Page 1

RLM-W14

User manual

Page 2

Barco nv Projection Division

Noordlaan 5, B-8520 Kuurne

Phone: +32 56.36.82.11

Fax: +32 56.36.883.86

Support: www.barco.com/esupport

Visit us at the web: www.barco.com

Printed in China

Revision: 06

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the

implied war- ranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes

to the product(s) and/or the program(s) described in this publication at any time without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the

information in this publication; these changes are incorporated in new editions of this publication.

The latest edition of Barco manuals can be downloaded from the Barco web site www.barco.com or from the secured Barco

web site https://my.barco.com.

Copyright

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not otherwise be recorded,

transmitted or stored in a retrieval system without the prior written consent of Barco.

©

EN55022/CISPR22 Class A ITE (Information Technology Equipment)

Class A ITE is a category of all other ITE which satisfies the class A ITE limits but not the class B ITE limits. Such equipment

should not be restricted in its sale but the following warning shall be included in the instructions for use:

Warning : This is a class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the

FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area may cause harmful interference, in which case the user will be responsible

for correcting any interference at his own expense.

Guarantee and Compensation

Barco provides a guarantee relating to perfect manufacturing as part of the legally stipulated terms of guarantee. On receipt,

the purchaser must immediately inspect all delivered goods for damage incurred during transport, as well as for material and

manufacturing faults Barco must be informed immediately in writing of any complaints.

The period of guarantee begins on the date of transfer of risks, in the case of special systems and software on the date of

commissioning, at latest 30 days after the transfer of risks. In the event of justified notice of complaint, Barco can repair the

fault or provide a replacement at its own discretion within an appropriate period. If this measure proves to be impossible or

unsuccessful, the purchaser can demand a reduction in the purchase price or cancellation of the contract. All other claims,

in particular those relating to compensation for direct or indirect damage, and also damage attributed to the operation of

software as well as to other services provided by Barco, being a component of the system or independent service, will be

deemed invalid provided the damage is not proven to be attributed to the absence of properties guaranteed in writing or due

to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out modifications or repairs on goods delivered by Barco, or if the goods are handled

incorrectly, in particular if the systems are commissioned operated incorrectly or if, after the transfer of risks, the goods

are subject to influences not agreed upon in the contract, all guarantee claims of the purchaser will be rendered invalid.

Not included in the guarantee coverage are system failures which are attributed to programs or special electronic circuitry

provided by the purchaser, e.g. interfaces. Normal wear as well as normal maintenance are not subject to the guarantee

provided by Barco either.

The environmental conditions as well as the servicing and maintenance regulations specified in the this manual must be

complied with by the customer.

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or copyrights of their

respective holders. All brand and product names mentioned in this manual serve as comments or examples and are not to be

understood as advertising for the products or their manufacturers.

Page 4

TABLE OF CONTENTS

1. SAFETY 1

1.1 General considerations 1

1.2 Important safety instructions 2

2. GENERAL 5

2.1 Installation requirements 5

2.2 Unpacking the projector 6

2.3 Initial inspection 7

2.4 Projector configurations 8

2.5 Lens Selection 10

2.6 Projector air inlets and outlets 11

2.7 Installation process overview 11

3. PROJECTOR PARTS AND FUNCTIONS 12

3.1 Projector front view 12

3.2 Projector Rear view 12

3.3 Input and Communication 13

3.4 Status lights of LED 15

3.5 Connecting the projector to devices 16

4. PHYSICAL INSTALLATION 22

4.1 Remote control unit (RCU) 22

4.2 Lenses 26

4.3 How to Mount the cable 26

4.4 Installing the lens with safety cable on an RLM projector 27

4.5 Connecting the projector with the power net 30

4.6 Alignment of a table mounted projector 31

4.7 Mounting the Ceiling mount 32

Page 5

TABLE OF CONTENTS

5. GETTING STARTED 33

5.1 RCU & Local keypad 33

5.2 Power on projector 33

5.3 Switching to standby 34

5.4 Power off projector 34

5.5 Source selection 34

5.6 Changing OSD language 34

5.7 Adjusting the lens by horizontal and vertical lens shift 35

6. OSD MENU 36

6.1 How to navigate in the OSD menu structure? 37

6.2 OSD menu memory 37

7. INPUT 38

7.1 Input menu overview 38

7.2 Input Selection 39

7.3 Input Configuration 39

7.4 Input Locking 39

7.5 Auto Power Off 40

7.6 Auto Power ON 40

7.7 No Signal 40

7.8 Auto Image Adjust 40

Page 6

TABLE OF CONTENTS

8. IMAGE 41

8.1 Image menu overview 41

8.2 Contrast 42

8.3 Brightness 42

8.4 Sharpness 43

8.5 Noise Reduction 43

8.6 Color Temperature 43

8.7 Input Balance 44

8.8 Aspect Ratio 45

8.9 Timings 46

8.10 Auto Image 48

9. LAYOUT 49

9.1 Layout menu overview 49

9.2 Zoom 50

9.3 Main Select 50

9.4 PIP Select 51

9.5 PIP Position 51

9.5 PIP 51

10. LAMP 52

10.1 Lamp menu overview 52

10.2 Mode 53

10.3 Lamps 53

10.4 High Altitude Mode 54

10.5 Power 54

10.6 Lamp1 Status 54

10.7 Lamp2 Status 54

10.8 Lamp1 Run Time 54

10.9 Lamp2 Run Time 54

10.10 lamp performance 54

Page 7

TABLE OF CONTENTS

11. ALIGNMENT 55

11.1 Alignment menu overview 55

11.2 Adjusting screen orientation 56

11.3 Rear Projection 57

11.4 Ceiling Mode 57

11.5 Lens Control 57

11.6 Lens To Midposition 57

11.7 Lens Calibration 57

11.8 Lens Memory 58

11.9 Dynamic Contrast 58

11.10 Gamma 58

11.11 Internal Patterns 58

11.12 Color Space 59

11.13 Custom Color Space 59

11.14 Warp 59

11.15 Blanking 62

11.16 ScenergiX 62

12. CONTROL 65

12.1 Control menu overview 65

12.2 IR Address 66

12.3 Eco Network Power 66

12.4 Network 66

12.5 Menu Position 68

12.6 Start Up Logo 68

12.7 Start Up Chime 68

12.8 Button 1 ~ 5 68

12.9 Trigger1 ~2 69

12.8 Auto Source 69

12.9 Language 69

Page 8

TABLE OF CONTENTS

13. SERVICE 70

13.1 Service menu overview 70

13.2 Service message of the projector 71

13.3 Lamp Hour Reset 71

13.4 Blue Only 71

13.4 Factory Reset 71

14. MAINTENANCE 72

14.1 Lamp Replacement 72

14.2 Replace the filter (for inlet Ventilation) 74

14.3 Clean the dust filter(for outlet Ventilation) 76

14.4 Cleaning the lens 76

14.5 Cleaning the exterior of the projector 76

14.6 Simple troubleshooting 77

15. PROJECTOR SPECIFICATION 79

15.1 Specifications 79

15.2 STANDARD SOURCE FILES 80

15.3 SDI FORMATS 81

15.4 Dimension 81

16. ENVIRONMENTAL INFORMATION 82

16.1 Disposal information 82

16.2 Rohs compliance 82

Page 9

1. SAFETY

About this chapter

Read this chapter attentively. It contains important information to prevent personal injury while installing and using a

RLM W14 projector. Furthermore, it includes several cautions to prevent damage to the RLM W14 projector. Ensure that you

understand and follow all safety guidelines, safety instructions and warnings mentioned in this chapter before installing

your RLM W14 projector. After this chapter, additional “warnings” and “cautions” are given depending on the installation

procedure. Read and follow these “warnings” and “cautions” as well.

1.1 General considerations

The content is applicable for following Barco products:

- RLM W14

WARNING: Ensure you understand and follow all the safety guidelines, safety instructions, warnings

and cautions mentioned in this manual.

WARNING: Be aware of suspended loads.

1.SAFETY

WARNING: Wear a hard hat to reduce the risk of personal injury.

WARNING: Be careful while working with heavy loads.

WARNING: Mind your fingers while working with heavy loads.

CAUTION: High pressure lamp may explode if improperly handled.

General safety instructions

Before operating this equipment please read this manual thoroughly and retain it for future reference.

•

Installation and preliminary adjustments should be performed by qualified Barco personnel or by authorized Barco service

•

dealers.

All warnings on the projector and in the documentation manuals should be adhered to.

•

All instructions for operating and use of this equipment must be followed precisely.

•

All local installation codes should be adhered to.

•

Notice on safety

This equipment is built in accordance with the requirements of the international safety standards IEC60950-1,

EN60950-1, UL60950-1 and CAN/CSA C22.2 No.60950-1, which are the safety standards of information technology

equipment including electrical business equipment. These safety standards impose important requirements on the use of

safety critical components, materials and insulation, in order to protect the user or operator against risk of electric shock and

energy hazard and having access to live parts. Safety standards also impose limits to the internal and external temperature

rises, radiation levels, mechanical stability and strength, enclosure construction and protection against the risk of fire.

Simulated single fault condition testing ensures the safety of the equipment to the user even when the equipment’s normal

operation fails.

RLM W14 17/04/2017

1

Page 10

1.SAFETY

Users definition

Throughout this manual, the term SERVICE PERSONNEL refers to persons having appropriate technical training and experience

necessary to be knowledgeable of potential hazards to which they are exposed (including, but not limited to HIGH VOLTAGE

ELECTRIC and ELECTRONIC CIRCUITRY and HIGH BRIGHTNESS PROJECTORS) in performing a task, and of measures to minimize

the potential risk to themselves or other persons. The term USER and OPERATOR refers to any person other than SERVICE PERSONNEL, AUTHORIZED to operate professional projection systems.

A RLM W14 projector is intended "FOR PROFESSIONAL USE ONLY" by AUTHORIZED PERSONNEL familiar with potential hazards

associated with high voltage, high intensity light beams, ultraviolet exposure and high temperatures generated by the lamp

and associated circuits. Only qualified SERVICE PERSONNEL, knowledgeable of such risks, are allowed to perform service

functions inside the product enclosure.

1.2 Important safety instructions

To prevent the risk of electrical shock

This product should be operated from a mono phase AC power source.

•

This apparatus must be grounded (earthed) via the supplied 3 conductor AC power cable. If none of the supplied power

•

cables are the correct one, consult your dealer. If you are unable to insert the plug into the outlet, contact your electrician

to replace your obsolete outlet. Do not defeat the purpose of the grounding-type plug.

Do not allow anything to rest on the power cord. Do not locate this product where persons will walk on the cord. To

•

disconnect the cord, pull it out by the plug. Never pull the cord itself.

Use only the power cord supplied with your device. While appearing to be similar, other power cords have not been safety

•

tested at the factory and may not be used to power the device. For a replacement power cord, contact your dealer.

Do not operate the projector with a damaged cord. Replace the cord.Do not operate the projector if the projector has

•

been dropped or damaged - until it has been examined and approved for operation by a qualified service technician.

Position the cord so that it will not be tripped over, pulled, or contact hot surfaces.

•

If an extension cord is necessary, a cord with a current rating at least equal to that of the projector should be used. A cord

•

rated for less amperage than the projector may overheat.

Never push objects of any kind into this product through cabinet slots as they may touch dangerous voltage points or short

•

out parts that could result in a risk of fire or electrical shock.

Do not expose this projector to rain or moisture.

•

Do not immerse or expose this projector in water or other liquids.

•

Do not spill liquid of any kind on this projector.

•

Should any liquid or solid object fall into the cabinet, unplug the set and have it checked by qualified service personnel

•

before resuming operations.

Do not disassemble this projector, always take it to an authorized trained service person when service or repair work is

•

required.

Do not use an accessory attachment which is not recommended by the manufacturer.

•

Lightning - For added protection for this video product during a lightning storm, or when it is left unattended and unused

•

for long periods of time, unplug it from the wall outlet. This will prevent damage to the device due to lightning and AC

power-line surges.

To prevent personal injury

Isolate electrically before replacing the lamp or lamp house. Caution: Hot lamp (house).

•

Caution: High pressure lamp may explode if improperly handled. Refer servicing to qualified service personnel.

•

To prevent injury and physical damage, always read this manual and all labels on the system before inserting the lamp

•

casing, connecting to the wall outlet or adjusting the projector.

To prevent injury, take note of the weight of the projector. Minimum 2 persons are needed to carry the projector.

•

To prevent injury, ensure that the lens and all covers are correctly installed. See installation procedures.

•

Warning: high intensity light beam. NEVER look into the lens ! High luminance could result in damage to the eye.

•

Warning: extremely high brightness lamps: This projector uses extremely high brightness lamps. Never attempt to

•

look directly into the lens or at the lamp. If the projection distance is less than 6 meter, any person needs to be at least 4

meters away from the projected image. Avoid close range reflection of the projected image on any reflecting surface (such

as glass, metal, …) . When operating the projector, we strongly recommend wearing suitable safety glasses.

Before attempting to remove any of the projector’s covers, you must turn off the projector and disconnect from the wall

•

outlet.

When required to switch off the projector, to access parts inside, always disconnect the power cord from the power net.

•

The power input at the projector side is considered as the disconnect device. When required to switch off the projector,

•

to access parts inside, always disconnect the power cord at the projector side. In case the power input at the projector side

is not accessible (e.g. ceiling mount), the socket outlet supplying the projector shall be installed nearby the projector and

be easily accessible, or a readily accessible general disconnect device shall be incorporated in the fixed wiring.

Do not place this equipment on an unstable cart, stand, or table. The product may fall, causing serious damage to it

•

2

RLM W14 17/04/2017

Page 11

and possible injury to the user.

It is hazardous to operate without lens or shield. Lenses, shields or ultra violet screens shall be changed if they have

•

become visibly damaged to such an extent that their effectiveness is impaired. For example by cracks or deep scratches.

Warning: Protection from ultraviolet radiation: Do not look directly in the light beam. The lamp contained in this

•

product is an intense source of light and heat. One component of the light emitted from this lamp is ultraviolet light.

Potential eye and

skin hazards are present when the lamp is energized due to ultraviolet radiation. Avoid unnecessary exposure. Protect

yourself and your employees by making them aware of the hazards and how to protect themselves. Protecting the skin

can be accomplished by wearing tightly woven garments and gloves. Protecting the eyes from UV can be accomplished

by wearing safety glasses that are designed to provide UV protection. In addition to the UV, the visible light from the lamp

is intense and should also be considered when choosing protective eye wear.

Exposure to UV radiation: Some medications are known to make individuals extra sensitive to UV radiation. The

•

American Conference of Governmental Industrial Hygienists (ACGIH) recommends occupational UV exposure for an-8

hour day to be less than 0,1 micro-watts per square centimeters of effective UV radiation. An evaluation of the workplace

is advised to assure employees are not exposed to cumulative radiation levels exceeding these government guidelines.

The exposer of this UV radiation is allowed for only 1 hour per day for maintenance and service persons.

Mercury Vapor Warnings: Keep the following warnings in mind when using the projector. The lamp used in the projector

•

contains mercury. In case of a lamp rupture, explosion there will be a mercury vapor emission. In order to minimize the

potential risk of inhaling mercury vapors:

- Ensure the projector is installed only in ventilated rooms.

- Replace the lamp module before the end of its operational life.

- Promptly ventilate the room after a lamp rupture, explosion has occurred, evacuate the room (particularly in case of a

pregnant woman).

- Seek medical attention if unusual health conditions occur after a lamp rupture, explosion, such as headache, fatigue,

shortness of breath, chest-tightening coughing or nausea.

1.SAFETY

To prevent fire hazard

Do not place flammable or combustible materials near the projector!

•

Barco large screen projection products are designed and manufactured to meet the most stringent safety regulations.

•

This projector radiates heat on its external surfaces and from ventilation ducts during normal operation, which is both

normal and safe. Exposing flammable or combustible materials into close proximity of this projector could result in the

spontaneous ignition of that material, resulting in a fire. For this reason, it is absolutely necessary to leave an “exclusion

zone” around all external surfaces of the projector whereby no flammable or combustible materials are present. The

exclusion zone must be not less than 50 cm (20”) for all DLP projectors. The exclusion zone on the lens side must be at

least 5 m. Do not cover the projector or the lens with any material while the projector is in operation. Keep flammable

and combustible materials away from the projector at all times. Mount the projector in a well ventilated area away from

sources of ignition and out of direct sun light. Never expose the projector to rain or moisture. In the event of fire, use

sand, CO 2 or dry powder fire extinguishers. Never use water on an electrical fire. Always have service performed on this

projector by authorized Barco service personnel. Always insist on genuine Barco replacement parts. Never use non-Barco

replacement parts as they may degrade the safety of this projector.

Slots and openings in this equipment are provided for ventilation. To ensure reliable operation of the projector and to

•

protect it from overheating, these openings must not be blocked or covered. The openings should never be blocked by

placing the projector too close to walls, or other similar surface. This projector should never be placed near or over a

radiator or heat register. This projector should not be placed in a built-in installation or enclosure unless proper ventilation

is provided.

Projection rooms must be well ventilated or cooled in order to avoid build up of heat.

•

Let the projector cool down completely before storing. Remove cord from the projector when storing.

•

Heat sensitive materials should not be placed in the path of the exhausted air or on the lamp house.

•

To prevent projector damage

This projector has been designed for use with a specific lamp (house) type. See installation instructions for its correct type.

•

The air filters of the projector must be cleaned or replaced on regular base (a "clean" booth would be monthly-

•

minimum).Neglecting this could result in disrupting the air flow inside the projector, causing overheating. Overheating

may lead to the projector shutting down during operation.

The projector must always be installed in a manner which ensures free flow of air into its air inlets and unimpeded

•

evacuation of the hot air from its cooling system.

In order to ensure that correct airflow is maintained, and that the projector complies with Electromagnetic Compatibility

•

(EMC)requirements, it should always be operated with all of it’s covers in place.

Slots and openings in the cabinet are provided for ventilation. To ensure reliable operation of the product and to protect it

•

from overheating, these openings must not be blocked or covered. The openings should never be blocked by placing the

product on a bed, sofa, rug, or other similar surface. This product should never be placed near or over a radiator or heat

register. The device should not be placed in a built-in installation or enclosure unless proper ventilation is provided.

RLM W14 17/04/2017

3

Page 12

1.SAFETY

Ensure that nothing can be spilled on, or dropped inside the projector. If this does happen, switch off and unplug the

•

mains supply immediately. Do not operate the projector again until it has been checked by qualified service personnel.

Do not block the projector cooling fans or free air movement around the projector. Loose papers or other objects may not

•

be nearer to the projector than 30 cm (12") on any side.

Do not use this equipment near water.

•

Special care for Laser Beams: Special care should be used when DLP projectors are used in the same room as laser

•

equipment. Direct or indirect hitting of a laser beam on to the lens can severely damage the Digital Mirror Devices TM in

which case there is a loss of warranty.

Never place the projector in direct sun light. Sun light on the lens can severely damage the Digital Mirror Devices TM in

•

which case there is a loss of warranty.

Save the original shipping carton and packing material. They will come in handy if you ever have to ship your equipment.

•

For maximum protection, repack your set as it was originally packed at the factory.

Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp cloth

•

for cleaning. Never use strong solvents, such as thinner or benzine, or abrasive cleaners, since these will damage the

cabinet. Stubborn stains may be removed with a cloth lightly dampened with mild detergent solution.

To ensure the highest optical performance and resolution, the projection lenses are specially treated with an anti-

•

reflective coating, therefore, avoid touching the lens. To remove dust on the lens, use a soft dry cloth. Do not use a damp

cloth, detergent solution, or thinner.

Rated maximum ambient temperature, t a= 40 °C (104 °F).

•

The lamp house shall be replaced if it has become damaged or thermally deformed.

•

On servicing

Do not attempt to service this product yourself, as opening or removing covers may expose you to dangerous voltage

•

potentials and risk of electric shock.

Refer all servicing to qualified service personnel.

•

Attempts to alter the factory-set internal controls or to change other control settings not specially discussed in this manual

•

can lead to permanent damage to the projector and cancellation of the warranty.

Unplug this product from the wall outlet and refer servicing to qualified service technicians under the following conditions:

•

- When the power cord or plug is damaged or frayed.

- If liquid has been spilled into the equipment.

- If the product has been exposed to rain or water.

- If the product does not operate normally when the operating instructions are followed. Adjust only those controls that

are covered by the operating instructions since improper adjustment of the other controls may result in damage and will

often require extensive work by a qualified technician to restore the product to normal operation.

- If the product has been dropped or the cabinet has been damaged.

- If the product exhibits a distinct change in performance, indicating a need for service.

Replacement parts: When replacement parts are required, be sure the service technician has used original Barco

•

replacement parts or authorized replacement parts which have the same characteristics as the Barco original part.

Unauthorized substitu- tions may result in degraded performance and reliability, fire, electric shock or other hazards.

Unauthorized substitutions may void warranty.

Safety check: Upon completion of any service or repairs to this projector, ask the service technician to perform safety

•

checks to determine that the product is in proper operating condition.

Possible explosion hazard: Always keep in mind the caution below:

•

CAUTION: Do not touch a lamp during operation and right after it is turned off as it is extremely hot. Lamp

contains mercury. It's brokeage might cause mercury or broken glass pieces to folow out of lamp housing.

To avoid exposure the risk of mercury poisoning. Don't drop, hit, force or scratch while handing a lamp.

To prevent battery explosion

Danger of explosion if battery is incorrectly installed.

•

Replace only with the same or equivalent type recommended by the manufacturer.

•

For disposal of used batteries, always consult federal, state, local and provincial hazardous waste disposal rules and

•

regulations to ensure proper disposal.

battery type: size-AAA (R03). Only Carbon-Zinc or Alkaline-Manganese Dioxide type batteries should be used.

•

4

RLM W14 17/04/2017

Page 13

2. GENERAL

About this chapter

Read this chapter before installing your RLM W14 projector. It contains important information concerning installation

requirements for the RLM W14 projector, such as minimum and maximum allowed ambient temperature, humidity conditions,

required safety area around the installed projector, required power net, etc.

Furthermore, careful consideration of things such as image size, ambient light level, projector placement and type of screen

to use are critical to the optimum use of the projection system.

Overview

Installation requirements

•

Unpacking the projector

•

Initial inspection

•

RLM W14 flight case

•

Projector configurations

•

Projector air inlets and outlets

•

Installation process overview

•

WARNING: Barco provides a guarantee relating to perfect manufacturing as part of the legally stipulated

terms of guar- antee. Observing the specification mentioned in this chapter is critical for projector

performance. Neglecting this can result in loss of warranty.

2.General

2.1 Installation requirements

Environment conditions

Table below summarizes the physical environment in which the RLM W14 projector may be safely operated or stored.

Environment Operating Non-Operating

Ambient Temperature

Humidity

Altitude

Let the projector acclimatize after unpacking. Neglecting this may result in a startup failure of the Light

Pro- cessor Unit.

10 °C (50 °F) to 40 °C (104 °F)

5% to 85% RH Non-condensed

-60 (-197Ft) to 3000m (9843Ft)

Cooling requirements

The projector is fan cooled and must be installed with sufficient space around the projector head, minimum 30 cm (12 inch)

to ensure sufficient air flow. It should be used in an area where the ambient temperature, as measured at the projector air

inlet , does not exceed +40°C (+104°F).

Clean air environment

A projector must always be mounted in a manner which ensures the free flow of clean air into the projectors ventilation

inlets. For installations in environments where the projector is subject to airborne contaminants such as that produced

by smoke machines or similar (these deposit a thin layer of greasy residue upon the projectors internal optics and imaging

electronic surfaces, degrading performance), then it is highly advisable and desirable to have this contamination removed

prior to it reaching the projectors clean air supply. Devices or structures to extract or shield contaminated air well away

from the projector are a prerequisite, if this is not a feasible solution then measures to relocate the projector to a clean air

environment should be considered.

-15°C (5°F) to 60°C (140°F)

5% to 95% RH Non-Condensed

-60 (-197Ft) to 10000m (32810Ft)

Only ever use the manufacturer’s recommended cleaning kit which has been specifically designed for cleaning optical parts,

never use industrial strength cleaners on the projector’s optics as these will degrade optical coatings and damage sensitive

optoelectronics components. Failure to take suitable precautions to protect the projector from the effects of persistent and

prolonged air contam- inants will culminate in extensive and irreversible ingrained optical damage. At this stage cleaning of

the internal optical units will be noneffective and impracticable. Damage of this nature is under no circumstances covered

under the manufacturer’s warranty and may deem the warranty null and void. In such a case the client shall be held solely

responsible for all costs incurred during any repair. It is the clients responsibility to ensure at all times that the projector

is protected from the harmful effects of hostile airborne particles in the environment of the projector. The manufacturer

reserves the right to refuse repair if a projector has been subject to knowingly neglect, abandon or improper use.

RLM W14 17/04/2017

5

Page 14

2.General

Main Power requirements

The RLM W14 projector operates from a nominal mono phase power net with a separate earth ground PE.

Projector Power requirements

RLM W14 AC INPUT 100-240V 9.2A 50/60Hz

The power cord required to connect the projector with the power net is delivered with the projector.

Projector weight

Do not underestimate the weight of the RLM W14 projector. The projector weights about ±37 kg (±82.7lb.) without lens. Be

sure that the pedestal or ceiling mount on which the projector has to be installed is capable of handling five (5) times the

complete load of the system.

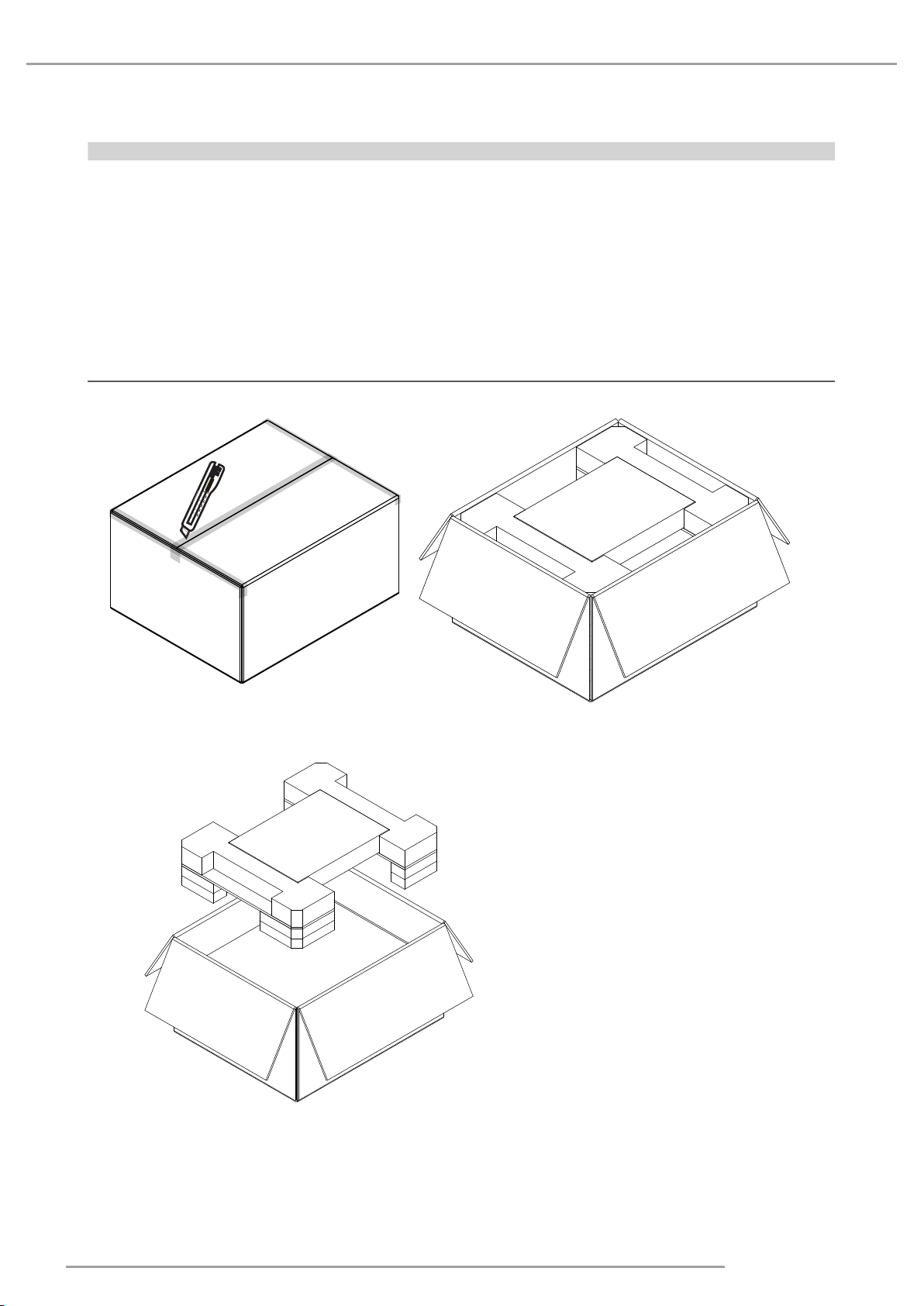

2.2 Unpacking the projector

1. Remove the tape around the carton box, then open the box.

2. Take out the foam upper the projector.

6

RLM W14 17/04/2017

Page 15

3. Take out the projector.

2.General

After unpacking let the projector acclimatizes to a room temperature higher then 10°C (50°F) and lower

then 40°C (104°F). Neglecting this may result in a start up failure of the Light Processor Unit.

Save the original shipping carton and packing material, they will be necessary if you ever have to ship your

projector. For maximum protection, repack your projector as it was originally packed at the factory.

The lens is delivered in a separate box.

2.3 Initial inspection

General

Before shipment, the projector was inspected and found to be free of mechanical and electrical defects. As soon as the

projector is unpacked, inspect for any damage that may have occurred in transit. Save all packing material until the inspection

is completed. If damage is found, file claim with carrier immediately. The Barco Sales and Service office should be notified as

soon as possible.

Box content

After unpacking the projector it is recommended to check if all following items where included:

Three power cords

•

One DVI-D to HDMI cable

•

CD (Contents has this installation manual)

•

One Safety manual

•

One remote control unit (RCU)

•

Two AAA size batteries for the RCU

•

RLM W14 17/04/2017

Two lamps are mounted inside the lamp house at delivery. The projector lenses are not included in the

package of the projector.

7

Page 16

2.General

Mechanical check

This check should confirm that there are no broken knobs or connectors, that the cabinet and panel surfaces are free of dents

and scratches, and that the operating panel is not scratched or cracked. The Barco Sales and Service office should be notified

as soon as possible if this is not the case.

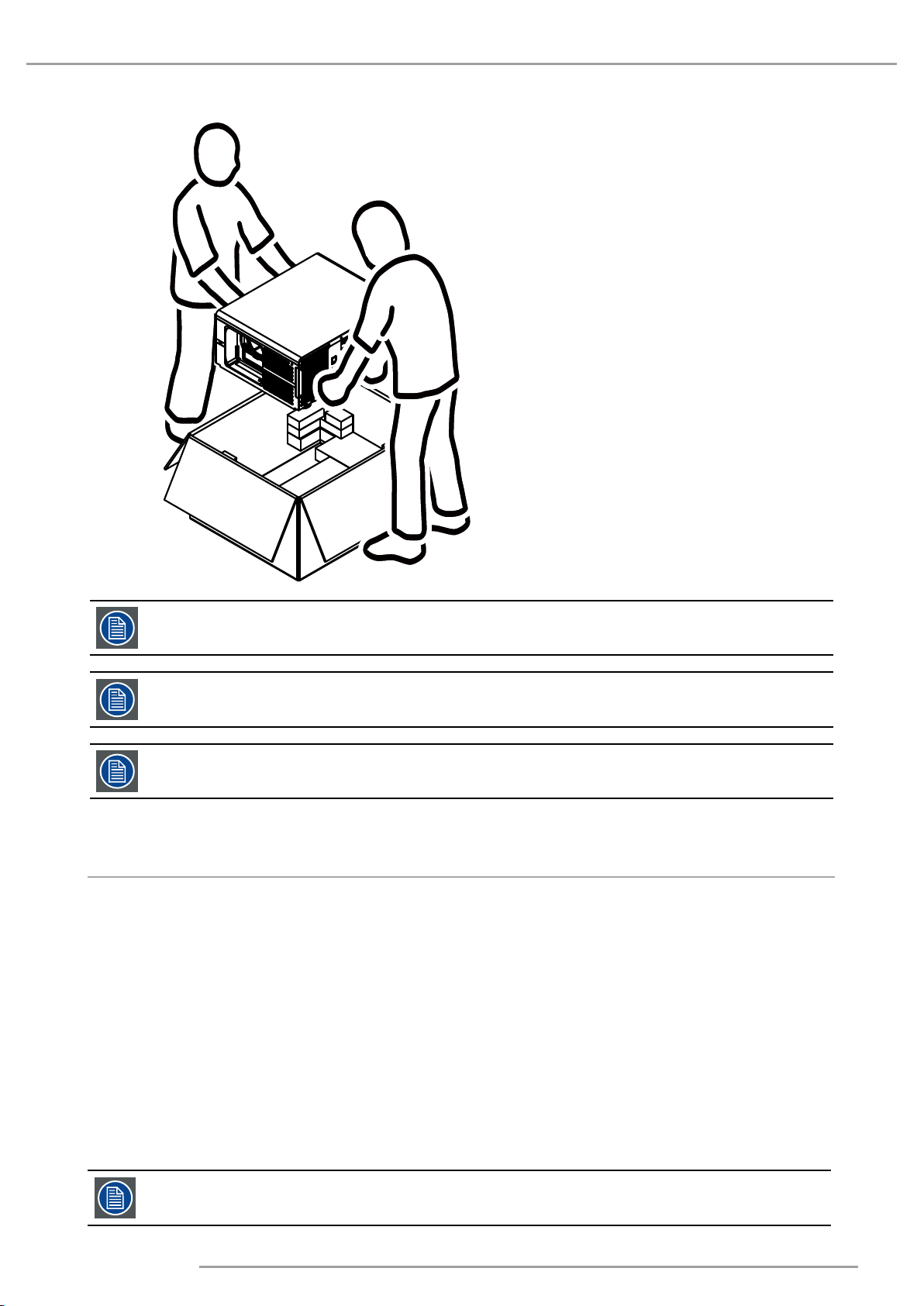

2.4 Projector configurations

The different configurations

Depending on the installation the projector can be mounted in different ways, the different configurations are:

1. Front / Table (F/T)

2. Front / Ceiling (F/C) (upside down)

3. Front / Ceiling (F/C) (table position)

4. Rear / Table (R/T)

5. Rear / Ceiling (R/C) (upside down)

6. Rear / Ceiling (R/C) (table position)

Front projection

The projector is installed, either in a table mount or ceiling mount configuration, at the same side of the screen as the

audience.

AUDIENCE

SCREEN

FLOOR

F/C

F/T

Front projection

AUDIENCE

FLOOR

F/C

SCREEN

Frontprojection,Ceilingmounted,intableposition

Rear projection

The projector is installed, either in a table mount or ceiling mount configuration, at the other side of the screen opposite the

audience.

AUDIENCE BACKSTAGE

R/C

SCREEN

FLOOR

Rear projection

AUDIENCE BACKSTAGE

SCREEN

FLOOR

Rear projection, ceiling mounted in table position

8

R/T

R/C

RLM W14 17/04/2017

Page 17

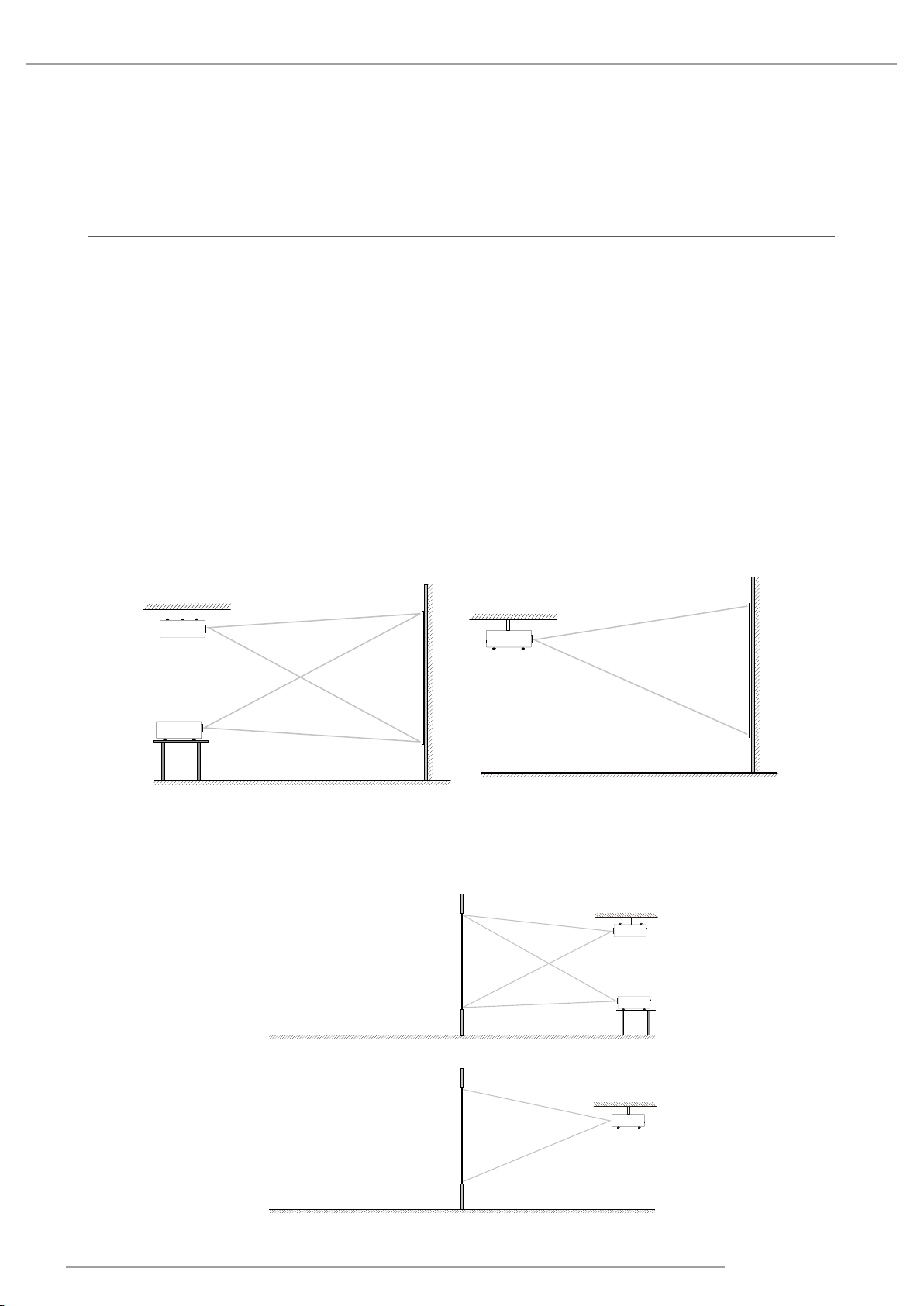

Positioning the projector

2.General

SW

PD

ACD

FLOOR

Positioning projector

SCREENSCREEN

SHB

SW

SHB

SCREEN

CD

The projector should be installed at right angles (horizontally and vertically) to the screen at a distance PD. Note the distance

(A) between lens centre and table surface is slightly variable. This distance (A) is nominal 14 cm in case all feet are turned in

completely and the vertical lens shift is set to zero (0).

On axis / off axis projection

The position of the projector with reference to the screen may also be different depending on the installation. Basically the

projector can be positioned in On-Axis or Off-Axis configuration. On-Axis configuration means that the projector is positioned

so as to have the centre of the lens coinciding with the centre of the screen. Off-Axis projection is obtained by shifting the

lens up, down, left or right. Several parameters can be calculated determining the position in any installation.

Formula to calculate the distance CD for On-Axis projection: CD = SH/2 + B - A

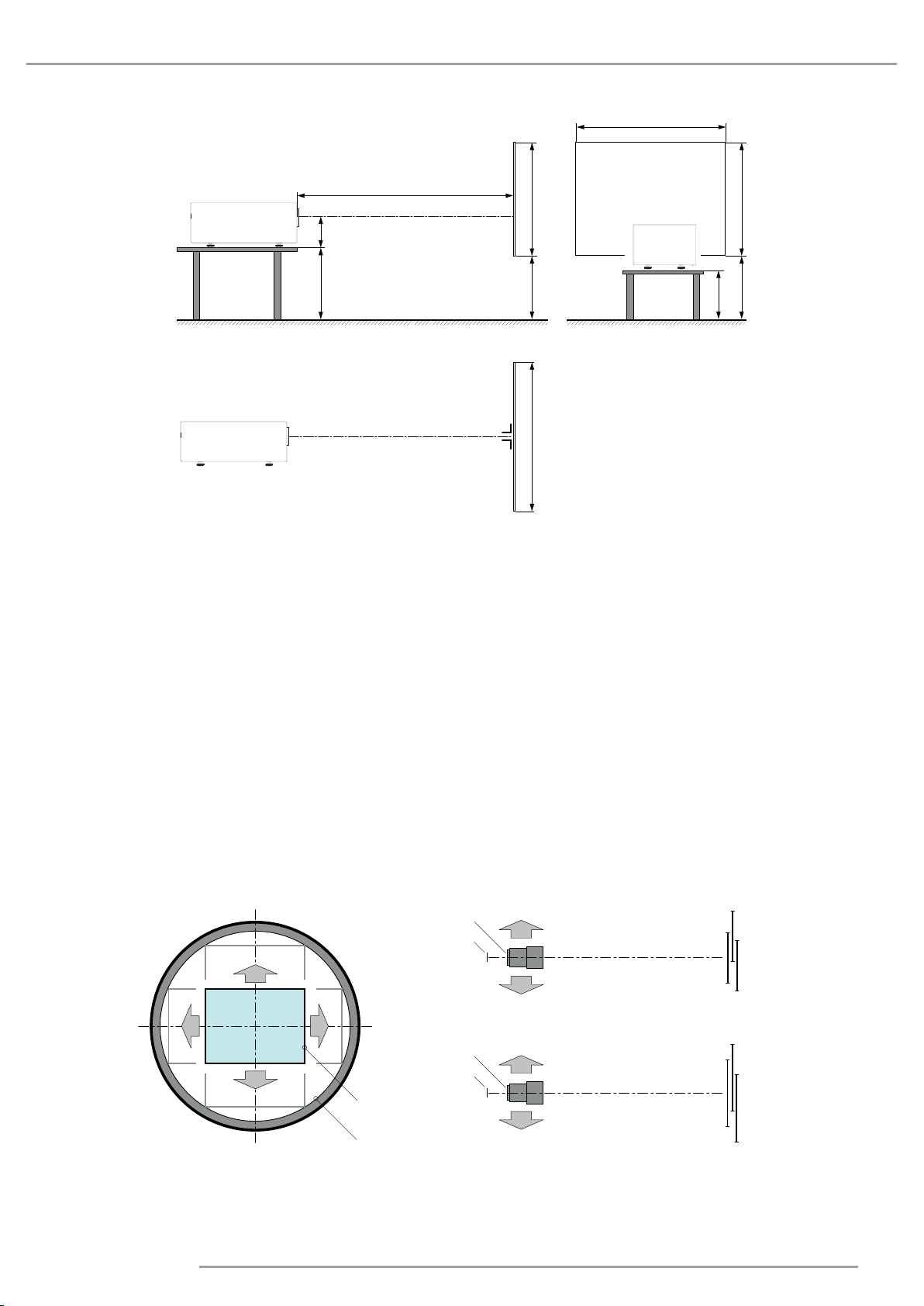

Shift range

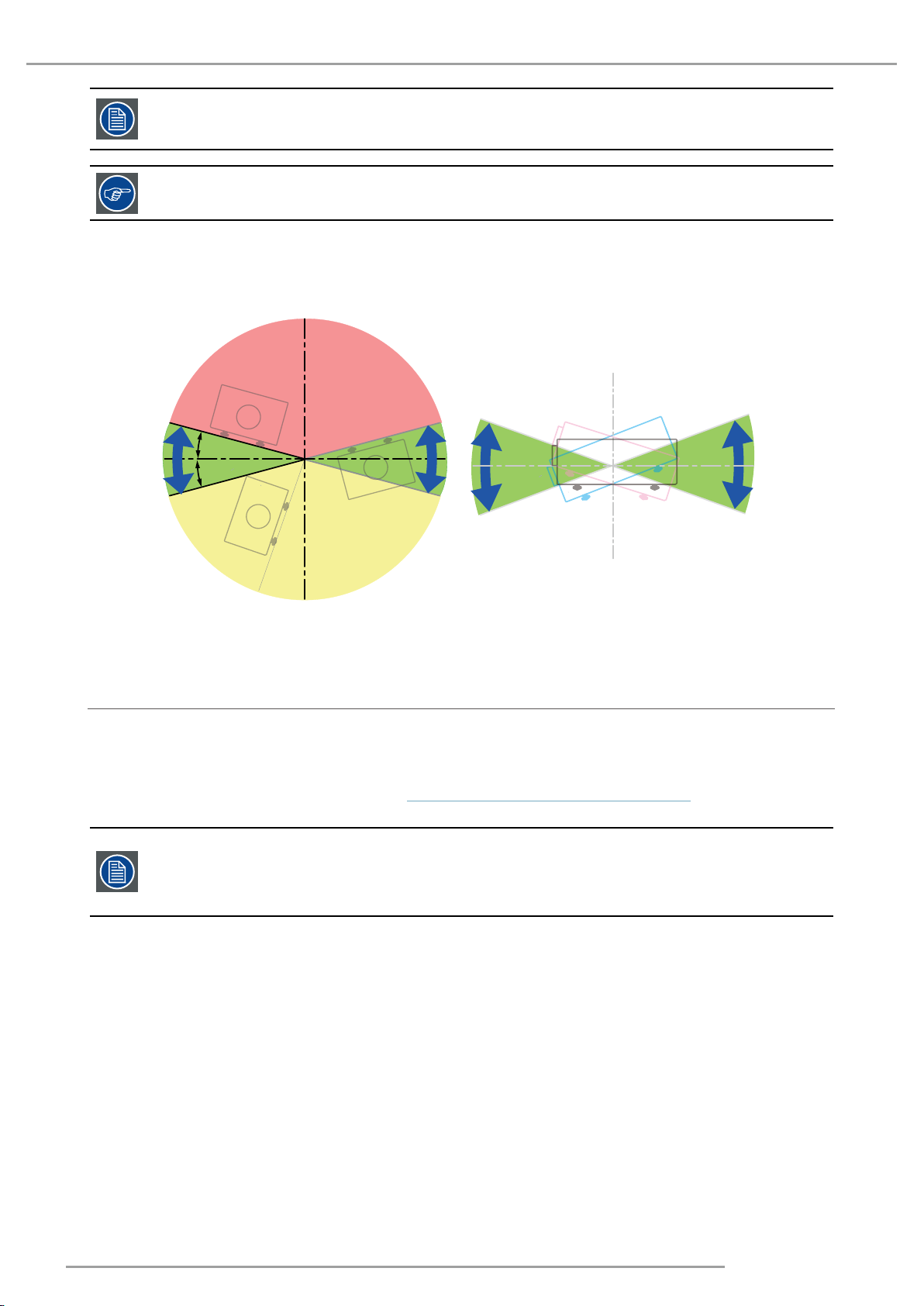

The lens can be shifted with respect to the DMD (P) which result in a shifted image on the screen (Off-Axis). A 100% shift

means that the centre point of the projected image is shifted by half the screen size. In other words, the centre point of

the projected image falls together with the outline of the image in an On-Axis projection. Due to mechanical and optical

limitations it’s recommended to keep the shift values within the field of view (F) as illustrated below. Within these shift

ranges the projector and lens perform excellently. Configuring the projector outside these shift ranges will result in a slight

decline of image quality.

+130%

+70%

+30%

+30%

U

+30% +30%

L R

D

Vertical and horizontal shift range

P DMD.

F Field of view.

+130%

+70%

F

P

U

SIDE VIEW

D

F

P

P

L

TOP VIEW

R

F

RLM W14 17/04/2017

9

Page 18

2.General

It is mechanical possible to shift outside the recommended field of view, but it will result in a decline of

image quality depending on the used lens and the zoom position of the used lens. Furthermore, shifting

too much in both directions will result in a blurred image corner.

Best image quality is projected in the On-Axis configuration.

Horizontal and vertical projector tilt ranges

Avoid to reduce the usage of lamp life. Suggest the projector rotated and mounted vertical angle not > ±15°.

Side to side tilt, however, must not exceed ±10°. This limit ensures that the lamp in the projector operates properly and safely.

B

MAX

10°

10°

A

A

MAX

10°

10°

MAX

±15° ±15°

MAX

A

C

A Tilting allowe d w ithout problems

B No tilting allowed in this are a

C No tilting allowed in this are a

2.5 Lens Selection

Procedure:

Determine the required screen width(SW).

1.

Determine the approximate position of the projector in the room.

2.

Start up the Lens Calculator on the Barco website: http://www.barco.com/en/tools/lenscalculator to determine the

3.

possible lenses for your configuration. As a result the Lens Calculator window opens.

The Lens Calculator can also be used to determine the position of the projector when the lens type and

screen width is known.

10

Due to lens tolerances the results of calculated values may be different from measured values. These

difference may vary +/-5%

RLM W14 17/04/2017

Page 19

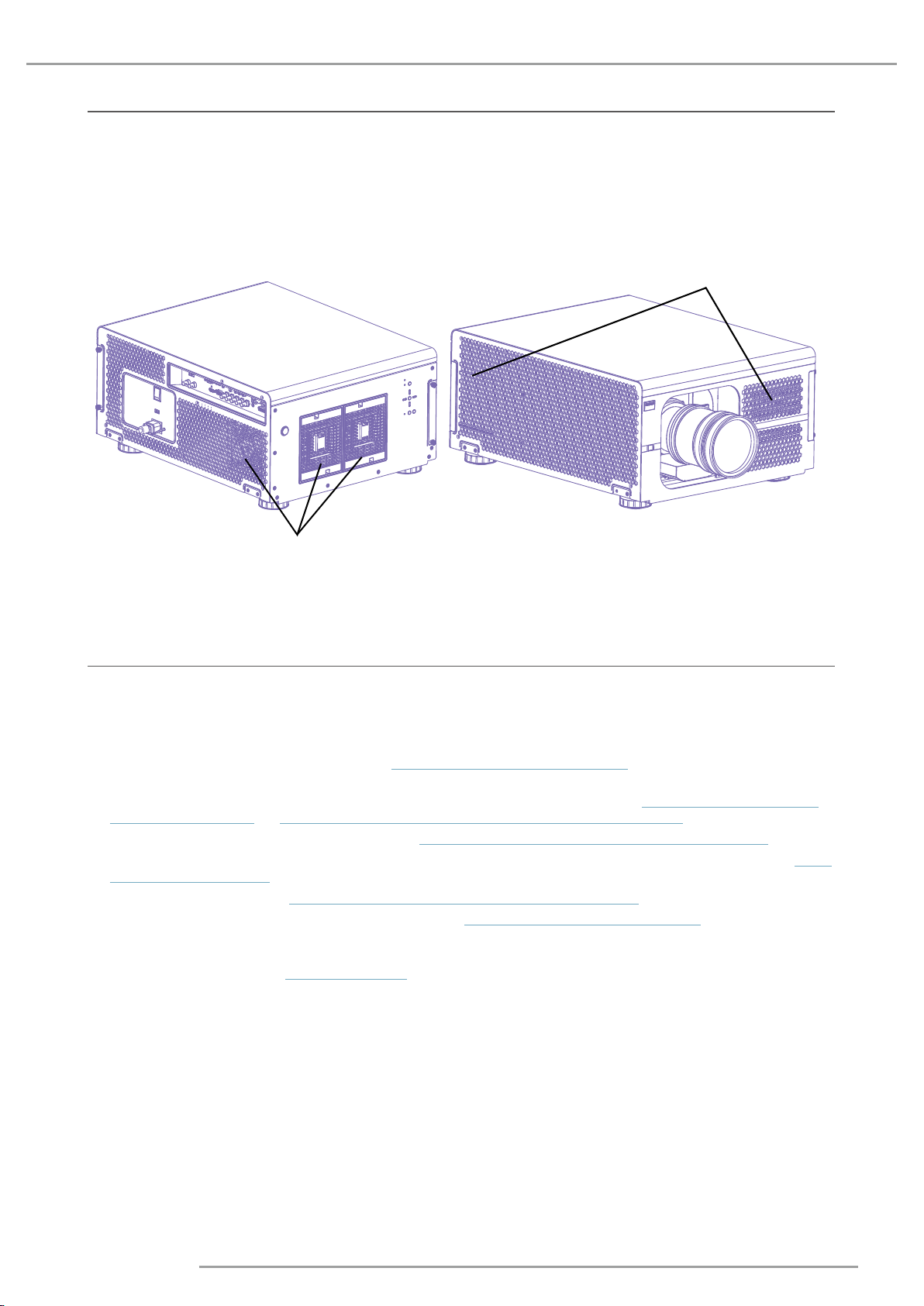

2.6 Projector air inlets and outlets

Ventilation inlet:

The internal cooling fan draws cool air from the ventilation inlet into the projector.

Ventilation outlet:

The hot air generated inside the projector is dispersed through the ventilation slot. Make sure the ventilation slot is free from

obstruction.

Ventilation inlet

2.General

Ventilation outlet

2.7 Installation process overview

Quick setup

The following steps describe briefly how to setup your RLM W14 projector in a table mount front projection. Note that each

step refers to a corresponding procedure, which is more detailed and illustrated.

Install the batteries of the remote control. See page 22: 4.1 Remote control unit (RCU)

4.

Place the projector on a solid table in front of the screen at the expected throw distance. Adjust the feet to ensure that

5.

the projector is installed at right angles (horizontally and vertically) with the screen. See page 31: 4.6 Alignment of a

table mounted projector and page 35: 5.7 Adjusting the lens by horizontal and vertical lens shift

Connect the projector with the local power net. See page 30: 4.5 Connecting the projector with the power net

6.

Select and install an appropriate lens, which covers the throw ratio ( = screen size / projector screen distance). See page

7.

9: Positioning the projector

Switch ON the projector. See page 30: 4.5 Connecting the projector with the power net

8.

Connect your source to the appropriate input module. See page 13: 3.3 Input and Communication

9.

Zoom and shift the lens until the image is properly projected on the screen, Do this by using the “ZOOM” and “FOCUS”

10.

key on the remote control unit or on the local keypad. If necessary, level the projector from side to side by turning the

adjustable feet in or out. See page 28: Lens zoom.

RLM W14 17/04/2017

11

Page 20

3. Projector parts and Functions

MENU

ON

ERROR

STBY

INPUTS

STBY

3. PROJECTOR PARTS AND FUNCTIONS

Overview

Projector front view

•

Projector Rear view

•

Input and Communication

•

Status lights of LED

•

Connecting the projector to other devices

•

3.1 Projector front view

Ventilation Inlet

Ventilation slot

The hot air generated

inside the projector is

dispersed through the

ventilation slot. Make sure

the ventilation slot is free

from obstruction.

Infrared sensor

Lens

3.2 Projector Rear view

Power switch

I -> ON

O -> OFF

Power inlet

Ventilation outlet

The internal cooling fan draws hot

air vis the ventilation outlet to the

projector.

Adjustable foot

Adjust the height and

angle of the projector

with the adjustable foot

Adjustable foot

Projector Keypad

Lamp 1 & Lamp 2

Infrared receiver

MENU

Displays or hides the OSD

adjustment screen

12

bottons

Use these buttons to scroll,

configure or adjust items on

the OSD or toggle between

different images.

Enter

The enter button selects a item when in the

menu.

When not in the menu the enter button will

activate the lens adjust function.

INPUT

Used to toggle between different

input signal source

STBY

Use this button to start up or shut down the

projector

switch off.

. keep pressing stby button for 3 sec to

RLM W14 17/04/2017

Page 21

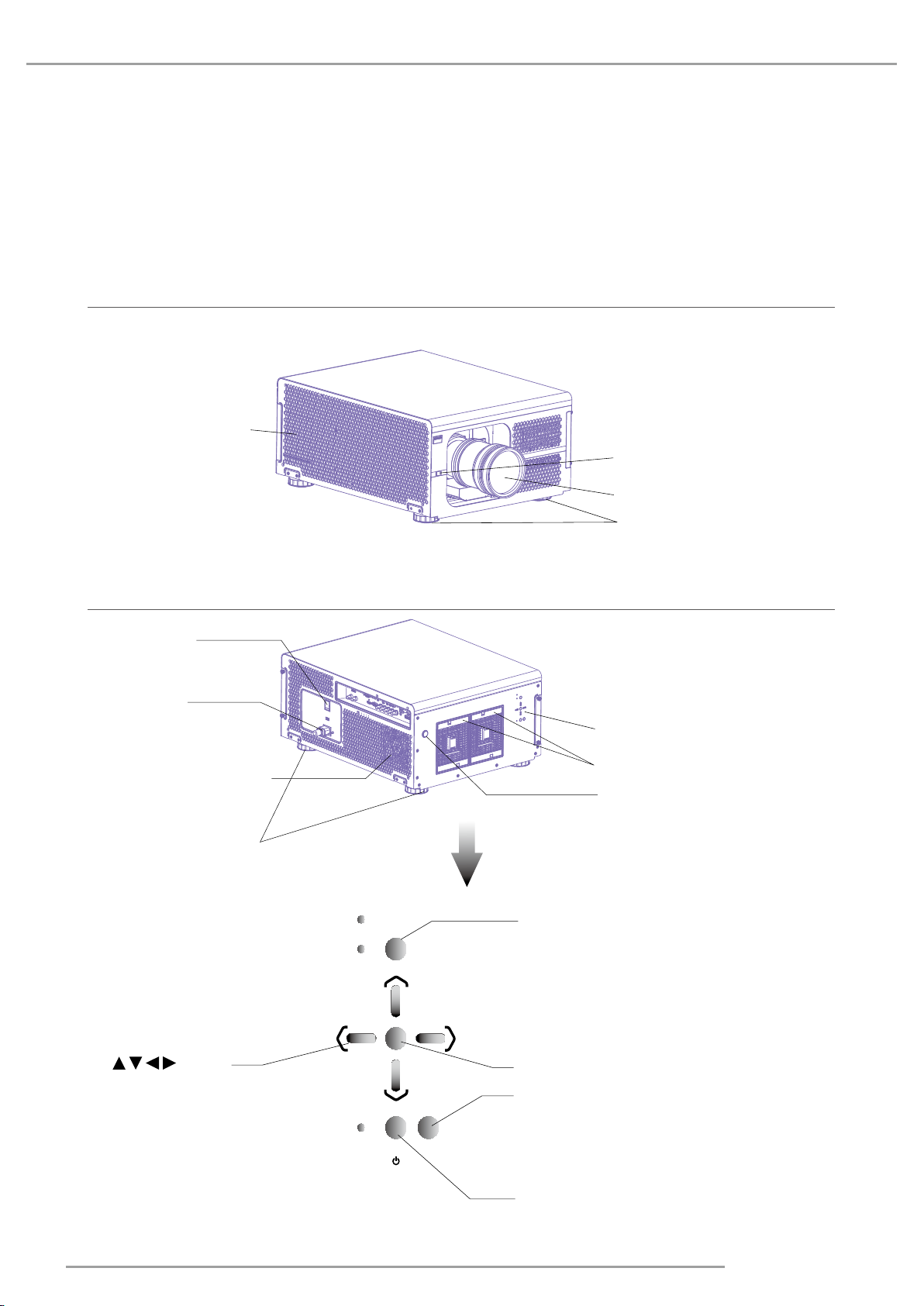

3.3 Input and Communication

3. Projector parts and Functions

8

21 3 4

200mA

9 10

5 7

11 12

6

. HDBaseT

Supports Full HD uncompressed video transmission from image devices compatible with HDBaseT. Audio and network are not

supported. For network connection refer to Page 14 "6. 10/100 BASE-T"

2. RS232

RS232 input

The communication interface of the RLM W14 projector supports RS232 serial communication.

You can use the RS232 input to connect a local PC to your RLM W14 projector. By this way you can configure and control your

RLM W14 projector from your local PC.

Advantages of using RS232 serial communication:

easy adjustment of the projector via PC (or MAC).

•

wide range of control possibilities.

•

sending data to the projector (update).

•

RS232 input (Sub-D) port

PIN Signal

1 (No connection)

2 RD

3 TD

4 (No connection)

5 Ground

6 (No connection)

7 RTS

8 CTS

9 (No connection)

RS232

An Electronic Industries Association (EIA) serial digital interface standard specifying the characteristics of

the commu- nication path between two devices using either D-SUB 9 pins or D-SUB 25 pins connectors.

This standard is used for relatively short-range communications and does not specify balanced control

lines. RS-232 is a serial control standard with a set number of conductors, data rate, word length and type

of connector to be used. The standard specifies com- ponent connection standards with regard to computer

interface. It is also called RS-232-C, which is the third version of the RS-232 standard, and is functionally

identical to the CCITT V.24 standard. Logical ’0’ is > + 3V, Logical ’1’ is < -

3V. The range between -3V an d +3V is the transition zone.

3. 12V TRIGGER

12 V output, maximum 200mA, available when projector is not in stand by.

RLM W14 17/04/2017

13

Page 22

3. Projector parts and Functions

4. IR EXT.

Receives input signal from compatible Niles or Xantech IR repeater systems.

5. YUV1

Standard and high definition (480i/480p/576i/576p/720p/1080i/1080p) component input, connects to DVD/HD-DVD/BD

player, HD set-top-box or other SD/HD input source.Also connects to RGB input from RGBS input source.

6. 10/100 BASE-T

Ethernet port

The projector can be connected to a LAN (local area network) using the Ethernet port on the communication interface. Once

connected to the LAN, users are capable of accessing the projector from any location, inside or outside (if allowed) their

company network using the control software: Projector Toolset. This toolset locates the projector on the network in case

there is a DHCP server or the user can insert the correct IP-address of the projector to access the projector. Once accessed,

it is possible to check and manipulate all the projector settings. Remote diagnostics, control and monitoring of the projector

can then become a daily and very simple operation. The network connectivity permits to detect potential errors and

consequently improve the time to servicing.

The connector used for the Ethernet ports (E) are of rugged Neutrik EtherCon RJ45 type, which is compatible

with standard RJ45 cable connector. Straight (most common) as well as cross linked network cables can be

used.

10/100 BASE-T - RJ45 port

PIN Description

1 TXD+

2 TXD3 RXD+

4 5 6 RXD7 8 -

SYNC IN ,OUT

7.

The 3D Sync in signal is generated from the 3D source to make sure the left/right eye content is synchronized to the user and

the projector.

8. SDI/HDSDI/3G

Serial digital interface. use BNC connects input or output the image.

9. HDMI

HDCP compatible digital image input; connects to sources using HDMI or DVI.

10.VGA

Standard 15-pin VGA connection socket to connect to RGB, high-definition component input or PC. The projector will

automatically detect the resolution of the input signal.

11. RGBHV/YUV2

Optional multi purpose input which can be inserted in the free slots.

RS232 input (Sub-D) port

Input Signal G/Y B/Pb R/Pr H V

RGBHV G B R H V

Composite Video Y Pb Pr - -

12. Stereo DVI

Use this DVI dual link to connect to a stereo 3D source - it is usually a computer with 3D Graphics card and 3D applications.

14

RLM W14 17/04/2017

Page 23

3. Projector parts and Functions

3.4 Status lights of LED

ON

MENU

ERROR

STBY

INPUTS

STBY

STAND BY

Turns blue Indicates that the projector is in standby mode; this also means the p rojector has not

been turned on by pressing the SOFT POWER button but has been connected to power.

The indicator is off This indicates that the projector has either been turned on and is working normally or

the projector is not connected to power.

ON

Turns green This indicates that the projector has been turned on and is working normally.

Flashes in green This indicates that the projector is currently warming up or cooling down and will not

respond to button operations.

The indicator is off This indicates that the projector is currently in stand by mode.

ERROR

Flashes once in red The projector lamp is faulty; check to see if the lamp is damaged or if it hasn't been

properly installed.

Flashes twice in red The lamp cover is not properly replaced.

Flashes three times in red The cooling fan inside the projector is not working; seek assistance from a qualified

service personnel.

Flashes four times in red The projector temperature is too high; try cleaning the ventilator slots or unplugging the

power cord to resolve the issue.

Flashes five times in red The projector filter might not have been inserted properly; check the ventilation slot and

make sure the filter has been properly replaced and inserted.

Warning

Flashes once in green and red: The lamp is approaching the end of life. It should be replaced with a new lamp.

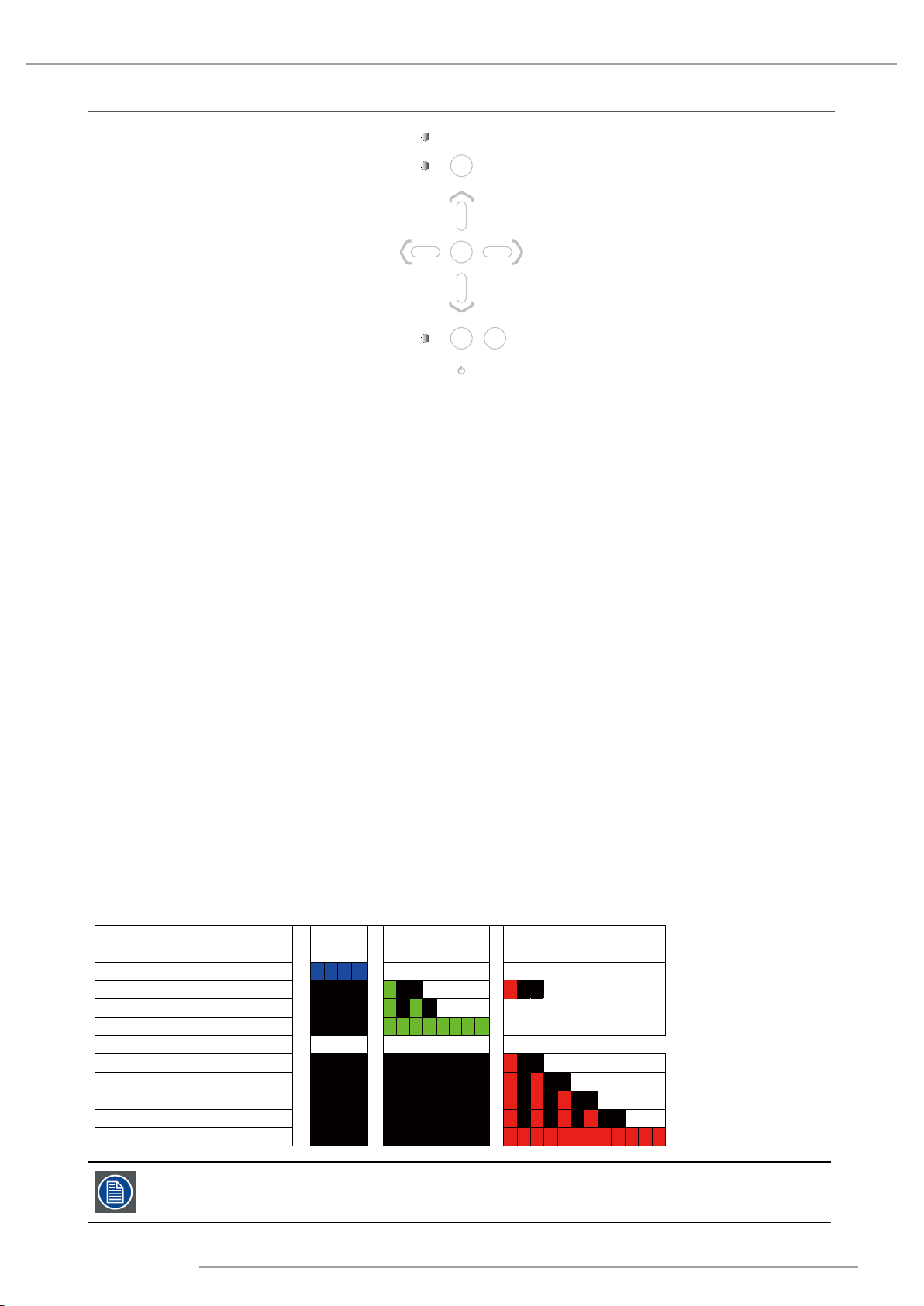

Status Blue

1. Standby

2. Lamp is approaching end of life repeat repeat

3. Cooling / Warm up repeat

4. Power on / Normal

5. Lamp fail repeat

6. Lamp door open repeat

7. Fan fail

8. Over Temperature repeat

9. System Error

(Standby)

Green

(Power)

Red

( Issue )

repeat

RLM W14 17/04/2017

The time period of each step in the above LED blinking pattern is 500 milliseconds, e.g., for“Cooling /

Warm up”state, the green LED will ON for 500 milliseconds, and then OFF 500 milliseconds, and then

repeat the above LED pattern.

15

Page 24

3. Projector parts and Functions

3.5 Connecting the projector to devices

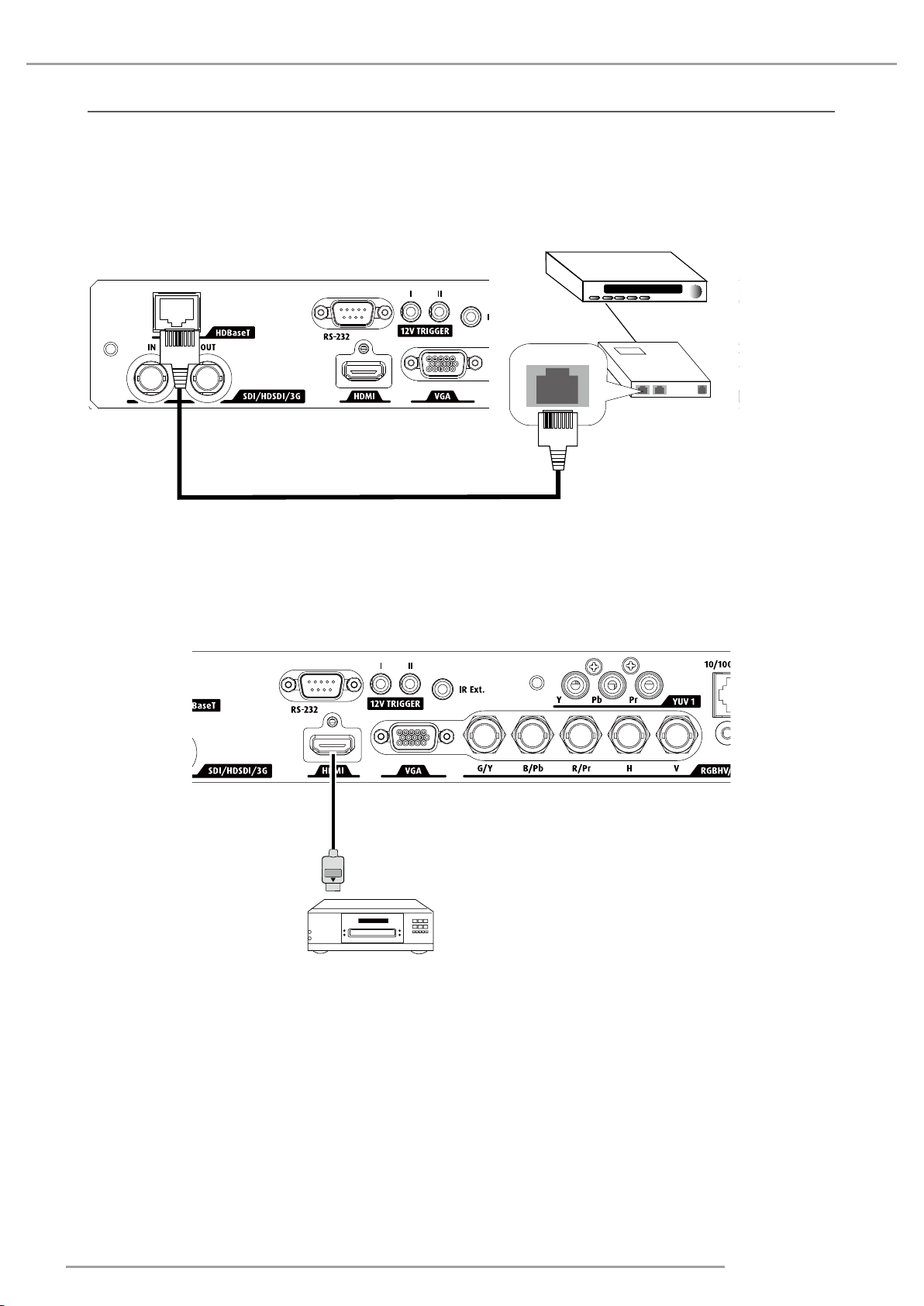

HDBaseT

Supports Full HD uncompressed video transmission from image devices compatible with HDBaseT. Audio and network are not

supported. For network connection refer to Page 14 "6. 10/100 BASE-T"

Hi-Def Source

200mA

HDBaseT

Transmitter

HDMI connection

Signals from image source offer the best projection image quality when sent through HDMI. Therefore, try to use input

devices with HDMI output as the source of image.

200mA

HDMI/DVI input source

(BD/HD-DVD/DVD player, HD set-top-box,

gaming consoles and so forth)

16

RLM W14 17/04/2017

Page 25

3. Projector parts and Functions

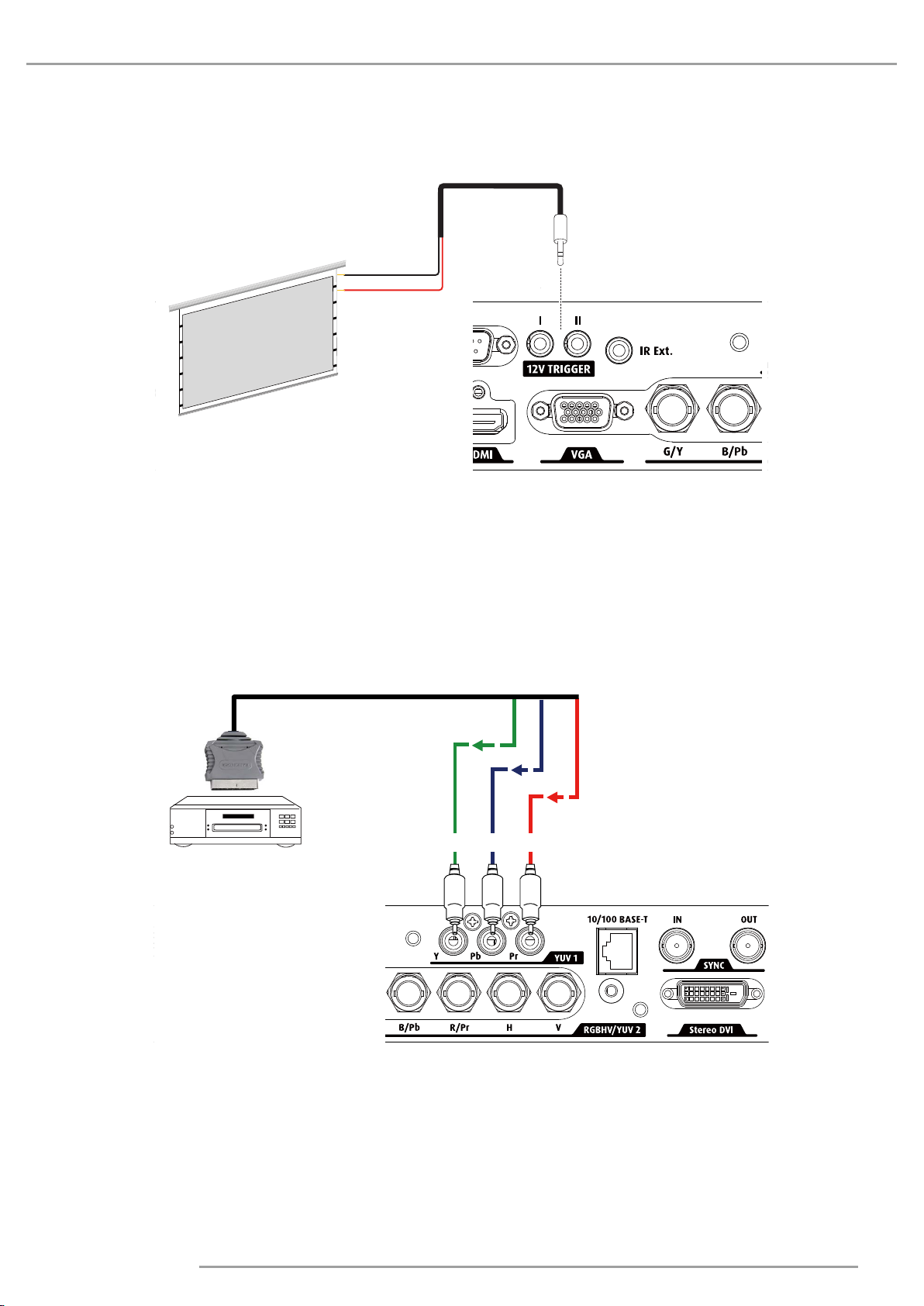

12V Trigger connection

If your home theatre system includes a projector screen, screen cover or other 12V Trigger equipment, please connect

such device/equipment to the projector’s 12V Trigger output as illustrated.After you have done so, Your screen will lower

automatically whenever you turn on your projector for your convenience.

Retractable screen or other

12V device

Sleeve = Ground

Tip = +12V

200mA

RGBs connection

f the source equipment uses composite image synchronized connectors to output VGA, please connect the green, blue and

red connectors to the Y, Pb, Pr jacks at the COMPONENT1/SCART inputs and the synchronized output to the VIDEO jack.

RLM W14 17/04/2017

DVD player or other SCART

Green Blue Red

RGBS input sources

200mA

17

Page 26

3. Projector parts and Functions

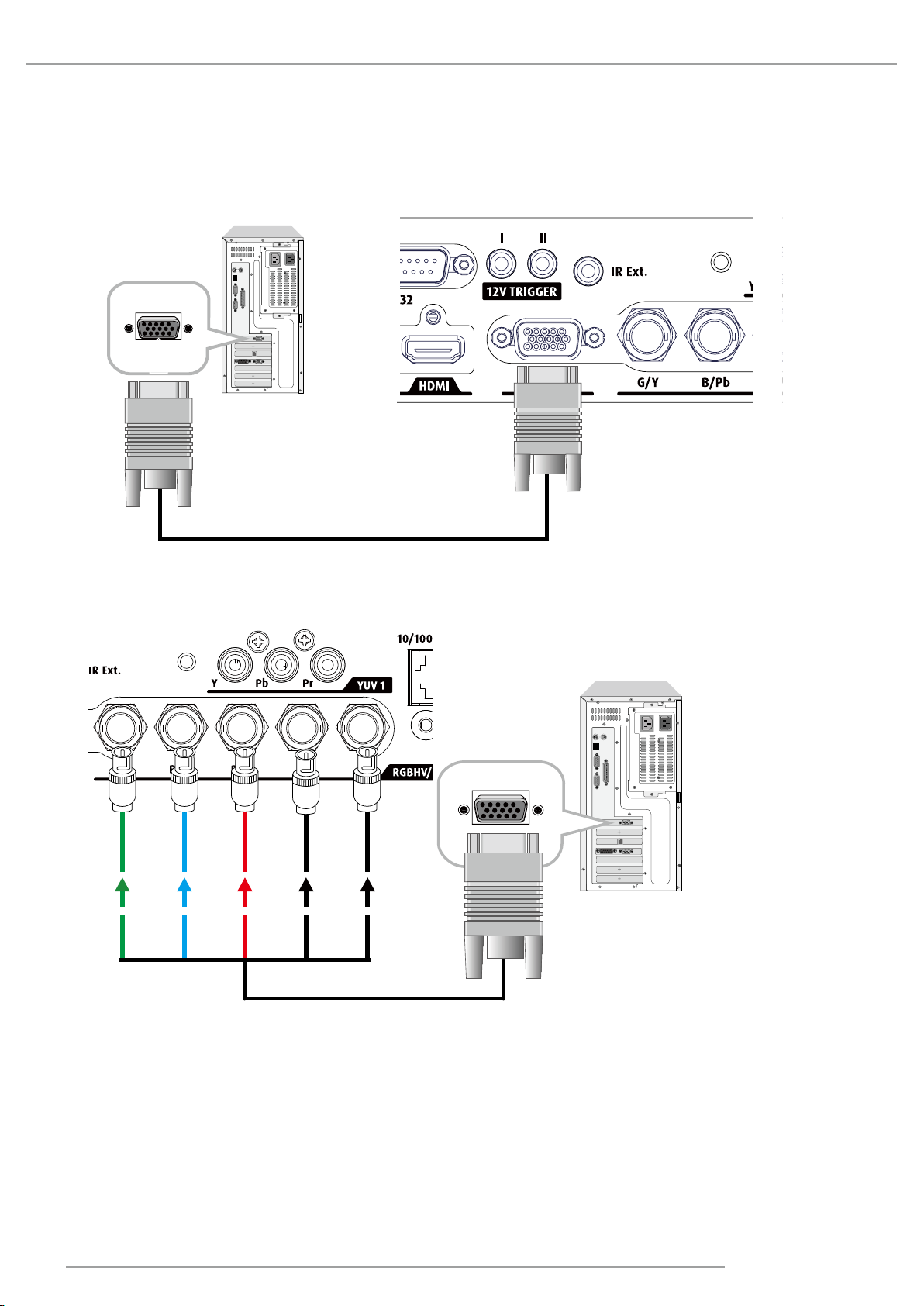

VGA connection

Connect your PC or other devices with VGAoutput to the VGAinput connectors on the projector to be used as the source of

image input.

Desk Top or Notebook

200mA

G/Y B/Pb R/Pr H V

Desk Top

or Notebook

18

RLM W14 17/04/2017

Page 27

3. Projector parts and Functions

200mA

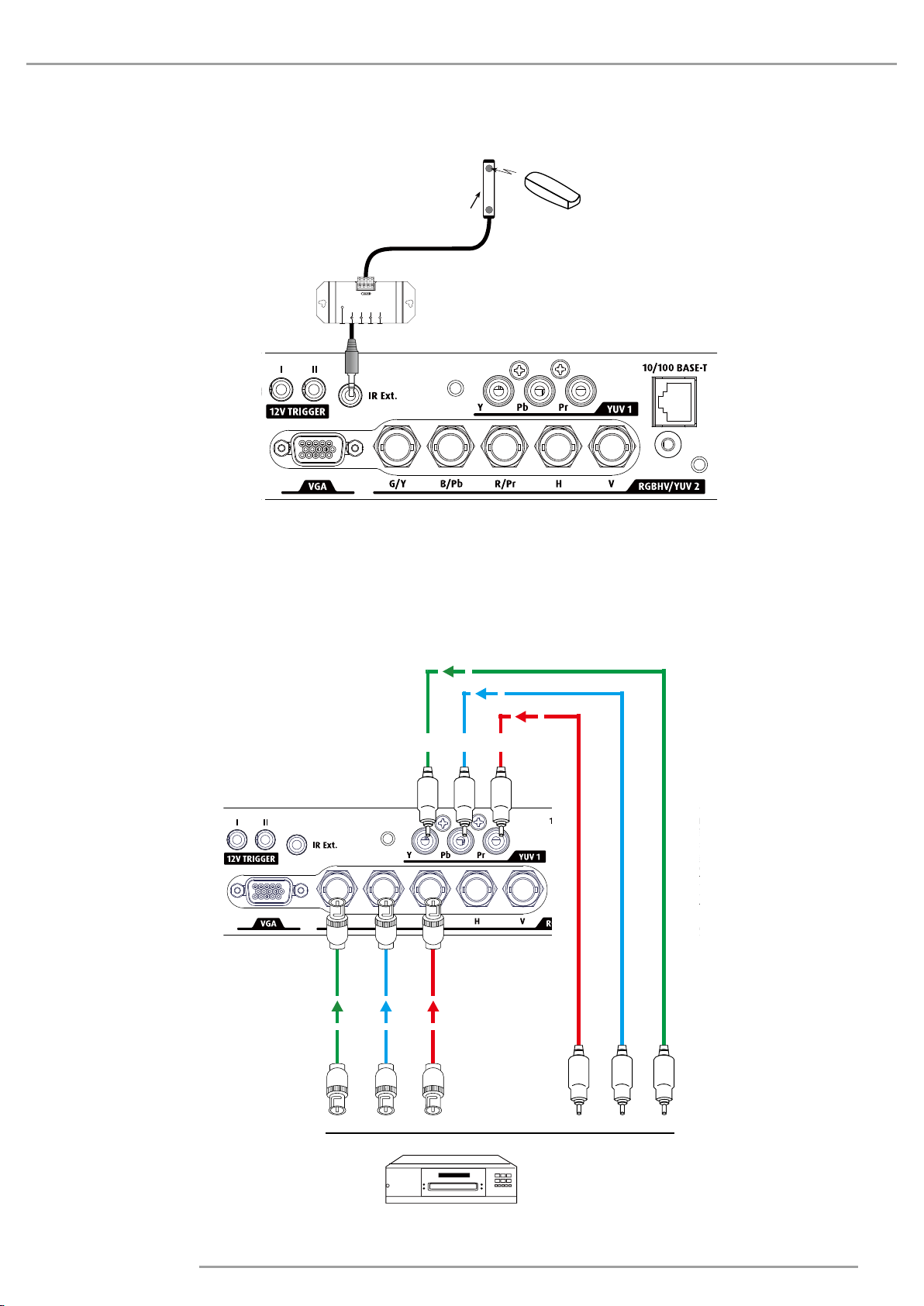

IR INPUT connection

If the projector is unable to pick up the IR signals from the remote controle due to distance or obstacles (i.e. wall or cabinet

doors), you can connect an external IR repeater to the projector’s IR INPUT jack to extend the effective signal reception range.

IR sensor

IR repeater

Remote control

200mA

COMPONENT connection

Take the 3/5 cabled RGB component video connectors from the source equipment to the projector’s COMPONENT1 SCART or

COMPONENT2 jacks.

Y Pb Pr

DTV

DTV set-top-box or other compo-

(YPbPr)

nent (YPbPr) input source

RLM W14 17/04/2017

19

Page 28

3. Projector parts and Functions

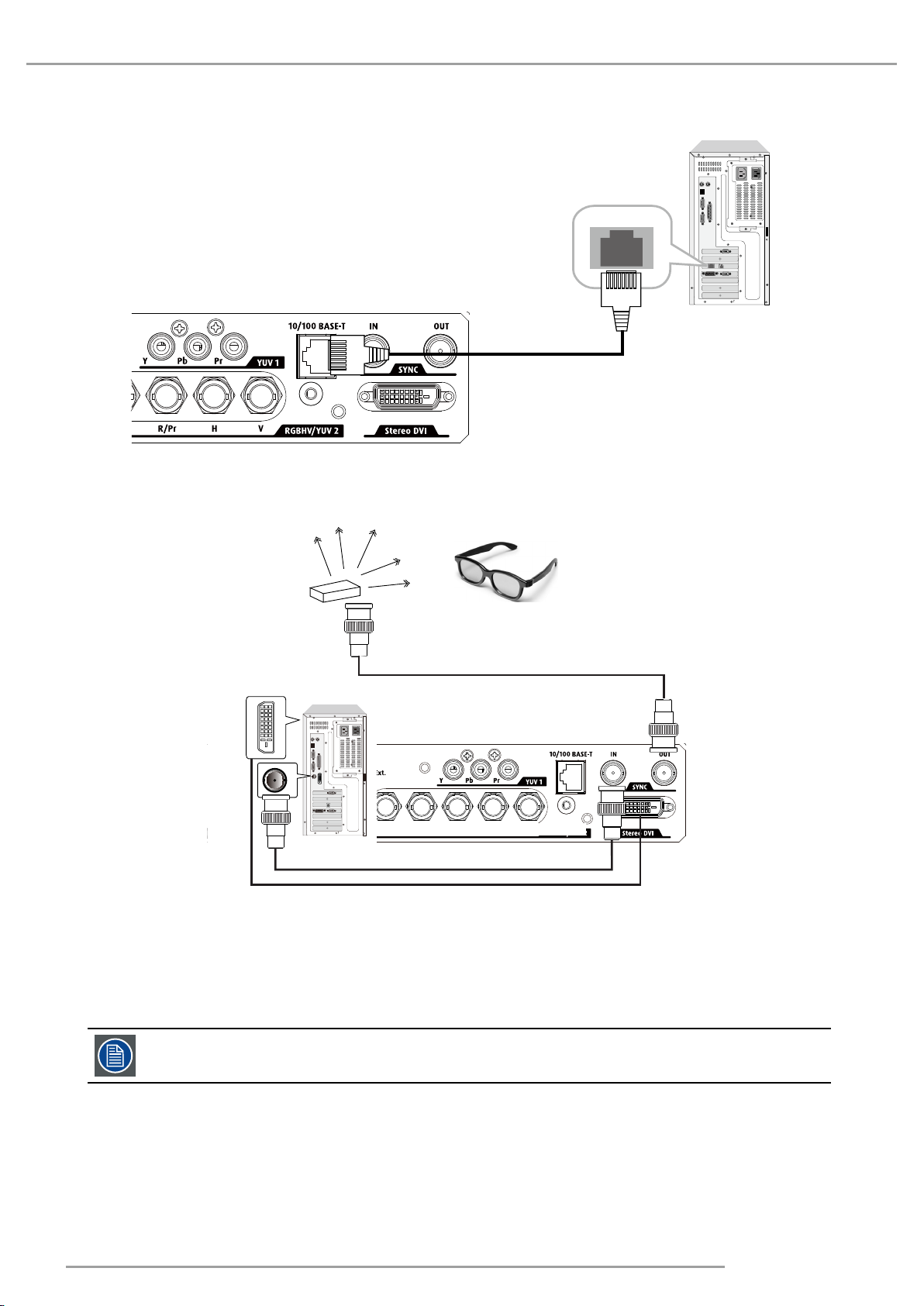

10/100 BASE-T

Connects the projector to your PC via network to have direct control of the projector from the PC.

Stereo DVI

Connect the Stereo DVI to a stereo 3D source - it is usually a computer with 3D Graphics card and 3D applications.

LAN

Desk Top

or Notebook

IR Emitter

3D Glasses

EMITTER L/R signals

200mA

L / R Sync signal

3D mode

There are few ways to go to the 3D mode

- OSD menu: Go to Main Menu “Input > Input Selection”, and select STEREO DVI

- Remote control: Press hot key “5” to go to STEREO DVI directly (factory default, not suitable for user-defined shortcuts )

- Network Webpage: Go to “Source/general” > “Source” and select STEREO DVI

- RS232 Commands : Use “ Input.sel = 1-8” to select any other source that is available.

20

There is no osd available when using the stereo dvi input. The projector needs to be controlled by projector

toolset web browser.

2D mode

Please note that OSD menu is not available in 3D mode. The ways to switch back to 2D mode are:

- Remote control: Press any of the input key 1-4 will switch back to 2D mode.

(factory default, not suitable for user-defined shortcuts )

- Network Webpage: Go to “Source/general” > “Source” and select any other source that are available.

- RS232 Commands: Use “ Input.sel = 1-8” to select any other source that are available.

RLM W14 17/04/2017

Page 29

3. Projector parts and Functions

3D with a Barco RLM W14

You need:

1.

RLM W14 + ImagePRO II with option "dual output card. 3rd party IR Transmitter and 3D glasses.

Connection:

2.

Connect the DVI out ImagePRO II to DVI connector (3D) of RLM W14.

This can only be done with a full dual link DVI cable, not with a HDMI-DVI cable or single link DVI cable.

There is no need to connect the projector's sync in.

Connect the sync out of the projector (BNC) to the 3th party IR emitter box.

Configure the Output

3.

Switch the ImagePRO II in 3D (menu system/mode) mode. Resolution: 1920x1200@120Hz or 1920x1200@100Hz (do not

configure in another format), 3D mode sequential (default mode).

Test with test pattern 3D 16 x 16 grid. Close one eye and then the other to check the 3D mode and adjust left eye and

right eye if required.

Configure the input

4.

Observe that the menu 3D appears in “input/processing” and only for digital sources.

In the menu “processing”, choose the correct type of 3D:

Off (default setting = no 3D),

“Side”, “Top/bottom”,

“sequential”,

“Left/right” (dual stream SDI 1 and 2 or twin DVI and HDMI)

or

“Frame packing” (specific for HDMI) is used only by Blueray players. Some Set-Top boxes can also use this format.

Do remember to adjust the HDCP for input and output of the ImagePRO II with a Blu - Ray or another source HDCP DVI output.

Dual HD-SDI

For an input in left and right stream with dual HDSDI select the input “nr 5” SDI and select in the input menu input/processing

set the 3D Left/right. At that moment input SDI 5 and SDI 6 both get active. Check at the bottom of the “L/R status” if ok in

the menu (if “N/A” or “invalid” there is no input with dual stream detected).

IR

Active system

for 3D glasses

DVI IN

(only 3D)

Sync out

3D Sync wire

IMAGE PRO 2

RLM W14 17/04/2017

DVI DUAL LINK

INPUTS

3D or 2D

21

Page 30

4.Physical Installation

4. PHYSICAL INSTALLATION

About this projector

This chapter describes how the mechanical set up of the projector has to be done and how to realize the electrical

connections.

Overview

Remote control unit (RCU)

•

Lenses

•

Connecting the projector with the power net

•

Alignment of a table mounted projector

•

Mounting the ceiling mount

•

4.1 Remote control unit (RCU)

Introduction

Remove the cover by sliding it in the

direction indicated by the arrow.

→

Insert two new AAA

batteries (observe the polarity).

Replace the cover.

→

Notes for the Remote control unit

Be sure to insert the batteries in the corresponding orientations to match the polarities.

•

Do not mix new batteries with used batteries as it would shorten the life of new batteries or cause leakage.

•

Only used AAA batteries as instructed; do not attempt to insert different types of batteries into the remote control.

•

If the remote is going to be unused for long periods of time, be sure to remove the batteries to prevent leakage, which

•

could damage the remote control.

The liquid contents in the batteries is harmful to the skin; do not touch the leakage with your bare hands directly. When

•

installing fresh batteries, be sure to clean up the leakage thoroughly.

Under most circumstances, you only need to point the remote control towards the screen and the IR signal would be

•

reflected off the screen and picked up by the IR sensor on the projector.But under specific circumstances, the projector may

fail to receive signals from the remote control due to environmental factors.When this happens, orient the remote control

at the projector and try again.

If the range of effective remote control signal reception decreases or if the remote control stops working, replace the

•

batteries.

If the infrared receiver is exposed to fluorescent lamp or strong sunlight, the remote control may not operate normally.

•

Refer to the regulations enforced by your local government on the disposal of used batteries; improper disposal could

•

damage the environment.

The battery life of remote control will be reduced when used wired IR remote control.

•

battery type R03. Only Carbon-Zinc or Alkaline-Manganese Dioxide type batteries should be used.

•

22

RLM W14 17/04/2017

Page 31

Remote Control overview

INPUT

4.Physical Installation

1

4

MENU

PAUSE TEXT

2

AUTO IMAGE

SHARPN

1

PHASE COLOR TINT

ADDRESSSWAPPIP

3

5

ASPECT

RATIO

IR LED’S

Basic Remote Command

result

RCU action Remark

start the projector press "on"

turn off the projector press "off"

select different image source press "1, 2, 3, 4 or 5"

show main menu on screen press "menu"

press "menu"

MENU

MENU

Wired remoted

connect to IR Ext.

These buttons on the remote control are the hotkeys

2

1

3

4

5

for different image source. By factory default, these

are:

Button 1=HDMI

Button 2=HDBaseT

Button 3=VGA

Button 4=RGBHV/YUV2

Button 5=Stereo DVI

RLM W14 17/04/2017

23

Page 32

4.Physical Installation

Basic Remote Command

result

return to previous menu without

selecting

RCU action Remark

press "menu"

move through menu press "arrow keys"

select button press "enter"

select and return to previous menu press "enter"

Picture Freeze

press "left arrow

key"x2

adjust aspect ratio press "aspect ratio"

halt projection temporarily press "pause"

operate the OSD menu normally or not press "text"

resync the image press "auto image"

increase or descrease image contrast press "contrast"

increase or descrease image brightness press "brightness"

adjust image sharpness press "sharpness"

adjust image phase press "phase"

adjust image color saturation press "color"

press "tint" This function not availavle for this model

display or hide pip press "PIP"

swap the input source of PIP press "swap"

MENU

ASPECT

RATIO

PAUSE

TEXT

PIP

SWAP

The enter button selects a item when in the

menu.

When not in the menu the enter button will

activate the lens adjust function.

Press ◄◄ (only available when an active

1.

signal is displayed)

The picture is frozen and appear II at top

2.

right screen 8 seconds then II disappear.

Press any button on remote control. Symbol

3.

II appear on screen again.

Press ◄◄ to unfreeze the picture.

4.

Freeze function is only on the main-

5.

window, not on PIP

The pause button will have a picture mute with

shutter close

When text is set to on, user can operate the

OSD menu normally. If set to Off, only can

use ON, OFF, 1~5, SWAP, PIP and PAUSE these

function

This function also apply to PIP input

1

When the image flicker, doubles, distorts or

appeare wavy, use this function to adjust

*only 2 address are possible*

24

change receiving address of the remote

control

press "address"

ADDRESS

Press and hold the ENTER until the remote

control panel flash once(approximately 5

seconds) to change the receiving address of

the remote control. if you use one remote

control to perate 2 different projectors. You can

assign different address for the 2 projectors so

that when you operate projector A, projector B

will not be affected.

RLM W14 17/04/2017

Page 33

Range of effective remote control signal reception

The diagram below illustrates the range of effective remote control signal reception.

40°

40°

25m

4.Physical Installation

25m

Avoid placing the remote control at places of high temperature or humidity as it could cause the remote

control to malfunction.

RLM W14 17/04/2017

25

Page 34

4.Physical Installation

4.2 Lenses

Available lenses for the RLM W14 projector projector

R9862000-TLD+ (0.73:1)

•

R9801414-TLD+ (0.8 - 1.16:1)

•

R9840776-TLD+ (1.2:1)

•

R9862010-TLD+ (1.5 - 2.0:1)

•

R9862020-TLD+ (2.0 - 2.8:1)

•

R9862030-TLD+ (2.8 - 4.5:1)

•

R9862040-TLD+ (4.5 - 7:5:1)

•

R9829997-TLD+ (7.5 - 11.2)

•

R9862005-TLD+ Ultra (1.25-1.6)

•

4.3 How to Mount the cable

The lens safety cable must be used in any circumstances to protect a mounted lens in the lens holder.

Projection lenses are optional accessories. Please contact your local dealer to acquire the projection lens

that suits your need most.

Paste four cable clips on the lens as illustrated (reference 1). Orient the open side of the clips towards the front of the

1.

lens.

2

2

1

image A

Snap the first loop end of the safety cable into one of the following clips and let the loop end point downwards.

2.

a) Configuration A: Use the upper clip on the side of the cable bundle (reference image A).

b) Configuration B: Use the upper clip on the non-wired side (reference image B).

Slide the rest of the cable around the lens counterclockwise. Click the cable into every clip it passes in this loop.

3.

Note: Make sure the cable passes between the lens and the cable bundle.

Slide the cable through the loop end at the beginning of the cable.

4.

1

image B

26

RLM W14 17/04/2017

Page 35

4.Physical Installation

Install a U-bolt on the lens holder, with the open ends oriented outwards (reference 3). Make sure that both a part of the

5.

loop end and the outgoing part of the safety cable are placed in the enclosure.

3

3

Close the U-bolt and tighten it.

6.

Note: Make sure the safety cable is tightened around the lens before tightening the U-bolt nuts.

Place the shackle through the free loop end of the safety cable.

7.

4.4 Installing the lens with safety cable on an RLM projector

This procedure assumes you know how to install a lens into the projector. If not, refer to the installation

manual of the projector.

How to install on RLM projectors

Place the lens in the lens holder, using the lens locking

1.

mechanism.

Caution: Always make sure the lens is really secured by trying to pull

the lens out of the lens holder.

Snap the shackle through the fixation ring near the lens opening.

2.

Secure the shackle by screwing the safety ring of the shackle over

3.

the open end.

How to remove the lens

Follow the drawing to press the button

1.

Press down the lever to release the lens

2.

Pull out the lens.

3.

RLM W14 17/04/2017

27

Page 36

4.Physical Installation

Lens focus

Press the button

buttons to adjust the lens' focus (clarity).

Make sure to hold the lens lever fully when install the lens (or remove the lens)

CAUTION: Never transport the projector with a Lens mounted in the Lens Holder. Always remove the Lens

before transporting the projector. Neglecting this can damage the Lens Holder and Prism.

It’s recommended to place the Lens caps of the original Lens packaging, back on both sides of the

removed Lens to protect the optics of the Lens.

MENU

on the remote control or MENU on the projector panel, Choose OSD -> LENS FOCUS , then use the

—>

Lens Focus : To adjust the lens focus with the RCU press “enter” when the OSD is not active.

Lens zoom

Press the button

buttons to adjust the size of the image that is projected onto the screen.

MENU

on the remote control or MENU on the projector panel, Choose OSD -> LENS ZOOM , then use the

Original image size Zoom out Zoom in

Lens Zoom: To adjust the lens zoom with the RCU press “enter” when the OSD is not active

28

Lens Shift

In addition to using the adjustable feet to adjust projection angle, you can also use the Lens Shift function to adjust the

projected image.

Moving the lens vertically

•

The distance of vertical lens movement is +100% , -30% of half the screen height in both directions.For instance, if you are

using a 80" × 50" screen, you will be able to move the image upwards no more than 27.5'' or downwards no more than

17. 5''.

RLM W14 17/04/2017

Page 37

Range of vertical

lens shift adjustment

Range of vertical

This illustration shows normal vertical

Range of

lens shift without the use of special

specification lens or projector.

Please make sure the center of lens is retangular to the center of the screen.

4.Physical Installation

lens shift

adjustment

Moving the lens horizontally

•

The distance of horizontal lens movement is 30% of half the screen width in both directions. For instance, if you are using

a 80" × 50" screen, you will be able to move the image left or right by no more than 12".

horizontal

lens shift

adjustment

Range of

horizontal

lens shift

adjustment

RLM W14 17/04/2017

This illustration shows normal horizontal lens shift without the use of special specification lens or projector.

29

Page 38

4.Physical Installation

4.5 Connecting the projector with the power net

Ensure that the power switch stands in the ’0’ (OFF) position (1).

1.

Tear off the warning label (2)

2.

Connect the female side of the power cord with the power input socket of the projector (3).

3.

Secure the power plug by locking the plug holder clamp (4).

4.

CAUTION: Use only the power cord provided with the projector.

Connect to Wall plug

VOIR LA NOTICE D’INSTALLATION

AVANT DE RACCORDER AU RÉSEAU

Connect the male side of the power cord to the local power net.

5.

30

For Europe and Korea For USA For China

Caution: Ensure that the power net meets the power requirements of the projector.

WARNING: Do not attempt operation if the AC supply and cord are not within the specified voltage and

power range.

RLM W14 17/04/2017

Page 39

4.Physical Installation

CAUTION: Once the projector is switched to standby, the lamp cooling fans will continue to run for approx-

imately five minutes to ensure that the projector and lamp have sufficiently cooled, at which point the

fans will automatically decrease to standby. To avoid thermal stress that can lead to premature lamp

failure, never unplug the power cord while the lamp cooling fans are running. Never unplug the power

cord to power down the projector, first switch off the power switch and then unplug the power cord.

4.6 Alignment of a table mounted projector

How to align the projector

Place the projector in the desired location. Take into account the zoom range of the used lens and the size of the screen.

1.

Project one of the internal hatch patterns on the screen.

2.

Turn the adjustable feet in or out until the projected hatch pattern has a perfect rectangle shape and is leveled.

3.

When this is achieved, the projector is set horizontal and vertical at right angles to the screen.

Angle adjustment

SCREEN

SCREEN

Angle adjustment

RLM W14 17/04/2017

31

Page 40

4.Physical Installation

4.7 Mounting the Ceiling mount

Necessary tools

Open wrench 17 mm

How to mount

Turn the projector upside down.

1.

Adjustment knob to the back of the projector. Make sure that the mounting holes matches the holes in the projector.

2.

Insert a bolt in each corner and turn in these bolts.

3.

Mounting bracket screw

3 holes of M8*15

187

532.001

53.200

265.4

142.400

220

6-M6 CILING MOUNT HOLE

160105

Mounting bracket screw

6 holes of M6*15

M8x15

M8x40

3 screws

3 bolts

32

112.9

305.001

Ceiling Mount Order Info:

1. R9849999-Ceiling mount

2. R9841260-Short Pulley 400mm to 765mm

3. R9841261-Long Pulley 800mm to 1165mm

NOte: Two holepatterns are available for ceiling mounting: M6x15(6pcs) or M8x15(3pcs)

Please check your support system for compatability.

RLM W14 17/04/2017

Page 41

5. GETTING STARTED

Overview

RCU & Local keypad

•

Power on projector

•

Switching to standby

•

Power off projector

•

Range of effective remote control signal reception

•

Source selection

•

Changing OSD language

•

Adjusting the lens by horizontal and vertical lens shift

•

5.1 RCU & Local keypad

How controlling the projector ?

The projector can be controlled by the local keypad or by the remote control unit.

Location of the local keypad ?

The local keypad is located on the input side of the projector.

5. Getting Started

Remote control functions.

This remote control includes a battery powered infrared (IR) transmitter that allows the user to control the projector remotely.

This remote control is used for source selection, control, adaptation and set up.

5.2 Power on projector

How to power on.

Press the power switch at the back of the projector to switch on this projector.

- When ’0’ is pressed, the projector is switched off.

- When ’1’ is pressed, the projector is switched on.

The projector starts up in standby.

The start up screen is displayed on the screen and when fully started up, it changes to the

overview screen.

When the projector is turned off, it is required to wait for at least 90 seconds to re-start the projector to

complete the cooling of lamp.

Starting image projection via the standby key.

STBY

Press

RLM W14 17/04/2017

key once on the local keypad or on the remote control.

33

Page 42

5. Getting Started

5.3 Switching to standby

How to switch to standby

Press Power button on keypad or remote control for 3 seconds for projector to go into standby.

1.

Wait until the projector completes the cooling process – at least 3~5 minutes.

2.

Please do not press any key on the keypad or remote control before the projector goes into standby mode.

3.

5.4 Power off projector

How to power off

Press Power button on keypad or remote control for 3 seconds for projector to go into standby.

1.

Wait until the projector completes the cooling process – at least 3~5 minutes.

2.

Switch off the projector with the power switch to ‘ 0”

3.

All custom settings are written to the internal backup device. A message ’Saving data ...’ indicates

this process. Never switch off the projector while this message is displayed.

When switching to standby, an after cooling process will start to cool down the projector. The after cool

time depends on the temperature inside the projector and can vary from 30 second to 5 minutes.

CAUTION: Never switch off the projector while the message ’Saving data ... ’ is displayed !

5.5 Source selection

Press No. 1-5 on the remote control to activate the input source that define in control OSD Or press on the keypad

to select the input source.

5.6 Changing OSD language

By factory default, the OSD menu of the projector is displayed in English. If you want to change default language. Press the

MENU on Remote control or keypad, then go to Control -> Languages to select the language that you want.

34

RLM W14 17/04/2017

Page 43

5. Getting Started

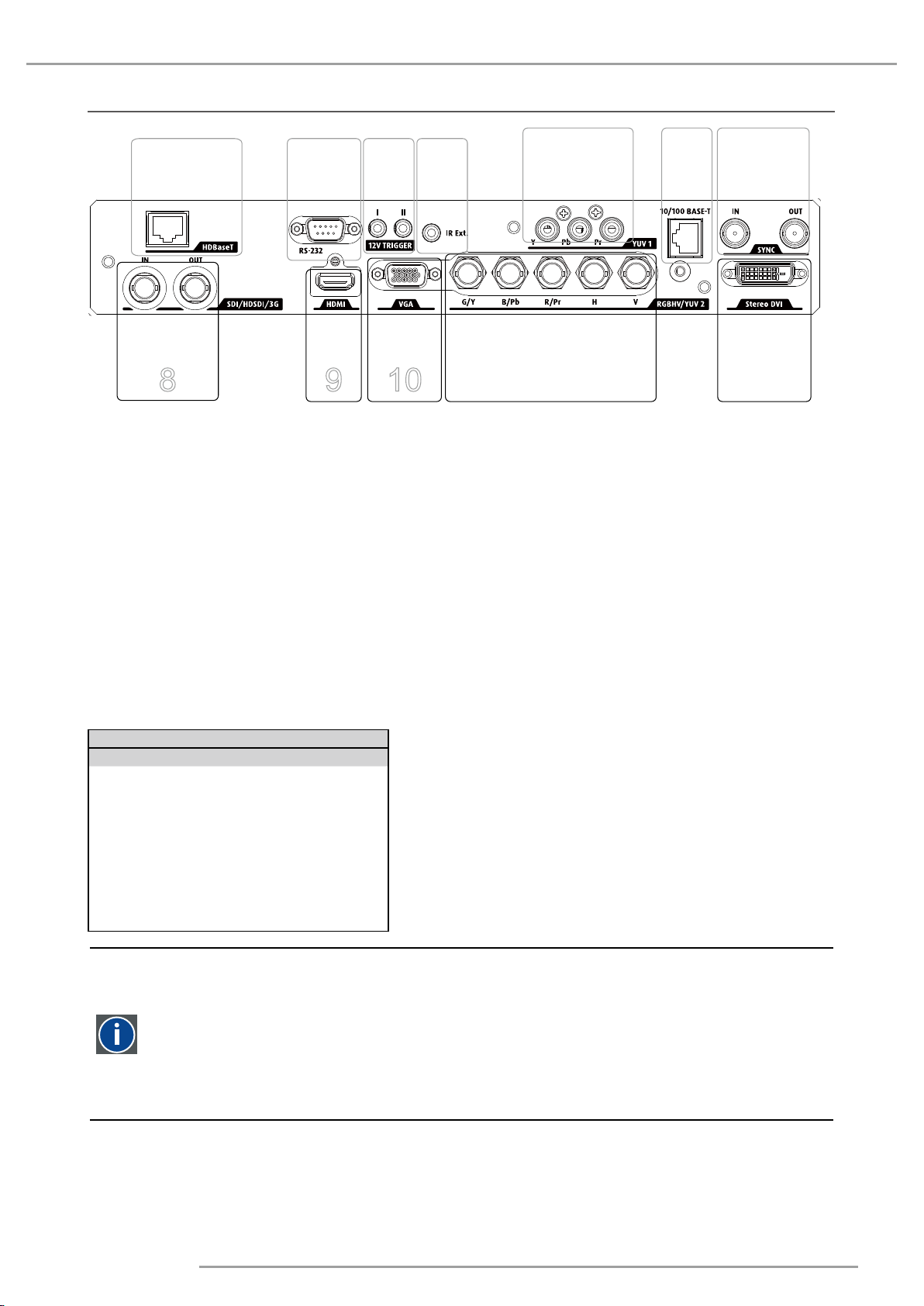

5.7 Adjusting the lens by horizontal and vertical lens shift

There has 2 methods to adjust the lens horizontal and vertical shift. Refer to below message.

Press the MENU button on the remote control and choose Alignment Lens Control; then use the ▼▲

•

adjust the horizontal or vertical position of the lens.

When the OSD is not active, press enter to activate lens adjust

Press the ENTER button on the remote control to access Lens Control adjustment screen before pressing ENTER once

•

again to access the menu and use the ▼▲

Press ENTER once to adjust

zoom and focus

Press ENTER again to adjust

vertical and horizontal lens

shift

->

Enter

buttons to adjust the horizontal or vertical position of the lens.

▼

▲

Press ENTER once to adjust

zoom and focus with cross

line

->

Enter

Enter

Press ENTER once to Adjust

Lines shift with cross line

->

Enter

buttons to

▲ ▼

RLM W14 17/04/2017

35

Page 44

6. Introduction the OSD menu

6. OSD MENU

Overview

The OSD menu is to control and align the projector, the following functions can be done:

OSD introduction.

•

Input setup: different Input settings can be adjusted such as specific input slot settings, locking, native resolution and no

•

signal settings.

Image adjustment: these adjustments are organized per image source and contain the aspect ratio, timings and image

•

settings.

Layout adjustment: set up of the main window and the picture in picture window.

•

Lamp: manage the lamp mode, the lamp use, lamp type and history

•

Alignment: groups all controls necessary during the setup of the projector onto a screen.

•

Control: contains the accessibility settings of the projector, such as address and communication setup.

•