Bard CTHAC241-D, CTHAC241-A, CTHAC361-A, CTHAC301-D, CTHAC361-G Installation Instructions Manual

...Page 1

Installation Instructions

Outdoor Condensing

Section

Models: CTHAC181-A CTHAC181-D

CTHAC241-A CTHAC241-D

CTHAC301-A CTHAC301-D

CTHAC361-A CTHAC361-G

CTHAC421-A CTHAC421-E

CTHAC421-F CTHAC421-G

CTHAC481-A CTHAC481-B

CTHAC481-E CTHAC481-E

CTHAC481-G CTHAC601-A

CTHAC601-B CTHAC601-E

CTHAC601-F CTHAC601-G

For Use With:

Matching Indoor Blower Coil Units and

Matching Add On Coil Units Only

Manual No.: 2100-292

Date: 12-19-96

Page 2

Contents

Split Air Conditioner General Information.................. 1

Split Air Conditioner Model Nomenclature................ 1

Application and Location............................................. 3

General..................................................................... 3

Shipping Damage ..................................................... 3

Application ................................................................ 3

Location .................................................................... 3

Mounting Unit Outside on Slab................................. 3

Important Installer Note ............................................ 3

Installing Refrigerant Tubing..................................... 3

Sweat Style Tubing Connections: Sweat

Indoor Unit and Sweat Outdoor Unit......................... 4

Wiring Instructions....................................................... 7

General..................................................................... 7

Control Circuit Wiring ............................................... 7

Option Controls ............................................................ 8

Installation Instructions — CMA-1 ............................ 8

Installation Instructions — CMA-2 ............................ 9

Installation Instructions — CMA-4 ............................ 9

Installation Instructions — CMA-5 .......................... 10

Installation Instructions — CMA-6 .......................... 10

Installation Instructions — CMA-11..........................11

Charging Instructions ................................................ 12

Pressure Service Ports ........................................... 12

System Start-Up (Indoor Units

Without Expansion Valves)..................................... 12

Service ........................................................................ 13

Service Hints .......................................................... 13

Fan Blade Setting Dimensions ............................... 13

FIGURES

Figure 1 .................................................................... 1

Figure 2 .................................................................... 3

Figure 3 .................................................................... 4

Figure 4 .................................................................... 4

Figure 5 .................................................................... 8

Figure 6 .................................................................... 8

Figure 7 .................................................................... 9

Figure 8 .................................................................... 9

Figure 9 .................................................................. 10

Figure 10 ................................................................ 10

Figure 11..................................................................11

Figure 12 ................................................................ 13

TABLES

Table 1...................................................................... 1

Table 2...................................................................... 1

Table 3...................................................................... 2

Table 4...................................................................... 3

Table 5...................................................................... 6

Table 6...................................................................... 7

Table 7.................................................................... 12

Table 8.................................................................... 12

Table 9.................................................................... 13

Table 10.................................................................. 14

Table 11 .................................................................. 14

Table 12.................................................................. 15

Table 13.................................................................. 15

Table 14.................................................................. 16

Table 15.................................................................. 16

Table 16.................................................................. 17

Page 3

Split Air Conditioner General Information

Split Air Conditioner Model Nomenclature

CTHAC 36 1 - A

Electrical Characteristics

A - 230/208-60-1

B - 230/200-60-3

D - 240/220-50-1

E - 220/200-50-3

F - 415/380-50-3

G - 220/200-50-1

Modification Code

Capacity -- 3 Ton or

Approx. 36,000 BTU

Basic Model Number

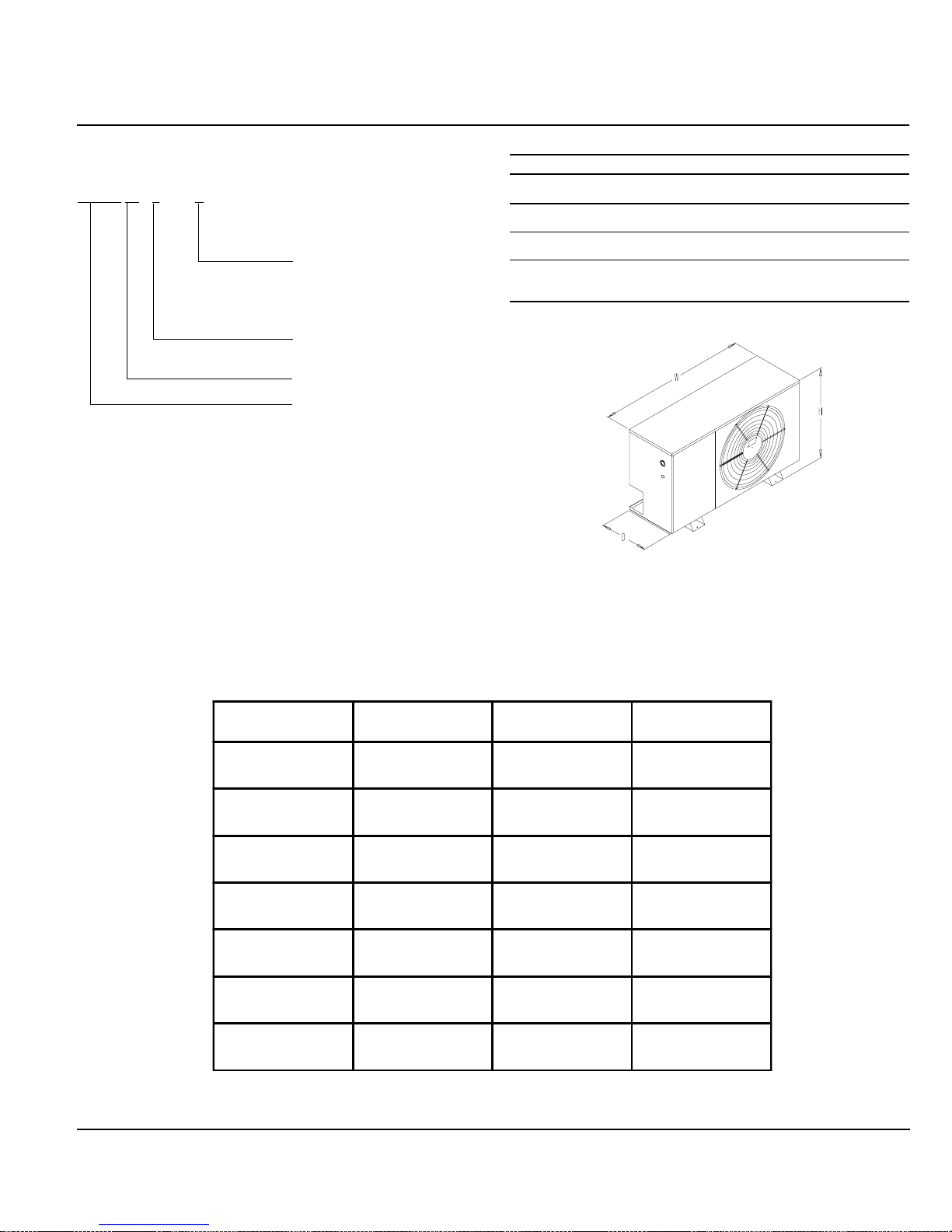

Table 1 — Dimensions

Model No. Width Depth Height

CTHAC181

CTHAC241

CTHAC301

CTHAC361

CTHAC421

CTHAC481 50" 15" 32"

CTHAC601

“W” “D” “H”

40" 15" 26"

45" 15" 26"

MIS-617

Figure 1

TABLE 2 – Rated CFM and Air Flow Data (Wet Coil – Cooling)

Co nd ensi ng Un it

Model Number

CTHAC181

CTHAC201

CTHAC301

CTHAC361

CTHAC421 FCP42 1225 0.078

CTHAC461

CTHAC601

Evapor ator Coil

Model Number CFM

FCP24

CEVA018

FCP24

CEVA024

FCP30

CEVA030

FCP36

CEVA036

FCP48

CEVA048

FCP60

CEVA060

600

600

800

800

1000

1000

1200

1200

1600

1600

2000

2000

System Orifice

Required

0.051

0.050

0.059

0.061

0.065

0.063

0.072

0.065

0.079

0.080

0.090

0.090

Page 1

Manual 2100-292

Page 4

Table 3 — Specifications

MODELS CTHAC181-A CTHAC241-A CTHAC301-A CTHAC361-A CTHAC421-A

Electrical Rating (60HZ/V/Ph) 230/208-1 230/208-1 230/208-1 230/208-1 230/208-1

Operating Voltage Range 197 - 253 197 - 253 197 - 253 197 - 253 197 - 253

Minimum Circuit Ampacity 15 1 5 1 9 2 0 2 5

Field Wire Size 14 1 4 1 2 1 2 1 0

Q

Delay Fuse Maximum or Circuit Breaker 20 2 0 3 0 3 0 40

R

T otal Unit Amps 230/208 7.9/8.6 10.2/11.4 13.4/14.0 14.5/15.8 19.1/19.6

COMPRESSOR

Volts 230/208 230/208 230/208 230/208 230/208 230/208

Rated Load Amps 6.8/7.5 9.1/10.3 12.3/12.9 13.4/14.7 17.6/18.1

Branch Circuit Selection Current 8.6 10.3 13.7 14.7 18.1

Lock Rotor Amps 230/208 49/49 56/56 75/75 82/82 105/105

Crankcase Heat None Immersion Type

FAN MOTOR AND CONDENSER

Fan Motor — HP/ RPM 1/6 - 825 1/4 - 825

Fan Motor — Amps 1.1 1.5

Fan — Diameter / CFM 20" - 2,000 24" - 2,600

SWEAT CONNECT SYSTEM

Suction Line Size ID 5/8" 3/4" 3/4" 3/4" 7/8"

Liquid Line Size ID 1/4" 3/8" 3/8" 3/8" 3/8"

Factory Charge R-22 Oz. 73 oz. 79 oz. 84 oz. 96 oz. 102 oz.

SHIPPING WEIGHT — Lbs. 155 155 180 180 250

Q

75º C copper wire size

R

Maximum time delay fuse or HACR type circuit breaker

Table 3 — Specifications (continued)

MODELS CTHAC481-A CTHAC481-B CTHAC601-A CTHAC601-B

Electrical Rating (60HZ/V/Ph) 230/208-1 230/208-3 230/208-1 230/208-3

Operating Voltage Range 197 - 253 187 - 253 197 - 253 187 - 253

Minimum Circuit Ampacity 26 17 35 21

Field Wire Size 10 12 8 10

Q

Delay Fuse Maximum or Circuit Breaker 45 25 60 3 5

R

Total Unit Amps 230/208 19.4/2 1.0 12.8/13 .4 22.7/2 6.7 15.3/17.2

COMPRESSOR

Volts 230/208 230/208 230/208 230/208

Rated Load Amps 230/208 17.9/1 9.5 11.3/11.9 21.2/25.2 13.8/15.7

Branch Circuit Selection Current 19.5 12.6 26.3 15.7

Lock Rotor Amps 230/208 102/102 91/91 135/135 150/150

Crankcase Heat Immersion Type None

FAN MOTOR AND CONDENSER

Fan Motor — HP / RPM

Fan Motor — Amps

Fan — Diameter

SWEAT CONNECT SYSTEM

Suction Line Size ID 7/8" 7/8" 7/8" 7/8"

Liquid Line Size ID 3/8" 3/8" 3/8"

Factory Charge R-22 Oz. 155 oz. 155 oz. 153 oz. 153 oz.

SHIPPING WEIGHT — Lbs. 250 250 255 255

Q

75º C copper wire size

R

Maximum time delay fuse or HACR type circuit breaker

1/4 - 825

1.5

24" - 2,600

Page 2

Manual 2100-292

Page 5

Table 4 — Specifications

MODELS CTHAC181-D CTHAC241-D CTHAC301-D CTHAC361-G CTHAC421-G CTHAC421-E CTHAC421-F

Electrical Rating (50HZ/V/Ph) 240/220-1 240/220-1 240/220-1 220/200-1 220/200-1 220/200--3 415/380-3

Operating Voltage Range 198 - 254 198 - 254 198 - 254 180 - 242 180 - 242 180 - 242 342 - 456

Minimum Circuit Ampacity 12 16 17 28 32 20 11

Field Wire Size 14 14 12 10 8 12 14

Q

Delay Fuse Maximum or Circuit Breaker 15 25 30 45 50 30 15

R

Total Unit Amps 9.6 12.8 14.9 21.2 23.0 14.8 8.1

Control Circuit

COMPRESSOR

Volts 240/220 240/220 240/220 220/200 220/200 220/200 415/380

Rated Load Amps 8.1 11.3 13.4 19.7 21.5 13.3 6.6

Branch Circuit Selection Current 8.1 11.3 13.7 21.1 23.7 14.7 7.0

Lock Rotor Amps 45.0 65.0 80.7 108.0 116.0 92.0 46.0

Crankcase Heat Immersion Type

FAN MOTOR AND CONDENSER

Fan Motor — HP / RPM 1/ 4- 825 1/4 - 825

Fan Motor — Amps 1.5 1.5

Fan — Diameter / CFM 20" - 2,000 24" - 2,600

SWEAT CONNECT SYSTEM

Suction Line Size ID 5/8" 3/4" 3/4" 3/4" 7/8" 7/8" 7/8"

Liquid Line Size ID 1/4" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8"

Factory Charge R-22 Oz. 73 oz. 79 oz. 84 oz. 96 oz. 102 oz. 102 oz. 102 oz.

SHIPPING WEIGHT — Lbs. 155 155 180 180 180 250 250

Q

75º C copper wire size

R

Maximum time delay fuse or HACR type circuit breaker

S

For high voltage control circuit options consult factory

24 Volt

R

Table 4 — Specifications (continued)

MODELS CTHAC481-G CTHAC481-E CTHAC481-F CTHAC481-G CTHAC601-E CTHAC601-F

Electrical Rating (50HZ/V/Ph) 220/200-1 220/200-3 415/380-3 220/200-1 220/200-3 415/380-3

Operating Voltage Range 180 - 220 180 - 242 342 - 456 180 - 220 180 - 242 342 - 456

Minimum Circuit Ampacity 38 23 13 40 27 1 5

Field Wire Size 8 10 14 8 8 14

Q

Delay Fuse Maximum or Circuit Breaker 60 40 20 6 0 45 20

R

T otal Unit Amps 25.9 16.0 9.0 29.7 18.5 10.3

Control Circuit

COMPRESSOR

Volts 220/200 220/200 415/380 220/200 220/200 415/380

Rated Load Amps 24.4 14.5 7.5 28.2 17.0 8.8

Branch Circuit Selection Current 28.8 17.3 9.0 30.1 20.5 10.2

Lock Rotor Amps 13 8 10 6 53 178 12 4 62

Crankcase Heat Immersion Type

FAN MOTOR AND CONDENSER

Fan Motor — HP / RPM

Fan Motor — Amps

Fan — Diameter

SWEAT CONNECT SYSTEM

Suction Line Size ID 7/8" 7/8" 7/8" 7/8" 7/8" 7/8"

Liquid Line Size ID 3/8" 3/8" 3/8" 3/8" 3/8" 3/8"

Factory Charge R-22 Oz. 155 oz. 155 oz. 155 oz. 153 oz. 153 oz. 153 oz.

SHIPPING WEIGHT — Lbs. 250 250 250 255 255 255

Q

75º C copper wire size

R

Maximum time delay fuse or HACR type circuit breaker

S

For high voltage control circuit options consult factory

24 Volt

R

1/4 - 825

1.5

24" - 2,600

Page 3

Manual 2100-292

Page 6

Application and Location

General

These instructions explain the recommended method to install the

air cooled remote type condensing unit, the interconnecting

refrigerant tubing and the electrical wiring connections to the unit.

The condensing units are to be used in conjunction with the

matching evaporator coils or evaporator blower units for comfort

cooling applications as shown in the specification sheet.

These instructions and any instructions packaged with any separate

equipment required to make up the entire air conditioning system

should be carefully read before beginning the installation. Note

particularly “Starting Procedure” and any tags and/or labels

attached to the equipment.

While these instructions are intended as a general recommended

guide, they do not supersede any national and/or local codes in any

way. Authorities having jurisdiction should be consulted before the

installation is made.

Shipping Damage

Upon receipt of equipment, the carton should be checked for

external signs of shipping damage. If damage is found, the

receiving party must contact the last carrier immediately,

preferably in writing, requesting inspection by the carrier’s agent.

Application

Size of unit for a proposed installation should be based on heat

loss calculation and air duct sizing made according to methods of

Air Conditioning Contractors of America. The air duct should be

installed in accordance with the Standards of the National Fire

Protection Association for the Installation of Air Conditioning and

Ventilating Systems of Other Than Residence Type, NFPA 90A,

and Residence Type Warm Air Heating and Air Conditioning

Systems, NFPA 90B. Where local regulations are at a variance

with instructions, installer should adhere to local codes.

Location

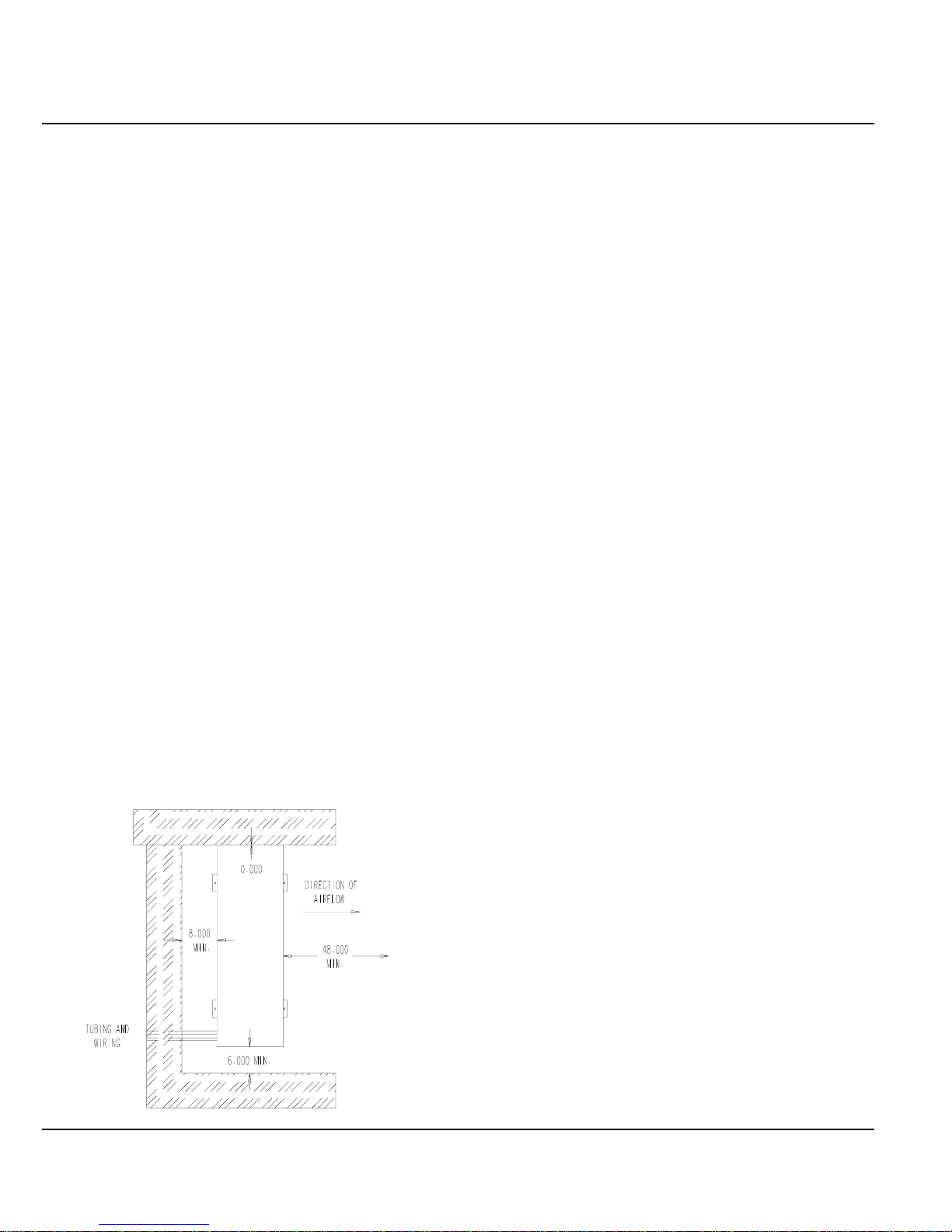

Figure 2 — Installation Clearance

The condensing unit is designed to be located outside with free and

unobstructed condenser air inlet and discharge. It must also permit

access for service and installation. Condenser air enters the coil

and discharges. Refrigerant and electrical connections are made

from the rear of the unit as shown in Figure 2 with electrical

service access.

Mounting Unit Outside on Slab

A solid level base or platform, capable to support the unit’s

weight, must be set at the outdoor unit predetermined location. The

base should be at least two inches larger than the base dimensions

of the unit and at least two inches higher than surrounding grade

level. The required unit minimum installed clearances must be

maintained as called out in Figure 2 when locating and setting the

base.

Remove the unit from its shipping carton and position the unit on

the prepared base or platform.

Do not attach the unit or its base to the building structure to avoid

the transmission of noise into the occupied area.

NOTE: These units employ internally sprung compressors;

therefore, it is not necessary to remove or loosen the base

mounting bolts on the compressor prior to operation.

Consideration should be given to the electrical and tubing

connections when placing the unit to avoid unnecessary bends or

length of material.

Important Installer Note

For improved start-up performance, wash the indoor coil with a

dishwater detergent.

NOTE: ALL DIMENSIONS

IN INCHES

Page 4

Manual 2100-292

Installation Refrigerant Tubing

The information that follows on installing refrigerant tubing and

for changing the system orifice (if required) covers applications

listed in the front of this installation instruction only. Although

other indoor units may be of similar construction, the installation

instructions for these units should be consulted for proper

installation of those units prior to installation.

Page 7

Figure 3 — Installing Refrigerant Tubing

Sweat Style Tubing Connections: Sweat

Indoor Unit and Sweat Outdoor Unit

Use only refrigeration grade (dehydrated and sealed) copper

tubing. Care must be taken to insure that the tubing is kept clean

and dry before and during installation. Do not remove the plugs

from the tubing ends, coil connections or base valves until the

connection is ready to be brazed.

The suction line must be insulated with a minimum of 3/8"

Armaflex or equivalent before cutting and making connections.

Step 1. Being careful not to kink, route both the suction line and

liquid line between the indoor unit and outdoor unit. Use

a tubing bender to make any necessary bends in tubing.

When necessary to bend the insulated tube suction line,

cut the insulation around its circumference at a distance

far enough beyond the point of the bend so as to clear the

tubing bender. Slip the insulation back together and

vapor seal the joint with tape. Coil any excess tubing in a

horizontal place with the slope of the tubing toward the

condensing unit. See Figure 3.

Step 2. The tubing ends should be cut square. Make sure it is

round and free of burrs at the connecting ends. Clean

the tubing to prevent contaminants from entering the

system.

NOTE: Do not braze line to units! If orifice needs to be

changed, change out orifice first.

If the orifice does not have to be changed, skip the

instructions outlined further in Step 3 and proceed to

Step 8.

Step 3. Disassemble Flow Control Assembly by turning

body hex.

Step 4. If existing orifice has not dropped out of the body when

disassembled, remove by using a pin or paper clip.

Discard this original orifice.

Step 5. Insert proper sized orifice fully into the flow control

body with rounded “bullet” nose towards the unit as

shown. Insure the orifice stays inserted in body before

connecting mating half. See chart in the outdoor unit

installation instructions for proper size.

CAUTION

Be sure there is no dirt introduced into the

flow control —orifice assembly. Be sure to

install the orifice with the bullet nose pointing

in the proper direction as shown in Figure 4.

Failure to do so will result in improper

operation.

CAUTION

1. Be careful not to tear the insulation when

pushing it through hole in masonry or frame

walls. 2. When sealing the tube opening in

house wall, use a soft material to prevent tube

damage and vibration transmission. 3. Avoid

excessive bending in any one place to avoid

kinking.

Figure 4 — Flow Control Assembly Field Orifice

Replacement Instructions

Step 6. Thread assembly halves together by hand to insure

proper mating of threads and tighten until bodies

“bottom” or a definite resistance is felt.

Step 7. Using a marker pen or ink pen, mark a line lengthwise

from the union nut to the bulkhead. Then tighten an

additional 1/6 turn (or 1 hex flat). The misalignment of

the line will show the amount the assembly has been

tightened. This final 1/6 turn is necessary to insure the

formation of the leakproof joint.

Page 5

Manual 2100-292

Page 8

Step 8. Wrap a wet rag around the copper stub before brazing.

Step 9. Flux the copper tube and insert into the stub. Braze the

joint using an alloy of silver or copper and phosphorus

with a melting temperature above 1,100° F for copper

to copper joints. The phosphorus will act as a flux,

therefore, no flux will be required.

A copper-silver alloy with a high silver content should

be used when iron or steel material is involved in the

joint. These alloys require the use of silver solder flux.

Alloys containing phosphorus should not be used with

iron or steel. Phosphorus reacts with the iron, forming

iron phosphate which is extremely brittle.

CAUTION

1. Brazing alloys with a melting temperature

below 700° F should not be used. 2. Lead-tin

or tin-antimony solders should not be used

due to their low melting point and necessity

for corrosive fluxes.

To further prevent the formation of copper oxide inside

the tubing, dry nitrogen may be purged through the

refrigerant system during brazing.

WARNING

Never purge or pressurize a system with

oxygen. An explosion and fire will result.

Step 10. After brazing, quench with wet rag to cool the joint and

remove any flux residue.

Step 11. Leak test all connections using an electronic leak

detector or a halide torch.

Step 12. Evacuate suction line, liquid line and indoor unit

through outdoor unit base valves.

Step 13. Open both the suction and liquid base valves to the

fully open position. Refer to section later in installation

instructions for details on setting proper system charge.

Table 5— Tubing Chart

Basic Refrigerant Line Length (Ft.)

Condensing 0 - 20 21 - 60 61 - 100

Unit Model Liquid Suction Liquid Suction Liquid Suction

CTHAC181 1/4" 5/8" 1/4" 5/8" 3/8" 3/4"

CTHAC241 3/8" 5/8" 3/8" 3/4" 3/8" 3/4"

CTHAC301 3/8" 5/8" 3/8" 3/4" 3/8" 3/4"

CTHAC361 3/8" 5/8" 3/8" 3/4" 1/2" 7/8"

CTHAC421 3/8" 3/4" 3/8" 7/8" 1/2" 7/8"

CTHAC481 3/8" 7/8" 3/8" 7/8" 1/2" 1-1/8"

CTHAC601 3/8" 7/8" 3/8" 7/8" 1/2" 1-1/8"

Page 6

Manual 2100-292

Page 9

Wiring Instructions

General

All wiring must be installed in accordance with the National

Electrical Code and local codes. In Canada, all wiring must be

installed in accordance with the Canadian Electrical Code and in

accordance with the regulations of the authorities having

jurisdiction. Power supply voltage must conform to the voltage

shown on the unit serial plate. A wiring diagram of the unit is

attached to the inside of the electrical cover. The power supply

shall be sized and fused according to the specifications supplied.

A ground lug is supplied in the control compartment for

equipment ground.

The unit rating plate lists a “Maximum Time Delay Fuse” or

“HACR Type” circuit breaker that is to be used with the

equipment. The correct size must be used for proper circuit

protection and also to assure that there will be no nuisance tripping

due to the momentary high starting current of the compressor

motor.

Control Circuit Wiring

For split systems, the minimum control circuit wiring gauge

needed to insure proper operation of all controls in both indoor and

outdoor units will depend on two factors.

1. The rated VA of the control circuit transformer.

2. The maximum total distance of the control circuit wiring. (This

is the distance between the wall thermostat to the indoor unit

plus the distance between the indoor unit to the outdoor unit.)

The following table should be used to determine proper gauge

of control circuit wiring required.

Table 6— Control Circuit Wiring

Rated VA of Transformer Distance of

Control Circuit Secondary Control Circuit

Transformer FLA @ 24V Wiring in Feet

40 1.6

50 2.1 16 gauge - 100

65 2.7 16 gauge - 85

Maximum Total

20 gauge - 65

18 gauge - 90

16 gauge - 145

14 gauge - 230

20 gauge - 45

18 gauge - 60

14 gauge - 160

12 gauge - 250

20 gauge - 40

18 gauge - 55

14 gauge - 135

12 gauge - 210

Example: 1. Control circuit transformer rated at 40VA.

2. Maximum total distance of control circuit wiring

85 feet.

From Table 6, minimum of 18 gauge wire should be used in the

control circuit wiring.

For control circuit transformers rated other then those listed, use

the next lower rated transformer listed.

Example: 1. Control circuit transformer rated at 55VA.

From table use 50VA transformer.

Page 7

Manual 2100-292

Page 10

Optional Controls

SK109 Low

Voltage Start Kit

CMA-5 Compressor

Time Delay Relay

CMA-1 High

Pressure

Control Lockout

Relay

MIS-592

CMA-6Llow Ambient

Fan Cycling Control

Terminal Block

Installation Instructions — CMA-1

Disconnect all power to unit. Remove control panel cover.

Step 1. Mount lockout relay in position shown in Figure 5.

Step 2. Disconnect yellow low voltage (Y) wire at compressor

contactor coil or (Y1) at optional CMA-5 and reconnect

to terminal #4 of the lockout relay.

Step 3. Connect yellow wire from terminal #3 of the lockout

relay to the (Y) terminal of the compressor contactor

coil or (Y1) at optional CMA-5. This is the terminal

that the wire was removed from in Step 2.

Step 4. Route high (red) pressure switch wires up through the

bushing in the bottom of the control panel. Connect the

high pressure switch wires between terminal #5 of the

lockout relay and the (Y) terminal of the compressor

contactor coil or (Y1) at optional CMA-5.

Step 5. Remove service port cap on the discharge line. Install

the high pressure switch on the discharge line with the

flare tee adapter that is brazed to the high pressure

switch. Check for pressure at the flare tee dill valves

after installation to insure that the dill valve in the unit

service port was depressed by the flare tee connector.

Check for leaks at the flare tee connectors. Replace

service port cap on the flare tee service port and tighten.

CMA-2 Low Pressure Control Assembly

CMA-4 High and Low Pressure Control Assembly

CMA-11 Dual Pressure and Low Ambient Fan Cycling

Control Assembly

Figure 5 — Component Mounting Location

MIS-592

Step 6. Recheck wiring. See Figure 6. Check for proper

operation of the unit by energizing in cooling mode for

at least 5 minutes. The unit should not go into lockout.

Step 7. Replace all panels and covers. This completes

installation.

MIS-597

Figure 6 — Installation Instructions for

CMA-1 High Pressure Control

Page 8

Manual 2100-292

Page 11

Installation Instructions — CMA-2

Disconnect all power to unit. Remove control panel cover.

Step 1. Snap control assembly into control panel as shown in

Figure 5.

Step 2. Disconnect yellow low voltage (Y) wire at compressor

contactor coil or (Y1) at optional CMA-5 and reconnect

to terminal #4 of the lockout relay.

Step 3. Connect yellow wire from terminal #3 of the low

pressure bypass TDR to the (Y) terminal of the

compressor contactor coil or (Y1) at optional CMA-5.

This is the terminal that the wire was removed from in

Step 2.

Step 4. Connect the black wire from terminal H of the low

pressure bypass TDR to the common (C) side of the

compressor contactor coil.

Step 5. Route low (blue) pressure switch wires up through the

bushing in the bottom of the control panel. Connect low

pressure switch wires between terminals #1 and #3 of

the low pressure bypass TDR.

Step 6. Remove service port caps on the suction line. Install the

low pressure switch on the suction line with the flare

tee adapter that is brazed to the low pressure switch.

Check for pressure at the flare tee dill valves after

installation to insure that the dill valve in the unit

service port was depressed by the flare tee connector.

Check for leaks at the flare tee connectors. Replace

service port caps on the flare tee service ports and

tighten.

Step 7. Recheck wiring. See Figure 7. Check for proper

operation of the unit by energizing in heating or cooling

mode for at least 5 minutes. The unit should not go into

lockout.

Step 8. Replace all panels and covers. This completes

installation.

Installation Instructions — CMA-4

Disconnect all power to unit. Remove control panel cover.

Step 1. Snap control assembly into control panel as shown in

Figure 5.

Step 2. Disconnect yellow low voltage (Y) wire at compressor

contactor coil or (Y1) at optional CMA-5 and

reconnect to terminal #4 of the lockout relay.

Step 3. Connect yellow wire from terminal #3 of the low

pressure bypass TDR to the (Y) terminal of the

compressor contactor coil or (Y1) at optional CMA-5.

This is the terminal that the wire was removed from in

Step 2.

Step 4. Connect the black wire from terminal H of the low

pressure bypass TDR to the common (C) side of the

compressor contactor coil.

Step 5. Route high (red) and low (blue) pressure control wires

up through the bushing in the bottom of the control

panel. Connect low pressure control wires between

terminals #1 and #3 of the low pressure bypass TDR.

Step 6. Connect the high pressure control wires between

terminal #5 of the lockout relay and terminal #1 of the

low pressure bypass TDR.

Step 7. Remove service port caps on both the suction and

discharge lines. Install the high pressure control on the

discharge line with the flare tee adapter that is brazed

to the high pressure switch. Install the low pressure

control on the suction line. Check for pressure at the

flare tee dill valves after installation to insure that the

dill valve in the unit service port was depressed by the

flare tee connector. Check for leaks at the flare tee

connectors. Replace service port caps on the flare tee

service ports and tighten.

Step 8. Recheck wiring. Refer to Figure 8. Check for proper

operation of the unit by energizing in heating or

cooling mode for at least 5 minutes. The unit should

not go into lockout.

Step 9. Apply “This unit equipped with CMA-4 control

module” label to inside of inner control panel cover

above wiring diagram. Leave these instructions in

the unit.

Step 10. Replace all panels and covers. This completes

installation.

Figure 7 — Installation Instructions for

CMA-2 Low Pressure Control

MIS-596

MIS-595

Figure 8 — Installation Instructions for

CMA-4 High and Low Pressure Control

Page 9

Manual 2100-292

MIS-595

Page 12

Installation Instructions — CMA-5

Installation Instructions — CMA-6

Disconnect all power to the unit. Remove control panel cover.

Step 1. Mount compressor TDR in position shown in Figure 5

with screw provided.

Step 2. Disconnect yellow low voltage (Y) wire at the

compressor contactor coil and reconnect to the Y1 or #3

terminal of the TDR.

Step 3. Connect yellow wire from terminal (Y) of the TDR to

the (Y) terminal of the compressor contactor coil. This

is the terminal that the wire was removed from in

Step 2.

Step 4. Recheck wiring. Refer to Figure 9. Energize unit.

Compressor should start. Remove power and reapply.

Compressor should not start until the 5 minute time

delay has expired.

Step 5. Apply “This unit equipped with CMA-5 control

module” label to inside of the inner control panel cover

above wiring diagram.

Step 6. Replace all panels and covers. This completes

installation.

Disconnect all power to unit. Remove control panel inner and

outer cover.

Step 1. Mount terminal block in position shown in Figure 5.

Step 2. Disconnect black high voltage outdoor motor lead from

compressor contactor and reconnect to terminal block.

Step 3. Route low ambient control wires up through the

bushing in the bottom of the control panel. Connect the

low ambient control wires between the terminal block

and T2 of the compressor contactor.

Step 4. Remove service port cap on discharge line. Install the

low ambient control on the discharge line with the flare

tee adapter that is brazed to the low ambient control.

Check for pressure at the flare tee dill valve after

installation to insure that the dill valve in the unit

service port was depressed by the flare tee connector.

Check for leaks at the flare tee connectors. Replace

service port cap on the flare tee service port and tighten.

Step 5. Recheck wiring. See Figure 10. Check for proper

operation of the unit by energizing in cooling mode.

The condenser fan motor should not run until the

discharge pressure has exceeded 300 PSI. Should the

discharge pressure fall below 200 PSI while running,

the condenser fan motor will de-energize until the head

pressure builds to 300 PSI.

Figure 9 — Installation Instructions for

CMA-5 Compressor Time Delay Relay

MIS-598

Step 6. Apply “This unit equipped with CMA-6 control

module” label to the inside of the control panel cover

above the wiring diagrams.

Step 7. Replace all panels and covers. This completes

installation.

MIS-594

Figure 10 — Installation Instructions for

CMA-6 Low Ambient Fan Cycling Control

Page 10

Manual 2100-292

Page 13

Installation Instructions — CMA-11

Disconnect all power to unit. Remove control panel inner cover.

Step 1. Snap control assembly into control panel as shown in

Figure 5.

Step 2. Disconnect yellow low voltage (Y) wire at compressor

contactor coil or (Y1) at optional CMA-5 and reconnect

to terminal #4 of the lockout relay.

Step 3. Connect the black wire from terminal H of the low

pressure bypass TDR to the common (C) side of the

compressor contactor coil.

Step 4. Connect yellow wire from terminal #1 or (Y) of the low

pressure bypass relay to the (Y) terminal of the

compressor contactor coil or (Y1) at optional CMA-5.

This is the terminal that the wire was removed from in

Step 2.

Step 5. Route high (red) and low (blue) pressure switch wires

up through the bushing in the bottom of the control

panel. Connect the high pressure switch wires between

terminal #5 of the lockout relay and terminal #1 of the

low pressure bypass TDR.

Step 6. Connect low pressure switch wires between terminals

#1 and #3 of the low pressure bypass TDR.

Step 10. Recheck wiring. Refer to Figure 11. Energize unit in

first stage cooling. Compressor should start. Run the

unit for at least 5 minutes. The unit should not go into

lockout. The condenser fan motor should not run until

the discharge pressure has exceeded 300 PSI. Should

the discharge pressure fall below 200 PSI while

running, the condenser fan motor will de-energize until

the head pressure builds to 300 PSI.

Step 11. Apply “This unit equipped with CMA-11 control

module” label to the inside of the inner control panel

cover above the wiring diagram.

Step 12. Replace all panels and covers. This completes

installation.

Step 7. Disconnect black high voltage outdoor motor lead from

compressor contactor and reconnect to terminal block.

Step 8. Route low ambient control wires up through the

bushing in the bottom of the control panel. Connect the

low ambient control wires between the terminal block

and T2 of the compressor contactor.

Step 9. Remove service port caps on both the suction and

discharge lines. Install the high pressure switch and low

ambient control on the discharge line with the flare tee

adapter that is brazed to the controls. Install the low

pressure switch on the suction line. Check for pressure

at the flare tee dill valves after installation to insure that

the dill valve in the unit service port was depressed by

the flare tee connector. Check for leaks at the flare tee

connectors. Replace service port caps on the flare tee

service ports and tighten.

MIS-593

Figure 11 — Installation Instructions for CMA-11

Dual Pressure and Low Ambient Fan

Cycling Control

Page 11

Manual 2100-292

Page 14

Charging Instructions

Pressure Service Ports

High and low pressure service ports are installed on all units so

that the system operating pressures can be observed. Pressure

tables can be found later in the manual covering all models. It is

imperative to match the correct pressure table to the unit by model

number.

System Start-Up (Indoor Units Without

Expansion Valves)

Step 1. Close disconnect switch(es) and set the thermostat to

cool and the temperature to the highest setting.

Step 2. Check for proper airflow across the indoor coil by

referring to indoor unit installation.

Step 3. Connect the service gauges and allow the unit to run for

at least 10 minutes or until pressures are stable. Check

pressures to the system pressure table attached to the

outdoor unit service panel. For optimum system

performance, go to Step 4.

Step 4. Install a thermometer on the suction line approximately

6" to 10" from the compressor. Optimum system

performance will occur with a refrigerant charge

resulting in a suction line superheat as determined from

the following calculations.

A. Measure outdoor air dry bulb temperature ________ºF

B. Measure indoor air wet bulb temperature ________ºF

C. Measure suction pressure ________PSIG

D. Measure suction line temperature ________ºF

E. Determine optimum system superheat

from Table 9 using outdoor air dry bulb

(Step B) and indoor air wet bulb (Step A) ________ºF

F. Determine saturated suction temperature

from suction pressure using Table 10 ________ ºF

G. Determine system superheat:

Suction line temperature (Step D) ________ºF

- Saturated suction temperature (Step F) - ________ºF

= System superheat = _______ºF

H. Adjust the system superheat (Step G) to the optimum

system superheat (Step E) by adding charge to lower the

superheat or removing charge to raise the superheat.

I. Check final system operating pressures to the system

pressure tables as was done in Step 3.

Table 7— System Superheat

Outdoor Ambient Return Air Temperature

Temperature º F — Wet Bulb

(º F Dry Bulb) 59 63 67 71

105 1 1 5 —

95 1 3 (8) 20

90 1 7 14 26

85 3 9 19 33

80 8 14 25 39

75 10 20 30 42

Table 8— Saturated Suction Temperature (R-22)

Saturated Suction

Suction Pressure PSIG Temperature (º F)

50 26

53 28

55 30

58 32

61 34

63 36

65 38

67 39

70 41

73 43

76 45

79 47

82 49

86 51

Page 12

Manual 2100-292

Page 15

Service

Service Hints

1. Caution homeowner to maintain clean air filters at all times.

Also, not to needlessly close off supply and return air registers.

This reduces air flow through the system, which shortens

equipment service life, as well as, increasing operating costs.

2. Check all power fuses or circuit breakers to be sure that they are

the correct rating.

3. Periodic cleaning of the outdoor coil to permit full and

unrestricted air flow circulation is essential.

Fan Blade Setting Dimensions

Shown in Figure 12 are the correct fan blade setting dimensions for

proper air delivery across the outdoor coil.

Any service work requiring removal or adjustment in the fan and/

or motor area will require that the dimensions below be checked

and blade adjusted in or out on the motor shaft accordingly.

A

Figure 12 — Fan Blade

Table 9— Fan Blade Setting Dimensions

Model Dimension A

CTHAC181

CTHAC241

CTHAC301

CTHAC361

CTHAC421

CTHAC481 3-1/4"

CTHAC601

3"

Page 13

Manual 2100-292

Page 16

TABLE 10 – CTHAC181

Return Air

Indoor Section

FCP24

CEVA018

Low side pressure ± 2 PSIG

High side pressure ± 5 PSIG

Tables are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct

operation charge being in the system, the charge should be removed, system evacuated, and recharged to

serial plate instructions.

Temperature Pressure 75 80 85 90 95 100 105 110 115

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

Low Side 70 72 74 76 78 80 82 84 86

High Side 187 202 217 231 246 260 275 290 304

Low Side 75 77 79 82 84 86 88 91 93

High Side 192 207 222 237 252 267 282 297 312

Low Side 81 83 85 88 90 92 95 97 99

High Side 198 214 229 245 261 277 293 308 324

Low Side 60 64 67 71 74 78 81 84 88

High Side 180 196 211 227 243 259 274 290 306

Low Side 65 68 72 75 79 82 86 89 93

High Side 185 201 218 234 250 266 282 298 315

Low Side 69 73 77 81 85 89 93 96 100

High Side 191 208 225 242 259 276 293 310 327

TABLE 11 – CTHAC241

Return Air

Indoor Section

FCP24

CEVA024

Low side pressure ± 2 PSIG

High side pressure ± 5 PSIG

Tables are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct

operation charge being in the system, the charge should be removed, system evacuated, and recharged to

serial plate instructions.

Temperature Pressure 75 80 8 5 9 0 95 100 105 110 115

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

Low Side 67 70 73 75 78 81 83 86 89

High Side 198 213 228 243 258 273 288 303 318

Low Side 72 75 78 80 83 86 88 91 94

High Side 203 219 234 249 265 280 296 311 326

Low Side 78 81 84 86 89 92 94 97 100

High Side 211 227 242 258 274 290 305 321 337

Low Side 62 65 68 71 74 77 80 83 86

High Side 198 214 229 244 260 275 291 306 321

Low Side 67 70 73 76 79 82 85 88 91

High Side 204 220 235 251 267 283 298 314 330

Low Side 71 75 78 81 85 88 92 95 99

High Side 211 227 244 260 276 292 308 324 340

Page 14

Manual 2100-292

Page 17

TABLE 12 – CTHAC301

Return Air

Indoor Section

FCP30

CEVA030

Low side pressure ± 2 PSIG

High side pressure ± 5 PSIG

Tables are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct

operation charge being in the system, the charge should be removed, system evacuated, and recharged to

serial plate instructions.

Temperature Pressure 75 80 8 5 9 0 95 100 105 110 115

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

Low Side 64 67 70 73 76 79 82 85 88

High Side 202 216 230 245 259 273 287 302 316

Low Side 69 72 75 78 81 84 87 90 93

High Side 208 222 237 251 266 280 295 310 324

Low Side 73 77 80 84 87 90 94 97 100

High Side 215 230 245 260 275 290 305 320 335

Low Side 61 64 67 70 73 76 79 82 85

High Side 196 211 226 241 256 271 286 301 316

Low Side 66 69 72 75 78 81 84 87 90

High Side 201 217 232 248 263 278 294 309 325

Low Side 70 74 77 81 84 87 91 94 98

High Side 207 223 239 256 272 288 304 320 336

TABLE 13 – CTHAC361

Return Air

Indoor Section

FCP36

CEVA036

Low side pressure ± 2 PSIG

High side pressure ± 5 PSIG

Tables are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct

operation charge being in the system, the charge should be removed, system evacuated, and recharged to

serial plate instructions.

Temperature Pressure 75 80 8 5 9 0 95 100 105 110 115

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

Low Side 65 67 69 72 74 76 79 81 83

High Side 185 200 216 231 247 262 278 293 308

Low Side 70 72 74 77 79 81 83 86 88

High Side 190 206 221 237 253 269 284 300 316

Low Side 74 77 80 82 85 88 90 93 96

High Side 196 221 229 245 262 278 295 311 328

Low Side 61 64 67 69 72 75 77 80 83

High Side 197 210 224 238 252 365 280 293 307

Low Side 66 69 72 74 77 80 82 85 88

High Side 202 216 230 245 259 273 287 301 316

Low Side 71 74 77 80 83 86 89 92 95

High Side 209 224 238 253 268 281 297 311 326

Page 15

Manual 2100-292

Page 18

TABLE 14 – CTHAC421

Return Air

Indoor Section

FCP42

Low side pressure ± 2 PSIG

High side pressure ± 5 PSIG

Tables are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct

operation charge being in the system, the charge should be removed, system evacuated, and recharged to

serial plate instructions.

Temperature Pressure 75 80 8 5 9 0 95 100 105 110 115

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

Low Side 68 70 72 75 77 79 81 84 86

High Side 184 199 215 231 247 263 278 294 310

Low Side 73 75 77 80 82 84 86 89 91

High Side 188 204 221 237 253 269 285 301 318

Low Side 78 81 83 86 88 90 93 95 97

High Side 194 211 228 245 262 279 296 313 330

TABLE 15 – CTHAC481

Return Air

Indoor Section

FCP48

CEVA048

Low side pressure ± 2 PSIG

High side pressure ± 5 PSIG

Tables are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct

operation charge being in the system, the charge should be removed, system evacuated, and recharged to

serial plate instructions.

Temperature Pressure 75 80 8 5 9 0 95 100 105 110 115

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

Low Side 70 72 74 77 79 81 84 86 88

High Side 191 205 220 234 249 263 278 293 307

Low Side 75 77 79 82 84 86 89 91 93

High Side 195 210 225 240 255 270 285 300 315

Low Side 81 83 85 88 90 92 95 97 99

High Side 202 218 233 249 264 278 295 310 326

Low Side 63 65 67 70 70 74 76 79 81

High Side 173 189 206 222 239 256 272 289 305

Low Side 68 70 72 75 77 79 82 84 86

High Side 177 194 211 228 245 262 279 296 313

Low Side 72 75 78 80 83 86 88 91 94

High Side 183 201 219 236 254 272 289 307 325

Page 16

Manual 2100-292

Page 19

TABLE 16 – CTHAC601

Return Air

Indoor Section

FCP60

CEVA060

Low side pressure ± 2 PSIG

High side pressure ± 5 PSIG

Tables are based upon rated CFM (airflow) across the evaporator coil. If there is any doubt as to correct

operation charge being in the system, the charge should be removed, system evacuated, and recharged to

serial plate instructions.

Temperature Pressure 75 80 85 90 95 100 105 110 115

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

75° DB/62° WB

80° DB/67° WB

85° DB/72° WB

Low Side 68 70 72 75 77 79 82 84 86

High Side 194 211 228 246 26 3 280 298 315 332

Low Side 73 75 77 80 82 84 87 89 91

High Side 199 217 235 252 270 288 30 5 323 341

Low Side 79 81 83 86 88 90 93 95 97

High Side 207 225 243 261 279 297 31 5 333 351

Low Side 60 61 63 64 65 66 67 68 70

High Side 197 210 222 235 248 261 27 3 286 299

Low Side 64 65 67 68 70 72 73 75 76

High Side 202 215 228 241 254 267 28 0 293 306

Low Side 69 70 72 73 75 77 78 80 81

High Side 209 222 236 250 263 276 28 9 303 317

Page 17

Manual 2100-292

Loading...

Loading...