Page 1

CONTROLLER INSTALLATION

OPERATION & QUICK START

Bard CompleteStat™

CS9B-THO, CS9B-THOC

CS9BE-THO, CS9BE-THOC

Manual: 2100-566D

Supersedes: 2100-566C

File: Tab 19

Date: 11-05-13

Manual 2100-566D

Page 1 of 20

Page 2

TABLE OF CONTENTS

Installation

Note ............................................................................Page 3

Controller Installation ................................................Page 3

Controller Connections ...............................................Page 3

Basic Operation

Note ............................................................................Page 4

Quick-Start Programming .....................................Page 4 & 5

Auxiliary Heat / Electric Heat Setup ............................Page 5

Compressor Lockout Temperature ........................Page 5 & 6

System Enable ............................................................Page 6

Temperature Setpoints ................................................Page 6

Terminal Descriptors ...................................................Page 6

Sequence of Operation .........................................Page 7 & 8

Wiring Diagrams

Wiring Diagram Table (Index) .....................................Page 9

Wiring Diagrams ..............................................Pages 10 - 20

Manual 2100-566D

Page 2 of 20

Page 3

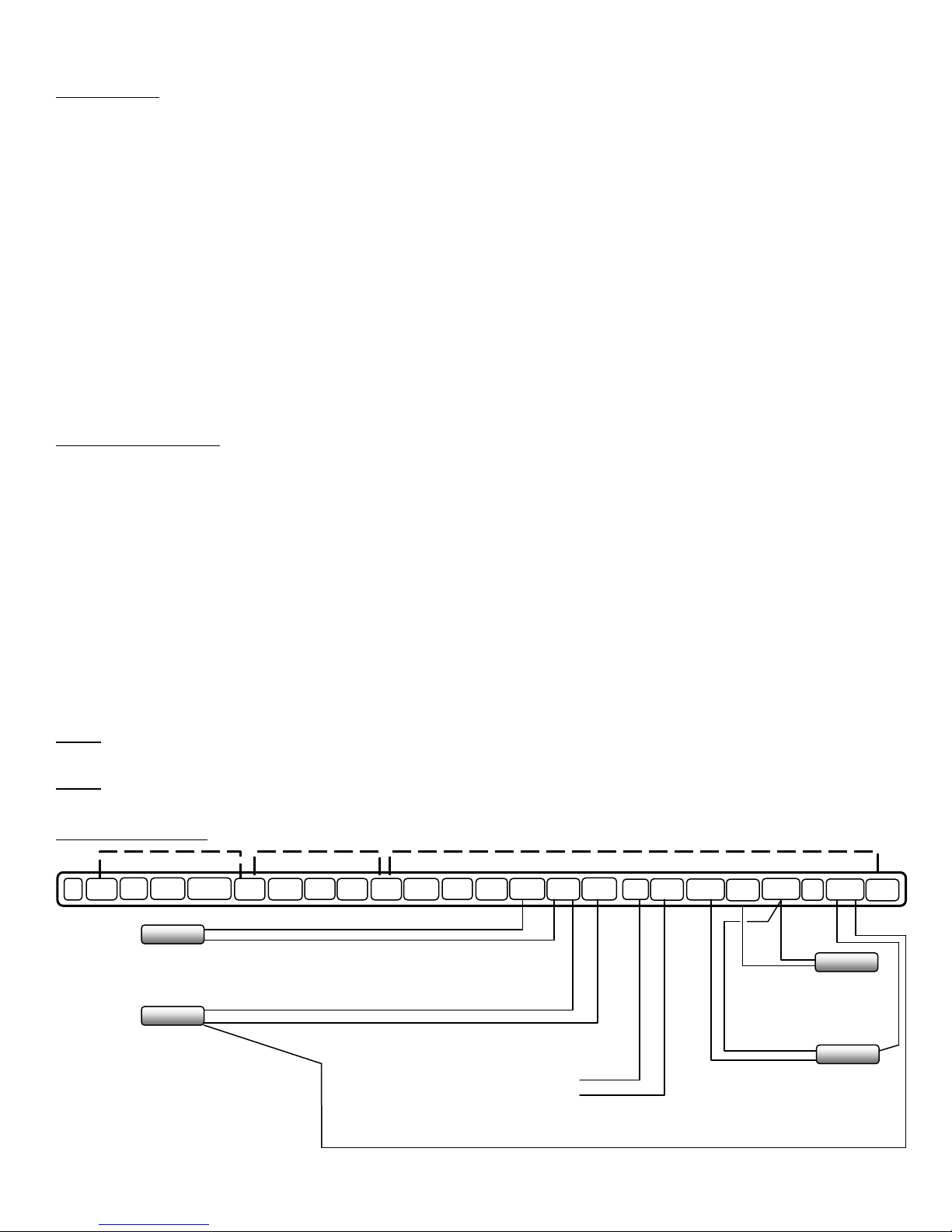

D

Dehumidification

Output

24VAC SPST RELAY

SC

24VAC to Relay Outputs D, A, W2

Power

A Ventilation Call

Output

24VAC SPST RELAY

W2

2nd Stage Heating

Output

24VAC SPST RELAY

W1/E

1st Stage Heating/Emer. Heat

Output

24VAC SPST RELAY

SC

24VAC to Relay Outputs W1/E, Y2, Y1

Power

Y2

2nd Stage Compressor

Output

24VAC SPST RELAY

Y1

1st Stage Compressor

Output

24VAC SPST RELAY

Y0

Economizer

Output

24VAC SPST RELAY

SC

24VAC to Relay Outputs YO, O/B, G

Power

O/B

Reversing Valve

Output

24VAC SPST RELAY

G

Indoor Blower

Output

24VAC SPST RELAY

IN9

Not Used

ROS

Remote Occupancy Sensor

Input

Dry Contact (Input to GND)

GND

REM

Remote Temperature Sensor

Input

10K Type II Thermistor

+B

Communications

-A

Communications

OAT

Outdoor Air Temperature Sensor

Input

10K Type II Thermistor

LAT

Leaving Air Temperature Sensor

Input

10K Type II Thermistor

GND

Control Ground

L

Lockout Alarm

Input

Dry Contact (Input to GND)

Com

24VAC Common

Power

24V

24VAC Hot

Power

*INSTALL NOTE: For optimum temperature sensor performance, the Bard CompleteStatTM must be mounted on an

interior wall and away from any heat sources, sunlight, windows, air vents, air circulation obstructions, and/or any other

cause of erratic or false temperature sensing.

Controller Installation: Mounting Controller

1. Complete rough-in wiring using a minimum 18 AWG solid-conductor control wiring, see Low Voltage Wiring

Diagrams in this Manual for exact number of conductors.

2. Turn the hex screws in the bottom and top of the controller clockwise (inward) until they clear the cover.

Remove base plate from controller.

3. Route completed wiring through base plate.

4. With the embossed “UP” arrows of the base plate pointing in the appropriate direction, fasten the base plate to

the desired wall location. A vertical/horizontal 2x4 wall handybox can be used for CO2-Sensing CompleteStat™,

and a vertical-only 2x4 wall handybox can be used for Non-CO2-Sensing CompleteStat™.

5. Make appropriate control wire connections (see Low-Voltage Wiring Manual) to terminal blocks.

6. Replace controller over base plate, being careful not to pinch/dislodge connections.

7. Turn hex screws in bottom/top of controller counter-clockwise (outward) to secure cover.

Controller Connections: Terminal legend

Terminal Function Type Form

2100-566D

Page 3 of 20

Page 4

Basic Operation: Home, Main Menu, and Override Screens

Navigate the menus & change settings by pressing a combination of various arrow buttons/the Enter button. Push the:

Enter button to select and/or exit value editing

Up or Down button to move among entries2

Right or Left button to move among value fields

Left button to return to the home screen

NOTE2: Although cooling/heating setpoints can be accessed by simply pressing the arrow keys during normal operation,

any changes made in this fashion will be for a specific length-of-time as an “override” feature only. This temperature

change will not be permanent. See the Temperature Setpoints for further information.

Quick Start Programming: System Selection, System Enable, Aux. Heat, and Temperature Setpoints.

System Selection – to select A/C or HP, stages of heating and cooling, and with/without economizer, press:

1. Right button to access the Main Menu screen

2. Down button through entries to highlight Advanced

3. Enter button to select Advanced and enter Advanced Screen

4. Enter button again to select/enter Applications Screen

5. Controller will ask for Admin Level Password

Factory Default Admin Level Password: BARD

Press Enter

6. Enter button to choose Degrees Scale (IF NECESSARY)1

*NOTE1: On changing temperature scale, the APP category must be set to

“NOT CONFIGURED” before the controller will allow you to change scale

7. Up/Down buttons to choose °Fahrenheit or °Celsius

8. Enter button to save selection of scale. See Note A.

9. Down button to highlight App

10. Enter button to highlight current selection

11. Up/Down buttons to choose from available System types:

A/C

HP

12. Enter button to select/save appropriate model

13. Down button to highlight Opt

14. Enter button to highlight current selection

15. Up/Down buttons to choose from available System Stages:

AC HP Note A. The change from "F" to "C"

1H/1C • 1 Stage will not take effect on the Home Screen

2H/2C • 2 Stage until the 24VAC power is cycled off and

1H/2C back on.

2H/1C

16. Enter button to select/save appropriate model stage

17. Down button to highlight Additional Setup

18. Enter button to select/enter Additional Setup Screen

19. Down button to highlight Damper, press Enter button to select

2100-566D

Page 4 of 20

Page 5

20. Enter button to highlight current economizer selection

21. Up/Down buttons to choose from available Economizer options:

None = No Economizer, or Standard Vent. Pkg. (ERV/CRV/MFAD)

En/Dis (Engage/Disengage) = Economizer in system

22. Enter button to select/save appropriate economizer options

23. Left arrow back to additional setup

24. Down button to locate & highlight Valve (if HP was chosen)

25. Enter button to select/enter Valve (if HP was chosen)

26. Right button to highlight Valve options (if HP was chosen)

27. Up/Down buttons to choose from Valve options: (if HP was chosen)

ACTIVE HTG

ACTIVE CLG

28. Enter button to save Valve option choice (if HP was chosen)

29. Left button (6x) to navigate back to home page

Auxiliary Heat/Electric Heat Setup – If a heat pump is chosen, then the

electric heat strips must be configured. These steps do not apply to air

conditioners or other types of conventional heating. To configure the

auxiliary heat from the home screen, press:

1. Right button to access the Main Menu screen

2. Down button through entries to highlight Advanced

3. Enter button to select Advanced and enter Advanced Screen

4. Enter button again to select/enter Applications Screen

5. Controller will ask for Admin Level Password

Factory Default Admin Level Password: BARD

Press Enter

6. Down button through entries to highlight Additional Setup

7. Enter button to select/enter Additional Setup Screen

8. Enter button again to select/enter Aux Heat

9. Enter button again to highlight Aux Heat choices

10. Up/Down buttons to toggle through available choices…

W/O Lockout – Auxiliary heat will activate regardless of compressor operation or outdoor air temperature (factory default)

- If W/O Lockout is chosen, proceed to set delay-on time

Comp Lockout – Compressor locks out below the selected Outdoor Air Temperature. (Requires optional 8301-

061 Outdoor Air Temperature Sensor.)

None – no auxiliary strip heat, controller will not energize W2

- If None is chosen, Left button (5x) to return to home screen

11. Down button to highlight Delay (mins)

12. Enter button to highlight default Delay minutes

13. Up/Down buttons to select the amount of minutes you would like to delay the electric heat before activation.

14. Enter button to save choice.

15. Left button (5x) to return to home screen.

Compressor Lockout Temperature – If you have chosen auxiliary heat strip configuration “Comp Lockout,” an

optional outdoor air temperature sensor will have to be installed/configured to specifically set the temperature at

which the compressor will no longer be allowed to operate. To install the 8301-061 Outdoor Air Temperature

Sensor, attach the leads to terminals “OAT” and “GND.” To set the compressor outdoor air temperature from

the home screen, press…

1. Right button to access the Main Menu screen

2. Down button through entries to highlight Advanced

3. Enter button to select Advanced and enter Advanced Screen

4. Down button through entries to highlight Limits

5. Enter button to select Limits and enter Limits Screen

6. Down through entries to highlight Comp OAT Low

7. Enter button to select current Comp OAT Low setting

8. Up/Down button to desired outdoor air temperature for compressor lockout

2100-566D

Page 5 of 20

Page 6

9. Enter button to save choice

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND L COM

24V

CompleteStatTM

8301-014 Leaving Air

Temperature Sensor

8301-061 Outdoor Air

Temperature Sensor

8301-062 Indoor Remote

Air Temperature Sensor

Remote Occupancy Sensor

(TBD)

BACnet Commercial

Controls Platform

10. Left button (3x) to home screen.

System Enable – to enable heating / cooling from home screen, press:

1. Right button to access the Main Menu Screen

2. Down button through entries to highlight System

3. Enter button to select System and enter System Screen

4. Enter button again to highlight current System Enable choice

5. Up/Down buttons to choose from available System Enable options

Auto: System is in “Auto-Changeover” mode. HVAC system will cycle heating and cooling automatically to

stay within preset heating and cooling setpoints.

Heating: System is in “Heating-Only” mode. HVAC system will cycle heating in reference to Heating

Setpoint only. Unit will not activate cooling sequence.

Cooling: System is in “Cooling-Only” mode. HVAC system will cycle cooling in reference to Cooling Setpoint

only. Unit will not activate heating sequence.

Emer HT: HP mode only.

Off: HVAC system is inactive.

6. Enter button to select/save appropriate mode selection

7. Left button (2x) to navigate back to home page.

Temperature Setpoints – to access temperature setpoints from the home screen, press:

1. Right button to access the Main Menu Screen

2. Down button through entries to highlight Setpoints

3. Enter button to select Setpoints and enter Setpoints Screen

4. Enter button to select Cool Setpt3

5. Up/Down buttons to enter appropriate cooling setpoint

6. Enter button to save new Cool Setpt4

7. Down button to highlight Heat Setpt

8. Enter button to select Heat Setpt

9. Up/Down buttons to enter appropriate heating setpoint

10. Enter button to save new Heat Setpt

11. *REPEAT STEPS IN LIKE FASHION FOR COOL SETBACK & HEAT SETBACK TEMPERATURES, DEHUM SETPOINT & SPAN,

& FOR C02 SETPOINT IN PARTS PER MILLION & C02 SPAN OF CONTROL IN PARTS PER MILLION (IF AVAILABLE).*

12. Left button (2x) to navigate back to home page

NOTE3: The controller will not allow heating/cooling setpoints to contradict one another, or to be within a degree of

conflicting operation.

NOTE4: Any system start-up with indoor ambient temperatures lower than 56° F., or above 86° F. will experience an

internal Low-Temperature or High-Temperature alarm. This will not affect normal operation, and can be cleared easily.

Terminal Descriptors – Optional Inputs

NOTE: Use twisted shielded pair for optional outdoor and indoor air sensors. Connect shield (drain) to 24V common.

2100-566D

Page 6 of 20

Page 7

Fan Only

X

1st Stage Cooling

X

X

2nd Stage Cooling (if employed)

X X

X 1st Stage Heating

X X

2nd Stage Heating (if employed)

X X

X

Dehumidification

X Ventilation1

X1 X

Fan Only

X

1st Stage Cooling (Economizer)

X

X

2nd Stage Cooling

X

X

X

3rd Stage Cooling (if employed)

X

X

X

X 1st Stage Heating

X X

2nd Stage Heating (if employed)

X X

X

Dehumidification

X

Ventilation1

X1 X

Fan Only

X

1st Stage Cooling

X

X

1st Stage Heating

X X X2

2nd Stage Heating

X X

X3

X2

Emergency Heat

X X

X3 Dehumidification

X

Ventilation1

X1 X

Sequence of Operation: Conventional 1H/1C, 2H/1C, 1H/2C, or 2H/2C without Economizer

Operation G Y/O Y1 Y2 W1/E W2 O/B D A

NOTE1: CS9B(E)-THOC (CO2 Sensing Capability) Models will activate both G and A terminals upon a ventilation call,

however the CS9B(E)-THO (NON-CO2 Sensing) Models will activate the A terminal only if there is an existing call for the

indoor blower, whether through space conditioning, or through constant fan operation.

Sequence of Operation: Conventional 1H/1C, 2H/1C, 1H/2C, or 2H/2C with Economizer

Operation G Y/O Y1 Y2 W1/E W2 O/B D A

NOTE1: CS9B(E)-THOC (CO2 Sensing Capability) Models will activate both G and A terminals upon a ventilation call,

however the CS9B(E)-THO (NON-CO2 Sensing) Models will activate the A terminal only if there is an existing call for the

indoor blower, whether through space conditioning, or through constant fan operation.

Sequence of Operation: One-Stage Heat Pump, no Economizer

Operation G Y/O Y1 Y2 W1/E W2 O/B D A

NOTE1: CS9B(E)-THOC (CO2 Sensing Capability) Models will activate both G and A terminals upon a ventilation call,

however the CS9B(E)-THO (NON-CO2 Sensing) Models will activate the A terminal only if there is an existing call for the

indoor blower, whether through space conditioning, or through constant fan operation.

NOTE2: CompleteStatTM controller can be configured to energize reversing valve in cooling (See System Selection).

NOTE3: Electric Heat must be configured for a Heat Pump application, see Auxiliary Heat/Electric Heat Setup.

2100-566D

Page 7 of 20

Page 8

Fan Only

X

1st Stage Cooling

X

X

2nd Stage Cooling

X X

X 1st Stage Heating

X X X2

2nd Stage Heating

X X

X

X2

3rd Stage Heating

X X

X X3 X2

Emergency Heat

X X

X3

Dehumidification

X Ventilation1

X1 X

Fan Only

X

1st Stage Cooling

X

X

2nd Stage Cooling

X

X

X

1st Stage Heating

X

X

X X2

2nd Stage Heating

X

X

X

X3

X2

Emergency Heat

X X

X3 Dehumidification

X Ventilation1

X1 X

Fan Only

X

1st Stage Cooling

X

X

2nd Stage Cooling

X

X

X

3rd Stage Cooling

X

X

X

X 1st Stage Heating

X

X

X X2

2nd Stage Heating

X

X

X

X

X2

3rd Stage Heating

X

X

X

X X3

X2

Emergency Heat

X X

X3

Dehumidification

X Ventilation1

X1 X

Sequence of Operation: Two-Stage Heat Pump, no Economizer

Operation G Y/O Y1 Y2 W1/E W2 O/B D A

NOTE1: CS9B(E)-THOC (CO2 Sensing Capability) Models will activate both G and A terminals upon a ventilation call,

however the CS9B(E)-THO (NON-CO2 Sensing) Models will activate the A terminal only if there is an existing call for the

indoor blower, whether through space conditioning, or through constant fan operation.

NOTE2: CompleteStatTM controller can be configured to energize reversing valve in cooling (See System Selection).

NOTE3: Electric Heat must be configured for a Heat Pump application, see Auxiliary Heat/Electric Heat Setup.

Sequence of Operation: Single-Stage Heat Pump, with Economizer

Operation G Y/O Y1 Y2 W1/E W2 O/B D A

NOTE1: CS9B(E)-THOC (CO2 Sensing Capability) Models will activate both G and A terminals upon a ventilation call,

however the CS9B(E)-THO (NON-CO2 Sensing) Models will activate the A terminal only if there is an existing call for the

indoor blower, whether through space conditioning, or through constant fan operation.

NOTE2: CompleteStatTM controller can be configured to energize reversing valve in cooling (See System Selection).

NOTE3: Electric Heat must be configured for a Heat Pump application, see Auxiliary Heat/Electric Heat Setup.

Sequence of Operation: Two-Stage Heat Pump, with Economizer

Operation G Y/O Y1 Y2 W1/E W2 O/B D A

NOTE1: CS9B(E)-THOC (CO2 Sensing Capability) Models will activate both G and A terminals upon a ventilation call,

however the CS9B(E)-THO (NON-CO2 Sensing) Models will activate the A terminal only if there is an existing call for the

indoor blower, whether through space conditioning, or through constant fan operation.

NOTE2: CompleteStatTM controller can be configured to energize reversing valve in cooling (See System Selection)

NOTE3: Electric Heat must be configured for a Heat Pump application, see Auxiliary Heat/Electric Heat Setup.

2100-566D

Page 8 of 20

Page 9

2100-566D

Page 9 of 20

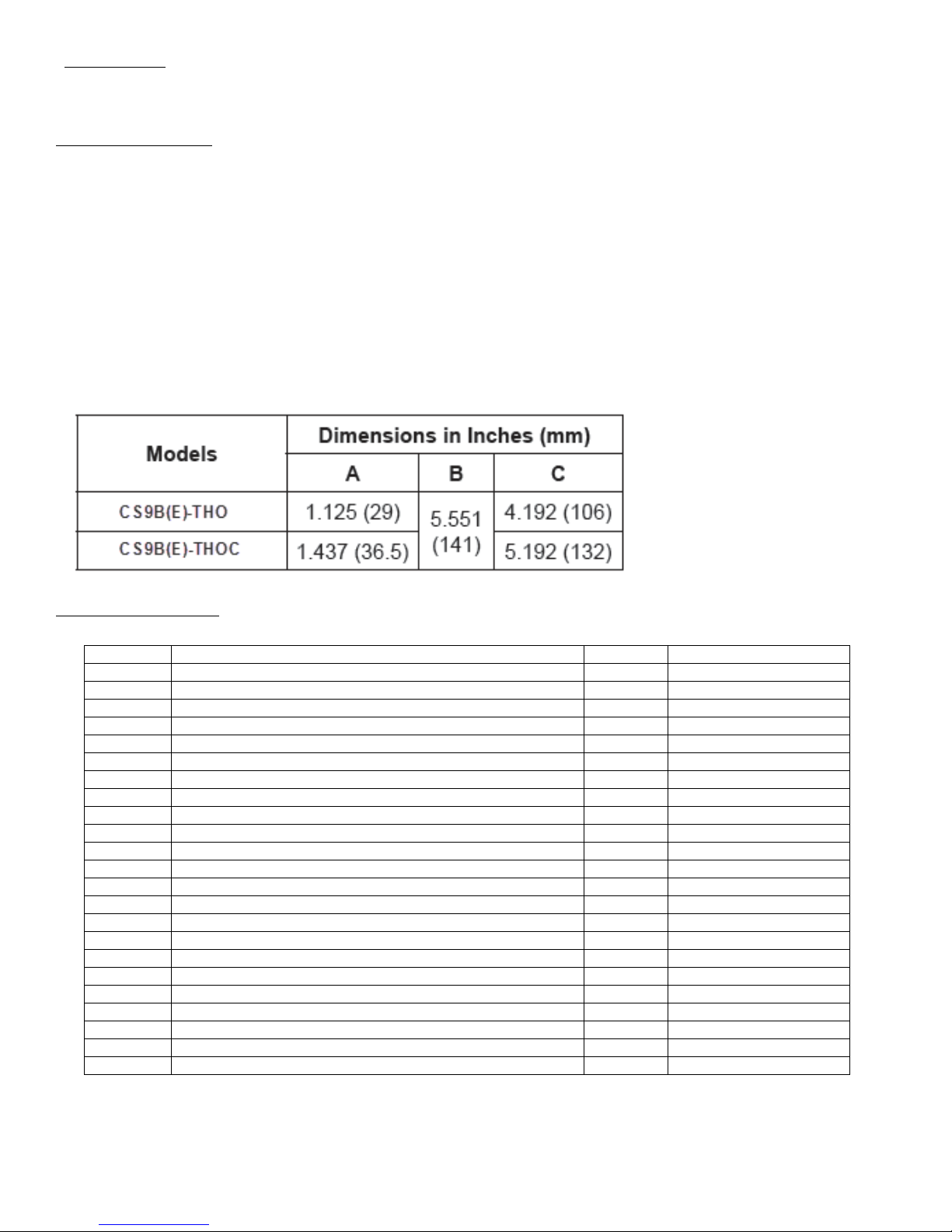

Wiring Diagram Table

Wiring

Diagram

No.

Unit Type

(Note A)

CompleteStat™

Model CS9B(E)-

CompleteStat™

System Type

System

Stages

Setting

Economizer

Setting

Use with Bard

Units

Ventilation System

Vent

Control

Type

1

A/C

THO, THOC

A/C

2H/2C

None

1 or 2-Stage A/C w/

or w/o Elec. Heat

CRV, ERV, MFAD

On/Off

2

A/C

THO, THOC

A/C

2H/2C

EN/DIS

1-Stage A/C with or

w/o Elec. Heat

EIFM Factory "E" Economizer w/W7459 Control

On/Off

3

A/C

THO, THOC

A/C

2H/2C

EN/DIS

1-Stage A/C with or

w/o Elec. Heat

ECONWM Factory "T" or "W" Economizer w/JADE

W7220 Control

On/Off 4 A/C

THO, THOC

A/C

2H/2C

EN/DIS

2-Stage A/C with or

w/o Elec. Heat

EIFM Factory "E" Economizer w/W7459 Control

On/Off 5 A/C

THO, THOC

A/C

2H/2C

EN/DIS

2-Stage A/C with or

w/o Elec. Heat

ECONWM Factory "T" or "W" Economizer w/JADE

W7220 Control

On/Off 6 HP

THO, THOC

HP

1 Stage

None

1-Stage HP with or

w/o Elec. Heat

CRV, ERV, MFAD

On/Off 7 HP

THO, THOC

HP

2 Stage

None

2-Stage HP with or

w/o Elec. Heat

CRV, ERV, MFAD

On/Off

8

HP

THO, THOC

HP

1 Stage

EN/DIS

1 & 2-Stage HP

with or w/o Elec.

EIFM Factory "E" Economizer w/W7459 Control

On/Off

9

HP

THO, THOC

HP

1 Stage

EN/DIS

1-Stage HP with or

w/o Elec. Heat

ECONWM Factory "T" or "W" Economizer w/JADE

W7220 Control

On/Off

10

HP

THO, THOC

HP

2 Stage

EN/DIS

2-Stage HP with or

w/o Elec. Heat

EIFM Factory "E" Economizer w/W7459 Control

On/Off

11

HP

THO, THOC

HP

2 Stage

EN/DIS

2-Stage HP with or

w/o Elec. Heat

ECONWM Factory "T" or "W" Economizer w/JADE

W7220 Control

On/Off

12

Gas/Electric

THO, THOC

A/C

1H/1C

None

1-Stage A/C with

Gas Heat

CRV, ERV, MFAD

On/Off

13

Gas/Electric

THO, THOC

A/C

1H/2C

None

2-Stage A/C with

Gas Heat

CRV, ERV, MFAD

On/Off

14

Gas/Electric

THO, THOC

A/C

1H/1C

EN/DIS

1-Stage A/C with

Gas Heat

EIFM Factory "E" Economizer w/W7459 Control

On/Off

15

Gas/Electric

THO, THOC

A/C

1H/2C

EN/DIS

2-Stage A/C with

Gas Heat

EIFM Factory "E" Economizer w/W7459 Control

On/Off

16

I-TEC HP

THO, THOC

HP

2 Stage

None

2-Stage HP with or

w/o Elec. Heat

None

On/Off

17

I-TEC HP

THO, THOC

HP

2 Stage

None

2-Stage HP with or

w/o Elec. Heat

CRV, ERV

On/Off

18

I-TEC HP

THO

HP

2 Stage

None

2-Stage HP with or

w/o Elec. Heat

Modulating ERV, use –THO plus 8403-067 CO2

controller

Modulating

19

Q-TEC QA

THO, THOC

A/C

2H/1C

None

1-Stage A/C with or

w/o Elec. Heat

CRV, ERV

On/Off

20

Q-TEC QH

THO, THOC

HP

1 Stage

None

1-Stage HP with or

w/o Elec. Heat

CRV, ERV

On/Off

21

QWS

THO, THOC

HP

2 Stage

None

2-Stage Geo/Water

Source HP

CRV, ERV

On/Off

Note A; Either THO or THOC version can be used. For THO the vent output "A" limits vent operation to Occupied periods. For THOC the vent output "A" operates vent based on CO2 level.

Page 10

Wiring Diagram 1: Conventional 1H/1C, 1H/2C, 2H/1C, or 2H/2C, with or without dehumidification and ventilation.

Remove jumper for 2-Stg. heat (15kW or more)

Field-installed wires and jumpers

Factory-installed wires and jumpers

3

Opt. Wire only for 2-Stg. Heating (15kW or more)

4

Wire only for 2-Stg. Cooling, if available

5

Wire not used on MFAD Ventilation option

2

Wire for Dehumidification Units Only

1

6

CompleteStat programmed for

Damper/Economizer: EN/DIS

D A W2

W1/E

Y2

Y* G C

R

3 4 2

1

CRV, ERV OR

MFAD

5

HVAC System

3 A W2

W1/E

Y2

Y1 G C

R

3 6 2

1

HONEYWELL

W7459A

HVAC System

Y E F

*NOTE: 2-Stage Units use

“Y1” Terminal Designation

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAS

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAS

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

RT

8

RT

8

7

W**A2 Units use “D” Terminal,

W**A1 Units use “3” Terminal

8

For Fire-Smoke/Emergency Shutdown, remove

factory jumper and connect NC contacts from fieldinstalled device to terminals “RT” and “R,” only

offered on single-stage W**A2 units.

7

7

Wiring Diagram 2: Conventional 1H/1C, 2H/1C with Honeywell W7459A Control Economizer, with or w/o dehum.

2100-566D

Page 10 of 20

Page 11

Remove jumper for 2-Stg. heat (15kW or more)

Field-installed wires and jumpers

Factory-installed wires and jumpers

3

Opt. Wire only for 2-Stg. Heating (15kW or more)

2

Wire for Dehumidification Units Only

4

CompleteStat programmed for Damper/Economizer: EN/DIS

1

D A W2

W1/E

Y2

Y1 G C

R

3 4 2

1

HONEYWELL

W7220

HVAC System

Y

D A W2

W1/E

Y2

Y1 G C

R

3 4 2

HONEYWELL

W7459

HVAC System

Y E F

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAS

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAS

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

RT

6

5

W**A2 units use “D” Terminal, W**A1 units use “3” Terminal

5

6

For Fire-Smoke/Emergency Shutdown, remove factory jumper and connect NC contacts

from field-installed device to terminals “RT” and “R,” only offered on single-stage W**A2

Wiring Diagram 3: Conventional 1H/1C, 2H/1C with Honeywell W7220 JadeTM Control Economizer, with or w/o dehum.

Wiring Diagram 4: Conventional 1H/2C, 2H/2C with Honeywell W7459A Control Economizer

2100-566D

Page 11 of 20

Page 12

Wiring Diagram 5: Conventional 1H/2C, 2H/2C with Honeywell W7220 JadeTM Control Economizer

Remove jumper for 2-Stg. Aux. heat (15kW or more)

Factory-installed wires and jumpers

Field-installed wires and jumpers

3 4 Field-Installed Wire Nut

5

Wire not used on MFAD Ventilation option

2

Wire for Dehumidification Units Only

1 6 CompleteStat programmed for Damper/Economizer: En/Dis

Opt. Wire only for 2-Stg. Heating (15kW or more)

3 A W2

W1/E

Y2

Y1 G C

R

3 4 2

HVAC System

Y

PINK

PURPLE

HONEYWELL

W7220

4

5

W3

01

W2 E Y2

Y1 G C

R

1

HVAC System

Y

CRV, ERV OR

MFAD

6

W1

B

L

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAS

SC

A+

B-

GND L COM

24V

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAS

SC

A+

B-

GND L COM

24V

CompleteStatTM

Wiring Diagram 6: Heat Pump 2H/1C, 3H/1C, with or without dehumidification and ventilation.

2100-566D

Page 12 of 20

Page 13

Wiring Diagram 7: Heat Pump 2-Stage, with or without dehumidification and ventilation.

CH*S-Series Heat Pumps use “DH” Dehumidification Terminal

Field-installed wires and jumpers

2

Wire for Dehumidification Units Only

3

CompleteStat programmed for Damper/Economizer: EN/DIS

1

E

F

Wire not used on MFAD Ventilation option

4 5 Factory-installed wires and jumpers

Field-Installed Wire Nut

W3

01

W2 E Y1 G C

R

1

HVAC System

Y E F

CRV, ERV OR

MFAD

3

W1 B L

2 4 1

HVAC System

PINK

PURPLE

HONEYWELL

W7459

4

5

W3

01

W2 E Y1 G C R Y E F

W1 B L

2

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B G IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND L COM

24V

CompleteStatTM

Wiring Diagram 8: Heat Pump 1-Stage, with Honeywell W7459A Control Economizer, with or w/o dehum.

2100-566D

Page 13 of 20

Page 14

Wiring Diagram 9: Heat Pump 1-Stage, with Honeywell W7220 JadeTM Control Economizer, with or w/o dehum.

CompleteStat programmed for Damper/Economizer: EN/DIS

Field-installed wires and jumpers

3

Field-Installed Wire Nut

2

Wire for Dehumidification Units Only

4 1 CH*S-Series Heat Pumps use “DH” Dehumidification Terminal

Factory-installed wires and jumpers

2

1

HVAC System

PINK

PURPLE

2

3

W3

01

W2 E Y1 G C R Y E F

W1 B L

4

HONEYWELL

W7459

E

F

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

Wiring Diagram 10: Heat Pump 2-Stage, with Honeywell W7459A Control Economizer, with or w/o dehum.

2100-566D

Page 14 of 20

Page 15

CH*S-Series Heat Pumps use “DH” Dehumidification Terminal

3

Field-Installed Wire Nuts

2

Wire for Dehumidification Units Only

4

CompleteStat programmed for Damper/Economizer: EN/DIS

1

Wire not used on MFAD Ventilation option

5 6 W**G-Series uses “A” Terminal for Ventilation

Field-installed wires and jumpers

Factory-installed wires and jumpers

2

1

HVAC System

PINK

PURPLE

2

4

W3

01

W2 E Y1 G C R Y E F

W1

B

L

HONEYWELL

W7220

3

3 F W2

W1 Y G C R

1

CRV, ERV OR

MFAD

6

HVAC System

5

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B G IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V D SC A W2

W1/E

SC

Y2

Y1

YO

O/B G IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND L COM

24V

CompleteStatTM

CompleteStatTM

Wiring Diagram 11: Heat Pump 2-Stage, with Honeywell W7220 JadeTM Control Economizer, with or w/o dehum.

Wiring Diagram 12: Gas/Electric 1H/1C with or without dehumidification and ventilation package

2100-566D

Page 15 of 20

Page 16

Wire not used on MFAD Ventilation option

3

W**G-Series uses “A” Terminal for Ventilation

2

Wire for Dehumidification Units Only

4

CompleteStat programmed for Damper/Economizer: EN/DIS

1

Field-installed wires and jumpers

Factory-installed wires and jumpers

3 F W2

W1

Y2

Y1 G C

R

1

CRV, ERV OR

MFAD

3

HVAC System

2

3 F W2

W1 Y G C R

1

HONEYWELL

W7459A

HVAC System

Y1

Y2

E

F

4

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B G IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

Wiring Diagram 13: Gas/Electric 1H/2C with or without dehumidification and ventilation package

Wiring Diagram 14: Gas/Electric 1H/1C with Honeywell W7459A Control Economizer, with or w/o dehum.

2100-566D

Page 16 of 20

Page 17

CompleteStat programmed for Damper/Economizer: EN/DIS

2

Wire for Dehumidification Units Only

1

Field-installed wires and jumpers

Factory-installed wires and jumpers

Wire not needed if Aux. Heat Strip is 10kW or less

3

3 F W2

W1 Y G C R

1

HONEYWELL

W7459A

HVAC System

Y1

Y2

E

F

D 3 4 A Y1

YO G C

R

1

HVAC System

6

W2

W3

Y2

B/W1

L

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

3

2

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

Wiring Diagram 15: Gas/Electric 1H/2C with Honeywell W7459A Control Economizer, with or w/o dehum.

Wiring Diagram 16: I-TEC 2-Stage Heat Pump Series with no ventilation package

2100-566D

Page 17 of 20

Page 18

Wire not needed if Aux. Heat Strip is 10kW or less

2

Wire for Dehumidification Units Only

1

Field-installed wires and jumpers

Factory-installed wires and jumpers

8403-067 to be used with Non-C02 Sensing CompleteStatTM

3

D 3 4 A Y1

YO G C

R

1

HVAC System

6

W2

W3

Y2

B/W1

L

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

CRV

2

D 3 4 A Y1

YO G C

R

1

HVAC System

6

W2

W3

Y2

B/W1

L

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

ERV

2

1

2

3

4

3

8403-067

5

6

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B G IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND L COM

24V

CompleteStatTM

Wiring Diagram 17: I-TEC 2-Stage Heat Pump Series with CRV ventilation package

Wiring Diagram 18: I-TEC 2-Stage HP Series with ERV ventilation package & 8403-067 CO2 Detector (fully modulating)

2100-566D

Page 18 of 20

Page 19

Q-Series with factory installed thermostat had no terminal board and were wired directly

from Plug#4. Use provided colors to wire CompleteStatTM

2

Wire for Dehumidification Units Only

1

Field-installed wires and jumpers

Factory-installed wires and jumpers

1 F W2

W1

Y1

G

C

R

4 5 9 3 7 6 11

10

HVAC

System

Plug #4

YEL

BRN

WHT

BRN

BLU

YEL

ORG

BLK

WHT

RED

WHT

2

1

4

01

W2 E Y1

G

C R 4 5 9 3 7 6 11

10

HVAC

System

Plug #4

YEL

BRN

RED

YEL

ORG

2

1

Y

W1

O/B

TAN

8

BLU

BLK

RED

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B G IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B

G

IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

Wiring Diagram 19: Q-TEC QA**/Q**A-Series 1-Stage Air Conditioners, with or without ventilation and dehumidification

Wiring Diagram 20: Q-TEC QH**/Q**H Series 1-Stage Heat Pump, with or without ventilation and dehumidification

2100-566D

Page 19 of 20

Page 20

Q-Series with factory installed thermostat had no terminal board and were wired directly

from Plug#4. Use provided colors to wire CompleteStatTM

2

Wire for Dehumidification Units Only

1

Field-installed wires and jumpers

Factory-installed wires and jumpers

1 A W2 E Y1

G

C

R

1 5 9 3 7 6 11

10

HVAC

System

Plug #4

BRN

YEL

ORG

2

1

Y

W1 O 8

BLU

Y2

4

PUR

PUR

WHT

BRN

WHT

RED

YEL

BLK

RED

WHT

BLU

YEL

ORG

(USE ENCLOSED RELAY)

L

12

PNK

BLK

WHT

RED

WHT

D

SC A W2

W1/E

SC

Y2

Y1

YO

O/B G IN9

ROS

GND

REM

OAT

LAT

SC

A+

B-

GND

L

COM

24V

CompleteStatTM

Wiring Diagram 21: QW*S-Series 2-Stage Heat Pump, with or without ventilation and dehumidification

Bard CompleteStatTM should be fully operational at this point. For further controller enhancement or operation detail,

please consult the Advanced Programming section.

2100-566D

Page 20 of 20

Loading...

Loading...