Page 1

RHDM-1701

16.5" LCD Broadcast Monitor

Maintenance Manual

K5960059-00

Page 2

Intentionally left blank

2 _______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 3

1About the manual

1.1 Contents of the maintenance manual

This manual consists of the following chapters:

Chapter 1: About the manual

Chapter 2: Important notices, product safety precautions and package

and storage

The chapter contains important notices and safety precautions providing

essential juridical and technical information about the purchased product.

Chapter 3: About the product

Chapter 4: Board location

This chapter gives an overview of the location of the electronic boards within the

unit.

Chapter 5: Hardware and software module overview

A hardware and software module overview plus a list of configuration

possibilities are shown and listed in the chapter.

Chapter 6: Diagnostics

In case the unit does not behave normal, some general tips are listed in this

chapter. By following the Fault Finding Tree, a service engine er will find, on an

easy way, the faulty unit.

Chapter 7: Removal and reinstallation of electronic boards

If a faulty board is detected by means of the previous chapter, then it can be

swapped following the procedures of this chapter.

Chapter 8: Interconnections

This chapter describes the internal connections between the different boards and

modules of the unit.

Chapter 9: Adjustment procedures

After swapping a board, it might be necessary to perform some adjustments, if

this is the case then these adjustments procedures are described here.

Chapter 10: Maintenance

This chapter contains the cleaning instructions of the LCD screen and the cover

of the unit.

It also describes the function and the general operation of the Barco keypad as

maintenance interface (if applicable).

An overview of preventive maintenance to be performed on regular bases is also

given in this chapter.

Chapter 11: List of abbreviations

About the manual

1.2 Change record

Revision Date Description

00 Aug-10 Initial release

Barco - RHDM-1701 - Maintenance Manual _______________________________________________ 3

Page 4

About the manual

1.3 Notation convention

Following notations are applicable to this manual and should be respected

throughout the manual.

WARNING

Warnings – presented in this manual, provide information, which if not adhered to, may result

in personal injury or death.

CAUTION

Cautions – presented in this manual, provide information, which if not adhered to, may result

in damage to the equipment.

NOTE

Notes – presented in this manual, provide information, which emphasize points, significant to

understand and operate the unit.

IMPORTANT

Important – presented in this manual, provide information, which is important to highlight.

:

:

:

:

4 _______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 5

Important notices, product safety precautions and package & storage

2 Important notices, product safety pre-

cautions and package & storage

2.1 Read carefully

IMPORTANT

Please read the important notices and safety precautions, mentioned in the following paragraphs, carefully. They provide essential juridical and technical information about the purchased product.

:

2.2 Important notice

2.2.1 Copyright

© Barco n.v., All rights reserved.

The information contained herein is Barco confidential information. No part of

the information contained herein may be disclosed outside of the organization of

the recipient, its sub-contractors, and customers in any form or by any means

and/or stored in a database or retrieval system without the prior written consent

of Barco.

2.2.2 Technical accuracy notice

Although every attempt has been made to achieve technical accuracy in this

document, we assume no responsibility for errors that may be found. Our goal is

to provide you with the most accurate and usable documentation possible; if you

discover errors, please let us know.

2.2.3 Federal Communication Commission (FCC) notice

This equipment has been tested and found to comply with the limits of an FCC

class (refer to the technical specifications of the specific unit for more details

about the corresponding class). These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his own expense.

2.2.4 Warranty

During the warranty period, Barco n.v. will do all repairs free of charge

(material and labor). The faulty parts or units have to be shipped freight

prepaid to a Barco n.v. regional service center. Barco n.v. will pay the

freight charges when the repaired parts are shipped back to the

customer's site.

Damage of equipment due to improper use or negligence of the safety

Barco - RHDM-1701 - Maintenance Manual _______________________________________________ 5

Page 6

Important notices, product safety precautions and package & storage

precautions incorporated in this manual are not covered by this

warranty.

The warranty does not include the following:

• Any hardware or software item procured from a source other than Barco n.v.

or their official agent or distributor and integrated by Customer or a third

party into Barco n.v. supplied equipment.

• Any host or system configuration not explicitly supported by Barco n.v..

• Consumables such as projector lamps, dust filters, ...

• All software installed on the system, whether they are acquired from Barco

n.v. or a third party. An exception is made for software delivered by Barco

n.v. that would prove to be a cause for the malfunctioning of the hardware

covered under this Agreement.

• If any payment remains outstanding from the Purchaser to the Seller.

• Normal wear and tear, use under circumstances exceeding specifications,

abuse, unauthorized repair or alteration, lack of proper maintenance.

• In the particular case of LCD displays, to the case of image retention phenomena (shadows, dark lines and other image artifacts), that may result

from a usage outside of the specificat ion.

• Any failures resulting from an accident, negligence (such as but not limited

to removing or deleting system files & licensed software product files), misuse, circuit failure or any change, damage due to fire, water, thunder or

lightning, power failure or fluctuation, disruption of communication lines or

due to force majeure, or any reason foreign to the equipment.

• Any specific services or procedures, asked for by the Customer, related to

verification of repaired equipment.

• If several failures occur which are excluded from warranty due to circumstances such as fire and if Barco n.v.’s understanding that these circumstances may result in damage to other hardware under agreement, then

Barco n.v. is entitled to terminate the contract. No fees will be paid back by

Barco n.v. in this case. Inspection of equipment will be required prior to the

continuation of this Agreement; the same terms and conditions as for the

inspection prior to the contract apply.

2.2.5 Trademarks

Brand and product names mentioned in this manual may be trademarks,

registered trademarks or copyrights of their respective holders. All brand and

product names mentioned in this manual serve as comments or examples and

are not to be understood as advertising for the products or their manufactures.

2.2.6 Open source license

This product contains software components released under an Open Source

license. A copy of the source code is available on request by contacting your

sales representative.

See appendix A for details.

6 _______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 7

Important notices, product safety precautions and package & storage

2.3 Safety precautions

2.3.1 Service safety precautions

WARNING

Electric shock or fire hazard can be caused if critical components are replaced by nonconforming components. These components are marked in this guide by a sign.

with conforming types only!

:

2.3.2 Product safety notice

WARNING

Many electrical and mechanical parts in display units have special safety-related

characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated

for higher voltage, wattage, etc. Replacement parts that have these special safety

characteristics are identified in this data and its supplements and bulletins. Electrical

components having such features are identified by or * on the schematics and on the

parts lists in this data and its supplements and bulletins. The use of a substitute replacement

that does not have the same safety characteristics as the recommended replacement part

shown in the parts lists in this data and its supplements and bulletins, may create shock or fire.

:

2.3.3 Earthing

Replace

WARNING

The display unit must be earthed correctly. Verify that the power cable is plugged into a

standard 3-pin power outlet which is effectively earthed. When using extension cords, make

sure that they contain a grounded connection. If in doubt, contact a qualified electrician.

Ignoring this warning may lead to personal injury or death.

:

2.3.4 Electro Static Discharge (ESD) notice

CAUTION

The unit contains ESD sensitive subassemblies. The equipment has been built in accordance

with the Barco ESD protection procedure.

tions!

:

Use an earth strap during service interven-

2.3.5 Electrical warnings and cautions

• Do not power the unit with other input sources as specified in the technica l

specifications.

• Always power-down the unit before disconnecting the power cable.

• Unplug the display unit from the power source when not in use.

Barco - RHDM-1701 - Maintenance Manual _______________________________________________ 7

Page 8

Important notices, product safety precautions and package & storage

IMPORTANT

Immediately unplug if:

• the power supply cord is damaged.

• the unit has been dropped or the cabinet is damaged.

• the unit does not operate normally by following the operation instructions.

WARNING

Do not remove the cover without authorization. Removal of the cover by non-qualified

personnel can cause personal injury.

:

:

2.3.6 Environmental cautions

• Do not use the display unit in a dusty or damp room.

• Do not submit the display unit to heavy shocks and/or vibrations.

• Do not cover the display unit while in operation to avoid overheating.

• Do not expose to direct sunli gh t.

• Do not use the display at extreme limits of temperature and humidity rang e.

Storage and operating limits are specified in the techni cal specifications of

the unit.

2.3.7 Requirement for dusty environments

The room in which the display unit is installed and operational must be dustfree. The room must comply with a dust class of 8 or better according to

ISO14644-1. If the room in which the display unit is installed does not comply

with the dust class stated above, please contact Barco to discuss possibilities to

protect the display unit against dust.

NOTE

:

All construction, reconstruction, decoration activities must be completed before the installation

and operation of the product.

2.3.8 LCD screen

• Do not apply pressure on the surface of the screen. If ‘waves’ are visible on

the screen below the pressing object (e.g. finger), the pressure is already

too high and the LCD may already break under these circumstances.

• Do not hit the LCD screen with hard objects.

• Do not rub the LCD screen with rough materials.

• Do not touch the LCD screen with hard materials. Hard materials can cause

scratches on the surface of the LCD screen. Examples of hard material are:

fingernails, pencils, pens and styluses, wooden, plastic or metal objects.

• While moving the display unit manually , hold the LCD screen away from your

body to avoid scratching the LCD screen.

8 _______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 9

Important notices, product safety precautions and package & storage

• Do not paste or stick objects with glues and/or adhesive tapes on the LCD

screen.

• Wipe off water droplets or oil immediately. Ignoring this precaution could

lead to staining and/or discoloration of the LCD screen.

• Do not expose the LCD screen to direct sunlight.

2.3.9 Cover

• Do not place objects on the cover.

• Do not spill fluids over the cover or the LCD screen.

• Do not push objects into ventilation openings of the display unit.

2.3.10 Hazardous materials

WARNING

The LCD panel is composed of multiple layers of glass and protective glass with a small amount

of liquid in between. Rough handling or dropping can cause the LCD panel to break. If any part

of the skin or body comes in direct contact with the liquid, immediately wash the affected areas

with plenty of water for at least 15 minutes. If any symptoms are present after washing, get

medical care.

:

2.4 Package and storage

2.4.1 General

A safe transport of the units can only be guaranteed if the original und amaged

package is used for shipping. Handle with care when transporting.

Keep your original packaging. It is designed for this unit and is the ideal

protection during transportation.

2.4.2 Procedure in case of damages

All shipments should be opened and inspected for concealed damage or pilferage

as soon as possible after the arrival at destination. The shipping cartons should

be retained for the surveyor’s inspection and full and accurate reserves must be

made by a letter or a fax message.

Depending upon the used means of transport, the written protest is subject to

different time-rules:

• by sea: the protest has to be issued against the captain and/or ship within 3

days of the delivery of the goods.

• by road: the protest has to be issued against the last road-carrier within 7

days after delivery of the goods.

• by air: the protest has to be issued against the air-carrier within 14 days

after delivery of the goods.

In all cases, a claim or potential claim should be reported as soon as possible

whether or not full documentation is immediately available.

Barco - RHDM-1701 - Maintenance Manual _______________________________________________ 9

Page 10

Important notices, product safety precautions and package & storage

After completion of all required steps, the claim should normally be finalized

within one month. For more information about the claims handling procedure,

contact Barco n.v.

2.4.3 Storage

It is best to store the display unit in its original packaging in a room that does

not exceed the storage conditions mentioned in the technical specif ic a t i o n.

2.4.4 Electrolytic capacitors

The display unit needs to be powered on for a period of 24 hours at least once

every 2 years to allow internal electrolytic capacitors to be reformed. Failure to

do so may lead to compromised reliability.

2.4.5 Packaging

• Packaging corresponds to standards for international transport by air / sea /

ground.

• Dimensions:

3 Height: 550 mm

3 Width: 675 mm

3 Depth: 400 mm

• An optional flight case is available for flexi ble demo purposes: contact Barco

for more details.

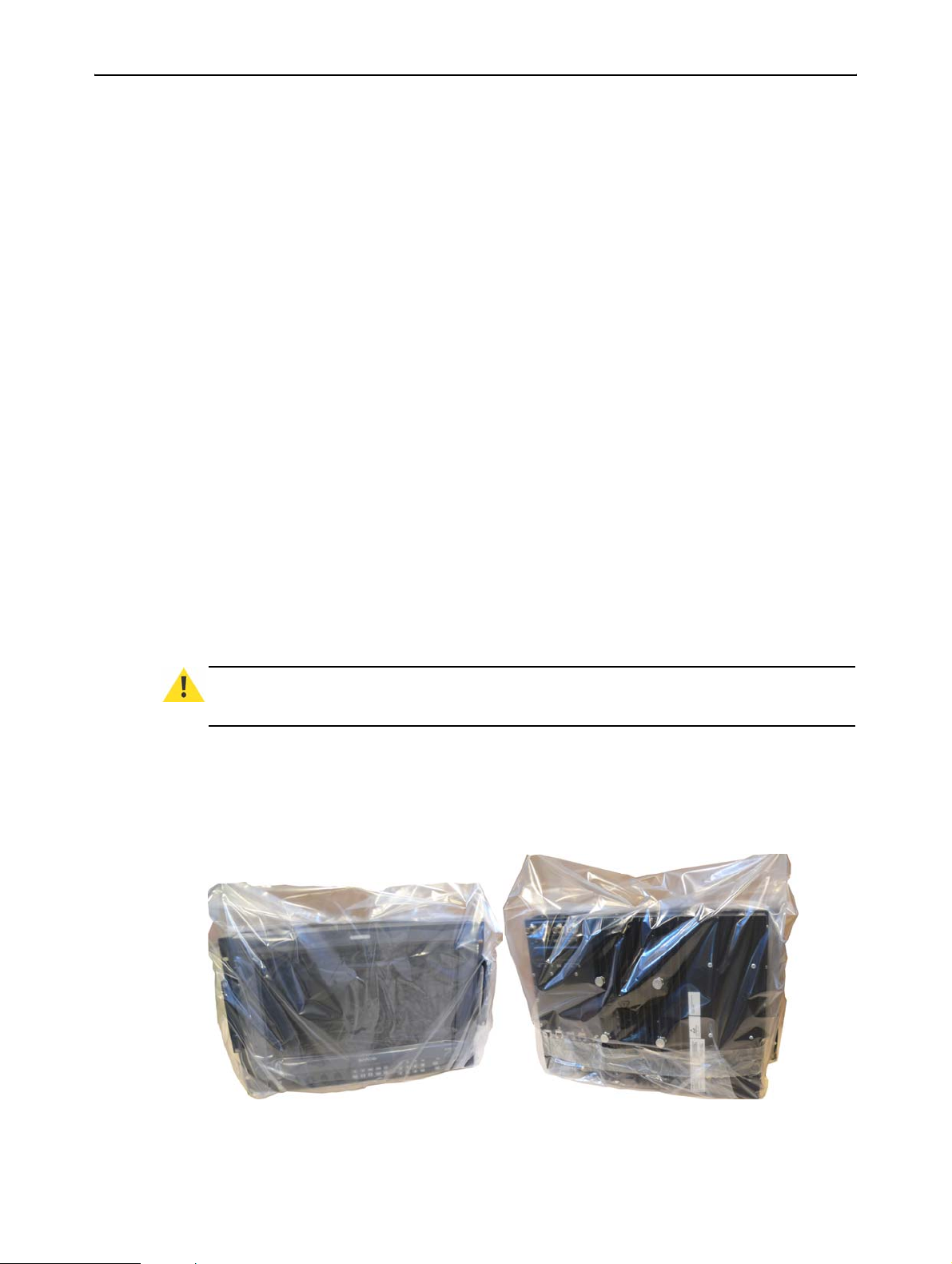

2.4.6 Repack instructions

CAUTION

To repack the display unit, please use the original packaging material.

• Place the box with the backside on a stable and flat surface.

• Make sure the rack brackets are mounted to the display unit and the stand,

• Place the display unit in the plastic bag and seal the plastic bag.

:

if there was one used, is removed.

• Place the 2 protective covers one on the left side of the display and one on

the right side of the display. Note that the left and right side are slightly dif-

10 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 11

Important notices, product safety precautions and package & storage

ferent and should be used correctly.

• Place the display unit gently in the box. The bottom side of the displa y facing

down. Include all original items provided with the display unit, including

cables, User manual and guiding sheets.

• Seal the box with tape.

2.5 Contact information

Belgium

Email: support.smd@barco.com

Phone: +32 56 262 350

Fax: + 32 56 233 013

United States

Email: Helpdesk.BCDUSA@barco.com

Phone: +1 866 992 2726

Fax: + 1 678 475 8124

Web sites

Public Web site: http://www .barco.com

Partner Web site: http://my.barco.com

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 11

Page 12

About the product

3 About the product

The RHDM-1701 is a reliable grade-1 reference monitor for color critical

applications in the broadcast and post-production markets, such as:

• camera control

• program and distribution monitoring

• signal QA (Quality Ass u rance)

•technical room

• color grading

• DI (Digital Intermediate)

The RHDM-1701 reference monitor brings value of trusted reference colors, no

calibration maintenance for a long period, and image quality comparable to CRT.

On top of that, the user-friendly interface and ease of use are unparalleled in

similar LCD monitors.

On the feature level, the color accuracy and stability with time and temperature,

perfect grey scale representation, deep and correct blacks, motion handling with

scanning backlights and a myriad of other features give large benefits to

professionals active in these markets.

The Key features of the display unit are:

LCD panel

• 16.5” (41,9cm) diagonal

• 1920x1080

• 10 bit panel

• Typical contrast 1000:1

• Barco guarantees the delivery of a RHDM-1701 monitor equipped with an

LCD panel selected zero dot defects at sparkle mode. Sparkle mode is when

the brightness of a dot is more than 16% at black.

Optical properties

• Wide gamut LED backlight

Processing of input signals

• 48 bit color processing (16 bit per color)

• 96-120 Hz native LCD driving

• Genlock and frame sync

• Quantified latency

• Scanning backlight functionality

Calibration and stability

• Compliant with following color standards:

3 EBU 3213

3 SMPTE C

3 ITU BT.709

3 xvYCC

3 sRGB

3 Adobe

12 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 13

About the product

3 DCI

• Selection of different opto-electric transfer function s (‘gamma’)

3 Rec.709

3 xvYCC

3 Pure gamma

3 Extended gamma

3 sRGB

3 SMPTE 240M

• Factory cross-talk calibration

• Thermal sensor circuit for LED stabilization with temperature

• Embedded spectrometer for overall color stabilization over time

• Embedded special sensors for LED uniformity and color stabilization over

time

• Front sensor for stabilization of LCD

Modular input configuration (4 slots)

• Slot 1 - 1 SDI input board (standard)

• Slot 2 – 1 SDI input board (optional)

• Slot 3 – future option (DVI)

• Slot 4 – future option (DVI)

SDI module specifications

• Possible inputs:

3 2 x SDSDI

3 2 x HDSDI

3 2 x 3Gb/s (option)

3 Combination of 2 signals out of: SDSDI, HDSDI or 3Gb/s (option)

3 1 Dual Link (option)

• Outputs: 2 loop-through outputs

Control

• Control panel with main functions and hot keys

• Ethernet interface with web server

• RS485 serial and parallel control of Tally/UMD

• USB: host, peripheral and support of mass storage devices, mouse, etc…

Feature packs and options

• The RHDM-1701 comes in different flavors. Depending on the specific applications that are targeted by the user, different feature packs can be

selected. Depending on the feature pack, additional options can be available.

• Broadcast – RHDM-1701/B: standard feature pack

3 Accepts SD and HD-SDI timings (2 inputs with loop-through outputs)

3 Selectable color space (EBU, SMPTE C, Rec.709 and Native), color tem-

perature and gamma

3 Configurable aspect ratio and safe area markers

3 Standard controls (picture, background, saturation, hue, color channel

selection, monochrome, input selection, aspect ratio and picture size,

interlace mode)

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 13

Page 14

About the product

• Post production – RHDM-1701/P has all features of the B version plus:

3 No cooling fans

3 Custom R, G, B primaries (in x,y)

3 Accepts Dual Link HD-SDI timings

3 Accepts 3Gb/s SDI timings

3 No cooling fans

14 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 15

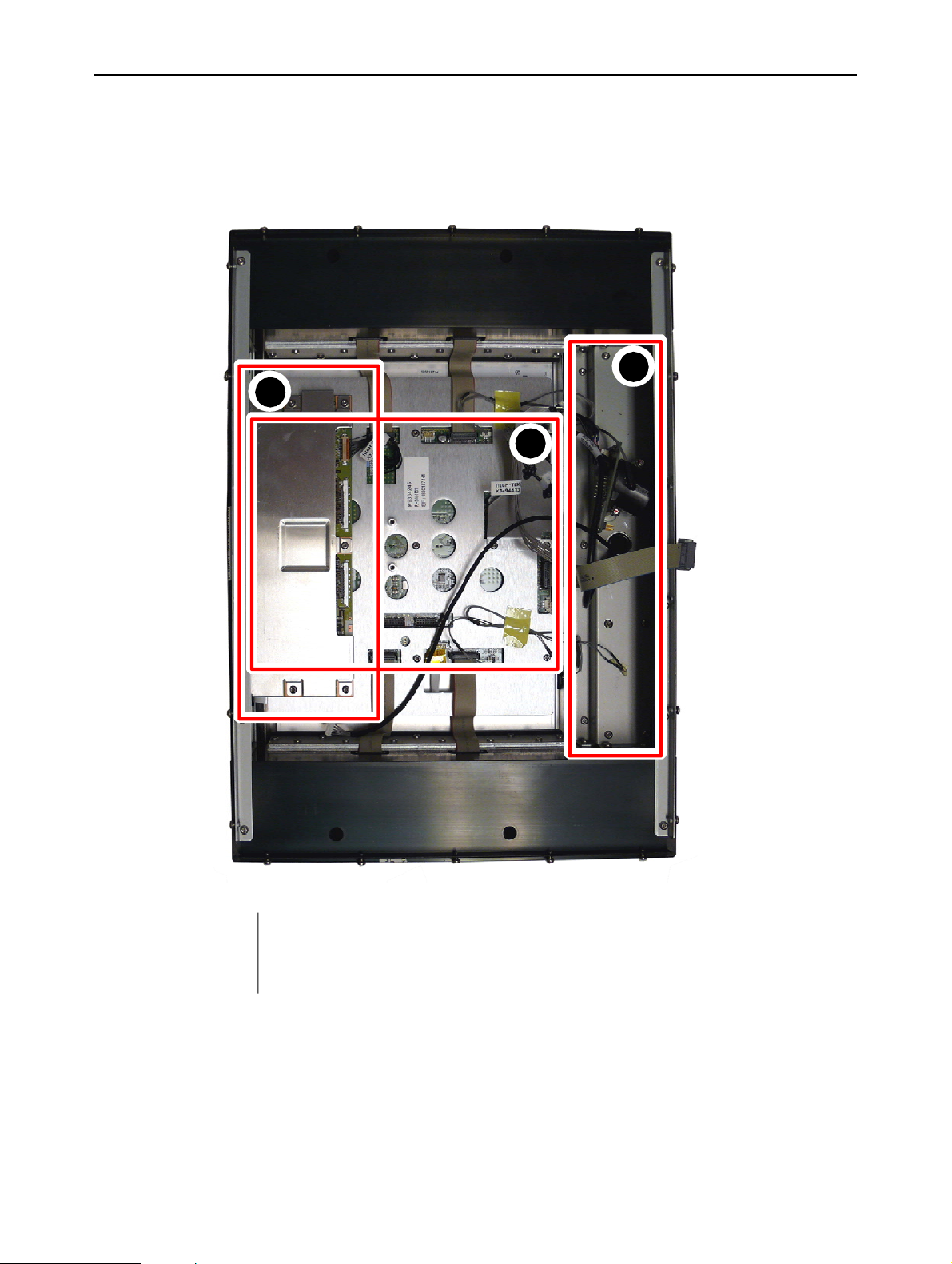

4 Board location

4.1 Front cover

2

Board location

3

1

LED dr iver board

1

Panel driver board

2

Control box

3

Figure 1: Front cover – module overview

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 15

Page 16

Board location

4.2 Back cover

1

2

3

5

Power supply

1

Power In terface Board

2

Iris board

3

HDSDI input board

4

Communication board

5

Figure 2: Back cover – module overview

4

16 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 17

Hardware & software module overview

5 Hardware & software module overview

5.1 Hardware tree

RHDM-1701

K9334245

ASSY

CONTROL BOX

SDI input board

Main (IRIS) Board

Power Interface Board

K5031234

K5831234

Communication

K5031237

K5831223

K5831238

V3.xx

K5831235

K5432074

B563073

Power Supply

K5960051

UM RHDM-1701

ASSY PACKING

Interface Board

SW APPLIC V3.

K59600511

Q REF sheet

K5960030

K5960058

CDR UM RHDM-1701

Q INSTALL sheet

ASSY FRONT

K5831236

K5031235

UN LED BOARD

ASSY BACKLIGHT

Spectrometer

B410199

K5831237

K5031232

LED Driver Board

ASSY MECH/COVER

K5031233

Figure 3: Hardware tree RHDM-1701

The hardware tree gives a schematic overview of all parts which are present in

the RHDM-1701. Each type of display unit and electronic board receives a unique

Barco number (K9334245).

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 17

Page 18

Hardware & software module overview

5.2 Software tree

RHDM-1701

K9334245

V3.xx

K54320161

POWER BOARD

K5831235

Power Interface Board

K5432074

SW APPLIC V3.xx

K54320611

SW APPLIC IRIS

K5831238

Main (IRIS) Board

Application software

Board level

Figure 4: Software tree RHDM-1701

The only part of the software which can be updated at a service center is the

Application Software. The instructions to update the main software is described

in the user manual.

18 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 19

6Diagnostics

6.1 Fault finding procedure

If you detect a problem with your configuration, please check the items listed in

the user manual first.

In case of malfunction it is important to follow a certain troubleshooting

procedure. Some of the steps in this procedure may seem obvious.

Nevertheless, they are worthwhile checking. As a malfunction on one board

(module) can influence the behavior of other boards (modules), it might be

necessary to replace the same board (module) twice in the same

troubleshooting procedure.

6.2 Start here

Check the fault finding trees as presented in the User manual (included below).

If the fault finding trees of the User manual do not solve the problem, check the

following items listed in this diagnostics chapter:

• Check if the right connections are present: See the section “Connections”

• Check if the issue is related to one of the following cases:

3 In case the monitor power LED stays off, or there is no image even if the

power LED is green.: See the section “Power diagnostics”

3 In case the monitor is switched on, but nothing is displayed on the

screen: See the section “Light diagnostics”

3 In case the monitor keeps showing the no valid sync message: See the

section “Image diagnostics”

3 In case there is no communication with the monitor, and you are sure

there are no network or IP address issues: See the section “Communication diagnostics”

3 In case color is not correct or color is unstable: See the section “Color

diagnostics”

3 To verify if the IRIS board is defect, see the section “IRIS board diagnos-

tics”

Diagnostics

6.3 Fault finding trees User Manual

6.3.1 Description fault finding trees

When the display unit is not working properly or the operation instructions do

not solve the problem, the troubleshooting may allow the user to identify the

source of the problem.

The fault finding trees are divided into three structures. They should be checked

according to the problem observe d by th e us er:

• “No power” fault finding tree: The display unit does not seem to be powered.

No LEDs are burning and nothing is observed on the screen.

• “Nothing observed on the screen” fault finding tree: The display unit is powered but no image is shown on the screen.

• “Verify input signal” fault finding tree: The display unit works correctly, but

the applied input signal is not reco g nized or not displayed on the screen.

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 19

Page 20

Diagnostics

• Image displayed on the screen is distorted, shows bands or stripes. In this

case something is wrong with the display unit. Contact Barco or your sales

representative.

6.3.2 "No power" fault finding tree

Check power

Power LED

on?

no

AC

power source

applied to display

unit?

no

yes

Apply a power source

that is conform to the

technical specifications

no

AC

power source conform

to technical

specifications?

yes

yes

switch on?

Swith power switch on

Power

LED on?

Power

no

Power

LED on?

no

no

yes

yes

yes

No further action

required

No further action

required

Contact Barco

No further action

required

Contact Barco

Figure 5: “No power” fault finding tree

20 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 21

6.3.3 "Nothing observed on the screen" fault finding tree

Nothing

observed on

screen

Diagnostics

Power LED

blinking?

no

Power LED

off?

no

Power LED

orange?

yes

yes

Wait until the display

unit reaches a steady

state (wait 40 seconds)

Apply a power source

that is conform to the

technical specifications

yes

Steady state

reached?

Unit in hard standby

Press

yes

Steady state

no

no

Unit in soft standby

Press

Power source

comform to the

technical speci-

Power LED

Power LED

reached?

no

fications?

green?

blinking?

no

yes

yes

No further action

required

yes

Contact Barco

Contact Barco

No further action

required

no

LEDs not lighted

Check the “No

Power” fault

finding tree

Press

yes

OSD menu

visible?

yes

Input applied to

the display unit?

no

Power LED

green?

no

yes

no

Contact Barco

Contact Barco

“Verify the input signal”

fault finding tree

Apply an input signal to

the display unit

Figure 6: “Nothing observed on the screen” fault finding tree

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 21

Page 22

Diagnostics

6.3.4 "Verify input signal" fault finding tree

Verify input

signal

“Invalid

signal” icon

shown on the

screen?

no

Status bar

shown on the

screen?

no

Set the status bar to

“Always visible” in

the OSD menu

yes

Apply a valid signal to the

display unit. Check if the

yes

signal is applied to the input

on the SDI board and not to

a loop-through output

Verify that the window to be

viewed is highlighted on the

status bar. Press

to select window. Verify that

the wanted input signal is

selected by the hightlighted

Figure 7: “Verify input signal” fault finding tree

6.4 Connections

Check if the following connections are present:

• 110V/220V power AC supply

• Input source cable

• LAN Network connection

window.

or

Input signal is

displayed on the

screen?

no

Input signal is

displayed on the

screen?

no

yes

yes

No further action

required

No further action

required

Contact Barco

6.5 Power diagnostics

In case the display unit power LED stays off, or there is no image even if the

power LED is green:

• Prepare the display unit for diagnosti cs

3 Remove or switch off power connection to the display unit

3 Remove back cover as described in “Removal and reinstallation back

cover”

3 Do not disconnect any cables inside the display unit

3 Check all connections to and from the PIB as listed in “R emov al and rein-

stallation of the power interface board (PIB)”

3 Apply the power connection to the display unit or switch on the power of

the display unit

• AC power supply only:

3 Check if LEDs D16 and D17 are on.

22 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 23

3 If both LEDs D16 and D17 are off, replace PIB as described in “Removal

and reinstallation of the power interface board (PIB)”

• Power supply and PIB are working, but still no image is observed on the

screen: See “Light diagnostics”

6.6 IRIS board diagnostics

1

Diagnostics

3

2

FPGA1 LED

1

FPGA2 LED

2

FREESCALE LED

3

Figure 8: IRIS board indicator LEDs

To verify if the IRIS board is defect, check the FPGA LEDs on the position n°1

and n°2. They light up orange after start-up and should go out when they are

configured. When one of those FPGA indicator LEDs does not go out, the IRIS

board is defect. The display unit should be send back to Barco.

The Freescale LED should light up green during operation. This LED is only for

development purposes and will not be present on the new version of the IRIS

board.

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 23

Page 24

Diagnostics

6.7 Light diagnostics

In case the display unit is switched on, but nothing is displayed on the screen,

even after exhausting the “Nothing observed on the screen” fault finding tree in

the User manual:

• Switch on the display unit. Check if the backlight switches on. (Even black

should become brighter)

If the backlight does not switch on:

• Prepare the display unit for diagnosti cs:

3 Remove the power connection to the display unit

3 Remove back cover as described in “Removal and reinstallation back

cover”

3 Do not disconnect any cables inside the display unit

3 Reapply or switch on the power connection to the display unit

• Check if LEDs D16 and D17 on the PIB are on. If not, replace PIB as

described in “Removal and reinstallation of the Power Interface Board (PIB)”

• Check if the backlight is c o nnected to the power (Connector J8 on PIB)

The fault is likely to originate in the IRIS board or the backlight board when:

• the backlight has power but is never switched on

• the backlight switches on but no menu or other picture can be made visible

on the screen

The IRIS board can only be replaced by Barco qualified personnel. Send the

display unit back to Barco.

6.8 Image diagnostics

In case the display unit shows the no valid sync message and the “Verify input

signal” fault finding tree from the User manual does not resolve the problem:

• Source validation:

3 Check the video source on another input board or on another display

unit

3 Check if a different video source applied to the same input of this display

unit shows an image on the screen

3 Check whether your source is a validated input timing for your firmware

version. (User manual)

• If the source is valid, try to resolv e the problem by installing a new/different

input board as described in “ Removal and reinstallation of HDSDI board”

• If installing a new/different input board is unsuccessful, the IRIS board is the

most likely to cause the problem. The IRIS board can only be replaced by

Barco qualified personnel. Send the display unit back to Barco.

6.9 Communication diagnostics

In case there is no communication with the display unit, and the problem is not

related to the network or the IP address, then the problem can be related to the

communication board. Replace the communication board as described in

“Removal and reinstallation of the communication board”.

24 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 25

If installing a new communication board does not solve the issue, the IRIS board

is the most likely cause of the problem. The IRIS board can only be replaced by

Barco qualified personnel. Send the display unit back to Barco.

6.10 Color diagnostics

Each display unit is calibrated in the factory with the highest precision to the

correct white point, primaries and gamma. Two main issues can cause color

problems:

•Defects

• Matching between the display unit and other types of displays (e.g. CRT

technology based display units)

Defects

Make a visual inspection of the displayed image. Check for the problems

described below:

• One horizontal stripe of the display unit has a different color than the rest of

the screen

• The whole image as an extreme color (such as purple, green, red, etc…)

Diagnostics

If one of the problems described above occurs, follow the diagnostics procedure

below:

• Restart the display unit

• If the problem persists or occurs frequently, try an update to the latest firmware

• If the above checks do not resolve the issue, the display unit will have to be

serviced and/or send back to Barco.

Matching problems

If the display color resembles the needed color (e.g. compared to a CRT), but is

slightly ‘off’ (white point slightly reddish, greenish, purplish etc) from the

expected color, several settings can be checked to obtain a better matching. The

points below describe the possible steps that can be taken to reach the desired

color matching:

• Make sure the display is warmed up (wait at least 20 minutes)

• Press the CAL button and select the appropriate color space (e.g. Rec.709

for HD content, EBU 3213 for European SD content, SMPTE C for US SD content, etc…)

• Check in the color working space menu (

or RGB primaries correspond to the standard values as specified in the User

Manual

• The white point of the RHDM can still differ slightly with respect to another

display unit (e.g. a reference CR T monitor). Try to manually adjust the white

point of the display unit. Differences in white point can be related to:

3 different technologies

3 different calibration sensors

3 metameric difference of a human observer because of difference

between LED and phosphor spectra

) if the white point, gamma and/

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 25

Page 26

Diagnostics

NOTE

:

When the colors of the display unit seem ‘greenish’, decrease the y coordinate of the white

point from 0.329 down to a value as low as 0.315 and increase the x coordinate of the white

point from 0.3127 up to a value of 0.315.

IMPORTANT

Do not measure the display unit with a colorimeter such as DK Technologies, Konica Minolta CA

210, Thoma, Klein K-10 etc. These probes will give erroneous results because the display unit

is a LED-based display. The color filters do not match. It is recommended to use a spectrophotometer for reliable results.

NOTE

The CRT can be measured with a corresponding probe (such as mentioned above). Use the

obtained values to manually adjust the (x,y) coordinates of the display unit.

If the above checks do not resolve the color matching issue, contact Barco for

further assistance. A display swap would probably not solve the problem as the

problem is related to the difficulty in matching different technologies.

:

:

26 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 27

Removal and reinstallation of electronic boards

7 Removal and reinstallation of electronic

boards

7.1 Service levels

Maintenance levels:

Level Swap

level

1 NONE • User level – adjustments

2 LRU Technical Services:

3 LRU Qualified regional service center:

4LRU

+

SRU

Description Required level and/

• User software uploads

• Swap of electronic boards described in

maintenance manual

• Calibration of display unit

• Swap of electronic boards described in

maintenance manual

• Repair of electronics

• Calibration of display unit

Product base:

• Swap of electronic boards described in

maintenance manual

• Repair of electronics

• Calibration of display unit

• Panel swap, optics and backlights

repair

• Iris board swap

• Firmware uploads

Table 1: Maintenance levels

or training

User

Product training

Product training

Certified “customer

personnel” or “partner”

Repair training

Repair training

The Maintenance manual may only be used by personnel with a level of 2 or

higher.

7.2 Module replacements (level 2 and level 3)

The following boards can be replaced at an authorized service center:

• Power supply (B563073)

• Power Interface Board (K5831235)

• HDSDI Input Board (K5831223)

• DVI Input Board (K5831220)

• Communication Board (K5831234)

• Control Box (K5031237)

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 27

Page 28

Removal and reinstallation of electronic boards

7.3 Module replacements (level 4)

• The Main (Iris) board (K5831238) cannot be replaced at a service center.

When the Main (Iris) board is defect, the whole display unit should be send

back to Barco for repair.

• The panel, the panel driver board and the LED driver board cannot be

replaced at a service center. When a part of the front cover is defect, the

whole display unit should be send back to Barco for repair.

7.4 Spare part kits (level 2 and level 3)

The following spare part kits can be ordered:

• RHDM Starter Spare kit – K5031254

3 RHDM Power Supply

3 RHDM Power Interface Board

3 RHDM HDSDI Input Board

3 RHDM Communication Board

3 RHDM Control box

3 RHDM Accessory kit

• RHDM Accessory kit – K5031253

3 Knobs

3 VESA screws

3 User manual

7.5 Removal and installation precautions

WARNING

Always disconnect the unit from mains before removing covers and/or replacing boards!

CAUTION

The units contain ESD sensitive subassemblies. Before commencing the removal/reinstallation

procedure of modules and/or boards, place the unit on an ESD safe work mat, the back cover

of the unit facing upwards.

Do not loosen any screws unless they are mentioned in the removal and

reinstallation procedure

:

:

7.6 Required tools

• Screwdriver for torx head screws – T20

• Screwdriver for torx head screws – T10

• Screwdriver for torx head screws – T7

• Wrench – size 16

• Screwdriver for crossed head screws – type PH0

28 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 29

7.7 Remove the brackets

The display unit is delivered with brackets for rack mounting.

First remove the 2 rack brackets with handles by unscrewing (2x) 3 torx head

screws T20.

1

Removal and reinstallation of electronic boards

Figure 9: Removal of rack brackets

7.8 Removal and reinstallation back cover

Removal of the back cover

IMPORTANT

Removing the back cover voids the warranty.

• Use a flat and stable table to handle th e di s p lay un it

• Cover the surface of the table with bubble wrap or a similar protective mate-

• Place the display with the LCD panel (front) facing down and the top of the

:

rial to avoid scratching of the LCD panel.

display unit away from the edge of the table. Y ou shoul d be positioned at the

bottom side of the display unit to be able to remove the back cover easily.

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 29

Page 30

Removal and reinstallation of electronic boards

2

2

2

2

2

2

2

1

1

2

2

2

2

2

1

2

1

2

2

2

1

2

2

2

Screws (4x) - remove completely

1

Screws (18x) - loosen only

2

Figure 10: Location of the screws that fix the back cover to the front cover

• The back cover is fixed to the front cover with 22 screws in total. Use a T10

torx screwdriver to loosen the screws. The screws of type 1 (see figure

above) must be removed completely, while the screws of type 2 should be

loosened only.

• To remove the back cover, do not force anything . D o not pull-off the back

cover completely, since several wires are connecting the electronic boards in

the back cover to electronic boards in the front c over. Lift-up the cover by

pulling at all sides evenly. When the back cover has lost contact with the

front cover, put the bottom side of the back cover on the edge of the front as

in figure below. Watch out that the back cover does not fall.

30 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 31

Removal and reinstallation of electronic boards

1

2

3

8

7

Open cover from the top

1

J8 - Power co nne ction to LED driver b oard (J1)

2

J7 - USB conn ec ti on to control box

3

J11 - flat cable from Iris board to LED driver board (J8)

4

J11 - Communi cation board connector to control box

5

6

LVDS cable connection area on the panel driver board

7

LVDS cable connection to panel driver board

8

Screws (2x) that fix the LVDS cables to the LED driver board

5

4

6

8

7

Figure 11: Location of cables that connect the electronic boards in the back

cover with the electronic boards in the front cover.

• Remove the cables that connect the electronic boards in the back cover to

the electronic boards in the front cover

3 Disconnect the cable of the power interface board connected to the LED

driver board (n°2 in the figure above)

3 Disconnect the cable of the main (Iris) board connected to the control

box (n°3 in the figure above)

3 Disconnect the flat cable of the main (Iris) board connected to the LED

driver board (n°4 in the figure above)

3 Disconnect the cable of the I/O board connector J11 connected to the

control box (n°5 in the figure above)

3 Disconnect the LVDS cables (2x) of the main (Iris) board connected to

the panel driver board (n°7 in the figure above).

3 Remove the clamps (2x) that fix the LVDS cables (n°8 in the figure

above).

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 31

Page 32

Removal and reinstallation of electronic boards

• The back cover is now disconnected and is ready for further maintenance

actions.

Reinstallation of the back cover

Execute all actions mentioned above in the reverse order.

Take the following points into account:

• After connecting the LVDS cables to the panel driver board, verify that the

clamps are placed over the stripped part of the LVDS cables.

2

1

Stripped part of LVDS cable

1

Copper clamp fixation

2

Figure 12: Correct clamping of the LVDS cables

7.9 Removal and reinstallation of the power supply

Figure 13: Top view of the power supply

Removal of the power supply

• Follow the removal instructions of the back cover to remove the back cover.

• Place the back cover on the table with the inside facing up.

32 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 33

Removal and reinstallation of electronic boards

3

4

5

3

2

6

6

1

6

1

J1 - Input AC power from AC i nput at the back

2

J204 - Output to PIB

J3 - Connection area J14 and J15 to the PIB

3

4

J14 - (+) Output to the PIB (red wire)

5

J15 - (-) Output to the PIB (black wire)

6

Screws (4x) that fix the power supply to the back cover

6

Figure 14: Location of screws and connectors of the power supply

• Place the back cover uprigh t

• Remove the crossed head screws (4x) located at the backside of the back

cover (n°6 in the figure above).

• Disconnect the cables connec ted to the power supply:

3 Cable from the AC input connector, connected to J1 (n°1 in the figure

above)

3 Cable to the power interface board, connected to J204 (n°2 in the figure

above)

3 Unscrew the red cable (J14) to the power interface board (n°4 in the fig-

ure above)

3 Unscrew the black cable (J15) to the power interface board (n°5 in the

figure above)

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 33

Page 34

Removal and reinstallation of electronic boards

Reinstallation of the power supply

• Execute all actions describ ed above in reverse order. It is convenient to connect the cables to the power supply before fixing the power supply to the

back cover.

7.10 Removal and reinstallation of the power interface board

Figure 15: Front view of the Power Interface Board

The Power Interface Board contains indicator LEDs that provide valuable

information about the status of the power distribution to the display unit.

Figure 16: Indicator LEDs on the Power Interface Board

• D16 – 12 V power supply: power conversion check

• D17 – 5 V power supply: power conversion check

Removal of the Power Interface Board

• Follow the removal instructions of the back cover to remove the back cover.

• Place the back cover on the table with inside facing up.

• Remove the screws (3x) that connect the power board to the back cover

(n°1 in the figure below)

• Disconnect the cables on the power board:

3 From power supply to J4 on PIB (n°2 in the figure below)

3 From power supply to J6 on PIB (n°3 in the figure below)

3 From J9 on PIB (n°4 in the figure below) to Iris board

3 From J10 on PIB (n°5 in the figure below) to Iris boa rd

34 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 35

Removal and reinstallation of electronic boards

2

1

3

1

5

6

4

1

Screws (3x) that fix PIB to the back cover

1

J4 - 24 Vdc input to PIB from AC power supply

2

J6 - XPPower

3

4

J9 - Power to Iris board

5

J10 - Comm uni cation to Iris boar d

6

LED indicators on the PIB

Figure 17: Location of screws, cables and indicator LEDs on the P ower Interface

Board

Reinstallation of the Power Interface Board

Execute all actions described above in reverse order.

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 35

Page 36

Removal and reinstallation of electronic boards

7.11 Removal and reinstallation of HDSDI board

Removal of HDSDI input board

1

Outside back cover

2

Inside back cover

4

3

5

5

Connectors on the HDSDI input board - back cover

1

Loosen or tighten the nuts (4x) with a size 16 wrench

2

Location of

3

Connector socket for HDSDI board on Iris board

4

Screws (2x) that fix the HDSDI board to the Iris board

5

the crincle washer at the HDSDI input connectors

Figure 18: Location of screws to remove/mount the HDSDI input board

• Follow the removal instructions of the back cover to remove the back cover.

• Place the back cover uprigh t.

• Unscrew and remove the nuts (4x) at the outside of the back cover with a

wrench (n°2 in the figure above).

• Place the back cover on the table with the inside facing up.

• Remove the screws (2x) that fix the HDSDI input board to the main (Iris)

board (n°5 in the figure above).

• Pull the HDSDI board gently from the slot.

36 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 37

Removal and reinstallation of electronic boards

Reinstallation of HDSDI input board

Execute all actions described above in reverse order.

Take the following points into account:

• Before fixing the HDSDI board to the back cover with the nuts, verify that at

all the BNC connectors, the crinkle washer is placed between the back cover

and the nut (n°3 in the figure above).

7.12 Removal and reinstallation of the communication board

Removal of the communication board

Outside back cover

2

1

1

1

3

Inside back cover

4

5

5

Torx (3x T10) that fix the communication board to the back cover

1

Torx (1x T7) screw that fixes the communication board to the back cover

2

Metal housing of USB connectors

3

Connector socket for communication board on Iris board

4

Screws that fix the communication board to the Iris board

5

Figure 19: Location of screws to replace the communication board

• Follow the removal instructions of the back cover to remove the back cover.

• Place the back cover on the table with the outside facing up.

• Remove the screws (4 in total) (n°1 torx T10 and n°2 torx T7, in the figure

above) that fix the communication board to the back cover.

• Flip-over the back cover and remove the screws (2x) that fix the communi-

cation board to the main (Iris) board (n°5 in the figure above).

• Pull the communication board gently out of the socket.

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 37

Page 38

Removal and reinstallation of electronic boards

Reinstallation of the communication board

Execute all actions described above in reverse order.

Take the following points into account:

• When placing the communication board in the back cover, verify that the

metal housing of the USB ports is nicely fitting in the holes (n°3 in the figure

above).

7.13 Removal and reinstallation of the control box

Figure 20: Control box

1

11

Torx (4x T10) that fix the control box to the front cover

1

Control panel removed from the front cover

2

Cable gap in front cover for control panel cables

3

1

1

2

3

Figure 21: Location of screws, cables to remove or install the control box

38 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 39

Removal and reinstallation of electronic boards

Removal of the control box:

• Follow the removal instructions of the back cover to remove the back cover.

• Place the front cover on the table with the inside facing upwards.

• Remove the control box by unscrewing 4 screws that fix the control panel to

the bottom of the display unit (n°1 in the figure above).

• Slide the cables through the cable gap (n°3 on the figure above), so that the

control box can be completely removed.

Reinstallation of the control box:

Execute all actions described above in reverse order.

Take the following points into account:

• To fasten the control box to the cov er. First place the 4 fixation screws in the

front cover and then locate the box on the front so that the screws fit in the

foreseen holes in the control box. Fasten the screws one by one.

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 39

Page 40

Interconnections

8 Interconnections

Figure 22: Interconnection drawing

40 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 41

9Adjustments

No specific adjustments are needed after replacement or reinstallation of a new

module.

It is recommended to update the software of the display unit to the newest

version after replacement of new electronic modules.

The IRIS board and the front cover of the display unit are the only parts that

need adjustment. Those parts have to be send back to Barco and will be

recalibrated and updated where needed in the factory.

Adjustments

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 41

Page 42

Maintenance

10 Maintenance

10.1 Cleaning precautions

• Take care not to damage or scratch the LCD surface. Be carefull with rings,

jewellery and rough materials. Handle the LCD with care to avoid scratches.

• Do not apply pressure on the LCD surface.

• Do not apply or spray liquid directly to the LCD surface or cover as excess

liquid may cause damage to internal electronics. Instead apply the liquid to

the cleaning cloth.

• Avoid dirt of fingerprints, oil, and fat staini ng on the LCD surface as they will

harm the LCD. Remove dirt by following the cleaning instructions below.

10.2 Cleaning instructions (for CIVIL)

Before cleaning:

• Switch off the display unit.

• Remove the power cord from the mains.

Cleaning the LCD screen:

• Wipe the screen surface with a soft cleaning cloth.

• To remove stains, use a damp cloth with non-aggressive cleaning products:

3 Do NOT use abrasive cleaning agents, glass cleaner or tissue paper.

3 Do NOT use alcohol/solvents at higher concentration > 5%.

3 Use non-aggressive cleaning products (water or a solution of distilled

water and IsoPropyl Alcohol).

• Do not rub or push on the LCD screen. Rubbing with tissue can degrade the

performance of the LCD screen.

Cleaning the cover:

• Use a soft cloth to remove dust. If necessary, a vacuum cleaner can be used

to clean the ventilation openings (if applicable).

• Use a damp cloth (if necessary with some mild detergent) to remove stains.

• Do not use a scouring pad, or other tools that my scratch and damage the

cover.

• Do not use strong detergents such as alcohol and thinner.

42 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 43

11 Abbreviations and acronyms

°C Degrees Celsius

°F Degrees Fahrenheit

A

ActEv Actions + Events (name of a Barco software product)

AGC Automatic Gain Control

ALC Automatic Light Control

AMLCD Active Matrix Liquid Crystal Display

ANSI American National Standards Institute

APA Automatic Phase Adjustment

AR Anti Reflective

a-Si TFT Amorphous Silicone Thin-Film Transistor

AWG American Wire Gauge

Abbreviations and acronyms

B

BARCO Belgian-American Radio Corporation

BCM Barco wall Control Manager

C

CAN Controller Area Network

CCFL Cold Cathode Fluorescent Lamp

CCIR Consulting Committee International

cd candela

CE Conducted Emissions, Conformity European (safety)

CIE Commission International de l’Éclairage (Illumination)

CM Console Mount

cm centimeter

CMS Control room Management Software

CoG Combined sync on Green

CR Contrast Ratio

CS Combined Sync

CS Conducted Susceptibility

CVBS Composite Video Blanking Sync

D

DAC Digital to Analog Converter

DC Direct Current

DDC Display Data Channel

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 43

Page 44

Abbreviations and acronyms

DM Display Module

E

EBU European Broadcast Union

EDID Extended Display Identification Data

EIA Electronic Industries Association

EMI / EMC Electromagnetic Interference / Electromagnetic Compatibility

EN European Norms

EOTF Electro Optical Transfer Function

ESD Electrostatic Discharge

F

FD Full Duplex

FLIR Forward Looking Infrared

FPDM Flat Panel Display Measurements

G

GPI General Purpos e Inte rface

H

HD Half Duplex

HDMI High Definition Multimedia Interface

HDSDI High Definition Serial Digital Interface

HE Highly Efficient

HEA High Efficiency Antireflective

HID Human Interface Device

HMI Human-Machine Interface

I

ICD Interface Control Document

IEC International Electrotechnical Commission

IP Ingress Protection

ISO International Standard Organization

ITO Indium Tin Oxide

ITU International Telecommunications Union

K

kg kilogram

L

LLuminance

LCD Liquid Crystal Display

LFC LCD Flicker Compensation

LRU Line Replaceable Unit

44 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 45

Abbreviations and acronyms

LUT Look Up Table

Lux Measure of illumination (lumens per meter squared)

M

mm millimeter

ms milliseconds

MTBF Mean-Time-Between-Failures

MTTR Mean-Time-To-Repair

N

NEMA National Electronics Manufacturers Association

NSL Near Seamless LCD

NTSC National Television Systems Committee

O

OSD On-Screen Display

P

PAL Phase Alternating Lines

ppi pixels per inch

PVA Patterned Vertical Alignment

PVC polyvinyl chloride

R

RE Radiated Emissions

RFU Reserved for Future Use

RGB Red, Green, Blue (letters/colors also referenced separately)

RH Relative Humidity

RHDM Reference High Definition Monitor

RM Rack Mount

ROT Rotator

RoHS Restrictions of Hazardous Substances

RS Radiated Susceptibility

S

SDI Serial Dig ital Inte rface

SDSDI Standard Definition Serial Digital Interface

SG Symbol Generator

SMPTE Society of Motion Picture and Television Engineers

SS Separate Sync

STANAG Standardization Agreement

SVGA Super Video Graphics Array

SXGA Super eXtended Graphics Array

T

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 45

Page 46

Abbreviations and acronyms

TBC To Be Confirmed

TBD To Be Defined

TBM To be Measured

TBT To Be Tested

TTL Transistor Transistor Logic

U

UMD Under Monitor Display

V

VDC Volts Direct Current

VESA Video Electronics Standards Association

VM VESA Mount

W

WWatt

46 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 47

Table of contents

12 Table of contents

1 About the manual.............................................................................. 3

1.1 Contents of the maintenance manual................................................... 3

1.2 Change record.................................................. ................................ 3

1.3 Notation convention .................................. ........................................ 4

2 Important notices, product safety precautions and package & storage...... 5

2.1 Read carefully .................................................................................. 5

2.2 Important notice............................................................................... 5

2.2.1 Copyright..........................................................................................5

2.2.2 Technical accuracy notice ....................................................................5

2.2.3 Federal Communication Commission (FCC) notice...................................5

2.2.4 Warranty...........................................................................................5

2.2.5 Trademarks.......................................................................................6

2.2.6 Open source license............................................................................6

2.3 Safety precautions ............................................................................ 7

2.3.1 Service safety precautions...................................................................7

2.3.2 Product safety notice ....... ...................................................................7

2.3.3 Earthing............................................................................................7

2.3.4 Electro Static Discharge (ESD) notice....................................................7

2.3.5 Electrical warnings and cautions...........................................................7

2.3.6 Environmental cautions.......................................................................8

2.3.7 Requirement for dusty environments ....................................................8

2.3.8 LCD screen........................................................................................8

2.3.9 Cover ...............................................................................................9

2.3.10 Hazardous materials .........................................................................9

2.4 Package and storage ......................................................................... 9

2.4.1 General.............................................................................................9

2.4.2 Procedure in case of damages..............................................................9

2.4.3 Storage........................................................................................... 10

2.4.4 Electrolytic capacitors ....................................................................... 10

2.4.5 Packaging ....................................................................................... 10

2.4.6 Repack instructions ................................................................... ....... 10

2.5 Contact information......................................................................... 11

3 About the product ........................................................................... 12

4 Board location ................................................................................ 15

4.1 Front cover .......................................................................... .......... 15

4.2 Back cover..................................................................................... 16

5 Hardware & software module overview............................................... 17

5.1 Hardware tree .............................................................. .................. 17

5.2 Software tree ...................... ........................................................... 18

6 Diagnostics .................................................................................... 19

6.1 Fault finding procedure .................................................. .................. 19

6.2 Start here....................................... ............................................... 19

6.3 Fault finding trees User Manual......................................................... 19

6.3.1 Description fault finding trees ............................................................ 19

6.3.2 "No power" fault finding tree.............................................................. 20

6.3.3 "Nothing observed on the screen" fault finding tree............................... 21

6.3.4 "Verify input signal" fault finding tree.................................................. 22

6.4 Connections .............................................................. ..................... 22

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 47

Page 48

Table of contents

6.5 Power diagnostics ........................................................................... 22

6.6 IRIS board diagnostics..................................................................... 23

6.7 Light diagnostics............................................................................. 24

6.8 Image diagnostics........................................................................... 24

6.9 Communication diagnostics .............................................................. 24

6.10 Color diagnostics........................................................................... 25

7 Removal and reinstallation of electronic boards ................................... 27

7.1 Service levels ...................................................... ........................... 27

7.2 Module replacements (level 2 and level 3)................................ .......... 27

7.3 Module replacements (level 4) .......................................................... 28

7.4 Spare part kits (level 2 and level 3)................................................... 28

7.5 Removal and installation precautions ................................................. 28

7.6 Required tools ........................................................ ........................ 28

7.7 Remove the brackets............................................................. .......... 29

7.8 Removal and reinstallation back cover ............................................... 29

7.9 Removal and reinstallation of the power supply................................... 32

7.10 Removal and reinstallation of the power interface board ..................... 34

7.11 Removal and reinstallation of HDSDI board....................................... 36

7.12 Removal and reinstallation of the communication board...................... 37

7.13 Removal and reinstallation of the control box.................................... 38

8 Interconnections............................................................................. 40

9 Adjustments................................................................................... 41

10 Maintenance................................................................................. 42

10.1 Cleaning precautions ..................................................................... 42

10.2 Cleaning instructions (for CIVIL)...................................................... 42

11 Abbreviations and acronyms ........................................................... 43

12.1 List of figures

Figure 1: Front cover – module overview .................................................................... 15

Figure 2: Back cover – module overview .................................................................... 16

Figure 3: Hardware tree RHDM-1701 ......................................................................... 17

Figure 4: Software tree RHDM-1701 .......................................................................... 18

Figure 5: “No power” fault finding tree ....................................................................... 20

Figure 6: “Nothing observed on the screen” fault finding tree ........................................ 21

Figure 7: “Verify input signal” fault finding tree ........................................................... 22

Figure 8: IRIS board indicator LEDs ........................................................................... 23

Figure 9: Removal of rack brackets ............................................................................ 29

Figure 10: Location of the screws that fix the back cover to the front cover ..................... 30

Figure 11: Location of cables that connect the electronic boards in the back cover with the elec-

tronic boards in the front cover. ................................................................................. 31

Figure 12: Correct clamping of the LVDS cables .......................................................... 32

Figure 13: Top view of the power supply .................................................................... 32

Figure 14: Location of screws and connectors of the power supply ................................. 33

Figure 15: Front view of the Power Interface Board ...................................................... 34

Figure 16: Indicator LEDs on the Power Interface Board ............................................... 34

Figure 17: Location of screws, cables and indicator LEDs on the Power Interface Board .... 35

Figure 18: Location of screws to remove/mount the HDSDI input board .......................... 36

Figure 19: Location of screws to replace the communication board ................................. 37

Figure 20: Control box .......................................... ................................................... 38

Figure 21: Location of screws, cables to remove or install the control box ....................... 38

48 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Page 49

Table of contents

Figure 22: Interconnection drawing .............................................................. ............. 40

12.2 List of tables

Table 1:Maintenance levels ....................................................................................... 27

Barco - RHDM-1701 - Maintenance Manual ______________________________________________ 49

Page 50

Table of contents

End of document

50 ______________________________________________ Barco - RHDM-1701 - Maintenance Manual

Loading...

Loading...