Page 1

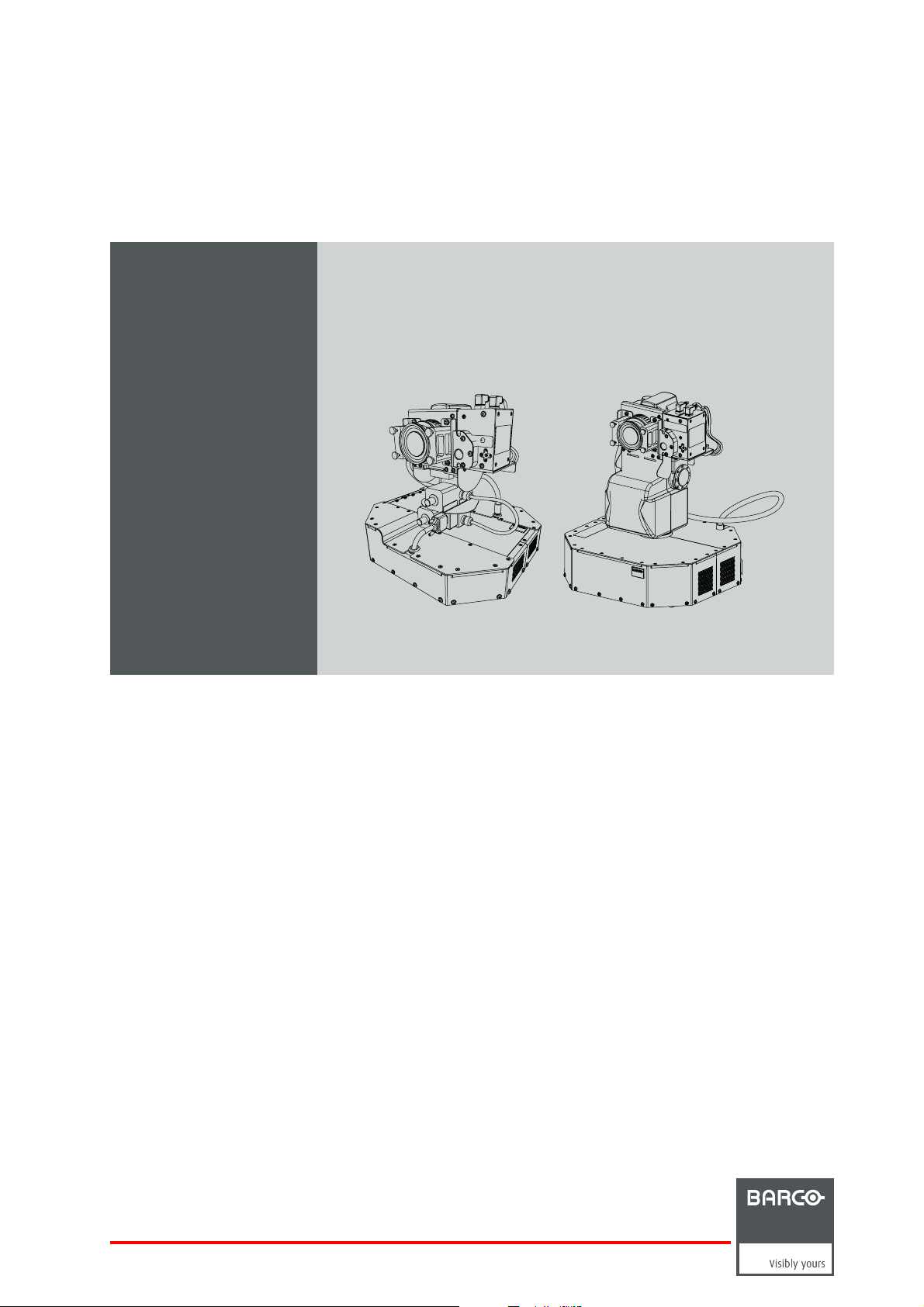

AutoAlignment Head Gen II

R59770509/10

26/11/2013

User and Installation guide

R9843500

R9843501

Page 2

Product revision

Software version: 3.11

Factory: Barco nv Advanced Visualization Systems

Noordlaan 5, B-8520 Kuurne

Phone: +32 56.36.82.11

Fax: +32 56.36.84.86

Support: www.barco.com/esupport

Visit us at the web: www.barco.com

Printed in Belgium

Page 3

Changes

Barco provides this manual ’as is’ without warranty of any kind, either expressed or implied, including but not limited to the implied warranties or merchantability and fitness for a particular purpose. Barco may make improvements and/or changes to the product(s) and/or the

program(s) described in this publication at any time without notice.

This publication could contain technical inaccuracies or typographical errors. Changes are periodically made to the information in this

publication; these changes are incorporated in new editions of this publication.

The latest edition of Barco manuals can be downloaded from the Barco web site w

h

ttps://my.barco.com.

ww.barco.com or from the secured Barco web site

Copyright ©

All rights reserved. No part of this document may be copied, reproduced or translated. It shall not otherwise be recorded, transmitted or

stored in a retrieval system without the prior written consent of Barco.

Barco XDS Software End-User License Agreement (EULA)

PLEASE READ THIS DOCUMENT CAREFULLY BEFORE OPENING OR DOWNLOADING AND USING SOFTWARE OR HARDWARE

PROVIDED TO YOU BY BARCO AS IT CONTAINS THE TERMS AND CONDITIONS BY WHICH BARCO OFFERS TO LICENSE THE

SOFTWARE. BY OPENING THE SOFTWARE PACKAGE, OR USING THE HARDWARE IN WHICH THE SOFTWARE IS EMBEDDED,

YOU AGREE TO BECOME BOUND BY THE TERMS OF THIS AGREEMENT. The Software as supplied by BARCO is licensed, not sold

to you, on a non-exclusive basis for use only under the terms of this license, and BARCO reserve all rights not expressly granted to you.

You own the disk(s) on which the Software is provided, but the Software is owned and copyrighted by BARCO or by third party suppliers.

Your license confers no title or ownership and is not a sale of any rights in the Software or its documentation.

By installing the Software, either as initial version or as an upgrade, update, patch or enhancement of a prior release, this Software License

shall supersede any terms and conditions previously agreed upon (whether or not in writing) between Barco and you with respect to the

subject matter of this Software License and such previous terms shall from the date hereof cease to have any force or effect; provided,

however that this Software License shall not be construed as a renunciation, discharge or waiver of any right or remedy provided in any

terms and conditions previously agreed upon with respect to a failure of either party to perform any of its obligations under any terms and

conditions previously agreed upon.

Software Specifications

The Software contains 2 main products:

• - XDS RACU (with Auto Alignment);

• - XDS Display Wall Software.

Software License Terms

1. This Software License is between you and BARCO NV, a corporation organized and existing under the laws of Belgium registered

under number BE 0473.191.041, Commercial Companies’ Register of Kortrijk, having its registered office President Kennedypark, 35

at B-8500 Kortrijk, Belgium ("Barco") for the use of the Software.

You hereby undertake to inform all Authorized Users of the terms of this Software License and to bind all Authorized Users to accept all

such terms of this Software License as applies to them. Barco grants you a limited, non-exclusive, non-assignable, non-transferable

license (without the right to grant sublicenses) and right to install the Software on your network for use by you and/or any Authorized

User(s). You agree to notify Barco prior to moving the Software to any network other than the originally installed network.

2. The Software is licensed to you as a network-enabled product. The Software component parts must not be separated or replicated

in any manner. You and Authorized Users are entitled to use the Software for the purposes and in the manner set out in this EULA

(and documentation), but neither you nor any Authorized User are entitled to: (i) sell or grant a security interest in the Software to

other parties in any way, or to rent, lease or sub-license the Software to others without the express prior written consent of Barco; or

(ii) exploit the Software or any of its component parts for any commercial purpose, other than use by you and/or Authorized Users of

the Software.

Page 4

3. Barco shall hold you harmless and indemnify you from and against direct damages, losses and expenses arising from infringement

or alleged infringement of any patent, trademark or copyright of such third party by the license and the right to install the Software as

permitted by this Software License and defend and settle at its sole expense any claim, action, suit or proceeding brought against you,

provided that (i) you promptly notify Barco in writing after a claim has been asserted against you or the commencement of any claim,

action, suit or proceeding, and (ii) Barco shall assume sole control of the defense and any settlement negotiations related to any claim,

action, suit or proceeding, and (iii) you shall not negotiate, settle or compromise any claim, action, suit or proceeding without the prior

written consent of Barco and (iv) you, at your cost, shall cooperate with Barco and provide assistance and support, as may reasonably

required by Barco, in connection with the defense and any settlement negotiations related to any claim, action, suit or proceeding.

Barco shall have no indemnity obligation for any Software, or any portion thereof, (i) that is based on specifications, drawings, models

or other data furnished by you or, (ii) that is not provided by Barco or, (iii) that is modified, in spite of the prohibition for you to modify

the software or, (iv) to the extent that you continue allegedly infringing activity after having been provided modifications that avoid the

alleged infringement, or (v) where the use of the Software, or the combination or thereof with other Software, processes or materials or

the distribution thereof rather than the Software itself is the primary cause of an alleged infringement. In case it has been determined

by a finally awarded judgment that Barco infringed or misappropriated such third party rights or earlier, at Barco’s discretion, it may, at

its option and cost, (i) modify the Software in such a way that it shall not infringe upon or misappropriate the rights of the third party or

(ii) obtain for you a license or other right to use the rights allegedly infringed or (iii) replace the Software in question with non-infringing

Software. The remedies set forth in this paragraph shall constitute your sole and exclusive remedy and Barco’s sole and exclusive

liability for a third party claim that the Product infringes or misappropriates any intellectual property right of a third party.

4. Barco (and Barco’s licensors, as appropriate) retain ownership of all intellectual property rights in the Software and any copies you or

any Authorized User may make of such Software. The Software is protected by national copyright laws, international copyright treaties

and conventions, and other applicable laws. All rights not expressly licensed to you in this Software License are reserved to Barco

and Barco’s licensors, as appropriate. The Software contains certain other licensed materials and Barco’s licensors may protect their

rights in the event of any violation of this Software License. Neither you nor any Authorized User may, whether in whole or in part,

copy, translate, reverse engineer, derive source code from, modify, disassemble, decompile, create derivative works based on the

Software, or remove any proprietary notices or labels on the Software, save as may be permitted by law or this Software License,

without the prior consent, in writing, of Barco.

This software uses:

- the OpenSSL library, (c) 1998-2008 The OpenSSL Project. The full license can be found in OpenSSLWin32License.txt;

- the Crypto++ library, (c) 1995-2009 by Wei Dai. The full license can be found in cryptopplicense.txt

- the Ogg Vorbis libraries, (c) 2002-2008 the Xiph.org Foundation. The full license can be found in oggvorbislicense.txt;

- the OpenCV library, (C) 2000-2006, Intel Corporation. The full license can be found in OpenCVLicense.txt

This software is based in part on the work of the Qwt project (http://qwt.sf.net).

5. The duration of this Software License will be from the date of your acceptance (as set forth above) of the Software, with no termination

date, unless otherwise specified. You may terminate

in your possession and returning all associated materials and documentation, to Barco or the appointed Barco reseller that sold or

provided these to you. Barco may terminate this Software License forthwith by informing you at any time if you and/or any Authorized

User are in breach of any of the Software License

6. YOU UNDERSTAND THAT THE SOFTWARE IS BEING PROVIDED TO YOU "AS IS". BARCO DOES NOT MAKE NOR INTENDS

TO MAKE ANY WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED AND SPECIFICALLY DISCLAIMS ALL IMPLIED

WARRANTIES OF MERCHANTABILITY FITNESS, FOR A PARTICULAR PURPOSE AND NON-INFRINGEMENT OF INTELLECTUAL PROPERTY AND DOES NOT WARRANT THAT THE SOFTWARE WILL BE FREE FROM ERRORS OR THAT SUCH ERRORS

WILL BE CORRECTED BY BARCO AND YOU ARE SOLELY RESPONSIBLE FOR ALL COSTS AND EXPENSES ASSOCIATED

WITH RECTIFICATION, REPAIR OR DAMAGE CAUSED BY SUCH ERRORS.

YOU ALSO ACKNOWLEDGE AND AGREE THAT:

BARCO ACCEPTS NO LIABILITY FOR ANY DAMAGES, LOSSES OR CLAIMS YOU OR ANY THIRD PARTY MAY SUFFER AS A

RESULT OF YOUR USE OF THE SOFTWARE, AND YOU HEREBY AGREE TO INDEMNIFY, KEEP INDEMNIFIED, DEFEND AND

HOLD HARMLESS BARCO AND BARCO’S AFFILIATES AND SUBSIDIARIES FROM AND AGAINST ANY AND ALL ACTIONS,

PROCEEDINGS, LIABILITY, LOSS, DAMAGES, FEES AND COSTS (INCLUDING ATTORNEYS’ FEES), AND OTHER EXPENSES

INCURRED OR SUFFERED BY BARCO ARISING OUT OF OR IN CONNECTION WITH ANY BREACH BY YOU OF THE TERMS OF

THIS SOFTWARE LICENSE. TO THE MAXIMUM EXTENT PERMITTED BY LAW, IN NO EVENT WILL BARCO BE LIABLE FOR ANY

INDIRECT, SPECIAL, PUNITIVE, INCIDENTAL OR CONSEQUENTIAL LOSS OR DAMAGES OF ANY KIND WHICH MAY ARISE

OUT OF OR IN CONNECTION WITH THE SOFTWARE, THIS SOFTWARE LICENSE OR THE PERFORMANCE OR PURPORTED

PERFORMANCE OF OR FAILURE IN THE PERFORMANCE OF BARCO’S OBLIGATIONS UNDER THIS SOFTWARE LICENSE

OR FOR ANY ECONOMIC LOSS, LOSS OF BUSINESS, CONTRACTS, DATA, GOODWILL, PROFITS, TURNOVER, REVENUE,

REPUTATION OR ANY LOSS ARISING FROM WORK STOPPAGE, COMPUTER FAILURE OR MALFUNCTION OF THE SOFTWARE AND ANY AND ALL OTHER COMMERCIAL DAMAGES OR LOSSES WHICH MAY ARISE IN RESPECT OF USE OF THE

SOFTWARE, EVEN IF BARCO HAS BEEN ADVISED OF THE POSSIBILITY OF THEIR OCCURRENCE; AND

7. You shall treat as confidential all information obtained from the other pursuant to this Software License which is marked ’confidential’

or the equivalent or has the necessary quality of confidence about it and shall not divulge such information to any persons without

Barco’s prior written consent provided that this Paragraph 7 shall not extend to information which was rightfully in the possession of

you prior to the commencement of the negotiations leading to this Software License, which is already public knowledge or becomes

so at a future date (otherwise than as a result of a breach of this paragraph 7), is required to be disclosed by law or which is trivial or

obvious. You are aware of and ensure to comply with the provisions of this paragraph 7. The foregoing obligations as to confidentiality

shall survive any termination of this Software License.

this Software License at any time by destroying all copies of the Software then

’s terms.

Page 5

8. You agree with and fully accept the following limited service and support statements.

Barco may limit or terminate any Support Services being provided if you use any Support Services in an abusive or fraudulent manner,

as determined by Barco in its reasonable discretion. Resale, assignment and transfer of ownership are strictly prohibited and will be

grounds for termination of the License Agreement, unless otherwise agreed in writing. A single support incident will be restricted

to support on an issue that focuses on one aspect of the product – e.g. use of a specific documented feature of the product or

assistance with a specific problem or error message. While this issue may involve other aspects of the product, addressing other

aspects constitutes a separate issue and requires an additional support incident. A single support incident may involve multiple phone

calls, emails and off-line research. Barco will determine what characterizes a single support incident and communicating this to you.

Unless a contractual agreement states differently, Barco will make reasonable efforts to resolve the issue but Barco cannot guarantee

that every issue will be resolved.

Barco shall not be obliged to provide any Support Services relating to problems or issues arising out of or from (i) the use of the

Software in a manner for which they were not designed; (ii) damage to the media on which the Software are provided or to the

computer on which the Software are installed; (iii) negligence, misuse, or modification of the Software; (iv) versions of Software other

than the most recent version (e.g., 5.x) and one version back (e.g., 4.x), provided that Barco shall also not be required to provide

any Support Services for Software that are no longer listed on the Barco Site as supported Software; (v) third-party Software and

technologies not associated with network installation assistance or (vii) conflicts related to replacing or installing hardware, drivers,

and software.

You will remain responsible for the maintenance of your hardware, operating system, the functioning of your network and in keeping

your systems virus-free. You acknowledge that the Software is a complex computer software application, and that the performance

thereof may vary depending hardware platform, software interactions and configuration. You acknowledge that the Software is not

designed and produced specifically to meet your specific requirements and expectations and the selection of the Software by you is

entirely your own choice and decision.

The Software has to be installed on a computer delivered by Barco or by yourself. The XDS Racu software is only compatible with

Microsoft Windows XP and Microsoft Windows XP Embedded. The XDS Display Wall Software is only compatible with Microsoft

Windows XP, Vista or Windows 7.

For the avoidance of doubt, nothing in this clause shall impose any obligation on Barco to provide Services not covered by the License

Agreement.

9. This Software License is the only understanding and agreement between you and Barco for use of the Software by you and/or Authorized Users. The Software License supersedes all other communications, understandings or agreements we had prior to this Software

License (with the exception of any continuing confidentiality agreement) although nothing in this Software License purports to exclude

liability for fraudulent misrepresentation. You may not export or re-export the Software or any copy or adaptation in violation of any

applicable laws or regulations. This Software License shall not be altered, amended or varied. If any provision of this Software License is determined to be illegal, void or unenforceable, or if any court of competent jurisdiction in any final decision so determines,

this Software License shall continue in full force save that such provision shall be deemed to be deleted with effect from the date of

such decision, or such earlier date.

10. You acknowledge that this Software may be subject to U.S. or other governments Export Jurisdiction. You agree to comply with all

applicable international and national laws that apply to the Software, including the U.S. Export Administration Regulations, as well as

end-user, end-use, and destination restrictions issued by the U.S. or other governments.

11. Barco shall be entitled to sub-contract all or any of Barco’s obligations hereunder to a third party and/or any of Barco’s affiliated

companies.

12. The construction, validity and performance of this Software License shall be governed in all respects by the laws of Belgium without

recourse to its conflict of law principles. All disputes arising in any way out of or affecting this Software License shall be subject

to the exclusive jurisdiction of the courts of Kortrijk, without prejudice to enforcement of any judgment or order thereof in any other

jurisdiction.

13. The United Nations Convention on Contracts for the International Sale of Goods (the "Convention") shall not apply to this Software

License, however, if the Convention is deemed by a court of competent jurisdiction to apply to this Software License, Barco shall not

be liable for any claimed non-conformance of the Software under Article 35(2) of the Convention.

Trademarks

Brand and product names mentioned in this manual may be trademarks, registered trademarks or copyrights of their respective holders.

All brand and product names mentioned in this manual serve as comments or examples and are not to be understood as advertising for

the products or their manufacturers.

Guarantee and Compensation

Barco provides a guarantee relating to perfect manufacturing as part of the legally stipulated terms of guarantee. On receipt, the purchaser

must immediately inspect all delivered goods for damage incurred during transport, as well as for material and manufacturing faults Barco

must be informed im

The period of guarantee begins on the date of transfer of risks, in the case of special systems and software on the date of commissioning,

at latest 30 days after the transfer of risks. In the event of justified notice of complaint, Barco can repair the fault or provide a replacement

at its own discretion within an appropriate period. If this measure proves to be impossible or unsuccessful, the purchaser can demand a

reduction in the purchase price or cancellation of the contract. All other claims, in particular those relating to compensation for direct or

indirect damage, and also damage attributed to the operation of software as well as to other services provided by Barco, being a component

mediately in writing of any complaints.

Page 6

of the system or independent service, will be deemed invalid provided the damage is not proven to be attributed to the absence of properties

guaranteed in writing or due to the intent or gross negligence or part of Barco.

If the purchaser or a third party carries out modifications or repairs on goods delivered by Barco, or if the goods are handled incorrectly,

in particular if the systems are commissioned operated incorrectly or if, after the transfer of risks, the goods are subject to influences not

agreed upon in the contract, all guarantee claims of the purchaser will be rendered invalid. Not included in the guarantee coverage are

system failures which are attributed to programs or special electronic circuitry provided by the purchaser, e.g. interfaces. Normal wear as

well as normal maintenance are not subject to the guarantee provided by Barco either.

The environmental conditions as well as the servicing and maintenance regulations specified in the this manual must be complied with by

the customer.

Disposal Information

Waste Electrical and Electronic Equipment

This symbol on the product indicates that, under the European Directive 2012/19/EU governing waste from electrical and electronic

equipment, this product must not be disposed of with other municipal waste. Please dispose of your waste equipment by handing it over to

a designated collection point for the recycling of waste electrical and electronic equipment. To prevent possible harm to the environment

or human health from uncontrolled waste disposal, please separate these items from other types of waste and recycle them responsibly

to promote the sustainable reuse of material resources.

For more information about recycling of this product, please contact your local city office or your municipal waste disposal service. For

details, please visit the Barco website at: h

ttp://www.barco.com/en/AboutBarco/weee

Federal Communications Commission (FCC Statement)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area may

cause harmful interference, in which case the user will be responsible for correcting any interference at his own expense

Turkey RoHS compliance

Türkiye Cumhuriyeti: AEEE Yönetmeliğine Uygundur.

[Republic of Turkey: In conformity with the WEEE Regulation]

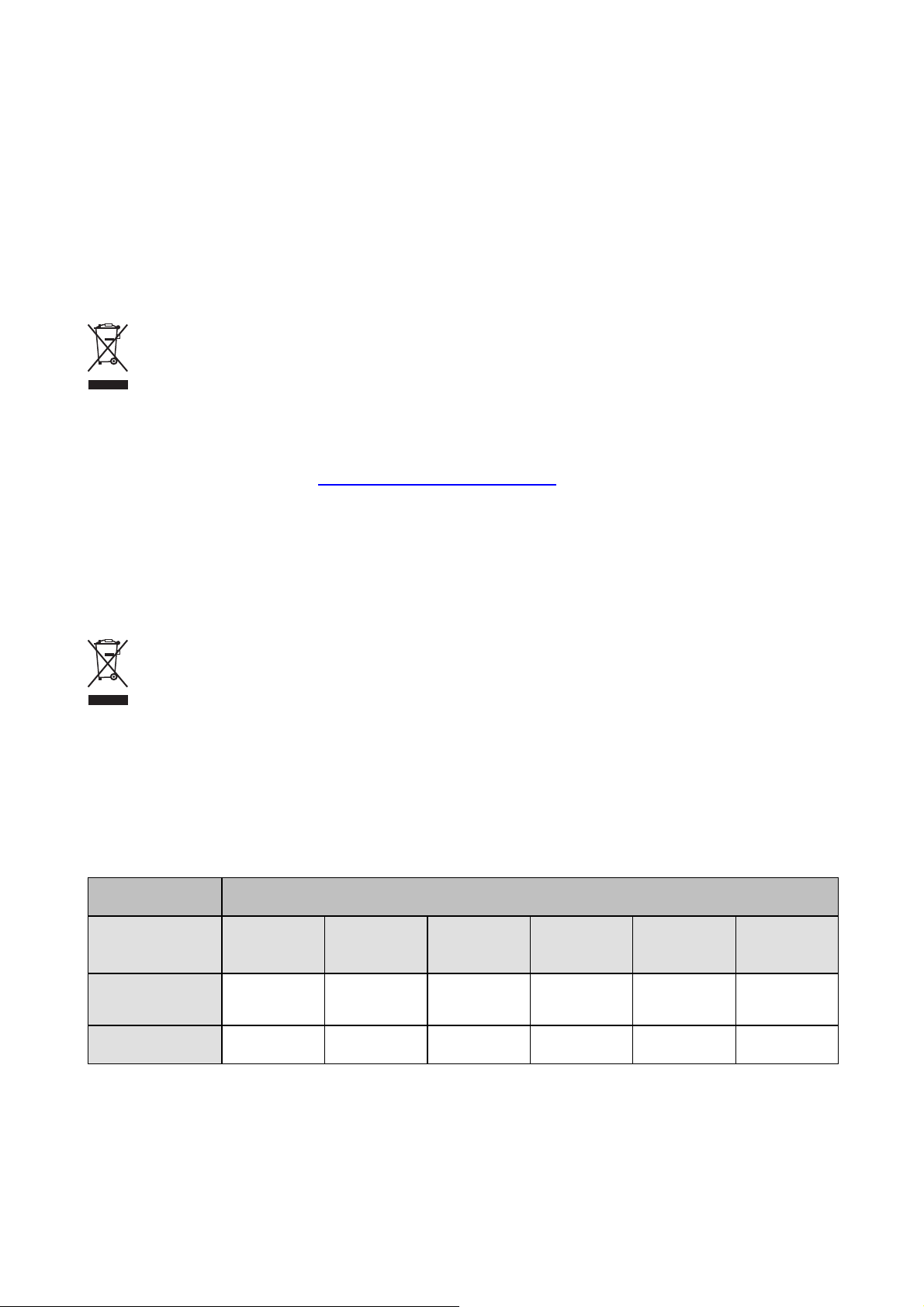

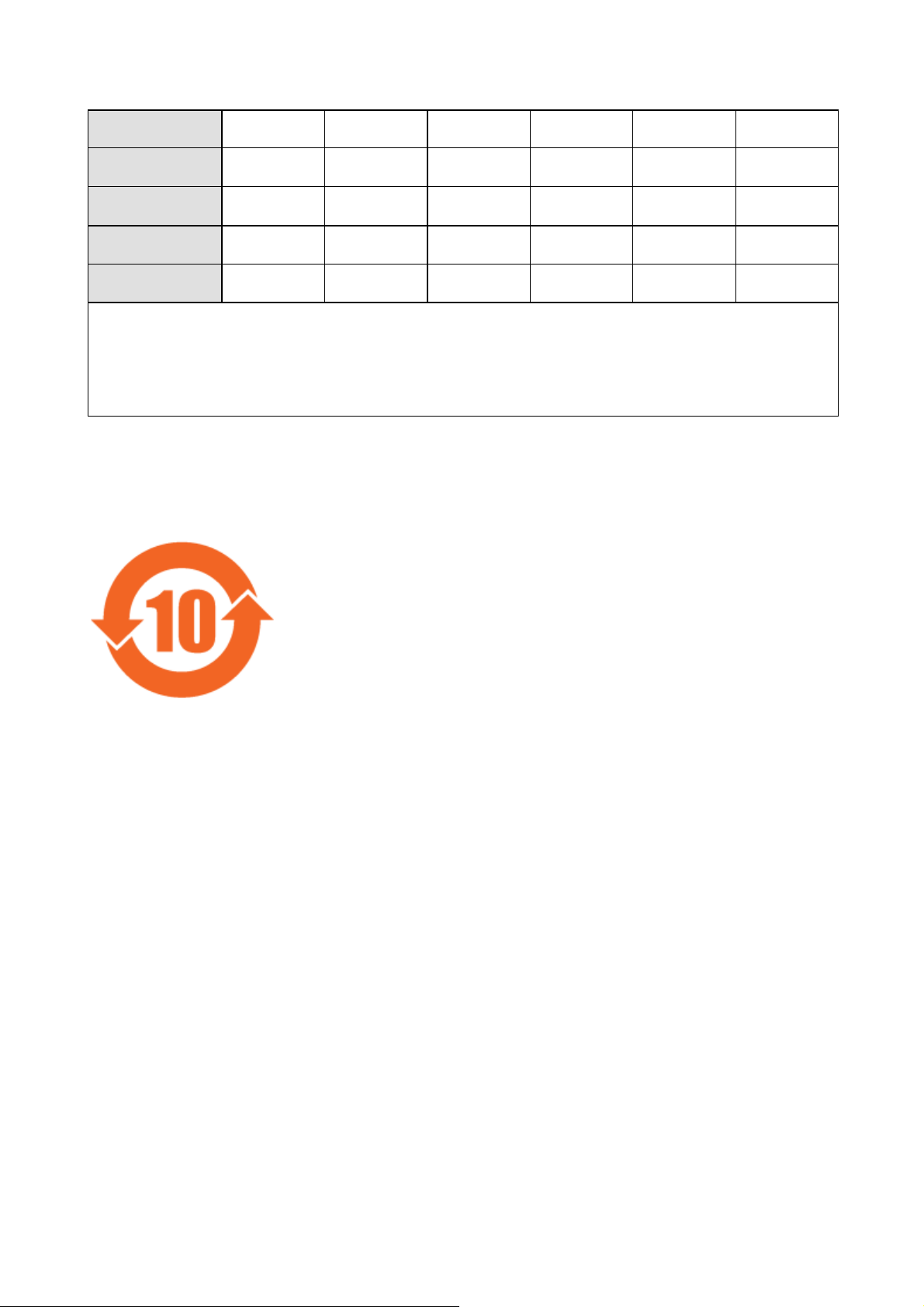

中国大陆 RoHS – Chines e Mainland RoHS

根据中国大陆《 电子信息产品污染控制管理办法》(也称为中国大陆 RoHS), 以下部分列出了Barco产品中可能包含的有毒和/或有害物质

的名称和含量。中国大陆RoHS指令包含在中国信息产业部MCV标准:“电子信息产品中有毒物质的限量要求”中。

According to the “China Administration on Control of Pollution Caused by Electronic Information Products” (Also called RoHS of Chinese

Mainland), the table below lists the names and contents of toxic and/or hazardous substances that Barco’s product may contain. The RoHS

of Chinese Mainland is included in the MCV standard of the Ministry of Information Industry of China, in the section “Limit Requirements

of toxic substances in Electronic Information Products”.

零件项目 (名称)

Component Name

印制电路配件

Printed Circuit

Assemblies

电( 线)缆

Cables

有毒有害物质或元素

Hazardous Substances or Elements

铅

(Pb)

x

x

汞

(Hg)

0

0

镉

(Cd)

六价 铬

(Cr6+)

x

x

000

000

多溴联苯

(PBB)

多溴 二苯醚

(PBDE)

Page 7

底架

Chassis

电源供应 器

x

x

0

0

x

x

000

000

Power Supply Unit

文件说明 书

000000

Paper Manuals

光盘说明 书

CD Manual

光学部件

000000

x

0

x

000

Optical components

O: 表示该有毒有害物质在该部件所有均质 材料中的含量均在 SJ/T 11363-2006 标准规定的限量要求以下.

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement in SJ/T11363-2006.

X: 表示该有毒有害物质至少在该部件的某一均质材料中的含量超出 SJ/T 11363-2006 标准 规定的限量要求.

X: Indicates that this toxic or hazardous substance contained in at least one of the homogeneous materials used for this part is

above the limit requirement in SJ/T11363 2006.

在中国大陆销售的相应电子信息产品(EIP)都必须遵照中国大陆《电子信息产品污染控制标识要求》标准贴上环 保使用期限(EFUP)标签。

Barco产品所采用的EFUP标签(请参 阅实例,徽标内部的编号使用于制定产品)基于中国大陆的《电子信息产品 环保使用期限通则》标准。

All Electronic Information Products (EIP) that are sold within Chinese Mainland must comply with the “Electronic Information Products

Pollution Control Labeling Standard” of Chinese Mainland, marked with the Environmental Friendly Use Period (EFUP) logo. The number

inside the EFUP logo that Barco uses (please refer to the photo) is based on the “Standard of Electronic Information Products Environmental Friendly Use Period” of Chinese Mainland.

Image -1

Page 8

Page 9

Table of contents

TABLE OF CONTENTS

1. About ................. ................ ................ ................ ................ ................ ................ 5

1.1 Versions............................................................................................................................... 5

1.2 About this manual . . .................................................................................................................. 5

1.3 Related products .. ................................................................................................................... 5

1.4 Symbols and fonts . ................................................................................................................... 6

2. Safety................................................................................................................. 7

2.1 Safetylabels.......................................................................................................................... 7

2.2 Safetyandwarnings.................................................................................................................10

2.2.1 Noticeon safety...............................................................................................................10

2.2.2 Installation instructions........................................................................................................11

2.2.3 Owner’s record................................................................................................................11

2.2.4 Warnings......................................................................................................................11

2.2.5 Plug types.....................................................................................................................11

2.2.6 Prevent personal injury .......................................................................................................12

2.2.7 Devicedamage ...............................................................................................................12

2.2.8 Environment condition check .................................................................................................12

2.2.9 Repacking .....................................................................................................................13

2.2.10 Emergency stop...............................................................................................................13

2.2.11 Moving parts ..................................................................................................................13

2.2.12 Class2 laser ..................................................................................................................14

2.2.13 SFTP Cat.5e cable warning ..................................................................................................14

2.2.14 Vibrations......................................................................................................................15

3. Compliancy.........................................................................................................17

3.1 EMC shieldingclamps...............................................................................................................17

4. Packaging...........................................................................................................19

4.1 Content...............................................................................................................................19

4.2 Unpacking . . . ........................................................................................................................19

4.3 Shipping bracket.....................................................................................................................22

4.3.1 Removing the shipping bracket...............................................................................................23

4.3.2 Installing the shipping bracket ................................................................................................23

5. Facility and system requirements........... ................ ................ ................ ................ ...25

5.1 Environmental requirements ........................................................................................................25

5.2 Dimensions ..........................................................................................................................25

5.3 Air flow requirements ................................................................................................................27

5.4 Power requirements .................................................................................................................28

5.5 View requirements. . .................................................................................................................28

5.6 Access requirements ................................................................................................................28

5.7 Luminance requirements . . . .........................................................................................................29

6. Specifications ......................................................................................................31

6.1 Hardware layout .....................................................................................................................31

6.2 Gimbal range ........................................................................................................................33

6.3 Camera FOV.........................................................................................................................34

7. Installation..........................................................................................................35

7.1 Mechanical installation ..............................................................................................................35

7.2 Hardware connections...............................................................................................................37

7.2.1 Preparing SFTP Cat.5e cable ................................................................................................37

7.2.2 Power connections............................................................................................................38

7.2.3 Connecting the LEX unit to the MCU. ........................................................................................39

7.2.4 Connecting the SFTP Cat.5e cable . . ........................................................................................39

7.2.5 Connection diagram . .........................................................................................................40

7.3 Driverinstallation ....................................................................................................................41

7.4 Uploading the calibration files.......................................................................................................41

7.4.1 Uploading the spectrometer calibration file ..................................................................................41

7.4.2 Uploading the camera calibration file ........................................................................................42

7.5 Importing the license file ............................................................................................................43

7.6 Camera settings .....................................................................................................................43

7.6.1 Fixed camera settings ........................................................................................................43

7.6.2 Lens cap.......................................................................................................................44

7.6.3 Zoom ..........................................................................................................................44

7.6.4 Focus.......................................................................................................................... 45

7.7 AutoAlignment parameters..........................................................................................................46

8. Getting started .............. ................ ................ ................ ................ .................. .....49

8.1 Starting up the MCU, eRACU and AutoAlignment Head...........................................................................49

8.1.1 Starting up theMCU..........................................................................................................49

8.1.2 Starting up theeRACU .......................................................................................................50

8.1.3 Starting up theAutoAlignment Head .........................................................................................50

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

1

Page 10

Table of contents

8.2 Connecting to a display .............................................................................................................51

8.3 Configuring the software ............................................................................................................ 52

8.4 Defining multiple head location . . . ..................................................................................................52

8.5 Setting Gimbal Home Position ......................................................................................................54

8.6 Defining positions....................................................................................................................55

8.6.1 Displaying the Positioning Page..............................................................................................55

8.6.2 Acurasposition................................................................................................................56

8.6.2.1 Defining Acuras 1-point position.......................................................................................57

8.6.2.2 Defining Acuras Multi-point ............................................................................................61

8.6.2.2.1 Description of theAcurasMulti-point............................................................................61

8.6.2.2.2 Defining the Panel Markers......................................................................................65

8.6.2.2.3 Defining the Gimbal positions....................................................................................71

8.6.3 AutoGeometryposition: Faceted display ....................................................................................76

8.6.3.1 Difference betweenAutoGeometryfaceted and warp display........................................................76

8.6.3.2 Defining AutoGeometry position: standard channels .................................................................77

8.6.3.3 Defining AutoGeometry position: Head-Up Display...................................................................85

8.6.3.4 Creating Mask image...................................................................................................89

8.6.4 AutoGeometryposition: Warpdisplay........................................................................................90

8.6.4.1 Difference betweenAutoGeometryfaceted and warp display........................................................90

8.6.4.2 Defining the AutoGeometry position...................................................................................90

8.6.5 OmniBlendposition ...........................................................................................................96

8.6.5.1 OmniBlendposition explained.........................................................................................96

8.6.5.2 Defining OmniBlend position...........................................................................................98

8.6.5.3 Creating Mask image..................................................................................................103

8.7 ECRcalibration .....................................................................................................................104

9. Dynacolor™ calibration ........................................................................................ 107

9.1 Dynacolorcalibration...............................................................................................................107

9.2 Matching Dynacolor setsof multiple projectors ...................................................................................109

9.3 Dynacolorcalibration: Color alignment............................................................................................112

9.4 Undoing a color alignment . ........................................................................................................113

10. Operating Acuras................................................................................................ 115

10.1 Preconditions .......................................................................................................................116

10.1.1 CLO regression principle ....................................................................................................116

10.1.2 Conditions for Acuras Capture and Realign ................................................................................118

10.2 Gray LevelCorrection ..............................................................................................................118

10.2.1 Startingthe Gray Level Correctionprocess.................................................................................119

10.2.2 Restoring the Gray Level Correction........................................................................................120

10.2.3 Undoing the Gray Level Correction .........................................................................................121

10.3 AcurasCapture.....................................................................................................................121

10.4 AcurasRealignment................................................................................................................124

10.5 Undoing an Acuras realignment . ..................................................................................................128

10.6 Restoringthe whiteuniformity factorysettings....................................................................................129

10.7 DeletingAcurasrealignment data..................................................................................................131

11. Operating AutoGeometry: Faceted display ................................................................ 133

11.1 AutoGeometryCapture.............................................................................................................133

12. Operating AutoGeometry: Warp display .................................................................... 137

12.1 AutoGeometryCapture.............................................................................................................137

12.2 AutoGeometryRealignment........................................................................................................139

12.3 DeletingWarp Realignment data ................................................................................................. .141

13. Operating OmniBlend ........... ................ ................ ................ ................ ............... 145

13.1 The OmniBlend process............................................................................................................145

13.2 Displaying the OmniBlend page .................................................................................................. .145

13.3 StartingOmniBlendprocess: projectorbasis......................................................................................146

13.4 StartingOmniBlendprocess: position basis.......................................................................................147

13.5 Undoing an OmniBlend process . . .................................................................................................148

14. Replacing devices.......... ................ ................ ................ ................ .................. ... 151

14.1 Replacinga camera ................................................................................................................151

14.2 Replacinga spectrometer..........................................................................................................152

14.3 Replacinga laser ...................................................................................................................152

15. Troubleshooting ................ .. . . . . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . 155

15.1 Empty displaylist ...................................................................................................................155

15.2 AutoAlignment Head ...............................................................................................................156

15.3 LEX Unit ............................................................................................................................156

15.4 Camera .............................................................................................................................157

15.5 Laserpointer........................................................................................................................159

15.6 Spectrometer .......................................................................................................................160

15.7 Gimbal ..............................................................................................................................162

15.8 USB device not detected...........................................................................................................163

2

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 11

Table of contents

A. CE declaration..................................................................................................... 165

A.1 CE declaration......................................................................................................................165

Index..................... .................. ................ ................ ................ ................ ............. 167

List of images.................... ................ ................ ................ ................ ................ ..... 171

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013 3

Page 12

Table of contents

4 R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 13

1. ABOUT

For the latest updates of this manual, browse to www.barco.com (public) or https://my.barco.com (secured)

or Intranet (Barco employees only).

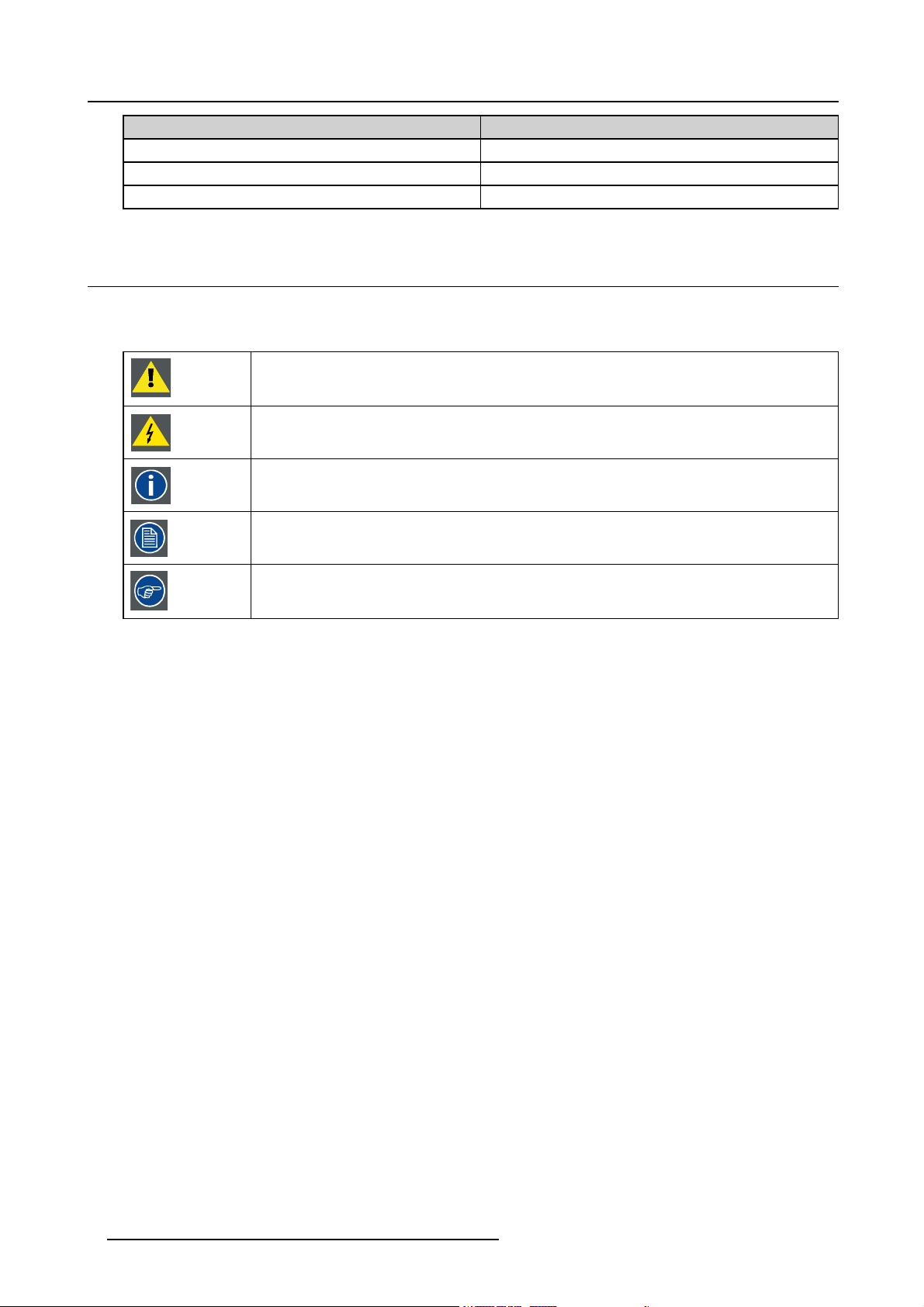

1.1 Versions

Versions

By the time of release of this manual, two different versions of AutoAlignment Head are available: AutoAlignment Head Gen II

(R9843500) and AutoAlignment Head Gen II Rugged (R9843501).

AutoAlignment Head Gen II is also referred to as AutoAlignment Head and MES ACURAS HEAD

CAUTION: Due to a supplier component change, the AutoAlignment Head Gen II Rugged (R9843501) uses

a new rugged gimbal from serial number 1199151060 onwards. The new gimbal is automatically detected

from XDS version V3.11 onwards. For existing installations (XDS below V3.11), a patch will be made available

through Barco support or an upgrade to XDS version 3.11 will be advised where needed.

1. About

1.2 About this manual

About this manual

Partnumber Description Level

R59770509 User and installation guide Installer and user

Always check for the latest version of the manual on https://my.barco.com.

Graphics and contents

Depending on the XDS RACU software version, some graphics might be slightly different to the ones used in this manual. This

however does not have any effect to the functionality.

Depending on the AutoAlignment Head version, some graphics might be slightly different for the given version to the ones used in

this manual. This however, does not have any effect on their functionality.

The differences between both AutoAlignment Head versions (standard and rugged) are illustrated through graphics and/or content.

If no version is specified in a procedure, it applies to both standard version and rugged version If a procedure applies to one version

only, it is explicitly stated.

1.3 Related products

Software related products

The main tools are the following:

Description Installed on the ...

XDS RACU server software MCU

XDS RACU client software eRACU hand held unit

Hardware related products

Description

MCU

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013 5

Used as/for ...

server

Page 14

1. About

Description

eRACU hand held unit

AutoAlignment Head Automatic measurements and alignment

Barco Rugged Automatic measurements and alignment

Used as/for ...

Remote control touch screen panel

1.4 Symbols and fonts

Symbol overview

The following icons are used in the manual :

Caution

Warning

Info, term definition. General info about the term

Note: gives extra information about the described subject

Tip: gives extra advice about the described subject

Font overview

• Buttons are indicated in bold, e.g. OK.

• Menu items are indicated in italic.

• Step related notes, tips, warnings or cautions are printed in italic.

• Procedure related notes, tips, warnings or cautions are printed in bold between 2 lines preceded by the corresponding icon.

6

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 15

2. SAFETY

Overview

• Safety labels

• Safety and warnings

2.1 Safety labels

Overview of the safety labels

The table below lists all of the safety related labels that are available on the MES ACURAS HEAD (standard and rugged) versions.

Carefully read these labels and act accordingly.

Label Description

Refer to the manual for more detailed information.

2. Safety

LASER RADIATION : DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL À LASER DE CLASSE 2

䉏⏘戟⺓ₜ尐⑬展䟄㽱

Max output / Puissance de sortie max / 㦏⮶戢⒉= 1mW

Wavelength / Longeur d’onde / 㽱栎 = 650 nm

儶䉏⏘ℶ䞮

IEC 60825-1 Ed. 2.0 2007

LASER APERTURE

OUVERTURE LASER

䉏⏘戟⺓ⷣ㈓

Fingers can be clamped between moving parts. (Only available

on standard version).

Class 2 laser radiation: do not stare into the beam.

Position of the laser aperture.

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013 7

Page 16

2. Safety

Label Description

WARNING: Hazardous moving parts.

Keep fingers and other body parts away.

ATTENTION: Parties mobiles dangereuses.

Tenir eloignés les doits et autres parties du corps.

巵⛙᧶☀棸扟┷捷ↅᇭ㓚㖖✛愺⇢␅Ⅵ捷⒕庆扫䱊

C

N

Y

M

E

E

E

G

R

D

T

Ê

R

R

A

S

U

’

T

R

G

O

E

N

P

C

E

Moving parts: keep fingers, other body parts, loose clothes,

jewelry, rings etc. away.

FDA compliancy

Emergency stop: engage in case of a dangerous situation. Do

not reset before the situation is fully safe again.

侶

㊴

! WARNING !

The RJ-45 connector is not an Ethernet connection. Do not connect

to an Ethernet port. Possible risk of damage to the equipment and port!

! ATTENTION !

Le connecteur RJ-45 n’est pas un connecteur Ethernet. Ne pas connecter

sur un port Ethernet. Risque d’endommager le matériel et le port!

巵⛙

5-扭㘴⣷ₜ㢾₹ⅴ⮹几扭㘴ↅᇭₜ尐㘴⏴ⅴ⮹几䵾♲ᇭ

♾厌㦘㗮⧞幍✛䵾♲䤓歝棸ᇭ

㷱

⋫

WARNING : Check manual for shipping instructions

ATTENTION : Consultez le manuel pour

les instructions d’expédition

巵⛙᧶㩴䦚孔扟㖖ⅳ㓚␛

This RJ45 connector is not a network connector. One of the

pins is a power signal.

Check manual for shipping instruction. (Only available on

rugged version).

8 R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 17

Position of the safety labels (on standard version)

Image 2-2

Image 2-1

Labels: position

1 Laser aperture

2 Laser radiation

3Clampedfingers

Labels: position

1 Clamped fingers

2Movingparts

3 Emergency stop

4 Refer to manual for information

5 RJ45 connector is not an Ethernet connection

2. Safety

Image 2-3

Labels: position

1Clampedfingers

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013 9

Page 18

2. Safety

2Clampedfingers

Position of the safety labels (on rugged version)

Image 2-4

Labels: position

1 Check manual for shipping instruction

2 Laser aperture

3 Laser radiation

Image 2-5

Labels: position

1Movingparts

2 Emergency stop

3 Refer to manual for information

4 RJ45 connector is not an Ethernet connection

2.2 Safety and warnings

About this chapter

It is necessary to read this chapter prior to starting any activity on the device. It contains valuable and critical information to ensure

safety of the operator, the service technician or other people in the neighborhood of the device.

Overview

• Notice on safety

• Installation instructions

• Owner’s record

• Warnings

• Plug types

• Prevent personal injury

• Device damage

• Environment condition check

• Repacking

• Emergency stop

•Movingparts

• Class 2 laser

• SFTP Cat.5e cable warning

• Vibrations

2.2.1 Notice on safety

Notice on Safety

This equipment is built in accordance with the requirements of the international safety standards IEC60950-1, EN60950-1,

UL60950-1 and CAN/CSA - C22.2 No.60950-1, which are the safety standards of information technology equipment including

electrical business equipment. These safety standards impose important requirements on the use of safety critical components,

10

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 19

materials and isolation, in order to protect the user or operator against risk of electric shock and energy hazard, and having access

to live parts. Safety standards also impose limits to the internal and external temperature rises, radiation levels, mechanical stability

and strength, enclosure construction and protection against the risk of fire. Simulated single fault condition testing ensures the

safety of the equipment to the user even when the equipment’s normal operation fails.

2.2.2 Installation instructions

Installation Instructions

• Before operating this equipment please read this manual thoroughly, and retain it for future reference.

• Installation and preliminary adjustments can be performed after reading the documentation manuals in detail.

• All warnings on the device and in the documentation manuals should be adhered to.

• All instructions for operating and use of this equipment must be followed precisely.

2.2.3 Owner’s record

Owner’s Record

The part number and serial number can be found on the label at the back side of the device. Record these numbers in the table

below. Refer to them whenever you call your Barco dealer regarding this product.

Part Number:

Serial Number:

Dealer:

2. Safety

2.2.4 Warnings

Safety warnings

• To prevent fire or electrical shock hazard, do not expose this equipment to rain or moisture!

• This product should be operated from an AC power source. Power input is auto-ranging from 100 V to 240 V.

• All equipment in the system is equipped with a 3-wire grounding plug, a plug having a third (grounding) pin. This plug will only

fit into a grounding-type power outlet. This is a safety feature. If you are unable to insert the plug into the outlet, contact your

electrician to replace your obsolete outlet. Do not defeat the purpose of the grounding-type plug.

• Do not allow anything to rest on the power cord. Do not locate this product where persons will walk on the cord. To disconnect

the cord, pull it out by the plug. Never pull the cord itself.

• If an extension cord is used with this product, make sure that the total of the Ampere ratings on the products plugged into the

extension cord does not exceed the extension cord Ampere rating.

• Never push objects of any kind into this product through cabinet slots as they may touch dangerous voltage points or short out

parts that could result in a risk of fire or electrical shock.

• Never spill liquid of any kind on the product. Should any liquid or solid object fall into the cabinet, unplug the set and have it

checked by qualified service personnel before resuming operations.

• Lightning - For added protection for this product during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet. This will prevent damage to the device due to lightning and AC power-line surges.

2.2.5 Plug types

WARNING: The AC mains power adapter must be grounded (earthed) via the supplied 3 conductor AC power

cable. If the supplied p ower cable is not the correct one, co nsu lt your dealer.

Plug types

a. Mains lead (AC Po wer cord) with C EE 7 plug u p to 16 A

CEE 7

E

L

N

Image 2-6

The colors of the mains lead are colored

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

in accordance with the following code:

11

Page 20

2. Safety

Green + yellow: Earth (Ground)

Blue: Neutral

Brown: Line (Live)

b. PowercordwithNEMA5/15plugupto15A

NEMA 5/15

E

L

N

Image 2-7

The wires of the power cord are colored in accordance with the following code.

Green or yellow + green: Earth (Ground)

Blue or white: Neutral

Brown or black: Line (Live)

2.2.6 Prevent personal injury

To prevent personal injury

To prevent injuries and physical damage, always read this manual and all labels on the system before connecting to the wall outlet.

To prevent injuries, take note of the weight of the device.

Before attempting to remove any of the device’s covers, you must turn off the device and disconnect from the wall outlet.

2.2.7 Device damage

To prevent device damage

In order to ensure that correct airflow is maintained, and that the device complies with Electro-Magnetic Compatibility requirements,

it should always be operated with all of it’s covers in place.

Ensure that nothing can be spilled on, or dropped inside the device. If this does happen, switch off and unplug the mains supply

immediately. Do not operate the device again until it has been checked by qualified service personnel.

The device must always be mounted in a manner which ensures free flow of air into its air inlets and unimpeded evacuation of the

hot air exhausted from its cooling system. Heat sensitive mat

erials should not be placed in the path of the exhausted air.

2.2.8 Environment condition check

Environment condition check

A device must always be mounted in a manner which ensures the free flow of clean air into the device’s ventilation inlets. For

installations in environments where the device is subject to excessive dust, then it is highly advisable and desirable to have this dust

removed prior to it reaching the device clean air supply. Devices or structures to extract or shield excessive dust well away from the

device are a prerequisite; if this is not a feasible solution then measures to relocate the device to a clean air environment should be

considered.

It is the clients responsibility to ensure at all times that the device is protected from the harmful effects of hostile airborne particles

in the environment of the device. The manufacturer reserves the right to refuse repair if a device has been subject to negligence,

abandon or improper use.

Ambient temperature conditions

Max. ambient temperature : +40°C or 104°F

Min. ambient temperature: 0°C or 32°F

Storage temperature: -20°C to +60°C (–4°F to 140°F)

Humidity Conditions

Storage: 0 to 98% relative humidity, non-condensing

Operation: 0 to 85% relative humidity, non-co

ndensing

Environment

Do not install the device in a site near heat sources such as radiators or air ducts, or in a place subject to direct sunlight, excessive

dust or humidity. Be aware that room heat rises to the ceiling; check that temperature near the installation site is not excessive.

12

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 21

Environment condition check

The device must always be mounted in a manner which ensures the free flow of clean air into the air intake and out of the air outlet.

2.2.9 Repacking

On Repacking

Save the original shipping carton and packing material; they will come in handy if you ever have to ship your e

mum protection, repack your set as it was originally packed at the factory.

2.2.10 Emergency stop

Emergency stop

The emergency stop button is the large, circular red switch located at the rear side of the device. Pressing the emergency stop

button will disconnect the main power going to the modules of the MES ACURAS HEAD (RUGGED). To release it, turn the button

in the direction of the arrow. It should only be re-enabled if the situation is fully safe.

Use the emergency stop button only in emergencies.

C

N

Y

M

E

E

E

G

R

D

T

Ê

R

R

A

S

U

’

T

R

G

O

E

N

P

C

E

quipment. For maxi-

2. Safety

侶

㊴

Image 2-8

Emergency button + label

2.2.11 Moving parts

WARNING: Make sure that nobody and nothing is present within an area of 1 meter around the AutoAlignment

Head during operation.

Moving parts

• Keep your hands and fingers away from all moving parts.

• Do not wear loose clothing or jewelry. Keep long hair, clothing, scarves, rings, bracelets, gloves and such away from moving

parts, since they can be caught in moving parts.

• No people are allowed to come near the unit when it is in operation

• Do not operate the unit when other people can come near to the unit.

• Keep children, outsider, and other untrained persons away from the unit and its moving parts.

• Ensure that there is no loose cabling from the unit that can get caught by the moving parts.

Immediately stop operation if Gimbal Pan/Tilt does not respond to control

• Test Gimbal Pan/Tilt movement when initially operating the unit.

• Ensure Pan movement is going full -180º and +180º.

• Ensure Tilt movement is going full -80º and +30º.

• Ensure all controls function smoothly and do not stick or bind when operated.

• Avoid any type of manual intervention when operating the unit.

⋫

㷱

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

13

Page 22

2. Safety

WARNING: Hazardous moving parts.

Keep fingers and other body parts away.

ATTENTION: Parties mobiles dangereuses.

Tenir eloignés les doits et autres parties du corps.

巵⛙᧶☀棸扟┷捷ↅᇭ㓚㖖✛愺⇢␅Ⅵ捷⒕庆扫䱊

Image 2-9

Moving parts warning label

Image 2-10

Moving parts warning label

2.2.12 Class 2 laser

Class 2 laser

• The laser device installed on the MES ACURAS HEAD (RUGGED) is classified as a Class 2 laser. Class 2 laser is not considered as an optically dangerous device as the eye reflex will prevent any ocular damage.

• Switch OFF the laser device when not in use.

• Never look into the laser beams directly.

• Avoid direct eye exposure.

• Never operate the unit if other people are in the same room.

• No bystanders are allowed near to or inside the room when the laser device is in operation.

• Never come near to unit during operation.

• Never aim the laser beams to a projector lens. Direct or indirect hitting of a laser beam on to the lens can severely damage to

the optical engines in which case there is a loss of warranty

Following labels can be found on the unit:

LASER RADIATION : DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL À LASER DE CLASSE 2

䉏⏘戟⺓ₜ尐⑬展䟄㽱

Max output / Puissance de sortie max / 㦏⮶戢⒉= 1mW

Wavelength / Longeur d’onde / 㽱栎 = 650 nm

儶䉏⏘ℶ䞮

LASER APERTURE

OUVERTURE LASER

䉏⏘戟⺓ⷣ㈓

Image 2-12

Laser warning label

IEC 60825-1 Ed. 2.0 2007

Image 2-11

Laser warning label

FDA compliancy

Image 2-13

2.2.13 SFTP Cat.5e cable warning

SFTP Cat.5e cable warning

The supplied SFTP Cat.5e cable is a RJ45 cable. It is used for communication between the MES ACURAS HEAD and the MCU via

LEX unit. The total length of the SFTP Cat.5e cable is 50 meter.

Never connect the SFTP Cat.5e cable to an Ethernet card, hub, switch or port or other Ethernet RJ45 connector of an Ethernet

device or MCU. Damage to devices connect

ed to the Ethernet may result.

14

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 23

! WARNING !

The RJ-45 connector is not an Ethernet connection. Do not connect

to an Ethernet port. Possible risk of damage to the equipment and port!

! ATTENTION !

Le connecteur RJ-45 n’est pas un connecteur Ethernet. Ne pas connecter

sur un port Ethernet. Risque d’endommager le matériel et le port!

巵⛙

5-扭㘴⣷ₜ㢾₹ⅴ⮹几扭㘴ↅᇭₜ尐㘴⏴ⅴ⮹几䵾♲ᇭ

♾厌㦘㗮⧞幍✛䵾♲䤓歝棸ᇭ

Image 2-14

SFTP Cat.5e cable warning label

2.2.14 Vibrations

Vibrations

The standard version of the AutoAlignment Head, being MES ACURAS HEAD (R9843500) is not motion base compatible. It is only

to be installed on still or non-moving structures.

The rugged version of the AutoAlignment Head, being MES ACURAS HEAD RUGGED (R9843501) is motion base compatible,

which means it can be installed on motion based simulators or on moving structures

2. Safety

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013 15

Page 24

2. Safety

16 R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 25

3. Compliancy

3. COMPLIANCY

Introduction

To meet EMC compliancy, it is required to take some precaution. See topic below.

Overview

• EMC shielding clamps

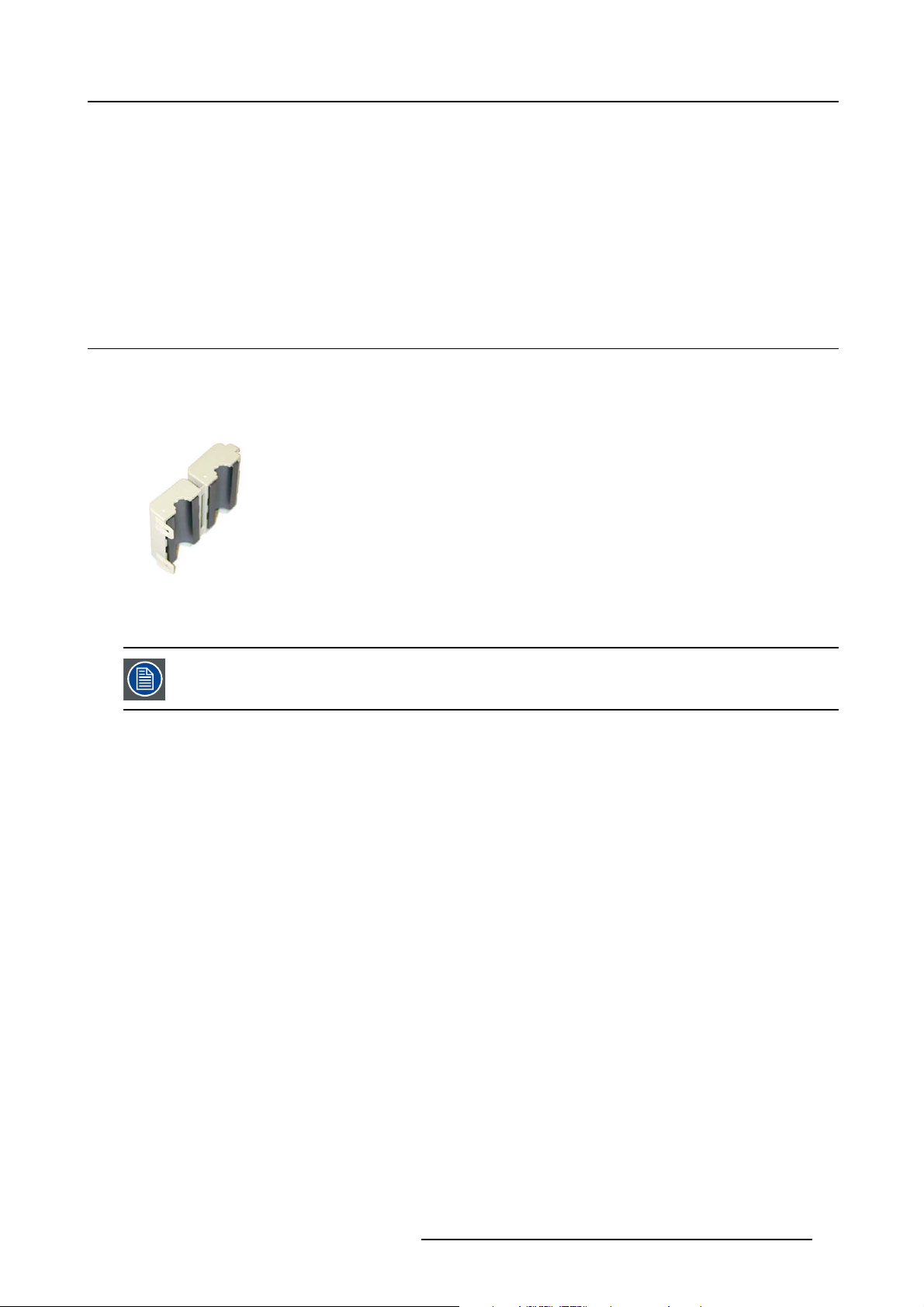

3.1 EMC shielding clamps

EMC shielding clamps

When replacing some of the cables, always put back the EMC shielding clamps (Ferrites) in their original position if they were present

before.

Image 3-1

EMC shielding clamp

Depending on the type of EMC shielding clamp, use a pair of cutting pliers and/or a slotted screwdriver to open the clamp.

Some cables must make a loop through the EC shielding clamps!

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013 17

Page 26

3. Compliancy

18 R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 27

4. PACKAGING

Overview

• Content

• Unpacking

• Shipping bracket

4.1 Content

Content

Description Article number

AutoAlignment Head (standard/rugged) R765840/R7658402

Power cord (connectors C13 and CEE7)

Power cord (connectors C13 and NEMA

5–15)

Power cord (connector C13 and PCR-3)

S/FTP CAT5e control cable (connectors

RJ45)

USB extender or LEX unit (Icron LEX)

Ferrite split core B195382 2

Adhesive label: WARNING No Ethernet

connection

AutoAlignment Head Quick install guide R59770598 1

AutoAlignment Head Service manual R59770510 1

AutoAlignment Head User and installation

manual

CD-ROM (Calibration files for

Spectrometer)

R326103 1

V326111 1

Z3487503 1

CBL-3380–61 1 (length 50m)

-

R870792 2

R59770509 1

-

4. Packaging

Quantity

1

1

1

4.2 Unpacking

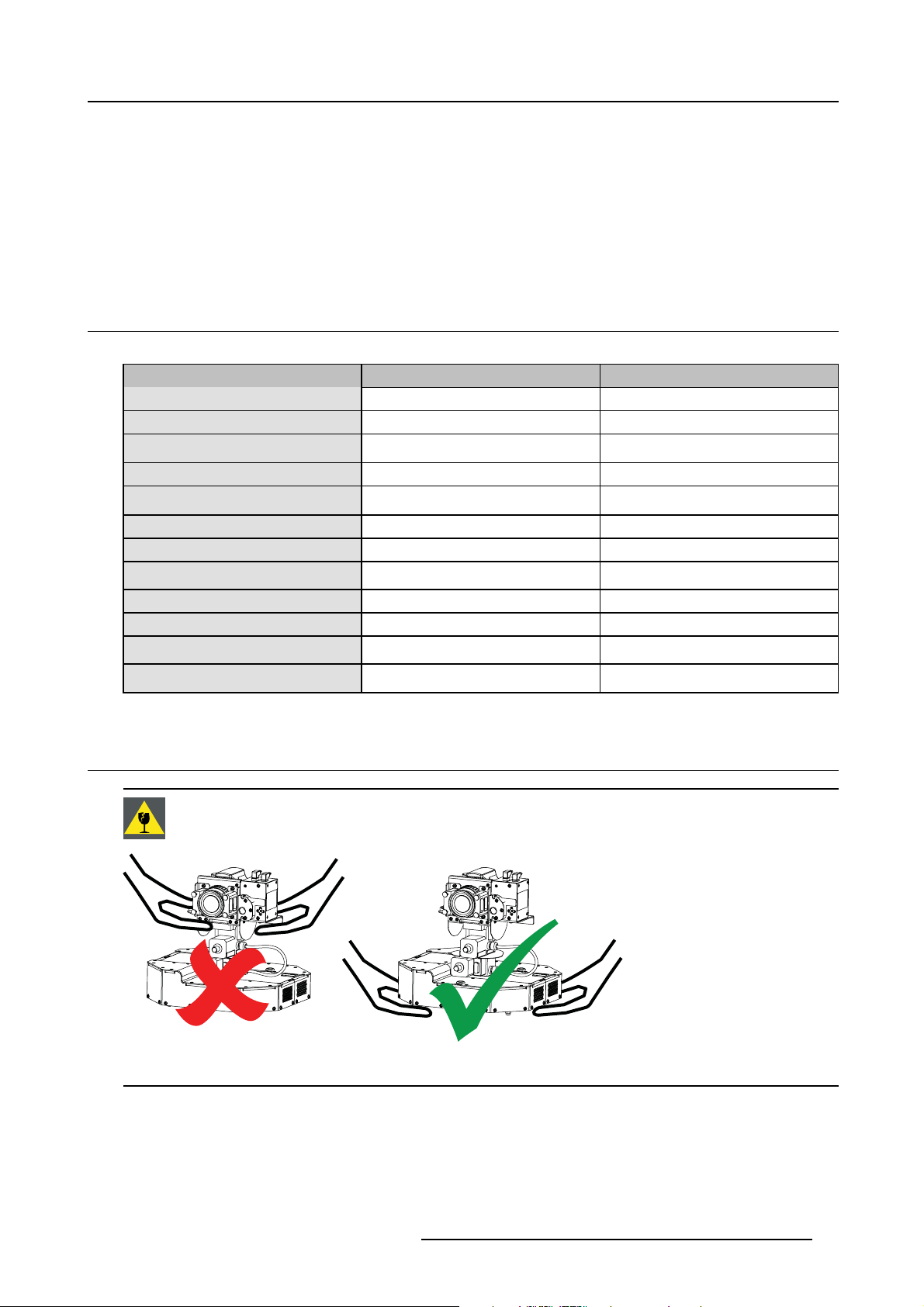

CAUTION: Hold the unit at the bottom box to lift and move it. Never hold the camera or Gimbal to lift theAu-

toAlignment Head.

Image 4-1

Lifting instructions: Barco (standard and rugged) version

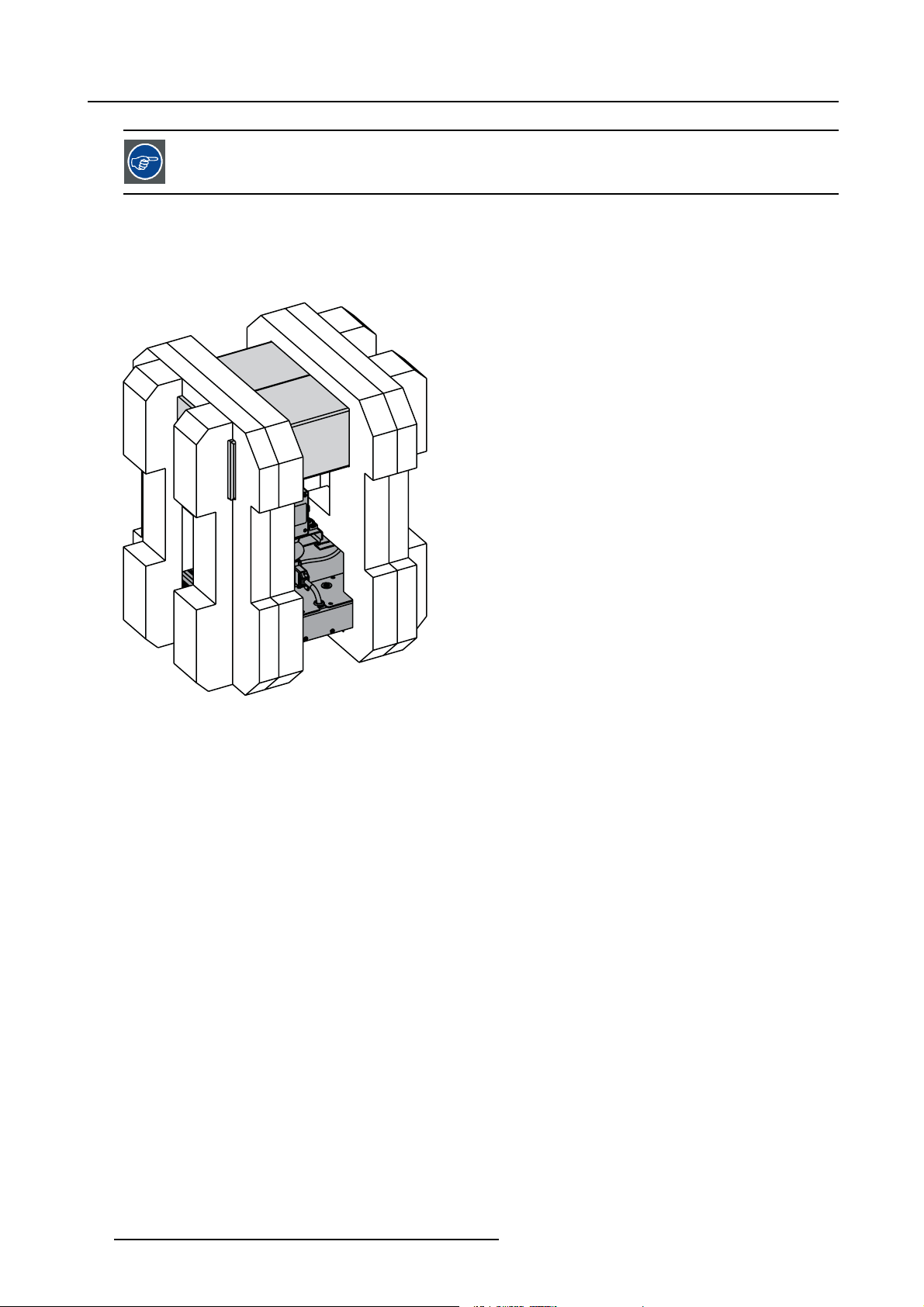

Packaging

Cardboard boxes and foam are used to protect the device during shipping.

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

19

Page 28

4. Packaging

Save the original packag ing for future shipment. For maximum protection while shipping the unit, always

pack it as it was packed during first delivery.

How to unpack the AutoAlignment Head?

1. Carefully cut the tape on the top lid of the box.

Warning: Follow the relevant safety precautions while using a knife.

2. Open the main box and carefully lift out the foam parts, carboard box and AutoAlignment Head as one unit

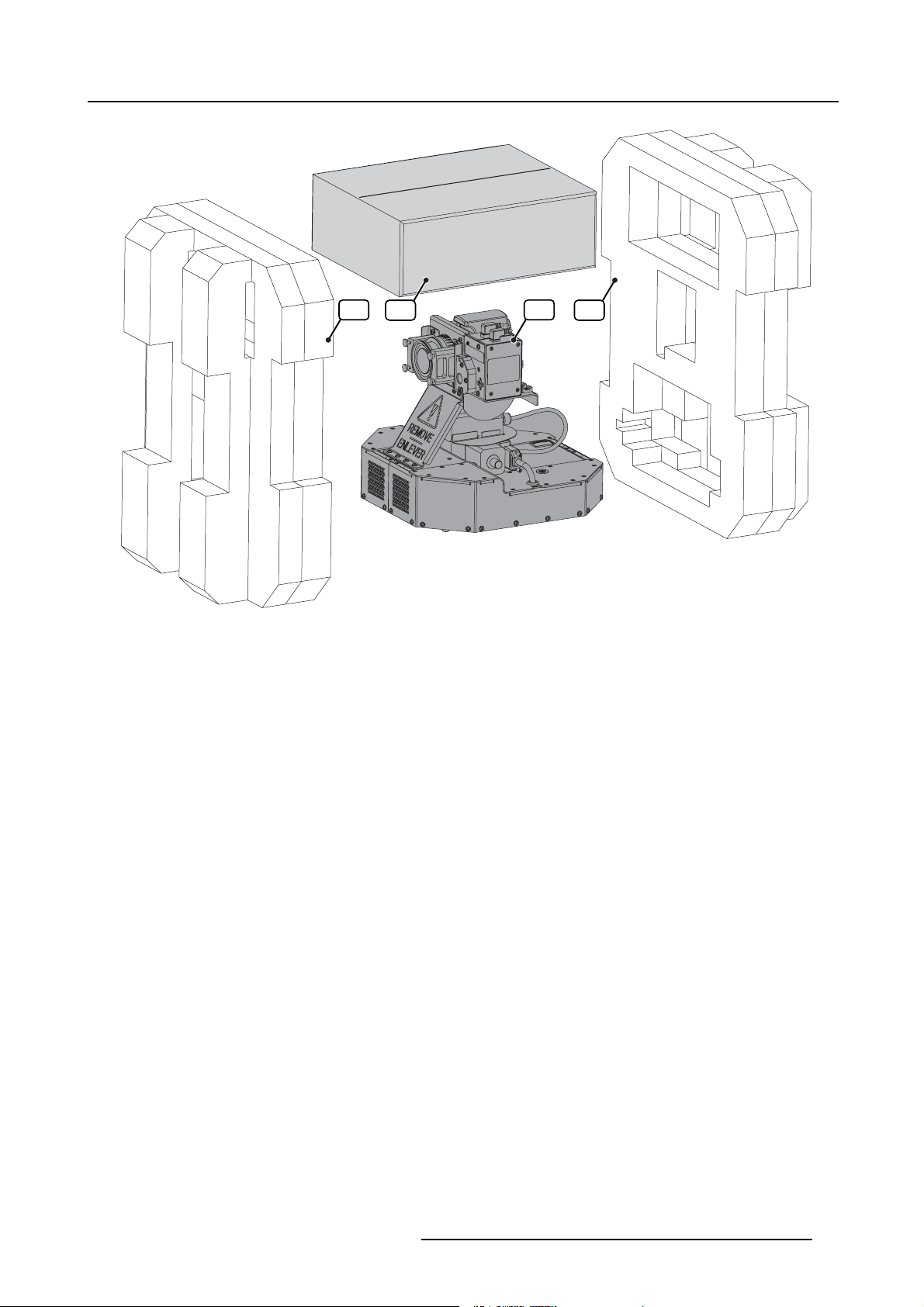

Image 4-2

Packaging: content of the m ain box

3. Remove the left and right foam part to release the AutoAlignment Head and a second cardboard box.

20

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 29

A B C D

4. Packaging

Image 4-3

Packaging: remove the foam parts (AutoAlignment Head standard version)

A Foam protection part

B Second cardboard box

C AutoAlignment Head

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013 21

Page 30

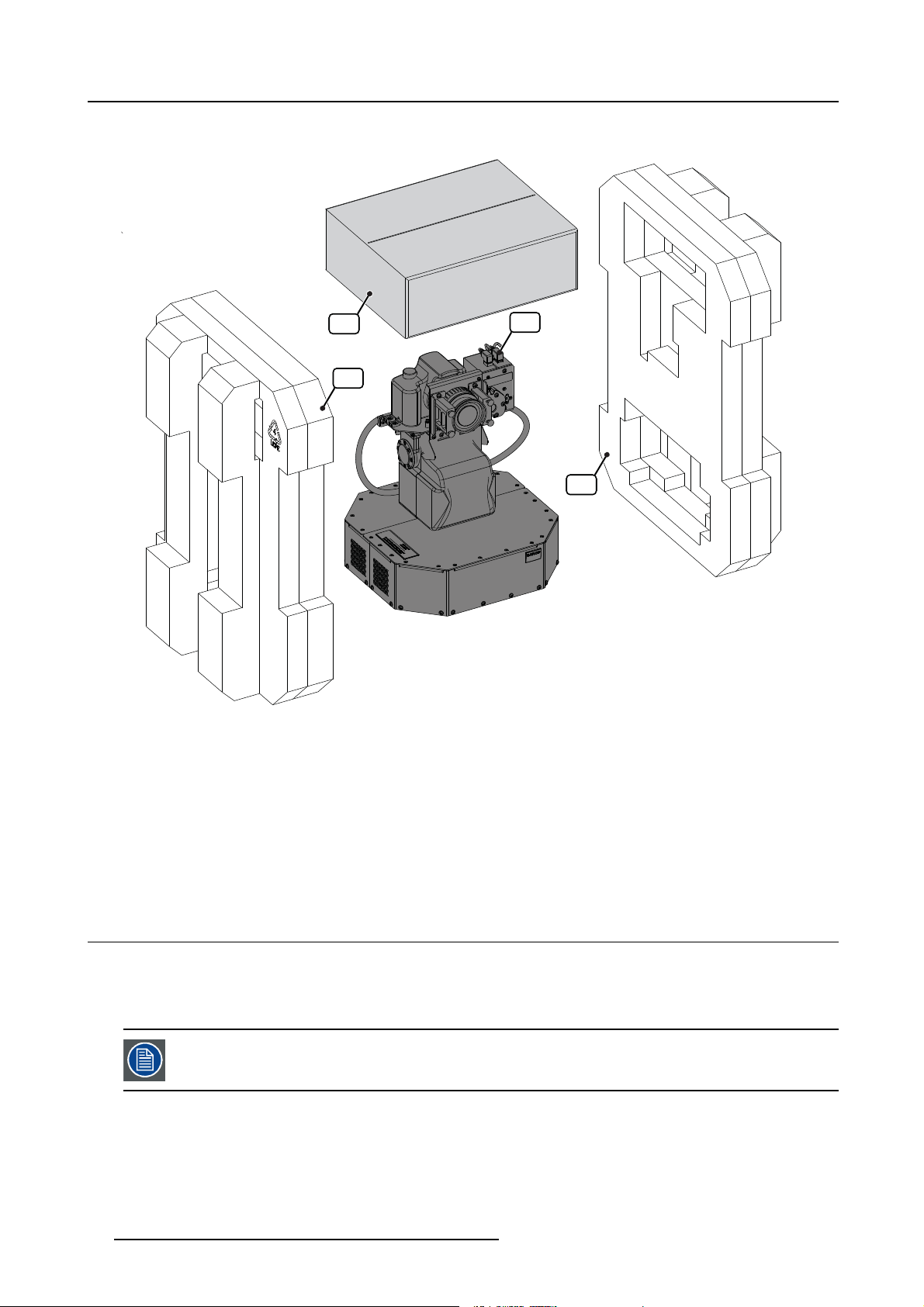

4. Packaging

D Foam protection part

B

A

Image 4-4

Packaging: remove the foam parts (AutoAlignment Head rugged version)

A Foam protection part

B Second cardboard box

C AutoAlignment Head

D Foam protection part

4. Carefully cut the tape on the top lid of the second cardboard box

Warning: Follow the relevant safety precautions while using a knife.

5. Remove the parts from this box.

6. Check if all parts are available. See "Content", page 19.

C

D

4.3 Shipping bracket

Introduction

When the AutoAlignment Head is shipped, the shipping bracket must be fixed to it. This bracket prevents the Gimbal unit from

being damaged due to handling actions during shipment. The shipping bracket must be removed prior to installing the unit.

If this AutoAlignment Head must be shipped ever again, it is necessary to first install the shipping bracket.

Overview

• Removing the shipping bracket

• Installing the shipping bracket

22

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 31

4.3.1 Removing the shipping bracket

Necessary tools

Torx screwdriver T10

How to remove the shipping bracket?

1. Remove all screws fixing the shipping bracket to the AutoAlignment Head.

4. Packaging

Image 4-5

Shipping bracket removal: standard version

Image 4-6

Shipping bracket removal: rugged version

2. Remove the shipping bracket.

3. Insert all screws in the AutoAlignment Head again and tighten them.

4.3.2 Installing the shipping bracket

CAUTION: The shipping bracket must always be installed on the AutoAlignment Head prior to shipping it!

Necessary tools

Torx screwdriver T10

How to install the shipping bracket?

1. Adjust pan and tilt to align the holes on the AutoAlignment Head exactly to the holes on the shipping bracket. This corresponds

to pan 90° / tilt 0° for the standard version and pan 0° / tilt 0° for the rugged version.

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

23

Page 32

4. Packaging

Image 4-7

Orientation to fix shipping bracket: standard version

Tip: On the standard version, this positioning can be done manually (Pan knob and Tilt knob) or through the XDS RACU us er

interface.

2. Power off the system and remove the power cord.

3. Disconnect the AutoAlignment Head.

4. Remove the AutoAlignment Head from its support.

5. Fix the shipping bracket to the unit.

Image 4-8

Orientation to fix shipping bracket: rugged version

Image 4-9

Shipping bracket: standard version

Tip: To install the shipping bracket, follow the removal procedure in reverse order.

24

Image 4-10

Shipping bracket: rugged version

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 33

5. Facility and system requirements

5. FACILITY AND SYSTEM REQUIREMENTS

About this chapter

This chapter provides information about the installation requirements such as temperature, humidity, dimensions, power net, safety

area around the device. Also the air intake and air outlet area of the device are considered.

Overview

• Environmental requirements

• Dimensions

•Airflow requirements

• Power requirements

• View requirements

• Access requirements

• Luminance requirements

5.1 Environmental requirements

Ambient temperature conditions

Storage:

• -20°C to +60°C (-4°F to 140°F)

Operation:

• Max. ambient temperature : +40°C or 104°F

• Min. ambient temperature : 0°C or 32°F

Humidity Conditions

Storage: 0 to 98% relative humidity, non-condensing

Operation: 0 to 85% relative humidity, non-condensing

Environment

Do not install the device in a site near heat sources such as radiators or air ducts, or in a place subject to direct sunlight, excessive

dust or humidity. Be aware that room heat rises to the ceiling; check that temperature near the device is not excessive.

Environment condition check

The device must always be mounted in a manner which ensures the free flow of clean air into the air intake and out of the air outlet.

Environmental light conditions

During operation of the AutoAlignment Head , the environment should be fully dark to guarantee correct measurements. Even the

light of a small standby LED which is visible on the screen may le

Next to that, there should be no light (not even stray light) pointing to the ocular while the diaphragm of the camera is open. A light

beam entering the ocular while the camera’s diaphragm is open may lead to damage to the camera.

ad to bad measurement results.

5.2 Dimensions

Dimensions

The total weight of the AutoAlignment Head standard version is 8.26 kg. The weight of the AutoAlignment Head Rugged version is

11. 5 k g.

Dimensions of both versions can be found in the drawings below.

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

25

Page 34

5. Facility and system requirements

Image 5-1

Dimension: AutoAlignment Head (standard version)

1 M6 Mounting stud

26 R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 35

2 Location pin Ø 6mm

5. Facility and system requirements

304,4

[11,984]

152,2

[5,992]

82,6

82,6

[3,252]

[3,252]

325,86

325,86

[12,829]

[12,829]

162,2

[6,386]

108

[4,252]

324,4

[12,772]

108

[4,252]

82,6

[3,252]

66,3 x45° (4x)

[2,610]

(3x)

14

[,551]

[8,931]

[8,931]

226,84

226,84

(=Gimbal Tilt Axis)

397,57

[15,652]

152,2

152,2

[5,992]

[5,992]

Image 5-2

Dimension: AutoAlignment Head (rugged version)

1 M6 Mounting stud

2 Location pin Ø 6mm

(=Gimbal Pan Axis)

13

[,512]

5.3 Air flow requirements

Air flow requirements

It is important to keep the air grids unblocked. A free area of at least 30 cm should be available around the air grids.

178,2

178,2

[7,016]

[7,016]

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

27

Page 36

5. Facility and system requirements

Image 5-3

AutoAlignment Head : position of air grids

5.4 Power requirements

Mains power

Mains power must be in the range 100–250V, 50–60Hz.

Power consumption

The total power consumption of the AutoAlignment Head is 25 Watt at 230 Volt.

5.5 View requirements

Design Eye Point

The Design Eye Point is the position from which the user is intended to view the total image for an optimal view of it.

Camera position

The best position for the AutoAlignment Head is that position where its camera is in the Design Eye Point.

Camera/Spectrometer field of view

Adequate space must be provided around the AutoAlignment Head. No physical or mechanical obstruction should be present in the

camera or spectrometer field of view.

5.6 Access requirements

AutoAlignment Head location and access

There must be enough space around the AutoAlignment Head to allow access to and flawless operation of the unit.

Following rules must be taken into account:

28

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 37

5. Facility and system requirements

• a minimum safety distance of 1 meter must be considered when the AutoAlignment Head is in operation i.e. no operator and/or

bystanders are allowed within the minimum safety distance during operation.

• never try to stop the moving parts manually, it may damage the motor of the AutoAlignment Head.

• do not wear loose clothing or jewelry. Keep long hair, clothing, scarves, rings, bracelets, gloves and such away from moving

parts, since they can be caught in moving parts.

• never cover the AutoAlignment Head (e.g. with a tissue) when it is powered on or just after it was powered off.

• no mechanical obstruction for the full AutoAlignment Head movement range.

5.7 Luminance requirements

Ambient light

Followings rules must be taken into account:

• stray light and reflections of it should be avoided, e.g. by using dark wall, ceiling and floor color.

• switch off all external light sources during measurements.

• only aimed spotlight should be used to illuminate small areas if required. Make sure that this aimed spotlight d

the screen during measurements.

oes not fall on

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

29

Page 38

5. Facility and system requirements

30 R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013

Page 39

6. SPECIFICATIONS

Overview

• Hardware layout

• Gimbal range

• Camera FOV

6.1 Hardware layout

Hardware layout: front view

6. Specifications

BA C

K

J

I

H

Image 6-1

AutoAlignment Head (standard version) : parts overview

Label in the image

A

B

C

K

I

D

E

F

G

Image 6-2

AutoAlignment Head (rugged version) : parts overview

Description (standard version) Description (rugged version)

Camera Camera

Spectrometer Spectrometer

Laser pointer Laser pointer

A

C

B

D

E

D Laser aperture Laser aperture

E

F

Optical filter Optical filter

Gimbal cable

PAN–TILT unit cable

G Gimbal Gimbal (PAN–TILT unit)

H

I

J

K

Manual pan knob (See note)

Camera cable Camera cable

Manual tilt knob (See note)

Thumb screws to fix the focus ring Thumb screws to fixthefocusring

not available

not available

F

G

Manual pan and tilt adjustment by using the knobs is only allowed when the AutoAlignment Head is not electrically powered. W hen the device is powered up, the manual pan and tilt knobs are blocked electronically.

Forcing a pan or tilt movement via the knobs might damage the device.

R59770509 AUTOALIGNMENT HEAD GEN II 26/11/2013 31

Page 40

6. Specifications

Hardware layout: top view

A

G

F

Image 6-3

AutoAlignment Head (standard version) : parts overview

Label in the image

A

B

C

B

D

G

F

E

Image 6-4

AutoAlignment Head (rugged version) : parts overview

A

D

B

Description (standard version) Description (rugged version)

Camera: Power On / Off Camera: Power On / Off

Camera: Rotary dial Camera: Rotary dial