 28

TO TB 30

TO TB 29

TO TB 27

MIS-3632

Manual 2100-620A

Page 34 of 107

Page 35

RBS HVAC 1

WHITE/GRAY

GREEN/BLACK

BROWN/RED

RED/BROWN

BLUE/WHITE

WHITE/GREEN

GREEN/WHITE

WHITE/BLUE

GRAY/WHITE

RED/ORANGE

ORANGE/RED

ALARM

RBS HVAC 2

ALARM

RBS HIGH TEMP.

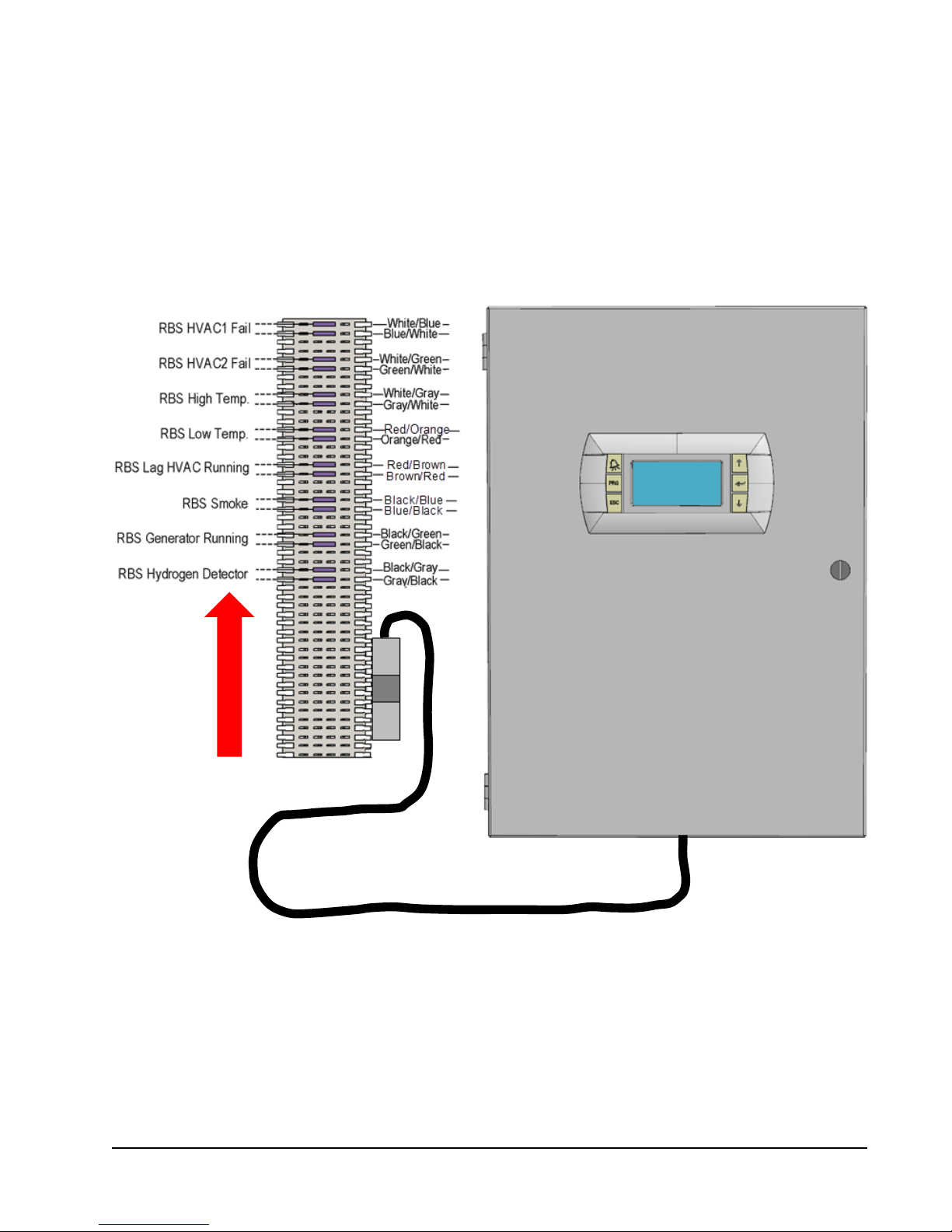

FIGURE 1.28

LC1500-100 Punch-Down Block Wiring

A

RBS LOW TEMP.

RBS LAG HVAC

RUNNING

RBS SMOKE

RBS GENERATOR

RUNNING

RBS HYDROGEN

DETECTOR

TO TERMINAL BLOCKS

JUMPER CONNECTED TO

TERMINAL PAIR TO PROVIDE

A DEMARCATION POINT

JUMPER CONNECTED TO

TERMINAL PAIR TO PROVIDE

A DEMARCATION POINT

RED/ORANGE

ORANGE/RED

DETAIL: A

WHITE/GREEN

GREEN/WHITE

JUMPER

BLACK/BLUE

BLUE/BLACK

BLACK/GRAY

GRAY/BLACK

BLACK/GREEN

GREEN/BLACK

RED/BROWN

BROWN/RED

WHITE/GRAY

GRAY/WHITE

WHITE/BLUE

BLUE/WHITE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35

DETAIL: A

MIS-3631

Manual 2100-620A

Page 35 of 107

Page 36

SYSTEM START-UP

FIGURE 1.29

Bard-LinkTM Controller Display

ALARM KEY

MENU KEY

ESCAPE KEY

ALARM KEY

Allows viewing of active alarms

Silences audible alarms

Resets active alarms

MENU KEY

Allows entry to Main Menu

ESCAPE KEY

Returns to previous menu level

Cancels a changed entry

UP KEY

Steps to next screen in the display menu

Changes (increases) the value of a modifiable field

ENTER KEY

Accepts current value of a modifiable field

Advances cursor

DOWN KEY

Steps back to previous screen in the display menu

Changes (decreases) the value of a modifiable field

1. Set Controller Date and Time

1) Shut down all breakers to system, both wall-

TM

mount units and the Bard-Link

controller.

2) Restore power (both AC and DC) to the two

wall-mount units.

TM

3) Turn on power to the Bard-Link

controller.

There is a forty (40) second delay prior to

any function (other than display backlight)

becoming active. The Status screen is the

default screen when the controller has power.

4) Access the Main Menu by pressing the Menu

key.

5) Press the UP or DOWN keys to scroll to the

Clock/Scheduler menu. Press the ENTER key

(see Figure 1.30).

6)

Move the cursor to the Date line by pressing

the ENTER key. Press the UP or DOWN keys to

change the date. The Day line will automatically

change when the date has been altered.

7) Press the ENTER key to move to the Hour line.

Press the UP or DOWN keys to change the

time. Press the ENTER key to set the time.

8) Press the ESCAPE several times to return to

the Status menu.

UP KEY

ENTER KEY

DOWN KEY

2. Verify Communication to Units

Check controller display to see that both units are

"ON-LINE" (see Figure 1.31). This typically takes 3-4

minutes after controller is powered.

FIGURE 1.30

Clock/Scheduler Menu

FIGURE 1.31

Status Display Showing Units "Online"

For shelter applications involving only a single

DUAL-TEC™ DC Free Cooling Unit, see page 38.

Manual 2100-620A

Page 36 of 107

Page 37

3. Conduct Run Test

Execute a run test on each unit to verify the equipment

is functioning correctly.

On Bard-Link

TM

controller, navigate to the Run Test

screen (Figure 1.32).

FIGURE 1.32

Executing Run Test

1) From the Main Menu screen, press the UP

or DOWN key to get to Technician menu, hit

ENTER key. (If not already on Main Menu

screen, press MENU key to get to Main Menu.)

2) Use Up or DOWN key to get to Service menu,

press ENTER key.

3) Use Up or DOWN key to get to Control menu,

press ENTER key.

4) Cursor will be flashing in upper left corner of

screen. Press ENTER key to scroll to U1 Run

Test.

5) Press UP key to change 'No" on screen to

"Yes". Unit 1 will begin the run test.

Note: While initiating the run test on each

unit, use this opportunity to appropriately label

each system as “Unit 1” or “Unit 2.”

6) After the Unit 1 run test ends, press ENTER

key to scroll to U2 Run Test.

7) Press UP key to change 'No" on screen to

"Yes". Unit 2 will begin the run test.

Run Test Approximate Timings (in Minutes)

Blower On: 0:00

Damper Open: 0:00 – 2:40

Closed: 2:41 – 4:57

Compressor On: 4:58

Off: 6:00

Heat On: 6:01

Off: 7:10

Blower Off: 8:19

4. Completing Installation

Once all the installation steps have been completed, and system verification and run test results were satisfactory,

TM

the installation can now be considered “complete.” The Bard-Link

PLC lead/lag controller has been pre-

programmed with what is widely considered to be the most efficient operating parameters—see Table 1.3 on page

40. Further information on exact sequence of operation and advanced programming changes can be found in the

Service section of this manual.

Cool Weather Operation (Free Cooling Available):

Stage 1 Cooling 78°F – Lead unit free-cooling damper opens (Setpoint + Cooling Stage 1 Differential)

Stage 2 Cooling 79°F – Lag unit free-cooling damper opens (+ Cooling Stage 2 Differential)

Stage 3 Cooling 81°F – Lead unit compressor, damper will stay open if conditions are conducive for free cooling

(+ Cooling Stage 3 Differential)

Stage 4 Cooling 83°F – Lag unit compressor, damper will stay open if conditions are conducive for free cooling

(+ Cooling Stage 4 Differential)

Hi-Temp Alarm #1 85°F

Hi-Temp Alarm #2 90°F – Emergency ventilation initiates, both dampers open, both blowers run

75°F – All cooling stops, blowers stop (Setpoint -2°F)

Stage 1 Heating 58°F – Lead unit heat strip activates

Stage 2 Heating 56°F – Lag unit heat strip activates

Low-Temp Alarm 45°F

62°F – All heating stops, blowers stop

Warm Weather Operation (No Free Cooling Available):

Stage 1 Cooling 78°F – Lead unit compressor (Setpoint + Cooling Stage 1 Differential)

Stage 2 Cooling 83°F – Lag unit compressor (+ Cooling Stage 2, Stage 3 and Stage 4 Differentials)

Hi-Temp Alarm #1 85°F

Hi-Temp Alarm #2 90°F – Emergency ventilation initiates, both dampers open, both blowers run

75°F – All cooling stops, blowers stop (Setpoint -2°F)

Manual 2100-620A

Page 37 of 107

Page 38

TABLE 1.3

Controller Default Settings

Description Default Setpoint

Temperature at local remote

(main) sensor

Temperature Setpoint 77°F

Heating Setpoint 60°F

Temperature High Limit –

Level 1

Temperature High Limit –

Level 2 (High Temp Alarm)

Temperature Low Limit 45°F

Cooling Stage 1 Differential 1°F

Cooling Stage 2 Differential 1°F

Cooling Stage 3 Differential 2°F

Cooling Stage 4 Differential 2°F

Heating Stage 1 Differential 2°F

Heating Stage 2 Differential 2°F

Minimum Compressor Run

Time

Minimum Compressor Off

Time

Comfort Mode Setpoint 72°F

Comfort Mode Operation

Time

DC Freecooling Setpoint 55°F

Lead/Lag Changeover Time

(Rotation)

Temperature Units °F

--

85°F

90°F

5 Minutes

2 Minutes

60 Minutes

1

WEB CARD COMMUNICATION BOARD

Note: A web card communications board allows remote

access, via Ethernet, to all functions of the controller

system. This is the same as if one was in the building

where the controller system is physically installed.

TM

Connect the Bard-Link

LC1000-100 or LC1500-100

controller Ethernet port to the existing Ethernet card in

the shelter (if applicable) using CAT 6 Ethernet cable.

TEC-EYE HAND-HELD DIAGNOSTIC

TOOL

The TEC-EYE hand-held diagnostic tool is included

with each Bard-Link

leaving the jobsite, make sure to store the TEC-EYE

hand-held diagnostic tool inside the shelter, preferably

close to the Bard-LinkTM PLC controller. The TEC-EYE

has integrated magnets on the back of the tool, so

it can even be attached to the front, sides, bottom,

or top of the PLC control box. Although the tool is

not necessary for installation purposes, the “TECEYE” will be very valuable to technicians performing

maintenance or repair procedures. Do not let the TECEYE leave the shelter.

TM

PLC lead/lag controller. Before

SINGLE HVAC UNIT SHELTERS ONLY

In certain applications, only one wall-mount unit

will be installed on a particular shelter. This may be

desirable due to space considerations, load specifics or

other non-typical situations. If only one Dual-Tec™ unit

will be connected to the Bard-Link

please follow the steps below to allow operation without

nuisance alarms.

1. Go to the Setpoints menu on Bard-Link

controller; press ENTER key.

2. Press DOWN arrow key seven (7) times to reach

"Number of Units" screen. Press ENTER key to

cause cursor to flash.

3. Press DOWN arrow key to change value to "1".

4. Cycle power to Bard-Link

TM

PLC controller,

TM

PLC controller.

TM

PLC

SPECIAL OPERATIONAL FORMAT: COASTAL MODE

In certain locations (geographical or situational), outdoor air used for “free cooling” can be corrosive or have

other non-desirable qualities. Although the DC-FCU system was meant to take full advantage of outdoor air

cooling, Bard Manufacturing has included a special operations format within the programming that will not

allow any damper activity for “free cooling.” By enabling the “Coastal Mode” function, the DC-FCU system

will only cool through mechanical (compressor) means. However, the damper will still open under emergency

conditions (high temperature #2 alarm or hydrogen alarm, if installed) to flood the room with outdoor air, and